Page 1

Operating Instructions

ParticleTrack G600Ex

Real-Time Particle Characterization

Hardware Manual

Page 2

2

Hardware Manual

No part of this publication may be stored in a

retrieval system, transmitted, or reproduced in

any way, including but not limited to photocopy,

photograph, magnetic or other record, without

the prior written permission of Mettler-Toledo

AutoChem, Inc.

FBRM®, iC Process™, iC FBRM™, PVM™, and

iCPVM™ are trademarks of Mettler-Toledo

AutoChem, Inc.

Microsoft® and Windows® are either registered

trademarks or trademarks of Microsoft Corporation

in the United States and/or other countries.

All other brand and product names are trademarks

or registered trademarks of their respective owners.

The information in this publication is provided for

reference only. All information contained in this

publication is believed to be correct and complete.

Mettler-Toledo AutoChem, Inc. shall not be liable

for errors contained herein nor for incidental or

consequential damages in connection with the

furnishing, performance, or use of this material. All

product specifications, as well as the information

contained in this publication, are subject to change

without notice.

For technical support, email: AutoChemCustomerCare@mt.com

For updates, webinars, and the latest documents: https://community.autochem.mt.com

Mettler-Toledo AutoChem, Inc.

7075 Samuel Morse Drive

Columbia, MD 21046

www.mt.com/AutoChem

Tel: + 1 866.333.6822

Fax: +1 410.910.8600

This publication may contain or reference

information and products protected by copyrights

or patents and do not convey any license under

the patent rights of Mettler-Toledo AutoChem, Inc.,

nor the rights of others. Mettler-Toledo AutoChem,

Inc. does not assume any liability arising out of

any infringements of patents or other rights of third

parties.

Mettler-Toledo AutoChem, Inc. makes no warranty

of any kind with regard to this manual, including

but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

1115 2 01 6

Page 3

3

1 Introduction

This manual covers specific safety and quality information relating to the

ParticleTrack™G600Ex with FBRM® (Focused Beam Reflectance Measurement)

technology. Throughout this manual, the system is referred to by the name:

ParticleTrack G600Ex or FBRM G600Ex. The ParticleTrack G600Ex system includes the

base unit with purge and pressurization system and a probe connected by a flexible

armored conduit. The purge and pressurization system for the base unit enclosure

enables use of the ParticleTrack G600Ex system in potentially explosive atmospheres in

an above-ground (Group II) application.

www.mt.com/ParticleTrack G600Ex

Contents

1 Introduction

2 Intended Use

3 Technical Data

4 Safety Information

5 Supplementary Documentation

6 Product Installation

7 Flexible Probe Mounting Options

8 Operating Instructions

9 Best Practices for Routine Operation

10 Troubleshooting

11 Product Maintenance

12 Disposal

Page 4

4

Hardware Manual

2 Intended Use

The METTLER TOLEDO AutoChem ParticleTrack G600Ex is an analyzer that provides

in-process real-time particle characterization. The apparatus is comprised of an Expo

Technologies Ltd PE2E stainless steel enclosure with dimensions of approximately 500

x 750 x 250 mm, complete with integral MiniPurge type px purge and pressurization

system, associated MiniPurge Interface Unit, and maintenance override switch. Refer to

the EXPO MiniPurge and Enclosure manual (ML482) for more information.

The installed electrical apparatus is comprised of a power supply; laser and detector

modules, laser current limiter assembly, fiber optic communications, PCBs, and

pneumatic controls. The apparatus is fitted with a permanently attached flexible armored

conduit, which is connected to the process probe.

The pressurized enclosure may be used in Zone 1 or Zone 21 hazardous areas, and

the probe may be used to monitor a process in Zone 0 or Zone 20 hazardous areas.

The flexible conduit connecting the probe to the main enclosure shall not be installed in

Zone0 / Zone 20.

