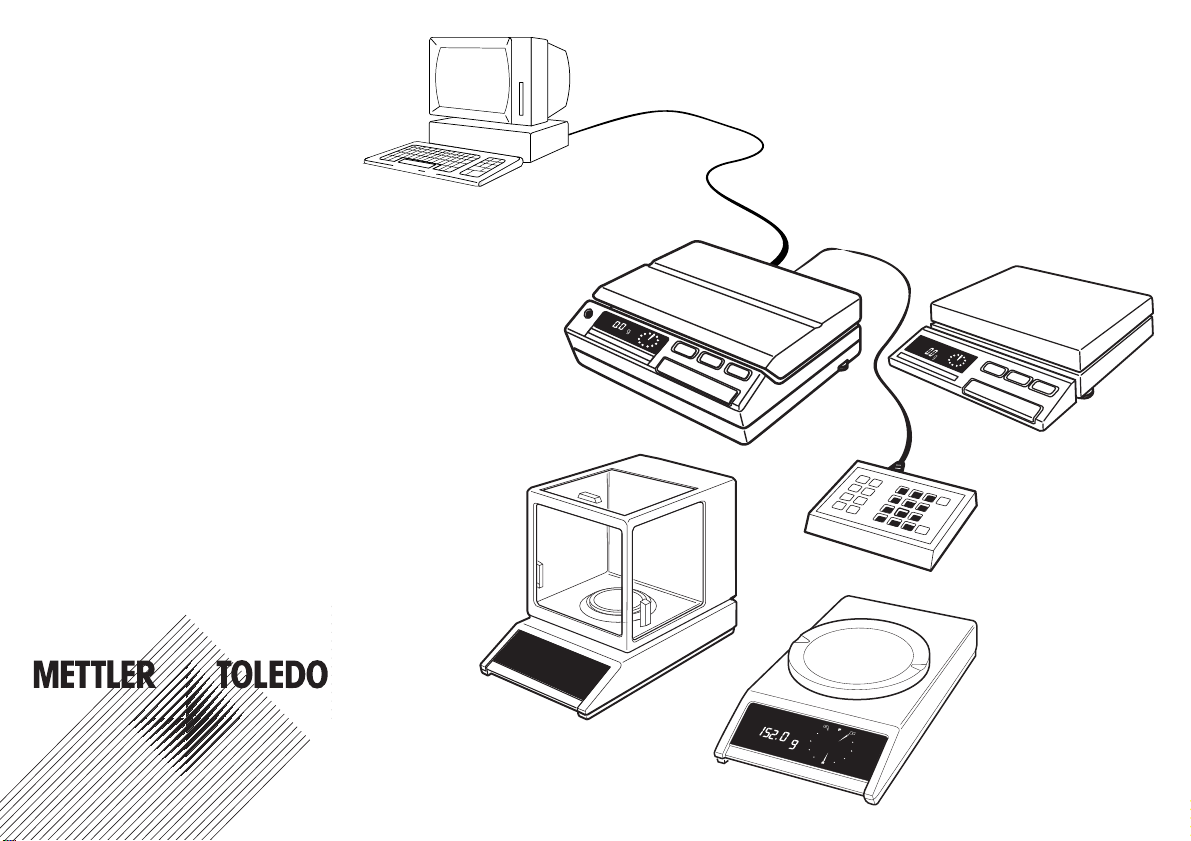

Page 1

Operating instructions

Bidirectional

Data Interface

AM-/PM-/SM Balances

and Scales

METTLER TOLEDO

DataPac-M

0.0

g

0.0

g

152.0

9

Page 2

Leer

Page 3

Contents Bidirectional Data Interface of the AM/PM/SM Balances and Scales – DataPac-M

1. Overview

1.1 What are the interface capabilities? 2

1.2 Dialog computer/weigh. station with the aid of DataPac-M 3

2. Preparation

2.1 Connector sockets of the balances 4

2.2 Matching the interface to the unit to be attached 6

2.3 Attaching units with current loop interface 7

2.4 Attaching units with RS232C interface 8

3. Interface

3.1 How does the interface function? 9

3.2 Hardware handshake RS232C 10

3.3 General information regarding CL interface 11

3.4 General information regarding RS232C interface 12

4. Data output

4.1 Initiating the data output 13

4.2 Data output using auxiliary switch 14

4.3 Data format 15

5. Commands to control the balance

5.1 General information regarding command setMnemonic 17

5.2 Send stable weighing result S 18

5.3 Send current weighing result SI 18

5.4 Send a dynamic and a stable weighing result

continuously SR 19

5.5 Send stable weighing results continuously SNR 20

5.6 Send all weighing results continuously SIR 20

5.7 Taring T 21

Mnemonic

5.8 Immediate taring TI 21

5.9 Subtracting a fixed value (tare preset) B 22

5.10Change weight unit U 22

Definition of a weight unit with self-selected divisor U 23

5.11Setting the vibration adapter

5.12Setting the weighing process adapter

5.13Setting the stability detection AsdMS 25

5.14Off/on switching of Auto Zero AZ MZ 26

5.15Off/on switching of weighing-in aid dd MA 26

5.16Resetting to default setting M 27

5.17Send identification ID 27

5.18Calibrate CA 28

5.19Display text D 28

5.20Entering limits for checkweighing/dispensing weigh. DY 30

5.21Controlling DeltaTrac DX 31

5.22Controlling peripherals from the balance W 32

6. DataPac-M

6.1 DataPac-M terminal 33

6.2 Defining the dialog computer – DataPac-M D 34

7. Programs to get started

7.1 Communication with the balance 38

7.2 Evaluation of the weighing data 38

7.3 Use of commands to control the balance 39

8. Malfunctions

8.1 What happens if …? 40

_MI 24

;ML 24

1

Page 4

A

A

1. Overview

DATA

200 - 240 V : T 63 m

I/O

100 - 120 V : T 125 m

GM

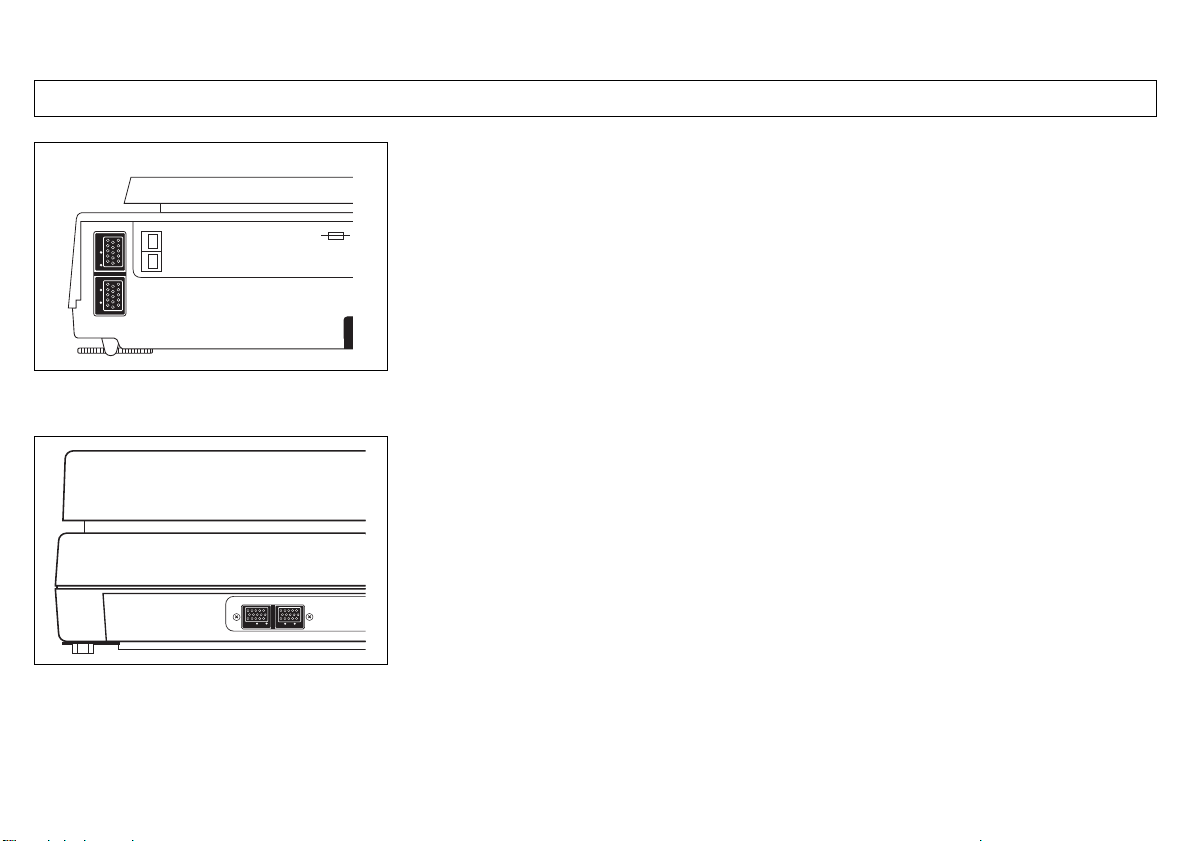

Rear of balance with interface sockets

2

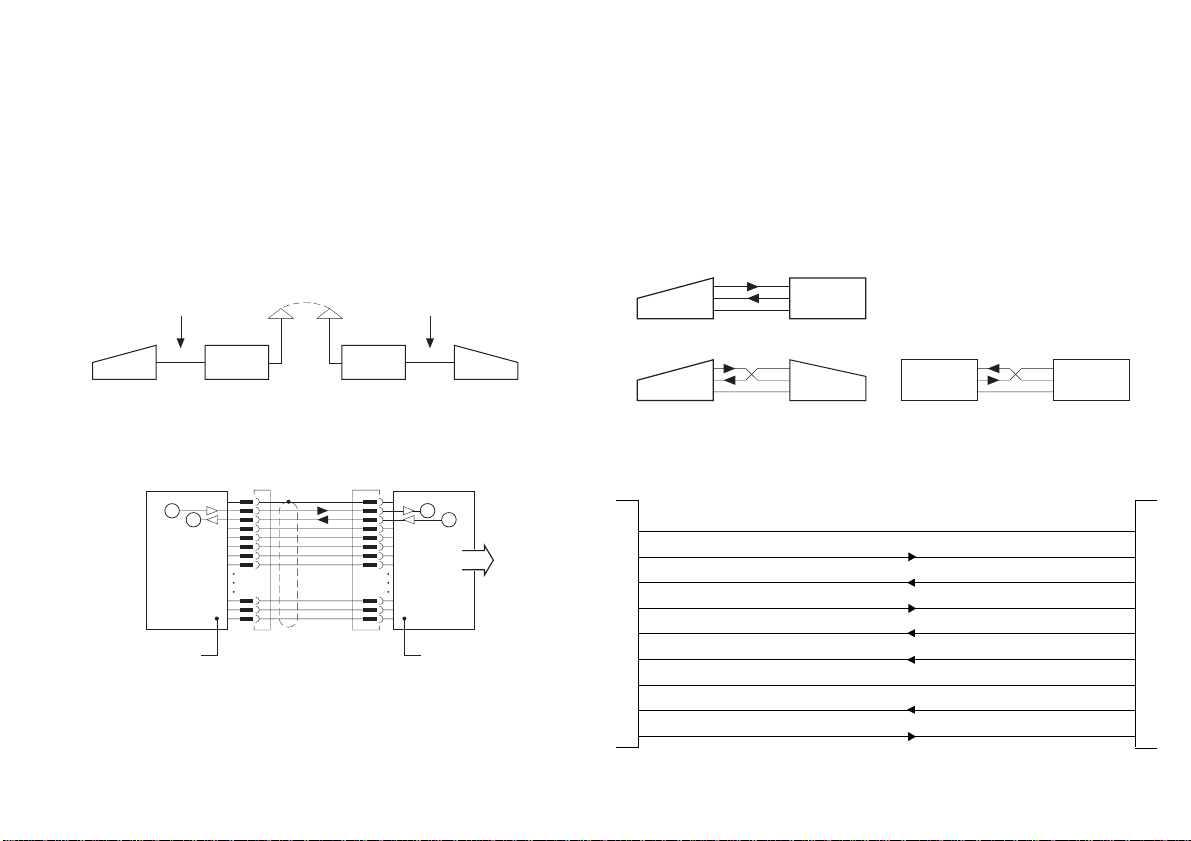

1.1 What are the interface capabilities?

The interface allows the balance to communicate with other devices, e.g. computers or

terminals. In addition, remote operation of the balance is possible. Virtually all commands which

can be entered using the Menu key can also be entered via the interface. Control is not only via

the balance display but also through acknowledgements at the interface.

