Page 1

User Manual

Easy Control Box

ECB

Page 2

Page 3

Table of Contents

1 Introduction

1.1 Scope of delivery 3

1.2 Check on arrival 4

2 Safety Information

2.1 Definition of signal warnings and symbols 5

2.2 Intended use 5

2.3 Product specific safety 5

3 Overview

4 Mount ECB on Lab Bar

5 Set up ECB

6 EasyMax port assignment

7 SmartConnect Sensor ports

7.1 Connecting cable to SmartConnect port 11

7.2 Adjust pressure sensors 11

8 pH Module

9 Gravimetric Dosing

9.1 Set up configuration settings on METTLER TOLEDO balances 17

10 Volumetric Dosing

11 Maintenance

11.1 Cleaning and Decontaminating 21

11.2 Calibration and Adjustment 21

11.3 Disconnecting the AC power adapter 21

11.4 Disposal 21

12 Technical data

12.1 General 22

12.2 Interface specifications 22

13 CE Certification

13.1 ECB Declaration of conformity 20160006 24

3

5

7

8

9

10

11

13

15

19

21

22

24

Table of Contents 1ECB

Page 4

Table of Contents2 ECB

Page 5

1 Introduction

Congratulations to your purchase of the Easy Control Box (named ECB in the following chapters).

This device can enhance the sensor and control capabilities of the METTLER TOLEDO thermostats.

The following main devices support the Easy Control Box:

• EasyMax 402 (Basic / Basic Plus / Advanced)

• EasyMax 102 (Basic / Basic Plus / Advanced)

• OptiMax 1001

• RX-10

The ECB can perform the following tasks:

• Support different sensors

• Enable gravimetric dosing

• Enable volumetric dosing (third-party pumps supporting the TTL interface)

• Measuring pH with the additional SevenExcellence™ pH module

One Easy Control Box can be connected to one main device and controlled via the touchscreen. The

Easy Control Box can also be used together with iControl or iC Data Center software.

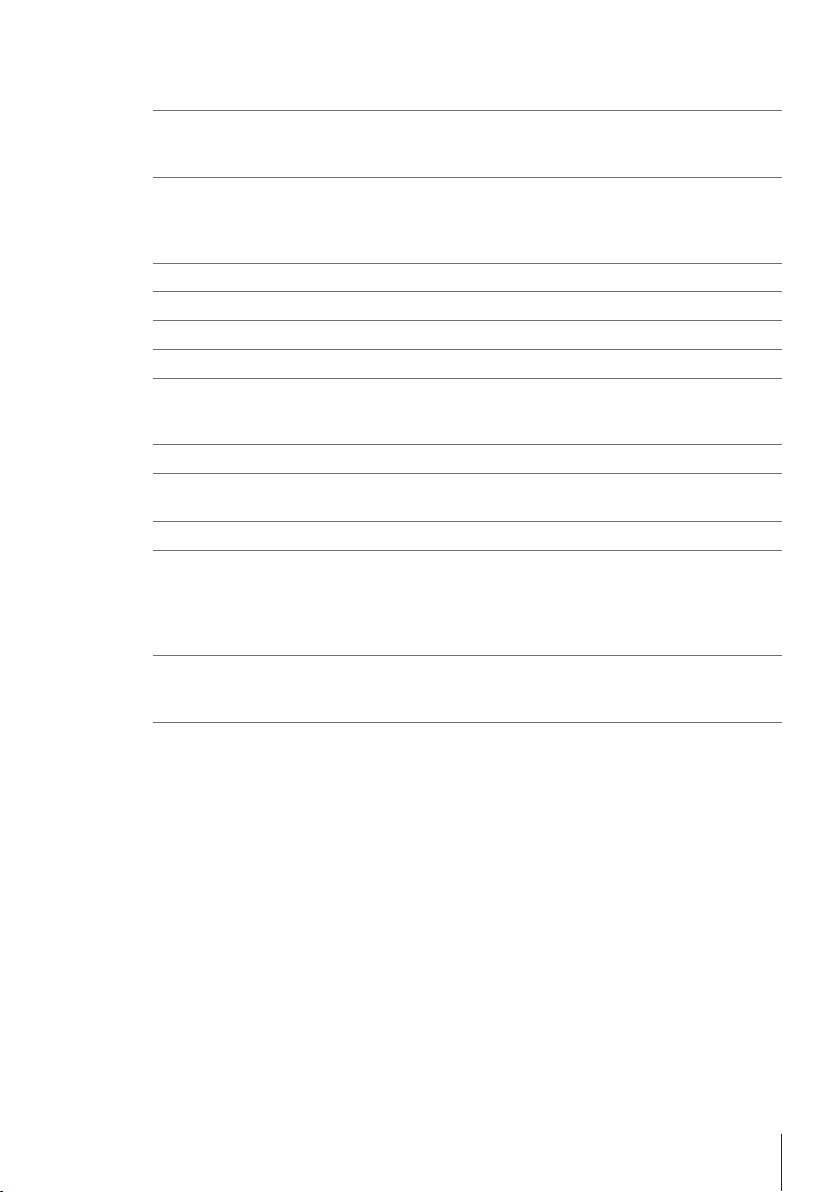

1.1 Scope of delivery

The following items are included in the ECB set (Order number: 30212440)

Number Order Number Amount Designation

1 30303439 1 ECB

2 51191988 1 CAN cable 1m

3 30281496 1 Lab Bar Holder

4 30251384 1 User Manual

30034475 2 Blank SevenExellence™ module

If an item is missing, please contact your local support.

