Page 1

Density Meters

DM40 / DM45 DeltaRange / DM50

Installation Information

Page 2

Page 3

Table of Contents

Introduction1 5

Safety measures2 6

Standard Equipment3 7

Layout of the Density Meters4 12

Getting Started5 15

Technical Specifications6 21

Optional Accessories3.1 8

Front View4.1 12

Rear View4.2 13

Removing Transport Lock and Connecting5.1 15

Connecting Hardware5.2 15

Defining Setup Settings5.3 16

Global Settings5.4 16

Care and Maintenance5.5 17

Cleaning the Measuring Cell5.6 17

Adjusting the Measuring Cell5.7 18

Creating an Adjustment Method5.7.1 18

Performing Adjustment5.7.2 18

Testing the Measuring Cell5.8 19

Creating a Test Method5.8.1 19

Performing the Test5.8.2 19

Performing a Density Measurement5.9 19

Creating a Measurement Method5.9.1 19

Performing the Measurement5.9.2 20

Maintenance and Service7 23

Disposal 8 24

Critical Errors9 25

Declaration of System Validation10 26

Declaration of Conformity11 27

Table of Contents 3

Page 4

Page 5

1Introduction

Simple and compact

The METTLER TOLEDO DM40/DM45 DeltaRange/DM50 Density Meters are modern, compact instruments suit

able for use in a vast diversity of application areas. They can be used, for example, in quality control as well as

in research and development and meet the most demanding requirements.

These compact density meters perfectly combine simple, easy-to-understand operation with a high level of

measuring accuracy and outstanding reliability. With their plug & play capability, they automatically detect

external devices and sensors.

The density meters can be operated as standalone instruments or run from a computer using the LabX PC soft

ware. Straightforward user guidance on the large color touchscreen enables intuitive operation. User-definable

shortcuts allow all functions to be activated directly from the home screen with a single click.

Touchscreen control of the instrument and the method function parameters are described in the Operating

Instructions. The Installation Instructions explain all the necessary steps for setting up your instrument. You are

then guided through the first density measuring process with the aid of a practical example.

If you have any additional questions, METTLER TOLEDO is always available to assist you.

5Introduction

Page 6

2Safety measures

These instruments have been tested for the applications documented in the appropriate operating instructions.

However, that does not absolve you of the responsibility to check for yourself the suitability of the products sup

plied by us for the procedures and purposes for which you intend to use them. You should therefore observe the

following safety measures.

Measures for your personal protection

Risk of electric

shock

Risk of explosion

Risk of corrosion

●

Ensure that you plug the supplied power cable into a socket that is grounded! In the

absence of grounding, a technical fault could be lethal.

●

Only use the power supply which was supplied with the device.

●

Never work in an environment subject to explosion hazards! The housing of the

instrument is not gas tight (explosion hazard due to spark formation, corrosion

caused by the ingress of gases).

●

Test highly combustible, poisonous or corrosive substances under an extractor

hood and follow the normal laboratory rules and precautions.

●

When using chemicals and solvents, comply with the manufacturer's instructions

and the general lab safety rules!

Measures for operating safety

●

Do not clean the measuring cell with conc. caustic soda (sodium hydroxide, NaOH)

or hydrofluoric acid (HF)! Both substances will chemically corrode the measuring

cell.

●

Caution

Exclude the following environmental influences:

- Direct sunlight

- Air humidity above 80%

- Ambient temperatures below 5 °C and above 35 °C

- Powerful electrical or magnetic fields capable of affecting the power supply due to

large load changes

- Strong vibrations

Only have the instrument serviced by an authorized METTLER TOLEDO Service agent!

