Page 1

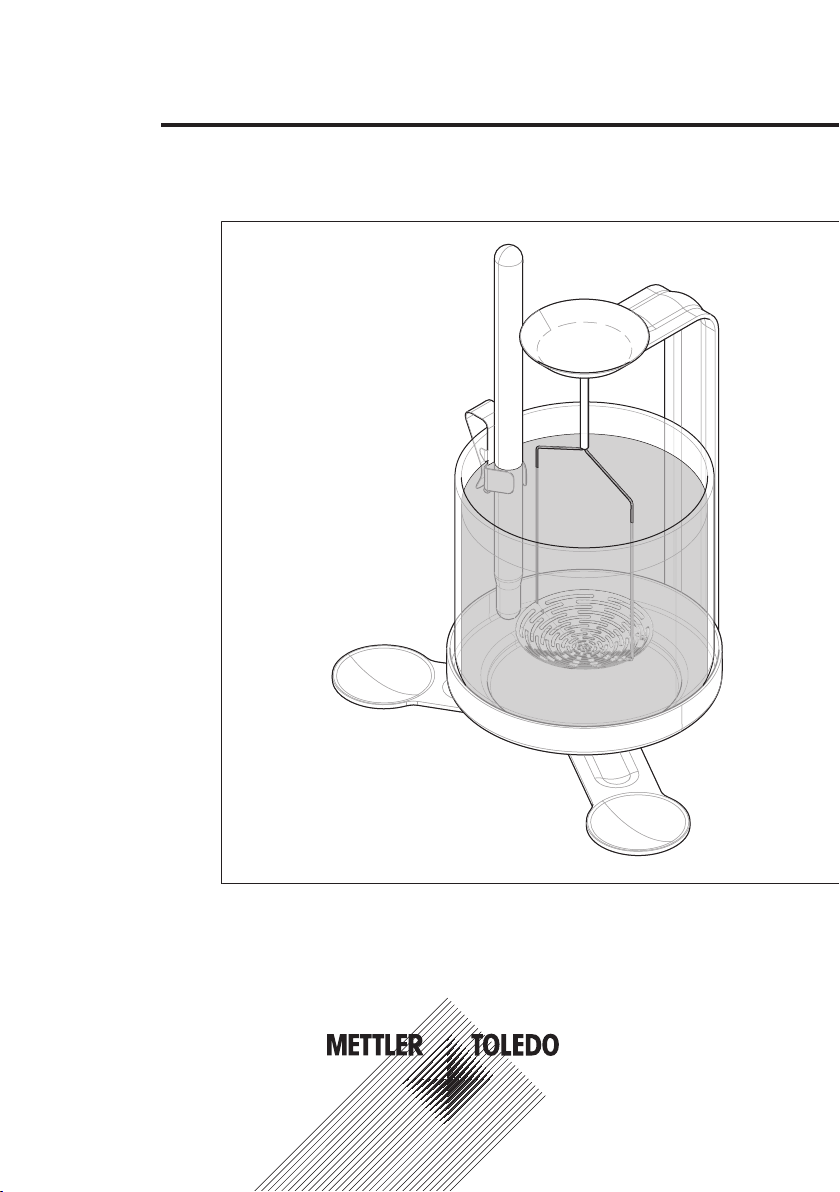

for Precision Balances XPR, XSR, XPE, XP, XS

Reference Manual

Density Kit

Page 2

Page 3

This Reference Manual provides information to handle the instrument in a safe and efficient manner.

Personnel must have carefully read and understood this manual before performing any tasks.

Additional languages available online

u www.mt.com/Density-Kit-precision-RM

3Density Kit

Page 4

1 Introduction

Thank you for choosing a METTLER TOLEDO density kit.

The density kit allows you to determine the density of solids and liquids. The kit is compatible with XPR, XSR,

XPE, XP, XS precision balances 0.1mg and 1mg.

Purpose of this document

This document explains how to work with the density kit. It provides the procedure for performing a density determination manually as well as instructions on the density determination software. If you need information on

operating your balance, please refer to the "Reference Manual (RM)" of your balance.

