Mettler Toledo Profibus-Module, DeviceNet-Module, EtherNet/IP-Module, ProfiNet IO-Module, CC-Link Module Operating Instructions Manual

Page 1

Modules

Fieldbus

Operating Instructions

Page 2

Leer

Page 3

Table of Content

1 Introduction...........................................................................................................................................6

1.1 General ..................................................................................................................................................6

1.2 Compatibility .......................................................................................................................................... 7

1.3 Related documentation ............................................................................................................................ 7

1.4 Internet addresses ................................................................................................................................... 7

2 Functional Overview .............................................................................................................................8

2.1 Data exchange model..............................................................................................................................8

3 Set-up Checklist .................................................................................................................................... 9

4 Step-by-Step Installation and Configuration .......................................................................................... 10

4.1 Configure the weighing sensor ................................................................................................................10

4.1.1 Adjustment of interface communication parameters of the weigh modules ...................................................10

4.1.2 Adjustment of interface communication parameters of other weighing sensors .............................................10

4.2 DIN-Rail mounting ................................................................................................................................11

4.3 Connect the Fieldbus-Module to a PC for initial configuration ......................................................................11

4.4 Connect the Fieldbus-Module to the weighing sensor .................................................................................12

4.4.1 WMS, WM and WMH weighing sensor .................................................................................................... 12

4.4.2 Other METTLER TOLEDO balances and weighing sensors ...........................................................................13

4.5 Connect the Fieldbus-Module to a power supply ....................................................................................... 13

4.6 Configure the Fieldbus-Module................................................................................................................14

4.6.1 PC terminal software ............................................................................................................................. 14

4.6.2 Weighing sensor interface ...................................................................................................................... 15

4.6.3 Baudrate .............................................................................................................................................. 15

4.6.4 Character format ................................................................................................................................... 15

4.6.5 Operation mode .................................................................................................................................... 15

4.6.6 Maximum response time........................................................................................................................15

4.6.7 Configuration from network ....................................................................................................................15

4.6.8 Automatic baudrate search .....................................................................................................................16

4.6.9 Save configuration to flash ..................................................................................................................... 16

5 Fieldbus-Modules ................................................................................................................................ 17

5.1 Profibus-Module ...................................................................................................................................17

5.1.1 General ................................................................................................................................................17

5.1.2 Supported features ................................................................................................................................17

5.1.3 Identification numbers ...........................................................................................................................17

5.1.4 Profibus node address ..........................................................................................................................17

5.1.5 Cabling ................................................................................................................................................18

5.1.6 Bus termination ...................................................................................................................................18

5.1.7 GSD configuration file ............................................................................................................................ 18

5.1.8 Configure and start the Profibus network .................................................................................................. 18

5.1.9 LED indication table .............................................................................................................................19

5.2 DeviceNet-Module ................................................................................................................................. 20

5.2.1 General ................................................................................................................................................20

5.2.2 Supported features ................................................................................................................................20

5.2.3 Identification numbers ...........................................................................................................................20

5.2.4 Network configuration ............................................................................................................................21

5.2.4.1 Mac address ........................................................................................................................................21

5.2.4.2 Baudrate .............................................................................................................................................. 21

5.2.5 Cabling ................................................................................................................................................21

5.2.6 EDS configuration file ............................................................................................................................21

5.2.7 Configure and start the DeviceNet network................................................................................................22

5.2.8 LED indication table ..............................................................................................................................22

5.3 EtherNet/IP-Module................................................................................................................................23

5.3.1 General ................................................................................................................................................23

5.3.2 Supported features ................................................................................................................................23

5.3.3 Identification numbers ...........................................................................................................................24

5.3.4 Network configuration ............................................................................................................................24

5.3.4.1 IP address ...........................................................................................................................................24

3Table of Content

Page 4

5.3.5 Cabling ................................................................................................................................................24

5.3.6 EDS configuration file ............................................................................................................................24

5.3.7 Configure and start the EtherNet/IP network .............................................................................................. 25

5.3.8 LED indication table ..............................................................................................................................25

5.3.9 IPConfig-Tool ........................................................................................................................................25

5.4 EtherNet/IP Configuration for Rockwell Add-on-Profile ................................................................................ 26

5.4.1 Connecting the EtherNet/IP-Module..........................................................................................................26

5.4.2 PLC configuration .................................................................................................................................26

5.4.3 EtherNet/IP-Network configuration ........................................................................................................... 28

5.5 ProfiNet IO-Module ................................................................................................................................ 31

5.5.1 General ................................................................................................................................................31

5.5.2 Supported features ................................................................................................................................31

5.5.3 Identification numbers ...........................................................................................................................31

5.5.4 Network configuration ............................................................................................................................31

5.5.4.1 IP address ...........................................................................................................................................31

5.5.4.2 Sub-network configuration......................................................................................................................31

5.5.5 Cabling ................................................................................................................................................32

5.5.6 GSDML configuration file ........................................................................................................................32

5.5.7 Configure and start the ProfiNet IO network...............................................................................................32

5.5.8 LED indication table ..............................................................................................................................33

5.5.9 IPConfig-Tool ........................................................................................................................................33

5.6 CC-Link Module .................................................................................................................................... 34

5.6.1 General ................................................................................................................................................34

5.6.2 Supported features ...............................................................................................................................34

5.6.3 Identification numbers ...........................................................................................................................34

5.6.4 Network configuration ............................................................................................................................34

5.6.4.1 Station range ........................................................................................................................................ 34

5.6.4.2 Baud rate ............................................................................................................................................. 34

5.6.5 Cabling ................................................................................................................................................35

5.6.6 Configuration and start the CC-Link network ............................................................................................. 35

5.6.7 Operation ............................................................................................................................................. 35

5.6.7.1 Basic-Mode .........................................................................................................................................35

5.6.7.2 Extended-Mode ....................................................................................................................................36

5.6.8 LED indication table ..............................................................................................................................37

5.6.9 Operations ...........................................................................................................................................37

6 Operations .......................................................................................................................................... 38

6.1 Basic-Mode ..........................................................................................................................................38

6.1.1 Output register Basic-Mode: 2 bytes ........................................................................................................ 38

6.1.2 Input register Basic-Mode: 8 bytes .......................................................................................................... 39

6.2 Extended-Mode .....................................................................................................................................40

6.2.1 Output register Extended-Mode: 32 bytes ................................................................................................. 40

6.2.2 Input register Extended-Mode: 32 bytes ................................................................................................... 41

6.3 Command codes / Response codes ........................................................................................................ 43

6.4 Weight units ......................................................................................................................................... 44

6.5 Repetitive weighing commands ..............................................................................................................44

6.6 Commands with multiple responses ........................................................................................................ 44

6.7 Sequence of the communication between the PLC and the weighing sensor ................................................. 45

6.7.1 Simple weighing commands .................................................................................................................. 45

6.7.2 Communication flowchart when executing a "S" command ........................................................................ 46

6.7.3 Commands for repetitive weighing ..........................................................................................................47

7 Error Handling, FAQ ............................................................................................................................. 48

7.1 Weighing sensor response status ............................................................................................................48

7.2 Timeout ...............................................................................................................................................48

7.3 Frequently asked questions .................................................................................................................... 49

7.4 Support ...............................................................................................................................................49

8 Checklist and Recommendations for Weigh Sensors .............................................................................. 50

9 Technical Specification .......................................................................................................................52

4 Table of Content

Page 5

9.1 Mechanical ..........................................................................................................................................52

9.2 Electrical characteristics ......................................................................................................................... 52

9.3 Environmental ......................................................................................................................................52

9.4 EMC Compliance ..................................................................................................................................52

9.5 UL/c-UL compliance .............................................................................................................................. 52

5Table of Content

Page 6

1 Introduction

1.1 General

The METTLER TOLEDO Fieldbus-Modules allow to connect METTLER TOLEDO weigh modules, industrial scales or laboratory

balances (subsequently referenced to as weighing sensors) to an industrial Fieldbus network and make it possible to control

the weighing sensor with a PLC master. For each weighing sensor is a separate Fieldbus-Module required.

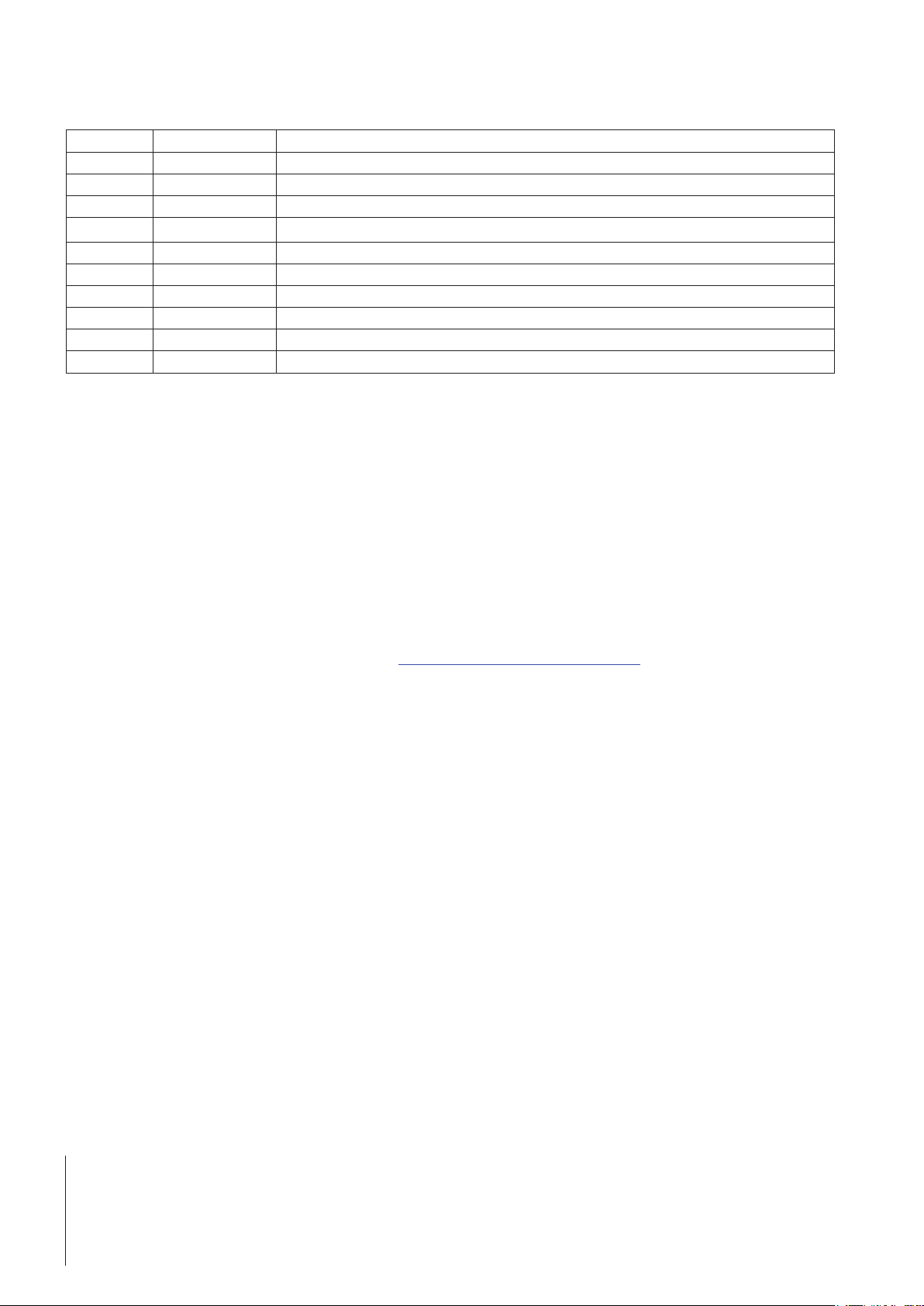

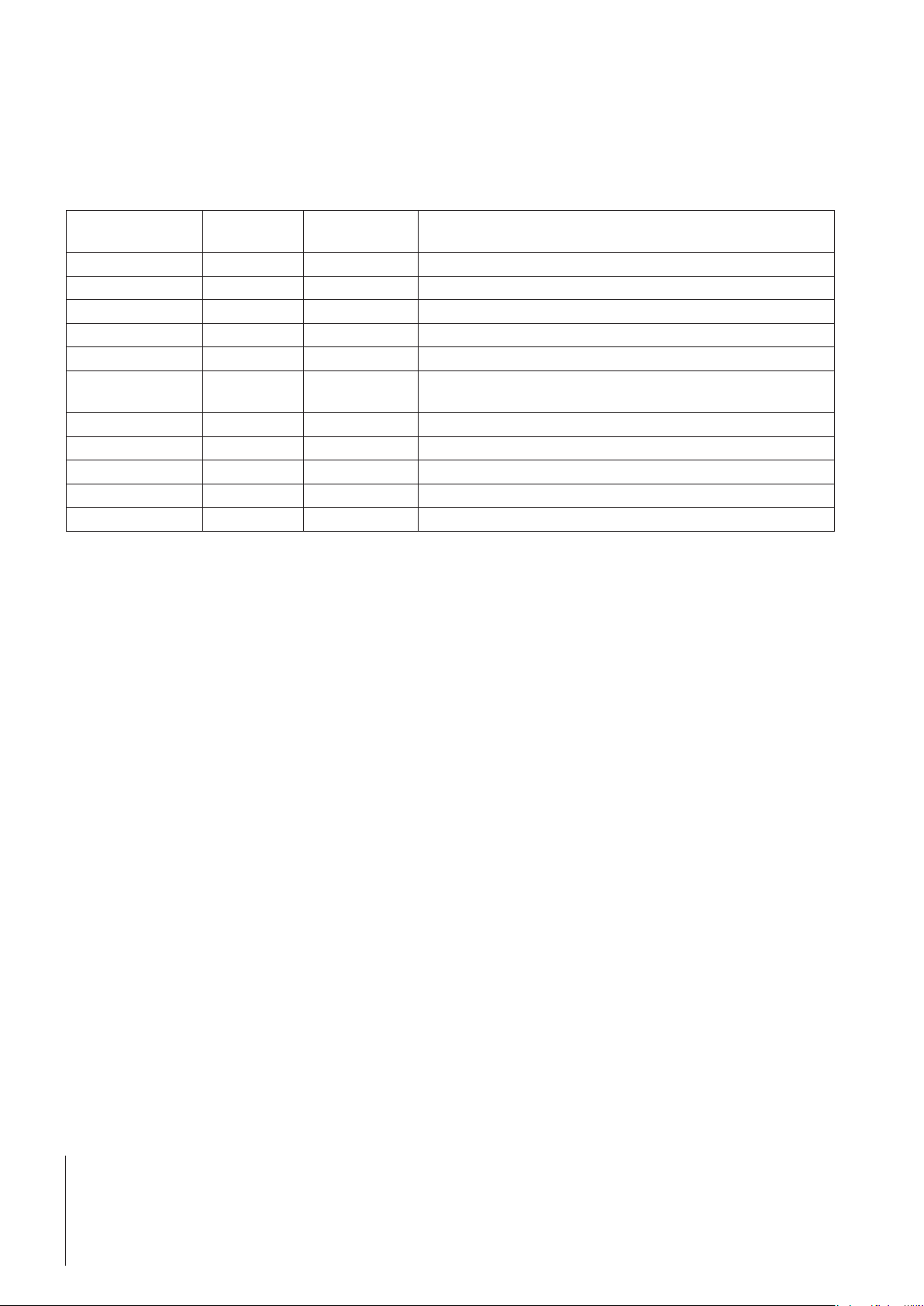

The following Fieldbus-Modules are currently available:

Part number Fieldbus-Module Chapter

42102809 METTLER TOLEDO Profibus-Module 5.1

42102810 METTLER TOLEDO DeviceNet-Module 5.2

42102860 METTLER TOLEDO EtherNet/IP-Module 5.3

42102859 METTLER TOLEDO ProfiNet IO-Module 5.5

30038775 METTLER TOLEDO CC-Link Module 5.6

6 Introducion

Page 7

1.2 Compatibility

The Fieldbus-Modules are compatible to all METTLER TOLEDO weighing sensors and balances communicating with MT-SICS

protocol via RS232, RS422 or RS485 Interfaces (see datasheet for list of compatible products).