The METTLER TOLEDO AM/PM/SM balances are fitted with a bidirectional data interface

(DATA I/O) and an interface for peripherals (GM) as standard. They can transmit weighing

results to a peripheral device at the DATA I/O socket via 20 mA current loop or RS232C, and

at the same time also receive commands to control the balance (full duplex operation). It is thus

possible to integrate AM/PM/SM balances in a controlled weighing system.

The interface can also be used for:

– automatic transfer of weighing results – selecting the balance operating mode (mat-

– taring and presetting of tare ching to weighing sample, surroundings, etc.)

– changing the weight unit – controlling the display (dialog text, DeltaTrac)

– calibration – controlling peripherals

– entering limits for checkweighings – identifying the balance

and dispensing weighings – defining the dialog with DataPac-M terminal

Software version

The present operating instructions describe the interface inserted software STANDARD

V10.50.00. This number can be checked on the inserted software cassette or on the balance/

scale display after switching on the balance or scale.

Applications, Technical Data, Accessories METTLER TOLEDO AM/PM/SM Balances and

Scales

This is the name of the brochure that is enclosed with every AM/PM/SM balance or scale. Here

you will find a complete overview of all peripherals and connection cables.

Page 5

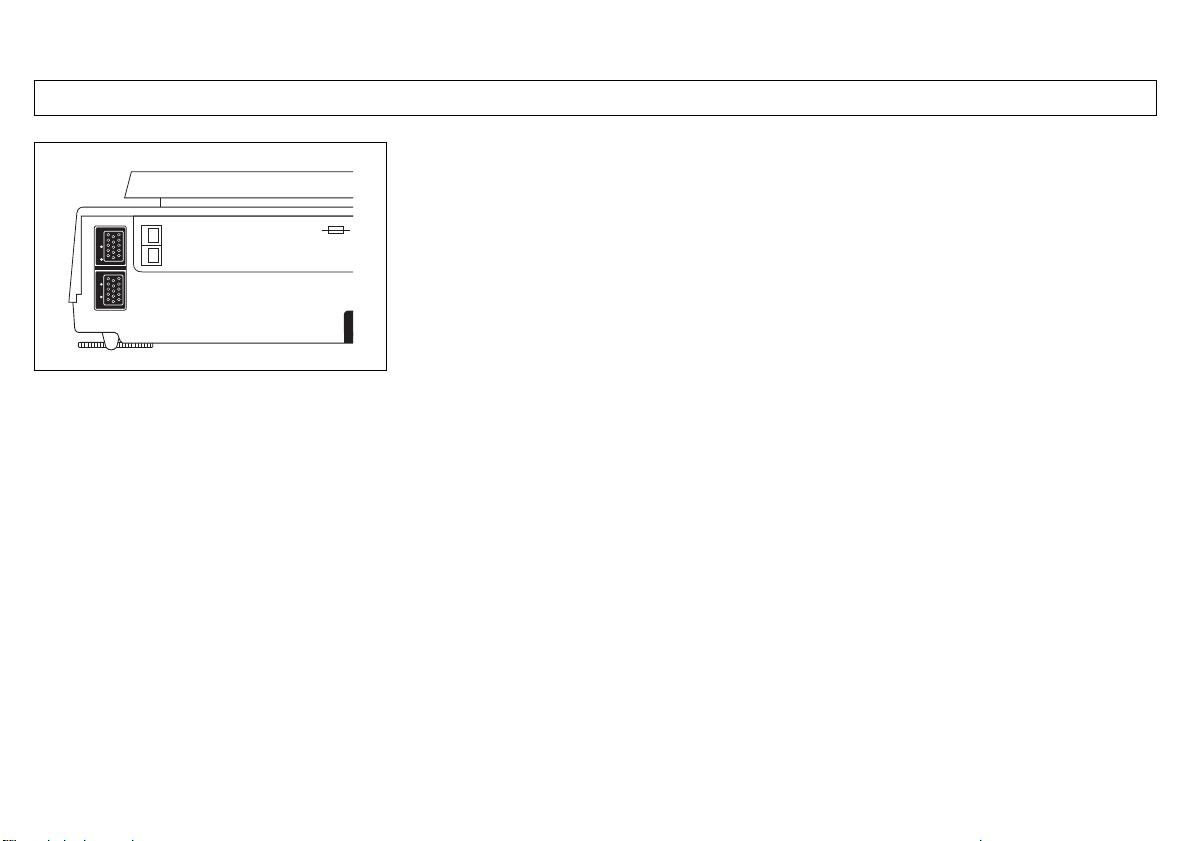

Weighing station terminal

1.2 Dialog between computer and weighing station with the aid of DataPac-M

The DataPac-M includes a keypad that operates together with the display of the balance as a

weighing station terminal. This makes communication between a computer and the weighing

station possible.

Thus, for example, weighing instructions to the operator can be transmitted from the computer.

Or the operator can call up certain weighing programs from the computer, select partial programs

with yes/no, or enter article and lot numbers.

Hardware of the DataPac-M

The DataPac-M comprises a keypad attachable to the GM socket of the balance as input device

and the DataPac software, which is already included in the standard software of the AM/PM/SM

balances. For dialog text the display of the balance is used. The computer is attached to the I/

O interface of the balance.

The DataPac-M can be used after software version STANDARD V10.20.

DATA

I/O

GM

Connection DataPac-M

200 - 240 V : T 63 mA

100 - 120 V : T 125 mA

User software of the computer

The form of the dialog between a computer and the weighing station is defined using the

computer. The operator response can be limited to a few alternatives, e.g. yes/no. This allows

the programming effort to be considerably reduced.

DataPac-M description

Since the interface of the balance is used for the dialog, the present interface description also

describes the operation of the DataPac-M (section 6).

3

Page 6

2. Preparation

A

A

DATA

I/O

GM

200 - 240 V : T 63 m

100 - 120 V : T 125 m

4

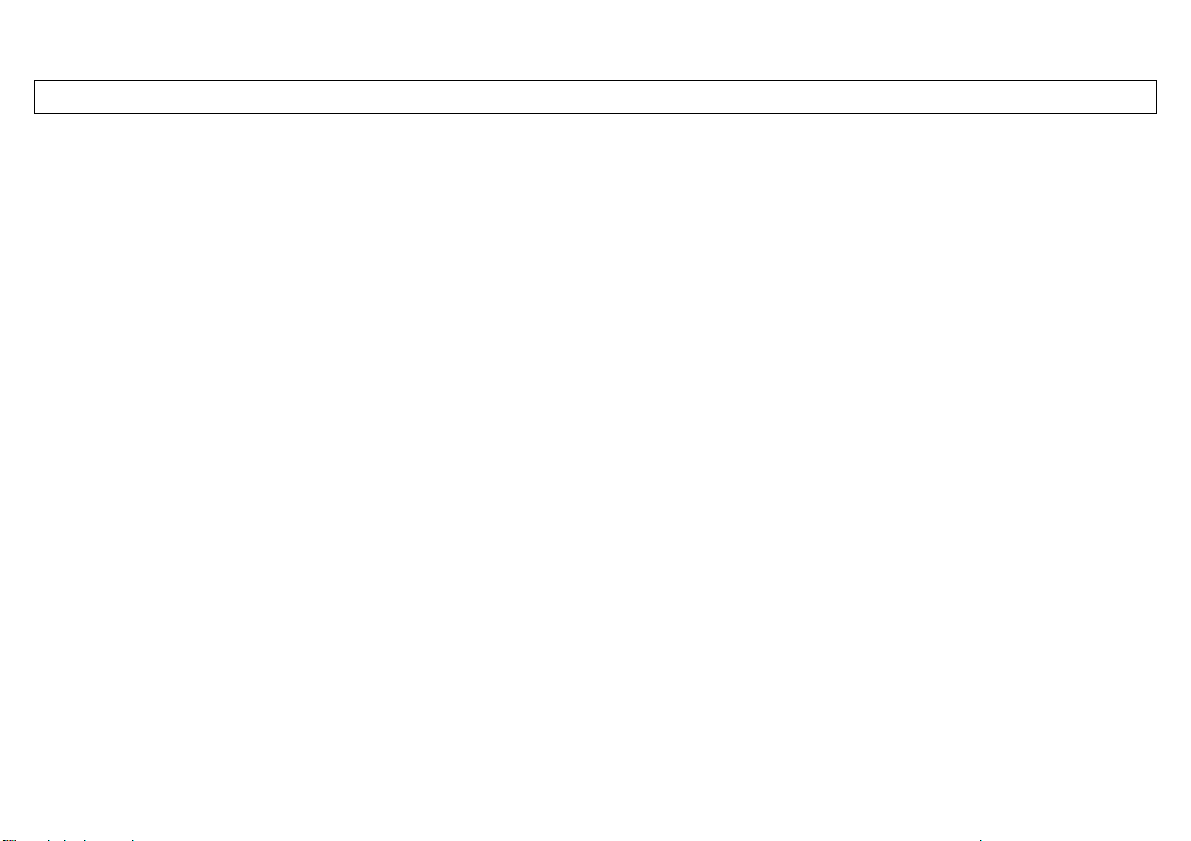

2.1 Connector sockets of the balances/scales

2.1.1 AM and PM balances

The balances have the following connector sockets:

DATA I/O: Devices with RS232C or CL interface, e.g. a computer (bidirectional operation),

printer, GA50 Peripheral Controller, adapter cable for data output using hand or

foot switch (unidirectional operation)

Rear of AM/PM balances

DATA I/O GM

Rear of high-capacity PM scales

GM: DataPac-M keypad, GM instruments with adapter plug, e.g. GM303 Control Unit,

secondary display, LV10 Automatic Feeder, adapter cable for taring using hand

or foot switch.

The coding pins at the sockets prevent improper insertion.