Introduction 3ECB

Page 6

1.2 Check on arrival

Check the following things once the package has arrived:

• The package is in good condition.

• The content shows no signs of damage (e.g. broken covers, scratches etc.)

• The content is complete (see Scope of delivery).

If one condition is not fulfilled, please contact your local support.

Introduction4 ECB

Page 7

2 Safety Information

The ECB has been tested for the applications and intended purposes documented in this operating

instructions. However, this does not absolve you from the responsibility of performing your own tests

of the product supplied by METTLER TOLEDO regarding its suitability for the methods and purposes

you intend to use it for. You should therefore observe the safety measures for your protection and for

operation.

2.1 Definition of signal warnings and symbols

Safety notes are marked with signal words and warning symbols. These show safety issues and

warnings. Ignoring the safety notes may lead to personal injury, damage to the instrument,

malfunctions and false results.

Signal words

DANGER

WARNING

CAUTION

NOTICE

Note

Meaning of safety symbols

General hazard Notice Explosion

for an imminent danger with high risk, resulting in severe injuries or death

if not avoided.

for a hazardous situation with medium risk, possibly resulting in severe

injuries or death if not avoided.

for a hazardous situation with low risk, resulting minor or medium injuries

if not avoided.

for a hazardous situation with low risk, resulting in damage to the device

or the property or in loss of data.

(no symbol)

for useful information about the product.

2.2 Intended use

The ECB is a control box which is used together with a METTLER TOLEDO thermostat. It supports

analog third-party sensors and enables volumetric and gravimetric dosing.

Always operate and use your device in accordance with the instructions contained in this manual. Do

only use it together with equipment specified in this documentation.

Any other type of use and operation beyond the limits of technical specifications without the written

consent from Mettler-Toledo GmbH, is considered as not intended.

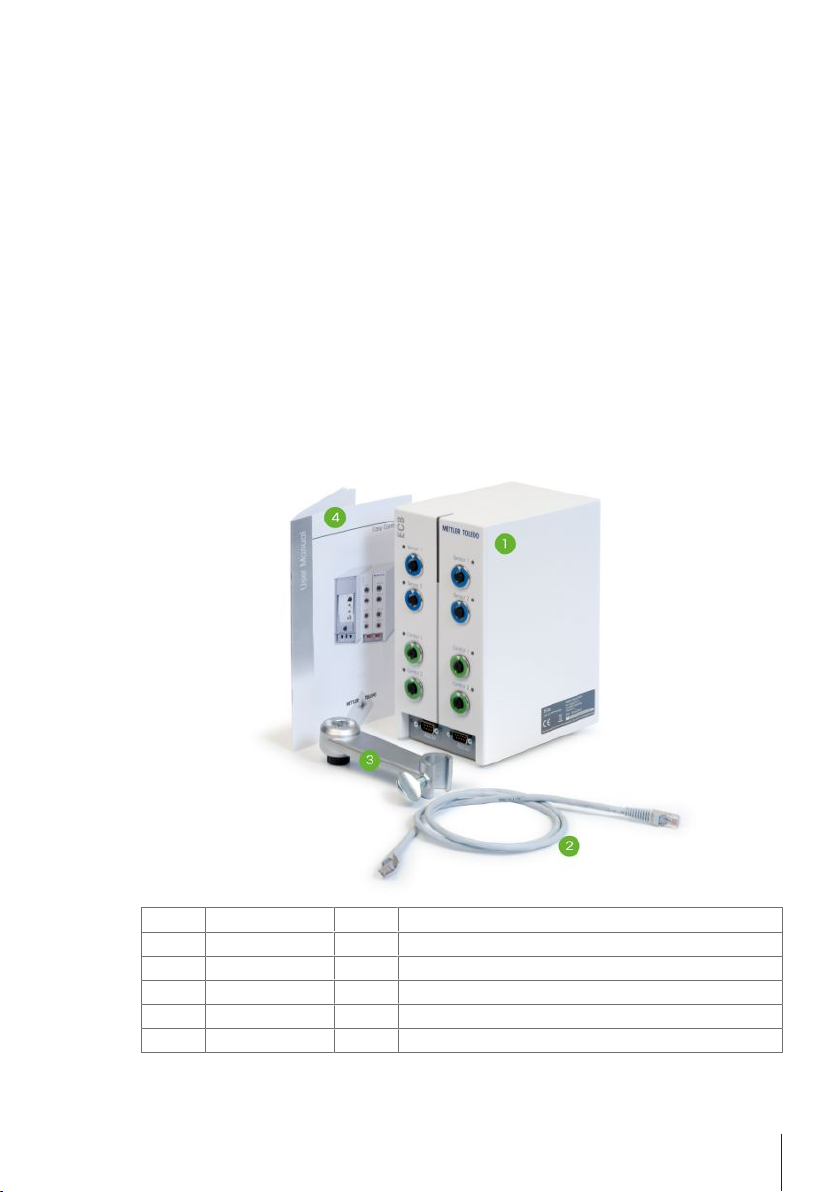

2.3 Product specific safety

WARNING

Control of valves

Implement suitable measures if you use valves which are not supplied by METTLER

TOLEDO! If electromagnets are attached, the output circuits of the valve outputs can start

to oscillate. The valves then remain open which could lead to a hazardous situation

with certain applications.

