Page 1

User’s Guide

POWERCELL

ACT350

Transmitter

Page 2

Service

ACT350 POWERCELL Transmitter

Essential Services for Dependable Performance of Your ACT350 Transmitter

Congratulations on choosing the quality and precision of METTLER TOLEDO. Proper use of your new equipment

ensures dependable and accurate operation, protecting your investment. Contact us about a service agreement

tailored to your needs and budget. Further information is available at

There are important ways to ensure you maximize your investment’s performance.

1. Register your product: We invite you to register your product at www.mt.com/productregistration so we

can contact you about enhancements, updates and important notifications concerning your product.

2. Contact METTLER TOLEDO for service: The value of a measurement is proportional to its accuracy – an

out of specification scale can diminish quality, reduce profits and increase liability. Timely service from

METTLER TOLEDO will ensure accuracy and optimize uptime and equipment life.

www.mt.com/service.

a. Installation, Configuration, Integration and Training: Our service representatives are factory-trained,

weighing equipment experts. We make certain that your weighing equipment is ready for production

in a cost effective and timely fashion and that personnel are trained for success.

b. Initial Calibration Documentation: The installation environment and application requirements are

unique for every industrial scale so performance must be tested and certified. Our calibration services

and certificates document accuracy to ensure production quality and provide a quality system record

of performance.

c. Periodic Calibration Maintenance: A Calibration Service Agreement provides on-going confidence in

your weighing process and documentation of compliance with requirements. We offer a variety of

service plans that are scheduled to meet your needs and designed to fit your budget.

d. GWP

®

Verification: A risk-based approach for managing weighing equipment allows for control and

improvement of the entire measuring process, which ensures reproducible product quality and

minimizes process costs. GWP (Good Weighing Practice), the science-based standard for efficient

life-cycle management of weighing equipment, gives clear answers about how to specify, calibrate

and ensure accuracy of weighing equipment, independent of make or brand.

Page 3

Statements

METTLER TOLEDO. This documentation contains proprietary information of

© METTLER TOLEDO 2018

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose without the express written

permission of METTLER TOLEDO.

U.S. Government Restricted Rights: This documentation is furnished with Restricted Rights.

Copyright 2018

METTLER TOLEDO. It may not be copied in whole or in part without the express written consent of

METTLER TOLEDO.

COPYRIGHT

METTLER TOLEDO® is a registered trademark of Mettler-Toledo, LLC. All other brand or product names

are trademarks or registered trademarks of their respective companies.

METTLER TOLEDO RESERVES THE RIGHT TO MAKE REFINEMENTS

OR CHANGES WITHOUT NOTICE.

FCC Notice

This device complies with Part 15 of the FCC Rules and the Radio Interference Requirements of the

Canadian Department of Communications. Operation is subject to the following conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and radiates radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his or her expense.

• The majority of our products fall within categories 8 and 9. Those categories currently do not fall

within the scope of the Directive 2002/95/EG (RoHS) of January 27, 2003. If our products are

intended for use in other products which themselves fall within the scope of the RoHS Directive,

compliance requirements have to be separately negotiated contractually.

• Those products which fall within categories 1-7 and 10 will be in compliance with the EU RoHS

Directive from no later than July 1, 2006.

• If it is not possible for technical reasons to replace any non-RoHS-compliant substances in any of

the above products as required, we plan to inform our customers in a timely manner.

We do not make direct use of harmful materials such as asbestos, radioactive substances or arsenic

compounds. However, we purchase components from third party suppliers that may contain some of

these substances in very small quantities.

RoHS Compliance Statement

Statement regarding harmful substances

Page 4

Warnings and Cautions

SAFETY COMPONENT. WHEN USED AS A COMPONENT PART OF A SYSTEM, ANY SAFETY

CIRCUITS MUST BE INDEPENDENT OF THE ACT350 AND REMOVE POWER FROM THE ACT350

OUTPUTS IN THE EVENT OF AN EMERGENCY STOP OR EMERGENCY POWER DOWN.

DESIGN MUST BE REVIEWED BY QUALIFIED PERSONNEL WHO ARE FAMILIAR WITH THE

CONSTRUCTION AND OPERATION OF ALL COMPONENTS IN THE SYSTEM AND THE POTENTIAL

HAZARDS INVOLVED. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY

HARM AND/OR PROPERTY DAMAGE.

IN THIS TRANSMITTER. ALL EQUIPMENT MUST BE INSTALLED IN ACCORDANCE WITH THE

INSTALLATION INSTRUCTIONS DETAILED IN THE USER’S GUIDE. INCORRECT OR SUBSTITUTE

COMPONENTS AND/OR DEVIATION FROM THESE INSTRUCTIONS CAN IMPAIR THE SAFETY OF

THE TRANSMITTER AND COULD RESULT IN BODILY HARM AND/OR PROPERTY DAMAGE.

LOAD CELLS, HARNESSES OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

BODILY HARM AND/OR PROPERTY DAMAGE.

Warnings and Cautions

• READ this manual BEFORE operating or servicing this equipment and FOLLOW these instructions carefully.

WARNING

THE ACT350 IS INTENDED TO BE USED FOR PROCESS CONTROL AND IS NOT APPROVED AS A

WARNING

ONLY USE RECOMMENDED 12-24 VDC POWER SUPPLY APPROVED AS NEC Class 2 OR RATED

AS LIMITED POWER PER IEC60950-1.

WARNING

WHEN THIS EQUIPMENT IS INCLUDED AS A COMPONENT PART OF A SYSTEM, THE RESULTING

WARNING

ONLY THE COMPONENTS SPECIFIED ON THE ACT350 DOCUMENTATION MEDIA CAN BE USED

WARNING

BEFORE CONNECTING/DISCONNECTING ANY INTERNAL OR EXTERNAL ELECTRONIC COMPONENTS,

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY CONNECTIONS

OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE PRECAUTIONS COULD RESULT IN

WARNING

INSTALLATION AND ANY SERVICE ON THIS EQUIPMENT MUST BE DONE ONLY AFTER THE AREA

IS SECURED AS NON-HAZARDOUS BY THE RESPONSIBLE PERSON ON-SITE AUTHORIZED TO

DO SO.

Page 5

Warnings and Cautions

COMBUSTIBLE OR

DO NOT ACTIVATE POWER OVER ETHERNET (PoE) ON ETHERNET SWITCHES ON THE ACT350

NETWORK. ACTIVATING PoE MAY RESULT IN DAMAGE TO THE ACT350 TRANSMITTER.

IN ORDER TO ENSURE PROPER DISSIPATION OF HEAT FROM THE TRANSMITTER’S PCBS,

TO

AVOID DAMAGE TO THE EQUIPMENT, THE ACT350 MUST BE MOUNTED VERTICALLY, ON A

HORIZONTAL DIN RAIL.

NOTICE

OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE DEVICES.

In conformance with the European Directive 2002/96/EC on Waste Electrical and

WARNING

THE ACT350 IS NOT INTRINSICALLY SAFE! DO NOT USE IN HAZARDOUS AREAS CLASSIFIED

AS DIVISION 1, ZONE 0, ZONE 20, ZONE 1 OR ZONE 21 BECAUSE OF

EXPLOSIVE ATMOSPHERES.

NOTICE

NOTICE

Disposal of Electrical and Electronic Equipment

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment.

AND

If you have any questions, please contact the responsible authority or the distributor from

which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

Page 6

Content

1. Introduction .......................................................................................... 5

1.1. Inspection and Contents Checklist ...................................................... 5

1.2. Model Identification .......................................................................... 6

1.3. Versions of PLC Interfaces ................................................................. 6

1.4. Physical Dimensions ........................................................................ 7

2. Operation .............................................................................................. 8

2.1. Front Panel ..................................................................................... 8

2.2. Display Layout ................................................................................ 9

2.3. Front Panel Keys ............................................................................ 10

2.3.1. LEDs Status ........................................................................ 11

2.5. ACT350 POWERCELL Device Main Menu .......................................... 12

2.5.1. Information Recall ................................................................ 14

2.5.2. x10 Resolution .................................................................... 15

2.5.3. Comparators ....................................................................... 15

2.5.4. Calibration .......................................................................... 17

2.5.5. Language ........................................................................... 23

2.5.6. Setup Access ....................................................................... 23

2.5.7. Password Security ............................................................... 23

2.5.8. Reset Configuration and Master Reset ..................................... 24

2.6. ACT350 POWERCELL Basic Operation Functions ............................... 25

2.6.1. Zero ................................................................................... 25

2.6.2. Tare ................................................................................... 26

2.6.3. Filter................................................................................... 26

2.6.4. Error Message ..................................................................... 26

3. Installation ......................................................................................... 29

3.1. Mechanical Installation ................................................................... 29

3.2. Electrical Installation....................................................................... 30

3.2.1. RS-232 Serial Connection ..................................................... 31

3.2.3. Digital Inputs and Outputs connecting Instruction ..................... 32

3.2.4. POWERCELL Load Cell Connection ........................................ 36

3.2.5. PLC Connection ................................................................... 36

Page 7

3.3. DIP Switches ................................................................................. 37

3.4. Legal for Trade .............................................................................. 38

3.5. Power Supply ................................................................................ 38

4. Fieldbus Communication ...................................................................... 39

4.1. Overview ....................................................................................... 39

4.1.1. Cyclic data .......................................................................... 39

4.1.2. Acyclic data ........................................................................ 40

5. Troubleshooting PLC Connectivity ......................................................... 41

6. Setup+™/Webserver Configuration and Maintenance Tool ..................... 42

6.1. General Overview ........................................................................... 42

6.1.1. Setup+ Configuration Tool ..................................................... 42

6.2. Setup+ Tool .................................................................................. 42

6.2.1. PC Installation ..................................................................... 42

6.2.2. Setup+ User Guide ............................................................... 43

6.3. Webserver ..................................................................................... 43

6.3.1. Webserver Setup .................................................................. 43

7. GEO Codes .......................................................................................... 47

7.1. Original Site Calibration .................................................................. 47

7.2. New Site GEO Code Adjustment ....................................................... 47

Page 8

5

METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide

30423600 | 01 | 09/2018

Introduction

1. Introduction

NOTICE

www.mt.com/ind-act350-downloads.

