Page 1

Reference Manual

Density Meter Excellence

D4/D5/D6

Page 2

Page 3

Table of Contents

1 Introduction 5

2 Safety information 6

2.1 Definitions of signal words and warning symbols ................................................................. 6

2.2 Product specific safety notes .............................................................................................. 6

3 Design and function 8

3.1 Overview density meter...................................................................................................... 8

3.2 Rear panel ....................................................................................................................... 9

3.3 Terminal .......................................................................................................................... 10

3.4 The principle of density measurement.................................................................................. 10

3.5 Design of the measuring cell and the temperature controller................................................... 12

4 Installation and commissioning 14

4.1 Scope of delivery .............................................................................................................. 14

4.2 Download the Reference Manual......................................................................................... 15

4.3 Unpack the density meter................................................................................................... 15

4.4 Position the density meter.................................................................................................. 15

4.5 Connect the density meter to the power supply ..................................................................... 16

4.6 Disconnect the density meter from the power supply ............................................................. 16

4.7 Connect, adjust and disconnect the terminal ........................................................................ 17

4.8 Install the syringe adapter.................................................................................................. 18

4.9 Install the waste tube......................................................................................................... 18

4.10 Install accessories ............................................................................................................ 18

4.11 Setup .............................................................................................................................. 20

4.7.1 Connect the terminal........................................................................................... 17

4.7.2 Adjust the angle of the terminal............................................................................ 17

4.7.3 Disconnect the terminal ...................................................................................... 17

4.10.1 Install and connect the syringe holder................................................................... 18

4.10.1.1 Install the syringe holder ................................................................................ 18

4.10.1.2 Connect the syringe holder ............................................................................. 19

4.10.2 Set up the drying pump....................................................................................... 19

4.10.2.1 Install the DryPro........................................................................................... 19

4.10.2.2 Connect the DryPro........................................................................................ 20

4.11.1 Adjustments & Tests ........................................................................................... 21

4.11.1.1 Adjustment Sets ............................................................................................ 21

4.11.1.2 Test Sets ...................................................................................................... 22

4.11.2 Hardware .......................................................................................................... 22

4.11.2.1 Cell ............................................................................................................. 22

4.11.2.2 Automation................................................................................................... 24

4.11.2.3 External Instruments ...................................................................................... 25

4.11.2.4 Peripherals ................................................................................................... 27

4.11.2.5 Sensors ....................................................................................................... 30

4.11.2.6 Auxiliary instruments ..................................................................................... 30

4.11.3 Language.......................................................................................................... 31

4.11.4 Screen .............................................................................................................. 32

4.11.5 Beep................................................................................................................. 32

4.11.6 Shortcuts........................................................................................................... 32

4.11.7 Keyboards......................................................................................................... 33

4.11.8 Global Settings .................................................................................................. 33

4.11.8.1 System ........................................................................................................ 33

4.11.8.2 User Management ......................................................................................... 33

4.11.8.3 Analysis and Resources Behavior.................................................................... 35

4.11.8.4 Physical properties ........................................................................................ 36

4.11.9 Tables & values ................................................................................................. 36

Table of Contents 1Density Meter Excellence

Page 4

4.11.9.1 Tables ......................................................................................................... 37

4.11.9.2 Auxiliary Values ............................................................................................ 38

4.11.10 Maintenance & Service ....................................................................................... 38

4.11.10.1 MT Service ................................................................................................... 39

4.11.10.2 Import / Export .............................................................................................. 39

4.11.10.3 Add External Cell ........................................................................................... 40

4.11.10.4 Reset to Factory Settings ................................................................................ 40

4.11.10.5 Firmware...................................................................................................... 40

4.11.10.6 Update ......................................................................................................... 40

4.11.10.7 Hardware / Firmware summary....................................................................... 41

4.11.10.8 Cell ............................................................................................................. 41

4.11.10.9 Export Adjustments / Tests / Measurements ...................................................... 42

5 Configuration of methods and products 43

5.1 Configure measurement methods........................................................................................ 43

5.1.1 Establishing Methods ......................................................................................... 43

5.1.2 Creating a Method Copy...................................................................................... 45

5.1.3 Modifying or Deleting Methods............................................................................. 45

5.1.4 Method Syntax................................................................................................... 45

5.1.5 Standard Data ................................................................................................... 47

5.1.6 Conditions and formulas..................................................................................... 48

5.1.7 Method Function ................................................................................................ 50

5.1.7.1 Title ............................................................................................................. 50

5.1.7.2 Configuration................................................................................................ 50

5.1.7.3 Sample ........................................................................................................ 51

5.1.7.4 Fill............................................................................................................... 52

5.1.7.5 Measure....................................................................................................... 53

5.1.7.6 Calculation................................................................................................... 56

5.1.7.7 Clean........................................................................................................... 57

5.1.7.8 Online Display .............................................................................................. 59

5.1.7.9 Report.......................................................................................................... 59

5.1.7.10 Adjustment ................................................................................................... 60

5.1.7.11 Test ............................................................................................................. 60

5.1.7.12 Cell Test ....................................................................................................... 61

5.1.7.13 Temperature Compensation ............................................................................ 61

5.1.7.14 Instruction .................................................................................................... 62

5.1.7.15 Auxiliary Value .............................................................................................. 62

5.1.7.16 Wait ............................................................................................................ 62

5.1.7.17 Auxiliary instrument ....................................................................................... 63

5.1.7.18 PowerShower ............................................................................................... 64

5.1.7.19 Stir .............................................................................................................. 65

5.1.7.20 Line rinse ..................................................................................................... 65

5.1.7.21 Park ............................................................................................................ 66

5.2 Configure products............................................................................................................ 66

5.2.1 Create Products ................................................................................................. 66

5.2.2 Linking Methods with Products ............................................................................ 67

5.2.3 Parameters for products...................................................................................... 67

5.2.4 Calculations in Products ..................................................................................... 69

6 Series 70

6.1 Delete Series .................................................................................................................... 71

6.2 Creating a series copy....................................................................................................... 71

7 Operation 72

7.1 Start up the density meter................................................................................................... 72

7.2 Shut down the density meter .............................................................................................. 72

7.3 Typical phases of density determinations............................................................................. 73

7.3.1 Fill the measuring cell......................................................................................... 73

Table of Contents2 Density Meter Excellence

Page 5

7.3.2 Rinse the measuring cell..................................................................................... 74

7.3.3 Dry the measuring cell........................................................................................ 74

7.4 Example: density determination using DryPro....................................................................... 75

7.4.1 Create the measurement method.......................................................................... 75

7.4.2 Configure the measurement method ..................................................................... 75

7.4.3 Create a shortcut on the home screen................................................................... 76

7.4.4 Determine the density ......................................................................................... 77

7.5 Viewing the results............................................................................................................ 80

7.6 Manual operation.............................................................................................................. 80

7.6.1 Automation........................................................................................................ 81

7.6.1.1 Action: Dry ................................................................................................... 81

7.6.1.2 Action: Rinse ................................................................................................ 81

7.6.1.3 Action: Drain ................................................................................................ 82

7.6.1.4 Action: Pump sample .................................................................................... 82

7.6.1.5 Action: PowerShower..................................................................................... 82

7.6.1.6 Action: Stir.................................................................................................... 82

7.6.1.7 Action: Move to position................................................................................. 83

7.6.1.8 Action: Move lift ............................................................................................ 83

7.6.2 Cell .................................................................................................................. 83

7.6.2.1 Action: Cell conditioning................................................................................. 83

7.6.2.2 Action: Cell test ............................................................................................. 83

8 Maintenance 84

8.1 Maintenance schedule....................................................................................................... 84

8.2 Clean the density meter ..................................................................................................... 84

8.2.1 Clean the housing .............................................................................................. 84