− Do connect a resistor-capacitor element next to the valve.

ð Use the schematics below on how to connect a resistor-capacitor element (RC

element).

Safety Information 5ECB

Page 8

Operational safety

For every instrument configuration used, you are responsible for ensuring that the entire system is

safe if a power failure occurs and that the reaction currently in progress cannot get out of control.

Site requirements

The instrument has been developed for indoor operation in a well-ventilated area. Avoid the following

environmental influences:

• Conditions outside of the ambient conditions specified in the technical data

• Powerful vibrations

• Direct sunlight

• Corrosive gas atmosphere

• Explosive atmosphere of gases, steam, fog, dust and flammable dust

• Powerful electric or magnetic fields

Note Gas Emission

The product does not emit any gases that could harm a person or damage the product.

Safety Information6 ECB

Page 9

3 Overview

1 4x SmartConnect Sensor Ports 2 4x SmartConnect Control Ports

3 2x RS232 for METTLER TOLEDO balances 4 CAN Bus OUT

5 Port for optional AC power adapter 6 CAN Bus IN

7 Slot for SevenExcellence™ pH modules 8 Statuslight™

Overview 7ECB

Page 10

4 Mount ECB on Lab Bar

This step is optional you can also place the ECB on any even surface.

1 Screw the lab bar holder to the lab bar.

2 Screw the ECB onto the lab bar holder.

Mount ECB on Lab Bar8 ECB

Page 11

5 Set up ECB

Connect to main device

− Connect the CAN cable to the CAN IN port of the

ECB and connect the other end of the cable to a

main device or any other CAN device connected

to a main device.

Connecting AC power adapter to the ECB

A message is shown on the touchscreen in case the connected CAN devices require more power than

provided by the main device.

Proceed as follows to connect the AC power adapter to the ECB.

1 Connect the AC power adapter to the ECB on the rear.

2 Make sure the arrow on the plug is facing upwards.

3 Connect the country-specific plug to the mains.

See [Disconnecting the AC power adapter}21] for proper disconnection.

Download Firmware

The firmware is automatically transmitted from the main device to the ECB. The ECB Statuslight is

white during this transmission.

See also

2 Disconnecting the AC power adapter [}21]

Set up ECB 9ECB

Page 12

6 EasyMax port assignment

Right ports assigned

to reactor 2

Left ports assigned

to reactor 1

For the EasyMax the ECB is divided. This happens automatically when you connect it to the EasyMax.

EasyMax port assignment10 ECB

Page 13

7 SmartConnect Sensor ports

The sensor ports are used to connect third-party analog sensors to the ECB. The ECB has four sensor

ports. The following signals can be read by the ECB:

• Temperature (Pt100)

• Current (mA)

• Voltage (V)

Ready-to-use cables are available. Technical aspects such as configuration and soldering of the

cables are described in the SmartConnect Cables User Manual (30260711).

Available SmartConnect sensor cables

Order No. Product Description Supported signal types

30267163 SmartConnect Pt100 cable with loose ends Pt100

30267165 SmartConnect generic sensor cable with loose ends Pt100, Current, Voltage

30254779 SmartConnect LEO3 / EV-120 pressure sensor cable Pressure via Current

WARNING

Default data for Leo3 / EV-120 cable (order no.: 30254779)

The default data for LEO or EV-120 cable is based on a 300 bar sensor. Reconfigure

your cable if needed, see [Adjust pressure sensors}11].

1 If you use a pressure sensor with different limits, please reconfigure your cable

according to the pressure range.

2 Check if the value on the touchscreen and the sensor are the same, if not recon-

figure the cable.

7.1 Connecting cable to SmartConnect port

Note: There are dedicated ports for sensors (blue) and final control elements (green). Make sure the

color of the cable plug corresponds with the color of the port.

1 To fit the plug into the socket, the arrow on the plug needs to be at the top.

2 The status LED (only available on ECB) turns green once the sensor or final control element is

ready to use.

7.2 Adjust pressure sensors

The default values for pressure sensors are based on a 300 bar sensor. This means connecting a

LEO3, 300 bar will not need any adjustment. For other sensors do the following:

§ Sensor must be connected to cable that will be configured.

1 Tap on main screen.

SmartConnect Sensor ports 11ECB

Page 14

2 Tap on *ECB.

3 Tap on the SmartConnect sensor port where the pressure sensor is connected.

4 Tap on Adjust sensor to reconfigure your pressure sensor.

5 For the Measured Value enter the lower limit of the measuring range (current) e.g. 4.00 mA. For

the Reference Value enter the pressure value that corresponds with the lower limit e.g. 0.00 bar.

6 Tap Next.

7 For the Measured Value enter the upper limit of the measuring range (current) e.g. 20.00 mA.

For the Reference Value enter the pressure value that corresponds with the upper limit e.g. 4.00

bar.

