Page 1

bPro

Compact Scale

User’s Guide

®

64067202.R1

Page 2

©Mettler-Toledo, LLC 2012

No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose without the

express written permission of Mettler-Toledo, LLC.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

Page 3

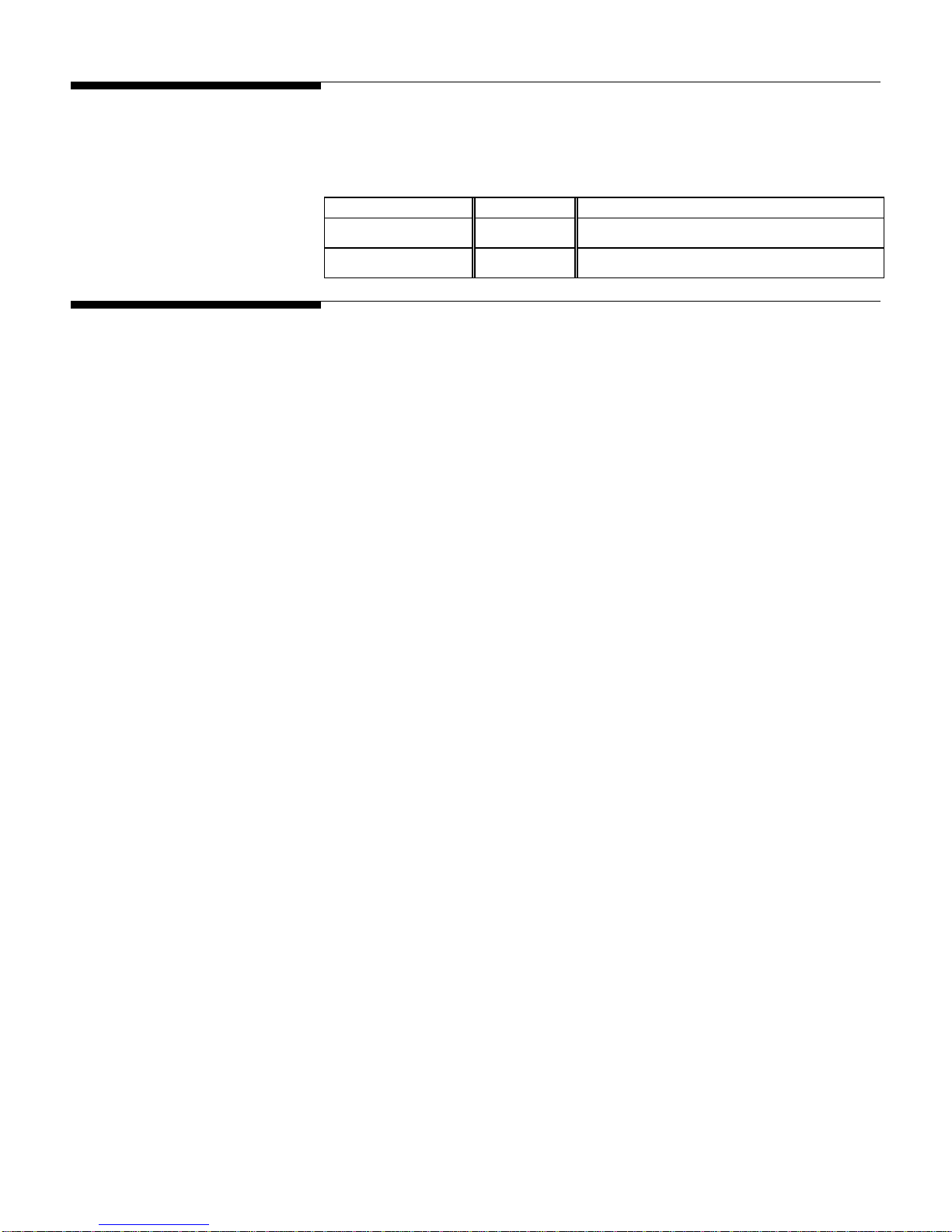

Publication Revision

History

Trademarks

Part Number Date Revisions

64067202

64067202

METTLER TOLEDO

Columbus, OH, USA.

12/08 New manual

04/10 Revisions to chapters 1, 2, 3, 5 and 6

®

bPro® are registered trademarks of Mettler-Toledo, LLC

Page 4

PRECAUTIONS

READ this manual BEFORE

operating or servicing this

equipment.

FOLLOW these instructions

carefully.

SAVE this manual for future

reference.

DO NOT allow untrained

personnel to operate, clean,

inspect, maintain, service, or

tamper with this equipment.

ALWAYS DISCONNECT this

equipment from the power

source before cleaning or

performing maintenance.

CALL METTLER TOLEDO

parts, information, and service.

METTLER TOLEDO

right to make refinements or

changes without notice.

®

for

®

reserves the

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS

EQUIPMENT. EXERCISE CARE WHEN MAKING CHECKS, TESTS AND

ADJUSTMENTS THAT MUST BE MADE WITH POWER ON. FAILING

TO OBSERVE THESE PRECAUTIONS CAN RESULT IN BODILY HARM

AND/OR PROPERTY DAMAGE.

WARNING

POWER OUTLETS MUST BE EASILY ACCESSIBLE AND LOCATED NO

FURTHER THAN THE LENGTH OF THE POWER CORD SUPPLIED

WITH THE PRODUCT. FAILURE TO DO SO COULD RESULT IN

PERSONNEL INJURY AND/OR PROPERTY DAMAGE.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT

TO PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE

GROUND PRONG.

WARNING

DISCONNECT & LOCK OUT ALL POWER TO THIS UNIT BEFORE

REMOVING THE FUSE OR SERVICING.

CAUTION

BEFORE CONNECTING OR DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT,

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO, OR DESTRUCTION OF THE EQUIPMENT

OR BODILY HARM.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

Page 5

CONTENTS

1 Introduction .................................................................................................... 1-1

General .............................................................................................................................. 1-1

Specifications ..................................................................................................................... 1-2

Power Switch ...................................................................................................................... 1-3

Network Connection ............................................................................................................ 1-3

Leveling the Scale ............................................................................................................... 1-4

2 Operating Instructions ..................................................................................... 2-1

Machine Configuration ........................................................................................................ 2-1

Keyboard ............................................................................................................................ 2-2

Text Editing Mode ............................................................................................................... 2-4

Main Screen ....................................................................................................................... 2-6

PLU Pricing Modes .............................................................................................................. 2-7

By-Weight PLU ....................................................................................................................... 2-7

By-Count PLU ........................................................................................................................ 2-7

Standard Pack PLU ................................................................................................................. 2-7

PLU Screens ....................................................................................................................... 2-8

Calling Up PLUs .................................................................................................................. 2-9

Printing Labels .................................................................................................................. 2-10

Temporary Overrides ......................................................................................................... 2-11

3 Configuration ................................................................................................. 3-1

Introduction ........................................................................................................................ 3-1

Program Menu .................................................................................................................... 3-2

Database ............................................................................................................................ 3-3

Quick PLU Change ................................................................................................................. 3-4

Database PLU ....................................................................................................................... 3-5

Database Extra Text .............................................................................................................. 3-7

Database Nutrifacts ............................................................................................................... 3-8

Database Special Message .................................................................................................... 3-9

Database COOL Text .............................................................................................................. 3-9

Database Traceability .......................................................................................................... 3-10

Database Delete ................................................................................................................. 3-11

Clone Scale ...................................................................................................................... 3-12

Print Reports ..................................................................................................................... 3-12

Service Mode .................................................................................................................... 3-12

Password Setup ................................................................................................................ 3-12

Unit Setup ......................................................................................................................... 3-13

PLU Auto Call ..................................................................................................................... 3-15

PLU Display Options ............................................................................................................ 3-15

Active Tare ......................................................................................................................... 3-16

PLU Display Align ............................................................................................................... 3-16

PLU Presets ........................................................................................................................ 3-17

Default Label Format ........................................................................................................... 3-17

Delete Custom Formats ....................................................................................................... 3-18

Serial Port .......................................................................................................................... 3-18

Network Address ................................................................................................................. 3-19

Page 6

Wireless Configuration ........................................................................................................ 3-20

Store Information ................................................................................................................ 3-20

Store Logo .......................................................................................................................... 3-21

Scale Number ..................................................................................................................... 3-21

Marquee ............................................................................................................................. 3-22

Barcode Settings ................................................................................................................. 3-23

PLU Settings ....................................................................................................................... 3-23

Set Time and Date ............................................................................................................... 3-24

Assign Group Names ........................................................................................................... 3-24

Enable Function Keys .......................................................................................................... 3-25

Language ............................................................................................................................ 3-25

User Define ........................................................................................................................ 3-26

Sales Online ....................................................................................................................... 3-27

Process Mode ................................................................................................................... 3-28

4 Labels ............................................................................................................ 4-1

Loading Labels .................................................................................................................... 4-1

Default Label Styles ............................................................................................................ 4-5

Label Requirements ............................................................................................................. 4-6

Label Paper .......................................................................................................................... 4-6

Label Stripping ..................................................................................................................... 4-7

Finished Label Roll Requirements .......................................................................................... 4-7

Finished Label and Roll Dimensional Requirements ............................................................... 4-10

Preprinted Labels .............................................................................................................. 4-12

Special Shaped Labels ...................................................................................................... 4-14

Definition of Transmission Optical Density .......................................................................... 4-14

Label and Liner Optical Density .......................................................................................... 4-15

Black Stripe Optical Density ............................................................................................... 4-15

5 Maintenance .................................................................................................. 5-1

Unit Cleaning ...................................................................................................................... 5-1

Printer Cleaning .................................................................................................................. 5-2

6 Appendix ....................................................................................................... 6-1

Define barcode Digits .......................................................................................................... 6-1

