Page 1

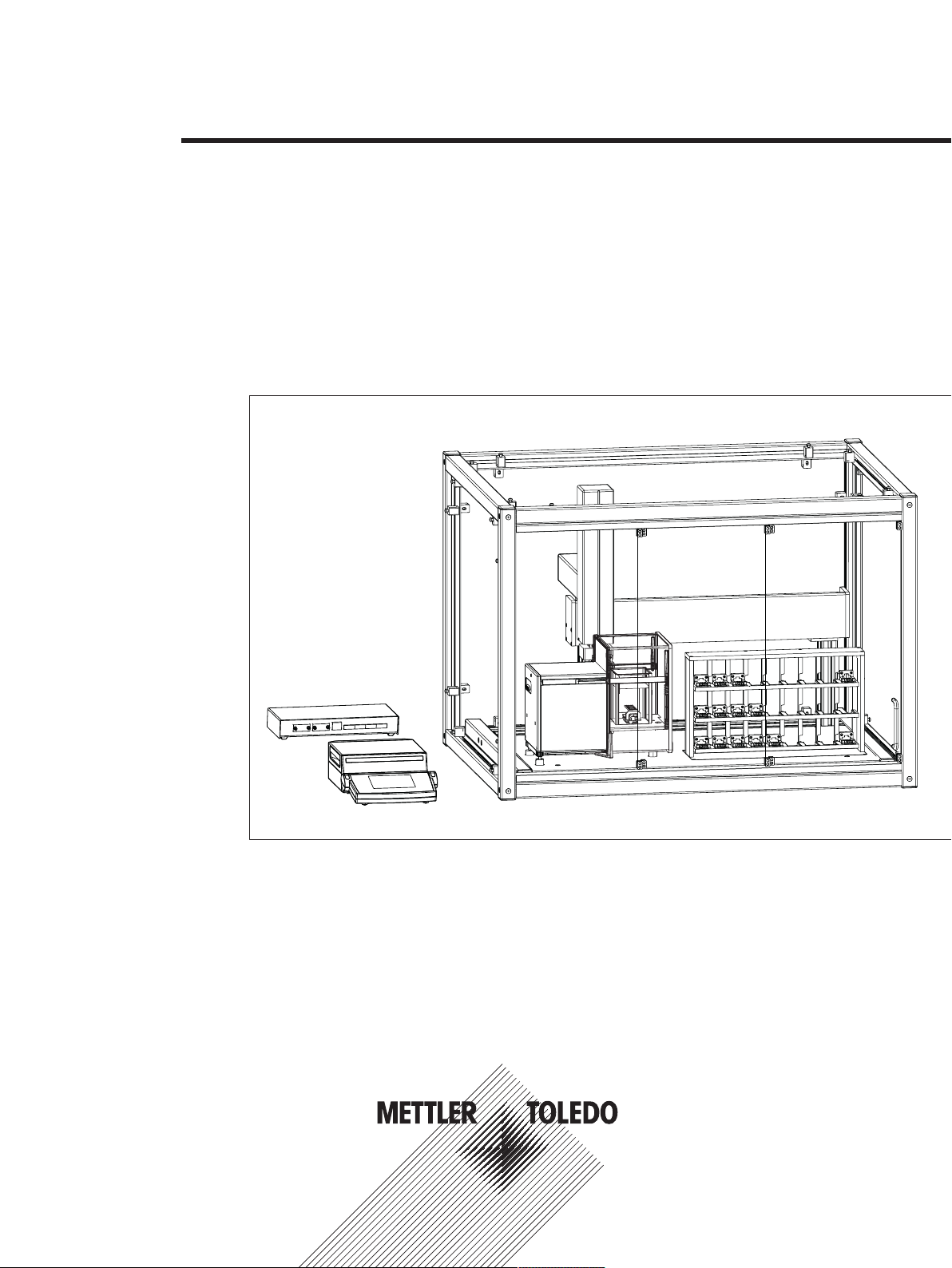

Robotic Mass Comparator

Reference Manual

e100

Page 2

Page 3

Table of Contents

1 Introduction 3

2 Safety Information 4

2.1 Definitions of signal warnings and warning symbols........................................................ 4

2.2 Product specific safety notes ......................................................................................... 4

2.3 Warning notices on the instrument................................................................................. 6

2.4 Stopping in case of emergency...................................................................................... 6

3 Design and Function 7

3.1 Overview instrument..................................................................................................... 7

3.2 Component descriptions ............................................................................................... 8

3.3 Wiring scheme ............................................................................................................ 12

3.4 Safety devices ............................................................................................................. 13

3.5 Status indication light................................................................................................... 13

4 Installation and Putting into Operation 14

4.1 Selecting the location ................................................................................................... 14

4.2 Scope of delivery ......................................................................................................... 14

4.3 Assembling the instrument............................................................................................ 15

4.4 Connecting and setting up the instrument ....................................................................... 15

4.5 Preparing the weight magazine ..................................................................................... 17

3.2.1 Overview AX106 balance ............................................................................... 8

3.2.2 Overview balance control unit......................................................................... 9

3.2.3 Overviw robot system .................................................................................... 10

3.2.4 Overview type plate ....................................................................................... 11

3.2.5 Overview robot system control unit.................................................................. 11

3.2.6 Control software............................................................................................ 11

4.5.1 Selecting a suitable weight carrier ................................................................... 17

4.5.2 Loading the weight magazine......................................................................... 20

5 Operation 22

5.1 Starting e100control..................................................................................................... 22

5.2 Entering and editing the weights data............................................................................. 23

5.2.1 Standards data ............................................................................................. 23

5.2.2 Test weights data .......................................................................................... 26

5.3 Allocating the weight magazine places........................................................................... 27

5.4 Determining the weighing process settings and series scheme .......................................... 28

5.4.1 Weighing process settings ............................................................................. 29

5.4.2 Series scheme .............................................................................................. 31

5.4.2.1 Series scheme in mode 'One-vs.-one comparisons' .................................... 32

5.4.2.2 Series scheme in mode 'Down-/upward calibration' .................................... 34

5.5 Choosing the report contents......................................................................................... 36

5.6 Adapting system settings .............................................................................................. 36

5.7 Starting and monitoring the weighing process ................................................................. 37

5.7.1 Starting the weighing process ......................................................................... 37

5.7.2 Monitoring the weighing process..................................................................... 38

5.8 Analyzing measurement data and report......................................................................... 40

5.8.1 Measurement report....................................................................................... 40

5.8.2 Calculations ................................................................................................. 45

5.9 Adjusting the balance................................................................................................... 49

5.10 Measuring the corner load error..................................................................................... 49

5.11 Upgrading e100control................................................................................................. 52

5.12 Remote-controlling the e100comparator......................................................................... 53

5.12.1 Generating a file importable into e100control as settings file .............................. 53

5.12.2 Importing an externally defined settings file into e100control.............................. 56

Table of Contents 1Robotic Mass Comparator

Page 4

5.12.3 Communicating via the serial port................................................................... 58

5.13 Selecting the application mode...................................................................................... 60

5.13.1 Interface to ODBC climate data sources: Overview............................................. 61

5.13.2 Read data via ODBC from an Access database................................................. 62

5.13.3 Read data via ODBC from an Excel sheet......................................................... 63

5.13.4 Read data via ODBC from a .csv text file.......................................................... 65

5.13.5 Read data via ODBC from other database systems............................................ 66

5.14 Sending emails............................................................................................................ 66

5.15 Reduce pre-run/centering time using ‘Standard’s centering history’ .................................... 68

5.16 Transmit measurement report data to a TCP/IP server....................................................... 69

6 Maintenance 71

6.1 Maintenance table........................................................................................................ 71

6.2 Performing routine tests................................................................................................ 71

6.3 Maintaining robot system.............................................................................................. 71

6.4 Cleaning..................................................................................................................... 72

6.4.1 Cleaning agents............................................................................................ 72

6.4.2 Cleaning the components............................................................................... 73

7 Technical Data 75

7.1 General data ............................................................................................................... 75

7.2 Dimensions................................................................................................................. 77

8 Accessories 78

9 Disposal 81

Index 83

Table of Contents2 Robotic Mass Comparator

Page 5

1 Introduction

In purchasing this automated mass comparator, you have chosen a talented, highly professional weighing

machine. Combining METTLER TOLEDO's world-class weighing sensor technology and robotic expertise e100

comparator - automated 100 g mass comparator - sets new standards in the field of high-resolution weighing.

Performance and reliability on the one hand, productivity on the other are of concern to metrologists. These

aspects were given great attention throughout the development of the e100 comparator. This product offers

new ways with respect not only to direct comparison, but to down-/upward calibration as well. e100

comparator and its smart, versatile e100control software will become in no time indispensable to any mass

standards laboratory.

To ensure that we can offer you personal service and provide you with the most efficient support, this product is

accorded special treatment: not only the complete installation of the automated mass comparator, but also the

instruction are handled by a specialist from Mettler-Toledo GmbH, Greifensee (Switzerland) or by a specialist

from your country who has been specially trained.

Disclaimer for comparators

In this document "balance" is a terminology preamble and stands for comparators.

Due to the high resolutions and differential weighing application, comparators are tested with differential

measurement only. Therefore the specification values defined are to be tested with differential methods only.

Software version

This document refers to the initially installed software version V 4.95.

Finding more information

u http://www.mt.com/lab-robotic-MC

Search for documents u www.mt.com/library

For further questions, please contact your authorized METTLER TOLEDO dealer or service representative.

u www.mt.com/contact

Conventions and symbols

Key and/or button designations and display texts are shown in graphic or bold text (e.g.

Refers to an external document.

Note

For useful information about the product.

, OK).

Elements of instructions

Prerequisites

§

1 Steps

2 ...

ð Intermediate results

ð Results

Introduction 3Robotic Mass Comparator

Page 6

2 Safety Information

Two documents named "User Manual" and "Reference Manual" are available for this instrument.

• The User Manual is printed and delivered with the instrument.

• The electronic Reference Manual contains a full description of the instrument and its use.

• Keep both documents for future reference.

• Include both documents if you transfer the instrument to other parties.

Only use the instrument according to the User Manual and the Reference Manual. If you do not use the

instrument according to these documents or if the instrument is modified, the safety of the instrument may be

impaired and Mettler-Toledo GmbH assumes no liability.

2.1 Definitions of signal warnings and warning symbols

Safety notes contain important information on safety issues. Ignoring the safety notes may lead to personal

injury, damage to the instrument, malfunctions and false results. Safety notes are marked with the following

signal words and warning symbols:

Signal words

WARNING

A hazardous situation with medium risk, possibly resulting in death or severe injury if

not avoided.

CAUTION

NOTICE

A hazardous situation with low risk, resulting in minor or moderate injury if not avoided.

A hazardous situation with low risk, resulting in damage to the instrument, other

material damage, malfunctions and erroneous results, or loss of data.

Warning symbols

Electrical shock Heavy object Crushing hazard

General hazard: read the User Manual or the Reference Manual for information about the hazards

and the resulting measures.

Personal protective equipment

Chemical resistant safety gloves are intended to protect hands against aggressive chemicals.

The protective goggles protect the eyes from flying parts and liquid splashes.

2.2 Product specific safety notes

Intended use

This instrument is designed to be used in laboratories by trained staff. The automated mass comparator is

intended for measuring calibration weights using direct comparison or down-/upward calibration.

Any other type of use and operation beyond the limits of technical specifications without written consent from

Mettler-Toledo GmbH is considered as not intended.

Responsibilities of the instrument owner

The instrument owner is the person holding the legal title to the instrument and who uses the instrument or

authorizes any person to use it, or the person who is deemed by law to be the operator of the instrument. The

instrument owner is responsible for the safety of all users of the instrument and third parties.

Safety Information4 Robotic Mass Comparator

Page 7

METTLER TOLEDO assumes that the instrument owner trains users to safely use the instrument in their

workplace and deal with potential hazards. METTLER TOLEDO assumes that the instrument owner provides the

necessary protective gear.

Trained personnel

Persons performing weighing processes must fulfill the following basic knowledge requirements regarding the

handling of METTLER TOLEDO instruments and associated software:

• Are able to complete the tasks entrusted to them and independently detect and avoid any possible dangers.

• Have expertise and experience as well as their familiarity with all applicable regulations.

• Able to prove that they have undergone training.

Safety notes

WARNING

Death or serious injury due to electric shock

Contact with parts that carry a live current can lead to death or injury.

1 Only use the approved METTLER TOLEDO power supply cable and AC/DC adapter with a

current-limited SELV output.

2 Connect the power cable to a grounded power outlet, ensure correct polarity.

3 Keep all electrical cables and connections away from liquids and moisture.

4 Check the cables and power plug for damage and replace damaged cables and power

plugs.

CAUTION

Freely accessible parts, which can move automatically

Injuries due to crushing are possible when reaching into the working area of the robot arm

during adjustment procedures or during normal operation.

− Do not reach into the working area when the robot arm is moving.

CAUTION

Damage on instrument due to incorrect moving or unsuitable location site

Moving the instrument yourself might lead to injuries or might damage the instrument.

1 Contact a METTLER TOLEDO representative before changing the location of the instrument.

2 Do not carry the instrument yourself. It's total weight exceeds the acceptable limit in

accordance to the applicable regulations.

NOTICE

Damage due to inappropriate use

Inappropriate use of the instrument may lead to significant material damage.

1 Installation, adjustment and repair work shall be carried out exclusively by specialists

from METTLER TOLEDO. Never undertake any installation, adjustment or repair, unless

duly instructed by the above mentioned specialists.

2 Do not open the instrument, the control units or the robot system. They do not contain any

parts which can be maintained, repaired, or replaced by the user. If you ever have

problems with your instrument, contact your METTLER TOLEDO dealer.

3 Use only original parts supplied or approved by the manufacturer.

A listing of all parts can be found in the Reference Manual (RM).

