Page 1

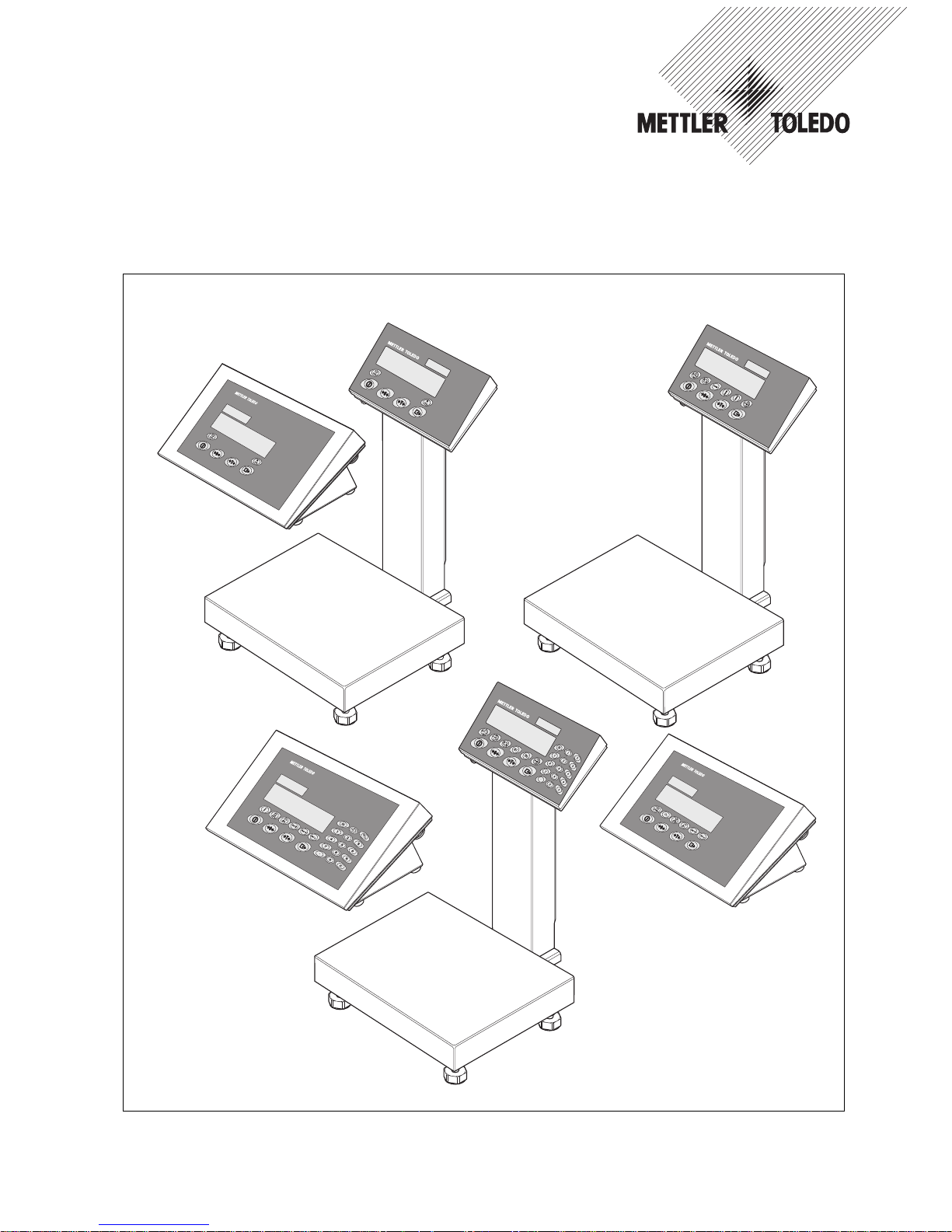

Installation information

METTLER TOLEDO

Weighing terminals IND4x9

Compact scales BBA4x9

www.mt.com/support

IND 429

IND 439

IND 449

Page 2

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper

use according to this Installation information and regular calibration and maintenance by our factory-trained service team ensure dependable and accurate operation, protecting your investment. Contact us about a ServiceXXL agreement tailored to

your needs and budget.

We invite you to register your product at www.mt.com/productregistration so we can

contact you about enhancements, updates and important notifications concerning

your product.

Page 3

Installation information 22013821A 04/06 3

Contents

IND4x9 / BBA4x9

Contents Page

1 General information..................................................................... 4

2 Safety instructions....................................................................... 5

2.1 Safety instructions for explosion protected weighing terminals

IND4x9xx .................................................................................... 5

2.2 Safety instructions for non-explosion-protected devices ..................... 7

3 Commissioning ........................................................................... 8

3.1 Connecting analog weighing platforms............................................ 8

3.2 Connecting IDNet weighing platforms.............................................. 10

3.3 Setting up the compact scale ......................................................... 11

3.4 Particular points when commissioning explosion protected

weighing terminals ....................................................................... 12

3.5 Connecting devices with a 12–24 V DC supply ................................ 12

4 Scale configuration...................................................................... 13

4.1 Calling up the service menu........................................................... 13

4.2 Overview ..................................................................................... 14

4.3 Service menu operation ................................................................. 14

4.4 Description of the service menu...................................................... 15

5 Commissioning and configuration of the interfaces........................ 20

5.1 Configuration and testing of the Ethernet interface ............................. 20

5.2 Installing the drivers for the USB interface......................................... 21

5.3 Configuration of the WLAN interface ................................................ 22

6 Structure of an analog weighing system........................................ 25

6.1 Selection of the weighing cell(s)..................................................... 25

6.2 Measurement range of the terminals................................................ 28

7 Technical data............................................................................. 29

7.1 General technical data................................................................... 29

7.2 Technical data of the analog scale interface ..................................... 30

7.3 Assignment of the interface connections .......................................... 31

Page 4

General information

4 Installation information 22013821A 04/06

IND4x9 / BBA4x9

1 General information

Documentation

The device is supplied with a CD containing the complete documentation on the

IND4x9 / BBA4x9 series.

These installation instructions provide information on installing and commissioning

the entire series.

IND4x9 / BBA4x9 weighing terminals and compact scales

Power supply variants

Normal version

Explosion protected

version

Weighing terminals

IND429

IND439

IND449

IND439check

IND449check+

IND429xx

IND439xx

IND449xx

IND439xx

check

IND449xx

check+

Compact scales

BBA429

BBA439check

BBA449check+

–

Normal version

Explosion protected

version

Built-in power supply

unit

Standard Standard

Built-in storage battery Optional Optional

External power supply

12–24 V DC

Optional Optional

Via external storage

battery

Optional (BBA4x9) –

Page 5

Safety instructions

Installation information 22013821A 04/06 5

IND4x9 / BBA4x9

2 Safety instructions

2.1 Safety instructions for explosion protected weighing terminals

IND4x9xx

The device fulfils Device category 3 and is approved for operation in Zone 2 (gases)

and Zone 22 (dusts) hazardous areas.

There is an increased risk of injury and damage when used in hazardous areas.

Special care must be taken when working in such hazardous areas. The code of

practice is oriented to the "Safe Distribution" concept drawn up by METTLER TOLEDO.

Competence ▲ The device, accompanying weighing platforms and accessories may only be

installed, maintained and repaired by authorised METTLER TOLEDO service

personnel.

▲ The mains connection may only be connected or disconnected by the owner’s

electrician.

Ex approval ▲ For the exact specification please refer to the statement of conformity.

▲ No modifications may be made to the terminal and no repair work may be

performed on the modules. Any weighing platform or system modules that are

used must comply with the specifications contained in the installation instructions.

Non-compliant equipment jeopardizes the safety of the system, cancels the Ex

approval and renders any warranty or product liability claims null and void.