6 Safety measures

Page 7

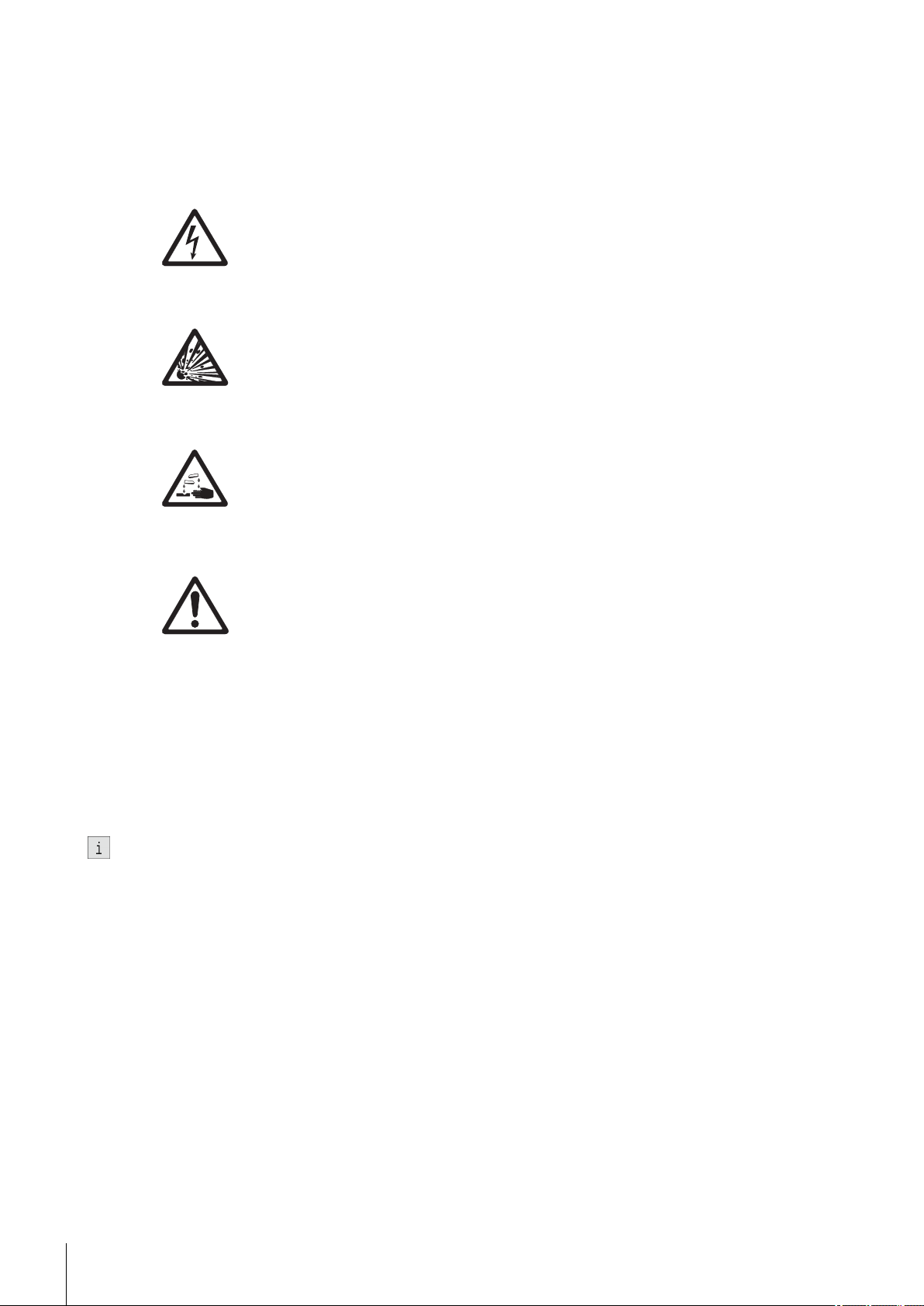

3Standard Equipment

All parts are specified with their ordering code and quantity in cases where more than one part is included.

Description Order number

Density Meter:

- DM40

- DM45 DeltaRange

- DM50

External power supply (100 – 240 Volt) 51192015

Power cable (country-specific) -

In use cover 51337079

51337000

51337001

51337002

Combination ring/open-ended wrench 51192087

Allen wrench 51192088

Disposable syringe (10mL)

(5 pcs.)