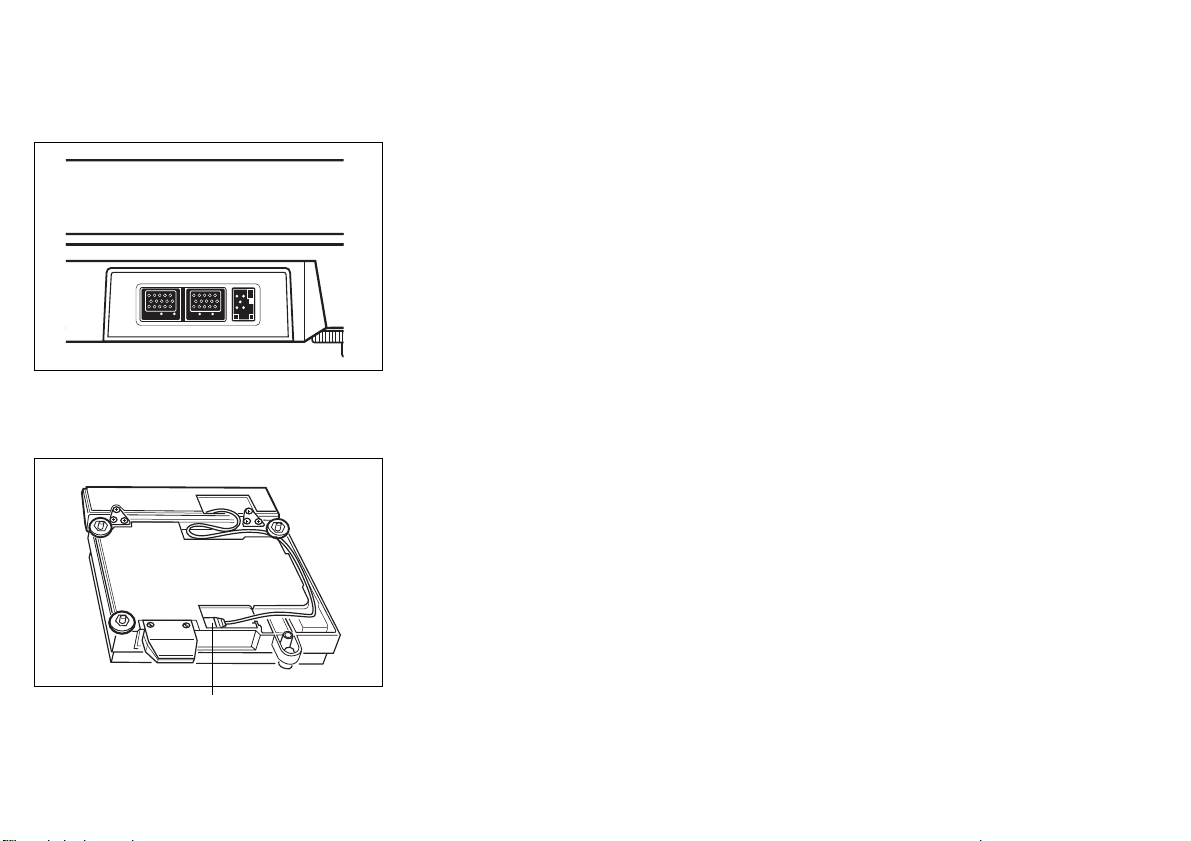

Page 7

Rear of SM scales

SM terminal connector or

system connector

at base of scale

2.1.2 SM scales

In addition to the DATA I/O and GM sockets mentioned, the SM scales have a third socket on

the underside of the weighing platform for the detachable SM terminal (scale display with keys).

Connection socket for the SM terminal

Different terminals

The SM scales can be operated with different terminals or, if in integrated in a network, also

without terminal. As a rule, a base terminal is attached to the scale that has either a fluorescent

display (VFD) or a liquid crystal display (LCD) (terminal model SM-F or SM-L). For special cases,

so-called application terminals with integrated DataPac-M keypad are available (terminal model

SM-AF with VFD or SM-AL with LCD).

Computer-controlled multistation weighing system with SM scales without terminal

If one or more weighing platforms of the SM scales are attached directly, i.e. without terminal,

with the aid of the serial interface to a computer, each weighing platform must be fitted with an

34490 system connector.

The SM scales do not recognize any standby operation and could not be switched on even via

the interface after a power outage. The system connector allows standby operation and is

inserted in the same place where the absent terminal would be attached. It keeps the weighing

platform permanently switched on.

5

Page 8

6

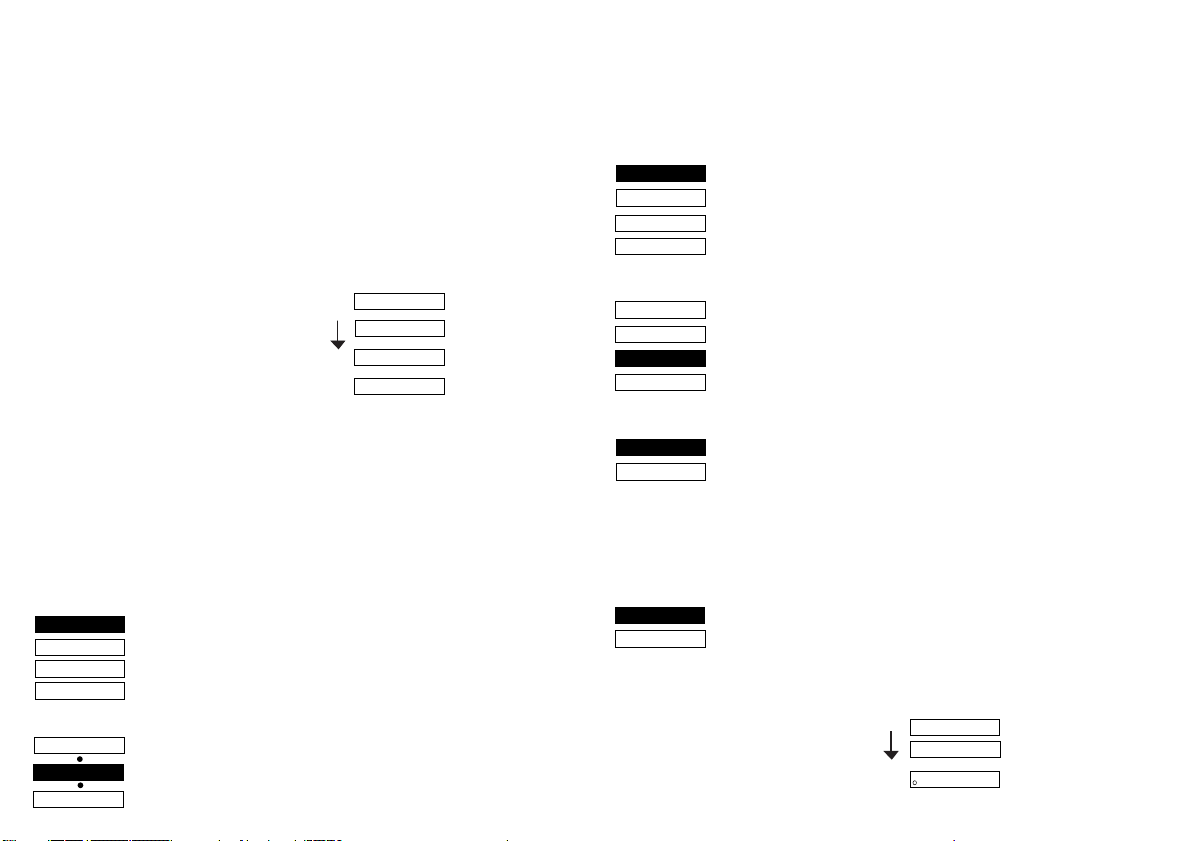

2.2 Matching the interface to the unit to be attached (configuration)

The configuration is described in detail in the operating instructions and

is thus repeated here only in brief.

To select the interface parameters, first the configuration register

has to be entered as follows:

– Switch of balance/scale ➝ standby no display.

– press control bar and

keep pressed until appears,

then release bar so that appears.

When in the configuration register, briefly pressing the control bar

allows switching from the sector “rESET” to the sectors “SCALE”,

“Unit” or “I-FACE”.

In an individual sector, the desired parameter is selected by pressing

and holding the control bar and then its value is determined by pressing

the control bar briefly (default value = black).

2.2.1 Sector "I-FACE"

Data transmission mode (see section 4):

S. Stb

S. ALL

S.Auto

S.Cont

stable single values

current single values (stable or not)

stable single value after each weight change

all values, continuous

Transmission rate (baud rate):

b 110

b 2400

b 9600

110 baud

2400 baud

9600 baud

------

-ConF-

rESEt

Parity:

P E

P -0-

P -S-

P -N-

Even

Odd

Space (use for 8-bit code)

Mark (use for “no parity”)

Pause between data lines and handshake:

PAUSE .0

PAUSE H

PAUSE 1

PAUSE 2

for rapid peripherals (computer etc.)

utilize handshake line

for slow peripherals (printer etc.),

1.0 or 2.0 sec. pause between the data lines

Auxiliary (suppression of auxiliary symbols)

Au oFF

Au on

Result with certification symbol <…> or * in animal wgh.

Suppression of these auxiliary symbols

2.2.2 Sector "Unit" Start data output

With the AM/PM balances, which have only a control bar, this can also

be used as an alternative method of initiating the data output.

Art oFF

Art on

Control bar normal

Control bar + print/data output/start function

2.2.3 Sector "rESEt" Resetting to default parameters (black):

o

YES

-End-

8.88 g

appears.

– Press key and

keep pressed until

Page 9

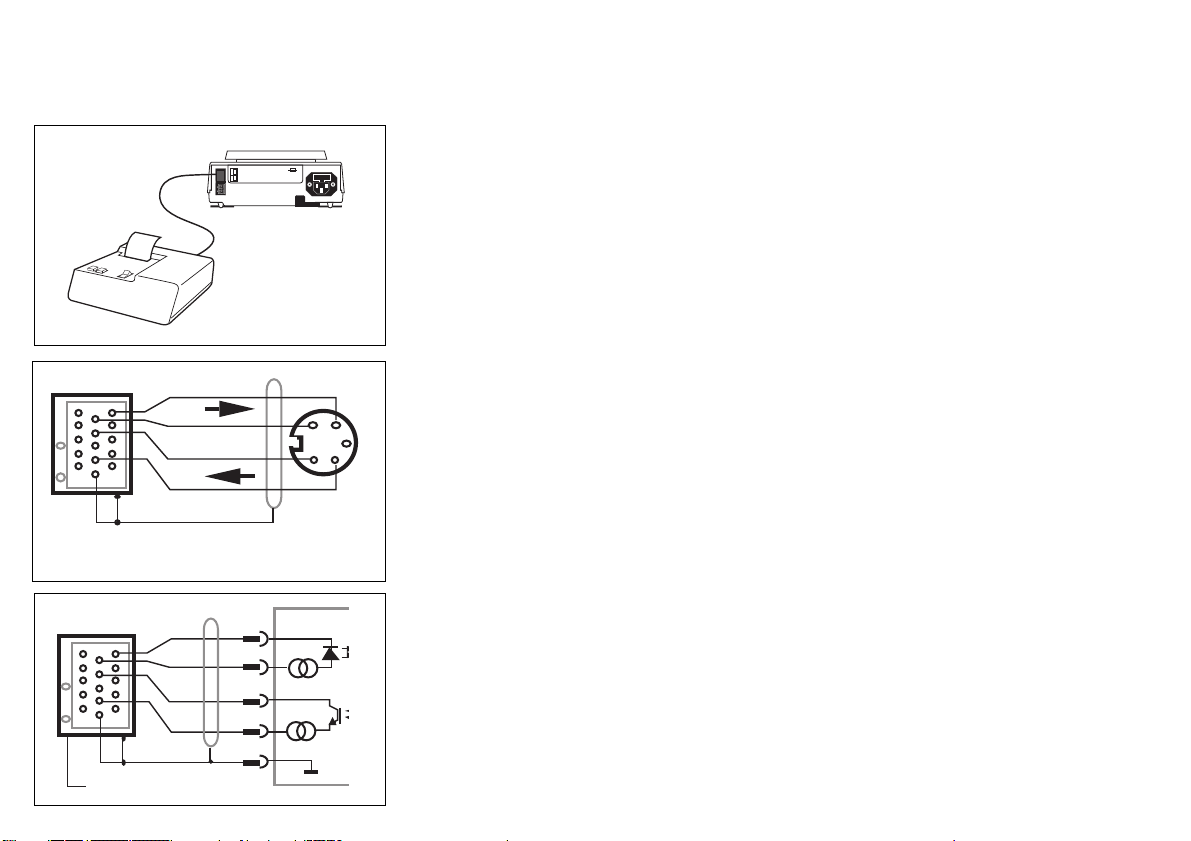

2.3 Attaching units with current loop interface

You will find a complete list of all cables in the brochure “Applications, Technical Data,

DATA

I/O

GM

200 - 240 V : T 63 mA

100 - 120 V : T 125 mA

Accessories METTLER TOLEDO AM/PM/SM Balances and Scales”.

The METTLER TOLEDO GA44 Printer can be attached directly. The cable is enclosed with the

printer (for additional cables: Order number 47926).

The balance should be configured with the default values.

15

10

9

7

6

View of cable side

47936

15

10

9

7

6

33930 (Solder side)

+

4

5

1

2

cable must be ordered. The illustration shows the wiring.