The ACT350POWERCELL® represents the latest in METTLER TOLEDO technology and is one of the

most versatile weighing transmitters available today for digital POWERCELL® weighing

technology. The PLC communication interface in a DIN-rail mounting scheme makes the ACT350

a perfect match for basic industrial process weighing applications including:

• Filling • Dosing • Checkweighing

The ACT350POWERCELL delivers fast, precise measurement data in grams, kilograms or lb in a

single cost-effective package that easily integrates into control panel systems.

The versatile ACT350 excels in controlling simple filling and dosing applications delivering bestin-class performance for fast, precise, accurate results in fully automatic operations. Utilize the

control capabilities of the ACT350POWERCELL to effectively manage project costs.

1.1. Inspection and Contents Checklist

Verify the contents and inspect the package immediately upon delivery.

The package should include:

• ACT350 POWERCELL transmitter

• Safety warnings in multiple languages

• Parts for installation, including ferrite, connectors, screwdriver, etc.

All relevant documentation, software, fieldbus files and sample codes are available at

Page 9

Introduction

1.2. Model Identification

Item

Number

Description / SKC Number

Fieldbus

Type

30278660

WEIGH TRANSM PBDP R35000D60000CP0030

ACT350POWERCELL

PROFIBU DP

30278661

WEIGH TRANSM PRNT R35000D6000LCT0030

ACT350POWERCELL

PROFINET IO

30278662

WEIGH TRANSM ETIP R35000D6000LCE0030

ACT350POWERCELL

EtherNet/IP

The ACT350 POWERCELL model number is located on the data plate on the back of the transmitter

along with the serial number. Refer to Figure2-1 to identify the ACT350 configuration.

30303895

Version

Figure2-1: ACT350 Model Identification Numbers

1.3. Versions of PLC Interfaces

The ACT350 comes factory-configured with PLC interface options including

• PROFIBUS DP

• EtherNet/IP

• PROFINET IO

Each product version is specific to the PLC interface and cannot be changed to a different fieldbus

type.

| 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 6

Page 10

7

METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide

30423600 | 01 | 09/2018

Introduction

NOTICE

PLC Device Description Files as well as PLC Sample Code are available at

www.mt.com/ind-act350-downloads.

NOTICE

2D and 3D drawings available at www.mt.com/ind-act350-downloads.

1.4. Physical Dimensions

igure2-2: ACT350 POWERCELL DIN Rail Mount Enclosure Dimensions

F

Page 11

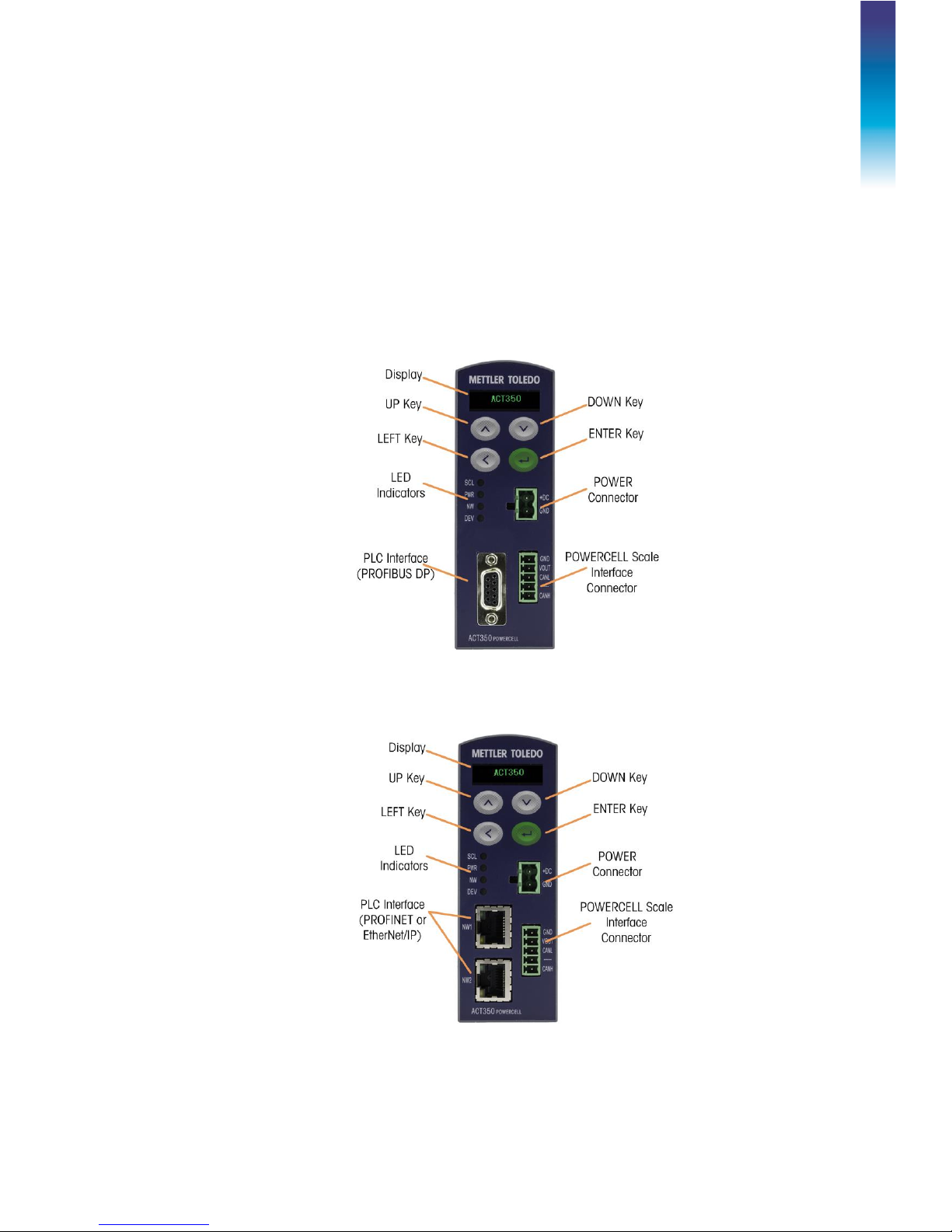

Operation

2. Operation

2.1. Front Panel

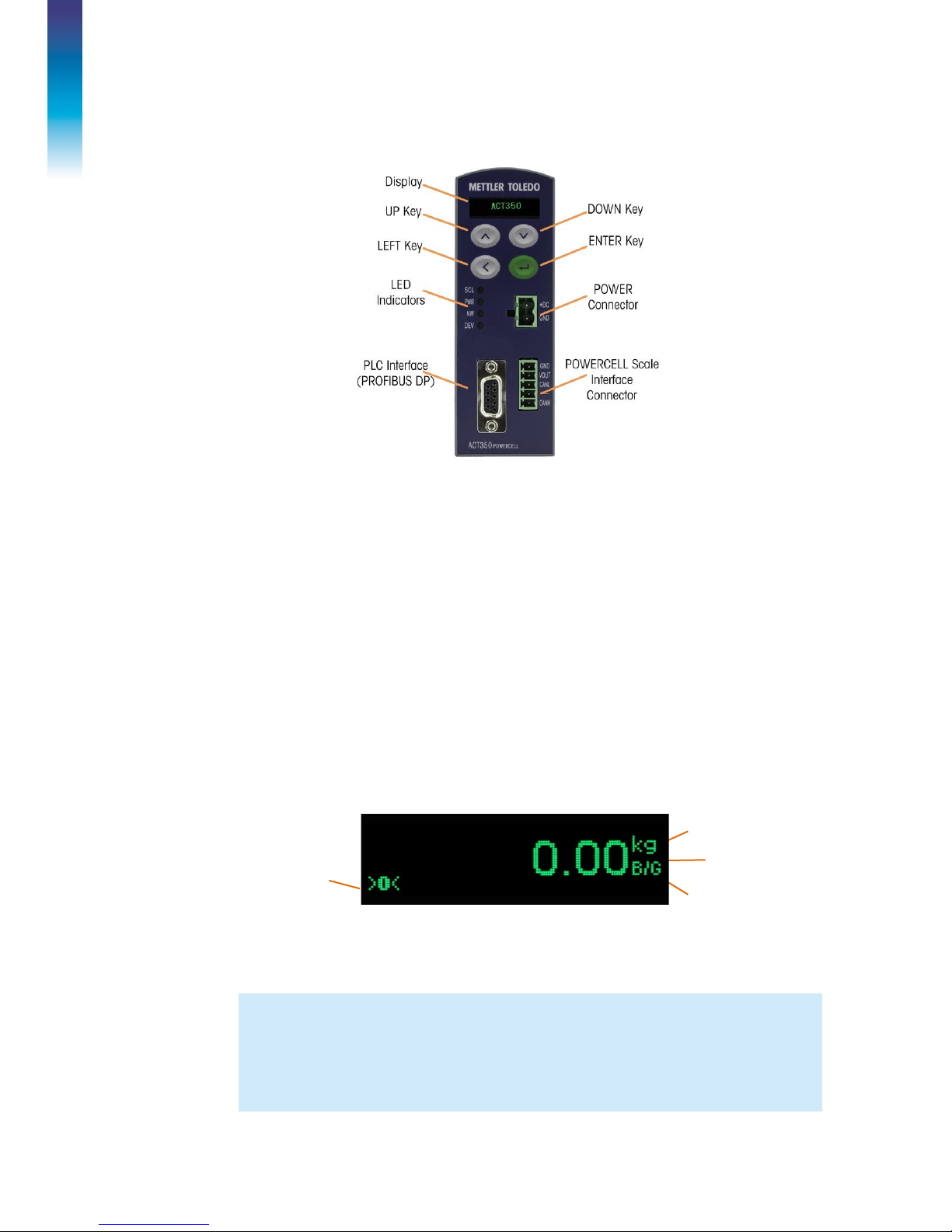

The ACT350 POWERCELL front panel is shown in Figure 3-1 and

Figure 3-2.

igure 3-1 ACT350 POWERCELL® Front Panel Layout – PROFINET or EtherNet/IP

F

30303895

| 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 8

Page 12

9

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

Figure 3-2 ACT350 POWERCELL Front Panel Layout – PROFIBUS

NOTICE

Center of

Zero

Unit of

measure

Gross mode

indication

Weight display

2.2. Display Layout

The ACT350 POWERCELL transmitter has an organic LED (OLED), 128 × 32 dot matrix graphic

display. The display is reserved for scale weight, units, Net/Gross indicator and error messages.

ditional information provided includes

Ad

eight unit ( Ib, kg, g )

• W

• Motion / no-motion condition

• Center of zero

• Gross or net mode

• RunFlat "R" mode

• Testing "T" mode

Fi

gure 3-3 Display in Weighing Mode

When ACT350 POWERCELL transmitter runs in RunFlat mode, a character "R" will

appear at the top-left corner of display and the whole display starts to blink

ACT350 POWERCELL Transmitter User's Guide

Page 13

Operation

3 seconds to access the device menu

NOTICE

When a POWERCELL® simulator is connected to ACT350 POWERCELL transmitter,

a character 'T' will appear at the top-left corner of display. The display will blink,

indicating a simulator is connected.

