Page 1

8146

Technical Manual

and

Parts Catalog

Page 2

INTRODUCTION

This publication is provided solely as a guide for individuals

who have received METTLER TOLEDO Technical Training in

servicing the METTLER TOLEDO product.

Information regarding METTLER TOLEDO Technical Training

may be obtained by writing to:

METTLER TOLEDO

Training Center

P.O. Box 1705

Columbus, Ohio 43216

(614) 438-4400

METTLER TOLEDO RESERVES THE RIGHT TO MAKE

REFINEMENTS OR CHANGES WITHOUT NOTICE.

Page 3

PRECAUTIONS

CAUTION

• • READ this manual before operating or

servicing this equipment.

• • ALWAYS REMOVE POWER and wait at

least 30 seconds BEFORE connecting or

disconnecting any internal harnesses.

Failure to observe these precautions may

result in damage to, or destruction of the

equipment.

• • ALWAYS take proper precautions when

handling static sensitive devices.

• • DO NOT connect or disconnect a load cell

scale base to the equipment with power

connected or damage will result.

WARNING

DISCONNECT ALL POWER

TO THIS UNIT BEFORE

REMOVING THE FUSE

OR SERVICING.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO

SERVICE THIS EQUIPMENT. EXERCISE CARE

WHEN MAKING CHECKS, TESTS, AND

ADJUSTMENTS THAT MUST BE MADE

WITH POWER ON.

• • SAVE this manual for future reference.

• • DO NOT allow untrained personnel to

operate, clean, inspect, maintain, service,

or tamper with this equipment.

• • ALWAYS DISCONNECT this equipment

from the power source before servicing.

• • CALL METTLER TOLEDO for parts,

information, and service.

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

Page 4

CONTENTS

1.0 GENERAL DESCRIPTION ......................................................................................1

1.1 STANDARD FEATURES.....................................................................................................................1

1.2 OPTIONAL FEATURES ......................................................................................................................1

2.0 SYSTEM DESCRIPTION........................................................................................2

2.1 AUTOMATIC ZERO MAINTENANCE (AZM)..........................................................................................2

2.2 NORMAL AND EXTENDED ZERO CAPTURE.........................................................................................2

2.3 LOAD CELL EXCITATION (APPLICABLE WITH ANALOG PCB ONLY) .......................................................2

2.4 REDUCED EXCITATION VOLTAGE (APPLICABLE WITH ANALOG PCB ONLY)...........................................3

2.5 INITIAL AND SPAN (APPLICABLE WITH ANALOG PCB ONLY)...............................................................3

2.6 OVERCAPACITY..............................................................................................................................3

2.7 DIGITAL FILTERING..........................................................................................................................3

2.8 LINE SYNCHRONIZATION (LINE SYNC) (APPLICABLE WITH ANALOG PCB ONLY)...................................3

2.9 LINEARITY CONNECTION (APPLICABLE WITH ANALOG PCB ONLY) ......................................................4

2.10 ANALOG VERIFICATION .................................................................................................................4

2.11 POWER UP SEQUENCE..................................................................................................................5

2.12 DIGITOL ® LOAD CELL CABLE DISTANCES (APPLICABLE TO DWP44 PCB ONLY)..............................5

3.0 SPECIFICATIONS ................................................................................................6

3.1 ELECTRICAL AND PHYSICAL SPECIFICATIONS...................................................................................6

3.2 INTERNAL FUNCTIONS.....................................................................................................................8

3.3 DISPLAY FORMATS .........................................................................................................................9

3.4 KEYBOARD SPECIFICATIONS .........................................................................................................10

3.5 FACTORY NUMBER CONFIGURATION AND OPTIONS .........................................................................10

3.6 DATA INTERFACE..........................................................................................................................12

4.0 INSTALLATION INSTRUCTIONS...........................................................................13

4.1 PRELIMINARY INSPECTION............................................................................................................13

4.2 OPERATING VOLTAGE SELECTOR....................................................................................................13

4.3 PRELIMINARY CALCULATIONS (APPLICABLE WITH ANALOG PCB ONLY)............................................14

4.4 JUMPER DESCRIPTION AND RECOMMENDED SETTINGS ..................................................................18

Page 5

5.0 PROGRAMMING PROCEDURE ............................................................................27

5.1 ANALOG SETUP AND CALIBRATION PROCEDURE .............................................................................28

5.2 DIGITOL ® SETUP AND CALIBRATION PROCEDURE..........................................................................37

5.3 SETUP AND CALIBRATION PROCEDURE FOR SINGLE CELL DIGITAL LOAD CELL SYSTEMS...................38

5.4 SETUP AND CALIBRATION PROCEDURE FOR T-LAN MULTIPLE DIGITAL LOAD CELL SYSTEMS..............41

5.5 SETUP AND CALIBRATION PROCEDURE FOR DIGITOL ® J-BOX.........................................................49

5.6 DWP44 GENERAL SETUP FOR ALL LOAD CELL TYPES......................................................................52

5.7 SETUP FOR PRINTER PORT AND 8146 OPTIONS..............................................................................55

6.0 INPUT/OUTPUT DESCRIPTIONS.......................................................................... 66

6.1 I/O CONNECTIONS........................................................................................................................66

6.2 PRINTER OUTPUT DESCRIPTION - I/O #1.........................................................................................76

6.3 DEMAND MODE OUTPUT ...............................................................................................................78

6.4 CONTINUOUS MODE OUTPUT.........................................................................................................78

6.5 USER DEFINED PRINT FORMAT.......................................................................................................80

6.6 REPORT OUTPUT FORMAT..............................................................................................................82