MT-SICS is a plain ASCII protocol (MT-SICS = METTLER TOLEDO Standard Interface Command Set) which is used for control and

configuration of the weighing sensor.

1.3 Related documentation

Important information of the weighing sensor products can be found in the following documents:

• Instructions for installation and operation (of the individual sensor)

• MT-SICS Reference Manual (for respective sensor type)

• Engineering Note: EN121 EtherNet/IP-DeviceNet and Logix5000

• Engineering Note: EN131 ProfiNet IO - Profibus and STEP 7

1.4 Internet addresses

METTLER TOLEDO Automated Precision Weighing

PROFIBUS Organization

Open DeviceNet Vendors Associaton

ProfiNet Organization

CC-Link Organisation

www.mt.com/APW

www.profibus.com

www.odva.org

www.profinet.com

www.cc-link.org

7Introducion

Page 8

2 Functional Overview

The METTLER TOLEDO Fieldbus-Module is designed to exchange data between a serial sub-network and a higher level network.

For easy transfer is a Basic-Mode (see chapter 6.1, page 38) implemented for the most frequent commands. With the ExtendedMode (see chapter 6.2, page 40) is the full flexibility ensured.

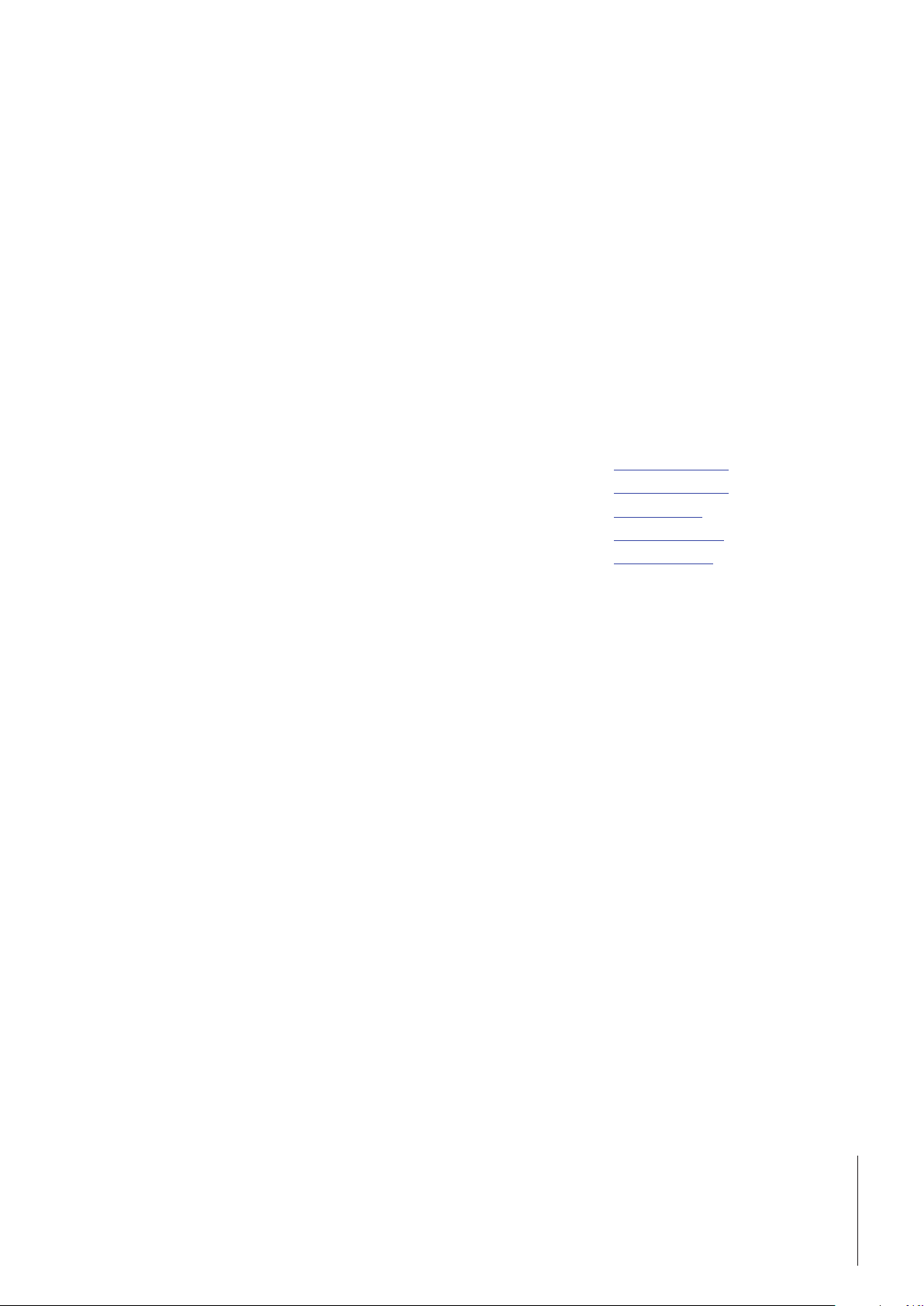

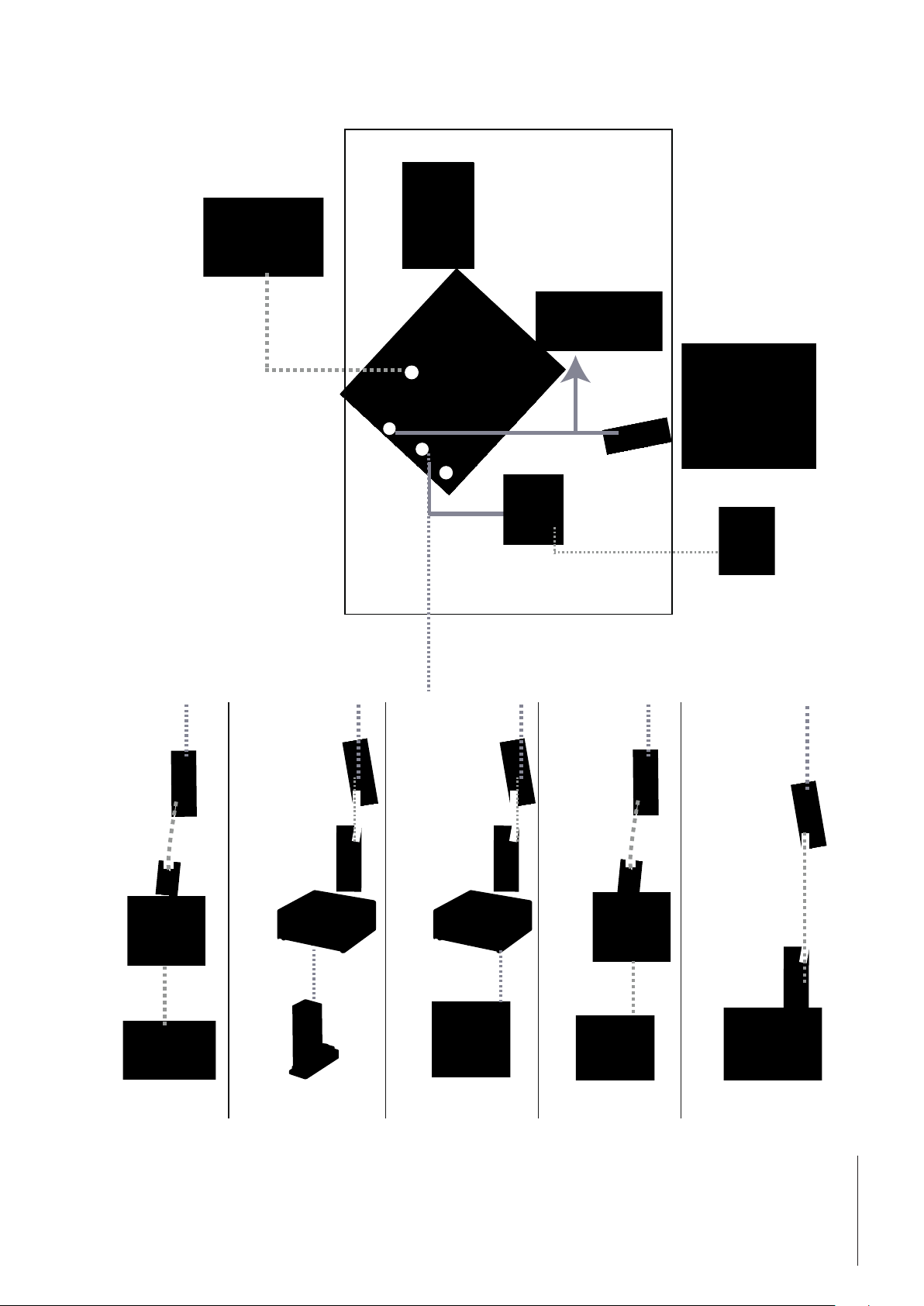

2.1 Data exchange model

PLC

The PLC receives data into its internal input area via the fieldbus

network from the IN area of the

Fieldbus-Module.

Fieldbus-Module

The IN area of the Fieldbus-Module contains data received from

the weighing sensor.

I/O I/O

Inputs Outputs

IN Area OUT Area Local Data

(000h) (200h) (400h)

Actual Weight

Value

PLC-memory

Actual Weight

Value

Internal memory buffer

Module

Settings

and

Commands

Weighing sensor

Module

Settings

and

Commands

Fieldbus

The PLC sends data via the fieldbus network, from its internal

output area to the OUT area of

the Fieldbus-Module.

The OUT area of the FieldbusModule contains output data

sent from the Fieldbus-Module

to the weighing sensor.