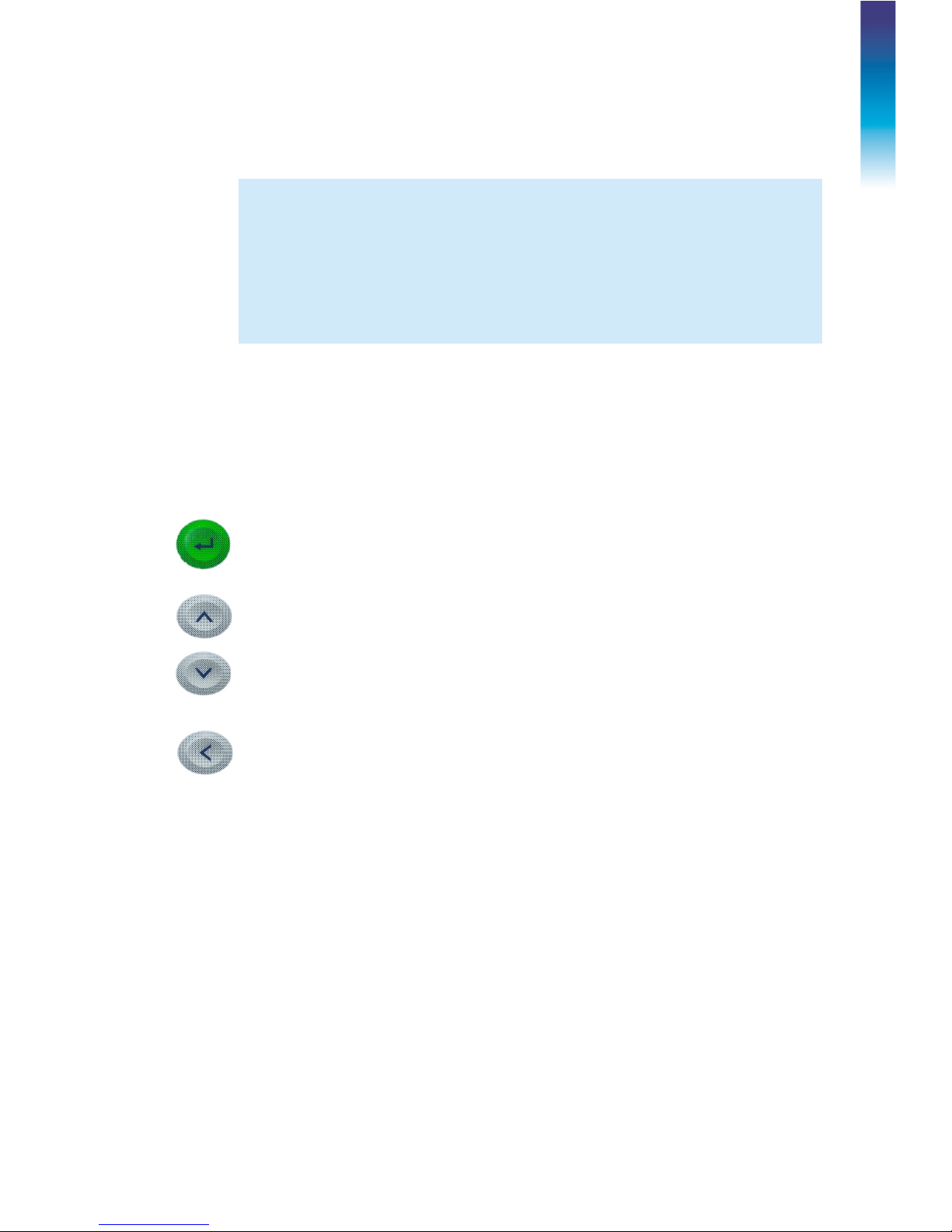

2.3. Front Panel Keys

Four dedicated function keys are located on the front panel to support manual setup

configuration. These provide the interface to navigate the setup menu hierarchy and data entry,

as well as make setup selections within data entry and drop down boxes.

Press the ENTER key for

ENTER

DOWN

to make a selection from the device menu and sub-menus.

When in a data entry field, press the ENTER key to accept the numeric value entered.

When the display is in weighing mode, briefly press the ENTER key to execute the zero

operation if the scale weight is within the Pushbutton zero range specified in Setup+.

Press the UP key to scroll within the device menu and sub-menus. The UP key is also

UP

used for incrementing numerals in the numeric data entry field.

Press the DOWN key to scroll within the device menu and sub-menus. The DOWN

key is also used for decrementing numerals in the numeric data entry field.

Press the LEFT key to navigate up one step on the device menu tree. The LEFT key is

also used to scroll to the numeral to the left in a data entry field. With the left most

numeric character highlighted, the next key press will wrap around to the right most

EFT

numeral.

. Press the ENTER key

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 10

Page 14

11

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

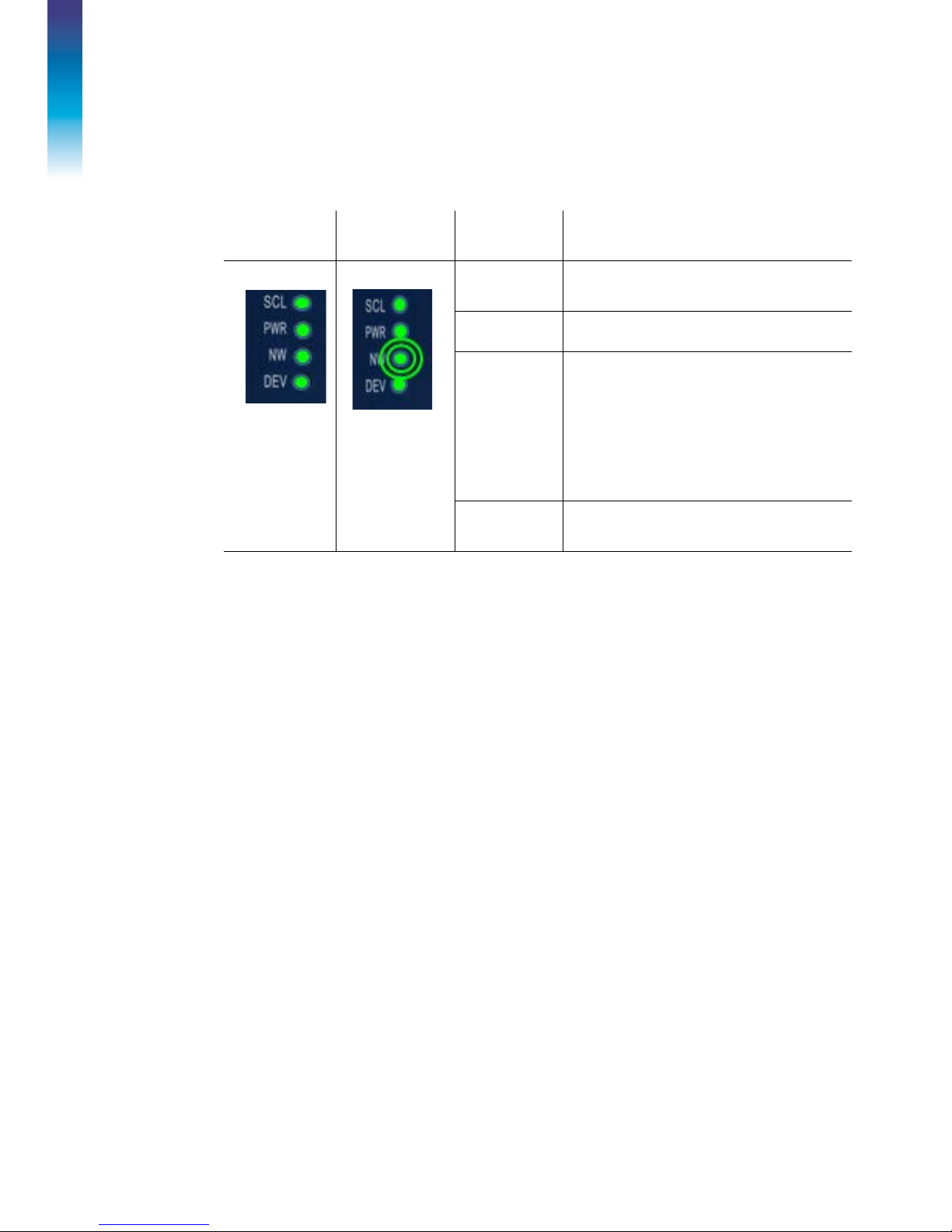

2.3.1. LEDs Status

Normal

Work

Network Error

(Example)

LED

STATUS

EtherNet/IP:

PROFINET IO / PROFIBUS DP:

SCL

PWR

NW

DEV

Scales status: ON okay, flashing indicates

scale error

Power status: ON okay, OFF error

After having the successfully

communication with PC or PLC, then

"NW" will always keep solid light;

When cyclic communication is used,

then "NW" will be solid light;

