Page 1

EasyClean 100/150

52 500 178

EasyClean100

EasyClean150

Instruction manual

Bedienungsanleitung

Instructions d’utilisation

Page 2

English: page 3

Deutsch: Seite 37

Français: page 71

Page 3

EasyClean100/150 3

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

EasyClean100

EasyClean150

Instruction Manual

Page 4

4 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

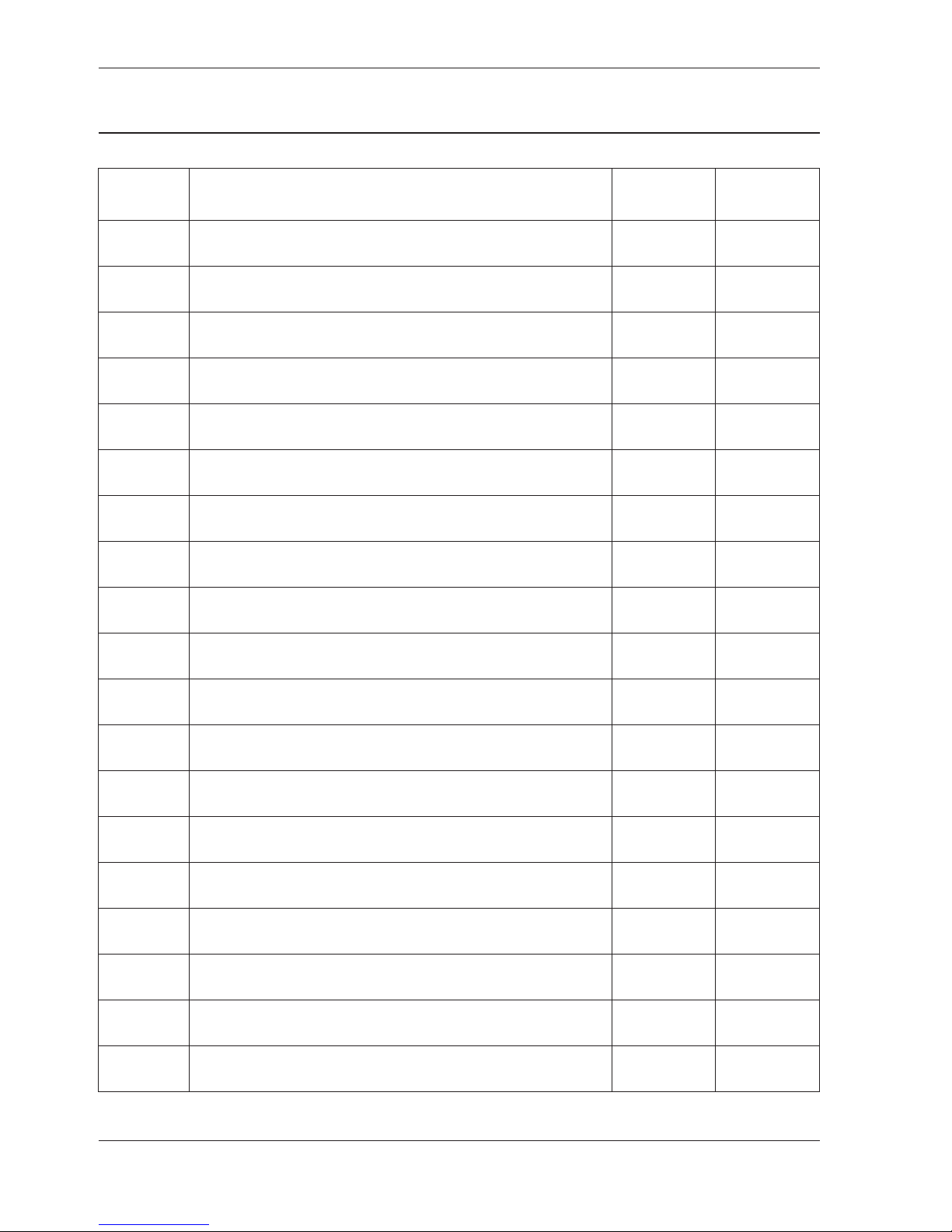

Product and maintenance log

D

ate Activity Performed Approved

by by

First installation

Page 5

EasyClean100/150 5

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

How to use this instruction manual

This instruction manual is an integral part of the EasyClean100 and EasyClean150 and

contains notes and instructions that are important for safety and operation.

All persons working on or with the EasyClean100 and/or EasyClean150 must have first

read and understood the sections appropriate to the work in hand.

Please read this instruction manual carefully before using the EasyClean system. Keep this

document close to the unit, so operating personnel may be easily refer to it at any time.

First read Chapter 2 ”Safety”!

© It is forbidden to reprint this instruction manual in whole or part.

No part of this manual may be reproduced in any form, or modified, copied or distributed using electronic systems,

in particular in the form of photocopies, photographs, magnetic or other recordings, without written consent of

Mettler-Toledo AG, Process Analytics, CH-8902 Urdorf.

All rights reserved, in particular reproduction, translation and patenting/registration.

InTrac, InDip are registered trade marks of Mettler-Toledo AG, CH-8606 Greifensee

Page 6

6 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

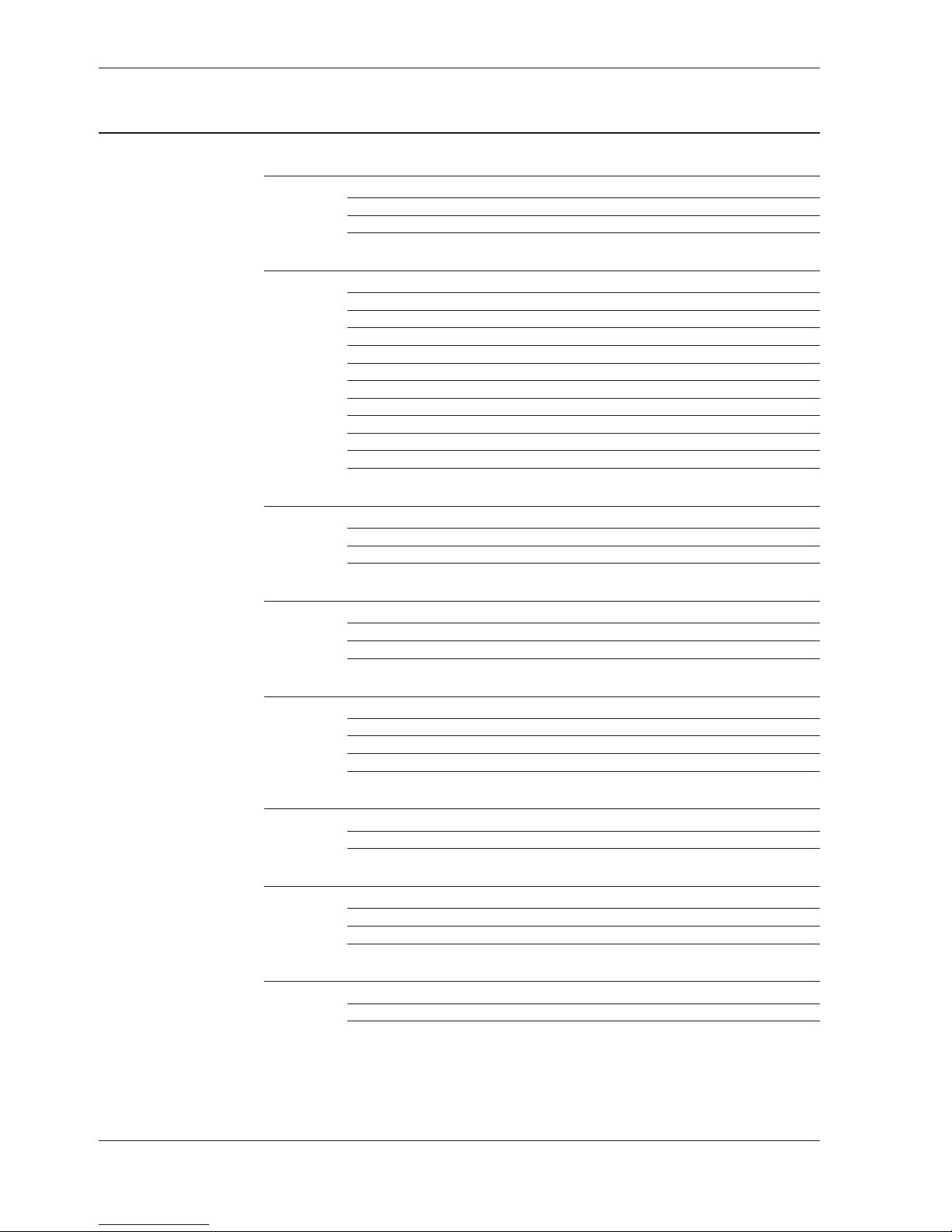

Contents

1 Product description 7

1.1 Introduction 7

1.2 Fittings and deliverables 7

1.3 Data and key characteristics EasyClean 100/150 8

2 Safety 10

2.1 Introduction 10

2.2 Intended use 10

2.3 Inappropriate use 10

2.4 Basic principles 11

2.5 Warning notices and symbols 11

2.6 Responsibility, organizational measures 12

2.7 Product-specific hazards 13

2.8 Residual hazards 13

2.9 Emergency measures 13

2.10 Safety measures 14

2.11 Modifications 14

3 Your device 15

3.1 Layout 15

3.2 Functions 16

3.3 Integration into a measurement system 17

4 Commissioning 18

4.1 Fitting 18

4.2 Connections 20

4.3 Installation and commissioning 24

5 Operation 26

5.1 Checks by the operator 26

5.2 Operating the EasyClean 100 26

5.3 Operating the EasyClean 150 26

5.4 Procedure in the event of a failure in the power supply 27

6 Maintenance and fault elimination 28

6.1 Maintenance 28

6.2 Fault elimination and repairs 29

7 Decommissioning, storage, disposal 31

7.1 Decommissioning 31

7.2 Storage 31

7.3 Disposal 31

8 Spare parts and accessories 32

8.1 List of spare parts and accessories EasyClean 100 32

8.2 List of spare parts and accessories EasyClean 150 34

Page 7

EasyClean100/150 7

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

1 Product description

Conformity EasyClean100 and EasyClean150 correspond to the following guidelines:

• Low voltage guideline:

– EU guidelines 73/23/EU

– Swiss guidelines SR734.26NEV

–

safety guidelines EN61010-1

– IP-rating EN60529 IP65

• Guidelines EMC:

– emission EN61326-1, Class B

– harmonics EN61000-3-2

– voltage deviations EN61000-3-3

– immunity EN61326-1

Certificates CE, GS

Identification The type plate is located on the left-hand exterior of the housing.

Deliverables EasyClean100 and150 are shipped without connecting cables. At the installation site,

cables are connected to the appropriate terminals in the unit (please refer to section 4.2

”Connections”).

Packaging The unit is packed in plain and padded cardboard.

We recommend that you retain the packing materials for subsequent storage or transportation

of the unit. Should you choose to discard the packing materials, observe local regulations and

section 7.3 ”Disposal”.

Good inspection Check the goods for damage while unpacking. Should you notice signs of damage, inform the

shipper and your supplier without delay.

Check the delivery against your order and the delivery note.

1.1 Introduction

1.2 Fittings and deliverables

Page 8

8 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

1.3 Data and key characteristics EasyClean100/150

Housing steel housing, powder-coated with polyester resin

m

aterial: mild steel DIN 1.1203 Ck55

attention: housing may not be cleaned with solvents

containing acetone

Weight of control unit approx. 3 kg (6.6 lb)

P

rotection rating IP65

Ambient conditions temp. in operation: 0 – +45° C (+32 – +113°F)

temp. storage/transportation: –10 – +70°C (+14 – +158°F)

degree of pollution: 2

overvoltage category: III

Power supply 100 – 230V AC, 50/60 Hz, 0.18 – 0.3 A (± 15%)

System control process initiation:

– via a wash contact in the associated transmitter

sequence:

– can not be set on unit

Control input 1 control input for wash contact in transmitter 24V

Transmitter METTLER TOLEDO transmitters:

– pH2050e, O

2

4050e, Cond7050e

– pH2100e, O24100e, Cond7100e, Trb8300

– alternatively via any standard transmitter with wash

contact and ”hold” function

Electrical connections Terminal strip 0.08 – 2.5 mm

2

Connection transmitter 4-wire control cable, 4 x 1.5 mm

2

length: 5 m (optional 10 m)

Cable ducts Ø 3.5 to 10 mm => M 16

Compressed air supply 4 – 8 bar (400 – 800 kPa, 58 – 116 psi)

– air quality according to ISO 8573-1

– moisture class 4 (water dew point +3°C)

– particles class 5 (filter 40 µm)

– max. oil content class 2 (0.1 mg/m3)

connection: thread G1/8"

Page 9

EasyClean100/150 9

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

Connection to InDip housing LDPE hose Ø 6/4 mm (1/8"/1/4")

optional: PTFE hose Ø 6/4 (1/8"/1/4")

Connection to InTrac housing LDPE hose Ø 6/4 mm (1/8"/1/4")

optional: PTFE hose Ø 6/4 mm (1/8"/1/4")

Flushing water supply pressure: 2 – 6 bar (200 – 600 kPa, 29 – 87 psi)

connection: thread G1/4" female

a

dapter:

1

/4"

NPT male (PP)

Spray head material PVC or PVDF

Materials in contact PP, LDPE, Viton

®

, brass,

with flushing water, stainless steel DIN 1.4105, 1.4303, 1.4310

compressed air or

Medias in connection with water 0 – 60 °C (32 °F – 140 °F)

the LDPE hose

Medias in connection with water 0 – 90 °C (32 °F – 194 °F)

the PTFE hose

Subject to technical changes

Page 10

10 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

2 Safety

2.1 Introduction

This instruction manual lists the main points of how to use the EasyClean100/150 efficiently,

in the intended manner. For safe, trouble-free operation, operators must be aware of these

s

afety instructions and comply with further warning notices in the instruction manual.

This instruction manual, and the safety requirements in particular, must be observed by the

operator and all other persons working with the EasyClean100/150. Compliance with local

regulations and statutory requirements is also essential.

The instruction manual must always be stored close at hand, in a place accessible to all

people working with the EasyClean100/150.

2.2 Intended use

EasyClean100 and EasyClean150 are intended solely for automatically controlled or manually

flushing of sensors, as described in this instruction manual.

Other prerequisites for appropriate use include:

– observing the instructions, notes and requirements set out in this instruction manual

– observing the prescribed inspection and maintenance intervals

– correct care and maintenance of the unit, according to the instruction manual

– observing the prescribed environmental and operational conditions, and permitted

installation positions.