8 Functional Overview

Input: Settings and Commands

Output: Weight value and Status

Page 9

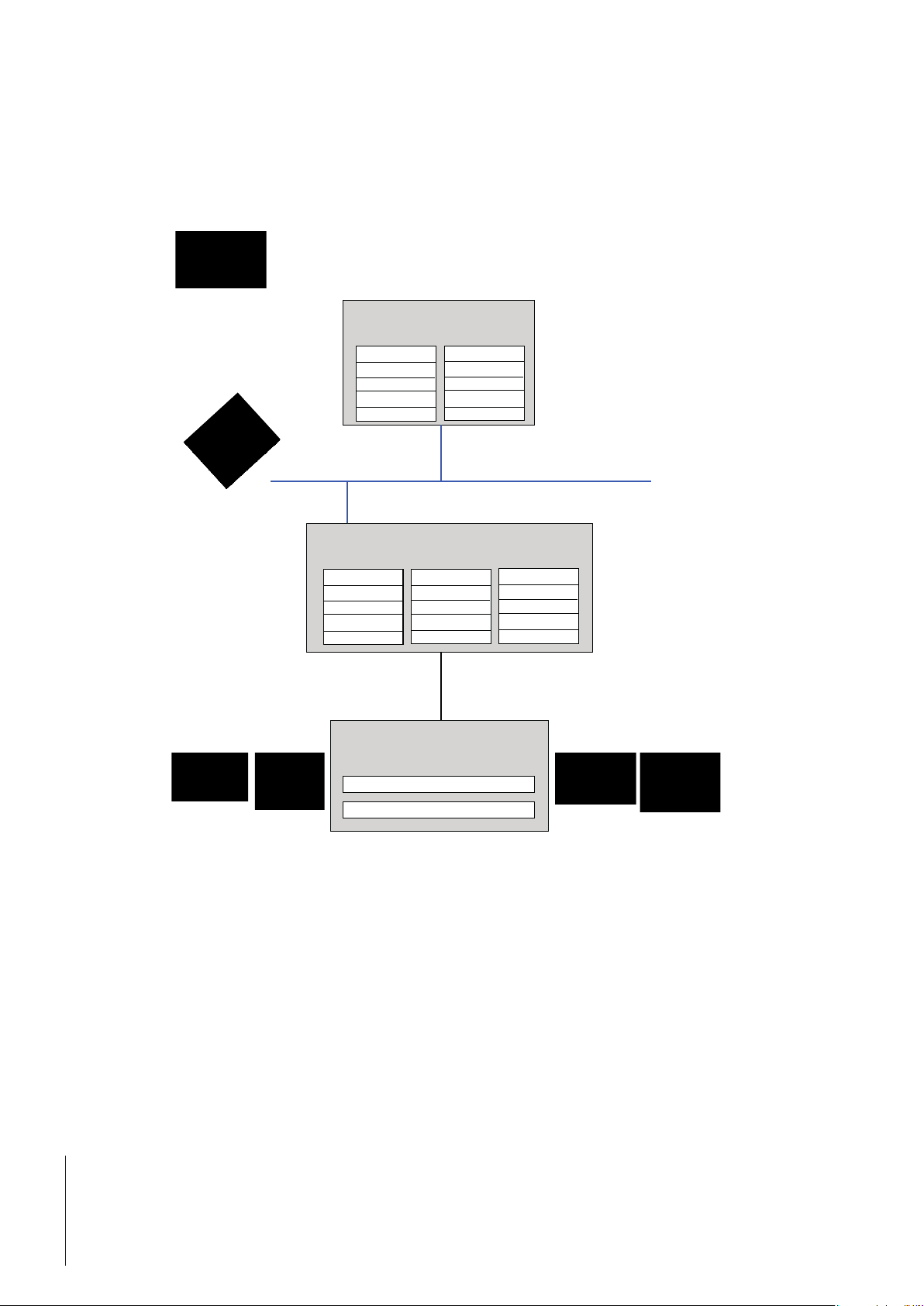

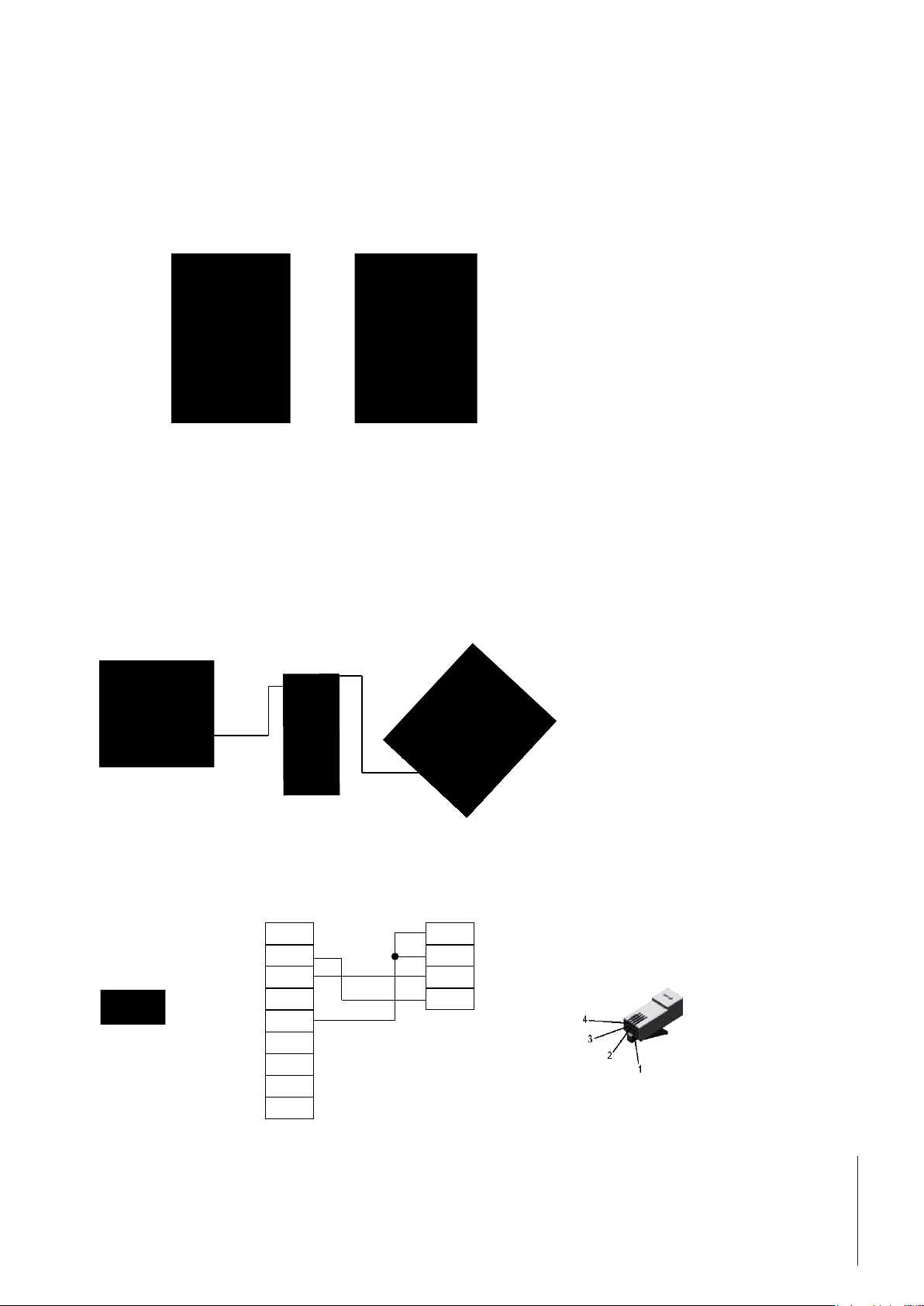

3 Set-up Checklist

PL

(e.g. Siemens S7

or Rockwell

RSLogix)

Legend

Included in delivery of Fieldbus-Module

C

1

User Manual

1 Fieldbus connector

2 PC connector

3 Subnet connector

4 Power connector

Fieldbus cable

2

3

4

Configuration cable

Power

connector

Power cable

Power supply

+24 VDC

D-Sub 9 male

11141979

open wires

ConBlock

PBK/PFK-APW

D-Sub 9 male D-Sub 9 male

RS232 Connection

cable

11601007

D-Sub 9 male D-Sub 9 male

WMC

Weigh Module

RS232 Connection

cable

11601007

WXS

Weigh Module

D-Sub 9 male

11141979

open wires

ConBlock

WMS

Weigh Module

D-Sub 9 male

RS232 Connection

cable

11601007

D-Sub 9 male

Industry Scale

e.g. BBK

9Functional Overview

Page 10

4 Step-by-Step Installation and Configuration

The following steps shall be performed to install and configure the weighing sensor and the Fieldbus-Module:

1. Configure the weighing sensor (see chapter 4.1, page 10)

2. DIN-Rail mounting (see chapter 4.2, page 11)

3. Connect the Fieldbus-Module to a PC for initial configuration (see chapter 4.3, page 11)

4. Connect the Fieldbus-Module to the weighing sensor (see chapter 4.4, page 12)

5. Connect the Fieldbus-Module to a power supply (see chapter 4.5, page 13)

6. Configure the Fieldbus-Module and activate the changes in the Fieldbus-Module (see chapter 4.6, page 14)

7. Connect the Fieldbus-Module to the network and check the LED indications (see chapter 5, page 17)

4.1 Configure the weighing sensor

Note

It is not possible to configure the weighing sensors, by use of the PC – Fieldbus-Module configuration cable connection.

Please refer to the configuration instructions of the individual weighing sensor.

4.1.1 Adjustment of interface communication parameters of the weigh modules

METTLER TOLEDO recommends to use the RS422 interface for if available the communication between weighing sensors and

the Fieldbus-Module. Configure the interface of the weigh module to a baud rate of 38400. Use MT-SICS command: COM (see

MT-SICS manual for more information).

Note

Set the data flow control to none if you connect any weighing sensor to a METTLER TOLEDO Fieldbus-Module!

METTLER TOLEDO recommends to set 19200 or 38400 baud to allow an update rate up to 92 updates.

Example: RS422, 38400 baud, 8 bit, no parity,1 stop bit and no handshake -> MT-SICS command: COM_1_8_3_0

4.1.2 Adjustment of interface communication parameters of other weighing sensors

The interface communication parameters can be set via the menu or with the data interface port. Please refer to the user manual

and/or the MT-SICS Reference Manual of the respective weighing sensor.

10 Step-by-Step Installation and Configuration

Page 11

A - Snap ON B - Snap OFF

D-sub 9 female

Fieldbus-Module

4.2 DIN-Rail mounting

To mount the Fieldbus-Module on a DIN-Rail follow the steps below:

Snap ON: To snap the Fieldbus-Module on, first press the Fieldbus-Module downward to compress the spring contacting the

DIN-Rail (1), then push the Fieldbus-Module against the DIN-Rail and release it to make it snap on (2).

Snap OFF: To snap the Fieldbus-Module off, push the Fieldbus-Module downward (1) and pull it away from the DIN-Rail (2)

to make it snap off from the DIN-Rail.

4.3 Connect the Fieldbus-Module to a PC for initial configuration

The PC connector is located at the bottom of the Fieldbus-Module. It is used to the configuration of the Fieldbus-Module. The

enclosed configuration cable shall be used (connector type is a Western Modular 4/4 on the Fieldbus-Module side).

Note

This cable connection is only suitable to configure the Fieldbus-Module, it cannot be used for weighing sensor configuration

(see also chapter 4.1).

Installs in PC’s

serial port

D-sub 9 female (PC)

RS232 RxD

5 1

9 6

(female)

RS232 TxD

Ground

1

2

3

4

Western Modular 4/4 connector

(Fieldbus-Module)

Ground

1

Ground

2

RxD

3

TxD

4

Western Modular 4/4

connector

5

6

7

8

9

11Step-by-Step Installation and Configuration

Page 12

4.4 Connect the Fieldbus-Module to the weighing sensor

The subnet connector is located at the bottom of the Fieldbus-Module and is used to connect a METTLER

TOLEDO weighing sensor equipped with either a RS232, a RS422 or a RS485 interface (configuration see

chapter 4.1). The respective pin assignment is shown in the table on next page.

Since the physical interface can be chosen by the Fieldbus-Module configuration dialog (see chapter 4.6.2), all necessary

signals for all three RS-versions are present at the D-Sub 9-connector.

Note

Make sure to connect only the necessary wires used in your application.

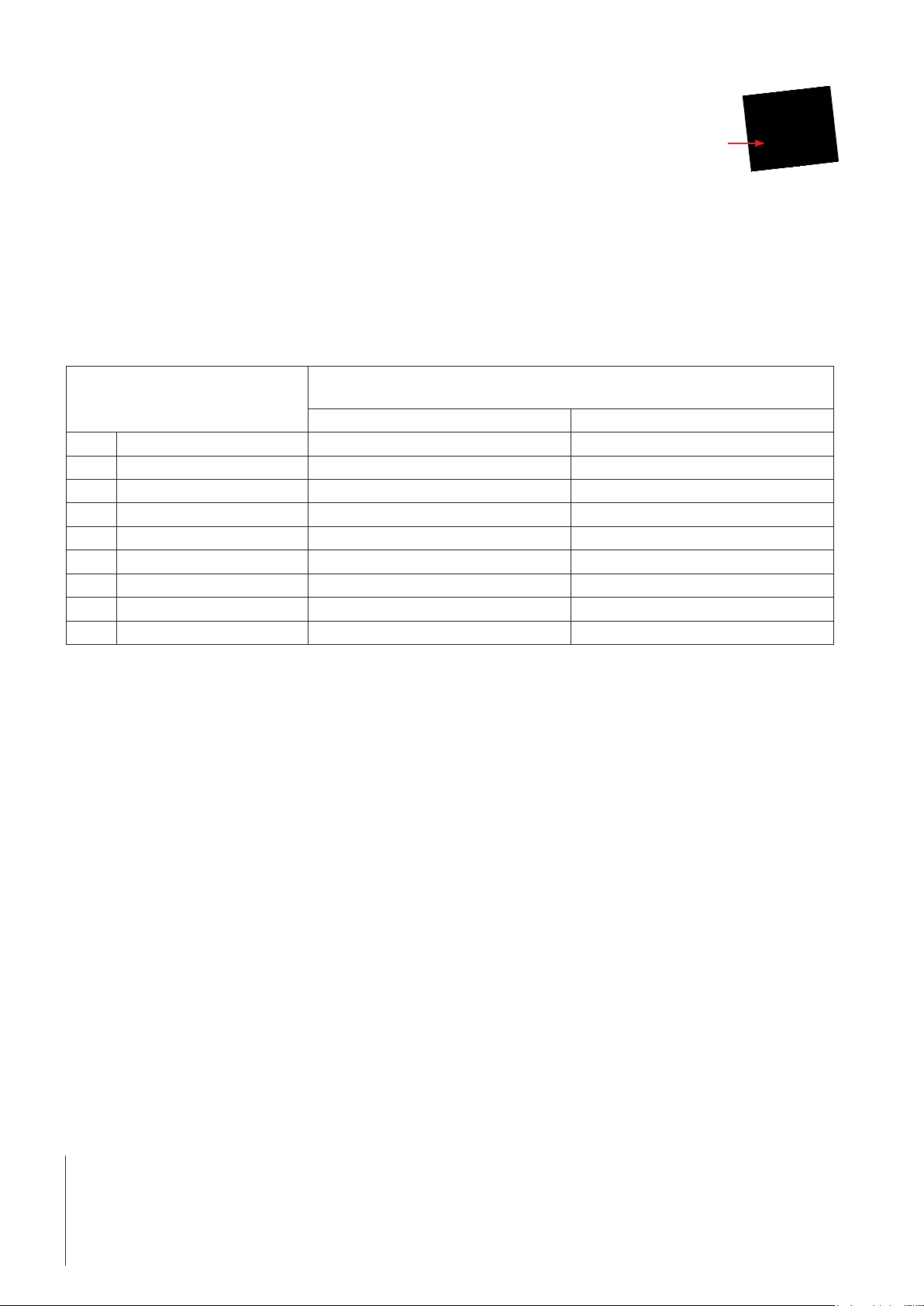

4.4.1 WMS, WM and WMH weighing sensor

DSub9

11141979

1 Black - -

2 Brown - TXD

3 Red - RXD

4 Orange - -

5 Yellow GND GND

6 Green Tx+ -

7 Blue Tx- -

8 Purple Rx+ -

9 Grey Rx- -

ConBlock (11152000) for the WMS weigh module

ConModule (42102811) for WM and WMH weigh module and platform

RS422 RS232

12 Step-by-Step Installation and Configuration

Page 13

1 2

Power Connector

51

96

4.4.2 Other METTLER TOLEDO balances and weighing sensors

For other balances and weighing sensors with MT-SICS protocol and either a RS232, a RS422 or a RS485 interface please refer

to the respective manual of the weighing sensor to determine the pin assignment of its interface.

Subnet connector Interface Type of weighing sensor

Pin Description RS232 RS422 RS485

1 + 5Volt

2 RS232 RxD

3 RS232 TxD

4 Not connected

5 Ground

6 RS422 Rx+

7 RS422 Rx-

8 RS485+ / RS422 Tx+

9 RS485- / RS422 Tx-

P Wires to be used (depending on weighing sensor’s interface type)

Make sure to connect only the necessary wires depending on the weighing sensor’s interface.