8 Tap Apply to save the data.

ð The pressure value is now visible on the touchscreen.

SmartConnect Sensor ports12 ECB

Page 15

8 pH Module

Mount the pH Module

It is possible to use SevenExcellence™ pH/mV module (30034472) or SevenExcellence™ pH/Ion

(30034471). The modules must be ordered separately. ECB is delivered with two blank modules.

Note: Only analog pH electrodes can be connected.

To install the SevenExcellence™ pH modules proceed as follows:

§ Make sure the ECB is not powered at the time a

SevenExcellence pH module is added or

removed.

1 Loosen the screw on the plate on the rear of the

ECB until you can slide down the plate.

2 Remove the blank module.

3 Insert the SevenExcellence™ pH/mV or Seven-

Excellence™ pH/Ion module.

4 Slide the plate up and tighten the screw on the

plate back .

5 Switch the main device back on.

ð The ECB can now measure pH. NOTICEA pH

value is displayed even if no pH probe is

connected.

Adjust a pH sensor

pH sensors connected to the ECB can be adjusted with a 2-point adjustment.

§ 2 Buffer solutions at room temperature (25°C) are needed: Choose the pH range according to

your experiment.

1 Tap on pH on the main screen.

pH Module 13ECB

Page 16

2 Tap on Adjust sensor.

3 Place the probe into the first buffer solution with the low pH.

4 Confirm the message on the touchscreen by tapping ok.

5 If necessary correct the Buffer solution pH value so it corresponds to the value of the buffer

solution the sensor is in.

6 Wait until the value Measured pH is stable and tap Apply.

7 Take out the pH sensor from the first buffer solution and clean the sensor carefully.

8 Place the sensor into the second buffer solution with the higher pH.

9 Confirm the message on the touchscreen by tapping ok.

10 If necessary correct Buffer solution pH value so it corresponds to the value of the buffer solution

the sensor is in.

11 Wait until the value Measured pH is stable and tap Apply.

ð The 2-point adjustment is finished.

Measure pH with the main device

Note Temperature compensation for pH is per default done with Tr. If there is no Tr available, Tj will

be used. Values from temperature probes integrated into the pH sensor are not considered for the

calculation of pH.

− Connect an analog pH sensor to the BNC port of the SevenExcellence™ pH module.

ð pH is displayed on the touchscreen of the connected main device.

pH Module14 ECB

Page 17

9 Gravimetric Dosing

Gravimetric dosing refers to a technique where the dosing pump is controlled based on a balance

signal. The amount to be dosed can be specified in grams.

Supported pumps for gravimetric dosing

Support for any third-party dosing pump with analog control interface for:

• Current (0…20 mA)

• Voltage (-10…10 V)

• Frequency (0…3 Hz)

• Pulse width modulation (24 V)

For some dosing pumps there are ready-to-use cables. Others have to use the SmartConnect control

cable with loose ends. See list below:

NOTICE

Use of SmartConnect cables with Watson-Marlow 120U

Watson-Marlow 120U peristaltic pumps are not protected against ground loops.

− Do NOT use a SmartConnect control cable with loose ends (order no.: 30267164).

Order the specific control cable for Watson-Marlow 120U (order no.: 30254806),

which has a built-in galvanic isolation

Order No. Designation

30267164 SmartConnect control cable with loose ends

30254805 SmartConnect KNF SIMDos control cable

30254804 SmartConnect ProMinent control cable

30254806 SmartConnect WatsonMarlow control cable

Technical aspects such as configuration and soldering of the cables are described in the SmartConnect Cables User Manual (30260711).

Set up for gravimetric Dosing

Note: Control cable and the RS232 cable have to be connected on the same side of the ECB,

otherwise the dosing will not work.

§ A supported pump is available.

§ A METTLER TOLEDO balance is available.

§ ECB is connected to the main device.

1 Connect the pump to a control port on the ECB with a suitable SmartConnect control cable.

NOTICEIf you have a Watson-Marlow pump, make sure the pump is turned off when

connecting the cable.

2 Connect the balance to the RS232 port.

3 Configure the balance according to the specifications in [Set up configuration settings on

METTLER TOLEDO balances}17].

Gravimetric Dosing 15ECB

Page 18

4 Put the substance to be dosed on the balance and connect the tube to the pump.

SmartConnect control cable

for dosing pump

RS232 cable for

balance

Pump

with analog

signal

ð The ECB is now ready to do gravimetric dosing.

RS232

For METTLER TOLEDO balances

METTLER TOLEDO balances with MT-SICS protocol

interface. See [Set up configuration settings on

METTLER TOLEDO balances}17] for the communication settings to be set on the balance.

Gravimetric dosing on the thermostat

§ A supported pump and balance is connected.

1 Tap Dosing on the main screen.

ð All connected Dosing Units and ECBs are displayed.

2 Select the dosing device that you have prepared.

3 Tap and hold Prime tubes to fill the tubes.

ð The pump is dosing with 50 % of maximum dosing rate.

