Page 1

User manual

METTLER TOLEDO

Compact scales BBA462 / BBK462

123

456

789

.0

a b c- , / & d e f

j k l

m n o

g h i

t u v

w x y z

p q r s

+ ...

C

www.mt.com/support

Page 2

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use

according to this Operating Manual and regular calibration and maintenance by our

factory-trained service team ensures dependable and accurate operation, protecting

your investment. Contact us about a ServiceXXL agreement tailored to your needs and

budget.

We invite you to register your product at www.mt.com/productregistration so we can

contact you about enhancements, updates and important notifications concerning your

product.

Page 3

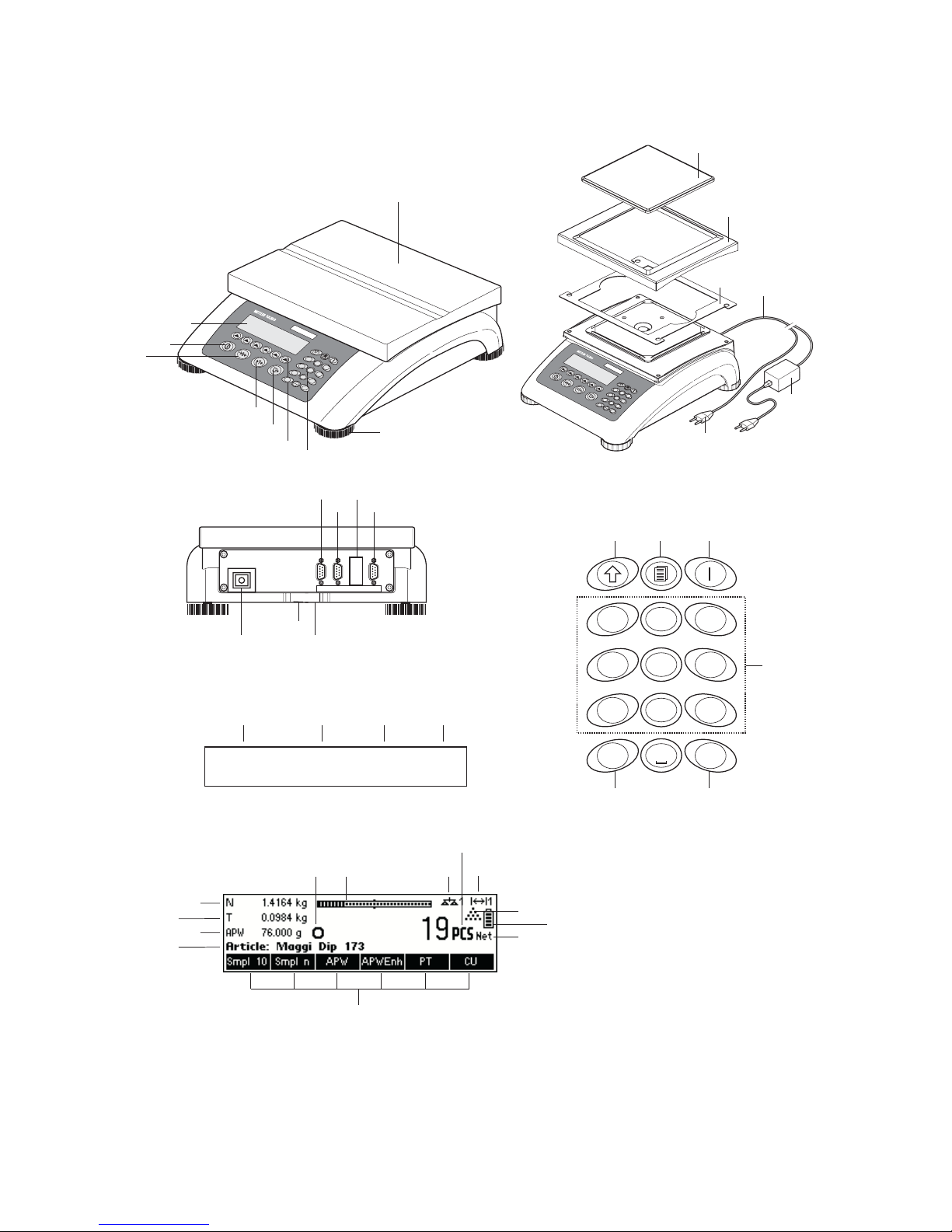

Overview

Rear of Scale

Scale specifications (example)

Keypad

Max1: 3kg Min1: 20g e1: 1g d1: 1g

Max2 6kg Min2: 40g e2 2g d2: 2g

18 19 20 21

Display

28

29

30

31

32 33 343536

37

38

39

40

10

10a

10b

9

9a

9b

1

2

3

4

5

6

7

8

9

22 23 24

25 26

27

14

151617

1311

12

2

a b c

3

d e f

1

-. / &

5

j k l

6

m n o

4

g h i

8

t u v

9

w x y z

7

q p r s

0

.

+...

C

123

456

789

.0

a b c

, / & d e f

j k l

m n o

g h i

t u v

w x y z

p q r s

+ ...

C

1

2

3

456

789

.

0

a b c

- , / &

d e f

j k l

m n o

g h i

t u v

w x y z

p q r s

+ ...

C

Page 4

Overview

1 Display

2 On/Off key

3 Tare key

4 Zero key

5 Enter key

6 Command softkeys

7 Keypad

8 Adjustable feet

9 Weighing pan

9a: wind protector

9b: shield

10 Power supply:

10a: power cord (scale w/o battery)

10b: AC adapter (scale with battery)

Rear of scale

11 Power supply

12 Model plate

13 Hole for anti-theft device

14 Spirit level (only on certified scales and those with

MonoBloc weighing cells)

Standard Interfaces:

15 PS2 connector for keyboard and/or BCR (Barcode

reader)

16 COM3 (RS232C interface)

17 COM2 (RS232C interface)

18 COM1 (RS232C interface)

Optional Interfaces:

15 PS/2 connector for keyboard and/or BCR (Barcode

reader)

16 Depending on configuration: RS232C interface or

Analog Base

17 Depending on configuration: Ethernet, USB,

Digital I/O or RS232 interface

18 Depending on configuration: RS232C or RS422/485

interface

Scale specifications

19 Maximum loads (ranges 1/2)

20 Minimum loads (ranges 1/2)

21 Verification scale interval (certified scale)

(ranges 1/2)

22 Max. resolution (ranges 1/2)

Keypad

23 Shift key

24 Database key

25 Info key

26 Special characters key

27 Clear key

28 Numeric/alphanumeric keys

Display

29 Info line 1

30 Info line 2

31 Info line 3

32 Info line 4

33 Stability detector

34 Weighing range bar graph

35 Active scale (in 2-scale systems)

36 Unit

37 no function

38 Piece counting symbol

39 Battery discharge status

40 Net weight indicator

41 Softkeys 1…6

Page 5

METTLER TOLEDO BBA462 / BBK462 Table of Contents

5

1 Setting up the scale......................................................................................................... 9

1.1 Safety and environment .........................................................................................................................9

1.2 Positioning and leveling the scale ........................................................................................................10

1.3 Connecting to power supply.................................................................................................................11

1.4 Battery operation ................................................................................................................................11

2 Basic functions.............................................................................................................. 12

2.1 Switching on and off and zeroing .........................................................................................................12

2.2 Setting date and time ..........................................................................................................................13

2.3 Language settings ..............................................................................................................................14

2.4 Simple weighing .................................................................................................................................14

2.5 Weighing with tare ..............................................................................................................................15

2.5.1 Taring by placing the weighing container on the scale...............................................................15

2.5.2 Entering the tare weight numerically (pre-tare)..........................................................................16

2.5.3 Determining the gross and net weights ....................................................................................17

2.6 Recording weighing results ..................................................................................................................17

3 Enhanced functions........................................................................................................18

3.1 General Info .......................................................................................................................................18

3.2 Database ...........................................................................................................................................19

3.2.1 Database editing functions .....................................................................................................19

3.2.2 Defining an article .................................................................................................................20

3.2.3 Erasing of individual article attributes ......................................................................................23

3.2.4 Save As Article function ..........................................................................................................24

3.3 Gross Weight Alarm ............................................................................................................................24

3.4 SmartManager....................................................................................................................................25

3.5 FlashLoader .......................................................................................................................................25

4 Application.................................................................................................................... 26

4.1 Counting pieces into a container ..........................................................................................................26

4.1.1 Determining the reference by placing pieces on the scale...........................................................26

4.1.2 Entering the reference when the piece weight is known ..............................................................27

4.2 Counting out pieces out of a container ..................................................................................................28

4.2.1 Determine reference by removing pieces ..................................................................................28

4.3 Reference optimization ........................................................................................................................29

Page 6

Table of Contents METTLER TOLEDO BBA462 / BBK462

6

4.4

Minimum sample weight .....................................................................................................................29

4.5 Using the info key ...............................................................................................................................30

4.6 Piece counting with 2-scale systems ....................................................................................................31

4.7 Accumulation .....................................................................................................................................32

4.8 Accumulation to target.........................................................................................................................34

4.9 Filling ................................................................................................................................................35

4.10 Checkweighing (+/-)...........................................................................................................................35

4.11 Custom Unit .......................................................................................................................................36

4.12 High resolution / Average weighing.......................................................................................................37

4.13 Alibi memory......................................................................................................................................38

5 Vision setup .................................................................................................................. 40

5.1 Overview and operation .......................................................................................................................40

5.2 Calling up the menu and entering the password.....................................................................................41

5.3 Menu overview ...................................................................................................................................42

5.3.1 Scale ...................................................................................................................................42

5.3.2 Application ...........................................................................................................................43

5.3.3 Terminal...............................................................................................................................45

5.3.4 Communications...................................................................................................................46

5.3.5 Diagnostics ..........................................................................................................................49

5.4 Scale settings (SCALE) ........................................................................................................................49

5.4.1 Adjust/calibrate (SCALE Æ Calibration) ...................................................................................50

5.4.2 Display resolution and weighing unit (SCALE Æ Display)..........................................................50

5.4.3 Tare settings (SCALE Æ Tare).................................................................................................51

5.4.4 Automatic zero point correction (SCALE Æ Zero) ......................................................................51

5.4.5 Automatic save of tare and zero values (SCALE Æ Restart) .......................................................51

5.4.6 Adaptation to environmental conditions and weighing mode (SCALE Æ Filter).............................52

5.4.7 Automatic adjustment (SCALE Æ FACT)...................................................................................53

5.4.8 Minimum weight monitoring (SCALE Æ Min Weigh) .................................................................53

5.4.9 Resetting scale to factory default settings (SCALE Æ Reset) .......................................................54

5.5 Application settings (APPLICATION) ......................................................................................................54

5.5.1 Settings for piece counting (APPLICATION Æ Counting) ............................................................55

5.5.2 Settings for database (APPLICATION Æ Database) ...................................................................58

5.5.3 Identification (APPLICATION Æ Identification) ...........................................................................59

5.5.4 Settings for accumulation (APPLICATION Æ Accumulation) .......................................................60

5.5.5 Settings for filling/checkweighing (APPLICATION Æ Filling/Checkweighing) .................................61

Page 7

METTLER TOLEDO BBA462 / BBK462 Table of Contents

7

5.5.6 Settings for the (optional) alibi memory -> APPLICATION-> Alibi memory....................................61

5.5.7 Settings for softkey configuration (APPLICATION Æ Softkey Configuration) ..................................62

5.5.8 Settings for Info/Help (APPLICATION Æ Info/Help).....................................................................63

5.5.9 Settings for reset (APPLICATION Æ Reset)................................................................................64

5.6 Terminal settings for device (TERMINAL Æ Device) ................................................................................65

5.6.1 Language settings (TERMINAL Æ Device Æ Language) ............................................................65

5.6.2 Sleep function (TERMINAL Æ Device Æ Sleep).........................................................................65

5.6.3 Adjusting the contrast of the display (TERMINAL Æ Device Æ Contrast)......................................66

5.6.4 Invert (TERMINAL Æ Device Æ Invert).....................................................................................66

5.6.5 Changing the size of weight display (TERMINAL Æ Device Æ Weight display) ............................66

5.6.6 Adjusting the date and time (TERMINAL Æ Device Æ Date Time) ...............................................67

5.6.7 Activating the beep (TERMINAL Æ Device Æ Beep) ..................................................................67

5.7 Define supervisor password (TERMINAL Æ Access) ...............................................................................67

5.8 Reset terminal settings to factory settings (TERMINAL Æ Reset) ...............................................................68

5.9 Communication settings (COMMUNICATIONS) .......................................................................................68

5.9.1 Mode (COMMUNICATIONS Æ Mode).......................................................................................69

5.9.2 Printer (COMMUNICATIONS Æ Printer) only in Printer Mode or Auto Print ....................................70

5.9.3 Parameters (COMMUNICATIONS Æ Parameters) ......................................................................71

5.9.4 Define I/O (COMMUNICATIONS Æ Def. I/O – only if Mode is Digital I/0) ......................................72

5.9.5 Reset communications (COMMUNICATIONS Æ Comx Æ Reset Com) .........................................73

5.9.6 Option Settings (COMMUNICATIONS Æ Option) ........................................................................73

5.9.7 PS2 Settings (COMMUNICATIONS Æ PS2) ...............................................................................76

5.9.8 User-defined printer (COMMUNICATIONS Æ User-defined printer) ...............................................76

Example: Configuration of a printer......................................................................................................78

5.10 Diagnostic settings (DIAGNOSTICS) ......................................................................................................79

5.10.1 Scale (DIAGNOSTICSÆ Test Scale) .........................................................................................80

5.10.2 Keyboard (DIAGNOSTICSÆ Keyboard Test) .............................................................................80

5.10.3 Display (DIAGNOSTICSÆ Display Test) ...................................................................................81

5.10.4 Serial Number 1 (DIAGNOSTICSÆ SNR1) ................................................................................81

5.10.5 Serial Number 2 (DIAGNOSTICSÆ SNR2) ................................................................................81

5.10.6 List 1 (DIAGNOSTICSÆ List 1) ...............................................................................................81

5.10.7 List 2 (DIAGNOSTICSÆ List 2) ...............................................................................................82

5.10.8 List memory (DIAGNOSTICSÆ List Memory) ............................................................................82

5.10.9 Working time (DIAGNOSTICSÆ Working time) .........................................................................82

5.10.10 Reset All (DIAGNOSTICSÆ Reset All) .......................................................................................82

Page 8

Table of Contents METTLER TOLEDO BBA462 / BBK462

8

6 Other important information ...........................................................................................83

6.1 Error messages ..................................................................................................................................83

6.2 Sample reports ...................................................................................................................................85

6.3 Variable and control sequences in entering a "Free Text" .........................................................................86

6.4 Cleaning instructions...........................................................................................................................87

7 Technical data, interfaces and accessories......................................................................88

7.1 General data and delivered items..........................................................................................................88

7.2 Dimensions........................................................................................................................................90

7.3 Interface technical data........................................................................................................................90

7.4 Accessories........................................................................................................................................91

7.5 Interface commands ...........................................................................................................................92

7.5.1 Preconditions........................................................................................................................92

7.5.2 SICS Command set................................................................................................................92

7.6 TOLEDO Continuous Mode...................................................................................................................93

7.6.1

TOLEDO Continuous commands

.............................................................................................93

7.6.2 Output format in TOLEDO Continuous Mode .............................................................................93

7.7 Information for verified scales...............................................................................................................95

7.8 Compliances ......................................................................................................................................95

8 Appendix.......................................................................................................................96

8.1 Safety checks .....................................................................................................................................96

Page 9

METTLER TOLEDO BBA462 / BBK462 Chapter 1: Setting up the scale

9

1 Setting up the scale

Please read through these operating instructions carefully and adhere to them at all times. If you discover that materials are

missing or that the wrong ones have been supplied, or if you have any other problems with your scale, please refer to the

dealer and salesperson concerned, or if necessary to the METTLER TOLEDO representative responsible.