Finding more information

u www.mt.com/lab-accessories

u www.mt.com/library

Conventions and symbols

Key and/or button designations and display texts are shown in graphic or bold text, e.g.,

Refers to an external document.

Elements of instructions

Prerequisites

§

1 Steps

2 ...

ð Intermediate results

ð Results

, Edit.

Introduction4 Density Kit

Page 5

2 Safety Information

Only use the accessory according to this "Reference Manual" and the "Reference Manual" of the main instrument.

If you do not use the accessory according to both documents or if it is modified, the safety of the main instrument

may be impaired and Mettler-Toledo GmbH assumes no liability.

2.1 Definition of signal warning symbols

Safety notes are marked with signal words and warning symbols. These show safety issues and warnings.

Ignoring the safety notes may lead to personal injury, damage to the instrument, malfunctions and false results.

Signal words

NOTICE

Warning symbols

Notice

Personal protective equipment

Wear gloves to avoid contamination.

2.2 Product-specific safety information

Intended use

Your density kit is used to determine the density of solids and liquids. Use the density kit exclusively for this

purpose. Any other type of use and operation beyond the limits of technical specifications without written consent

from Mettler-Toledo GmbH is considered as not intended.

Intended use also includes compliance with all the instruction in this "Reference Manual" and the "Reference

Manual" of your balance.

Responsibilities of the instrument owner

The instrument owner is the person holding the legal title to the instrument and who uses the instrument or

authorizes any person to use it, or the person who is deemed by law to be the operator of the instrument. The

instrument owner is responsible for the safety of all users of the instrument and third parties.

METTLER TOLEDO assumes that the instrument owner trains users to safely use the instrument in their workplace

and deal with potential hazards. METTLER TOLEDO assumes that the instrument owner provides the necessary

protective gear.

Safety notes

A hazardous situation with low risk, resulting in damage to the instrument, other material

damage, malfunctions and erroneous results, or loss of data.

NOTICE

Damage or malfunction due to the use of wrong parts

Through the use of the wrong or defective parts, dangers for personnel can occur and damage,

malfunction or total instrument failure can occur.

− Use only original parts supplied or approved by the manufacturer.