8.3 Clean the measuring cell ................................................................................................... 84

8.3.1 Typical phases of cleaning the measuring cell....................................................... 84

8.3.2 Example: clean using the drying pump................................................................. 85

8.3.2.1 Create the cleaning method ............................................................................ 85

8.3.2.2 Configure the cleaning method........................................................................ 86

8.3.2.3 Clean using deionized water and acetone ........................................................ 87

8.4 Check the measurement accuracy....................................................................................... 89

8.4.1 Typical phases of checking the measurement accuracy .......................................... 89

8.4.2 Example: test with a water standard ..................................................................... 89

8.4.2.1 Create the test method ................................................................................... 89

8.4.2.2 Configure the test method............................................................................... 90

8.4.2.3 Perform the test............................................................................................. 92

8.5 Replace the waste tube...................................................................................................... 95

8.6 Replace the syringe adapter ............................................................................................... 95

8.7 Replace the protective sleeve.............................................................................................. 95

8.7.1 Remove the protective sleeve............................................................................... 95

8.7.2 Install the protective sleeve.................................................................................. 96

8.8 View the firmware version .................................................................................................. 96

8.9 Update the firmware .......................................................................................................... 96

8.10 Prepare the density meter for storage................................................................................... 96

8.11 Transport the density meter ................................................................................................ 96

8.12 Dispose of the density meter .............................................................................................. 97

9 Troubleshooting 98

9.1 View and export system information.................................................................................... 98

9.1.1 View system information of the density meter ........................................................ 98

9.1.2 View system information of connected accessories ................................................ 98

10 Technical data 99

10.1 Density meter ................................................................................................................... 99

10.2 Terminal .......................................................................................................................... 100

10.3 Measurement ................................................................................................................... 101

Table of Contents 3Density Meter Excellence

Page 6

11 Accessories 102

11.1 Standards ........................................................................................................................ 102

11.2 Sensors ........................................................................................................................... 102

11.3 Sample changers and pumps............................................................................................. 102

11.4 External measuring cells.................................................................................................... 106

11.5 Tubes.............................................................................................................................. 106

11.6 External instruments.......................................................................................................... 107

11.7 Peripheral instruments....................................................................................................... 108

11.8 Software .......................................................................................................................... 109

11.9 Miscellaneous accessories................................................................................................. 110

Index 111

Table of Contents4 Density Meter Excellence

Page 7

1 Introduction

Thank you for choosing a METTLER TOLEDO density meter. The density meters D4, D5 and D6 are easy-tooperate, high-performance instruments for measuring the density of liquid samples.

About this document

The instructions in this document refer to density meters D4, D5 and D6 running firmware version 1.0 or

higher.

The firmware license is subject to the End User License Agreement EULA version 3.0. See the following link for

the license text:

u www.mt.com/legal

For third party licenses and open source attribution files, see the following link:

u www.mt.com/licenses

If you have any additional questions, contact your authorized METTLER TOLEDO service representative or

dealer.

u www.mt.com/contact

Conventions and symbols

Note

For useful information about the product.

Refers to an external document.

Elements of instructions

Prerequisites

§

1 Steps

2 Steps

ð Intermediate results

3 Steps

ð Results

Introduction 5Density Meter Excellence

Page 8

2 Safety information

Two documents named "User Manual" and "Reference Manual" are available for this instrument.

• The User Manual is printed and delivered with the instrument.

• The electronic Reference Manual contains a full description of the instrument and its use.

• Keep both documents for future reference.

• Include both documents if you transfer the instrument to other parties.

Only use the instrument according to the User Manual and the Reference Manual. If you do not use the

instrument according to these documents or if the instrument is modified, the safety of the instrument may be

impaired and Mettler-Toledo GmbH assumes no liability.

User Manual and Reference Manual are available online.

u www.mt.com/library

2.1 Definitions of signal words and warning symbols

Safety notes contain important information on safety issues. Ignoring the safety notes may lead to personal

injury, damage to the instrument, malfunctions and false results. Safety notes are marked with the following

signal words and warning symbols:

Signal words

WARNING

A hazardous situation with medium risk, possibly resulting in death or severe injury if

not avoided.

NOTICE

A hazardous situation with low risk, resulting in damage to the instrument, other

material damage, malfunctions and erroneous results, or loss of data.

Warning symbols

Electrical shock

2.2 Product specific safety notes

Intended use

The density meters D4, D5 and D6 are designed to be used by trained staff. The density meters are intended for

measuring the density of liquid samples that are compatible with the materials with which they come into

contact.

Any other type of use and operation beyond the limits of use stated by Mettler-Toledo GmbH without consent

from Mettler-Toledo GmbH is considered as not intended.

Responsibilities of the instrument owner

The instrument owner is the person holding the legal title to the instrument and who uses the instrument or

authorizes any person to use it, or the person who is deemed by law to be the operator of the instrument. The

instrument owner is responsible for the safety of all users of the instrument and third parties.

METTLER TOLEDO assumes that the instrument owner trains users to safely use the instrument in their

workplace and deal with potential hazards. METTLER TOLEDO assumes that the instrument owner provides the

necessary protective gear.

Safety information6 Density Meter Excellence

Page 9

Safety notes

WARNING

Danger of death or serious injury due to electric shock!

Contact with parts that carry a live current can lead to death or injury.

1 Only use the METTLER TOLEDO power supply cable and AC adapter designed for your

instrument.

2 Connect the power cable to a grounded power outlet.

3 Keep all electrical cables and connections away from liquids and moisture.

4 Check the cables and the power plug for damage and replace damaged cables and

power plugs.

NOTICE

Risk of damage to the instrument due to the use of unsuitable parts!

Using unsuitable parts with the instrument can damage the instrument or cause it to

malfunction.

− Only use parts from METTLER TOLEDO that are intended to be used with your instrument.

FCC Rules

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Safety information 7Density Meter Excellence