4 Tap Dosing of Substance 1 to enter the name of the chemical that is dosed.

5 Enter the Amount and Duration or Rate according to your experiment setting.

6 You can activate Hold dosing if to pause the dosing once the defined Tr value is exceeded.

ð The dosing will automatically continue once Tr falls below the defined threshold.

7 Tap Start to start the dosing.

ð The dosing starts immediately.

Gravimetric Dosing16 ECB

Page 19

9.1 Set up configuration settings on METTLER TOLEDO balances

Please refer to the Operating Instructions of the balances on how to change these settings.

Balance type Parameters

Excellence Series XA / XS / XP/ XPE • Host = RS232 built-in

• Baud rate = 9600

• Bit/Parity = 8/No

• Stop bit = 1

• Handshake = Xon / Xoff

• End of Line = <CR><LF>

• Character set = ANSI/Win

• Continous mode = off

MS / ML • RS232 = Host / SEND.OFF

• Baudrate = 9600

• Bit/Par. = 8/No

• HD.Shake = XON / XOFF

• RS E.O.L. = <CR><LF>

• RS Char = ANSI/WIN

• USB = SEND.OFF

PL-S • Function = F none

• Weighing mode = Std

• Weighing unit1/2: mg, g, or kg

• Autozero = no A.Zero

• Auto shut off = A.OFF –

• Peripheral unit = HoSt

• Send mode = S. oFF

• Send format = S.SICS

• Baud rate = bd 9600

• Bit / Parity = 8b-no

• Handshake = HS Soft

Gravimetric Dosing 17ECB

Page 20

PB-S/FACT, PB-L • Adjustment = CAL int (PB-S only)

• FACT = FACt oFF (PB-S only)

• Function = F none

• Weighing mode = Std

• Weighing unit1/2: mg, g, or kg

• Autozero = no A2Zero

• Peripheral unit = HoSt

• Send format = SICS

• Send mode = S. oFF

• Baud rate = bd 9600

• Bit / Parity = 8b-no

• Handshake = HS Soft

PB-G • Adjusment = oFF

• Function = F none

• Vibration adapter = 2

• Weighing proc. ad.: 2

• Repeatability = Good

• Weighing unit1/2: mg, g, or kg

• Autozero = AZ.oFF

• Autom. Shutdown = A.oFF –

• Power up mode = 9z.StArt

• Icons = on

• Peripheral unit = HoSt

• Data transfer mode = S. oFF

• Baud rate = bd 9600

• Bit / Parity = 8b-no

• Handshake = HS Soft

• Settings = List

Gravimetric Dosing18 ECB

Page 21

10 Volumetric Dosing

RS232 cable for syringe

pumps

Volumetric dosing refers to a technique where a syringe pump is used. The amount to be dosed can

be specified in milliliters.

Supported pumps for volumetric dosing

Support for selected KDS/Harvard syringe pumps with 9 or 15 pin TTL interface.

For some syringe pumps there are ready-to-use cables. See list below:

Order No. Designation

30254800 SmartConnect KDS/Harvard TTL cable (15 pin)

30254801 SmartConnect KDS/Harvard TTL cable (Legacy 9 pin)

Set up for volumetric Dosing

If only one dosing is connected to the main device it will be displayed automatically.

§ A supported syringe pump is available and prepared.

§ ECB is connected to main device.

− Connect the pump to a control port on the ECB with a control cable.

ð The dosing is now available on the touchscreen of the main device.

Volumetric dosing on the main device

Note: Syringe pumps are controlled through a so-called TTL (Transistor to Transistor Logic). The ECB

can only trigger the start and stop of a pre-programmed ramp on the syringe pump. The dosing is

controlled by the syringe pump. To capture the dosed amount you have to enter the same rate on the

ECB (see step 3). The captured amount may not be fully accurate so if necessary correct it in the

experiment data in iControl.

§ A supported and pre-programmed syringe pump is connected.

1 Tap Dosing on the main screen.

ð All connected Dosing Units and the ECB are displayed.

2 Select the syringe pump that you have prepared.

Volumetric Dosing 19ECB

Page 22

3 Optionally enter the Rate to capture the dosed amount. Enter the same dosing rate as pre-

programmed on the syringe pump.

4 Tap Start to start the dosing.

ð The dosing starts immediately.

Volumetric Dosing20 ECB

Page 23

11 Maintenance

11.1 Cleaning and Decontaminating

Clean the outside of the housing with a cloth moistened with ethanol.

The device can only be cleaned on the outside. In case chemicals contaminate the inside of the box,

the box has to be disposed.

11.2 Calibration and Adjustment

Keep in mind that the ports of your device need regular calibration and adjustment to generate the

most accurate data. Please contact a Field Service Engineer to perform a calibration and an

adjustment.

11.3 Disconnecting the AC power adapter

NOTICE

Do not disconnect the cables by pulling on the cable

This could damage the connectors. Only pull out the cable at the end using the plug.

To disconnect the AC power adapter proceed as follows:

§ The main device is turned off.

1 Pull back the movable part of the plug.

2 Use gentle force to disconnect the AC power adapter from the device.

11.4 Disposal

In conformance with the European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment. If you have any questions, please contact

the responsible authority or the distributor from which you purchased this device. Should

this device be passed on to other parties (for private or professional use), the content of

this regulation must also be related.

Thank you for your contribution to environmental protection.

