Page 1

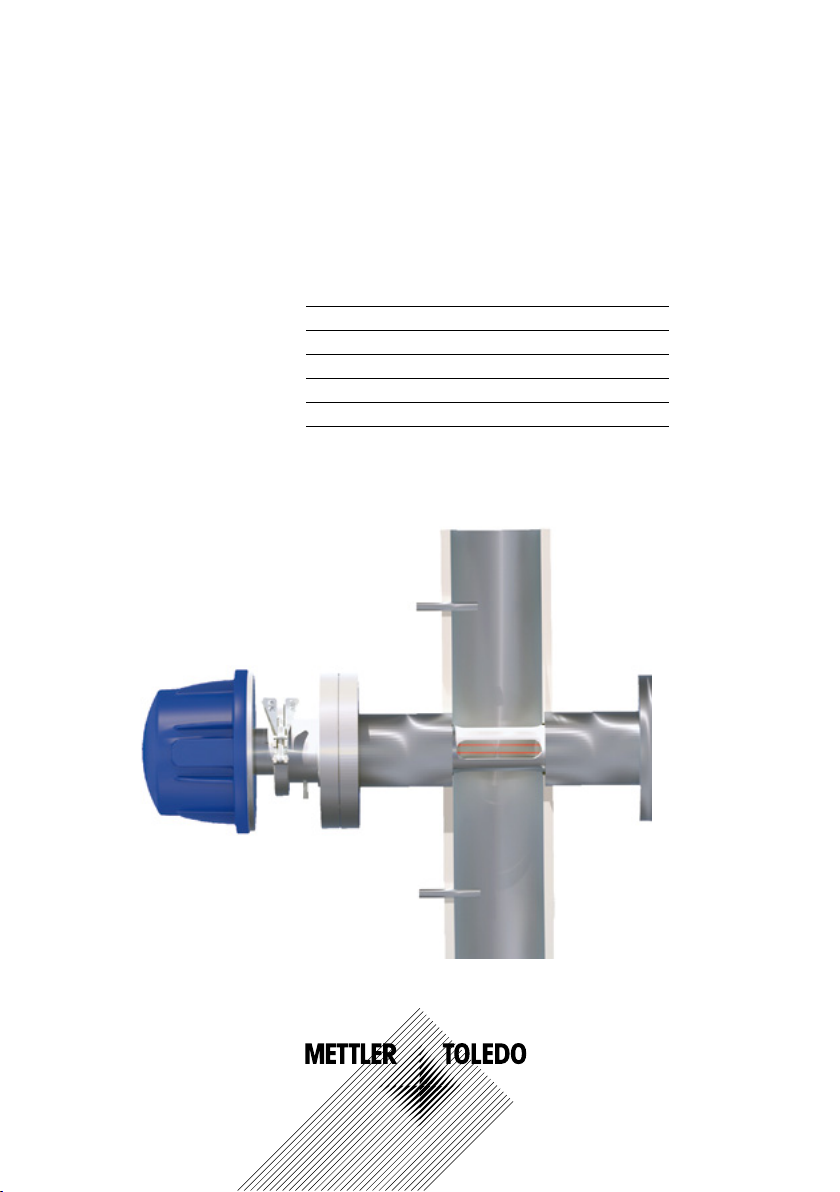

GPro™ 500 Quick Setup Guide

English 3

German 29

French 55

Portuguese 81

中国的 107

한국의 133

Page 2

Page 3

Quick Setup Guide TDL GPro™ 500

GPro™ 500

Quick Setup Guide

Content

1 Preparation 5

Packing content 5

Site Requirements 5

Ambient operating conditions 5

What you also need 5

Optional accesssories 6

2 Before the installation 7

Flange placement 7

Flange requirements 7

Flow conditions at measuring point 8

Purging 9

Purging with thermalbarrier 10

Grounding and wiring (ATEX) 11

Active analog inputs (ATEX Version) 12

Loop powered analog inputs (ATEX) 13

Grounding and wiring (FM) 14

Active analog inputs (FM Version) 15

Loop powered analog inputs (FM Version) 16

GPro™ 500 cables 17

Cable connections in M400 19

English

3 Installation 20

General Setup (applies for all parameters) 20

Channel Selection 20

Calibration 20

TDL Installation 20

Setting the correct process side purging 23

4 Verification and Maintenance 24

One-point calibration for TDL gas sensors 24

Process calibration for TDL gas sensors 24

Calibration using a calibration cell 25

5 Error messages 26

3

Page 4

Quick Setup Guide TDL GPro™ 500

4

Page 5

Quick Setup Guide TDL GPro™ 500

1 Preparation

– GPro™ 500 Tunable Diode Laser Analyzer

Packing content

– 1 Safety Instruction

– 1 Documentation CD with Instruction manual and MT-TDL Software Suite.

Site Requirements

– 24 VDC, 5 W for power supply of the GPro™ 500

– 110 / 220 VAC for the power supply of M400

– Purge gas, > 99.7% purity (minimum recommended), 0.5…5 L /min.

The purity requirements are:

conform to standard set by ISO 8573.1, class 2–3, analog to instrument air.

For oxygen TDL, nitrogen or any other ”O

used.

Ambient operating

– 20…+ 55 °C (– 4…+ 131 °F) during operation

conditions

What you also need

• 1 M400 T3 Transmitter (p / n 52121350)

• 1 Ethernet cable CAT5

• RS 485 cable (< 250 m)

• 1 Laptop (WinXP / 7 / 8) with MT-TDL software installed

• Flat gasket 82.14 3 3.53 mm

• Check valve

• 2 pcs open-end wrenches (spanners) for M16 bolts

• 1 pcs Allen key 5 mm for the locking screws on anges and Tx lid screws

• 1 pcs Allen key 3 mm for the RS 232 cover screws

• 2 Flat keys for Swagelok

• 1 pcs at screwdriver 2.5 mm for electrical connections

• 1 pcs at (6 mm) or cross head (No 2) screwdriver for Rx lid screws

• Adjustable wrench (spanner) for purge connections

• Torque wrench for FM version

free” clean and dry gas can be

2

5

Page 6

Quick Setup Guide TDL GPro™ 500

Optional accesssories

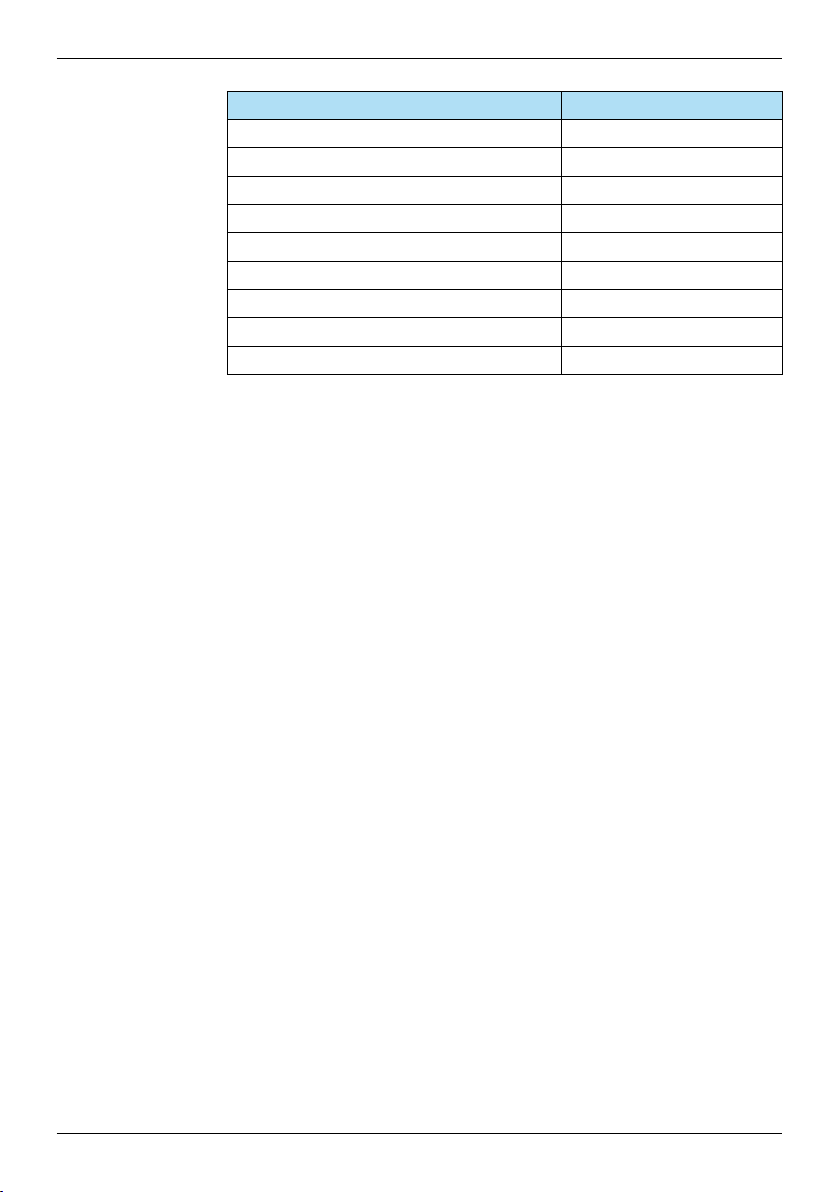

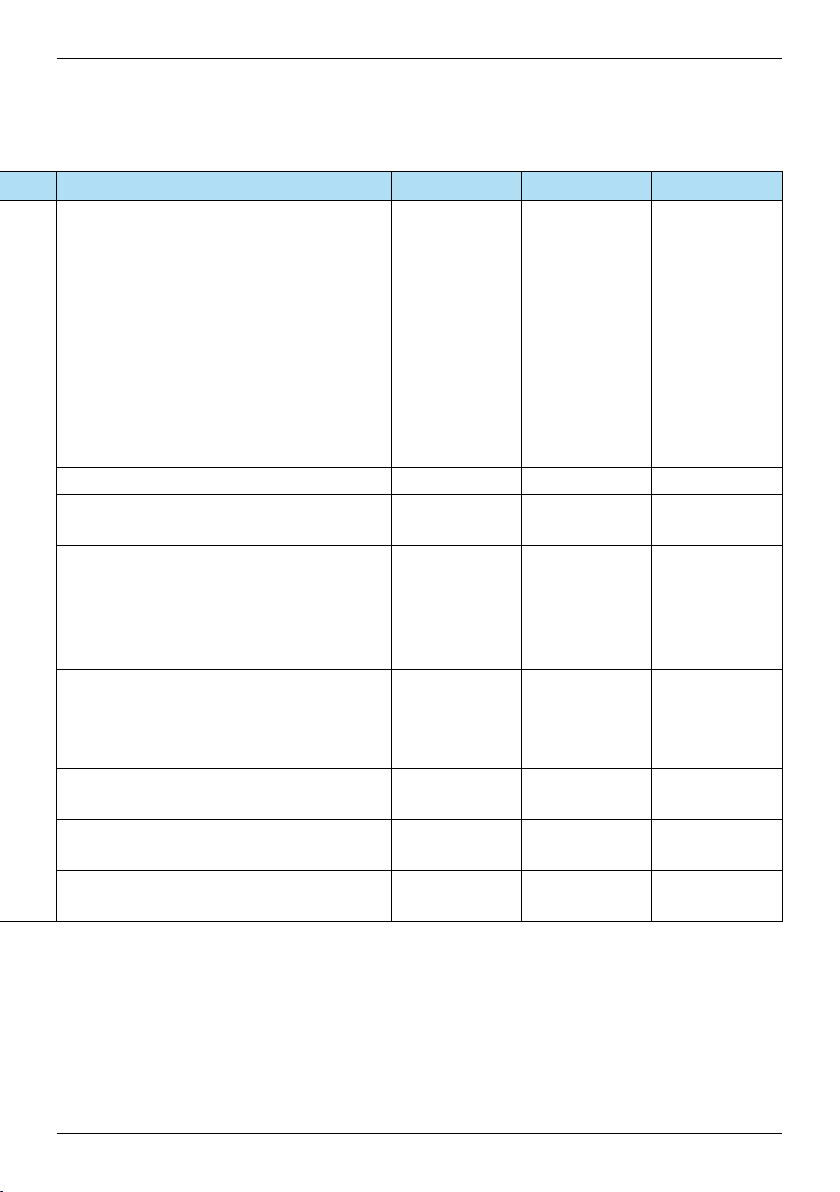

Accessory Order number

Thermal barrier 30 034 138

Junction box 30 034 149

Purging box for M400 Ex d 30 034 148

Calibration kit 30 034 139

O

2

Kit Flat gasket ST 30 080 914

Kit Flat gasket HT (Graphite) 30 080 915

Cable GPro 500 ATEX, FM 5 m 30 077 735

Cable GPro 500 ATEX, FM 15 m 30 077 736

Cable GPro 500 ATEX, FM 25 m 30 077 737

6

Page 7

Quick Setup Guide TDL GPro™ 500

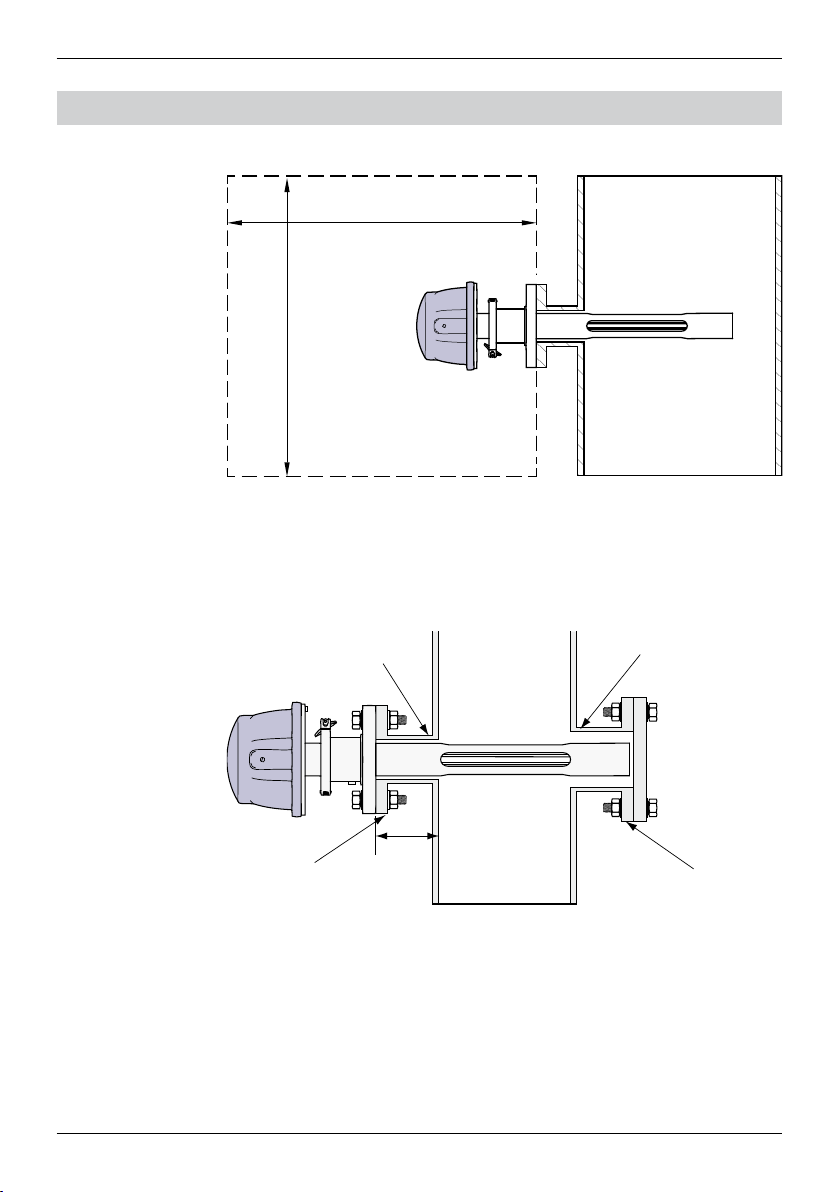

2 Before the installation

Flange placement

)

"

60 cm (23.6

The TDL head should be easily accessible. A person should be able to stand in

front of it and adjust the M16 xing bolts using two standard spanners. There

should be at least 60 cm free space measured from the ange xed to the stack

and outwards as shown below.