Page 10

3 Design and function

1

4

5

6

2

3

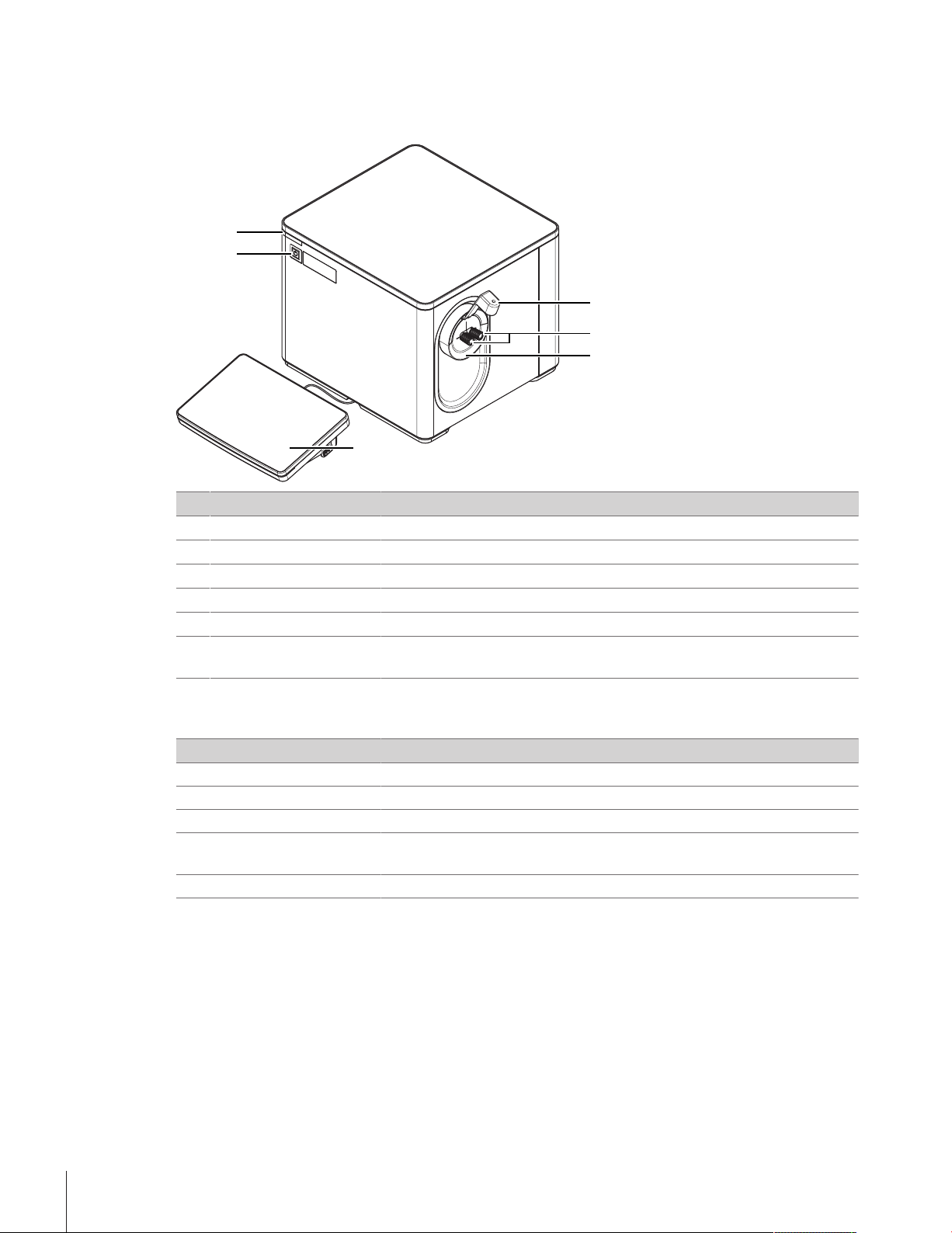

3.1 Overview density meter

No. Name Function

Syringe holder

1

Cell adapters Used to fill, drain and dry the measuring cell

2

Protective sleeve Prevents liquid from entering through the opening around the cell adapters

3

Terminal Displays information and is used to enter information

4

Power button Starts up and shuts down the density meter

5

Instrument status light

6

(StatusLight™)

1)

Only included in the scope of delivery of D6

1)

Prevents disturbance of the measuring-cell when the user injects a sample

Provides information about the status of the density meter

Status light

StatusLight Density meter status

Steady, green light The density meter is ready for operation.

Blinking, green light The density meter is performing a task.

Steady, orange light The density meter waits for the user to perform an action.

Blinking, orange light A task has been interrupted, for example because a value lies outside of its

limits.

Steady, red light An error has occurred during task execution.

Design and function8 Density Meter Excellence

Page 11

3.2 Rear panel

1

15 13 34678910111214 5

2

No. Name Function

1 DryPro / pH/Cond

Fan and ventilation

2

openings

3 Air In

4 CAN out

5 Power Supply

6 USB 1 / USB 2

7 PC

8 SPR200

9 Terminal

10 DryPro

11 Ethernet

12 Aux

13 Automation

14 LevelSens

15 ErgoSens

Mounting plate to attach a DryPro, or an external flow cell to measure pH or

conductivity

Move air over the heat sink of the Peltier element

Gas inlet to connect a source of dry air and prevent condensation outside of

measuring cell

RJ12 socket to connect a LevelSens box

DC Socket to connect the AC adapter

USB-A socket to connect USB devices, for example printers, barcode readers

or an InMotion™ Autosampler

USB-B socket to connect a computer

6-pin Mini-DIN socket to connect the filling pump SPR200

19-pin Mettler-HDMI socket with non-standard pin assignment, reserved to

connect the terminal and no other display device

5-pin Mini-DIN socket to connect the drying pump DryPro

RJ45 socket to connect a network

5-pin Mini-DIN socket to connect an auxiliary instrument

9-pin male D-sub socket to connect a sample delivery and cleaning unit

5-pin Mini-DIN socket to connect the fluid-level sensor LevelSens

3.5mm jack socket to connect the infrared motion-sensor ErgoSens

See also

2 Accessories}Page102

Design and function 9Density Meter Excellence

Page 12

3.3 Terminal

1

2

3

456

T

s

t

A

B

A

f =

1

T

[s

-1

]

No. Name Function

Touch screen Displays information and can be used to enter information

1

USB-A socket Is used to transfer data to and from a USB flash drive

2

Terminal status light

3

(StatusLight™)

4

Provides information about the status of the density meter

Opens a window with general information about the density meter

5

6

Opens the home screen

Ends all running tasks

3.4 The principle of density measurement

The density measurement is based on the electromagnetically

induced oscillation of a U-form tube made of glass. A magnet is

fixed to the U-tube and a transmitter induces the oscillation. The

period of oscillation T is measured by a sensor.

A complete forward and backward vibration is known as a

period, its duration is the oscillation period T. The maximum

deflection in the vertical direction is the amplitude A.

Measuring tube with defined volumetric capacity:

A) Excitation: Magnetic

B) Detection: optical

The number of periods per second is the frequency f. Each glass tube oscillates with its own intrinsic frequency:

Design and function10 Density Meter Excellence

Page 13

The frequency is a function of the total mass and changes when the tube is filled with a gas or liquid. If the

T =

[s

]

2π

ρ

V

c

+

m

c

K

ρ

ρ

=

K

4π

2

V

c

T

2

-

m

c

V

c

ρ = AT + B

2

F =

4

π

2

V

K

c

T

2

=

ρ Aρ

W

-

T

2

A

T

2

W

-

ρ

ρ

F (

OSC

2

A

OSC

2

S

-

)

=

ρ Aρ

S

-()

ρ

S

=

ρ

A

-

F (

OSC

2

A

OSC

2

S

-

)

mass is increased, the frequency falls, i.e. the period of oscillation T becomes longer, according to the below

formula:

: Density of the sample in the measuring cell [g/cm3]

VC: Volume of the sample (capacity of the measuring cell) [cm3]

mc: Mass of the measuring cell [g]

K: Measuring cell constants [g/s2]

The density ρ can hence be calculated as follows:

The relationship between the density and the period of oscillation T is as follows:

A and B are constants that depend on the elasticity, structure and mass of the measuring cell. As they vary from

cell to cell, they must be determined by means of direct measurement. This is known as a coefficient determination or adjustment of the instrument. The coefficient F of the measuring cell is calculated by measuring the

period of oscillation T of two standard substances (usually air and water) with known densities:

= Density of air [g/cm3]

A

= Density of water [g/cm3]

W

TA = Period of oscillation of the air measurement [s]

TW = Period of oscillation of the water measurement [s]

After the coefficient F of the measuring cell has been determined by an adjustment, the unknown density of a

substance S can be calculated via the following formulas, whereby TA, TS and TW in the following formulas no

longer represent the period of oscillation itself but the oscillation value OSC derived from it:

The following diagram shows the how the density of an unknown substance is determined:

Design and function 11Density Meter Excellence

Page 14

OSC

2

A

OSC

2

OSC

2

S

OSC

2

W

Note

The coefficient F is temperature-dependent. The volume of the measuring cell and hence its period of oscillation

changes with the temperature. For very precise measurements, the coefficient of the cell should be determined

for the temperature at which you measure your samples.

The oscillation value OSC described here is required to calculate the coefficient of the measuring cell and hence

the density of the unknown sample. The period of oscillation T itself is not displayed on the instrument. The

density meters only display the so-called oscillation value OSC that is directly derived from the period of oscillation T.

The oscillation value OSC is thus only an auxiliary value that represents the period of oscillation in high

resolution as a whole number without digital places.