▲ The cable glands must be tightened so that a strain relief of ≥ 20 N per mm cable

diameter is ensured.

▲ Ensure that the supply voltage at the installation site amounts to 230 V.

▲ When connecting external devices, always observe the maximum permissible

connected loads, see Page

29. It must be ensured that no voltages are fed into

the device than it itself provides. The interface parameters have to fulfil the

standard.

▲ Peripheral devices without an Ex approval may only be operating in non-

hazardous areas. It must be ensured that no voltages are fed into the device than

it itself provides. In addition the maximum permissible connected loads have to

be observed, see Page

29. The interface parameters have to fulfil the standard.

▲ The safety of a weighing system is only guaranteed when the weighing system is

operated, installed and maintained in accordance with the respective

instructions.

▲ Also comply with the following:

– the instructions for the system modules

– the regulations and standards in the respective country

– the statutory requirement for electrical equipment installed in hazardous areas

in the respective country

– all instructions related to safety issued by the owner

▲ Before initial start-up and following service work, check the explosion-protected

weighing system for the proper condition of all safety-related parts.

Page 6

Safety instructions

6 Installation information 22013821A 04/06

IND4x9 / BBA4x9

Installation and

retrofitting

▲ Only install or perform maintenance work on the weighing terminal,

accompanying weighing platforms and accessories in the hazardous zone if the

following conditions are fulfilled:

– the owner has issued a permit ("spark permit" or "fire permit"),

– the area has been rendered safe and the owner's safety co-ordinator has

confirmed that there is no danger,

– the necessary tools and any required protective clothing are provided (danger

of the build-up of static electricity).

▲ The certification papers (certificates, manufacturer’s declarations) must be

present.

▲ Connection values of externally connectable devices and cables of other

manufacturers must be known, e.g. capacitances, inductances and current

consumption.

▲ Lay cables in such a way that they are protected from damage.

▲ Only route cables into the housing of the system modules via the earthing cable

gland or METTLER TOLEDO plug and ensure proper seating of the seals. Ensure

that the cable shields are connected correctly and that they have a secure

connection to the housing.

▲ If the device is used in conjunction with an automatic or manual filling plant, all

of the system modules must be equipped with a permanently wired emergency

stop circuit, independent of the system circuit, in order to prevent personal injury

or damage to other items of equipment.

▲ Establish an equipotential bonding.

▲ If the weighing platforms are installed in a pit, test whether primary explosion

protection is required.

▲ Cover unused connection sockets with protective caps.

▲ Mount the labelling for operation in hazardous areas, see Section 3.4.3.

▲ After connectors have been mounted, screw on the securing clamps for external

connectors.

Operation ▲ Prevent the build-up of static electricity. Therefore:

– Always wear suitable working clothes when operating or performing service

work on the system.

– Do not rub or wipe off the keyboard surface with a dry cloth or glove.

▲ Do not use protective hoods.

▲ Prevent damage to the weighing terminal. Hairline cracks in the keyboard

membrane are also considered damage.

▲ If the weighing terminal, accompanying weighing platforms or accessories are

damaged:

– Switch off the weighing terminal

– Separate the weighing terminal from the mains in accordance with the

applicable regulations

– Secure the weighing terminal against accidental start-up

▲ Always charge the storage batteries in a safe zone.

Page 7

Safety instructions

Installation information 22013821A 04/06 7

IND4x9 / BBA4x9

2.2 Safety instructions for non-explosion-protected devices

▲ Do not use the device in a hazardous environment!

Special devices are available in our range of products for hazardous

environments.

▲ Ensure that the power socket outlet for the device is earthed and easily

accessible, so that it can be de-energized rapidly in emergencies.

▲ Ensure that the supply voltage at the installation site lies within in the range of

100 V to 240 V.

▲ The safety of the device cannot be ensured if it is not operated in accordance with

these operating instructions.

▲ Only authorised personnel may open the device.

▲ Check the power cable regularly for damage. If it is damaged, disconnect the

device immediately from the power supply.

▲ Ensure that there is a space of at least 3 cm at the rear in order to prevent the

power cable from being bent too strongly.

Page 8

Commissioning

8 Installation information 22013821A 04/06

IND4x9 / BBA4x9

3 Commissioning

3.1 Connecting analog weighing platforms

Any analog weighing platforms that fulfil the required specifications can be connected

to weighing terminals with an analog weighing interface, see Section

7.2.

Weighing platforms for hazardous areas require the corresponding approval.

3.1.1 Information on the weighing cells

Weighing cells with or without SENSE cables

➜ In the case of cells without SENSE cables short-circuit the connections +Ex

(Excitation) and +Se (Sense) or –Ex and –Se at the connector or at the

connection terminal.

3.1.2 Connection of weighing platforms with several weighing cells

Up to four weighing cells can be connected to a weighing terminal in parallel. A

junction box is usually used to connect several weighing cells.

The sum of the nominal capacities of the individual cells corresponds to the total

capacity of the weighing system. When entering the scale capacities in the menu

(Section

4.4.5), select values in such a way that the individual cells cannot be

overloaded.

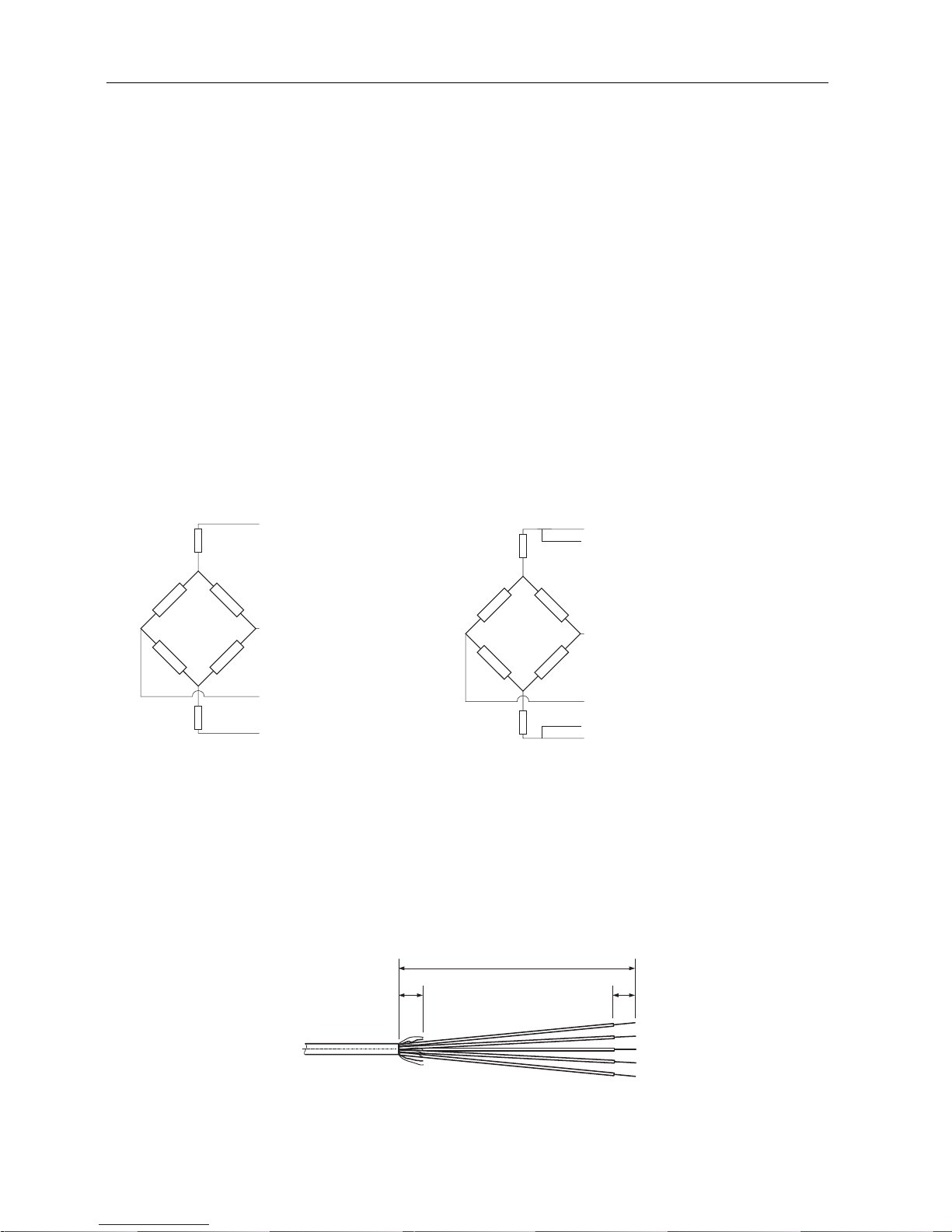

3.1.3 Preparation of the weighing platform connection cable

➜ Strip the cell cable in accordance with the figure.