Safety Information 5Density Kit

Page 6

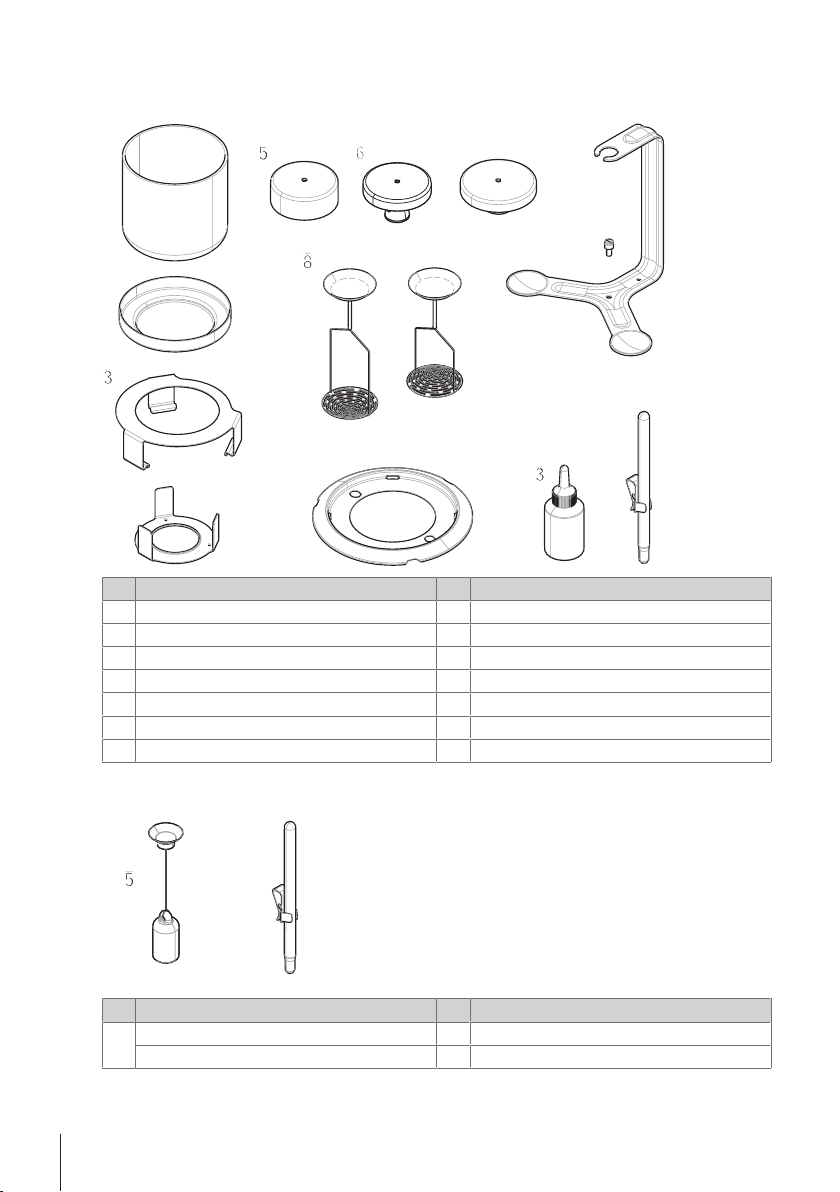

3 Installation and putting into operation

11

22

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

3.1 Scope of delivery

No. Designation No. Designation

1 Glass beaker ø 80mm, high 8 Holder for sinking solids

2 Pan 9 Holder for floating solids

3 Pan holder, big 10 Draft ring ø 90mm

4 Pan holder, small 11 Bracket

5 Compensation weight, white, for XP/XPE 0.1mg 12 Screw

6 Compensation weight, white, for XPR 0.1mg 13 Wetting agent

7 Compensation weight, chrome steel, for 1 mg 14 Precision thermometer with holder

3.2 Accessories

No. Designation No. Designation

15 Sinker 10 ml 16 Precision thermometer, calibrated

Sinker 10 ml, calibrated

Installation and putting into operation6 Density Kit

Page 7

3.3 Installing the density kit

22

4

4

6

6

11

11

12

12

6

6

11

11

12

12

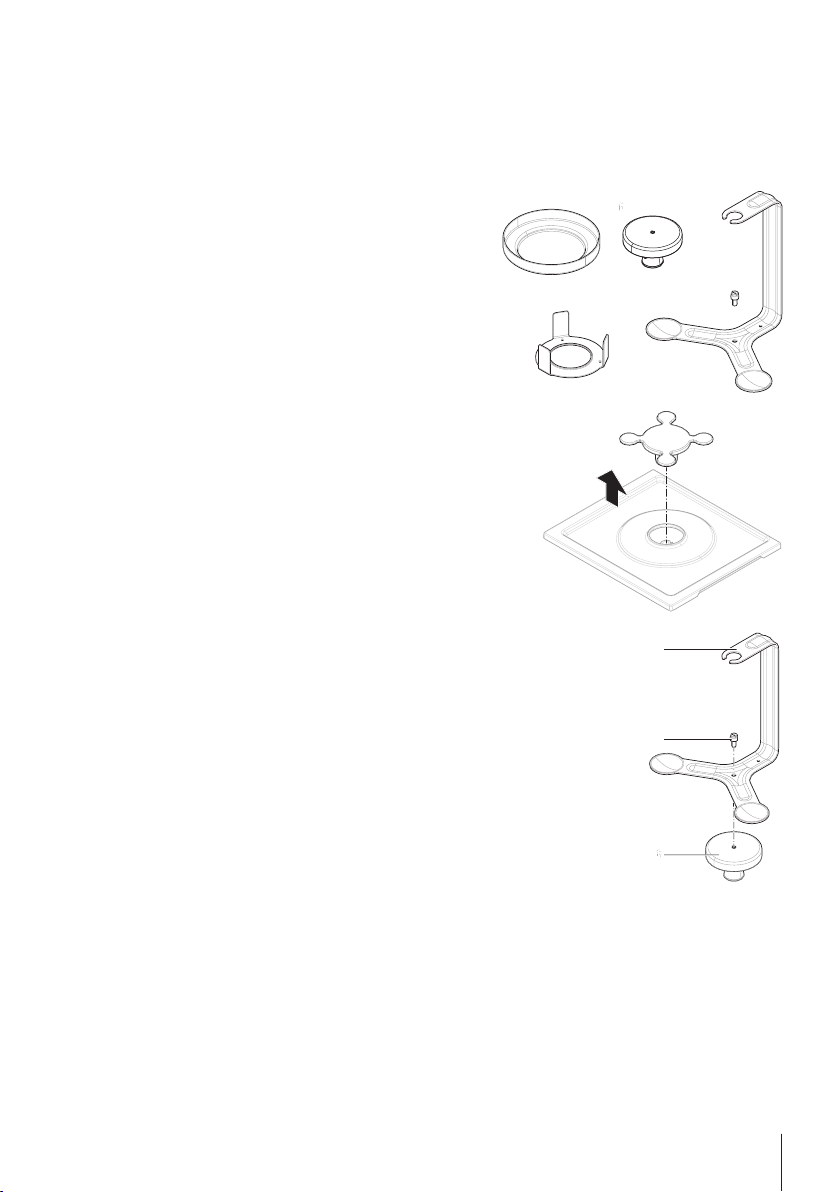

3.3.1 Installing on XPR 0.1mg

These installation instructions are suitable for precision balances with names of the type:

• XPRx04S

The following parts are available:

§

1 Open the draft shield.

2 Remove the SmartPan.

3 Assemble the bracket (11) and the compensation weight

(6) with the provided screw (12).

Installation and putting into operation 7Density Kit

Page 8

4

4

22

4 Place the pan holder (4) on the drip tray plate.

5 Install the compensation weight and bracket on the

weighing cell.

6 Place the pan (2) on top of the pan holder (4). The pan

should not touch the bracket nor the screw.

ð To operate the density kit, refer to the section "Operation".

Installation and putting into operation8 Density Kit

Page 9

3.3.2 Installing on XP/XPE 0.1mg

22

11

11

12

12

3

3

5

5

11

11

12

12

5

5

These installation instructions are suitable for precision balances of the type:

• XPEx04S

• XPx04S

The following parts are available:

§

1 Assemble the bracket (11) and the compensation weight

(5) with the provided screw (12).