60 cm (23.6")

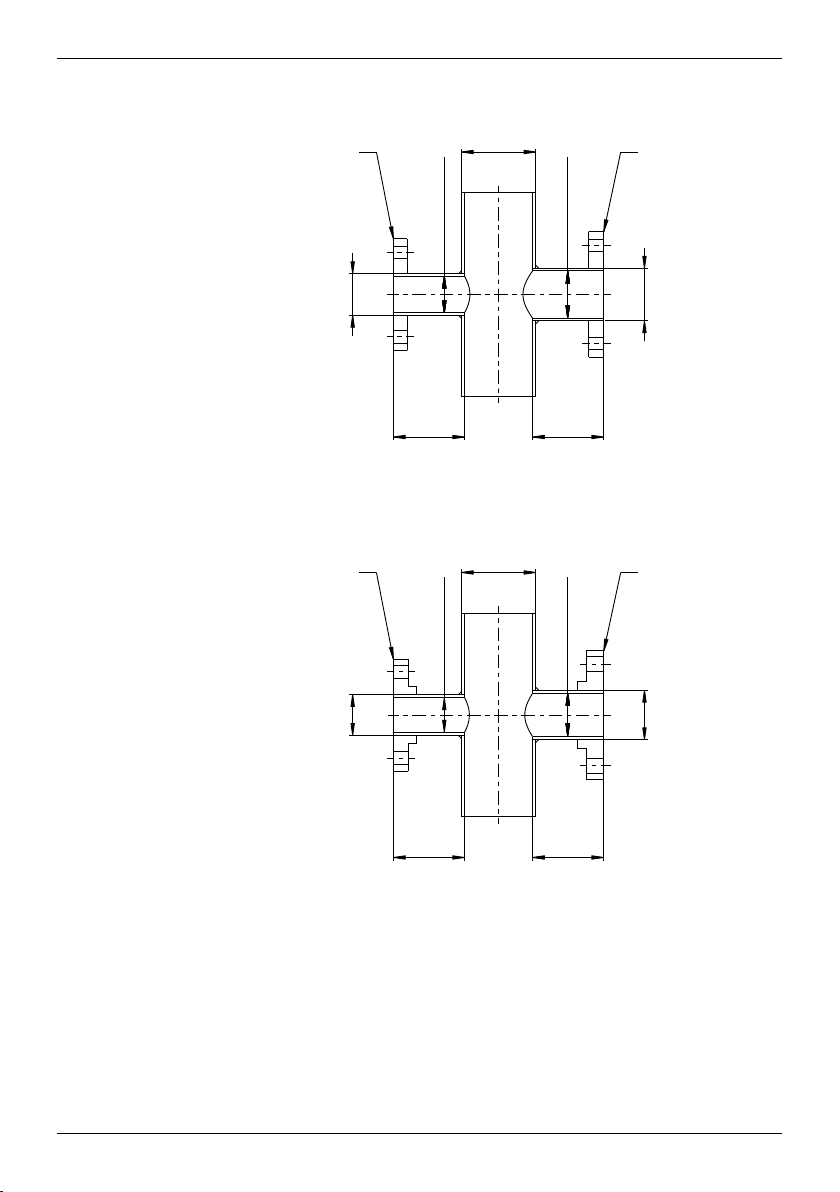

Flange requirements

min. clearance: 61,5 mm

(schedule 40)

DIN 50 or ANSI 2"

min. clearance: 77,5 mm

(schedule 80)

100 mm

(4")

DIN 65 or ANSI 2½"

7

Page 8

Quick Setup Guide TDL GPro™ 500

DIN

DN50/PN25 DN65/PN25

DN 50

100 mm 100 mm

DN100

min. Ø 54 mm

min. Ø 67 mm

DN65

ANSI

4"

min. 2.12"

2"

min. 2.64"

ANSI 2.5"/300 lbsANSI 2"/300 lbs

2.5"

4" 4"

When deciding the placement of the GPro™ 500 TDL in the process, we recom-

Flow conditions at measuring point

mend a minimum of 5 stack diameters of straight duct before and 3 stack diameters of straight duct after the point of measure.

This will lead to laminar ow conditions which is favorable for stable measurement conditions.

8

Page 9

Quick Setup Guide TDL GPro™ 500

Purging

1 Purge gas inlet for instrument side (6 mm or ¼" tube tting).

2 Purge gas inlet for process side (must have a check valve).

3 Purge gas outlet for instrument side (6 mm or ¼" tube tting).

4 Process gas ow.

5 Region that denes the boundaries of the effective path length.

0…1 L /min

0…10 L /min

RotameterPressure regulator

WARNING

Always start purging at maximum flow before starting the process.

WARNING

Purging must always be switched on in order

to avoid dust deposition onto the optical surfaces.

WARNING

Do not remove and / or disassemble the purge gas inlet for processes (2).

If disassembled, the PED pressure certificate is void.

WARNING

Do not connect instrument and process side purging in series, otherwise

when disassembling the sensor heat the probe purging will stop.

9

Page 10

Quick Setup Guide TDL GPro™ 500

Purging

with

thermalbarrier

Purging configuration

1 Purge gas inlet for thermal barrier (6 mm or ¼" tube tting)

2 Purge gas outlet for thermal barrier (6 mm or ¼" tube tting)

3 Purge gas inlet for process side (Must have a check valve)

4 Mandatory check valve (to be supplied by the user)

21 4

3

WARNING

The purge gas for the thermal barrier must always be turned on

when the process is running in order to protect the sensor head

from permanent damage.

10

WARNING

The failure of the instrument side and thermal barrier purging

system must trigger an alarm. This alarm has to be implemented

in th DCS ny the user.

Page 11

Quick Setup Guide TDL GPro™ 500

Grounding

andwiring(ATEX)

External earth point

for > 4 mm

(M6 × 12)

2

cables

Exernal earth point.

11

Page 12

Quick Setup Guide TDL GPro™ 500

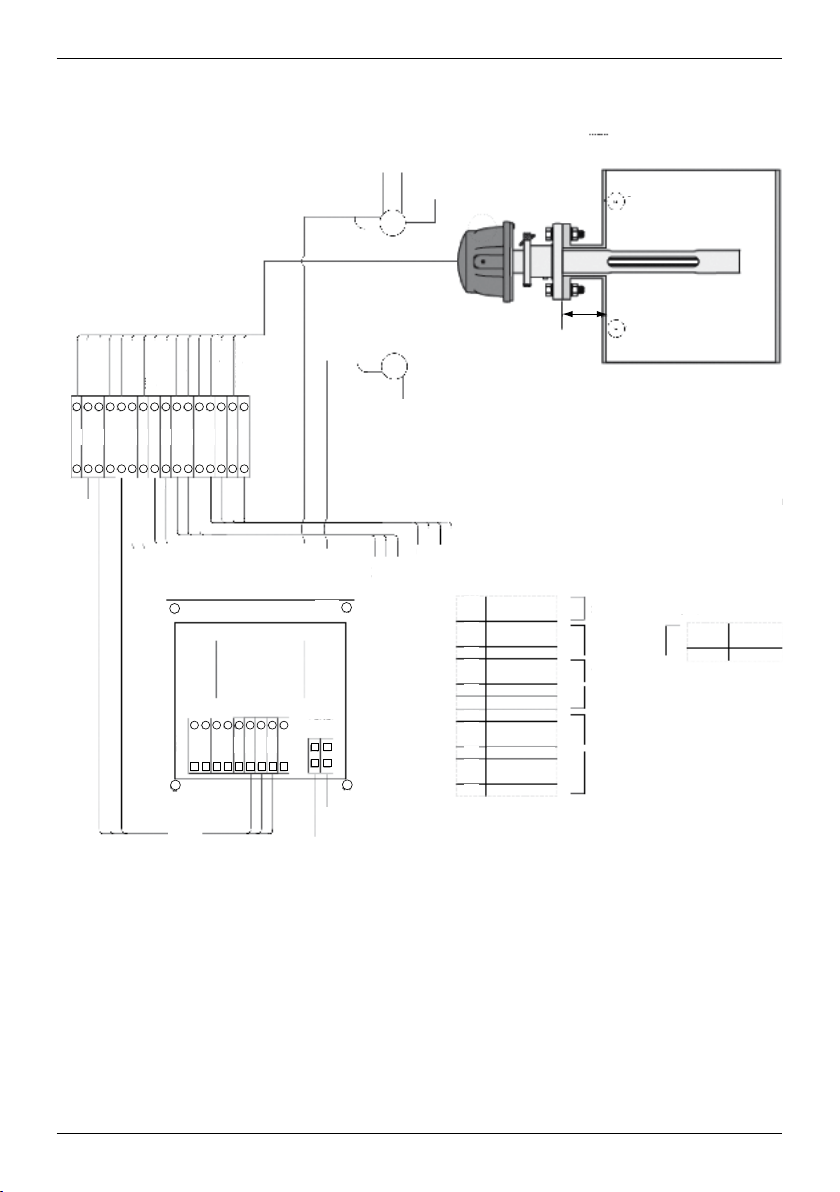

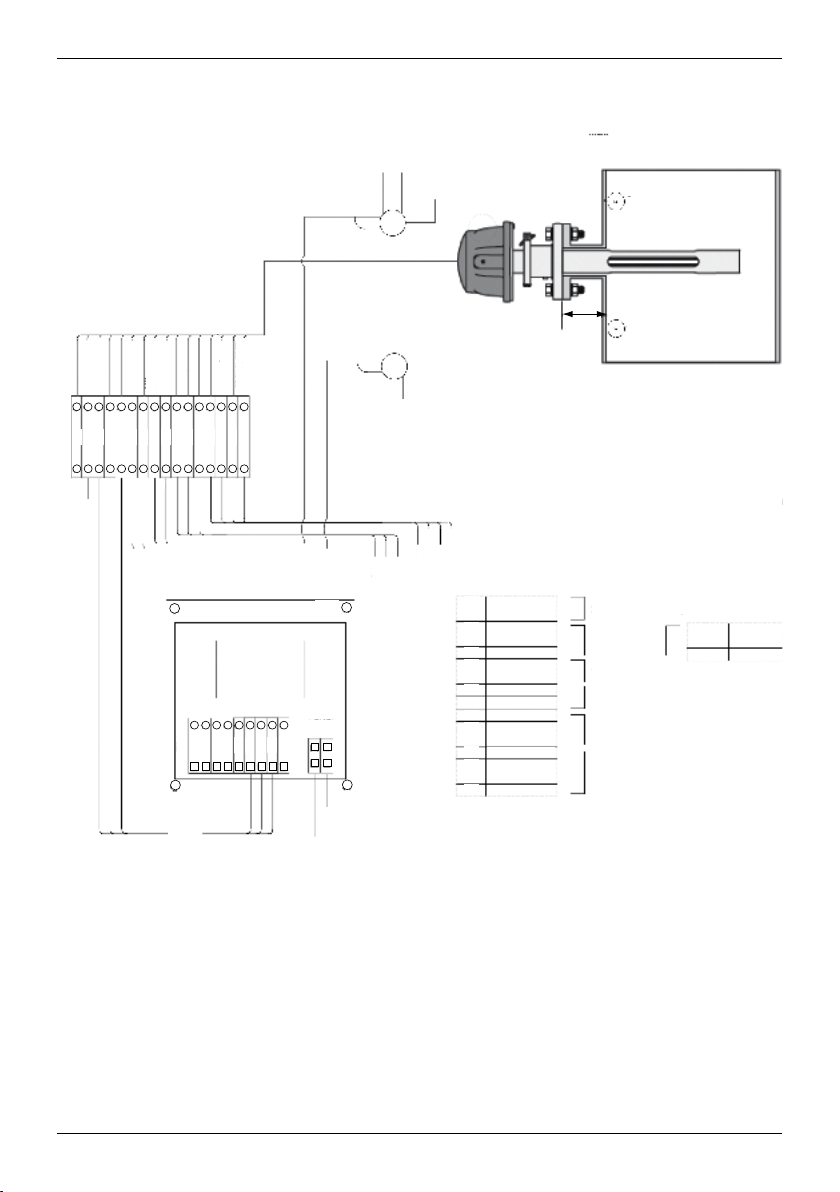

RS-485 A

Activeanaloginputs(ATEXVersion)

ACTIVE ANALOG INPUTS

24 VDC

User-provided

GND

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

+

Purple

+

xT

–

100 mm

+

xT

Power

L N

M400

–

24 VDC

Analog

Outputs

GND

Ethernet

1

24 VDC

GND

2

3

RS-485 A

RS-485 B

4

5

RS-485 GND

6

+Ain 1 4…20 mA

7

–Ain 1 4…20 mA

8

+Ain 2 4…20 mA

9

–Ain 2 4…20 mA

10

24 VDC

11

Aout 1

Aout 2

12

13

TX+

14

TX–

15

RX+

16

RX–

Black

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

987654321

+

–

–

16151413121110

TB4

987654321

Pressure

(4")

Temperature

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

12

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

Page 13

Quick Setup Guide TDL GPro™ 500

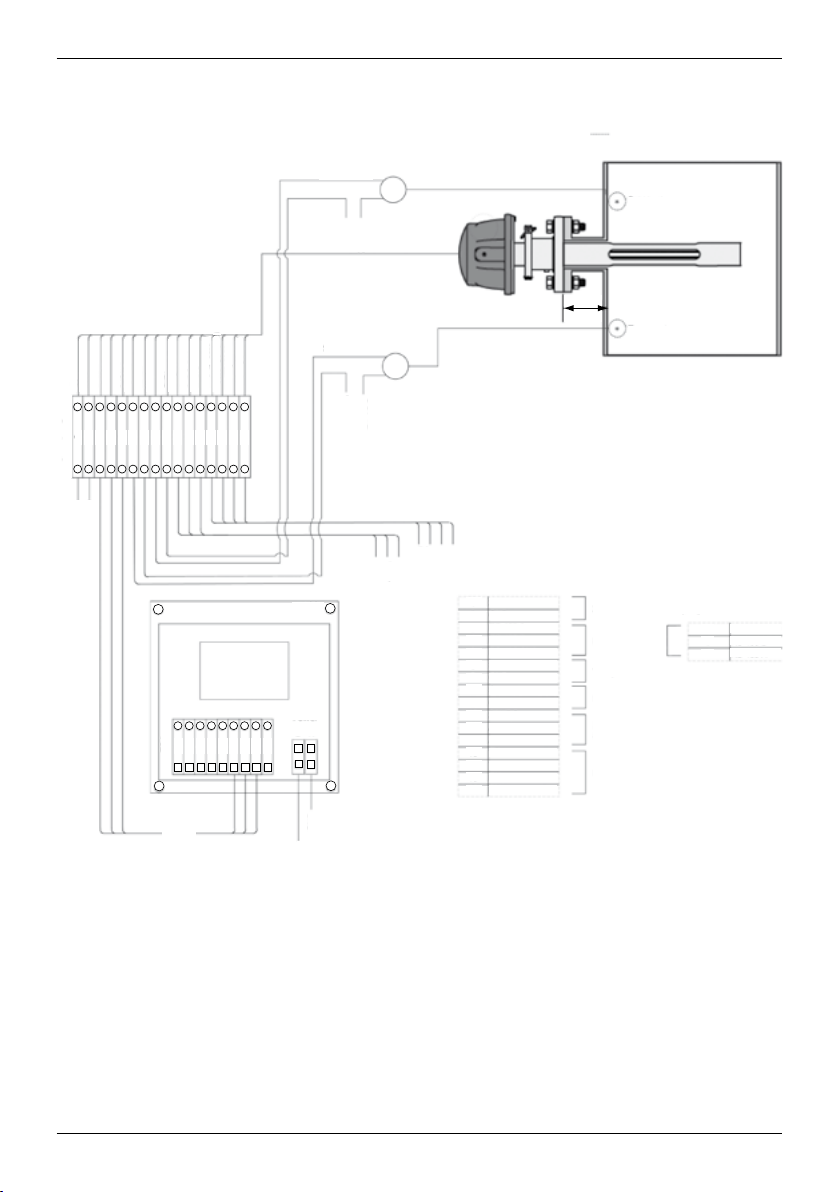

Looppoweredanaloginputs(ATEX)

User-provided

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

Purple

Black

SENSOR IN

xT

GND

24 VDC

100 mm

(4")

Pressure

Temperature

SENSOR IN

xT

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

GND

987654321

TB4

16151413121110

M400

Power

L N

987654321

24 VDC

Analog

Outputs

Ethernet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 VDC

GND

RS-485 A

RS-485 B

RS-485 GND

Sensor In

GND

Sensor In

GND

24 VDC

Aout 1

Aout 2

TX+

TX–

RX+

RX–

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

WARNING

All openings have to be closed with certified cable glands

or blocking plugs of the same degree of certification as the GPro™ 500.