+Si

+Se

+Ex

–Se

–Ex

–Si

+Si

+Se

+Ex

–Se

–Si

–Ex

Cells without SENSE cables

Cells with SENSE cables

required for certifiable weighing systems

15 mm

135 mm

5mm

Page 9

Commissioning

Installation information 22013821A 04/06 9

IND4x9 / BBA4x9

3.1.4 Connection of an analog weighing platform to the weighing terminal

The weighing terminals IND439 / IND439xx and IND449 / IND449xx can be

equipped with a second analog weighing interface.

The connection of a second weighing platform requires that a weighing platform

already be connected directly to the weighing terminal.

DANGER OF ELECTRIC SHOCK

➜ Disconnect the weighing terminal from the power supply before beginning

installation work.

Opening the weighing terminal and drawing in the weighing platform cable

1. In the case of explosion protected weighing terminals remove the plug protection

strip at the rear of the terminal.

2. Open the terminal. To do so, unscrew the hex bolts and lay the cover down.

When doing so, take care of the cable connections.

3. Remove the cable gland of the desired scale connection and the blind plugs from

the cable gland.

4. Slide the union nut (3) and moulded seal (2) over the cable sheathing. If any

braided screen cores loosen in the process, these may not contact any

conductive system parts.

5. Unbraid the exposed screen and place it evenly over the moulded seal (2).

6. Insert the moulded seal with the cable into the anti-twist guard of the metal

housing (1).

7. Screw the union nut onto the metal housing and tighten it.

Connecting the first analog weighing platform

1. Pull off the green 7-pin connector in the weighing terminal. The connector has a

tab that facilitates its removal and plugging.

2. Fasten the conductors of the connecting cable to the connector. The connector

assignment is shown in the adjacent figure.

The 7-pin connector has an additional connection in the middle for the signal

earth. The signal earth can optionally be applied to this connection or to the

screening and moulded seal (2).

When connecting METTLER TOLEDO weighing platforms observe the connection

scheme supplied with the weighing platform.

3. Plug the connector in the weighing terminal. Ensure that the connector sits

exactly centred on the socket. Otherwise not all the pins contact.

1

2

3

+Ex +Se +Si -Si-Se -Ex

Si = Signal

Ex = Excitation

Se = Sense

Page 10

Commissioning

10 Installation information 22013821A 04/06

IND4x9 / BBA4x9

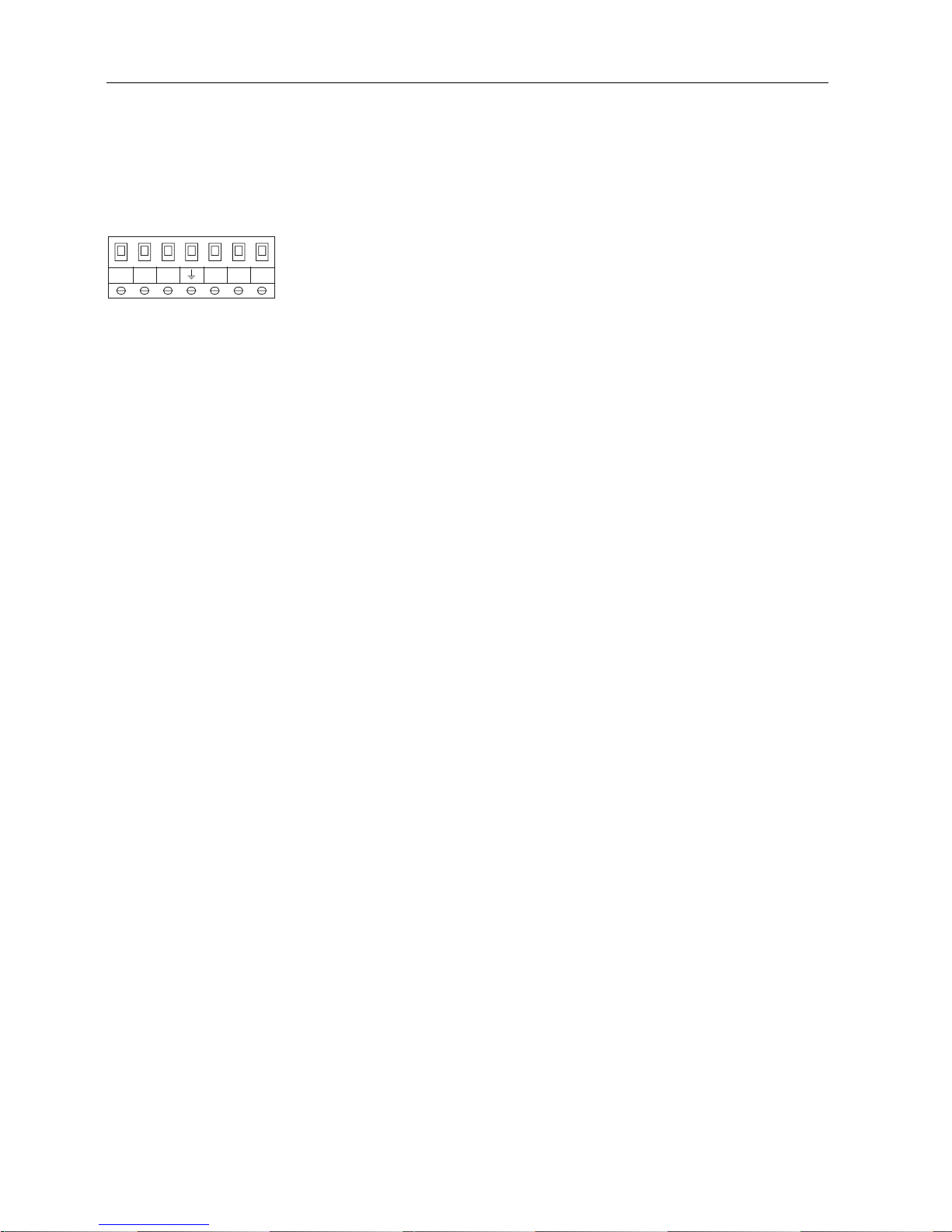

Connecting the second analog weighing platform

(only IND439 / IND439xx and IND449 / IND449xx)

➜ Connect the conductors of the connecting cable to the 7-pin terminal block on the

second analog PCB. The terminal assignment is shown in the adjacent figure.

The 7-pin terminal block has an additional connection in the middle for the

signal earth. The signal earth can optionally be applied to this connection or to

the screening.

When connecting METTLER TOLEDO weighing platforms observe the connection

scheme supplied with the weighing platform.

Note • In the factory setting the second scale is configured as a quantity scale (BULK).

REF (reference scale) or AUXILIARY (auxiliary scale) can be selected instead in the

COMMUNICATION –> OPTION –> MODE interface menu. The BYPASS setting can

be used to de-activate the weighing platform.