Device Status: ON okay; flashing contact

service

ACT350 POWERCELL Transmitter User's Guide

Page 15

Operation

Information

Recall

Resolution

Comparators

Calibration

zero and span

Error Message

Language

Setup

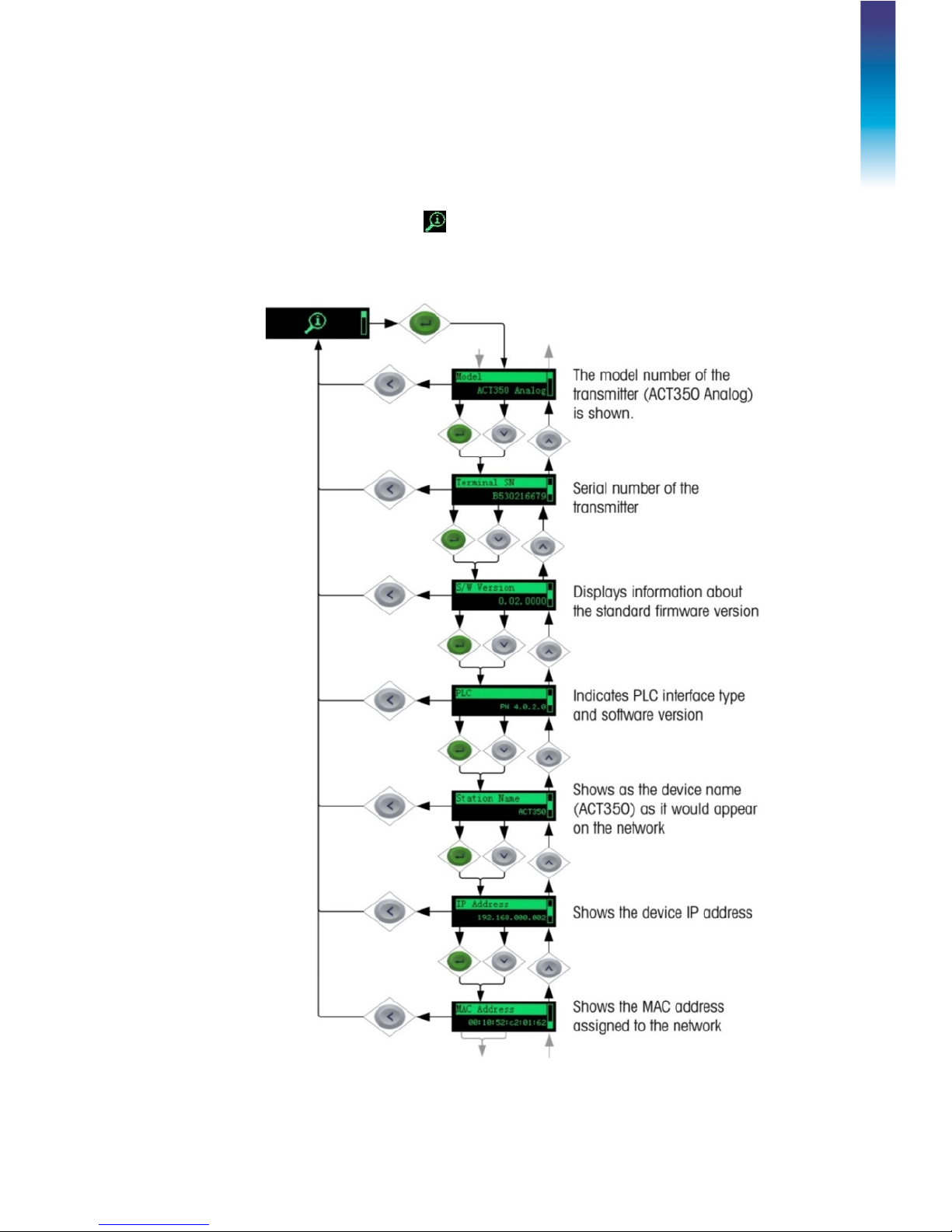

2.5. ACT350 POWERCELL Device Main Menu

From the front panel press and hold the ENTER key for three seconds to access the device

menu f The display will change from showing the standard weight display to showing the

Information Recall icon. Press the UP or DOWN key on the front panel to

display icons for the various functions listed in Table 3-1.

Recall mode list most transmitter information fields.

Temporary expands weight display resolution for diagnostic

purposes

Access to the limit value for all comparators.

Access to calibration menu including

Table 3-1 Device Menu Icons

Once focus is in a value field, repeated presses of the UP, DOWN or LEFT keys will cycle back

to the beginning, so if the LEFT key is pressed when focus is in the left-most position, focus

returns to the right-most position. In the case of the UP and DOWN keys, the numerical value

will cycle through numerical values and the decimal point as follows:

0 > 1 > 2 > 3 > 4 > 5 > 6 > 7 > 8 > 9 > . > 0 > 1 > …

adjustment (in non-approved mode only).

Access to list of current error messages

Selects between English and Chinese

Access to all setup parameters for the transmitter.

After accepting the value by pressing ENTER and the focus has moved to the parameter

description, press the LEFT key to exit to the next higher level of the menu.

Pressing the LEFT Key multiple times will exit the device menu.

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 12

0 > 9 > 8 > 7 > 6 > 5 > 4 > 3 > 2 > 1 > 0 > . > …

Page 16

13

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

Figure 3-4 shows an example of how to access and modify the value of a parameter. The

currently selected item (in focus) is indicated by reverse video.

ACT350 POWERCELL Transmitter User's Guide

Figure 3-4 Numerical Data Entry Example

Page 17

Operation

2.5.1. Information Recall

Once the Information Recall icon appears, press the ENTER key to recall specific information

about the transmitter. Figure 3-5

sequence in which they occur. Note that some items may not appear, depending on the

configuration of the transmitter.

shows the elements of the Information Recall menu in the

30303895

| 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 14

gure 3-5 Information Recall Menu

Fi

Page 18

15

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

NOTE

THE x10 DISPLAY RESOLUTION SETTING IS THE ONLY PARAMETER THAT CANNOT BE

CONFIGURED USING SETUP+.

to determine the validity of data received by the PLC.

2.5.2. x10 Resolution

Used to expand the weight display resolution by 10 so that a finer weight increment can be seen.

This function can be enabled by pressing the ENTER key when the transmitter’s device

menu has been accessed and the icon is displayed on screen:

Figure 3-6 x10 Indication

The function is intended for diagnostic purposes only. The transmitter should not be used in

the x10 expanded mode for normal operation. The Data OK bit is set to zero when in x10

display mode to indicate that the ACT350 POWERCELL is not in normal operating mode. The

PLC should continuously monitor the Data Ok bit in the ACT350 POWERCELL communication

2.5.3. Comparators

The device supports a total of five comparators. The limit of each Comparator may be modified

by accessing the Comparator menu in the setup menu. Comparator values are limited to 7 digits,

and can be written to the device or read from it by the PLC.

2.5.3.1. Setting Comparators

Access to the Comparator menu using the device's front panel is accomplished by pressing the

ENTER key when the transmitter’s device menu has been accessed and the icon is

displayed on the device.

ACT350 POWERCELL only supports a logical comparison of “>=”, greater than or equal, for

each comparator. For example, the limits is set to “24.00” kg, that means if the live weight is

greater than or equal to 24.00 kg, the output of DIO will act if this output is assigned to link the

Comparator.

The operator of range and other comparisons are NOT supported by ACT350POWERCELL.

ACT350 POWERCELL Transmitter User's Guide

Page 19

Operation

NOTE

Comparator outputs are not latched and are not suitable for directly controlling material feed devices

To edit parameters other than limits, Comparator configuration must be accessed in setup. Refer

to the Numerical Data Entry

section for the method used to modify numerical values.

Figure 3-7 Setting Comparator Values (Limits)

Only absolute numbers are permitted when setting comparators.

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 16

Page 20

17

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

2.5.4. Calibration

Calibration is the process of adjusting the display of weight values, so that when the scale is

empty, the display shows zero gross weight and, with a specific amount of weight on the scale,

shows an accurate weight value.

The ACT350 POWERCELL transmitter calibration menu enables entry of a Geo Code adjustment

value, setting selection for linearity adjustment –

traditional zero calibration and three different types of span calibration:

• Traditional span calibration - using certified test weights

• Step Adjust Calibration – using a build-up or substitution method of calibration (for large

vessels where only a portion of the required test weights can be placed on the scale)

• CalFreePlus Calibration – the transmitter will automatically calculate the span; no test

weights are required

none [default], three, four or five point, perform

2.5.4.1. Setting Calibration

Access to the Calibration menu using the device’s front panel is accomplished with a key press

of the ENTER key when the (test weight) icon is displayed on the device. The Calibration

menu can also be accessed using the PC-based Setup+ Configuration Tool.

ACT350 POWERCELL Transmitter User's Guide

Figure 3-8 Calibration Menu – Overview

Page 21

Operation

None

Linearity is disabled

3

Zero, midpoint and highpoint

4

Zero, lowpoint, midpoint and highpoint

5

Zero, lowpoint, midpoint, mid-highpoint, highpoint

NOTE

performed.

Prior to Calibration, POWERCELLS must be addressed if this has not already been

2.5.4.2. Setting Geo Code

The Geo Code, which sets the appropriate adjustment value for the current geographical location,

is selected here. Geo codes are numbered 0–31. See Figure 3-8 for Geo code setting using the

transmitter’s front panel buttons, and refer to GEO Codes to find the appropriate Geo Codefor the

installation location.

2.5.4.3. Setting Linearity

To set the Linearity Adjustment value, see Figure 3-8. Select the number of linearity points from

the selection box. Options are

None [default], 3 point, 4 point, 5 point.

Points are distributed as follows:

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 18

Page 22

19

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

2.5.4.4. Zero Calibration and Under Zero Blanking

Scale zero is set simply by emptying the scale and running the “Set Zero” calibration routine, as

shown in Figure 4-1.

Figure 4-9 Zero Calibration

If the transmitter detects scale motion during the calibration process, it will retry the start of

calibration several times and then proceed, displaying a motion indication. In this case, when

calibration is complete the transmitter will present two options – accept or reject the value.