WARNING

It is essential that you observe all provided information

and warnings. The system must be closed and grounded

before switching on the system.

13

Page 14

Quick Setup Guide TDL GPro™ 500

Groundingandwiring(FM)

External earth point

for > 4 mm

(M6 ×12)

2

cables

Exernal earth point.

Protective grounding

Material: chromated AISi7Mg0.3

Size: M6 × 12 mm

Protective grounding.

14

2 options for inner protective grounding

Material: 1.4404 (AISI 316L)

Size: M4 × 6 mm

Hex cap screw

Connect with 4 mm2 cable

Page 15

Quick Setup Guide TDL GPro™ 500

RS-485 A

Activeanaloginputs(FMVersion)

ACTIVE ANALOG INPUTS

24 VDC

User-provided

GND

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

+

Purple

+

xT

–

100 mm

+

xT

Power

L N

M400

–

24 VDC

Analog

Outputs

GND

Ethernet

1

24 VDC

GND

2

3

RS-485 A

RS-485 B

4

5

RS-485 GND

6

+Ain 1 4…20 mA

7

–Ain 1 4…20 mA

8

+Ain 2 4…20 mA

9

–Ain 2 4…20 mA

10

24 VDC

11

Aout 1

Aout 2

12

13

TX+

14

TX–

15

RX+

16

RX–

Black

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

987654321

+

–

–

16151413121110

TB4

987654321

Pressure

(4")

Temperature

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

15

Page 16

Quick Setup Guide TDL GPro™ 500

Looppoweredanaloginputs(FMVersion)

User-provided

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

Purple

Black

SENSOR IN

xT

GND

24 VDC

100 mm

(4")

Pressure

Temperature

SENSOR IN

xT

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

GND

987654321

TB4

16151413121110

M400

Power

L N

987654321

24 VDC

Analog

Outputs

Ethernet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 VDC

GND

RS-485 A

RS-485 B

RS-485 GND

Sensor In

GND

Sensor In

GND

24 VDC

Aout 1

Aout 2

TX+

TX–

RX+

RX–

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

16

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

Page 17

Quick Setup Guide TDL GPro™ 500

GPro™ 500 cables

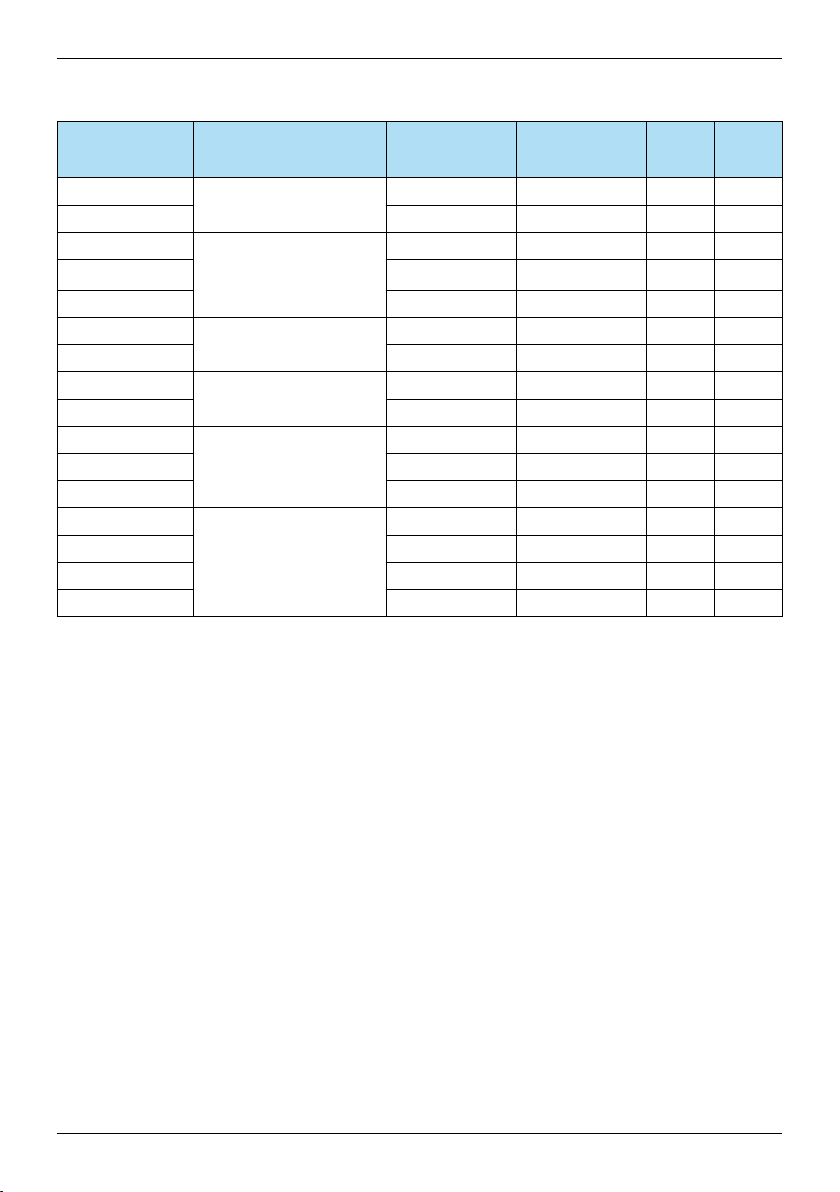

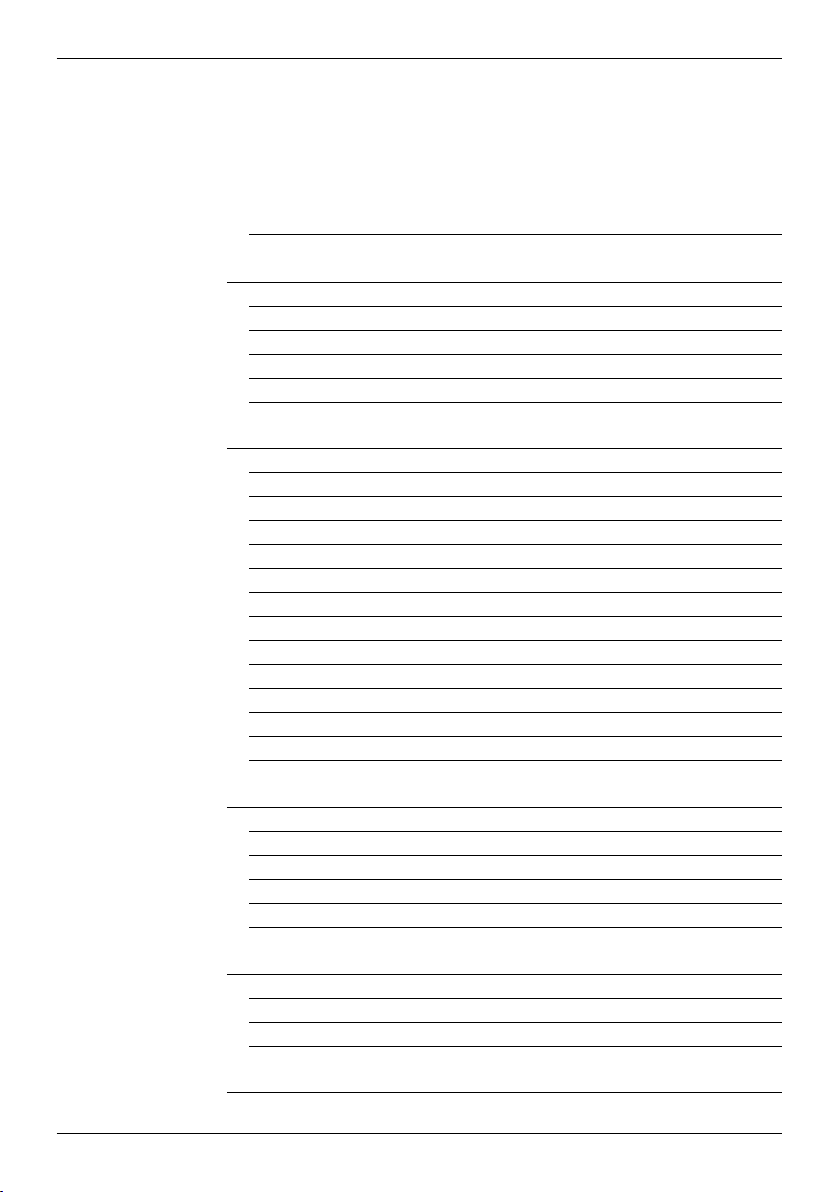

Signal Description Cable no. Color TB1 TB2

Junction Box Pin no Pin no

Power + 24 V

GND (Power) 2 Blue 2

Power 24 V, 5 W

RS 485 A

RS 485 B 4 Yellow 4

Interface M400

(RS 485)

1 Red 1

3 Green 3

RS 485 GND 5 Brown 5

4...20 mA pos

4...20 mA neg 7 Black 7

4...20 mA pos

4...20 mA neg 9 Grey 9

+ 24 V

Out 1 11

Out 2 12 White 12

Current input

temperature

Current input

pressure

Direct anolog output

(2 3 4 … 20 mA)

(optional)

TX+

TX– 14

RX+ 15

Ethernet interface

for communication

with PC

RX– 16

6 Purple 6

8 Pink 8

10

Red / Blue 10

Grey / Pink 11

13

White / Yellow 1

Yellow / Brown 2

White / Green 3

Brown / Green 4

17

Page 18

Quick Setup Guide TDL GPro™ 500

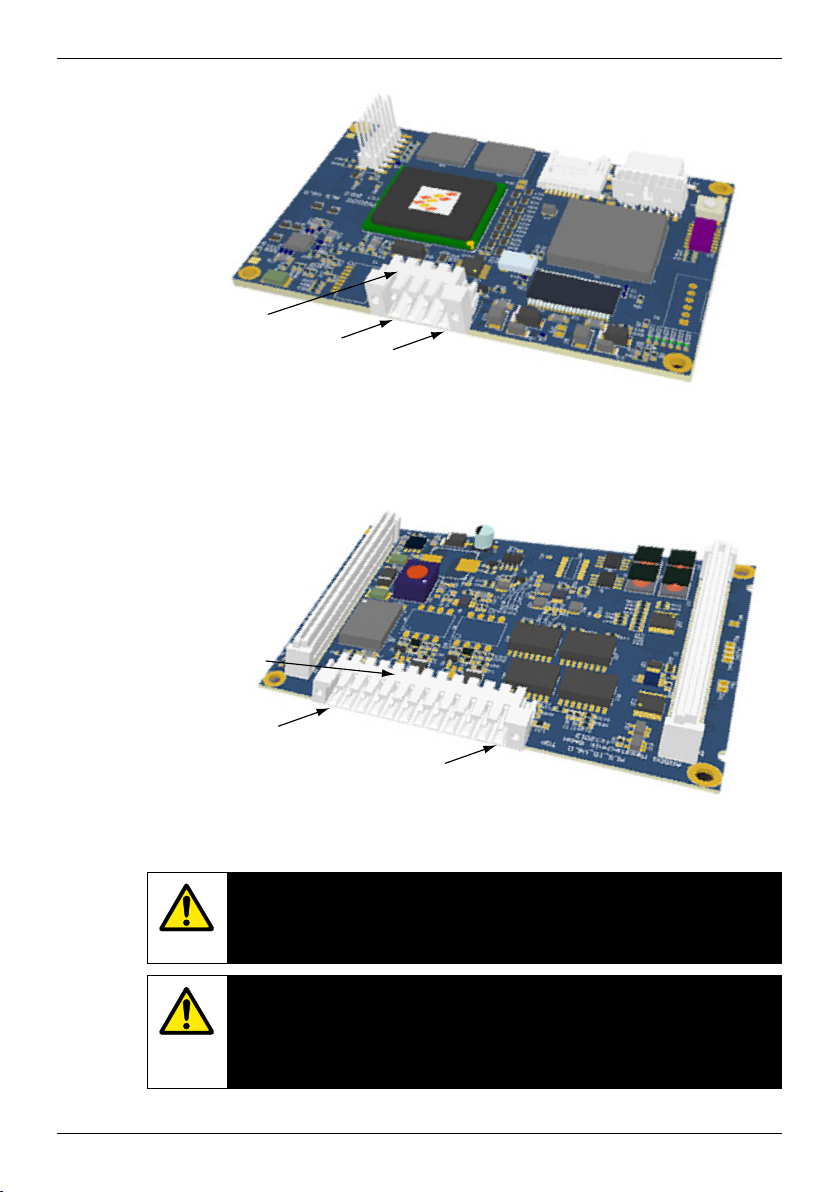

TB1

Pin 1

Pin 4

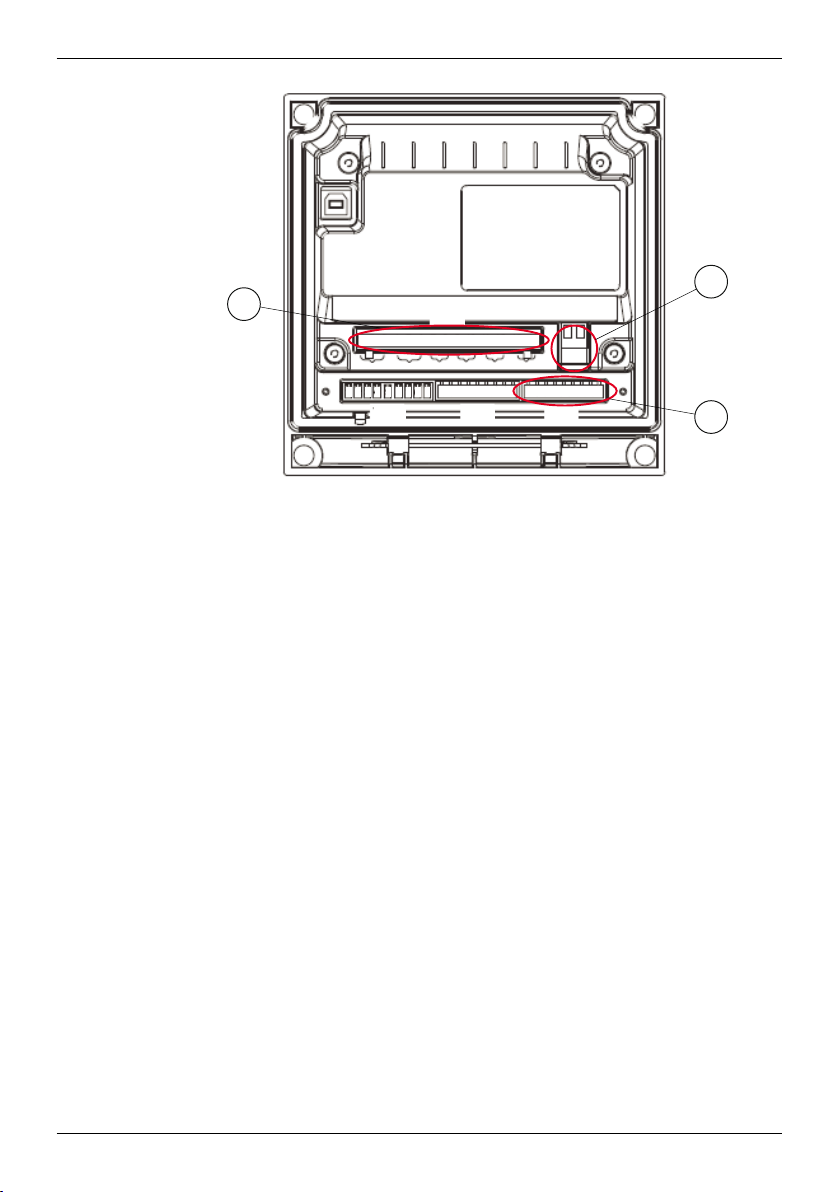

Connections on motherboard in the sensor head.