• Subsequently calibrate the second analog weighing platform (SCALE 2).

Closing the terminal

1. Position the cover and screw on the hex bolts. Ensure that no cables are pinched

and that the cover sealing ring is positioned correctly.

2. Tighten the union nut of the heavy-gauge screw joint(s).

3. In the case of explosion protected weighing terminals mount the plug protection

strip over the connections at the rear of the terminal.

3.2 Connecting IDNet weighing platforms

Alternatively to the analog scale connection the weighing terminals can also be

equipped with IDNet scale interfaces. At IND439/IND439xx and IND449/IND449xx a

second IDNet weighing platform can be connected optionally.

Information about two-scales systems

The scale with the higher address is defined by the weighing terminal as the second

scale, irrespective of the socket to which the scale is connected. When brand new

scales are commissioned, the weighing terminal automatically assigns an address.

If an IDNet scale already has an address, this can be reset in the scale service mode

(RES ALL). In the process the ID code is increased at certified scales.

–Ex –Se –Si +Si +Se +Ex

Page 11

Commissioning

Installation information 22013821A 04/06 11

IND4x9 / BBA4x9

Procedure

1. Set up the (first) weighing platform, refer to the installation instructions of the

weighing platform.

2. Lay the weighing platform cable to the weighing terminal.

3. Ensure that the weighing terminal is switched off.

4. In the case of explosion protected devices remove the plug protection strip at the

rear.

5. Plug the weighing platform connector into the weighing terminal and tighten the

screws.

6. Switch on the weighing platform. This weighing platform has the scale number 1.

7. If necessary, repeat Steps 1 to 6 for the second scale. Scale number 2 is

assigned to the second scale.

8. In the case of explosion protected devices mount the plug protection strip over the

connections at the rear.

Note In the factory setting the second scale is configured as a quantity scale (BULK). REF

(reference scale) or AUXILIARY (auxiliary scale) can be selected instead in the

COMMUNICATION –> OPTION –> MODE interface menu. The BYPASS setting can be

used to de-activate the weighing platform.

3.3 Setting up the compact scale

1. Set up the compact scale at the desired installation site.

2. Level the compact scale; refer to the PBA430 weighing platform operating

instructions.

Page 12

Commissioning

12 Installation information 22013821A 04/06

IND4x9 / BBA4x9

3.4 Particular points when commissioning explosion protected

weighing terminals

3.4.1 Equipotential bonding

The equipotential bonding must be installed by a professional electrician when using

the weighing platforms in hazardous areas.

➜ Connect equipotential bonding of all devices in accordance with the country-

specific regulations and standards. In the process, make sure that all device

housings are connected to the same potential via the PA terminals.

Weighing terminal

equipotential bonding

terminal

The equipotential bonding clamp of the weighing terminal is found on the COM1

socket.

3.4.2 Limited mobility

EXPLOSION HAZARD

The device may only be operated in Zone 2 and 22 hazardous areas.

Cabling

➜ Protect data and signal cable extensions against inadvertent disconnection.

➜ Secure the interface connections on the rear using the plug protection strip.

3.4.3 Labelling for operation in a hazardous area

The following signs must be mounted on the weighing terminal, accompanying

weighing platforms and accessories so that they are clearly visible:

• Model plate with the device’s model data, manufacturer and serial number

• Safety instructions

• Explosion protection identification

• If appropriate, temperature range

3.5 Connecting devices with a 12–24 V DC supply

Explosion protected IND429xx weighing terminals are supplied with a fixed-mounted

2.5 m long connecting cable with open ends.

Non-explosion-protected devices are equipped with a socket for connecting the power

supply. A connecting cable with open ends is included with the device.

Connected values 12 V DC – 24 V DC, max. 800 mA

Connection end Open ends

Colour code Brown – plus

White – minus

Page 13

Scale configuration

Installation information 22013821A 04/06 13

IND4x9 / BBA4x9

4 Scale configuration

4.1 Calling up the service menu

4.1.1 At non-certifiable analog scales and IDNet scales

1. Press and hold until COdE appears.

2. Enter the service password .

The SCALE menu item is displayed.

Note

Access to the service menu is secured by means of a software seal (ID code) at

IDNet scales. If changes are carried out at a scale that is set to certifiable, the ID code

is increased by 1 and stored in the scale. After configuration has been terminated, the

ID code at the connector of the scale has to be set to the same value as the stored

one. This setting has to be stored by certifiable means.

4.1.2 At certifiable analog scales

Due to metrological regulations direct access to the service menu (technician mode)

is blocked at certified or certifiable scales. The calibration seal is destroyed when the

device is opened. After the configuration has been completed, the device has to be

recalibrated by an authorised company and a new calibration seal attached before it

may be used again as a calibrated scale.

DANGER OF ELECTRIC SHOCK

The power supply unit under the power supply unit cover is energized.

➜ Do not carry out service work on the power supply unit and mains cable.

Procedure

1. Devices with power connection: Disconnect from the power supply. Devices with

storage battery: Switch off.

2. Open the housing cover.

3. Remove the cover and set it down or fix it. When doing so, take care of the cable

connections.

4. Devices with power connection: Connect to the power supply. Devices with

storage battery: Switch on.

5. Press the Pushbutton 1 on the PCB of the first scale interface. Use a suitable tool

to this purpose, for example, the blunt end of a pencil.

The device starts up and the first block of the SCALE servicemenu is displayed.

6. Replace the cover and carry out the service settings.

7. After the settings have been completed, disconnect the power plug again at

devices with a power connection.

8. Close the housing cover with the hex bolts. Ensure proper seating of the cover

sealing ring when doing so.

1

Page 14

Scale configuration

14 Installation information 22013821A 04/06

IND4x9 / BBA4x9

4.2 Overview

After the service menu has been called up, the entire menu is available, also the user

and supervisor menu. The following overview shows the SCALE menu block, the

remaining menu is described in the operating instructions.

Note

Only the menu blocks in bold are displayed at IDNet scales. At IDNet scales the

service mode of the scale is shown after SCALE (1/2) has been selected. The query

rEtUrN? appears. With

SNr is displayed as the next menu item.

4.3 Service menu operation

Operation in the service menu is the same as in the user and supervisor menu.

Numerical values, for example capacity, can be entered via the numerical keypad, if

present.

Numerical input at devices without number block

1. Press the key in order to activate the input.

The first number begins to flash.

2. Change the number using the and keys.

3. Confirm the modified number with the key.

The next number begins to flash.

4. Repeat Steps 2 and 3 until all the numbers have been entered.

Block Meaning Page

SCALE MEtrOLO Determining the admissibility for certification 15

SCALE 1 /

SCALE 2

Selection of the scale to be configured, is only displayed at two-scale

systems

15

rAMP Display of the excursion of the A/D converter (ramp) 15

SNr Query/Modification of the serial number 15

SCAL.bLd Input of the configuration data 16

GEO Setting of the Geo value 16

LIN-CAL Linearization with calibration 18

CAL Basic calibration 18

CONtrOL Activation of the control mode 18

ZErO Settings for the zero point 19

Min.WEiG Setting the minimum weighing-in quantity 19

T

T

Page 15

Scale configuration

Installation information 22013821A 04/06 15

IND4x9 / BBA4x9

4.4 Description of the service menu

4.4.1 Admissibility for certification

4.4.2 SCALE1/SCALE2 – Selecting a scale

This menu item appears only if a second scale or weighing platform is connected.

4.4.3 Querying the value of the A/D converter

4.4.4 Querying the serial number of the terminal or compact scale

MEtrOLO Setting the admissibility for certification

NO APPr Scale not certifiable

OIML Certify scale to OIML

ntEP Certify scale to NTEP, valid for the USA

Note If a scale is certified, various scale settings are no longer available or are only

available to a limited extent. Direct access to the menu for service personnel is,

furthermore, blocked subsequently.

rAMP

rMP 20 Display of the percentage deflection of the analog/digital converter (ramp)

Note This value can be used to determine whether the weighing cell operates correctly.