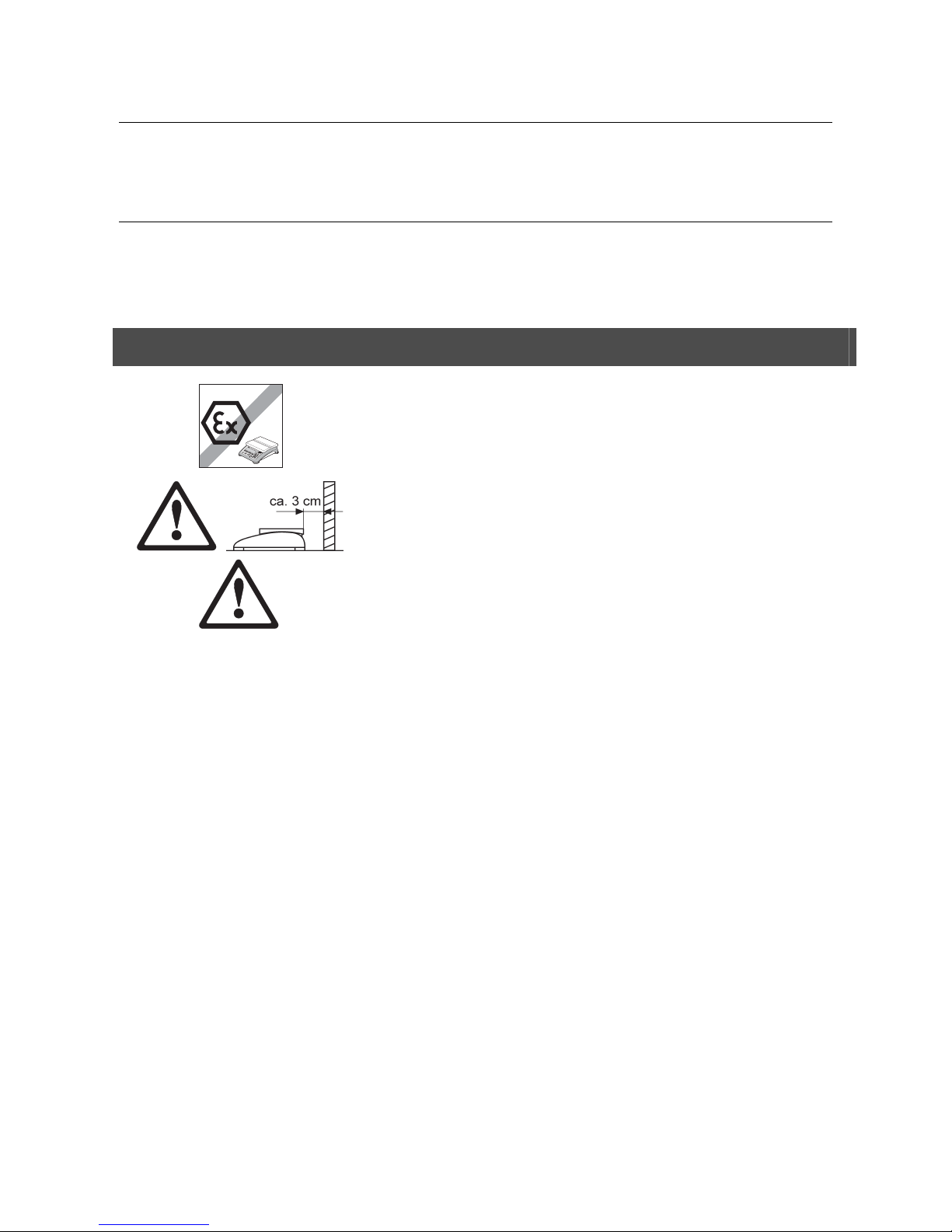

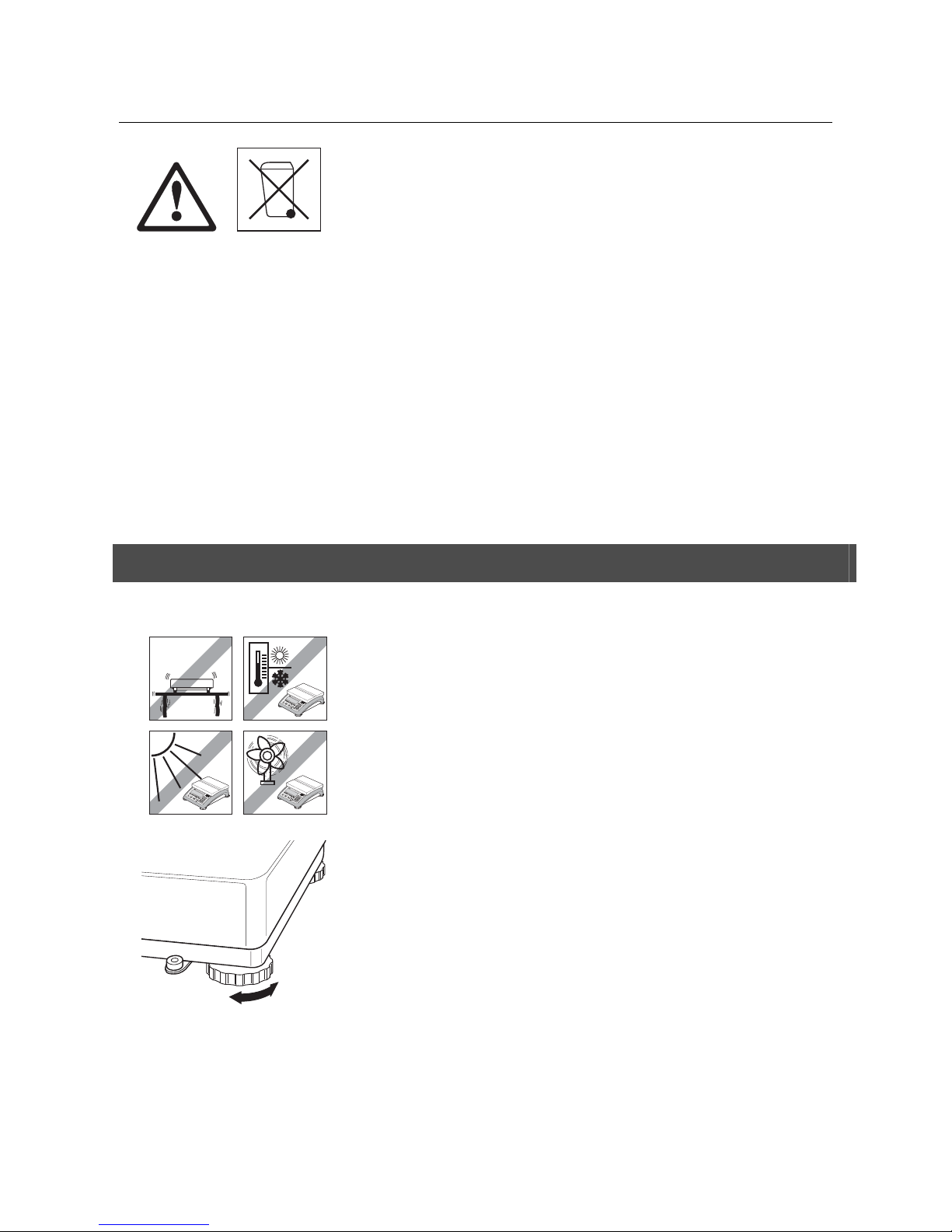

1.1 Safety and environment

Do not use BBA462 / BBK462 in hazardous areas!

Our product range includes special devices for hazardous areas.

If the power cord is damaged, the scale must no longer be operated.

Therefore check the cable regularly and ensure that a free space of about 3

cm is left at the rear of the scale, so that the cable is not kinked too severely.

DANGER!

Electric shock hazard!

Always pull out the mains plug before any work on the device.

DANGER!

Electric shock hazard if the mains cable is damaged!

Check the mains cable for damage regularly and replace it immediately if

it is damaged.

On the rear side of the device, maintain a clearance of at least 3 cm in

order to prevent the mains cable bending too much.

CAUTION!

On no account open the device!

The warranty is void if this stipulation is ignored. The device may only be

opened by authorized persons.

Call METTLER TOLEDO Service.

CAUTION!

Handle the compact scale with care.

The scale is a precision instrument.

When the weighing pan has been removed, never clean the area under

the load plate holder with a solid object!

Do not put excessive loads on the scale.

Avoid banging the weighing pan.

Parts of the scale coming into contact with foodstuffs have smooth surfaces

and are easy to clean. The materials used do not splinter and are free of

harmful substances.

With foodstuffs, it is recommended to use the supplied protective cover.

- Clean the protective cover regularly and carefully.

- Replace damaged or very dirty protective cover immediately.

Page 10

Chapter 1: Setting up the scale METTLER TOLEDO BBA462 / BBK462

10

In conformance with the European Directive 2002/96 EC on Waste Electrical

and Electronic Equipment (WEEE) this device may not be disposed of with

domestic waste. This also applies to countries outside the EU, per their

specific requirements.

➜ Please dispose of this product in accordance with local regulations at the

collecting point specified for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the

distributor from which you purchased this device.

Should this device be passed on to other parties (for private or professional

use), the content of this regulation must also be related.

Thank you for your contribution to environmental protection.

If the device is equipped with a storage battery: The nickel metal hydride

(NiMH) storage battery does not contain any heavy metals. However, it may

not be disposed of with the normal refuse.

➜ Observe the local regulations on the disposal of materials that are

hazardous to the environment.

1.2 Positioning and leveling the scale

The correct location is a decisive factor in ensuring accurate weighing results.

- Choose a stable and vibration-free location (particularly important for high-

resolution scales using Mettler Toledo MonoBloc technology). Place the scale on

a surface that is as horizontal as possible and strong enough to bear its weight

when fully loaded.

- Check the ambient conditions.

- Avoid:

- direct sunlight

- strong drafts (e.g. from fans or air conditioning systems)

- excessive temperature fluctuations.

Turn the adjustable feet so that the scale is horizontal. If a spirit level is filled, the

bubble must be located within the inner circle.

Note: The BBA462 / BBK462 has a special filter that accelerates certain procedures

(zeroing, taring, determining the reference weight for piece counting) in a nontranquil environment. This inevitably means that there is a slight loss of accuracy

with the results. For high-precision results, care must be taken to ensure as tranquil

and stable an environment as possible, so that the filter is not activated.

Page 11

METTLER TOLEDO BBA462 / BBK462 Chapter 1: Setting up the scale

11

Major changes in geographical location:

The manufacturer adjusts each scale to the local gravity conditions (GEO value). In

the event of major geographical location changes, this setting must be adjusted by a

service technician. Certified scales must also be recertified observing the national

certification regulations. These steps are not necessary for scales with an internal

calibration weight.

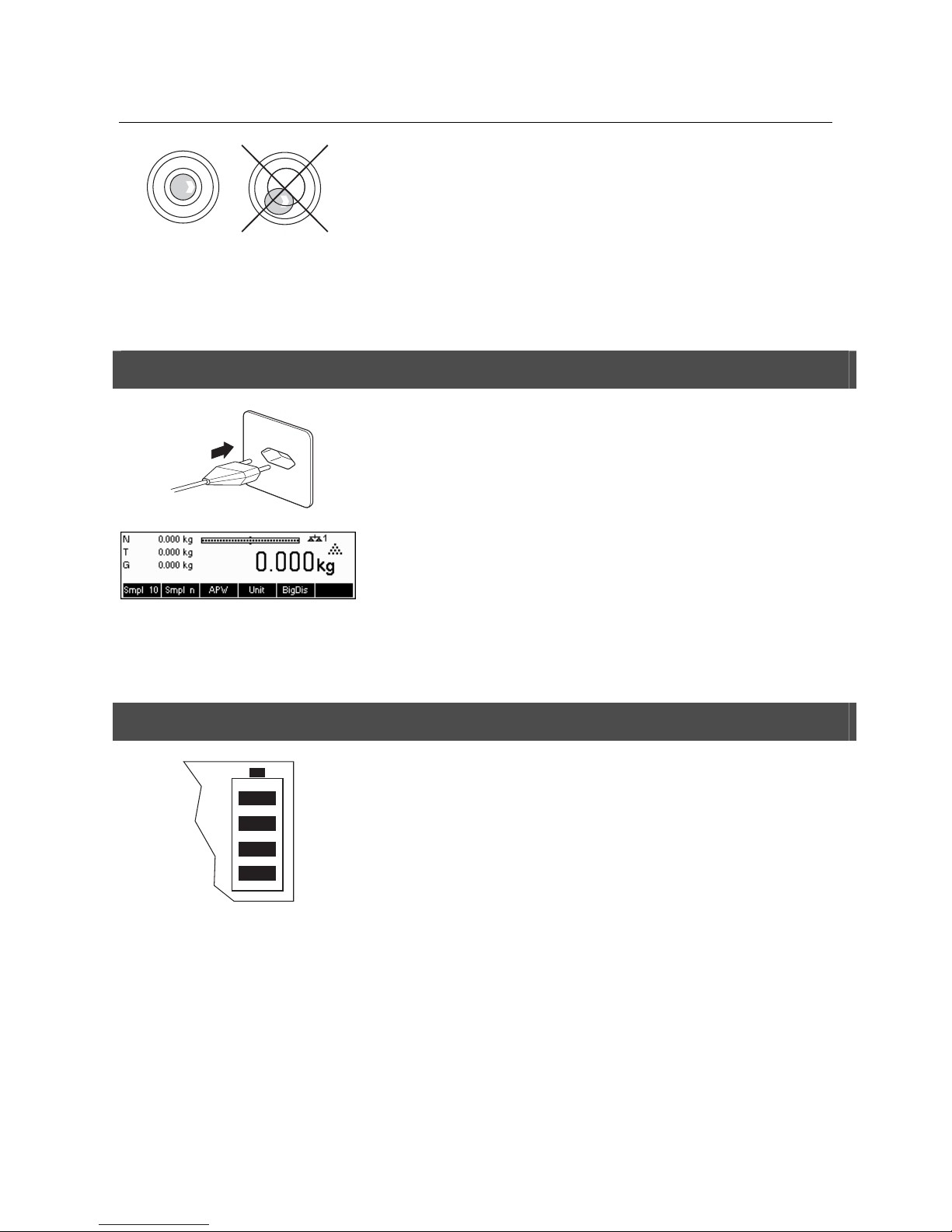

1.3 Connecting to power supply

Before connecting the power supply plug or AC adapter (AccuPac version), verify that

the voltage stated on the model plate is the same as the local power line voltage.

Connect the power cord plug or the AC adapter plug to the supply, then connect the

AC adapter (AccuPac version) via the jack at the rear of the scale.

Powering up the scale initiates a display test in which all the segments and then the

software version are briefly displayed. Once the decimal zero appears in the display,

the scale is ready to operate.

For maximum possible precision, adjust/calibrate the scale after installing it (Chapter

5.4.1). Note: Certified scales must be adjusted by an authorized organization.

Please consult your dealer.

1.4 Battery operation

Scales with a built-in battery can work independently from the mains for

approximately 30 hours in normal operation. A prerequisite for this is that the

background lighting is switched off and that no peripheral devices are connected.

The device automatically switches to battery operation as soon as the mains supply

is interrupted. When the mains supply is restored, the device automatically switches

back to mains operation.

The battery symbol indicates the present charging level of the battery. 1 segment

corresponds to approx. 25 % capacity. When the symbol flashes the battery must be

charged (min. 4 hours). The charging period is extended if work is continued during

charging. The battery is protected against overcharging.

The charging time of the storage battery amounts to approx. 6 hours. If the device

continues to be operated during the charging process, the charging time is extended.

The storage battery has a service life of approx. 1,000 charging/discharging cycles.

The storage battery is also suitable for permanent mains operation.

➜ In order to obtain the full nominal capacity we recommend that you discharge the

storage battery at regular intervals (approx. every 4 weeks) through normal

operation.

Page 12

Chapter 2: Basic functions METTLER TOLEDO BBA462 / BBK462

12

2 Basic functions

This Chapter describes how to switch the scale on and off, zero and tare it, weigh materials and record the results.

All displays are based on default settings “US English”.