– compliance with local statutes

2.3 Inappropriate use

Any other use, or use not mentioned here, that is incompatible with the technical specifications

is deemed inappropriate. The operator is solely responsible for any damage arising from such

use.

The following are deemed particularly inappropriate:

– use of hydraulic fluid in place of compressed air

– use of suspensions as cleaning media

Page 11

EasyClean100/150 11

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

2.4 Basic principles

EasyClean100/150 and the spray head are state-of-the-art constructions and comply with

engineering safety guidelines.

All the same, there are certain risks and hazards:

–

if the unit is operated by inadequately trained personnel.

– if the unit is not used in the intended manner.

EasyClean 100/150 and the spray head must only be used while in perfect working order,

for its intended purpose, with due awareness of associated safety and hazard issues and

in compliance with the instruction manual.

Defects or damage that impact the unit’s safety and functionality must be immediately repaired

by the operator or a suitably qualified person, and reported in writing to the manufacturer.

2.5 Warning notices and symbols

This instruction manual identifies safety instructions by means of the following symbols:

DANGER!

Warns of a hazard that could lead to extensive material damage, death or grievous bodily

injuries.

CAUTION!

Warns of a potentially hazardous situation that could lead to minor bodily injury and/or

material damage.

NOTICE!

Information relating to technical requirements. Non-observance could lead to defects,

inefficient operation and possible loss of production.

Page 12

12 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

2.6 Responsibility, organizational measures

Operator’s

responsibilities

– The operator must only permit personnel to work with the EasyClean if they are acquainted

with basic regulations concerning workplace safety and accident prevention, and familiar

with operating the unit. This instruction manual serves as a basis.

– In addition to the instruction manual, the operator must provide instruction in general statu-

tory and other binding regulations concerning workplace safety and accident prevention,

as well as environmental protection.

– Personnel safety and hazard awareness must be monitored regularly.

– Steps must be taken to ensure that the EasyClean is operated only while in a safe, properly

functional state.

Personnel

responsibilities

– All persons working with the EasyClean must have read the section on safety and

responsibilities the warning notices contained in this instruction manual.

– In addition to the instruction manual, generally applicable statutory and other binding regu -

lations concerning workplace safety and accident protection must also be observed.

– Avoid any hazardous working practices that exceed the unit’s intended purpose.

Personnel selection and

qualification

– basic responsibilities

– Only dependable, trained or supervised personnel may work with the EasyClean. Operators

must read this instruction manual beforehand.

– Responsibilities for operating, maintaining, installing, etc. the unit must be clearly defined.

– Appropriate steps must be taken to ensure that the unit is used by authorized personnel only.

– Personnel under instruction, supervision or general training may only work with the unit

under constant supervision by an experienced person.

– Work on electrical parts of the unit may only be performed by a qualified electrician in

compliance with electrical engineering regulations.

Constructional

modifications on the unit

– The unit may not be modified, extended or rebuilt in a way that impacts its safety without

written permission from Mettler-Toledo GmbH, Process Analytics.

– Any parts that are not in perfect working order must be replaced without delay.

Page 13

EasyClean100/150 13

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

2.7 Product-specific hazards

Electrical hazards!

Opening the unit for installation or repair work exposes live electrical parts.

C

lose the unit immediately after work is completed!

Compressed air/water hazards!

Pressurized pipes (compressed air, water) must be isolated and depressurized before

commencing repair work!

2.8 Residual hazards

Despite all precautionary measures, there remain residual hazards such as:

– a pipe bursting

– hazards arising from a defect in a supervisory controller.

2.9 Emergency measures

Should fluid come into contact with the eyes, rinse thoroughly under running water for

at least 15 minutes. A doctor must be consulted for subsequent diagnosis.

Fluid coming into contact with the skin must be immediately washed away with water.

Medical assistance is mandatory for symptoms that clearly arise from skin or eye

contact with a medium. Inform the doctor about the type and specific identity of all

materials used.

Page 14

14 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

2.10 Safety measures

Always observe local statutes and regulations. They are not incorporated in this instruction

manual.

Personal safety equipment like protective goggles and clothing must be worn.

The unit must only be operated while closed.

The operator is responsible for personnel instruction. By way of assistance, the instruction

m

anual can also be ordered in other languages. Being an integral part of the unit, this instruc-

tion manual must always be available at the unit’s location.

The operator should immediately inform the manufacturer about all safety-related events

occurring during use of the unit.

2.11 Modifications

Modifications are permitted only after prior consultation and written approval from the

manufacturer.

Only those parts of the unit essential to fulfilling its function may be removed and refitted.

This may be accomplished by hand, or with the supplied tools. Except for authorized service

personnel, it is forbidden to remove protective guards and covers using a regular tool.

Touching live electrical parts represents a lethal hazard.

Page 15

EasyClean100/150 15

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

3 Your device

3.1 Layout

EasyClean100

4 5

7

6

21

5 6 74

1 3

10

11

12

13

14 15

2

5 Connection terminal control cable

6 Compressed air/water valve

7 Power supply unit

1 Main connection

2 Control cable connection

3 Compressed air or water connection

4 Connection terminal main cable

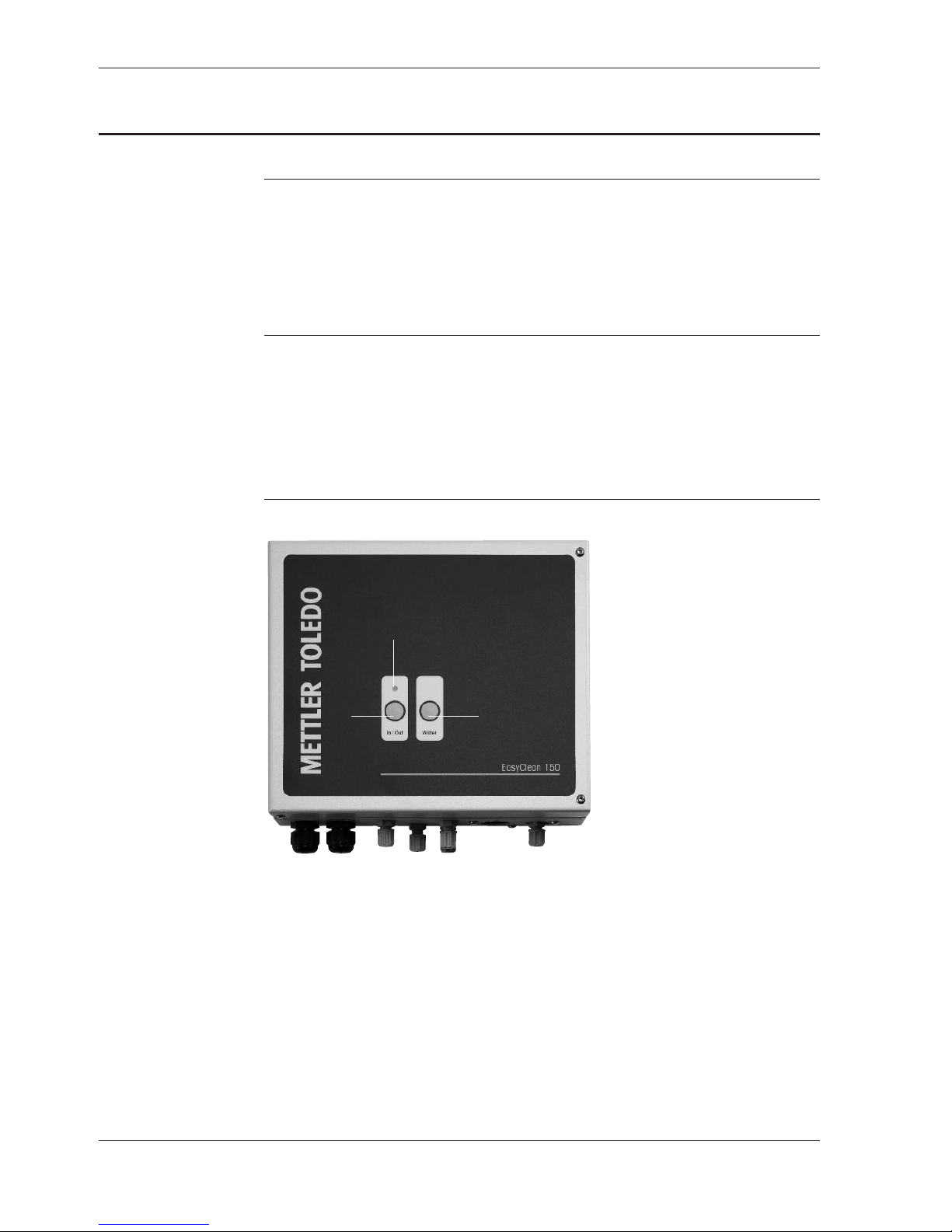

EasyClean150

1 ”In/Out” push button (position selector switch)

2 Pilot light LED

3 ”Water” push button

4 Main connection

5 Control cable connection

6 Compressed air connection

7 Air discharge

8 Compressed air outlet housing

9 Water connection

10 Water valve

11 Compressed air valve

12 Power supply unit

13 Control print

14 Connection terminal main cable

15 Connection terminal control cable

8 9

3

Page 16

16 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

3.2 Functions

General The EasyClean100/150 controls the supply of compressed air or water to an electrode tip,

w

hich is integrated into an InDip housing (EasyClean100) or into a retractable housing

(EasyClean150). The flow is released and stopped via the transmitter’s washing contact.

Types of operation The transmitter assumes overall control of the device.

Basic setting The valves are de-energized when closed.

In the event of a loss of pressure the InTrac housing remains in its last position. In the event of

a power failure in the EasyClean150, the sensor moves out of the process and the transmitter

changes to ”hold mode” (reading is frozen).

In the event of a power failure, all functions of the EasyClean100 cut out, with no impact on

the reading.

Hold function For the exact function and settings of the Hold relay, please refer to the instruction manual for

the transmitter in question.

Pilot lights

The EasyClean100 has no pilot lights.

The EasyClean150 has a pilot light (LED) built into the front. The light is connected to the

control valve that controls the housing movement. It does not therefore indicate any fault in

the operation of the housing, but only indicates the key status (automatic operation or in

retracted ”service mode”).

Program sequence The rinse and wash time is indicated by the control signal (wash contact) of the transmitter,

(see transmitter’s instruction manual).

Page 17

EasyClean100/150 17

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

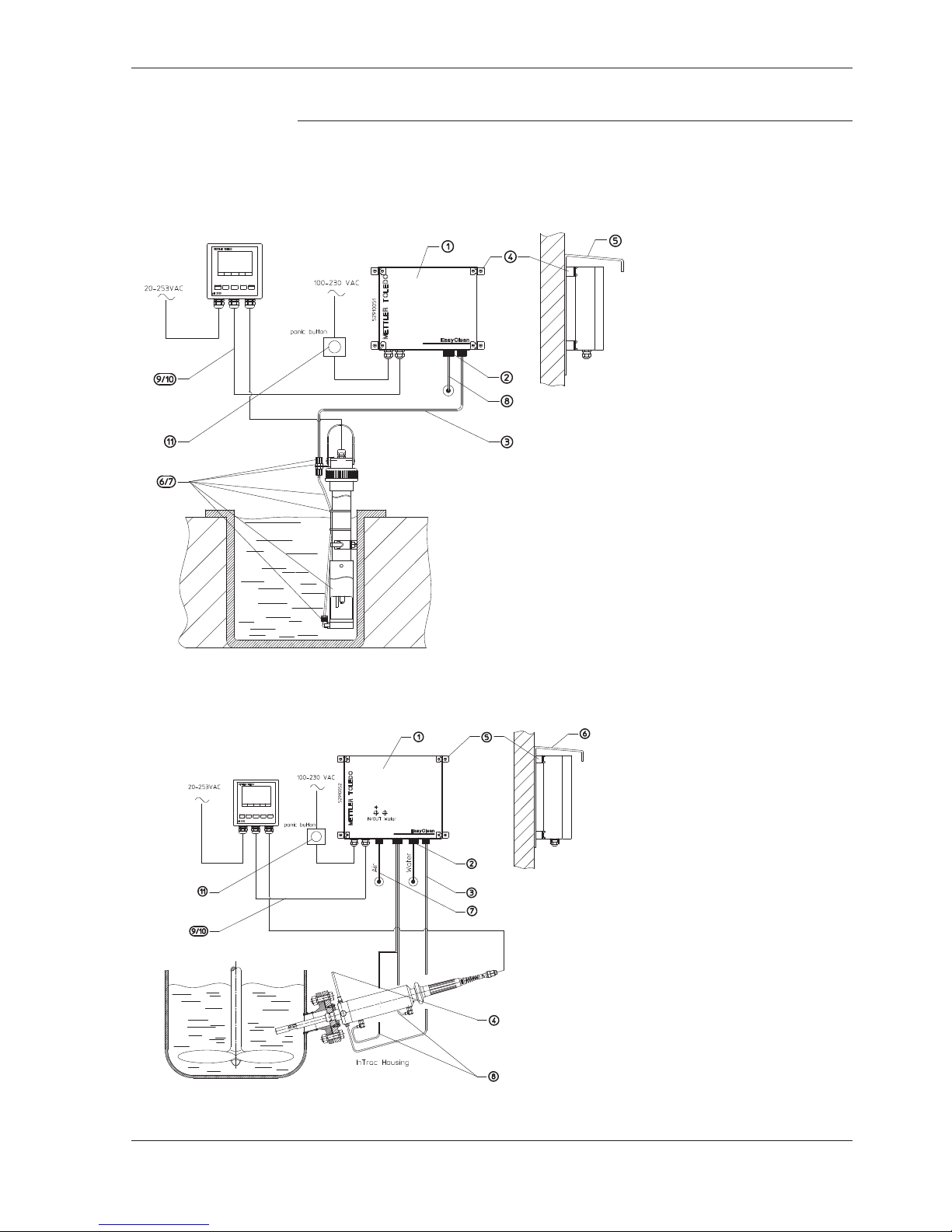

3.3 Integration into a measurement system

The following diagrams show typical examples of the integration of the EasyClean 100 or

the EasyClean150 respectively into a measurement system.