Scales with identical and a weighing cell that functions correctly have more or less

the same ramp values. The value is dynamic and changes when the load changes.

SNr

1234567 Display or modification of the serial number.

Note The serial number should not be changed except, for example, after a new main

printed circuit board has been installed.

Page 16

Scale configuration

16 Installation information 22013821A 04/06

IND4x9 / BBA4x9

4.4.5 Entering configuration data

4.4.6 Setting the Geo value

SCAL.bLd Input of the configuration data

SCAL.tYP Defining the scale type

SINGLE.r Single Range: Single-range scale

2MULt.IN Multi interval: Scale with rough range and 1 shiftable fine range.

Automatic switching between the ranges in both directions.

2MULt.rN Multi Range: Scale with rough range and 1 fixed fine range.

Automatic change to the rough range. Return to the fine range at

zero pass.

3MULt.IN Multi Interval: Scale with rough range and 2 shiftable fine ranges

3MULt.rN Multi Range: Scale with rough range and 2 fixed fine ranges.

bAS.UNIt Specify the basic unit for entering in the service menu

g Grams

kg Kilograms

oz Ounces

lb Pounds

t Tons

SCL.CAP Entry of the scale capacity in the selected basic unit

rESOL Selection of the resolution in the selected basic unit

The available resolutions depend on the capacity of the weighing system.

Note In case of multi-range or multi-interval scales the blocks SCL.CAP and rESOL

are available separately for each range.

They are displayed in the following sequence:

SCL.CAP 1, rESOL 1, SCL.CAP 2, rESOL 2, SCL.CAP 3, rESOL 3

GEO The Geo value is used to adapt the weighing system to the local gravity conditions.

0 ... 31 Setting range: 0 ... 31, see following table

Page 17

Scale configuration

Installation information 22013821A 04/06 17

IND4x9 / BBA4x9

Table of Geo values

Northern or southern latitude in degrees and minutes

Height above sea level in meters

0

325

325

650

650

975

975

1300

1300

1625

1625

1950

1950

2275

2275

2600

2600

2925

2925

3250

3250

3575

Height above sea level in feet

0

1060

1060

2130

2130

3200

3200

4260

4260

5330

5330

6400

6400

7460

7460

8530

8530

9600

9600

10660

10660

11730

0° 0’ – 5° 46’ 5 4 4 3 3 2 2 1 1 0 0

5° 46’ – 9° 52’ 5 5 4 4 3 3 2 2 1 1 0

9° 52’ – 12° 44’ 6 5 5 4 4 3 3 2 2 1 1

12° 44’ – 15° 6’ 6 6 5 5 4 4 3 3 2 2 1

15° 6’ – 17° 10’ 7 6 6 5 5 4 4 3 3 2 2

17° 10’ – 19° 2’ 7 7 6 6 5 5 4 4 3 3 2

19° 2’ – 20° 45’ 8 7 7 6 6 5 5 4 4 3 3

20° 45’ – 22° 22’ 8 8 7 7 6 6 5 5 4 4 3

22° 22’ – 23° 54’ 9 8 8 7 7 6 6 5 5 4 4

23° 54’ – 25° 21’ 9 9 8 8 7 7 6 6 5 5 4

25° 21’ – 26° 45’ 10 9 9 8 8 7 7 6 6 5 5

26° 45’ – 28° 6’ 10 10 9 9 8 8 7 7 6 6 5

28° 6’ – 29° 25’ 11 10 10 9 9 8 8 7 7 6 6

29° 25’ – 30° 41’ 11 11 10 10 9 9 8 8 7 7 6

30° 41’ – 31° 56’ 12 11 11 10 10 9 9 8 8 7 7

31° 56’ – 33° 9’ 12 12 11 11 10 10 9 9 8 8 7

33° 9’ – 34° 21’ 13 12 12 11 11 10 10 9 9 8 8

34° 21’ – 35° 31’ 13 13 12 12 11 11 10 10 9 9 8

35° 31’ – 36° 41’ 14 13 13 12 12 11 11 10 10 9 9

36° 41’ – 37° 50’ 14 14 13 13 12 12 11 11 10 10 9

37° 50’ – 38° 58’ 15 14 14 13 13 12 12 11 11 10 10

38° 58’ – 40° 5’ 15 15 14 14 13 13 12 12 11 11 10

40° 5’ – 41° 12’ 16 15 15 14 14 13 13 12 12 11 11

41° 12’ – 42° 19’ 16 16 15 15 14 14 13 13 12 12 11

42° 19’ – 43° 26’ 17 16 16 15 15 14 14 13 13 12 12

43° 26’ – 44° 32’ 17 17 16 16 15 15 14 14 13 13 12

44° 32’ – 45° 38’ 18 17 17 16 16 15 15 14 14 13 13

45° 38’ – 46° 45’ 18 18 17 17 16 16 15 15 14 14 13

46° 45’ – 47° 51’ 19 18 18 17 17 16 16 15 15 14 14

47° 51’ – 48° 58’ 19 19 18 18 17 17 16 16 15 15 14

48° 58’ – 50° 6’ 20 19 19 18 18 17 17 16 16 15 15

50° 6’ – 51° 13’ 20 20 19 19 18 18 17 17 16 16 15

51° 13’ – 52° 22’ 21 20 20 19 19 18 18 17 17 16 16

52° 22’ – 53° 31’ 21 21 20 20 19 19 18 18 17 17 16

53° 31’ – 54° 41’ 22 21 21 20 20 19 19 18 18 17 17

54° 41’ – 55° 52’ 22 22 21 21 20 20 19 19 18 18 17

55° 52’ – 57° 4’ 23 22 22 21 21 20 20 19 19 18 18

57° 4’ – 58° 17’ 23 23 22 22 21 21 20 20 19 19 18

58° 17’ – 59° 32’ 24 23 23 22 22 21 21 20 20 19 19

59° 32’ – 60° 49’ 24 24 23 23 22 22 21 21 20 20 19

60° 49’ – 62° 9’ 25 24 24 23 23 22 22 21 21 20 20

62° 9’ – 63° 30’ 25 25 24 24 23 23 22 22 21 21 20

63° 30’ – 64° 55’ 26 25 25 24 24 23 23 22 22 21 21

64° 55’ – 66° 24’ 26 26 25 25 24 24 23 23 22 22 21

66° 24’ – 67° 57’ 27 26 26 25 25 24 24 23 23 22 22

67° 57’ – 69° 35’ 27 27 26 26 25 25 24 24 23 23 22

69° 35’ – 71° 21’ 28 27 27 26 26 25 25 24 24 23 23

71° 21’ – 73° 16’ 28 28 27 27 26 26 25 25 24 24 23

73° 16’ – 75° 24’ 29 28 28 27 27 26 26 25 25 24 24

75° 24’ – 77° 52’ 29 29 28 28 27 27 26 26 25 25 24

77° 52’ – 80° 56’ 30 29 29 28 28 27 27 26 26 25 25

80° 56’ – 85° 45’ 30 30 29 29 28 28 27 27 26 26 25

85° 45’ – 90° 00’ 31 30 30 29 29 28 28 27 27 26 26

Page 18

Scale configuration

18 Installation information 22013821A 04/06

IND4x9 / BBA4x9

4.4.7 Linearization with simultaneous calibration

4.4.8 Basic calibration

4.4.9 Activating the control mode

LIN-CAL A basic calibration must have been carried out at least once for linearization with

simultaneous calibration.

➜ If available, apply the preload.