2 Open the draft shield.

3 Remove the weighing pan.

Installation and putting into operation 9Density Kit

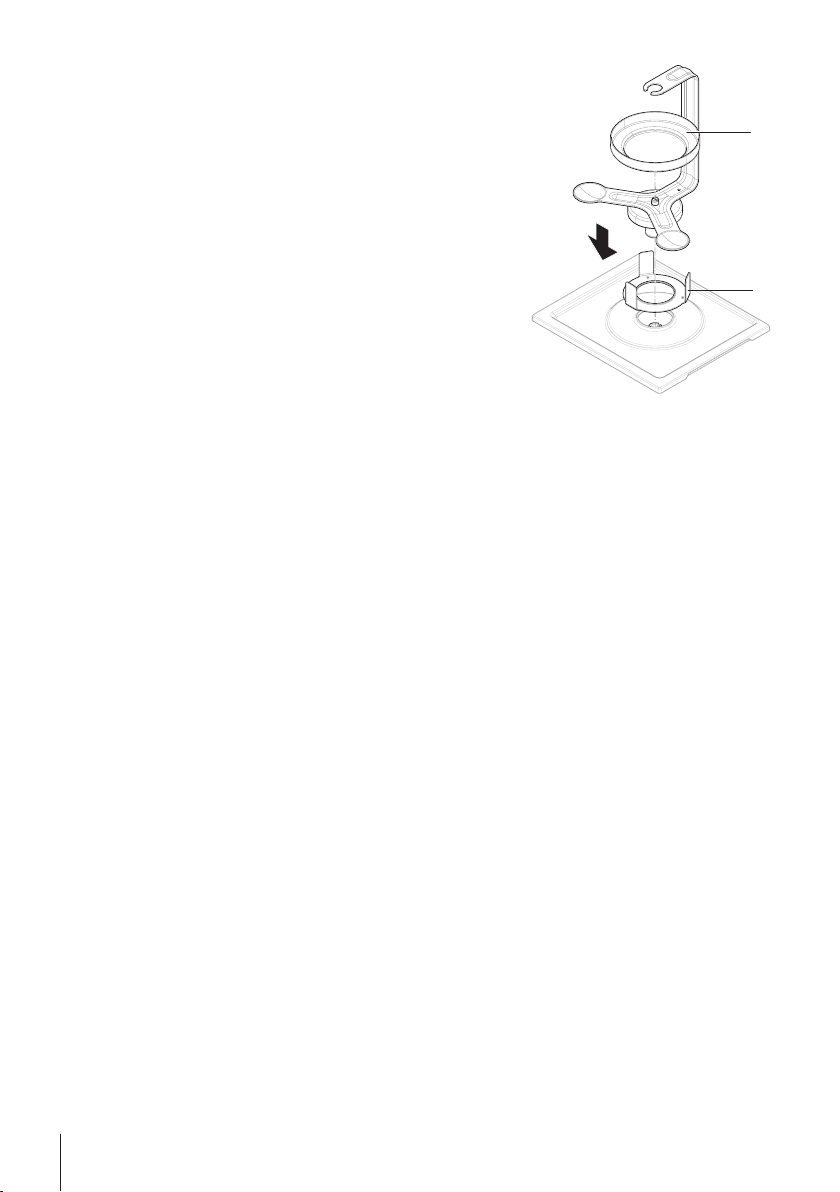

Page 10

22

3

3

10

10

4 Install the compensation weight and bracket on the

weighing cell.

5 Place the pan holder (3) on the draft ring (10). Make sure

that the thinner side of the pan holder's rim is facing the

bracket.

6 Place the pan (2) on top of the pan holder (3). The pan

should not touch the bracket nor the screw.

ð To operate the density kit, refer to the section "Operation".

Installation and putting into operation10 Density Kit

Page 11

3.3.3 Installing on XSR/XPR/XS/XPE 1mg with SmartPan

22

4

4

11

11

12

12

7

7

11

11

12

12

7

7

These installation instructions are suitable for precision balances with names of the type:

• XSRxx03S and XSRxx03SN

• XPRxx03S and XPRxx03SN

• XPExx03S and XPExx03SN with SmartPan

• XSxx03S and XSxx03SN with SmartPan, from SNR B543000000 on

The following parts are available:

§

1 Open the draft shield, if applicable.

2 Remove the SmartPan and weighing pan (if applicable).

3 Assemble the bracket (11) and the compensation weight

(7) with the provided screw (12).

Installation and putting into operation 11Density Kit

Page 12

4

4

22

4 Place the pan holder (4) on the drip tray plate.

5 Install the compensation weight and bracket on the

weighing cell.

6 Place the pan (2) on top of the pan holder (4). The pan

should not touch the bracket nor the screw.

ð To operate the density kit, refer to the section "Operation".

Installation and putting into operation12 Density Kit

Page 13

3.3.4 Installing on XP/XPE/XS 1mg with standard pan

22

11

11

12

12

3

3

10

10

7

7

11

11

12

12

7

7

These installation instructions are suitable for precision balances with names of the type:

• XPxx03S

• XPExx03S

• XSxx03S with traditional pan, up to SNR B542999999

The following parts are available:

§

1 Open the draft shield, if applicable.

2 Remove the weighing pan and support pan.

3 Assemble the bracket (11) and the compensation weight

(7) with the provided screw (12).

Installation and putting into operation 13Density Kit

Page 14

22

3

3

10

10

4 Place the draft ring (10) on the balance plate, aligning the

holes of the draft ring with the pins of the balance plate.

5 Install the compensation weight and bracket on the

weighing cell.