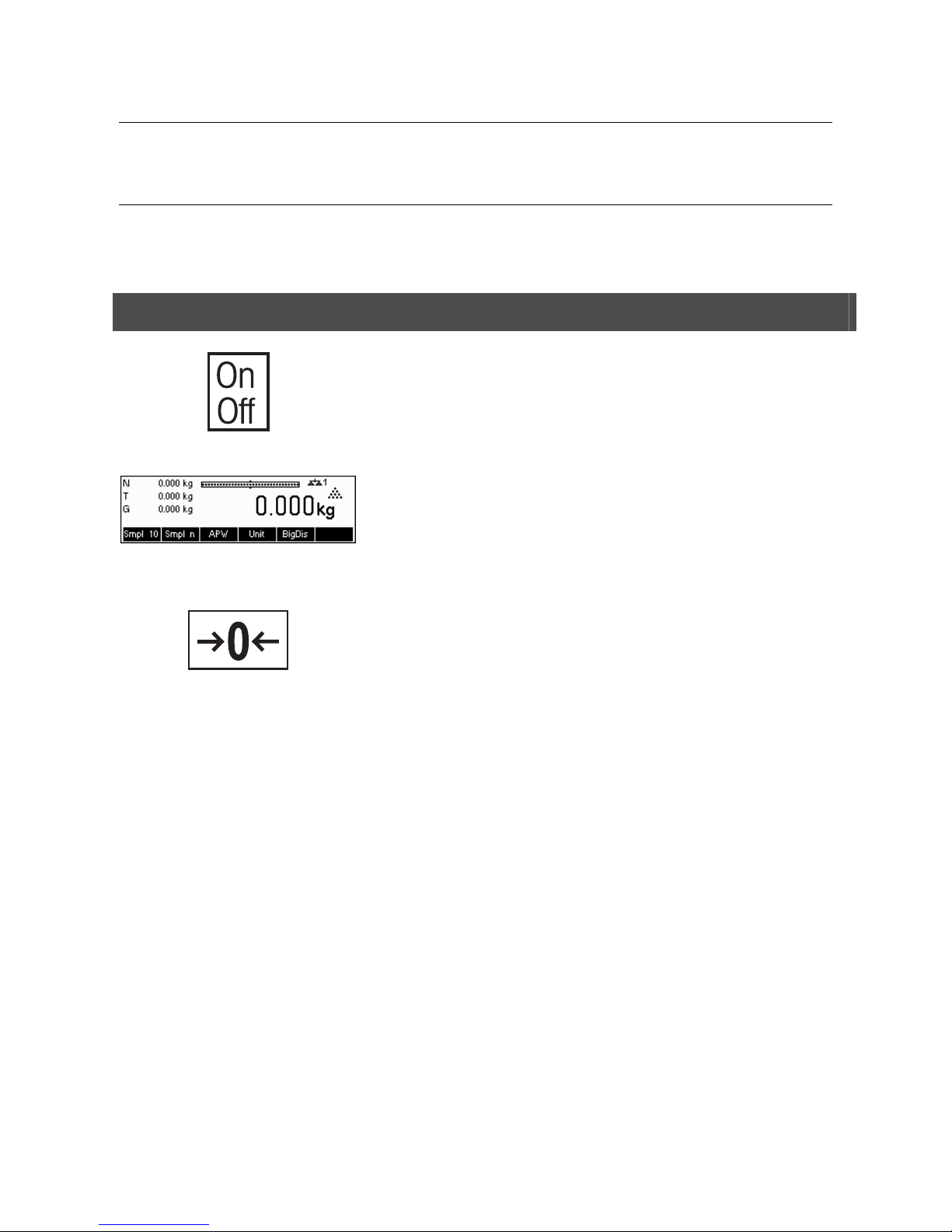

2.1 Switching on and off and zeroing

Briefly pressing «On/Off»

key switches the scale on or off.

The scale carries out a display test (Chapter 1.3). Once the weight display appears,

the scale is ready to operate and automatically zeroed.

Note: The screen display shown here may not necessarily be the same as the

display appearing on your scale. Please refer to Chapter 5 on how to navigate within

the 'Vision Setup'-menu and how to define softkeys for each function.

Note: If necessary, the scale can be zeroed at any time with the line «Æ0Å»

key.

Page 13

METTLER TOLEDO BBA462 / BBK462 Chapter 2: Basic functions

13

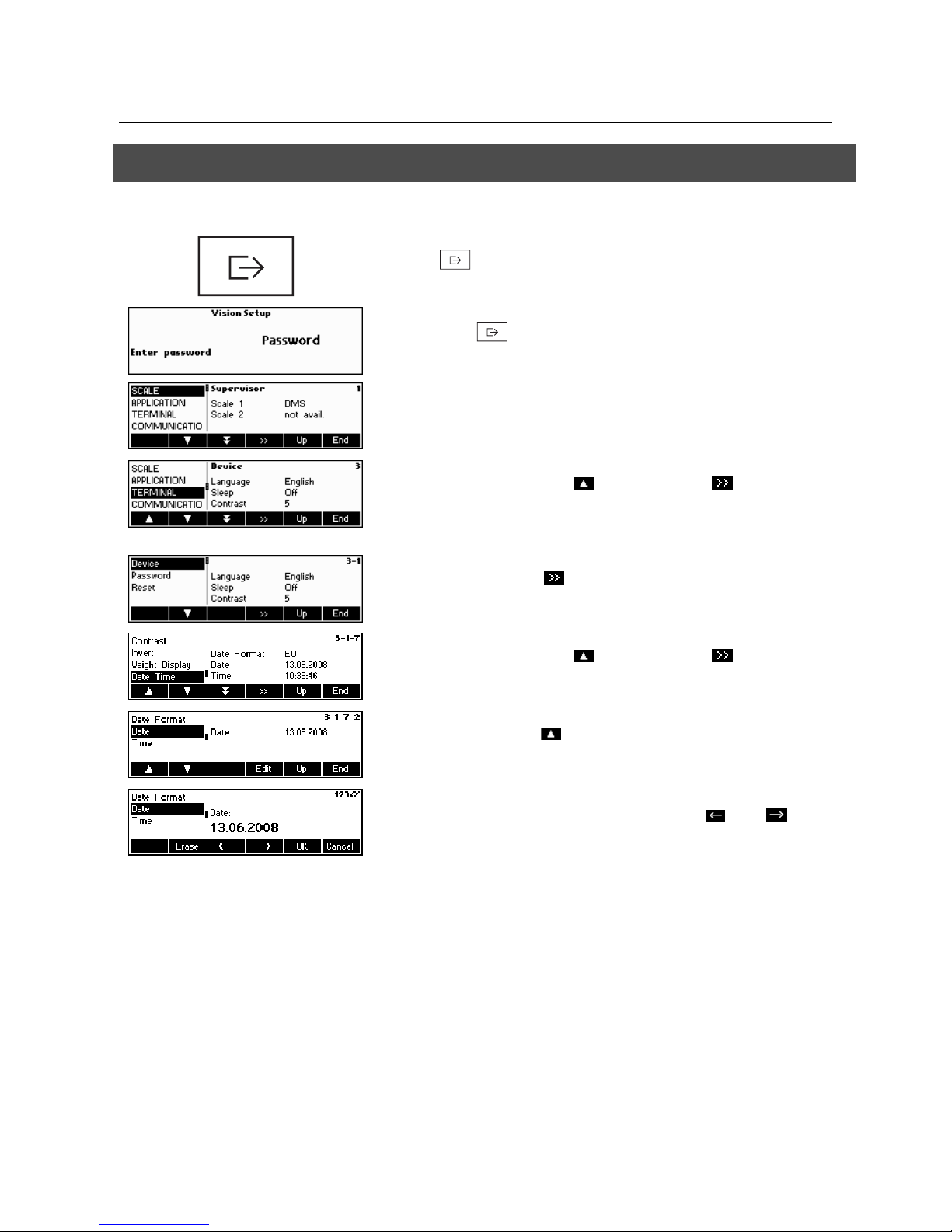

2.2 Setting date and time

Time can be set in 24 hours or 12 hours format, and the date in European or US format.

Press the «

» key continuously for about 2 seconds.

Briefly press the «

» key again.

Select TERMINAL by pressing the «

» key and press the « » key.

Select Device and press the «

» key.

Select Date Time by pressing the «

» key and press the « » key.

Select Date by pressing the «

» key and press the «Edit» key.

Use the numeric keypad to enter the date and confirm with the «OK» key.

Incorrect inputs can be deleted with the «Erase»

key. The « » and « »

keys can be used to scroll the characters that are entered.

To set the correct time, do the same procedure but select Time instead of

Date.

To leave Vision Setup, press the «End»

key. Save changes and confirm by

pressing the «Yes»

key

Page 14

Chapter 2: Basic functions METTLER TOLEDO BBA462 / BBK462

14

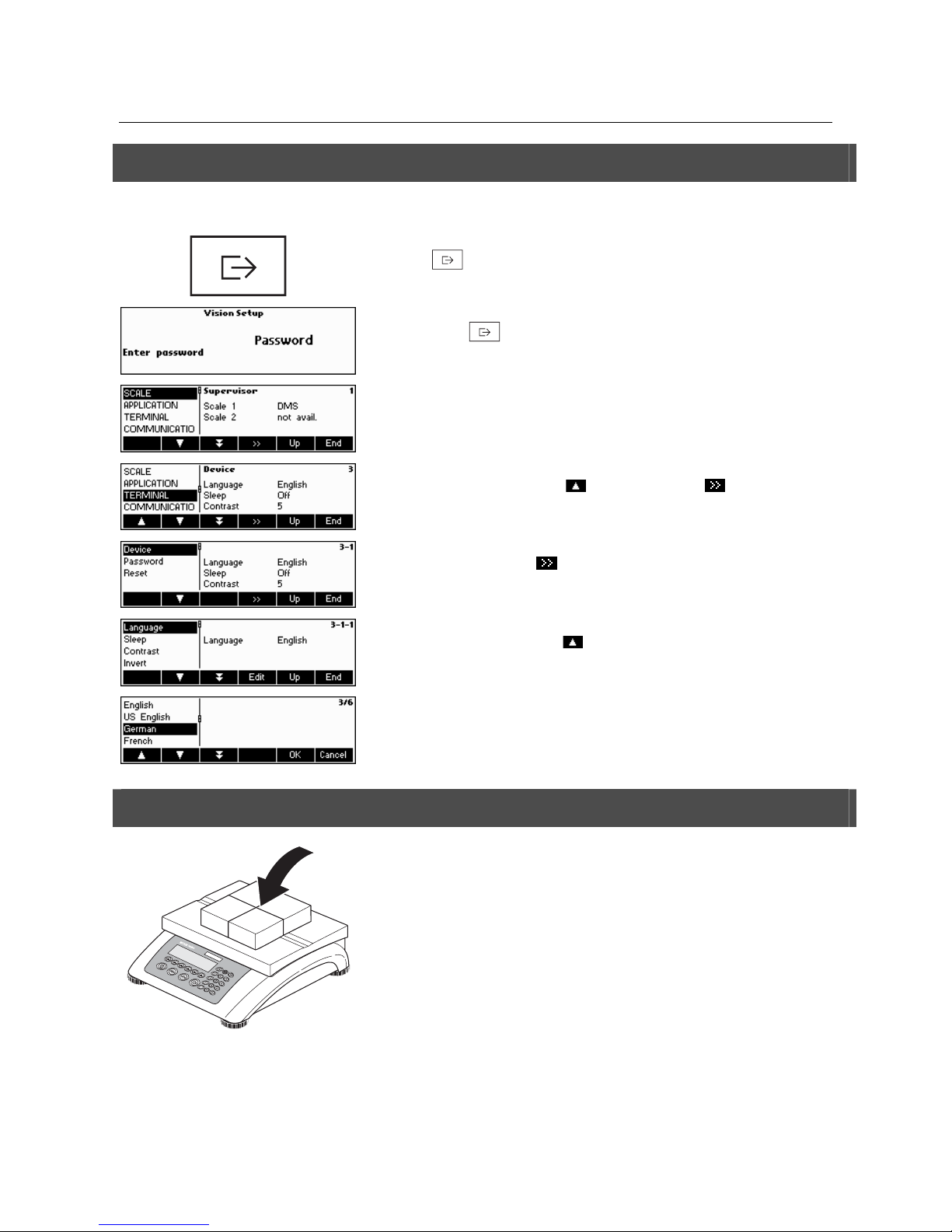

2.3 Language settings

Language can be set into US English, English, German, French, Spanish or Italian.

Press the «

» key continuously for about 2 seconds.

Briefly press the «

» key again.

…appears on the screen.

Select TERMINAL by pressing the «

» key and press the « » key.

Select Device and press the «

» key.

Select Language by pressing the «

» key and then press the «Edit» key.

Choose the desired language and then press the «OK» key.

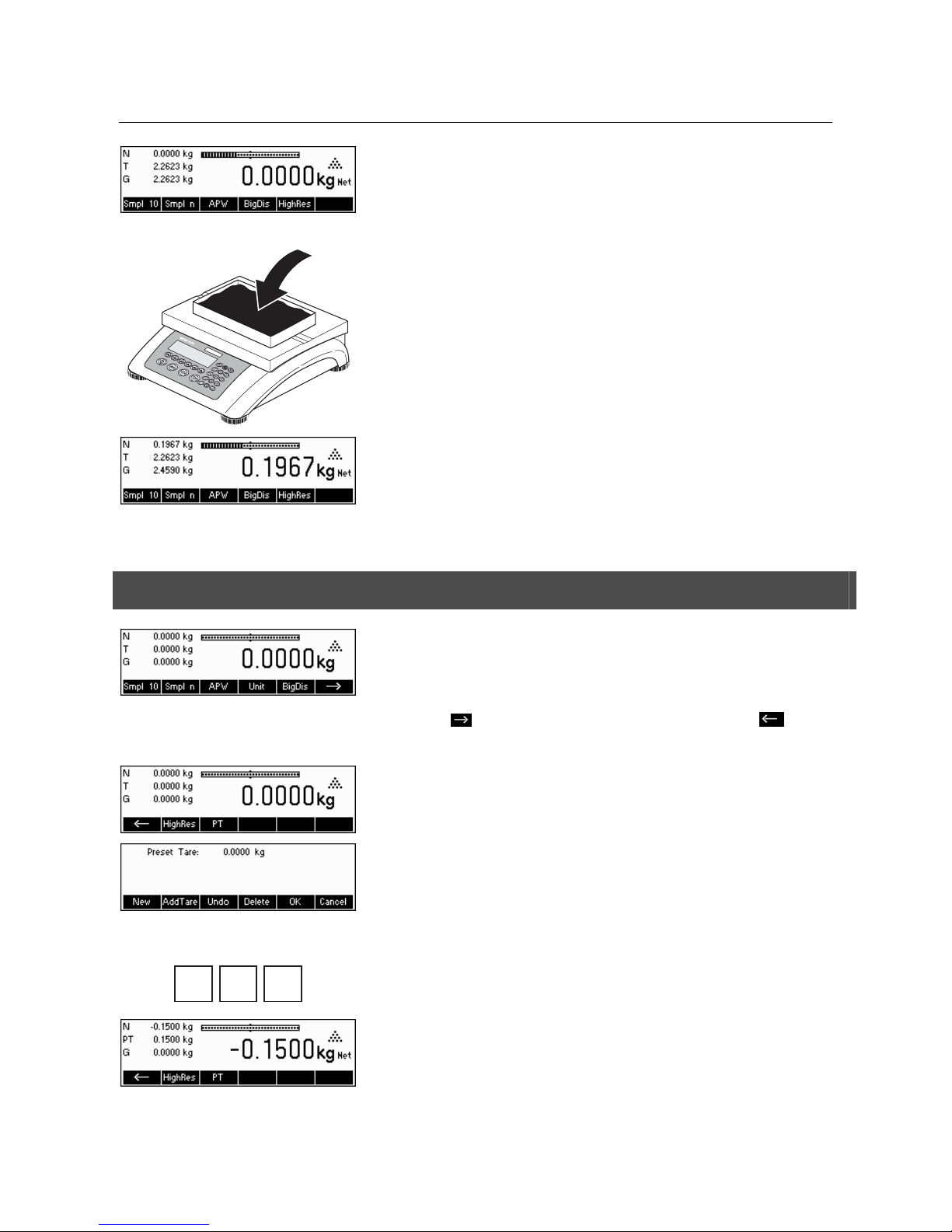

2.4 Simple weighing

Place the object to be weighed on the scale.