3 POINt /

5 POINt

• 3-point linearization (by default at 0 %, 50 % and 100 % of the full load)

• 5-point linearization (by default at 0 %, 25 %, 50 %, 75 % and 100 % of the

full load)

1. Confirm the type of linearization.

The display begins to flash, the scale determines the zero point automatically.

The scale next requests the first weight.

2. If appropriate, change the displayed weight value.

3. Place the displayed weight on the scale and confirm with .

4. Repeat Steps 2 and 3 for each additional sample.

After all the weights have been applied, donE is displayed.

Notes

• Determining the zero point can be skipped by pressing . In this case the

existing zero point is used as the reference.

• Linearization/calibration can be cancelled at any time with the key.

T

CAL Calibration can be carried out with preload in basic calibration.

PrELOAd

1. Load the desired preload and confirm with .

The scale next requests the calibration weight corresponding to the full load.

2. If appropriate, change the displayed weight value.

3. Place the displayed weight on the scale and confirm with .

After calibration has been carried out, donE is displayed.

Notes

• Determining the preload can be skipped with . In this case the existing zero

point is used as the reference.

• Calibration can be cancelled at any time with the key.

• In order to achieve particularly high precision carry out calibration under full

load.

T

CONtrOL In control mode the current weighing result is displayed with a high resolution and

without a weight unit. This allows the scale to be checked, for example after

calibration and/or linearization.

Page 19

Scale configuration

Installation information 22013821A 04/06 19

IND4x9 / BBA4x9

4.4.10 Settings for the zero point

4.4.11 Specifying the minimum weighing-in quantity

ZErO Settings for the zero point

Z-CAPt Specify the zero capturing range

-2 18 Zero capturing range –2 % to +18 %

–2 2 Zero capturing range –2 % to +2 %, mainly for certifiable scales

SEt.ZErO Move the calibration zero point. This is necessary if an auxiliary preload is used or

if the preload (for example roller conveyor) cannot be used for calibration or if they

lie outside the zero capturing range.

1. Apply the preload and confirm with .

The query SUrE is displayed.

2. Confirm moving of the zero point with or cancel with .

3. If underload or overload is displayed after the menu has been exited, switch the

device off and on again.

AZM Setting for the automatic zero compensation mode, refer to the operating

instructions.

Note The zero capturing range limits the nominal capacity of the scale. If the capacity of

a weighing cell is to be used to its complete extent, the zero capturing range can be

limited to –2 % to +2 %.

T

Min.WEiG Entry of the minimum weighing-in quantity in the selected basic unit.

When the minimum weighing-in quantity is activated, * is displayed if the weight on

the scale falls below the stored minimum weight.

Page 20

Commissioning and configuration of the interfaces

20 Installation information 22013821A 04/06

IND4x9 / BBA4x9

5 Commissioning and configuration of the interfaces

5.1 Configuration and testing of the Ethernet interface

5.1.1 Configuration of the Ethernet interface in the menu of IND4x9 / BBA4x9

The configuration of the Ethernet interface in the menu is described in the operating

instructions (COMMUNI –> OPTION –> ETHERNET).

Ask your network administrator for the correct settings for the IP address, subnet

mask and gateway.

5.1.2 Establishing a network connection between the Ethernet interface and the PC

If the PC is already connected via a switch/hub to the network, no further settings are

required for the network card in the PC.

In the case of a direct connection between the Ethernet interface and the PC via a

cross-patch cable the settings for the TCP/IP Internet protocol have to be observed.

1. Call up Start –> Control Panel –> Network Connection.

2. Select "Local Area Connection" and right-click it to select "Properties".

3. Select "Internet Protocol (TCP/IP)" and click "Properties".

4. Enter the IP address, subnet mask and gateway in accordance with the settings

in the menu.

5.1.3 Testing the Ethernet interface

The "Ping" command can be used to check whether a user exists in the network and

can also be addressed.

1. Open a DOS box (command prompt) at the PC (Start –> Run).

2. Enter the "Ping" command followed by the IP address at the weighing terminal or

compact scale.

With the default address the command is as follows: Ping 192.168.1.1

3. The answer is, for example, Bytes = 32, Time = 2 ms, TTL = 64.

If no response appears, repeat the command with correct entries.

5.1.4 Establishing a connection with HyperTerminal

1. Select the DIALOG setting for the Ethernet interface in the menu under COMMUNI

–> COM2 –> MODE.

2. Start HyperTerminal and create a new connection.

3. Select "TCP/IP (Winsock)", specify the IP address of the Ethernet interface

(factory setting: 192.168.1.1) enter the port number (factory setting: 8000).

4. Select the following settings under "File –> Properties –> Settings –> ASCII

Configuration":

– Transmitted characters end with line feed

– Output entered characters locally (local echo)

– Write lines that are too long in the terminal window

SICS commands can now be transmitted at the weighing terminal or compact scale.

Page 21

Commissioning and configuration of the interfaces

Installation information 22013821A 04/06 21

IND4x9 / BBA4x9

5.1.5 Configuration of the Ethernet interface via a Web browser

The Ethernet interface is equipped with a Web server through which the further

settings can be carried out.

1. Start a Web browser on the PC, for example Internet Explorer, and enter "http://

192.168.1.1" as the target address.

The starting page of the Ethernet Web server is displayed.

2. Use the "Client Server –> Help" menu item to call up further information on setting

the Ethernet interface.

5.2 Installing the drivers for the USB interface

For weighing terminals or compact scales with a USB interface a CD with the required

drivers is provided additionally. The drivers are installed in two steps.

The following section describes the installation for a PC with Windows XP.

5.2.1 Installing USB drivers

1. Connect the USB interface of the weighing terminal or compact scale to the PC

with a USB cable.

The message "New hardware found" is displayed at Windows XP.

2. Insert the supplied CD into the PC.

The wizard for searching for new hardware is displayed.

3. Select "Install software from a list or specific location (for advanced users)" in the

initial screen and click "Next".

4. In the next step select "Browse removable media (floppy disk, CD, etc.)" and

click "Next".

The required files are searched for and copied.

A warning is displayed since the drivers on the CD ROM have not been certified by

Microsoft WHQL. However, the drivers were tested extensively by METTLER TOLEDO

and are suitable for installation under Windows XP.

5. Click "Continue Anyway".

6. Click "Finish" in the next screen.

The installation is completed. The message "New hardware found" is displayed.

Subsequently The VCP driver still has to be installed subsequently.

5.2.2 Installing VCP drivers

The wizard for searching for new hardware is displayed again.

➜ Repeat Steps 3 to 6 as described under Section 5.2.1 for the VCP driver.

Page 22

Commissioning and configuration of the interfaces

22 Installation information 22013821A 04/06

IND4x9 / BBA4x9

5.2.3 Setting the Virtual COM Port (VCP)

The installation of the VCP driver makes an additional serial interface available on the

PC. This interface can be used to access weighing terminals or compact scales with

a USB interface.

1. Call up "Start –> Control Panel" and double-click "System".

2. Select the "Hardware" tab and click the "Device Manager".

3. Search for the entry "Ports (COM & LPT)" and click the adjacent "+" symbol.

All the available ports are displayed.

4. Double-click "METTLER TOLEDO Serial Port".

The "Properties of METTLER TOLEDO Serial Port" screen is displayed.

5. Select the "Port settings" tab and click "Advanced".

6. Select the desired COM port number from the drop-down menu list and confirm

with "OK".

5.2.4 Establishing a connection with HyperTerminal

1. Select the DIALOG setting for the USB interface in the menu under COMMUNI –>

COM2 –> MODE.

2. Start HyperTerminal and create a new connection.

3. Select the desired COM port number and carry out the following settings:

9600 bits/s, 8 data bits, no parity, protocol Xon/X0ff.