Maintenance 21ECB

Page 24

12 Technical data

12.1 General

AC power adapter rating

(optional)

Instrument rating

Dimensions (WxDxH)

Weight

Number of ECBs connected to one main device

Humidity

Altitude

Overvoltage category

Pollution degree

Ambient temperature

Usage

Line voltage 100…240 VAC

Input frequency 50/60 Hz

Input current 1.8 A

Output voltage 24 VDC

Output current 5 A

Mains supply voltage fluctuations Up to ± 10 % of the nominal

voltage

Input voltage 24 VDC supplied via CAN Bus

Max. power 120 W

110 mm x 152 mm x 215 mm (4.33” x 5.98” x

8.47”)

2.5 kg

Max. 1

Max. relative humidity 80 % for temperatures up to

31°C decreasing linearly to 50 % relative humidity

at 40°C

Up to 2000 m

II

2

5 °C…40 °C

For indoor use only

12.2 Interface specifications

SmartConnect

Sensor port

(4x)

Technical data22 ECB

Signal Measuring

Pt100

(Temperature)

Current (mA) 0/4…20mA

Voltage (V) ±10V over

Range

-120…400 °C 0.01K -50…300 °C:

with 100Ω

impedance

1GΩ

Resolution Accuracy Supports

4 or 2-wire

±0.2 K

0.002 mA 0.005 mA Any sensor /

0.001 V 0.005 V Any sensor /

temperature

sensors

transmitter with

Current (mA)

output

transmitter with

Voltage (V)

output

Page 25

SmartConnect

Control Port

Signal Control Range Resolution Accuracy Supports

Current (mA) 0/4…20 mA with

(4x)

Voltage (V) 0…10V with

PWM (Pulse

width

modulation)

Frequency 0…3Hz with

TTL (Transistor

to transistor

logic) In/Out

pH Module

Port Measuring

(2x)

BNC 0…14 pH 0.001 ±0.05 Analog

RS232

For METTLER TOLEDO balances

max 500Ω

0.005 mA 0.01 mA Dosing pumps

0.0025 V 0.01 V Dosing pumps

I

= 10mA

max

0…100% of one

0.01 s 0.02 s Dosing valves

second 24V with

33Ω min.

(I

=0.7 A)

max

0.008 Hz 0.008 Hz Dosing pumps

20ms pulse with

20mA max load

Triggering start of preprogrammed

dosing ramp

Resolution Accuracy Supports

Range

METTLER TOLEDO balances with MT-SICS protocol

interface. See [Set up configuration settings on

METTLER TOLEDO balances}17] for the communication settings to be set on the balance.

n/a Syringe pumps

electrodes

Technical data 23ECB

Page 26

13 CE Certification

METTLER

TOLEDO

®>

EU

Declaration

of

Conformity / EU-Konformitätserklärung / OV

Declaration

de

conformite

europeenne

/

CfC>

Declaraciön

de

conformidad UE

/

;

JÜ

Certificazione

di

conformitä

UE

/

0®

EC

AeiuiapauMH

3a

ctoTBeTCTBHe / ®

EU

Prohläseni o shode

/ ;M>

EU-overensstemmelseserklaering

/

OD

ArjAuior)

auuu6p<pu)ar|q

E.E. / O0

ELi

vastavusdeklaratsioon / OD EU-

vaatimustenmukaisuusvakuutus / Dearbhü Comhreireachta

AE / 'Ä-

EU

izjava o sukladnosti

/

<b§>

EU

Megfelelösegi

nyilatkozat

/

Q\)

EU

JS^a!" / <&>

EU

»fj-'g I C-t)

ES

atitikties

deklaracija / 0£>

ES

atbilstibas deklaräcija

/ (®

Dikjarazzjoni

ta'

Konformitä

tal-UE / 0®

EU-

conformiteitsverklaring

/ 00

Deklaracja

zgodnosci

UE / 00

Declaracäo

de

Conformidade

da

UE

/

<M>

Declaratje

de

conformitate

UE

/ !3©>

fleK/iapaMMH o cooTBeTCTBMM

Tpe6oBaHHHM

EC / 0*0

EÜ

Vyhläsenie o zhode / 00

Izjava o skladnosti

EU / 00

EU-försäkran

om

överensstämmelse / ®

ianSn^ua^nn'5iJäijfiPi'i»jjj'iPi'5§nuJlMfinv(^T,3iJ

(Declaration

of

Conformity) / EU

—

ProdllCt

/

Produkt / Produit /

Producta / Prodotto / rtpoflynT/

Vyrobek / Produkt /

npolöv/

Toode

/Tuote

/Täirge /

Proizvod / Termek / HA£ / 7

Gamlnys / Izsträdajums / Prodott / Product / Produkt / Produto / Produs

/

npoflyKiiMsi / Produkt / l/delek / Produkt / rutfiii

/

Control

Unit

Easy

Control Box (ECB)

Manufactltrer

/

Hersteller /

Fabricant / Fabricante

/ Produttore /

npon3BO/inren / Vyrobce / Producent

/

KaraoKEuaoTri?/

Tootja / Valmistaja/

Deantiisöir / Proizvodac / Gyärtö / Ii— 1

afläi'äs]

/Gamintojas ; Raiots

js

/

Manrfattur/

Producent / Producent / Fabricante / Producätor/ npon3BOAnrejib /Vyrobca / Proizvajalec

/THIverkare

/

fjuSst

/

WäfiiS

Mettler-Toledo

GmbH

Im

Langacher 44

8606

Greifensee

SWITZERLAND

This

declaration of

conformity

is

issued

underthe

sole

responsibility of the manufacturer.