EasyClean100

1 EasyClean100

2 Compressed air/water connection

3 Compressed air or water hose

4 Wall mounting kit

5 Protective hood (optional)

6/7 Spray head

8 Compressed air inlet or water hose

9/10 Control cable

11 Panic button (optional)

1 EasyClean150

2 Water connection

3 Water hose

4 Drainwater hose

5 Wall mounting kit

6 Protective hood (optional)

7 Compressed air inlet (entrance)

8 Compressed air hoses (housing)

9/10 Control cable

11 Panic button (optional)

EasyClean150

Page 18

18 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

4 Commissioning

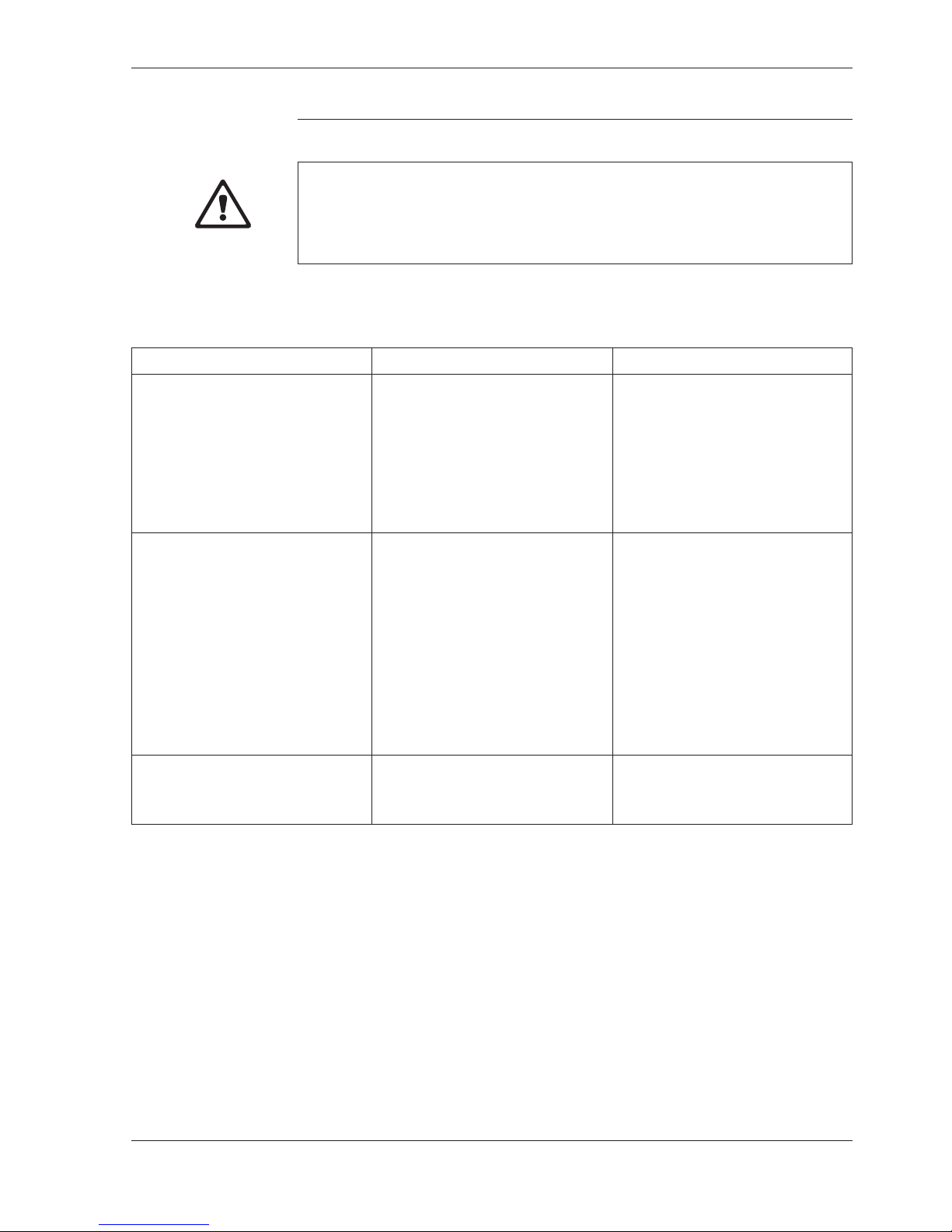

DANGER

P

lease refer to chapter 2 ”Safety”.

All work on the system’s electrical components may only be performed by authorized,

specialist staff.

NOTICE

During commissioning, please proceed according to section 4.3 ”Installation and

commissioning”. Note the references to more detailed information.

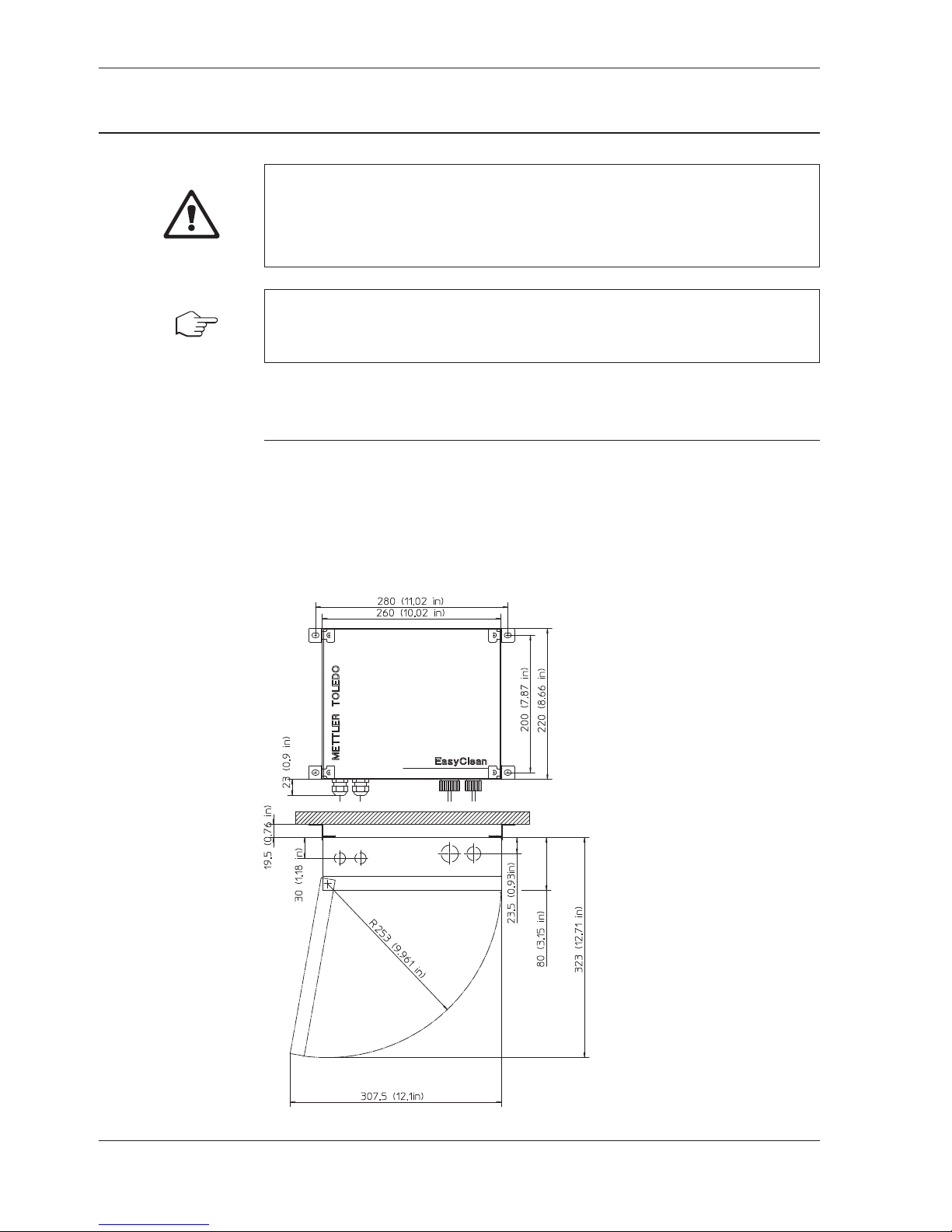

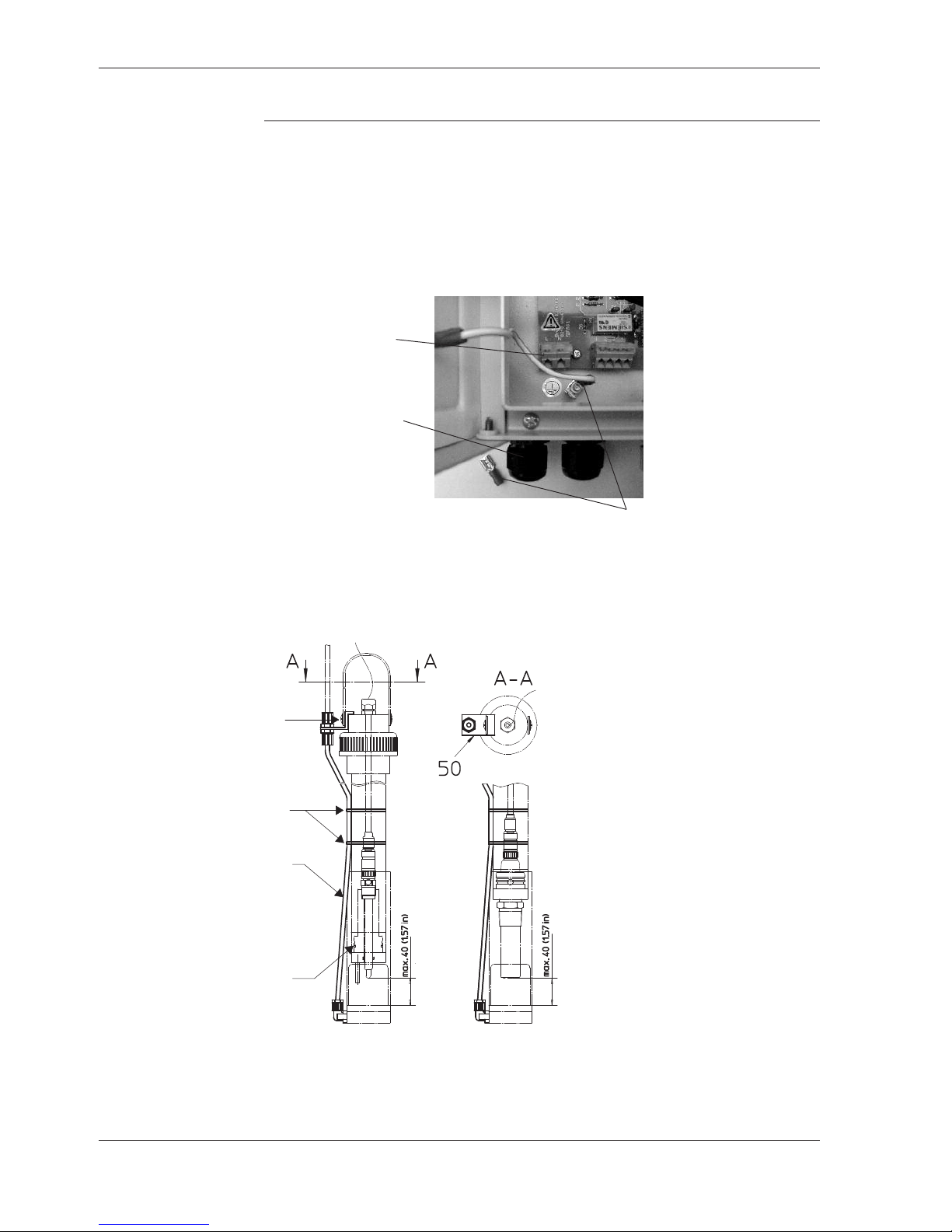

4.1 Fitting

The EasyClean100 and 150 are designed to be fitted directly (c-rails), on to walls or posts/

pipes. The EasyClean 100 and 150 are built into the same type of housing and therefore have

the same dimensions.

The fitting location must have sufficient stability and must as far as possible be free of vibration.

Please make sure that the lengths of the leads are as short as possible.

Wall mounting

Page 19

EasyClean100/150 19

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

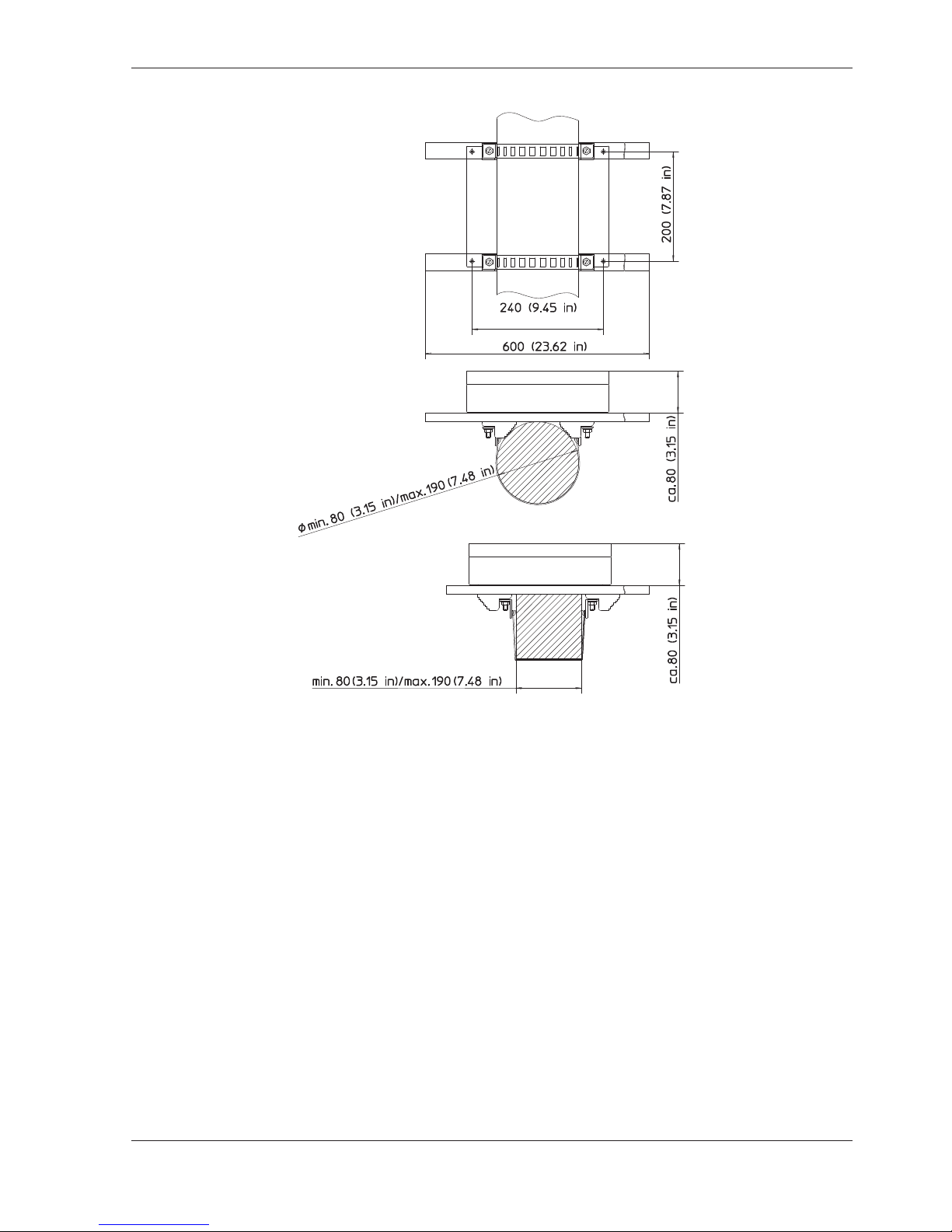

Pipe/post mounting

For the detailed procedure when fitting the suspended item, please refer to the installation

manual supplied separately.