4. Select the following settings under "File –> Properties –> Settings –>

ASCII Configuration":

– Transmitted characters end with line feed

– Output entered characters locally (local echo)

– Write lines that are too long in the terminal window

SICS commands can now be transmitted at the weighing terminal or compact scale.

5.3 Configuration of the WLAN interface

The following section describes the installation for a PC with Windows XP. It is

assumed that the WLAN interface of the weighing terminal or compact scale is in the

state of delivery with the following network parameters:

IP address 192.168.0.1

Subnet 255.255.255.0

Gateway 0.0.0.0

5.3.1 Configuration of the WLAN interface in the menu of IND4x9 / BBA4x9

The configuration of the WLAN interface in the menu is described in the operating

instructions (COMMUNI –> OPTION –> WLAN).

Ask your network administrator for the correct settings for the IP address, subnet

mask and gateway in the encrypted company network.

Page 23

Commissioning and configuration of the interfaces

Installation information 22013821A 04/06 23

IND4x9 / BBA4x9

5.3.2 Establishing an ad-hoc connection to the WLAN network

1. Ensure that the weighing terminal or the compact scale with the WLAN interface

is switched off.

2. Call up the WLAN configuration program on the PC and carry out the following

settings.

– Set the SSID to "Connect".

– Select no encryption.

– Set the parameters for the ad-hoc connection: 2.4 GHz, 11 Mbps.

– Ensure that a free channel is used or that the channel is selected automatically.

– Ensure that no WLAN connection is active.

3. Ensure that no further network connections are active, for example LAN

connection via Ethernet cable.

4. Call up Start –> Control Panel –> Network Connection.

5. Select "Wireless Network Connection" and click "Internet Protocol (TCP/IP)".

6. Click "Properties" and carry out the following settings:

– Set the IP address 192.168.0.10.

A different IP address can also be selected in the subnet 192.168.0.x. The IP

address of the weighing terminal or compact scale with WLAN interface

(192.168.0.1) may not be selected.

– Subnet mask: 255.255.255.0.

– No gateway setting

7. Call up the WLAN configuration program on the PC and activate the WLAN

connection.

8. Switch on the weighing terminal or compact scale with WLAN interface.

The WLAN interface is equipped with a Web server through which the further settings

can be carried out.

5.3.3 Configuration via Web browser

1. When an active ad-hoc connection is displayed at the PC, start a Web browser

on the PC, for example the Internet Explorer.

2. Enter the target address "http://192.168.0.1".

The log-on page of the WLAN Web user interface is displayed.

3. Log on with the user name "admin" and the password "admin".

4. Carry out the network settings for the encrypted company network under

Configuration –> Network.

Page 24

Commissioning and configuration of the interfaces

24 Installation information 22013821A 04/06

IND4x9 / BBA4x9

5.3.4 Establishing a connection with HyperTerminal

1. Select the DIALOG setting for the WLAN interface in the menu under COMMUNI –>

COM2 –> MODE.

2. Start HyperTerminal and create a new connection.

3. Select "TCP/IP (Winsock)", specify the IP address of the WLAN interface (factory

setting: 192.168.0.1) and enter the port number (factory setting: 2101).

4. Select the following settings under "File –> Properties –> Settings –> ASCII

Configuration":

– Transmitted characters end with line feed

– Output entered characters locally (local echo)

– Write lines that are too long in the terminal window

SICS commands can now be transmitted at the weighing terminal or compact scale.

Page 25

Structure of an analog weighing system

Installation information 22013821A 04/06 25

IND4x9 / BBA4x9

6 Structure of an analog weighing system

6.1 Selection of the weighing cell(s)

The following data are required to determine the capacity of the weighing cell:

• Scale capacity – Usually corresponds to the heaviest weighing sample that is to

be weighed using the weighing system.

• Preload – Contains the total weight of all the parts that lie on the weighing cell.

These include the top section of the weighing platform, the weighing pan and all

the assemblies, such as a roller conveyor, weighing vessel etc.

• Total zero setting range – Consists of the desired activation zero capturing range

(+18/–2 % or +/–2 %) and the zero setting range available to the user through

the

key (2 %). The total zero-set range thus amounts to either 20 % or 4 %

of the scale capacity.

The addition of the scale capacity, preload and total zero setting range results in the

required capacity of the weighing cell. It is advisable to include an additional safety

margin in order to avoid overloading of the weighing cell.

.

In the case of systems with several weighing cells divide the determined total

capacity by the number of cells in order to determine the capacity of the individual

cell. A sufficiently large safety margin is particularly important if a strong load is to be

expected in the corner areas of the scale so that the load is no longer distributed

evenly amongst all the cells.

In the case of systems with a lever mechanism divide the determined total capacity

by the transmission ratio of the lever mechanism in order to determine the capacity of

the individual cell.

Take the following further parameters into consideration when selecting the weighing

cell(s):

• The smallest desired display step

• Requirements for admissibility for certification, if necessary

• Number and type of the weighing ranges

• The approval for hazardous areas in the case of explosion protected weighing

systems

Total capacity of the weighing cell(s) = Scale capacity + Preload + Total zero setting range + Safety margin

Page 26

Structure of an analog weighing system

26 Installation information 22013821A 04/06

IND4x9 / BBA4x9

The terminal provides a supply voltage of 8.2 V for the weighing cell(s). Depending

on the sensitivity of the weighing cell this results in the following maximum weighing

signal (product of supply voltage and sensitivity):

* Only 20 mV can be measured by the A/D converter. Therefore the max. weighing

capacity may not exceed 81 % of the cell capacity.

Sensitivity of the cell 2 mV/V 3 mV/V

Supply voltage 8.2 V 8.2 V

Max. weighing signal * 16.4 mV 24.6 mV *

Min. weighing signal per display step (for certifiable scales) 0.5 µV/e 0.5 µV/e

Page 27

Structure of an analog weighing system

Installation information 22013821A 04/06 27

IND4x9 / BBA4x9

How do I set up my

scale?

Scale parameters:

– heaviest weight?

– weight of pan holder?

– smallest display step?

– certified scale?

– 1 or 2 ranges/intervals?

Required cell capacity

E

min

=

Max + E

0

+

Max* E

N

100

N

Data of weighing cell

Example A:

OIML R60: C3

E

max

(=E): 10 kg

n

LC

(=n): 3000

V

min

:E

max

/7500

C

N

(=S): 2 mV/V

Data of weighing cell

Example B:

OIML R60: C3/30%

R.C. (=E): 10 kg

(–> n: 3000)

(–> V

min

:E

*

30%/ n

R.O. (=S): 2 mV/V

Data of weighing cell

Example C:

OIML R60: C3

E

max

(=E): 550 kg

n

LC

(=n): 3000

V

min

: 0.01%* C

n

Cn (=S): 1.94 mV/V

Check

(in case of several weighing

ranges check the finest one)

0.5 µV

e

=

U

min

e

U

e

* S*

Max* 1000

n* E* N

>=

Data of terminal

(acc. to certification)

U

e

:8.2V

U

min

: 0.5 µV/e

n

max

: 7500e

Entries in menu block

“SCALE”

Max – > SCL.CAP

E

N

–> 2 - CAPt

V

min

–> RESOL.

Key:

Max [kg]: weighing range

N: no. of weighing cells

E

0

[kg]: preload (weight of pan holder, container, etc.)