`

Page 7

1 Introduction

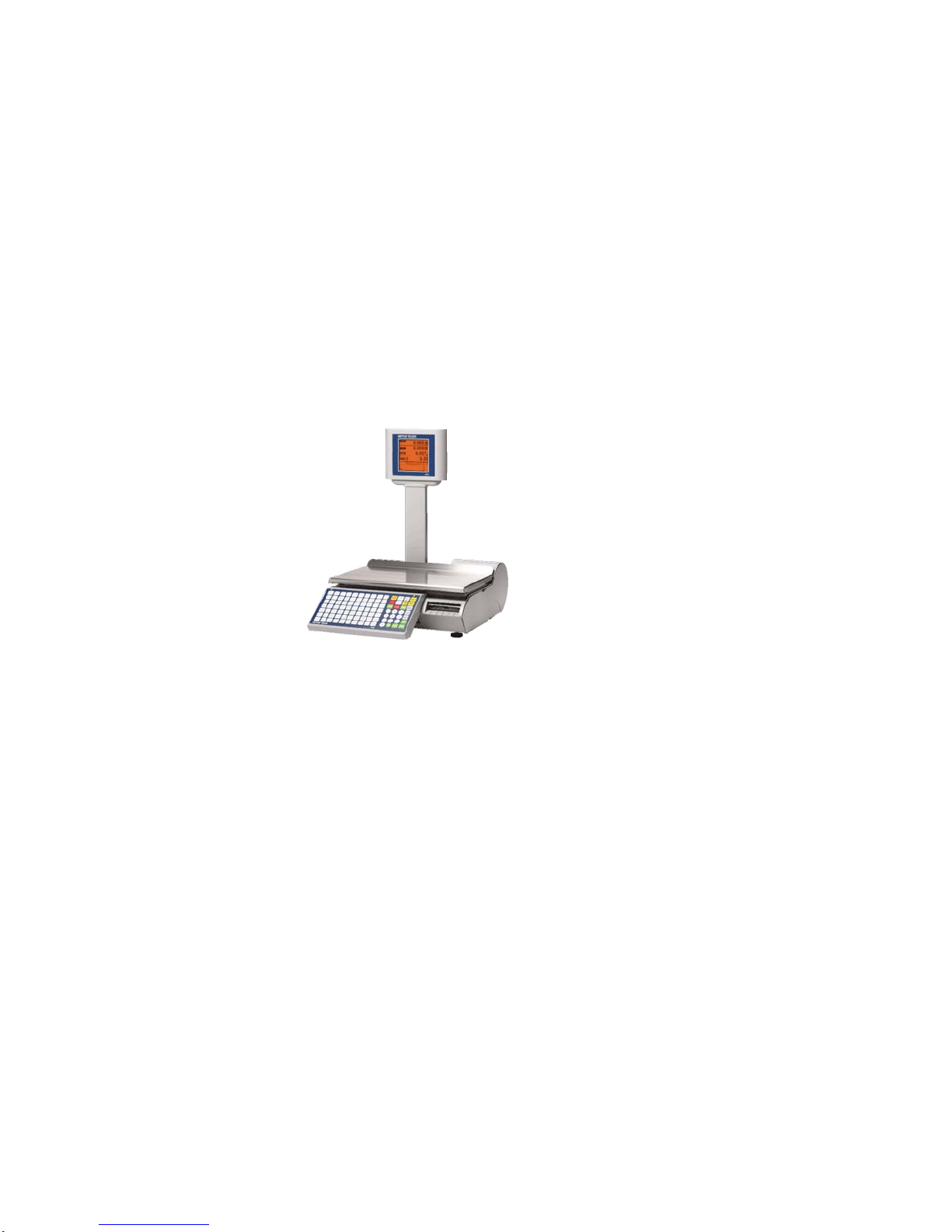

General

Thank you for purchasing the feature rich bPro® scale. METTLER TOLEDO designed the

bPro series as a solution for both current and future requirements. The bPro can handle

a variety of operations and easily adapts to changing process and data requirements.

This flexibility protects your investment and helps you keep pace with rapidly changing

production and customer demands.

Chapter 1: Introduction

The METTLER TOLEDO bPro scale offers intuitive functionality with a user friendly

interface. All scales contain a built-in thermal label printer designed for easy roll

changes and maintenance as well as a reliable, state-of-the-art load cell to ensure

years and years of accurate product usage.

1-1

Page 8

METTLER TOLEDO bPro User's Guide

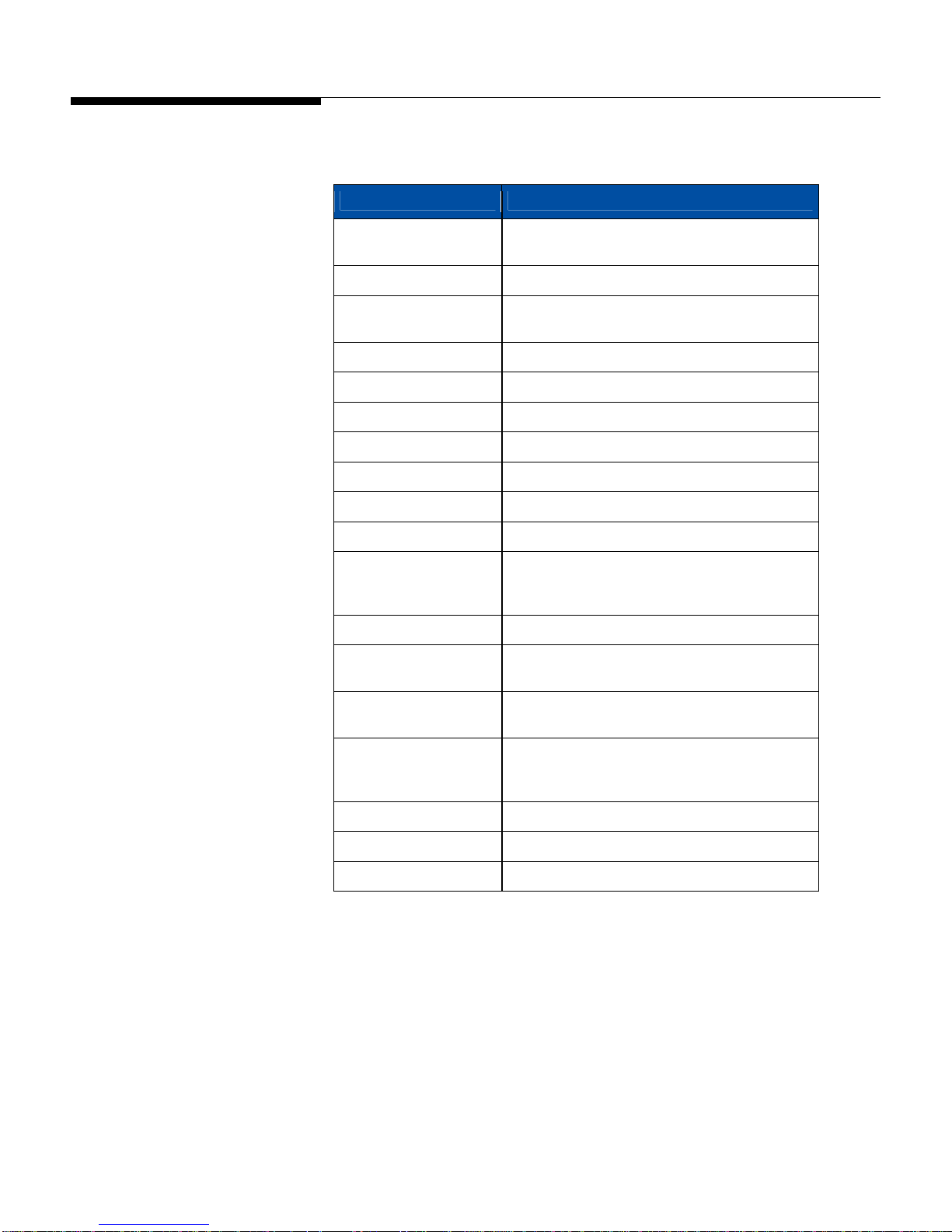

Specifications

Description Specifications – bPro

Capacity x Division

Weighing Modes lb , kg, (single and dual interval)

Dimensions

Platter Dimension W: 15.75” x D: 9.75”

Weight of Unit 23.0 lb (10.5 kg)

Shipping Weight 24.9 lb (11.3 kg)

Base Construction Aluminum die cast

Operator Display Backlit monochrome 240 x 240 LCD

Operator Keyboard 98 key tactile keypad with rubber overlay

Customer Display Backlit monochrome 240 x 240 LCD

Printer

Power 100-240 VAC, 50/60 Hz, 1.0A

Operating Temperature

6 x 0.002 kg / 15 x 0.005 kg

15 x 0.005 lb / 30 x 0.01 lb

H: 19.3”, W: 15.4”, D: 20.9”

H: 492mm, W: 390mm, D: 530mm (max)

2.2” (56mm) max width labels at up to 4.5”

(115mm)/sec

4.7”/120mm roll capacity

0º C to 40º C, humidity

5% to 95% non condensing

Storage Temperature

Network Interface

Memory 4 Megabytes SDRAM

Optional Extended Memory 8 Megabyte expansion

Available Serial port One

-20º C to 70º C with humidity from

5% to 95% non -condensing

Ethernet Standard 10/100 MBPS

RF optional 802.11b/g RF

RS-232 Host Communications

1-2

Page 9

Power Switch

Chapter 1: Introduction

The power switch and power cord jack are located under the keypad at the left front of

the scale.

Press | to turn the scale on. Before turning the unit off, exit any screen-editing menus.

Network Connection

The bPro can connect to your Ethernet network using a cable or via the optional wireless

radio. If you use a wired network connection and experience connection problems,

make sure your Ethernet cable is connected and seated securely in the jack, located

under the keypad at the front of the scale.

The bPro wireless card connects to the normal Ethernet port via a supplied cable that

must be routed through either of the two access holes shown in the above photograph.

1-3

Page 10

METTLER TOLEDO bPro User's Guide

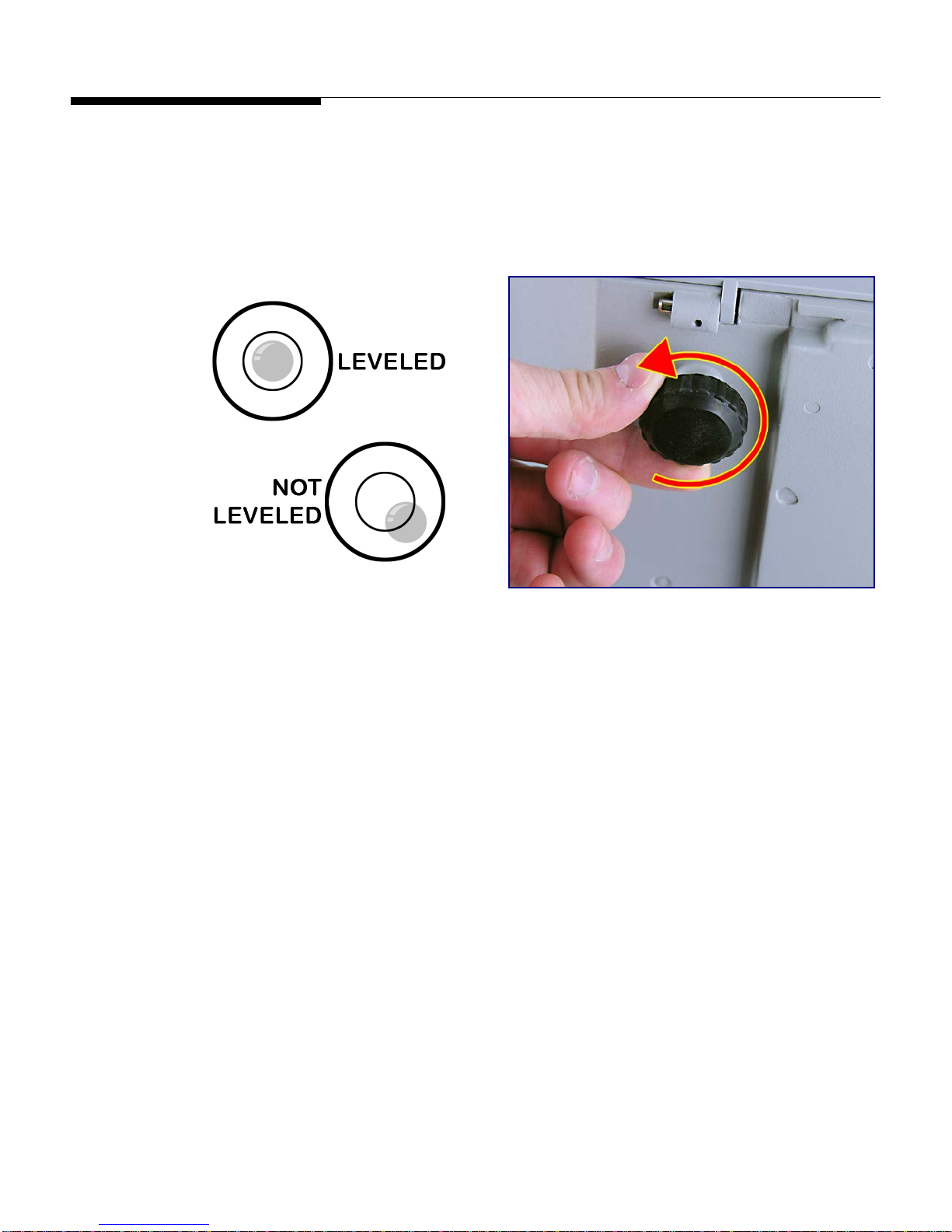

Leveling the Scale

Adjust the four feet until the bubble, located under the scale platter, is in the center of the

leveling circles. Adjust the foot-lock jam-nuts until the feet are secure.