+

A non-METTLER TOLEDO unit can be attached to the BB balance as shown in the illustration.

The non-METTLER TOLEDO unit must take over the power supply of the CL interface and here

it is essential that the limiting data described in section 3.3 are observed. The I/O balance

connector (“MiniMETTLER”) can be ordered as an accessory: 33930.

7

For the attachment of other METTLER TOLEDO units with CL interface (solder side) the 47936

Page 10

8

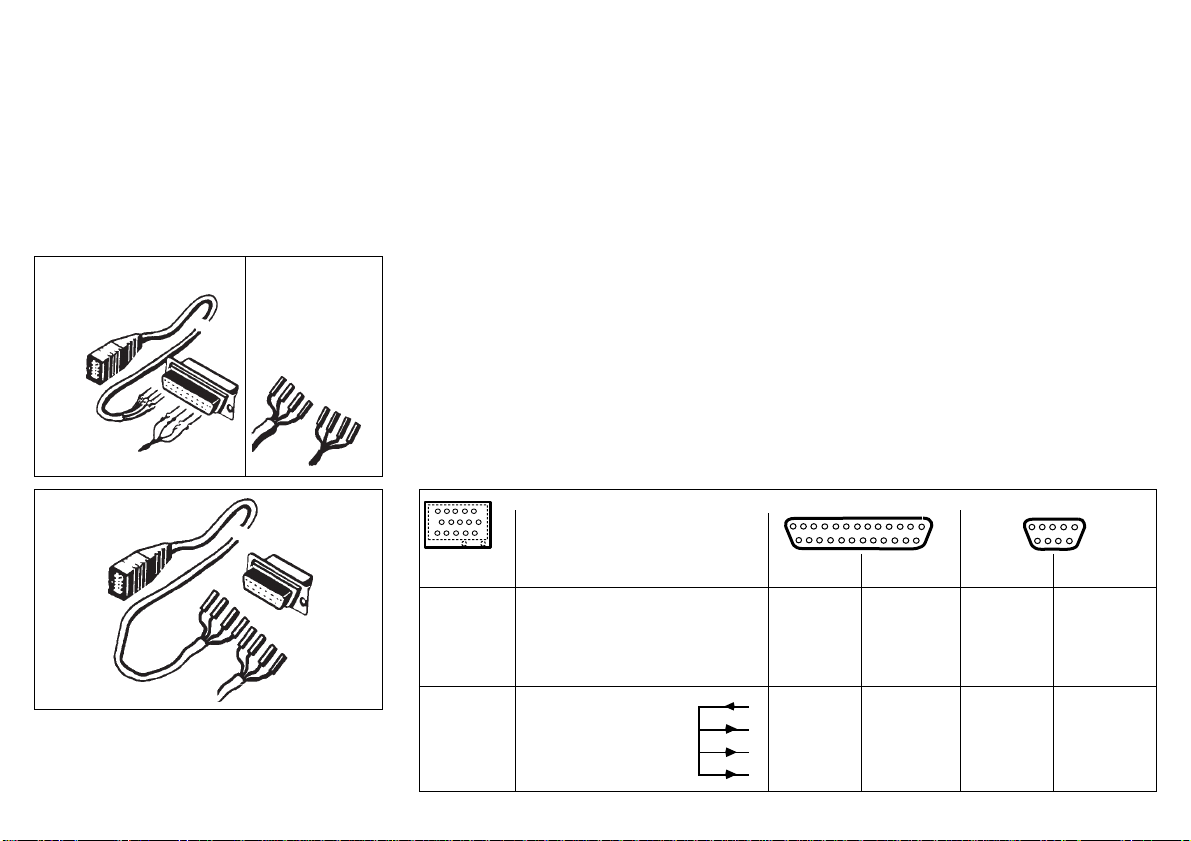

2.4 Attaching units with RS232C interface

You will find a complete list of all cables in the brochure “Applications, Technical Data, Accessories METTLER TOLEDO AM/PM/SM Balances

and Scales”.

Prepared cables are available for the following units: Printer EPSON P-40 Order No. 33688

Computer EPSON PX-4 33982

HX-20 33955

33640

33783

33995

For other units with an RS232C interface, cables with freely attachable contacts can be

ordered. One end of the cable carries the permanently attached I/O balance connector, the other

end the connector with the freely attachable contacts.

Order No.

Cable set with 25-pin connector (male), e.g. for printer 33640

Cable set with 25-pin coupling (female), e.g. for IBM-PC, IBM-XT 33995

Cable set with 9-pin coupling (female), e.g. for IBM-AT, Toshiba T1000 33783

Depending on whether the unit to be attached is a data terminal unit (DTE see also 3.4) or a data

communications unit (DCE), the cable must be wired as follows:

11

6

1

Connector, view from cable end

1

14

13

25

1

69

5

Balance Description of the function DTE DCE DTE DCE

2,green data (commands) for balance 2 3 32

12,brown data from balance 3 2 2 3

13,white signal ground 7 7 5 5

3,yellow handshake for balance 4/20 5/6 4/7 6/8

short-circuiting link 20/4 6/5 7/4 8/6

(optional) 5 4 8 7

6206 4

81

Page 11

3. Interface

3.1 How does the interface function?

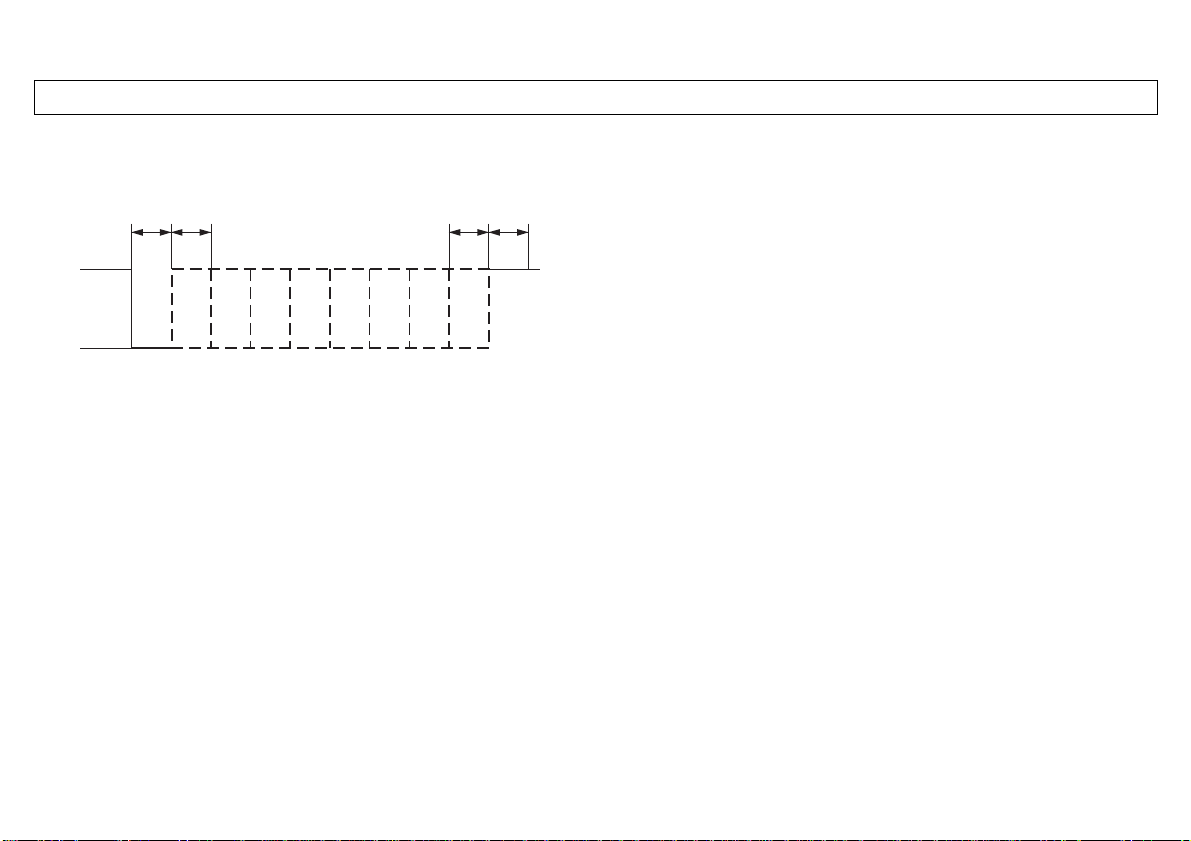

Serial data transmission

TTTT

High

Low

Start Bit Bit 1 Bit 2 Bit 7 Parity Stop Bit

The data are transmitted serially, i.e. character by character one

character after the other. Each character is represented by a 7-bit

binary code. The individual bits of the character are also transmitted

serially. A wire pair thus suffices for the data transmission in one

direction.

In the idle state (no data transmission), the relevant data line is active

(20 mA quiescent current with current loop, potential “high” with

RS232C).

The transmission of a 7-bit character is initiated with a start bit

(transition from 20 to 0 mA or “high” to “low”) followed by the 7 data bits.

The order of the data bits starts with the least significant bit (LSB) and

ends with the most significant bit (MSB).

A subsequent parity bit allows the correctness of the data transmission

to be checked. It is added to the number of “1’s” of the data bits of a

character to make an even or odd number (even or odd parity).

The 10th bit (stop bit) is again “high” and shows the end of the

transmission for this character. A chain of characters transmitted

successively is called a data string.

The AM/PM/SM interface

The balance has an RS232C voltage-controlled data interface and a

passive 20 mA current loop interface (CL), both led out to the

DATA I/O socket.

These interfaces can be used both unidirectionally and in bidirectional

full duplex operation.

The data outputs of both interfaces operate in parallel. Both outputs can

be used at the same time, but only one input either CL or RS232C.

The data inputs are ready to receive as soon as the display has been

switched on. The data outputs remain blocked until the start routine is

complete.

Transmission principle: serial by bit, asynchronous (1 start bit), 7-bit

code ASCII ISO646 + parity bit, 1 stop bit

(receive), 2 stop bits (send)

In bidirectional operation, switching off the other device or a break in the

interface cable (BREAK) resets the balance/scale to the configured

status. In other words, all functions that have been triggered by

commands via the interface (transmission mode, tare preset, text

display, etc.) are reset.

Configuration of the interface parameters is described in section 2.2.

9

Page 12

10

3.2 Hardware handshake RS232C

Operating modes: – Free Mode

– Handshake Mode

Software handshake according to “Technical Information Bulletin” TIB: “The

METTLER TOLEDO CL Interface”. Order

No. in section 3.3 “General information

regarding METTLER TOLEDO CL

interface”.

These operating modes can also be used for the RS232C interface.

Matching of data supply and demand between balance and unit to

be attached

Data losses can selectively be prevented as follows without the need

for handshake lines:

1. With the handshake mode (software handshake)

2. With an adjustable pause time between the data strings of up to

2 seconds.

3. By selective request of the weighing result with the command

CRL

SI

F . If the balance can not provide a valid result, it sends “SI”

immediately. The controlling computer is thus informed at all times

that it must once again request a measured value.

The hardware handshake described in what follows also offers a

possibility to control the data flow.

With the aid of a separate signal line (DATA I/O socket pin 3, connection

cable yellow litz wire), the transmission of data via the RS232C

interface of the AM/PM/SM balances can be “curbed”, i.e. the balance

sends data only if the attached device reports operational readiness.

The attached device must have handshake functions and be wired in

accordance with section 2.4.

The signal is evaluated when “PAUSE H” has been set in the configuration and when the line is actually wired up.

If a positive voltage is applied to the handshake line or if it is open, the

balance sends. In the case of a negative voltage it does not send. If the

level changes from positive to negative during a transmission, maximum 2 additional characters are transmitted.

If this handshake function is used, the data output may not be

triggered with an auxiliary switch as described in section 4.2.