/

Die alleinige Verantwortung

für

die Ausstellung dieser

Konformitätserkiärung

trägt der Hersteller. / La presente declaration

de

conformite est etablie

sous

la seule responsabilite du fabricant.

/

La

presente declaraciön

de

conformidad se expide

bajo

la

exciusiva responsabilidad

del

fabricante. / La presente certificazione

di

conformitä e rilasciata

sotto

la

responsabilitä

esclusiva

del produttore. / HacTomuaTa

neKnapauufi

3a

cbOTBeTCTBHe e H3/ia,neHa

no/i

e/iMHCTBeHaxa

OTTOBOPHOCT

Ha

npon3BOflMTenR. / Toto

prohläseni 0 shode

vydava vyrobce na svou

vlastni

odpovednost. / Producenten

er

eneansvarlig

for

udstedelsen

af

denne

overensstemmelseserklaering. / H

Trapoüoa öhAiuan auppöp<pü)or|? EKÖförrai

pE

omoicAeiOTiKr)

cuBuvrj

TOU

KQTO.cnccUQOTr|. / See vastavusdeklaratsioon

on

väljastatud

tootja

ainuvastutusel.

/

Vaatimustenmukaisuusvakuutus

on annettu valmistajan yksinomaisella vastuulla. / Is

faoi

fhreagracht an

deantüsöra

amhäin a eisitear an dearbhü comhreireachta

seo. / Ova

Izjava o sukladnosti

izdaje

se pod

punom

odgovomoscu

proizvodaöa. / Az

aläbbi

megfelelösegi

nyilatkozat

kiadäsäert

kizärölag a gyärtö

feielös. / ZOMfS

Ä*»li/-A-©IMtt*ffl=fcL^TftfT**l*'f.

/ol 05

*A^o\o\\

^IStlsisLlcK/SiatitiktiesdeklaracijaiSduotatikgamintojo

atsakomybe. / 51

atbilstibas

deklaräcija

ir

izdota

vienigi

uz

razotäja

atbildlbu. / Din

id-dikjarazzjoni

ta'

konformitä

hi

man

rüg a taftt

ir-responsabbilta

unika

tal-

manifattur. / Deze

conformiteitsverklaring

wordt

verstrekt onder de exciusieve verantwoordelijkheid van

de

producent. / Ta deklaracja zgodnosci

zostaJa

wystawiona

na

wytaczna.

odpowiedzialnosc producenta. / Esta

deciaragao

de

conformidade e emitida sob a responsabilidade exciusiva

do

fabricante. / Prezenta

decfara(ie

de

conformitate

este

emisa*

pe

räspunderea exclusivä a produeätorului. / HaciOKmaH

AeruiapauHH c COOTBCTCTBHM

Bbiiiymena

IIOA

MCKJirOHHrejibnyto

oiBeiciBennoc

ib

npon3Bo/inTenp!. / Toto vyhläsenie o zhode vydäva vyrobca

na

vlastnü zodpovednosf.

/2a

izdajo

te

izjave o skladnosti

je

odgovoren

izkljucno

proizvajalec. / Denna

försäkran

om överensstämmelse utfärdas

pä

tillverkarens eget ansvar. / iöntfnwdfwmidÖuÄfnujn«isiu&

/

jRfej*^

The

object

of

the declaration described above

is in

conformity

with

the

following

European directives and

Standards

or

normative

documents:

/

Der oben

beschriebene

Gegenstand

der Erklärung erfüllt die Vorschriften der folgenden europäischen

Richtlinien

und

Normen

oder normativen Dokumente: / L'objet

de la

declaration decrit

ci-dessus

est en conformite

avec

les

directives

et

normes

europeennes

suivantes

et

autres documents ä vocation normative : /

El objeto

de la

declaraciön descrita

ante

norm

ente se ajusta a lo

establecido

en

las siguientes directivas,

normas y documentos normatives europcos:

/L'oggetto

della dichiarazione

di

cui

sopra e conforme a direttive, norme o Standard europei

di

seguito: / npe^rvierbT

na

AeKJiapauiiHia.

oinican

110-iope, e B

cto

laeic

IBUC

ebe

cjiejinme

eßpoueriCKH

^petoMBM M crait^aprn

wwi

noprvia

IHBHM

AOKyMetuK: / VySe popsany

predmöt

prohläseni

je v souladu s näsledujtcimi

evropskymi

smemicemi a normami

nebo normativnimi

dokumenty: / Genstanden

for

erkiaeringen,

som

beskrevet ovenfor,

er

i

overensstemmelse

med folgende

europasiske

direktiver

og

standarder eller normative

dokumenler: / To

avTiKEfpEvo

Jt\<;

örjAwanc.