DM tube / syringe adaptor

(1 pc.)

51338100

51337154

7Standard Equipment

Page 8

Waste tube:

- M8 / 600 mm

Tubing:

- M8 / M8 / L280 mm

- M8 / M8 / L400 mm

Combined density / refractive index standard water (9mL) 51338010

51337223

51337224

51337226

3.1Optional Accessories

Software

External measuring cells

Density modules:

DM40/45 DeltaRange/50 CD containing operating and instal

lation instructions

●

LabX (PC software for the instrument)

●

Device licenses for the instrument

- DX40

- DX45 DeltaRange

- DX50

51710776

LabX

51337005

51337006

51337007

Refractive index modules:

●

RM / RX flow cell with connecting set, incl.

- Tubing, M8 / M8 / L400

- Tubing, M8 / M8 / L550

- Tubing, M8 / L400

- O-ring for flow cell

- Protection plate

8 Standard Equipment

- RX40

- RX50

- RX fixing device (for securing the refractive index

module vertically)

51337008

51337009

51337025

51337024

51337226

51337227

51337223

51192068

51337189

Page 9

Automation

DryPal (drying pump) complete with

- desiccator

- silicon tube, D6/d3 L500

- silica gel

FillPal (sampling pumps):

- FillPal Food

- FillPal Chem

- Tubing set FillPalFood complete

- Tubing set FillPalChem complete

- Shielded sampling tube, L = 25 cm

- Tubing, M8 / M8 / L400

- Tubing, M8 / M8 / L550

●

SC1/SC30 automation units:

- SC1 (sample and cleaning unit)

- SC1H (heated version of SC1)

- SC30 (sample and cleaning unit for 30 samples)

- SC30H (heated version of SC30)

●

InMotion™ Autosampler

- Bundle: Flex Base with 100mL rack

51337029

51337180

51337228

51337241

51337027

51337028

51337219

51337218

51337236

51337226

51337227

51326000

51326400

51327000

51327500

30094290

- Flex Base

- Flex Rack Kit 25mL beaker (50 samples)

- Flex Rack Kit 80mL beaker (27 samples)

- Flex Rack Kit 100mL beaker (18 samples)

30094291

30094124

30094125

30094126

30094292

- Pro Base

- Pro Rack Kit 25mL beaker (182 samples)

- Pro Rack Kit 80mL beaker (69 samples)

30094129

30094130

30094131

- Pro Rack Kit 100mL beaker (34 samples)

30094293

- Max Base

- Max Rack Kit 25mL beaker (303 samples)

- Max Rack Kit 80mL beaker (113 samples)

30094134

30094135

30094136

- Max Rack Kit 100mL beaker (55 samples)

External instruments

●

SevenCompact S220 pH/Ion 30019028

●

pH connecting kit complete with

- Tubing, M8/M8 L400

- Tubing, M8/M8 L550

- Cable for pH electrode

- USB/RS adaptor for SevenEasy™ / SevenCompact™ pH meter

- RS-232C cable

- pH electrode

- External flow cell

51337023

51337226

51337227

59902392

51105851

51190589

59902917

51337190

51337197

- Holding plate for pH / Conductivity flow cell

●

SevenCompact S230 Conductivity 30019033

9Standard Equipment

Page 10

●

Conductivity connecting kit complete with

- Tubing, M8/M8 L400

- Tubing, M8/M8 L550

- USB-RS adaptor for SevenEasy™ / SevenCompact Conductivity™

- RS-232C cable

- Conductivity sensor

- External flow cell

- Holding plate for pH / Conductivity flow cell

51337022

51337226

51337227

51105852

51190589

51302885

51337190

51337197

Colorimeter

●

Color connecting kit Lovibond complete with

- Flow cell

- USB-RS adaptor for Lovibond colorimeter

51337021

51337295

51105853

The Lovibond Type PFX8XX, 9XX or PFXi8XX, 9XX colorimeter is obtainable from Tintometer AG.