3.5 Design of the measuring cell and the temperature controller

For a specific determination of the density a very precise measurement and adjustment of the temperature must

be ensured.

As the temperature of the probe cannot be measured directly in the U-form tube without falsifying the

measurement of the oscillation, the temperature is measured via three thermistors at different locations. The

temperature is measured at four different points:

Temperature 1: Sensor in the measuring cell, directly above the surface of the U-tube. This temperature

is shown as a status display (cell temperature).

Temperature 2: Temperature of the thermoblock (block temperature) (not displayed)

Temperature 3: Reference temperature (not displayed)

Temperature 4 Ambient temperature (not displayed)

The following schematic diagram shows the design of the module:

Design and function12 Density Meter Excellence

Page 15

1

2

3

4

5

6

7

8

9

10

1: Temperature controller

t

3

2

4

1

2: Peltier element

3: Magnetic excitation/ oscillation measurer

4: Heat insulation

5: Magnet

6: Temperature sensor 2 (block

temperature)

7: Temperature sensors 1 (cell

temperature) and 3 (reference

temperature)

8: U-tube

9: Thermoblock

10: Temperature sensor 4

(ambient temperature)

During a measurement the temperature of the sample must be regulated (heating or cooling) to precisely

correspond to the selected measuring temperature. The density of the sample changes during heating or

cooling (density is temperature-dependent!). The same is true for the resonance frequency of the U-tube. The

sample temperature corresponds exactly to the selected temperature (and hence the cell temperature, Sensor 1)

when the resonance frequency stabilizes. However it takes a long time before this thermal equilibrium is

completely established. With respect to the shorter measuring times, various measurement reliabilities can be

chosen so that even before the measurement is completed the temperature and the OSC can be extrapolated to

stable end values. This means that sufficiently accurate results can be obtained before stabilization:

End of the measurement with:

1) Meas. reliability "Maximum":

T and OSC stable

2) Meas. reliability "High": T

and OSC extrapolated; narrow

tolerance

3) Meas. reliability "Medium": T

and OSC extrapolated; medium

tolerance

4) Meas. reliability "Minimum":

T and OSC extrapolated; greater

tolerance

Design and function 13Density Meter Excellence

Page 16

4 Installation and commissioning

4.1 Scope of delivery

Part Order number D4 D5 D6

Density meter – • • •

Extern. Power Supply 120W 30298362 • • •

Power cable (country-specific) – • • •

Terminal WVGA 7inch AnaChem

• Terminal

• HDMI cable

Syringe adapter (1 pc) 51337154 • • •

Waste tube

600mm, M8 connector

Disposable syringe (3 pcs)

10mL

Syringe Holder Dx

• Protective sleeve for syringe holder

• Syringe holder and 2 screws

• Syringe adapter

• Tube with 2 M8connectors,

length 280mm

• Torx screwdriver 10

Combined water standard

9mL, density/refractive index

– • • •

51337223 • • •

– • • •

30474897 – – •

51338010 • • •

User Manual – • • •

Declaration of conformity – • • •

Installation and commissioning14 Density Meter Excellence

Page 17

Part Order number D4 D5 D6

Test report – • • •

4.2 Download the Reference Manual

1 Go to the website www.mt.com/library.

2 Select the Technical Documentation tab.

3 Enter the product type in the search field and start the search.

4 Select the Reference Manual from the result list.

5 Select the link.

ð The Reference Manual is either opened or downloaded depending on the browser settings.

6 Check which firmware version is installed on your density meter.

7 If the Reference Manual is not written for the installed firmware version, contact your authorized METTLER

TOLEDO service representative or dealer.

u www.mt.com/contact

See also

2 Introduction}Page5

2 View the firmware version}Page96

4.3 Unpack the density meter

1 Remove the density meter from the protective packaging.

2 Store the packing material for later transport over long distances.

3 Check if you received all parts listed in the scope of delivery.

4 Inspect the parts visually for flaws or damage.

5 If parts are missing or damaged, report it to your authorized METTLER TOLEDO service representative or

dealer.

u www.mt.com/contact

See also

2 Scope of delivery}Page14

4.4 Position the density meter

The density meter has been developed for indoor operation in a room with stable temperature.

The following site requirements apply:

• Dew point below measurement temperature

• Ventilation as needed by the chemicals that are used

• Ambient conditions within the limits specified in the technical data

• No powerful vibrations

• No direct sunlight

• No corrosive gas atmosphere

• No explosive atmosphere

• No powerful electric or magnetic fields

Procedure

1 Place the density meter on a level surface.

2 Make sure that there are at least 15 cm clearance behind the density meter.

Installation and commissioning 15Density Meter Excellence

Page 18

3 Make sure that nothing blocks the ventilation openings in the rear panel of the density meter.

1

See also

2 Technical data}Page99

4.5 Connect the density meter to the power supply

The AC adapter is suitable for all supply line voltages ranging from 100...240 V AC and 50/60 Hz.

WARNING

Danger of death or serious injury due to electric shock!

Contact with parts that carry a live current can lead to death or injury.

1 Only use the METTLER TOLEDO power supply cable and AC adapter designed for your

instrument.

2 Connect the power cable to a grounded power outlet.

3 Keep all electrical cables and connections away from liquids and moisture.

4 Check the cables and the power plug for damage and replace damaged cables and

power plugs.

NOTICE

Danger of damage to the AC adapter due to overheating!

If the AC adapter is covered or in a container, it is not sufficiently cooled and overheats.

1 Do not cover the AC adapter.

2 Do not put the AC adapter in a container.

1 Install the cables in such a way that they cannot be damaged or interfere with operation.

2 Insert the plug of the power cable in the socket of the AC adapter.

3 Insert the plug of the AC adapter in the Power

Supply(1) socket on the rear panel.

4 Insert the plug of the power cable into a grounded

power outlet that is easily accessible.

4.6 Disconnect the density meter from the power supply

The density meter is shut down.

§

1 Pull the plug of the power cable out of the power outlet.

2 Pull the plug of the AC adapter out of the Power Supply socket on the rear panel.

Installation and commissioning16 Density Meter Excellence

Page 19

4.7 Connect, adjust and disconnect the terminal

1 2

1

1

4.7.1 Connect the terminal

The density meter is shut down.

§

1 Insert one of the plugs of the supplied terminal cable in the socket(1) on the back of the terminal.

2 Insert the other plug of the terminal cable into the Terminal socket(2) on the rear panel.

3 Start up the density meter.

ð The density meter automatically detects the terminal and activates it.

See also

2 Start up the density meter}Page72

4.7.2 Adjust the angle of the terminal

The angle of the terminal has twopositions.

Procedure

No task is running.

§

− To increase the angle of the terminal, fold out the two

feet(1) at the underside of the terminal.

4.7.3 Disconnect the terminal

The density meter is shut down.