Note:ThesensorheadcoverofATEXversionshouldneverbeen

opened,asthiswillinvalidatetheATEXcertification.

TB2

Pin 1

Pin 12

Connections on IO board in the sensor head.

WARNING

All openings have to be closed with certified cable glands

or blocking plugs of the same degree of certification as the GPro™ 500.

WARNING

It is essential that you observe all provided information

and warnings. The system must be closed and grounded

before switching on the system.

18

Page 19

Quick Setup Guide TDL GPro™ 500

Cable connections

inM400

USB

3

1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9

TB1

141 2 3 4 5 6 7 8 9 10111213

TB2 TB3 TB4

1 Connection terminal for the power cable

2 TB4 – connection terminal for the GPro™ 500

3 TB1 – connection terminal for the relays.

These can be congured with the M400.

- +

N L

POWER

1

2

19

Page 20

Quick Setup Guide TDL GPro™ 500

3 Installation

GeneralSetup(appliesforallparameters)

(PATH: Menu / Quick Setup)

While in Measurement mode press the [MENU] key to bring up the Menu selec-

20.9 %V O

25.0 °C

MENU

Quick Setup

Please select the type of Sensor:

A

A

Channel Select=ISM

Parameter=Auto

6.0 pH

25.0 °C

2

tion. Select QUICK SETUP and press the [ENTER] key.

Display Convention:

u

1st line on display → a 3rd line on display

2nd line on display → b 4th line on display

→

→

c

d

Select the units of measurement for a and b. Only lines a and b can be congured in Quick Setup. Go to the Conguration Menu to congure lines c and d.

Channel Selection

Analog: For conventional analog sensors (will be displayed on channel “A”).

ISM: For ISM sensors (will be displayed on channel ”B”).

u

Please select the parameter requirement:

The choice of parameter depends on the level of transmitter. If an ISM sensor is

selected, the setting “Auto” means, all possible ISM sensors will be recognized

and accepted. If a special parameter is chosen, only this parameter will be

recognized and accepted on the transmitter.

Calibration

The GPro 500 is calibrated at the factory and does not require calibration at

installation & Startup.

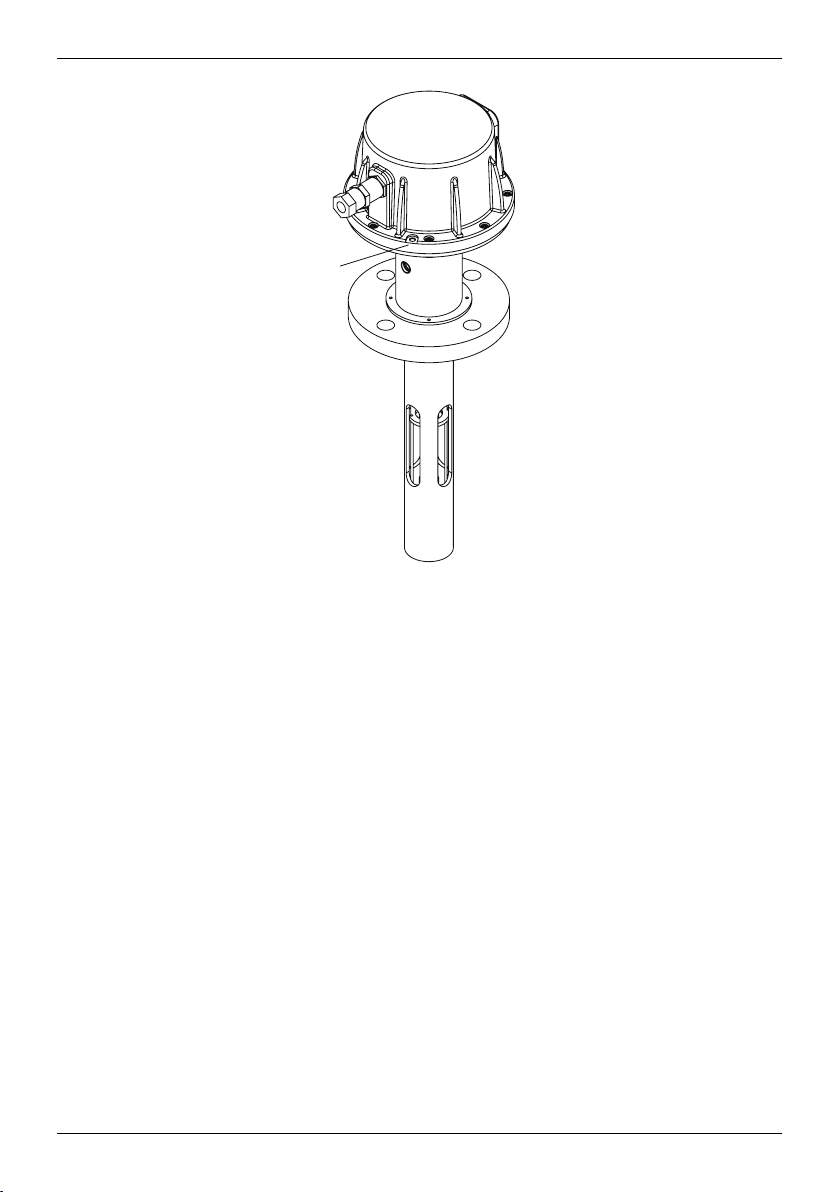

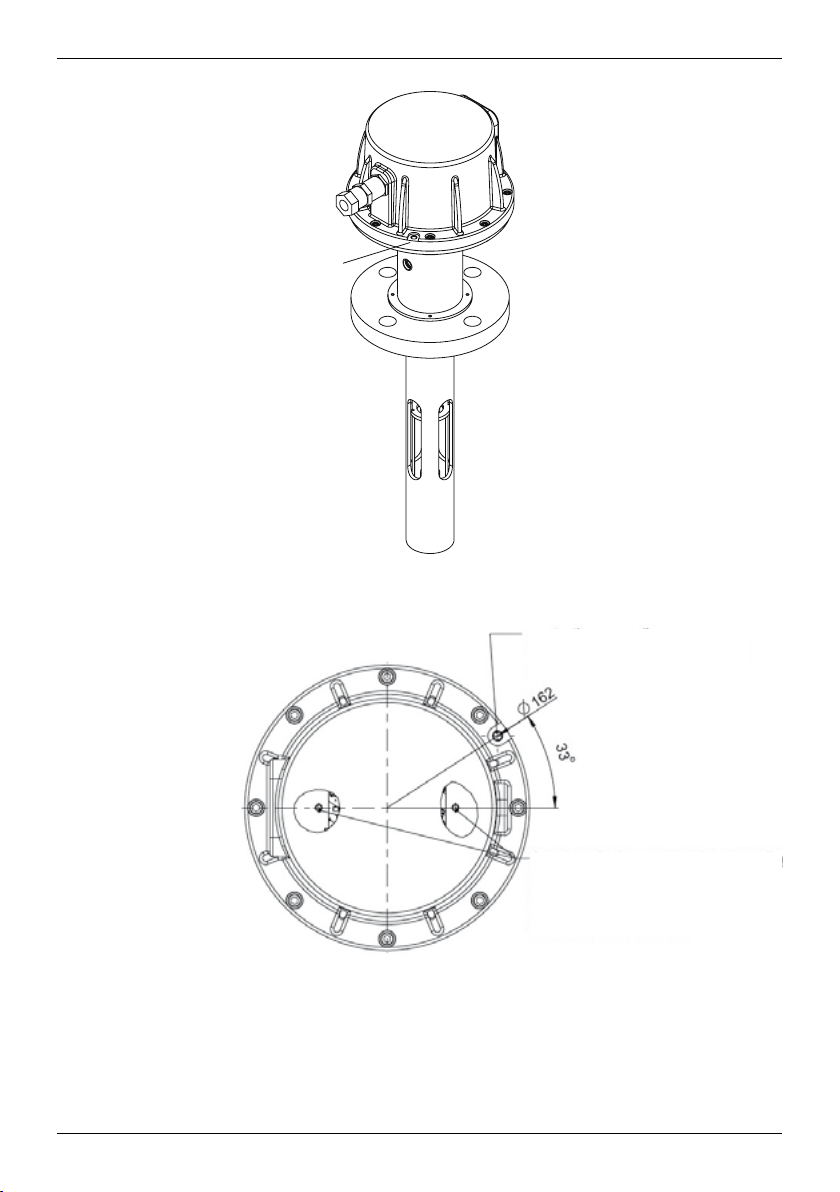

TDLInstallation

(path: Quick Setup / TDL / Installation)

While in measurement mode press the key [MENU] . Press the m or . key to

B

20.9 %V O

B

20.9 %Trm

MENU

Quick Setup

In this mode, the current live value of the % transmission is displayed during

B

20.9 %V O

B

20.9 %Trm

Transmission Signal

021 %

2

select the TDL and then the Installation menu item.

u

2

5 minutes until it automatically returns to the Measurement mode. Use this

value to rotate the blue sensor head attached with a loose clamp connection on

u

to the probe until the maximum transmission is found. In this position, and

secure the blue sensor head into position and tighten the clamp.

20

Page 21

Quick Setup Guide TDL GPro™ 500

TDLCommissioning(path: Quick Setup / TDL / Commissioning)

B

20.9 %V O

B

20.9 %Trm

–TDL

O

2

Commissioning

2

While in measurement mode press the key [MENU] . Press the m or . key to

select the TDL and then the Commissioning menu item.

u

First, select the type of pressure compensation selected:

– External: current external pressure value coming from a pressure transducer

of 4.. 20 mA analog output

– Fixed: pressure compensation uses a xed value to be set manually.

Note: if this pressure compensation mode is selected, a considerable gas concentration measurement error resulting from a nonrealistic pressure value can take place.

If External compensation is selected, then the minimum (4 mA) and maximum

B

20.9 %V O

B

20.9 %Trm

Pressure=External

2

(20 mA) analog output signals from the pressure transducer must be mapped

to the corresponding Analog input of the TDL. Key in the minimum and maxi-

u

mum values of the pressure in the following units:

– hPa – mmHg – mbar

– psi – kPa

In general, METTLER TOLEDO recommends the use of absolute pressure trans-

B

20.9 %V O

B

20.9 %Trm

Ain 4 mA = 940.0 mbar

Ain 20 mA = 2000. mbar

2

ducers for more accurate signal compensation over a broad pressure range.

If, however, small pressure variations around atmospheric pressure are to be

u

expected, relative pressure sensors will produce better results; but the variations

of the underlying barometric pressure will be ignored.

For relative pressure sensors, the minimum and maximum values must be

mapped so that the TDL can interpret the analog pressure signal as “absolute”,

i.e. a xed barometric pressure of 1013 mbar (for example) has to be added to

the mapped values.

If Fixed compensation is selected, the xed pressure value with which the mea-

B

20.9 %V O

B

20.9 %Trm

Pressure=fixed

B

20.9 %V O

B

20.9 %Trm

Pressure=1013. mbar

If External compensation is selected, then the minimum (4 mA) and maximum

B

20.9 %V O

B

20.9 %Trm

Temperature=External

2

surement signal will be calculated has to be keyed in manually. For the xed

pressure, the following units can be used:

u

– hPa – mmHg – mbar

– psi – kPa

2

u

2

(20 mA) analog output signals from the temperature transducer must be

mapped to the corresponding Analog input of the TDL. Key in the minimum and

u

maximum values of the temperature in °C.

21

Page 22

Quick Setup Guide TDL GPro™ 500

B

20.9 %V O

B

20.9 %Trm

Ain 4 mA = 0.000 °C

Ain 20 mA = 250_0 °C

If Fixed compensation is selected, the xed temperature value with which the

B

20.9 %V O

B

20.9 %Trm

Temperature=Fixed

B

20.9 %V O

B

20.9 %Trm

Temperature=320.0 °C

Last, select the initial optical path length corresponding to the probe length in-

B

20.9 %V O

B

20.9 %Trm

Pathlength=00200 mm

2

u

2

measurement signal will be calculated has to be keyed in manually. For the xed

temperature, only °C can be used.

u

2

u

2

stalled:

– 290 mm probe: 200 mm

u

– 390 mm probe: 400 mm

– 590 mm probe: 800 mm

This initial value is valid when instrument purging on the instrument and on the

process side is running. Depending on the process conditions and after the

optimum of the process purging ow has been found (see next chapter), this

value may have to be slightly adapted.