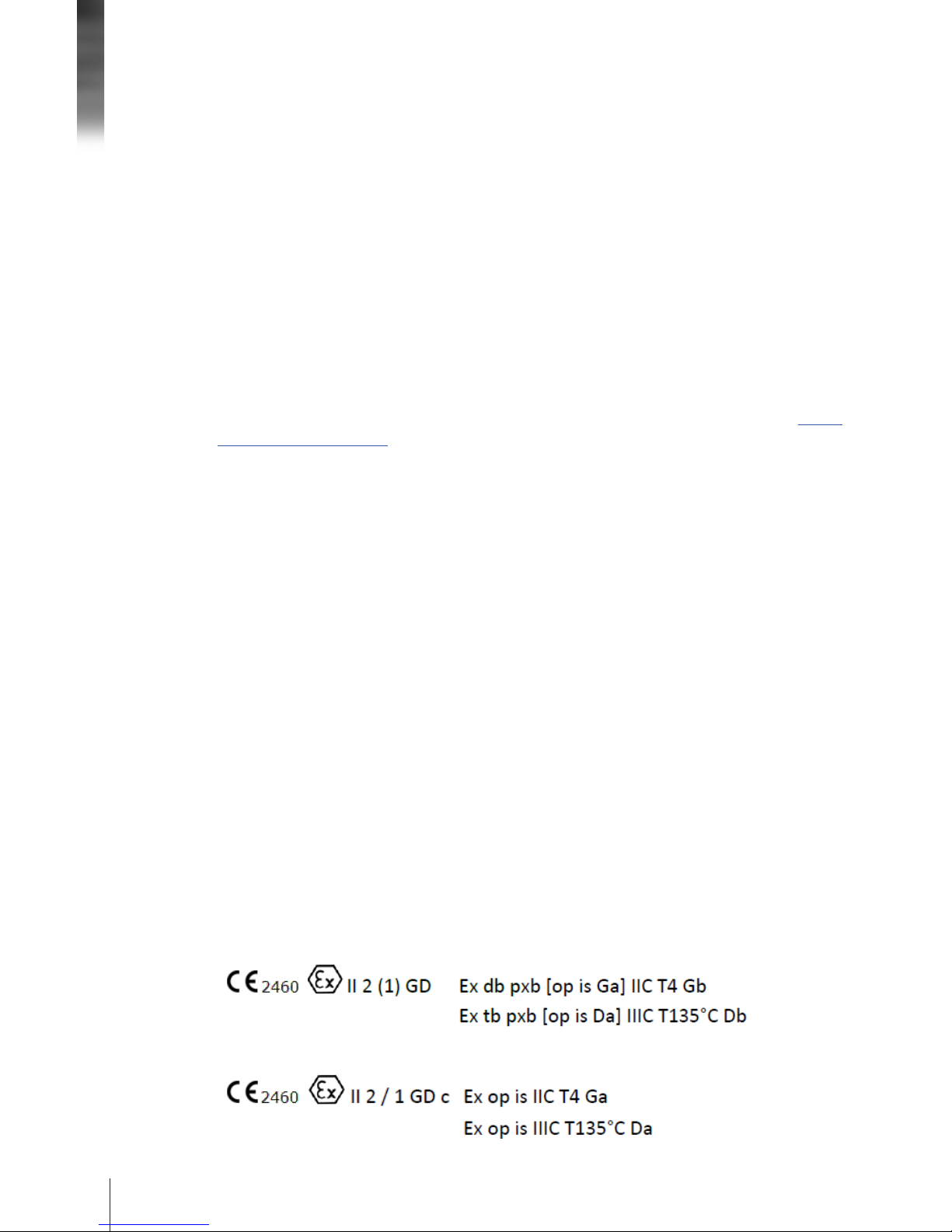

The analyzer and probes have been analyzed according to the ATEX directive and are

marked as follows:

Analyzer:

Probe:

The purge and pressurization system controls the flow of instrument air (or inert gas)

into the base unit enclosure and maintains a constant pressure that is slightly higher

than the ambient pressure outside the enclosure. The overpressure in the enclosure

ensures gas from outside the enclosure cannot enter the base unit. If the pressure is

lost for any reason, the power to the base unit shuts down automatically. The purge

and pressurization system operates pneumatically and requires no electrical supply to

function.

ParticleTrack G600Ex with FBRM technology is a rugged probe-based instrument that

is inserted directly into large-scale vessels or pipelines to track changing particle size

and count in real time at full process concentrations. Particles, particle structures, and

droplets are monitored continuously, as process parameters vary, enabling engineers to

effectively troubleshoot and improve processes effectively. Click the link to see the FBRM

Method of Measurement video (requires internet connection).

Page 5

5

Purge gas Instrument air

Purge ow rate 225 L/min

Minimum overpressure 0.5 mbarg

Maximum overpressure 12 mbarg

Minimum purging time 5 minutes

Air supply pressure 4 to 8 barg

Maximum leakage rate

30 L/min

Purge Parameters

Table 1. Purge parameters

System certications

Class I/Division 1 Group A-D, T4

ATEX and IECEx

Analyzer (Enclosure): CE

2460

Ex II 2 (1) GD Ex db pxb [op is Ga] IIC T4 Gb

Ex tb pxb [op is Da] IIIC 135°C Db

Probe: CE

2460

Ex II 2/1 GD c Ex op is IIC T4 Ga

Ex op is IIIC T135°C Da

Laser classication Class 1 Laser Device, Compliant with 21 CFR 1040.10 and

1040.11 and IEC 60825-1

Ingress protection IP66

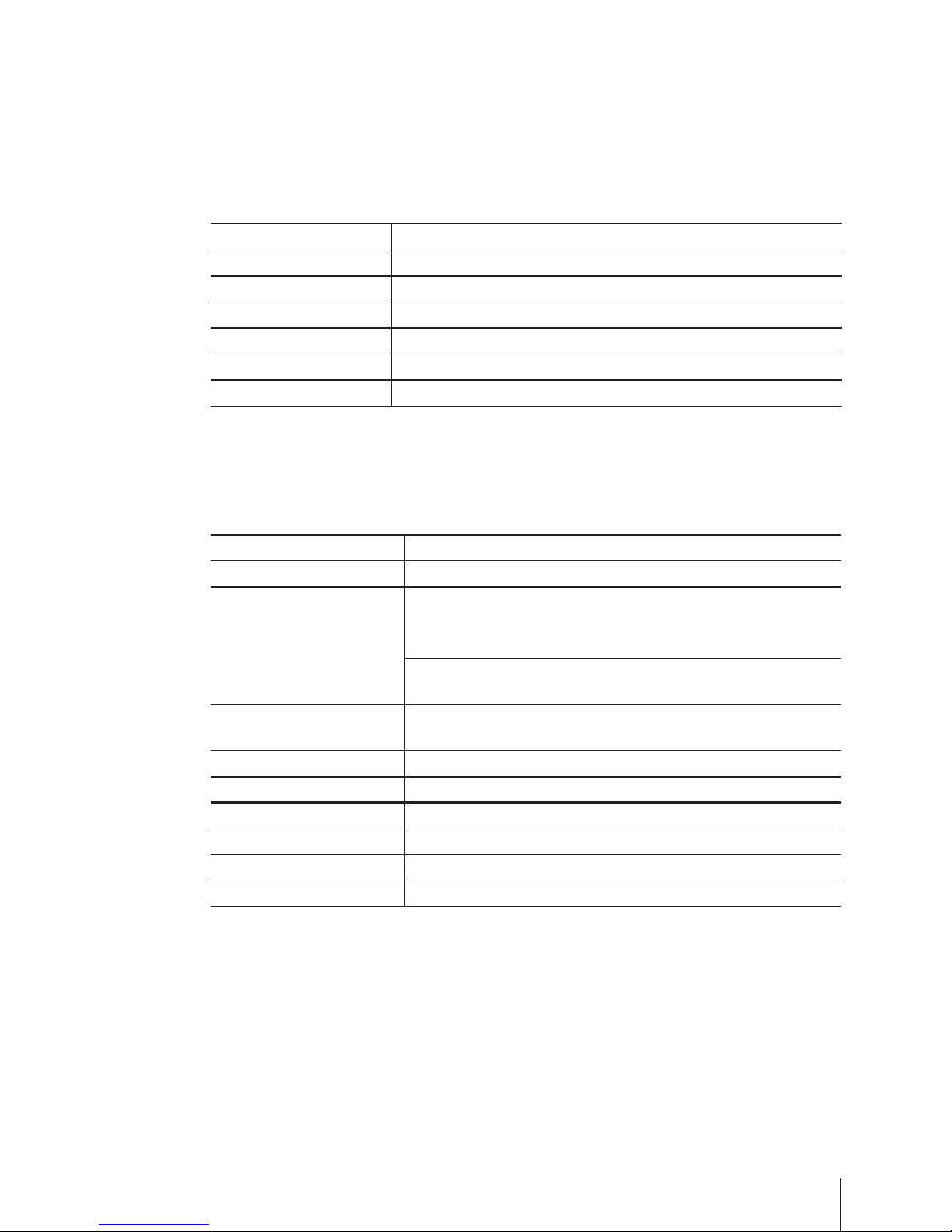

Functional specications

Method of Measurement Focused Beam Reectance Measurement (FBRM®)