Page 20

20 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

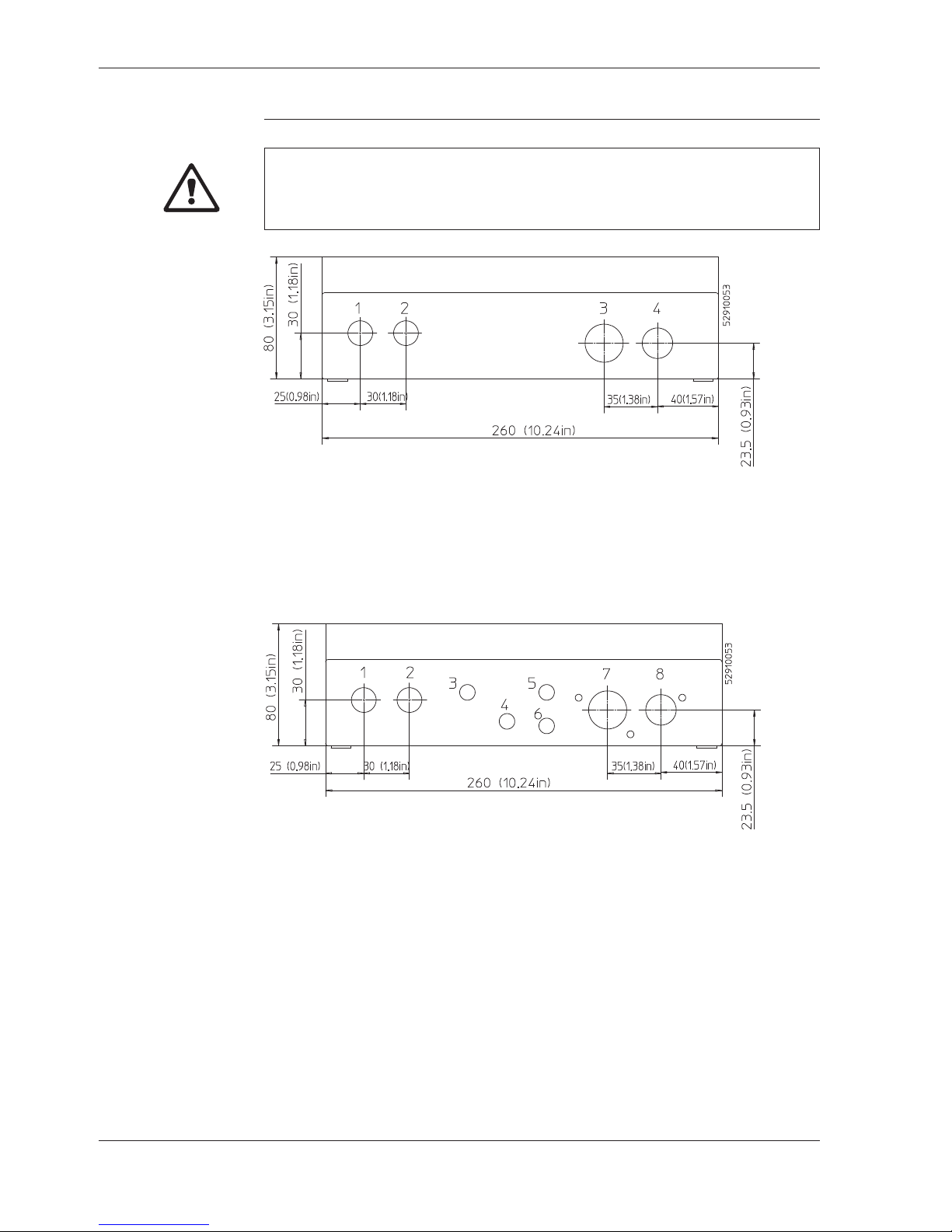

4.2 Connections

CAUTION

B

efore making connections, check that the connection values as described in section

1.3 ”Data and key characteristics” are observed.

Connections to the

housing floor

EasyClean100

1 Main cable sleeve M16

2 Transmitter cable sleeve, M16

3 Air/water input G1/4" NPT, female

4 Output to InDip housing (Ø 6/4 mm hose)

Connections to the

housing floor

EasyClean150

1 Main cable sleeve, M16

2 Transmitter cable sleeve, M16

3 Air input (Ø 6/4 mm hose)

4 Air discharge

5 Compressed air output for InTrac housing ––> function: ”Back”

6 Compressed air output for InTrac housing ––> function: ”Forwards”

7 Water input G

1

/4", female,

8 Output to housing (Ø 6/4 mm hose)

Page 21

EasyClean100/150 21

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

NOTICE

For purposes of efficiency, a valve is installed for water and compressed air from the building

close to the EasyClean100/150. This facilitates maintenance work and increases working

s

afety during fitting and dismantling of the device.

Please observe the local regulations for pneumatic and water installations.

Connections to the

immersion housing

The spray head is designed for the Mettler-Toledo InDip550. If the spray head is used with a different housing, installation and operation of the spray head is at the operator’s own risk.

For the installation of the retractable housing, please refer to the corresponding instruction

manual for the housing.

Electrical connections The EasyClean100 and 150 are designed for the Mettler-Toledo transmitter as described in

section 1.3. For the correct installation to other transmitters, please refer to the relevant manual.

DANGER

The mains connection may only be performed by authorized specialist staff in accordance

with electrical engineering rules.

Please also observe local regulations for the mains connection to the building.

NOTICE

The protective power switch has to be installed from the building installation and must be

placed near the EasyClean system.

Page 22

22 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

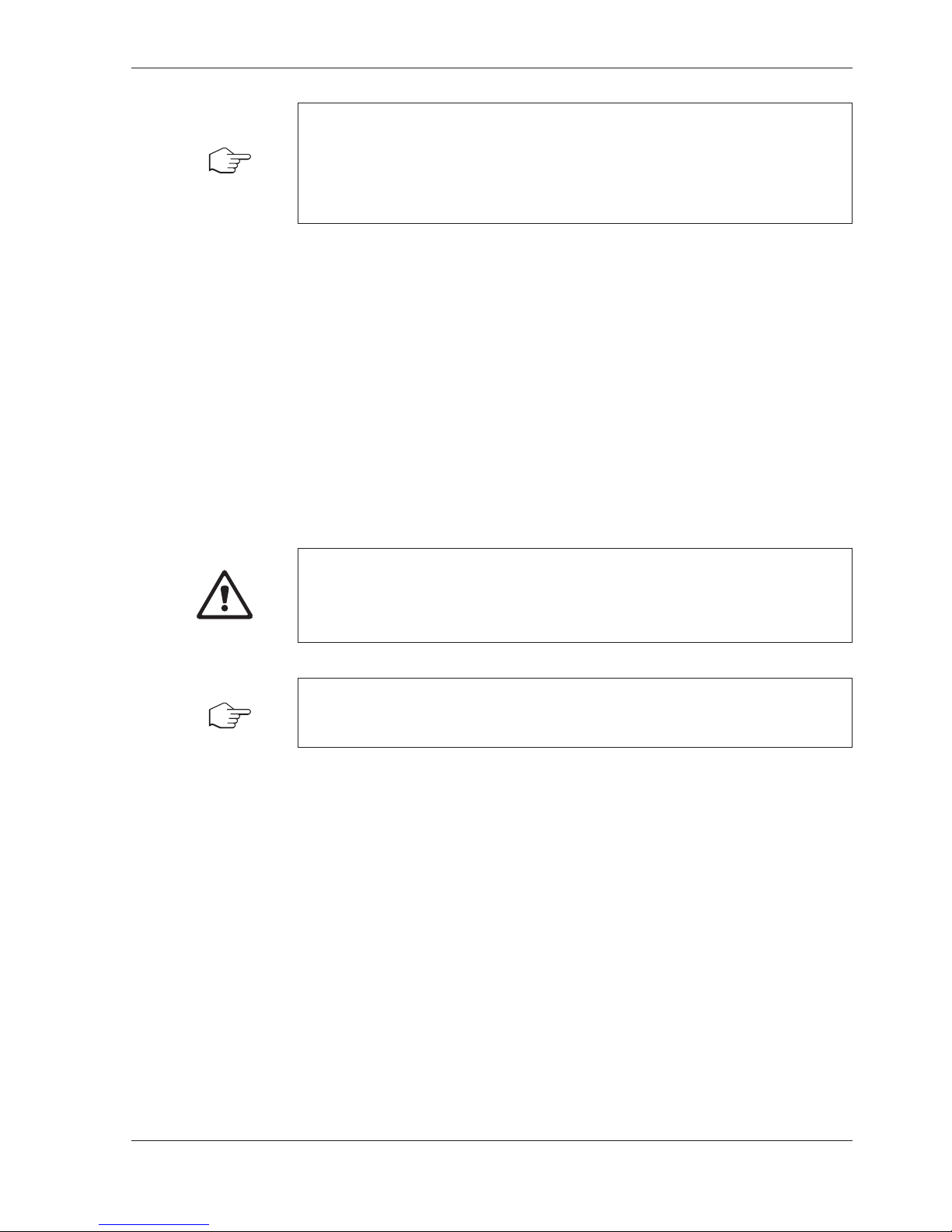

T

ransmitter

Electrical connections EasyClean100 with Mettler-Toledo transmitters

EasyClean 100

X100 e

1

Inp. 1

+24 VDC

17

18

Wash

2

E

asyClean 100

M300

1

Inp. 1

+24 VDC

2

1

TB1(1/2 DIN)

or

TB1B (1/4 DIN)

2

EasyClean 100

M700

1

Inp. 1

+24 VDC

3

4

K3

2

EasyClean 100

Trb 8300

1

Inp. 1

+24 VDC

TB5/6

TB5/5

Wash

2

Electrical connections

Transmitter X100 e

Define rinse interval and rinse time according to the process

require ments on the transmitter X100 e.

Transmitter M300

Set relay #1 (default) or #2, #3, #4 on the transmitter to

rinse contact.

Define rinse interval and rinse time according to the process

requirements on the transmitter M300.

Transmitter M700

Set relays K3 (or K1 or K2) to rinse contact. Set it on NO

(normally open).

Define the rinse interval and rinse time according to the process requirements.

Transmitter Trb 8300

Define rinse interval and rinse time according to the process

requirements on the transmitter Trb 8300.

Page 23

EasyClean100/150 23

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

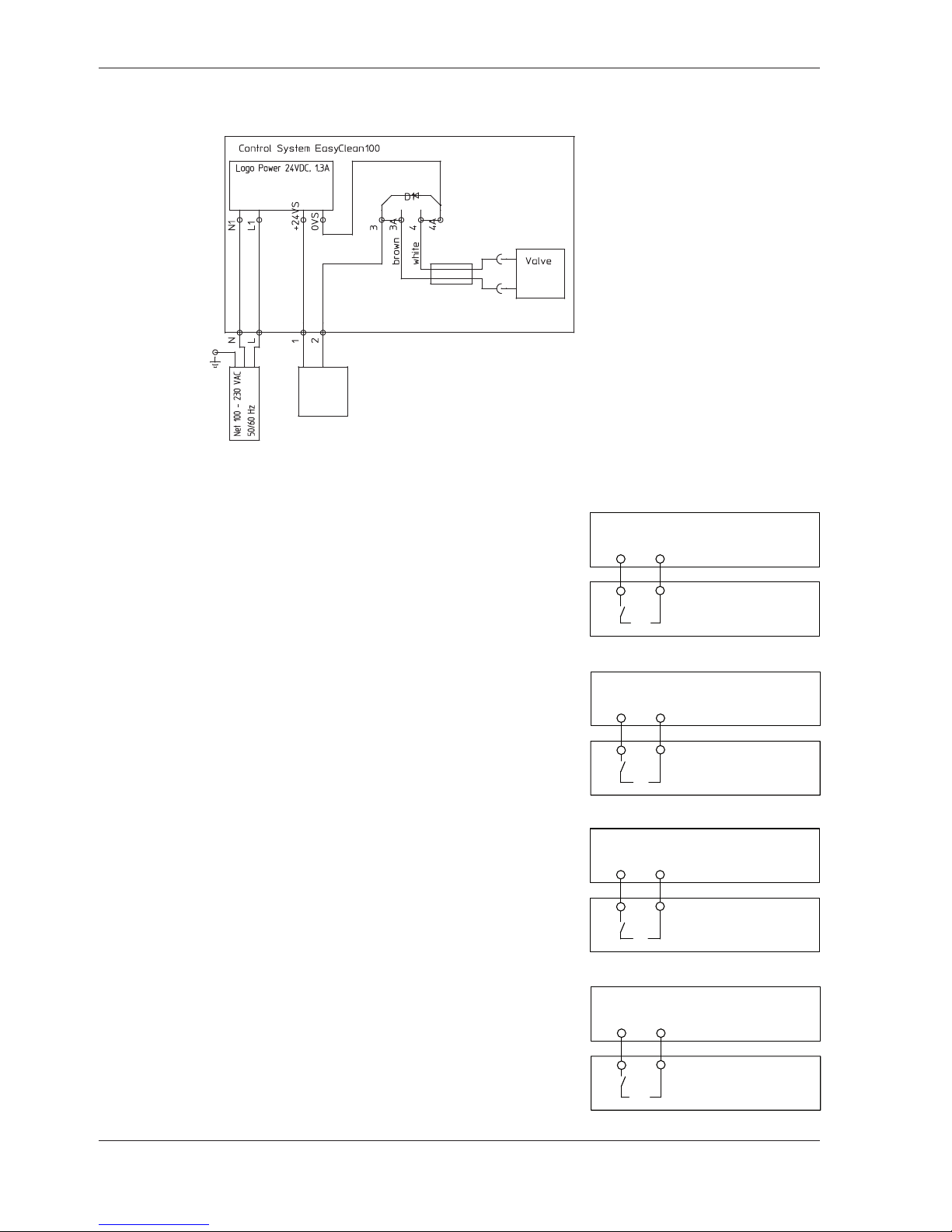

Electrical connections EasyClean150 with Mettler-Toledo transmitters

EasyClean100 and 150 are designed to work together with Mettler Toledo transmitters.