1-4

Page 11

2 Operating Instructions

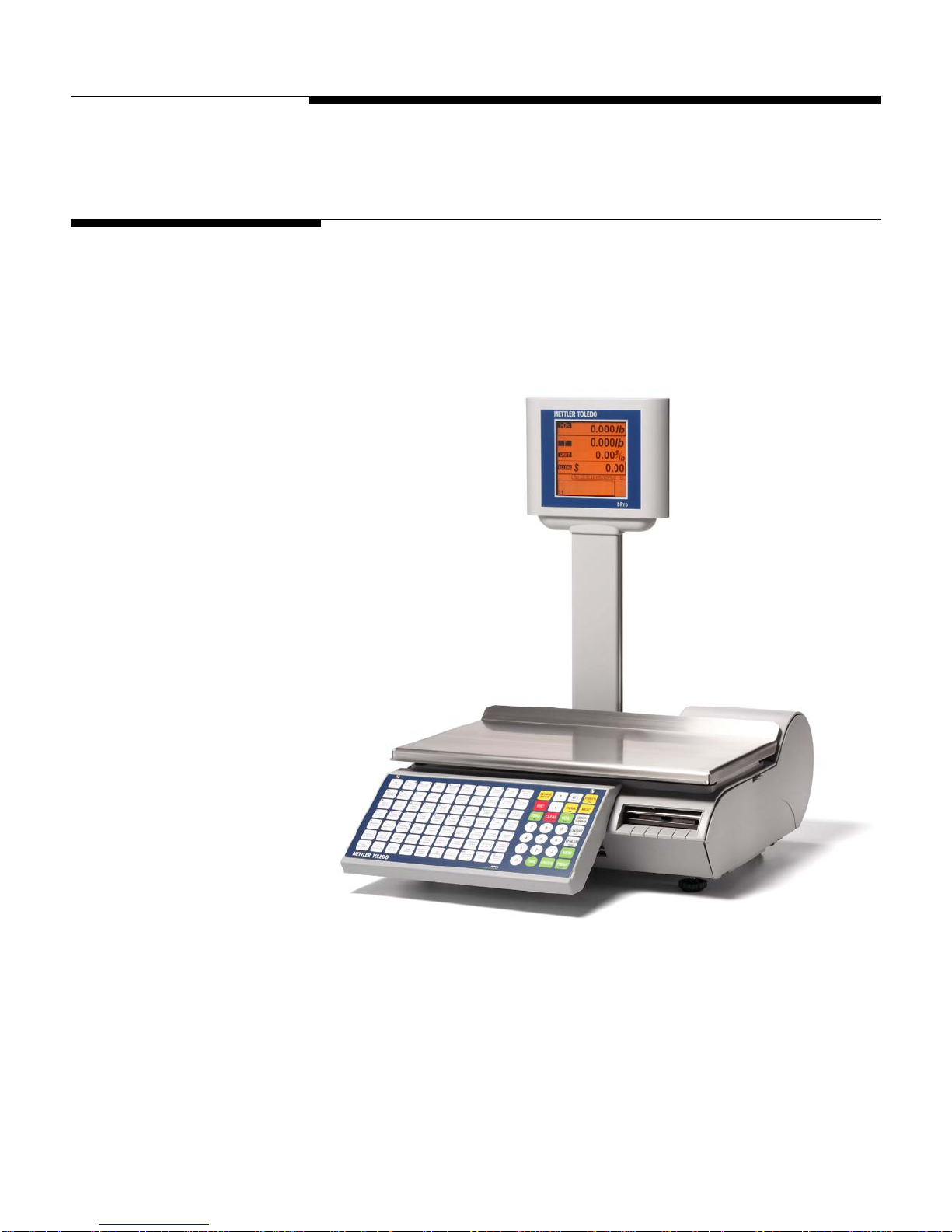

Machine Configuration

The customer/operator display of the bPro unit mounts to the tower behind the weigh

platter and has a vivid orange over black. The primary user interface is the keypad at the

front of the scale; the right side of the keypad hosts the navigation functions whereas the

left side is used mostly for typing, preset selection and specific numbering.

Chapter 2: Operating Instructions

Machine Configuration

2-1

Page 12

METTLER TOLEDO bPro User's Guide

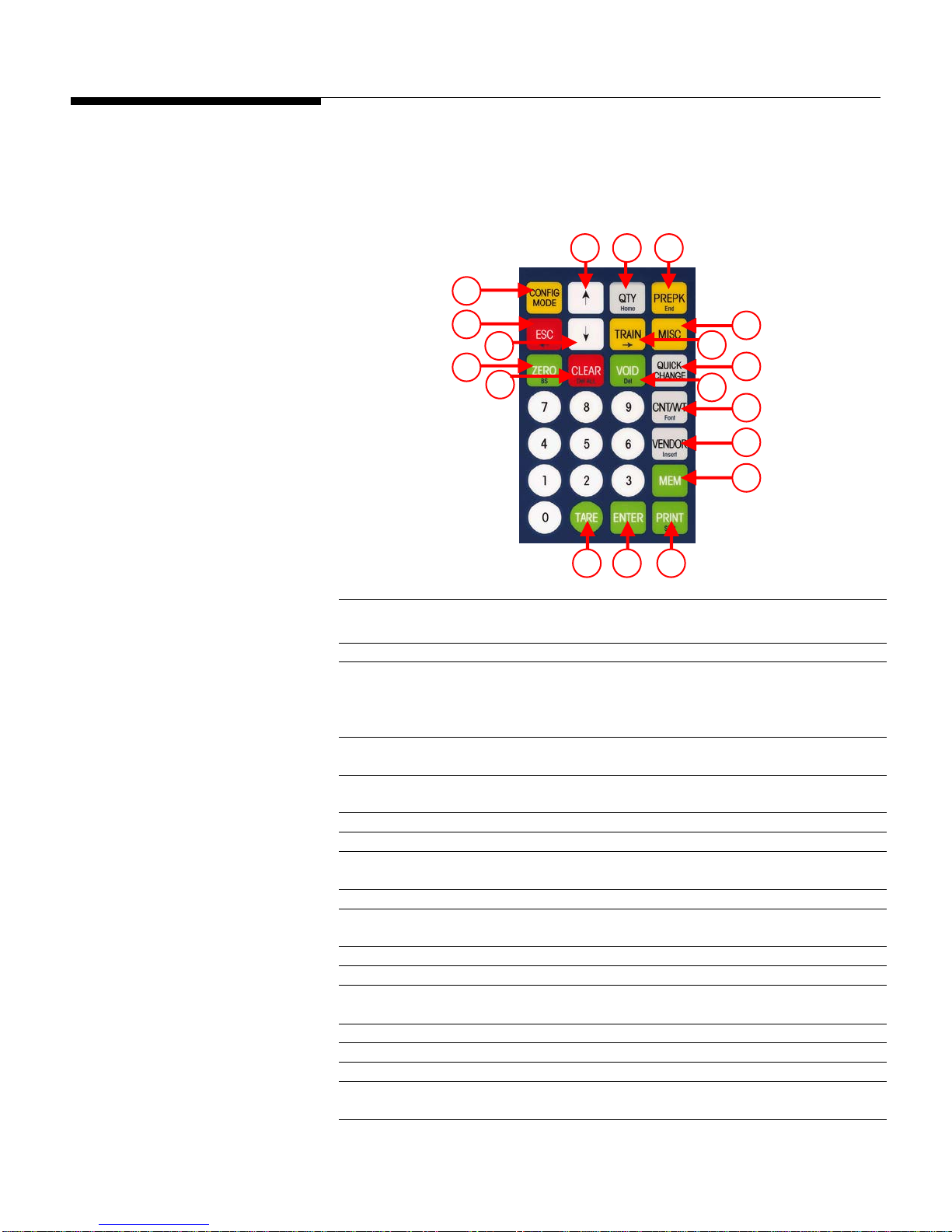

Keyboard

The keyboard consists of a membrane switch-pad and an overlay that provides tactile

feedback and an audible tone when the keys are pressed. The 28 keys on the righthand keypad are used for entering basic scale functions in the various scale modes.

Any alternate functionality is listed in smaller text on each key.

04

02 01

17

16

18

15

14

05

03

06

07

08

09

10

11 12 13

Keyboard Functions

1 Used to scroll through possible selections including yes/no paths and selects

between preset layers 1 and 2

2 Enters the quantity of PLU labels to be printed in batch mode

3 Training Mode – transactions are not registered in reports when in this mode. In

receipt mode, “training” will be printed on the ticket. In label mode a horizontal

line will be painted on the label to indicate an invalid label. This function can be

password protected

4 Toggles between Prepack and Service mode. In Prepack mode, a label is printed

each time the weight on the platter fluctuates (corresponding to a new package)