Measurement range 0.5 to 2,000 µm

Scan speed 2 m/s (standard); 4 m/s (optional)

3 Technical Data

Table 2. System certications and functional specications

Page 6

6

Hardware Manual

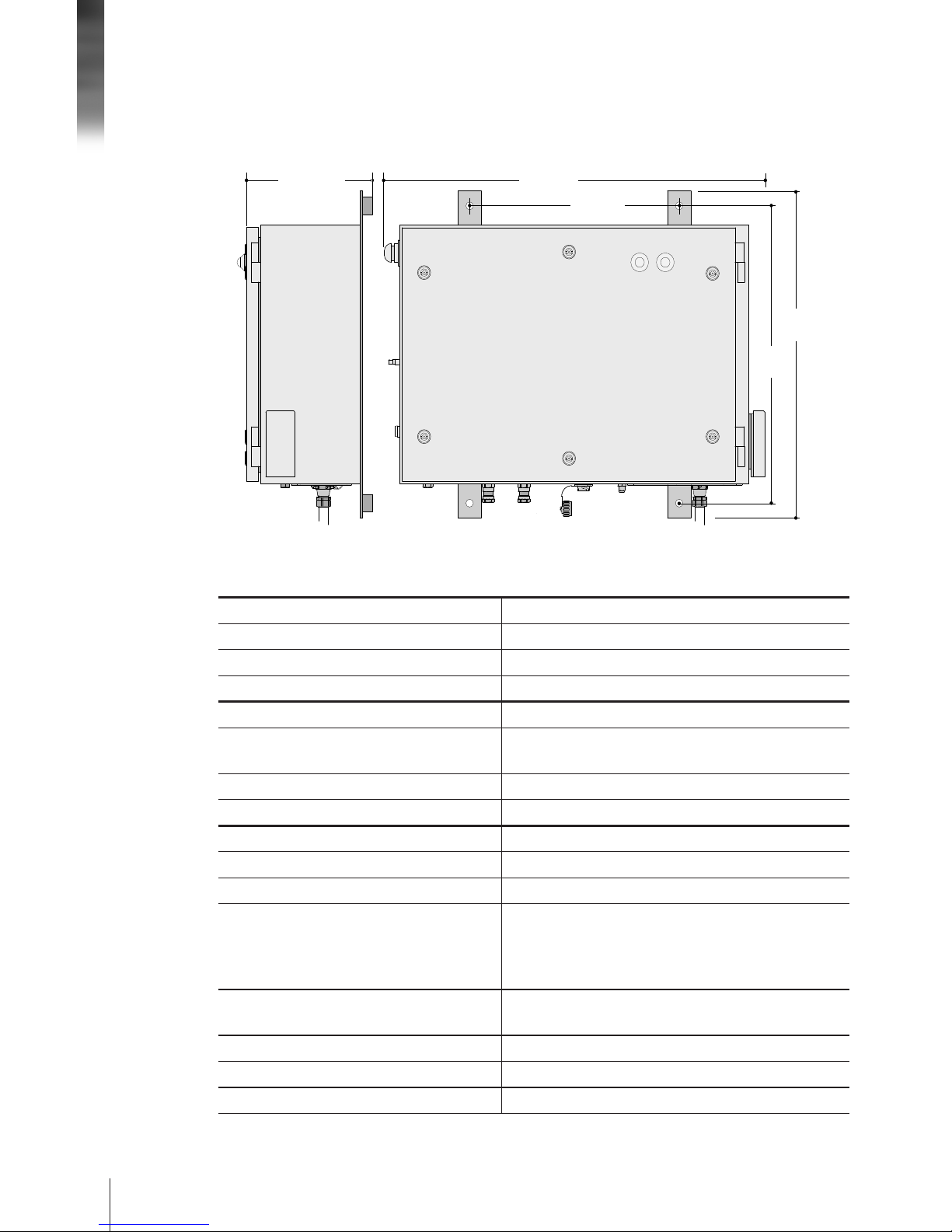

450 mm

[

17.7”

]

660 mm

[

26.0”

]

809 mm

[

31.9”

]

600 mm

[

23.6”

]

284 mm

[

11.2”

]

Figure 1. Base unit enclosure dimensions

Environmental

Operating humidity range 0 to 85%

Operating temperature range 0 to 40 °C

Installation

Earth/Ground strap (customer-provided) Minimum 3.31 mm2 [12 AWG]

to 6.35 mm stud on enclosure

External connection Hawke type ICG 635 or equivalent

General

Material of construction SS316

Ingress protection IP 66 (4X equivalent)

Power Ratings Voltage: 100–125 V or 200–240 V

Frequency: 50/60 Hz

Max Current: 0.5 A

Max Power Consumption: 60 W

Fuses Main power fuse: 2.0 A, 250 V Slow Blow, Type T

Laser fuse: 0.15 A, 205 V, T-LAG

Weight 54.4 kg [120 lb]