Please consult relevant instruction manuals of third party transmitters for proper installation.

EasyClean 150

X

100 e

1

Inp. 1

+24 VDC

TAO

17

18

6

7

Wash

Hold

2

4

3

EasyClean 150

M300

1

Inp. 1

+24 VDC

TAO

2

1

7

8

TB2

Hold

2

4

3

TB1(1/2 DIN)

o

r

TB1B (1/4 DIN)

EasyClean 150

M700

1

Inp. 1

+24 VDC

TAO

3

4

11

13

OK1

2

4

3

K3

EasyClean 150

Trb 8300

1

Inp. 1

+24 VDC

Hold

2

4

3

Wash

TB5/6

TB5/5

TB2/6

TB2/2

Transmitter X100 e

NOTICE

Bridge terminal 2 and 3 in the EasyClean 150.

Define rinse interval and rinse time according to the process

requirements on the transmitter X100 e.

Transmitter M300

NOTICE

Bridge terminal 2 and 3 in the EasyClean 150.

Set relay #1 (default) or #2, #3, #4 on the transmitter to

rinse contact.

Define rinse interval and rinse time according to the process

requirements on the transmitter M300.

Transmitter M700

NOTICE

Bridge terminal 2 and 3 in the EasyClean 150.

Set relays K3 (or K1 or K2) to rinse contact and NO (normally open). Define the rinse interval and rinse time according to

the process requirements.

Set input OK1 to HOLD (active 10–30 V) for the external hold

signal.

Transmitter Trb 8300

Define rinse interval and rinse time according to the process

requirements on the transmitter Trb 8300.

Electrical connections

Page 24

24 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

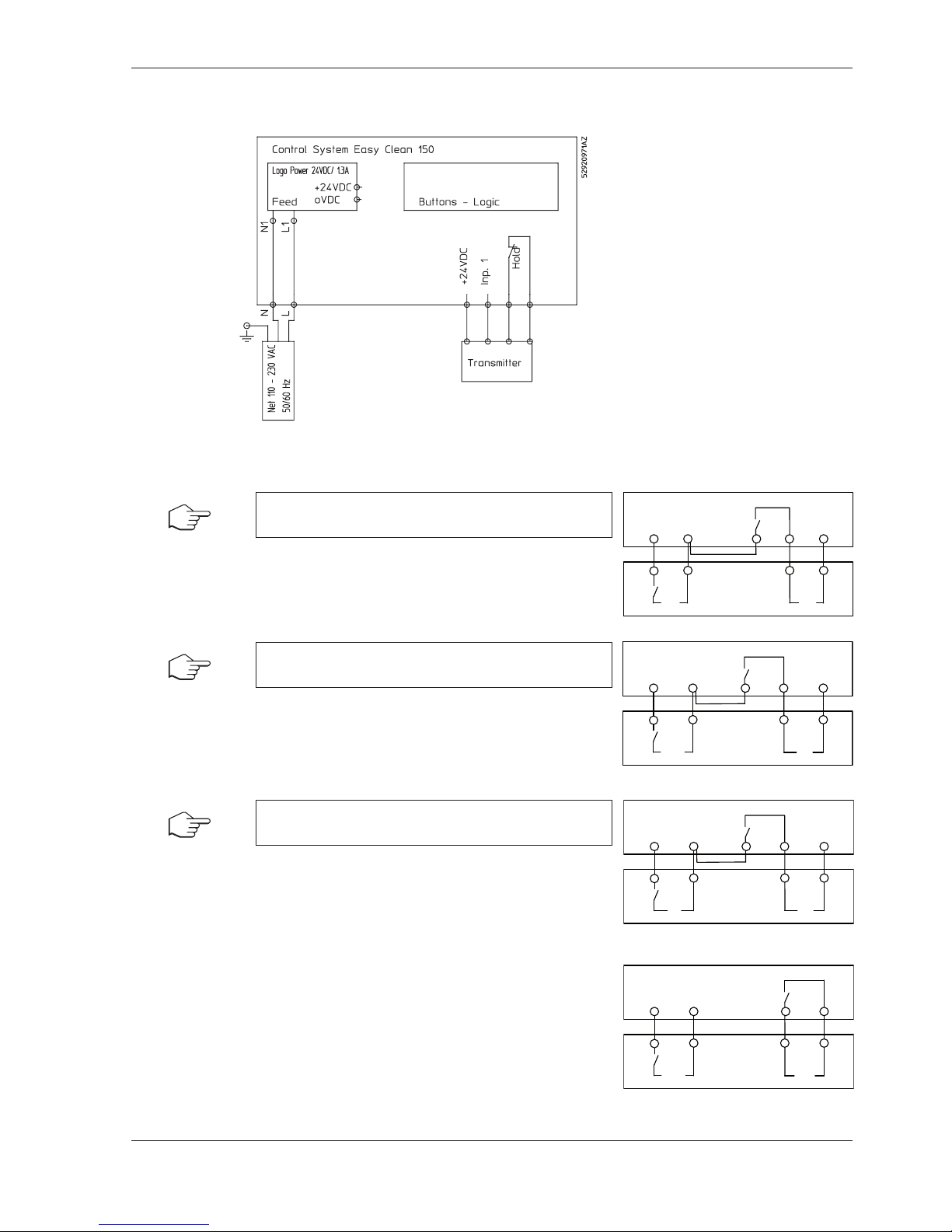

b

c

d

a

4.3 Installation and commissioning

a Push the spray head over the end

of the InDip housing that is to be

immersed. The distance between

the air outlet opening and the electrode should be approx. 1 cm.

b Install the hose system as follows:

Place a screw in the holding band

on the InDip housing, and use this

screw to secure the bracket to the

upper end of the housing.

c Insert the hose between the spray

head and the bracket as follows:

First of all, loosen the hose screw.

Push the hose by hand, without the

use of any tools, into the screw

housing, tighten the screw.

d Secure the loose hose to the tube

of the InDip housing using a cable

binder.

EasyClean100

1. Fit the EasyClean to a wall or a pipe/post, so that the connections are facing downwards.

2. Connect the transmitter to the EasyClean device (see section 4.2 ”Connections”).

3

. Connect compressed air and water from the building, taking care to ensure that the media

pressure does not exceed the specified device pressure. (see section 1.3 ”Data and key

characteristics”)

4. Connect hoses to the compressed air/water output and install the corresponding housing

c

onnections.

5. Connect the main cable.

Terminal for

N and L wires

Cable sleeve

When connecting the grounding wire use the

supplied blade terminals.

Crimp the terminals from both sides.

6. Fitting the spray head for the EasyClean100:

Page 25

EasyClean100/150 25

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

EasyClean150 1. Connect the hoses to the EasyClean as described in section 3.3 ”Integration into a

measurement system”.

2. For the correct way to connect to the retractable housing, please refer to the corresponding

manual. Please note that no position indicator can be connected to the EasyClean150.

However, to monitor its function it is possible to used pneumatic check-back position

indicators, which indicate the position of the sensor.

3. Check before commissioning:

• Are compressed air and rinsing water correctly connected?

• Are all hose connections carefully (not bent!) secured?

4. First commissioning of the EasyClean150

• Connect the EasyClean to the power supply.

• Open the main tap (if available) for compressed air and water.

• Extend/retract the housing using the ”IN/OUT” push button.

• In extended position (maintenance) the LED must not lit and the transmitter must

be in ”HOLD” mode.

• Press the ”Water” push button ––> water valve opens.

• Release the ”Water” push button ––> water flow stops.

• Activate ”IN/OUT” push button ––> housing changes the position.

5. Control via transmitter

• Activate the transmitter’s washing contact (see transmitter manual).

• Check whether the valves are activated by the transmitter signal.

––> The housing must move and the water valve must be opened at the same time.

• The time interval for the washing contact is set on the transmitter (see transmitter

manual).

• When the time interval has expired, the water valve closes and the housing returns

to the measurement position.

7 Check before commissioning:

•

Are compressed air and rinsing water correctly connected?

• Are all hose connections carefully (not bent!) secured?

8. First commissioning of the EasyClean100

• Connect the EasyClean to the power supply.

• Open the main tap (if available) for compressed air and/or water.

9. Control via transmitter

•

Check whether the valves are activated by the transmitter signal.

––> Compressed air discharge by the spray head.

• Submerge the spray head under water and set the air volume to the required flow rate.

The air throughput can be regulated using a reducing valve.

Page 26

26 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

5 Operation

5.1 Checks by the operator

When switching the device on, every day and when a new shift starts, check whether a

sufficient supply of: compressed air, rinsing water and electrical power is guaranteed,

and that the housing is functioning smoothly. For any kind of maintenance work on the

housing, please refer to the relevant manual.

5.2 Operating the EasyClean100

The EasyClean100 has no actuators. Its function can only be tested via the transmitter’s

wash contact.

If its function can no longer be guaranteed, please refer to section 6.2 ”Fault elimination

for the EasyClean100”.

5.3 Operating the EasyClean150

1 ”IN/OUT” push button

housing movement (retract,

extend)

2 ”Water” push button

opens the water valve (only

active as long as the button

is pressed).

3 Operational status indicator

(LED)

LED is lit when the housing

is in the measuring position.

Operating the EasyClean150

1. The housing can be moved using the ”IN/OUT” button.

2. If the housing is in maintenance position (out of process), the LED indicator is not lit.

The LED indicator only shows the position of the push button for the housing position.

No direct testing of the housing position or function is possible.

If the LED indicator is not lit, the transmitter is in ”HOLD” mode.

3. Rinsing with water can only be activated manually in the maintenance position.

This cycle runs for as long as the button is pressed down. No timer is activated.

12

3

Page 27

EasyClean100/150 27

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

5.4 Procedure in the event of a failure in the power supply

EasyClean100

Failure in the

power supply

In the event of a power failure, all functions of the EasyClean100 cut out, with no impact on

the reading. The EasyClean100 is inactive. This means:

– The electrode continues to measure. If the transmitter is still being powered, the measure-

m

ent results can be used.

– The rinse function is closed. It is no longer possible to rinse the electrode.

NOTICE

When the power supply is reconnected the system is automatically returned to the state

specified by the transmitter.

EasyClean150

EasyClean valves are de-energized in the following positions.

– Water valve: closed

– Air valve: the housing or sensor moves out of the process and the transmitter

goes into ”HOLD” mode.

NOTICE

If the EasyClean150 is provided with power once more, the housing always moves into

the measuring position.

In the event of a loss of compressed air the sensor remains in its last position.

NOTICE

If the housing is in the process, it can be pushed into the maintenance position by means

of back pressure. In this case the transmitter continues to measure. As there is no indication

of the position of the housing, the EasyClean150 does not recognize the position of the

housing. A loss of compressed air does not, however, have any effect on the measurement.

Failure in the

power supply

Failure in the

compressed air supply

Page 28

28 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

6 Maintenance and fault elimination

If you have any questions about faults or repairs, please contact your local METTLER TOLEDO

customer service. The addresses may be found at the end of this instruction manual.

6.1 Maintenance

The EasyClean100/150 is very service reduced.

To remove dust, dirt and stains, the external surfaces of the device can be wiped with a soft,

damp cloth. If necessary a mild detergent can also be used.

CAUTION

The housing may not be cleaned with any solvent containing acetone.

For further cleaning (e.g. blowing out the housing), you may use filtered compressed air that

is free of oil and water (pressure < 6 bar/87 psi).

CAUTION

The inside of the housing may not be cleaned using a liquid or a damp cloth.

The spray head is made of PVC or PVDF. You may use diluted acids or alkalis to remove dirt.

Page 29

EasyClean100/150 29

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

6.2 Fault elimination and repairs

DANGER

Please refer to Chapter 2 ”Safety”!

Repair work may only be performed by specialists. Before the device is opened,

it must be disconnected from the power supply!

EasyClean100

Failure Cause Remedy

No air generated in the InDip housing Compressed air not switched on.

Air pressure too low.

Compressed air valve not

opening.

Air hoses incorrectly fitted (crimped) or

defective.

Spray head blocked.

Switch on compressed air.

Increase pressure.

Clean valve.

Check hoses for leaks, bends or any

kinks.

Clean the spray head.

Insufficient cleaning by the electrode Insufficient air flow.

Rinse interval too long and/or rinse

times too short.

Openings on the spray head are

blocked.

Air does not reach the electrode.

Increase the flow or clean the hoses

and spray head.

Shorten the interval on the transmitter,

increase rinse times.

Remove and clean the spray head.

Decrease the distance between the

spray head and the electrode tip.

Place the InDip housing somewhere

with less flow.

Increase pressure.

Rinsing does not start

(auto and/or manual)

The rinse interval from the transmitter is

not recognized by the device.

The valve is not receiving any power.

Check the cabling with reference to the

circuit diagram.

Check the power supply.

