Page 1

8510pm

Technical Manual

and

Parts Catalog

A13401900A

+ Addendum for 8510-200XX

Revised 1/97

Page 2

INTRODUCTION

This publication is provided solely as a guide for individuals

who have received METTLER TOLEDO Technical Training in

servicing the METTLER TOLEDO product.

Information regarding METTLER TOLEDO Technical Training

may be obtained by writing to:

METTLER TOLEDO

Training Center

P.O. Box 1705

Columbus, Ohio 43216

(614) 438-4400

METTLER TOLEDO RESERVES THE RIGHT TO MAKE

REFINEMENTS OR CHANGES WITHOUT NOTICE.

This manual includes updated Information from the B13608000A Addendum. Revised 1/97.

Page 3

PRECAUTIONS

CAUTION

• • READ this manual before operating or

servicing this equipment.

• • ALWAYS REMOVE POWER and wait at

least 30 seconds BEFORE connecting or

disconnecting any internal harnesses.

Failure to observe these precautions may

result in damage to, or destruction of the

equipment.

• • ALWAYS take proper precautions when

handling static sensitive devices.

• • DO NOT connect or disconnect a load cell

scale base to the equipment with power

connected or damage will result.

WARNING

DISCONNECT ALL POWER

TO THIS UNIT BEFORE

REMOVING THE FUSE

OR SERVICING.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO

SERVICE THIS EQUIPMENT. EXERCISE CARE

WHEN MAKING CHECKS, TESTS, AND

ADJUSTMENTS THAT MUST BE MADE

WITH POWER ON.

• • SAVE this manual for future reference.

• • DO NOT allow untrained personnel to

operate, clean, inspect, maintain, service,

or tamper with this equipment.

• • ALWAYS DISCONNECT this equipment

from the power source before servicing.

• • CALL METTLER TOLEDO for parts,

information, and service.

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

Page 4

CONTENTS

1. GENERAL DESCRIPTION............................................................................... 1

2. SPECIFICATIONS......................................................................................... 1

2.1 ELECTRICAL ...............................................................................................................................1

2.2 OPERATING/STORAGE TEMPERATURE AND HUMIDITY........................................................ 1

2.3 CAPACITY/INCREMENT SELECTION TABLE............................................................................1

2.4 ANALOG BUILD PRELIMINARY CALCULATIONS .....................................................................2

2.5 CONFIGURATION GUIDE ............................................................................................................4

2.6 HAZARDOUS AREAS ..................................................................................................................4

2.7 LOAD CELL SPECIFICATIONS...................................................................................................4

2.8 OVERCAPACITY AND UNDER ZERO .........................................................................................4

2.9 DIGITAL DISPLAY .......................................................................................................................4

2.10 ENCLOSURE TYPE AND CLEANING ........................................................................................4

2.11 ZERO ..........................................................................................................................................5

2.12 TARE...........................................................................................................................................5

3. INSTALLATION ............................................................................................ 6

3.1 SET UP PROCEDURE .................................................................................................................6

3.2 DIGITAL LOAD CELL ADAPTER HARNESS INSTALLATION....................................................7

3.3 PANEL INSTALLATION...............................................................................................................8

3.4 JUMPER DESCRIPTIONS..........................................................................................................10

3.5 POWER REQUIREMENTS.........................................................................................................11

3.6 POWER UP SEQUENCE............................................................................................................11

4. PROGRAMMING AND CALIBRATION............................................................ 12

4.1 ACCESSING PROGRAMMING/CALIBRATION MODE..............................................................12

4.2 KEYBOARD FUNCTIONS.......................................................................................................... 12

4.3 QUICK REFERENCE CHART FOR SOFTSWITCHES............................................................... 13

4.4 PROGRAMMING AND CALIBRATION MODE...........................................................................14

5. RS232 SERIAL INPUT/OUTPUT................................................................... 28

5.1 SERIAL DATA OUTPUT IN DEMAND MODE ............................................................................28

5.2 SERIAL DATA OUTPUT IN CONTINUOUS MODE....................................................................30

5.3 AUTOPRINT AT SETPOINT.......................................................................................................32

5.4 REMOTE COMMAND INPUT .....................................................................................................32

5.5 PIN CONNECTIONS FOR RS232 SERIAL PORT...................................................................... 32

Page 5

6. LOAD CELL CONNECTIONS ........................................................................ 33

6.1 DIGITAL LOAD CELL CONNECTIONS .....................................................................................33

6.2 ANALOG LOAD CELL CONNECTIONS.....................................................................................35

6.3 JUNCTION BOX CONNECTIONS..............................................................................................36

7. SETPOINT/ANALOG/BCD OPTIONS .............................................................. 39

7.1 BCD AND SETPOINT OPTION INSTALLATION .......................................................................39

7.2 SETPOINT MODULE EXTERNAL WIRING AND OPERATION ................................................41

7.3 BCD OUTPUT WIRING AND SIGNAL DESCRIPTION ...............................................................44

7.4 ANALOG OUTOPUT OPTION INSTALLATION ........................................................................45

7.5 ANALOG OUTPUT I/O WIRING AND OPERATION...................................................................49

8. TROUBLESHOOTING .................................................................................. 51

8.1 VOLTAGE CHECKS ...................................................................................................................51

8.2 ERROR CODES .........................................................................................................................56

9. ACCESSORIES .......................................................................................... 57

10. INTERCONNECTING DIAGRAMS................................................................ 58

10.1 SYSTEM INTERCONNECTING DIAGRAM ..............................................................................58

10.2 OPTION KIT INTERCONNECTING DIAGRAMS......................................................................59

11. REPLACEMENT PARTS............................................................................. 60

11.1 8510 FRONT PANEL................................................................................................................60

11.2 8510 PCB’S & HARNESSES ILLUSTRATION .........................................................................61

11.3 8510 PCB’S & HARNESSES PARTS LIST.............................................................................62

11.4 BCD OUTPUT MODULE ...........................................................................................................63

11.5 SETPOINT MODULE................................................................................................................64

11.6 ANALOG OUTPUT MODULE ...................................................................................................65

Page 6

1. GENERAL DESCRIPTION

The Toledo 8510-2001 and 8510-2011 are panel mount digital indicators, intended for use with Toledo

DigiTOL ® Digital Load Cell Scale Bases or an Analog Load Cell Scale Bases or an Analog Load Cell

Scale Base using up to 4-350 ohm analog load cells. Weight and setup information is displayed on a 6digit 7-segment vacuum fluorescent display. Setup and calibration are performed using softswitches in

a “setup mode”. The setup information is retained in memory if power is removed from the 8510. The

keyboard is a 5-position non-tactile membrane type. Serial RS232 output is provided for the METTLER

TOLEDO 8806, 8860, 8840, 8842, and 8843 printers, or to a host device. Remote print, tare, clear, and

zero commands can be input from a host using certain ASCII characters through the RS232 serial port.

Options include an Analog Output kit, a BCD kit, and a Setpoint kit.

2. SPECIFICATIONS

2.1 ELECTRICAL

The Model 8510 Panel Mount Indicator does not have an ON/OFF Switch and is connected directly to the

power source with a line cord. Input power is approximately 10 watts. The incoming power is internally

fused by F1 on the Power supply PCB. Configurations are available for 120 VAC/60 Hz and 220/240

VAC/50 Hz. The Model 8510 Panel Mount Indicator is designed to operate at the following voltage

ranges:

FACTORY

NUMBER

8510-2001 120 VAC 100 TO 130 VAC .15A 59 TO 61 HZ

8510-2011 220/240 VAC 187 TO 264 VAC .08A 49 TO 51 HZ

Being micro-computer based, the Model 8510 is designed, manufactured, and tested to withstand certain

levels of voltage spikes, AC power sags and surges, and RFI (radio frequency interference). The Model

8510 requires AC power that is free of power noise, sags, and surges beyond the tested parameters and

within the rated voltage range.

The AC power must not be “shared with” equipment that is known to generate AC power noise in the

form of line spikes, voltage sags, or voltage surges. The term “shared with” means that the 8510 AC

power is connected on the same line or distribution box as the noise generating equipment, and that the

8510 does not have a noise isolation type transformer between it and the incoming power that is capable

of blocking the noise being generated.

2.2 OPERATING/STORAGE TEMPERATURE AND HUMIDITY

The Model 8510 will operate in a temperature range between -10 degrees C (14 degrees F) to 45 degrees

C (113 degrees F) with non-condensing relative humidity between 10 to 95%.

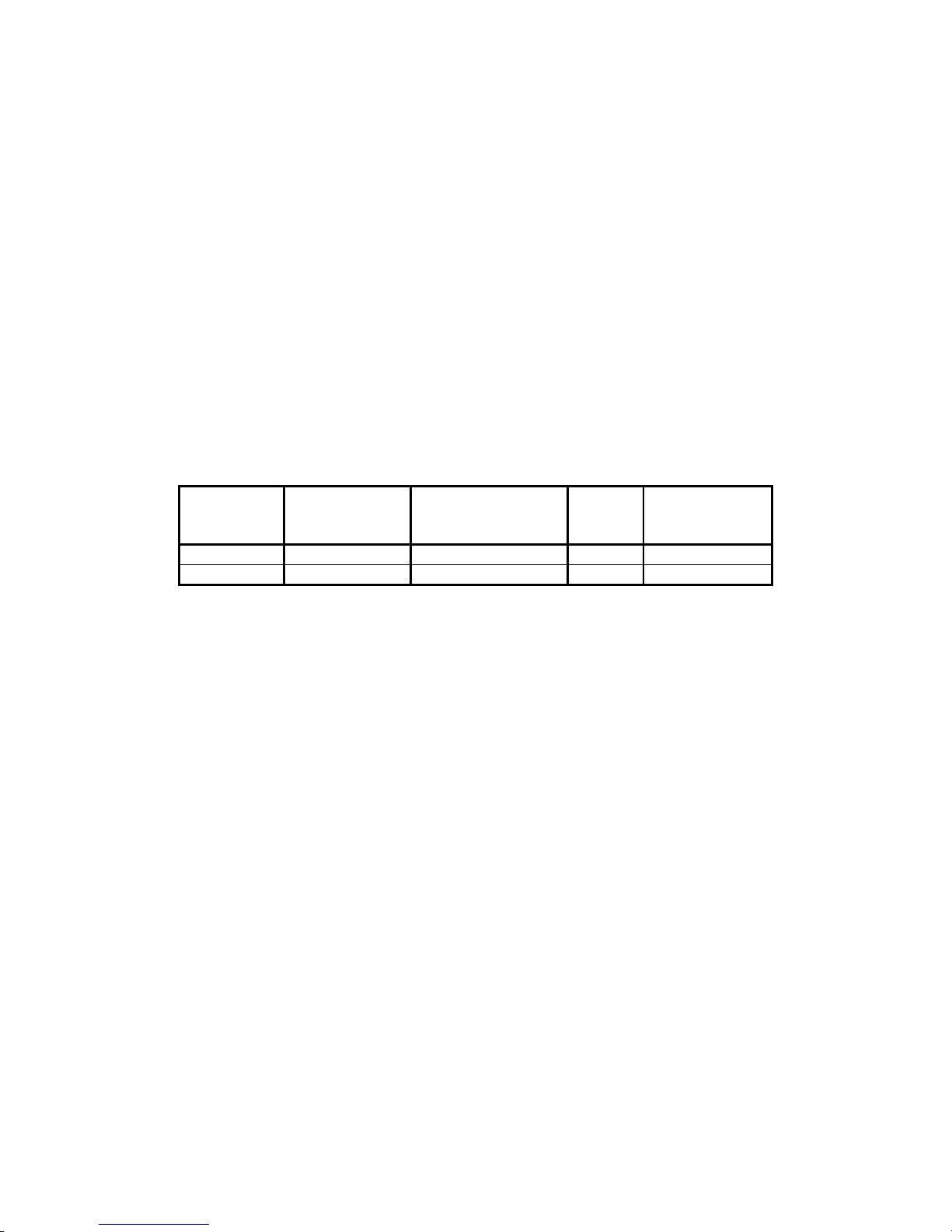

2.3 CAPACITY/INCREMENT SELECTION TABLE

Scale capacity and increment size is selected in the set-up mode and is limited to the combinations

listed in Table 1. Refer to the load cell or scale base data plate or the respective technical manual for

valid capacity/increment selections.