Communication interface Fiber Option to USB 2.0

Installation (overvoltage) category II

Base Unit Specifications

Table 3. Base unit specications

Page 7

7

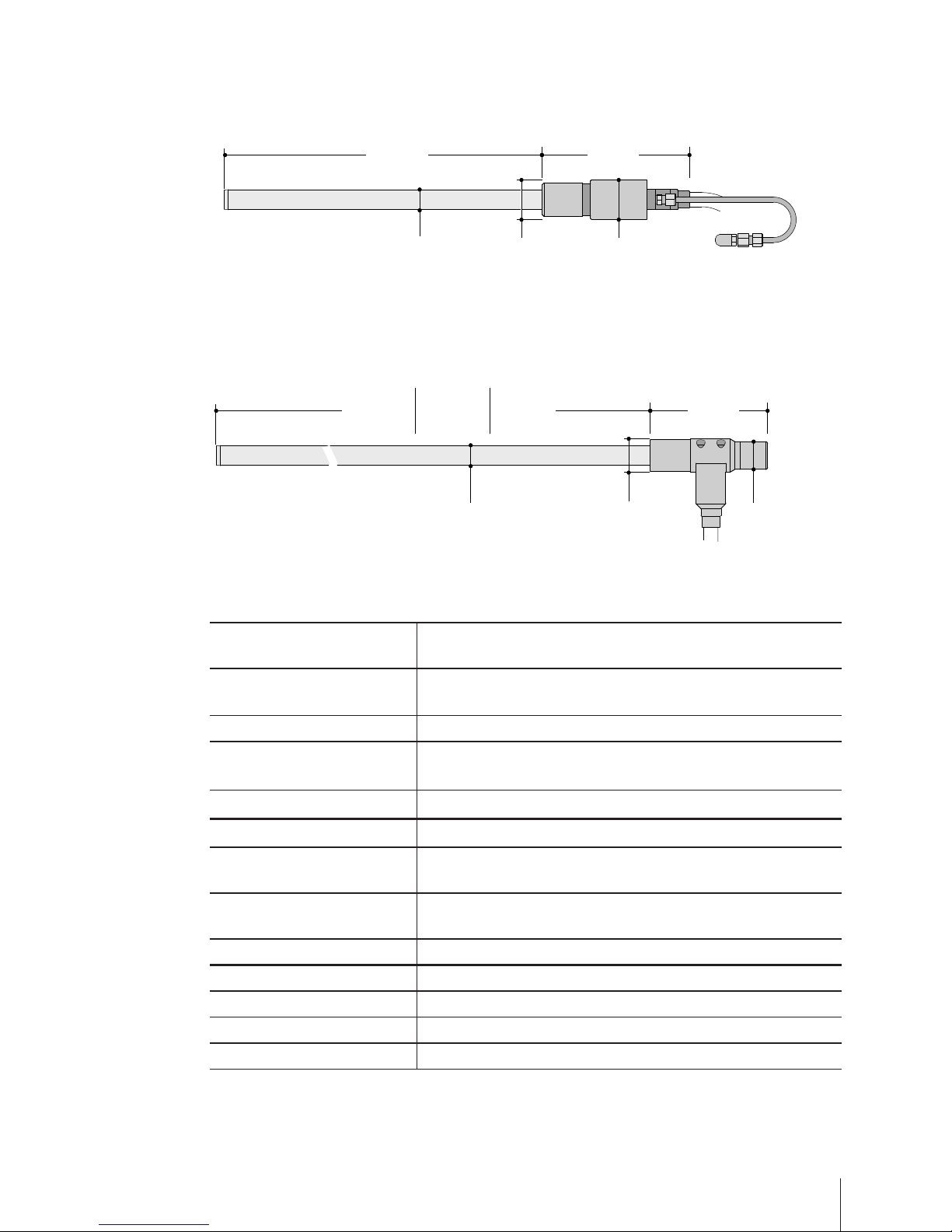

419 mm

[

16.5”

]

368 mm

[

14.5”

]

206 mm

[

8.1”

]

500 mm

[

19.7”

]

546 mm

[

21.5”

]

25 mm

[

Ø 0.98”

]

42 mm

[

Ø 1.66”

]

50 mm

[

Ø 1.95”

]

400 mm

[

15.75”

]

182 mm

[

7.18”

]

Figure 2. Probe dimensions—G600R

Figure 3. Probe dimensions—G600T, P, X

419 mm

[

16.5”

]

368 mm

[

14.5”

]

206 mm

[

8.1”

]

500 mm

[

19.7”

]

546 mm

[

21.5”

]

25 mm

[

Ø 0.98”

]

35 mm

[

Ø 1.38”

]

42 mm

[

Ø 1.66”

]

148 mm

[

5.82”

]

T

400 mm

[

15.75”

]

P

1000 mm

[

39.40”

]

X

Custom

Length

25 mm

[

Ø 0.98”

]

42 mm

[

Ø 1.66”

]

50 mm

[

Ø 1.95”

]

400 mm

[

15.75”

]

182 mm

[

7.18”

]

Wetted materials of

construction

Probe tip SS316L (standard)

Alloy C22 (optional)

Probe window Sapphire

Probe window seals Kalrez® 6375 (standard)

TM [Thermo-Mechanical press-t] (optional)

Environmental

Operating pressure range 0 to 10 barg (standard)

Up to 250 barg (optional, requires custom engineering design)

Operating temperature range -10 to 120 °C (Kalrez® 6375 window seal)

-80 to 120 °C (TM window seal)

Installation

Conduit length 15 m [49.2 ft]

Conduit bend radius (min.) 20 cm [8 in]

Probe and conduit weight 6.8 kg [15 lb]

Table 4. Probe specications

Probe Specifications

Page 8

8

Hardware Manual

Site preparation for the METTLER TOLEDO ParticleTrack G600Ex system is the end user's

responsibility. The following should be considered to ensure successful installation of the

system:

Power Requirements

A temporary power cord is provided with the ParticleTrack G600Ex system for

convenience of installation and commissioning. The final installation must comply

with EN60079-14 and use fittings and wiring rated appropriately for the location. The

equipment shall be permanently installed to the main power supply through metal conduit

with > 75 °C temperature-rated cable and connected to protective earthing. A 10-ampere

circuit breaker should be included in the building installation to provide overcurrent

protection. The circuit breaker should be within easy reach of the operator and marked as

the disconnecting device for the connection.

Air/Gas Requirements

A ParticleTrack G600Ex system requires a source of clean, dry, and pressure-regulated

instrument air or inert gas to drive the probe optical scanner. The quality of the air or

gas supply must meet the specifications of the American National Standards Institute/

Instrument Society of America (ANSI/ISA) S7.0.01-1996 Quality Standard for Instrument

Air. Air/gas must:

• Have a dew point at least 10 °C [50 °F] lower than the minimum temperature to

which any part of the system will be exposed.