P (TxD)

P (RxD)

P (GND) P (GND) P (GND)

P (Tx+)

P (Tx-)

P (Rx+) P (Rx+)

P (Rx-) P (Rx-)

(female)

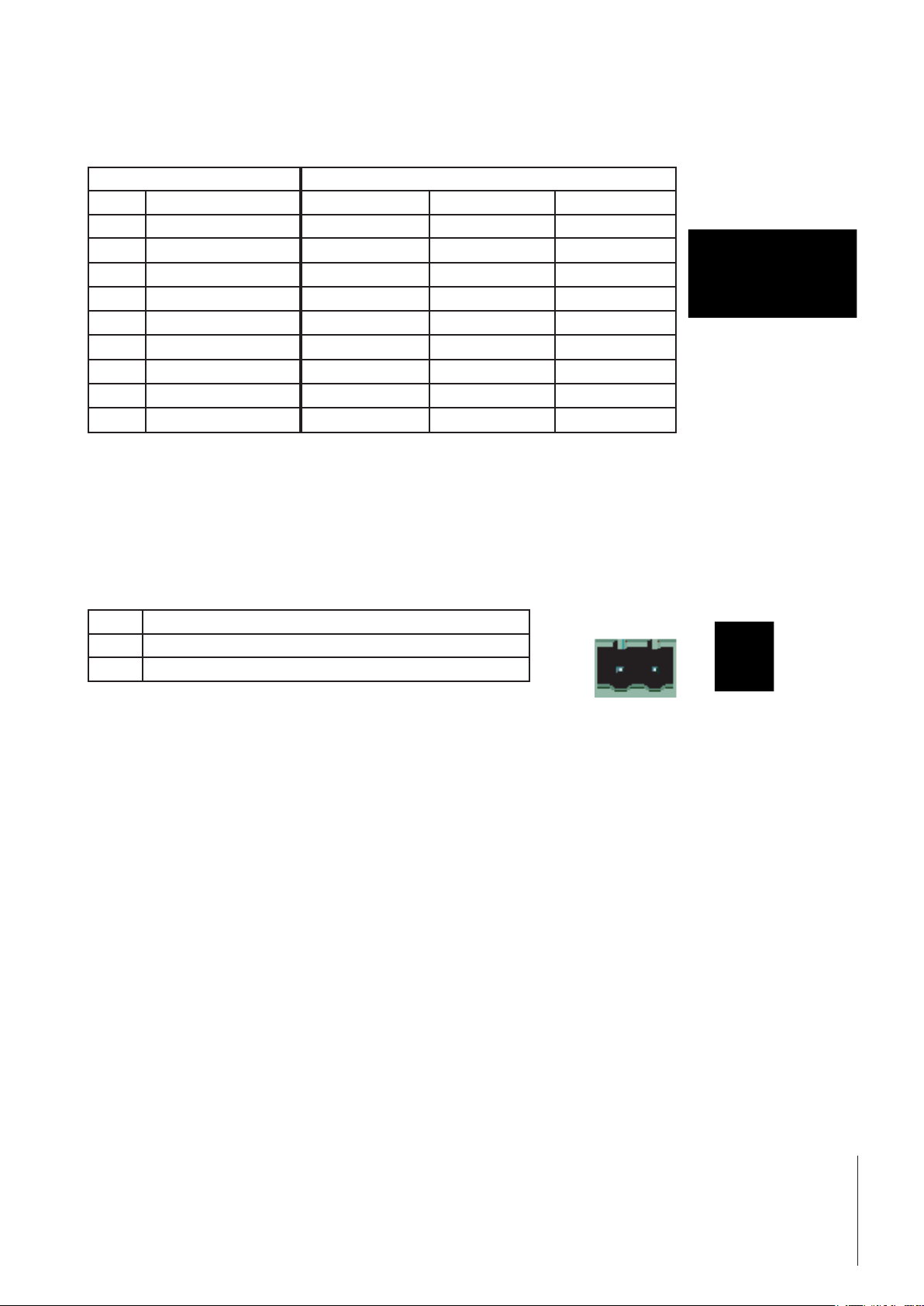

4.5 Connect the Fieldbus-Module to a power supply

The power supply connector is located at the bottom of the Fieldbus-Module.

Pin Description

1 + 24V DC +/- 10%, 280 mA max.

2 GND

An appropriate connector (type MSTB 2.5/2-ST-5.08) with screw terminals is included in the delivery. The appropriate cable

diameter ranges from 0.2 mm2 to 2.5 mm2 (AWG 24 to AWG 12). Use 60/75 or 75°C copper (CU) wire only. The terminal

tightening torque must be between 0.5 - 0.8 Nm (5 - 7 lbs-in).

(2)

+

(1)

13Step-by-Step Installation and Configuration

Page 14

4.6 Configure the Fieldbus-Module

4.6.1 PC terminal software

The Fieldbus-Module provides a serial configuration dialog, which allows to configure the communication parameters of the

subnet communication by use of a PC. After power-up, the Fieldbus-Module sends an ASCII based configuration dialog via the

PC connector to a terminal or a PC. In case of using a PC, a terminal emulation program (such as hyper terminal which is a

standard component of Windows) shall be started before power-up of the Fieldbus-Module.

Use the following interface settings at your PC for the terminal program:

• Baud rate: 38400 bps.

• 8 data bits

• 1 stop bit

• No parity check

• No flow control

The dialog will show the following initial Menu on the screen (from a ProfiNet-Module):

The last saved settings will be displayed.

Note

The configuration dialog will be disabled after 60 seconds if no buttons are pressed.

You can always press the Esc button to display the main menu again.

Press the number of the option you want to change and then press enter. A new dialog will be displayed where you can enter

your new setting. After a new setting is entered, the main menu will be displayed again. The current setting will now show the

settings you have configured, but they will not be permanently stored until you save them to the flash by pressing "S" (save

configuration to flash) in the main menu.

To start using the new settings you must power down and restart the Fieldbus-Module.

14 Step-by-Step Installation and Configuration

Page 15

4.6.2 Weighing sensor interface

The Fieldbus-Module can communicate with weighing sensors using the following different interfaces:

• RS232, full duplex, no handshake.

• RS422, full duplex, no handshake (default).

• RS485, half duplex, no handshake.

Note

Set the handshake control to none if you connect any weighing sensor to a METTLER TOLEDO Fieldbus-Module!

4.6.3 Baudrate

The Fieldbus-Module can communicate using the following baudrates:

• 1200 bps

• 2400 bps.

• 4800 bps.

• 9600 bps.

• 19200 bps. (Default)

• 38400 bps.

• 57600 bps

4.6.4 Character format

The Fieldbus-Module supports the following character formats:

• 7 None 1 (7 data bits, no parity and 1 stop bit)

• 8 None 1 (8 data bits, no parity and 1 stop bit) (default)

• 7 Even 1 (7 data bits, Even parity and 1 stop bit)

• 7 Odd 1 (7 data bits, Odd parity and 1 stop bit)

4.6.5 Operation mode

The Fieldbus-Module can be used in two different modes (Detail see chapter 6.1, page 38 and chapter 6.2, page 40).

1. The Basic-Mode is the default operation mode and supports the most important MT-SICS commands

2. The Extended-Mode supports all MT-SICS commands and uses 32 bytes for communication.

4.6.6 Maximum response time

With the "Max response time"-option you can set the maximum time between two successive responses from the balance. If the

Fieldbus-Module does not receive a new response from the balance within the defined maximum response time, the FieldbusModule will indicate this communication problem by setting the connection status bit to "False" and the subnet status LED to

red (see chapter 7.2, page 48).

The connection status bit will be set to true (operational) again when cleared by the connection status clear bit.

The "Max response time" is defined to 60 seconds as default and can be changed between 10 sec and 9999 sec or completely

switched off. In that case the timeout feature is not working anymore. This might be useful for some applications where longer

periods of inactivity may occur.

4.6.7 Configuration from network

This menu point is only available in the ProfiNet IO-Module.

If "Configuration from network" is enabled, all parameters must be configured via network from the configuration program (e.g.

PLC). In this case no other configurations from the terminal program are possible.

The default setting for "Configuration from network" is enabled.

15Step-by-Step Installation and Configuration

Page 16

4.6.8 Automatic baudrate search

All Fieldbus-Modules have the ability to automatically search for correct baudrate and character format on the subnet side. If you

want to use automatic baudrate search you first have to configure the correct "Weighing sensor interface" under menu option 1,

after that you can start the search by pressing "A" (Perform Automatic baudrate search) in the main menu. The Fieldbus-Module

will send a command string to the weighing sensor in all different baudrates and character formats, and if the weighing sensor

responds, the Fieldbus-Module has found the correct settings.

Note

Automatic baudrate search can be used for subnet connection test. It will find no baudrate setting in case of failure.

Example of dialog using the automatic baudrate search option:

----------------------------------------------------------------------------------------------

Automatic baudrate search

----------------------------------------------------------------------------------------------

Searching with RS232 interface

Pressing ESCAPE interrupts the search.

Testing: 9600 bps, 8 none 1

Interface setting:

9600 bps, 8 none 1, no handshake.

Do you want to save the interface parameters? (Y/N)

>

If N (No) is pressed the Fieldbus-Module will reject the setting and return to the main menu.

If Y (Yes) is pressed the Fieldbus-Module will automatically save the new settings to the flash, therefore no additional "Save

configuration to flash" is necessary in the main menu.

Note

If an automatic baudrate search is used, the Fieldbus-Module will stop the normal communication with the weighing sensor.

Please refer the LED Indication Table (e.g. for Profibus-Module chapter 5.1.9) for explanations of the LED-signals during automatic baudrate search.

4.6.9 Save configuration to flash

To store the configuration permanently to the Fieldbus-Module you must press "S" (Save configuration to flash).

Before the new settings can be used, the Fieldbus-Module must be restarted by switching off and on the power supply from the

Fieldbus-Module.

16 Step-by-Step Installation and Configuration

Page 17

5 Fieldbus-Modules

5.1 Profibus-Module

The Profibus version of the METTLER TOLEDO Fieldbus-Module is called MT Profibus Module and has the METTLER TOLEDO

Part number: 42102809

5.1.1 General

The METTLER TOLEDO Profibus-Module is designed as a Profibus-DP slave (DPV0) according to EN 50170. It supports all

mandatory functions of a Profibus-DP slave.

A Profibus master (e.g. a PLC) can send commands and receive data from the Profibus-Module.

For the SIMATIC STEP 7 PLC there is a Engineering note and also a example, specific to METTLER TOLEDO products with SICS

communication protocol, available on www.mt.com/ind-APW-fieldbus-support. They significantly shorten integration time and

save valuable resources and development time for system integrators and end users.

5.1.2 Supported features

• Auto baudrate detection supported. Baudrate range: 9.6 kbit – 12 Mbit.

• Hardware prepared for DP-V1 extensions.

• Save / Load configuration in Flash supported.

• Address range: 1-99. The node address of the Profibus connection shall always be set via the configuration switches.

• Support all standard diagnostic messages according to standard EN 50170.

Profibus

5.1.3 Identification numbers

Identification number: 0x0642 Hex.

Product name: "MT Profibus Module"

Part number: 42102809

5.1.4 Profibus node address

Before installing the Profibus-Module in the Profibus network, the node address is to be set with two rotary

switches under the lid on the front. The address range is 1 to 99. The lower switch is used for the first digit

of the address (value x 10), the upper switch for the second digit of the address (value x 1).

Example

Address = 45 => lower switch to value 4 and upper switch to value 5.

Note

The node address cannot be changed during operation. A new address setting is valid after power-off and

power-on of the Profibus-Module.

17Step-by-Step Installation and Configuration

Page 18

5.1.5 Cabling

The Profibus-Module connects to a Profibus network with the female D-sub 9 connector on the front.

Pin Name Function

Housing Shield Connected to PE (connected to spring contacting the DIN-Rail).

1 Not connected 2 Not connected 3 B-Line Positive RxD/TxD-signals according to RS485 specification.

4 RTS Request to send*

5 GND BUS Isolated GND (RS485 side)*

6 +5V BUS Isolated +5 V (RS485 side)*

7 Not connected 8 A-Line Negative RxD/TxD-signals according to RS485 specification.

9 Not connected -

* +5 V BUS and GND BUS are used for bus termination. Some devices, like optical transceivers (RS485 to fiber optics) might

require external power supply from these pins (max. 80 mA). RTS is used in some equipment to determine the direction of

transmission. In standard applications only A-line, B-line and Shield are used.

5.1.6 Bus termination

The first and the last device of each Profibus line must be terminated with termination resistors to avoid reflections on the bus.

Also the METTLER TOLEDO Profibus-Module can be installed as the first or the last device of a Profibus line. The termination is

typically done by switching on the termination switch of the Profibus connector of the bus cable at the first and last device. At

all other devices of a Profibus line the termination switch should be turned off.

5.1.7 GSD configuration file

Each Profibus-Master (e.g. PLC) requires a GSD file for integration of the METTLER TOLEDO Profibus-Module. The GSD file for

the METTLER TOLEDO Profibus-Module is provided on www.mt.com/ind-APW-fieldbus-support.

5.1.8 Configure and start the Profibus network

For general installation and configuration see chapter 4, page 10.

The Profibus node address must be configured shown in chapter 5.1.4.

Correct communication between the Profibus-Module and the weighing sensor is indicated by the following LED status (see

chapter 5.1.9): 5 green steady, 6 green steady. Refer to chapter 7.3 if LED’s show different status.

Note

The integration shall be carried out by PLC system experts. The respective support for PLC systems is not under METTLER

TOLEDO responsibility.

18 Step-by-Step Installation and Configuration

Page 19

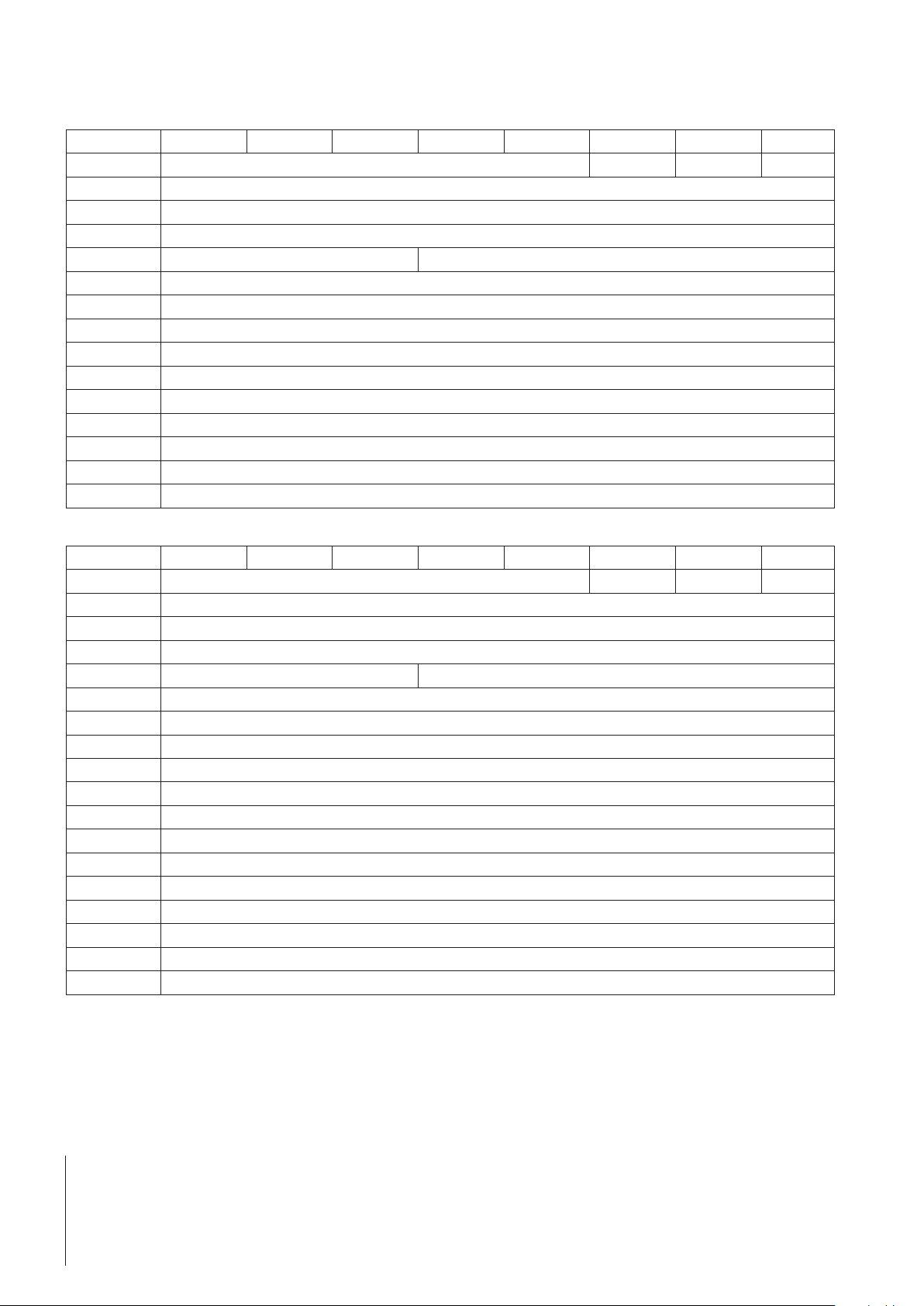

5.1.9 LED indication table

LED Indication Description

1 – Network status Off Profibus not online

Green, steady Profibus online

2 – Profibus status Off Profibus not offline

Red, steady Profibus offline

3 – Reserved - Not used

4 – Fieldbus diagnostic Off No diagnostic present

Red, 1 Hz-flashing Error in configuration from the Profibus master side

Red, 2 Hz-flashing User parameter data error

Red, 4 Hz-flashing Error in initialization of Profibus ASIC (internal fault)