§

1 Pull the plug of the terminal cable out of the socket on the back of the terminal.

2 Pull the plug of the terminal cable out of the Terminal socket on the rear panel.

See also

2 Shut down the density meter}Page72

Installation and commissioning 17Density Meter Excellence

Page 20

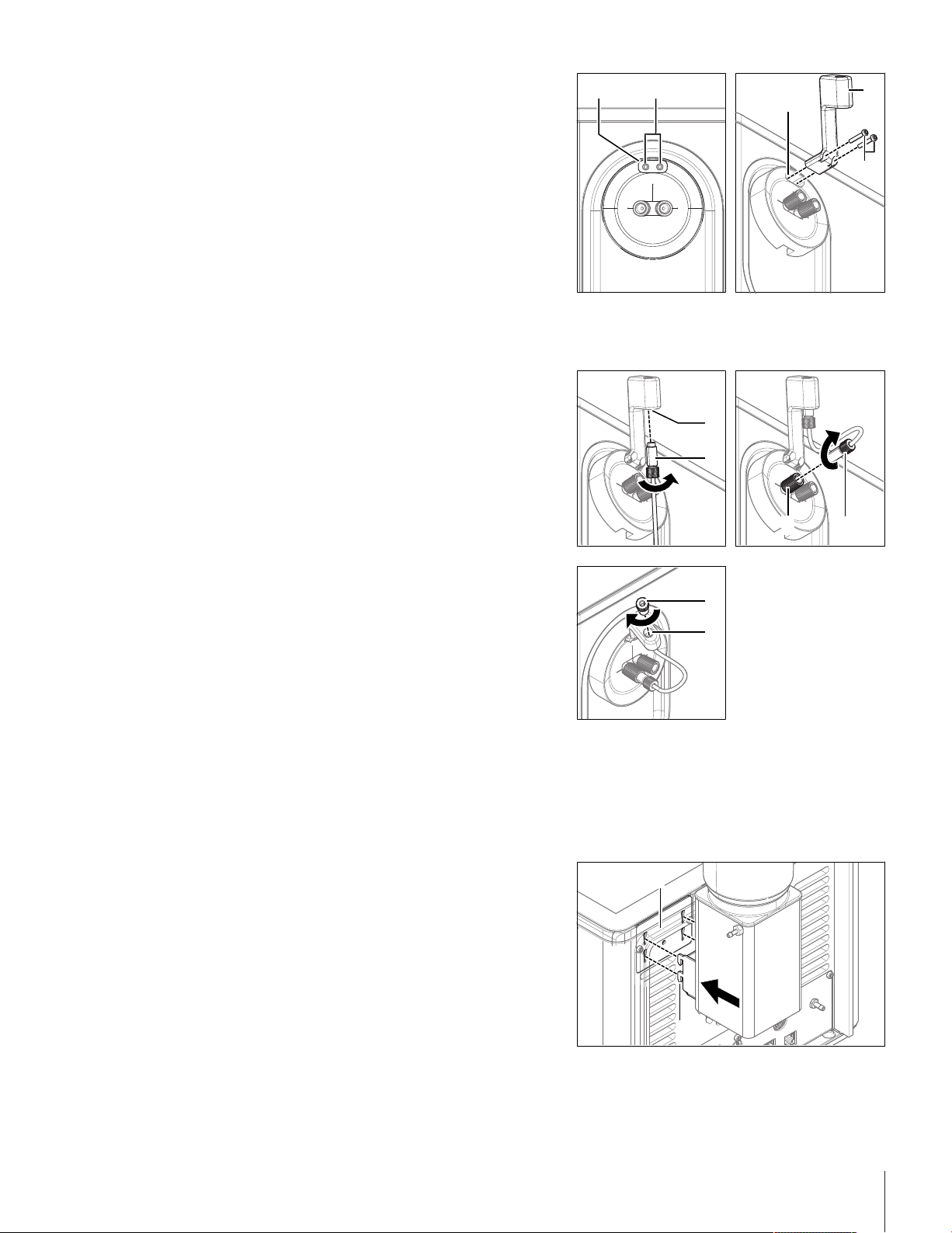

4.8 Install the syringe adapter

1

2

1

2

1

2

1 Screw the syringe adapter(2) into the front cell

adapter(1).

2 Make sure that the connection is tight.

4.9 Install the waste tube

1 Screw the connector of the waste tube(2) into the rear

cell adapter(1).

2 Make sure that the connection is tight.

3 Place the end of the waste tube(1) into the waste

container(2).

4 Shorten the waste tube so that the end of the waste

tube(1) is above the level of the waste.

4.10 Install accessories

4.10.1 Install and connect the syringe holder

4.10.1.1 Install the syringe holder

1 Remove the protective sleeve. See [Remove the protective sleeve}Page95].

Installation and commissioning18 Density Meter Excellence

Page 21

1 2

3

4

5

2 Install the protective sleeve supplied with the Syringe

1

2

3 4

1

2

1

2

Holder Dx.See [Install the protective

sleeve}Page96].

3 Make sure that the opening for the syringe holder(1) is

over the two mounting holes for the syringe holder(2).

4 Insert the syringe holder(4) in the opening for the

syringe holder(3).

5 Insert the two screws(5) in the two openings in the

syringe holder and the mounting holes.

6 Screw in the screws and tighten them.

4.10.1.2 Connect the syringe holder

The syringe holder is installed.

§

1 Screw one of the M8 connectors(2) of the syringe-

holder tube from below about halfway into the

opening(1).

2 Screw the other M8 connector(4) of the syringe holder

tube into the front cell adapter(3) and tighten it.

3 Screw the syringe adapter(1) from above into the

opening(2) and tighten it.

4.10.2 Set up the drying pump

4.10.2.1 Install the DryPro

The DryPro is assembled as described in its User Manual.

§

The density meter is shut down.

§

1 Align the hooks(2) of the DryPro with the openings of

the mounting plate(1).

2 Insert the hooks into the openings.

Installation and commissioning 19Density Meter Excellence

Page 22

3 Move the DryPro downward until it clicks in place.

21

Home

Tasks

Log out User data Barcode start Start

Methods /

Products

Series

Results

Setup

Manual

08/15/2018Administrator

20.00

1

D5

0.00122

d [g/cm3]

4.10.2.2 Connect the DryPro

The DryPro is installed.

§

The density meter is running.

§

The home screen is open.

§

1 Insert the plug(2) of the DryPro in the DryPro

socket(1) on the rear panel.

ð The density meter detects and configures the

DryPro.

2 Go to Setup(1) > Hardware > Automation.

3 Check that the DryPro has the Status Installed.

See also

2 Start up the density meter}Page72

4.11 Setup

This section tells you how to set up the density meter in accordance with your requirements so that you can

carry out the measurements.

The following summary shows the buttons available in Setup for the various setting options:

Adjustments & Tests

Hardware

Adjustment sets

Test sets

Cell

Automation

External instruments

Peripherals

Sensors

Auxiliary instruments

Installation and commissioning20 Density Meter Excellence

Page 23

User settings

Language

Screen

Beep

Shortcuts

Keyboards

Global settings

Tables & Values

Maintenance & Service

System

User management

Analysis and resources behavior

Physical Properties

Tables

Auxiliary values

MT service

Import / Export

Add external cell

Reset to factory settings

Firmware

Update

Hardware / Firmware summary

Cell

Touch screen adjustment

Export of adjustments / Tests / Measurements

The "Expired Resources" button

The Expired Resources button is located on the setup overview screen. It provides you with a summary of all

expired resources, stating the: type, name and expiration date of the respective resource.

Expired resources are entered if the setting "Monitoring adjustment set/test set/auxiliary value" is activated

during setup.

Below you will find a detailed description of the setting options available in setup:

4.11.1 Adjustments & Tests

Navigation: Home > Setup > Adjustments & Tests

Adjustment and test sets can be administered as described below. You can create new sets and delete existing

ones (when deleting you receive a prompt with the option to cancel). Before an adjustment or test can be

performed, an adjustment or test set must be defined.

A maximum of six different adjustment sets or test sets respectively can be entered in the set list.

Before an adjustment or test can be performed, an adjustment or test set must be defined.

4.11.1.1 Adjustment Sets

Via the button Adjustment sets you will obtain a list of the defined sets. The default set "Air&Water20.00C" is

always available and cannot be deleted. When you click the sets, you obtain more detailed information about

the individual sets. The parameters "Adjustment mode", "Temperature" and "Set name" are displayed.

Creating adjustment sets

You can create your own adjustment sets via the button New. The Adjustment set parameters dialog opens.

Installation and commissioning 21Density Meter Excellence

Page 24

Parameter Description Values

Adjustment mode Defines the standard that is used for the adjustment procedure.