6 Place the pan holder (3) on the draft ring (10). Make sure

that the thinner side of the pan holder's rim is facing the

bracket.

7 Place the pan (2) on top of the pan holder (3). The pan

should not touch the bracket nor the screw.

ð To operate the density kit, refer to the section "Operation".

Installation and putting into operation14 Density Kit

Page 15

4 Operation

=

V

m

ρ

(ρ0 - ρL)+ ρ

L

ρ =

A-B

A

V =

ρ0 - ρ

L

A-B

α

This section provides theoretical and practical information about how to determine the density of solids and

liquids using the density kit. It also includes recommendations to improve the results' accuracy and precision.

Depending on your balance model and software version, the main operation steps and necessary calculations

might be implemented in the balance software; follow the instructions from the wizard for support.

For full information, always consult and download the Reference Manual (RM).

4.1 Principle of density determination

The density ρ is the quotient of the mass m and the volume V.

The international system of units specifies kg/m3 as the unit of

density. However, the unit g/cm3 is better suited to laboratory

purposes.

Density determinations are frequently performed by Archimedes'

principle, which is also used with this density kit. Archimedes'

principle states that a body immersed partially or fully in fluid

experiences a buoyant force acting upwards on it. The

magnitude of this force is equivalent to the weight of the fluid

displaced by the body.

The procedure for the density determination by Archimedes'

principle depends on whether the density of solids or liquids has

to be determined.

4.1.1 Density determination of solids

The density of a solid is determined with the aid of a liquid whose

density ρ0 is known. Water or ethanol are frequently usually used

as auxiliary liquids. The solid is weighed in air (A) and then in the

auxiliary liquid (B). The density ρ can be calculated from the two

weighing results.

Density:

Density:

Volume:

Legend

A Weight of sample in air

B Weight of sample in the auxiliary liquid

ρ Density of sample

ρ0Density of auxiliary liquid

ρLDensity of air (0.0012 g/cm3)

α Balance correction factor (0.99985). It takes air buoyancy of the adjustment weight(s) into account.

Operation 15Density Kit

Page 16

4.1.2 Density determination of liquids

ρ =

+ ρ

L

V

A-B

α

ρ =

+ ρ

L

V

P

α

The density of a liquid is determined using a sinker of known

volume. The sinker is weighed in air and then in the liquid whose

density is to be determined. The density ρ can be determined from

the two weighing results.

With an electronic balance, it is possible to determine the weight

of the displaced liquid P(P=A-B), and thus the buoyancy,

leading to a simplified formula.

Legend

A Weight of sinker in air

B Weight of sinker in the liquid

P Weight of displaced liquid (P=A-B)

V Volume of sinker

ρ Density of liquid

ρLDensity of air (0.0012 g/cm3)

α Balance correction factor (0.99985). It takes air buoyancy of the adjustment weight(s) into account.

Density:

Density simplified:

4.2 Determining the density of solids

NOTICE

Erroneous results due to improper handling

− Always use gloves when touching parts that are immersed in liquid.

To improve the accuracy of the results, take the following precautionary measures:

• The effect of temperature on liquids can cause density changes of order of magnitude 0.1 to 1‰ per°C. To

obtain accurate results, take the temperature of the auxiliary liquid into account in all density determinations.

• Adhesion of the auxiliary liquid to the suspension wires of the basket causes an apparent weight increase of

up to 3mg. If the greatest possible accuracy is required, pour a few drops of the wetting agent in the

auxiliary liquid.

• To avoid air bubbles:

– Use enclosed wetting agent or organic liquids. The density change due to the addition of wetting agent

can be neglected.

– Remove grease traces from solvent-resistant solids.

– Clean basket at regular intervals.

– Remove adhering air bubbles with a fine brush.

– Gently move the basket on first-time immersion to dislodge any air bubbles.

Operation16 Density Kit

Page 17

Preparing the density kit

22

3

3

11

4

4

5

5

6

6

The draft shield doors are closed (if applicable).

§

1 Tap to zero the balance.

2 Open the draft shield.

3 Attach the supplied thermometer (1) to the beaker (2) and

place the beaker on the pan (3).