• Contain less than 1 ppm total oil or hydrocarbons

• Contain less than 1 ppm particulates at a maximum size of 3microns

• Be free of any corrosive contaminants and flammable or toxic gases.

Air supply pressure 4.5 to 5.2 barg [65–75 psig]

Maximum ow rate 40 L/min [1.4 SCFM]

Table 5. Probe air/gas specication

Area of Intended Use

Ensure the area of intended use has adequate space to mount the base unit and a

support structure capable of supporting the system weight. The base unit has mounting

tabs for four (4) 8 mm [5/16 inch] minimum diameter stainless steel bolts (end user-

provided). The support structure must not be subject to excessive vibration. The probe

conduit should not bend beyond 20 centimeters (8 inches) and it should not be put

into an “S” shape. Include a suitable work location for the control computer that allows

connectivity through a USB cable.

The base unit must be convenient for access (eye level) and readily accessible for

service. It can also operate in a horizontal position—placed back side down on a

flat horizontal surface. Position the base unit to enable easy access to the purge and

pressurization system air supply. The ParticleTrack G600Ex base unit contains sensitive

electronic components that should be protected from severe environmental conditions.

If the area is outdoors in warmer climates, the base unit must be shaded from direct

sunlight.

Page 9

9

The CE Mark applies only to unmodied instruments as supplied by MettlerToledo AutoChem, Inc. Modications may require on-site testing for compliance

verication. If the equipment is used in a manner not specied by the manufac-

turer, the protection provided by the equipment may be impaired.

Caution—Read all safety warnings before installing or operating this equipment. Failure to follow the instructions and caution/warning statements could

result in personal injury and/or product damage that could void the warranty.

WARNING—Main power shall be supplied through a metal conduit following

local and governmental regulations.

WARNING—Only skilled, trained technicians can service this equipment.

WARNING—Pressurized Enclosure. Do Not Open When Flammable Gas Is

Present Even When De-Energized.

WARNING—Do Not Open When An Explosive Atmosphere Is Present

WARNING—Power shall not be restored after the enclosure has been opened

until combustible dust accumulations within the enclosure have been removed.

Table 6. Safety cautions and warnings

4 Safety Information

Special Conditions of Safe Use

1. The user shall ensure that the exit of air from the purge cannot disturb surrounding

dust deposits and hence create a dust cloud.

2. Cable glands used for connection to the flameproof terminal compartment shall

be Ex-certified flameproof type, certified as apparatus and employ sealing around

individual cores. Additional thread adapters shall not be used.

3. The optical cable connecting between the purge enclosure and the USB-to-Fiber

converter must be protected from damage that could allow the release of optical

energy. This may be accomplished by either using armored type optical cable, or by

routing the cable via rigid conduit.

4. The protective non-metallic cover of the purge indicators presents a potential

electrostatic charging hazard. Do not rub with a dry cloth or clean with solvents.

Clean only with a water damp cloth.

Page 10

10

Hardware Manual

Laser Classification

All standard-model FBRM G600 Ex instruments are in compliance with the U. S.

Department of Health and Human Services (DHHS) Radiation Performance and in

accordance with International Standards.

THE FBRM G600 Ex IS A CLASS 1 LASER PRODUCT COMPLIANT WITH

DHHS 21 CFR 1040.10 AND 1040.11

EXCEPT FOR DEVIATIONS PURSUANT TO LASER NOTICE 50, DATED JUNE 24, 2007.

THE FBRM G600 Ex IS A CLASS 1 LASER PRODUCT COMPLIANT WITH IEC 60825-1

Laser de Classe 1

Conforme à la norme 21 CFR 1040.10 et 1040.11

À l'exception des écarts conformement à l'avis Laser 50 en date du 24 Juin 2004,

et conforme à la norme IEC 60825-1

LASER SAFETY WARNING

Opening the enclosure and making adjustments, or performing procedures

other than those specied in the instrument manual may result in hazardous

radiation exposure.

Caution—Use of controls or adjustments or performance of procedures other

than those specied in the instrument manual may result in hazardous

radiation exposure.

There are no user-serviceable components in the laser module. Only skilled,

trained technicians can service this equipment.

Looking directly into the aperture of any laser-emitting device is never advised.

Table 7. Laser safety warnings and cautions

5 Supplementary Documentation

An electronic ParticleTrack G600Ex Hardware Documentation Portfolio, shipped with the

instrument, includes the following documents in addition to this manual:

• QuickRef: “Positioning the ParticleTrack or ParticleView Probe” (MK-PB-0050-AC)

• “Calibration Validation in iC FBRM” (MK-PB-0071-AC)

• “System Calibration in iC FBRM” (MK-PB-0082-AC)

• “Calibration Validation in iC Process for FBRM” (MK-PB-0109-AC)

• “System Calibration in iC Process for FBRM” (MK-PB-0110-AC)

Please refer to the iC FBRM and iC Process for FBRM software user assistance and

Documentation Portfolios for software publications.

Check the https://community.autochem.mt.com site for the latest portfolios.

Page 11

11

6 Product Installation

ParticleTrack G600Ex system installation involves three connections to the power, air,

and communication inlets at the bottom of the base unit. A qualified METTLER TOLEDO

Field Service Engineer performs a ParticleTrack G600Ex system installation. After initial

installation, if the system requires relocation or installation after depot repair, use the

steps outlined below. METTLER TOLEDO is available to provide the service if necessary.

Connect Power (A)

Ensure that your power supply meets the electrical specifications in section 3 "Technical

Data" on page 5.

1. Run power, using fittings and wiring rated appropriately for the location, from the

main supply to the terminal block inside the purge and pressurization system;

interface through the base of the enclosure (A in Figure 4 and Figure 5). The purge

and pressurization system bypass, located inside the enclosure, must be hard-wired

for 115 V or 230 V, as applicable.