Temperature Defines the temperature at which the procedure is performed. 0.00…100.00°C |

Set name Specify a descriptive name of your choice. 1…30 characters

Delete adjustment sets

1 To delete a created set, click the desired entry in the Adjustment sets dialog.

2 In the Adjustment set parameters dialog, click the button Delete.

ð When a set is deleted, the set history will also be deleted. Methods that refer to the deleted set are no

longer executable.

4.11.1.2 Test Sets

Via the button Test sets you receive a list of the defined sets. The default set "Water20.00C" is always available

and cannot be deleted. When you click the test sets, you obtain more detailed information about the individual

sets. The parameters "Test mode", "Temperature", "Set name" and depending on the mode "Standard name" are

displayed.

Creating test sets

You can create your own test sets via the button New. The Test set parameters dialog is opened.

Standards requires a valid adjustment with Air&Water at this

temperature. (Air&Standard and Water&Standard are not

available for refractometers).

Air&Water |

Air&Standard |

Water&Standard |

Standards

32.00…212.00°F

Parameter Description Values

Test mode Defines the standard that is used for the test procedure. Air | Standard | Brix

Temperature Defines at which temperature the test will be performed. -

Standard name Specify a descriptive name of your choice. 1…30 characters

Set name Specify a descriptive name of your choice. 1…30 characters

Delete test sets

1 To delete a created set, click the desired entry in the Test sets dialog.

2 In the Test set parameters dialog click the button Delete.

ð When a set is deleted, the set history will also be deleted. Methods that relate to the deleted set are no

longer executable.

4.11.2 Hardware

Navigation: Setup>Hardware

In this dialog window you can configure all the hardware components connected to the meter. These include:

• Cell

• Automation

• External instruments

• Peripherals

• Sensors

• Auxiliary instruments

standard

4.11.2.1 Cell

Navigation: Home > Setup > Hardware > Cell

Installation and commissioning22 Density Meter Excellence

Page 25

The measuring cell is connected via an internal interface in the compact device. The instrument can be

extended to create a 2–cell instrument (see also "Setup: Maintenance & Service > [Add external

cell}Page40]").

− Touch the button Cell in the Hardware dialog.

ð With single cell instruments you go directly to the list with the cell parameters

ð In the case of two cell instruments the connected cells are listed. You have to touch one of the displayed

cells so that the Cell parameters dialog opens.

ð The Cell parameters dialog is opened.

Parameter Description Values

Cell Name of the measuring cell -

Type Measuring cell type -

Status Shows whether the cell is connected. -

Serial number Serial number of the cell -

If an adjustment has been performed, an entry in the adjustment set appears in the setup of the corresponding

cell. If you touch the entry, the data of the most recent adjustment that was executed with the set will be

displayed.

Parameter Description Values

Adjustment set By touching the set entry, you obtain the values for the most

-

recent adjustment of this set.

Monitoring

adjustment set

Monitoring of the service life of the adjustment can be activated.

The process, if the service life of a set has expired, is defined in

-

the method function "Measure".

Adjustment

interval

Reminder Before the set expires, a message appears indicating that the

Days before

Validity of adjustment "Monitoring adjustment

set" activated

"Monitoring adjustment

adjustment or test has expired.

set / test set" activated

Specifies the number of days after which a warning is triggered. "Reminder" activated

expiration

If a test has been performed, an entry in the test set appears in the setup of the corresponding cell. If you touch

the entry, the data of the most recent adjustment that were executed with the set will be displayed.

Parameter Description Values

Test set By touching the set you go to the values for the most recent test

-

for this set.

Monitoring test

set

Monitoring of the service life of the test can be activated. The

process, if the service life of a set has expired, is defined in the

-

method function "Measure".

Test interval Service life of test "Monitoring test set"

activated

Parameter Description Values

Reminder Before the set expires, a message appears indicating that the

adjustment or test has expired.

Days before

Specifies the number of days after which a warning is triggered. "Reminder" activated

"Monitoring adjustment

set / test set" activated

expiration

Via the button History you go to a list that contains a maximum of ten adjustment or test entries for the selected

set.

For the adjustment, the oscillation values OSC1 and OSC2 (for both adjustment standards) are displayed, while

for the cell test the deviation of the measured density (d

) from the nominal value

meas

) is shown.

set

Installation and commissioning 23Density Meter Excellence

Page 26

The history can be displayed in graphic form via the button Graph. You can view the history data by touching

an entry.

See also

2 Add External Cell}Page40

4.11.2.2 Automation

Navigation: Home > Setup > Hardware > Automation

The automation units that can be installed are listed below:

• DryPro (drying pump)

• SPR200 (sample pump)

• SC1 (automation unit for a sample)

• SC30 (automation unit for 30 samples)

• InMotion (automation unit for up to 303 samples)

The peripheral devices have an automatic PnP (Plug and Play) – identification. They can also be manually

created in the setup.

Via the button Automation in the Hardware dialog, you access a list with defined automation units. By

touching a list entry, you obtain more detailed information about the corresponding automation unit.

Parameter Description Values

Type Instrument Type -

Power purge unit The external diaphragm (Optional) has a much higher output

Heating option This is where the heating option is activated. The temperature is

Limit sensor Optical sensor that detects the sample and prevents it leaving the

External drain

valve

Solvent 1 Specifies the solvent at the connection Rinse 1 "Type" = "SC1"/ "SC30"

Solvent 2 Specifies the solvent at the connection Rinse 2 "Type" = "SC1"/ "SC30"

Speed "Low" Value for speed level "Low" of the SPR200 or InMotion

Speed "Medium" Value for speed level "Medium" of the SPR200 or InMotion

Speed "High" Value for speed level "High" of the SPR200 or InMotion

than the diaphragm pump integrated in the SC1/SC30. The pump

is actually adjusted at the SC1/SC30.

directly set on the heating unit.

heated area of the heating option (info field).

Located in the heating unit. Prevents the samples flowing back

after filling process (info field).

autosampler (in % of the maximum speed).

autosampler (in % of the maximum speed).

autosampler (in % of the maximum speed).

"Type" = "SC1"/ "SC30"

"Type" = "SC1"/ "SC30"

"Type" = "SC1"/ "SC30"

"Type" = "SC1"/"SC30"

"Type" = "SPR200" /

"InMotion"

"Type" = "SPR200" /

"InMotion"

"Type" = "SPR200" /

"InMotion"

Rate at 100% Value for max. possible pump output (depending on the installed

"Type" = "InMotion"

pump which is defined as sampling pump).

Stirrer output Specifies the pump/stirrer port on the InMotion where your stirrer

"Type" = "InMotion"

is connected.

Sampling pump

output

PowerShower

output

Specifies the pump/stirrer port on the InMotion where your

sampling pump is connected.

Specifies the pump/stirrer port on the InMotion where your pump

for PowerShower is connected.

"Type" = "InMotion"

"Type" = "InMotion"

Rate Value for required pump output for PowerShower. "Type" = "InMotion"

Beaker height Specifies the height of the used beakers. "Type" = "InMotion"

Installation and commissioning24 Density Meter Excellence

Page 27

A distinction should be made between the following two cases in the installation of instruments:

1. There is still no setup entry available in the unit (delivery state).

A new entry has been generated and the parameters automatically generated.

2. A setup entry was previously manually created in the instrument:

The PnP parameters are automatically entered, the remaining parameters, previously edited by the user,

remain unchanged.

When a PnP instrument is unplugged, the status changes to "not installed".

Below is described how you can administer the various devices in setup. This includes the creation of devices

or changing the parameters in the setup.

Create automation units

So that methods for the application of automation units can be created and configured without the automation

unit being connected, these units must be created in the setup via the button New.

Delete automation unit

It is not possible to delete the entry of a connected device.