5 Miscellaneous key allows the user to enter a unit price and print a label for an

item that is not in the PLU database. This function can be password protected

6 Accesses the menu for temporary overrides of Price, Shelf Life, Date, etc.

7 Voids a PLU transaction from accumulation totals

8 Overrides quantity/count of Standard Pack/By Count PLUs. Overrides the net

weight field within a Standard Pack PLU

9 Input operator ID

10 Input PLU in transactional receipt mode; input functional preset key in

programming mode

11 Prints a label or feeds a blank label when the weight value is at zero

12 Accepts displayed data or displayed selection

13 Overrides programmed tare of a called By-Weight PLU. Enter the tare numerically

(keyboard tare) or place an item on the platter and press TARE twice

14 Clears incorrect entries or messages from the display. Backs out of PLU screens

15 Sets weight value to zero

16 Backs up in the Menu

17 Accesses Setup Mode and Database functions; press CONFIG and PRESET for

functionality quick key

18 Call PLU by item number

2-2

Page 13

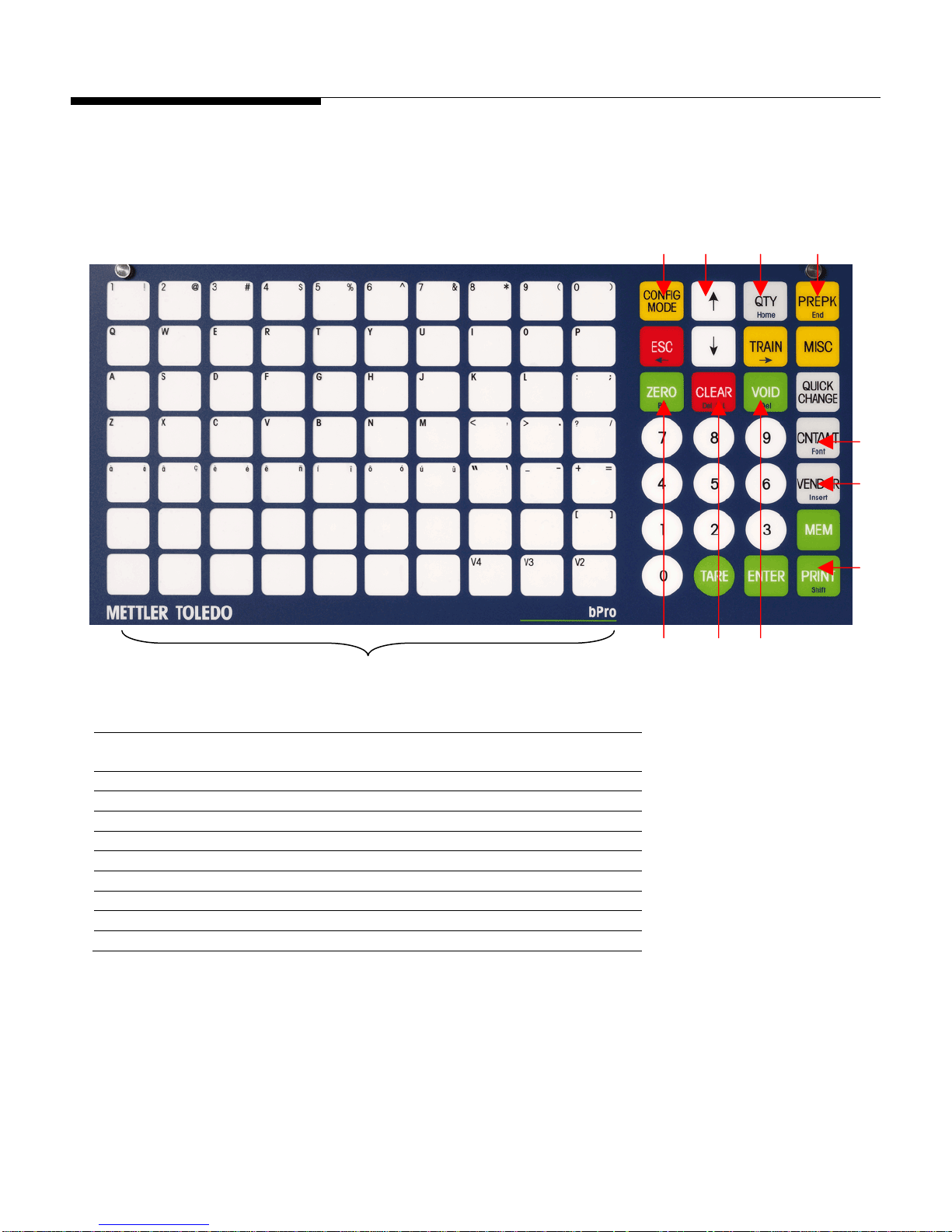

Chapter 2: Operating Instructions

Keyboard

Special functions

Pressing PRINT when there is no weight on the platter will advance a blank label.

Pressing CONFIG then PRINT will list the scale information on a label such as software

version, IP address, MAC Address, scale type, scale ID, as well as the Product ID of the

scale.

Power On while pressing Tare will show the IP Address

The 70 keys on the left keypad can be programmed as direct access keys (Presets).

There are two levels to the preset keys for a total of 140 PLU Presets. The Preset keys

should be configured first before being used.

To recall a PLU simply press the key once to access the Level 1 preset. To access the

Level 2 Preset, hit the key twice. Alternatively, select the proper level by pressing the ↑

key to view L1 (Level 1) or L2 (Level 2) on the display, than press the desired Preset.

The key provides PLU selection via item number.

Shortcut keys can also be programmed as quick access keys to particular setup

functions.

To set a key as a quick access key, go to the desired point in the setup menu and

press MEM , then press the preset key, then press ENTER.

To access the functional preset, press CONFIG then press the newly-appointed

preset key.

To clear a functional button, press MEM, clear and the desired preset button.

Press ENTER to delete a shortcut key.

In addition, the Preset keys (Left side) also provide the QWERTY keyboard for whenever

the scale allows text editing. These keys can be used as word processing keys while

entering the PLU description, store address, Extra Text Ingredients, COOL statements,

etc.

2-3

Page 14

METTLER TOLEDO bPro User's Guide

Text Editing Mode

When editing text fields, the user will find the bPro very flexible. The buttons do doubleduty when typing, allowing the previously defined functions to change toward a more

language-friendly configuration (as seen below).

1 2 3 4

EMPTY KEYS = SPACE KEYS

1

Press CONFIG to escape text editing mode

2

Navigation group – ESC moves cursor left, Train moves cursor right

3

Acts as home key to move cursor to the beginning of the line

4

Acts as end key to move cursor to the end of the line

5

Font used to access symbols, Unicode or Pin/YIN characters

6

Switch between insert and overwrite modes

7

Acts as shift lock to change between uppercase and lowercase keystrokes

8

Deletes selected character

9

Clears all text

10

Acts as backspace to delete previous character

5

6

7

10 9 8

Type Functions

2-4

Page 15

Chapter 2: Operating Instructions

Text Editing Mode

Text Editing Window

There are up to 15 lines per Text item. There can be multiple sentences per line. A line is

a hard carriage return. To go to the next line, press the ↓ or ↑ keys. In each line the text

will wrap in the allocated space as needed.

Bottom Left (Lower) shows the status of the Text.

Bottom Right (198) shows how many characters are remaining for that TEXT

description.

In pressing Font (5 – CNT/WGT) while in Text Editing Mode, you can navigate through

entering a Symbol, Unicode character or PIN YIN character

2-5

Page 16

METTLER TOLEDO bPro User's Guide

Main Screen

Initially, the bPro boots to a screen that looks much like the one pictured below. This

home screen allows for direct input of PLUs via the keyboard at the front of the unit as

well as editing of various parameters that are attached to said PLUs. Depending on the

PLU, this screen can take various forms (detailed below), with each containing an array

of slightly-different fields.

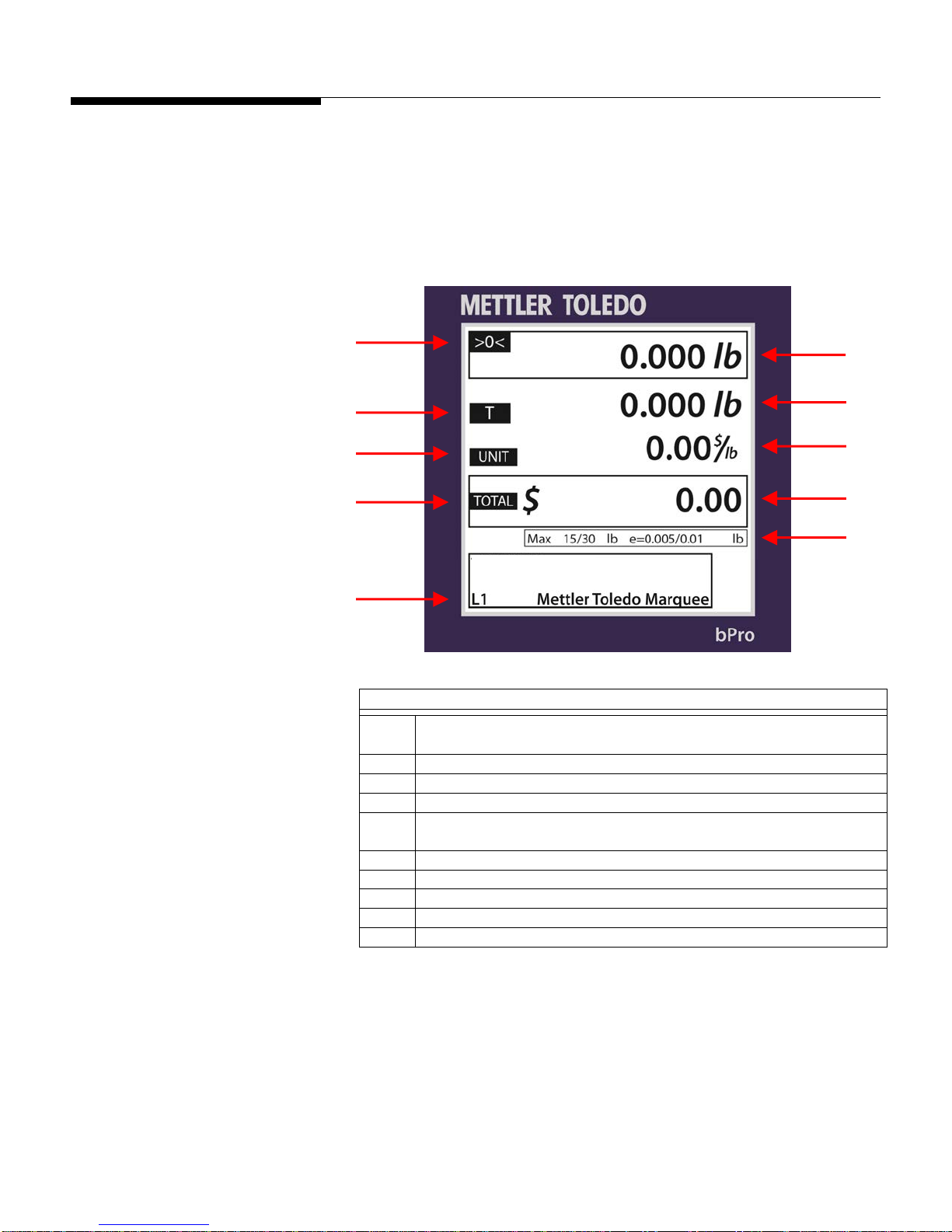

1

2

3

4

6

7

8

9

10

5

>0< indicates scale is at zero weight

1

NET indicates scale is in net weight mode and a tare value is in use

2 Tare symbol

3 Unit price

4 Total price

5 L1 indicates Preset layer 1 will be used

L2 indicates Preset layer 2 will be used

6 Platter weight display

7 Tare weight value being used

8 Unit cost of the specified PLU

9 Total price display value

10 Displays scale capacity and weighing increments as well as weight units

Operator Main Screen Components

2-6

Page 17

PLU Pricing Modes

By-Weight PLU

Chapter 2: Operating Instructions

PLU Pricing Modes

PLU is an abbreviation for Price Look Up. The PLU is a reference number assigned to a

product's record including fields such as the description, price, tare, etc.

Different PLUs will have different pricing modes. Meat is normally sold "By Weight" by

the pound or kilogram. Many bakery products are sold "By Count". Other products may

be sold in a “standard package”.

Examples of products sold By Weight are meats, cheese, poultry, and produce. ByWeight items can be priced in three ways:

Priced "Per Pound/kg" - Typically weighed items are priced per pound or kilogram. The

weight multiplied by the unit price equals the total price of the product.

Priced "Per Fraction of a Pound/Kg" (fractional) - The item may be priced by the

fraction of the pound or kilogram (where legal and desired). When the unit is calibrated

in lb. mode, ¼ and ½ pricing are available. In kg mode, 100 gram pricing is available.

"Pounds/kilos for price" - The PLU may be sold with a pounds-for-price (rather than

price per pound). For example, “2 pounds for $1.00” rather than “$0.50/pound.”

By-Count PLU

Standard Pack PLU

Examples of items sold by the count are cookies, donuts, rolls, bread, etc. Example: 4

Apples for $0.69. Pricing is entered as a certain quantity of items for a set price.

An example of an item sold by Standard Pack would be whole, precooked chickens, a

sheet cake or a loaf of bread. These labels use a fixed net weight and total price for the

item.

2-7

Page 18

METTLER TOLEDO bPro User's Guide

PLU Screens

The PLU screen will vary based on the type of PLU that is being displayed: By Weight,

By Count or Standard Pack.