Safety Information 5Robotic Mass Comparator

Page 8

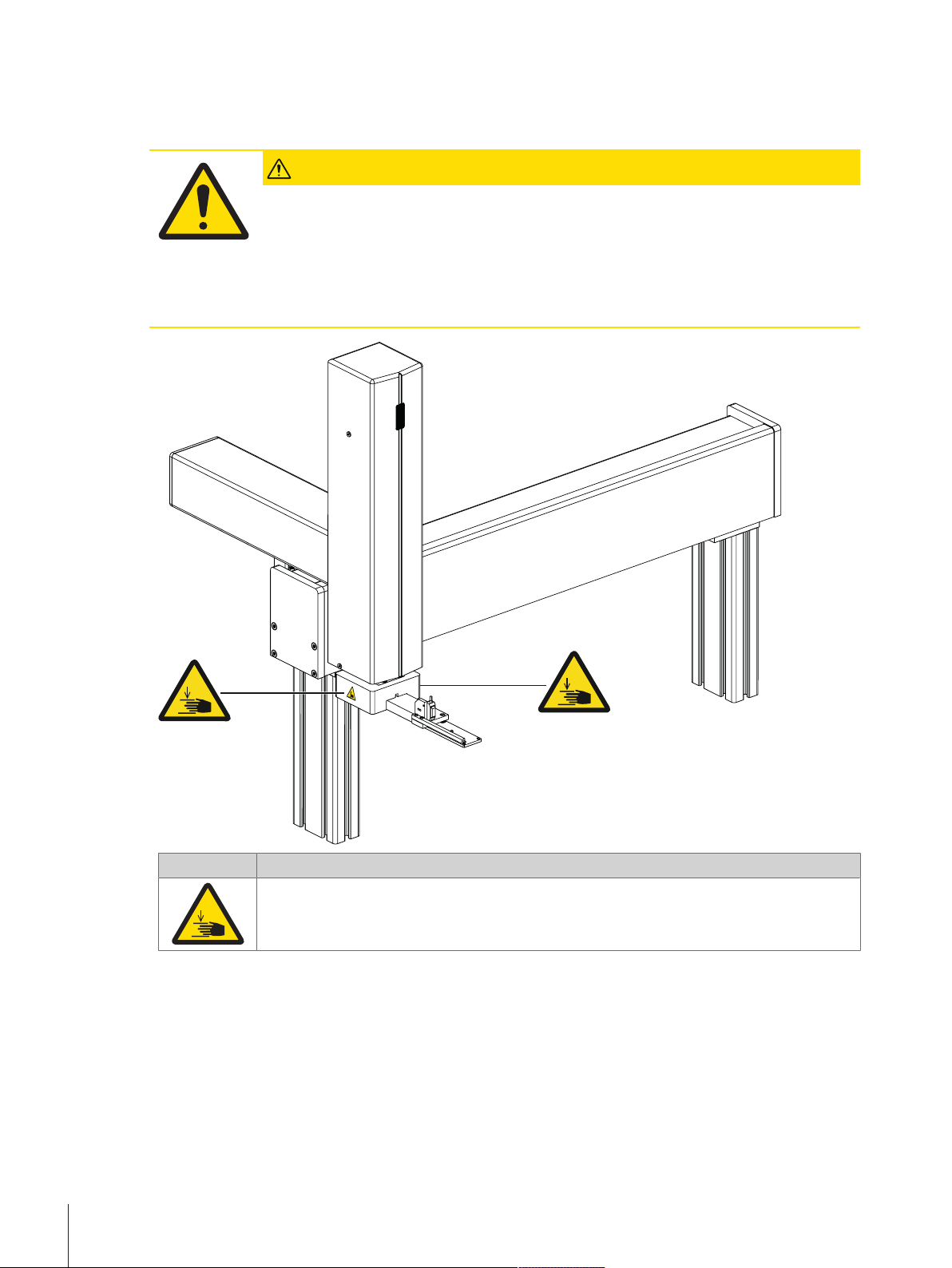

2.3 Warning notices on the instrument

The following symbols are attached to the instrument. They relate to the direct environment where they have

been put up.

CAUTION

Illegible signage

Stickers and signs can get dirty or become illegible. The risks can no longer be recognized

and necessary operating instructions can no longer be adhered to. This presents a risk of

injury.

1 Always keep safety, warning and operating notices in good legible condition.

2 Immediately replace damaged signs or stickers.

Symbol Meaning

Indicates the possibility of personal injury due to crushing when the robot hand is moving up

and down. Pay attention that the robot hand may move without any prior warning. Do not

reach into the working area when parts of the instrument are moving.

2.4 Stopping in case of emergency

To stop the instrument in case of an emergency, proceed as follows:

1 Switch off the power supply by pulling out the power plug.

2 Secure the instrument against switching on again.

3 Have fault repair performed by expert personnel or personnel of METTLER TOLEDO.

4 Before starting up again, check the instrument and make sure that there is no risk of danger.

Safety Information6 Robotic Mass Comparator

Page 9

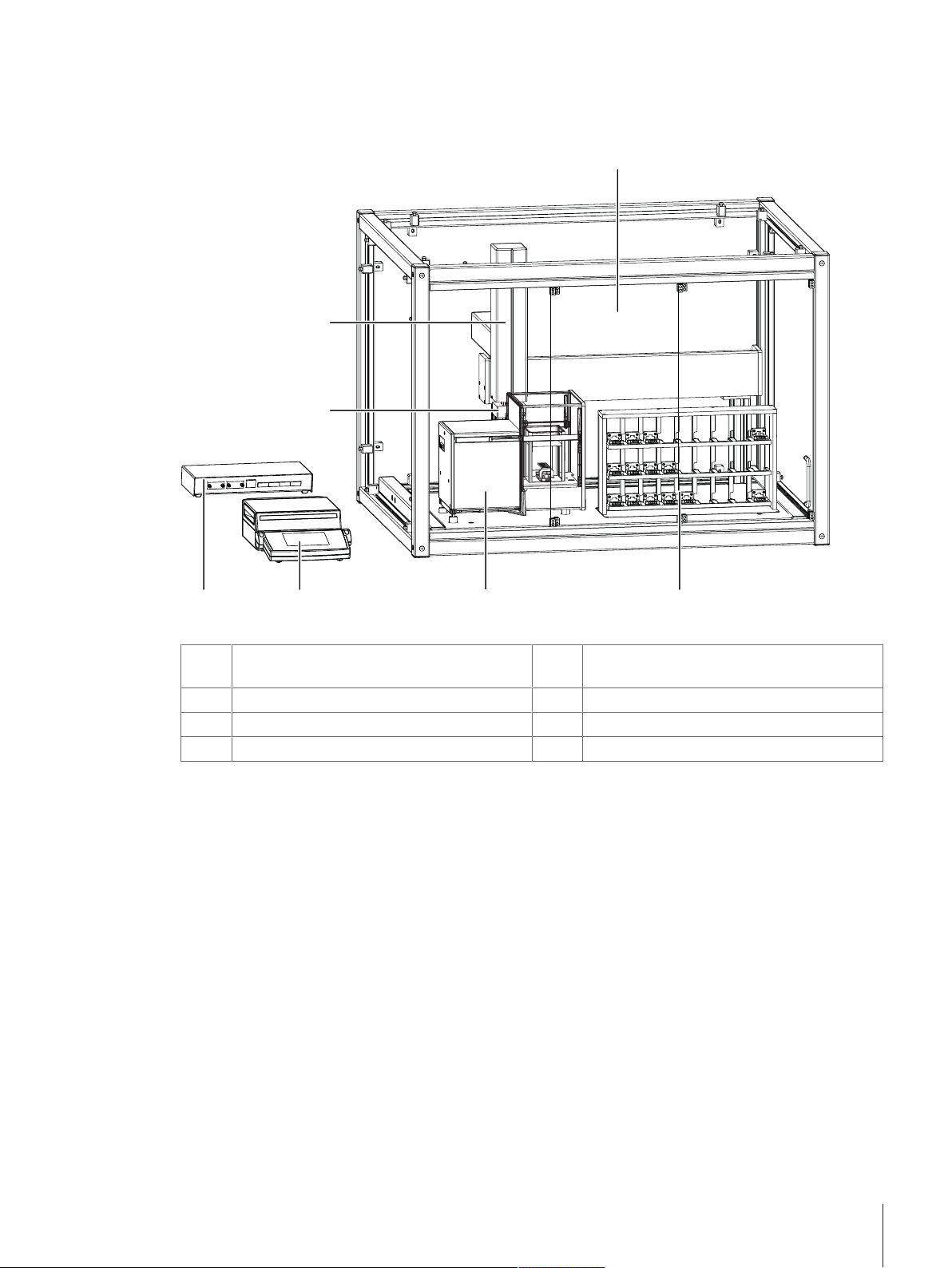

3 Design and Function

1

2

6

7

45

3

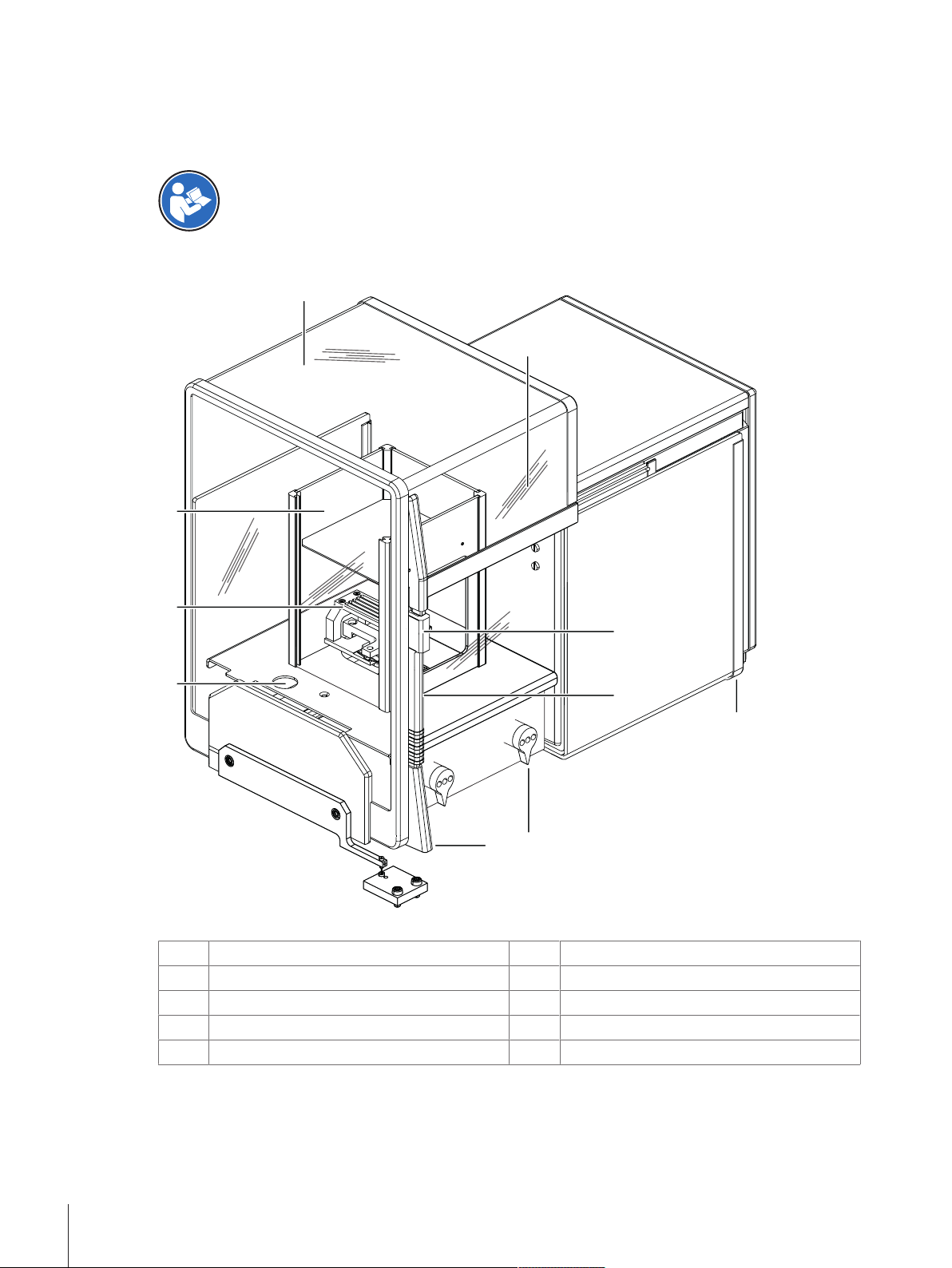

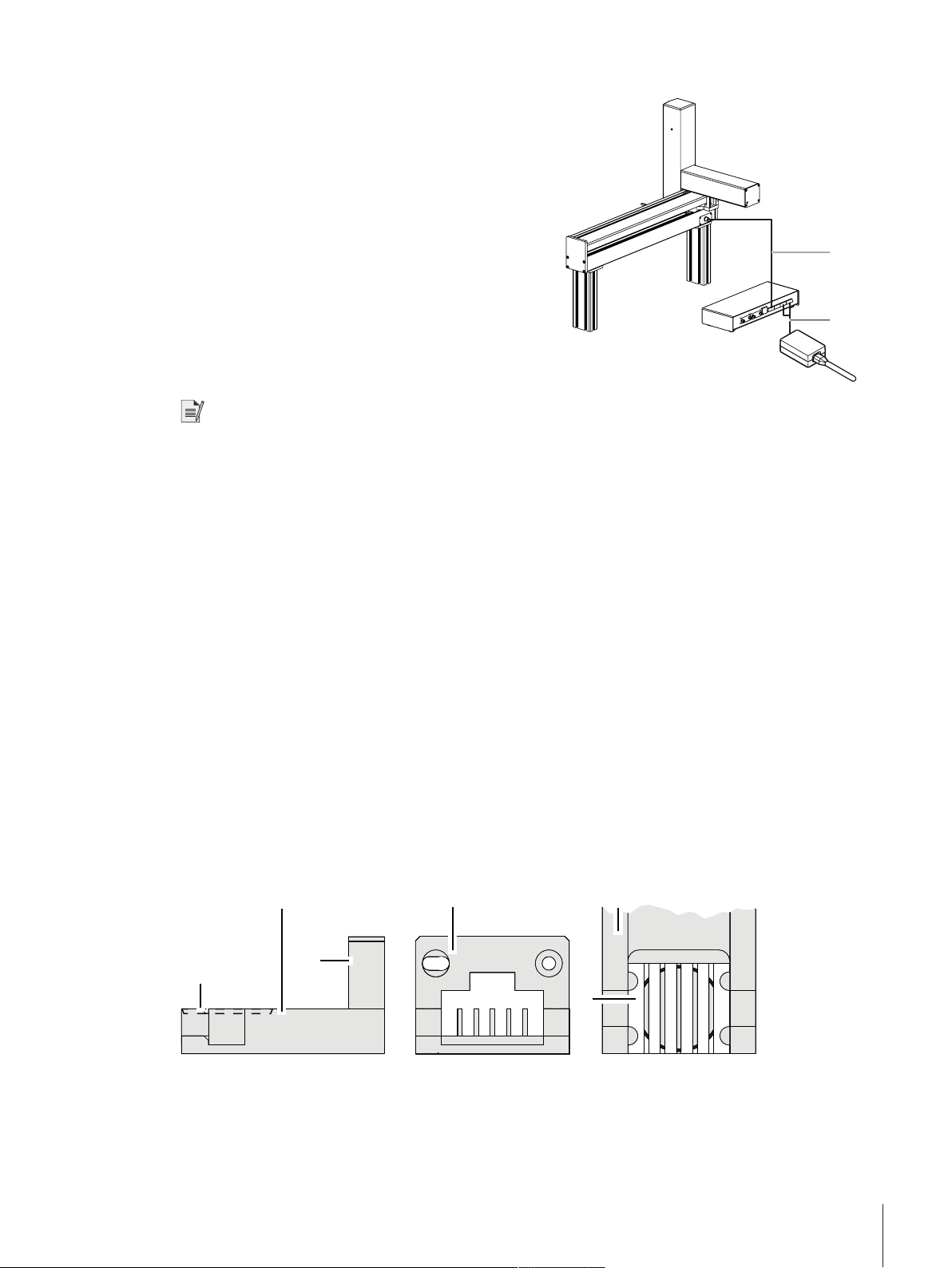

3.1 Overview instrument

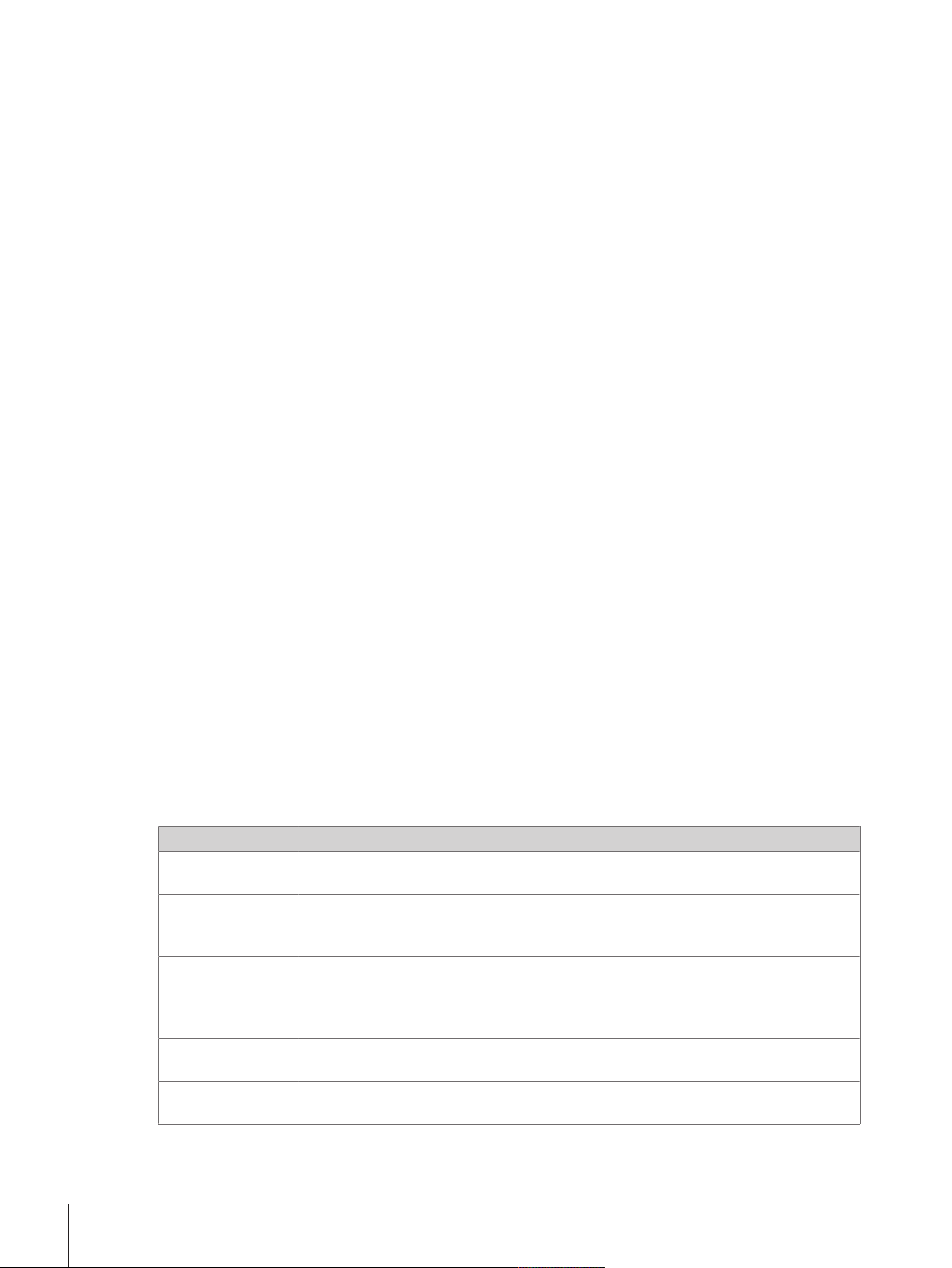

Legend overview instrument

Weighing chamber accessible through sliding

1

door

Balance (AX106 mass comparator)

3

Robot system control unit

5

3-axis robot system

7

Weight magazine with 27 weight carriers

2

Balance control unit

4

Robot hand with light barrier

6

Design and Function 7Robotic Mass Comparator

Page 10

3.2 Component descriptions

2

1

3

8

6

4

5

7

9

10

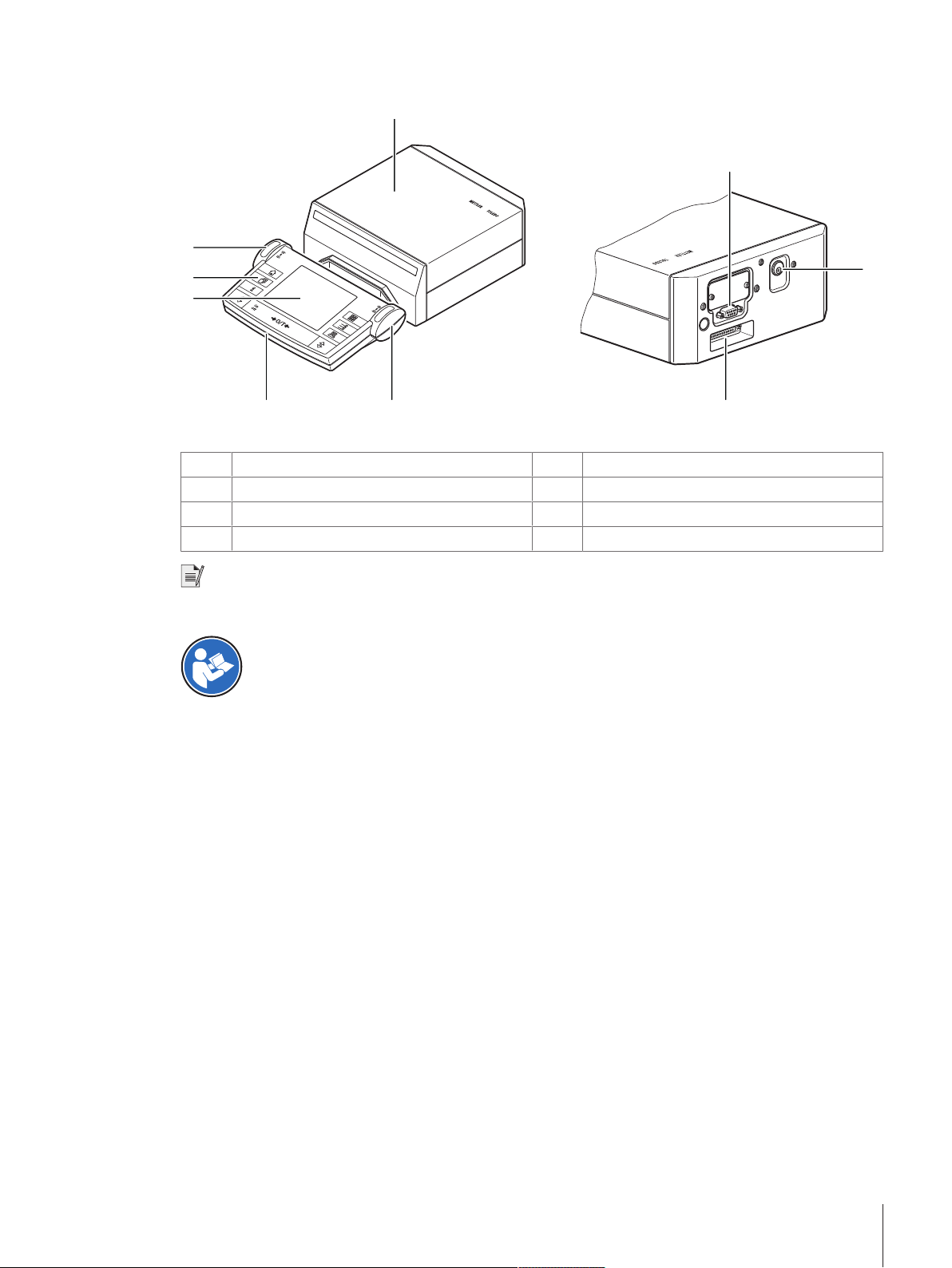

3.2.1 Overview AX106 balance

As balance the AX106 comparator is used.

For full information, always consult and download the Operating Instructions (OI).

u www.mt.com/ax-comparator-OI

Legend overview balance

Glass draft shield

1

Inner draft shield

3

Level indicator

5

Door handle

7

Door follower handle

9

Type name

2

Weighing pan

4

Door coupling element

6

Control knobs for dial weights

8

Leveling screw

10

Design and Function8 Robotic Mass Comparator

Page 11

3.2.2 Overview balance control unit

For con

n

ectio

n

to

balan

c

e

onl

y

R

S

2

3

2C

Powe

r

s

u

p

p

l

y

2

5

4

1

3 2

6

7

8

Legend overview balance control unit

Balance control unit

1

Terminal

3

Operating keys

5

Socket for AC/DC adapter

7

SmartSens sensors

2

Display

4

RS232C serial interface

6

Connecting socket for weighing cell

8

Note

No changes must be made on the terminal of the balance. During weighing, the terminal of the balance is

disabled.

For full information, always consult and download the Operating Instructions (OI).

u www.mt.com/ax-comparator-OI

Design and Function 9Robotic Mass Comparator

Page 12

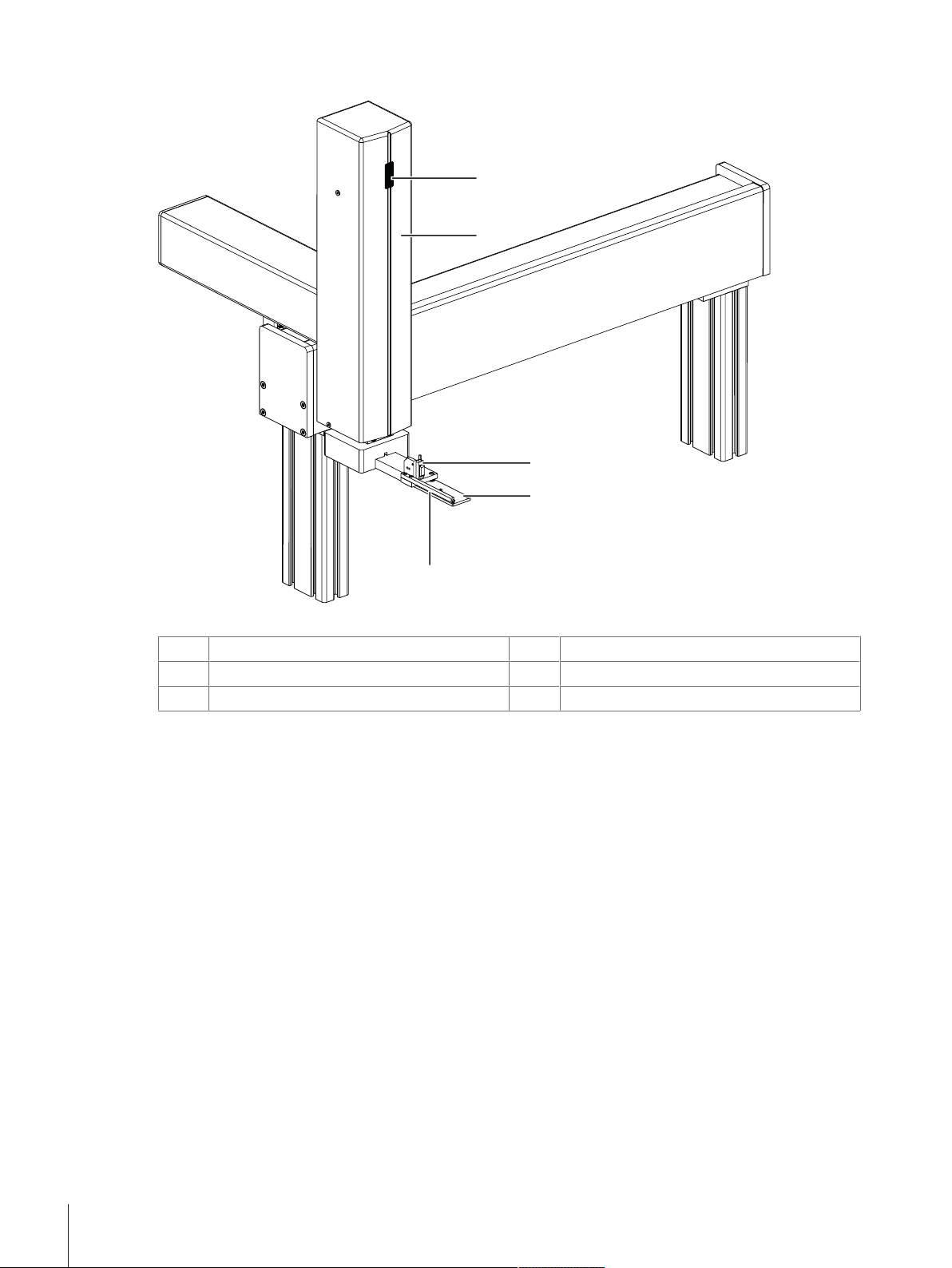

3.2.3 Overviw robot system

1

2

3

4

5

Legend overview robot system

Status indication light

1

Light barrier

3

Manipulator

5

2

4

Robot arm

Robot hand

Design and Function10 Robotic Mass Comparator

Page 13

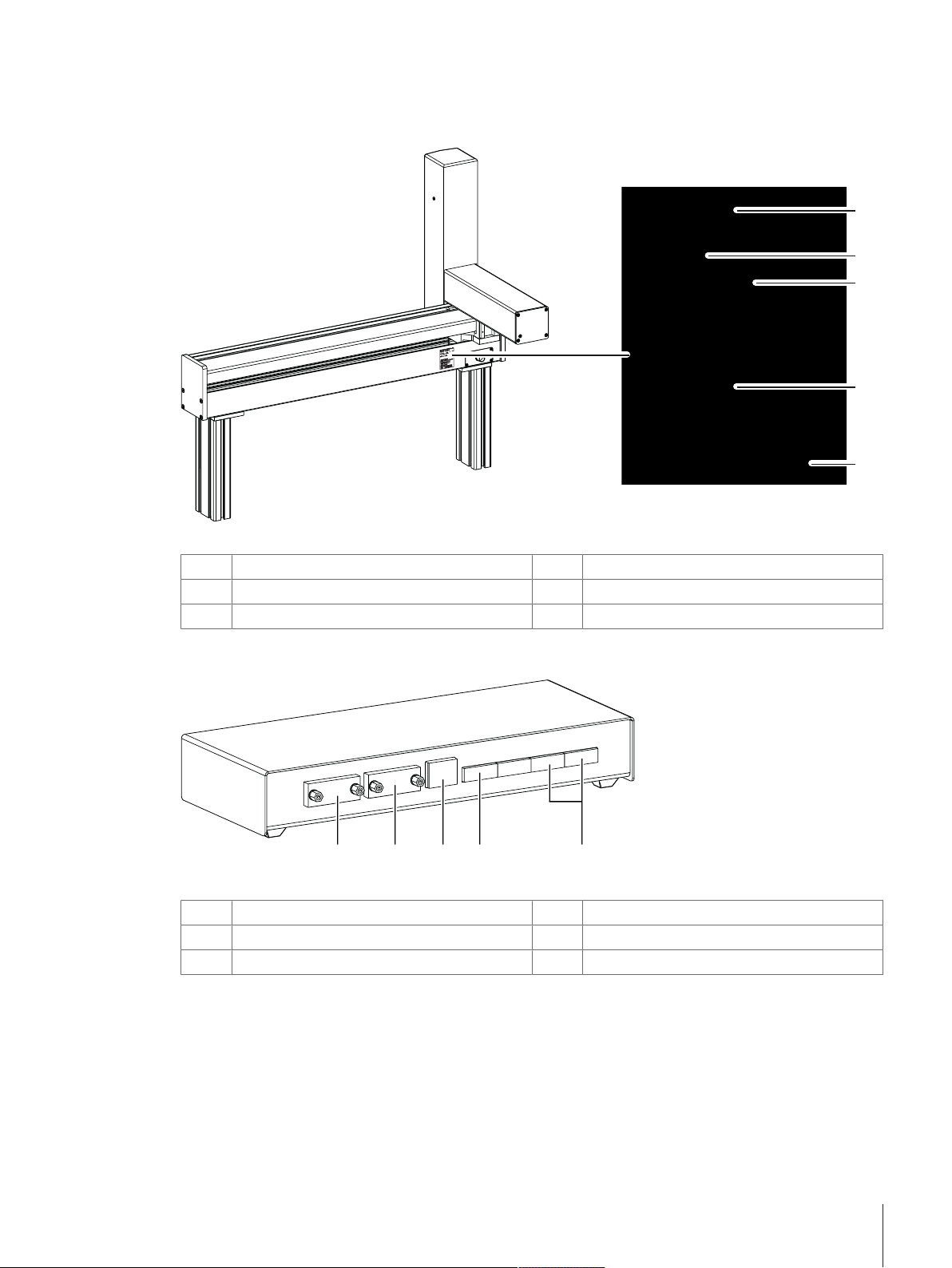

3.2.4 Overview type plate

1

2

3

4

5

1 2 3 4 5

The type plate of the robot system is located on the backside of the robot system next to the socket for the AC/

DC adapter.