●

Color connecting kit Konica Minolta complete with

- Flow cell

- USB A-B cable

30025477

51337295

51191926

The colorimeter Type CM-5 or CR-5 and the needed transmittance specimen holder is obtainable from Konica

Minolta.

Auxiliary Instruments

●

Adapter Auxiliary Instruments (USB-RS232 convertor) 51105856

Sensors

●

LevelSens (fluid level sensor for waste bottle, incl. attachment strap and 2m cable)

- Extension cable 1 m for LevelSens (optional)

●

WasteSens (fluid level sensor for waste bottle) inc.

- WasteSens holder

●

AtmoSens (atmosheric pressure sensor) 51337186

●

ErgoSens (motion sensor) 11132601

51109863

51108308

51337026

51337157

Peripherals

●

ScanStraight (built-in barcode reader) complete 51337185

●

Barcode reader (hand-held)

- USB cable for barcode reader

●

LogStraight (fingerprint reader) 51192107

●

Printer (USB-P25) inc. cable

- paper rolls (2 pcs.)

- ink ribbon (black)

21901297

21901309

11124301

12120799

12120798

10 Standard Equipment

USB data export box 51105855

Page 11

Miscellaneous accessories

●

Packing complete DM/DX 51337284

●

DM/DX transport lock set 51337164

●

Cell adaptor (PTFE) 51337158

●

Mounting tool cell adapter (used for mounting the cell adapter) 51337293

●

Protective sleeve (blue) 51337078

●

Coupling piece for M8 screws (set of 2) 51337179

●

Tubing, M8/M8 L280

●

Tubing, M8/M8 L400

●

Tubing, M8/M8 L550

●

Tubing, M8/M8 L800

51337224

51337226

51337227

51322234

11Standard Equipment

Page 12

4Layout of the Density Meters

A

B

C

D

E

F

4.1Front View

A: Connection for outlet tube

B: Connection for inlet tube

C: On/Off button

D: Indicator lamp

E: Touchscreen

F: Internal cell and viewing window

12 Layout of the Density Meters

Page 13

4.2Rear View

Connection Description

DryPal

pH/Cond

RX Socket for fixing plate for stabilizing the external RX refractometer cell

ErgoSens Connection for infrared motion sensor

WasteSens Connection for fluid level sensor (WasteSens/ LevelSens)

Aux Service connection

DryPal Connection for drying pump

FillPal Connection for sampling pump

Power Supply Power supply connection

Automation Connection for automation unit SC1 or SC30

Ethernet Network interface for LabX PC software, network export, network printer

PC USB interface for LabX PC software

Socket for:

●

DryPal (drying pump)

●

External flow cell: pH or conductivity

13Layout of the Density Meters

Page 14

Connection Description

USB 1/USB 2 For connection of various USB devices:

●

Density Module/Refractiv Index Module

●

InMotion™ Autosamplers

●

External instruments

●

Fingerprint reader

●

Barcode reader

●

USB-P25 printer

●

AtmoSens

●

USB memory stick

14 Layout of the Density Meters

Page 15

5Getting Started

a

a

a

a

a

a

a

a

The following sections describe how to connect the instrument, set it up and adjust it, and how to carry out the

first measurement.

5.1Removing Transport Lock and Connecting

Removing transport lock

After unpacking the device, the eight screws (a) on the underside of the unit must be removed before the instru

ment is connected electrically. To remove the screws, use the combination ring/open-ended wrench supplied.

When shipping or transporting the instrument over long distances, you should refit the transport screws and the

original packaging.

Connecting the power cable

Plug the power cable into the connection labeled "Power Supply" on the rear panel of the device. Switch on the

instrument so that it can adjust to operating temperature.

●

Connect the instrument only to a grounded power outlet socket.

●

Make sure it matches the instrument's power supply rating.

●

The power outlet socket must be easily accessible.