NOMINAL

VOLTAGE

ACCEPTABLE

VOLTAGE RANGE

RATED

AMPS

ACCEPTABLE

FREQ. RANGE

1

Page 7

Increment

Size

Displayed Divisions

(Capacity Selections)

lb, kg 1000 2000 3000 4000 5000 6000 10000

0.001 1 2 3 4 5 6 10

0.002 2 4 6 8 10 12 20

0.005 5 10 15 20 25 30 50

0.01 10 20 30 40 50 60 100

0.02 20 40 60 80 100 120 200

0.05 50 100 150 200 250 300 500

0.1 100 200 300 400 500 600 1000

0.2 200 400 600 800 1000 1200 2000

0.5 500 1000 1500 2000 2500 3000 5000

1 1000 2000 3000 4000 5000 6000 10000

2 2000 4000 6000 8000 10000 12000 20000

5 5000 10000 15000 20000 25000 30000 50000

10 10000 20000 30000 40000 50000 60000 100000

50 40000 100000 150000 200000 250000 300000 500000

TABLE 1 - CAPACITY/INCREMENT SELECTIONS FOR 8510-20X1

2.4 ANALOG BUILD PRELIMINARY CALCULATIONS

Before connecting the 8510 to an analog understructure, it must be determined if the load cell(s) are of a

size that will work correctly with the instrument and platform. If the installation is a standard build,

proceed with the installation. However, if the installation is a special build or a conversion of an

existing mechanical scale base, the microvolt per increment rating must be calculated. First calculate

the microvolts per increment, then check with the charts to make sure the proposed load cell(s) are the

correct size.

2.4.1 To find the microvolt per increment build, you must first find:

a) Scale capacity*

b) Increment size*

c) Number of load cells or total lever ratio

d) Capacity of load cell(s)*

e) Cell output rating in mV/V (millivolts per volt of excitation)j

* In lb or kg depending on how the scale is to be calibrated and used.

2.4.2 Next find the total load cell output in millivolts by multiplying the cell output rating* by the 8510

excitation voltage, 12.5 volts.

NOTE: Toledo load cells are 2mV/V. Other types may be 1mV/v, 1.75mV/V, or 3mV/V.

2.4.3 Use the following formula to calculate the microvolt per increment ratio.

Increment Size X Total Load Cell Output (mV) X 1000 Load

Cell Capacity X Number of Cells (or lever ratio)

2.4.4 Divide the scale capacity by the increment size to determine the number of increments to be

programmed.

2.4.5 Refer to Table 2 (2Mv/V Load Cells) or Table 3 (3mV/V Load Cells) for the check to see if the build

is necessary.

2

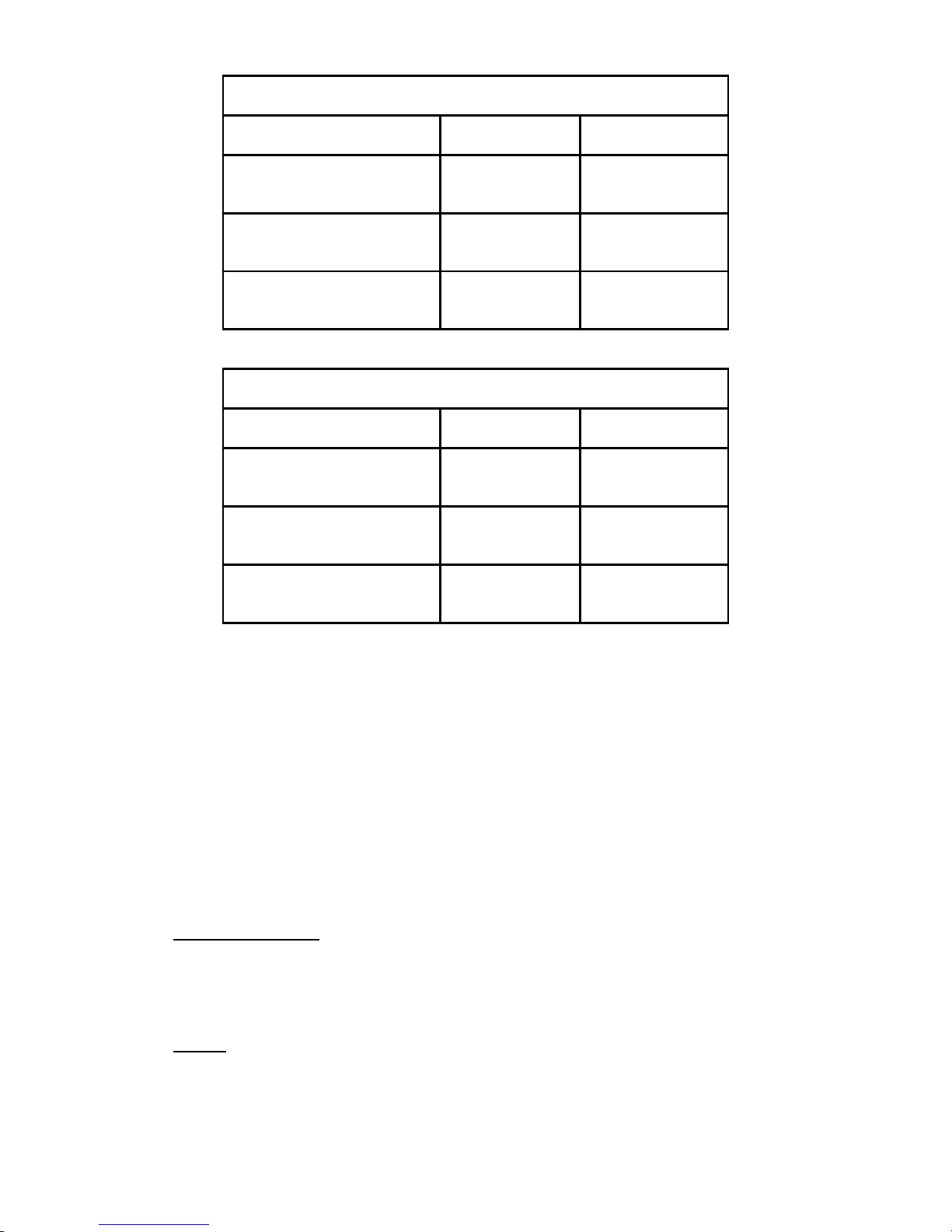

Page 8

NUMBER OF

INCREMENTS

1000

2000

2500

3000

4000

5000

6000

8000

10000

NUMBER OF

INCREMENTS

1000

2000

2500

3000

4000

5000

6000

8000

10000

TABLE 2 - 2MV/V LOAD CELLS

MICROVOLT PER INCREMENT CHART

FOR 2MV/V LOAD CELLS

MINIMUM

µV/INC

3.0

1.5

1.2

1.0

0.75

0.6

0.5

0.375

0.3

MAXIMUM

µV/INC

26

13

10.4

8.7

6.5

5.2

4.4

3.3

2.6

TABLE 3 - 2 MV/V LOAD CELLS

MICROVOLT PER INCREMENT CHART

FOR 2MV/V LOAD CELLS

MINIMUM

µV/INC

3.0

1.5

1.2

1.0

0.75

0.6

0.5

0.375

0.3

MAXIMUM

µV/INC

38

19

15.2

12.7

9.5

7.6

6.4

4.8

3.8

2.4.6 EXAMPLE FOR FINDING µV/INC:

MODEL 2155

Scale Capacity 5000 lb

Increment Size 1 Lb

Number of Cells 4

Capacity of Cell 2000 Lb

Cell Output Rating 2 mV/v

Step 1) Find total load cell output (mV)

2 mV/v X 12.5V = 25 mV

Step 2) Use the formula for finding µV/Inc.

1 lb X 25 mV X 1000

2000 lb X 4 = 3.13 µV/Inc.

Step 3) Divide scale capacity by increment size to determine number of increments to be

programmed.

5000 lb

1 lb = 5000 Increments

Step 4) Check the Microvolt Per Increment Chart Table 2 or 3, to see if this build fits into the 5000

increment range. If it does, this will be a satisfactory build.

3

Page 9

2.5 CONFIGURATION GUIDE

The Factory Configuration for the Model 8510 is as follows:

FACTORY

NUMBER CONFIGURATION

8510-2001

8510-2011

120 VAC 50/60 Hz PANEL MOUNT

220/240 VAC 50/60 Hz PANEL MOUNT

2.6 HAZARDOUS AREAS

DO NOT USE THE 8510 in locations classified as hazardous by the NATIONAL

ELECTRICAL CODE (NEC) because of combustible or explosive atmospheres.

2.7 LOAD CELL SPECIFICATIONS

2.7.1 ANALOG LOAD CELLS

The 8510 supplies 12.5 VDC load cell excitation voltage for up to four 350 ohm analog load cells (87.5

ohm max load). Jumper W1 on the Power Supply PCB is used to select either 2mv/v or 3mv/v load cells.

The initial range is adjustable from 0 to 15mV. Span is adjustable from 3 to 25 mV.

2.7.2 DIGITAL LOAD CELLS

A supply of 20 VDC at 180 ma is provided for the METTLER TOLEDO DigiTOL® digital load cell.

2.8 OVERCAPACITY AND UNDER ZERO

Overcapacity is indicated by display blanking and occurs at full capacity plus five (+5) increments.

Weight under zero will be displayed up to the negative out-of-range limit. The negative weight indication

will be preceded by a minus (-) sign. When the negative out-of-range limit is reached, the display will

blank.

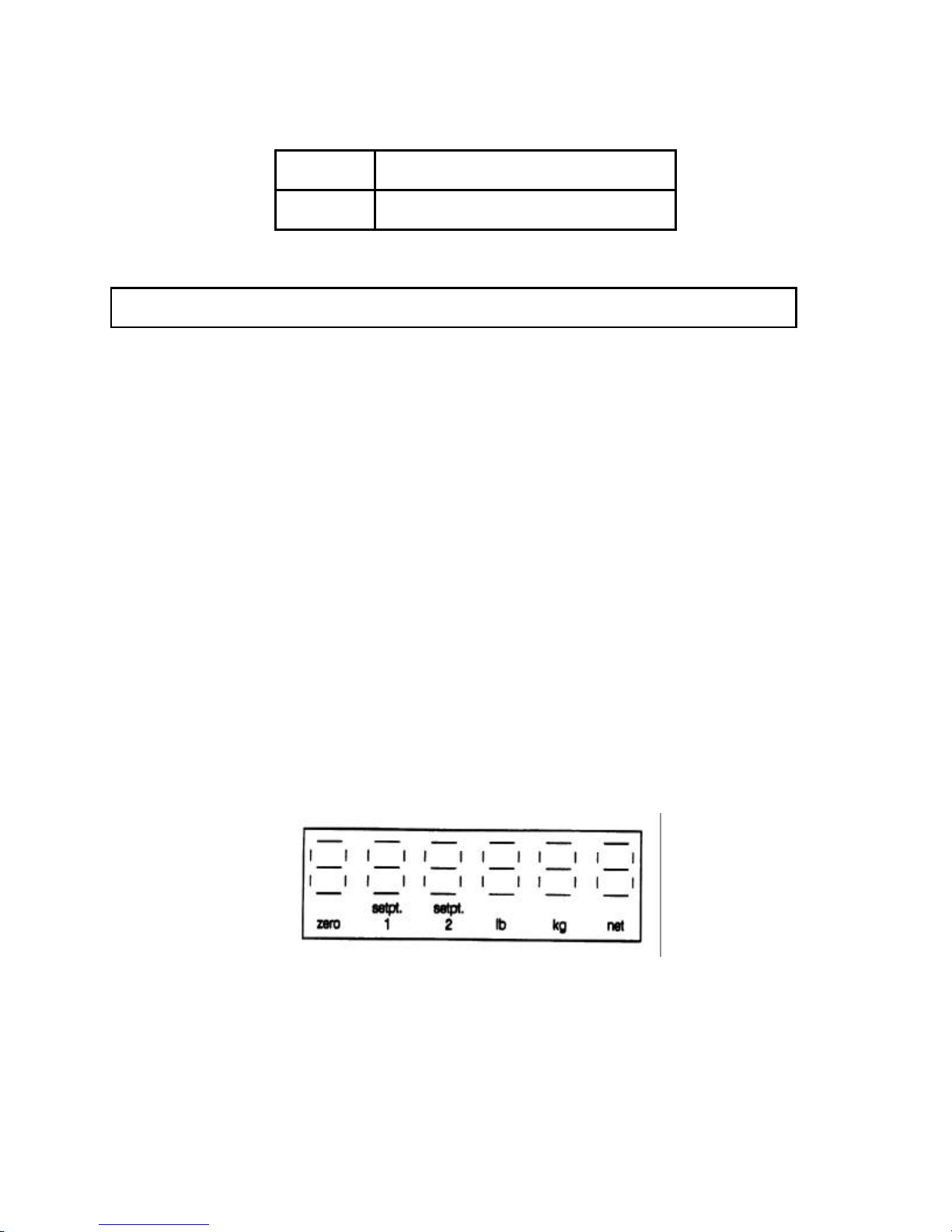

2.9 DIGITAL DISPLAY

The display is a green-blue vacuum fluorescent type. It consists of six 0.5” seven-segment digits with

lighted decimal point. Six fluorescent indicators are located below the display to correspond to printed

legends on the display lens, as shown in Figure 1. The display update rate for analog and digital load

cells is 12 updates/second.