Page 13

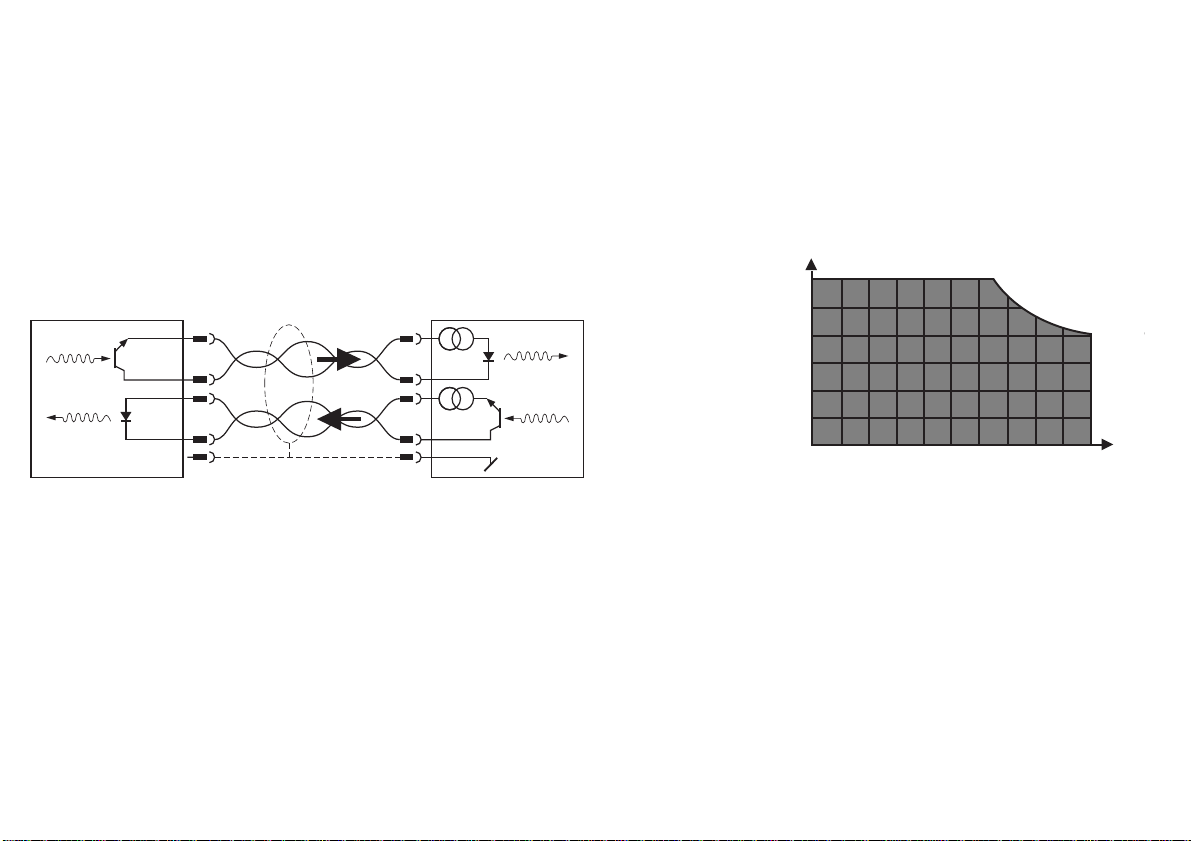

3.3 General information regarding CL interface

W

The CL interface of the balance is primarily suitable for transmissions

over relatively long distances (> 15 m) or for operation of the balance

in the case of severe power line disturbances. It is completely separated

galvanically from the balance by an optocoupler and thus prevents the

intrusion of disturbances in the electronics.

The CL interface has two passive transmission loops independent of

each other.

passive active

passiv aktiv

PeripheralBalance

The passive current loops of the balance must thus be supplied by

external current sources. To avoid damage to the CL interface by these

external current sources, it is essential to observe the following limiting

data:

I

(mA )

I max 30 mA

The U/I characteristic

P max 800 m

of the source must lie

within the hatched

area.

U max 40V

U

( V )

40

The interfaces of the METTLER TOLEDO units require the following

specifications:

– voltage excursion of source 15 V (+10%/–0%)

– current (high) between 18 mA and 24 mA

– rate of change 2...20mA/µs

– cable: shielded, twisted pairs,

0,14 mm2, 125 ohm + 130nF/km

max. length: 1000 m/300 baud, 500 m/2400 baud

For further information see also “The METTLER TOLEDO CL Interface”,

720106 (German), 720107 (English), 720108 (French),

720109 (Spanish).

11

Page 14

E

3.4 General information regarding RS232C interface

12

Voltage-controlled interface in accordance with the standards EIA

RS232C, DIN 66020. These standards conform to the CCITT recommendations V.24 and V.28.

A distinction is made between two types of equipment:

– Data Terminal Equipment (DTE), e.g. teleprinter, printer, IBM-PC

– Data Communications Equipment (DCE), e.g. modem, transmitter

RS232C RS232C

DTE DCE DCE DTE

The RS232C interface was originally conceived to link such data

terminal equipment with data communications equipment. The lines

and signals have been designed for this original configuration, which is

still in use today.

DTE

1

2

3

E

4

5

6

7

8

23

24

25

E

DCE

Modem

S

Example:

S

Computer

– A DTE unit sends its data via connection 2

(data direction DTE ➝ DCE).

– A DCE unit sends its data via connection 3

(data direction DCE ➝ DTE)

For short distances (< 15 m) where data highways are not practical, the

RS232C interface is also used for any two units, i.e. the combinations

DTE – DTE and DCE – DCE are entirely possible. Certain signals and

lines can be omitted in such cases. A minimum configuration can be

implemented with two (unidirectional operation) or three lines (bidirectional operation).

2

3

7

DTE DCE

2

3

7

DTE DTE

2

3

7

2

3

7

2

3

7

DCE DCE

2

3

7

In addition to the above-mentioned interface lines the most common

handshake lines are shown below:

1 Protective Ground 1

2 Transmit Data TxD 2

3 Receive Data RxD 3

4 Request to Send RTS 4

5 Clear to Send CTS 5

DT

6 Data Set Ready DSR 6

7 Signal Ground GND 7

8 Data Carrier Detect DCD 8

20 Data Terminal Ready DTR 20

The definition of the above terms is from the angle of the DTE.

DCE

Page 15

4. Data output

4.1 Initiating the data output

The balance has always a current weighing result available that can

either be stable or unstable, valid or invalid. All four combinations are

possible.

Depending on the application, the data output can be initiated in the

following ways:

– Print key or control bar of the balance

– external print key (auxiliary switch or “PRT” key on GA44)

– automatic operation (configuration: “S.Auto”, “S.Cont”)

– commands via the interface (send commands)

– loading or unloading the balance (send commands “SR”, “SNR”)

The default setting for the data transmission mode is:

S. Stb A stable single value is transmitted if the data transmis-

sion has been triggered by a key.

The transmission mode can be modified in the configuration register

(I-Face), (see also section 2).

S. All A current single value (stable or unstable) is transmitted

if the data transmission has been triggered by a key.

S. Auto A stable value is automatically transmitted after every

load change. (Magnitude of change, see Table under

SNR command, section 5.5.)

S. Cont All values are transmitted automatically in step with the

configured pause – with “Pause 0” in step with the

display update speed, see also SIR command, section 5.6 – or with handshake.

Nonstable weighing results are marked in the identification block with “SD” and stable ones with “S/” (see

section 4.2, Data format).

In bidirectional operation these transmission modes can be selected

via the interface with send commands (see section 5), irrespective of

the configured transmission mode.

Transmission mode corresponding send command

S. Stb * S

S. All * SI

S. Auto SNR

S. Cont SIR

* initiate transmission with key

In the case of an interface break, the transmission mode is lost if it has

been selected via the interface. On the other hand, the configured

transmission mode remains stored until a new one is configured.

Note: The default setting for the pause between the data

strings is 1 second (for GA44 Printer). In the case of

operation with a computer this pause is too long. Therefore, in most cases, it has to be configured at (0).

13

Page 16

4.2 Data output using auxiliary switch

14

42500

GM303

The data output can be initiated by a hand or foot switch.

If a hand switch is needed directly at the balance for the AM/PM

balances, the GM303 Control Unit can be installed.

If the switch has to be positioned somewhat apart from the balance, a

separate hand or foot switch can be used.

An adapter cable is also needed for the attachment of this switch. This

extends the I/O interface socket of the balance to the rear and carries

a 2-pin socket on a Tee joint for attachment of a hand or foot switch.

Adapter cable Order No. 47473

Hand switch 42500

Foot switch 46278

If the data output is triggered using the auxiliary switch (or by means

of the PRT key at the GA44 Printer), the handshake function

described in 3.2 is not possible.

46278

47473

Page 17

4.3 Data format

Format of weighing result

Each valid weighing result is available at the data output in a standard

format. The data string can be divided into three blocks. It is always

terminated with Carriage Return (

/ = (Space)

01 02 03 04 05 06 07 08 09 10 11 12 13 14....

/

Identification block Data block Unit block

C

R) and Line Feed (LF).

/

L

C

R

Char. Information Code Explanation

04…12 Weighing result x 9 characters, result right-aligned

including sign “–” directly in front of

the first numeral, decimal point;

leading zeros are replaced by spaces.

F

Outside the DeltaRange or if unstable results, the last digit is shown as

a /. Drops therefore the decimal

point, it will be replaced by /.

Char. Information Code Explanation

01 Type of data triggered from the balance

/

initiation with auxiliary switch or print key,

or animal weighing, triggered in

any way

S triggered via the interface with

Send commands or balance in the

“Send Continuous” mode

(“S.Cont”)

02 Status messages stable result

/

D unstable result (dynamic)

* animal weighing

1)

14... Weighing unit x 0…4 characters, terminated imme-

CR L

diately with

F: g or one of 10 other

units, depending on requirements.

Example:

CR L

SD////-24.37/g

1)

* can be replaced by /, if “Au on” is

configured in sector I-FACE.

15

F

Page 18

16

Messages on invalid weight result

In special operating modes (e.g. during overload, underload, error

message etc.) the balance can not provide a valid weight result. It thus

sends only a status message. This also indicates whether the data

output has been initiated by means of a key or command or configuration.

Status messages on initiation by means of a key (“Print”, “PRT”,

auxiliary switch) and configuration “S. All”or “S. Cont.” :

/I

/I +

/I -

CR L

F invalid result

CR L

F overload

CR L

F underload

2)

Status messages on initiation of the data output by means of com-

mands or through the transmission mode “S.Cont”:

CR L

F invalid result

SI

CR L

SI +

SI -

F overload

CR L

F underload

2)

If the balance transmits neither a result nor a status message after

initiation of the data output, this means that it is waiting for a stable

weight value.

2)

e.g. data transfer during taring process which could not be completed

because of instability

General status messages

CR L

F Message in bidirectional operation of the ba-

TA

lance: The automatic taring process after

switching on the balance is complete or taring

has been performed with a key.

CB/< Text >

STANDARD ///V10.50.00

CR L

F Response on calibration

CR L

F

Start message, software version

Error messages → section 8

Examples of printouts

Configuration “S. Cont” Configuration “S. All”

********************

Standard V10.50.ØØ

S -Ø.Ø2 g

SI

TA

S Ø.ØØ g

SD 8.2 g

SD 2ØØ.4 g

SI+

S 195.47 g

S 195.46 g

********************

Standard V10.50.ØØ

-Ø.Ø5 g

I

Ø.ØØ g

D 17.8 g

19.25 g

19.24 g

19.24 g

Page 19

5. Commands to control the balance

5.1 General information regarding command set

AM/PM/SM balances with full duplex interfaces can not only send

weighing results but also receive control commands at the same time.

These commands are described in what follows.

Entry of cammands

After software version STANDARD V10.42, uppercase or lowercase

letters can be used for commands.

Each command must be terminated with the character sequence

CARRIAGE RETURN (

Per command, maximum 64 text characters are possible incl.

A command without associated parameters generally resets the appro-

priate function.

Note: Simple examples for application programs can be found

in section 7.