Page 30

30 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

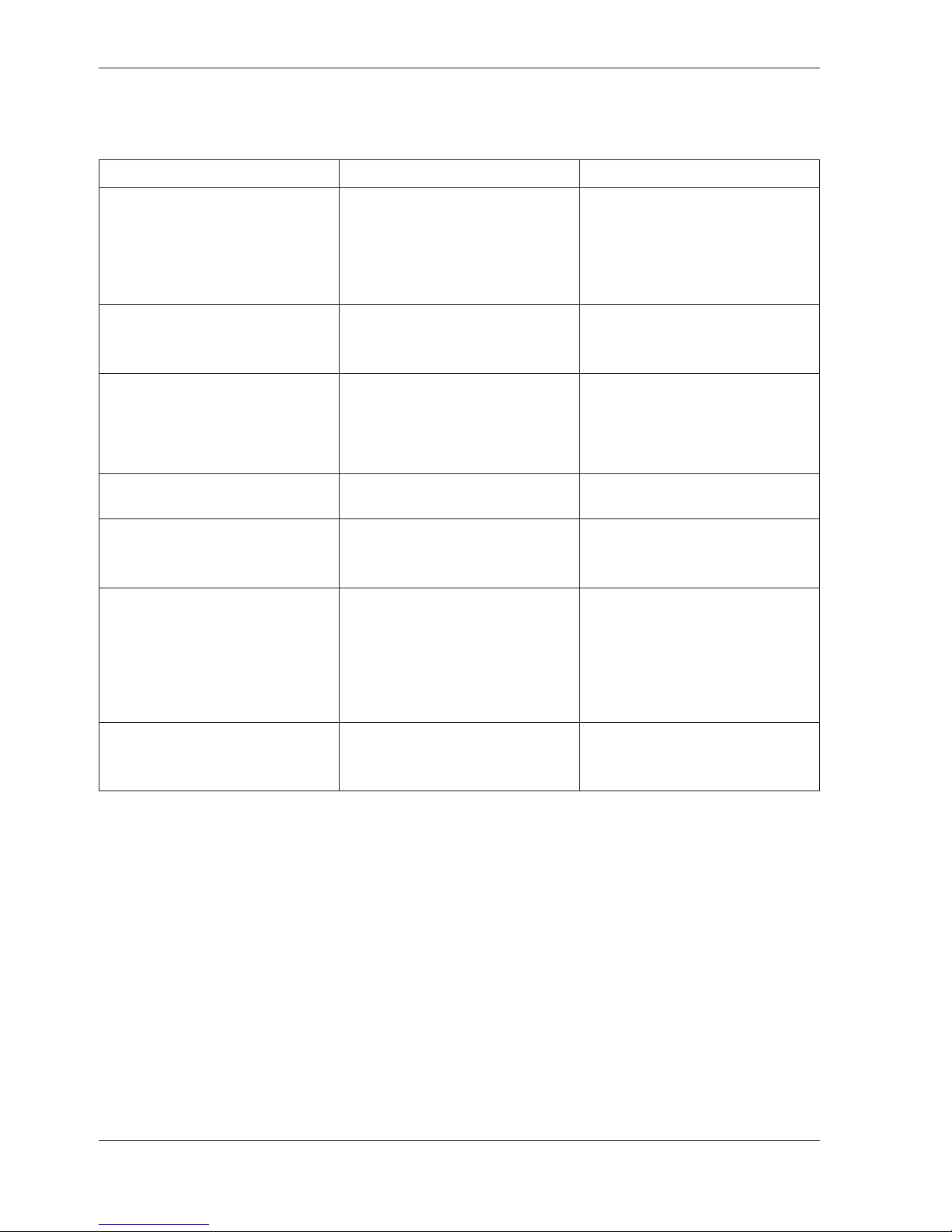

EasyClean150

Failure Cause Remedy

The InTrac housing does not move.

T

he sensor does not move out of or

into the process

Compressed air not switched on.

Air pressure too low.

Compressed air valve not opening.

Air hoses incorrectly fitted or defective.

Switch on compressed air.

Increase pressure (see specifications).

Clean valve.

Check hoses for leaks, bends or any

kinks.

The InTrac housing moves out of the

process independently

Compressed air pressure < process

pressure.

Sudden loss of pressure.

Increase air pressure

(see specifications).

Check connections and hoses for leaks.

Insufficient rinsing of the electrode Water flow insufficient.

Rinse interval too long.

Rinse times too short.

Rinsing chamber blocked.

Increase the flow.

Shorten the interval on the transmitter.

Increase rinse times.

Remove and clean the housing.

LED does not light LED defective / device working

normally.

No effect on functionality.

Transmitter does not go into

HOLD mode

Hold relay defective.

Connections for the transmitter are

loose or incorrectly connected.

Contact specialist.

Check connections and if necessary

re-install.

Rinsing cannot be activated Housing is in measuring position.

Rinse button defective.

Water valve defective..

No water flow.

Rinsing in measuring position not

possible.

Check cable. Contact supplier.

Clean water valve or replace if

necessary.

Check the lead to the EasyClean150.

Rinsing does not start

(auto and/or manual)

The rinse interval from the transmitter

is not recognized by the device.

The valve is not receiving any power.

Check the cabling with reference to

the circuit diagram.

Check the power supply.

Page 31

EasyClean100/150 31

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

7 Decommissioning, storage, disposal

DANGER

Please refer to chapter 2 ”Safety”.

Decommissioning may only be performed by trained staff or specialists.

7.1 Decommissioning

1. Switch off the power supply, the compressed air supply and the water supply to the device.

2. Disconnect the device from the main unit.

3. Disconnect any signal leads used.

4. Disconnect leads for compressed air.

5. Remove the EasyClean from its mounting.

6. Rinse the hoses and valves with fresh water.

7. Clean the device with a damp cloth.

8. Allow the device to dry.

7.2 Storage

Store the EasyClean in a dry place, as described in section 1.3.

7.3 Disposal

It is recommended that the operator dispose of the device in accordance with local regulations.

The operator must deliver the device to either a licensed private or a public disposal company

or dispose of it himself in accordance with prevailing regulations.

Waste is to be recycled or disposed of without causing any risk to human health and without

using procedures or methods that might damage the environment.

EC guidelines 75/442/EEC

91/156/EEC

Procedure

Sorting takes place by placing the device into waste groups as listed in the current European

Waste Catalogue (EWC). This catalogue is valid for all waste, whether it is intended for disposal

or recycling.

The packaging contains the following materials:

– cardboard

– foam plastic

The device contains the following materials:

– steel

– electronic materials (cables, components)

– various components as described in the printed description

– the spray head consists of PVC or PVDF (depending on the version ordered).

Sorting

Page 32

32 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

8 Spare parts and accessories

When ordering spare parts, please state the following details:

–

article number of the device

– serial number of the device

– ordering number from the following list of spare parts

– quantity required.

The addresses of manufacturers and customer services may be found at the end of this

instruction manual.

NOTICE

Spare parts must correspond to the technical requirements of the manufacturer of the device!

Only use original spare parts.

8.1 List of spare parts and accessories EasyClean100

Page 33

EasyClean100/150 33

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

14

15

Pos. Art. no. Description

1 52 402 291 Spray head for InDip550/ PVC

2 52 402 290 Spray head for InDip550/ PVDF

3 52 402 370 Fitting set for spray head

4 52 402 306 Wall mounting kit, complete

5 52 402 308 Mast mounting kit, complete

6 52 402316 Weatherproof hood

7 52 402 283 Tubing PTFE Ø 6/4 mm, 5 m / 15 ft.

8 52 402 314 Hose LDPE Ø 6/4 mm / 20 m, for compressed air connection

9 52 402 337 Fittingset pneum./hydr.

10 52 402 336 Grommet set for cable

11 52 300 265 Connecting cable: control unit > transmitter (5 m)

12 52 300 266 Connecting cable: control unit > transmitter (10 m)

13 52 402 317 Panic button (emergency shutdown)

14 52 402 305 Power unit

15 52 402 309 Water valve

52 500 178 Instruction manual EasyClean100/150

Page 34

34 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

8.2 List of spare parts and accessories EasyClean150

12

13

14

15

Page 35

EasyClean100/150 35

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

Pos. Art. no. Description

1 52 402 306 Wall mounting kit, complete

2

52 402 308 Mast mounting kit, complete

3

52 402316 Weatherproof hood

4 52 402 283 Tubing PTFE Ø 6/4 mm, 5 m / 15 ft.

5 52 402 314 Hose LDPE Ø 6/4 mm / 20 m, for compressed air connection

6 52 401 322 Pneumatics hose PU Ø 6/4 mm, 10 m

7 52 402 337 Fittingset pneum./hydr.

8 52 402 336 Grommet set for cable

9 52 300 265 Connecting cable: control unit > transmitter (5 m)

10 52 300 266 Connecting cable: control unit > transmitter (10 m)

11 52 402 317 Panic button (emergency shutdown)

12 52 402 305 Power unit

13 52 402 338 Print EasyClean150

14 52 402 309 Water valve

15 52 402 320 Compressed air valve

52 500 178 Instruction manual EasyClean100/150 (g/e/f)

Page 36

Management System

certified according to

ISO 9001 / ISO 14001

9001

certified

ISO

140 01

certified

ISO

METTLER TOLEDO Market Organizations

Sales and Service:

Australia

Mettler-Toledo Ltd.

220 Turner Street

Port Melbourne

AUS- 3207 Melbourne/VIC

Phone +61 1300 659 761

Fax +61 3 9645 3935

e-mail info.mtaus@mt.com

Austria

Mettler-Toledo Ges.m.b.H.

Südrandstraße 17

A-1230 Wien

Phone +43 1 604 19 80

Fax +43 1 604 28 80

e-mail infoprocess.mtat@mt.com

Brazil

Mettler-Toledo Ind. e Com. Ltda.

Avenida Tamboré, 418

Tamboré

BR- 06460-000 Barueri/SP

Tel. +55 11 4166 7400

Fax +55 11 4166 7401

e-mail mettler@mettler.com.br

service@mettler.com.br

China

Mettler-Toledo Instruments

(Shanghai) Co. Ltd.

589 Gui Ping Road

Cao He Jing

CN- 200233 Shanghai

Phone +86 21 64 85 04 35

Fax +86 21 64 85 33 51

e-mail mtcs@public.sta.net.cn

Croatia

Mettler-Toledo d.o.o.

Mandlova 3

HR-10000 Zagreb

Phone +385 1 292 06 33

Fax +385 1 295 81 40

e-mail mt.zagreb@mt.com

Czech Republic

Mettler-Toledo s.r.o.

Trebohosticka 2283/2

CZ-100 00 Praha 10

Phone +420 2 72 123 150

Fax +420 2 72 123 170

e-mail sales.mtcz@mt.com

Denmark

Mettler-Toledo A/S

Naverland 8

DK- 2600 Glostrup

Phone +45 43 27 08 00

Fax +45 43 27 08 28

e-mail info.mtdk@mt.com

France

Mettler-Toledo

Analyse Industrielle S.A.S.

30, Boulevard de Douaumont

F-75017 Paris

Phone +33 1 47 37 06 00

Fax +33 1 47 37 46 26

e-mail mtpro-f@mt.com

Germany

Mettler-Toledo GmbH

Prozeßanalytik

Ockerweg 3

D-35396 Gießen

Phone +49 641 507 333

Fax +49 641 507 397

e-mail prozess@mt.com

Great Britain

Mettler-Toledo LTD

64 Boston Road, Beaumont Leys

GB- Leicester LE4 1AW

Phone +44 116 235 7070

Fax +44 116 236 5500

e-mail enquire.mtuk@mt.com

Hungary

Mettler-Toledo Kereskedelmi KFT

Teve u. 41

HU-1139 Budapest

Phone +36 1 288 40 40

Fax +36 1 288 40 50

e-mail mthu@axelero.hu

India

Mettler-Toledo India Private Limited

Amar Hill, Saki Vihar Road

Powai

IN- 400 072 Mumbai

Phone +91 22 2857 0808

Fax +91 22 2857 5071

e-mail sales.mtin@mt.com

Italy

Mettler-Toledo S.p.A.

Via Vialba 42

I-20026 Novate Milanese

Phone +39 02 333 321

Fax +39 02 356 2973

e-mail

customercare.italia@mt.com

Japan

Mettler-Toledo K.K.

Process Division

6F Ikenohata Nisshoku Bldg.

2-9-7, Ikenohata

Taito-ku

JP-110-0008 Tokyo

Phone +81 3 5815 5606

Fax +81 3 5815 5626

e-mail helpdesk.ing.jp@mt.com

Malaysia

Mettler-Toledo (M) Sdn Bhd

Bangunan Electroscon Holding, U 1-01

Lot 8 Jalan Astaka U8/84

Seksyen U8, Bukit Jelutong

MY- 40150 Shah Alam Selangor

Phone +60 3 78 44 58 88

Fax +60 3 78 45 87 73

e-mail

MT-MY.CustomerSupport@mt.com

Mexico

Mettler-Toledo S.A. de C.V.

Ejercito Nacional #340

Col. Chapultepec Morales

Del. Miguel Hidalgo

MX- 11570 México D.F.

Phone +52 55 1946 0900

e-mail ventas.lab@mt.com

Poland

Mettler-Toledo (Poland) Sp.z.o.o.

ul. Poleczki 21

PL- 02-822 Warszawa

Phone +48 22 545 06 80

Fax +48 22 545 06 88

e-mail polska@mt.com

Russia

Mettler-Toledo Vostok ZAO

Sretenskij Bulvar 6/1

Office 6

RU-101000 Moscow

Phone +7 495 621 56 66

Fax +7 495 621 63 53

e-mail inforus@mt.com

Singapore

Mettler-Toledo (S) Pte. Ltd.

Block 28

Ayer Rajah Crescent #05-01

SG-139959 Singapore

Phone +65 6890 00 11

Fax +65 6890 00 12

+65 6890 00 13

e-mail precision@mt.com

Slovakia

Mettler-Toledo s.r.o.

Hattalova 12/A

SK- 83103 Bratislava

Phone +421 2 4444 12 20-2

Fax +421 2 4444 12 23

e-mail predaj@mt.com

Slovenia

Mettler-Toledo d.o.o.

Pot heroja Trtnika 26

SI-1261 Ljubljana-Dobrunje

Phone +386 1 530 80 50

Fax +386 1 562 17 89

e-mail keith.racman@mt.com

South Korea

Mettler-Toledo (Korea) Ltd.

Yeil Building 1 & 2 F

124-5, YangJe-Dong

SeCho-Ku

KR-137-130 Seoul

Phone +82 2 3498 3500

Fax +82 2 3498 3555

e-mail Sales_MTKR@mt.com

Spain

Mettler-Toledo S.A.E.

C/Miguel Hernández, 69-71

ES- 08908 L’Hospitalet de Llobregat

(Barcelona)

Phone +34 902 32 00 23

Fax +34 902 32 00 24

e-mail mtemkt@mt.com

Sweden

Mettler-Toledo AB

Virkesvägen 10

Box 92161

SE-12008 Stockholm

Phone +46 8 702 50 00

Fax +46 8 642 45 62

e-mail sales.mts@mt.com

Switzerland

Mettler-Toledo (Schweiz) GmbH

Im Langacher

Postfach

CH- 8606 Greifensee

Phone +41 44 944 45 45

Fax +41 44 944 45 10

e-mail salesola.ch@mt.com

Thailand

Mettler-Toledo (Thailand) Ltd.

272 Soi Soonvijai 4

Rama 9 Rd., Bangkapi

Huay Kwang

TH-10320 Bangkok

Phone +66 2 723 03 00

Fax +66 2 719 64 79

e-mail

MT-TH.CustomerSupport@mt.com

USA/ Canada

METTLER TOLEDO

Process Analytics

900 Middlesex Turnpike, Bld. 8

Billerica, MA 01821, USA

Phone +1 781 301 8800

Freephone +1 800 352 8763

Fax +1 781 271 0681

e-mail mtprous@mt.com

Mettler-Toledo AG, Process Analytics

Im Hackacker 15, CH-8902 Urdorf, Switzerland

Tel. + 41 44 729 62 11, Fax +41 44 729 66 36

www.mt.com/pro

Subject to technical changes.