Legend overview type plate

Model designation

1

Power supply

3

Serial number (SNR)

5

Year of manufacture

2

Manufacturer

4

3.2.5 Overview robot system control unit

Legend overview robot system control unit

RS232C (balance control unit)

1

Ethernet (not applicable)

3

Sockets for AC/DC adapter

5

3.2.6 Control software

All settings and the operation of the instrument are controlled with the software e100control. The software is

installed on a notebook provided by METTLER TOLEDO.

The software is used to visualize the instrument data and measuring results and to interact with the instrument.

The interaction encompasses starting and aborting weighing processes, configuring the instrument and defining

process specific data (as comparison scheme etc.).

RS232C (PC with control software)

2

Socket for interface cable robot system

4

Design and Function 11Robotic Mass Comparator

Page 14

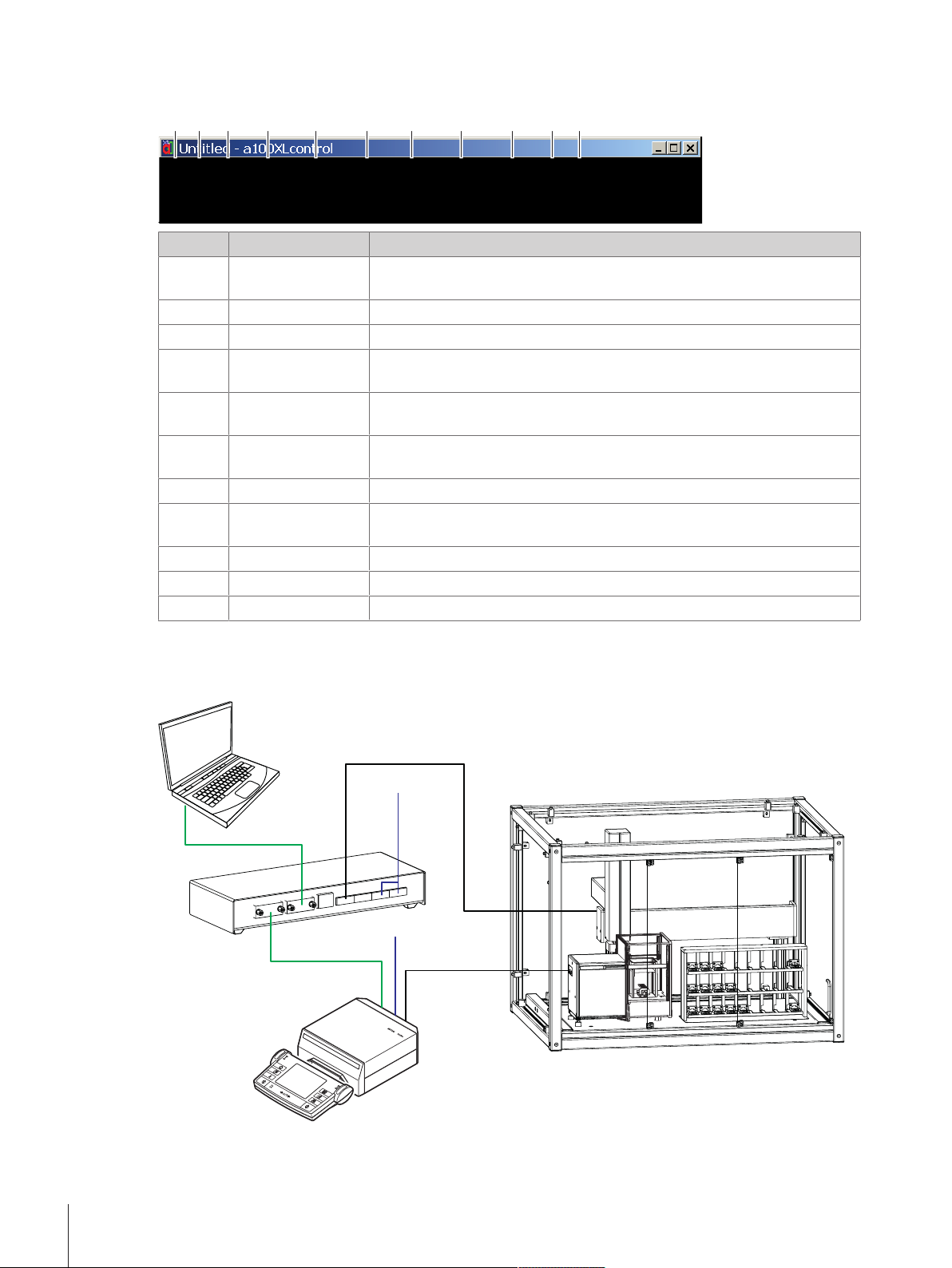

The following illustration gives an overview about the main functions of the software. For further information see

1 2 3 4 5 6 7 8 9 10 11

RS 232

RS 232

AC

AC

Cable load

cell

Cable robot

control

[Operation}Page22]:

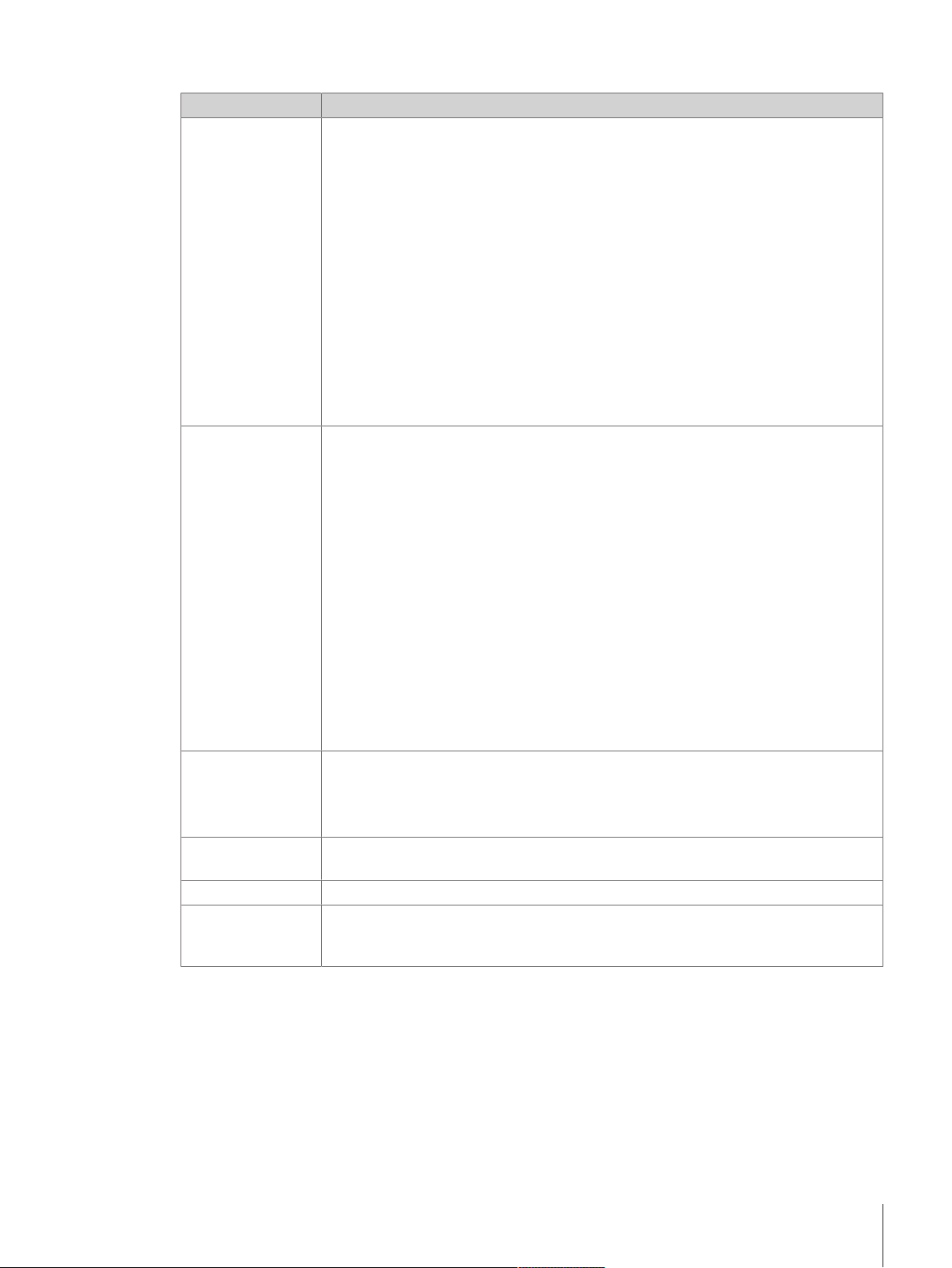

Nr. Parameter Description

1 File

Contains file related commands like creating a new file, opening an existing

file, importing a text file, saving current file, quitting program etc.

2 Edit

3 View

4 Weights

Contains various functions to edit the file (similar to Windows).

Contains various functions to adapt the view (similar to Windows).

Gives access to the weights database which contains all relevant data on

your standards and test weights.

5 Magazine

Opens the menu to identify and register the weights placed in the weight

magazine.

6 Process

Opens the menu to set comparisons of which the weighing process shall

consist, as well as its precise timing and sequence.

7 Report

8 Adjustment

Gives access to define the content of the report file.

Allows you to start the adjustment procedure using the built-in balance

adjustment weights.

9 System

10 Start

11 Help

Contains various system settings.

Hosts the command to start the measurement.

Contains the help file and further information about the software.

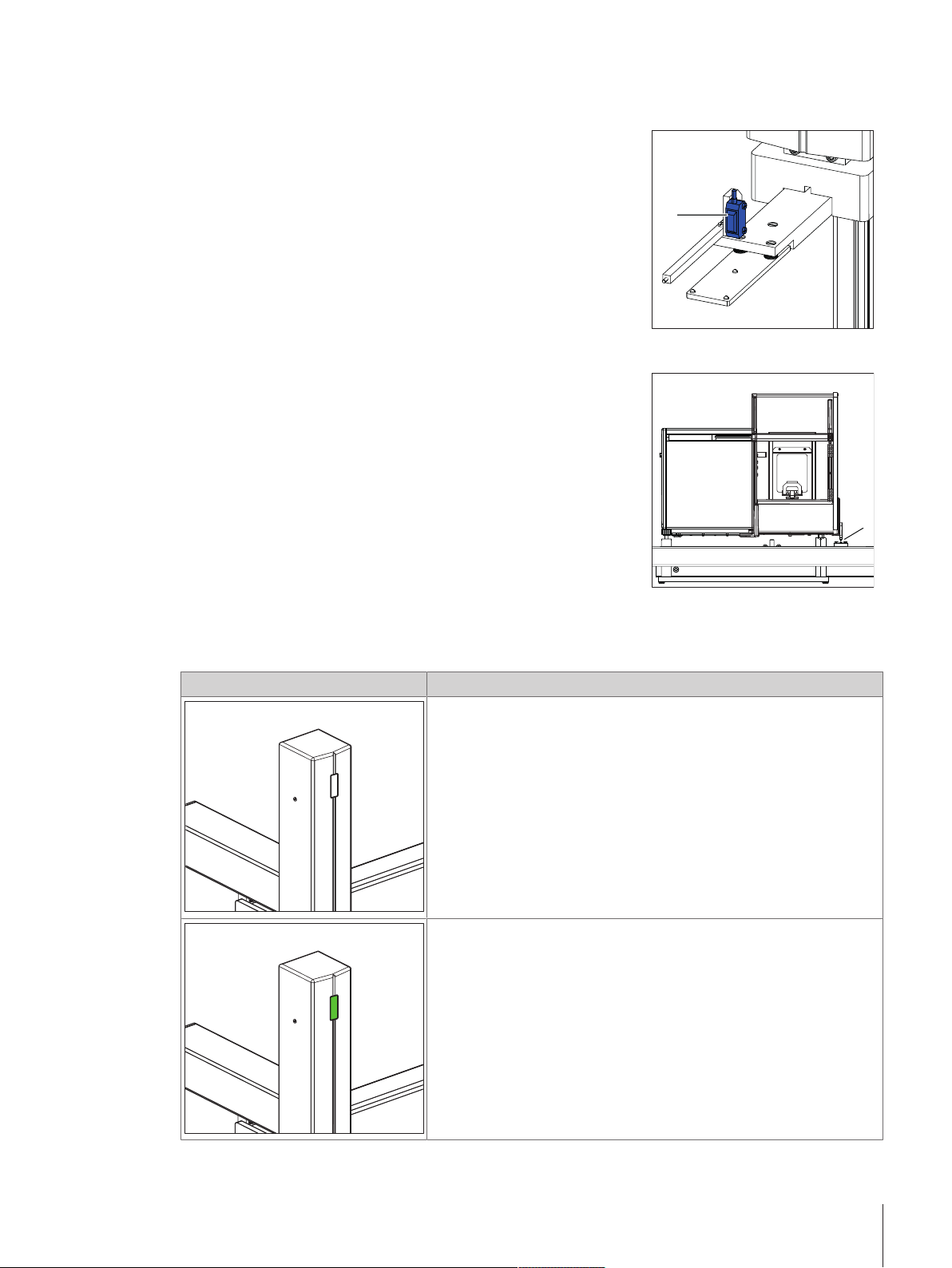

3.3 Wiring scheme

The illustration below shows how the different components of the instrument are connected to each other:

Design and Function12 Robotic Mass Comparator

Page 15

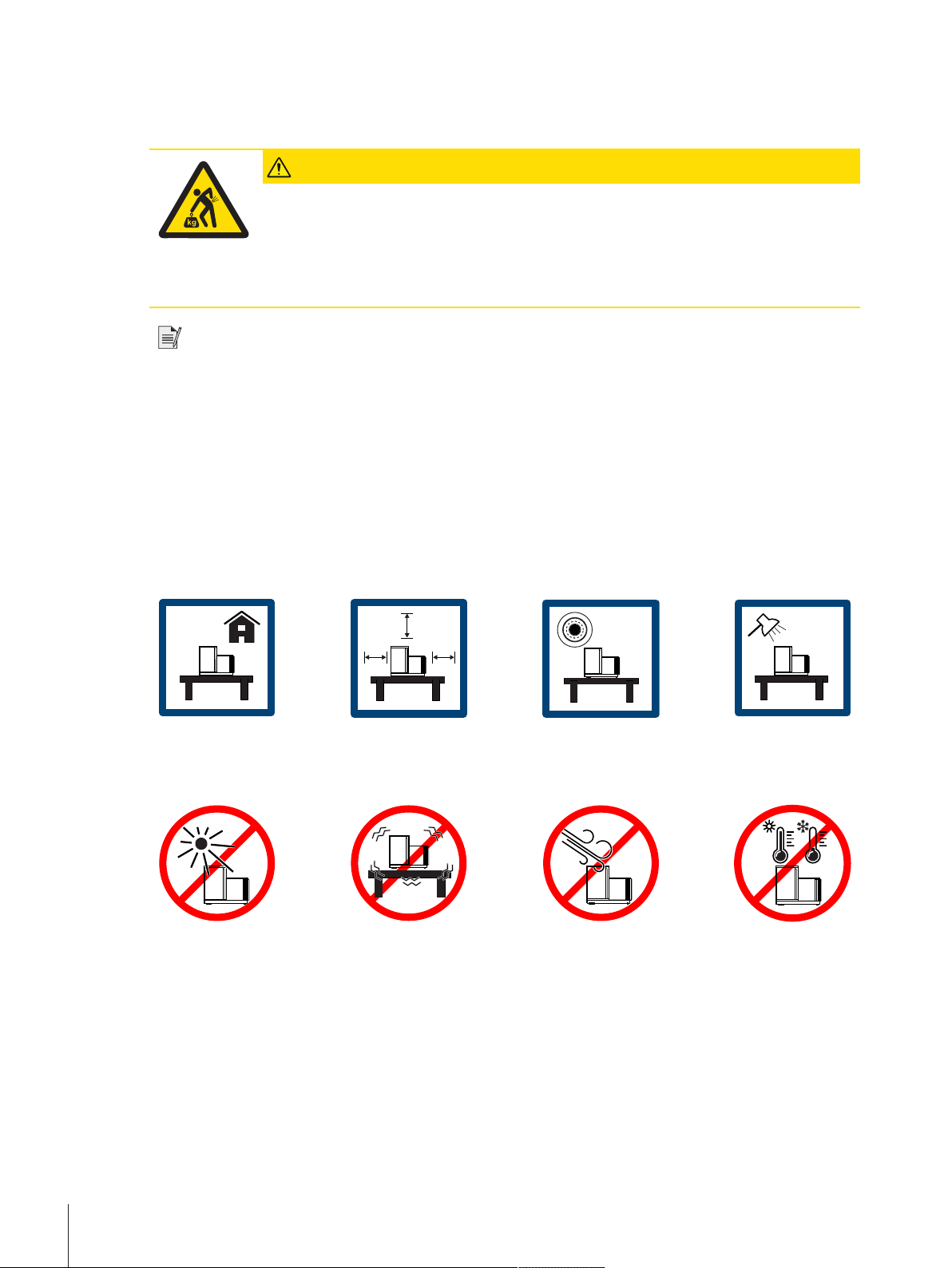

3.4 Safety devices

1

1

Light barrier

At the very beginning of the measurement each weight carrier is

checked by means of the light barrier located on the robot hand (1).

Should a unsuitable weight carrier be detected, the process aborts.

Balance position sensor

The position of the balance is monitored by means of the balance

position sensor (1). To avoid crashes, the balance must stay in the

position which was precisely defined during system installation.

Therefore, never move or reposition the balance (e. g. while cleaning).

Should a position error be detected, do contact a METTLER TOLEDO

representative.

3.5 Status indication light

The robot arm is equipped with a status LED. The LED indicates whether the instrument is enabled or not.

Status LED Meaning

LED is off

When the LED is off, the robot arm is not in operating mode. No

automatic movement of the robot arm is possible.

LED is on

When the LED is on, the robot arm is in operating mode. This means,

that the robot arm may move automatically.

Proceed with caution when performing manual operations while the

LED is on.

Design and Function 13Robotic Mass Comparator

Page 16

4 Installation and Putting into Operation

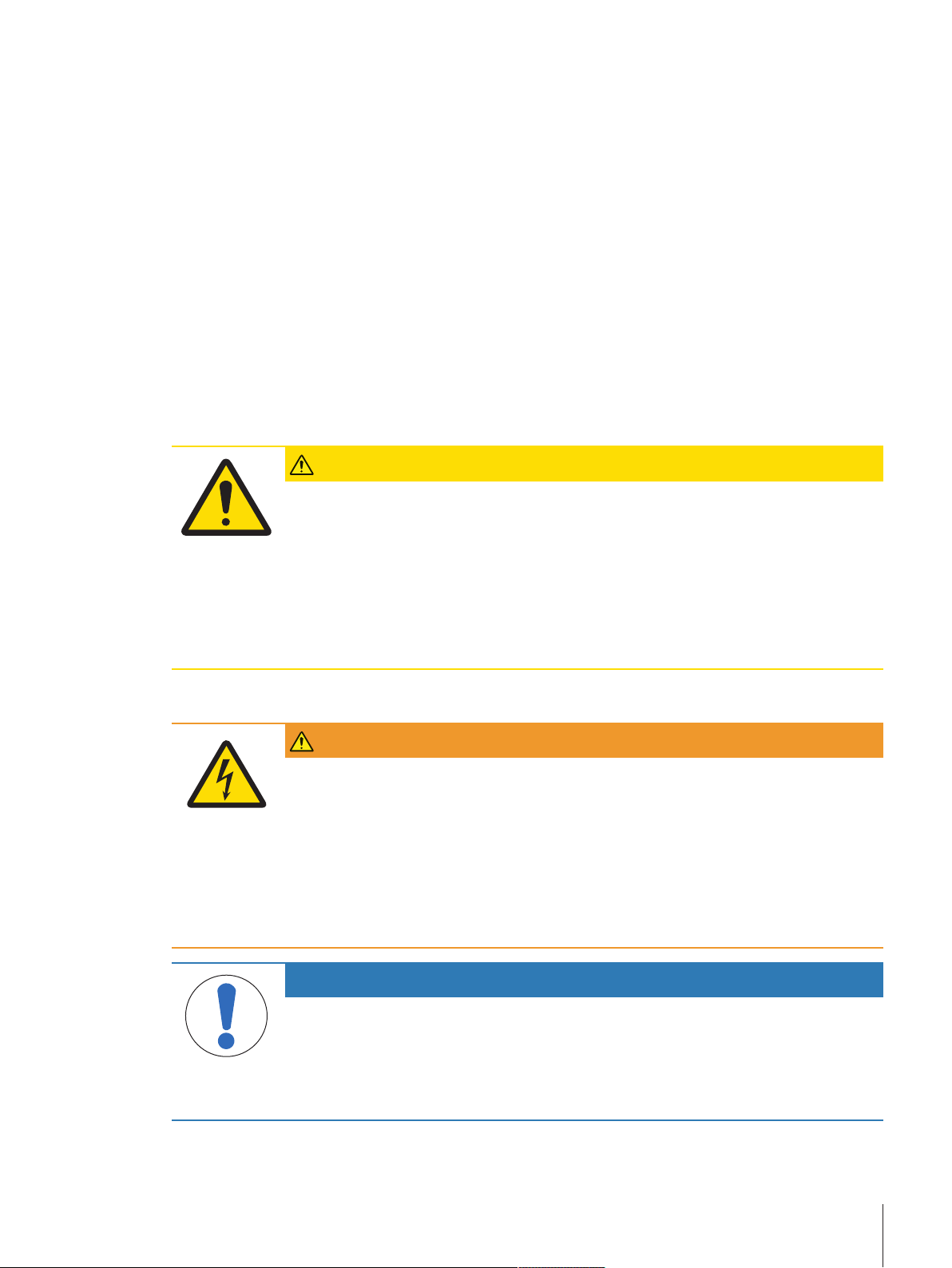

4.1 Selecting the location

CAUTION

Damage on instrument due to incorrect moving or unsuitable location site

Moving the instrument yourself might lead to injuries or might damage the instrument.

1 Contact a METTLER TOLEDO representative before changing the location of the instrument.

2 Do not carry the instrument yourself. It's total weight exceeds the acceptable limit in

accordance to the applicable regulations.

Note

Ensure that at least 30 cm free space is available on the left side of the instrument to position the balance

control unit and the robot system control unit. Its recommended to position the notebook on another table in

order to avoid interferences due to vibrations.

A balance is a sensitive precision instrument. The location where it is placed will have a profound effect on the

accuracy of the weighing results.

Requirements of the location

According to the environmental condition, see chapter "General data".

Ensure there is:

• indoor on

stable table

• with sufficient

distance (>

30 cm)

• in level • adequate lit

Avoid:

• direct sunlight • vibrations • strong drafts • temperature

4.2 Scope of delivery

• 3-axis robotic system with all electric components

• 1 Magazine with 27 positions

• 1 AX106 mass comparator

• 1 Draft shield

• 1 Controller (laptop)

• e100control software

• 16 Weight carriers design 1, e100

• 11 Weight carriers design 3, e100

fluctuations

Installation and Putting into Operation14 Robotic Mass Comparator

Page 17

• 3 Weight carrier inserts diameter 26 mm

• 2 Weight carrier inserts diameter 24 mm

• 4 Weight carrier inserts diameter 22 mm

• 2 Weight carrier inserts diameter 20 mm

• 4 Weight carrier inserts diameter 18 mm

• 4 Weight carrier inserts diameter 14 mm

• 4 Weight carrier inserts diameter 10 mm

• 4 Weight carrier inserts diameter 6 mm

• 1 Tweezer for 1 mg to 50 g

• 1 Tweezer for 1 g to 200 g

• 1 Rubber air bellow

• 1 User Manual

• 1 Declaration of conformity

• 1 Production certificate

4.3 Assembling the instrument

CAUTION

Injury and property damage due to inappropriate assembling and commissioning

of the instrument

Errors during the assembling and commissioning can cause life-threatening situations and

significant property damage.

1 Only allow assembling and commissioning to be handled by employees of the

manufacturer or people authorized by the manufacturer.

2 Do not attempt to handle installation and location changes yourself.

3 Contact METTLER TOLEDO prior to perform any task not described in this manual.

4.4 Connecting and setting up the instrument

WARNING

Death or serious injury due to electric shock

Contact with parts that carry a live current can lead to death or injury.

1 Only use the approved METTLER TOLEDO power supply cable and AC/DC adapter with a

current-limited SELV output.

2 Connect the power cable to a grounded power outlet, ensure correct polarity.

3 Keep all electrical cables and connections away from liquids and moisture.

4 Check the cables and power plug for damage and replace damaged cables and power

plugs.

NOTICE

Damage to the AC/DC adapter due to overheating

If the AC/DC adapter is covered or in a container, it is not sufficiently cooled and will

overheat.

1 Do not cover the AC/DC adapter.

2 Do not put the AC/DC adapter in a container.

Installation and Putting into Operation 15Robotic Mass Comparator

Page 18

Handling the AC/DC adapters

11

2

2

F

o

r

c

o

n

n

e

c

t

i

o

n

t

o

b

a

l

a

n

c

e

o

n

l

y

R

S

2

3

2

C

P

o

w

e

r

s

u

p

p

l

y

3

The balance is supplied with a universal AC/DC adapter or an AC/DC adapter with a country-specific power

cable.

• Install the cables so that they cannot be damaged or interfere with operation.

• Insert the power cable in a grounded power outlet that is easily accessible.

Note

When the instrument is connected to the power grid, it starts automatically. To switch off the instrument and to

disconnect it from the power supply, the power plug has to be plugged out.

Setting up the instrument

To power and set up the instrument proceed as follows:

NOTICE

Damaged balance because of weight or weight carriers on robot hand or balance

If the robot hand or the balance are not empty during the start up procedure, the balance can

get damaged.

− Make sure to remove everything from the balance and the robot hand before powering on

the balance.

The instrument is complete and fully cabled by the manufacturer. The balance and the robot system power

§

cables are not plugged in yet.

The robot hand and the balance pan are empty.

§

1 Make sure both control knobs (2) on the balance are

on position 0. If not, turn them manually to position 0.

2 Place a 100g weight on the weighing pan (1).

1 Connect the power cable (3) to the balance and the

control unit. Plug in the balance power cable (3).

ð The start-up procedure begins automatically. The

balance door opens and closes again.

2 Once the start-up procedure is completed, remove the

100g weight manually.

ð The balance is now powered.

1 Ensure that the cable between the robot system and the

robot system control unit (4) is plugged in.

Installation and Putting into Operation16 Robotic Mass Comparator

Page 19

2 Plug in the power cable at the robot system control unit (5).

4

5

1

2

4

5

6

3

ð The robot system is now powered. The start-up

procedure includes the following steps:

• The carriage of the balance opens and closes.

• The robot system initializes. Each axis of the robot

system is driven to its respective home position.

• The robot hand opens and closes the balance door.

• The robot arm moves to its home position.

The instrument is set up and the weights can be loaded on

the weight magazine, see [Preparing the weight

magazine}Page17]. Prior to start weighing, wait at

least 120 minutes after connecting the balance to the

power supply. This allows the components to get at room

temperature.

Note

• If any of the following situations is detected, each robot axis is driven to its respective home position but no

further action is taken:

– Balance is turned off.

– Interface connection is inactive.

– Balance has been moved from its original position.

To ensure optimum weighing conditions, leave the robot system on all the time.

4.5 Preparing the weight magazine

Each test weight or standard used during the weighing process needs to be placed onto one weight carrier. The

selection of the adequate weight carrier type is determined by the weight geometry.

In order to ensure a trouble-free operation of the comparator and to minimize corner load errors, strict rules

must be followed when it comes to choose the right carrier type. Consult and follow the weight carrier selection

guide each time you load weights onto the magazine.

Pay attention to the following:

• Do not touch the weight carriers or the weights by hand. Use the delivered tweezers or powder free latex

gloves.