FIGURE 1

2.10 ENCLOSURE TYPE AND CLEANING

The 8510-2001 and the 8510-2011 are housed in aluminum panel mount NEMA 1 enclosures with a

stainless steel front plate. An additional aluminum enclosure can be mounted on the back to house the

Analog, BCD, or Setpoint options. The enclosure is designed to be periodically cleaned only with a

clean cloth dampened with a mild window type cleaner. DO NOT USE ANY TYPE OF INDUSTRIAL

SOLVENT OR CHEMICALS. DO NOT SPRAY CLEANER DIRECTLY ONTO THE UNIT. DO NOT HOSE

DOWN.

4

Page 10

2.11 ZERO

2.11.1 AUTO ZERO MAINTENANCE (AZM)

The range of zero maintenance is limited to ± 2% of scale capacity, with the center of the range

determined during calibration. Weight variations which occur at a rate of 0.2 increments per second or

slower will be compensated. AZM can be disabled in the setup mode.

2.11.2 PUSHBUTTON ZERO

A front panel pushbutton provides re-zeroing of the scale over a range of ± 2% of scale capacity. The

ZERO pushbutton must be depressed while the scale is in a no-motion condition and at gross zero.

Pushbutton zero can be disabled in the setup mode.

2.11.3. POWER UP ZERO

When power is first applied to the scale, zero is automatically captured provided the weight is within +

2% of scale capacity, and a no-motion condition exists.

2.11.4 ZERO INDICATOR

The zero increment is ± 0.,5 increment wide. The display’s “zero indicator” is ON whenever the weight is

within ± 0.25 increment of the center of the zero increment.

2.12 TARE

2.12.1 PUSHBUTTON TARE

The TARE pushbutton on the keyboard can be used to tare a weight on the scale platform if the scale is

in a no-motion condition. If the weight is then removed from the scale platform, the Net Weight will be

displayed as a negative value. The NET indicator will be illuminated whenever a tare weight exists in the

Net Storage Register. Pushbutton Tare can be disabled in the setup mode. If the tare operation results

in a six digit negative net weight, the display will alternate between the weight value and a blank display

with a minus sign.

2.12.2 REMOTE TARE

If enabled in setup mode, a remote tare command using ASCII input will tare the weight on the scale

platform, providing the scale is in a no-motion condition. A remote tare clear command from a host will

clear the tare value if the weight has settled to a no-motion condition. See Section 5.4 for details.

2.12.3 MANUAL AND AUTO CLEAR TARE

Tare can be cleared manually by use of the CLEAR pushbutton, or automatically if the weight has settled

to a no-motion condition at a weight greater than 10 increments and returned to less than 0.5 major

increments from zero gross weight.

5

Page 11

3. INSTALLATION

Follow the instructions in this section carefully to install and program the Model 8510. Make sure that all

requirements in the specifications Section 2 of this manual have been met and verified before

proceeding. If any problems are encountered when programming, refer to the Troubleshooting Section

of this manual (Section 8).

3.1 SET UP PROCEDURE

3.1.1 Examine the shipping carton for any signs of damage. IF DAMAGE IS FOUND, FILE A CLAIM WITH

THE CARRIER IMMEDIATELY.

3.1.2 Open the carton and continue the inspection, checking for damaged or missing parts. The carton

should contain the following:

1 - 8510 Digital Indicator

1 - P/N 13358900A Digital Load Cell Harness

1 - P/N 13401400A Template for Panel Mounting

1 - P/N 13401300A Gasket

1 - DB-9 Connector Kit for Load Cell Cable

1 - Technical Manual

3.1.3 CAUTION! THE TYPE OF SCALE BASE (ANALOG OR DIGITAL) MUST BE VERIFIED BEFORE

PROCEEDING. The 8510 is shipped with the analog load cell harness installed. If the scale base is the

standard analog type, install the supplied DB-9 connector to the load cell cable as described in Section

6.2 of this manual. The analog load cell scale base can then be connected to the Load Cell Port without

further modification to the 8510. A listing of recommended Toledo Analog Scale Bases can be found in

Section 2.4 of this manual.

CAUTION!

DO NOT CONNECT AN ANALOG SCALE BASE TO THE 8510 WITH THE DIGITAL LOAD CELL

ADAPTER HARNESS INSTALLED OR DAMAGE WILL RESULT. DO NOT CONNECT A DIGITAL

SCALE BASE TO THE 8510 WITH THE ANALOG LOAD CELL HARNESS INSTALLED OR

DAMAGE WILL RESULT.

If a digital load cell scale base will be used with the 8510, the internal analog load cell harness must be

removed and the digital load cell adapter harness, p/n 13358900A shipped with the 8510, must be

installed. A list of recommended Toledo Digital Load Cell Scale Builds can be installed. A list of

recommended Toledo Digital Load Cell Scale Builds can be found in Section 2.3 of this manual. Refer to

Section 3.2 for instructions on installing the digital load cell adapter harness, and Section 6.1 for

instructions on connecting the supplied DB-9 connector kit to the digital load cell scale base cable.

3.1.4 Install option kits at this time. Instructions for installing the Analog, BCD, or Setpoint Modules

can be found in Section 7 of this manual.

3.1.5 Set the internal jumpers listed in Section 3.4 for the application. Jumper W2 must be shorted to

enable access into the setup mode used to program the 8510.

3.1.6 If installing the 8510 in a panel mount, refer to Section 3.3.

3.1.7 Refer to section 3.5 to make sure all power requirements have been met before connecting the

8510 to the power source. Make sure the power matches the voltage listed on the equipment data

plate. Before connecting power make sure all external wiring and cables are connected.

6

Page 12

3.1.8 After all options are installed and all external wiring and cables are connected, the 8510 can be

connected to AC power. Refer to Section 3.6 for the Power Up Sequence. If problems are

encountered, refer to Section 8, Troubleshooting in this manual.

3.1.9 The 8510 is now ready for programming and calibration. Refer to Section 4 for programming and

calibration instructions.

3.2 DIGITAL LOAD CELL ADAPTER HARNESS INSTALLATION

If a digital load cell scale base is used with the model 8510, the analog load cell harness, p/n 13356700A,

must be removed and the internal digital load cell adapter harness, p/n 13358900A shipped with the

8510, must be installed prior to connecting the digital scale base.

CAUTION!

DO NOT CONNECT OR DISCONNECT A DIGITAL LOAD CELL TO THE 8510 WITH POWER ON

OR DAMAGE TO THE 8510 AND THE DIGITAL LOAD CELL MAY RESULT.

To install the 13358900A digital load cell adapter harness in the 8510:

3.2.1 Disconnect power to the 8510 Indicator.

WARNING!

DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE FUSE

OR SERVICING.

3.2.2 Remove the four nuts holding the back enclosure to the front plate assembly. Set the nuts aside

for later use. Separate the back enclosure from the front plate assembly.

3.2.3 Disconnect the printer harness at J3, the analog load cell harness at J4, and the power cord at J5

on the Power Supply PCB. Remove the analog load cell harness DB-9 connector mounted on the

rear cover.

3.2.4 Install the DB-9 connector on the new 13358900A digital load adapter harness in the hole in the

8510 rear cover where the analog load cell harness was located. Use the existing screwlock kit to

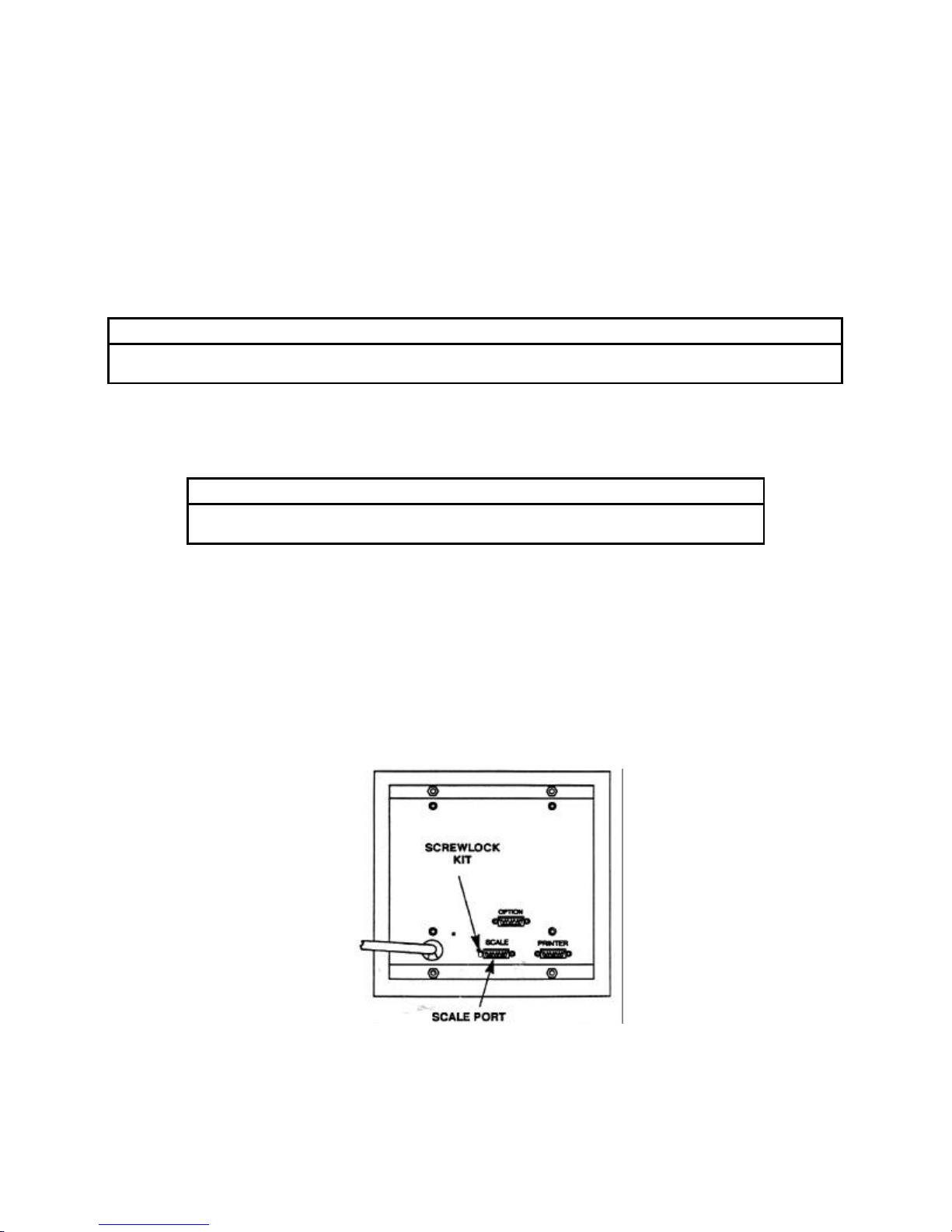

secure the connector. (See Figure 2)

FIGURE 2

7

Page 13

3.2.5 Connect the dual-5 connector from the 13358900A digital load cell adapter harness to J2 on the

OPEN

6.75

7.25

7.75

7.62

6.62

6.00

Power Supply PCB. The connector is keyed at pin 3. (Refer to Figure 6 for connector locations).

3.2.6 Reconnect the printer harness to J3 on the Power Supply PCB. Reconnect the power cord to J5

on the Power Supply PCB.

3.2.7 Reassemble the back cover to the front cover plate assembly using the four nuts removed in Step

2.