E

N

[%]: zero setting range (2%) + zero capturing

range

(+18/–2% or ±2%) = 20% or 4%

E

min

[kg]: required load capacity per weighing cell

U

e

[V]: power supply from terminal

S [mV/V]: cell output signal

n [e]: resolution

E [kg]: load capacity of selected weighing cell

U

min

[µV/e]: minimum voltage per verification interval

n

max

[e]: maximum resolution

V

min

[g]: display step

Application

– simple weighing IND429/IND429xx

– simple counting IND439x/IND439xx

– simple IND439check/

checkweighing IND439xx check

– convenient counting IND449/IND449xx

– convenient IND449check/

checkweighing IND449xx check

– 2 scale counting

system Analog option

Page 28

Structure of an analog weighing system

28 Installation information 22013821A 04/06

IND4x9 / BBA4x9

6.2 Measurement range of the terminals

When designing a weighing system observe the measurement range of the terminal

in accordance with the following overview.

a Total preload applied to the weighing cell during calibration (platform top

section, weighing pan, roller conveyor, etc.)

b Activation zero capturing range: +18/–2 % or +/–2 % of the weighing

capacity, can be selected in the menu

c Zero setting range with 0 key: +/–2 % of the scale capacity, cannot be

modified

d Safety margin

a b Scale capacity d

0% 100%

0% 100%

–4mV 0mV 16,4mV 20 mV

Total capacity of weighing cell(s)

Deflection of the A/D converter ("Ramp")

Weighing cell signal, range of A/D converter

c

Page 29

Technical data

Installation information 22013821A 04/06 29

IND4x9 / BBA4x9

7 Technical data

7.1 General technical data

Mains connection Direct connection to power supply (supply voltage fluctuation not exceeding ±10 %

of the rated voltage)

• Non-explosion-protected weighing terminals IND4x9:

Rated voltage 100 ... 240 V AC / 47 ... 63 Hz / 300 mA

• Explosion protected weighing terminals IND4x9xx:

Rated voltage 230 V AC ±10 % / 47 ... 63 Hz / 300 mA

• Compact scales BBA4x9:

Rated voltage 100 ... 240 V AC / 47 ... 63 Hz / 300 mA

Storage battery operation Supply at device: 24 V DC / 1.0 A

If the supply voltage is interrupted, the scale switches automatically over to storage

battery operation

For operating life refer to the operating instructions

Ignition protection type

IND4x9xx

(to IEC 60079-15)

• Hazardous area Zone 2:

Device category II 3G EEx nA II T4,

Temperature range

–10 °C ... +40 °C / 14 °F ... 104 °F

• Hazardous area Zone 22:

Device category II 3D IP66 T 70 °C

Ambient conditions • Application

•Height

• Temperature range Class III

• Temperature range Class II

• Overvoltage category

• Degree of soiling

• Relative humidity

In interiors

up to 2,000 m

–10 ... +40 °C / 14 ... 104 °F

0 ... +40 °C / 32 ... 104 °F

II

2

up to max. 80 %, non-condensing

Interfaces

• 1 RS232 interface integrated

• 1 further optional interface possible

Max. permissible connected

values

• The total of the connected values of COM1 and COM2 may not exceed 100 mA

• At an installed Ethernet option COM1 may not exceed 50 mA

Page 30

Technical data

30 Installation information 22013821A 04/06

IND4x9 / BBA4x9

7.2 Technical data of the analog scale interface

Calculation example for the differential signal

Data of the weighing cell: Sensitivity 2 mV/V, cell capacity 100 kg

Differential signal for nominal load (60 kg)

2 mV/V * 8.2 V * 60 kg/100 kg = 9.84 mV

Differential signal for half load (30 kg)

2 mV/V * 8.2 V * 30 kg/100 kg = 4.92 mV

Prerequisites for certifiable scales

• Certifiable weighing cell with SENSE cables (6 leads),

Sensitivity of the cells 2 mV/V or 3 mV/V

• Scale configured in the Service menu as certifiable

• Labelling in accordance with regulations by the plant engineer, if the complete

scale was not supplied by METTLER TOLEDO

Analog scale interface

Resolution 300,000 points for non-certifiable applications

7,500 points for certifiable applications

Weighing ranges Up to 3 weighing ranges can be defined in the menu, incl. shiftable or fixed fine

ranges.

In the case of certifiable/certified applications the minimum voltage per calibration

value (0.5 µV/e) has to be ensured or 7,500 e may not be exceeded.

Calibration Basic calibration and calibration during linearization

Zero setting range (key) 2 % of the defined max. useable load, cannot be modified

Autozero range 2 % of the defined max. useable load, cannot be modified

Activation zero-set

range

–2 % ... 18 % or –2 % ... 2 % referenced to the defined max. useable load

can be selected in the menu

Linearity 0.01 % of the defined max. useable load

Units g, kg, oz, lb, t

Numerical steps

n

1, 2, 5 x 10n, can be selected in the menu

Cell power supply 8.2 V

Requirements for the weighing cell

Nominal load 0.1 ... 999,999.9 (g, kg, lb, oz, t)

Permissible impedance ≥ 80 Ω

Differential signal –1 mV ... 25 mV (see the following calculation example)

Page 31

Technical data

Installation information 22013821A 04/06 31

IND4x9 / BBA4x9

7.3 Assignment of the interface connections

RS232

Socket 8-pin circular plug, socket

Pin 1

Pin 2

Pin 3

Pin 5

Pin 6

Shield

TXD, scale transmission line

RXD, scale reception line

+5 V

Factory setting: +5 V de-activated (OFF)

GND

External view

Note For max. connected values refer to Section 7.1

RS422/485

Socket 6-pin circular plug, socket

External view

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

RS422

GND

+5 V

Factory setting:

+5 V on (ON)

TXD+

TXD–

RXD–

RXD+

RS485

GND

+5 V

Factory setting:

+5 V on (ON)

TXD+/RXD+

TXD–/RXD–

–

–

Note For max. connected values refer to Section 7.1

Ethernet

Socket 16-pin circular plug, socket

Pin 1

Pin 2

Pin 4

Pin 12

TX+

TX–

RX–

RX+

External view

Note For max. connected values refer to Section 7.1

3

5

7

1

4

6

8

2

5

3

4

1

2

6

1

2

12

4

Page 32

Technical data

32 Installation information 22013821A 04/06

IND4x9 / BBA4x9

USB

Socket 16-pin circular plug, socket

External view

Pin 10

Pin 15

Pin 13

D–

D+

GND

Digital I/O

Socket 19-pin circular plug, socket

External view

Pin A, L

Pin B

Pin C

Pin D

Pin E

Pin M, U *

Pin N

Pin O

Pin P

Pin R

Not assigned or

+12 V, max. 400 mA

Output 1

Output 2

Output 3

Output 4

Floating GND or

terminal GND

Input 1

Input 2

Input 3

Input 4

Cable

00 504 458

Black

White

Brown

Green

Yellow

Purple

Grey/pink

Red/blue

White/green

Brown/green

Outputs Electrically isolated via relay contacts

Supply Limit values

External 500 mA (max. 30 V DC) per output

Internal 400 mA (at 12 V DC)

Total Output 1 ... 4

Inputs Electrically isolated via optocoupler

Supply Limit values

External 1 mA (min. 5 V DC)

8 mA (max. 30 V DC)

Internal 3 mA (at 12 V DC)

Jumper Factory setting (electrically isolated)

* Factory settings are indicated in bold print;

switching is carried out by using the jumpers on the PCB.

MU

K

L

J

T

N

C

B

A

H

D

SO

PR

G

E

F

Page 33

Technical data

Installation information 22013821A 04/06 33

IND4x9 / BBA4x9

WLAN

Data transfer WLAN IEEE 802.11b, to 11 Mbps

Frequency 2.4 GHz

Encryption WEP 64/128 bit; WPA 128 bit, PSK, 802.1x EAP

Transmission power Typ. 16 dBm

Page 34

*22013821A*

22013821A

Subject to technical changes © Mettler-Toledo (Albstadt) GmbH 04/06 Printed in Germany 22013821A

Mettler-Toledo (Albstadt) GmbH

D-72458 Albstadt

Tel. ++49-7431-14 0, Fax ++49-7431-14 232

Internet: http://www.mt.com

Loading...

Loading...