Note

If you want to delete an entry for a unit that is not connected from the list, a message with the termination

option appears indicating that after deletion the methods that use the external instruments will no longer be

executable.

4.11.2.3 External Instruments

Navigation: Home > Setup > Hardware > External instruments

The external instruments that can be installed are listed below. They all have automatic PnP – identification:

• METTLER TOLEDO S20 – SevenEasy™ pH

• METTLER TOLEDO S30 – SevenEasy™ Conductivity

• METTLER TOLEDO S220 - SevenCompact™ pH/Ion

• METTLER TOLEDO S220 - SevenCompact™ Conductivity

• Lovibond colorimeters PFX880/ PFXi880, PFX950/ PFXi950 and PFX995/ PFXi995 series, Tintometer

• Minolta colorimeters CM-5/ CR-5

Note

• The Lovibond colorimeters can be connected to the USB interfaces. For this purpose the USB – RS232

adapter is required (contained in the connection kit).

• For each device type only one entry is possible.

Install devices

A distinction should be made between the following two cases in the installation of instruments:

1. There is still no setup entry available in the unit (delivery state).

A new entry has been generated and the parameters automatically generated.

2. A setup entry was previously manually created in the instrument:

The PnP parameters are automatically entered, the remaining parameters, previously edited by the user,

remain unchanged.

When a PnP instrument is unplugged, the status changes to "not installed".

• Via the button External instruments in the Hardware dialog, you can obtain the list of instruments. By

touching a list entry, you obtain more detailed information about the corresponding instrument.

Create device

So that methods can be created and configured with external instruments, without having to connect the

instrument, the setup entries of the external instruments can be manually created via the button New.

Note

• The pH and conductivity meters can be assigned names individually using the "Instrument" parameter.

Installation and commissioning 25Density Meter Excellence

Page 28

Delete devices

It is not possible to delete the entry of a connected device.

Note

If you want to delete an entry for a unit that is not connected from the list, a message with the termination

option appears indicating that after deletion the methods that use the external instruments will no longer be

executable.

SevenEasy™ / SevenCompact™ pH/ion and conductivity meters

1 Select the following for the SevenEasy™ and SevenCompact™ measuring instruments (also refer to the

operating instructions for the measuring instrument concerned):

Manual end point measured value acquisition,

set the unit [pH]" ([mV] not supported).

2 For the SevenCompact pH and conductivity meters, the following must also be selected (also refer to the

relevant operating instructions):

an interval time of 1s (in menu>Interval measurements),

interface=printer (in menu>Data transmission),

"Send data to interface" (in "Type of data transmission").

3 For temperature compensation, set the unit [°C] at the measuring instruments. Two types of temperature

compensation exist:

- ATC (automatic temperature compensation) with a temperature sensor connected.

- MTC (manual temperature compensation) with no temperature sensor connected.

Note:

The pH or conductivity meters switch automatically, depending on the arrangement.

If the temperature unit at the pH meter or conductivity meter is set to [°C], the results "TpH" and "TCond" will

be converted to the temperature unit set in the instrument, i.e. either [°C] or [°F] . By contrast, if [°F] is set

at the pH or conductivity meter, no result will be calculated. "--" will be output in the results field.

Note

The conductivity units are [mS/cm]/ [μS/cm] (depending on the range) or [mS/m][μS/m] (depending on the

range). However, the results are expressed in [μS/cm]. If you wish to have the result displayed in [mS/cm] or

[mS/m][μS/m], it will be necessary to recalculate the result using the "Calculation" method function.

Colorimeter

- Lovibond

The Lovibond colorimeter can be used for extinction or transmission measurements. The wavelengths are

output in 5nm (in the range 420 – 710nm).

Note

A color measurement may take longer than 25s.

- Minolta colorimeters CM-5 / CR-5

The Minolta colorimeters can be used for transmission measurements (liquids).

Transmission data are supplied in 10nm increments within the spectral range 360 – 740nm.

A color measurement takes approximately 1s.

The measurements involve high-energy light flashes. For this reason, color scales are not offered for reflection

measurements in the crude oil industry.

Note

• The CR-5 colorimeter does not supply any spectral data.

• Calibration is possible directly at the colorimeter only. The USB link must be disconnected.

• "Illuminant" and "Observer" can be set in the "Configuration" method function. For more information, see

"[Methods and products: Method functions> Configuration}Page50]".

- Color scales

Navigation: Home > Setup > Hardware > External instruments > Parameters

Installation and commissioning26 Density Meter Excellence

Page 29

− Click on "Colorimeter".

ð The "External instrument parameters" dialog appears.

If a device has been connected, a list of color scales is displayed via the Color scales button, that were

available in the most recently connected device. If the device has been manually configured and no device has

yet been connected, then the list is empty.

4.11.2.4 Peripherals

Navigation: Home > Setup > Hardware > Peripherals

In the dialog Peripherals, the following devices and settings can be configured:

• Barcode reader

• USB stick

• Fingerprint reader

• Printer

• Personal Computer (PC) – settings

• Network settings

• Network storage

Below is described how you can administer the various devices in setup. This includes the creation of devices

or changing the parameters in the setup.

Barcode reader

Barcode readers have Plug&Play (PnP) recognition and can be installed via the USB interface.

The following barcode readers can be installed:

• Handheld readers

• Built-in readers

You can create the barcode readers via New. A maximum of one entry can be created for both types.

Parameter Description Values

Type Instrument Type -

Serial number Serial number of the corresponding device -

Barcode Information

Sample ID: on the barcode there is only the sample ID.

Method ID: on the barcode there is the method ID (with this a

-

saved method can be selected during scanning).

Product ID: on the barcode there is the product ID (with this a

saved product can be selected during scanning).

Sample ID/Method ID: on the barcode there are the sample ID and

method ID (with this a saved method can be selected during

scanning).

Sample ID/Product ID: on the barcode there are the sample ID

and product ID (with this a saved product can be selected during

scanning).

Start pos. sampleIDStart position of the sample ID on the barcode "Barcode information"

with sample ID

Number of

characters

Length of the sample ID on the barcode "Barcode information"

with sample ID

Start pos. methodIDStart position of the method ID on the barcode "Barcode information"

with method ID

Number of

characters

Length of the method ID on the barcode "Barcode information"

with method ID

Start pos. productIDStart position of the product ID on the barcode "Barcode information"

with product ID

Installation and commissioning 27Density Meter Excellence

Page 30

Number of

characters

Immediate start If this parameter has been activated, when a task is started with

Length of the product ID on the barcode "Barcode information"

with product ID

"Type" = "Handheld

the barcode reader, the Start analysis dialog is skipped and the

task is started immediately.

reader",

"Barcode information"

with method ID, product

ID or sample ID

Example of barcode with sample ID and method ID (161218522). (Sample ID=1612 and method ID 18522).

• Start pos. sample ID 1

• Number of characters 4

• Start pos. method ID 5

• Number of characters 5

USB stick

Commercially available USB sticks from USB Version 1.1 are supported.

Fingerprint reader

You can use a fingerprint reader to authenticate users on the titrator. In order to do this, the fingerprint reader

must be activated on the titrator. The following parameters are available for this:

Parameter Description Values

Activate

Activates the connected fingerprint reader. -

fingerprint reader

Printer (and USB-RS232 data export)

• Date can be printed with the USB-P25 (strip printer) or with a network printer.

• Data can be exported using the USB data export box. The data are exported in the XML (UTF-8) formats.

Note

• For data export to an RS interface, you need the USB RS232 adapter (USB data export box).

• As desired, data can be printed either as a summary or in a user defined format (via "Print Mode" parameter

"Report" method function; also see "Methods and products: Methods> Method functions> Report")

Note

For printing/USB data export, the following should be taken into consideration:

• In the "Report" method function, the "Print / USB-RS232 data export" parameter must be selected.