© Mettler-Toledo AG, Process Analytics

11/14 Printed in Switzerland. 52 500 178

Page 37

EasyClean100/150 37

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

EasyClean100

EasyClean150

Bedienungsanleitung

Page 38

38 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

Produkt- und Unterhaltsjournal

D

atum Tätigkeit Durchgeführt Abgenommen

durch von

Erstinstallation

Page 39

EasyClean100/150 39

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

Verwendung dieser Betriebsanleitung

D

iese Betriebsanleitung ist integrierender Bestandteil von EasyClean100 und EasyClean150

und enthält wichtige Hinweise und Instruktionen für Sicherheit und Betrieb.

Alle Personen, die an und mit EasyClean100 und/oder EasyClean150 Arbeiten ausführen,

m

üssen vorgängig die für ihre Tätigkeit relevanten Kapitel gelesen und verstanden haben.

Lesen Sie diese Betriebsanleitung vor Gebrauch des EasyClean-Systems sorgfältig durch.

Bewahren Sie dieses Dokument in unmittelbarer Umgebung des Gerätes auf, um ein späteres

Nachschlagen durch das Bedienungspersonal jederzeit zu ermöglichen.

Lesen Sie zuerst das Kapitel 2 «Sicherheit»!

© Der Nachdruck dieser Betriebsanleitung, auch auszugsweise, ist verboten.

Ohne schriftliche Bewilligung der Firma Mettler-Toledo AG, Process Analytics, CH-8902 Urdorf, dürfen keine Teile

davon in irgendeiner Form reproduziert oder unter Anwendung elektronischer Systeme, insbesondere in Form von

Photokopien, Photos, Magnetverfahren oder anderen Aufzeichnungsarten, verarbeitet, vervielfältigt oder verbreitet

werden.

Alle Rechte, insbesondere das Recht der Vervielfältigung und Übersetzung sowie Patent- oder Registrierungsrechte,

sind vorbehalten.

InTrac, InDip sind registrierte Handelsmarken von Mettler-Toledo AG, CH-8606 Greifensee.

Page 40

40 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

Inhaltsverzeichnis

1 Produktbeschreibung 41

1.1 Einleitung 41

1

.2 Ausstattung und Lieferumfang 41

1.3 Daten und Kenngrössen EasyClean 100/150 42

2 Sicherheit 44

2.1 Einleitung 44

2.2 Bestimmungsgemässe Verwendung 44

2.3 Nicht bestimmungsgemässe Verwendung 44

2.4 Grundsätze 45

2.5 Warnhinweise und Symbole 45

2.6 Verantwortlichkeiten, Organisatorische Massnahmen 46

2.7 Produktspezifische Gefahren 47

2.8 Restgefahren 47

2.9 Massnahmen im Notfall 47

2.10 Sicherheitsmassnahmen 48

2.11 Modifikationen 48

3 Ihr Gerät 49

3.1 Aufbau 49

3.2 Funktionen 50

3.3 Integration in ein Messsystem 51

4 Inbetriebnahme 52

4.1 Montage 52

4.2 Anschlüsse 54

4.3 Installation und Inbetriebnahme 58

5 Bedienung 60

5.1 Kontrollen durch den Bediener 60

5.2 Bedienung EasyClean 100 60

5.3 Bedienung EasyClean 150 60

5.4 Verhalten bei Ausfall der Energieversorgung 61

6 Wartung und Störungsbehebung 62

6.1 Wartung 62

6.2 Störungsbehebung und Instandsetzung 63

7 Ausserbetriebsetzung, Lagerung, Entsorgung 65

7.1 Ausserbetriebsetzung 65

7.2 Lagerung 65

7.3 Entsorgung 65

8 Ersatzteile und Zubehör 66

8.1 Ersatzteilliste und Zubehör für EasyClean 100 66

8.2 Ersatzteilliste und Zubehör für EasyClean 150 68

Page 41

EasyClean100/150 41

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

1 Produktbeschreibung

1.1 Einleitung

Konfomität EasyClean 100 und EasyClean150 entsprechen folgenden Bestimmungen:

• Niederspannungsrichtlinien:

– EU Richtlinien 73/23/EG

–

Schweizer Richtlinie SR734.26NEV

– Sicherheitsbestimmungen EN61010-1

– IP-Schutzgrad EN60529 IP65

• EMV-Richtlinien:

– Emission EN61326-1, Klasse B

– Oberschwingungen EN61000-3-2

– Spannungsschwankungen EN61000-3-3

– Immunität EN61326-1

Zertifikate CE, GS

Kennzeichnung Das Typenschild befindet sich auf der linken Aussenseite der Geräte.

1.2 Ausstattung und Lieferumfang

Lieferumfang EasyClean-Geräte werden ohne Anschlusskabel geliefert. Die bauseitigen Anschlusskabel

werden an den dafür bestimmten Klemmen im Gerät angeschlossen (beachten Sie dazu

Abschnitt 4.2 «Anschlüsse»).

Verpackung

Die Verpackung besteht aus Karton und Kartonpolsterung.

Bewahren Sie die Verpackung, für eine spätere Lagerung oder einen Transport des Geräts, auf.

Falls Sie die Verpackung jedoch entsorgen wollen, beachten Sie die lokalen Vorschriften sowie

Abschnitt 7.3 «Entsorgung».

Achten Sie beim Auspacken auf Beschädigungen. Falls Sie solche feststellen, melden Sie dies

umgehend dem Transporteur und ihrem Lieferanten.

Überprüfen Sie die Lieferung anhand Ihrer Bestellung und der Lieferpapiere.

Kontrolle der Lieferung

Page 42

42 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

1.3 Daten und Kenngrössen EasyClean100/150

Gehäuse mit Polyesterharz pulverbeschichtetes Stahlgehäuse

M

aterial: Vergütungsstahl DIN 1.1203 Ck55

Achtung: darf nicht mit azetonhaltigen Lösungsmitteln

g

ereinigt werden

Gewicht Steuergerät ca. 3 kg (6.6 lb)

S

chutzart IP65

Umgebungsbedingungen Temp. Betrieb: 0 – 45°C (+32 – +113 °F)

Temp. Transport/Lagerung: –10 – +70°C (+14 – +158°F)

Verschmutzungsgrad: 2

Überspannungskategorie: III

Spannungsversorgung 100 – 230V AC, 50/60 Hz, 0.18 – 0.3 A (± 15%)

Systemsteuerung Prozessauslösung:

durch einen Waschkontakt des angeschlossenen Transmitters

Ablauf:

nicht im Gerät einstellbar

Steuereingänge 1 Steuereingang für Waschkontakt vom Transmitter, 24V

Transmitter METTLER TOLEDO Transmitter:

– pH2050e, O

2

4050e, Cond 7050e

– pH2100e, O24100e, CondI7100e, Trb8300

– alternativ durch Transmitter mit Waschkontakt und

«Hold»-Funktion

Anschlüsse Anschlussklemmen 0.08 ... 2.5 mm

2

Verbindung zum Transmitter 4-adriges Steuerkabel, 1.5 mm

2

Länge: 5 m (optional 10 m)

Kabeldurchführungen Ø 3.5 – 10 mm => M 16

Druckluftversorgung 4– 8 bar (400 – 800 kPa, 58 – 116 psi)

– Luftqualität gemäss ISO 8573-1

– Luftfeuchte Klasse 4 (Wassertaupunkt +3° C)

– Feststoffe Klasse 5 (Filter 40 µm)

– max. Oelgehalt Klasse 2 (0.1 mg/m

3

)

Anschluss: Gewinde G1/8"

Page 43

EasyClean100/150 43

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

Verbindung zu InDip-Armatur Schlauch LDPE Ø 6/4 mm (1/8" / 1/4")

optional: Schlauch PTFE Ø 6/4 mm (1/8" / 1/4")

Verbindung zu Wechselarmatur Schlauch LDPE Ø 6/4 mm (1/8" / 1/4")

optional: Schlauch PTFE Ø 6/4 mm (1/8" / 1/4")

Versorgung Spülwasser Druck: 2 – 6 bar (200 – 600 kPa, 29 – 87 psi)

Anschluss: Innengewinde G1/4"

A

dapter:

1

/4"

NPT Aussengewinde (PP)

Sprühkopfmaterial PVC, PVDF

Materialien in Berührung PP, LDPE, Viton

®

, Messing,

mit Spülwasser oder Druckluft rostfreier Stahl DIN 1.4105, 1.4303, 1.4310

Medien in Verbindung mit Wasser 0 – 60 °C (32 °F – 140 °F)

LDPE-Schlauch

Medien in Verbindung mit Wasser 0 – 90 °C (32 °F – 194 °F)

PTFE-Schlauch

Technische Änderungen vorbehalten

Page 44

44 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

2 Sicherheit

2.1 Einleitung

Die Betriebsanleitung enthält die wichtigsten Angaben, um EasyClean100/150 und den Sprühkopf effizient und bestimmungsgemäss zu nutzen. Grundvoraussetzung für den sicherheits g

erechten Umgang und den störungsfreien Betrieb ist die Kenntnis dieser Sicherheits vorschriften

und die Beachtung der weiteren Warnhinweise in der Betriebsanleitung.

Diese Betriebsanleitung, insbesondere die Sicherheitsvorschriften, sind vom Betreiber und allen

Personen zu beachten, die mit EasyClean100/150 oder dem Sprühlkopf arbeiten. Darüber

hinaus sind die für den Einsatzort geltenden Regeln und gesetzlichen Vorschriften zu beachten.

Die Betriebsanleitung muss ständig griffbereit aufbewahrt werden und für jede Person, die mit

Easy Clean 100/150 oder dem Sprühkopf arbeitet, zugänglich sein.

2.2 Bestimmungsgemässe Verwendung

EasyClean100/150 und der Sprühkopf sind ausschliesslich für Spülen und Reinigen von

Sensoren bestimmt und wie in dieser Betriebsanleitung beschrieben einsetzbar.

Zur bestimmungsgemässen Verwendung gehören zudem:

– Die Beachtung der Anweisungen, Vorschriften und Hinweise in der vorliegenden

Betriebsanleitung.

– Die korrekte Instandhaltung und Pflege des Gerätes gemäss dieser Betriebsanleitung.

– Der Betrieb unter der Beachtung der vorgeschriebenen Umwelt- und Betriebsbedingungen

und den zulässigen Einbaulagen.

– Die Einhaltung der örtlichen Gesetzgebung

2.3 Nicht bestimmungsgemässe Verwendung

Jede andere als die oben erwähnte Verwendung sowie jede Anwendung, die nicht den technischen Daten entspricht, gilt als nicht bestimmungsgemäss. Für allfällige Schäden, die auf eine

solche Verwendung zurückzuführen sind, trägt der Betreiber das alleinige Risiko.

Insbesondere folgende Anwendungen sind unzulässig:

– Verwendung von Hydraulikflüssigkeiten anstelle von Druckluft

– Verwendung von Suspensionen und Lösungsmittel als Reinigungsmittel

Page 45

EasyClean100/150 45

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

2.4 Grundsätze

EasyClean100/150 und der Sprühkopf sind nach dem Stand der Technik und den anerkannten

sicherheits technischen Regeln gebaut.

Dennoch können von dem Gerät Risiken und Gefahren ausgehen:

–

wenn das Gerät von ungenügend ausgebildeten Personen bedient wird.

– wenn das Gerät nicht bestimmungsgemäss verwendet wird.

EasyClean100/150 und der Sprühkopf dürfen nur in technisch einwandfreiem Zustand sowie

b

estimmungsgemäss, sicherheits- und gefahrenbewusst unter Beachtung der Betriebsanleitung

benutzt werden.

Störungen oder Beschädigungen, die die Sicherheit und Funktion beeinträchtigen, sind umgehend durch den Betreiber oder einer Fachperson zu beseitigen und dem Hersteller schriftlich

zu melden!

2.5 Warnhinweise und Symbole

In dieser Betriebsanleitung werden folgende Symbole zur Kennzeichnung von Sicherheitshin weisen benutzt:

GEFAHR!

Warnung vor einer Gefahr, die zu hohem Sachschaden, zum Tode oder zu schweren Körperverletzungen führen kann.

VORSICHT!

Warnung vor einer möglicherweise gefährlichen Situation, welche zu leichten Körperver letzungen und/oder Sachschäden führen kann.

HINWEIS!

Information, die auf technische Erfordernisse hinweist. Nichtbefolgung kann zu Störungen,

Unwirtschaftlichkeit und evtl. zu Produktionsverlusten führen.

Page 46

46 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

2.6 Verantwortlichkeiten, Organisatorische Massnahmen

Verpflichtung des

B

etreibers

– Der Betreiber verpflichtet sich, nur Personen an EasyClean arbeiten zu lassen, die mit den

g

rundlegenden Vorschriften über Arbeitssicherheit und Unfallverhütung vertraut und in die

Handhabung des Geräts eingewiesen sind. Die vorliegende Bedienungsanleitung gilt hierfür

a

ls Grundlage.

– Ergänzend zur Betriebsanleitung sind allgemeingültige gesetzliche und sonstige verbindliche

Regelungen zur Arbeitssicherheit und Unfallverhütung sowie zum Umwelt schutz durch den

B

etreiber bereitzustellen und zu instruieren.

– Sicherheits- und gefahrenbewusstes Arbeiten des Personals ist in regelmässigen Abständen

zu überprüfen.

– Massnahmen sind zu treffen, damit EasyClean nur in sicherem, funktionsfähigem Zustand

betrieben wird.

Verpflichtung des

Personals

– Alle Personen, die mit Arbeiten an EasyClean beauftragt sind, verpflichten sich, das Kapitel

Sicherheitsvorschriften und die Warnhinweise in dieser Betriebsanleitung zu lesen.

– Ergänzend zur Betriebsanleitung sind allgemeingültige gesetzliche und sonstige verbindliche

Regelungen zur Arbeitssicherheit und Unfallverhütung zu beachten.

– Jede sicherheitsbedenkliche Arbeitsweise welche die bestimmungsgemässe Verwendung

des Gerätes überschreitet, ist zu unterlassen.

Personalauswahl

und -qualifikation

– grundsätzliche Pflichten

– Arbeiten an EasyClean dürfen nur von zuverlässigem, geschultem oder unterwiesenem

Personal durchgeführt werden. Das Bedienungspersonal muss das diese Betriebsanleitung

vorgängig gelesen haben.

– Zuständigkeiten des Personals für das Bedienen, Warten, Instandsetzen etc. sind klar

festzulegen.

– Es ist sicherzustellen, dass nur dazu beauftragtes Personal am Gerät tätig wird.