5.2Connecting Hardware

Connect your additional devices (e.g. printer, sensors, external measuring cells or automation units) to the

appropriate sockets on the rear panel of the density meters (see also "Layout of Density Meter: Rear view

(page13)").

●

For detailed information on the installation of such devices and the attachment of tubes to the automation

units and rinsing/waste reservoirs, please refer to the instruction manuals for the devices concerned.

●

When connecting PnP-compatible devices, the PnP parameters are automatically transferred to the instru

ment setup.

15Getting Started

Page 16

5.3Defining Setup Settings

This section briefly describes which hardware settings you should customize:

●

Connecting an SC1/SC30:

Navigation: Home > Setup > Hardware > Automation > SC1 or SC30

If you are connecting an SC1 or SC30 automation unit, in the setup you must specify the solvents that are

connected to the connections "Rinse 1" and "Rinse 2" on the SC1/SC30.

●

Connecting an InMotion autosampler

Navigation: Home > Setup > Hardware > Automation > InMotion

If you are connecting an InMotion autosampler, in the setup you must define on which port the sampling

pump is connected. Optionally also on which port the stirrer and/or PowerShower pump is connected.

●

Connecting a colorimeter:

Navigation: Home > Setup > Hardware > External instruments > Parameters

In addition to the device-specific information boxes, there are editable fields for entering the four wave

lengths for the colorimeter.

●

Connecting fingerprint reader:

Navigation: Home > Setup > Hardware > Peripherals > Fingerprint reader

If you are using a fingerprint reader, the parameter "Activate fingerprint reader" must be set.

●

Connecting ErgoSens/WasteSens:

Navigation: Home > Setup > Hardware > Sensors

If you are using these sensors, the parameters "Activate ErgoSens"/"Activate WasteSens" must be set.

●

Connecting barcode reader:

Navigation: Home > Setup > Hardware > Peripherals > Barcode reader >

Parameters

The format of the barcode must be defined as set out in the Operating Instructions.

●

Connecting auxiliary instruments:

Navigation: Home > Setup > Hardware > Auxiliary instruments

The auxiliary instruments must be defined as set out in the Operating Instructions.

5.4Global Settings

●

Entering device identification:

Home > Setup > Global settings > System > Identification

In the Instrument identification dialog box you can enter your own user-defined ID code in the text box for

the parameter "Instrument ID".

●

Setting date and time:

Navigation: Home > Setup > Global settings > System > Date/Time

●

Defining physical properties:

Navigation: Home > Setup > Global settings > Physical properties

- Select the desired unit for the parameter "Temperature unit".

- If you are not using an atmospheric pressure sensor (AtmoSens), enter the standard atmospheric pressure

for your location (elevation above sea level) according to the table below.

Note: If an AtmoSens is connected, the current atmospheric pressure is displayed and used.

16 Getting Started

Page 17

Density in relation to pressure

Height above sea level Atmospheric

[m] [feet] [hPa] [m] [feet] [hPa]

0 0 1013

100 328 1001 1400 4593 856

200 656 990 1500 4921 846

300 984 978 1600 5249 835

400 1312 966 1700 5577 825

500 1640 955 1800 5906 815

600 1969 943 1900 6234 805

700 2297 932 2000 6562 795

800 2625 921 2100 6890 785

900 2953 910 2200 7218 776

1000 3281 899 2300 7546 766

1100 3609 888 2400 7874 756

1200 3937 877 2500 8202 747

*)

Factory setting

5.5Care and Maintenance

Attaching an external measuring cell:

Navigation: Home > Setup > Mainten. & Service > Add external cell

Perform the action "Add external cell". In the Cell dialog box, the cell type must be selected (Home > Setup

> Hardware > Cell).

pressure

Height above sea level Atmospheric

pressure

*

1300 4265 867

5.6Cleaning the Measuring Cell

Before you adjust the device, the measuring cell must be cleaned. To do so, first rinse the cell with water and

then with acetone. When doing so, proceed as follows:

Manual operation

1 Attach the syringe adaptor to the lower measuring cell connection (inlet) (note: adaptor must be firmly seat

ed).