4 Fill the beaker with the auxiliary liquid. Add enough liquid

to ensure that the solid is covered by at least 1cm of liquid

after immersion.

5 Hang the holder (4) for floating or sinking solids on the

bracket (5). Make sure that no air bubbles adhere to the

immersed part of the holder. Remove air bubbles by either

moving the holder or by using a fine brush.

6 For floating solids: If the buoyancy of the solid is greater

than the weight of the holder, the holder must be weighted

by placing an additional weight (6) on the top weighing

pan of the holder. This additional weight must remain on

top of the weighing pan during the entire procedure.

7 Close the draft shield.

8 Tap

to tare the balance.

Operation 17Density Kit

Page 18

Weighing the sample in air

11

22

11

B

A

A

1 Open the draft shield.

2 Place the sample on one of the two weighing pans (1) of

the bracket or, if the weight of the sample is > 20 g, in the

pan at the top of the holder (2).

3 Wait until the balance has reached stability and note the

displayed value (corresponding to "A" in the formula).

4 Open the draft shield.

5 Remove the sample from the pan.

Weighing the sample in liquid

1 For sinking solids, place the sample in the holder's basket

(A). For floating solids, place the sample under the

holder's basket (B).

2 Ensure that no air bubbles adhere to the sample. Remove

any air bubbles with a fine brush.

3 Close the draft shield.

4 Wait until the balance has reached stability and note the

displayed value (corresponding to "B" in the formula).

5 Determine the density ρ of the solid according to the corre-

sponding formula.

See also

2 Density determination of solids}Page15

Operation18 Density Kit

Page 19

4.3 Determining the density of liquids

22

3

3

11

44

5

5

NOTICE

Erroneous results due to improper handling

− Always use gloves when touching parts that are immersed in liquid.

To avoid air bubbles, take the following precautionary measures:

• Use enclosed wetting agent or organic liquids. The density change due to the addition of wetting agent can

be neglected.

• Remove grease traces from solvent-resistant solids.

• Clean sinker at regular intervals.

• Gently move sinker on first-time immersion to dislodge any air bubbles.

• Remove adhering air bubbles with a fine brush.

Preparing the density kit

The sinker is available.

§

The draft shield doors are closed (if applicable).

§

1 Tap

2 Open the draft shield.

3 Attach the supplied thermometer (1) to the beaker (2) and

place the beaker on the pan (3).

4 Hook the sinker (4) to the bracket (5) and ensure that it

does not touch either the beaker or the thermometer.

5 Close the draft shield.

6 Tap

to zero the balance.

to tare the balance.

Operation 19Density Kit

Page 20

Weighing the sinker in liquid

1 Open the draft shield.

2 Fill the beaker with the liquid whose density you want to

determine. Add enough liquid to ensure that the sinker is

covered by at least 1cm of liquid after immersion.

3 Ensure that no air bubbles adhere to the immersed part of

the sinker. Remove air bubbles by either moving the sinker

or by using a fine brush.

4 Close the draft shield.

5 Wait until the balance has reached stability and note the

displayed value (corresponding to "P" in the formula).

6 Determine the density ρ of the liquid at the temperature

indicated by the thermometer according to the corre-

sponding formula.

See also

2 Density determination of liquids}Page16

Operation20 Density Kit

Page 21

5 Technical Data

5.1 Wires

Wire of holder Wire of sinker 10 ml

Material Stainless steel Platinum

Diameter 0.6 mm 0.2 mm

5.2 Sinker 10 ml

• The nominal volume of the sinker is 10.00cm

• The calibrated volume of the sinker is available in the calibration certificate (measurement uncertainty of

±0.05%).

• Using the nominal volume of the sinker, i.e., 10.00cm

temperature of 20°C leads to a maximum error of ±0.5%, i.e., ±0.005g/cm3.

• Using the calibrated volume of the sinker for the density calculation contributes to the uncertainty of the

density value by ±0.05%.

• When the sinker is immersed under 10mm of liquid, the additional immersed volume of wire is 0.001cm

3

with a tolerance of ±0.5%.