3.2.8 Refer to Section 6.1 to connect the digital load base to the model 8510 digital load cell port.

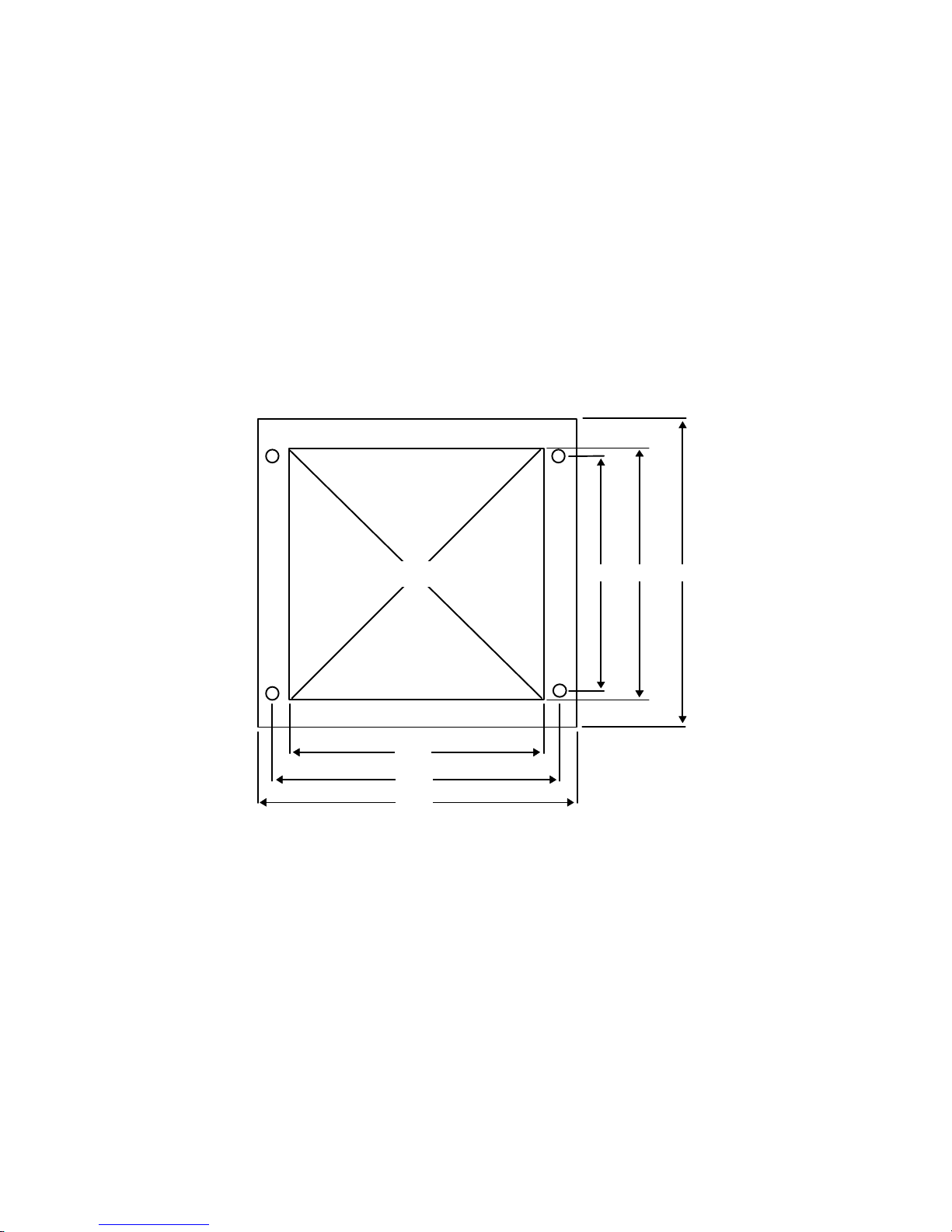

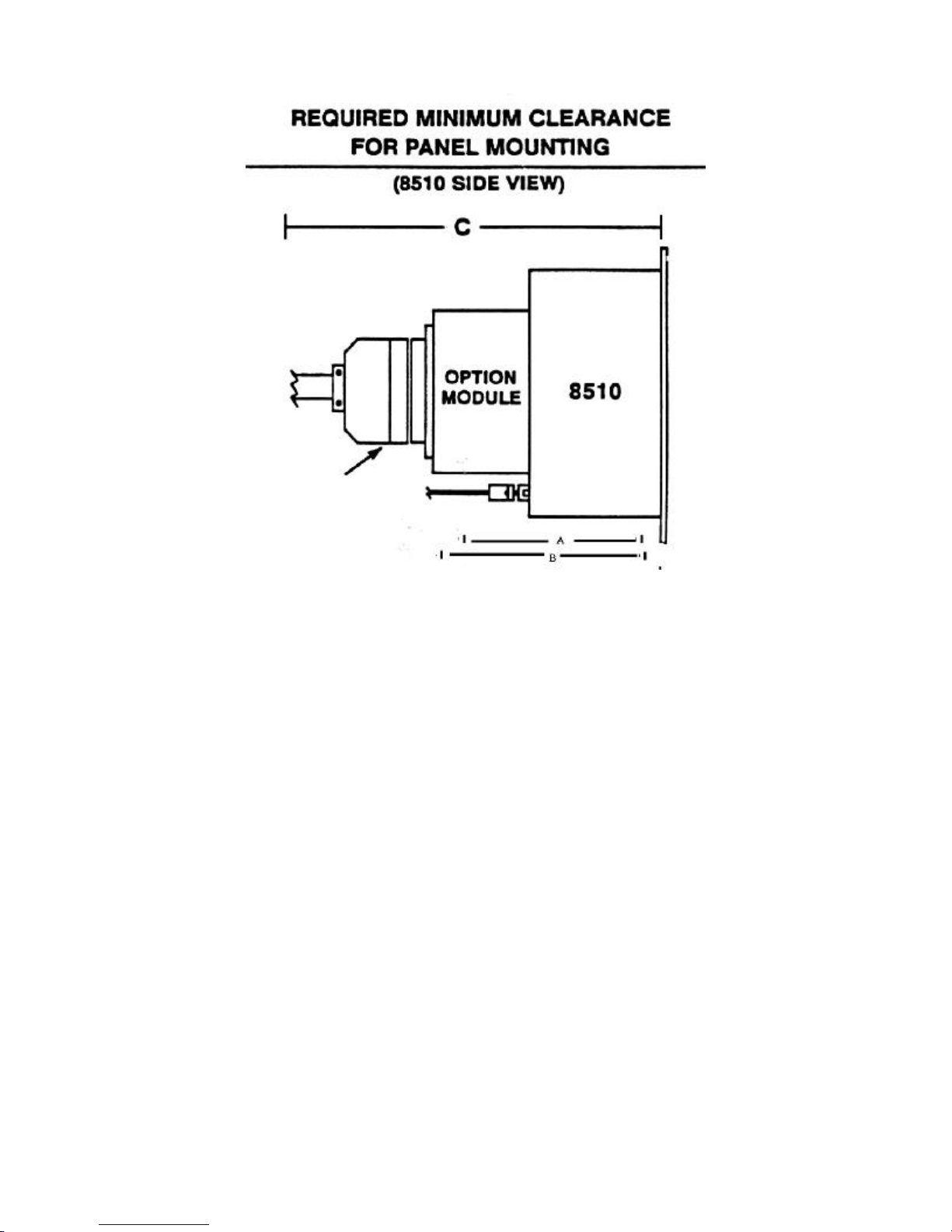

3.3 PANEL INSTALLATION

The models 8510-2001 and 8510-2011 are designed for panel mounting applications. The 8510 can be

mounted in a 6.75” x 6.62” cutout in a panel. To install the 8510 directly in a panel, use the template

shipped with the unit as a guide for the cutout and holes necessary to mount the 8510. The dimensions

for the cutout and mounting holes and minimum clearance required are listed below in Figure 3 and

Figure 4.

FIGURE 3

REQUIRED MINIMUM CLEARANCE

FOR PANEL MOUNTING

(8510-20XX SIDE VIEW)

8

Page 14

BCD Connector

A = 6” MIMIMUM CLEARANCE REQUIRED FOR 8510 W/O OPTION MODULE

B = 7” MINIMUM CLEARANCE REQUIRED FOR 8510 WITH SETPOINT MODULE OR ANALOG MODULE

C = 9” MINIMUM CLEARANCE REQUIRED FOR 8510 WITH BCD MODULE AND CONNECTOR

FIGURE 4

9

Page 15

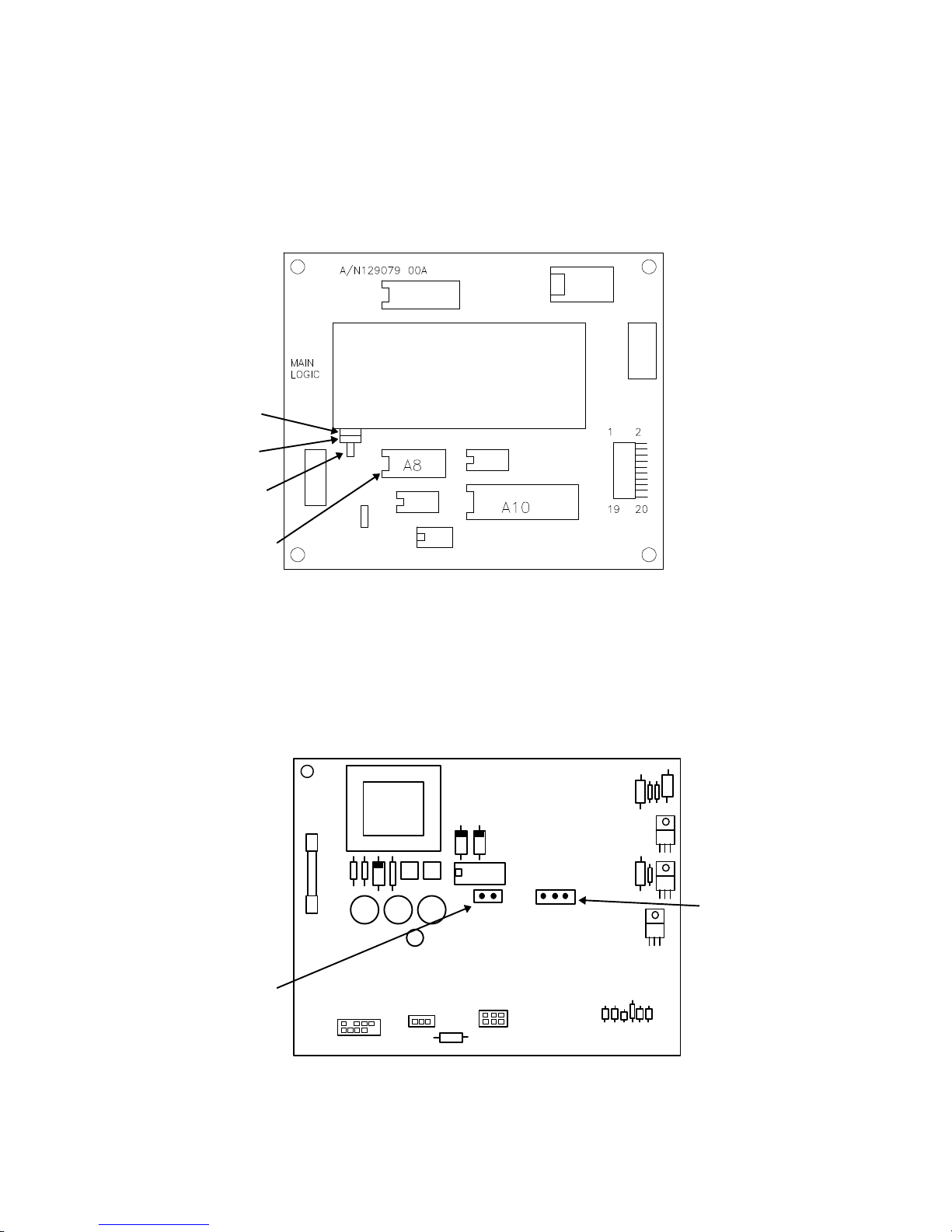

3.4 JUMPER DESCRIPTIONS

A1

2mV/V 3mV/V

CALIBJ4J3

3.4.1 The jumpers on the Main Logic PCB are as follows: (Refer to Figure 5)

W1 - Open = Display Decimal Point

Shorted = Display Metric Comma

W2 - Pins 1 & 2 Shorted = 256K EPROM in use (normal position).

Pins 2 & 3 Shorted = 512K EPROM in use

W3- Shorted = Normal Position

Open = Factory Use Only

W1

W2

W3

EPROM A8

FIGURE 5

3.4.2 The jumpers on the Power Supply PCB are as follows: (Refer to Figure 6)

W1 - 2 mv/v or 3 mv/v load cell select

W2 - Open = Disable entry into Setup Mode

Shorted = Enable entry into Setup Mode by pressing the ZERO and PRINT

pushbuttons simultaneously.