2 Make sure that the outlet tube feeds into a waste reservoir.

3 Clean the cell thoroughly several times using a syringe – first using a suitable cleaning agent (e.g. water)

and then with a mildly volatile solvent (e.g. acetone).

Note: If the cell is heavily soiled, other solvents such as Deconex (0.3%) must be used as well.

4 After the measuring cell has been cleaned it must be dried. For that purpose you should connect the outlet

tube to the DryPal drying tube.

5 In the Automation dialog, select the parameters "Action = Dry" and "Dry mode = Automatic" (Navigation:

Home > Manual > Automation).

6 Touch Start.

The drying process will start.

Note: The drying pump switches off automatically when the cell is dry. The drying process should be

completed in approx. 3 minutes.

Automatic operation

When using the instrument with a FillPal/SC1/SC30, the actions "Dry" and "Rinse" of the manual operation

"Automation" can be used.

For details, refer to the Operating Instructions, "Manual operations > Automation > Action: Dry/Action: Rinse"

17Getting Started

Page 18

See also

●

Rear View (page13)

5.7Adjusting the Measuring Cell

5.7.1Creating an Adjustment Method

Navigation: Home > Methods/Products > Methods

This section describes how to create an adjustment method.

You must define a suitable method for adjustment. In the Adjustments and Tests setup there is the adjustment

set "Air&Water20.00C". You can use that adjustment set for your first adjustment.

1 Touch the New button in the Methods dialog box.

The Method templates dialog box opens.

2 In the dialog box, touch the method template "ADJUSTMENT".

The Configuration dialog box appears.

3 Touch OK.

4 Touch the method function "Title".

5 In the "Method ID" parameter box, enter an ID.

6 Touch OK.

The parameters do not have to be changed for the subsequent method functions; the preset parameters

can be accepted.

7 Save the method.

5.7.2Performing Adjustment

Make sure that the measuring cell is clean and completely dry.

Switch on the device and wait for it to reach operating temperature, which will take at least 15 minutes in

the case of the DM40 and 30 minutes with the DM45 or DM50.

Note: Immediately after switching on, this adjustment is not correct for very long as the volume of the mea

suring cell's glass vessel changes slightly during the warming-up phase. Therefore, you should check regu

larly at the start of a series of measurements, e.g. by measuring the density of water, whether the instrument

is still measuring accurately. If you identify a systematic deviation, you should perform the adjustment

again. The DM40 should be completely stable after approx. 2 hours. With the 5-digit instruments (DM45

and DM50), it can take up to 48 hours.

1 Open the new adjustment method you defined at Home > Methods/Products > Methods.

2 Touch Start.

The Start analysis dialog box opens.

3 In the dialog box, touch Start.

The cell is adjusted according to the settings previously entered.

Manual method:

When the prompt "Add sample" appears, slowly inject water into the measuring cell with the aid of the syringe

and then confirm by pressing OK.

Operation with FillPal:

When the prompt "Immerse aspiration tube in sample" appears, place the aspiration tube in the sample beaker

and press OK to confirm.

Operation with SC1/SC30:

place the sample vial in the automation unit before starting adjustment.

Operation with InMotion Autosampler:

place a beaker with water in the rack before starting adjustment.

18 Getting Started

Page 19

●

In order to obtain a meaningful reading, the sample should run a minimum of approx. 15 cm out of the

measuring cell.

●

If you have a printer connected, a summary of the adjustment data is printed out at the end of the adjust

ment process.

See also

●

Cleaning the Measuring Cell (page17)

5.8Testing the Measuring Cell

The purpose of this test is to check that the device is fully functional. To be able to perform the test, you have to

create a test method.

This section describes how to create a test method and carry out the test.

5.8.1Creating a Test Method

Navigation: Home > Methods/Products > Methods

1 Touch the New button in the Methods dialog box.

The Method templates dialog box opens.