Figure 1-10 Zero Calibration with Motion

ACT350 POWERCELL Transmitter User's Guide

Page 23

Operation

NOTICE

of 99 disables blanking under zero and the transmitter will display a weight as far under as possible.

Blanking of the display is used to indicate an under-zero condition when the weight on the

scale falls below the current zero reference. Set the under zero blanking for the number of

divisions (d) that the transmitter is permitted to go under zero before blanking.

A setting value of 0-98 blanks the display at the specified number of divisions below gross zero. A value

2.5.4.5. Span Calibration

The scale’s span calibration can be performed either with or without a linearity adjustment. With

linearity disabled, a single reference point for span is used to calibrate the scale. This is the

normal method of span calibration. In Figure 1-3 the transmitter is configured with three-point

linearity – low, mid and high. The low point is set during zero calibration, the mid and high

points during this procedure.

Figure 1-11 Span Calibration

If linearity is enabled, additional mid-range weight reference points are added to the adjustment

procedure. Linearity can be enabled or disabled in the Calibration branch of the device menu.

Refer to the Numerical Data Entry Example section for the method used to modify numerical

values.

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 20

Page 24

21

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

2.5.4.6. Step Adjust

Step adjustment is an iterative process in which a build-up or material substitution method of

calibration is used to calibrate the span. Each step calibrates a portion of the full span.

This method is typically used with large vessels where only a portion of the required calibration

test weights can be placed on the scale at one time. Figure 1-4 Figure 1-4 Step Adjustment

shows the logic of the procedure using a simple, two-step example. When sufficient steps have

been calibrated, pressing the LEFT button returns the view to the calibration menu.

ACT350 POWERCELL Transmitter User's Guide

Page 25

Operation

First, a test load is defined by entering its

weight

Confirm the value entry by pressing ENTER

The ACT350 POWERCELL prompts for the

addition of the test load

Press ENTER to start the first step

The ACT350 POWERCELL indicates its

progress

Once the first step is completed, the

ACT350 POWERCELL sets a temporary

zero point, and prompts for the removal of

the test load. A live weight display

indicates that the scale has been cleared

Press ENTER to confirm the scale is empty

The ACT350 POWERCELL now prompts to

add the test load again

The live weight indicates that the test load

is on the scale

Press ENTER to start the second step

The ACT350 POWERCELL indicates its

progress

Press LEFT to complete calibration and exit

the procedure

The ACT350 POWERCELL indicates that

the calibration has succeeded

Press either LEFT or ENTER to return to the

calibration menu

Figure 1-12 Step Adjustment

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 22

Page 26

23

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

2.5.4.7. CalFreePlus™

The ACT350 POWERCELL transmitter provides a method to calibrate a scale without using test

weights. This method of calibration can be used for initial check-out and testing of systems or

when a large structure is used as the weighing vessel and it is not possible to apply test weights

to the structure. METTLER TOLEDO highly recommends that test weights be used whenever

possible as this provides the most accurate method of calibration.

Notes on Load Cell Capacity and Rated Cell Output

For systems with passive dummy load cells, enter the value as if all supports have live load

cells. For example, for a system with two 50t live load cells and two passive supports, enter

200,000 kg.

Figure 1-13 CalFreePlus

2.5.5. Language

The ACT350 POWERCELL supports a device menu in English [default] and in Chinese.

2.5.6. Setup Access

The last icon displayed in the device menu from the front panel is Setup , where many of the

transmitter’s programming parameters can be viewed and modified. It is not intended that

operators enter the setup mode after a weighing system is installed and is operational, it should

not be necessary for an operator to access setup.

2.5.7. Password Security

Note that a security password can be enabled in setup from the PC-based Setup+ Configuration Tool.

When a password is set, it must be entered to access setup. This protects the setup parameters from

inadvertent changes.

ACT350 POWERCELL Transmitter User's Guide

Page 27

Operation

Figure 1-14 Password Entry Screen

2.5.8. Reset Configuration and Master Reset

2.5.8.1. Reset Configuration

To reset all configured items except calibration data:

1. Remove power from the transmitter.

2. Locate the DIP switches, accessible from the underside of the housing.

3. Set DIP switches, 1 and 2, to ON (up, in Figure 1-7), and restore power to the

transmitter.

Figure 1-15 DIP Switches

4. Set both DIP switches to OFF.

2.5.8.2. Master Reset

A master reset restores all settings to their factory default values:

1. Remove power from the transmitter.

2. Set switch 2 to its ON position and restore power to the transmitter. The ACT350 will prompt

for confirmation.

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 24

Figure 1-16 Master Reset Confirmation

Page 28

25

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

3. Press ENTER on the front panel to perform the master reset.

4. Set Switch 2 to OFF.

2.6. ACT350 POWERCELL Basic Operation

Functions

2.6.1. Zero

The Zero function is used to set or reset the initial zero reference point of the scale There are two

types of zero setting modes:

2.6.1.1. ENTER Button

The Zero function can be accomplished by a short press of the green ENTER scale

function key. The Zero range selections include Disabled,

from the calibrated zero point. A change to the default setting is done via the PC-based Setup+

Configuration Tool. If the current scale weight is outside the zero range when a pushbutton

zero is commanded, the transmitter will display a message:

2% [default] or 20% plus or minus

Figure 1-17 ENTER button Zero Failure Message

Remote initiation of the semi-automatic Zero function is possible via a command initiated by the

PLC interface.

2.6.1.2. Power Up

The Power Up mode setting determines at power up, whether the transmitter will restart with the

most recent zero reference point stored prior to power down or if it will reset to the calibrated

zero reference.

The selections include Reset [default] and Restart.

2.6.1.3. Reset

With the setting on Reset, the last zero calibration value will be used as the zero reference point.

The Power Up Zero capture range selections include

minus. If the range setting is enabled, the Power Up Zero is applied only when the weight reading

on the scale is within the selected range around the originally calibrated zero reference. For

example, if the range setting for Power Up Zero is set at +/- 2%, Power Up Zero will only occur

when the weight reading on the scale is within +/- 2% of scale capacity above the original

calibrated zero reference. If the weight on the scale is outside of the zero range, the display will

indicate

EEE until the weight is adjusted to be within this range and zero is captured.

Disabled [default], 2% or 10% plus or

ACT350 POWERCELL Transmitter User's Guide

Page 29

Operation

Limit Frequency

Selections from 1 to 20 in this drop-down box set the cut-off frequency, in Hertz, above

Weighing Mode

Sets the type of weighing, Normal and Dynamic, for which the ACT350POWERCELL is

being used in the current application.

Environment

Sets the type of environment in which the ACT350POWERCELL is working, depending

on how stable the scale is likely to be.

Error

ACT350POWERCELL

Display

Description

Action

002

"Remote calib."

Remote Calibration (by

in process

Do calibration to finish

005

"NW Module init.fail"

SAI initialization failure

Cycle power; call

persists

006

"NW connection

disconnected"

Network connection lost

Check network cable

or connector

Restart

A setting of Restart enables the transmitter to reuse the most recent zero reference weight after a

power cycle so it returns to the same, previously-displayed gross weight value. The Power Up

Zero setting is configured using the PC-based Setup+ Configuration Tool.

2.6.2. Tare

The tare value is subtracted from the gross weight measurement, providing the computation of

the net weight (material weight without the container). The tare function can also be used to

track the net amount of material being added to or removed from a vessel or container. In the

second case, the weight of the material in the container is included with the tare weight of the

container and the display then reflects the net amount being added to or removed from the

vessel. Tare is captured and cleared by PLC command.

2.6.3. Filter

The Filter section offers three settings:

which the filter actively attenuates the signal.

2.6.4. Error Message

With the Errors icon in view, press the ENTER key to access a listing of current error

messages.

Table 2-1 lists and explains errors that may be observed.

Table 2-1: ACT350 POWERCELL Faults

Setup+ or WebServer) is

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 26

Service if error

Page 30

27

METTLER TOLEDO

30423600 | 01 | 09/2018

Operation

009

"Board info. err"

Hardware error

Cycle power; call

persists

010

"Calib. block err"

Calibration block data lost

Perform master reset

Re-calibrate

011

"Scale block err"

Scale block data lost

Perform master reset

block

012

"Term. block err"

Terminal block data lost

Perform master reset

terminal block

013

"APP. block err"

Application block data lost

Perform master reset

application block

014

"COM. block err"

Communication block

Perform master reset

communication block

015

"Maint. block err"

Statistics block data lost

Perform master reset

maintenance block

018

"Zero failed Motion"

Scale in motion when Zero

Zero when scale is

unstable load cell/s

019

"Zero failed net

mode"

Scale in net mode when

Zero attempted

Clear tare before

zeroing

020

"Zero failed out of

range"

Weight out of Zero range

Unload scale and zero

021

"Zero failed Zero

disabled"

Zero attempted when

function disabled in setup

Enable Zero function

in Setup

022

"Tare failed Motion"

Scale in motion when Tare

attempted

Tare when scale is

stable

027

"Tare failed Not

Preset tare value not in

The preset tare value

the same increment

028

"Tare failed Value

Tare value too small

The preset tare value

029

"Tare failed Zero not

Power-up zero not

attempted

Disable zero capture

030

"Tare Failed, Scale

Tare was attempted while

Remove weight and

range

service if issue

Access setup for scale

Access setup for

Access setup for

data lost

attempted

Access setup for

Access setup for

stable. Replace

rounded value"

too small"

display increment size

must be rounded to

must be minimum of

1 display increment

captured"

Over capacity"

ACT350 POWERCELL Transmitter User's Guide

captured; Zero not

captured after power cycle

(with Zero capture

enabled) when tare was

scale was over capacity

at power-up or unload

scale and power-up

again, then tare

tare within weighing

Page 31

Operation

031

"Tare failed Negative

Tare value is less than

value

The preset tare value

non-zero

038

"LC Supply Beyond

Overvoltage or under

Check the power

application

039

" LC Supply Over

Overcurrent of power

Check the power supply,

040

" LC Enclosure

Gas sensor value of LCs is

between -5% and 10%

Replace load cell

041

"LC Temperature

The LC temperature is

10℃~40℃)

Replace load cell

042

" LC Temperature

The LC temperature is

for PDX)

Check the environment of

043

" LC Communication

Lost communication

ACT350POWERCELL

Check the active LC counts

044

" LC Over Load

The weight value is

capacity

Check the weighing scale

045

LC Over Load

The weight value is more

The LCs could be

condition.