POWER SUPPLY PCB

W1W2

W2

W1

DLC

FIGURE 6

10

Page 16

3.5 POWER REQUIREMENTS

WARNING!

FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD, CONNECT TO

A PROPERLY GROUNDED OUTLET. DO NOT REMOVE THE GROUND

PRONG.

The 8510 requires a properly grounded dedicated AC power line which must not be shared with other

types of electrical equipment which may generate “noise spikes” or “power surges”. The equipment

ground prong on the power cord must not be removed or bypassed using an adapter plug.

No AC voltage should exist between the Neutral and Ground lines. Voltage readings (between Neutral

and Ground) above 0.1 VAC indicate a problem with the ground line, and should be corrected before

connecting the 8510 to the line.

The supplied AC voltage to the 8510 must be within tolerances shown on the chart in Section 2.1, and

transient free. An isolation/regulation type transformer for electronic equipment may be required if these

types of problem conditions exist, and cannot be corrected at the source.

3.6 POWER UP SEQUENCE

On power up, the 8510 will display the following:

[888888] - All segments will momentarily illuminate.

[129123] - The Software Part Number will briefly display.

[L RR] - The Revision Level (RR) of the Software will briefly display. Example: L05 = “E” revision

software)

[xxxxxx] - The weight (x) will display next (or zero). If the Setpoint Option is enabled (F11), when the

weight or zero is displayed, the setpoint outputs will immediately turn ON if below SP1/SP2

target values or zero tolerance (SP3) will turn ON if within the preset tolerance from zero. If

the Analog Output is installed, the outputs will increase to maximum and the switched

output will open. If F4 is set to 1, 2, or 3, zero will be captured on power-up if the weight is

within ± 2% of scale capacity.

11

Page 17

4. PROGRAMMING AND CALIBRATION

4.1 ACCESSING PROGRAMMING/CALIBRATION MODE

To access the Programming/Calibration mode, jumper “W2” on the power Supply PCB (Refer to Figure

6) must first be installed on the two pins at location W2. Jumper W2 may be left on permanently, or

removed to prevent unauthorized entry into the setup mode after initial installation. When W2 is

installed, press and hold the PRINT key, then press the ZERO key to enter the Programming/Calibration

mode.

4.2 KEYBOARD FUNCTIONS

The functions of the keyboard in Normal Mode and Program Mode are as follows:

KEY FUNCTION MODE

Normal Mode:

ZERO

Program Mode:

Pressing this key will return the indicator to a gross

zero condition. (per section 2.11)

Used as a cursor key to backup to the previous

softswitch or to increment the active digit by one.

SELECT

SETPT.

TARE Normal Mode:

CLEAR Normal Mode:

PRINT Normal Mode:

Normal Mode:

Program Mode:

Program Mode:

Program Mode:

Used to select setpoints when the optional setpoint kit

is enabled. (f11)

Toggles fast/slow mode in f11.5, etc.

Used to tare the applied weight on the scale platform

(per section 2.12)

Used to change the status of the soft switch (on/off) or

to toggle through a selection of softswitch options.

When variable data is required, the tare key selects the

active (blinking) digit. At softswitch f11.4 tare is used

to bypass preact entry and advance to f12

USED TO CLEAR DISPLAYED TARE weight.

Advance to end of setup mode (cal off) or zero the

display and start over. At softswitch f11.3 when sp1 is

displayed, pressing clear will bypass setpoint entry and

advance to f11.4.

Used to initiate data transfer through the serial port to

host or printer.

Program Mode:

Advance to next softswitch and accept the displayed

data or softswitch status.

12

Page 18

4.3 QUICK REFERENCE CHART FOR SOFTSWITCHES

Following is a quick reference chart for the Model 8510 softswitches in program mode. The softswitch

number (SSW#) will be listed first followed by the initial default setting at power up.

(Example: [F0 X] where F0 = SSW#, and X = default setting)

SSW#/DEFAULT DESCRIPTION

[F0 0] SPAN ADJUST

[F1 0] ZERO ADJUST

[F2 0] LOAD CELL TYPE

[F3 1] CALIBRATION UNITS LB OR KG (LB = 1)

[F4 1] AUTOZERO MAINTENANCE (1 = 0.5d)

[F5 0] PUSHBUTTON ZERO ENABLE

[F6 0] MOTION SENSITIVITY

[F7 0] FILTER SENSITIVITY (0 = OFF)

[F7.1 0] DigiTOL® LOAD CELL FILTER

[F8 0] EXPANDED DISPLAY

[F9 1] TARE ACTIVE

[F10 0] AUTO TARE CLEAR

[F11 0] SETPOINT OPTION SELECT

[F11.1 0] SETPOINT ZERO TOLERANCE RANGE

[F11.2 0] BCD MOTION SYNC

[F11.3 0] SETPOINT VALUE ENTRY IN SETUP ONLY

[F11.4 0] SELECT PREACT VALUES

[F11.5 0] ANALOG OUTPUT TRIMMING

[F11.6 0] CALIBRATION OF ANALOG OUTPUT

[F11.7 0] ANALOG ZERO CALIBRATION WITH TEST WEIGHTS

[F11.8 0] ANALOG ZERO CALIBRATION VIA KEYBOARD

[F11.9 0] ANALOG SPAN CALIBRATION WITH TEST WEIGHTS

[F11.E 0] ANALOG SPAN CALIBRATION VIA KEYBOARD

[F12 0] PRINTER OUTPUT SETPUP CONTINUOUS OR DEMAND

[F12.1 1] CONTINUOUS OR DEMAND OUTPUT (1 = DEMAND)

[F12.2 ] BAUD RATE [9600 ]

[F12.3 2] PARITY SELECT (2 = EVEN)

[F12.4 0] STX/CHECKSUM SELECT

[F12.5 0] DATA FORMAT (0 = DISPLAYED WGT ONLY) EXPANDED PRINT ENABLE

[F12.6 0] EXPANDED PRINT ENABLE

[F12.7 0] AUTOPPRINT AT SP1

[F12.8 0] AUTOPRINT AT SP2

[F13 0] ENABLE REMOTE COMMAND INPUTS

[F14 0] LOAD CELL QUANTITY/SHIFT ADJUST

[F15 0] DISPLAY INDIVIDUAL CELL OUTPUT

[F19 0] ZERO CURSOR ENABLE

[F99 0] RESET TO FACTORY DEFAULTS

[CAL 0] CALIBRATION MODE

NOTE: THE LEVEL L05 OR HIGHER SOFTWARE (“E” OR HIGHER REVISION EPROM 12912300A)

AUTOMATICALLY DETECTS OPTION HARDWARE INSTALLED AND WILL DISPLAY ONLY VALID

SOFTSWITCHES.

13

Page 19

4.4 PROGRAMMING AND CALIBRATION MODE

SSW #/PROMPT DESCRIPTION

[F0 ] CALIBRATION ADJUST FEATURE

NOTE: TEST WEIGHTS MUST BE ON THE SCALE BEFORE ENTERING THIS STEP CALIBRATION

ADJUST IS A FINE ADJUSTMENT FEATURE TO BE USSED ONLY AFTER FULL CALIBRATION.

0 = Bypass OD and Go to SSW F1

[000000]

1 = Start span calibration adjustment. First place test weight on platform. Display

will show [000000] with the MSD (most significant digit) active (blinking). (If

PRINT is pressed with display showing [000000], the procedure is aborted).

Enter the value of the test weight.

- Press ZERO to increment the active digit by one

- Press TARE to move to the next lower MSD

- Press PRINT to accept displayed value and go to F1

- Press CLEAR to zero the display and start over

[F1 ] ZERO ADJUST

0 = Bypass SSW and go to F@

1 = Enter current initial weight on scale as zero. Display will count down from 15 while setting

the new initial. Scale motion will cause countdown to restart from 15.

- Press PRINT to start procedure

- Press CLEAR during countdown to abort procedure

[F2 ] LOAD CELL TYPE

0 = Analog load cell(s)

1 = Digital load cell/Power Module

[F3 ] CALIBRATION UNITS

1 = Pounds

0 = Kilograms

14

Page 20

[F4 ] AUTOZERO MAINTENANCE (AZM, REFER TO SECTION 2.11)

AZM is a feature that maintains the displayed zero in the center of the zero increment. This step

selects the size of the window over which zero change is compensated for at the rate of 0.2

increments per second. If the weight exceeds the AZM window, then AZM is disabled. As long as

the weight is within the AZM window selected, the 8510 will remove 0.2 increments of the zero

change per second. AZM will correct for zero drift up to a maximum of ±4% of scale capacity, with

the center of the zero range determined during calibration.

Normal AZM is disabled when the 8510 is in the net weight mode. Selection 4 permits AZM to

operate in the net weight mode as well as in the gross mode when the weight on the scale is

within 3 increments of gross zero. When AZM is enabled, zero is captured at power-up if the

weight on the scale is within ±2% of scale capacity of gross zero.

Selection AZM Window Legal-For-Trade Application

0 AZM Disabled Not Applicable

1 ± 0.5 Increment (Gross Mode Only) Animal, Food, & Retail Scale

2 ± 1 increment (Gross Mode Only) All other Industrial Scales

3 ± 3 Increment (Gross Mode Only) Vehicle Scales

4 ± 3 Increment (Gross Mode Only) Not Applicable

[F5 ] PUSHBUTTON ZERO

0 = Pushbutton Zero Disabled

1 = ± 2 of Scale Capacity

2 = ± 20 of Scale Capacity

[F6 ] MOTION SENSITIVITY

The 8510 includes a weight in motion detector which requires three successive weight readings

within the selected range of either 1.0 or 3.0 increments for a “no-motion” signal. The motion

detector signal inhibits pushbutton or remote ZERO, TARE, and PRINT.

0 = Disable Motion Detector

1 = 1.0 increment sensitivity

2 = 3.0 increment sensitivity

[F7 ] FILTER SENSITIVITY

The 8510 has a low pass multi-pole digital filter that is selectable for various environmental

conditions. The display update rate is slowed slightly when more filtering is selected. By

selecting higher filter rates, more movement or vibrations to the scale platform can be filtered out.

0 = No added filtering (Least)

1 = Light filtering

2 = Medium filtering

3 = Heavy filtering

15

Page 21

[F7.1 ] DigiTOL® LOAD CELL FILTER

DigiTOL® load cell bases provide a built-in digital filter that can interfere with slow speed filling or

batching operation. This filter MUST be disabled for setpoint applications. This step is only

displayed if the 8510 is configured for DigiTOL® load cell base.

0 = DigiTOL® Load Cell Filter Disabled

1 = DigiTOL® Load Cell Filter Enabled (default)

[F8 ] EXPANDED DISPLAY

This feature will allow the 8510 to display minor increments (0.1 d) on the display. This feature is

used for test purposes only. Operate in the normal display mode only.

0 = Normal display mode

1 = Minor increments are displayed

[F9 ] TARE MODE

When auto-tare is selected, a tare is taken whenever the 8510 is in the gross weight mode and the

scale settles on a weight greater than 5 increments above gross zero.

0 = Tare disabled. Advance to F11

1 = Pushbutton Tare mode only. Advance to F10

2 = Auto-Tare mode only

[F10 ] AUTO CLEAR TARE

When enabled, Auto Clear Tare will automatically clear the entered tare value if the weight has

settled to a no-motion condition at a weight greater than 10 d increments and then returned to less

than 0.5 d increments from gross zero.

0 = Disable Auto Clear Tare

1 = Enable Auto Clear Tare. Tare will clear with return to gross zero

NOTE: THE LEVEL L05 (“E” OR HIGHER REVISION SOFTWARE) AUTOMATICALLY DETECTS ANY

INSTALLED OPTION MODULES. IF THE SETPOINT HARDWARE IS CONNECTED, F11.1 WILL BE

THE NEXT PROMPT. IF BCD HARDWARE IS CONNECTED, F11.2 WILL BE THE NEXT PROMPT. IF

ANALOG HARDWARE IS CONNECTED, F11.5 WILL BE THE NEXT PROMPT. IF NO HARDWARE IS

ATTACHED, F11 WILL E THE NEXT PROMPT. ONLY VALID SELECTIONS ARE DISPLAYED.

[F11 ] SETPOINT OPTION SELECT (no hardware attached)

0 = Setpoint option not enabled. Proceed to F12

1 = Setpoint Option enabled. Proceed to F11.1

[F11.1 ] SELECT ZERO TOLERANCE RANGE

Zero tolerance range provides ability to select a bandwidth in which Setpoint SP3 is turned on.