Page 15

METTLER TOLEDO BBA462 / BBK462 Chapter 2: Basic functions

15

The bar graph at the top of the display shows how much of the weighing range is

being used and how much is still available (as % of total scale capacity).

Wait until the stability detector (a small ring at the left edge of the display)

disappears, then…

… read the indicated net weight and press the «HighRes» key.

The «HighRes» key enables the weighing result to be displayed in control mode, i.e.

with a higher resolution.

Note: Each of the highest possible resolutions will be displayed in DMS scales. In

MonoBloc scales, the resolution will be ten times higher. Control mode is not

available if the maximum resolution has already been selected in Vision setup

(Chapter 5).

Press «Average» key to perform average weighing or press «Cancel» key to go back

to the normal weighing mode. The averaged value corresponds with the average

weight and the procedure takes about 20 seconds.

2.5 Weighing with tare

The tare can be specified by placing the weighing container on the scale or by entering the tare weight numerically. The two

possibilities are described below. Moreover, the gross and net weights can be determined separately.

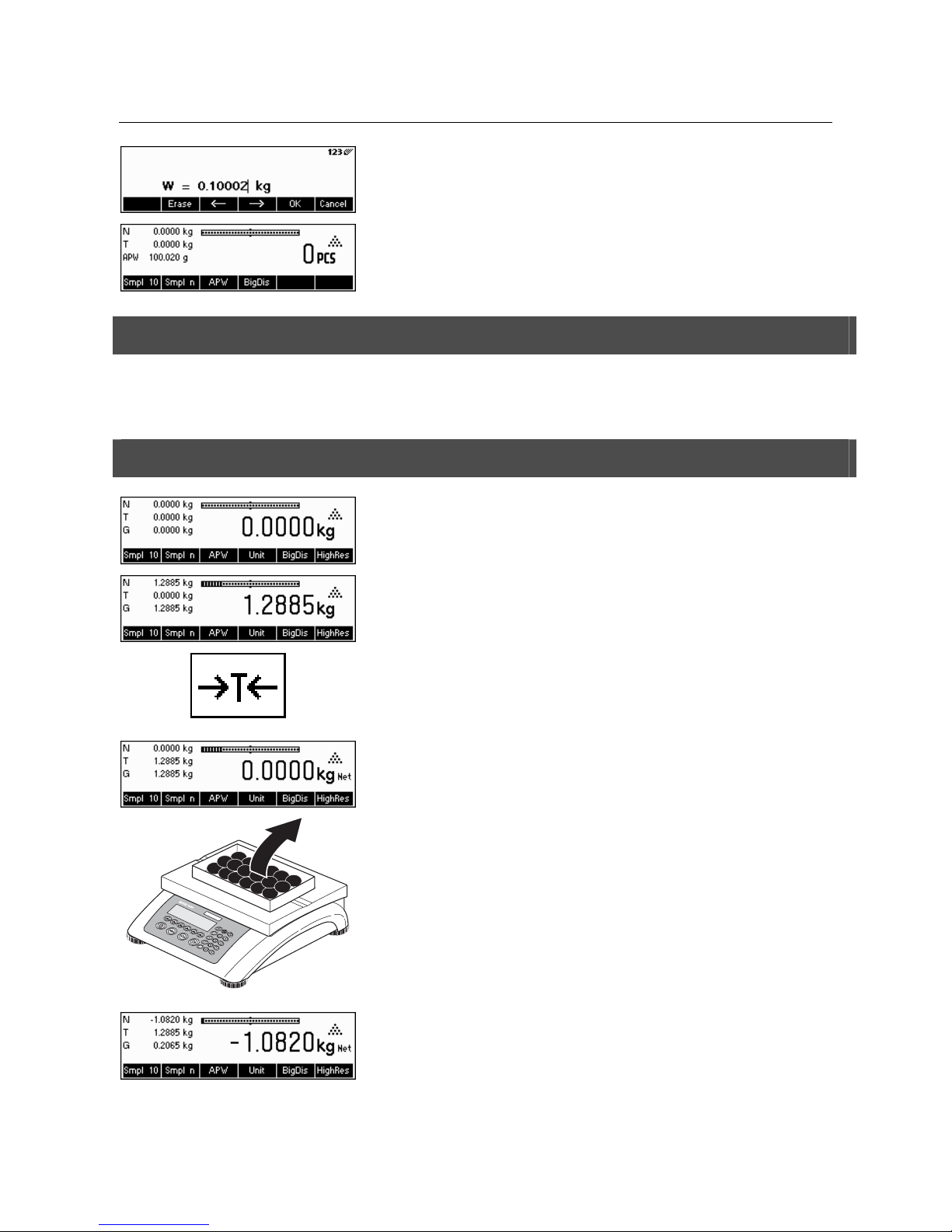

2.5.1 Taring by placing the weighing container on the scale

Place the empty weighing container or packaging on the scale.

Press the «ÆTÅ»

key briefly to tare the scale.

Page 16

Chapter 2: Basic functions METTLER TOLEDO BBA462 / BBK462

16

The zero display and the “Net” (net weight) symbol appear. Note: If the automatic

tare function has been activated in Vision Setup (Chapter 5.4.3), there is no need to

press the «ÆTÅ»

key. Prerequisite: The packaging material must be heavier than 9

display steps of the scale.

Place the material to be weighed in the container, then…

… read the result (net weight of the weighing sample).

Note: The tare weight is retained until either a new tare is determined, or the scale is

set to zero or switched off. If the automatic taring function is active, the tare is

automatically cleared when weighing is completed and the weighing pan emptied;

the scale is then ready for the next taring and weighing.

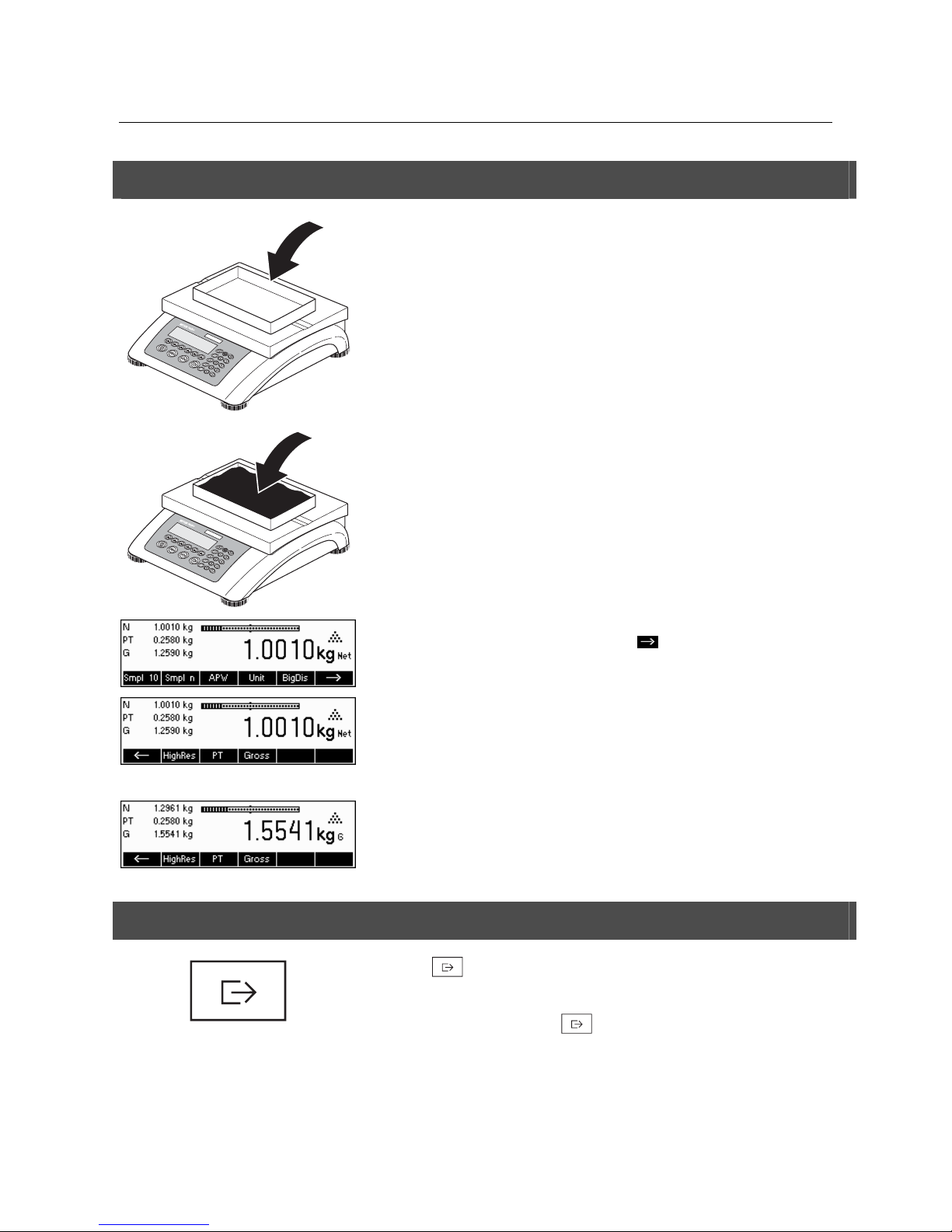

2.5.2 Entering the tare weight numerically (pre-tare)

Note: The «PT» softkey is not given as a standard softkey, because pre-tare can also

be inputted using the Short Input Mode (see Chapter 3.1). This function key must

thus be defined separately in Vision Setup. To define function keys, see Chapter

5.5.7. You will find an overview of all function keys that can be defined in Chapter

5.3.2. Press «

» to show other available function keys and press « » to go

back to the first page of the function keys.

Press the «PT» softkey.

… appears on the screen.

Press the «New» softkey to enter the tare weight. If you want to work further with other

tare weights, you can set and define the «Add. Tare» key. The additional tare weights

will be added to the actual tare weights. The «Undo» softkey deletes the last defined

"Add. Tare Weight". The «Delete» softkey deletes the whole tare weight.

.

1 5

Press the «New» softkey now and using the numeric keypad, enter the known tare

weight in the current weighing unit and confirm with «OK».

The tare values entered appear in the display with a negative sign and the symbol

“Net” (net weight). As soon as the weighing container with the corresponding weight

is placed on the scale, the zero display appears.

Page 17

METTLER TOLEDO BBA462 / BBK462 Chapter 2: Basic functions

17

2.5.3 Determining the gross and net weights

Place the empty weighing container or packaging on the scale and then press the

«ÆTÅ»

key briefly, or press the «PT» softkey if a known tare weight has already

been established.

Place the material to be weighed in the container, then…

… read the indicated net weight. Scroll on the «

» key.

Press the «Gross»

softkey. This function causes the gross weight to be displayed (the

“G” symbol appears and replaces the “Net” symbol).

Note: «Gross» is not given as a standard softkey and must be defined separately in

Vision Setup. In order to define the «Gross» softkey, see Chapter 5.5.7.

After a few seconds, the scale goes back automatically to net weight display.

2.6 Recording weighing results

Press the «

» key to send the current weighing result to the peripheral device

(printer, computer) via the interface.

Note: A multiple print out can be generated by entering a number with the numeric

keypad followed by pressing the «

» key. (only TLP/LP2844, TLP/LP2824,

MT8863).

Please refer to Chapter 5.3.4 for instructions on configuring the interface(s).

Page 18

Chapter 3: Enhanced functions METTLER TOLEDO BBA462 / BBK462

18

3 Enhanced functions

This Chapter describes the BBA462 / BBK462 features that simplify working with the application.

3.1 General Info

BBA462 / BBK462 provides several features which make working with the application easier.

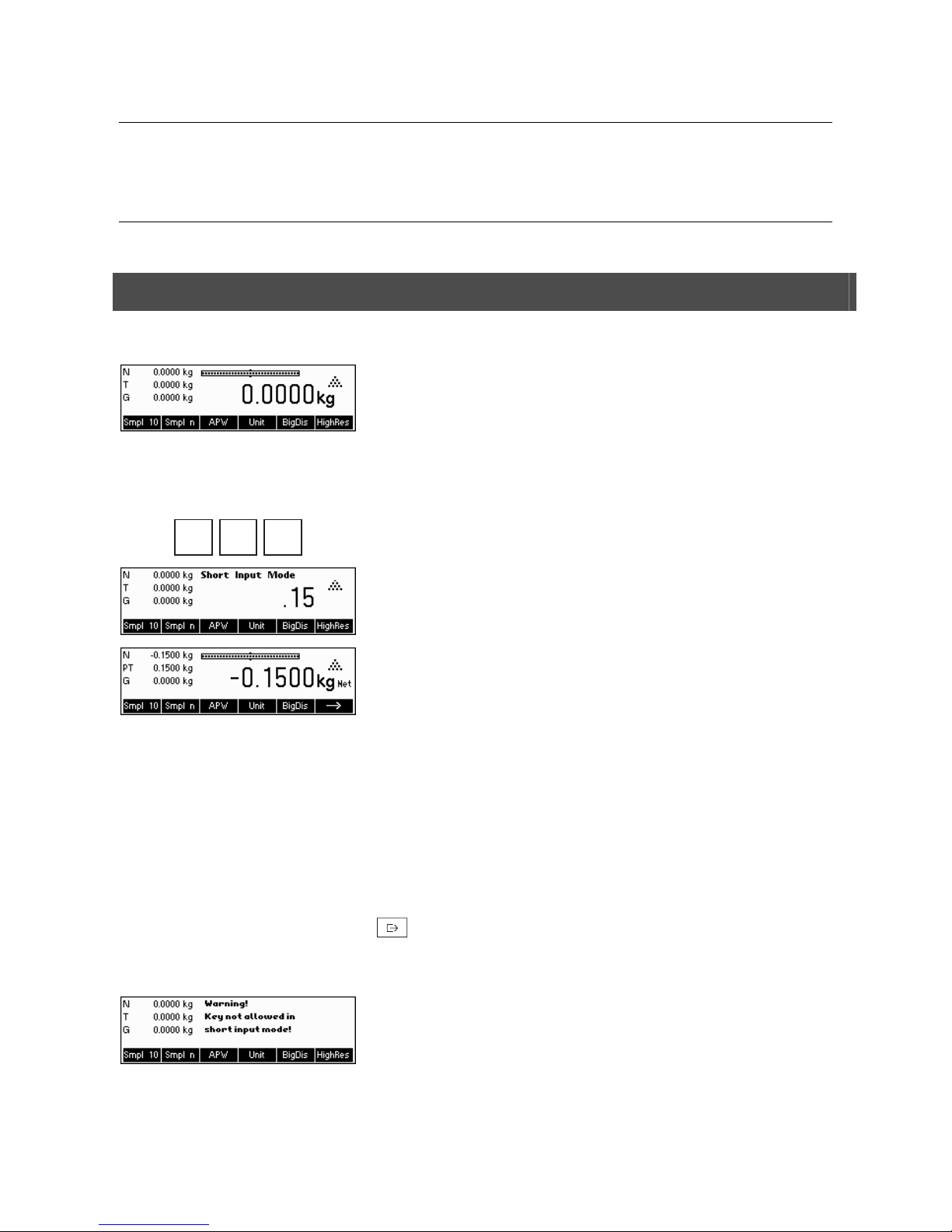

Short Input Mode

For some BBA462 / BBK462 functions, it is possible to use a short-cut method of

user input.

As in the example for entering the pre-tare weight in Chapter 2.5.2, the normal

procedure for initiating user input is to press the function softkey first before entering

the data. However, it is also possible to key in the data first prior to selecting the

function the data is intended for.

.

1 5

This example shows how to enter the pre-tare weight using short-input mode.

While in standby mode, use the numeric keypad to enter the known tare weight in

the current weighing unit.

Then press the «PT» softkey or the «ÆTÅ» key to set this value as the pre-tare

weight.

The result is the same as in Chapter 2.5.2.

Short-input mode works with the following function softkeys:

«Smpl X» The value keyed in replaces the value of X (Chapter 5.5.1) and

performs a reference weight determination using the value as reference

number of pieces (Chapter 4.1.1). Default value for X is 10.

«Smpl n» The value keyed in will be used as the reference number of pieces for

the reference weight determination.

«APW» The value keyed in will be used as the average piece weight.