The following symbols are used in this section:

/ space

: = definition

parameter

[ ] optional

C

R) und LINE FEED (LF).

parameter

CR L

F.

Interface commands and applications

Commands that intervene in an application, abort this application.

For example, the U command terminates the unit switching by means

of the control bar. The D, DY and B commands terminate piece

counting (Stk, PCS) and percent calculation (%).

Switching on the balance

In bidirectional operation of the interface the handshake is set up on

startup before the switch-on zero has been determined. It is thus

essential that the computer waits for the message “TA” from the

balance before it sends commands. Otherwise, it must be anticipated

that, e.g. SR and B commands are overwritten during this operation.

Communication failures

Commands that could not yet be executed are overwritten by newly

received ones, i.e. they are lost.

A BREAK condition (see section 3) clears all commands and the

balance again behaves as if it had been switched off and then on.

If the balance has not received a command properly or can not evaluate

or execute it, it sends an appropriate error message (see section 4.3).

17

Page 20

18

5.2 Cmd: S (Send value)

Format: S

Function: The balance sends the next possible stable

Notes: On stability, the current result is sent immediately.

Example: Computer Balance

CR L

F

weighing result.

With “S

CRL

F” send commands previously transmitted

can be cancelled by overwriting.

CR L

S

F

stability

S////100.00/g

or on overload

CR L

SI+

or on underload

CR L

SI-

CR L

F

F

5.3 Cmd: SI (Send Immediate value)

Format: SI

Function: The balance sends the current weighing result.

Note: Unstable results are marked with the status message

Example: Computer Balance

F

CR L

F

“D” (dynamic); with valid results “SI” is transmitted.

(→ 4.3 Data format).

CR L

SI

F

SD////98.54/g

CR L

F

or on stability

S////100.00/g

CR L

F

or if invalid

CR L

SI

F

or on overload

CR L

SI+

F

or on underload

CR L

SI-

F

Page 21

5.4 Cmd: SR (Send value and Repeat)

Format: SR [

//

/

threshold

//

]

CR L

F

Function: The balance sends the next possible stable result

and then on each load change of a certain magnitude

a dynamic and the subsequent stable result.

Parameter: The magnitude of the load change can be entered in

absolute terms as a

threshold

value, in the weight unit

selected under “Unit 1”, numerical value at least 3d*.) If

only “SR

CRL

F” is entered, the magnitude is 12.5% rela-

tive to the last stable value or at least 30d*.

Notes: The entry of a threshold value is advisable primarily in

automatic additive weighing operation. Here, an absolute response threshold is necessary since with “SR

CR L

the threshold fixed as a relative value would increase

with increasing total weight.

This automatic transmission mode remains in force until

the balance receives some other send command or the

interface experiences a break.

* d = digit = smallest display increment

Example: Computer Balance

CR L

SR

F

stability

S////100.00/ g

deflection

SD///115.78/ g

stability

F”

S////150.00/ g

etc.

Certified The SR command leads to the error message “EL”.

balances: However, it is usable after configuration “Au on”.

threshold

If

is not added, the load change is 25% or 30 d.

CR L

CR L

CR L

F

F

F

19

Page 22

20

5.5 Cmd: SNR (Send Next value and Repeat)

Format: SNR

Function: The balance sends the next stable result and then

Notes: Readability balance (g) 0,0001 0,001 0,01 0,1 1

Example: Computer Balance

Certified This command leads to the error message “EL”.

balances: However, it is usable after configuration “Au on”.

CR L

F

after every load change automatically a further

stable result.

Load change (g) ≥ 0,2 1 1 1 5

In contrast to the SR command no dynamic values are

transferred.

This automatic transmission mode remains in force until

the balance receives any other type of send command

or the interface experiences a break.

CR L

SNR

F

F

stability

S////100.00/ g

CR L

F

deflection min. 1 g

stability

S////150.00/ g

CR L

F

etc.

5.6 Cmd: SIR (Send Immediate value and Repeat)

Format: SIR

Function: The balance sends in every case the current result

Notes: Particularly suitable for dynamic weight determination.

Example: Computer Balance

CR L

F

and then automatically all further results, at a maximum rate in step with the balance display (i.e.

approx. every 130 ms; SW < 10.50 every 160 ms).

Owing to the large data volume of the balance the baud

rate must be correspondingly high if no value is to be

lost.

If a printing interval of 0.0 has not been configured, the

transmit clock corresponds to the pause time (1 or

2 seconds). Intermediate values are lost.

This automatic transmission mode remains in force until

the balance receives any other type of send command

or the interface experiences a break.

CR L

SIR

F

SD////98.54/ g

SD////95.76/ g

SD////95.32/ g

S/////95.40/ g

CR L

CR L

CR L

CR L

F

F

F

F

etc.

Page 23

5.7 Cmd: T (Tare)

5.8 Cmd: TI (Tare Immediately)

Format: T

CR L

F

Function: With this command, taring can be performed via the

interface and the balance switched on again after a

power outage.

Notes: If an SI or an SIR command follows a T command while

the balance is still waiting for stability, it returns “SI”.

If no stable condition has been attained after approx.

10 s, the error message “EL” follows.

With the AM/PM balances, –OFF– appears in the display

after a power outage. The balance can be switched on

again with "T

CR L

F"

The time needed for taring can vary; no acknowledgement is sent when it is complete. In the case of

overload/underload, taring can not be performed. The

error message “EL” is sent immediately.

Example: Computer Balance

CR L

T

F Instability:

– – – – – – (wait)

Stability: 0.00 g

Format: TI

CR L

F

Function: The balance is tared immediately without waiting for

stability.

Notes: Applications for this command are:

– Taring of the balance during a consumption measure-

ment or during a continuous dispensing operation.

– Taring from a computer that defines the stability

criterion itself.

– Taring in an externally clocked system.

If taring is by chance performed below the startup zero

point the balance must store this zero point again. As

here a high stability is necessary; taring can take up to

12 s. No acknowledgement follows when the operation

is complete.

Example: Computer Balance

CR L

TI

F Unstable or stable state:

0.00g

21

Page 24

22

5.9 Cmd: B (Base)

Format: B [

//

/

offset

//

Function: After receipt of this command the balance continu-

ously subtracts the value

results (tare preset).

Parameter:

offset

: =

Numerical value, max. 7 digits.

Enter sign only for negative values. “B

command.

offset

refers to the unit that has been programmed in the

configuration under Unit 1. The value must lie within the

admissible weighing range, i.e.

offset

+ tare weight = 0…maximum load.

offset

is rounded off to the balance resolution before

calculation.

Notes: The tare symbol appears in the display. Taring cancels

the offset command. If the offset value is outside the

weighing range, the error message “EL

transmitted.

Example: Computer Balance

B/100

CR L

]

F

offset

Display: 0.00 g

CR L

F Display: -100.00g

from all weighing

CR L

F”

cancels the

CR L

F“ will be

5.10 Cmd: U (Unit)

Format 1: U [

//

/

//

Function: Selection of the weight unit.

Parameter:

unit

: =

g, kg, lb, oz, ozt, tl, GN, dwt, ct, C.M., k., no entry (no

display of unit, Display value in the base unit of the

balance.

Entry of “U

back to the unit which is configured under Unit 1.

Uppercase letters can also be entered.

Note: The entered U command remains active until it is overw-

ritten by another command or the interface experiences

a break.

Example: Computer Balance

U/kg

Certified As

unit

balances: of Standards can be selected.

CR L

unit

]

F

CR L

F” only cancels the U command and switch

Display: 2054 g

CR L

F Display: 2.054 kg

, only units allowed by the respective Bureau

Page 25

Format 2: U [

dec

]

//

/

divisor

//

[

//

/

//

name

[

//

/

//

step

] ]

CR L

F

Function: Definition of a weight unit with self-selected divisor

(scaling).

Parameters:

dec

: =

Number of places after the decimal point (truncated if

weighing result more accurate than resolution allows).

divisor

: =

Number which divides all weighing results referred to

the unit configured under “Unit 1”. Magnitude at least 1

d (smallest readout increment).

name

: =

#, PCS for display “PCS”

STK, Stk for display “Stk”

% for display “%”

step

: =

Readout increment in digits: 1, 2, 5, 10, 20, 50, 100

Without entry of

dec

, the converted values are outputted

with the maximum number of places after the decimal

point allowed by the balance.

name

With no entry of the

, no unit is either displayed or

transmitted.

step

should always be specified with balances with

DeltaRange (recallable fine range).

Example: Programing of the balance/scale as a piece counter with

the piece weight entered as divisor.

Computer Balance/scale

Load 1 PCS

123.4 g

CR L

U 0/123.4/PCS /1

F 1 PCS

Load 50 PCS

Notes:

dec , divisor , name

requirements.

and

step

can be used according to

50 PCS

Certified The U command leads to the error message “EL”.

balances: However, it is usable after configuration “Au on”.

23

Page 26

24

5.11 Cmd

Format: MI [

:

MI (Modify ambient vibration) after SW version 10.42

//

/

number

//

]

CR L

F

Function: Setting the vibration adapter

(configuration of the balance via the interface)

Parameter:

number

: = Balance display

1 Very stable surroundings —

short weighing time

2 Normal surroundings _

(default setting)

3 Unstable surroundings –

relatively long weighing time

CR L

F"

"MI

resets the vibration adapter to the default

setting.

Note: The weighing time also depends on the balance model,

readout increment and on whether the animal weighing

mode has been selected.

Example: Computer Balance display

CR L

MI/3

F –

5.12 Cmd

Format: ML [

:

ML (Modify display adaption) after SW version 10.42

//

/

number

//

]

CR L

F

Function: Setting the weighing process adapter and selection

of the animal weighing mode or start of animal

weighing (configuration of the balance via the interfa-

ce)

Parameter:

number

: = Balance display

1 In dispensing, all decimal places ˛

are always displayed

2 In dispensing/weighing, the last ;

decimal place is suppressed until

stability (default setting) except if

“dd off” has been selected

3 Absolute weighing, ------ is ∞

displayed during weighing until

stability

4 Select animal weighing mode or ,

start animal weighing

CR L

F"

Entry of "ML

resets the weighing process adapter

to the default setting.

Page 27

5.13 Cmd

:

MS (Modify stability detection) after SW vers. 10.42

Notes: When used for the first time, the command “ML/4”

selects the animal weighing mode; in all other cases it

starts an animal weighing.

The cycle time is selected with the MI command:

— approx. 4 s _ approx. 6 s – approx. 8 s

The result is marked with “/” for identification if the

configuration has not been changed with “Au on”.

Example: Computer Balance display

CR L

ML/1

F ∞

Format: MS [

//

/

number

//

]

CR L

F

Function: Setting the automatic stability detection (configura-

tion of automatic stability detection “ASd” via the interface)

Parameter:

number

: =

1 Coarse for good weighing results not with standing

unstable surroundings; the balance recognizes sta-

bility despite small fluctuations.

2 Default setting

3 Fine

4 Very fine, for best weighing results in stable surroun-

dings; the balance recognizes stability only if the

fluctuations remain very small.

CRL

F”

“MS

resets the stability detection to the default

setting.

Example: Computer Balance display

CR L

MS/4

F

As soon as the surroundings are

completely stable, the ASd indicator disappears.

25

Page 28

26

5.14 Cmd: MZ (Modify Auto Zero) after SW version 10.42

Format: M Z [

//

/

number

//

Function: Off/on switching of Auto Zero (configuration of Auto

Zero “AZ” via the interface)

Parameter:

number

: =

0 off

1 on (default setting)

CR L

F"

"MZ

resets Auto Zero to the default setting

Notes: Auto Zero corrects zero point drifts or contamination of

the weighing pan automatically, but only in the range of

the internal decimal places not displayed.

Conditions for response of Auto Zero are:

Balance display must show 0000000 and ASd indicator

must have blanked out for at least one weighing cycle

(depends on balance model).