22

Page 23

Quick Setup Guide TDL GPro™ 500

Setting the correct

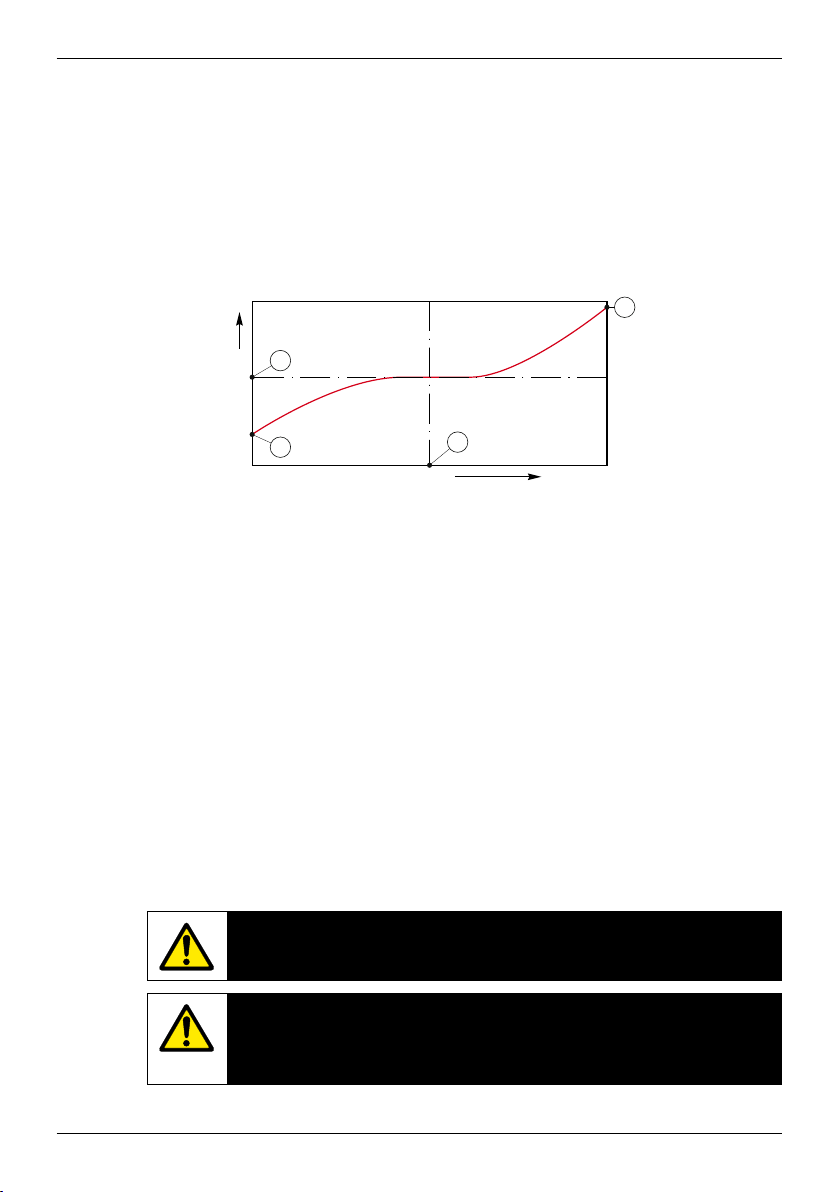

The ow rate of the purging will affect the effective path length and conse-

process side purging

quently the measurement value.

Therefore the following procedure should be used. Start with a very high ow

rate and gradually decrease it. The measurement value will then start at a low

value and increase with decreasing purge ow. At some point it will level out

and stay constant for a while and then again start increasing. Choose a purge

ow in the middle of the constant region.

2

1

Inecreased reading

Decreasing purge flow

Optimizing the purge ow

On the x-axis there is purge ow and on the y-axis there is the instrument concentration reading.

1 Concentration reading with high purge ow. The path length is now shorter

than the effective path length since the purge tubes is completely lled with

purging gas and some of the purging gas is owing into the measurement

path.

2 Concentration reading with optimized purge ow. The path length is now

equal to the effective path length since the purge tubes are completely lled

with purge gas. See the illustration below.

3 Concentration reading with no purge ow. The path length is now equal to

the nominal path length since the probe is completely lled with process

gas.

4 The optimized purge ow.

3

4

WARNING

Always start purging at maximum flow before starting the process.

WARNING

Purging must always be switched on in order

to avoid dust deposition onto the optical surfaces.

23

Page 24

Quick Setup Guide TDL GPro™ 500

4 VericationandMaintenance

One-pointcalibrationforTDLgassensors

Enter calibration mode as described in section 7.1 “Enter Calibration Mode”.

B

20.9 %V O

B

25.0 °C

Calibrate Sensor

Channel B TDL

Select 1 point as calibration type.

B

20.9 %V O

H

25.0 °C

TDL Calibration

Type = 1 Point

Enter values for the effective temperature and pressure values of the gas used

B

20.9 %V O

25.0 °C

Pressure = 1013 hPa

Temperature = 23.00 °C

Place the sensor in the calibration gas (e.g. air). Press [ENTER].

B

20.9 %V O

25.0 °C

Press ENTER when

Sensor is in Gas

2

A one-point calibration of gas sensors is always a slope (i.e. with air) calibration. A one point slope calibration is done in air or any other calibration gas with

u

dened gas concentration.

2

Press [ENTER].

u

2

for calibration. When using the calibration tube for calibration, use values measured manually for the gas present in the calibration tube.

u

Adjust the optical path length for your individual system.

2

Depending on the used drift control (see chapter 8.2.3.5) one of the two following modes is active.

u

ProcesscalibrationforTDLgassensors

Enter calibration mode as described in section 7.1 “Enter Calibration Mode”.

B

12.1 %V O

B

25.0 °C

Calibrate Sensor

Channel B Oxygen

Select Process as the calibration type.

B

12.1 %V O

25.0 °C

TDL Calibration

Type = Process

Take a sample and press the [ENTER] key again to store the current measuring

B

12.1 %V O

B

25.0 °C

Press ENTER to Capture

=0.0000 V% O2 u

B O

2

2

A process calibration of gas sensors is always a slope calibration.

u

2

Press [ENTER]

u

2

value. To show the ongoing calibration process, A or B (depending on the channel) is blinking in the display.

After determining the concentration value of the sample press the

c

key again

to proceed with the calibration.

24

Page 25

Quick Setup Guide TDL GPro™ 500

150 mm (5.91")

Enter the concentration value of the sample then press the [ENTER] key to start

B

12.1 %V O

B

25.0 °C

B Point1 = 56.90 %sat

= 57.1 %air u

B O

2

After the calibration the slope ”S” is displayed.

B

12.1 %V O

B

25.0 °C

S=– 0.070 nA Z=0.0000 nA

O

2

Save Adjust

2

the calculation of the calibration results.

2

In case of a successful calibration, the calibration values are stored in the cal

history and taken over (Adjust), stored in the cal history and not taken over

u

(Calibrate) or discarded (Abort).

If ”Adjust” or ”Calibrate” are chosen, the message ”Calibration successful” is

displayed. The M400 returns to the measuring mode.

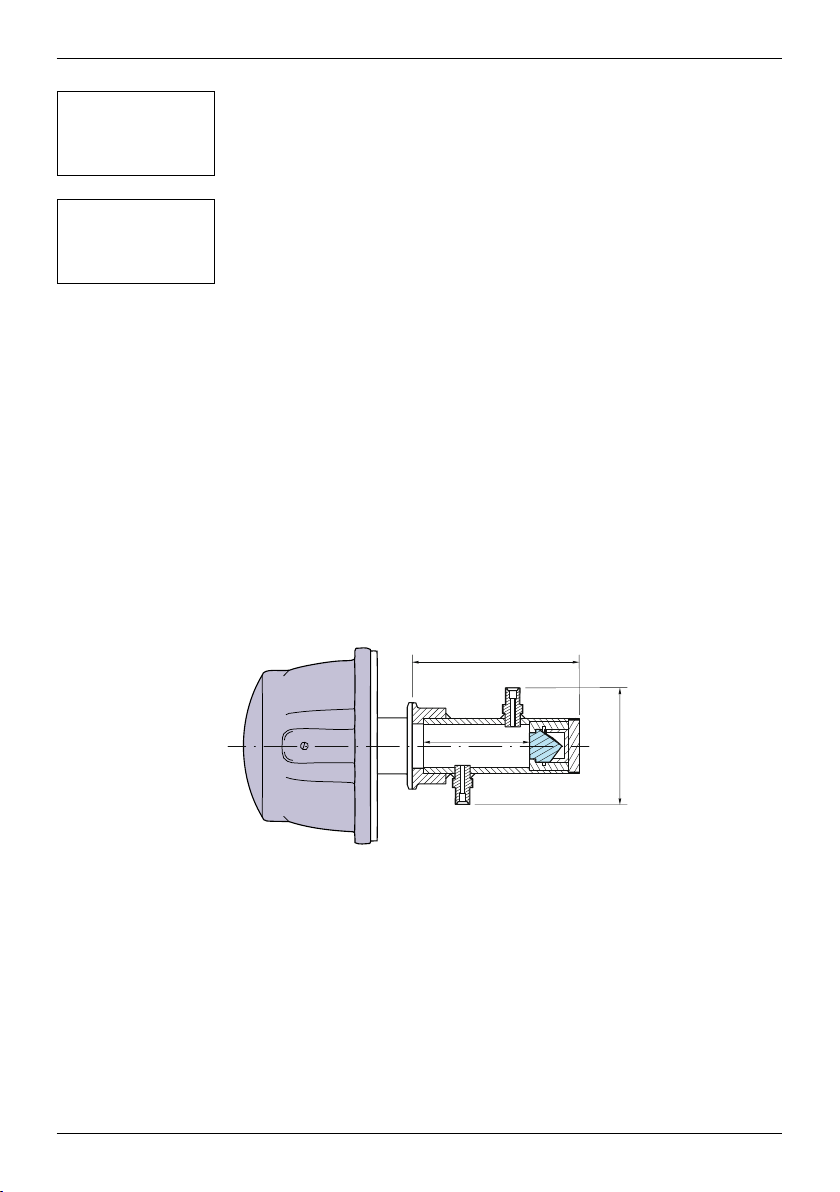

Calibration using a calibration cell

For a more accurate calibration the calibration cell can be used. Doing this the

TDL (the units head) needs to be removed from the probe. Then it has to be

mounted on the calibration cell according to the illustration below. Before calibration is started new values for path length, temperature and pressure have to

be entered on M400. Then the calibration gas is owed through the calibration

cell and the calibration is done in the calibration menu of M400.

During calibration with the calibration cell the process is still sealed and no

extra precautions need to be taken.

Calibration cell.

EPL

2 × 100 mm (3.94")

104,6 mm (4.12")

25

Page 26

Quick Setup Guide TDL GPro™ 500

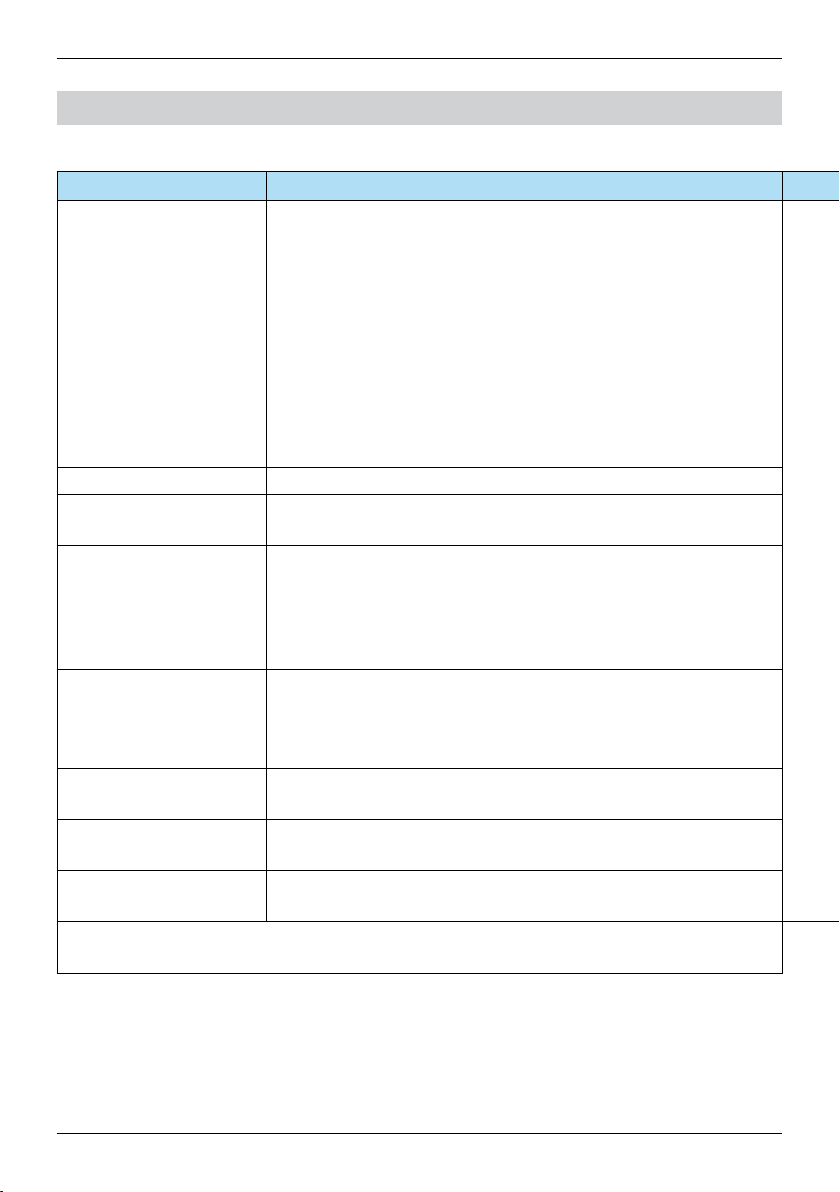

5 Error messages

Message Comment Action Source Relay State Mapping

No sensor on channel 3 The M400 is unable to detect any of the ISM sensor(s) it can identify.

If no sensor is found it will disply the message NO SENSOR DETECTED

Signal Processing Failed Fitting of the line proles failed. Send unit back to METTLER TOLEDO TDL Fault Software error

Laser Source Error The laser wavelength has shifted. Readjustment of the laser tempera-

ture necessary

Bad Signal Quality Transmission lower than 5% threshold Clean corner cube and process window.

Flashcard Error Missing or bad calibration and / or database data Perform a calibration with the calibration

Pressure Input Error Pressure reading out of extended range: 0.6 bara < P < 8 bara

4 – 20 mA input error: 4 mA > P > 20 mA

Temperature Input Error Pressure reading out of extended range: –20°C<T<1000°C

4 – 20 mA input error: 4 mA > P > 20 mA

Conguration Mode Ethernet port in use: diagnostic or conguration in progress Disconnect Ethernet cable TDL Maintenance

The GPro™ 500 error messages can be found in the M400 under the following path:

Menu ➝ Service ➝ Diagnostics ➝ TDL ➝ Messages

26

Page 27

Quick Setup Guide TDL GPro™ 500

– This is the initial message after Power on.

M400 Fault B disconnected

– Wait for the GPro™ 500 to fully boot.

– Check if the GPro™ 500 is powered and

wait until the system is fully started.

– Check the RS485 wiring of the

GPro™ 500 to the M400

– Check with the MT-TDL software and the

Ethernet port if the system is running

correctly.

– If timeout still occurs after 60 s, send unit

back to METTLER TOLEDO.

Send unit back to METTLER TOLEDO TDL Fault System error

TDL Fault System error

Check the gasket between TDL and probe.

Rotate TDL on the probe to maximize Trans-

mission.

Reduce the dustload in the process.

TDL Fault Software error

tube.

If still not successful, send unit back to

METTLER TOLEDO for Flashcard exchange.