By Weight By Count

Standard Pack

2-8

Page 19

Calling Up PLUs

Chapter 2: Operating Instructions

Calling Up PLUs

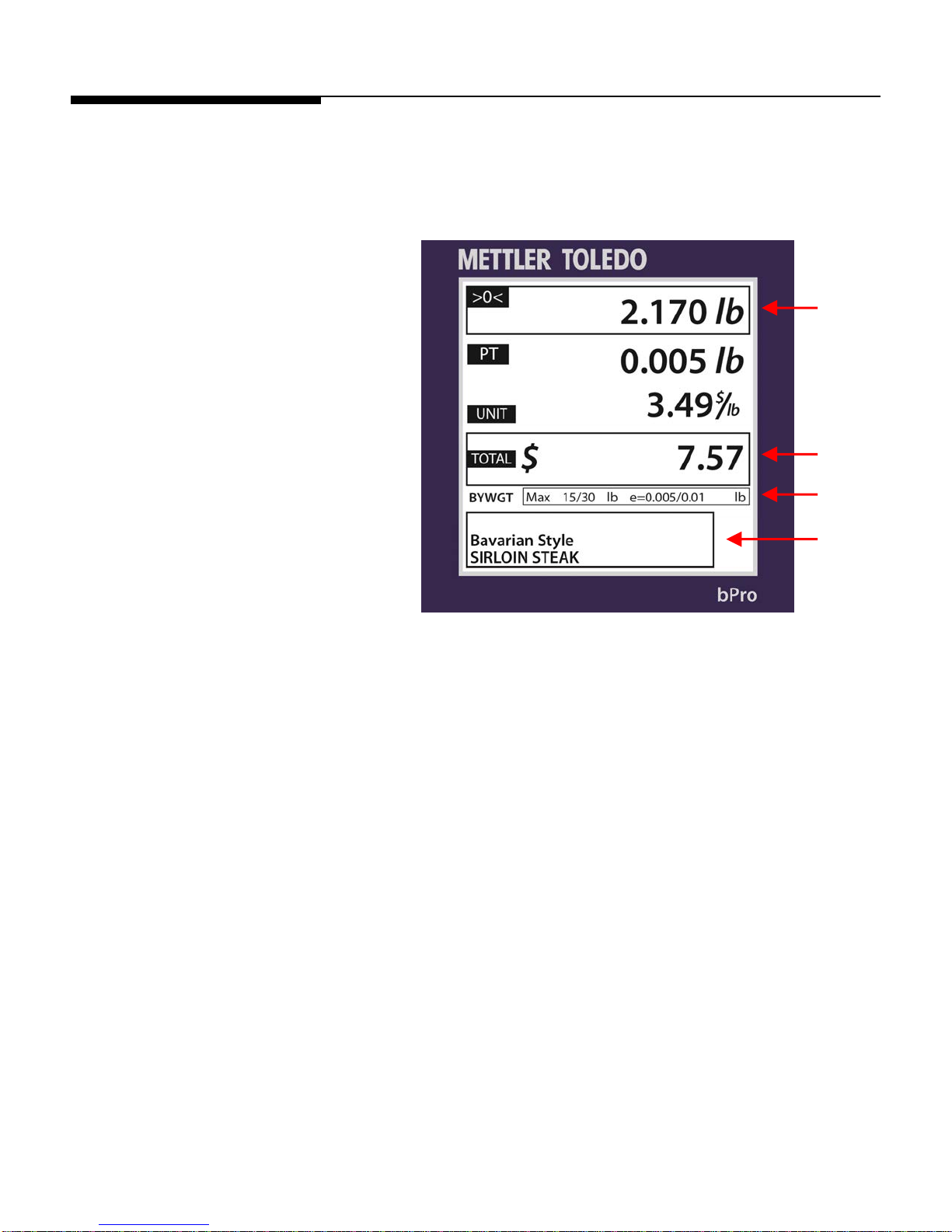

When the bPro® is in Service Mode, the screen will display the Main PLU management

array, from which all transactions may be conducted.

Note: “Service Mode” is normally the default on the PLU/PLU Edit screen. After the

product has been weighed, a label has been printed and the item has been removed

from the scale, the PLU will clear and the scale will return to the home screen, ready for

the next item.

To begin a transaction, call up the PLU record by keying in the PLU number or pressing

a Preset key. Depending on the scale’s PLU auto call setting, the PLU record will be

automatically called after entering a defined number of digits.

To use the Preset keys, it is possible to select Layer 1 or Layer 2 by using the up arrow.

The default state is Layer 1.

For by-weight PLU, place the item on the weight platter; this can be done before or after

a PLU number has been called. The machine will compensate depending on which

method you choose.

Call up the PLU Record. To do this, find or key-in the Preset PLU related to the product. It

may be a By-Weight, By-Count or Standard Pack item.

After keying-in the PLU, the screen will vary slightly in appearance depending on

whether it is a By Weight, By Count or Standard Pack entry.

Depending on how the PLU has been set up, you may be able to edit some of the

values for this current selection. If allowed, you can change items such as Shelf Life,

Tare, etc by pressing the Quick Change button and navigating to the appropriate field.

Any changes made will remain until the called PLU is overridden by pressing the clear

button.

Quick changes are specific to the transaction and do not make permanent changes to

the PLU record.

2-9

Page 20

METTLER TOLEDO bPro User's Guide

Printing Labels

Once the PLU has been called up, make any needed changes, and then press the Print

button on the keypad to print a label.

Take the label and remove the item from the scale to complete the transaction.

The bPro can be configured to be used in Service Mode or Prepack Mode depending

on the needs of the user.

In Service Mode, once the PLU has been called, it will be necessary to press the PRINT

key to get additional labels. The scale can be set for “Auto Clear” enable, whence it will

clear out of the selected PLU after the label has been printed. If Auto Clear is disabled,

then it will be possible to remove the first item, place a second item on the platter and

then press the PRINT key to get a label for that item. Service Mode is the normal default

mode.

In Prepack Mode, each time a new item is placed on the platter, a label will be printed

(corresponding with a fluctuation in the weight on the platter). This mode allows for

weighing multiple packages without pressing the PRINT key.

2-10

Page 21

Temporary Overrides

Chapter 2: Operating Instructions

Temporary Overrides

Temporary Overrides are certain values can be adjusted for the current transaction

through the Quick Change button on the right center of the keypad. The changes are

temporary – on a per-transaction basis, in other words – and will NOT be retained in the

original PLU data.

Depending on how the bPro has been configured, you may be able to perform

Temporary Overrides on some of the PLU values for the current PLU. These include Unit

Price, Tare, Use By Date, etc. The changes are temporary on a per-transaction basis

and, thus, are NOT retained in the original PLU’s dataset.

To change a value, call up a PLU and then press the Quick Change key. This will bring

you to a scrollable list of the values that can be changed. Use the up and down arrows

to navigate and then press the ENTER key to select the field to perform a temporary

override. Enter the temporary value and then press ENTER to accept or ESC to not

accept. Press the ESC key to get back to the PLU.

If the message No Selection is displayed, no fields have been enabled in the Quick

Change setup menu. If only Price Change has been enabled, the Price Change menu

will be displayed without going to the scrollable list.

2-11

Page 22

METTLER TOLEDO bPro User's Guide

For your notes

2-12

Page 23

3 Configuration

Introduction

Setup for the bPro® is controlled from the Configuration screen. This is accessed by

pressing the yellow CONFIG MODE button on the Operator keypad.

Chapter 3: Configuration

Introduction

From here the Database, Print Report, Unit Setup, Service Mode, Password Setup and

Clone Scale options can be accessed and modified.

At any time, the user may press ESC to return to the main transaction screen. Use the

and arrows to scroll through the various options and press Enter to make a selection.

3-1

Page 24

METTLER TOLEDO bPro® User's Guide

Program Menu

Database

Quick PLU Change Edit Lot Nr, Proc date, Supplier info Enable- Void Key, Over-ride, Etc Reset to Default

Quick Price Change List Lot Nr, Proc date, Supplier info Language Scale Total

Quick Tare 1 Change Copy Lot Nr, Proc date, Supplier info User Define PLU Total

Quick Tare 2 Change Database : Delete Display – Marquee, Tare, Screen Saver Promote Total

Quick use by date – see items above Print Label Configure Group Reports

Quick shelf life Change Print Receipt Config Group Timely

Quick Extra Text 1 Unit Setup

Quick Extra Text 2 PLU Auto Call – Set Qty Digits Sales Online Settle Report

Quick COOL Change PLU Display Option – PLU Description Process Mode ST/VOID Report

Quick Trace Lot Change PLU Display Alignment Operator Report

Quick Process Date PLU Presets Service Mode

Quick Supplier Info Assign Presets – Manual, Auto Initialize Database Monthly Report

Quick Label Change Delete All Presets Reset Configuration Yearly Report

Quick Spec Message List Presets Assign Memory Combine Reports

Quick Nutrifact List all Short Key Calibration – Press Cal switch Clear Reports

Graphic 1 Active Tare Price Format - Currency Clear Accumulator

Graphic 2 Default Label Format Expand Wt Solution

COOL Production By-Weight – Service, Prepack Minimum Print Password Setup

COOL Country By-Count– Service, Prepack Digi Filter – Light, Heavy Change PW: Database

COOL Pretext Standard Pack – Service, Prepack Geo Code? Change PW: Unit

TLV Handbyweight – Service, Prepack Load cell – Int, External Change PW: Service

Frequent Shopper Handbycount – Service, Prepack Weight Separator Change PW: Password

Database: PLU Total Allow Fractional WT Change PW: Quick Change

Edit PLU – PLU Type, Item #, Dpt # Delete Custom Formats Qty Label By Wgt Change PW: Misc Key

Description 1 – 4

Fix WT, tare1/1%/2/2%, Shelf Life, Host Baud Rate Label Printer Setup

Use By, Spec Msg, Allow Price Chg, Host Data Bits Print Speed Clone Scale

ET, ET2, Label/PLU, Force Flag, Host Parity Printer Dot Density Local - Remote

Blank Flag Host Stopbits Strip Motor Remote - Local

Copy PLU Host Timeout MS Label Type

List PLU Network Enable Take-Up Sensor

Verify Labels IP Address Label Backup

Edit PLU Added Items – NF, use SH, User Subnet Label Eject Length

Graphic ½, COOL Text, COOL Gateway Label Take-up Sensor

production, COOL country, COOL MAC Test Printer Sensor

pretext, TLV, freq. shop type, Trace Idle Time Printer Test

Lot Nr, Trace Proc Date, Supplier Wireless Configuration Receipt Printer Setup

Info, 2nd Price Store Information Resistance

Copy PLU Added Items Store Logo Print Speed

Database: ET Scale Number Printer Dot Density

Edit Extra Text Marquee Paper End Check

List Extra Text Bar Code Settings Test Printer Sensor

Copy Extra Text Bar Code Number Printer Test

Database: Nutrifacts Bar Type Function Tests

Copy Nutrifacts Define Bar Code Digits Display Test

List Nutrifacts PLU Setting Printer Test

Nutrifact Format Power Up – Service, Prepack Keyboard Test

Database: Spec Message Print Mode – Print Key, After Motion Display Configuration

Edit Special Message Auto clear Contrast Adjust

List Special Message Back to zero Invert Background

Copy Special Message Set Time Date History Path Grey

Database Cool Text Set - Date, Time Beeper – On/Off

Edit COOL Format – Year, Time, Date Separator Debug

List COOL Assign Group Name Serial Port Debug

Copy COOL Edit Group Name Assert Debug

Copy Group Name Predictive Maintenance

Delete a Group Name Print Head

Delete All Group Names Check Text

List Group Names Print All Menus

,Group, Price, Qty,

atabase Traceability Enable Function Keys Print Reports

Print Paper Type – Receipt, Label Hourly Report

Weekly Report

Serial Port Calibrate Change PW: Training

3-2

Page 25

Database

Chapter 3: Configuration

Database

This path takes the user to the Database cascade where he or she may make changes

to the individual PLUs.

Use the or keys to make a choice. Press the Enter key to bring up the selected

menu options or ESC to return to the main screen. They are as follows:

Quick PLU Change

Use this menu to make permanent changes to selected PLU data. This menu allows

easier access to PLU specifics without having to scroll through the massive list of

parameters the user is otherwise faced with. Data is entered only for the specifically

chosen PLU.

Quick PLU Change Select (shown left)

Brings up a list of selectable options that can be toggled with the Enter key. Use the

arrow keys to select fields from the list.

DB PLU

This menu allows a user to make permanent changes to any and all PLU data. Data is

entered for a specific PLU number.