0 = 0 Increments (SP3 output off)

1 = 1 d Increment

5 = 5 d Increments

- Press TARE to display selections

- Press PRINT to enter selection and advance to F11.3

16

Page 22

[F11.2 ] SELECT BCD MOTION SYNC (Displayed only when BCD is installed)

0 = BCD and status lines active all the time

1 = BCD and status lines Over, Under, and Net, updated only during no-motion conditions.

Motion line is inactive.

- Press TARE to toggle selection

- Press PRINT to enter selection and advance to F12

[F11.3 ] SELECT SETPOINT ENTRY ONLY FROM SETUP

0 = Setpoint values can be entered or changed using the “Select Setpt.” pushbutton on the 8510

front panel during normal operation. Proceed to F11.4.

1 = Setpoint values can be recalled for display only using the “Select Setpt.” pushbutton. The

setpoint values must be entered or changed in the setup mode using the following steps:

[SP1 ] SETPOINT 1

Press PRINT to advance to CURRENT SETPOINT 1 VALUE

- Press CLEAR to advance to [F11.4]

- Press ZERO to back up to [F11.3].

[XXXXXX] CURRENT SETPOINT 1 VALUE

Display now shows previous setpoint 1 value (x).

- Press ZERO to back up [SP1]

- Press PRINT to accept displayed value and go to [SP2]

- Press CLEAR to zero display before entering a new value

[E20 ] ERROR 20

May display when an incorrect entry is made. Indicates existing Preact value is greater than

setpoint value. Clear setpoint value, then re-enter SP1 value. (E20 will display for 2 seconds, then

SP1 prompt will display again). Refer to [F11.4].

[000000] ENTER NEW SETPOINT 1 VALUE

When CLEAR is pressed, the display will show zeros with the MSD as the active digit.

- Press TARE to move to the next decade position

- Press ZERO to increment active digit by one

- Press PRINT to accept displayed value and advance to SP2

- Press CLEAR to zero display and start over

17

Page 23

[SP2 ] SETPOINT 2

- Press PRINT to advance to CURRENT SETPOINT2 VALUE

- Press CLEAR to advance to [F11.4]

- Press ZERO to back up to [SP1]

[XXXXXX] CURRENT SETPOINT 2 VALUE

The display will show the previous Setpoint 2 value (x).

- Press ZERO to back up to [SP1 ]

- Press PRINT to accept value and go to [F11.4]

- Press CLEAR to zero display and enter new value

[000000] ENTER NEW SETPOINT 2 VALUE

When CLEAR is pressed the display will show zeros with the MSD as the active digit.

- Press TARE to move to the next decade position

- Press ZERO to increment active digit by one

- Press CLEAR to zero display and start over

- Press PRINT to accept the displayed value and proceed to [F11.4]

E20 ] ERROR 20

May display when an incorrect entry is made. Indicates existing Preact value is greater than

setpoint value. Clear setpoint value, then re-enter SP1 value. (E20 will display for 2 seconds, then

SP1 prompt will display again.) Refer to [F11.4].

[F11.4 ] SELECT PREACT VALUES

Preact Values are used to adjust the corresponding setpoint values as follows:

Setpoint = Setpoint value - Preact Value.

- Press TARE to bypass preact entry and advance to [F12]

- Press PRINT to enter or recall/modify preact values

[P1 ] ENTER/RECALL PREACT FOR SETPOINT 1

- Press CLEAR to advance to end of setup

- Press PRINT to advance to CURRENT PREACT VALUE FOR SETPOINT 1

[XXXXXX] CURRENT PREACT VALUE FOR SETPOINT 1

- Press ZERO to back up to [P1]

- Press PRINT to accept entry and go to [P2]

- Press CLEAR to zero display before entering a new value

18

Page 24

[000000] ENTER NEW PREACT VALUE FOR SETPOINT 1

Display now shows zeros with the MSD as the active (blinking) digit.

- Press ZERO to increment active digit by one

- Press TARE to move to the next LSD

- Press PRINT to accept displayed value and advance toP2. (E20 = preact value is greater than

the value entered for setpoint).

- Press CLEAR to zero display and start over

[P2 ] ENTER/RECALL PREACT FOR SETPOINT 2

- Press CLEAR to advance to end of setup

- Press PRINT to advance to CURRENT PREACT VALUE FOR SETPOINT 2

- Press ZERO to back up to [P1]

[XXXXXX] CURRENT PREACT VALUE FOR SETPOINT 2

Display now shows previous preact entry or zeros.

- Press ZERO to back up to [P2]

- Press PRINT to accept entry and go to [F12]

- Press CLEAR to zero display before entering a new value

[000000] ENTER NEW PREACT VALUE FOR SETPOINT 2

Display now shows zeros with the MSD as the active (blinking) digit.

- Press ZERO to increment active digit by one

- Press TARE to move to the next LSD

- Press PRINT to accept displayed value and go to F12. (E20 = preact value is greater than the

value entered for setpoint.) Prompt will advance to F12

- Press CLEAR to zero display and start over

[F11.5 ] ANALOG OUTPUT TRIMMING

This step allows trimming of the analog output to fine tune the remote device. Limitations are ±

3% of full scale for zero adjustment and ± 8% for span adjustment.

0 = Bypass F11.5 and advance to F11.6

1 = Start analog trimming as follows:

- Press CLEAR to abort and advance to [CALOFF]

- Press ZERO to step back to F9 or F10 depending on F9 Tare active or disabled

- Press TARE to toggle selection

- Press PRINT to accept displayed selection

19

Page 25

[0 FAS] Fast Mode zero reading analog output adjustment

[0 SLO] Slow Mode zero reading analog output adjustment

Alters zero reading analog output at a fast (FAS) or slow (SLO) rate. To increase the analog

reading at scale zero, press the TARE key, or to decrease, press the ZERO key. (Change is one

“click” per key press.) Press SELECT SETPOINT key to toggle between Fast Mode and Slow Mode

rate of adjustment.

- Press SELECT SETPOINT key to toggle between FastMode (FAS) and Slow Mode (SLO) rate

of adjustment

- Press TARE to increase analog output

- Press ZERO to decrease analog output

- Press CLEAR to abort adjustment and advance to [CALOFF]

- Press PRINT to accept displayed value and advance to span adjustment

[S FAS] Fast Mode span reading analog output adjustment

[S SLO] Slow Mode span reading analog output adjustment

Alters span reading at a fast (FAS) or slow (SLO) rate. To increase the analog reading at full scale,

press the TARE key, or to decrease, press the ZERO key. (Change is one “click” per keypress.)

Press SELECT SETPOINT key to toggle between Fast and Slow Mode rate of adjustment.

NOTE: During this adjustment, the analog output will output voltage or current equal to full

capacity of the scale. The display will not show weight, however, the analog output will reflect full

scale output.

- Press SELECT SETPOINT key to toggle between Fast (FAS) and Slow Mode (SLO)

- Press TARE to increase analog output

- Press ZERO to decrease analog output

- Press CLEAR to abort adjustment and advance to [CALOFF]

- Press ZERO to return to F11.5 and start over

- Press PRINT to accept displayed value and advance to F11.6

[F11.6 ] CALIBRATION OF ANALOG OUTPUT

0 = No offset or span adjustments are applied to calibrated scale zero or full scale readings.

Zero and full scale analog output coincides with scale zero and full scale digital display.

F11.7, F11.8, F11.9, and F11.E will be bypassed.

1 = Adjustment of zero and span is made using calibration constants. Zero and full analog

output may not coincide with zero and full scale digital display. The span must be a

minimum of 1000 divisions of displayed weight. Failure to meet the minimum will result in

an error message [E 32]. The prompt will then advance to F11.7

[F11.7 ] ANALOG ZERO CALIBRATION WITH TEST WEIGHTS

0 = Bypass F11.7 and advance to F11.8

1 = Initiate zero calibration as follows:

- Press CLEAR to abort setup and advance to [CALOFF]

- Press ZERO to backup to F11.6

- Press TARE to toggle selection

- Press PRINT to accept displayed selection

[0 Ld ] Press PRINT to acknowledge additional “dead load” at zero is on scale platform

20

Page 26

[15 CAL] Display will count down from 15 while zero reading is taken. After reading is taken,

advance to F11.9. SPAN CALIBRATION MUST BE PERFORMED AFTER ZERO

CALIBRATION.

[F11.8 ] ANALOG ZERO CALIBRATION VIA KEYBOARD

0 = Bypass F11.8 and advance to F11.9

1 = Initiate keyboard adjustment of analog zero as follows:

- Press CLEAR to abort setup and advance to [CALOFF]

- Press ZERO to backup to F11.7

- Press TARE to toggle selection

- Press PRINT to accept displayed selection

[XXXXXX] ZERO OFFSET VALUE

Display now shows previous weight offset value.

- Press PRINT to accept displayed value and advance to F11.9.

- Press CLEAR to zero display and to enter new value. Advance to ENTER NEEW ZERO

OFFSET VALUE

[X00000] ENTER NEW ZERO OFFSET VALUE

CLEAR was pressed, and display now shows zeros with the MSD (most significant digit) blinking.

(X = blinking MSD).

- Press ZERO to increment blinking digit by one

- Press TARE to move to the next least MSD (one position to the right)

- Press PRINT to accept displayed value and advance to F11.9

- Press CLEAR TO ZERO display and start over

[F11.9 ] ANALOG SPAN CALIBRATION WITH TEST WEIGHTS

0 = Bypass F11.9 and advance to F11.E

1 = Start Span Calibration with Test Weights. Scale must be at zero reference point to begin

span calibration

- Press CLEAR to abort setup and advance to [CALOFF]

- Press ZERO to backup to F11.9

- Press TARE to toggle selection (0 = Off, 1 = ON).

- Press PRINT to accept displayed selection

[15 CAL] Display will count down to 0 while weight reading for span is determined. Count will

restart at 15 if vibration is detected.

[Add Ld] Place load equal to desired FULL ANALOG OUTPUT WEIGHT (at least 1000 divisions

of calibrated scale) on scale platform.

- Press CLEAR to abort and advance to CALOFF

- Press ZERO to return to F11.9 and start over

- Press PRINT to continue

21

Page 27

[15 CAL] Display will count down to 0 while span reading is determined. If no errors occur, the

prompt then advances to F12. If a weight representing less than 1000 d is used, error

[E 32] is displayed and the previous span calibration is retained. To clear the error:

- Press ZERO to backup to F11.9 and start over

- Press CLEAR to abort setup and advance to [CALOFF]

- Press PRINT to start over at F11.9

[F11.E ] ANALOG SPAN CALIBRATION VIA KEYBOARD

0 = Bypass F11.E and advance to F12.

1 = Start span calibration via keyboard

- Press CLEAR to abort setup and advance to [CALOFF]

- Press ZERO to backup to F11.E

- Press TARE to toggle selection

- Press PRINT to accept displayed selection

[XXXXXX] SPAN OFFSET VALUE

Display now shows previous weight stored as the span offset value.

- Press ZERO to backup to F11.E

- Press PRINT to accept value and advance to F12

- Press CLEAR to zero display and enter new value. Advance to ENTER NEW SPAN OFFSET

VALUE

[X00000] ENTER NEW SPAN OFFSET VALUE

CLEAR was pressed, and display now shows zeros with the MSD (most significant digit) blinking.

(X = blinking digit). Enter the weight value to use as the new span offset.

- Press ZERO to increment blinking digit by one

- Press TARE to move to the next least significant digit (one position to the right)

- Press PRINT to accept value and advance to F12

- Press CLEAR to zero display and start over

If a weight representing less than 1000 d is entered error (E32] is displayed and the previous span

calibration is retained. To clear the error:

- Press ZERO to backup to F11.E and start over

- Press CLEAR to abort setup and advance to [CALOFF]

- Press PRINT to start over at F11.E

[F12 ] PRINTER OUTPUT SETUP

Press TARE to bypass printer setup and advance to calibration. Press PRINT to continue with

F12.1.

[F12.1 ] SERIAL DATA OUT

0 = Continuous Output Mode

1 = Demand Output Mode

22

Page 28

[F12.2 ] BAUD RATE

[XXXX ]

Previously selected baud rate (XXXX) will be displayed. Press TARE to display the next baud rate,

and PRINT to enter selection and advance to F12.3. Valid selections are:

- Demand Mode: 300, 1200, 2400, 4800, or 9600 baud

- Continuous Mode: 4800, or 9600

[F12.3 ] PARITY

0 = Parity always “0” (space)

1 = Odd parity

2 = Even parity

[F12. 4 ] STX/CHECKSUM

Checksum is defined as the 2’s complement of the 7 low order bits of the binary sum of all

characters proceeding the checksum, including STX (start of text) and CR (carriage return). Bit 8

of the checksum character is the parity bit of the 7 low order bits of checksum. This character is

used as a means to verify transmitted data. The receiving device must be capable of computing

and comparing a checksum also.