Check external pressure sensor and mapping TDL Maintenance

System error

request

Check external temperature sensor and

mapping

TDL Maintenance

request

System error

Software error

request

27

Page 28

Page 29

Quick Setup Guide TDL GPro™ 500

GPro™ 500

Quick Setup-Leitfaden

Inhaltsverzeichnis

1 Vorbereitung 31

Lieferumfang 31

Anforderungen vor Ort 31

Umgebungs-bedingungen 31

Außerdem erforderlich 31

Optionales Zubehör 32

2 Vor der Installation 33

Montageort für Flansch 33

Anforderungen an den Flansch 33

Strömungs-verhältnisse anderMessstelle 34

Spülen 35

Spülen mit Wärmeschutz 36

Erdung und Verdrahtung (ATEX) 37

Aktive Analogeingänge (ATEX-Ausführung) 38

Schleifengespeiste Analogeingänge (ATEX-Ausführung) 39

Erdung und Verdrahtung (FM) 40

Aktive Analogeingänge (FM-Ausführung) 41

Schleifengespeiste Analogeingänge (FM-Ausführung) 42

GPro™ 500 Kabel 43

Kabelanschlüsse im M400 45

German

3 Installation 46

Allgemeines Setup (gilt für alle Parameter) 46

Kanalwahl 46

Kalibrierung 46

TDL Installation 46

Einstellung der korrekten Spülung der Prozessseite 49

4 Verifizierung und Wartung 50

Einpunktkalibrierung von TDL-Gassensoren 50

Prozesskalibrierung für TDL-Gassensoren 50

Kalibrierung mit einer Kalibrierzelle 51

5 Fehlermeldungen 52

29

Page 30

Quick Setup Guide TDL GPro™ 500

30

Page 31

Quick Setup Guide TDL GPro™ 500

1 Vorbereitung

– GPro™ 500 Analysator mit durchstimmbarem Diodenlaser– GPro™ 500 Analysator mit durchstimmbarem Diodenlaser GPro™ 500 Analysator mit durchstimmbarem DiodenlaserGPro™ 500 Analysator mit durchstimmbarem Diodenlaser

Lieferumfang

–

1 Sicherheitshinweise

–

1 Dokumentations-CD mit Bedienungsanleitung und MT-TDL Software Suite.

– 24 VDC, 5 W für die Stromversorgung des GPro™ 500– 24 VDC, 5 W für die Stromversorgung des GPro™ 500 24 VDC, 5 W für die Stromversorgung des GPro™ 50024 VDC, 5 W für die Stromversorgung des GPro™ 500

Anforderungen vor Ort

–

110 / 220 VAC für die Stromversorgung des M400

– Spülgas, > 99,7% Reinheit (empfohlener Mindestwert), 0,5…5l/min.

Die Reinheitsanforderungen sind:

normgemäß nach ISO 8573.1, Klasse 2–3, analog zur Geräteluft.

Für Sauerstoff TDL kann Stickstoff oder jedes andere «sauerstofffreie»

saubere und trockene Gas verwendet werden.

− 20 bis + 55 °C (− 4 bis + 131 °F) im laufenden Betrieb

Umgebungsbedingungen

• 1 M400 T3 Transmitter (Bestell-Nr. 52121350)

Außerdem

•

erforderlich

1 Ethernetkabel CAT5

•

RS485-Kabel (< 250m)

• 1 Laptop (WinXP / 7 / 8) mit installierter MT-TDL Software

• Flachdichtung 82,14 mm 3 3,53 mm

• Absperrventil

•

2 Gabelschlüssel (Schraubenschlüssel) für Schrauben M16

•

1 Imbusschlüssel 5 mm für die Klemmschrauben an den Flanschen

und Tx-Deckelschrauben

•

1 Imbusschlüssel 3 mm für die Schrauben der

RS232-Schnittstellenabdeckung

•

2 Flachschlüssel für Swagelok-Rohrverschraubungen

•

1 Schlitz-Schraubendreher (2,5 mm) für die elektrischen Anschlüsse

•

1 Schlitz-Schraubendreher (6mm) oder Kreuzschraubendreher (Nr. 2)

für die Rx-Deckelschrauben

•

Rollgabelschlüssel (Schraubenschlüssel) für die Spülgasanschlüsse

•

Drehmomentschlüssel für die FM-Ausführung

31

Page 32

Quick Setup Guide TDL GPro™ 500

Optionales Zubehör

Zubehör Bestellnummer

Wärmeschutz 30 034 138

Anschlussbox 30 034 149

Spülbox für M400 Ex d 30 034 148

Kalibrierkit 30 034 139

O

2

Kit Flachdichtung ST 30 080 914

Kit Flachdichtung HT (Graphit) 30 080 915

Kabel GPro 500 ATEX, FM 5 m 30 077 735

Kabel GPro 500 ATEX, FM 15 m 30 077 736

Kabel GPro 500 ATEX, FM 25 m 30 077 737

32

Page 33

Quick Setup Guide TDL GPro™ 500

2 Vor der Installation

Montageort für Flansch

Der TDL-Kopf muss leicht zugänglich sein. Eine Person muss vor dem Sensor

stehen können und mit zwei normalen Gabelschlüsseln die M16 Befestigungsschrauben erreichen. Um den quer in die Leitung eingebauten Flansch herum

müssen mindestens 60 cm Platz sein, wie unten dargestellt.

60 cm (23.6")

)

"

60 cm (23.6

Anforderungen an den Flansch

Mindestabstand: 61,5mm

(Schedule 40)

DIN 50 oder ANSI 2"

Mindestabstand: 77,5mm

(Schedule 80)

100 mm

(4")

DIN 65 oder ANSI

2½"

33

Page 34

Quick Setup Guide TDL GPro™ 500

DIN

DN50/PN25 DN65/PN25

DN 50

100 mm 100 mm

DN100

min. Ø 54 mm

min. Ø 67 mm

DN65

ANSI

4"

min. 2.12"

2"

min. 2.64"

ANSI 2.5"/300 lbsANSI 2"/300 lbs

2.5"

4" 4"

Bei der Wahl des Einbauorts des GPro™ 500 TDL in den Prozess ist darauf zu Bei der Wahl des Einbauorts des GPro™ 500 TDL in den Prozess ist darauf zu

Strömungsverhältnisse

anderMessstelle

achten, dass vor der Messstelle eine gerade Einlaufstrecke von mindestens dem

5-fachen des Leitungsdurchmessers und nach der Messstelle von mindestens

dem 3-fachen des Leitungsdurchmessers frei bleibt.

So können sich laminare Strömungsverhältnisse einstellen, die eine Voraussetzung für stabile Messbedingungen sind.

34

Page 35

Quick Setup Guide TDL GPro™ 500

Spülen

1 Spülgaseinlass Geräteseite (6mm- oder ¼"-Anschluss).

2 Spülgaseinlass Prozessseite (Absperrventil erforderlich).

3 Spülgasauslass Geräteseite (6 mm- oder ¼"-Anschluss).

4 Prozessgasuss.

5

Bereich der Grenzen der effektiven optischen Weglänge.

0 −1 l/min

0 −10 l/min

RotameterDruckregler

WARNUNG

Bevor der Prozess gestartet wird, ist der Spülgasfluss

immer auf maximalen Durchfluss einzustellen.

WARNUNG

Die Spülung muss immer aktiviert sein, um Staubablagerungen

auf den optischen Flächen vorzubeugen.

WARNUNG

Entfernen und / oder demontieren Sie keinesfalls den Spülgaseinlass auf

der Prozessseite (2). Durch Demontieren des Einlasses erlischt

die Zulassung gemäß Druckgeräterichtlinie (DGRL).

WARNUNG

Schalten Sie die Spülung des Geräts und der Prozessseite nicht

in Serie, sonst wird die Sensorspülung beim Demontieren

des Sensorkopfes angehalten.

35

Page 36

Quick Setup Guide TDL GPro™ 500

Spülen mit

W

ärmeschutz

Konfiguration beim Spülen

1

Spülgaseinlass in die thermische Barriere (6 mm- oder ¼"-Anschluss)

2

Spülgasauslass aus der thermischen Barriere (6 mm- oder ¼"-Anschluss)

3 Spülgaseinlass Prozessseite (erfordert ein Absperrventil)

4 Absperrventil vorgeschrieben (muss vom Benutzer bereitgestellt werden)

Das Spülgas für die thermische Barriere muss immer aktiviert sein,

21 4

3

WARNUNG

wenn der Prozessgasstrom aktiviert ist, um den Sensorkopf vor

dauerhafter Beschädigung zu schützen.

36

WARNUNG

Störungen im Spülsystem der Geräteseite und der thermischen Barriere

müssen zwingend einen Alarm auslösen. Dieser Alarm ist von

Anwenderseite im PLS zu implementieren.

Page 37

Quick Setup Guide TDL GPro™ 500

Erdung und

Verdrahtung

(ATEX)

Externer

Erdungspunkt

für Kabel mit

> 4 mm

(M6 × 12)

Externer Erdungspunkt

2

37

Page 38

Quick Setup Guide TDL GPro™ 500

RS-485 A

AktiveAnalogeingänge(ATEX-Ausführung)

ACTIVE ANALOG INPUTS

24 VDC

User-provided

GND

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

+

Purple

+

xT

–

100 mm

+

xT

Power

L N

M400

–

24 VDC

Analog

Outputs

GND

Ethernet

1

24 VDC

GND

2

3

RS-485 A

RS-485 B

4

5

RS-485 GND

6

+Ain 1 4…20 mA

7

–Ain 1 4…20 mA

8

+Ain 2 4…20 mA

9

–Ain 2 4…20 mA

10

24 VDC

11

Aout 1

Aout 2

12

13

TX+

14

TX–

15

RX+

16

RX–

Black

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

987654321

+

–

–

16151413121110

TB4

987654321

Pressure

(4")

Temperature

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

38

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

Page 39

Quick Setup Guide TDL GPro™ 500

SchleifengespeisteAnalogeingänge(ATEX-Ausführung)

User-provided

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

Purple

Black

SENSOR IN

xT

GND

24 VDC

100 mm

(4")

Pressure

Temperature

SENSOR IN

xT

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

GND

987654321

TB4

16151413121110

M400

Power

L N

987654321

24 VDC

Analog

Outputs

Ethernet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 VDC

GND

RS-485 A

RS-485 B

RS-485 GND

Sensor In

GND

Sensor In

GND

24 VDC

Aout 1

Aout 2

TX+

TX–

RX+

RX–

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

WARNUNG

Alle Öffnungen sind mit zugelassenen Kabelverschraubungen oder

Verschlussstopfen zu verschließen, die über die gleichen

Zertifizierungen verfügen wie der GPro™ 500.

WARNUNG

Sämtliche in dieser Bedienungsanleitung gegebenen Informationen und

enthaltenen Warnungen sind einzuhalten. Das System muss vor der

letztendlichen Inbetriebnahme geschlossen und geerdet sein.

39

Page 40

Quick Setup Guide TDL GPro™ 500

Erdung und

Verdrahtung(FM)

Externer

Erdungspunkt

für Kabel mit

> 4 mm

(M6 × 12)

Externer Erdungspunkt

2

40

Schutzerdung

Schutzerdung

Werkstoff: AISi7Mg0,3 verchromt

Größe: M6 × 12mm

Zwei Optionen für die innere Schutzerdung

Werkstoff: 1.4404 (AISI 316L)

Größe: M4 × 6mm

Sechskantschraube

Anschluss mit Kabel 4 mm

2

Page 41

Quick Setup Guide TDL GPro™ 500

RS-485 A

AktiveAnalogeingänge(FM-Ausführung)

ACTIVE ANALOG INPUTS

24 VDC

User-provided

GND

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

+

Purple

+

xT

–

100 mm

+

xT

Power

L N

M400

–

24 VDC

Analog

Outputs

GND

Ethernet

1

24 VDC

GND

2

3

RS-485 A

RS-485 B

4

5

RS-485 GND

6

+Ain 1 4…20 mA

7

–Ain 1 4…20 mA

8

+Ain 2 4…20 mA

9

–Ain 2 4…20 mA

10

24 VDC

11

Aout 1

Aout 2

12

13

TX+

14

TX–

15

RX+

16

RX–

Black

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

987654321

+

–

–

16151413121110

TB4

987654321

Pressure

(4")

Temperature

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

41

Page 42

Quick Setup Guide TDL GPro™ 500

SchleifengespeisteAnalogeingänge(FM-Ausführung)

User-provided

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

Purple

Black

SENSOR IN

xT

GND

24 VDC

100 mm

(4")

Pressure

Temperature

SENSOR IN

xT

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

GND

987654321

TB4

16151413121110

M400

Power

L N

987654321

24 VDC

Analog

Outputs

Ethernet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 VDC

GND

RS-485 A

RS-485 B

RS-485 GND

Sensor In

GND

Sensor In

GND

24 VDC

Aout 1

Aout 2

TX+

TX–

RX+

RX–

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

42

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

Page 43

Quick Setup Guide TDL GPro™ 500

GPro™ 500 Kabel

Signal Beschreibung Kabel-Nr. Farbe TB1 TB2

Anschlussbox Pin-Nr. Pin-Nr.

Stromversorgung

+ 24 V

GND (Stromver-

Stromversorgung 24 V,

5 W

sorgung)

RS485 A

RS485 B 4 Gelb 4

Schnittstelle M400

(RS485)

1 Rot 1

2 Blau 2

3 Grün 3

RS485 GND 5 Braun 5

4 ... 20 mA pos

4 ... 20 mA neg 7 Schwarz 7

4 ... 20 mA pos

4 ... 20 mA neg 9 Grau 9

+ 24 V

Out 1 11

Out 2 12 Weiß 12

Stromeingang

Temperatur

Stromeingang Druck

Direkter Analogausgang

(2 3 4 – 20 mA)

(optional)

TX+

TX– 14

RX+ 15

Ethernet-Anschluss für

Kommunikation mit PC

RX– 16

6 Violett 6

8 Rosa 8

10

Rot / Blau 10

Grau / Rosa 11

13

Weiß / Gelb 1

Gelb / Braun 2

Weiß / Grün 3

Braun / Grün 4

43

Page 44

Quick Setup Guide TDL GPro™ 500

TB1

Anschlüsse an der Hauptplatine im Sensorkopf

Hinweis: DieAbdeckungdesSensorkopfsdarfbeiderATEX-

Pin 1

Pin 4

Ausführung keinesfalls geöffnet werden, da sonst

dieATEX-ZertifizierungihreGültigkeitverliert.

44

TB2

Pin 1

Pin 12

Anschlüsse auf E / A-Platine im Sensorkopf

WARNUNG

Alle Öffnungen sind mit zugelassenen Kabelverschraubungen oder

Verschlussstopfen zu verschließen, die über die gleichen

Zertifizierungen verfügen wie der GPro™ 500.

WARNUNG

Sämtliche in dieser Bedienungsanleitung gegebenen Informationen und

enthaltenen Warnungen sind einzuhalten. Das System muss vor der

letztendlichen Inbetriebnahme geschlossen und geerdet sein.

Page 45

Quick Setup Guide TDL GPro™ 500

Kabelanschlüsse im M400

USB

3

1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9

TB1

141 2 3 4 5 6 7 8 9 10111213

TB2 TB3 TB4

1 Anschlussklemme für Stromversorgungskabel

2 TB4 – Anschlussklemme für den GPro™ 500 TB4 – Anschlussklemme für den GPro™ 500TB4 – Anschlussklemme für den GPro™ 500

3 TB1 – Anschlussklemme für die Relais.

Diese können mit dem M400 konguriert werden.

- +

N L

POWER

1

2

45

Page 46

Quick Setup Guide TDL GPro™ 500

3 Installation

AllgemeinesSetup(giltfüralleParameter)

(PFAD: Menu / Quick Setup)

20.9 %V O

25.0 °C

MENU

Quick Setup

A

A

Kanal Auswahl=ISM

Parameter=Auto

6.0 pH

25.0 °C

Drücken Sie im Messmodus die Taste [MENU], um das Menü aufzurufen.

2

Wählen Sie Quick Setup und drücken Sie die Taste [ENTER].

Zeilenbezeichnung:

u

1. Zeile des Displays

2. Zeile des Displays

➝ a 3. Zeile des Displays ➝ c

➝ b 4. Zeile des Displays ➝ d

Wählen Sie die Maßeinheiten für a und b. Es können nur die Zeilen a und b im

Quick Setup konguriert werden. Gehen Sie zum Kongurationsmenü, um die

Zeilen c und d zu kongurieren.

Kanalwahl

Bitte wählen Sie den Sensortyp:

Analog:

Für herkömmliche analoge Sensoren (werden auf Kanal «A» angezeigt).