4.5.1 Selecting a suitable weight carrier

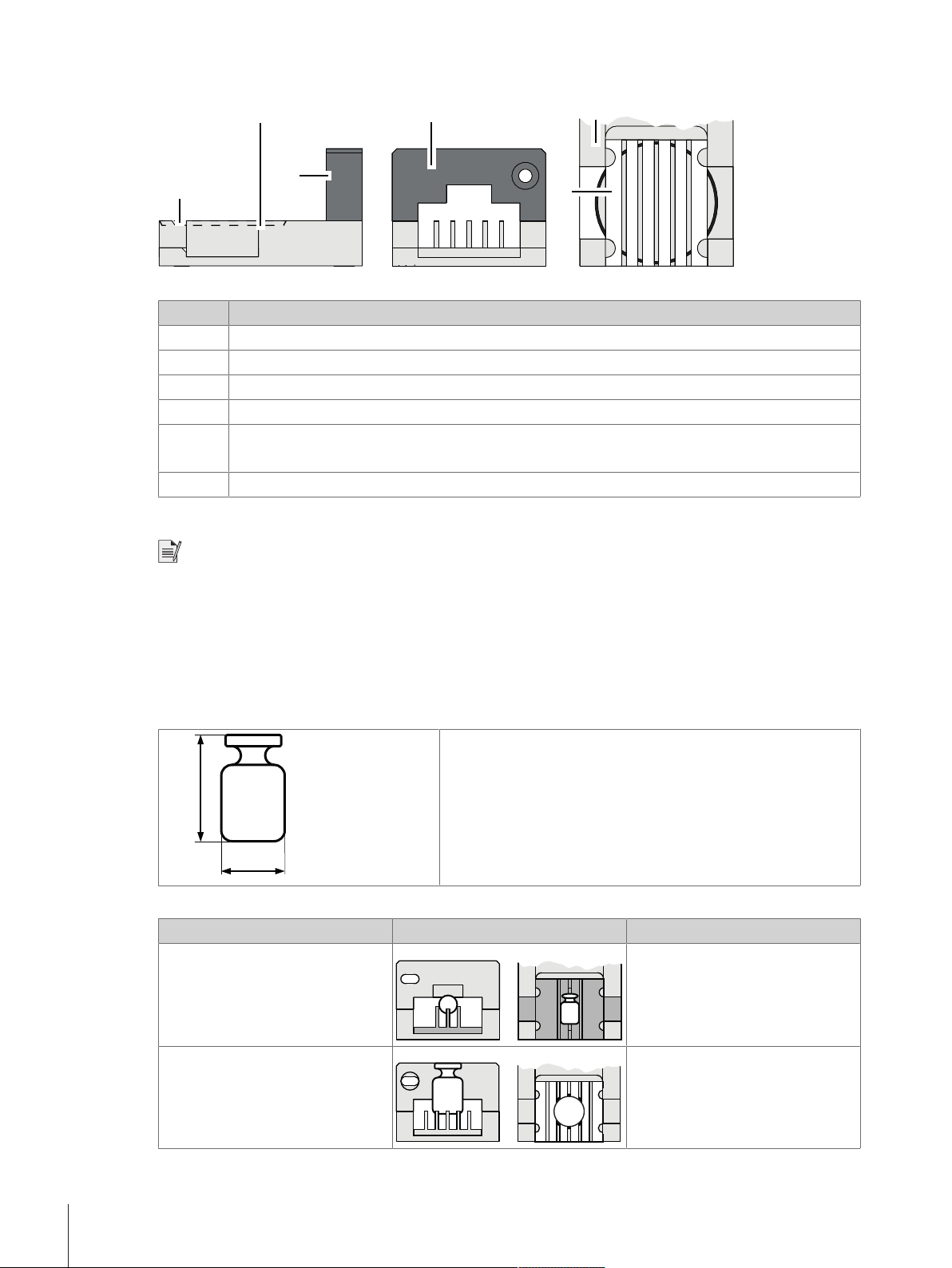

There are two designs of weight carriers available for this weight magazine.

Design nr. 1: small to medium weights

Installation and Putting into Operation 17Robotic Mass Comparator

Page 20

Design nr. 3: medium to big weights

1

6

5

4

2

3

hc

dc

Legend

Nr. Description

1

2

3

4

5

6

Side view

Front view

Top view

Sunken position for cylindrical weights

Grey frame for design nr. 1

Red frame for design nr. 3

Interchangeable insert

Choosing the correct insert

Note

• Weights which do not fit in one of the categories listed below must not be loaded on the carriers.

• Weights must never be placed over the edge of the sunken position.

In the mode down-/upward calibration combinations of up to three weights can be weighed:

• Design nr. 1: up to three weights, placed each on its own carrier, can be weighed.

• Design nr. 1 in combination with design nr. 3: up to two weights, placed each on its own carrier, can be

weighed.

The weight dimensions are measured including the weight knob.

Design nr. 1

Weight dimension Figure Insert

dc = 6 mm

hc ≤ 12 mm

Ø 6 mm

6 mm < dc ≤ 10 mm

hc ≤ 20 mm

Installation and Putting into Operation18 Robotic Mass Comparator

Ø 10 mm

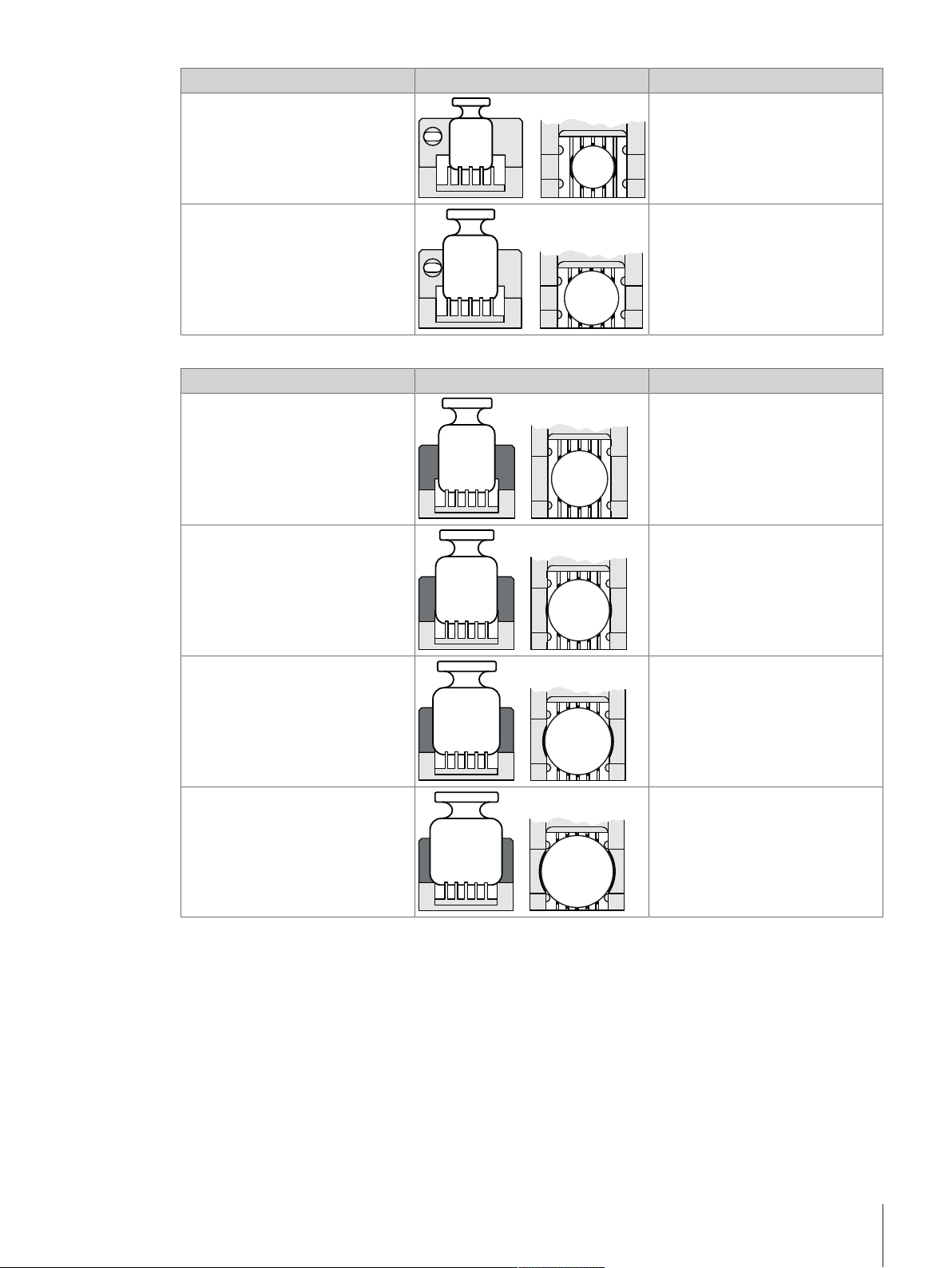

Page 21

Weight dimension Figure Insert

10 mm < dc ≤ 14 mm

Ø 14 mm

hc ≤ 28 mm

14 mm < dc ≤ 18 mm

Ø 18 mm

hc ≤ 36 mm

Design nr. 3

Weight dimension Figure Insert

18 mm < dc ≤ 20 mm

Ø 20 mm

hc ≤ 40 mm

20 mm < dc ≤ 22 mm

Ø 22 mm

hc ≤ 44 mm

22 mm < dc ≤ 24 mm

Ø 24 mm

hc ≤ 48 mm

24 mm < dc ≤ 26 mm

hc ≤ 50mm

Ø 26 mm

Installation and Putting into Operation 19Robotic Mass Comparator

Page 22

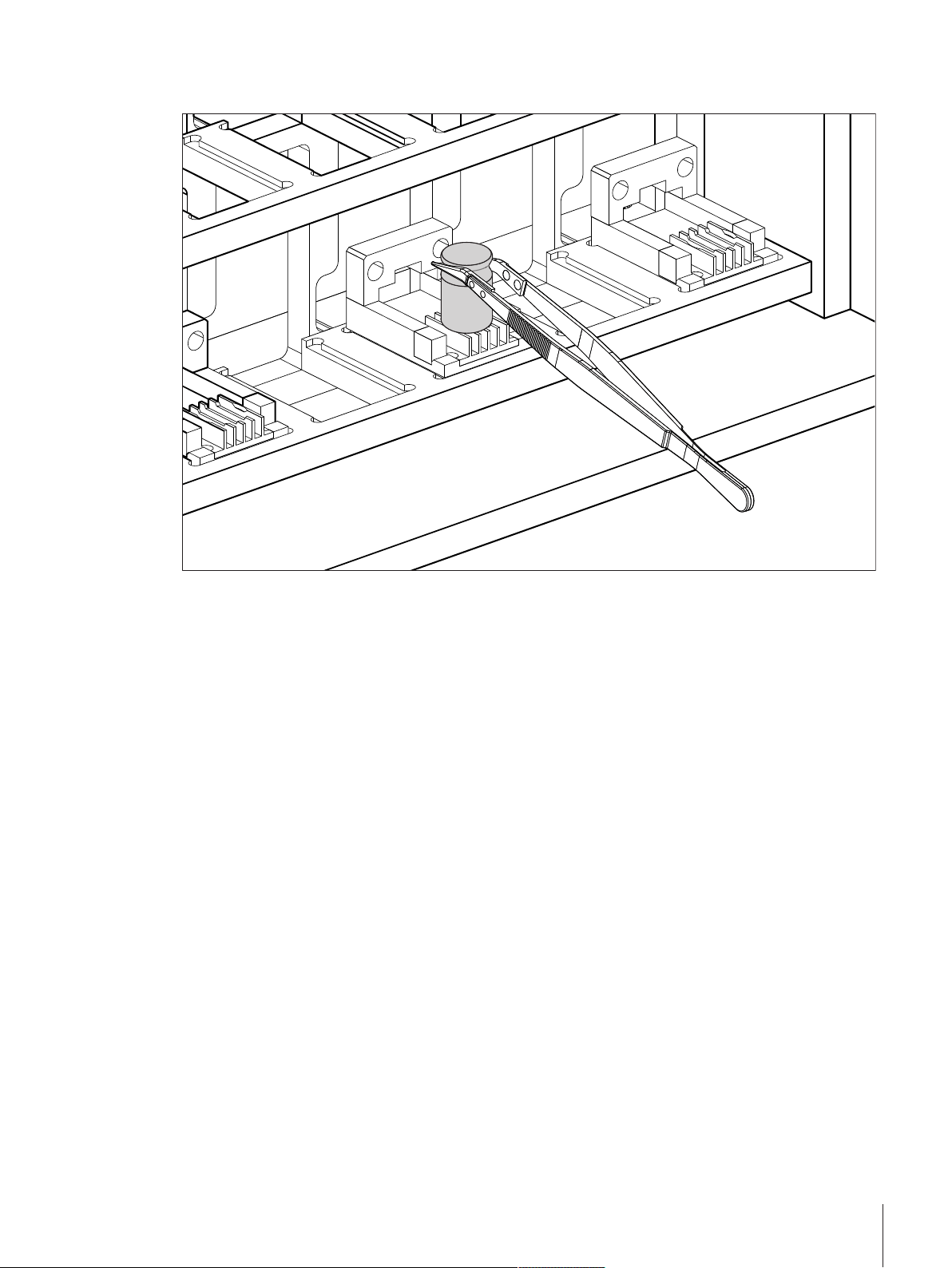

4.5.2 Loading the weight magazine

To place the weights onto their respective weight carrier in the magazine proceed as follows:

The instrument has been started successfully, see Setting up the instrument.

§

1 Open the weighing chamber doors.

2 Insert the respective weight carriers design nr. 1 or design nr. 3 into the weight magazine. To position the

weight carriers correctly, pay attention to the following:

3 - The carriers must be centered within the sunken frame of the magazine position.

4 - Do not touch the weight carriers by hand. Use the delivered tweezers or powder free latex gloves.

Installation and Putting into Operation20 Robotic Mass Comparator

Page 23

5 Place the weights on the respective weight carriers using the delivered tweezers. Do not touch the weights

by hand. Pay attention to place the weights the right way on the right carrier type.

6 Once the magazine is loaded, close the weighing chamber doors.

Installation and Putting into Operation 21Robotic Mass Comparator

Page 24

5 Operation

This section describes the e100control software and refers to its version 4.95.

5.1 Starting e100control

Starting e100control

− Double click e100control icon (e100control.exe) to start e100control.

ð The program starts and a new, blank settings file named 'Untitled.e100’ opens.

Description of the commands

The e100control main menu comprises the following items:

e100control - main window

Edit, View and Help offer functions and options that are standard in common Windows® applications and

therefore may not require further description. File lists the following commands:

e100control - File menu

Command Description

New

Open…

Import…

Save

Save As…

Operation22 Robotic Mass Comparator

Closes the current settings file and opens a new, blank file named ‘Untitled.e100’. If

changes were made to the currently open file, you are prompted to save them.

Prompts you to select and open an existing file. Once a particular file is selected, the

currently open settings file closes. If changes were made to it, you are prompted to save

them.

Prompts you to select an existing text file (extension ‘.imp’ or ‘.txt’), generated by an

external application according to a defined format, and converts it into a new standard

settings file (extension: ‘.e100’). The new settings file will immediately be loaded. For

details see [Remote-controlling the e100comparator}Page53].

Saves the changes made to the current settings file under the current file name

(extension: '.e100').

Prompts you to enter a new file name and saves the current settings file under the name

you just entered (extension: '.e100').