046

" LC Mixture err "

LC Type Mix

detected

Check the LC type.

allowed to be connected.

047

"LC UnderLoad

The load cell weight output

Check the shift adjust

whether it is normal

048

" LC configure

block err"

POWERCELL configuration

block data lost

Perform master reset

Perform setup for LC block

value"

Voltage"

Current "

Broken "

Beyond Normal"

Beyond Operate "

capture or saved zero

voltage of power supply

for LCs

supply for LCs

beyond normal range(-

beyond operate

range(depend on LC type,

for example -30

℃~55℃

must be positive and

supply and

ACT350POWERCELL

product type whether

support hazardous

ACT350POWERCELL,LCs

and confirm if all are

normal

weighing scale and

conform if LC is normal

Error"

Beyond Normal "

Beyond Operate

Error"

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 28

between LCs and

between 101% and

150% of normal LC

than 150% of normal LC

capacity

Different types of LCs are

is negative out of normal

range

and connection cables

damaged.

Check the weighing scale

Only one type of LCs is

parameters;

Check the load cell

Page 32

29

METTLER TOLEDO

30423600 | 01 | 09/2018

Installation

Upper mounting

Sliding latch

Grounding

3. Installation

3.1. Mechanical Installation

The ACT350 POWERCELLS are standard DIN rail-mounted components. DIN mount includes a

sliding green latch, visible in

Figure 5-1.

Figure 5-1 DIN-Mount Latch

To mount the ACT350 POWERCELL on a rail, slide the latch down, then position the transmitter

so that its upper mounting tabs rest on the DIN rail.

Use a screwdriver to close the latch and secure the transmitter in position.

tabs

To remove the ACT350 POWERCELL, simply put the blade of a screwdriver in the latch and press

it downward.

ACT350 POWERCELL Transmitter User's Guide

Figure 5-2 Latch Closure

Page 33

Installation

NOTICE

to the equipment, the ACT350 POWERCELL must be mounted vertically, on a horizontal din rail.

NOTICE

is grounded to the DIN rail.

In order to ensure proper dissipation of heat from the transmitter’s PCBs, and to avoid damage

3.2. Electrical Installation

Figure 5-3 indicates the ACT350 POWERCELL's connectors and their functions.

Figure 5-3 ACT350 POWERCELL Interfaces – PROFIBUS (left) and PROFINET or EtherNet/IP

(right)

The special automatic grounding system at the back of the unit is present to ensure that the unit

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 30

Page 34

31

METTLER TOLEDO

30423600 | 01 | 09/2018

Installation

NOTICE

PC via Setup+ Configuration Tool

This tool is available online and can be downloaded at www.mt.com/ind-act350-downloads

3.2.1. RS-232 Serial Connection

The serial RS-232 connection on top of the transmitter is used for service purposes only. See Figure

5-4.

Figure 5-4 ACT350 POWERCELL, Top View

Figure 5-5 present the correct RS-232 wiring connection.

The

Figure 5-5: RS-232 Wiring Connection

The RS-232 can be used to connect ACT350POWERCELL to the

.

ACT350 POWERCELL Transmitter User's Guide

Page 35

Installation

Input

Output

Permissible input

voltage

Logical Low-level

0 ~ 5 VDC

Logical High-level

Input resistance

>3Kῼ

Max.current of one

output

Accumulated current of

all outputs

Support Sinking

GND connected to IN-

COM

Support Sourcing

Power source to IN-COM

Power source to OUT-COM

Default function

Zero

Polarity Value

Available Functionality

None; Center of Zero;

NET; Over Capacity; Under Zero

3.2.3. Digital Inputs and Outputs connecting Instruction

Three digital inputs and five outputs are allocated on a top of each ACT350 POWERCELL

0 ~ 24 VDC 5~30 VDC

10 ~ 24 VDC

<150mA

<750mA

GND connected to OUT-COM

+True(Default) or –True

None; Clear Tare; Tare;

Zero

Figure 5-6: Digital Inputs and Outputs Specification

Example:

Using a rising-edge input signal to trigger the ACT350 POWERCELL to perform a Zero operation,

"Polarity" can be set as "+ True" and "Assignment" as "Zero". Refer to Figure 5-7

Comparator 1-5; Fault; Motion;

Figure 5-7 A Rising-edge Trigger Signal on Input

Using a falling-edge signal on Input to trigger ACT350 POWERCELL perform a Tare operation,

"Polarity" can be set as "- True" and "Assignment" as "Tare". Refer to Figure 5-8.

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 32

Page 36

33

METTLER TOLEDO

30423600 | 01 | 09/2018

Installation

1 10

IN COM

IN1

IN2

IN3

OUT1

OUT2

OUT3

OUT4

OUT5

OUT COM

LOAD

LOAD

LOAD

LOAD

LOAD

Voltage Source

Common

+ Voltage Source

PLC or Other

Discrete Output

Device

COM

OUT1

OUT2

OUT3

SUPP

SUPP

SUPP

SUPP

SUPP

+ Voltage Source

Voltage Source

Common

NOTICE

input signal result.

Figure 5-8 A Falling-edge Trigger Signal on Input

The input voltage range between 5 – 10 VDC must not be used, as it can create an unstable

ACT350 POWERCELL supports both Sinking and Sourcing wiring on DIO Input and Output. Please

refer to Figure 5-9 - Figure 5-12 for details.

ACT350 POWERCELL Transmitter User's Guide

Figure 5-9 Sinking Input, Sourcing Output

Page 37

Installation

1

10

IN COM

IN1

IN2

IN3

OUT1

OUT2

OUT3

OUT4

OUT5

OUT COM

LOAD

LOAD

LOAD

LOAD

LOAD

Voltage Source

Common

+ Voltage Source

PLC or Other

Discrete Output

Device

COM

OUT1

OUT2

OUT3

SUPP

SUPP

SUPP

SUPP

SUPP

+ Voltage Source

Voltage Source

Common

1 10

IN COM

IN1

IN2

IN3

OUT1

OUT2

OUT3

OUT4

OUT5

OUT COM

LOAD

LOAD

LOAD

LOAD

LOAD

Voltage Source

Common

+ Voltage Source

PLC or Other

Discrete Output

Device

COM

OUT1

OUT2

OUT3

SUPP

SUPP

SUPP

SUPP

SUPP

+ Voltage Source

Voltage Source

Common

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 34

Figure 5-10 Sinking Input, Sinking Output

Figure 5-11 Sourcing Input, Sourcing Output

Page 38

35

METTLER TOLEDO

30423600 | 01 | 09/2018

Installation

1

10

IN COM

IN1

IN2

IN3

OUT1

OUT2

OUT3

OUT4

OUT5

OUT COM

LOAD

LOAD

LOAD

LOAD

LOAD

Voltage Source

Common

+

Voltage Source

PLC or Other

Discrete Output

Device

COM

OUT1

OUT2

OUT3

SUPP

SUPP

SUPP

SUPP

SUPP

+ Voltage Source

Voltage Source

Common

Figure 5-12 Sourcing Input, Sinking Output

ACT350 POWERCELL Transmitter User's Guide

Page 39

Installation

3.2.4. POWERCELL Load Cell Connection

For EMC requirement, cabling for the POWERCELL load cell must include a ferrite, included with

the transmitter.

Install the ferrite by passing it through the ferrite and wrapping it around as indicated in Figure 5-13.

It is recommended to strip the outer shielding of the wires about 31 cm.

Figure 5-13 Ferrite Installed on POWERCELL Cable

Table 3-1: Scale Interface Connection

3.2.5. PLC Connection

For EMC requirement, cabling for the PROFIBUS DP interface must include a ferrite, included with

the transmitter.

Install the ferrite as indicated in figure 3-14:

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 36

Figure 5-14 Ferrite Installed on PROFIBUS DP Cable

Page 40

37

METTLER TOLEDO

30423600 | 01 | 09/2018

Installation

Legal for

Trade

Switch 1

Switch 2

Function

OFF

OFF

Normal operation

ON

OFF

Legal-for-trade mode;

calibration data protected

OFF

ON

Master reset of all data

up

ON

ON

Reset of all except

transmitter power-up

For the PROFIENT IO and Ethernet/IP interfaces, the cables shall be industry standard 8P8C (also

called RJ45) to allow the customer to quickly interface/connect modules.

ACT350 POWERCELL transmitter with PROFINET or EtherNet/IP interface supports Media

Redundancy Protocol and Device Level Ring topology, respectively.

3.2.5.1. Media Redundancy Protocol (MRP) Topology

MRP protocol enables implementing a redundant PROFINET communication through ring topology

without the need for switches. MRP can compensate for an individual failure in a PROFINET /

Industrial Ethernet in a simple ring topology. As meshed networks are not supported, MRP is both

simple and reliable. MRP in PROFINET networks can achieve reconfiguration times of 200ms.

3.2.5.2. Device Level Ring (DLR) Topology

DLR protocol provides high network availability in a ring topology and is intended primarily for

implementation in EtherNet/IP end-devices that have two Ethernet ports and embedded switch

technology. It provides fast network fault detection and reconfiguration in order to support the most

demanding control applications. For example, a ring network of 50 nodes implementing the DLR

protocol has the worst case fault recovery time of less than 3ms.

3.3. DIP Switches

Two DIP switches, 1 and 2, are accessible from the underside of the ACT350 POWERCELL’s

housing. Table 3-2 summarizes their functions.

ACT350 DIP Switches

Reset

during transmitter power-

calibration data during

Table 3-2: DIP Switch Functions

ACT350 POWERCELL Transmitter User's Guide

Page 41

Installation

NOTICE

significant settings cannot

be accessed

approval, unit, capacity, increment size, calibration, zero and stability settings

3.4. Legal for Trade

When the transmitter is certified as legal for trade, DIP switch 1, accessible on the underside of

the housing, must be set to ON. A metrological seal must be placed over the DIP switch array in

order to prevent this setting from being changed.