You can define the following parameters via the Printer button (Home>Setup>Hardware>Peripherals):

Parameter Description Values

Printer type

USB compact printer

The USB compact printer does not support all languages. This

printer can only print out a limited quantity of analysis data and

results.

USB-RS232 data export

For the RS-232 data export, the data is transmitted regardless of

the selected language. Only a limited quantity of data and results

can be exported.

Network printer

Every connected printer in your local network that supports HP

PLC 3 or Epson ESC/P 2 can be used.

Status Indicates whether the selected printer type is installed (info field). Only for printer type

"USB compact printer"

and "USB-RS232 data

export"

Installation and commissioning28 Density Meter Excellence

Page 31

Baud rate The baud rate for data transmission via the USB-RS232 interface. "Printer type"= "USB-

RS232 data export"

Data bit The number of data bits is displayed (info field). "Printer type"= "USB-

RS232 data export"

Stop bit The number of stop bits is displayed (info field). "Printer type"= "USB-

RS232 data export"

Parity Defines the parity protocol. ("Even", "Odd", "None") . "Printer type"= "USB-

RS232 data export"

Handshake Data transmission via the RS-232 interface ("Xon-Xoff", "None"). "Printer type"= "USB-

RS232 data export"

Type Choose the printer protocol. "Printer type"= "Network

printer"

Network name Define your local network name here. "Printer type"= "Network

printer"

Port number Define your local port number here. "Printer type"= "Network

printer"

Paper size Choose the print-format of the report (A4 / Letter). "Printer type"= "Network

printer"

PC settings

Only one PC connected per measuring instrument can be present at one time. You can select if you wish to set

up a connection to the laboratory program "LabX".

Parameter Description Values

Set up connection

to LabX at start

up

If this parameter is activated, a connection to LabX will be established on startup.

-

Note

Changes to the PC settings are not implemented until after the measuring instrument is rebooted.

Network settings

You can define the following parameters for the network – settings:

Parameter Description Values

Type Type of network connection -

Obtain IP address

automatically

IP Address IP address of the instrument -

Subnet mask Subnet mask of the device -

Standard gateway Standard gateway of the device "Type" = "Ethernet"

If this device has been activated, the device automatically obtains

an IP address.

"Type" = "Ethernet"

Note

The device automatically reboots after any change to the network settings.

Network storage

You can define the following parameters for a network – storage:

Parameter Description Values

Transfer via

Server PC or server name. Users should have read-write access.

Share name Name of the share which is defined for the shared folder. -

Method for transferring data (only Network share).

Maximum 60 alphanumeric characters.

-

-

Installation and commissioning 29Density Meter Excellence

Page 32

User name Type in the user name for accessing the shared folder. The user

name must be defined in the setup for the shared folder.

Domain Domain name of the server where the shared folder is located. -

Password Password for the network share. -

Target folder

Defines the name of the Target folder where the data is saved.

The Target folder is a subfolder in the shared folder.

-

-

First folder level If specified, the First folder level is a sub-folder in the Target

Second folder

level

4.11.2.5 Sensors

Navigation: Home > Setup > Hardware > Sensors

Sensors can be activated in the setup. The following sensors can be connected:

ErgoSens: Infrared sensor for contactless start of measurement (see "Analysis sequence: Start of analyses").

Before you can use ErgoSens, it has to be activated:

Parameter Description Values

Activate ErgoSens Activates the ErgoSens -

WasteSens or LevelSens: Level sensors for waste bottle.

It is determined whether the maximum filling level of the waste bottle is reached. If the maximum filling level

has been reached, a message appears prompting the operator to empty the waste bottle. The task is then interrupted.

Before you can use WasteSens or LevelSens, it has to be activated:

folder. This folder can optionally be used to sort data. (None |

User name | Titrator ID | Date | Method ID)

Default: None

If specified, the Second folder level is a second sub-folder in the

Target folder. This folder can optionally be used to sort data.

(None | User name | Titrator ID | Date | Method ID)

Default: None

Only if First folder level = activated

-

-

Parameter Description Values

Activate

WasteSens/

LevelSens

AtmoSens: Atmospheric pressure sensor for measuring the absolute air pressure.

If an AtmoSens is connected, the atmospheric pressure (if required) is measured with the AtmoSens. If no

AtmoSens is connected, the air pressure is read out from the current value from Home > Setup> Global

settings> Physical properties.

Parameter Description Values

Verify AtmoSens

availability

activates the WasteSens or LevelSens -

If this parameter is activated, the use of the AtmoSens is enforced

for tasks which require the pressure.

4.11.2.6 Auxiliary instruments

Navigation: Setup>Hardware>Auxiliary Instruments

Auxiliary instruments can be any instruments that access the 24V output or USB-RS232 adapter of the

measuring instrument and that are to be used in a method.

An auxiliary instrument that accesses the 24V output is switched on for a predefined period and then switched

off again via the corresponding command. The instruments are controlled via the "Auxiliary instrument" method

function.

-

Installation and commissioning30 Density Meter Excellence

Page 33

Auxiliary instruments form part of a method, while peripheral devices are classified as input/output devices

(printers, barcode readers etc.), which do not have direct access to methods.

Starting from the auxiliary instrument list, you can add new auxiliary instruments or select existing ones or

modify their parameters. In addition, the selected auxiliary instruments can be deleted.

Note

A maximum of 30 auxiliary instruments can be entered.

Choose the New button in the Auxiliary Instruments dialog window to open the Auxiliary Instrument

§

Parameters dialog.

1 Before a new auxiliary instrument can be added, you must first use the "Control type" parameter to select

the manner in which the auxiliary instrument is to be controlled:. The following values are available for

"Control type":

ð 24V output

ð USB-RS-232

2 You can assign a name of your choice to the auxiliary instrument.

The parameters for the control types are listed below:

24V output

Parameter Description Values

Control type The control type of the auxiliary instrument. USB-RS232 | Output

24V

Name Defines the name of the auxiliary instrument. -

USB-RS-232 interface

Parameter Description Values

Control type The control type of the auxiliary instrument. USB-RS232 | Output

24V

Name Defines the name of the auxiliary instrument. -

Adapter Defines which adapter is used. Maximum 2 auxiliary instruments

of type USB-RS-232 can be used in the same method (by using

adapter 1 and 2)

Parameter Description Values

Baud rate The baud rate for data transmission via the RS-232 interface of

the adapter.

Data bit Defines the number of data bits. "Control type" = "USB-

Stop bit Defines the number of stop bits. (2 stop bits can only be selected

if 7 data bits are also selected at the same time.)

Parity Defines the parity protocol. "Control type" = "USB-

Handshake Data transmission via the RS-232 interface of the adapter. "Control type" = "USB-

"Control type" = "USBRS232"

"Control type" = "USBRS232"

RS232"

"Control type" = "USBRS232"

RS232"

RS232"

Note

A suitable adapter (USB data export box) is required for the USB-RS-232 connection.

4.11.3 Language

Navigation: Home > Setup > User settings > Language

The following languages are available:

• German

Installation and commissioning 31Density Meter Excellence

Page 34

• English

• French

• Italian

• Polish

• Portuguese

• Spanish

• Chinese

• Russian

The language can be defined both for the operation of the terminal as well as for the protocols that are to be

printed out from a printer.

Parameter Description Values

Touchscreen Language of the user interface -

Report

Note

*

Chinese can not be selected as language for reports

4.11.4 Screen

Navigation: Home > Setup > User – settings > Screen

The following parameters can be set in the screen settings:

Language of the printout*

-

Parameter Description Values

Primary color Color of the user interface -

Brightness Brightness of the display -

Button shape Shape of buttons on the touchscreen -

Screen saver Activates screen saver -

Wait time Time for the display of the screen saver Activates screen saver

4.11.5 Beep