Page 25

Command Description

Save as Text…

This command allows you to select and save, in the current directory but in a separate

text file (current name with extension ‘.txt’), the settings which you may want to be

printed out separately and archived in your record. By ticking the adjacent boxes, you

may select the following options:

• Standards data for selected sets [Standards data}Page23]

• Test weights data [Test weights data}Page26]

• Magazine places allocation [Allocating the weight magazine places}Page27]

• Weighing process settings [Weighing process settings}Page29]

• Series scheme [Series scheme}Page31]

• Report heading [Starting the weighing process}Page37]

Exit Prompts you to save the unsaved changes you made and quits e100control.

5.2 Entering and editing the weights data

The Weights menu gives access to the weights database which contains all relevant data on your standards

and test weights. While the data on your test weights are, like other settings, specific to the process and, thus,

to the current settings file (extension .e100), the data on your standards are kept in a separate database

(‘MyStandards.st2’). These data are specific to your mass standards laboratory, not to the weighing process,

and, thus, need to be accessible from any settings file.

Noteworthy is the fact that ‘MyStandards.st2’ must be left in the same directory as your application file

(‘e100control.exe’) and your setting files. For safety purpose, you may want to keep a backup file of the

standards database.

e100control - Weights menu

5.2.1 Standards data

Entering standards data

To enter the standards data, proceed as follows:

1 Select Weights > Standards data….

ð The window shown below is displayed. A list box gives all standards which have been entered. All

entries are numbered (column Pos) and listed alphabetically by Set-ID (identification - limited to 8

characters - of the weight set to which this standard belongs) and by descending nominal values

Operation 23Robotic Mass Comparator

Page 26

(Nom.value [g]) given in gram only. Besides, each record contains a Standard-ID (identification limited to 8 characters - of this particular standard) and the error (Error [mg]), given in mg only, as

well as a field for some further information on this standard (Notes, limited to 35 characters).

Entering/editing standards data

2 Change the currently stored standards data by clicking either the Add…, Modify…, Delete or Delete all

command button.

3 Before allowing you to access the data and to modify them,

e100control prompts you to enter the password. The default

password is ‘’ (empty character string = no character).

Click Change… to change the password. Enter the current

password, the new one and, again, the new one as confirmation.

The password is limited to maximum 12 characters.

4 Once the password is accepted, you may proceed with the modifications (the access to the data remains

free until you close the Standards data window by clicking either OK or Cancel). For information

concerning the different commands, see the table below.

5 Once you are satisfied with the changes you have made, return to the main window by clicking OK. Should

you wish to ignore all the changes made, click Cancel.

ð The standards data are stored in the file ‘MyStandards.st2’.

Operation24 Robotic Mass Comparator

Page 27

Overview about the commands

Command Description

Add… Opens the Add standards data window which allows you to enter a new record in the

standards database. Return to the Standards data window after confirming your new

entry OK or ignoring it Cancel.

Modify… Opens the Modify standards data window which allows you to modify the error and the

notes. Return to the Standards data window after confirming the changes OK or

ignoring them Cancel.

Default density…

Delete

Delete all

Save as text

Opens a window where the default density can be entered. This default density is used

when a new standard is added.

The button is inactive, if standards and test weights have no density values, see

[Selecting the application mode}Page60].

Deletes the record which is presently selected (to select a particular record from the list,

simply click on it).

Deletes all database records.

This command allows you to save, in the current directory but in a separate text file

(‘MyStandards.txt’) the standards data which you may want to be printed out separately

and archived in your record.

Selecting a standards set

As above described, each standard belongs to a particular set, identifiable through its Set-ID. In your mass

standards laboratory, likely more than one set are available, so that you may wish to select only one (or more)

particular set to be used during the weighing process which you are preparing. To do so, proceed as follows:

1 Select Weights > Standards sets selection….

ð The window Standards sets selection is displayed.

2 Select in the Not selected list the set you want to use for this particular weighing process.

Operation 25Robotic Mass Comparator

Page 28

3 Click «.

ð The weights belonging to the non-selected sets will not appear in any of the windows in which e. g. the

magazine places are allocated, the series scheme is designed etc..

Selecting a standards set

5.2.2 Test weights data

Entering test weights data

To enter the test weights data, proceed as follows:

1 Select Weights > Test weights data….

ð A window entitled Test weights data is displayed. A list box gives all test weights which are to be

determined during this particular weighing process. All entries are numbered (column Pos) and listed

alphabetically by Set-ID (identification - limited to 8 characters - of the weight set to which this test

weight belongs) and by descending nominal values (Nom. Value [g]) given in gram only. Besides,

each record contains a Weight-ID (identification - limited to 8 characters - of this test weight) and a

field for some further information on this test weight (Notes), limited to 35 characters.

2 Following the procedure described in [Standards data}Page23], change the presently stored test weights

data by using one of the commands in the table below.

3 Once you are satisfied with the changes you have made, return to the main window by clicking OK. Should

you wish to ignore all the changes made, click Cancel.

Overview about the commands

Command Description

Add… Opens the Add test weights data window which allows you to enter a new record in the

list of test weights. After entering a Set-ID and a nominal value, you may use the auto

numbering button to create up to 100 test weights all having the same Set-ID and

nominal value, and consequent numbers as weight ID’s.

Example: Entering ‘00145’ as first number and ‘00180’ as last number will create 36

test weights, with Weight-ID’s ‘00145’, ‘00146’, and so on, up to ‘00180’.

Return to the Test weights data window after confirming your new entry OK or ignoring

it Cancel.

Modify… Opens the Modify test weights data window which allows you to modify the notes.

Return to the Test weights data window after confirming the changes OK or ignoring

them Cancel.

Operation26 Robotic Mass Comparator

Page 29

Command Description

Change Set ID… Opens the Change Set ID window which allows you to change the Set ID of all test

weights belonging to one test weights set. This gives you an excellent possibility to

adapt a saved settings file to a new measurement, just by changing the Set-ID of the test

weights involved in the measurement.

Default density…

Delete

Delete all

Opens a window where the default density can be entered. This default density is used

when a new test weight is added.

The command is inactive, if standards and test weights have no density values, see

[Selecting the application mode}Page60].

Deletes the record which is presently selected in the list box (in order to select a

particular record from the list, simply click on it).

Deletes all records.

5.3 Allocating the weight magazine places

Once the standards and test weights are defined in their respective database, their position on the weight

magazine needs to be identified and registered in e100control. For this purpose, proceed as follows:

− Select Magazine > Places allocation….

ð The window Allocation of weight magazine places is displayed.

Allocating magazine places

Operation 27Robotic Mass Comparator

Page 30

The Allocation of weight magazine places window contains two list boxes:

• The upper one shows all defined weights - i. e. all standards which belong to the selected sets [Standards

data}Page23], identified by an ‘S’ in the ‘S/T’ column, and all test weights [Test weights data}Page26]

identified by a ‘T’ in the ‘S/T’ column.

• The lower list box shows all available magazine places, identified by their number:

– from a1 (left) to a9 (right) for the most upper magazine row

– from b1 (left) to b9 (right) for the 2nd magazine row

– from c1 (left) to c9 (right) for the lowest magazine row

The allocation of one magazine place to one weight selected from the upper list is made as follows:

1 Select the weight by clicking on the proper record in the upper list box.

2 Select, by clicking on the proper line in the lower list box, the magazine place you want to be allocated to

the weight you just selected.

3 Click Place.

ð The selected weight is removed from the upper list box, and entered into the lower one, on the line

which carries the number of the magazine place which is now allocated to this particular weight

(placing a weight whose nominal value exceeds 111 g is rejected).

4 Should a place be wrongly allocated, clear it again by

selecting it in the lower list box and clicking Clear.

Should all places have to be cleared, click simply

Clear all.

ð The weight data which were contained in the

cleared record are transferred back into the upper

list box.

5 Once the allocation of the magazine places is

completed, click OK, if you wish the allocation to be

confirmed, or Cancel, to ignore it, and return to the

main window.

Magazine places allocation completed

Note

• An alternative to the above described procedure - which has to be repeated for each weight to be used

during the weighing process - is to place all weights by default. To do so, simply click Place all by default.

See also

2 Entering and editing the weights data}Page23

5.4 Determining the weighing process settings and series scheme

After defining standards and test weights and determining on which magazine place each of these weights is

located, you need now to set the comparisons of which the weighing process shall consist, as well as their

precise timing and sequence.

It might be useful at this point to clarify the terminology used to identify the main phases of any weighing

process:

Operation28 Robotic Mass Comparator

Page 31

Term Description

Comparison or

(comparison)

Each single comparison between a weight (or a combination of weights) B, and a

weight (or a combination of weights) A.

weighing

Group

Sequence of n identical and successive comparisons, whose results are statistically

exploited.

Series

Sequence of all groups. The comparison (weight B vs. weight A) performed in each

group and the sequence of all groups are defined in the series scheme (design).

(Weighing) process

Sequence of n identical and successive series, preceded by the following (if so

requested):

• Centering phase: centering of all weight carriers on their respective magazine place

• Pre-run: check of the nominal value of each weight

• Waiting time: start delay

5.4.1 Weighing process settings

1 Select Process > Settings….

ð The window Weighing process settings is displayed.

Setting the process parameters

2 After opening the Weighing process settings window, you may determine the following parameters:

Operation 29Robotic Mass Comparator

Page 32

Parameter Description

Weighing mode

Provided your system is equipped with the ‘professional’ software edition, i. e.

e100control with option for down-/upward calibration, you can choose between the

following options:

• One-vs.-one comparisons: direct comparisons between a single weight B and a

single weight A

• Down-/upward calibration: comparison between two combinations of up to three

weights each

The ‘standard’ software allows One-vs.-one comparisons only.

Default setting: One-vs.-one comparisons

Pre-run requested

By ticking the adjacent check box, the system carries out an initial check which

basically consists in comparing the measured value of each weight with its defined

nominal value. Any placing error is indicated in a message box and causes the process

to abort.

It is strongly recommended to activate the Pre-run requested.

Default setting: Pre-run requested: check

History-specific

pause requested

By ticking the adjacent check box, the system makes certain that a minimum time

elapses between the last measurement of the previous group and the first reported

measurement of the current group, under the following circumstances only:

• At least one of the weights involved in the current group - but not all of them -,

whose nominal value equals or exceeds 10 g, was involved in the previous group

as well.

• The effective duration of the pause is determined as the duration of the 'history-

specific pause' (entered, in minutes, in the adjacent input box) minus the estimated

duration of the non-reported pre-weighings of the current group (should this

difference be negative, the effective duration of the pause is zero).

• This measure eliminates the drift affecting the weight difference between two weights

when one of them has reached a higher temperature than the other because of a

longer exposure to the environment of the balance weighing chamber which is

slightly warmer than the environment of the weight magazine.

Recommended and default setting: History-specific pause requested: check 20 min

Start delay

Time, entered in hours and minutes, between the end of the initial check(s) (centering

and, if requested, pre-run) and the start of the first series.

Default setting: 0 h 0 min; max.: 99 h 59 min

No. of nonreported

preweighings per

group (0-5)

In order to reduce the 'first weighing effect' (drift) noticeable in particular after a change

of nominal value, you may want the system to carry out one or several pre-weighing(s)

without getting the data reported. Each pre-weighing consists in the sequence A-B,

regardless of the selected comparison scheme.

Recommended and default setting: ‘3'

No. of reported

comparisons per

Number of statistically independent comparative weighings in each group.

Default setting: '5'

group (1-20)

No. of series (1-20)

Number of series.

Default setting: '1'

Stabilisation time

(10-60 s)

Time in seconds between loading the balance pan and start of the reading period whose

duration is determined under Integration time (0-60 s).

Default setting: '25' s

Integration time

(0-60 s)

Time in seconds which runs after the stabilisation time has elapsed and during which

the system records one measurement value every second. The average of the recorded

values is given as result in the measurement report.

Default setting: '5' s

Operation30 Robotic Mass Comparator

Page 33

Parameter Description

Comparison scheme You may choose either the A-B-A or A-B-B-A scheme. For details see [Calcu-

Sensitivity check

Sensitivity check

standard

Note

• The Weighing process (total) is an estimation of the total time needed to complete the weighing process.

To save a changed parameter, click Update.

5.4.2 Series scheme

As a next step, it remains to determine the series scheme (design), i. e. which comparisons shall be performed

and in which sequence. For this purpose, proceed as follows:

− Select Process > Settings… > Series scheme….

ð The window Series scheme is displayed.

lations}Page45].

Default setting: A-B-A

Should you wish to monitor the balance 'sensitivity' (in its electrical weighing range)

during the weighing process, select Check after each series. The sensitivity check -

determination of the value of the check standard (see next item) - will be performed

before the first series starts and at the end of each series). Each sensitivity check

consists of the non-reported sequence 0-B (pre-check), followed by the reported

sequence 0-B-0.

Default setting: No check

Provided the sensitivity check was requested (see previous item), this list box shows all

standards whose nominal value does not exceed 11 g and to which a magazine place

is allocated. The check standard is chosen by clicking on one of the records.

Operation 31Robotic Mass Comparator

Page 34

5.4.2.1 Series scheme in mode 'One-vs.-one comparisons'

If the mode One-vs.-one comparisons is selected, the following window is displayed:

Determining the series scheme in mode One-vs.-one comparisons

Before setting the series scheme, you need to consider the following three options:

• Comparisons between weights of different nominal values enabled: if so requested, tick it off by clicking

in the adjacent check box

• Comparisons between standards enabled: if so requested, tick it off

• Comparisons between test weights enabled: if so requested, tick it off

The upper left list box (Weight B:) contains all the weights which are available as weight B (“test weights”).

This list contains either:

• All available test weights to which one magazine place is allocated, provided Comparisons between

standards enabled are not enabled (middle check box not ticked)

• All available test weights and all selected standards to which one magazine place is allocated , provided

Comparisons between standards enabled are enabled (middle check box ticked), see [Allocating the

weight magazine places}Page27]

The upper right list box (Weight A:) contains all the weights which can be chosen as weight A (“standard”) for

the presently selected (clicked) weight B (“test weight”), according to the values given to the above described

check boxes. The series scheme consists of a list of comparisons between two single weights - weight B vs.

weight A - which will be performed in the order of their entry (amendments can be made to the sequence as

explained below).

Each comparison is entered as follows:

Operation32 Robotic Mass Comparator

Page 35

1 Select first the weight B by clicking on the proper record in the Weight B: list box.

2 Select the weight A by clicking on the proper record in the Weight A: list box.

3 Click Add.

ð A new comparison - selected weight B vs. selected weight A - is entered in the Scheme: list box.

4 Repeat the above sequence until the new series scheme is fully determined.

5 Once the series scheme is completed, click OK to store it. By clicking Cancel, the modifications are ignored.

Further commands

Command Description

Default scheme

Delete

Delete all

Move last entry

See also

2 Weighing process settings}Page29

Instead of entering each comparison one after the other, you may prefer to let

e100control propose its own scheme. By clicking the command e100control selects for

each weight B a matching weight A.

The command is active only if none of all 3 options is enabled.

To delete a wrong entry in the scheme.

To delete all entries in the scheme.

The sequence of comparisons can be changed by moving the last entry up:

1 Select the line up to which you want the last entry to move.

2 Click Move last entry.

ð The record on the selected line and all records below it are consequently shifted

downward.