2. Use ground strap (customer-provided) with minimum 3.31 mm2 [12 AWG] and

connect to the earth/ground stud on right side of enclosure

3. If necessary, provide an AC Line Conditioner for noisy power.

US B

Figure 4. Instrument connections: (A) Power; (B1) Air inlet for enclosure purge and

pressurization; (B2) Air inlet for probe scanner; (C) Fiber communication connection;

(D) Fiber-to-USB extender; (E) USB cable; (F) Extender power supply

E

C

F

D

B1

B2

A

Page 12

12

Hardware Manual

Figure 5. Wiring: Power to

purge and pressurization

interface unit

Wire * Coil (ABB) Terminals

100–125 V

Green/Yellow GND (Ground from power cable)

Brown 1L1 (Line from power cable) 115 (Jumper from 1L1)

Blue 3L2 (Neutral from power cable) N (Jumper from 3L2)

200–240 V

Green/Yellow GND (Ground from power cable)

Brown 1L1 (Line from power cable) 230 (Jumper from 1L1)

Blue 3L2 (Neutral from power cable) N (Jumper from 3L2)

* NOTE: Wire color may vary depending on the global location.

Table 8. Permanent power cord wiring

NOTE: Figure 5 shows a typical layout for wiring. The orientation of the bypass block can

vary. Please wire to the empty 115 V and 230 V locations per Table 8 below.

A

3L2

N

230

115

GND

1L1

Page 13

13

Connect Air Supply (B1 and B2)

A ParticleTrack G600Ex system requires instrument quality air connections for the

enclosure purge/pressurization system and for the pneumatically driven probe scanner.

Air Supply to Purge and Pressurization System

The purge and pressurization system comes standard with an air regulator/filter

assembly. The required 1/2" tubing is rated for 8 barg [120 psig] air service and flame

retardant. Tubing may be made of polypropylene, PVC, or nylon.

1. Clean/purge all air lines and tubes before connection to the ParticleTrack G600Ex

instrument.

2. Connect air for the purge and pressurization system via the air regulator/filter

assembly provided to the air inlet (B1 in Figure 4) identified at the bottom of the

enclosure.

Air Supply to Probe Scanner

A ParticleTrack G600Ex system requires instrument quality air for the pneumatically

driven probe scanner and comes standard with an air regulator. The regulator/filter

assembly has two filters, a general purpose filter and a coalescing filter, that can be

replaced if they become dirty. The required tubing is 1/4" OD, rated for 8 barg [120 psig]

air service and flame retardant. Tubing may be made of polypropylene, PVC, or nylon.

1. Install air regulator and filter within six feet (two meters) of the enclosure.

2. Clean/purge all air lines and tubes before connecting to the ParticleTrack G600Ex.

3. Connect the tubing between the air supply, the regulator, and the scanner air inlet

(B2 in Figure 4) at the bottom of the ParticleTrack G600Ex base unit.

NOTE: Air flows in the direction indicated by the arrow on the front of the coalescing

filter.

4. Ensure the bowl assembly on the general purpose filter is fully inserted and locked in

place by rotating it to the right.

Page 14

14

Hardware Manual

Connect Fiber-to-USB Communications (C, D, E, F)

The ParticleTrack G600Ex connects to the computer by a custom fiber optic cable with an

industrial LC-type connector via a Fiber-to-USB Extender (D). Both the fiber optic cable

and the extender are supplied with the system. Follow the steps below.

1. Locate the fiber optic input at the bottom of the ParticleTrack G600Ex base unit and

connect one end of the supplied fiber optic cable to the input (C).

2. Plug the other end of the fiber optic cable to the fiber optic input on the Fiber-to-USB

extender (D).

3. Connect the USB cable (E) from the Host input of the extender to a USB port on the

control computer.

4. Connect the power supply (F) to the USB extender and an AC outlet.

Install Probe

A variety of probe mounting options are available using the METTLER TOLEDO Flexible

Mounting System ("Flexible Probe Mounting Options" on page 16). Due to the complex

nature of multi-phase flow, proper installation is very important for successful application

of inline particle and droplet measurement techniques. Installation and mounting of

probe-based instruments for particle characterization should consider multiple factors

including:

• Existing or planned process equipment

• Scale and control capabilities of existing installation ports

Page 15

15

B CA

D

Figure 6. Implementation of a ParticleTrack instrument: (A) ush with wall of vessel or pipeline; (B) inserted

tangentially to process ow; (C) inserted perpendicular to process ow at an elbow; and (D) inserted at

optimal angle (45°) relative to process ow.

• Expected ranges of process variables such as temperature, pressure, flow

rates, and/or flow patterns

• Expected range of particle/droplet size and concentration

• Probe location and orientation (Figure 6)

Page 16

16

Hardware Manual

7 Flexible Probe Mounting Options

The Flexible Mounting System enables the attachment of both industry standard and

custom designed flange adapters and fittings without permanent modification of the

probe. Length reducers are an option for use with flange adapters and other flexible

mounting kits to provide a practical means of decreasing the probe wetted length when a

shorter insertion depth is required. The innovative design from METTLER TOLEDO allows

probes with this flexible mounting adapter to be easily moved from one installation point

to another at a lower overall cost. Figure 7 shows some of the standard options available

for mounting to the Flexible Mounting Adapter (A).

Figure 7.

ParticleTrack G600Ex

exible mounting options

1 2 3 4

A

Page 17

17

In addition to the standard Flexible Mounting System options, METTLER TOLEDO can

provide custom and special-order probe designs. Custom probes can be manufactured

with permanently welded flange adapters and fittings to meet specific installation

requirements that are not possible with the existing Flexible Mounting System. All

custom and special order installation requirements should be discussed with your

METTLER TOLEDO Technology and Applications Consultant, and may involve custom

engineering and design charges.

G600T

G600P

G600R

1

Flange Adapter Kits

For installation of probe through industry standard (ANSI) flanged

ports.

• • •

2

Tri-Clamp® Adapter Kits

For installation using industry standard Tri-Clamp® flanges.

• • •

3

Dip Pipe Installation Kits

For simplified installation in large vessels using a custom dip pipe.

Dip Pipe Adapters allow probes to be installed inside dip pipes of

customized lengths to extend the effective length of the probe up to 5

meters. A Dip Pipe Installation requires the purchase of two separate

accessories including (1) a Dip Pipe Installation Kit and (2) a Dip

Pipe Adapter that is welded to a standard pipe during the construction

of the dip pipe. The dip pipe is supplied by the customer.