«ÆTÅ» The value keyed in will be used as the pre-tare weight.

«PT» The value keyed in will be used as the pre-tare weight.

«

» The value keyed in defines the number of printouts (only for label

printer).

«Æ0Å» The value keyed in defines the threshold for the Gross Weight Alarm.

BBA462 / BBK462 recognizes if the function softkey pressed is not compatible with

short-input mode and will display a warning indicating so.

Page 19

METTLER TOLEDO BBA462 / BBK462 Chapter 3: Enhanced functions

19

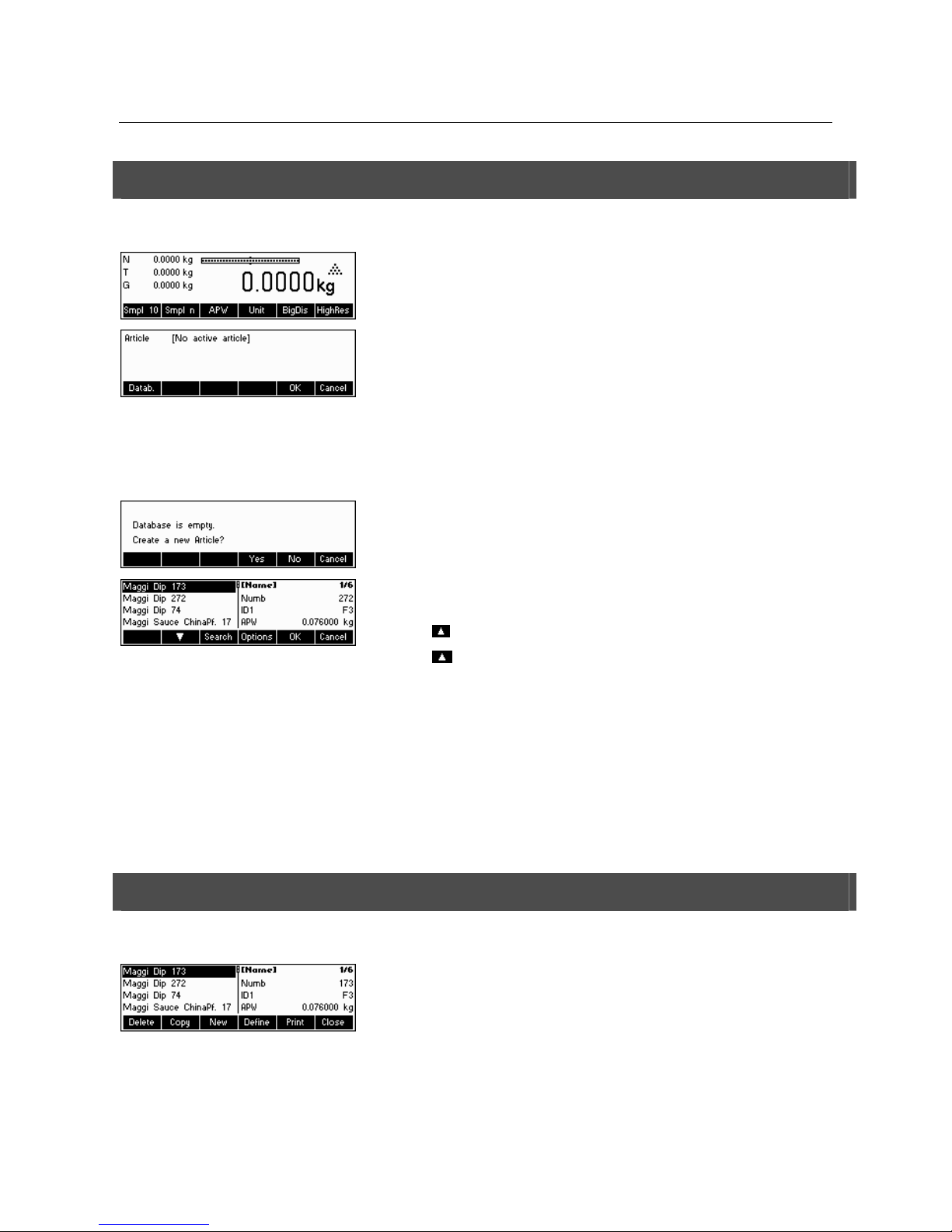

3.2 Database

The following describes the operations for working with the article database.

Briefly press the «

» key.

If in the "Vision Setup->APPLICATION->Database" the ID overview is set "On", you

will enter a submenu into the database in which you can define additional

information/identification. (Please view chapter 5.5.2 for the use of the IDs).

To enter the article database menu, press the «Datab.» softkey.

Note: If 'Vision Setup Æ APPLICATION Æ Database Æ ID Overview' is not active,

this screen will be skipped and you will be brought directly to the article database

menu.

The first time the article database is accessed, the database will be empty and

BBA462 / BBK462 will prompt you to create a new article.

If articles have been previously defined, you will be presented with several options for

working with the article database:

Press the «

» key to select the previous article in the list.

Press the «

» key to select the next article in the list.

Press the «Search» key to find an article in the list.

Press the «Options» key to perform other operations on the currently selected article

(Chapter 3.2.1).

Press the «OK» key to make the currently selected article the active one for use with

the various BBA462 / BBK462 applications and leave the article database menu.

Press the «Cancel» key to leave the article database menu. The article that was

active before entering the article database menu will be retained except if that article

was deleted. Other changes made to the database with the «Options» key will not be

undone.

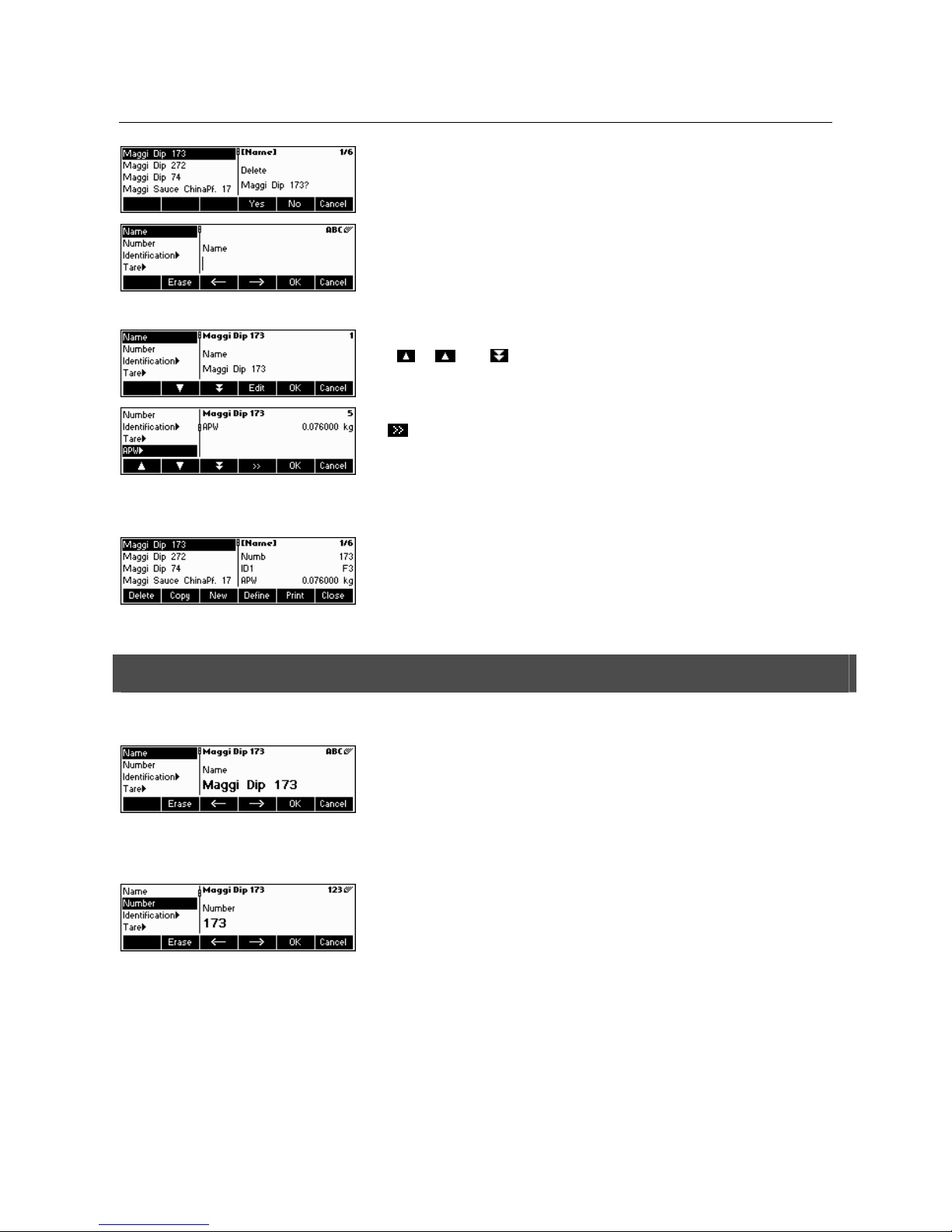

3.2.1 Database editing functions

The following describes various operations that could be performed on articles.

With the desired article selected in the article list, press the «Options» key. You can

then choose an operation to be done on the article.

Note: If a password was defined in 'Vision Setup Æ APPLICATION Æ Database Æ

Article Æ Password' (Chapter 5.5.2) then you will be asked to enter the password

before you can modify the selected article.

Page 20

Chapter 3: Enhanced functions METTLER TOLEDO BBA462 / BBK462

20

Press «Delete» to remove the current article from the database. You will be asked to

confirm deletion of an article.

Press «Copy» to create a duplicate of the selected article. All the parameters of the

current article, except the name and number, will be copied into the newly created

article.

Press «New» to create a blank article.

Press «Define» to modify the selected article. Select the desired parameter by using

the «

», « », or « » softkeys, then press «Edit» to modify the selected

parameter.

A «

» softkey in place of the «Edit» softkey indicates that there is a submenu for

the selected item.

Press «Print» to print out the parameters of the selected article.

Press «Close» to leave the article editing menu and return to the article selection

menu.

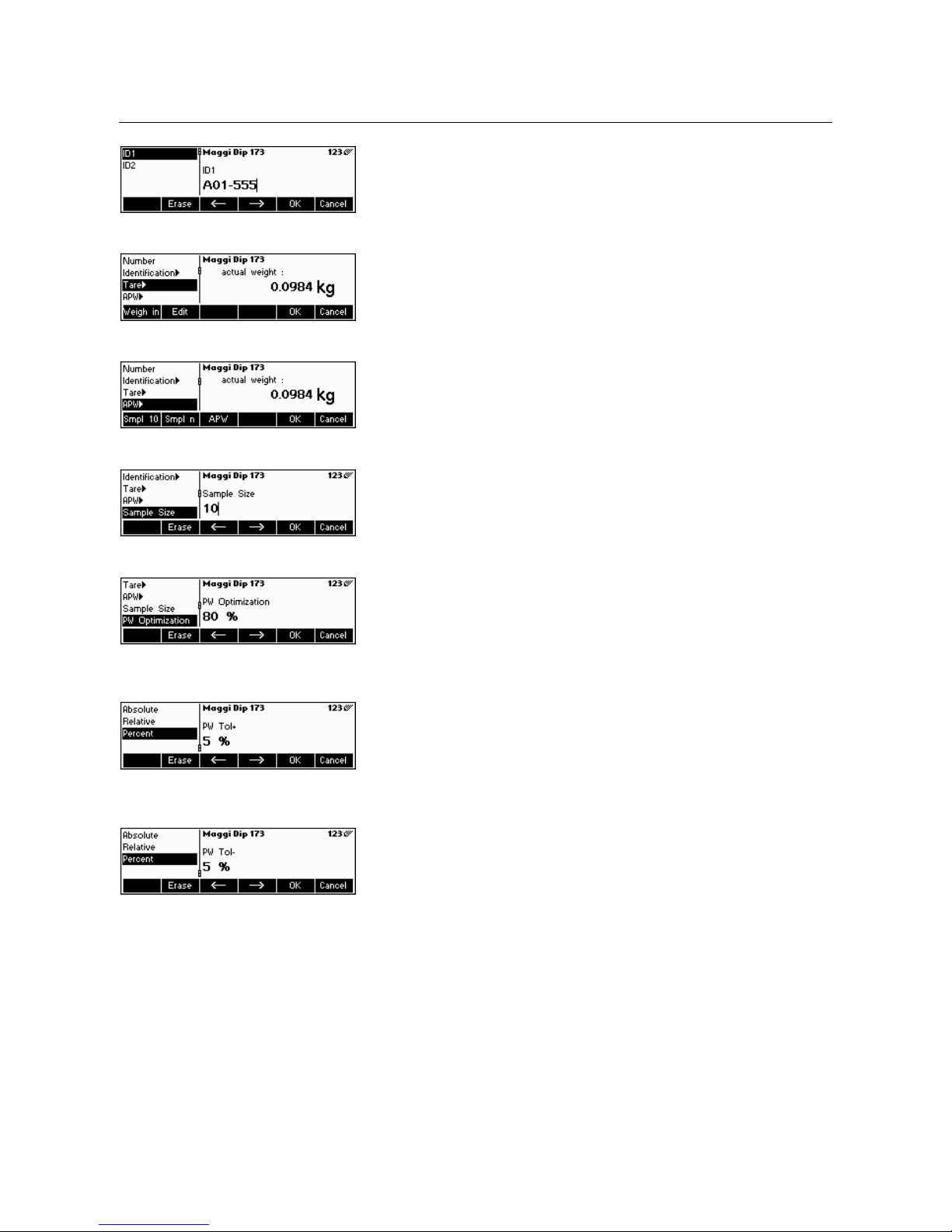

3.2.2 Defining an article

The following describes the parameters of a BBA462 / BBK462 article.

Name

The name of the article can contain up to a maximum of 24 alphanumeric

characters. If 'Vision Setup Æ APPLICATION Æ Database Æ Article Æ Search

criterion' is set to “By name”, this parameter is used for searching in the article

database.

Number

The number of the article can contain up to a maximum of 24 alphanumeric

characters. If 'Vision Setup Æ APPLICATION Æ Database Æ Article Æ Search

criterion' is set to “By number”, this parameter is used for searching in the article

database.

Page 21

METTLER TOLEDO BBA462 / BBK462 Chapter 3: Enhanced functions

21

Identification / ID1 and ID2

Additional identification parameters for the article that can contain up to a maximum

of 24 alphanumeric characters. These parameters could be used to provide

additional information about the article in the report printouts.

Tare

Pre-defined tare weight for the article. The pre-defined tare weight can both be

weighed-in or entered manually. Enter the weight value manually, in case the tare

weight is already known.

APW

Define the average piece weight of the article. It is possible to set the average piece

weight for the article by performing a reference weight determination (Chapter 4.1.1)

or by manually entering a known piece weight (Chapter 4.1.2).

Sample size

Define the reference number of pieces. This value will override the one set in 'Vision

Setup Æ APPLICATION Æ Counting ÆSample_X' (Chapter 5.5.1) while the article is

active.

PW optimization

The correction factor for optimizing the piece weight. The new value of the APW will

be adjusted by this factor in relation to the previous APW. Note: This works only if

PW Tol+ and PW Tol- are set and the APW is within the tolerances, and also if a

reference quantity (reference number of pieces) is defined.

See also below Example.

PW Tol+

The upper limit for a new average piece weight. If the new piece weight is above this

value, a warning will be displayed prompting the operator whether or not he wants to

accept the new piece weight. Note: APW must already be defined before setting the

PW Tol+, otherwise the PW Tol+ entry will be cleared.

PW Tol-

The lower limit for a new average piece weight. If the new piece weight is below this

value, a warning will be displayed prompting the operator whether or not he wants to

accept the new piece weight. Note: APW must already be defined before setting the

PW Tol+, otherwise the PW Tol+ entry will be cleared.