5 – Subnet status Off Power Off

Green, steady Communication with weighing sensor OK

Green, flashing Receiving data from weighing sensor

Red, steady Communication with weighing sensor failed (timeout)

6 – Device status Off Power Off

Green, steady Profibus-Module initialized and running

Green, flashing Performing auto baudrate detection

Red, steady Unrecoverable error

Red, flashing Auto baudrate detection failed

Profibus

19Step-by-Step Installation and Configuration

Page 20

5.2 DeviceNet-Module

The DeviceNet version of the METTLER TOLEDO Fieldbus-Module is called MT Devicenet Module and has the METTLER TOLEDO

Part number: 42102810.

5.2.1 General

The DeviceNet-Module functions as a DeviceNet adapter according to EN 50325-2. It supports all mandatory functions for

polled I/O slave messaging of a DeviceNet adapter.

It acts as a device slave on the network and presents the weighing sensor data to the master controller.

As of RSLogix5000 Version 16, a complimentary open-source Rockwell Automation Logis5000 function block and faceplates

with a Engineering note, specific to METTLER TOLEDO products with SICS communication protocol, available on www.mt.com/

ind-APW-fieldbus-support. They significantly shorten integration time and save valuable resources and development time for

system integrators and end users.

5.2.2 Supported features

• MAC ID and baudrate can be set via onboard switches.

• Explicit messaging

• Polled I/O

• Bit-strobed I/O

• Change-of-state / Cyclinc I/O

• Galvanically isolated bus electronics

• All standard DeviceNet baudrates from 125 kbit/s to 500 kbit/s are supported. Baudrate and node address shall be set via

the configuration switches.

• Implemented objects:

• DeviceNet objects:

1. Identity object, class 01h

2. Message router object, class 02h

3. DeviceNet object, class 03h

4. Assembly object, class 04h

5. Connetion object, class 05h

6. Acknowledge handler object, class 2Bh

• Vendor specific objects:

7. I/O data Input mapping object, class A0h

8. I/O data output mapping object, class A1h

9. Diagnostic object, class AAh

10. Parameter data Input mapping object, class B0h

11. Parameter data output mapping object, class B1h

5.2.3 Identification numbers

Vendor ID: 90

Device ID: 12

Product code: 40

Product name: "MT Devicenet Module"

Part number: 42102810

20 Step-by-Step Installation and Configuration

Page 21

5.2.4 Network configuration

5.2.4.1 Mac address

Before installing the DeviceNet-Module on a DeviceNet network, it must have a unique Mac ID. The Mac ID

shall be set between 0 and 63.

The Mac ID is configured by the DIP-switches 3 to 8 under the lid on the front.

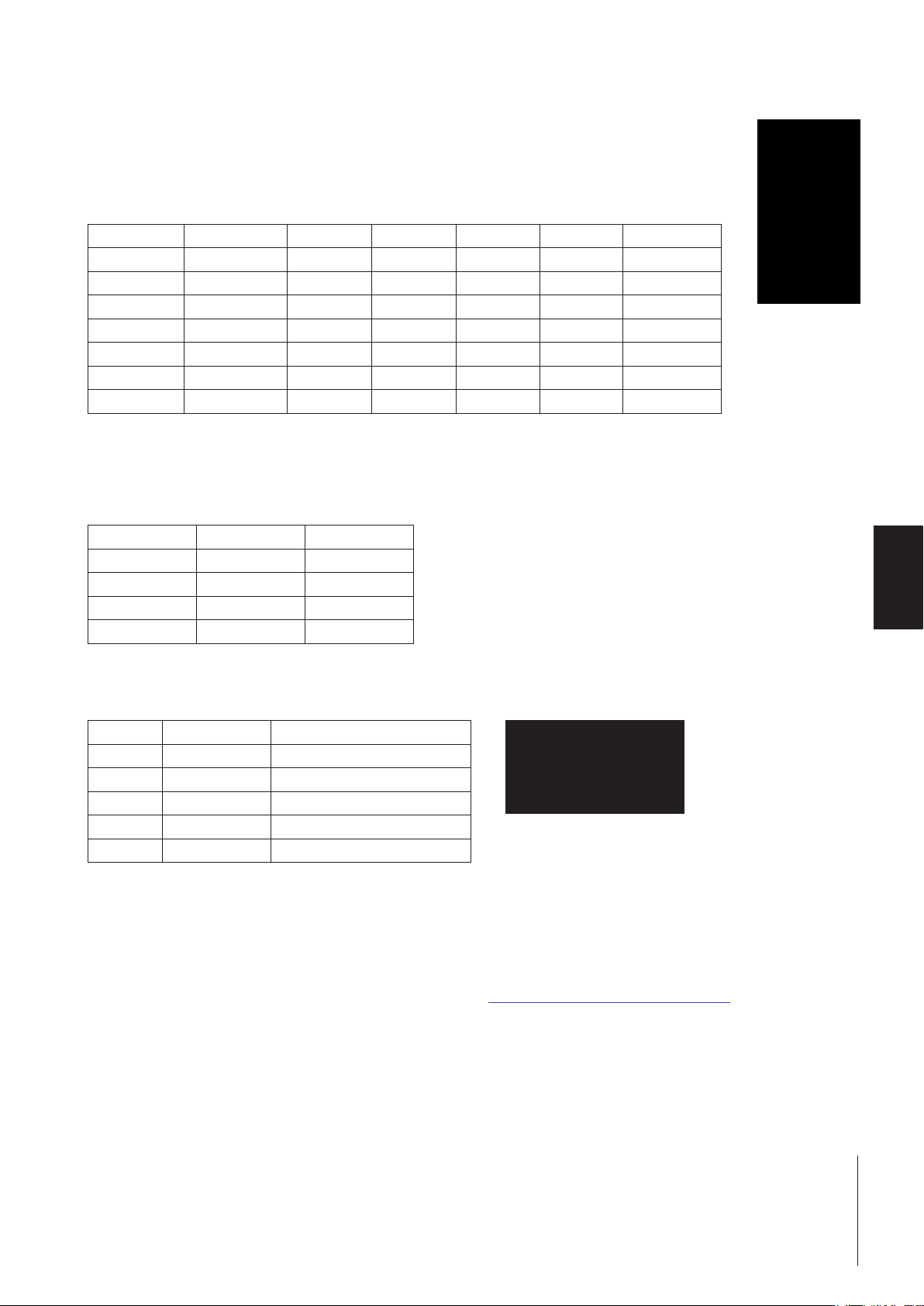

MAC ID Sw. 3 (MSB) Sw. 4 Sw. 5 Sw. 6 Sw. 7 Sw. 8 (LSB)

0 OFF OFF OFF OFF OFF OFF

1 OFF OFF OFF OFF OFF ON

2 OFF OFF OFF OFF ON OFF

3 OFF OFF OFF OFF ON ON

- - - - - - -

62 ON ON ON ON ON OFF

63 ON ON ON ON ON ON

5.2.4.2 Baudrate

There are three different baudrates for DeviceNet: 125kbit/s, 250kbit/s and 500kbit/s.

Switches 1 and 2 are used to set the baudrate of the DeviceNet-Module.

Baudrate Sw. 1 Sw. 2

125k OFF OFF

250k OFF ON

500k ON OFF

(reserved) ON ON

DeviceNet

5.2.5 Cabling

The DeviceNet-Module connects to a DeviceNet network with a connector with screw terminals at the front.

Pin Signal Description

1 V- Negative supply voltage*

2 CAN_L CAN_L bus line

3 SHIELD Cable shield

4 CAN_H CAN_H bus line

5 V+ Positive supply voltage*

Note

* The bus interface shall be externally supplied with 24V DC +/- 10%.

5.2.6 EDS configuration file

During configuration of the DeviceNet-Module at the DeviceNet master scanner (e.g. PLC), an EDS file (Electronic Data Sheet)

is required. This EDS file for the DeviceNet-Module is provided on www.mt.com/ind-APW-fieldbus-support.

21Step-by-Step Installation and Configuration

Page 22

5.2.7 Configure and start the DeviceNet network

For general installation and configuration see chapter 4, page 10.

The DeviceNet address (MAC ID) and baudrate must be configured shown in chapter 5.2.4.1 and 5.2.4.2.

Correct communication between the DeviceNet-Module and the weighing sensor is indicated by the following LED status (see

chapter 5.2.8): 5 green steady, 6 green steady. Refer to chapter 7.3 if LED’s show different status.

Note

The integration shall be carried out by PLC system experts. The respective support for PLC systems is not under METTLER

TOLEDO responsibility.

5.2.8 LED indication table

LED Indication Description

1 – Network status Off Not online

Green, steady Link OK, not connected

Green, flashing Online, not connected

Red, steady Critical link failure

Red, flashing Connection timeout

2 – DeviceNet status Off Power Off

Green, steady Device operational

Green, flashing Data size bigger than configured

Red, steady Unrecoverable fault

Red, flashing Minor fault

3 – Reserved - Not used

4 – Reserved - Not used

5 – Subnet status Off Power Off

Green, steady Communication with weighing sensor OK

Green, flashing Receiving data from weighing sensor

Red, steady Communication with weighing sensor failed

(timeout)

6 – Device status Off Power Off

Green, steady DeviceNet-Module initialized and running

Green, flashing Performing auto baudrate detection

Red, steady Unrecoverable error

Red, flashing Auto baudrate detection failed

22 Step-by-Step Installation and Configuration

Page 23

5.3 EtherNet/IP-Module

The EtherNet/IP version of the METTLER TOLEDO Fieldbus-Module is called MT Ethernet/IP Module and has the METTLER

TOLEDO Part number: 42102860

5.3.1 General

The EtherNet/IP-Module functions as an EtherNet/IP adapter according to EN 50325-2. It supports all mandatory functions for

polled I/O slave messaging of an EtherNet/IP adapter.

The Industrial Ethernet Protocoll (EtherNet/IP) was originally developed by Rockwell Automation and is now managed by the

Open DeviceNet Vendors Associaton (ODVA).

EtherNet/IP is standardized in the International standard IEC 61158.

As of RSLogix5000 Version 16, a complimentary open-source Rockwell Automation Logis5000 function block and faceplates

with a Engineering note, specific to METTLER TOLEDO products with SICS communication protocol, available on www.mt.com/

ind-APW-fieldbus-support.They significantly shorten integration time and save valuable resources and development time for

system integrators and end users.

5.3.2 Supported features

• Supported shielded (FTP) and unshielded (UTP) cables

• Flexible file system providing both volatile and non-volatile storage areas

• Security framework

• Integrated FTP server provides easy file management using standard FTP clients.

• Server side include (SSI) capability

• Web server

• E-mail client (messages can be triggered by data events or directly by the application)

• All standard EtherNet/IP baudrate 10/100 Mbit are supported. It will detect the actual transmission speed of the bus automatically.

• The node address of the EtherNet/IP connection shall always be set via the IPConfig-Tool (see chapter 5.3.9)

• The following CIP-objects are implemented:

• Mandatory objects:

1. Identity object, class 01h

2. Message router object, class 02h

3. Assembly object, class 04h

4. Connection manager, class 06h

5. Port object, class F4h

6. TCP/IP interface object, class F5h

7. Ethernet link object, class F6h

• Vendor specific objects:

8. I/O data input mapping object, class A0h

9. I/O data output mapping object, class A1h

10. Diagnostic object, class AAh

11. Parameter data input mapping object, class B0h

12. Parameter data output mapping object, class B1h

EtherNet/IP

23Step-by-Step Installation and Configuration

Page 24

1 8

5.3.3 Identification numbers

Vendor ID: 666

Device ID: 12

Product code: 42860

Product name: "MT Ethernet/IP Module"

Part number: 42102860

5.3.4 Network configuration

5.3.4.1 IP address

Make sure each node on the network has a unique IP address. The IP settings of the EtherNet/IP-Module can

be configured in various ways. It is recommended to use the IPConfig-Tool (see chapter 5.3.9) for configuring the IP-settings.

The IP address of the EtherNet/IP-Module can be also set with the configuration switches in the range

192.168.0.1 – 192.168.0.254.

If the switches are set to zero, the settings are specified by the system file "ethcfg.cfg" e.g. with the IPConfigTool (see chapter 5.3.9).

Note that the switches are read once during startup; any changes require a reset in order to have effect.

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8 DHCP Subnet Gateway IP

OFF OFF OFF OFF OFF OFF OFF OFF (settings determined by ‘ethcfg.cfg’)

OFF OFF OFF OFF OFF OFF OFF ON OFF 255.255.255.0 192.168.0.255 192.168.0.1

OFF OFF OFF OFF OFF OFF ON OFF OFF 255.255.255.0 192.168.0.255 192.168.0.2

… … … … … … … … … … … …

ON ON ON ON ON ON ON OFF OFF 255.255.255.0 192.168.0.255 192.168.0.254

ON ON ON ON ON ON ON ON (invalid setting)

To read and write the IP configuration is also possible to use the EtherNet/IP website (e.g. http://192.168.0.1).