ISM:

Für ISM-Sensoren (werden auf Kanal «B» angezeigt).

u

Bitte wählen Sie die Parameter-Anforderungen:

Die Auswahl der Parameter richtet sich nach dem verwendeten Transmitter. Wird

ein ISM-Sensor ausgewählt, bedeutet die Einstellung «Auto», dass alle ISMSensoren erkannt und akzeptiert werden. Wird ein bestimmter Parameter ausgewählt, wird nur dieser Parameter vom Transmitter erkannt und akzeptiert.

Kalibrierung

Der GPro 500 ist werksseitig kalibriert und erfordert bei Installation und Inbetriebnahme keine Kalibrierung.

TDLInstallation

(Pfad: Quick Setup / TDL / Installation)

B

20.9 %V O

B

20.9 %Trm

MENU

Quick Setup

B

20.9 %V O

B

20.9 %Trm

Transmissionssignal

021 %

46

Drücken Sie im Messmodus die Taste [MENU]. Drücken Sie die Taste m

2

oder

., um den TDL auszuwählen und anschließend den Menüpunkt

Installation.

u

In diesem Modus wird auf dem Display für fünf Minuten der aktuelle Transmis-In diesem Modus wird auf dem Display für fünf Minuten der aktuelle Transmis-

2

sionswert in Prozent angezeigt. Danach kehrt die Anzeige automatisch wieder

in den Messmodus zurück. Anhand dieses Werts können Sie den blauen Sen-

u

sorkopf drehen, der mit einer losen Klemmverbindung an dem Sensor befestigt

ist, bis Sie die maximale Transmission gefunden haben. Halten Sie den blauen

Sensorkopf in dieser Position und ziehen Sie die Klemme fest.

Page 47

Quick Setup Guide TDL GPro™ 500

B

20.9 %V O

B

20.9 %Trm

–TDL

O

2

Inbetriebnahme

B

20.9 %V O

B

20.9 %Trm

Druck=ext. Sensor

B

20.9 %V O

B

20.9 %Trm

Ain 4 mA = 940.0 mbar

Ain 20 mA = 2000. mbar

TDLInbetriebnahme(Pfad: Quick Setup / TDL / Commissioning)

2

Drücken Sie im Messmodus die Taste [MENU]. Drücken Sie die Taste m

oder

u

., um den TDL auszuwählen und anschließend den Menüpunkt Inbetrieb-

nahme.

Wählen Sie als Erstes die Art der Druckkompensation:

–

Extern: aktueller Wert des externen Drucks, der von einem Drucksensor am

Analogausgang 4 ... 20 mA eingespeist wird

– Fest: Druckkompensation verwendet einen festen Wert, der manuell ein- Fest: Druckkompensation verwendet einen festen Wert, der manuell ein-Fest: Druckkompensation verwendet einen festen Wert, der manuell ein- Druckkompensation verwendet einen festen Wert, der manuell ein-Druckkompensation verwendet einen festen Wert, der manuell ein-

gestellt wird.

Hinweis: Wird dieser Druckkompensations-Modus ausgewählt,

kann aufgrund eines unrealistischen Druckwerts ein erheblicher

Messfehler bei der Gaskonzentration auftreten.

Wird die externe Kompensation ausgewählt, müssen die minimalen (4mA) und

2

die maximalen (20 mA) Analogausgangssignale des Drucksensors dem entsprechenden Analogeingang des TDL zugeordnet werden. Geben Sie die mini-

u

malen und maximalen Druckwerte in den folgenden Einheiten ein:

–

hPa – mmHg – mbar

–

psi – kPa

Im Allgemeinen emp ehlt METTLER TOLEDO die Verwendung von Absolutdruck-Im Allgemeinen empehlt METTLER TOLEDO die Verwendung von Absolutdruck-

2

sensoren für eine genauere Signalkompensation über einen breiten Druckbereich. Wenn jedoch kleine Druckabweichungen rund um den atmosphärischen

u

Druck zu erwarten sind, erzielen Relativdrucksensoren bessere Ergebnisse. Die

Abweichungen des zugrundeliegenden barometrischen Drucks werden dabei

ignoriert.

B

20.9 %V O

B

20.9 %Trm

Druck=fester Wert

B

20.9 %V O

B

20.9 %Trm

Pressure=1013. mbar

B

20.9 %V O

B

20.9 %Trm

Temperatur=ext. Sensor

Bei Relativdrucksensoren müssen die Minimal- und die Maximalwerte so zugeordnet werden, dass der TDL das analoge Drucksignal als «absolut» interpretieren kann. Den Werten wird dabei beispielsweise ein fester barometrischer Druck

von 1013mbar zugeordnet.

Ist die feste Kompensation ausgewählt, muss der für die Berechnung des Mess-Ist die feste Kompensation ausgewählt, muss der für die Berechnung des Mess-

2

signals erforderliche feste Druckwert manuell eingegeben werden. Für den festen

Druck können die folgenden Einheiten verwendet werden:

u

–

hPa – mmHg – mbar

– psi – kPa

2

u

Wird die externe Kompensation ausgewählt, sind die minimalen (4 mA) und

2

maximalen (20 mA) Analogausgangssignale des Temperaturfühlers dem entsprechenden Analogeingang des TDL zuzuordnen. Geben Sie die Minimal- und

u

Maximalwerte der Temperatur in °C ein.

47

Page 48

Quick Setup Guide TDL GPro™ 500

B

20.9 %V O

B

20.9 %Trm

Ain 4 mA = 0.000 °C

Ain 20 mA = 250_0 °C

B

20.9 %V O

B

20.9 %Trm

Temperatur=fester Wert

B

20.9 %V O

B

20.9 %Trm

Temperatur=320.0 °C

B

20.9 %V O

B

20.9 %Trm

Opt. Weglänge=00200 mm

2

u

Ist die feste Kompensation ausgewählt, muss der für die Berechnung des Mess-Ist die feste Kompensation ausgewählt, muss der für die Berechnung des Mess-

2

signals erforderliche feste Temperaturwert manuell eingegeben werden. Die feste

Temperatur kann nur in °C eingegeben werden.

u

2

u

Zuletzt wählen Sie die optische Weglänge aus, die der installierten Sensorlänge

2

entspricht:

–

290mm Sensor: 200 mm

u

–

390mm Sensor: 400 mm

–

590mm Sensor: 800 mm

Dieser Wert ist gültig, wenn die Gerätespülung am Gerät und an der Prozessseite läuft. In Abhängigkeit der Prozessbedingungen und nachdem der optimale

Prozess-seitigen Spüldurchuss gefunden wurde (siehe nächstes Kapitel),

muss dieser Wert eventuell leicht angeglichen werden.

48

Page 49

Quick Setup Guide TDL GPro™ 500

Einstellung

Die Durchussrate des Spülgases beeinusst die effektive optische Weglänge

der korrekten

Spülung der

Prozessseite

und damit den Messwert.

Daher ist die folgende Vorgehensweise unbedingt einzuhalten! Zu Beginn mit

einer sehr hohen Durchussrate anfangen und diese schrittweise verringern. Der

Messwert ist zunächst sehr klein und steigt mit abnehmendem Spülgasuss. Bei

einem bestimmten Punkt wird er sich einpendeln und eine Zeit lang konstant

bleiben, bis er wieder zu steigen beginnt. Wählen Sie einen Spülgasuss im

mittleren Bereich der konstanten Messwertanzeige.

3

2

Messwert steigt

1

Spülgasfluss verringern

Spülgasuss optimieren

4

Auf der x-Achse ist der Spülgasuss und auf der y-Achse der vom Gerät angezeigte Messwert für die Konzentration dargestellt.

1

Messwert für die Konzentration bei hohem Spülgasuss. Die optische

Weglänge ist hier kürzer als die effektive Weglänge, weil die Spülgasleitungen komplett mit Spülgas gefüllt sind und das Spülgas in den Messweg

hineinießt.

2 Messwert für die Konzentration bei optimiertem Spülgasuss. Die optische

Weglänge ist hier gleich der effektiven Weglänge, weil die Spülgasleitungen

komplett mit Spülgas gefüllt sind.

3 Messwert für die Konzentration ohne Spülgasuss. Die optische Weglänge

ist hier gleich der nominellen Weglänge, weil der Sensor komplett mit

Prozessgas gefüllt ist.

4

Optimierter Spülgasuss.

WARNUNG

Bevor der Prozess gestartet wird, ist der Spülgasfluss

immer auf maximalen Durchfluss einzustellen.

WARNUNG

Die Spülung muss immer aktiviert sein, um Staubablagerungen

auf den optischen Flächen vorzubeugen.

49

Page 50

Quick Setup Guide TDL GPro™ 500

4 VerizierungundWartung

EinpunktkalibrierungvonTDL-Gassensoren

B

20.9 %V O

B

25.0 °C

Justieren Sensor

Kanal B TDL

B

20.9 %V O

H

25.0 °C

TDL Justierung

Typ = 1 Punkt

B

20.9 %V O

25.0 °C

Druck = 1013 hPa

Temperatur = 23.00 °C

B

20.9 %V O

25.0 °C

ENTER drücken wenn

Sensor in Messgas

B

12.1 %V O

B

25.0 °C

Justieren Sensor

Kanal B Sauerstoff

Rufen Sie den Kalibrierungsmodus auf, siehe Abschnitt 7.1 «Justiermodus auf-

2

rufen».

Eine Einpunktkalibrierung eines Gassensors ist stets eine Kalibrierung der Steil-

u

heit (d.h. mit Luft). Eine Einpunktkalibrierung der Steilheit wird in Luft oder einem beliebigen Kalibriergas mit bekanntem Gasgehalt durchgeführt.

Wählen Sie Einpunktkalibrierung als Kalibrierart.

2

Drücken Sie [ENTER].

u

Geben Sie die Werte für die effektiven Temperatur- und Druckwerte des für die

2

Kalibrierung verwendeten Gases ein. Wird das Kalibrierrohr für die Kalibrierung

genutzt, verwenden Sie manuell gemessene Werte für das im Kalibrierrohr vor-

u

handene Gas.

Abstimmung der Länge des optischen Weges für Ihr System ().

Tauchen Sie den Sensor in das Kalibriergas (z.B. Luft). Drücken Sie [ENTER].

2

u

ProzesskalibrierungfürTDL-Gassensoren

Rufen Sie den Kalibrierungsmodus auf, siehe Abschnitt 7.1 «Justiermodus auf-

2

rufen».

Eine Prozesskalibrierung eines Gassensors ist stets eine Kalibrierung der Steil-

u

heit.

B

12.1 %V O

25.0 °C

TDL Justierung

Typ=Prozess

B

12.1 %V O

B

25.0 °C

ENTER drücken, um Konz

=0.0000 V% O2 u

B O

2

50

Wählen Sie Prozess als Kalibrierart.

2

Drücken Sie [ENTER]

u

Nehmen Sie eine Probe und drücken Sie die Taste [ENTER] erneut, um den

2

aktuellen Messwert zu speichern. Der laufende Kalibrierprozess wird mit einem

blinkenden A oder B (je nach Kanal) im Display angezeigt.

Nach der Bestimmung des Konzentrationswertes der Probe drücken Sie die

Taste

c erneut, um mit der Kalibrierung fortzufahren.

Page 51

Quick Setup Guide TDL GPro™ 500

150 mm (5.91")

B

12.1 %V O

B

25.0 °C

B Punkt1 = 56.90 %sat

= 57.1 %air u

B O

2

B

12.1 %V O

B

25.0 °C

S=− 0.070 nA Z=0.0000 nA

O

2

Speichern Justierung

Geben Sie den Konzentrationswert der Probe ein und drücken Sie dann die Taste

2

[ENTER], um die Ergebnisse für die Kalibrierung zu berechnen.

Nach der Kalibrierung wird der Steilheitsfaktor «S» angezeigt.

2

Nach der Kalibrierung werden die Kalibrierwerte übernommen, im Kalibrierprotokoll gespeichert und für die Messungen verwendet (Justierung), im Kalibrier-

u

protokoll gespeichert, aber nicht verwendet (Kalibrierung) oder verworfen

(Abbrechen).

Wurden «Justierung» oder «Kalibrierung» ausgewählt, wird «Kalibrierung erfolgreich» angezeigt. Der M400 kehrt in den Messmodus zurück.

Kalibrierung mit einer Kalibrierzelle

Für eine genauere Kalibrierung kann die Kalibrierzelle verwendet werden. Dazu

muss der TDL (der Kopf) vom Sensor entfernt werden. Anschließend wird dieser

auf die Kalibrierzelle montiert, wie unten dargestellt. Bevor mit der Kalibrierung

begonnen werden kann, sind noch neue Werte für die Länge des optischen

Wegs, Temperatur und Druck am M400 einzugeben. Das Kalibriergas ießt

durch die Kalibrierzelle und die Kalibrierung erfolgt mit dem Kalibrationsmenü

des M400.

Während der Kalibrierung mit der Kalibrierzelle ist der Prozess auch weiterhin

abgedichtet. Spezielle Vorkehrungen sind nicht erforderlich.

Kalibrierzelle

EPL

2 × 100 mm (3.94")

104,6 mm (4.12")

51

Page 52

Quick Setup Guide TDL GPro™ 500

5 Fehlermeldungen

Fehlermeldung Beschreibung Maßnahme Quelle Relais-

Kein Sensor auf Kanal3 M400 kann keinen bekannten ISM-Sensor feststellen.

Wenn kein Sensor gefunden werden kann, erscheint die

Meldung KEIN SENSOR ERKANNT im Display.

Signalverarbeitung Störung Fit der Linienprole fehlgeschlagen. Senden Sie das Gerät zurück an METTLER TOLEDO TDL Fehler Software-

Laser Störung Die Wellenlänge des Lasers hat sich verändert. Erneuter Abgleich

der Lasertemperatur ist erforderlich

Signalqualität schlecht Transmission geringer als der Schwellenwert von 5%. Corner Cube und Prozessfenster reinigen.

Flashcard Störung Fehlende oder schlechte Kalibrierung und / oder Daten der Datenbank Führen Sie eine Kalibrierung mit der Kalibrierzelle durch.

Fehler Druckeingang Druckanzeige außerhalb des erweiterten Bereichs:

0,6 bara < P < 8 bara

4 ... 20 mA Eingabefehler: 4 mA > P > 20 mA

Fehler Temperatureingang Druckanzeige außerhalb des erweiterten Bereichs:

− 20 °C < T < 1000 °C

4 ... 20 mA Eingabefehler: 4 mA > P > 20 mA

Kongurationsmodus Verwendete Ethernet-Schnittstelle: Diagnose oder Konguration läuft Trennen Sie das Ethernetkabel. TDL Wartungs-

Die Fehlermeldungen des GPro™ 500 sind im M400 unter folgendem Pfad zu nden:

Menu ➝ Service ➝ Diagnostics ➝ TDL ➝ Messages

52

Page 53

Quick Setup Guide TDL GPro™ 500

Zuordnung

zustand

– Dies ist die erste Meldung nach dem Einschalten.

M400 Fehler B getrennt

– Warten Sie, bis der GPro™ 500 vollständig Warten Sie, bis der GPro™ 500 vollständig Warten Sie, bis der GPro™ 500 vollständig

hochgefahren ist.

– Prüfen Sie, ob der GPro™ 500 mit Strom versorgt Prüfen Sie, ob der GPro™ 500 mit Strom versorgt Prüfen Sie, ob der GPro™ 500 mit Strom versorgt

wird und warten Sie, bis das System vollständig

hochgefahren ist.