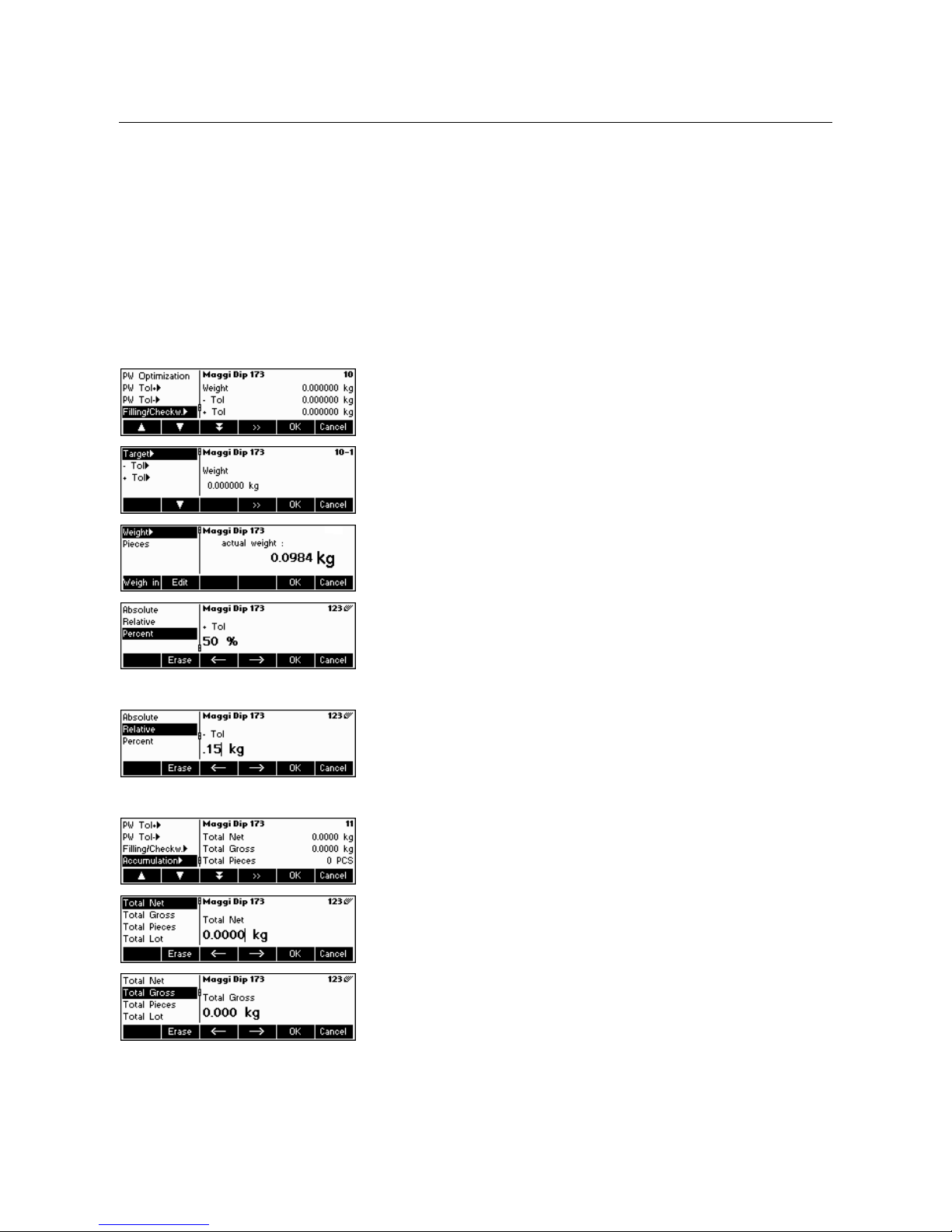

Page 22

Chapter 3: Enhanced functions METTLER TOLEDO BBA462 / BBK462

22

Example: In order to have the wearing down of the filling machine reflected, the

already existing value should be rated higher with 20% whereas the new piece

weight is rated with 80%.

To ensure that only 'good' pieces are used to build a new reference, they are only

allowed to derive max. 5% from the currently saved average piece weight.

Currently saved average piece weight = 0,1000kg

PW Optimization = 80%

PW Tol + = 5%

PW Tol - = 5%

New piece weight = 0,0970kg ( = within the tolerance +/- 5% of 0,1000kg)

=> new piece weight in the database = 0,0976kg (0,1000kg x 20% + 0,0970kg

x 80%)

Filling/checkweighing nominal

The nominal value used for the filling (Chapter 4.9) and checkweighing (Chapter

4.10) applications. It is possible to define the nominal value in pieces or as weight

value. This parameter must be filled in first before defining Tol+ and Tol-.

Note: If a target weight is defined this value will be used for the “accumulation to

target” function (see chapter 4.8).

Filling/checkweighing Tol+

The upper limit for filling (Chapter 4.9) and checkweighing (Chapter 4.10)

applications. It is possible to define this parameter as an absolute value, relative to

the Nominal, or as a percentage of Filling / Nominal.

Filling/checkweighing Tol-

The lower limit for the filling (Chapter 4.9) and checkweighing (Chapter 4.10)

applications. It is possible to define this parameter as an absolute value, relative to

the nominal, or as a percentage of nominal.

Accumulation

- Accumulation total net

The total net weight for the Accumulation application (Chapter 4.7)

- Accumulation total gross

The total gross weight for the Accumulation application (Chapter 4.7)

Page 23

METTLER TOLEDO BBA462 / BBK462 Chapter 3: Enhanced functions

23

- Accumulation total pcs.

The total number of pieces for the Accumulation application (Chapter 4.7)

- Accumulation total lot

The total number of lots for the Accumulation application (Chapter 4.7)

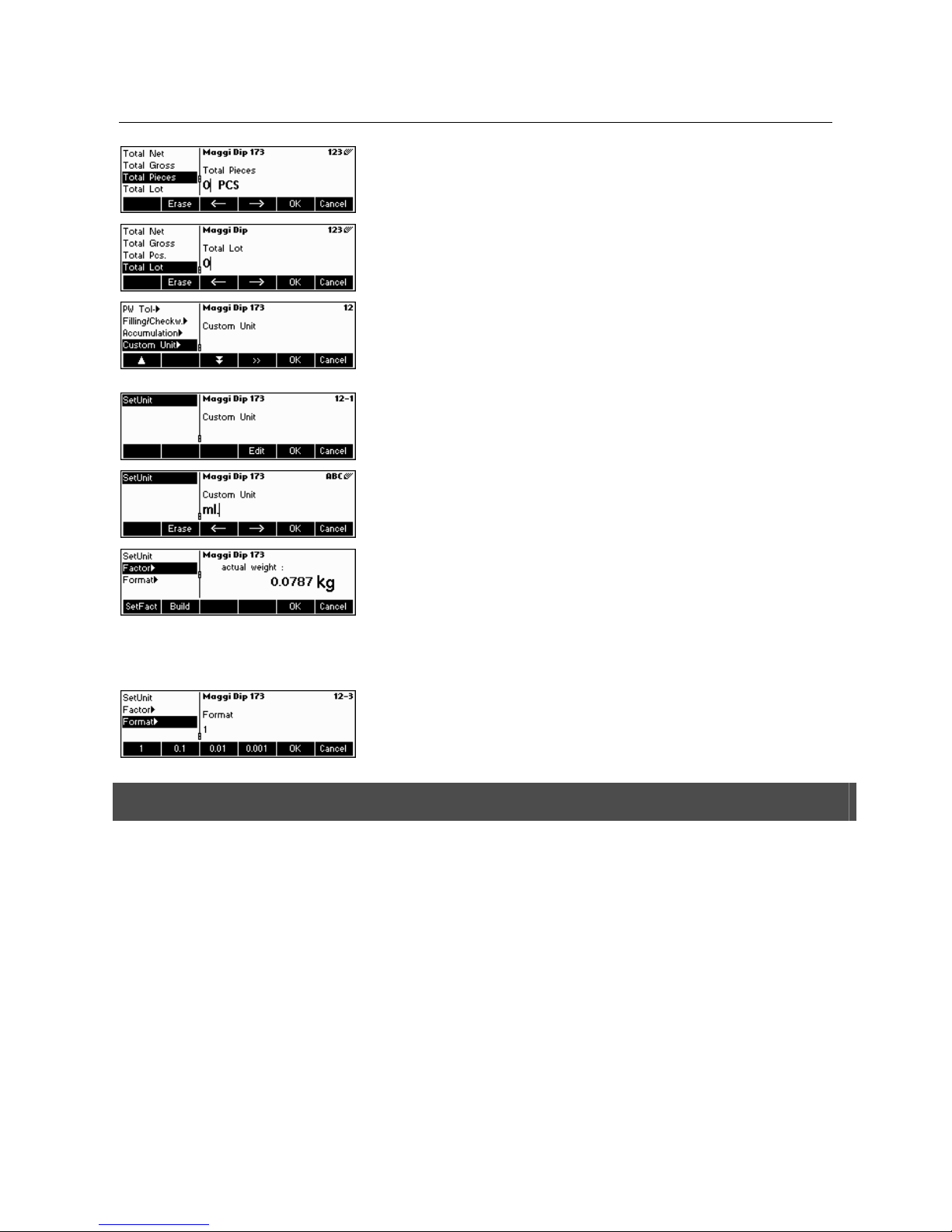

Custom Unit

This application enables the user to define any unit (mass) for each article. (See also

Chapter 4.11).

Unit

Short-cut for the custom unit. This name can contain a maximum of seven

characters.

Factor

Factor of the custom unit. This can be determined or manually keyed in, in case it is

already known. This menu appears only if "Unit" is chosen.

Note

If a piece weight was entered for an article, the number of pieces is used for recalling

and defining the free unit.

Format

The type of format in which "Custom Unit" should be displayed.

3.2.3 Erasing of individual article attributes

In order to ease working with the data base, BBA462 / BBK462 provides a possibility for erasing of individual article attributes.

Please proceed like this:

Choose the attribute to be erased (e.g. Free Unit).

Press the 'C'-key now to erase it.

Note: Erasing of the article name is only possible if the search criterion is 'By number' (see chapter 5.3.2). Similar, article

number can only be erased if the search criterion is 'By name'

Page 24

Chapter 3: Enhanced functions METTLER TOLEDO BBA462 / BBK462

24

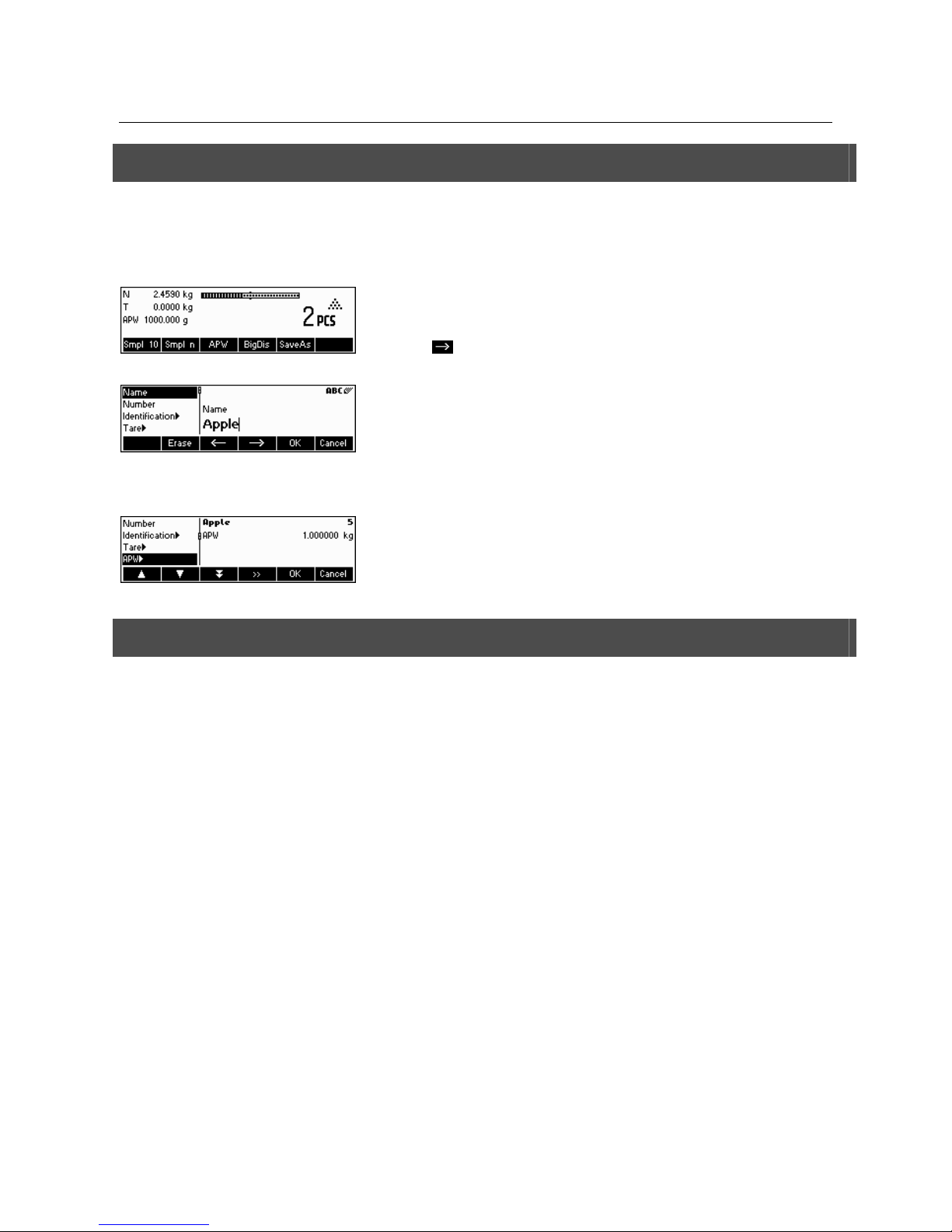

3.2.4 Save As Article function

In the course of working with BBA462 / BBK462, you may wish to save the current state into an article. The Save As Article

function makes this possible.

Define a softkey for "Save As Article" in the softkey configuration (See Chapter 5.5.7). A new softkey «SaveAs» will be created.

In this example, a reference weight determination has already been performed

(Chapters 4.1.1 and 4.1.2).

Press the «

» softkey, if necessary, to scroll to the next set of softkeys unitl the

«SaveAs» key is visible. Press the «SaveAs» softkey…

…BBA462 / BBK462 asks for the Name you wish to use for this article.

Note: If 'Vision Setup Æ APPLICATION Æ Database Æ Article Æ Search criterion' is

set to "By number", BBA462 / BBK462 will ask you for the Number. Please note that

Article Name cannot be used also as a Number.

From this point on, the procedure is the same as defining a normal article (Chapter

3.2.2).

Note however, that the parameter APW is already defined and its value is set to the

APW that was active before «SaveAs» was pressed.

Aside from the APW, the article parameters that will also be saved are Tare, Sample

Size, the Filling/Checkweighing parameters, and the Accumulation parameters.

3.3 Gross Weight Alarm

Using the Short-input mode (see chapter 3.1) it is possible to define a Gross Weight Alarm. In case it is defined, there will be an

uninterrupted alarm beep as soon as the gross weight reaches the defined threshold. The beep sound will stop as soon as the

weight is either below the threshold or any key is pressed.

Note: After switching off the alarm using a key press, it will only become active again if the gross weight felt under the threshold

for a while before reaching it again. The Gross Weight Alarm can be deactivated by the 'C' key or by setting the threshold

parameter to 0.

Page 25

METTLER TOLEDO BBA462 / BBK462 Chapter 3: Enhanced functions

25

3.4 SmartManager

To make working with the article database even easier, as well as to save the settings of the scale and its configuration, the

BBA462 / BBK462 comes with its own (optional) computer program (SmartManager). SmartManager requires MS Windows XP

or 2000. This program offers you the possibility to administer and manage your article data and also gives you the ability to

import and export files using MS Excel. For Configuration and operation please read the operator manual of the SmartManager

software.

BBA462 / BBK462 is able to get direct and immediate access to archived database using SmartManager. BBA462 / BBK462

functions in this case, as "Client". Hence it directly gets hold of data on an external database. In this mode, its own internal

Database will not be used and will stay unchanged. Please make the necessary settings of "Access" on "External" in Vision Setup

Æ APPLICATION Æ Database.

This functionality is also possible to connect a scale that has access to its own database, with several scales. If the internal

database of BBA462 / BBK462 is being used, SmartManager can create a backup copy of the database and this will be played

back again on the scale.