0 = No STX or Checksum sent

1 = STX will be sent as the first character of data. Checksum character will be transmitted after

the carriage return (CR) character in the data output.

NOTE: STX/CHECKSUM MUST BE ENABLED FOR OPERATION WITH THE METTLER

TOLEDO MODEL 8860 PRINTER

NOTE: IF CONTINUOUS MODE IS SELECTED F12.5 AND 12.6 WILL NOT DISPLAY.

[F12.5 ] DATA FORMAT (DEMAND MODE ONLY)

0 = Single line, displayed weight only

1 = Single line, gross, tare, and net

2 = Multiple line, gross, tare and net

[F12.6 ] EXPANDED PRINT (DEMAND MODE ONLY)

0 = Normal print

1 = Expanded print. The gross or net weight will be proceeded by the control character “SO”

(shift out) to indicate to the receiving device that this weight field is to be printed larger than

the previous data if the receiving device is capable of doing so. The control character “SI”

will then follow after the field to shift the device back to normal print mode.

NOTE: IF THE SETPOINT OPTION IS NOT SELECTED, SSW F12.7 AND F12.8 WILL BE BYPASSED.

[F12.7 ] AUTO PRINT AT SETPOINT 1

0 = Disable auto print at setpoint 1

1 = Auto print at setpoint 1 after returning from zero

23

Page 29

[F12.8 ] AUTO PRINT AT SETPOINT 2

0 = Disable auto print at setpoint 2

1 = Auto print at setpoint 2 after returning from zero

[F13 ] ENABLE REMOTE COMMANDS

0 = Remote ASCII input is disabled. Characters will be ignored

1 = Remote ASCII input characters will duplicate the keyboard functions: PRINT, TARE, ZERO,

and CLEAR. (Refer to Section 5.4).

[F14 ] LOAD CELL QUANTITY/SHIFT ADJUST (DigiTOL ® Power Module Only)

This selection allows the number of load cells connected to the DigiTOL ® Power Module to be

entered and shift adjustment to be performed on each cell. The shift adjustment allows

compensation for differences in output from each of the load cells used with the model 2157 Floor

Scale. the model 2157 uses four load cells. This step must be performed before calibrating the

Power Module/2157.

0 = Bypass step F14 and advance to F15

1 = Select quantity of load cells and perform shift adjustment

[X LCS] SELECT NUMBER OF LOAD CELLS (DigiTOL ® Power Module Only)

This prompt indicates the previously stored load cell quantity (X). After selecting the number of

cells, the 8510 will enter shift compensation mode.

- Press TARE to toggle between 2, 3, or 4 load cells

- Press PRINT to accept displayed value

[E SCL] EMPTY SCALE

Empty the scale platform, then press the PRINT key. The indicator will count down from 15 to 0

while zero reference is checked. Any change from motion to no-motion will cause the count to

reset each time to 15 before starting over. If the count is continually reset or if any errors are

displayed, refer to the troubleshooting section.

[CELL 1] ADD LOAD TO CELL #1

This step will shift adjust load cell #1. First place a test weight above cell #1. The weight does not

have to be a specific amount, although the greater the weight used, the more accurate the shift

compensation will be. After placing the weight above the cell, press PRINT to start the shift

adjustment on cell #1. The display will count down from 15 to 0 while the adjustment value is

calculated. When complete, the prompt for the second load cell [CELL2] will display. Perform the

same procedure for the remaining cells. When the last cell has been shift adjusted, the prompt will

advance to F15.

24

Page 30

Load Cell #1 is the cell to the right of the J-Box (viewed from the top of the deck) as shown in the

following diagram. Cells 2, 3, and 4 are located clockwise from cell #1.

Cell #2

Cell #4

2157 Base

J-Box

Cell #1

Cell #3

[F15 ] DISPLAY INDIVIDUAL CELL OUTPUT (DigiTOL ® Power Module Only)

This step allows the display of raw count output for each load cell connected to a DigiTOL ®

Power Module or Model 2157 floor scale. Verification of the initial load cell raw count output is

necessary to determine that each load cell is carrying an even share of the load. Before

performing this test, the scale base must be level and must not rock. The procedure for correcting

these conditions is found in the scale base technical manual. All load cells must be within 1000

counts of each other. If required shim the base to obtain this reading. Refer to the scale base

technical manual for shimming instructions.

NOTE: When the DigiTOL ® Power Module is used to convert a vessel such as a tank or hopper

into a scale, the load cells may not receive even loading due to the construction of the vessel.

This variance may be reflected in uneven initial raw count outputs that cannot be shimmed out.

- Press TARE to toggle between load cells

- Press CLEAR to quit and advance to [CAL]

[F16 ] ZERO CURSOR

The zero cursor is used in one of two modes controlled by setpoint operation. If setpoints are

disabled [F11 0], then the zero cursor is illuminated when the wei8ght on the scale is within the

±0.25 increments of zero. If setpoints are enabled [F11 1], then the zero cursor is illuminated when

the weight on the scale is within the zero tolerance of gross or net zero.

0 = Zero Cursor Disabled

1 = Zero Cursor Enabled

[F99 ] RESET TO DEFAULT SELECTIONS

0 = Skip resetting to default settings and advance to calibration

1 = Advance to [LOAd 0] and load default settings

25

Page 31

[LOAd 0 ] RESET TO FACTORY DEFAULTS

- Press Tare key to change displayed selection to a 1

0 = Skip resetting to default settings and advance to calibration

1 = Reset to factory defaults as shown below:

Step Description Default Step Description Default

F0 Span Adjust N/A F11.5 Analog Output Trimming N/A

F1 Zero Adjust N/A F11.6 Analog Output Limited Range 0

F2 Load Cell Type N/A F11.8 Analog Output Zero Zero

F3 Calibration Units N/A F11.9 Analog Output Capacity Capacity

F4 Auto Zero Maintenance 1 F12.1 Data Output Mode 1

F5 Pushbutton Zero Enable 1 F12.2 Baud Rate 9600

F6 Motion Sensitivity 1 F12.3 Parity 2

F7 Filter 0 F12.4 STX/Checksum 0

F7.1 DigiTOL® Load Cell Filter 0 F12.5 Weight Data Format 0

F8 Expanded Weight Display 0 F12.6 Expanded Weight Printing 0

F9 Tare Enable 1 F12.7 Autoprint at SP1 0

F10 Auto Clear Tare 0 F12.8 Autoprint at SP2 0

F11 Setpoint Enable 0 F13 Enable ASCII Input 0

F11.1 Zero Tolerance Range 0 F14 Load Cell Quantity N/A

F11.2 BCD Motion Sync Disable 0 F15 Display Load Cell Counts N/A

F11.3 Setpoint Data Entry Enable 0 F16 Zero Cursor Enable 1

F11.4 Preact Value Entry Enable 0 F99 Reset To Factory Defaults N/A

CAL Calibration N/A

[CAL ] SCALE CALIBRATION PROCEDURE

This step calibrates the scale base and must be performed when first installing the 8510 or after

performing a shift adjustment.

- Press PRINT to enable calibration mode

- Press CLEAR to bypass calibration and go to [CALOFF]

[C1 ] SCALE CAPACITY SELECT

[000100]

The display shows the previously stored capacity or defaults to the first legal value. Only valid

capacities may be selected. The value of which digit is incremented is limited to legal scale

capacities. Refer to valid capacity selection Table 1 in Section 2.3.

- Press ZERO to increment the blinking digit by one unit

- Press TARE to go to the next MSD

- Press CLEAR to zero display and start over

- Press PRINT to accept the displayed value

26

Page 32

[C2 ] INCREMENT SIZE

[ 00]

The previously programmed or default increment size is displayed. Only valid increment

selections will be displayed and selected.

- Press TARE to display the next valid increment size

- Press PRINT to accept the displayed increment size

[E SCL ] EMPTY SCALE PLATFORM

Empty the scale platform to set initial, then press PRINT to continue.

[15 CAL] SET INITIAL

The display will count down from 15 to 0 while initial is set, then advance automatically to [Add

Ld]. If any errors are displayed, refer to Section 8.2. If motion is detected in this mode, the count

will be reset to 15 and the initial adjustment will start over.

[Add Ld] ADD LOAD

Place the selected test weight on the scale platform, then press PRINT to continue.

[00000 ] ENTER LOAD

Enter the test weight value by entering digits from left to right. The digit that is blinking is the

active digit. No decimal value is permitted. The maximum test weight value is 105% of the full

scale capacity.

- Press TARE to move the active digit one position to the right

- Press ZERO to increment the active digit by one

- Press PRINT to enter the displayed value

[15 CAL] SET SPAN

The display will count down from 15 to 0 while span is set. (Note: If F2 = 1 (Digital Load Cell), the

display will show [CAL d] if calibration was successful and will not prompt again for empty scale.)

[E SCL] EMPTY SCALE

Empty the scale platform, then press PRINT to continue.

[15 CAL] RECHECK INITIAL

The display will count down from 15 to 0 while initial is rechecked.

[CAL d ] CALIBRATION DONE

This prompt is momentarily displayed when calibration was successful. If any error codes are

displayed, refer to Error Code Summary Section 8.

[CALOFF ] END OF SOFTSWITCHES

Press ZERO to return to the [CAL] prompt, or press ZERO and PRINT simultaneously to exit the

program mode. Press PRINT then ZERO while PRINT is still depressed.

27

Page 33

5. RS232 SERIAL INPUT/OUTPUT

5.1 SERIAL DATA OUTPUT IN DEMAND MODE

The model 8510 will transmit RS232C serial data when a print command is issued using the PRINT

pushbutton, Auto Print, or a remote print command from a host. The data format, baud rate, checksum,

parity, etc. are selectable in the setup mode. The serial data is output in an 10-bit ASCII frame which

includes: 1 start bit, 7 data bits, 1 parity bit, and 1 stop bit. Parity is selectable as zero, odd, or even

using SSW F12.3. STX/Checksum can be enabled or disabled using SSW F12.4. All demand mode

printing is inhibited during motion and when the weight is under gross zero. Printing is allowed on

power-up whether or not zero is captured if AZM is enabled (SSW F4). The available formats are as

follows:

5.1.1 SINGLE LINE DISPLAYED WEIGHT FORMAT

N

DATA SOX X X X X X X S

NOTES A B C D D D D D D F G G H I J K

NOTES

A - SO = Shift-Out character (optional). If SSW F12.6 = 1, expanded print is enabled if receiving device

is capable of using SO for enabling expanded (double-width) printing.

B - STX = Start of Text character (optional). If SSW F12.4 = 1, STX and checksum characters will be

sent in this position.

C - X = weight data digit, minus sign (-) for negative weight or tare, or space character will be sent in

this position.

D - X = Weight data digit or decimal point character.

E - SP = Space character.

F - LB sent for pounds when SSW F3 = 1. KG sent for kilograms when SSW F3 = 0.

G - Space character and NET will be sent if displayed weight is a net weight.

H - SI = Shift-In character. If SSW F12.6 = 1, SI will reset receiving device to normal print mode (if

receiving device is capable of using SO/SI to toggle between expanded and normal print modes.)

I - CR = carriage return character.

J - CHK = checksum character (optional). Checksum will be sent with STX if SSW F12.4 = 1.

K - LF = line feed character.

5.1.2 SINGLE LINE GROSS/TARE/NET FORMAT

L

P

BSP

ETS

I

C

C

HKL

R

F

DATA S

TX* X X X X X X SPLBSP* * X X X X X SPLBSPTRSPSO* X X X

Notes A B B B B B B B C D C E E E E E E E C D C F C G H H H H

NOTES

A - STX = Start of Text character (optional). If SSW F12.4 = 1, STX and checksum characters will be

sent in data string

N

X X X SPLBS

H H H C D C I J K L M

ETSIC

P

28

C

HKL

R

F

Page 34

B - Gross weight data field (7 characters). (* = digit, minus sign (-), or space, X = digit or decimal

point.)