5.3.5 Cabling

Pin Signal

Housing Cable shield

1 TD+

2 TD-

RJ45

3 RD+

4 Termination

5 Termination

6 RD-

7 Termination

8 Termination

5.3.6 EDS configuration file

The EDS file is provided on www.mt.com/ind-APW-fieldbus-support and has the function of an electronic data sheet and includes all parameter and options that an EtherNet/IP device supports. The EtherNet/IP-Module requires one EDS file that contains

the necessary definitions for the Basic and the Extended-Mode.

24 Step-by-Step Installation and Configuration

Page 25

5.3.7 Configure and start the EtherNet/IP network

For general installation and configuration see chapter 4, page 10.

The IP address must be configured shown in chapter 5.3.4.1.

Correct communication between the EtherNet/IP-Module and the weighing sensor is indicated by the following LED status (see

chapter 5.3.8): 5 green steady, 6 green steady. Refer to chapter 7.3 if LED’s show different status.

Note

The integration shall be carried out by PLC system experts. The respective support for PLC systems is not under METTLER

TOLEDO responsibility.

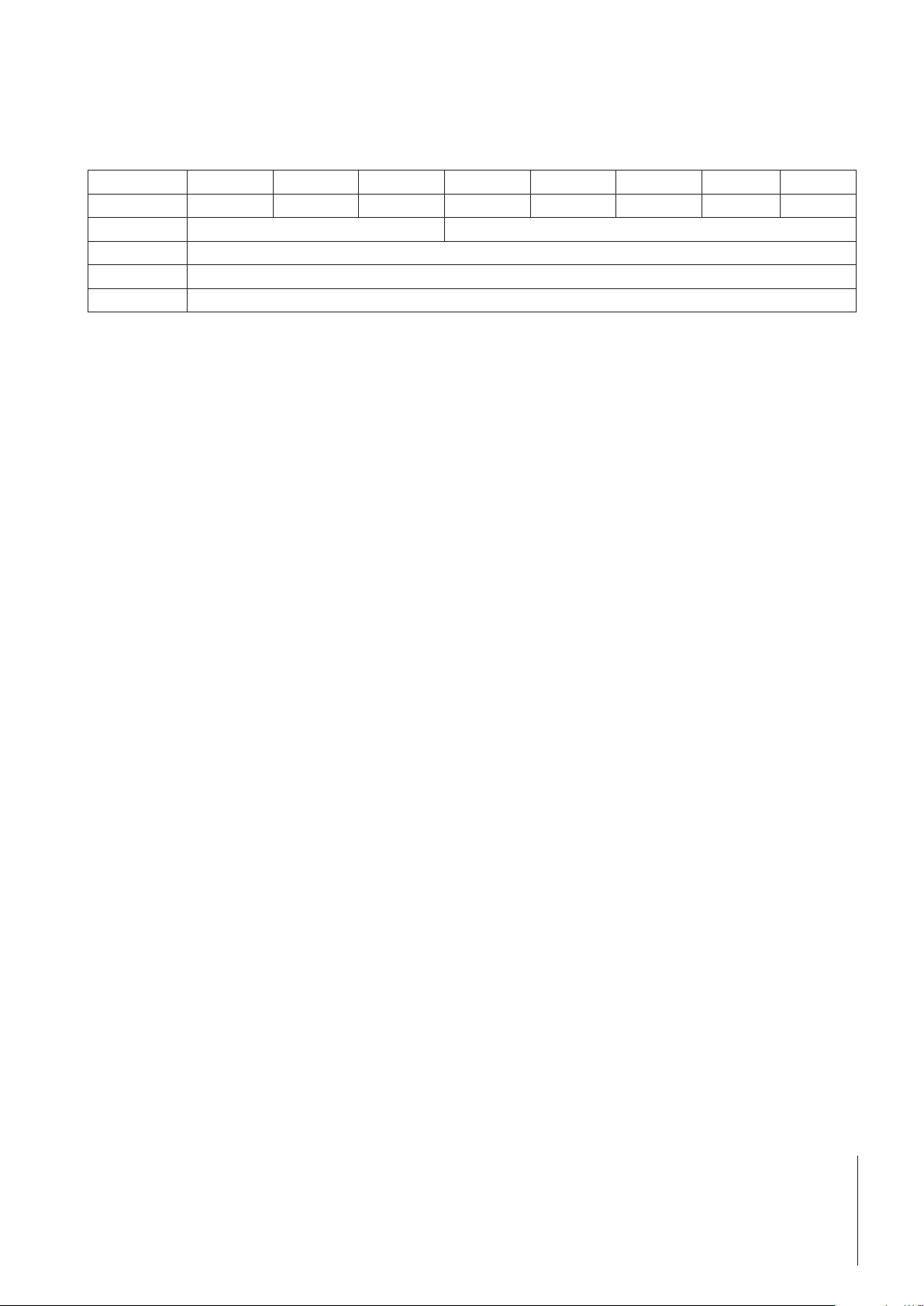

5.3.8 LED indication table

LED Indication Description

1 – Module status Off (no power)

Green, steady Normal operation

Green, flashing Stand by, not initialized

Red Major fault

Red, flashing Minor fault

Alternating Red/Green (self test)

2 – Network status Off No IP address (or no power)

Green, steady EtherNet/IP connection(s) established

Green, flashing No EtherNet/IP connection(s) established

Red Duplicate IP address detected

Red, flashing One or several connections time out

Alternating Red/Green (self test)

3 – Link Off No link (or power off)

Green Connected to an Ethernet network

4 – Activity Off No Ethernet activity (or no power)

Green Receiving or transmitting Ethernet packet

5 – Subnet status Off Power Off

Green, steady Communication with weighing sensor OK

Green, flashing Receiving data from weighing sensor

Red, steady Communication with weighing sensor failed (timeout)

6 – Device status Off Power Off

Green, steady EtherNet/IP-Module initialized and running

Green, flashing Performing auto baudrate detection

Red, steady Unrecoverable error

Red, flashing Auto baudrate detection failed

EtherNet/IP

5.3.9 IPConfig-Tool

The EtherNet/IP-Module has to be configured for the same I/O size and IP-settings as in the PLC configuration. The IPConfig-Tool

(can be found on www.mt.com/ind-APW-fieldbus-support) can be used to configure the IP settings of all EtherNet/IP-Modules.

The IPConfig-Tool scans the network for EtherNet/IP-Modules. To configure the settings manually (default DHCP is activated)

double click on the desired module and enter the desired IP-settings.

25Step-by-Step Installation and Configuration

Page 26

5.4 EtherNet/IP Configuration for Rockwell Add-on-Profile

After installation the EtherNet/IP-Module must be configured in the PLC.

5.4.1 Connecting the EtherNet/IP-Module

Refer to the EtherNet/IP-Module instructions for installation and operation for details.

On chapter 4.4.1 you can find information about the RS422 cable connection between the ConModule to the DeviceNet-Module.

5.4.2 PLC configuration

To create a new configuration, open the file menu and select "New". In the appearing dialogue select the desired type of PLC,

in this case the type 1756-L55 is used. Also enter a name for the controller and select chassis type, slot number and project

path. To accept the settings press "OK".

Then add the Ethernet I/O-Module. Right click on the I/O Configuration directory in the navigation list to the left as seen.

26 Step-by-Step Installation and Configuration

Page 27

Click on "New Module" and select the desired Ethernet-Module, in this case the Ethernet-Bridge. This Module is the ScannerModule in the PLC.

Then enter the desired settings and press "Finish".

EtherNet/IP

27Step-by-Step Installation and Configuration

Page 28

5.4.3 EtherNet/IP-Network configuration

To add the METTLER TOLEDO EtherNet/IP-Module (Generic Ethernet Module) to the configuration in the PLC, the program setting

must be in offline mode. Add the module with a right click on the "EtherNet/IP-Bridge" in the I/O Configuration, and select "New

Module".

Now a dialogue window will appear. In this dialogue window, select "Generic Ethernet Module" and press "OK".

In the next dialogue window, RSLogix 5000 will ask for information regarding the communication to the METTLER TOLEDO

Ethernet/IP-Module. First enter a name for the METTLER TOLEDO Ethernet/IP-Module (1). In the example below we call it

METTLER_TOLEDO. This name will create a tag in RSLogix 5000, which can be used to access the memory location in the

PLCs memory where the data for the METTLER TOLEDO Ethernet/IP-Module will be stored. A description can also be added, but

that is optional.

28 Step-by-Step Installation and Configuration

Page 29

Next step is to select the Comm Format, which tells RSLogix 5000 the format of the data (2). In our example, we have selected

Data-INT, which will represent the data in the METTLER TOLEDO Ethernet/IP-Module as a field of 16-bit values. It is also possible to select Data-SINT, which will represent the data as 8-bit values, and Data-DINT, which will represent it as 32 bit values.

In our case (Basic-Mode we are using 64-bit (8 byte) values of input and 16-bit (2 byte) of output data. In this case, the size

that we enter in (3) is: 4×16-bit as input and 1×16-bit as output value. If we had been using other data type like Data-SINT or

Data-DINT, we would have to recalculate the size to match the data type.

I/O data is accessed in input instance 100 and output instance 150, so these values have to be entered as the instance values

for input and output (4). The size of the input connection and the output connection shall correspond to the size that we have

configured the METTLER TOLEDO Ethernet/IP-Module for.

The METTLER TOLEDO Ethernet/IP-Module does not have a configuration assembly instance by default, but RSLogix 5000

requires a value for this anyway. An instance value of 0 or 255 is not a valid instance number, but any other non-zero value

will work, here we have selected the value 1 (5). The data size of the configuration instance has to be set to 0, otherwise the

configuration instance will be accessed and the connection will be refused (6). As a final step we enter the IP address that we

have configured for the module, here 192.168.1.50 (7).

EtherNet/IP

29Step-by-Step Installation and Configuration

Page 30

In this tab we will enter a value for the time between each scan of the Module. In this example, we have set the interval to 50ms

to reduce the network load. Make sure that Inhibit Module is not checked. After this, press "OK".

Note

Once settings are saved ("OK" clicked), the Comm Format cannot be changed. The Generic Ethernet-Module must be deleted

and then re-entered if a different Comm Format is desired. All other settings may be edited.

Now the METTLER TOLEDO EtherNet/IP-Slave has been added to the I/O Configuration in RSLogix 5000.

30 Step-by-Step Installation and Configuration

Page 31

5.5 ProfiNet IO-Module

The ProfiNet IO version of the METTLER TOLEDO Fieldbus-Module is called MT Profinet Module and has the METTLER TOLEDO

Part number: 42102859

5.5.1 General

The ProfiNet IO-Module functions as a ProfiNet IO slave according to IEC 61784 (CPF-3/3) and supports ProfiNet IO baudrate

100 Mbit.

For the SIMATIC STEP 7 PLC there is a Engineering note and also a example, specific to METTLER TOLEDO products with SICS

communication protocol, available on www.mt.com/ind-APW-fieldbus-support. They significantly shorten integration time and

save valuable resources and development time for system integrators and end users.

5.5.2 Supported features

• Supported shielded (FTP) and unshielded (UTP) cables

• Flexible file system providing both volatile and non-volatile storage areas

• Security framework

• Integrated FTP server provides easy file management using standard FTP clients.

• Server side include (SSI) capability

• Web server

• E-mail client (messages can be triggered by data events or directly by the application)

• Only slot 0 and 1 is used for the ProfiNet IO-Module and no subslots.

• The standard ProfiNet IO baudrate 100 Mbit is supported. It will detect the actual transmission speed of the bus automatically.

• The note address of the ProfiNet IO connection shall always be set via the IPConfig-Tool (see chapter 5.5.9).

5.5.3 Identification numbers

Vendor ID: 142

Device ID: 1111

Product name: "MT Profinet Module"

Part number: 42102859

5.5.4 Network configuration

5.5.4.1 IP address

Make sure each node on the network has a unique IP address. The IP settings of the ProfiNet IO-Module can be configured in

various ways. It is recommended to use the IPConfig-Tool (see chapter 5.5.9) for configuring the IP-settings.

To read and write the IP configuration is also possible to use the ProfiNet IO website (e.g. http://192.168.0.1).

5.5.4.2 Sub-network configuration

An additional parameter according to the sub-network parameters (see chapter 4.6.7, page 16) is available to define how the

sub-network parameters will be configured.

ProfiNet IO

31Step-by-Step Installation and Configuration

Page 32

5.5.5 Cabling

1 8

Pin Signal

Housing Cable Shield

1 TD+

2 TD-

RJ45

3 RD+

4 Termination

5 Termination

6 RD-

7 Termination

8 Termination

5.5.6 GSDML configuration file

The GSDML file is provided on www.mt.com/ind-APW-fieldbus-support and has the function of an electronic data sheet and

includes all parameter and options that an ProfiNet IO device supports. The ProfiNet IO-Module requires one individual GSDML

file that contains two Module definitions: Module 1: Basic-Mode and Module 2: Extended-Mode.

5.5.7 Configure and start the ProfiNet IO network

For general installation and configuration see chapter 4, page 10.

The ProfiNet IO MAC and IP address can be read out with the IPConfig-Tool (see chapter 5.5.9) or from the printed label on the

ProfiNet IO-Module. Use this information to configure the PLC.

Correct communication between the ProfiNet IO-Module and the weighing sensor is indicated by the following LED status (see

chapter 5.5.8): 5 green steady, 6 green steady. Refer to chapter 7.3 if LED’s show different status.

Note

The integration shall be carried out by PLC system experts. The respective support for PLC systems is not under METTLER

TOLEDO responsibility.