wo« TrcpiYpÖ9£Tai napoTTtivui

ouppoptpüvETai

pe

Tic,

napaKÖTUJ

EupconaiKEC,

oönY'EC.

tai

npöTinra

i*j

KavovioriKä

tyypaya: I Ülafkirjeldatud

deklareerilav

toode on kooskölas

järgmiste

Euroopa

direktiivide

ja

standardile

vöi

normdokumentidega: / Yllä määritetyn

vakuutuksen

tavoite

noudattaa seuraavien eurooppalaisten

direktiivien,

normien

tai

normatüvisten

asiakirjojen vaatimuksia: / Ta

euspeir

an dearbhaithe a dtugtar

cur-sios

air thuas

de

reir na dtreoracha agus

na

gcaighdeän Eorpach

rjö

de

reir

na

ndoieimead

normatach

Eorpach seo a leanas: / Predmet

izjave naveden iznad u skladu

je

sa

sljedeeim

europskim

dlrektivama i normama

normativnih

dokumenata:

/

A

fent

emlitett

nyilatkozat tärgya

megfelei

az

aläbbi euröpai iränyelveknek,

szabvänyoknak,

illetve normativ

dokumentumoknak:

/±.j&0!>md)§ftltt:«

ttSA^löLTÖ!)

R«Ä^teJ:tfa**4^tt«SÄ#(=aÄLTL^CÄ:tlt*-r*CfC-r:

o\ #<>i2.\

E^EI

5^

EE^

T?^

§AI§

^^sfb

cij

SisLlct- / Pirmiau

aprasytas

deklaracijos objektas atitinka

Sias

Europos direktyvas

ir

standartus

ar

norminius

dokumentus: / leprieks

aprakstltais

deklaräctjas

prieksmets

atbilst

tsiak

norädllajcm

Eiropas

direktiväm

un

standartiem

vai

norma'Tvajiem

dokumentiem: / L-ofigett

tad-dikjarazzjoni

deskritta hawn fuq

hu

konformi

mad-direttivi

Ewropej u l-istandards

jew

id-dokumenti

normattivi

Ii

gejjin: / Het

voorwerp van voornoemde verklaring

is in

overeenstemming

met

de

volgende

Europese

richtlijnen

en

normen

of

normatteve

docurnenten: / Tresi

powyzszej deklaracji jest zgodna z nast^puja.cymi

dyrektywami

europejskimi

oraz normami

lub

dokumentami

normalizuja.cymi: / O

objeto

da

deciaragao

aeima

mencionada

estä

em

conformidade com as seguintes diretrizes e normas europeias

ou

documentos

normativos: / Oblectul

declaratiei

descris

mai

sus este

In

conformitate cu urmätoarele directive

$i

standarde europene sau acte normative: / npe/iMST

/ieKnapannn,

onncaHHbin

Bbiiue,

cooiBeiciBye i cjieüyrotuMM

c-cponencKuri

iitipeKH'Bari n c

ian^f

piar.i

HJIM

uopMEi

I^BMUM

floKyMemaM: / Predmet

vySsie

uvedeneho vyhlasenia

o

zhode je v sülade s nasledujücimi

euröpskymi

smernicami a normami

alebo

normativnymi

dokumentmr: / redmet

zgoraj opisane izjave

je

skladen z naslednjimi

evropskimi

direktivami

in

Standard!

ali

normativnimi

dokumenti: / Föremälet för försäkran som beskrivs ovan överensstämmer med följande europeiska direktiv och

standarder

eller harmoniserade dokument: / ^^#^0*18^^

WoSuiuW

/

j-^

Page

1 of 3

13.1 ECB Declaration of conformity 20160006

CE Certification24 ECB

Page 27

EC - DECLARATION

OF CONFORMITY

KD

No.:

Document

No.: 20160006

The

undersigned,

representing

the

following

manufacturer

Mettler-Toledo

GmbH

Im

Langacher

44

8606

Greifensee, SWITZERLAND

herewith

declares that the product

Control

Unit

Easy

Control Box

(ECB)

For

additional types, see page Type code

certified

model:

is

in

conformity with

the

provisions

of

the following

EC

directives

(incl.

amendments)

2006/95/EC;

2014/35/EC

***)

Low voltage (LVD)

2004/108/EC;

2014/30/EC

***)

Electromagnetic compatibility

(EMC)

and

that the

Standards have been

applied. ***)

valid

after

20.04.2016

References

of

Standards

for

this declaration

of

"conformity,

or

parts thereof:

Harmonized

Standards

of

Europe and Switzerland:

Safety

Standards:

IEC/EN61010-1:2010

EMC

Standards

(*

Emission;

**

Immunity):

IEC61326-1:2012 / EN61326-1:2013

(class

B *)

IEC61326-1:2012 / EN61326-1:2013

(Industrial requirements

**)

Metrological

Standards:

IP

Standards:

Standards

for

Canada, USA and Australia:

Page

2 of 3

CE Certification 25ECB

Page 28

Mettler-Toledo GmbH

Im Langacher 44

8606 Greifensee, Switzerland

www.mt.com/contact

Subject to technical changes.

© Mettler-Toledo GmbH 08/2016

30251384A

www.mt.com/Autochem

For more information

*30251384*

Loading...

Loading...