DB Extra Text

Add, edit, copy or list the extra text options for the selected PLU via linked record number

DB Nutrifacts

Ability to copy or list embedded Nutrifact data to another link number. Also allows for

the selection of the Nutrifact format.

DB Special Message

Add, edit, copy or list the special message attached to the specified record number

DB COOL

Add, edit, copy or list the COOL text attached to the selected PLU

DB Traceability

Add, edit, copy or list a Traceability Statement with its linked record number for the Lot

Number, Process Date or Supplier Information.

DB Delete

Remove a record or all records of a type from the list. WILL DELETE ALL DATA!

3-3

Page 26

METTLER TOLEDO bPro® User's Guide

Quick PLU Change

The Quick PLU Change menu is meant to allow for modification of the selected PLU with

fewer keystrokes than if the user went through the other Database menus. By listing

many of the most commonly changed categories in a head-to-tail fashion, the Quick

PLU Change menu will likely become an oft-visited destination for unit operators.

NOTE: Available list is configured via Quick PLU Change Select.

As should be evident by the list layout, the editable parameters are arranged in a moreor-less “most-often modified” order beginning with Price Change and moving outward

both up and down. A complete list of the categories follows.

Quick Price Change (shown left; all screens in this category follow this layout)

Change the selected PLU’s unit price

Quick Tare 1 and Tare 2 Change

Change the selected PLU’s tare weight. The below screen is representative of the dataentry fields used in the rest of the screens in this cascade.

Quick Use-By Date Change

Change the selected PLU’s Use-By date. Should only be modified for new products.

Quick Shelf Life Change

Change the selected PLU’s shelf life.

Quick Extra Text 1 and 2 Change

Change the selected PLU’s primary and secondary extra text entries.

Quick COOL Change

Enable, disable or modify the selected PLU’s COOL information.

Quick Trace Lot Number Change

Enable or disable the selected PLU’s trace lot number functionality

Quick Process Date Change

Change the selected PLU’s process date

3-4

Quick Supplier Info Change

Change the selected PLU’s supplier information

Page 27

Chapter 3: Configuration

Quick Label Change

Change the selected PLU’s first and second label printing characteristics

Quick Special Message Change

Add or modify the selected PLU’s special message(s)

Quick Nutrifacts Change

Change the selected PLU’s Nutrifacts

Graphic 1

Assign a graphic number to the first graphic field on the label

Graphic 2

Assign a graphic number to the second graphic field on the label

COOL Production

To be implemented in a future software version

COOL Country

To be implemented in a future software version

COOL Pretext

To be implemented in a future software version

TLV

To be implemented in a future software version

Database

Database PLU

Frequent Shopper

Allow frequent shopper option to be used

The Database PLU cascade allows for fine-point editing of the available PLUs. From

here, a user will be able to do everything from simply listing all available products to

verifying the labels assigned to each PLU to actually modifying which products

correspond to which PLU numbers.

A breakdown of the individual categories follows.

3-5

Page 28

METTLER TOLEDO bPro® User's Guide

Edit PLU

Via the Edit PLU menu, a user may completely redefine a product entry. Listed in a

continuous loop are the categories PLU Type, Item Number, [4] Description lines,

Group, Unit Price, Unit Quantity, Input Fixed Weight, Tare, Shelf Life (days), Use-By

(days), Special Message text, Extra Text Number and Labels per PLU.

Within this area, you may also set permissions for price changes to the specified PLU.

Copy PLU

Creates a redundant entry of the selected PLU within the database under a new PLU

number

List PLUs

Prints a list of consecutive PLUs with their product designations. The user may select the

range of PLUs which will be printed, i.e. 1 – 6 or 650000 – 655000.

Verify Labels

Prints a series of labels to verify the format and number as per the PLU data

Edit PLU Added Items

This menu allows the user to edit and otherwise modify any of the added parameters of

the PLU. These parameters include Nutrifact, Safe Handling, Graphics 1&2, COOL

Text, Frequent Shopper Type, Traceability, Trace Process, Supplier and Second

Price.

Copy PLU Added Items

As with the Edit PLU Added Items menu, this one deals with the extraneous bits of data

attached to the specified PLU. Through this menu, a user can clone entries for use in

other PLUs

3-6

Page 29

Database Extra Text

Chapter 3: Configuration

Database

The Database Extra Text menu is responsible for the modification of existing extra text

entries as well as the addition of new ones.

A user may use this cascade to make changes to any of the extra text entries in the

system. Simply enter an entry number and add text until satisfied.

Refer to Chapter 2, Text Edit Mode, for text edit key functions.

Press Enter when complete.

3-7

Page 30

METTLER TOLEDO bPro® User's Guide

Database Nutrifacts

In order to best use the Database Nutrifacts menu, the user should be familiar with the

process of assigning numbers to and modifying Nutrifact entries.

Copy Nutrifacts

Allows the user to duplicate a Nutrifacts entry for use in another PLU

List Nutrifacts

The user selects a range of Nutrifact entries which the machine then prints on whatever

label stock it has available. Useful for cataloguing purposes.

Nutrifacts Format

This menu enables the user to select between various Nutrifact formats depending on

the part of the world in which the scale resides.

3-8

The choices are shown above and can be selected with the arrow keys and the Enter

key.

Page 31

Database Special

Message

Chapter 3: Configuration

Database

The Database Special Message menu allows the user to alter, copy or list-print the

special messages in the system memory.

Database COOL Text

Simply choose which path you’d like to take and press Enter. As per the previous

menus, the Edit function allows the user to modify existing messages; the Copy

command duplicates the existing information for use elsewhere and the List function

prints a run of the current messages within a user-selected range.

This menu allows the Database COOL Text to be modified along the same lines as the

extra text and special messages detailed above. As such, the same protocol applies.

Press Enter when finished.

3-9

Page 32

METTLER TOLEDO bPro® User's Guide

Database Traceability

Edit Lot Number; Edit Process Date; Edit Supplier Information

Upon entering any of these three arrays, the user will be prompted to type in the number

of a specific entry. After that, a text window will appear wherein he may edit or add to

any of the information contained within.

Press the Enter key when finished and Escape to back out to the main Traceability

menu.

List Lot Number; List Process Date; List Supplier Information

Selecting among these three menus will allow the user to print a range of the queried

data on whatever label stock is available.

Copy Lot Number; Copy Process Date; Copy Supplier Information

Each of these menus works in the same way. The unit operator selects the number of a

current entry, selects a new number for the duplicate entry and hits Enter. From that

point on, the new number will reference a data string identical to the copied bit.

3-10

Page 33

Database Delete

Chapter 3: Configuration

Database

As one might expect, this menu is used to permanently delete entries from the unit

database.

CAUTION! UNLESS YOU HAVE A BACKUP OF YOUR DATABASES, THEY WILL BE LOST

UPON EXECUTION OF THIS COMMAND. BE SURE YOU ARE PREPARED BEFORE

DELETING ANY DATA.

As the names would suggest, the Delete All _____ entries revolve around emptying the

database completely of those data strings.

The more-specific Delete A _____ are for the precision elimination of single entries

within each heading. As is the case with the editing and management of PLUs and PLU

data bits, simply key in the number of the PLU, Extra Text entry, Special Message, etc.

and choose to delete it.

No deletions should be made before a complete and known-working backup image of

the scale is on hand, as deleted entries cannot be retrieved once erased.

3-11

Page 34

METTLER TOLEDO bPro® User's Guide

Clone Scale

Print Reports

Service Mode

DISCLAIMER: The Clone Scale function is meant to be used by trained Mettler-Toledo

technicians ONLY. Failure to properly execute the process will result in an unusable

product and the scheduling of a service call.

If this is something with which you are comfortable, reference the bPro Service Manual

(PN 64067201) section (x-x) for explicit instructions.

DISCLAIMER: The Print Reports function is meant to be used by trained Mettler-Toledo

technicians ONLY. Failure to properly execute the process will result in an unusable

product and the scheduling of a service call.

DISCLAIMER: The Service Mode functions are meant to be used by trained MettlerToledo technicians ONLY. Failure to properly execute these processes will result in an

unusable product and the scheduling of a service call.

Password Setup

DISCLAIMER: The Password Setup function is meant to be used by trained Mettler-

Toledo technicians ONLY. Failure to properly execute the process will result in an

unusable product and the scheduling of a service call.

3-12

Page 35

Unit Setup

Chapter 3: Configuration

Unit Setup

The Unit Setup menu contains many of the options necessary to tune the bPro unit to a

user’s specific needs. To access it, the user will need to press the Config Mode button

on the keypad and cycle past the Database and Print Reports options.

The various submenus of the Unit Setup main screen are listed below with short

descriptions; that you may go immediately to the area concerning your needs.

PLU Auto Call

Set the auto call limit – the number of digits entered before the database is searched for

a corresponding PLU of that number.

PLU Display Options

Select between the various PLU display options (L1, L12, L24, etc.) as well as which

PLU lines to display

PLU Display Align

Choose either left or center alignment for the PLU display

PLU Presets

Manage presets via modification, assignment, deletion and listing

Active Tare

Denote whether Tare 1 or Tare 2 will be applied to the PLU

Default Label Format

Select the default label format to be used for the different modes of operation.

Delete Custom Formats

Used to delete all custom formats that exist in the scale. IRREVERSIBLE.

Serial Port

The user may view and modify the port information via this menu

Network Address

View all manner of IP, Network, Subnet, MAC, etc. addresses assigned to the scale unit

Wireless Configuration

Configures the wireless card, if installed

3-13

Page 36

METTLER TOLEDO bPro® User's Guide

Store Information

Edit the store info text field. This data is printed on the label in the field of the same

name. Typically includes store location and addresses.

Store Logo

Use this menu to select a specific store logo from the list of uploaded graphics

Scale number

Select a network identification number for the scale

Marquee

Use this menu to make changes to the scrolling marquee text

Barcode Settings

Define the style and specifics of the unit’s barcode recognition and printing

PLU Settings

Configure Power-Up Mode, Prepack Print Mode, Auto Clear and Back to Zero.

Set Time and Date

Specify the time and date

Assign Group Names

Modify, copy, delete or list the group names available on the scale

Enable Function Keys

Enable or disable the various function keys on the keypads

Language

Select the scale’s displayed language

User Define

Modify the settings for the bPro display as well as the parameters for the printer

Sales Online

Enable or disable the sales online application

Process Mode

Enable/Disable process mode feature and configure process mode parameters

3-14

Page 37

PLU Auto Call

Chapter 3: Configuration

Unit Setup

The PLU Auto Call menu allows the user to determine how many keystrokes will be

required to be entered before starting a PLU search.

Setting the number at one, for example, will allow a user to press one on the keypad

and have the database pull up the corresponding PLU. Conversely, if the number is set

to six, the unit will not automatically bring up data corresponding to a PLU until either

a.) all six of the PLU’s digits are entered or b.) the Enter key is pressed after a smaller

PLU string is keyed in.

PLU Display Options

To change the layout of the PLU descriptions on the scale display, the user will need to

visit the PLU Display Options menu.

Up to TWO lines of PLU description may be displayed on the PLU edit screen. Select

which lines to show and in what order to display them.

3-15

Page 38

METTLER TOLEDO bPro® User's Guide

Active Tare

Selects whether Tare 1 or Tare 2 will be used when a PLU is called.

PLU Display Align

Simply put, the PLU Display Align menu allows the user to choose whether the PLU

description text will be left aligned or centered on the PLU screen. Use the arrow keys to

move the cursor and press Enter to make a selection.

3-16

Page 39

PLU Presets

Chapter 3: Configuration

Unit Setup

The PLU Presets menu allows the user to assign PLUs to the left-hand keys on the bPro

keypad.