32 Step-by-Step Installation and Configuration

Page 33

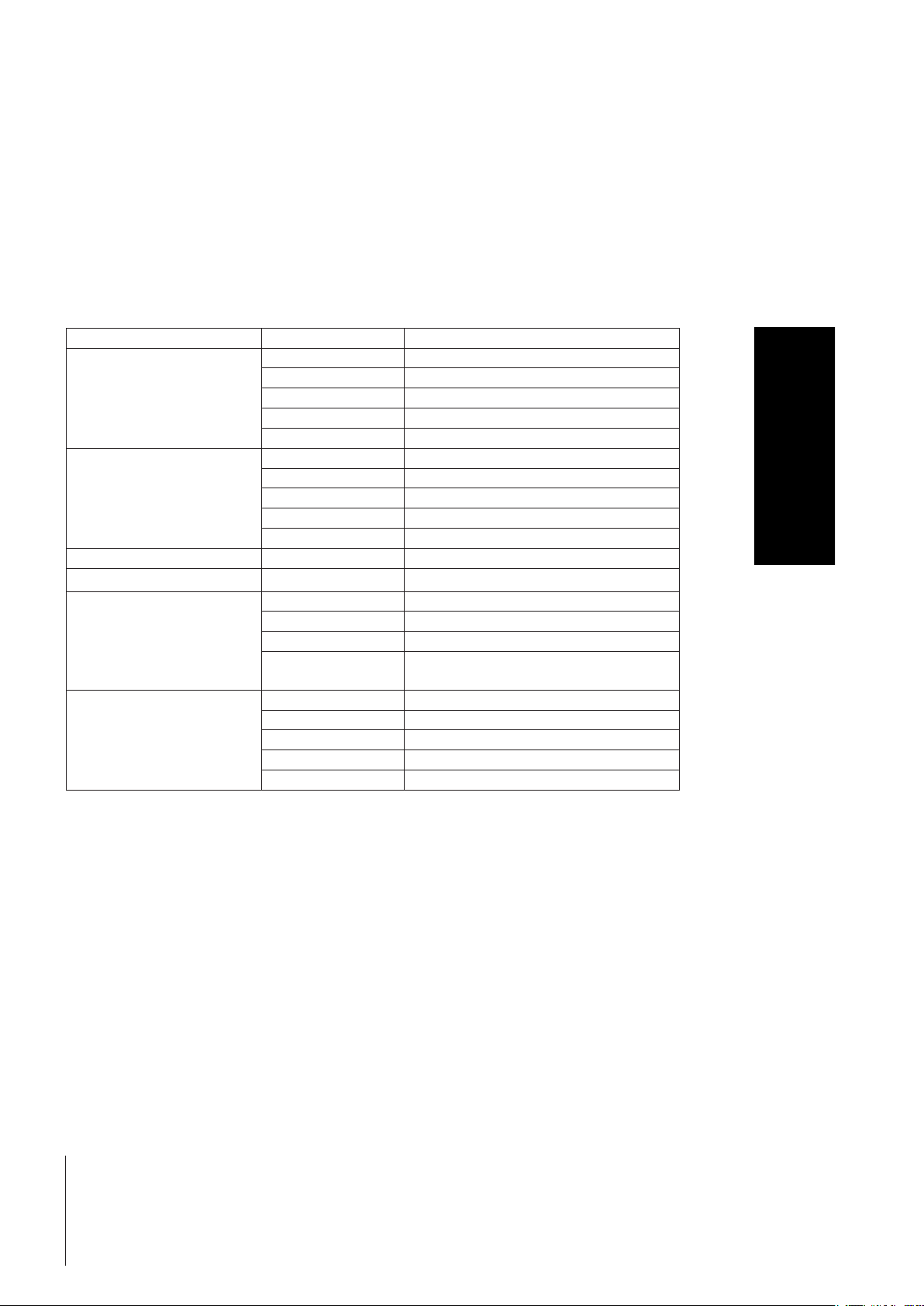

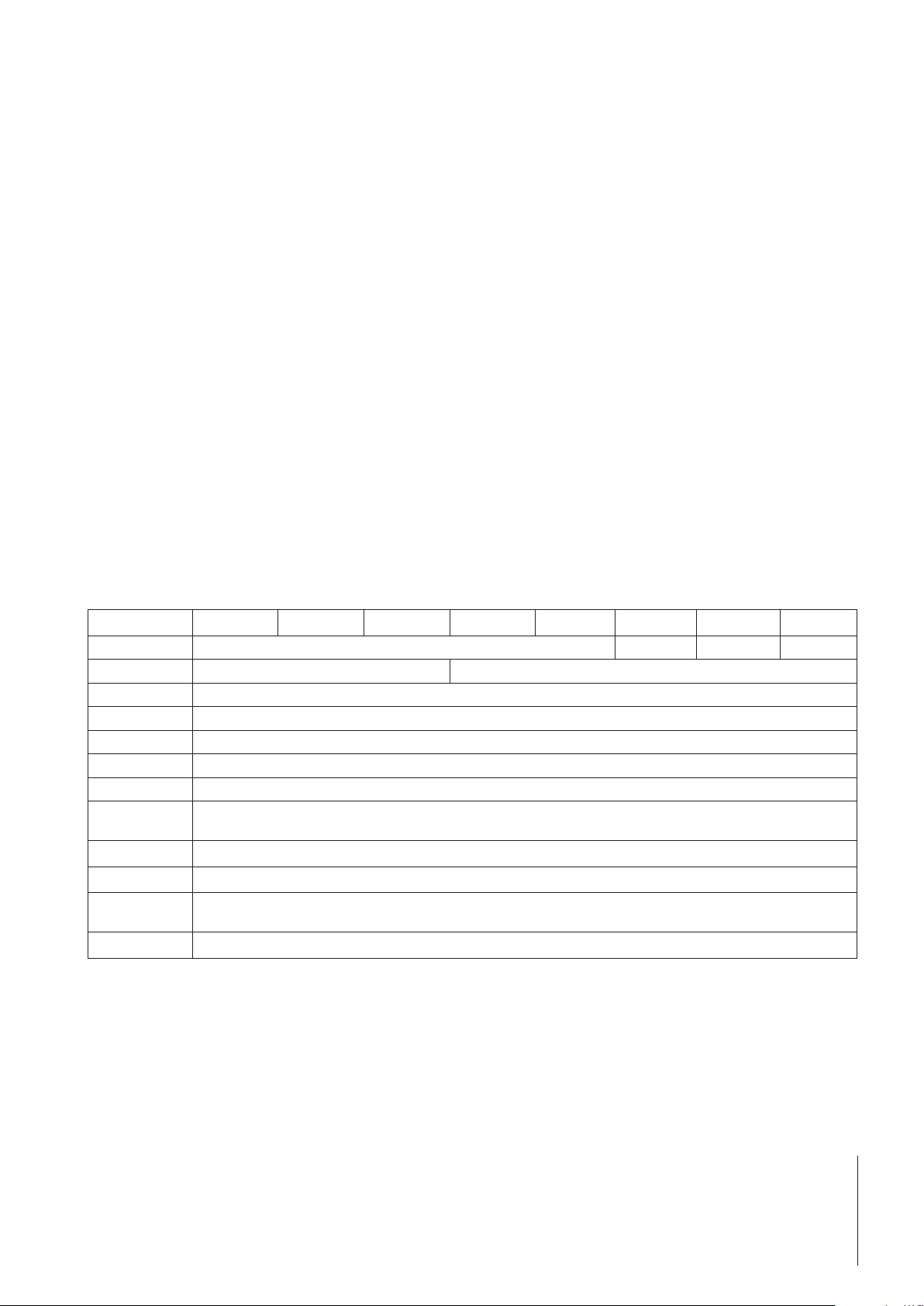

5.5.8 LED indication table

LED Indication Description

1 – Comm. status

2 – Module status Off No power or not initialized

3 – Link / Activity Off No link or power off

4 – (not used) - -

5 – Subnet status Off Power Off

Off

Green, steady

Green, flashing

Green, steady Initialized, no error

Green, 1 flash Diagnostic data available

Green, 2 flashes Blink. Used by engineering tools for identification

Red, 1 flash

Red, 3 flashes No station name or no IP address assigned

Red, 4 flashes Internal error

Green Link established

Green, flashing Receiving / transmitting data

Green, steady Communication with weighing sensor OK

Green, flashing Receiving data from weighing sensor

Red, steady Communication with weighing sensor failed (timeout)

Offline

- No connection with IO Controller

Online, RUN

- Connection with IO Controller established

- IO Controller in RUN state

Online, STOP

- Connection with IO Controller established

- IO Controller in STOP state

Configure error

- Too many modules / submodules

- I/O size or configuration mismatch

6 – Device status Off Power Off

Green, steady ProfiNet IO-Module initialized and running

Green, flashing Performing auto baudrate detection

Red, steady Unrecoverable error

Red, flashing Auto baudrate detection failed

5.5.9 IPConfig-Tool

The ProfiNet IO-Module has to be configured for the same I/O size and IP settings as in the PLC configuration. The IPConfig-Tool

(can be found on www.mt.com/ind-APW-fieldbus-support) can be used to configure the IP settings of all ProfiNet IO-Modules.

The IPConfig-Tool scans the network for ProfiNet IO-Modules. To configure the settings manually (default DHCP is deactivated)

double click on the desired module and enter the desired IP-settings.

ProfiNet IO

33Step-by-Step Installation and Configuration

Page 34

5.6 CC-Link Module

The CC-Link version of the METTLER TOLEDO Fieldbus-Module is called MT CC-Link Module and has the METTLER TOLEDO Part

number: 30038775.

5.6.1 General

The CC-Link Module functions as CC-Link slave according to BTP-05026-D and supports baud rates from 156kb/s to 10Mbit/s.

5.6.2 Supported features

• All mandatory functions of a CC-Link remote device

• Baud rate set via onboard switches

• Address range: 1-64 (Basic-Mode), 1-61 (Extended-Mode)

• CC-Link Version 1.0

5.6.3 Identification numbers

Vendor ID: 1715

Model code: 0x0033 (weight indicator)

Product name: "MT CC-Link Module"

Part number: 30038775

5.6.4 Network configuration

5.6.4.1 Station range

1-64 (if more than one station is used then the upper limit will be lowered with the same number of stations).

The station number of the CC-Link connection shall always be set via the configuration switches of the CCLink Module. The Module will be delivered with station number 01.

Set the CC-Link station number by using the switches as follows:

Station number = (switch B * 10) + (switch A * 1).

5.6.4.2 Baud rate

Choose the desired baud rate using the baud rate switch.

0. 156k

1. 625k

2. 2.5M

3. 5M

4. 10M

34 Step-by-Step Installation and Configuration

Page 35

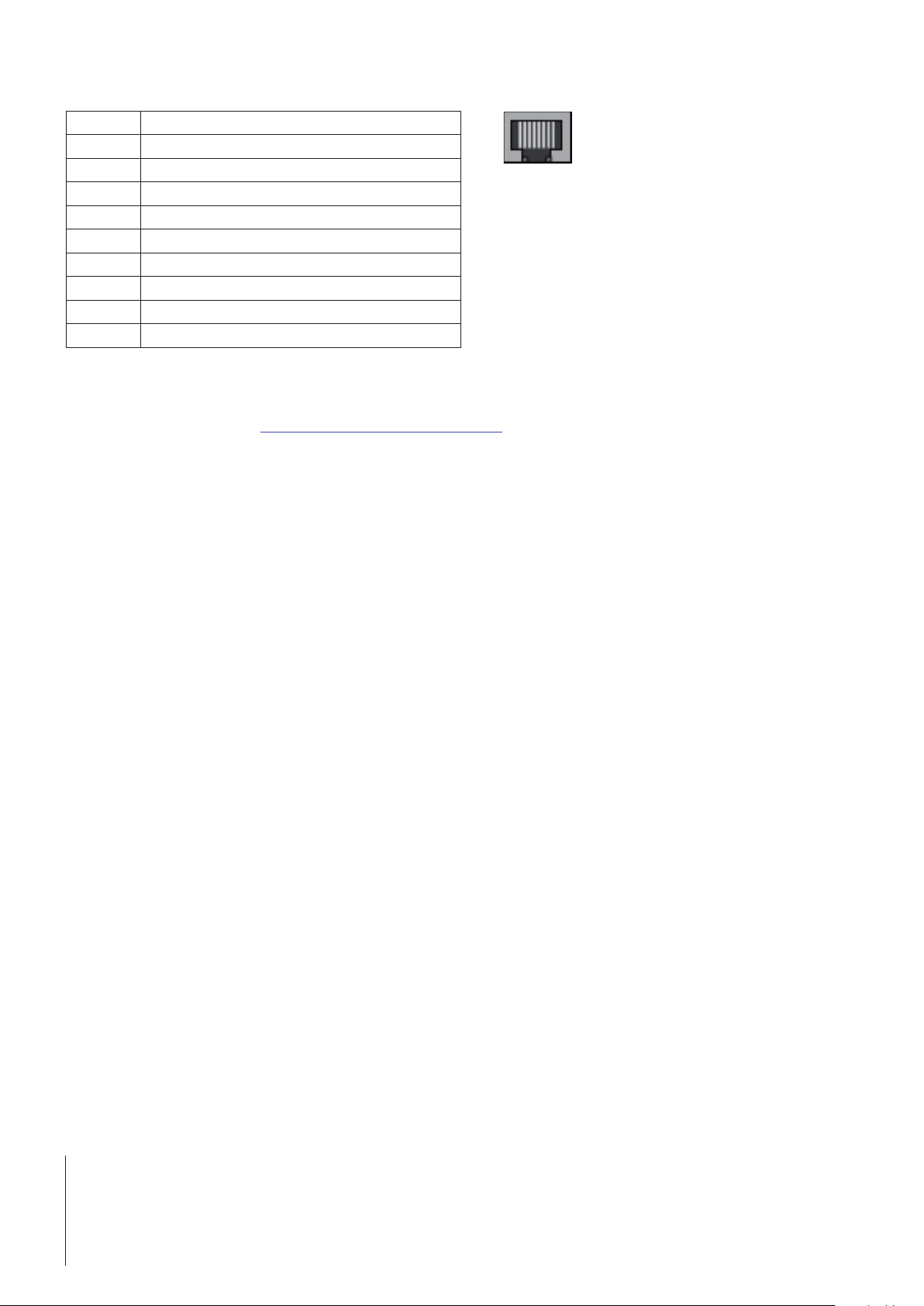

5.6.5 Cabling

Pin Signal

1 DA (Communication signal)

2 DB (Communication signal)

3 DG (Digital ground)

4 Shield (Cable shield)

5 FG / PE (Frame ground)

5.6.6 Configuration and start the CC-Link network

For general installation and configuration see chapter 4, page 10.

Correct communication between the CC-Link Module and the weighing sensor is indicated by the following LED status (see

chapter 5.6.8): 5 green steady, 6 green steady. Refer to chapter 7.3 if LED’s show different status.

Note

The integration shall be carried out by PLC system experts. The respective support for PLC systems is not under METTLER

TOLEDO responsibility.

5.6.7 Operation

The tables below show the specific data area layout for the CC-Link Module.

Due to CC-Link’s rigid data structure with reserved space for separated bit data and word data, it is required to initialise larger

data areas than with other METTLER TOLEDO Fieldbus-Modules. This is the reason why this layout is different than our other

Fieldbus Modules.

Basic-Mode uses 12 bytes in the output area and 12 bytes in the input area whilst Extended-Mode requires 48 bytes in the

output area and 48 bytes in the input area. In Basic-Mode, the CC-Link device requires 1 station whilst in Extended-Mode 4

stations are required.