Please refer to Figure 5-4 for method to seal ACT350 POWERCELL Transmitter.

Figure 5-15 ACT350 POWERCELL Sealing Diagram

When the ACT350POWERCELL is in approved mode, metrological

through ACT350POWERCELL’s interfaces or in Setup+. These settings include

3.5. Power Supply

The ACT350 POWERCELL transmitter is powered only by external DC input (24V).

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 38

Page 42

39

METTLER TOLEDO

30423600 | 01 | 09/2018

Fieldbus Communication

NOTICE

4. Fieldbus Communication

4.1. Overview

The Standard Automation Interface (SAI) is a protocol designed to exchange data between

METTLER TOLEDO devices and third-party automation systems. This interface provides the

following:

• A common data layout for load cells, terminals and other devices regardless of the physical

interface or automation network used.

• A single protocol for the convenience of automation integrators, control system programmers

and our automation customers.

• A flexible protocol for diverse devices.

Communication Modes

The protocol has two primary modes of operation.

• cyclic data • acyclic data

Acyclic data is also referred to as asynchronous data or explicit messaging.

4.1.1. Cyclic data

Cyclic data is broken up into sections of data. Each section represents a block. Each block of data

contains four words of 16 bits each.

The data within these words can express numeric values, string values or individual bits which

represent state or command depending on the type of block specified.

There are two types of cyclic blocks supported on the ACT350 POWERCELL:

• Measuring block (IEEE 754 floating point data)

– Used for numeric values

– Decimal point and sign are included and do not require special data handling.

• Status block

– Used for numeric values

ACT350 POWERCELL Transmitter User's Guide

Page 43

Fieldbus Communication

NOTICE

NOTICE

SAI Reference Manual available at www.mt.com/ind-act350-downloads.

– Status block data is grouped together in 16 bit words.

4.1.2. Acyclic data

With acyclic messages, the variable can be accessed directly through a unique name or number

defined by the control system's acyclic message block.

Acyclic data is also referred to as asynchronous data or explicit messaging.

For more details regarding Fieldbus Communication please refer to ACT-Weight Transmitters

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 40

Page 44

41

METTLER TOLEDO

30423600 | 01 | 09/2018

Troubleshooting PLC Connectivity

5. Troubleshooting PLC

Connectivity

If the ACT350 POWERCELL does not communicate with PLC, do the following:

• Power cycle the ACT350 POWERCELL to reestablish communications.

• A solid green NW LED on the front panel implies that the ACT350 POWERCELL is on the

network. A blinking NW LED indicates that the ACT350 POWERCELL is not on the fieldbus

network.

• Check LED status of the connection socket. The top LED should be solid green. If the top LED

is not solid green then this implies that no hardware connection is being seen by the device

-check cabling and connector insertions. The bottom LED will blink amber if data is being

transferred. If the top LED is solid green, but the bottom LED is not blinking then this implies

a configuration issue either in the ACT350 POWERCELL or the PLC.

• Confirm that the ACT350 POWERCELL can respond to a ping on the Network. If the ping fails,

then check the wiring and network connections.

• Diagnose and correct specific Network error conditions such as IP Address conflicts.

• Confirm that the ACT350 POWERCELL settings for address, format and byte order match those

in the PLC and that each ACT350 POWERCELL has a unique address.

• Check the Electronic Keying from in the PLC program. Confirm that the firmware revision of

the Ethernet/IP module in the ACT350 POWERCELL greater than or equal to the firmware

revision specified in the ACT350 POWERCELL’s communication module in the PLC. Change

the firmware revision being looked for in the PLC’s communication module or change the

electronic keying setting in the PLC.

• Contact METTLER TOLEDO for replacement of the ACT350 transmitter.

• Visit the METTLER TOLEDO web page at

actual Troubleshooting information.

www.mt.com/ind-act350-downloads to check

ACT350 POWERCELL Transmitter User's Guide

Page 45

Setup+/Webserver

6. Setup+™/Webserver

Configuration and

Maintenance Tool

6.1. General Overview

ACT350 POWERCELL transmitter supports two types of configuration and maintenance tools:

Setup+ and Webserver.

6.1.1. Setup+ Configuration Tool

Figure 8-1 Setup+ Splash Screen

Setup+ is a PC tool available online to support the following functions:

• Configuring of the ACT350 Transmitter using local PC

• Saving transmitter configuration to a local PC

• Loading a saved configuration to other transmitters performing similar applications

• Restoring to a ‘last known good state’ for service purposes

• ACT350 Transmitter software upgrade and maintenance

6.2. Setup+ Tool

6.2.1. PC Installation

Please follow the Setup+ installation guide on your PC after downloading the Setup+ software

www.mt.com/ind-act350-downloads.

from

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 42

Page 46

43

METTLER TOLEDO

30423600 | 01 | 09/2018

Setup+/Webserver

NOTICE

Make sure the PC and ACT350 POWERCELL Transmitter are in the same local network.

6.2.2. Setup+ User Guide

The User Guide is available to be downloaded at www.mt.com/ind-act350-downloads.

Additionally the document is available by click on Help icon in the toolbar to download Setup+

User Guide.

Figure 8-2 Setup+ Home Screen

6.3. Webserver

Webserver supports the following functions:

• Configuring of the ACT350 POWERCELL Transmitter via web browser, such as IE, Chrome

and Safari;

• Accessing diagnostic and maintenance information for service purposes;

Figure 8-3 Webserver Splash Screen

By inputting the IP address of ACT350 Transmitter in the web browser, the startup screen of

webserver will be displayed.

6.3.1. Webserver Setup

PC setup

ACT350 POWERCELL Transmitter User's Guide

Page 47

Setup+/Webserver

NOTICE

IP address: 192.168.0.2, Subnet Mask: 255.255.255.0, Gateway: 192.168.0..

The typical PC's configuration:

IP address: 192.168.0.X (X = 0 ~ 255, exclude 2), Subnet Mask: 255.255.255.0, (Statement

needed for Gateway)

The default setting of ACT350 POWERCELL Transmitter is as follower:

Internet Option -> LAN setting -> Automatically detect settings should be unchecked.

IE setup

Figure 8-4 Local Area Connection Setting

Figure 8-5 IE setting

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 44

Page 48

45

METTLER TOLEDO

30423600 | 01 | 09/2018

Setup+/Webserver

6.3.1.2. Connect to webserver

By inputting the IP address of ACT350 POWERCELL Transmitter in the web browser, the startup

screen of webserver will be displayed.

6.3.1.3. Change network setting of ACT350 POWERCELL

Transmitter

Network setting of ACT350 POWERCELL Transmitter can be changed in

Communication->Ethernet/IP (PROFINET) menu.

Figure 8-6 Network setting of ACT350 POWERCELL Transmitter

6.3.1.4. Password

There is password protection for configurations. By default, password protection is disabled, and

user can read and write configurations. It can be enable in the Login->Change Password menu

as below:

Figure 8-7 Enable password protection

After password protection is enabled, user can only read configurations without password. If user

wants to write configurations, password needs to be entered in the Login->Login/Logout menu:

ACT350 POWERCELL Transmitter User's Guide

Page 49

Setup+/Webserver

NOTICE

IP address: 192.168.0.2, Subnet Mask: 255.255.255.0, Gateway: 192.168.0.

The default setting of ACT350 POWERCELL Transmitter is as follower:

The default password is 000000.

• User can change the password in Login->Change Password, the password supports

up to 6 digits.

• If user forgets the password, there is a super password, which is valid all the time for

individual unit. It is the serial number which can be found on data plate. Total 10 digits,

including letters and numbers

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 46

Page 50

47

METTLER TOLEDO

30423600 | 01 | 09/2018

Setup+/Webserver

7. GEO Codes

The GEO code feature provided in the ACT350 POWERCELL transmitter permits calibration

readjustment due to changes in elevation or latitude without reapplying test weights. This

adjustment assumes a previously accurate calibration was completed with the GEO code set

properly for that original location, and that the GEO code for the new location can be accurately

determined. The procedure for using this feature is as follows.

7.1. Original Site Calibration

1. Use the GEO code chart on the following pages to determine the GEO code for the original

altitude and location at which the scale will be calibrated.

2. Enter that GEO value into the GEO code parameter in setup at Scale > Calibration.

3. Immediately after entering the GEO code, perform a zero and span adjustment using accurate

test weights.

4. Exit the setup menu tree

5. The scale can now be used in its new location.

7.2. New Site GEO Code Adjustment

When ACT350 POWERCELL is to be reinstalled at a different geographic location, gravitational

and altitude changes can be accounted for by changing the Geo Code. Note that this procedure

is not necessary if an on-site recalibration is performed.

1. Use the GEO code chart) on the following pages to determine the GEO code for the new

altitude and location at which the scale will be used.

2. Enter that GEO value into the GEO code parameter in Setup at Scale > Calibration.

3. Immediately after entering the GEO code, exit the setup menu tree. DO NOT perform a

normal calibration.

The calibration has now been adjusted for the differences in gravity from the original site of

calibration to the new site of use.

• Using the GEO code value for calibration adjustment is not as accurate as using certified test

weights and re-calibrating the scale at a new location.