– Prüfen Sie die RS485-Verkabelung GPro™ 500 Prüfen Sie die RS485-Verkabelung GPro™ 500 Prüfen Sie die RS485-Verkabelung GPro™ 500

zum M400.

–

Prüfen Sie anhand der MT-TDL-Software und der Ethernet-

Schnittstelle, ob das System korrekt funktioniert.

– Wenn weiterhin nach 60 Sekunden die Zeitabschaltung er- Wenn weiterhin nach 60 Sekunden die Zeitabschaltung er-Wenn weiterhin nach 60 Sekunden die Zeitabschaltung er-

folgt, senden Sie das Gerät zurück an METTLER TOLEDO.

fehler

Senden Sie das Gerät zurück an METTLER TOLEDO TDL Fehler Fehler

System

TDL Fehler Fehler

Dichtung zwischen TDL und Sensor prüfen.

System

TDL auf dem Sensor drehen, um die Transmission zu

maximieren.

Staubmenge im Prozess reduzieren.

TDL Fehler Software-

Falls die Fehlermeldung weiterhin erscheint, senden Sie

fehler

das Gerät zurück an METTLER TOLEDO, um die Flashcard

auswechseln zu lassen.

Prüfen Sie den externen Drucksensor und die Zuordnung. TDL Wartungs-

anforderung

Fehler

System

Prüfen Sie den externen Temperaturfühler und

die Zuordnung.

TDL Wartungs-

anforderung

anforderung

Fehler

System

Software-

fehler

53

Page 54

Page 55

Quick Setup Guide TDL GPro™ 500

GPro™ 500

Guide de paramétrage rapide

Sommaire

1 Préparation 57

Contenu de l‘emballage 57

Exigences en ce qui concerne le site 57

Conditions de fonctionnement ambiantes 57

Ce dont vous avez également besoin 57

Accessoires en option 58

2 Avant l‘installation 59

Mise en place de la bride 59

Exigences en ce quiconcerne la bride 59

Conditions de débit au point de mesure 60

Purge 61

Purge avec barrière thermique 62

Mise à la terre etcâblage(ATEX) 63

Entrées analogiques actives (version ATEX) 64

Entrées analogiques alimentées par boucle (ATEX) 65

Mise à la terre et câblage (FM) 66

Entrées analogiques actives (version FM) 67

Entrées analogiques alimentées par boucle (version FM) 68

Câbles GPro™ 500 69

Branchements des câbles sur le M400 71

French

3 Installation 72

Paramétrage général (s‘applique à tous les paramètres) 72

Choix de la voie 72

Étalonnage 72

Installation de TDL 72

Configuration de la purge correcte côté procédé 75

4 Vérification et maintenance 76

Étalonnage en un point pour les sondes TDL pour oxygène gaz 76

Étalonnage procédé pour sondes TDL pour oxygène gaz 76

Étalonnage à l‘aide d‘une cellule d‘étalonnage 77

5 Messages d‘erreur 78

55

Page 56

Quick Setup Guide TDL GPro™ 500

56

Page 57

Quick Setup Guide TDL GPro™ 500

1 Préparation

– GPro™ 500 Analyseur à diode laser– GPro™ 500 Analyseur à diode laser GPro™ 500 Analyseur à diode laserGPro™ 500 Analyseur à diode laser

Contenu de l‘em-

–

ballage

Exigences en ce

– 24 VCC, 5 W pour l‘alimentation électrique de GPro™ 500– 24 VCC, 5 W pour l‘alimentation électrique de GPro™ 500 24 VCC, 5 W pour l‘alimentation électrique de GPro™ 50024 VCC, 5 W pour l‘alimentation électrique de GPro™ 500

qui concerne le site

Conditions de fonc-

– – 20 °C … + 55 °C en cours de fonctionnement

tionnement

ambiantes

1 manuel d‘instructions de sécurité

–

1 CD de documentation accompagné d‘un manuel d‘instructions et

du logiciel MT-TDL.

–

110 / 220 VCA pour l‘alimentation électrique de M400

– Gaz de purge d‘une pureté > 99,7% (minimum recommandé),

0,5 à 5l/min.

Les exigences en matière de pureté sont:

conformes à la norme dénie par ISO 8573.1, classe 2–3, semblable à

l‘air instrumentation.

Pour l‘analyseur TDL oxygène, il est possible d‘utiliser de l‘azote ou tout

autre gaz propre et sec sans O

.

2

Ce dont vous avez

• 1 transmetteur M400 T3 (n° de réf. 52121350)

également besoin

•

1 câble Ethernet CAT5

•

Câble RS 485 (< 250 m)

• 1 ordinateur portable (WinXP / 7 / 8) sur lequel le logiciel MT-TDL est installé

• Joint plat 82,14 3 3,53 mm

• Clapet anti-retour

•

2 clés plates pour écrous M16

•

1 clé Allen de 5 mm pour les vis de fermeture sur brides et les vis

du couvercle Tx

•

1 clé Allen de 3 mm pour les vis du couvercle RS 232

•

2 clés plates pour Swagelok

•

1 tournevis plat de 2,5 mm pour les branchements électriques

•

1 tournevis plat (6 mm) ou cruciforme (Nº 2) pour vis du couvercle Rx

•

Clé à molette pour les raccords de purge

•

Clé dynamométrique pour la version FM

57

Page 58

Quick Setup Guide TDL GPro™ 500

Accessoires en option

Accessoires Référence

Barrière thermique 30 034 138

Boîte de jonction 30 034 149

Boîtier de purge pour M400 Ex d 30 034 148

Kit d‘étalonnage O

2

30 034 139

Kit Joint plat ST 30 080 914

Kit Joint plat HT (Graphite) 30 080 915

Câble GPro 500 ATEX, FM 5 m 30 077 735

Câble GPro 500 ATEX, FM 15 m 30 077 736

Câble GPro 500 ATEX, FM 25 m 30 077 737

58

Page 59

Quick Setup Guide TDL GPro™ 500

2 Avant l‘installation

Mise en place de la bride

La tête TDL doit être facilement accessible. Une personne doit pouvoir se tenir

debout face à celle-ci et serrer les boulons de xation M16 à l‘aide des deux

clés standard. Il convient de prévoir au moins 60cm d‘espace libre entre la

bride xée au raccord et l‘extérieur comme indiqué ci-dessous.

60 cm (23.6")

)

"

60 cm (23.6

Exigences en ce

quiconcernelabride

Dégagement min. : 61,5 mm

(schedule 40)

100 mm

(4")

DIN 50 ou ANSI 2"

Dégagement min. : 77,5 mm

(schedule 80)

DIN 65 ou ANSI 2½"

59

Page 60

Quick Setup Guide TDL GPro™ 500

DIN

DN50/PN25 DN65/PN25

DN 50

100 mm 100 mm

DN100

min. Ø 54 mm

min. Ø 67 mm

DN65

ANSI

4"

min. 2.12"

2"

min. 2.64"

ANSI 2.5"/300 lbsANSI 2"/300 lbs

2.5"

4" 4"

Lors de la détermination de l‘emplacement du GPro™ 500 TDL dans le Lors de la détermination de l‘emplacement du GPro™ 500 TDL dans le

Conditions de débit au point de mesure

procédé, il est recommandé de prévoir une section rectiligne minimale de

5 3 le diamètre de la conduite en amont du point de mesure et 3 3 en aval.

Cela donnera des conditions de débit laminaire, favorables pour des

mesures stables.

60

Page 61

Quick Setup Guide TDL GPro™ 500

Purge

1 Arrivée du gaz de purge pour le côté instrument (raccord de tube de 6 mm

ou de ¼").

2

Arrivée du gaz de purge pour le côté procédé (clapet anti-retour requis).

3

Sortie du gaz de purge pour le côté instrument (raccord de tube de 6 mm

ou de ¼").

4

Débit du gaz de procédé.

5

Zone dénissant les limites de la longueur de chemin effective.

0…1 L /min

0…10 L /min

RotameterPressure regulator

AVERTISSEMENT

Il faut toujours démarrer la purge au débit maximum avant

de lancer le procédé.

AVERTISSEMENT

La purge doit toujours être activée afin d‘éviter les dépôts

de poussière sur les surfaces optiques.

AVERTISSEMENT

Vous ne devez ni retirer ni démonter l‘arrivée du gaz de purge

pour les procédés (2). En cas de démontage, le certificat

de pression PED est annulé.

AVERTISSEMENT

Ne raccordez pas la purge côté instrument et côté procédé en série,

sinon la purge s‘arrêtera lors du démontage de la sonde.

61

Page 62

Quick Setup Guide TDL GPro™ 500

Purge avec

barrière thermique

Configuration de la purge

1

Arrivée du gaz de purge pour la barrière thermique (raccord de tube de

6 mm ou de ¼")

2 Sortie du gaz de purge pour la barrière thermique (raccord de tube de

6 mm ou de ¼")

3 Arrivée du gaz de purge pour le côté procédé (clapet anti-retour requis)

4

Clapet anti-retour obligatoire (à fournir par l‘utilisateur)

Le gaz de purge pour la barrière thermique doit toujours être activé

pendant le fonctionnement du procédé, afin d‘éviter d‘endommager

21 4

3

AVERTISSEMENT

la sonde de façon définitive.

62

AVERTISSEMENT

La défaillance de la purge du côté de l’instrument et de la barrière

thermique doit déclencher une alarme. Celle-ci doit être mise en

œuvre dans le DCS de l‘utilisateur.

Page 63

Quick Setup Guide TDL GPro™ 500

Miseàlaterreetcâblage(ATEX)

Point de mise

à la terre externe

pour câbles

> 4 mm

(M6 × 12)

Point de mise à la terre externe

2

63

Page 64

Quick Setup Guide TDL GPro™ 500

RS-485 A

Entréesanalogiquesactives(versionATEX)

ACTIVE ANALOG INPUTS

24 VDC

User-provided

GND

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

+

Purple

+

xT

–

100 mm

+

xT

Power

L N

M400

–

24 VDC

Analog

Outputs

GND

Ethernet

1

24 VDC

GND

2

3

RS-485 A

RS-485 B

4

5

RS-485 GND

6

+Ain 1 4…20 mA

7

–Ain 1 4…20 mA

8

+Ain 2 4…20 mA

9

–Ain 2 4…20 mA

10

24 VDC

11

Aout 1

Aout 2

12

13

TX+

14

TX–

15

RX+

16

RX–

Black

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

987654321

+

–

–

16151413121110

TB4

987654321

Pressure

(4")

Temperature

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

64

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

Page 65

Quick Setup Guide TDL GPro™ 500

Entréesanalogiquesalimentéesparboucle(ATEX)

User-provided

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

Purple

Black

SENSOR IN

xT

GND

24 VDC

100 mm

(4")

Pressure

Temperature

SENSOR IN

xT

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

GND

987654321

TB4

16151413121110

M400

Power

L N

987654321

24 VDC

Analog

Outputs

Ethernet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 VDC

GND

RS-485 A

RS-485 B

RS-485 GND

Sensor In

GND

Sensor In

GND

24 VDC

Aout 1

Aout 2

TX+

TX–

RX+

RX–

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

AVERTISSEMENT

Toutes les ouvertures doivent être fermées avec des presse-étoupes ou

des connecteurs de blocage certifiés répondant au même degré

de certification que le GPro™ 500.

AVERTISSEMENT

Il est indispensable d‘observer toutes les informations et tous

les avertissements donnés. Il convient de refermer le système et

de le mettre à la terre avant de l‘allumer.

65

Page 66

Quick Setup Guide TDL GPro™ 500

Miseàlaterreetcâblage(FM)

Point de mise

à la terre externe

pour câbles

> 4 mm

(M6 × 12)

Point de mise à la terre externe

2

66

Mise à la terre de protection

Mise à la terre de protection

Matériau : AISi7Mg0,3 chromé

Taille : M6 × 12 mm

2 options de mise à la terre

de protection intérieure

Matériau : 1.4404 (AISI 316L)

Taille : M4 × 6 mm

Vis à tête hexagonale

Connexion avec un câble de 4 mm

2

Page 67

Quick Setup Guide TDL GPro™ 500

RS-485 A

Entréesanalogiquesactives(versionFM)

ACTIVE ANALOG INPUTS

24 VDC

User-provided

GND

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

+

Purple

+

xT

–

100 mm

+

xT

Power

L N

M400

–

24 VDC

Analog

Outputs

GND

Ethernet

1

24 VDC

GND

2

3

RS-485 A

RS-485 B

4

5

RS-485 GND

6

+Ain 1 4…20 mA

7

–Ain 1 4…20 mA

8

+Ain 2 4…20 mA

9

–Ain 2 4…20 mA

10

24 VDC

11

Aout 1

Aout 2

12

13

TX+

14

TX–

15

RX+

16

RX–

Black

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

987654321

+

–

–

16151413121110

TB4

987654321

Pressure

(4")

Temperature

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

67

Page 68

Quick Setup Guide TDL GPro™ 500

Entréesanalogiquesalimentéesparboucle(versionFM)

User-provided

Red

Blue

Junction Box

GND

24 VDC

Green

Yellow

Brown

Purple

Black

SENSOR IN

xT

GND

24 VDC

100 mm

(4")

Pressure

Temperature

SENSOR IN

xT

Pink

Grey

Red/Blue

Grey/Pink

White

White/Yellow

Yellow/Brown

White/Green

Brown/Green

GND

987654321

TB4

16151413121110

M400

Power

L N

987654321

24 VDC

Analog

Outputs

Ethernet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24 VDC

GND

RS-485 A

RS-485 B

RS-485 GND

Sensor In

GND

Sensor In

GND

24 VDC

Aout 1

Aout 2

TX+

TX–

RX+

RX–

24 VDC Power 0.2 A (5W)

M400 TB4

Temperature sensor

Pressure sensor

2x 4…20 mA

passive analog outputs

Ethernet

6

7

8

RS-485 GND

RS-485 B

RS-485 A

68

RS-485

GND

20 – 30 VDC or

100 – 230 VAC +/– 10%

Page 69

Quick Setup Guide TDL GPro™ 500

CâblesGPro™500

Signal Description N°câble Couleur TB1 TB2

Boîte de

jonction

Alimentation

+ 24 V

Terre

Alimentation 24 V, 5 W

(alimentation)

RS 485 A

RS 485 B 4 Jaune 4

Interface M400

(RS 485)

1 Rouge 1

2 Bleu 2

3 Vert 3

Broche n° Broche n°

RS 485 GND 5 Marron 5

4...20 mA pos

4...20 mA nég 7 Noir 7

4...20 mA pos

4...20 mA nég 9 Gris 9

+ 24 V

Sortie 1 11

Sortie 2 12 Blanc 12

Température d‘entrée

actuelle

Pression d‘entrée

actuelle

Sortie directe analogique

(2 3 4 … 20 mA)

(en option)

TX+

TX– 14

RX+ 15

Interface Ethernet

pour communication

avec le PC

RX– 16

6 Violet 6

8 Rose 8

10

Rouge / bleu 10

Gris / rose 11

13

Blanc / jaune 1

Jaune / marron 2

Blanc / vert 3

Marron / vert 4

69

Page 70

Quick Setup Guide TDL GPro™ 500

TB1

Connexions à la carte mère intégrée à la tête de l’électrode

Remarque : Lecouvercledelatêtedel‘électrodeversionATEXnedoit

Pin 1

Pin 4

jamaisêtreouvertcarcelaannulelacertificationATEX.

70

TB2

Pin 1

Pin 12

Connexions à la carte E / S intégrées à la tête de sonde

AVERTISSEMENT

Toutes les ouvertures doivent être fermées avec des presse-étoupes

ou des connecteurs de blocage certifiés répondant au même degré

de certification que le GPro™ 500.