In manual mode, the user selects particular PLUs to assign to the first and second levels

of each button (as desired). This is simply done by pressing a preset button and then

keying in a PLU number. Repeat as necessary.

Default Label Format

NOTE: within each label format, it is

possible to define a label number. Refer

to chapter 4 for a table of the default

label formats and their numbers.

If the stock label types are not adequate,

you may use a custom label format

number to define a particular setup that

has been added to the system.

Automatic assignment takes the first 140 PLUs in the database and assigns them in

sequence, 1-70 and 71-140, to levels L1 and L2 respectively.

In the name of efficiency, the label formats are easy to change with a quick glance at

the Default Label Format menu. Here a user is able to choose the particulars of the

default label format for each of the various scale modes.

Within each label submenu, the user will be able to enable various switches such as

Print Pack Date, Print Sell-By Date, Print Use-By Date, etc. Simply use the arrows to

select yes or no for each and press Enter to change between selections. Hit the ESC key

to exit after making your choices.

3-17

Page 40

METTLER TOLEDO bPro® User's Guide

Delete Custom Formats

Serial Port

This option allows you to delete the custom label formats in the database. Select yes or

no on the popup.

WARNING! Once you select YES, all of your custom label formats will be deleted. There

is no recovery function, so be sure this is something you wish to do.

The Serial Port menu allows the User to view and modify (within ranges) the serial

communication parameters of the bPro unit.

Host Baud Rate

The user may select from a variety of choices within the range of 300 – 115200.

Host Data Bits

Select between five, six, seven or eight

Host Parity

Either “None”, “Even” or “Odd” at the user’s discretion

Host Stop Bits

The user may select either one or two

Host Timeouts (in milliseconds)

The timeout can be set to anything the user desires. Be sure to input the choice in

milliseconds and not base seconds.

3-18

Page 41

Network Address

Chapter 3: Configuration

Unit Setup

To check the various address specifics of the unit, a user needs simply go to the

Network Address menu. Here they will find a list of the current addresses attached to

the machine and its immediate network(s).

After toggling to NETWORK, press the ENTER key. Use the up/down arrows to toggle

between IP ADDR, SUBNET, GATEWAY, MAC Address, and IDLE TIME. The MAC

address selection is for information only and cannot be changed. Press ESC key to exit

and then ENTER to save the setting.

121BIP ADDRESS

Press ENTER at NETWORK to display the current scale IP address. The IP Address

identifies the client on the network. The IP Address is a unique number consisting of four

parts separated by periods (Ex: 146.207.40.1).

To change the IP Address, press ENTER, and then enter the new IP Address. The IP

address is entered one octet at a time. The default value for this field is

255.255.255.000.

122BSUBNET

The Subnet Mask is used to identify the local network when accessing IP address on the

Ethernet network. The mask is entered one octet at a time. The default value is

255.255.255.000.

123BGATEWAY

Gateway Router IP address is used when accessing devices outside of the local

network. The IP address is entered one octet at a time. The default value is

255.255.255.000.

124BSERVER ADDRESS

Displays and allows for modification of the server’s IP address.

125BMAC

This is the hardware MAC (Media Access Control) address. The MAC address will be

displayed but cannot be changed. It will display 6 sets of 2 numbers that start with

00:E0:7C:xx:xx:xx. The last 6 digits will vary with each scale.

126BIDLE TIME

This is the time (measured in seconds) that the bPro will wait after no communication

before it closes an Ethernet socket connection.

3-19

Page 42

METTLER TOLEDO bPro® User's Guide

Wireless Configuration

Store Information

This section allows you to set up your wireless device via a few simple switches –

Wireless CONFIG to ON or OFF

Set default number to ON or OFF

Set Auto IP to ON or OFF

Enter SSID

Enter Infrastructure

The Store Information menu allows the user to type out a description or catch phrase

associated with their store. Simply use the keypad to enter a message or statement and

then press Enter. This text will be printed on labels using the store info field.

3-20

Page 43

Store Logo

Chapter 3: Configuration

Unit Setup

To select a Store Logo that will print on many of the unit’s labels, a user must simply

make a selection from the database of uploaded images. Key in the number of your

choice and press Enter to apply the graphic to the appropriate functions.

Scale Number

The Scale Number menu allows the user to quickly identify a unit on the network. The

selection of scale numbers is 1 – 255.

3-21

Page 44

METTLER TOLEDO bPro® User's Guide

Marquee

A user may enable or modify the marquee features of the bPro by accessing the

Marquee menu in the Unit Setup cascade. As with the other user-friendly menus, one

simply follows the intuitive menus to choose when the marquee begins to scroll, how

fast it moves across the screen and what exactly it says.

Press Enter when finished with each section.

3-22

Page 45

Barcode Settings

Chapter 3: Configuration

Unit Setup

In the Barcode Settings menu, the user can not only select the format of the barcodes

that will be produced on every receipt, but also the specific digit-definitions for those

barcode strings*. As with all other bPro menus, simply navigate up and down with the

arrow keys and press Enter to make a selection.

When finished, the ESC button will take you back to the main Unit Setup screen.

PLU Settings

*See Define Barcode Digits in the appendix for more information

The PLU Settings menu allows the user to select what mode the scale will boot into as

well as the label printing configuration when in prepack mode. Also included are the

options to set Auto Clear and Back to Zero (which affect the weighing conventions

between placement of product on the weigh platter or after printing of a label).

Power-up modes include Service, Prepack and Last.

The prepack printing modes include Auto and Manual.

Auto Clear is a toggle which requires the scale to return to the ready screen after a label

is printed

Back to Zero requires that the weigh platter be vacated and reloaded between printings.

3-23

Page 46

METTLER TOLEDO bPro® User's Guide

Set Time and Date

As its name suggests, the Set Time and Date menu deals with synchronizing the scale

to the current time and date. Here the user may also select such trivialities as formatting

of the individual values and the punctuation marks separating the fields.

Assign Group Names

Press ESC when finished.

The Assign Group Names menu array deals mainly with the management of existing

groups with an allowance for copying complete groups to new numbers.

3-24

Page 47

Enable Function Keys

Chapter 3: Configuration

Unit Setup

This menu allows the user to set the functionality for each of the unit’s keys. The

individual keys can be switched on or off for users of a certain permission level.

Pressing Enter toggles the key on or off.

Language

Press the ESC key when finished making changes.

The Languages menu allows the user to choose the language in which all unit text will

be displayed. Simply use the arrow keys and press Enter to confirm your choice.

Pressing ESC exits the screen.

3-25

Page 48

METTLER TOLEDO bPro® User's Guide

User Define

The User Define menu allows various parameters to be changed that dictate the

appearance of the display screen and various printed materials. Select a category and

press ENTER to see more menus.

Display – allows the user to determine whether or not the marquee, tare and screen

saver will be displayed. Should the screen saver be enabled here, further menus will

appear wherein the user may choose the clock or picture (selected from list) as well as

the activation time delay (from 1 – 255 seconds).

Pressing ENTER selects/deselects and pressing ESC advances the menus without

making changes and will eventually return you to the main User Define screen.

See the bPro Service Manual for more details.

Print Label Configuration – the user may define what prints on the label within the

following list: PLU number, store name, header, footer, stub, barcode (stub or receipt)

and total weight. ENTER toggles, ESC cancels.

Print Receipt Configuration – the user may define what prints on the receipt within the

following list: PLU number, store name, header, footer, stub, barcode (stub or receipt)

and total weight. ENTER toggles, ESC cancels.

Print type – select what will print at the end of a transaction: receipt mode, label mode

receipt + total, total.

3-26

Page 49

Sales Online

Chapter 3: Configuration

Unit Setup

SALES ONLINE is a scale application that allows floating vendor functionality where

multiple PLU transactions are placed on one label or receipt. The Sales Online

application will communicate the transaction list to the POS system. The Sales Online

Scale application needs to work with the Sales online Server software (external

application not included with the scale). By selecting Enable, the scale will look to

communicate with the server software application, and send the transactional data as

required.

Press Enter to choose and ESC to unpack the corresponding menu tree. Upon selection

of either choice, the following options will appear, able to be modified per necessity.

Offline Barcode – select a number for the PLU’s offline barcode.

Online Barcode – select a number for the PLU’s online barcode.

Label print Direction – choose between normal and convert, which will print label

information top-to-bottom or bottom-to-top, respectively.

Department Number – select a number for the PLU’s department.

UPC Number – select a number for the PLU’s UPC.

3-27

Page 50

METTLER TOLEDO bPro® User's Guide

Process Mode

The Process Mode menu allows the user to designate PLUs as certain types, thus

assigning them certain barcode formats, by way of transaction.

When this option is enabled, the user will be prompted to select from the five choices

listed. Once chosen, the user will have the option of renaming the category per the

barcode number (format style) they select.

The window that houses the five choices can be brought up at any point in the PLU

editing process by pressing the MISC button on the keypad.

Once a selection is made, successive PLU transactions will acquire the barcode format

assigned to the initial PLU. In order to avoid this, if you do not wish a string of PLUs to

be specifically branded, simply disable Process Mode.

3-28

Page 51

4 Labels

Loading Labels

Chapter 4: Labels

Loading Labels

NOTE: A label loading

diagram can be found on

the printer for quick

reference.

NOTE: When changing a

label roll, always look for

any buildup. See Chapter 5

for cleaning procedures.

The bPro label loading procedure is a simple one and can be worked through by any

user who reads the following section.

1.) Open the printer door by pressing down on the release tab.

2.) Pull the printer out using the green pull-tab.

4-1

Page 52

METTLER TOLEDO bPro® User's Guide

3.) Unlock the printhead by pressing on the green lock-lever.

4.) Install the label roll on the supply spool and remove about 6 inches of labels from

the liner. Slide the labels under the guides and printhead as shown in the illustration.

4-2

Page 53

NOTE: The green knob does not

come all the way out! Do not

use excessive force to pull out

on the green knob! Using

excessive force to push the knob

in can result in broken locking

tabs on the green knob.

Chapter 4: Labels

Loading Labels

5.) Pull the liner back and route it under the bottom guide. Gently pull out on the green

knob on the liner take-up spool (1) and then slide the liner into slot in the roller (2).

6.) Gently push in on the green knob to lock the liner into place, and then turn the roller

clockwise to take up some of the slack in the liner.

4-3

Page 54

METTLER TOLEDO bPro® User's Guide

7.) Press down on the printhead latch until it locks down.

8.) When the printer has been loaded with properly installed labels, as below, push the

printer back in and close the door.

4-4

Page 55

Default Label Styles

Chapter 4: Labels

Default Label Styles

Below is a list of default label styles broken into their default numbers (left

column) and a description of their size and function (right column).

Bolded text has been used to differentiate label styles based on common size.