C - SP = Space character

D - LB = pounds when SSW F3 = 1, KG = kilograms when SSW F3 = 0

E - Tare weight data field (7 characters). (* = digit, minus sign (-), or space, X = digit or decimal point

F - TR = characters for tare weight

G - SO = Shift-Out character (optional). If SSW F12.6 = 1, expanded print is enabled (if receiving device

is capable of using SO for enabling expanded (double-width) printing

H - Net weight data field (7 characters), (* = digit, minus sign (-), or space, X = digit or decimal point.)

I - NET = characters for net weight

J - SI = Shift-in character. If SSW F12.6 = 1, SI will reset receiving device to normal print mode (if

receiving device is capable of using SO/SI to toggle between expanded and normal print modes.)

K - CR = carriage return character

L - CHK = checksum character (optional). Checksum will be sent with STX if SSW F12.4 =1

M - LF = line feed character

5.1.3 THREE LINE GROSS/TARE/NET FORMAT

LINE 1

GROSS WEIGHT

Line

One

Data

S

TXX X X X X X X SPLBC

C

H

R

K

Notes A B B B B B B B C D E G

LINE 2

TARE WEIGHT

Line

One

Data

X X X X X X X SPLBSPTRC

C

HKL

R

F

Notes H H H H H H H C D C I E F G

LINE 3

NET WEIGHT

Line

One

DataSO

X X X X X X X SPLBS

N

ETSIC

P

C

HKL

R

F

Notes J K K K K K K K C D C L M E F G

NOTES

A - STX = Start of Text character (optional). If SSW F12.4 = 1, STX and checksum characters will be

sent in data string

B - Gross weight data field (7 characters). (* = digit, minus sign (-), or space, X = digit or decimal

point.)

C - SP = Space character

D - LB = pounds when SSW F3 = 1, KG = kilograms when SSW F3 = 0

E - CR = carriage return character

F - CHK = checksum character (optional). Checksum will be sent with STX if SSW F12.4 = 1

G - LF = line feed character

H - Tare weight data field (7 characters), (* = digit, minus sign (-), or space, X = digit or decimal point)

I - TR = characters for tare weight

J - SO = Shift-out character (optional). If SSW F12.6 = 1, expanded print is enabled (if receiving

device is capable of using SO for enabling expanded (double-width) printing).

K - Net weight data field (7 characters), (* = digit, minus sign (-), or space, X = digit or decimal point)

L - NET = characters for net weight

M - SI = Shift-in character. If SSW F12.6 = 1, SI will reset receiving device to normal print mode (if

receiving device is capable of using SO/SI to toggle between expanded and normal print modes)

29

Page 35

5.2 SERIAL DATA OUTPUT IN CONTINUOUS MODE

A 2400, 4800, or 9600 baud continuous output may be selected instead of the print on demand output.

This data consists of 16 or 18 bytes transmitted in a 10-bit ASCII frame consisting of: 1 start bit, 7 data

bits, 1 even parity bit, and 1 stop bit. The format is as follows:

CHARACTER FUNCTION

1 STX (Start of text - Optional)

2 Status Word A

3 Status Word B

4 Status Word C

5 Weight MSD

6 Weight

7 Weight

8 Weight

9 Weight

10 Weight LSD

11 Tare Weight MSD

12 Tare Weight

13 Tare Weight

14 Tare Weight

15 Tare Weight

16 Tare Weight LSD

17 CR (carriage return)

18 CKSM (Checksum - Optional

Non-significant weight data and tare data digits will be transmitted as spaces. A description of the

status words A, B, and C is shown in Tables 4-6.

TABLE 4A - CONTINUOUS MODE STATUS WORD A - SETPOINTS ENABLED (F11)

STATUS WORD A - SETPOINT OPTION ENABLED (F11)

Bit 0, 1, 2 Encoded Decimal Point

Display Bit 2 Bit 1 Bit 0

XXXXX0

XXXXXX

XXXXX.X

XXXX.XX

XXX.XXX

0

0

0

1

1

0

1

1

0

0

1

0

1

0

1

Bit 3 Setpoint Output 1

(0 = less than setpoint value)

Bit 4 Setpoint Output 2

(0 = less than setpoint value)

Bit 5 Always = 1

Bit 6 Always = 1

Bit 7 Parity of Status Word A

30

Page 36

TABLE 4B - CONTINUOUS MODE STATUS WORD A

- SETPOINTS DISABLED (F11)

STATUS WORD A - SETPOINTS OPTION DISABLED (F11)

Bit 0, 1, 2 Encode Decimal Point

Display Bit 2 Bit 1 Bit 0

Bit 3, 4 Increment Size 3 4

Bit 5 Always = 1

Bit 6 Always = 1

Bit 7 Parity of Status Word A

XXXXX0

XXXXXX 0

XXXXX.X 0

XXXX.XX 1

XXX.XXX 1

X1 0

X2 1

X5 1

0 01

1 0

1 1

0 0

0 1

1

0

1

TABLE 5 - CONTINUOUS MODE STATUS WORD B

STATUS WORD B

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Gross = 0, Net = 1

Minus sign = 1

Overcapacity = 1

Motion = 1

lb = 0, kg = 1

Always = 1

- If setpoints enabled (F11 = 1),

bit 6 = within zero tolerance.

- If setpoints disabled (F11 = 0),

bit 6 = Power Up Flag.

Parity of Status Word B

TABLE 6 - CONTINUOUS MODE STATUS WORD C

TABLE 6 - CONTINUOUS MODE STATUS WORD C

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Always = 0

Always = 0

Always = 0

Print = 1

Always = 1

Always = 1

Always = 1

Parity of Status Word C

31

Page 37

5.3 AUTOPRINT AT SETPOINT

An autoprint at setpoint function can be enabled for each of the two setpoints in setup mode. This

function is operational when the setpoint option is enabled. During a weighing operation, if a setpoint

threshold is crossed and the scale settles to a no-motion condition, an autoprint is initiated. Any further

autoprinting based on that setpoint is inhibited until the scale returns to 10 display increments or less of

gross or net zero with no motion. The autoprint for the two setpoints operates independently of each

other.

5.4 REMOTE COMMAND INPUT

The Model 8510 Digital Indicator is capable of performing certain functions when a particular uppercase

ASCII character is transmitted to it. The data format must be set as follows: 1 start bit, 7 data bits, one

parity bit (selectable in setup mode), and 1 stop bit. When the Remote Input Softswitch is enabled (F13

set for 1), the following uppercase ASCII characters can be input to the Model 8510 through the serial

port from a host:

CHARACTER FUNCTION

P Print request. Data is transmitted

according to the format selected. This

command is disabled if autoprint for

SP1/SP2 is enabled.

T Perform tare when scale is not at gross

zero and in a no-motion condition.

C Clear Tare and return scale to gross

zero.

Z Zero scale if within ± 2% of capacity

from zero, and scale is in a no-motion

condition at gross zero.

NOTE: THE CARRIAGE RETURN CHARACTER IS IGNORED.

5.5 PIN CONNECTIONS FOR RS232 SERIAL PORT

The female DB-9 connector marked “PRINTER,” located on the rear of the 8510 provides RS232 serial

input or output. No handshaking lines are provided. The pin configuration is as follows:

PIN# DESCRIPTION

2 Receive Data

3 Transmit Data

5 Signal Ground

32

Page 38

6. LOAD CELL CONNECTIONS

Before any load cell connections are made, the type of load cell to be connected (analog or digital) must

be determined. The model 8510 is shipped with the 13356700A Analog Load Cell Internal Harness

Installed. If a DigiTOL ® digital scale base is to be connected, the 13356700A Analog Load Cell Harness

must be removed and the 13356700A Digital Load Cell Harness must be installed. Refer to Section 3.1 -

3.2 for information on the analog and digital internal adapter harnesses.

CAUTION!

DO NOT CONNECT AN ANALOG SCALE BASE TO THE

8510 WITH THE DIGITAL LOAD CELL ADAPTER HARNESS

INSTALLED OR DAMAGE WILL RESULT.

DO NOT CONNECT A DIGITAL SCALE BASE TO THE 8510

WITH THE ANALOG LOAD CELL HARNESS INSTALLED

OR DAMAGE WILL RESULT

6.1 DIGITAL LOAD CELL CONNECTIONS

CAUTION!

DO NOT CONNECT OR DISCONNECT A LOAD CELL TO THE

8510 WITH POWER ON. DAMAGE TO THE 8510 AND THE LOAD

CELL MAY RESULT. ALWAYS WAIT AT LEAST 30 SECONDS

BEFORE CONNECTING OR DISCONNECTING A LOAD CELL

FROM THE 8510.

This section of the manual explains how to connect the 8510 to a DigiTOL ® digital load cell scale base.

CAUTION!

REFER TO SECTION 3.2 FOR INSTALLATION OF THE DIGITAL

LOAD CELL ADAPTER HARNESS IN THE 8510 BEFORE

PROCEEDING. THE 8510 IS SHIPPED WITH THE ANALOG LOAD

CELL HARNESS INSTALLED FROM THE FACTORY. THE

INTERNAL LOAD CELL HARNESS MUST BE REMOVED, AND

THE INTERNAL DIGITAL LOAD CELL ADAPTER HARNESS MUST

BE INSTALLED BEFORE ANY EXTERNAL CONNECTIONS ARE

MADE.

The Toledo Models 1996, 2096, and 2196 Bench/Portable DigiTOL ® scale bases are shipped with the p/n

13011500A 10’ load cell interconnecting cable. The p/n 13011500A interconnecting cable (included with

the base) is assembled with a dB-9 connector at one end (to attach to the base) and open ended at the

other end. The open end will have different color wires exposed to connect the DB-9 connector shipped

with the Model 8510 Indicator. Figure 7A illustrates the proper connections between the 8510 DBG-9

load cell connector port and the DB-9 connector at the scale base end of the cable. If a longer cable is

required, use bulk cable part number 510624-370 to fabricate a longer cable. This cable is ordered by the

foot. Do not exceed a maximum cabled length of 50 ft. for the DigiTOL ® Bench/Portable scale bases.

The Models 1997, 2097, and 2197 Bench/Portable Stainless Steel DigiTOL ® scale bases are supplied

with an integral 10’ load cell cable for connection to the indicator. Use the supplied DB-9 connector to

attach the base to the 8510. Refer to Figure 7A for connecting these bases to the Model 8510-20X1.

33

Page 39

If the 8510-20X1 software revision level is L05 or higher, it can be connected to the DigiTOL ® Power

Module/2157. Figure 7A lists the cable connections from the 8510 to the Carbon Steel Power Module

terminal block TB-5, and the Stainless Steel watertight connector. Use bulk cable part number 510620370 (ordered by the foot) to connect the units up to a maximum of TB-5 on the Power Module connection

PCB.

DigiTOL ® SCALE BASE TO 8510-20X1 LOAD CELL CONNECTIONS

8510

DB-9

LC PORT

CABLE

WIRE

COLOR

1996/

2096 2196

DB-9

CONNECT

OR

1997/

2097 2197

WIRE

COLOR

CODE

DigiTOL ® POWER MODULE/2157

STAIN-

CARBON

TB-5

LESS

STEEL

FUNCTION

1 RED 1 RED 3 A RxD A

5 GREEN 5 GREEN 6 E +20 VDC

7 BLUE 7 BLUE 5 G GROUND

8 BLACK 8 BLACK 1 H TxD A

FIGURE 7A

CAUTION!

The WHITE wire in the load cell cable MUST NOT BE

CONNECTED to the 8510 when the 8510 is used with any standard

Bench and Portable scale bases, (Models 1996, 2096, 2097, 2196

or 2197). DAMAGE TO THE LOAD CELL IN THESE BASES MAY

RESULT IF THIS WHITE WIRE IS CONNECTED TO THE 8510.

Fold back and tape this wire to prevent shorting.

CARBON STEEL DigiTOL® POWER MODULE/2157 TB-5 LOCATION

CABLE

WIRE

FIGURE 7B

34

Page 40

6.2 ANALOG LOAD CELL CONNECTIONS

This section describes connections to and from an analog load cell base to the model 8510.

6.2.1 ANALOG LOAD CELL CABLE

The recommended cable for use with the Model 8510 and analog load cell is Toledo Scale number

510620-370. This cable is ordered by the foot. The maximum recommended cable length is 300 feet.

Attach the load cell cable to the DB-9 connector supplied with the 8510 as shown in Figure 8:

8510 DB-9 SIGNAL DESCRIPTION WIRE COLOR*

1 + Excitation White

2 + Sense Yellow

3 Shield (Gnd) Orange

4 - Sense Red

5 - Excitation Blue

6 Key - Not used 7 + Signal Green

8 - Signal Black