ACT350 POWERCELL Transmitter User's Guide

Page 51

Table 7-1: GEO Adjustment Values

Height Above Sea Level, in Meters

Latitude

North

or South,

in

Degrees

and

Minutes

0 325 650 975 1300 1625 1950 2275 2600 2925 3250

325 650 975 1300 1625 1950 2275 2600 2925 3250 3575

Height Above Sea Level, in Feet

0 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660

1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 11730

0° 0'–5°

46'

5° 46'–9°

52'

9° 52'–

12° 44'

12° 44'–

15° 6'

15° 6'–

17° 0'

17° 10'–

19° 2'

19° 2'–

20° 45'

20° 45'–

22° 22'

22° 22'–

23° 54'

23° 54'–

25° 21'

5 4 4 3 3 2 2 1 1 0 0

5 5 4 4 3 3 2 2 1 1 0

6 5 5 4 4 3 3 2 2 1 1

6 6 5 5 4 4 3 3 2 2 1

7 6 6 5 5 4 4 3 3 2 2

7 7 6 6 5 5 4 4 3 3 2

8 7 7 6 6 5 5 4 4 3 3

8 8 7 7 6 6 5 5 4 4 3

9 8 8 7 7 6 6 5 5 4 4

9 9 8 8 7 7 6 6 5 5 4

25° 21'–

26° 45'

26° 45'–

28° 6'

28° 6'–

29° 25'

29° 25'–

30° 41'

30° 41'–

31° 56'

10 9 9 8 8 7 7 6 6 5 5

10 10 9 9 8 8 7 7 6 6 5

11 10 10 9 9 8 8 7 7 6 6

11 11 10 10 9 9 8 8 7 7 6

12 11 11 10 10 9 9 8 8 7 7

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 48

Page 52

49

METTLER TOLEDO

30423600 | 01 | 09/2018

Latitude

North

or South,

in

Degrees

and

Minutes

Height Above Sea Level, in Meters

0 325 650 975 1300 1625 1950 2275 2600 2925 3250

325 650 975 1300 1625 1950 2275 2600 2925 3250 3575

Height Above Sea Level, in Feet

0 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660

1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 11730

31° 56'–

33° 9'

33° 9'–

34° 21'

34° 21'–

35° 31'

35° 31'–

36° 41'

36° 41’–

37° 50’

37° 50’–

38° 58’

38° 58’–

40° 5’

40° 5’–

41° 12’

41° 12’–

42° 19’

42° 19’–

43° 26’

12 12 11 11 10 10 9 9 8 8 7

13 12 12 11 11 10 10 9 9 8 8

13 13 12 12 11 11 10 10 9 9 8

14 13 13 12 12 11 11 10 10 9 9

14 14 13 13 12 12 11 11 10 10 9

15 14 14 13 13 12 12 11 11 10 10

15 15 14 14 13 13 12 12 11 11 10

16 15 15 14 14 13 13 12 12 11 11

16 16 15 15 14 14 13 13 12 12 11

17 16 16 15 15 14 14 13 13 12 12

43° 26’–

44° 32’

44° 32’–

45° 38’

45° 38’–

46° 45’

46° 45’–

47° 51’

47° 51’–

48° 58’

48° 58’–

50° 6’

50° 6’–

51° 13’

17 17 16 16 15 15 14 14 13 13 12

18 17 17 16 16 15 15 14 14 13 13

18 18 17 17 16 16 15 15 14 14 13

19 18 18 17 17 16 16 15 15 14 14

19 19 18 18 17 17 16 16 15 15 14

20 19 19 18 18 17 17 16 16 15 15

20 20 19 19 18 18 17 17 16 16 15

ACT350 POWERCELL Transmitter User's Guide

Page 53

Height Above Sea Level, in Meters

Latitude

North

or South,

in

Degrees

and

Minutes

0 325 650 975 1300 1625 1950 2275 2600 2925 3250

325 650 975 1300 1625 1950 2275 2600 2925 3250 3575

Height Above Sea Level, in Feet

0 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660

1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 11730

51° 13’–

52° 22’

52° 22’–

53° 31’

53° 31’–

54° 41’

54° 41’–

55° 52’

55° 52’–

57° 4’

57° 4’–

58° 17’

58° 17'–

59° 32'

59° 32'–

60° 49'

60° 49'–

62° 9'

62° 9'–

63° 30'

21 20 20 19 19 18 18 17 17 16 16

21 21 20 20 19 19 18 18 17 17 16

22 21 21 20 20 19 19 18 18 17 17

22 22 21 21 20 20 19 19 18 18 17

23 22 22 21 21 20 20 19 19 18 18

23 23 22 22 21 21 20 20 19 l9 18

24 23 23 22 2\2 21 21 20 20 19 19

24 24 23 23 22 22 21 21 20 20 19

25 24 24 23 23 22 22 21 21 20 20

25 25 24 24 23 23 22 22 21 21 20

63° 30'–

64° 55'

64° 55'–

66° 24'

66° 24'–

67° 57'

67° 57'–

69° 35'

69° 5'–

71° 21'

71° 21'–

73° 16'

73° 16'–

75° 24'

26 25 25 24 24 23 23 22 22 21 21

26 26 25 25 24 24 23 23 22 22 21

27 26 26 25 25 24 24 23 23 22 22

27 27 26 26 25 25 24 24 23 23 22

28 27 27 26 26 25 25 24 24 23 23

28 28 27 27 26 26 25 25 24 24 23

29 28 28 27 27 26 26 25 25 24 24

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 50

Page 54

51

METTLER TOLEDO

30423600 | 01 | 09/2018

Latitude

North

or South,

in

Degrees

and

Minutes

Height Above Sea Level, in Meters

0 325 650 975 1300 1625 1950 2275 2600 2925 3250

325 650 975 1300 1625 1950 2275 2600 2925 3250 3575

Height Above Sea Level, in Feet

0 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660

1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 11730

75° 24'–

77° 52'

77° 52'–

80° 56'

80° 56'–

85° 45'

85° 45'–

90° 00'

29 29 28 28 27 27 26 26 25 25 24

30 29 29 28 28 27 27 26 26 25 25

30 30 29 29 28 28 27 27 26 26 25

31 30 30 29 29 28 28 27 27 26 26

ACT350 POWERCELL Transmitter User's Guide

Page 55

C

M

CalFree · 22

CalFreeplus Calibration · 16

Comparators · 14

Model Identification · 6

P

D

Physical Dimensions · 7

Device Description Files · 7

DIP switches · 36

Display Layout · 9

S

F

Front Panel · 8

Front Panel Keys · 9

I

Information Recall · 13

Sample Code · 7

Setting Linearity · 17

T

tare · 25

The Zero function · 24

V

L

LEDs Status · 10

Versions of PLC Interfaces · 6

X

x10 Resolution · 14

30303895 | 001 | 09/2018 METTLER TOLEDO ACT350 POWERCELL Transmitter User's Guide 52

Page 56

53

METTLER TOLEDO

30423600 | 01 | 09/2018

Figure1-1: ACT350 Model Identification Numbers ............................................................ 6

Figure1-2: ACT350 POWERCELL DIN Rail Mount Enclosure Dimensions ............................. 7

Figure 2-1 ACT350 POWERCELL® Front Panel Layout – PROFINET or EtherNet/IP ................ 8

Figure 2-2 ACT350 POWERCELL Front Panel Layout – PROFIBUS ...................................... 9

Figure 2-3 Display in Weighing Mode ............................................................................ 9

Figure 2-4 Numerical Data Entry Example ..................................................................... 13

Figure 2-5 Information Recall Menu ............................................................................. 14

Figure 2-6 x10 Indication ........................................................................................... 15

Figure 2-7 Setting Comparator Values (Limits) .............................................................. 16

Figure 2-8 Calibration Menu – Overview ....................................................................... 17

Figure 2-9 Zero Calibration ......................................................................................... 19

Figure 2-10 Zero Calibration with Motion ...................................................................... 19

Figure 2-11 Span Calibration ...................................................................................... 20

Figure 2-12 Step Adjustment ....................................................................................... 22

Figure 2-13 CalFreePlus ............................................................................................. 23

Figure 2-14 Password Entry Screen ............................................................................. 24

Figure 2-15 DIP Switches ........................................................................................... 24

Figure 2-16 Master Reset Confirmation ......................................................................... 24

Figure 2-17 ENTER button Zero Failure Message ............................................................ 25

Figure 3-1 DIN-Mount Latch ........................................................................................ 29

Figure 3-2 Latch Closure ............................................................................................ 29

Figure 3-3 ACT350 POWERCELL Interfaces – PROFIBUS (left) and PROFINET or EtherNet/IP

(right) ...................................................................................................................... 30

Figure 3-4 ACT350 POWERCELL, Top View ................................................................... 31

Figure 3-5: RS-232 Wiring Connection ......................................................................... 31

Figure 3-6: Digital Inputs and Outputs Specification ....................................................... 32

Figure 3-7 A Rising-edge Trigger Signal on Input ........................................................... 32

Figure 3-8 A Falling-edge Trigger Signal on Input ........................................................... 33

Figure 3-9 Sinking Input, Sourcing Output ..................................................................... 33

Figure 3-10 Sinking Input, Sinking Output ..................................................................... 34

Figure 3-11 Sourcing Input, Sourcing Output ................................................................. 34

Figure 3-12 Sourcing Input, Sinking Output ................................................................... 35

Figure 3-13 Ferrite Installed on POWERCELL Cable ........................................................ 36

Figure 3-14 Ferrite Installed on PROFIBUS DP Cable ....................................................... 36

Figure 3-15 ACT350 POWERCELL Sealing Diagram ....................................................... 38

Figure 6-1 Setup+ Splash Screen ................................................................................. 42

Figure 6-2 Setup+ Home Screen .................................................................................. 43

Figure 6-3 Webserver Splash Screen ............................................................................ 43

Figure 6-4 Local Area Connection Setting ...................................................................... 44

Figure 6-5 IE setting .................................................................................................. 44

Figure 6-6 Network setting of ACT350 POWERCELL Transmitter ....................................... 45

Figure 6-7 Enable password protection ........................................................................ 45

ACT350 POWERCELL Transmitter User's Guide

Page 57

www.mt.com

For more information

Mettler-Toledo, LLC

To protect your METTLER TOLEDO product’s future:

Congratulations on choosing the quality and precision

of METTLER TOLEDO. Proper use according to these

instructions and regular calibration and maintenance by

our factory-trained service team ensure dependable and

accurate operation, protecting your investment. Contact

us about a METTLER TOLEDO service agreement tailored

to your needs and budget.

We invite you to register your product at

www.mt.com/productregistration so we can contact you

about enhancements, updates and important notifications

concerning your product.

1900 Polaris Parkway

Columbus, OH 43240

Phone 800 438 4511

Fax 614 438 4900

© 2018 Mettler-Toledo, LLC

30423600 Rev. 01, 09/2018

Document version - V1

Loading...

Loading...