2 In the dialog box, touch the method template "TEST".

Note: The remaining procedure is analogous to that described in the section Creating an adjustment method

(page18).

3 Touch the method function "Test".

4 Set the parameter "Tolerance d" as follows:

DM40

Tolerance: 0.0002 g/cm3

DM45/50

Tolerance: 0.00004 g/cm

5 Save the method.

3

5.8.2Performing the Test

– Start the test method previously created.

A message will inform you whether the test succeeded or failed. If the test fails, you will be given sug

gestions for possible causes.

See also

●

Cleaning the Measuring Cell (page17)

●

Performing Adjustment (page18)

5.9Performing a Density Measurement

For the first measurement sequence, a simple measurement using water can be carried out.

5.9.1Creating a Measurement Method

This section describes how to create a measurement method.

1 Touch the New button in the Methods dialog box (Navigation: Home > Methods/Products >

Methods).

The Method templates dialog box opens.

2 Touch the method template "MEASURE" in the Method templates dialog box.

Note: The remaining procedure is analogous to that described in the section "Creating an adjustment

method (page18)".

19Getting Started

Page 20

5.9.2Performing the Measurement

Carry out the first measurement using water at 20°C by starting the method previously created.

See also

●

Cleaning the Measuring Cell (page17)

20 Getting Started

Page 21

6Technical Specifications

Density Meters DM40 / DM45 DeltaRange / DM50

Technical specifications of measuring cell

Measuring cell DM40 DM45 Delta Range DM50

Density

(Peltier)

Permanently stored concentration table

Alcohol

Viscosity correction Yes Yes Yes

Pressure range in the cell

Required sample volume at least 1.2 mL (manual injection with syringe)

Typical measuring times

(inc. thermostatic control)

Parts in contact with sample Borosilicate glass, PTFE, FEP, PP (syringe adaptor)

1)

Up to 100% by extrapolation

2)

measuring cell only

Technical specifications of hardware

Measuring range

[g/cm3]

Limits of error

[g/cm3]

Repeatability (SD)

[g/cm3]

Resolution

[g/cm3]

Range [°C] 0 - 91 0 - 91 0 - 91Temperature

Limits of error [°C] 0.05 (10 – 30)

Range [% v/v] 0 - 100 0 - 100 0 - 100

Limits of error

[% v/v]

Repeatability

(SD) [% v/v]

Range [% w/w] 0 - 83

Brix

Limits of error

[% w/w]

Repeatability

(SD) [% w/w]

Power supply

0 – 3 0 – 3 0 – 3

0.0001 0.00002

(d: 0.7 - 1)

0.00005

(d: 0 - 3)

0.00002

(d: 0 - 1)

0.00003

(d: 1 - 2)

0.00004

(d: 2 - 3)

0.00005 0.000005 0.000005

0.0001 0.00001 0.00001

0.1 (0 - 91)

0.02 (15 – 20)

0.05 (0 - 91)

0.02 (10 – 30)

0.05 (0 - 91)

0.1 0.02 0.02

0.1 0.01 0.01

1)

0 - 83

1)

0 - 83

1)

0.03 0.02 0.006

0.03 0.015 0.003

2)

up to 10 bar max.

at least 2 mL (complete cycle with attached automation unit)

approx. 1 to 4 minutes (manual)

approx. 2 to 10 minutes (complete cycle with attached automation

unit)

Input voltage 100–240 VAC ±10%

Input frequency 50–60 Hz

Primary connection socket 3 pin, IEC C14

Power consumption 120 VA

Connected load 24 VDC, 5 A

Secondary connection plug 4 pin, DC plug

Processor Marvel PXA270

CPU

312 MHz

SDRAM 64 MB

Flash memory 256 MB (industrial SD card)

21Technical Specifications

Page 22

Connections

Dimensions

Materials

Ambient conditions

ErgoSens Socket

Automation

PC PC connection via USB USB full speed

Display

Input Technology Full-coverage touchscreen

Width 272 mm (ex. cell connection)