– Zu schulendes, anzuweisendes oder im Rahmen einer allgemeinen Ausbildung befindliches

Personal darf nur unter ständiger Aufsicht einer erfahrenen Person am Gerät tätig werden.

– Arbeiten an der elektrischen Ausrüstung des Geräts dürfen nur von einer Elektrofachkraft

gemäss den elektrotechnischen Regeln vorgenommen werden.

Bauliche Veränderungen

am Gerät

– Es dürfen keine Veränderungen, An- und Umbauten am Gerät, die die Sicherheit beeinträch -

tigen, ohne schriftliche Genehmigung von Mettler-Toledo GmbH, Prozess Analytik vorge nommen werden.

– Teile in nicht einwandfreiem Zustand sind sofort auszutauschen.

Page 47

EasyClean100/150 47

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

2.7 Produktspezifische Gefahren

Gefährdung durch elektrische Energie!

Wenn das Gerät für die Durchführung von Installations- und Reparaturarbeiten geöffnet

wird, werden spannungsführende Teile freigelegt.

Schliessen Sie das Gerät nach Durchführung der Arbeiten sofort wieder!

Gefährdung durch Druckluft/Wasser!

Zu öffnende Druckleitungen (Druckluft, Spülwasser) vor Beginn von Reparaturarbeiten

absperren und drucklos machen!

2.8 Restgefahren

Trotz aller getroffenen Vorkehrungen bestehen Restgefahren wie z.B.:

– Bersten einer Leitung.

– Gefährdung durch Störung an einer übergeordneten Steuerung.

2.9 Massnahmen im Notfall

Falls Flüssigkeit in die Augen gelangt, sofort unter fliessendem Wasser mindestens

15 Minuten abspülen. Anschliessend muss ein Arzt zur Kontrolle aufgesucht werden.

Flüssigkeit auf der Haut sofort mit Wasser abwaschen.

Ärztliche Hilfe ist immer erforderlich bei Symptomen, die offensichtlich durch die Ein wirkung eines Kontaktes mit einem Medium auf Haut oder Augen zurückzuführen

sind. Informieren Sie den Arzt über Art und Kennzeichnung aller verwendeten Stoffe.

Page 48

48 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

2.10 Sicherheitsmassnahmen

Die lokalen Gesetze und Vorschriften müssen immer beachtet werden. Sie sind nicht Bestandteil

dieser Betriebsanleitung.

Das Tragen von persönlicher Schutzausrüstung wie Schutzbrille und Schutzkleidung ist

g

rundsätzlich erforderlich.

Das Gerät darf nur in geschlossenem Zustand betrieben werden.

D

er Betreiber ist für die Instruktion des Personals verantwortlich. Dazu kann diese Betriebs an leitung auch in weiteren Sprachen nachbestellt werden. Diese Betriebsanleitung muss als

Bestandteil des Gerätes jederzeit dem Bedienungspersonal am Einsatzort des Gerätes zur

Verfügung stehen.

Der Betreiber informiert den Hersteller umgehend über alle sicherheitsrelevanten Vorkommnisse,

die sich bei der Verwendung des Gerätes ereignen.

2.11 Modifikationen

Modifikationen sind nur nach Rücksprache und schriftlicher Genehmigung des Herstellers

gestattet.

Es dürfen nur die zur Erfüllung der Funktion bestimmten Teile des Gerätes ein- und ausgebaut

werden. Dies ist von Hand oder mit den mitgelieferten Werkzeugen möglich. Entfernen von

Schutzvorrichtungen und Abdeckungen unter Zuhilfenahme von handelsüblichen Werkzeugen

ist – ausser von autorisiertem Instandsetzungspersonal – verboten. Bei Berührung spannungsführender Teilen besteht Lebensgefahr.

Page 49

EasyClean100/150 49

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

3 Ihr Gerät

3.1 Aufbau

EasyClean100

1 Netzanschluss

2 Steuerkabelanschluss

3 Druckluft-/Wasseranschluss

4 Klemme Netzanschluss

1 Drucktaste «In/Out» (Armatursteuerung)

2 Meldeleuchte

3 Drucktaste «Water» (Wasser)

4 Netzanschluss

5 Steuerkabelanschluss

6 Druckluftanschluss

7 Abluftanschluss

8 Druckluftausgänge Armatur

EasyClean150

5 Klemme Steuerkabelanschluss

6 Druckluft-/Wasserventil

7 Netzteil

9 Wasseranschluss

10 Wasserventil

11 Druckluftventil

12 Netzteil

13 Steuerprint

14 Klemme Netzanschluss

15 Klemme Steuerkabelanschluss

4 5

7

6

21

5 6 74

1 3

10

11

12

13

14 15

2

8 9

3

Page 50

50 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

3.2 Funktionen

Allgemeines Das EasyClean100/150 steuert die Zufuhr von Druckluft resp. Wasser zu einer Elektrodenspitze,

welche in einer InDip-Armatur (EasyClean100) oder in einer Wechselarmatur (EasyClean150)

eingebaut ist. Der Ablauf wird durch den Waschkontakt des Transmitters ausgelöst und wieder

g

estoppt

B

etriebsarten

Der Transmitter übernimmt die gesamte Steuerung des Gerätes.

Grundstellung Die Ventile sind stromlos geschlossen.

Die InTrac-Armatur bleibt bei Druckausfall in der letzten Position stehen. Bei Stromausfall im

EasyClean 150 fährt der Sensor aus dem Prozess aus und der Transmitter geht in den «Hold Modus» (Messwert wird eingefroren).

Bei Stromausfall entfallen alle Funktionen des EasyClean100 ohne Einfluss auf die Messung.

Hold-Funktion

Für die genaue Funktion und Einstellungen des Hold-Relais konsultieren Sie die Betriebsanleitung des jeweiligen Transmitters.

Meldeleuchten EasyClean100 ist mit keinen Meldeleuchten ausgestattet.

EasyClean150 verfügt über eine Meldeleuchte (LED) welche in der Front eingebaut ist. Die

Leuchte ist mit dem Steuerungsventil welches die Armaturenbewegung auslöst gekopplet.

Es zeigt also keine Fehlfuktionen der Armatur, sondern nur den Tasterzustand an (Automatik betrieb oder in der ausgefahrenen «Service»-Position).

Programmablauf Die Spül- resp. Waschzeit wird durch das Steuersignal (wash contact) des Transmitters

vorgegeben. (siehe Betriebsanleitung des Transmitters).

Page 51

EasyClean100/150 51

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

3.3 Integration in ein Messsystem

In den nachfolgenden Schemas ist ein typisches Beispiel für die Integration von

EasyClean100 bzw. EasyClean150 in ein Mess system dargestellt.

EasyClean100

1 EasyClean150

2 Wasseranschluss

3 Wasserschlauch

4 Abwasserschlauch

5 Wandbefestigung

6 Wetterschutzdach (optional)

7 Druckluftschlauch (Eingang)

8 Druckluftschläuche (Armatur)

9/10 Steuerkabel

11 Not-Aus Schalter (optional)

1 EasyClean100

2 Druckluft-/Wasseranschluss

3 Druckluft- bzw. Wasserschlauch

4 Wandbefestigung

5 Wetterschutzdach (optional)

6/7 Sprühkopf

8 Druckluft- bzw. Wasserschlauch

9/10 Steuerkabel

11 Not-Aus Schalter (optional)

EasyClean150

Page 52

52 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

4 Inbetriebnahme

GEFAHR

Beachten Sie Kapitel 2 «Sicherheit».

Alle Arbeiten an elektrischen Komponenten des Systems dürfen nur durch autorisiertes

Fachpersonal durchgeführt werden.

HINWEIS

Gehen Sie bei der Inbetriebnahme gemäss Abschnitt 4.3 «Checkliste für Installation und

Inbetriebnahme» vor. Achten Sie auf die Verweise für weitergehende Informationen.

4.1 Montage

EasyClean100und 150 sind für direkte Montage (C-Schiene), Wand- oder Mastmontage

vor gesehen. EasyClean 100 und EasyClean150 sind im gleichen Gehäusetyp eingebaut

und haben dem zu Folge die gleichen Abmessungen.

Der Montageplatz muss eine ausreichende Festigkeit haben und möglichst vibrationsfrei sein.

Achten Sie darauf, dass die Leitungslängen möglichst kurz sind.

Wandmontage

Page 53

EasyClean100/150 53

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

Mastmontage

Das genaue Vorgehen bei der Montage der Aufhängung entnehmen Sie der separat beigelegten

Installationsanleitung.

Page 54

54 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

4.2 Anschlüsse

VORSICHT

Kontrollieren Sie vor dem Anschliessen, dass die Anschlusswerte gemäss Abschnitt

1.3 «Daten und Kenngrössen» eingehalten sind.

Anschlüsse am Gehäuseboden EasyClean100

1 Durchführung Netzkabel, M16

2 Durchführung Transmitterkabel, M16

3 Luft/Wasser Eingang G1/4" NPT, female

4 Ausgang zur InDip-Armatur (Schlauch Ø 6/4 mm)

Anschlüsse am Gehäuseboden EasyClean150

1 Durchführung Netzkabel, M16

2 Durchführung Transmitterkabel, M16

3 Drucklufteingang (Schlauch Ø 6/4 mm)

4 Abluft

5 Druckluftausgang zur InTrac-Armatur ––> Funktion: «Zurück»

6 Druckluftausgang zur InTrac-Armatur ––> Funktion: «Vor»

7 Wassereingang G

1

/4", female,

8 Ausgang zur Armatur (Schlauch Ø 6/4 mm)

Page 55

EasyClean100/150 55

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

HINWEIS

Z

weckmässigerweise wird für Wasser und Druckluft gebäudeseitig ein Absperrorgan in der

Nähe des EasyClean 100/150 installiert. Dies erleichtert Wartungsarbeiten und erhöht die

Arbeitssicherheit bei der Montage und Demontage des Gerätes.

Beachten Sie die örtlichen Vorschriften für Pneumatik- und Wasserinstallationen.

Anschlüsse an die

Eintaucharmatur

Der Sprühkopf ist für die Mettler-Toledo InDip550 ausgelegt. Wird der Sprühkopf mit einer

anderen Armatur benutzt, erfolgt das Betreiben und die Montage des Sprühkopfes auf die

Gefahr des Betreibers.

Für die Installation an der Wechselarmatur konsultieren Sie die entsprechende Betriebsanleitung

der Armatur.

Elektrische Anschlüsse Die EasyClean100 und 150 sind für die Mettler-Toledo Transmitter wie in Abschnitt 1.3

beschrieben ausgelegt. Für die korrekte Installation an anderen Transmittern konsultieren

Sie die jeweilige Anleitung.

GEFAHR

Der Netzanschluss darf nur durch autorisiertes Fachpersonal entsprechend den elektro-

technischen Regeln ausgeführt werden.

Für den gebäudeseitigen Netzanschluss beachten Sie auch die örtlichen Vorschriften.

Hinweis

Der Leitungsschutzschalter muss in der Gebäudeinstallation und in der Nähe des EasyCleanGerätes montiert sein.

Page 56

56 EasyClean100/150

© 11/14 Mettler-Toledo AG, CH-8606 Greifensee EasyClean100/150

Printed in Switzerland 52 500 178

Elektrische Anschlüsse EasyClean100 mit Mettler-Toledo Transmittern

T

ransmitter

EasyClean 100

X

100 e

1

Inp. 1

+24 VDC

17

18

Wash

2

EasyClean 100

M300

1

Inp. 1

+24 VDC

2

1

TB1(1/2 DIN)

or

TB1B (1/4 DIN)

2

EasyClean 100

M700

1

Inp. 1

+24 VDC

3

4

K3

2

EasyClean 100

Trb 8300

1

Inp. 1

+24 VDC

TB5/6

TB5/5

Wash

2

Elektrische Anschlüsse

Transmitter X100 e

Spülintervall und Spülzeit gemäss Applikationsbedingungen

am Transmitter X100 e einstellen.

Transmitter M300

Relais # 1 (Standardeinstellung) oder # 2, # 3, # 4 beim

Transmitter auf Spülkontakt setzen.

Spülintervall und Spülzeit gemäss Applikationsbedingungen

am Transmitter M300 einstellen.

Transmitter M700

Relais K3 (K1 oder K2) auf Spülkontakt und NO (Arbeits kontakt) setzen.

Spülintervall und Spülzeit gemäss Applikationsbedingungen

einstellen.

Transmitter Trb 8300

Spülintervall und Spülzeit gemäss Applikationsbedingungen

am Transmitter Trb 8300 einstellen.

Page 57

EasyClean100/150 57

EasyClean100/150 © 11/14 Mettler-Toledo AG, CH-8606 Greifensee

52 500 178 Printed in Switzerland

Elektrische Anschlüsse EasyClean150 mit Mettler-Toledo Transmittern

EasyClean100 und150 sind für die Mettler-Toledo Transmitter ausgelegt.

Für die korrekte Installation an anderen Transmittern konsultieren Sie die jeweilige Anleitung.

E

asyClean 150

X100 e

1

Inp. 1

+24 VDC

TAO

17

18

6

7

Wash

Hold

2

4

3

EasyClean 150

M300

1

Inp. 1

+24 VDC

TAO

2

1

7

8

TB2

H

old

2

4

3

TB1(1/2 DIN)

o

r

TB1B (1/4 DIN)

EasyClean 150

M700

1

Inp. 1

+24 VDC

TAO

3

4

11

13

OK1

2

4

3

K3

EasyClean 150

Trb 8300

1

Inp. 1

+24 VDC

Hold

2

4

3

Wash

TB5/6

TB5/5

TB2/6

TB2/2

Transmitter X100 e

HINWEIS

Brücke setzen an Klemme 2 und 3 im EasyClean 150.

Spülintervall und Spülzeit gemäss Applikationsbedingungen

am Transmitter X100 e einstellen.

Transmitter M300

HINWEIS

Brücke setzen an Klemme 2 und 3 im EasyClean 150.

Relais # 1 (Standardeinstellung) oder # 2, # 3, # 4 beim

Transmitter auf Spülkontakt setzen.

Spülintervall und Spülzeit gemäss Applikationsbedingungen

am Transmitter M300 einstellen.

Transmitter M700

HINWEIS

Brücke setzen an Klemme 2 und 3 im EasyClean 150.

Relais K3 (K1 oder K2) auf Spülkontakt und NO (Arbeits kontakt) setzen. Spülintervall und Spülzeit gemäss Applika tionsbedingungen einstellen.

Eingang OK1 auf HOLD setzen (aktiv 10…30V).

Transmitter Trb 8300

Spülintervall und Spülzeit gemäss Applikationsbedingungen

am Transmitter Trb 8300 einstellen.

Elektrische Anschlüsse

Page 58