Example: Computer Balance display

CR L

MZ/0

F no visible effect (the zero point is

CR L

]

F

no longer automatically corrected)

5.15 Cmd: MA (Modify DeltaDisplay) after SW version 10.42

Format: MA [

//

/

number

//

Function: Off/on switching of weighing-in aid

(configuration of the DeltaDisplay “dd” via the interface)

Parameter:

number

: =

0 off

1 on (default setting)

CRL

"MA

F" resets the weighing-in aid to the default

setting.

Note: At the start of weighing-in during rapid dispensing, the

DeltaDisplay suppresses the last place of the balance

display. In fine dispensing, it is switched on again.

Example: Computer Balance display

CR L

MA/

F In dispensing/weighing the last

CR L

]

F

decimal place is suppressed until

fine weighing-in.

Page 29

5.16 Cmd

:

M (Modified settings reset) after SW version 10.42

5.17 Cmd: ID (Identify)

Format: M

CR L

F

Function: Simultaneous resetting of all M commands to the

default setting

Notes: For all M commands, it generally holds that they should

not be used dynamically.

When an interface break (BREAK) occurs, the settings

made with the M commands are lost. In contrast to the

send commands, the settings are reset to the default

setting and not to the values configured using the Menu

key.

Example: Computer Balance

CR L

F Default setting of all configura-

M

tions initiated via the interface

Format: ID

CR L

F

Function: The balance sends its identification (3 lines):

< Software Version >

TYPE: < balance type >

INR: < identification number >

Example: STANDARD V10.50.00

TYPE : PM 4600

INR : 720889

CR L

CR L

CR L

F

F

F

27

Page 30

28

5.18 Cmd: CA (Calibrate) after SW version 10.45

Format: CA

Function: The balance is calibrated.

CR L

F

With balances without a built-in (internal) calibration

weight, the value of the (external) calibration weight to be

loaded appears in the display. The following display

0.000 g signals that the balance should be unloaded.

The progress of the calibration is reported via the interface.

Computer Balance

CR L

CA

F busy

CB///– – – – – – –

*

CB////0.000/ g

if loaded, balance must be

unloaded

*

CB///200.000/ g

load calibration weight

*

CB////0.000/ g

unload balance

CR L

CR L

CR L

CR L

5.19 Cmd

Format: D

:

D (Display)

//

/

text

//

[ ;

unit [ symbol

] ]

CR L

F

Function: A text combined with a weight unit and a weight

symbol is displayed. “D

CR L

“D

F” frees it again for the weight display.

L

xCR

F” clears the display,

The balance continues to operate normally during the

display. The execution of send commands is not affected.

F

8.8.8.8.8.8.8

8.8.8.8.8.8.8

F

text

Parameter:

: =

G B N TAZ

All printable characters of the ISO646 code table. The

limited representation by the 7-segment display should

F

be taken into account.

text

is shown left justified. If

text

is longer than the

balance display allows, the section first inputted is cut

off.

F

* These steps are unne-

cessary with balances

with an internal calibration weight.

CB/1

CB/0

CR LF

EL

CR L

F successful or

CR L

F unsuccessful or

inadmissible

Page 31

Representation of text characters in balance display

The following table shows the 7 segment display for all 95 printable

characters of the ISO 646 code table.

KK

K

''

..

'

.

''

..

ww

õõ

w

õ

ww

SP ! " # $ % & ' ( ) * • , - . /

00

11

0

00

ø123456 789: ; <=>?

cc

c

cc

@ABCDE F GH IJ K LMNO

22

1

2

11

22

AA

BB

A

B

AA

BB

ú

õõ

33

3

4

33

CC

C

D

CC

ëë

èè

ë

è

``

êê

ëë

èè

`

ê

``

êê

úú

úú

44

55

5

44

55

DD

EE

E

DD

EE

''

[[

'

''

66

77

6

7

66

77

FF

GG

F

G

FF

GG

]]

[

] °

[[

]]

88

99

8

9

88

99

HH

II

H

I

HH

II

KK

..

--

.

-

..

--

cc

c

ûû

û

ûû

JJ

J

JJ

cc

êê

ê

êê

KK

K

KK

≠

LL

MM

L

M

LL

MM

êê

--

ê

-

êê

--

..

.

..

cc

c

cc

22

2

22

NN

OO

N

O

NN

OO

unit

: = Balance display

U g (kg, lb, …; selected unit)

#, PCS PCS

STK,Stk Stk

éé

é

éé

%%

symbol

B

N (net)

T (tare)

G (gross)

: = Balance display

(brutto = gross)

B

N

T

G

PP

QQ

RR

SS

TT

UU

VV

WW

XX

YY

ZZ

òò

44

ôô

mm

P

Q

R

S

T

U

V

W

X

Y

Z

ò

4

PP

QQ

RR

SS

TT

UU

VV

WW

XX

YY

ZZ

òò

PQRSTUVWX YZ [ \] ` _

``

aa

bb

cc

dd

ee

ff

gg

hh

ii

jj

`

a

b

c

d

e

f

g

h

``

aa

bb

cc

dd

ee

ff

gg

`abcdefgh ij k lmno

PP

qq

rr

ss

tt

uu

vv

P

q

r

s

t

PP

qq

rr

ss

pqrs tuvwx yz { |}~

u

tt

uu

ww

v

w

vv

ww

i

hh

ii

xx

yy

x

y

xx

yy

kk

j

k

jj

kk

zz

ññ

z

ñ

zz

ññ

ô

44

ôô

ll

mm

l

m

ll

mm

ll

óó

l

ó

ll

óó

__

m

_

mm

__

nn

oo

n

o

nn

oo

åå

å

åå

Note: While the D command is effective, a * is shown in the top

left of the display. It indicates that the display is no longer

linked with the balance, but is controlled via the interface.

Examples: Computer Balance display

400.0 g

CR L

D/ Prog . 5

D/ 285.94; UN

Certified: For

balances configured beforehand.

29

unit

only “U” can be selected if “Au on” has been

F * Pro9. 5

N

CR L

F * 285.94 g

Page 32

30

5.20 Cmd

Format: DY

Function: Entry of target weight and tolerances for checkweig-

Function: The DeltaTrac is controlled so that it supports dispensing

:

DY (Display Y)

//

[

/

target

//

hings or dispensing weighings with the DeltaTrac.

and checkweighings by analog, optical signals.

[

//

/

//

//

tol 1

[

/

tol 2

//

2 tolerance vanes appear above the

DeltaTrac and show the admissible

limits of the weight deviation.

During weighing-in, a coarse indicator

moves from 9 o-clock in the direction

of 6 o-clock and a fine indicator from

9 o-clock in the direction of 12 o-clock.

When the fine indicator is between the

two tolerance vanes, the target weight

has been reached with the selected

accuracy.

] ] ]

CR L

F

Parameters:

target

: =

Target weight; numerical value, max. 7 digits, decimal

point as required, minimum value 100 d.

tol

. : =

Admissible deviation from target weight, min. 2.5 d

Definition Weight deviation

none -2,5% +2,5%

tol 1 tol 1 tol 1

tol 1

and

target

and

“Unit 1”.

CR L

“DY

graphic indicator.

Example: Computer

DY/ 200/18/9

Balance display

DeltaTrac range from 6 to 12 o-clock corresponds to

200 g, fine indicator at –tolerance vane means weight

deviation = –9 g, at +tolerance vane = +18 g.

F” resets the DeltaTrac to the usual dynamic

downward (-) upward (+)

tol 2 tol 2 tol 1

tol

refer to the weight unit configured under

CR L

F

Notes: A possible tare preset with the aid of the B command

must be added to the target weight.

A subsequent DX command clears the DY command.

Page 33

5.21 Cmd: DX (Display X) after SW version 10.42

Format 1: DX [

//

/

number

//

[

//

/

number

//

] ] [

//

/T ]

//

CR L

F

Function: Control of one or two indicators and the tolerance

vanes of the DeltaTrac

Format 2: DX [

//

/

number

//

[ -

number

] ] [

//

/T ]

//

CR L

F

Function: Control of a range between two indicators and the

tolerance vanes of the DeltaTrac

Parameter:

Number

: =

Natural number in the range 0…59, corresponding to

the minutes of a clock.

CR L

F"

"DX

fades out the controlled indicators.

Notes: The DX command is intended for a static display. For

dynamic control of the DeltaTrac as a weighing-in aid

etc., DY should be used.

A DY command following a DX command clears the DX

command.

Examples: Computer DeltaTrac

DX/15/45/T

CR L

F

DX/15 - 23

CR L

F

31

Page 34

32

5.22 Cmd

Format: W

:

W (Write )

//

/

//

s0

[

//

/

//

t1

//

/

//

s1

…

//

/

//

t4

CR L

//

/

s4

]

//

F

Function: Control of a GM54 Output Module or an LV10 Auto-

matic Feeder attached to the GM socket.

The 8 output contacts are closed/opened with the 8bit status word

after time

s0

. If required, it can be overwritten

t1

with the status word s1. The W command thus allows up to 4 status changes to be

preprogrammed.

Parameter:

s (status)

=:

Decimal value between 0…255, corresponding to the

8-digit binary number which opens/closes the output

contacts C

Example: Contact C7C6C5C4C3C2C1C

. Contact closed = binary value 1.

0…C7

0

Status off off off off off off on on

Binary numb. 0 0 0 0 0 0 1 1

s

Calculation Contact C

7C6C5C4C3C2C1C0

3

of s: Dec. value 128 64 32 16 8 4 2 1

t (time)

Parameter:

=: 25…65535 (ms)

Accuracy: ± 3%, max. ± 50 ms

Note: "W

CR L

F" or an interface break opens all contacts. If the

computer sends a second W command to the balance

before the first has been executed, the first is overwritten.

Example 1: Computer W/1/500/130

GM54 Output module

C

7 C6 C5 C4 C3 C2 C1 C0

---------------------------------off-off-off-off-off-off-off-on

500 ms

on-off-off-off-off-off-on-off

Example 2: Computer

W/255/100/ 2 /200/8/300/ 32/400/128

GM54 Output module

C

7 C6 C5 C4 C3 C2 C1 C0

------------------------------------on-on-on-on-on-on-on-on

100 ms

off-off-off-off-off-off-on-off

200 ms

off-off-off-off-on-off-off-off

300 ms

off-off-on-off-off-off-off-off

400 ms

on-off-off-off-off-off-off-off

CR L

F

CR L

F

Page 35

6. DataPac-M

A B

C D

E F

G H

7 8 9

4 5 6

1 2 3

0

DataPac-M keypad

6.1 DataPac-M terminal

CLEAR

.

ENTER

–

The DataPac-M terminal has three key fields:

– Function keys A…H, independent of the other keys.

– Numeric keypad 0…9 with decimal point and sign – (These keys can also be programmed

as additional function keys.)

– Correction key CLEAR and termination key ENTER, the latter can also be programmed as

a PRINT key.

The keypad operates together with the balance display as a terminal which sends and receives

data and can thus enter into dialog with a partner device, usually a computer.

With the aid of the enclosed felt pen, the function keys can be inscribed according to the

application requirements. The inscription can be removed with alcohol.

The keypad is provided with a cable with a MiniMettler connector and can be plugged into the

GM socket at the rear of the balance.

Function keys

When one of these keys is pressed, the DataPac-M immediately sends the key code KF/…(

Key

Function) to the computer:

Computer DataPac-M

/ A

KF

KF

/ B

:

KF/ H

CR L

F AB…H

CR L

F

CR L

F

Note:

The function keys can also be pressed during

a numeric entry without influencing it.

Other keys

Their action differs according to the application. It is described in what follows.

33

Page 36

34

6.2 Cmd

Format: D [

:

D (Display/Dialogue mode set)

format

] [ x[

text

] ]

CR L

F

Function: Selection of the dialog mode and the format of the

response of the DataPac-M to the computer with

transmission of dialog text from the computer to the

display of the balance.

Note: General information on DataPac-M, see 1.2.

Dialog mode: There are 2 dialog modes. They can be selected through

format

the insertion or omission of

in the D command

sent from the computer to the balance.