Depth 385 mm

Height 215 mm

Weight 13.53 kg

Housing PP HCT540

Cover sheet PET

Protective cover Barex 201

Chassis Stainless steel

Inlet/outlet tube FLEXILON® PFA

Ambient temperature 5 °C - 35 °C

Relative humidity Max. 80% (non-condensing) at 31

°C, with linear reduction to 50% at

35°C

Use In interior spaces

Overvoltage category II

Pollution degree 2

Max. installation height 2000 m (above sea level)

3.5mm

(input for infrared sensor)

Socket 5-pin mini-DINWasteSens

Voltage 24 V DC ±5% (max. 1000 mA)

Socket 5-pin mini-DINAux

Voltage 24 V DC ±5% (max. 1000 mA)

Socket 5-pin mini-DINDryPal

Voltage 24 V DC ±5% (max. 1000 mA)

Socket 5-pin mini-DINFillPal

Voltage 24 V DC ±5% (max. 1000 mA)

Socket 9-pin male D-sub

Configuration Full-duplex

Baud rate 4800

Handshake X-On / X-Off

Galvanic isolation No

ESD stability Min. 1000 V

Short-circuit protection Yes

Socket RJ45Ethernet

Speed 10/100 MBit/s

USB host USB full speedUSB1 / USB2

Max. power load 400 mA

Technology Color TFT

Size 5.7"

Resolution 640 x 480 pixels

Backlighting LED

Brightness control Per software 50–100%

22 Technical Specifications

Page 23

7Maintenance and Service

Cleaning

Clean the casing of the instrument using a cloth moistened with alcohol.

The measuring cell is cleaned using the method function "Clean" (for details refer to "Cleaning the measuring

cell (page17)").

23Maintenance and Service

Page 24

8Disposal

In compliance with European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment (WEEE), this instrument must not be disposed of together with domestic

waste. This also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting

point specified for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the distributor

from which you purchased this instrument.

Should this instrument be passed on to other parties (for private or professional use),

the content of this regulation must also be related.

Thank you for your contribution to environmental protection.

24 Disposal

Page 25

9Critical Errors

Error code Error

E007 Fan 1 stopped

E030 Fan 2 stopped

E028 Temperature sensor malfunction

E029 Thermomodule malfunction

E031 Hardware error

E033 Memory error

E064 Maximum temperature exceeded

E075 Electric current too high

E076 Voltage too high

25Critical Errors

Page 26

10Declaration of System Validation

Density Meters (DM40 / DM45 DeltaRange / DM50)

We hereby give notice that this product / system and its software and accessories were developed, tested and

successfully certified on the basis of the product life-cycle policies of Mettler-Toledo AG, Analytical. These poli

cies are based on ISO Standard 9001:2000. Life-cycle checkpoint details were reviewed and approved by the

Project Steering Group (PSG). The products / systems were tested in respect of functionality and specification

prior to shipment. In order to support GLP and validation requirements, we will make the following documents

available to authorized persons for inspection:

●

Performance specifications

●

Market and technical requirements

●

Quality plan

●

Project management system

●

Plan and Test results

●

Review reports

Mettler-Toledo AG, Analytical will retain possession of all documents and their reproductions and may wish to

conclude a nondisclosure agreement with those requesting access to these documents.

Schwerzenbach,

December 2011

Chris Radloff

General Manager

Business Unit Analytical

Christian Walter

Manager Business Area

AnaChem

26 Declaration of System Validation

Page 27

11Declaration of Conformity

27Declaration of Conformity

Page 28

28 Declaration of Conformity

Page 29

29Declaration of Conformity

Page 30

Page 31

Page 32

Mettler-Toledo AG, Analytical

CH-8603 Schwerzenbach, Switzerland

Tel. +41 (0)44 806 77 11

Fax +41 (0)44 806 73 50

www.mt.com

www.density.com

For more information

Subject to technical changes.

© Mettler-Toledo AG 03/2014

51710780C

*51710780*

Loading...

Loading...