3.5 FlashLoader

The BBA462 / BBK462 software is stored in flash memory and the FlashLoader program enables you to upgrade the software of

your scale when updates are available.

Note: This should only be operated by authorized personnel. You should always make a back-up copy of your data prior to

performing this procedure.

To be able to update your software using the FlashLoader, you will need the following:

• PC with Microsoft Windows ® operating system (version 2000, or XP)

• Computer-to-scale connection cable (RS232 cable, 9-pin sub-D plug m/f, order number 00410024)

• FlashLoader program

The FlashLoader program will guide you through the updating process.

Page 26

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

26

4 Application

Your scale has a number of powerful application functions that can be activated in the menu (see Chapter 5.5.1). This

chapter describes the some of the functions that have been activated at the factory.

4.1 Counting pieces into a container

Place empty container on the scale and tare with the «ÆTÅ»

key.

Note: If the automatic taring function is active (Chapter 5.4.3), you need not press

the «ÆTÅ»

key, because the scale registers the tare weight automatically as soon

as the container is placed on the weighing pan.

Before your scale can be used for counting parts, it must know the average piece

weight (the so-called reference). The reference is then used to do the counting. The

reference can be determined by placing a number of pieces on the scale. If the piece

weight is known, it can be manually entered and used as the reference.

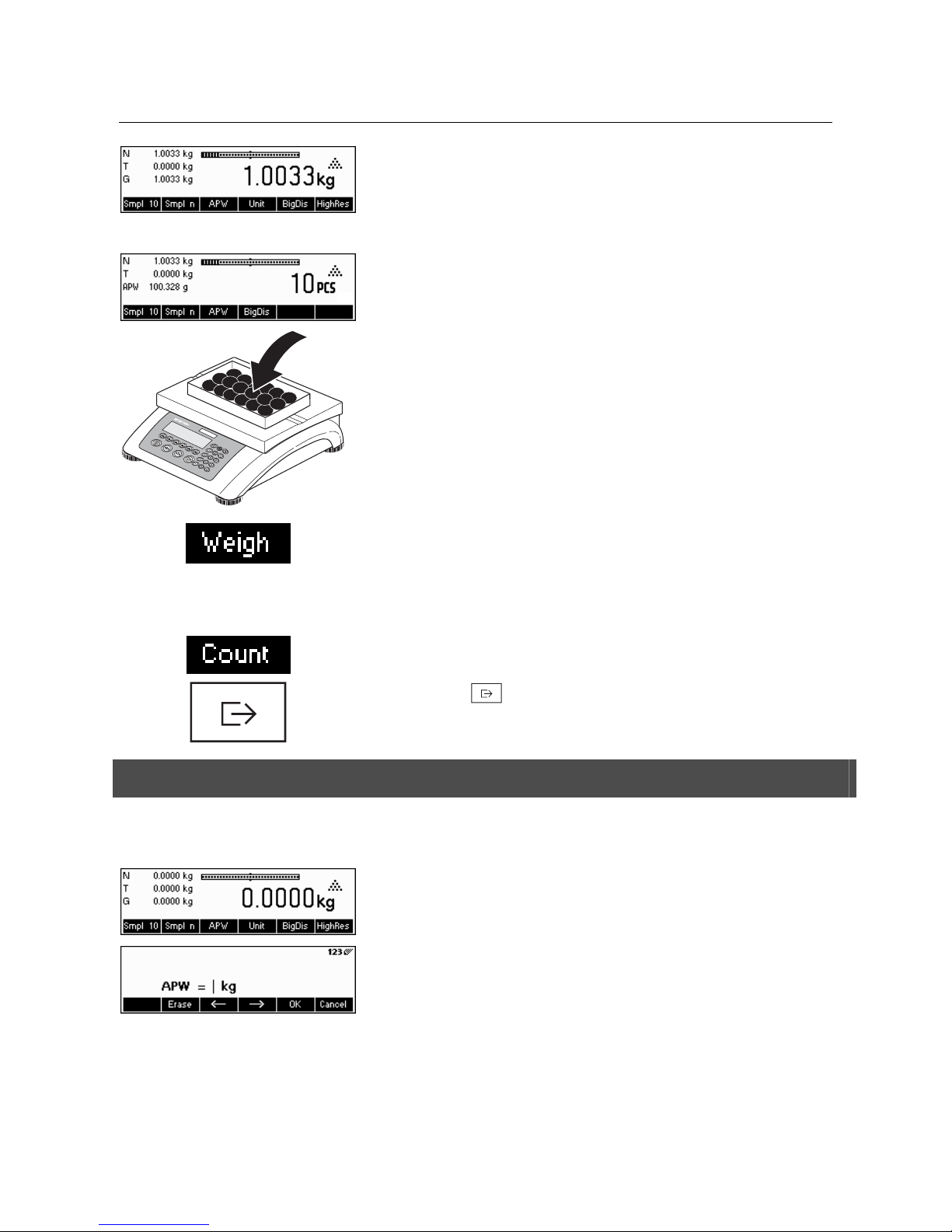

4.1.1 Determining the reference by placing pieces on the scale

The softkeys "Smpl X" and "Smpl n" are already given as standard function keys. In case they are not visible on the display,

define a softkey for "Smpl X" and "Smpl n" in the softkey configuration (See Chapter 5.5.7). After the softkeys have been defined,

do the following steps:

…appears on the screen (standard setting for Smpl X = 10)

Note: The standard value for "X" in Smpl X can be defined in Setup (see Chapter

5.5.1)

…place 10 pieces of materials to be weighed to determine the reference weight.

Page 27

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

27

Press the «Smpl 10» key.

Note: If a different number of pieces has been placed on the scale, please use the

Short Input Mode (see Chapter 3.1). The value that you have entered for "X" is still

saved, and will not change until after you overwrite it with a new value.

A reference weight has been established.

If a different number of pieces has been placed on the scale, press the «Smpl n»

key and choose from among the choices of 5, 20, 30, 40 or 50 pieces. If the

number of pieces is different, choose the «Var» key and enter the desired number of

pieces.

Note: The Short Input Mode is also available for the functions «Smpl X» and

«Smpl n» (see Chapter 3.1).

Once a reference has been determined, you can use the «Weigh» key to switch back

to the weight display at any time.

Note: This function is not given as a standard function key, because Gross, Tare and

Net will be continuously shown on the upper left of the display. To activate it,

proceed similar like activating « Smpl X» or « Smpl n» (see Chapter 5.5.7).

Press «Count» key to switch back again to counting mode.

You can use the « » key to transmit the piece counting result via the interface to

a peripheral device (printer, computer) (for sample report see Chapter 6.2).

4.1.2 Entering the reference when the piece weight is known

The softkey "APW" is already given as a standard function key. In case it is not visible on the display, define a softkey for "APW"

in the softkey configuration (See Chapter 5.5.7). After the APW softkey has been defined, do the following steps:

In standby mode, press the «APW»

key.

Enter piece weight, example: 0.02931 kg

Page 28

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

28

Press the «OK» key.

The scale has established a known reference weight and is now ready for piece

counting.

4.2 Counting out pieces out of a container

Counting out pieces from a weighing container differs in a few essentials from counting them in (Chapter 4.1).

4.2.1 Determine reference by removing pieces

…initially appears on the screen.

Place the full weighing container on the pan and tare the scale with the «ÆTÅ»

key.

… appears on the screen again.

Remove the reference number of pieces from the weighing container.

Remove further pieces until the desired number has been reached.

… a negative weight value appears on the screen.

Page 29

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

29

Press the «Smpl 10» or «Smpl n» keys to determine the reference, as described in

the previous chapter.

The scale is now ready for piece counting.

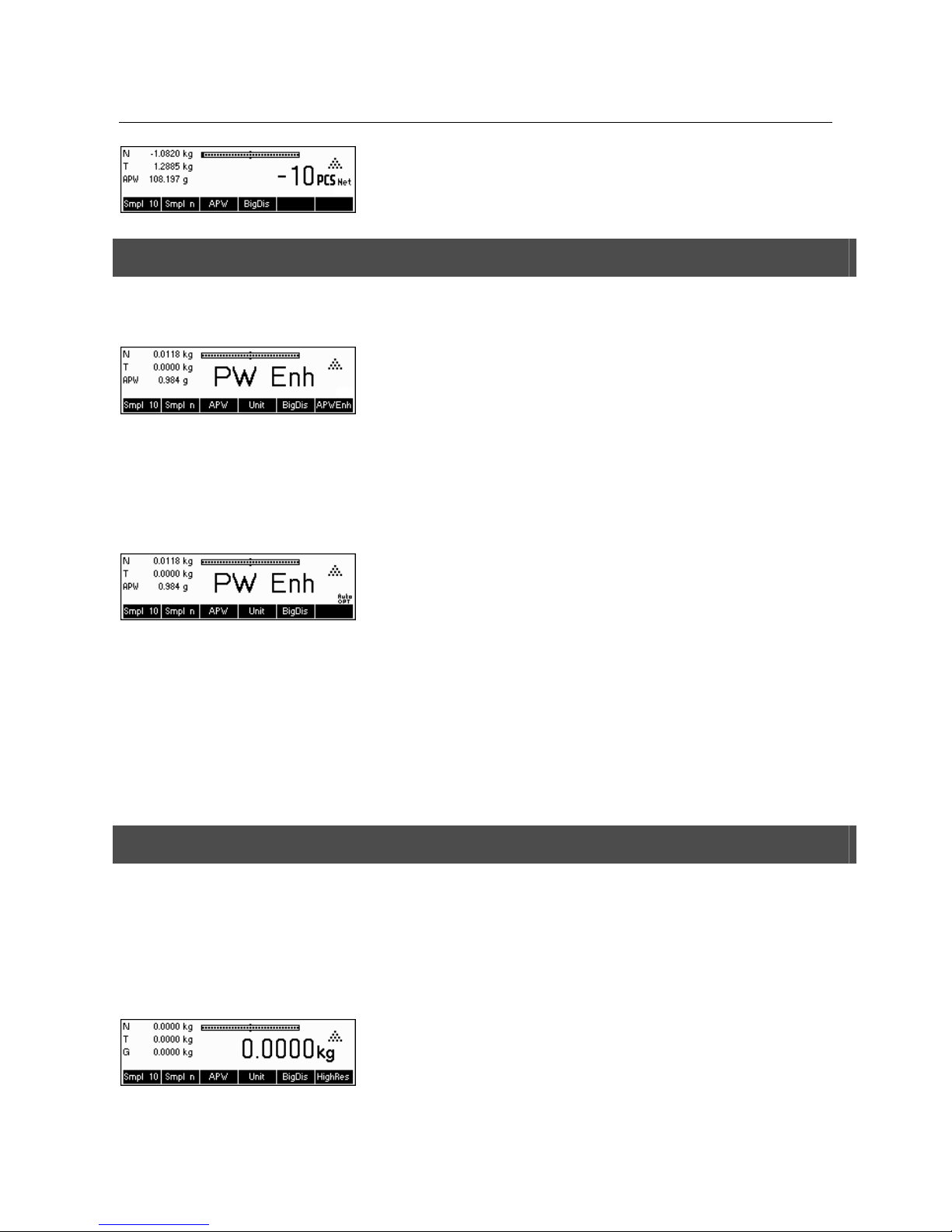

4.3 Reference optimization

Reference optimization serves to enhance the accuracy of the average piece weight by re-calculating it using a greater number of

reference pieces. Reference optimization can be performed either manually or automatically.

Manual Reference Optimization

Define a softkey for Reference Optimization in the softkey configuration (See Chapter

5.5.7). The Reference Optimization softkey is displayed as «PW Enh» and it will only

be active while in piece counting mode. If the scale is in weighing mode, this softkey

will not appear even if it is part of the softkey configuration.

To perform a reference optimization at any time, press the «PW Enh» softkey. The

average piece weight will be re-calculated using the current weight and the current

number of pieces on the scale. At each optimization, the message “PW Enh” appears

briefly and the new total number of pieces is then displayed.

Automatic Reference Optimization

No action is required during operation for automatic reference optimization and it

functions both in "Counting in" (Chapter 4.1) and "Counting out" (Chapter 4.2). The

“Auto OPT” symbol (located near the lower right corner of the screen) appears in the

display indicates that automatic reference optimization is switched on.

Each time you place additional parts on the scale, it optimizes automatically. You do

not have to press a key to perform optimization. At each optimization, the message

“PW Enh” appears briefly and the new total number of pieces is then displayed.

Note: Automatic optimization only functions if the number of additional pieces placed

on the scale is not greater than the number already on the weighing pan. If t the

differences between the parts are too big, the reference optimization will not be

executed.

4.4 Minimum sample weight

To ensure that a more accurate average piece weight is attained during reference weight determination, it is possible to set a

desired minimum percentage accuracy as determined by the reference weight placed on the scale. To enable minimum sample

weight checking, set 'Vision Setup Æ APPLICATION Æ Counting Æ Min. Sample WT' (See Chapter 5.5.1) to the desired

percentage accuracy.

To be able to view the percentage accuracy for a reference weight determination, set 'Vision Setup Æ APPLICATION Æ Counting

Æ Accuracy Disp.' (See Chapter 5.5.1) to 'On'.

In this example, the minimum reference weight was set to 99.5% and accuracy

display is active.

Page 30

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

30

10 samples were placed on the scale and «Smpl 10» was pressed.

BBA462 / BBK462 calculates the average piece weight as discussed in Chapter

4.1.1 but it has determined that the percentage accuracy for the reference weight is

below the value set as Minimum Sample Weight.

It will calculate the number of pieces that you have to place on the pan to reach the

desired percentage accuracy.

After placing the specified number of pieces on the scale, the average piece weight

will be optimized (Chapter 4.3) and, since accuracy display is active, the percentage

accuracy will be displayed for approximately 4 seconds.

Note that in this example, the percentage accuracy is at 99.54% which is above the

desired minimum sample weight of 99.5%.

BBA462 / BBK462 is now ready to perform piece counting using the optimized

average piece weight.

It is possible to override the minimum sample weight checking by pressing the «C»

key when you are prompted to add pieces on the scale. This will enable you to use

the calculated piece weight, but note that a "*" appears on the display to indicate that

the sample weight is below the desired percentage accuracy.

Adding mode works both with "Counting in" (Chapter 4.1) and with "Counting out"

(Chapter 4.2).