3

, for the density determination of water at a

5.3 Density of distilled water

T/ °C 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

0.99970 0.99969 0.99968 0.99967 0.99966 0.99965 0.99964 0.99963 0.99962 0.99961

10

0.99960 0.99959 0.99958 0.99957 0.99956 0.99955 0.99954 0.99953 0.99952 0.99951

11

0.99950 0.99949 0.99947 0.99946 0.99945 0.99944 0.99943 0.99941 0.99940 0.99939

12

0.99938 0.99936 0.99935 0.99934 0.99933 0.99931 0.99930 0.99929 0.99927 0.99926

13

0.99924 0.99923 0.99922 0.99920 0.99919 0.99917 0.99916 0.99914 0.99913 0.99911

14

0.99910 0.99908 0.99907 0.99905 0.99904 0.99902 0.99901 0.99899 0.99897 0.99896

15

0.99894 0.99893 0.99891 0.99889 0.99888 0.99886 0.99884 0.99883 0.99881 0.99879

16

0.99877 0.99876 0.99874 0.99872 0.99870 0.99869 0.99867 0.99865 0.99863 0.99861

17

0.99859 0.99858 0.99856 0.99854 0.99852 0.99850 0.99848 0.99846 0.99844 0.99842

18

0.99840 0.99838 0.99836 0.99835 0.99833 0.99831 0.99828 0.99826 0.99824 0.99822

19

0.99820 0.99818 0.99816 0.99814 0.99812 0.99810 0.99808 0.99806 0.99803 0.99801

20

0.99799 0.99797 0.99795 0.99793 0.99790 0.99788 0.99786 0.99784 0.99781 0.99779

21

0.99777 0.99775 0.99772 0.99770 0.99768 0.99765 0.99763 0.99761 0.99758 0.99756

22

0.99754 0.99751 0.99749 0.99747 0.99744 0.99742 0.99739 0.99737 0.99734 0.99732

23

0.99730 0.99727 0.99725 0.99722 0.99720 0.99717 0.99715 0.99712 0.99709 0.99707

24

0.99704 0.99702 0.99699 0.99697 0.99694 0.99691 0.99689 0.99686 0.99684 0.99681

25

0.99678 0.99676 0.99673 0.99670 0.99667 0.99665 0.99662 0.99659 0.99657 0.99654

26

0.99651 0.99648 0.99646 0.99643 0.99640 0.99637 0.99634 0.99632 0.99629 0.99626

27

0.99623 0.99620 0.99617 0.99615 0.99612 0.99609 0.99606 0.99603 0.99600 0.99597

28

0.99594 0.99591 0.99588 0.99585 0.99582 0.99579 0.99577 0.99574 0.99571 0.99568

29

0.99564 0.99561 0.99558 0.99555 0.99552 0.99549 0.99546 0.99543 0.99540 0.99537

30

ISO 15212-1:1998 Oscillation-type density meters – Part 1: Laboratory instruments

3

.

Technical Data 21Density Kit

Page 22

6 Spare Parts and Accessories

11

2

2

3

3

4

4

55

6

6

7

7

8

8,

9

9

10

10,

11

11

Order no. Designation Remarks

11142289 Glass beaker ø 80mm, high –

1

238164 Pan –

2

238175 Holder for sinking solids –

3

238173 Holder for floating solids –

4

11132682 Compensation weight, white, for XP/XPE

5

11131531 Draft ring ø 90mm –

6

72409 Wetting agent –

7

210260 Sinker 10 ml –

8

210672 Sinker 10 ml, calibrated –

9

238767 Precision thermometer with holder –

10

11132685 Precision thermometer, calibrated –

11

0.1mg

–

Spare Parts and Accessories22 Density Kit

Page 23

Page 24

Mettler-Toledo GmbH

30357070

Im Langacher 44

8606 Greifensee, Switzerland

www.mt.com/contact

Subject to technical changes.

© Mettler-Toledo GmbH 11/2018

30357070Aen

www.mt.com/lab-accessories

For more information

Loading...

Loading...