Operation 33Robotic Mass Comparator

Page 36

5.4.2.2 Series scheme in mode 'Down-/upward calibration'

If the mode Down-/upward calibration is selected, the following window is displayed:

Determining the series scheme in mode Down-/upward calibration

The upper list boxes Weight B: and Weight A: both contain all available weights, i. e. all test weights and all

standards to which one magazine place is allocated, see [Allocating the weight magazine places}Page27].

The series scheme, displayed in the lower list boxes (Scheme - Weight B: and Scheme - Weight A:), consists

of a list of comparisons between two combinations of up to three weights each. These comparisons will be

performed in the order of their entry (amendments can be made to the sequence as explained below).

Each comparison is entered as follows:

1 Select first the weight B by clicking on the proper record in the upper Weight B: list box.

2 Click Add B.

ð The selected weight B is entered in the Scheme - Weight B: list box.

3 If you wish to enter a combination of more than one weight, repeat the previous two steps (the symbol ‘+’

in the Scheme list boxes indicates that a combination is entered and the total nominal value of the combination is displayed on the top of the Scheme list boxes).

4 Once the (combination of) weight(s) B is entered, select the weight A by clicking on the proper record in the

upper Weight A: list box.

5 Click Add A.

ð The selected weight A is entered in the Scheme - Weight A: list box.

6 If you wish to enter a combination of more than one weight A, repeat the two previous steps.

7 Repeat the above sequence until the new series scheme is fully determined.

Operation34 Robotic Mass Comparator

Page 37

8 Once the series scheme is completed, click OK to store it. By clicking Cancel, the modifications are ignored.

Note

• Should the nominal value of a weight combination exceed 111 g, the scheme entry is rejected.

Further commands

Command Description

Default scheme

Instead of entering each comparison one after the other, you may prefer to let

e100control propose its own scheme. By clicking the command e100control selects for

each weight B a matching weight A.

The command is active only if none of all 3 options is enabled.

Delete

Delete all

Move last entry

To delete a wrong entry in the scheme.

To delete all entries in the scheme.

The sequence of comparisons can be changed by moving the last entry up:

1 Select the line up to which you want the last entry to move.

2 Click Move last entry.

ð The record on the selected line and all records below it are consequently shifted

downward.

Complete series scheme in mode Down-/upward calibration

See also

2 Weighing process settings}Page29

Operation 35Robotic Mass Comparator

Page 38

5.5 Choosing the report contents

Before starting the weighing process, the contents of the report file can be defined. For this purpose, proceed as

follows:

1 Select Report > Contents….

ð The window Report contents is displayed.

2 Enter a User name.

3 Enter some Notes (brief description of the process) which will help ensure an easy traceability of your

measurement reports.

4 Define of which information blocks the report, produced both in a text (Microsoft® Word® file: ‘.doc’

extension) and spreadsheet (Microsoft® Excel® file: ‘.xls’ extension) format, shall consist.

See an example of a report printout in [Measurement report}Page40].

Note

• The report file name itself is not yet entered at this point: e100control will prompt you to define it once the

Start command is given.

Defining the report contents

Note

• An efficient way of exploiting e100control’s flexibility is to define the settings file (.e100) as a template for a

particular measurement (e. g. ‘100g-10g.e100’: settings file for the determination of a 100 g - 10 g weight

set) and to describe the job specifics (e. g. reference of the person/organization who is responsible for this

particular weighing process, reference of the person/organization who placed the order for these services

etc.) in the report under User name and Notes.

See also

2 Starting the weighing process}Page37

2 Measurement report}Page40

5.6 Adapting system settings

Before starting the weighing process, the serial communication needs to be established and the controller’s

serial port properly set. Proceed as follows:

Operation36 Robotic Mass Comparator

Page 39

1 Select System > Comparator serial port….

ð The window Serial port is displayed.

2 Activate the port to which the interface cable 1 is connected.

The other menu points in the System menu are explained later in this Reference Manual:

Menu point Description

Import/Export mode… See [Importing an externally defined settings file into

e100control}Page56]

Application mode… See [Selecting the application mode}Page60]

Software upgrade… See [Upgrading e100control}Page52]

Corner load error measurement… See [Measuring the corner load error}Page49]

Balance pan adjustment...

For METTLER TOLEDO service purposes only.

Email sender configuration… See [Sending emails}Page66]

ReportTransmitter configuration…

For information how to transmit measurement report data to a

TCP/IP server using ReportTransmitter configuration… see

[Transmit measurement report data to a TCP/IP

server}Page69].

Standard’s centering history…

For information how to reduce pre-run/centering time using

Standard’s centering history… see [Reduce pre-run/centering

time using ‘Standard’s centering history’}Page68].

5.7 Starting and monitoring the weighing process

5.7.1 Starting the weighing process

Preconditions

Prior to start the weighing process, ensure the following:

• The needed weights are positioned on the respective weight carriers in the magazine,

see [Preparing the weight magazine}Page17].

• The weights data (test weights and standards data) are entered in e100control,

see [Entering and editing the weights data}Page23].

• The weight magazine places are allocated in e100control,

see [Allocating the weight magazine places}Page27].

• The weighing process settings and the series scheme are determined,

see [Determining the weighing process settings and series scheme}Page28].

• If needed, the content of the report is defined, see [Choosing the report contents}Page36].

• All system settings are adapted to the instrument, see [Adapting system settings}Page36].

Starting the weighing process

To start the weighing process, proceed as follows:

1 Select Start > Start measurement.

2 Once the process is started, enter the name and location of the measurement report file.

3 Confirm your entry by clicking Save (clicking Cancel would abort the process).

Operation 37Robotic Mass Comparator

Page 40

4 After creating the report file, e100control displays a

message box which indicates the process timing, as

well as the maximum balance load. Click OK to pursue

the process (clicking Cancel would abort it).

5 Monitor the weighing process according to [Monitoring

the weighing process}Page38].

Entering the report file name

Weighing process information - Timing and maximum

balance load

5.7.2 Monitoring the weighing process

Overview

Once the weighing process has been started, e100control displays the weighing process monitor which allows

you to follow the process on-line, step by step. The two upper boxes Weight B: and Weight A: show which

comparison weighing is currently being carried out - which weight B vs. which weight A. The large text box first

reminds you of the process settings you defined; it records every single process step and displays the detailed

measurement data, in a format which is similar to the report format. Furthermore, it provides in the ‘status

field’ (area at the bottom left) useful information on the current action, as well as valuable advice with respect

to troubleshooting, should an error be detected.

Operation38 Robotic Mass Comparator

Page 41

Note

1

Should an error be detected, do pay careful attention to the information given in the process status field and

proceed accordingly.

Weighing process monitor

Commands

The following command buttons are available:

Command Description

Suspend and

Resume

The Suspend command interrupts temporarily the process and allows access to the

weighing chamber.

Stop The Stop command aborts the process. You are prompted to chose between aborting

the process immediately, and aborting the process after the robot system has brought

the weight(s), which is (are) being determined, back to the magazine. Should the

process be aborted, the measurement results gathered up to this point as well as the

summary table of the completed series are nevertheless documented in the report file.

Info… e100control indicates the estimated date and time of the completion of the

measurement process, as well as the time (in hours and minutes) remaining until

completion. Please be aware that the process is suspended as long as this information

window is open.

Exit

Closes the weighing process monitor and returns to the main window.

Initial checks

The process starts with a centering phase, during which each weight carrier is checked - by means of the light

barrier located on the robot hand (1) - and centered on its magazine position. If the pre-run is requested, each

weight is weighed and its nominal value checked, after its carrier has been centered.

The following initial checks are performed during centering/pre-run. Should a failure be detected, the process

aborts (except for the dead load check):

• The serial communication is established.

• The authorization was duly given for Down-/upward calibration, if selected.

Operation 39Robotic Mass Comparator

Page 42

• The authorization was duly given for Online climate data input, if selected.

1

• The robot hand is free of any weight carrier.

• The balance dead load - weight (force) generated by the electromagnetic balance sensor, when the balance

pan is free of any weight - has kept stable within an acceptable range since the last process start.

• Each allocated magazine place carries a weight carrier.

• If the mode Down-/upward calibration is chosen, no weight involved in a 3-weight combination is placed

on a weight carrier of design 3 (red frame, see [Selecting a suitable weight carrier}Page17]) - this check

is performed during the centering phase.

• During pre-run only: the difference between measured and nominal weight value does not exceed 10% of

the nominal value.

Checks during each weighing

Beside these initial checks, further ones are performed during each weighing. Should a failure be detected, the

process aborts:

• The carrier type (design) has not changed.

• The difference between measured and nominal weight (combination) value does not exceed 10% of the

(total) nominal value.

• The current group standard deviation, calculated after the second and each following comparison, does not

exceed 20 µg.

• The balance shows neither overload nor underload, once the robot hand has lowered the weight or weight

combination onto the balance pan.

Monitoring of sensors

Finally, the status of the balance position sensor is permanently monitored (see electrical drawing):

• The balance must stay in the position which was precisely defined during system installation - should a

position error be detected, do contact your supplier!

Before weighing, e100control sets the position of the four built-in tare weights in function of the nominal value

of the weight or weights combination. The set of tare weights consists of two 10 g weights, whose position is

set by means of a motor controlled via the balance interface, and two weights, 50g and 30 g, whose

respective position is set by means of a knob controlled by the finger of the robot hand (1).

5.8 Analyzing measurement data and report

5.8.1 Measurement report

The following figures show a report generated by e100control after running a weighing process consisting of

one series of 7 groups of 5 A-B-A comparison weighings. The selected weighing mode is Down-/upward

calibration.

Operation40 Robotic Mass Comparator

Figure 'Report - Part 1' shows the report heading, comprising the following information:

• The report file name (‘.doc’)

• The name of the settings file (‘.e100’)

Page 43

• The process start date and start time

• The duration of the process

• The user identification

• Some notes

• The weighing process settings

• The magazine places allocation

• The series scheme

• The balance settings

Note

• Be reminded that the report contents can be adapted to your needs, see [Choosing the report

contents}Page36].

Figure 'Report - Part 2' shows the measurement data. Each table line consists of the 8 following fields:

Field Description

Day/Time

Meas.no.

Measurement day and time recorded in day/hours:minutes:seconds.

Measurement number which indicates the series number, the group number and the

weighing number.

Example: ‘010203A’ stands for series no. 01, group no. 02, comparison no. 03 and

weight A. When a sensitivity check is carried out, the measurement number shows the

series number and ‘sc’ (for sensitivity check).

Place(s)

Indicates the magazine place(s) of the weight(s).

Noteworthy is the fact that, in case of a weight combination, the reported combination

(e. g. ‘a10 + b2 + b1’) differs from the combination entered in the series scheme (‘a10

+ b1 + b2’): it indicates in which order the weights were put onto the balance pan.

e100control chooses this order in such a way that the error due to corner load is

minimized (see 'Indication of corner load error' further in the current section).

Value

Indicates the recorded weight(s) value in mg. This value is the calculated average of all

values collected during the integration time [Weighing process settings}Page29] and

shows therefore an extra decimal place.

Diff. (B-A)

Indicates for each comparison the calculated difference between weight B and weight A.

The differences listed for a particular group are statistically independent [Calculations}Page45].

Diff.average

Indicates for each group the calculated average of all differences [Calculations}Page45].

WeightB-error

Indicates for each group the calculated error of the weight B, provided the error of the

weight A is known - this applies to a single standard only [Calculations}Page45].

Std.dev.

Indicates for each group the calculated standard deviation of the difference average

[Calculations}Page45].

If the climate data input source is online via serial port [Selecting the application mode}Page60], the

program collects online climate data and the measurement data table consists of additional fields: Each sensor

enabled to be reported has its own field.

Operation 41Robotic Mass Comparator

Page 44

At last, figure 'Report - Part 3' presents the results summary table from which you get, at a glance, the

essentials in a compact, but explicit format. Should the process consist of more than one series, the summary

table indicates the average of the difference averages (Average:).

Report - Part 1: heading and process settings

Operation42 Robotic Mass Comparator

Page 45

Report - Part 2: measurement data

Operation 43Robotic Mass Comparator

Page 46

Report - Part 2: measurement data (cont’d)

Report - Part 3: summary of results

Indication of corner load error

As above mentioned, e100control automatically handles the comparison of two weight combinations in such a

way (placing sequence) that the remaining corner load error is minimized. In the case of a comparison '20 g +

20 g + 10 g' vs. '50 g', the combination entered as '20 g + 20 g + 10 g' will be placed onto the balance pan

in the sequence '20 g + 10 g + 20 g': the center of gravity of the weights combination is located on the same

vertical axis as the 50 g weight and, consequently, the remaining corner load error equals zero. However, in

certain cases, in particular when non OIML weights are involved in a combination (e.g. '30 g + 20 g' vs. '50

g'), a certain error due to corner load remains. Knowing the measured corner load error, e100control

Operation44 Robotic Mass Comparator

Page 47

calculates for each comparison the remaining error due to corner load and, if not zero, indicates it under 'CrLd-

(Val_B

010101

- Val_A

010101

) + (Val_B

010101

- Val_A

010101’

)

Diff

010101

=

2

(Val_B

010102

- Val_A

010102

) + (Val_B

010102’

- Val_A

010102

)

Diff

010102

=

2

(Val_B

010103

- Val_A

010103

) + (Val_B

010103

- Val_A

010103’

)

Diff

010103

=

2

etc.

(Val_B

010101

+ Val_B

010101’

) - (Val_A

010101

+ Val_A

010101’

)

Diff

010101

=

2

(Val_B

010102

+ Val_B

010102’

) - (Val_A

010102

+ Val_A

010102’

)

Diff

010102

=

2

etc.

err' in the results summary table of the measurement report. The corrected difference average (not indicated in

the report) equals 'Diff.average' minus 'CrLd-err'.

Indication of corner load error

See also

2 Measuring the corner load error}Page49

5.8.2 Calculations

The figure below schematically represents the reported measurement data and the differences B-A calculated

during a weighing process, whose comparison scheme was set to A-B-A and A-B-B-A respectively. The calculations are given below for the series 1, group 01 as example.

The differences B-A are reported in the column Diff.(B-A) and, if the comparison scheme A-B-A was selected,

calculated as follows (see the figure below, top diagram):

If the comparison scheme A-B-B-A was selected, the differences B-A, reported in the column Diff.(B-A), are

calculated as follows (see the figure below, bottom diagram):

Operation 45Robotic Mass Comparator

Page 48

The difference average is reported, for each group of n comparisons, in the column Diff.average, and

n

Diff.average

0101

= (1 / n) å Diff

0101 i

i=01

n

S

td.dev.

0101

= [1 / (n-1)] å (Diff

0101 i

– Diff.average

0101

)

2

i=01

WeightB-error

0

101

= WeightA-error

0101

+ Diff.average

0101

(Val_SC00- Val_000) + (Val_SC00- Val_0

00’

)

Diff_SC00= (initial check)

2

(Val_SC01- Val_001) + (Val_SC01- Val_0

01’

)

Diff_SC01= (check done after series 01)

2

etc.

calculated as follows (for both comparison schemes):

The standard deviation of the difference average is reported, for each group, in the column Std.dev., and

calculated as follows (for both comparison schemes):

Provided the error of the weight A is known, the error of the weight B is reported, for each group, in the column