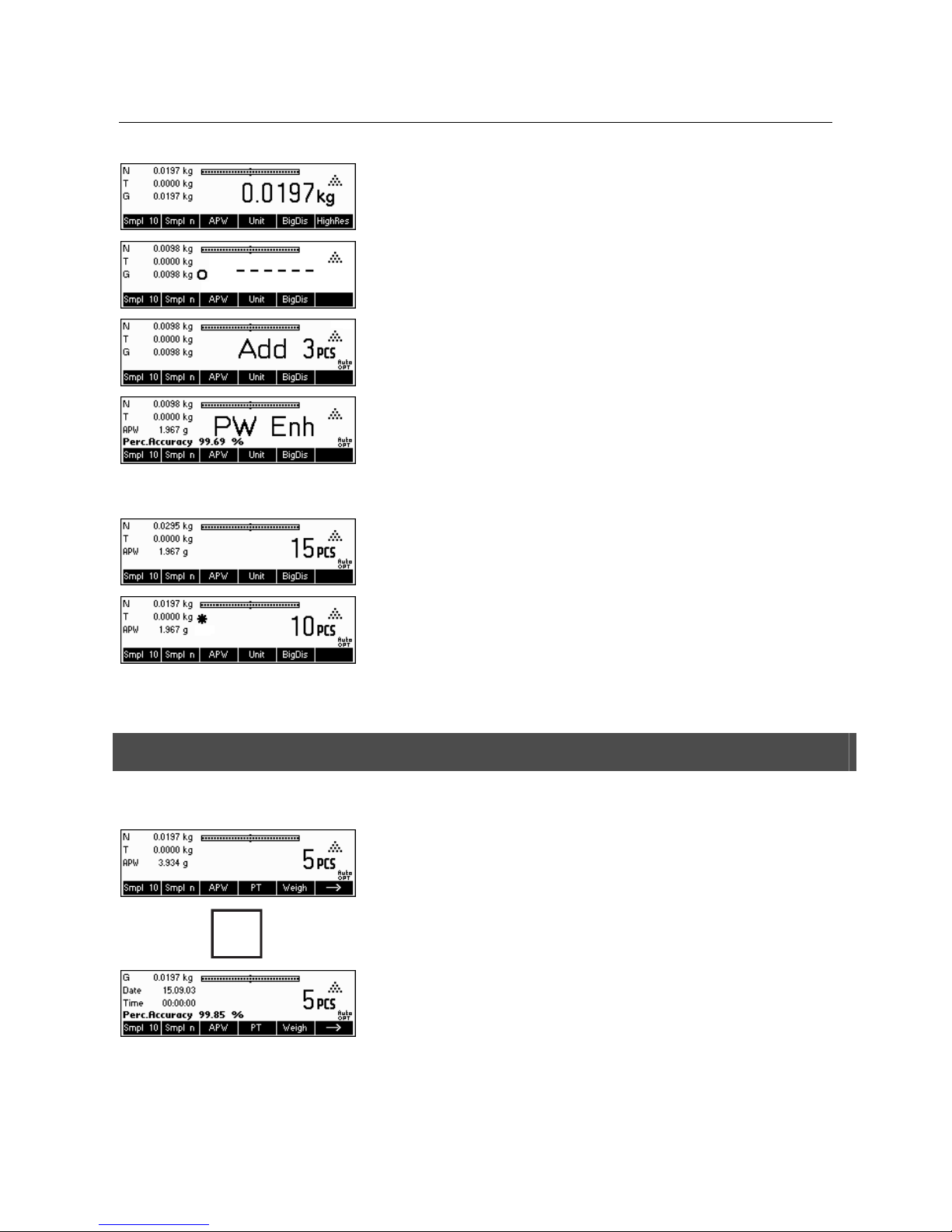

4.5 Using the info key

Use the «

i» key to call up additional information as defined in the Info/Help menu under Application (Chapter 5.5.8).

i

In this example, Info lines 1 to 4 were configured to show the gross weight, date,

time, and percentage accuracy respectively.

Pressing the «

i» key will toggle between a screen that shows the default content of

the Info lines and another window that shows the additional information configured

such as the Gross Weight, Date, Time and Percentage Accuracy.

For a list of the additional information that can be displayed on the Info lines, please

refer to Chapter 5.5.8.

Page 31

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

31

4.6 Piece counting with 2-scale systems

You can hook up your BBA462 / BBK462 scale to a second scale, e.g. a floor scale for counting a large number of pieces that

would exceed the capacity of the BBA462 / BBK462.

Select "Communications" Æ "Com1/Com2/Com3" Æ "Mode" in the Vision Setup

menu or “Communications” Æ “Option” Æ “Analog” if an optional analog second

scale interface is installed.

Setting 1/1 Second scale auxiliary scale, first scale active

(Ref: 1, Bulk: 1)

Setting 1/2 First scale reference scale, second scale bulk scale

(Ref: 1, Bulk: 2)

Setting 2/1 Second scale reference scale, first scale bulk scale

(Ref: 2, Bulk: 1)

Setting 2/2 First scale auxiliary scale, second scale active

(Ref: 2, Bulk: 2)

In settings 1/1 and 2/2 the display automatically switches to the scale selected (for

1/1 to the intern scale, for 2/2 to the external scale).

Press and hold

key for switching from reference scale to bulk scale and for

entering the modes.

There are three modes that can be assigned to the second scale:

Reference The second scale is to be used for reference weight determination only.

The APW will be calculated using the weight placed on the second scale

regardless of the active scale. This is used if the second scale has a finer

resolution than the BBA462 / BBK462 scale to achieve a more precise

piece weight.

Bulk The second scale is to be used as bulk weight only. The APW will be

calculated using the weight placed on the first scale (BBA462 / BBK462

scale), regardless of the active scale, then the weight on the second scale

will be used for counting. This is used if the sample to be weighed is

heavier than the maximum load of the BBA462 / BBK462 scale.

Auxiliary The second scale can be used as either reference or bulk scale. The

reference can be determined and also counted on both scales. The active

scale will not be automatically switched after the reference weight

determination.

Note: The interface of the second scale must be set as follows:

- For BBA/BBK4.. scales:

"Mode": "Dialog" (9600 bd, 8b no parity, Xon/Xoff)

- For PB-S scales:

"Mode": "Host" (9600 bd, 8b no parity, Xon/Xoff)

- For other METTLER TOLEDO products:

MT-SICS-compatible interface (9600 bd, 8b no parity, Xon/Xoff)

Page 32

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

32

Note: You can specify in Vision Setup "APPLICATION Æ Counting Æ Total

Pieces", whether…

• only the counting result of the bulk scale

• or the counting result of the bulk scale and that of the reference

scale (both scales together) will be displayed.

When an interface is set to one of the three modes above, the scale switch key will

be added to the softkeys. In case it is not visible on the display, define this softkey in

the softkey configuration (See Chapter 5.5.7).You can toggle between the two scales

with the «

» softkey.

To determine reference weight while in Reference or Bulk modes, the scale will

automatically switch from reference scale to bulk scale. You can override this

automatic switching by keeping the «

» softkey pressed for 1 second. Info line 4

will indicate which scale will be used for reference weight determination.

The scale symbol on the top right in the display indicates the active scale: "

1" =

BBA462 / BBK462 scale, "

2" = second scale.

When the second scale is active, you can zero and tare it with the BBA462 /

BBK462 «Æ0Å»

and «ÆTÅ» keys, respectively.

4.7 Accumulation

If the scale is in piece counting mode, you can do several piece counts and then determine the total number of pieces weighed

and their total weight. If the scale is in weighing mode, several weighings can also be accumulated to determine their total.

There are several report printouts that are available in the Accumulation application. To select the desired settings and to connect

and configure a printer, see Chapter5.9.2 and Chapter 5.9.3 respectively.

Define a softkey for Accumulation in the softkey configuration (See Chapter 5.5.7). After an Accumulation softkey has been

defined, do the following steps:

If a weighing container is used, it must be tared.

Determine the reference (see Chapter 4.1)

Press the «

» softkey to go to the next menu.

Press the «Accum» softkey to start the accumulation function.

Page 33

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

33

Press the «+» softkey to add the current number of pieces to the total, or the «-»

softkey to deduct the current number of pieces from the total.

The quantity of the first lot has been saved in the memory. If Lot printing is active

(Chapter5.5.4) the lot number, net weight and number of pieces will be printed out

automatically.

Place the desired quantity of the second lot and press the «+» softkey to add again

or the «-» softkey to deduct.

Press the «n» softkey to limit the number of lots to accumulate.

If Max n is defined, it will only be possible to accumulate as many lots as the value

set. Once the number of lots accumulated reaches the value of Max n, a warning will

be displayed indicating that maximum items have been reached.

Press the «Delete» softkey to clear all the lots from the memory. A summary report

with the total number of lots, total weight, and total number of pieces will be printed

out.

Press the «Undo» key to discard the last lot added.

To close the Accumulation application at any time, press the «Cancel» key. This will

return the scale to standby mode but the lots accumulated will be retained in

memory.

To close the Accumulation application and clear all the lots from memory, press the

«C» key. This will also generate a summary report.

Note: If an article was active when the Accumulation application was started, the

Accumulation parameters (Chapter 3.2.2) of the article will be updated by the

transactions done with the application. That means the total net or gross weight, the

total pieces, and the number of lots will be added to the values already stored in the

database for the active article.

Page 34

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

34

4.8 Accumulation to target

The „accumulation to target“ function allows accumulation up to a predefined weight value. To enable this function, a

target value for an article has to be defined in the article database (comp. chapter 3.2.2). If the scale is setup to

“accumulate to target,” this value will be used as the target value.

I

Example: A truck has a max. loading capacity of 1000 kg. This maximum loading capacity must not be exceeded while

loading the truck.

Proceed as follows:

1. Define an article with a corresponding target weight

2. In the vision menu under Application -> Accumulation -> set Target Wt. to „ On“ (comp. chapter

3.2.2)

3. Define the softkey „Totalising” in the softkey-configuration (see chapter 5.5.7). In the scale display the

key «Total» is now shown.

If a container is used it has to be tared.

4. Load the desired article (in this case “the truck”) out of the article database and press the key «Total»

Now, the loading procedure can start.

The current weight and the available remaining capacity until reaching the

target weight are now displayed.

Pressing the Info key gives further information. In this case: article name:

“Truck 0012“, Number of accumulated lots „1“ and target weight „1000.00

kg“

If the target weight is exceeded while accumulating an additional lot, a

warning message will be displayed. Additional accumulations will no longer

be possible.

Page 35

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

35

4.9 Filling

The filling application simplifies weighing of small parts (e.g. liquid or powder) until a target amount or weight is reached. It

provides the user a visual indication of the amount currently on the scale in relation to the target amount. If activated in the Vision

Setup, the scale will also beep if the amount is already within the tolerance limits defined.

Define a softkey for Filling in the softkey configuration (See Chapter 5.5.7). After a Filling softkey has been defined, do the

following steps:

In standby mode, press the «

» softkey to scroll to the next menu.

Press the «Filling» softkey.

In this example, Target (target weight), + Tol (positive tolerance) and – Tol

(negative tolerance) have been defined. The first bar graph that appears is the coarse

range indicator. The fine range, as shown by the gray area in the bar graph, depends

on the tolerance limits set. As the tolerance limits are increased or decreased, the

size of the fine range will also be adjusted accordingly.

Place sample to be weighed on the scale.

As soon as the weighed amount reaches the start of the fine range, a second bar

graph appears that shows the fine range. For very small tolerance limits, there will be

a third-stage indicator that will appear to show the fine range.

In addition, it is possible to directly switch from Filling to Accumulation. Therefore,

simply press «Accum» and continue as described in Chapter 4.7 Accumulation.

Please refer to the Notes in Chapter 4.10 for additional information.

4.10 Checkweighing (+/-)

The checkweighing application simplifies verification of sample weights or amounts. It provides the user with visual indicators to

show whether or not weight of the sample is within tolerance limits of a specified target weight or amount.

Define a softkey for Checkweighing in the softkey configuration (See Chapter 5.5.7). After a checkweighing (+/-) softkey has been

defined, do the following steps:

In standby mode, press the «

» softkey to scroll to the next menu.

Page 36

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

36

Press the «+/-» softkey.

In this example, Target (target weight), + Tol (positive tolerance) and – Tol

(negative tolerance) have been defined.

Place sample to be weighed on the scale.

The indicators help the user easily verify the weight if the sample is within the targets

defined.

In addition, it is possible to directly switch from Checkweighing to Accumulation.

Therefore, simply press «Accum» and continue as described in Chapter 4.7

Accumulation.

Notes:

The Filling and CheckWeighing applications use the filling parameters stored in the article database (Chapter 3.2.2) if they are

defined and if they are in the same mode (weighing or piece counting). For example, if Filling/Checkweighing Nominal is

defined as weight and the scale is currently in weighing mode, it will not be possible to define Target, Tol+, and Tol- while the

Filling or Checkweighing applications are active. The values for these parameters will be taken from those defined in the

current article. If however, Filling/Nominal is defined as weight and the scale is in counting mode, the Filling parameters of the

article will not be used and the Target, Tol+ and Tol- parameters of the Filling or Checkweighing applications will have to be

defined inside the application.

Clearing the currently selected article by pressing the «C» softkey while in standby mode will not clear the values defined for

Target, Tol+, and Tol-. To clear these parameters, the «C» has to be pressed while inside the Filling or Checkweighing

applications.

4.11 Custom Unit

The Custom Unit weighing function allows weighing using a unit that can be customized (a unit specified by the customer). You

may choose to use this function through a function key or Database menu.

Define a softkey for Custom Unit in the softkey configuration (See Chapter 5.5.7). After a Custom Unit softkey has been defined,

do the following steps:

In standby mode, press the «

» softkey to scroll to the next menu.

To start the application press the «CU» softkey.

From the main Custom Unit screen you can define the text for the custom unit, set the

factor to use for weighing, recall previous definitions, or save the current definition.

Note: The «Esc» softkey is available only if a "Custom Unit" is defined in the

database.

Page 37

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

37

Press the «SetUnit» softkey and enter the abbreviation of the custom unit. Confirm by

pressing «OK».

The factor can either be entered manually or can be calculated from the weight of

samples placed on the scale.

Press the «Factor» softkey. To manually enter the factor, press the «SetFact» softkey.

To calculate the factor using the weight of samples placed on the scale, press the

«Build» softkey.

Define the factor manually, by pressing the «SetFact» softkey.

Note

If a piece weight was entered for an article, the number of pieces is used for recalling

and defining the free unit.

To use the automatically calculated factor, place the sample on the scale, press the

«Build» softkey and enter the reference mass.

To change the resolution of the display, press the «Format» softkey and select the

desired format.

You can save the factor and unit you have just defined by pressing the «Save»

softkey. While in this screen, you can delete other Factor/Unit definitions you have

already saved or save your current definition.

To save the current definition, press «Save» and enter the name you wish to give this

definition. You can save up to 25 Factor/Unit definitions.

To recall previous Factor/Unit definitions, press the «Recall» softkey and select the

name of the Factor/Unit definition you wish to use.

Note: the customer unit can also be determined individually in the database for each

single article.

4.12 High resolution / Average weighing

The "High resolution" function displays the net weight at a higher resolution.

This function allows weighing of unstable goods (e.g. animals) with a higher precision. It takes around 20 seconds to calculate

the average weight of the load. This function also works in piece counting mode.

Define a softkey for "High resolution" in the softkey configuration (See Chapter 5.5.7). This softkey is already defined as a

standard softkey. After this softkey has been defined, do the following steps:

Page 38

Chapter 4: Application METTLER TOLEDO BBA462 / BBK462

38

Press the «HighRes» softkey in order to display the net weight at a higher resolution.

Note: When using strain gauge scales, the highest possible resolution will be

shown. For MonoBloc scales the resolution will become 10 times higher.

Place the load on the scale and press the «Average» softkey. BBA462 / BBK462 will

then take weight readings for 10 seconds and average these weight values.

The "Average" function can also be placed as a function key outside the "High

resolution".

After some more seconds, BBA462 / BBK462 will display the average weight of the

load.

While in this mode, the weight displayed is frozen and small variations in the actual

weight due to the unstable load will not be reflected on the display.

If the load changes more than 10% then the weight display will be released and

Average weighing is no longer active.

You can leave this function by pressing the «Esc» softkey.

Note: Certified scales will automatically leave the "High resolution" function after 3

seconds.

4.13 Alibi memory

The alibi memory is an optional fitting, depending on the individual specification of the BBA462 / BBK462.

The alibi memory serves to store weighing data of the past, in order to have them accessible at a later time in case of necessity.

As soon as a 'stable value' is generated by the scale, it will be stored in the alibi memory. Such stable values can be generated

by either pressing the

key, after responding to certain SICS commands (S, SU, SR, SRU, P101, P102, PRN etc.), the 'Toledo

Continuous' command P or the Auto Print mode.

Define the "Alibi memory" softkey in "Vision Setup Æ APPLICATION Æ Function keys", as discussed in Chapter 5.5.7. This

softkey is already defined as a standard softkey.

To be able to save in the alibi memory, "Vision Setup Æ APPLICATION Æ Alibi memory Æ On/Off" should be turned "On".

In standby mode, press the «

» softkey to scroll to the next menu.

In order to go to the Alibi memory application, press the «Alibi» softkey.

The entries that have been previously saved will be shown. Press the «*» softkey to

directly go to the last (newest) entry. This is marked by an asterisk as well.

Page 39

METTLER TOLEDO BBA462 / BBK462 Chapter 4: Application

39

Press the «Search» softkey in order to reach the search mask of the alibi memory.

With this function, you can define search criteria that will serve as a basis for

searching entries. Press the «Change» softkey and select the desired search criteria.

There are two steps to follow when entering search criteria: First the "From Border"

should be entered and then afterwards the "To Border". The search criteria "Scale"

and "Auxiliary Field" does not give out any information regarding "From/To".

Press the «Details» softkey in order to reach the detail mask. It represents the alibi

data of the chosen entries located on the side of the screen. This can be printed out.