Default Label Format Number Label Format Name

101 48_ByWgt_SellBy.blbl

102 48_ByCnt_SellBy.blbl

103 48_StdPack_SellBy.blbl

104 48_ByWgt_PackDate.blbl

105 48_ByCnt_PackDate.blbl

106 48_StdPack_PackDate.blbl

110 53_ByWgt_SellBy.blbl

111 53_ByCnt_SellBy.blbl

112 53_StdPack_SellBy.blbl

113 53_ByWgt_PackDate.blbl

114 53_ByCnt_PackDate.blbl

115 53_StdPack_PackDate.blbl

120 60mmByWgt_SellBy_BCtop.blbl

121 60mmByCnt_SellBy_BCtop.blbl

122 60mmStdPack_SellBy_BCtop.blbl

123 60mmByWgt_SellBy_BCmid.blbl

124 60mmByCnt_SellBy_BCmid.blbl

125 60mmStdPack_SellBy_BCmid.blbl

126 60mmByWgt_SellBy_ET_BCtop.blbl

127 60mmByCnt_SellBy_ET_BCtop.blbl

128 60mmStdPack_SellBy_ET_BCtop.blbl

129 60mmByWgt_SellBy_ET_BCmid.blbl

130 60mmByCnt_SellBy_ET_BCmid.blbl

131 60mmStdPack_SellBy_ET_BCmid.blbl

140 84mmByWgt_SellBy_ET_BCtop.blbl

141 84mmByCnt_SellBy_ET_BCtop.blbl

142 84mmStdPack_SellBy_ET_BCtop.blbl

143 84mmByWgt_SellBy_ET_BCmid.blbl

144 84mmByCnt_SellBy_ET_BCmid.blbl

145 84mmStdPack_SellBy_ET_BCmid.blbl

146 84mmByWgt_SellBy_ET_SH_BCtop.blbl

150 94mmByWgt_SellBy_ET_BCtop.blbl

151 94mmByCnt_SellBy_ET_BCtop.blbl

152 94mmStdPack_SellBy_ET_BCtop.blbl

153 94mmByWgt_SellBy_ET_SH_BCtop.blbl

160 107mmByWgt_SellBy_ET_BCtop.blbl

161 107mmByCnt_SellBy_ET_BCtop.blbl

162 107mmStdPack_SellBy_ET_BCtop.blbl

163 107mmByWgt_SellBy_ET_SH_BCtop.blbl

170 119mmByWgt_SellBy_ET_BCtop.blbl

171 119mmByCnt_SellBy_ET_BCtop.blbl

172 119mmStdPack_SellBy_ET_BCtop.blbl

173 119mmByWgt_SellBy_ET_SH_BCtop.blbl

180 130mmByWgt_SellBy_ET_BCtop.blbl

182 130mmByCnt_SellBy_ET_BCtop.blbl

183 130mmStdPack_SellBy_ET_BCtop.blbl

184 130mmByWgt_SellBy_ET_SH_BCtop.blbl

4-5

Page 56

METTLER TOLEDO bPro® User's Guide

These t

Label Requirements

Label Paper

These thermal labels requirements apply to the BPro® printers. This section includes

dimensional requirements, for labels and label rolls, as well as general requirements for

label paper, thermal coatings, preprinting inks and adhesives.

Use of label materials and designs which meet with these requirements is necessary to

ensure operation of the printers in compliance with their respective functional

specifications and satisfactory performance of the label in the end use environment.

Labels which do not comply with all of the requirements may function with limitations,

but would need to be tested by the customer to insure adequate performance in their

application. Customer specified (COD) software is not covered under this specification.

DESCRIPTION, PRICE LABEL: Premium white color, black imaging, with protective

coating

WEIGHT: 72 ± 7 grams/square meter

THICKNESS: 82 ± 14 μ meter (0.0032 inch)

ACTIVATION TEMPERATURE

STANDARD: Initial 74°C (165°F); Optimum 83°C (181°F)

HIGH SPEED: Initial 66°C (151°F); Optimum 77°C (170°F) – for highest speed

printing

HOT BOX: Initial 83°C (181°F); Optimum 91°C (195°F) - for use on food items

which are kept warm (Slow print speed setup required)

SURFACE SMOOTHNESS: The surface of the finished coated paper must be smooth to

prevent premature print head failure. Smoothness must be 40 Sheffield units or

smoother.

ION CONTENT: Ions such as sodium (Na) and chlorine (Cl) can cause premature failure

of the glass overcoat of a thermal print head. Paper manufactured specifically for

thermal printing with low ion content must be used.

STORAGE LIFE: 18 months minimum when stored at less that 85% relative humidity

and less than 35°C (95°F)

ADHESIVE

Permanent pressure sensitive – Nominal thickness 10 μ meter (0.0004 inch)

Label must adhere to product with a surface temperature of -15° C (5° F) minimum.

Bond strength must remain permanent over a temperature range of 2°C to 35°C

(35°F to 95° F)

4-6

RELEASE LINER

DESCRIPTION: White semi-bleached supercalendered Kraft paper with silicone

release coating.

BASIS WEIGHT: 68 ± 3 gram/square meter

THICKNESS: 67 ± 7 μ METER (0.0026 INCH)

Page 57

Label Stripping

Chapter 4: Labels

Label Requirements

TOTAL THICKNESS LABEL + ADHESIVE + LINER

Total Thickness Label + Adhesive + Liner: 159 ± 17 μ METER (0.0056 to 0.0069

inch)

LIGHT TRANSMISSION FOR GAP SENSOR OPERATION:

Light transmission at 800 to 900 NM wave length through the liner only must be at

least 3 times the transmission through the liner and label together. This means that the

transmission optical density of the liner must be at least 0.48 less than the that of the

liner and label together.

Light transmission at 800 to 900 NM wave length through the liner and label together

must be at least 2% of incident light. This corresponds to an optical density of 1.7.

Also see OPTICAL DENSITY DEFINITION further in this chapter.

Labels must strip from the liner over a temperature range of 2°C (26°F) at 50% RH

to 43°C (110°F) at 85% RH.

Finished Label Roll

Requirements

CORE AND METHOD OF LABEL ATTACHMENT

The label stock must not be permanently attached to the cardboard core. The liner must

separate cleanly from the core with 1.0 pound pull tangent to the core as shown in the

figure below. No core material, tape, or adhesive is to remain on the label or liner after

separation. Material, especially hot melt adhesive, remaining on the label will damage

the print head.

DIE CUTTING

Die cutting of the labels must not perforate the release liner.

4-7

Page 58

METTLER TOLEDO bPro® User's Guide

SLITTING

The release liner must be slit cleanly and be made free of edge slivers and dust by

vacuuming or some equally effective process.

WINDING

The labels must be wound face out as shown

in the figure to the right. The finished roll must

be made free of paper dust and loose particles

by vacuuming or some equally effective

process.

LABEL CURL

Stripped labels must not curl more than 0.20 inch as specified in the figure below.

Note: Dimensions in

inches with

millimeters

shown in ( ).

4-8

Page 59

Chapter 4: Labels

Label Requirements

SPLICING

Each roll may contain one splice on non-label side of liner using 0.002 inch maximum

thickness tape as shown in the next figure.

4-9

Page 60

METTLER TOLEDO bPro® User's Guide

Finished Label and Roll

Dimensional

Requirements

A B

C

A

D

Item Description Range

A Liner Width

B

C

D Label Width

E Gap Width

F Label Length

G

H

Roll

Diameter

Core Inside

Diameter

Effective

Print Width

Left side

Offset

Max 3.268 83

Min 1.575 40

Max 4.7 120

Min 1.575 40

Max 3.150 80

Min 1.575 40

Max 0.236 15

Min 0.078 2

Max 7.8 200

Min 0.9 23

Max 2.10 54

Min 0.157 4

BPro

2"

Inches MM

E

F

H

G

4-10

Page 61

Typical Dimensions – 2” Label Roll

Chapter 4: Labels

Label Requirements

4.7 [120] max

0.9 min [23]

12 max [300]

0.9 min [23]

7.8 max [200]

1.575 min [40]

3.15 max [80]

NOTE: Dimensions in inches with millimeters

shown in [ ].

bPro only prints 54mm wide

4-11

Page 62

METTLER TOLEDO bPro® User's Guide

Preprinted Labels

To ensure trouble free operation of the printer gap sensor, and to achieve normal print

head life, no pre printing should be placed on the label in the gap sensor path or in

areas which will be printed by the scale printer (see following figure). However, since

preprinting is commonly used by many customers the following guidelines must be

followed.

1. Inks used for preprinting must be specially formulated for use in thermal printers. If

proper inks are not used they can adhere to the print head. This ink build up on the

print head will interfere with heat transfer from the print head to the paper and cause

printing elements to burn out. Another problem with inks not formulated for thermal

printing is that they can contain chemicals which will cause the glass overcoat to chip

off of the print head, causing failure to print in the chipped areas.

2. If black ink is used in preprinting in the gap sensor path shown in the figure below, a

dense black stripe will have to be printed on the back of the liner, as shown in the Black

Stripe figure, to prevent the gap sensor from being affected by the black preprinting.

(Colors other than black might also be a problem and should be tested by the

customer) The black stripe must have gaps which correspond to the label gaps. The

black stripe on the liner must have a minimum transmission optical density of 2.3 and

must be uniform. In addition, the gap sensor circuit will need to be adjusted for

operation with the black stripe as explained in the product service manual. This

adjustment will need to be checked any time label paper is changed, for example when

labels are procured from a new supplier.

GAP SENSOR PATH BLACK STRIPE

4-12

Page 63

Chapter 4: Labels

Preprinted Labels

3. If an optical density of at least 2.3 cannot be achieved in the black stripe on the

back of the liner. The sensor path in the center of the label must be free of black

preprinting.

No Dark Preprinting in this

area

4-13

Page 64

METTLER TOLEDO bPro® User's Guide

Special Shaped Labels

Labels with shapes other than rectangular will cause gap detection errors if the gap

dimension (in the gap sensor path) is outside the limits given in this document, or if the

edge of the label shape crosses into and out of the sensor path as shown below. For

these cases the black stripe will have to be printed on the back of the liner as shown

previously. Tests will be needed to determine if the stripe will be adequate or if

additional liner width will be required. The safe approach is to use the black stripe

configuration shown previously on all odd shaped labels.

EXAMPLES OF ODD SHAPPED LABELS

WHICH WILL CAUSE GAP SENSOR

PROBLEMS AND WILL NEED BLACK STRIPE

Definition of

Transmission Optical

Fish Oval or Round

Density

4-14

Transmission optical density is defined as:

Optical Density = log

(incident light / transmitted light) = log10 (100 / % light

10

transmission)

Transmission optical density can be measured with a transmission densitometer that

meets ANSI standards. Examples are the Macbeth model TD903 and TD932.

Optical density for 100% light transmission = log

Optical density for 0.1% light transmission = log

(100/100) = log10 (1) = 0

10

(100/0.1) = log10 (1000) = 3

10

Page 65

Label and Liner Optical

Density

Chapter 4: Labels

Label and Liner Optical Density

If liner paper transmits 2% of the light which is incident on it, the optical density

(100/2) = 1.7

is log

10

If the light transmitted through the liner is 3 times the light transmitted through the liner

and label, the relative optical densities are:

Black Stripe Optical

Density

Optical Density of Liner + Label = log

Optical Density of Liner Only = log

= log

= log

= log

(100 / X)

10

(100 / 3X)

10

(0.3333X)

10

0.3333 + log10 (X)

10

(X) – 0.48

10

Therefore, if the liner must transmit 3 times the light that the liner and label transmits,

the transmission optical density of the liner must be 0.48 less than the transmission

optical density of the liner and label.

If only 0.5 % of incident light is transmitted through the black stripe, the optical density

is:

log

(100 / 0.5) = log10 (200) = 2.3

10

The purpose of specifying a transmission optical density of at least 2.3 for the printed

black stripe on the back of the label is to minimize any variation in light transmission as

a result of black pre-printing on the front of the label. This variation due to black

preprinting can cause the gap sensor to give gap detection errors.

4-15

Page 66

METTLER TOLEDO bPro® User's Guide

For your notes

4-16

Page 67

5 Maintenance

Unit Cleaning

Disconnect all power to this unit before installing, servicing,

cleaning, or removing the fuse. Failure to do so could result in

bodily harm and/or property damage. Do not spray or wash down.

Hazard of electrical shock or burn.

Disconnect Power

Open the printer door by pressing down on the release tab.

Do not use solvents or commercial cleaners on the unit. They may harm the surfaces

or damage the Keypad.

Do not spray directly on or at the unit!

Chapter 5: Maintenance

Unit Cleaning

WARNING