Terminal

mode:

Parameter

Transmission of the D command with

format

:

format

sets the

DataPac-M keypad to the terminal mode. In other words,

keyed-in numeric values are written into the balance

display, can be corrected with CLEAR and are transmitted to the computer after ENTER has been pressed.

At the same time, the possibilities to enter numeric

values using the DataPac-M keypad are restricted to the

following:

format

: = Example

N (natural) Numbers from digits 0…9 1059

R (real) as N, also “-” and “.” -10.59

G (general) as R, but several “-”,“.” 1.0-5.9

Q (query) 1/0 (Display:YES/no)

With numeric entries, the DataPac-M transmits the

following codes to the computer:

Computer Balance display DataPac-M

K//123

Parameter

CR L

F 123 or weighing result 123 ENTER

text

:

This parameter is defined in the same way as in the

D command in section 5.19 (all printable characters of

the ISO646 code table).

Transmission of the D command with

//

/text over-

//

writes the balance display with text. (Transmission

with / alone overwrites it with “blanks”.)

Subsequently, only one numeric entry is possible. It

remains in the balance display even after ENTER until

the computer continues with a further D command.

CLEAR or ENTER without preceding numeric entry

transmits only its key code to the computer.

Computer Balance display DataPac-M

CR L

KFx _

KFx ^

F no change CLEAR

CR L

F no change ENTER

( _ is ASCII character hex 5F, “underline”,

^ the ASCII character hex 5E)

Page 37

"Power on"

/BREAK:

x

text

Sending of the D command without

redisplays

the weighing result.

Any number of numeric entries are subsequently possible.

After ENTER, the weighing result always reappears.

CLEAR or ENTER without preceding numeric entry acts

as follows:

Computer Balance display DataPac-M

no action no change CLEAR

weighing result flashes briefly ENTER

Switching on the balance or a break in the data line

sets the DataPac-M keypad to the terminal mode as if the

command “DG

CR L

F ” had been sent.

Function

key mode:

Parameter

Sending the D command without

format

:

format

sets the DataPac-M keypad to the function key mode. Here, in the

case of numeric entries the key code is sent directly to

the computer without being shown in the balance display:

Computer Balance display DataPac-M

CR L

KD/1

KD/2

KD/3

Parameter

F flashes briefly 123

CR L

F

CR L

F

text

:

has the same function as in the terminal mode except

that CLEAR transmits its key code "KF_/

CR L

F" in all

cases.

Note: If the balance display is cleared or a text is displayed, a

* appears at the top left to show that the display is no

longer linked to the balance, but is controlled via the

interface.

35

Page 38

36

Application DataPac-M, Example 1:

Weighing-in of additives 1, 2, etc. of a chemical substance No. 44

Computer Balance DataPac-M Comment

display

CR L

KF/A

F A By pressing key A of the DataPac-M keypad, the operator

requests the computer to prepare the weighing-in program for

substance No. 44 (in the computer, function key A is assigned

to the weighing-in program for substance No. 44).

DQ/SUB 44 ?

CR L

F SUb 44 ? The computer prepares the operator response by setting the

*

DataPac-M keypad to the terminal mode, at the same time the

response range of the operator is restricted to “yes/no” and

acknowledged with “Sub 44?”.

CR L

K//1

DQ/Add 1

F YES 1 ENTER The operator responds with “yes”.

CR L

F Add l The computer requests that additive 1 be weighed in.

*

*

CR L

K//1

CR L

D

F YES 1 ENTER The operator reports its readiness with “yes”.

F 0.000 g The computer initiates the display of the weighing result and

*

sets the DataPac-M keypad to the function key mode so that

ENTER acts as a PRINT key and CLEAR can be used to transmit

a correction signal.

//////12.050/g

DQ/ADD 2

CR L

CR L

F 12.050 g ENTER The operator weighs in additive 1.

F Add 2 The computer requests that additive 2 be weighed in.

*

Page 39

Application DataPac-M, Example 2

Storage of the article number and determination of the weight of a series of products

Computer Balance DataPac-M Comment

display

CR L

KF/B

F B By pressing key B of the DataPac-M keypad,

the operator requests the computer to make

storage program 26 ready.

DQ/SAFE/26

CR L

F SAFE 26 The computer acknowledges with “SAFE 26”

*

and prepares a yes/no response.

CR L

K//1

F YES 1 ENTER The operator responds with “yes”.

DR/– –.– –

CR L

F – –.– – The computer requests entry of the article number

*

with – –.– – and with DR prepares a limited response

comprising numbers and a decimal point.

K//45.12

DQ

CR L

F 45.12 45.12 ENTER The operator enters the article number.

CR L

F 0.000 g The computer enables the display for the weighing

*

result and prepares a yes/no response.

S/////59.456/g

CR L

F 59.456 g The operator loads the article. The “send auto”

*

configured balance sends a stable weighing

result to the computer.

DR/ – –.– –

CR L

F – –.– – The computer requests the operator to enter the

*

next article number.

37

Page 40

7. Programs to get started

38

7.1 Communication with the balance

The below auxiliary programs enable a computer to operate as a simple

terminal. They can be used to send control commands via the interface

to the balance and likewise to display a weighing result and status

message on the screen. It is thus possible to observe the basic mode

of action of the commands.

Interface parameters (default setting of the balance):

2400 baud, even Parity, 7 data bits and 1 stop bit

Warning: The punctuation must be adhered to exactly when typing

in the programs.

Terminal program for IBM-PC

1Ø OPEN "coml:24ØØ,E,7,1,CS,CD,DS,RS,LF" AS #1

2Ø IF LOC(1)>Ø THEN PRINT INPUT$(LOC(1),#1);

3Ø K$=INKEY$ : IF K$< >"" THEN PRINT#1,K$; : PRINT K$;

5Ø GOTO 2Ø

Terminal program for Epson HX-20

1Ø TITLE "TERM"

2Ø WIDTH2Ø,4

3Ø OPEN"O",#1,"COMØ : (57E1F)"

4Ø OPEN"I",#2,"COMØ : (57E1F)"

5Ø IF LOF (2)>Ø THEN PRINT INPUT$(LOF(2),#2);

6Ø K$=INKEY$:IFK$< >"" THEN PRINT#1,K$; :PRINTK$;

7Ø IF K$=CHR$(13)THEN K$=CHR$(1Ø):PRINT#1,K$; :PRINTK$;

8Ø GOTO 5Ø

Terminal program for Epson PX-4

1Ø OPEN "O",#1,"COMØ:(C7E1F)"

2Ø OPEN "I",#2,"COMØ:(C7E1F)"

3Ø IF LOC(2) >Ø THEN PRINT INPUT$(LOC(2),#2);

4Ø K$=INKEY$ : IF K$< > "" THEN PRINT#1,K$; : PRINT K$;

5Ø IF K$=CHR$(13) THEN K$=CHR$(1Ø) : PRINT#1,K$; : PRINT K$;

6Ø GOTO 3Ø

7.2 Evaluation of the weighing data

For further processing of the weighing result the data string from the

interface must be analyzed. The data string structure shown in section

4.3 can be examined as follows:

1. Read in data string

2. Examine first three characters of the data string

(i.e. S//, SD/, SI, SI+, SI–, TA, EL, ET, ///, /D/, ...)

3. Process remaining data string in accordance with the first part

Program example in BASIC

Evaluation of the string

"S///////23,4 g"

Identification

X$ is the received data string from the balance

6Ø IDENT$ = LEFT$(X$, 3) (search for identification)

7Ø IF IDENT$ = "S//" THEN GOSUB 110

further distinctions with IF as listed under paragraph 2.

11Ø WEIGHT = VAL (MID$ (X$, 3)) (search for weighing result)

12Ø LE = LEN (X$) (search for weight unit, 120...160)

13Ø FOR I = LE-1 TO 1 STEP –1

14Ø ST = INSTR(I,X$," ") : IF ST <> Ø THEN I = 1

15Ø NEXT

16Ø UNIT$ = RIGHT$(X$,LE-ST)

further processing of WEIGHT and UNIT$

leading zeros

Page 41

7.3 Use of commands to control the balance

Evaluation of the weighing data

Program example in PASCAL

GetString1 = Input buffer

BEGIN

inputstring :=GetString1;

Weight := ''; Unit :=''; j := 1;

Ident := Copy (inputstring, 1, 3);

IF Ident = 'S ' THEN

BEGIN

WHILE (Ord (inputstring[j]) < 65) AND

(j <=Length (inputstring)) DO

BEGIN

Weight := Weight + inputstring[j];

j := j + 1;

END;

Unit := Copy (inputstring, j, 4);

END ELSE

further distinctions with IF as listed under paragraph 2,

further processing of Weight and Unit

END.

Program example in C

char InputString[3Ø];

char Unit[5];

char Ident[4];

float Weight;

sscanf(InputString,"%3s%f%s",Ident,&Weight,Unit);

if(strcmp(Ident,"S") == Ø) /* stable weight */;

Use of base, unit, DeltaTrac and send and repeat command

(bidirectional communication)

Task: Control of packages with small parts (e.g. screws) with

the aid of the DeltaTrac

Weight of package (tare) 51,50 g

Piece weight of parts 1,58 g

Number of parts per package 100

PCS

Tolerances for DeltaTrac +1 PCS = 1,85 g

–5 PCS = 7,90 g

Program in BASIC for EPSON PX-4:

1Ø OPEN "I",#1"COM0:(C7E1F)"

2Ø OPEN "O",#2"COM0:(C7E1F)"

3Ø PRINT#2,"B 51.5" (tare preset)

4Ø PRINT#2,"U0 1.58 PCS 1" (integer number of pieces in single steps)

5Ø PRINT#2,"DY 209.5 1.58 7.9" (target weight and tolerances for DeltaTrac)

6Ø PRINT#2,"SR" : CLS

7Ø INPUT#1,X$ : PRINT X$

8Ø GOTO 70

9Ø END

Note for users of Epson HX-20:

Only the interface parameters in lines 10 and 20 are different, “C7E1F”

changes to “57E1F”.

39

Page 42

40

8. Malfunctions

8.1 What happens if …?

… one of the following error messages

is transmitted at the interface?

ES A received command is wrong (Syntax Error); the required command structure has not been

adhered to.

EL A received command is semantically (in content) wrong (Logistical Error). It is syntactically

correct but can not be executed for some reason or other.

Example: tare command, if balance in overload or underload.

ET The received character sequence has not been correctly received (Transmission Error).

Probably the transmission parameters of computer and data interface of the balance do not

match.

… the data output is too slow/too fast? The standard setting for the pause between the data strings is 1 second (for GA44

Printer).The pause can be selected in the configuration register, sector I-FACE:

PAUSE 0, H, 1, 2 seconds. H = handshake, no pause.

… functions not be executed Owing to technical improvements, certain functions have been changed or supplemented.

as described? The start message on the balance display or the version of the software used must be

checked.

Possibly the balance in question is a certified unit in which certain functions are blocked in

compliance with national regulations.

… the balance displays – – – – – –? The “busy line” shows that the balance is busy. It appears when the balance/scale is waiting

for stability after taring, after weighing-in ( ∞ ) or in animal weighing. However, it also

shows that the computer is receiving keypad entries of the DataPac-M – transmitted in the

handshake mode, see 3.1. – too slowly.

In troubleshooting note also the operating instructions of the balance.

Page 43

Printed on 100 % chlorine-free Paper, for the sake of our environment.

Page 44

To protect your METTLER TOLEDO product's future:

METTLER TOLEDO Service assures the quality, measuring accuracy and preservation

of value of all METTLER TOLEDO products for years to come.

Please send for full details about our attractive terms of service.

Thank you.

Subject to technical changes and to the availability

*P702178*

of the accessories supplied with the instruments.

© Mettler-Toledo GmbH 1998 702178A Printed in Switzerland 9809/2.12

Mettler-Toledo GmbH, Laboratory & Weighing Technologies, CH-8606 Greifensee, Switzerland

Phone +41-1-944 22 11, Fax +41-1-944 30 60, Internet: http://www.mt.com

Loading...

Loading...