•

4

Ball Valve Assembly

For installation into an active pipeline, the FBRM Ball Valve Assembly

is designed to allow the insertion or removal of a probe into a flowing

stream without requiring shut down of the process. Using a ball valve

assembly also helps avoid spills to minimize exposure of personnel

and environment to the contents of the process stream.

• •

Table 9. Flexible mounting options

Page 18

18

Hardware Manual

8 Operating Instructions

During system installation, a trained METTLER TOLEDO engineer makes all system

connections and verifies the system is ready for use.

1. Verify the base unit door is securely locked. Use the supplied key to lock the six

latches on the enclosure door.

2. Start inlet air supply to the Probe Scanner and regulate flow to:

4.5–5.2 barg [65–75 psig].

3. Start up the purge and pressurization system.

a. Apply inlet air supply to purge and pressurization system and regulate flow

at 4.8barg [70 psig]. The acceptable regulated pressure range is 4–8barg

[60–120 psig].

b. The purge system starts automatically and the purge indicators (Table 10) on the

enclosure cover change color. Before air is applied, the indicators are Red-Black.

After air is applied, the indicators change to Green-Yellow (Purging), followed by

Green-Black when the enclosure is purged/pressurized.

c. Purge for a minimum of 5 minutes at a minimum purge flow rate of 225 L/min.

d. Observe purge indicators change to Green-Black when the enclosure is purged

and pressurized.

e. After the purge completes, the purge and pressurization system interface unit

automatically applies power to the ParticleTrack G600Ex system.

Unpressurized / Alarm Condition

"Purging"

The process takes approximately ve (5) minutes.

"Pressurized"

Purge complete.

Table 10. Purge and pressurization system indicators

Page 19

19

Indicators LED State Status

Host ON (Solid Green) USB cable between PC and HOST is properly connected

Power ON (Solid Green) Power supply is properly connected to extender

Link

ON (Solid Green) Powered, HOST is identified, and Fiber is properly

connected

LOS

ON (Solid Red) Loss of Signal—No communication between

instrument and PC

Table 11. USB Extender LEDs

NOTES:

- If the right indicator remains yellow or changes to yellow during operation, the

purge air flow is inadequate. Check the air supply and connections.

- Venting of the relief valve during operation is considered normal. The airtight

enclosure relies on the use of the relief valve to ensure a consistent level of

pressurization is maintained within the enclosure.

- Ensure the ParticleTrack G600Ex system has been powered ON for 30 minutes

before performing calibration validation or recording process measurements.

4. Observe LED indicators on USB Extender.

5. Turn on control computer and start the software. To add/configure the

instrument in iC FBRM or iC Process for FBRM, please refer to the applicable online

User Assistance.

Page 20

20

Hardware Manual

9 Best Practices for Routine Operation

Ensure Reliable Instrument Performance

• Follow recommended calibration validation procedures monthly or quarterly as

determined by your SOP.

• Follow preventative maintenance guidelines for your ParticleTrack instrument.

• Check probe window cleanliness as part of routine SOP.

Ensure Measurement Sensitivity by Optimizing Probe Location and Positioning

• Probe should be positioned in the process where it can obtain maximum sensitivity to

changes in particle or droplet system.

• Probe must be oriented to ensure particle system flows optimally across the probe

window surface.

• Probe tip must remain fully immersed to provide measurements of the particle/droplet

system.

• Probe location is more critical under the following conditions:

- Extreme difference between particle density compared to the carrying solution

density (ranges from very low or very high)

- Lower Rheology

- Larger median particle dimension

- Greater deviation between average particle shape and a sphere (more irregular

particles or particle structures)

• Probe location is less critical under the following conditions:

- Smaller difference between particle density compared to carrying solution density

- Higher solids concentration (or higher dispersed phase in liquids)

- Smaller median particle dimension

- Narrower particle distribution

- Smaller deviation between average particle shape and a sphere (fewer irregular

particles or particle structures)

Page 21

21

Track Particle Systems Reliably

• Use iC FBRM for routine monitoring of particle and droplet systems in the laboratory.

Use iC Process for FBRM for secure and reliable monitoring of particle and droplet

systems in batch or continuous processes.

• Use iC FBRM for advanced data analysis of data collected in either iC FBRM or iC

Process for FBRM.

• Use iC FBRM for further improvement and optimization of Process Methods to be used

in SOPs.

Develop a Standard Operating Procedure (SOP)

• Select or create an appropriate iC FBRM template for each given application. A welldesigned template will simplify the startup procedure and ensure consistent operation

in each experiment.

• Include appropriate statistical trends that can directly track particle and product and

quality parameters of interest.

• Include reference and target distributions as process milestones or final product

quality set-points.

• Optimize the measurement configuration (measurement interval and averaging

settings) to ensure robust repeatable measurement and to maximize sensitivity to

dynamic changes in the particle system.

Save Experiment Settings as a Template—Make sure to develop the right template for

a specific particle or droplet system. Save a template that includes trends and reference

distributions that are important to track to characterize the particle or droplet system.

Manage Reference Distributions—Distributions can be saved as references and

designated as targets for subsequent experiments. Reference distributions or target

distributions can be saved in particle-specific templates.

Check Probe Window Cleanliness—The probe window must be clean before mounting

in particle or droplet system and before performing Calibration Validation.

Page 22

22

Hardware Manual

Warnings

Table 13. Troubleshooting warnings

Warning Message Description Possible Cause

Effective Duration

Low

Effective Duration is a

measure of the data

transfer efficiency. Normal

operation results in an

Effective Duration of

approximately 50%.

Effective Duration Low may indicate that

PC specifications are inadequate. A low

Effective Duration may reduce the

precision of the measurement.

If the Effective Duration is significantly less

than 40%, contact METTLER TOLEDO.

The measurement interval can also impact

Effective Duration. Only select an interval

<10 s where you expect rapid process

changes.

Average Signal

Intensity High

Average Signal Intensity is

an indicator of the amount

of light backscattered by

the particles or droplets

being measured.

Average Signal Intensity High may indicate

that the particles being measured are

highly reflective. Very high backscatter

may saturate the sensor, resulting in

erroneous measurements.