5.6.7.1 Basic-Mode

Output register

Bit 7 6 5 4 3 2 1 0

Byte 0 Reserved (Bit 3-7) STC QTB QDV

Byte 1 Reserved

Byte 2 Reserved

Byte 3 Reserved

Byte 4 CMD (RWw0, least significant byte)

Input register

Bit 7 6 5 4 3 2 1 0

Byte 0 Reserved (Bit 3-7) ST RTB RDV

Byte 1 Reserved

Byte 2 Reserved

Byte 3 Reserved

Byte 4 RES (RWr0, least significant byte)

Byte 5 Scale Response Status (BRS) (RWr0, most significant byte)

Byte 6 Weight Unit (WU) (RWr1, least significant)

Byte 7 Reserved

Byte 8-11 Weight Value (WV) (RWr2-RWr3)

CC-Link

35Step-by-Step Installation and Configuration

Page 36

5.6.7.2 Extended-Mode

Output register

Bit 7 6 5 4 3 2 1 0

Byte 0 Reserved (Bit 3-7) STC QTB QDV

Byte 1 Reserved

… …

Byte 15 Reserved

Byte 16 Reserved (bit 5-7) CMD (RWw0, least significant byte)

Byte 17 …

Byte 18 MT-SICS Command (1st byte)

Byte 19 MT-SICS Command (2nd byte)

… …

th

Byte n MT-SICS Command (n

Byte n+1 CR (Carriage return 0Dhex)

Byte n+2 LF (Line feed 0Ahex)

Byte n+3 00hex

… …

Byte 47 00hex

Input register

Bit 7 6 5 4 3 2 1 0

Byte 0 Reserved (Bit 3-7) ST RTB RDV

Byte 1 Reserved

… …

Byte 15 Reserved

Byte 16 Reserved (bit 5-7) RES (RWr0, least significant byte)

Byte 17 Scale Response Status (BRS) (RWr0, most significant byte)

Byte 18 Weight Unit (WU) (RWr1, least significant byte)

Byte 19 Reserved

Byte 20-23 Weight Value (WV) (RWr2-RWr3)

Byte 24 MT-SICS Command (1

Byte 25 MT-SICS Command (2nd byte)

… …

Byte n MT-SICS Command (nth byte)

Byte n+1 CR (Carriage return 0Dhex)

Byte n+2 LF (Line feed 0Ahex)

Byte n+3 00hex

… …

Byte 47 00hex

byte)

st

byte)

36 Step-by-Step Installation and Configuration

Page 37

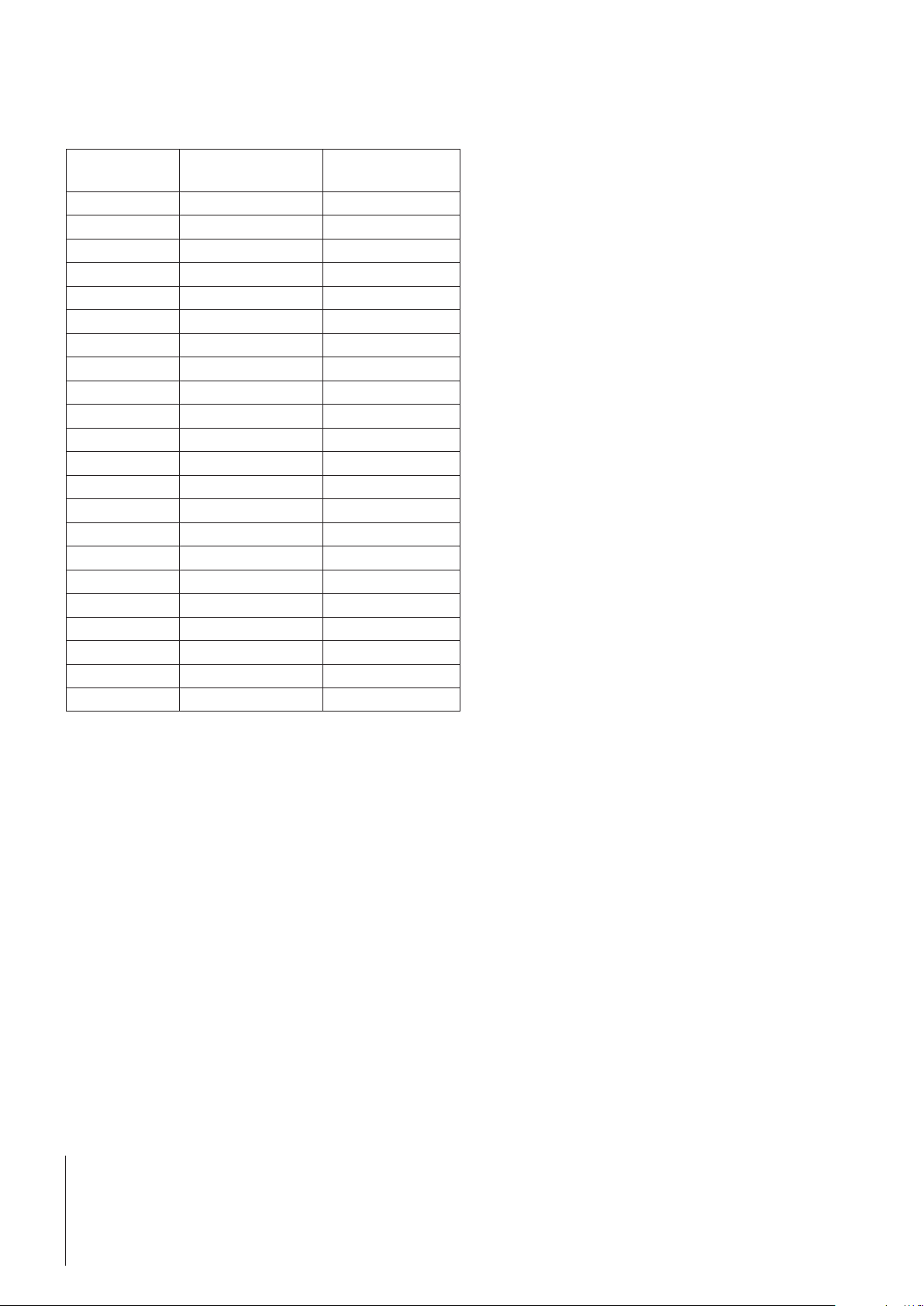

5.6.8 LED indication table

LED Indication Description

1 – ERRL Red CRC error; illegal station number or baud rate

Off Normal operation

2 – EDLED Green Receiving data

Off Not receiving data

3 – RUN Green Normal operation

Off No network connction or timeout (or no power)

4 – SDLED Green Transmitting data

Off No data transmission (or no power)

5 – Subnet status Off Power Off

Green, steady Communication with weighing sensor OK

Green, flashing Receiving data from weighing sensor

Red, steady Communication with weighing sensor failed (timeout)

6 – Device status Off Power Off

Green, steady CC-Link Module initialized and running

Green, flashing Performing auto baudrate detection

Red, steady Unrecoverable error

Red, flashing Auto baudrate detection failed

5.6.9 Operations

CC-Link Module uses a specific data area layout. For more details please see chapter 5.6

37Step-by-Step Installation and Configuration

CC-Link

Page 38

6 Operations

The Fieldbus-Module operates in the Basic-Mode with 2 output bytes and 8 input bytes and in the Extended-Mode with 32 output

bytes and 32 input bytes in the I/O-area of the PLC.

6.1 Basic-Mode

The Basic-Mode instructions contain the most important commands to operate a weighing sensor (see chapter 6.3 for detailed

information of supported commands). The coding of these commands is short and simple and allows a simple PLC interface

that requires only 2 bytes in the output area and 8 bytes in the input area of the PLC. In this mode the Fieldbus-Module encodes

and decodes the ASCII strings and converts the weight values.

The PLC interface will operate in the Basic-Mode if the user has chosen this option during the configuration of the Fieldbus master

and the Fieldbus-Module has been set into the same mode during the Fieldbus-Module configuration dialog, see chapter 4.6.6.

6.1.1 Output register Basic-Mode: 2 bytes

This part contains the information that is sent from the PLC to the weighing sensor i.e. the commands that are sent from the

PLC program to the weighing sensor.

Bit 7 6 5 4 3 2 1 0

Byte 1 Reserved (bit 3-7) STC QTB QDV

Byte 2 Reserved (bit 5-7) CMD (bit 0-4)

Query data valid (QDV)

The PLC program sets this bit to true if the code in the CMD field is valid and respectively to false if the data in the CMD field is not

valid. This bit is controlled by the PLC program and processed by the Fieldbus-Module. It is not visible to the weighing sensor.

Query toggle bit (QTB)

The PLC program toggles this bit (from 0 to 1 or 1 to 0) every time a new command shall be executed. Before the bit is toggled,

a valid command code must be present in the CMD field. This bit is controlled by the PLC program and processed by the

Fieldbus-Module. It is not visible to the weighing sensor.

Connection status clear (STC)

This bit is used as an acknowledge signal for the connection status bit (ST), see chapter 6.1.2. It is low (false) during normal

operation. If the connection between the balance and the Fieldbus-Module is lost ST is set false by the Fieldbus-Module. The PLC

reads this bit and acknowledges its value by setting STC true. If STC is true the Fieldbus-Module clears ST back to true. This in

turn is being read by the PLC and the STC is set back to false again. This short handshake process ensures that each connection

failure is properly sensed and taken care of by the PLC.

Reserved bits

These bits are reserved for future use and are not visible to the weighing sensor.

Weighing sensor command code (CMD)

The PLC program uses this field to specify the selected weighing sensor command. The Fieldbus-Module will convert this code

into the ASCII coded MT-SICS-command string. The maximum number of commands is limited to 32 (Basic-Mode only). See

chapter 6.3 for detailed information of supported commands.

38 Operation

Page 39

6.1.2 Input register Basic-Mode: 8 bytes

This part contains the information that is sent from the weighing sensor to the PLC, i.e. the response strings that are generated

by the weighing sensor as answers to the query commands from the PLC.

Bit 7 6 5 4 3 2 1 0

Byte 1 ST RTB RDV

Byte 2 Reserved (bit 5-7) RES (bit 0-4)

Byte 3 Weighing Sensor (Balance) Response Status (BRS)

Byte 4 Weight Unit (WU)

Byte 5-8 Weight Value (WV)

Response data valid (RDV)

The Fieldbus-Module will set the response data valid (RDV) bit to true if the data in the weighing sensor (Balance) response

bytes 2 – 8 (RES, BRS, WU and WV) are valid and comply with the query specified in the weighing sensor query command.

Response toggle bit (RTB)

The Fieldbus-Module will set the response toggle bit (RTB) to the same value as the query toggle bit after it has sent the query

command to the weighing sensor. At the same time, the Fieldbus-Module will reset the response data valid bit (RDV). Both bits

are controlled by the Fieldbus-Module and are not visible to the weighing sensor.

Connection status bit (ST)

This bit indicates the status of the serial connection between the Fieldbus-Module and the weighing sensor. It is controlled by the

Fieldbus-Module and not visible to the weighing sensor. This bit is valid at any time and independent from the RDV bit.

True = serial connection to weighing sensor operational

False = serial connection to weighing sensor not operational (timeout)

Reserved bits

These bits are reserved for future use and are not visible to the weighing sensor.

Weighing sensor response code (RES)

This field is used to indicate the response code that the Fieldbus-Module has received from the weighing sensor. It is controlled

by the Fieldbus-Module and not visible to the weighing sensor. During regular operation, it should always have the same value

as the CMD code if RDV=True. If the two codes differ, the serial link between the PLC and the weighing sensor may have lost

synchronization. In this case a reset command should be issued to re-synchronize the system. Please refer to the flow chart in

chapter 6.7.2 for details.

Weighing sensor (Balance) response status (BRS) [Byte 3]

BRS contains the status information that the Fieldbus-Module has received from the weighing sensors response message. In

most of the MT-SICS response strings this is the status information (S, D, A, I, +, -, L) following the first blank character after the

MT-SICS-command. The Fieldbus-Module will decode the response message from the weighing sensor, will suppress unnecessary information and will encode the RES status field as defined in chapter 7.1 of this document. The values shown in this table

are the hexadecimal equivalent of the ASCII values (S, D, A, I, +, -, L).

Weight unit (WU) [Byte 4]

WU contains the hexadecimal equivalent of the weight unit as defined in chapter 6.4.

Weight value (WV) [Byte 5-8]

WV contains the weight value if applicable for the selected command. The Fieldbus-Module will decode the ASCII coded weight

value that it has received from the weighing sensor, will suppress unnecessary information and will convert it into a 32 bit single

precision real number according to IEEE 754. The weight value is presented in Motorola format MSB in byte 5 and LSB in byte

8. If no weight value is associated with the selected command, the Fieldbus-Module will set this field to 0000hex.

39Operation

Page 40

Note

If the weight value is not indicated correctly on the PLC please check the endian order. The bytes from the communicator

(Fieldbus-Module) is in big endian order (MSB first) but the PLC could use little endian (LSB first). To achieve correct indication

please swap byte 5 and 8 and swap byte 6 and 7 in the PLC.

6.2 Extended-Mode

The Extended-Mode is available for the more sophisticated user of the weighing sensor and is recommended only if the PLC

has sufficient free I/O bytes available. The Extended-Mode makes all commands, options and parameters of all the weighing

sensors available to the PLC program. It offers full flexibility and all options for the definition of new MT-SICS commands without

the need to change the Fieldbus-Module firmware.

The PLC interface will operate in the Extended-Mode, if the user has chosen this option during configuration of the Fieldbus

master and the Fieldbus-Module has been set into the same mode during the Fieldbus-Module configuration dialog see chapter

4.6.6.

The principle of the Extended-Mode is that all commands of the Basic-Mode are available and that in addition, the ASCII based

MT-SICS commands can be transferred via the Fieldbus and the Fieldbus-Module directly to the weighing sensor and vice versa.

If the ASCII coded MT-SICS commands are used, they will not be interpreted by the Fieldbus-Module.

The possibility to still use the Basic-Mode commands in the Extended-Mode has the big advantage that the ASCII-to-real conversion of the weight values and other response values is still done in the Fieldbus-Module and doesn’t have to be programmed

into the PLC.

6.2.1 Output register Extended-Mode: 32 bytes

This part contains the information that is sent from the PLC/PC to the weighing sensor i.e. the commands that are sent to the

weighing sensor.

Bit 7 6 5 4 3 2 1 0

Byte 1 Reserved (bit 3-7) STC QTB QDV

Byte 2 Reserved (bit 5-7) CMD (bit 0-4)

Byte 3 MT-SICS Command (1st byte)

Byte 4 MT-SICS Command (2nd byte)

: :

th

Byte n MT-SICS Command (n

byte)

Byte n+1 CR (Carriage return 0Dhex)

Byte n+2 LF (Line feed 0Ahex)

Byte n+3 00hex

: :

Byte 32 00hex