Table 12. Troubleshooting errors

Error Message Description Possible Cause

Air Filter Pressure

High / Low

Pressure measured at the

outlet of the internal air

filter is outside the

recommended range

Possible causes include scanner inlet

pressure is not set within recommended

range or filter is clogged and needs

replacement.

Box Temperature

High / Low

Internal temperature of

base unit has fallen

outside of the

recommended operating

temperature range.

The base unit is installed in a location that

is not within recommended specification.

Scan Speed or

Scan Frequency

High / Low

Desired scan speed or

frequency is outside

acceptable range.

Air pressure to probe scanner is set

incorrectly. Check the pressure and

regulate to proper range. If error continues,

contact METTLER TOLEDO.

Tach Pulse

Missing

Data acquisition error. Verify USB and fiber connections are

secure. If error continues, contact

METTLER TOLEDO.

10 Troubleshooting

Errors are generally hardware-related issues that affect data acquisition. The

following table documents how hardware errors are displayed in the control software,

describes what the error means and provides possible root causes to assist with

troubleshooting and resolving the issue. If the issue cannot be resolved, please contact

AutoChemCustomerCare@mt.com for assistance.

Errors

Page 23

23

11 Product Maintenance

METTLER TOLEDO warrants its products against defects in materials and workmanship for

twelve months from the date of installation or fifteen months from the date of shipment,

whichever comes first. For details, please refer to the warranty provided with the

instrument. For assistance, please email AutoChemCustomerCare@mt.com.

It is recommended that you retain the original packing materials if you need to return

the ParticleTrack system. If factory service is required, your METTLER TOLEDO service

engineer will issue you a Return Material Authorization (RMA) form.

There are no user-serviceable parts inside a ParticleTrack G600Ex. Contact your

METTLER TOLEDO Field Service Engineer for all service needs. Unauthorized service may

damage the instrument.

Schedule the routine maintenance tasks outlined below. To facilitate maintenance (with

the ParticleTrack G600Ex door open) when the purge and pressurization system cannot

be used, a key is provided. The key operates the Bypass switch (A in Figure 8). System

must be in a safe location.

When the enclosure is opened for service, observe the warning inside the enclosure (and

shown in Table 6 on page 9 under "Safety Information").

• Ensure the air/gas supply meets the required standards.

• Replace the ParticleTrack G600Ex air filter if it becomes dirty. Since instrument quality

air should not result in a dirty filter, look for and correct the problem that is causing

the air contamination.

• Run the Calibration Validation procedure for the probe every three to six months, if

the probe is dropped or relocated, and after new software is installed, if desired. If the

Calibration Validation does not pass, follow the System Calibration procedure.

• The ParticleTrack G600Ex system is designed for indoor or outdoor use. The base unit

can be sprayed with water jets to clean in plant environments and the system is easily

cleanable with a water-damp cloth. Use caution when cleaning exhaust on probe. The

protective non-metallic cover of the purge indicators presents a potential electrostatic

charging hazard. Do not rub with a dry cloth or clean with solvents. Clean only with a

water-damp cloth.

• Periodically perform the following maintenance task to verify purge and pressurization

system function.

a. With the enclosure closed, turn on

the purge and pressurization air and

adjust the pressure gauge to 4.8 barg

[70 psig].

b. Verify the Purge Cycle time is at least

five (5) minutes.

c. Verify the purge cuts power to the

system when door is opened.

d. Close door.

Figure 8. Bypass switch

A

Page 24

24

Hardware Manual

Relocation, Shipment, or Storage

To prevent and minimize damage to the ParticleTrack G600Ex, follow the instructions

below to prepare the system for relocation, shipment, or storage.

1. Close the iC FBRM or iC Process for FBRM software application and shutdown the

computer according to normal operating procedures.

2. Disconnect the power, air, and communications from the bottom panel of the base

unit enclosure.

3. Disconnect the Fiber-to-USB Extender from the power supply and from the control

com puter.

4. Store the system and all components in the factory-supplied crate.

Replacement Interval Part

Annually PVC Reference Sample, G600

• customer-replaceable

• PVC life: 10 uses or one year, whichever comes rst

• included in annual PM

Internal Filter Assembly

External Air Regulator, Filter (customer-replaceable)

Every two (2) years Control Valve

Every three (3) years Laser Board

Table 14. Parts life expectancy

METTLER TOLEDO has offices around the world. Contact the Mettler-Toledo AutoChem,

Inc., headquarters in the USA for technical support or service. To arrange for specific

application assistance from a METTLER TOLEDO Technology and Applications Consultant,

or for assistance, contact Customer Care through the toll-free number on page 2.

Recommended Maintenance

A qualified METTLER TOLEDO Field Service Engineer should perform regular Preventive

Maintenance (PM) on the system. Table 14 shows the normal life expectancy of several

components and identifies any customer-replaceable parts. Use this information for

planning potential cost of ownership.

Page 25

25

12 Disposal

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment.

If you have any questions please contact the responsible authority or the distributor from

which you purchased this device.

Thank you for your contribution to environmental protection.

Notes

Page 26

Mettler-Toledo AutoChem, Inc.

7075 Samuel Morse Drive

Columbia, MD 21046 USA

Telephone +1 410 910 8500

Fax +1 410 910 8600

Email autochem@mt.com

Internet www.mt.com/autochem

Subject to technical changes

© 11/2016 Mettler-Toledo AutoChem, Inc.

Printed in USA MK-PB-0079-AC Rev E DCN 3000

Visit for more information

www.mt.com/ParticleTrack

Our on-demand webinars (online seminars) provide application

and industry information relevant to you. These interactive

presentations, provided by industry experts and our own

applications team, give you an opportunity to learn more about

your specific area of interest.

Topics include:

• Improving Crystallization and Precipitation Processes

• The Importance of Mixing in Process Development

• Avoiding Incidents During Scale-up

• Recent Advances in Organic Chemistry

• Calorimetry Best Practices

• Characterization of Catalytic Hydrogenations

• Plus other applications including green chemistry, organic

synthesis, fermentation, high pressure chemistry and more

www.mt.com/ac-webinars

Learn More with our

Technical Webinar Program

Loading...

Loading...