6.7 HOST COMMUNICATION INTERFACE DESCRIPTION - I/O #3 (OPTIONAL) ...........................................83

6.8 BAR CODE INTERFACE DESCRIPTION - I/O #2 (OPTIONAL)...............................................................93

6.9 SETPOINT INTERFACE DESCRIPTION - I/O #4 (OPTIONAL)................................................................96

7.0 PREVENTIVE MAINTENANCE..............................................................................98

7.1 REQUIRED TOOLS AND SUPPLIES...................................................................................................98

7.2 MAINTENANCE SCHEDULE.............................................................................................................98

7.3 CLEANING....................................................................................................................................98

7.4 TROUBLESHOOTING ......................................................................................................................98

7.5 ERROR CODES..............................................................................................................................99

8.0 GENERAL INFORMATION..................................................................................109

8.1 RECOMMENDED SPARE PARTS....................................................................................................109

8.2 CABLES AND MATING CONNECTORS............................................................................................109

8.3 ASCII Chart................................................................................................................................111

Page 6

Reference Drawings 134382 - 8146 Block Diagrams

9.0 PARTS CATALOG..............................................................................................112

9.1 DESK MOUNT..............................................................................................................................112

9.1.1 ENCLOSURE AND LENSES.......................................................................................................... 112

9.1.2 REAR PANEL ................................................................................................................................. 113

9.1.3 DISPLAY PCB’S............................................................................................................................. 114

9.1.4 FRONT PANEL AND KEYBOARD................................................................................................. 115

9.1.5 TRANSFORMER AND HARNESS .................................................................................................. 116

9.1.6 PCB’S............................................................................................................................................ 117

9.1.7 POWER SUPPLY........................................................................................................................... 118

9.1.8 CARD CAGE .................................................................................................................................. 119

9.1.9 CHASSIS........................................................................................................................................ 120

9.2 WALL MOUNT.............................................................................................................................121

9.2.1 BEZEL AND LINE CORD............................................................................................................... 121

9.2.2 DATA DISPLAY PCB ..................................................................................................................... 122

9.2.3 FRONT PANEL AND KEYBOARD................................................................................................. 123

9.2.4 WT. DISPLAY PCB ........................................................................................................................ 124

9.2.5 PCB’S............................................................................................................................................. 125

9.2.6 POWER SUPPLY........................................................................................................................... 126

9.2.7 TRANSFORMER AND HARNESS .................................................................................................. 127

9.3 MISCELLANEOUS.........................................................................................................................128

9.3.1 KITS OF PARTS ............................................................................................................................ 128

9.3.2 MATING CONNECTORS, DESK..................................................................................................... 128

9.3.3 MATING CONNECTORS, WALL..................................................................................................... 128

9.3.4 INTERCONNECTING CABLES...................................................................................................... 129

Page 7

1

1.0 GENERAL DESCRIPTION

The Model 8146 Electronic Digital Indicator is intended for use with both strain gauge load cell and

DigiTOL ® load cell scales. Units include a sixteen character dot matrix display PCB and up to four

weight displays. The 8146 is available in desk and wall mounting enclosures. Weight information is

transmitted to a printer or compatible accessory device in a bit serial ASCII code.

1.1 STANDARD FEATURES

• • Selectable full scale number of increments 1000, 1200, 1500, 2000, 2500, 3000, 4000, 5000, 6000,

8000, 10,000, 12,000, 15,000, 16,000, 20,000, 25,000, 30,000, 32,000, 35,000, 40,000, 45,000, 48,000,

and 50,000

• • Available in a desk mount, or a NEMA 4X, stainless steel wall mount enclosure

• • Automatic zero maintenance

• • Expanded AZM up to ± 10% of scale capacity

• • Digital filtering provides the ability to select one of four filtering rates for display and data output

• • Motion detection sensitivity is selectable from ±0.5 to ±3.0 increments over a period of 1-30

successive A/D updates

• • Display of pounds and kilograms simultaneously on single scale unit

• • Three-point linearization capability during scale calibration

• • Keyboard setup and calibration

• • Line sync capability

• • Weight summing, when more than one scale is configured

• • Operator programmable printer formats

• • Battery-backed RAM

• • Expanded zero push button range (2-20%) of full scale capacity

• • Alphanumeric keyboard with additional function keys

• • Rate of weight change display

• • Operator definable weight conversion factors

• • Non-volatile storage for ID’s, Tare Registers and Accumulators

1.2 OPTIONAL FEATURES

• • Additional scale(s) - Three additional scales may be added

• • Bar Code interface

• • Host communications interface

• • Serial Setpoint output up to 12 Setpoints

Page 8

2

2.0 SYSTEM DESCRIPTION

This section of the manual describes the various operating features available for use in your installation.

2.1 AUTOMATIC ZERO MAINTENANCE (AZM)

The 8146 is equipped with an AZM feature. AZM is used to keep the instrument on zero in spite of small

weight changes on the platform. AZM corrections operate at a rate of approximately one minor

increment per second. The AZM range is selectable for either 2% or 10% of full scale capacity.

AZM may be disabled lin the setup procedure

2.2 NORMAL AND EXTENDED ZERO CAPTURE

The 8146 has a front mounted zero pushbutton which allows the operator to reset the scale to a zero

condition. The normal range of the pushbutton is ±2% of full scale capacity. The 8146 permits

increasing this capture range* to ± 20% full scale capacity.

The zero pushbutton may be disabled in the setup procedure.

NOTE: Increasing the zero capture range may conflict with Local and State Weights and Measures laws

when the 8146 is installed in a “Legal for Trade” installation.

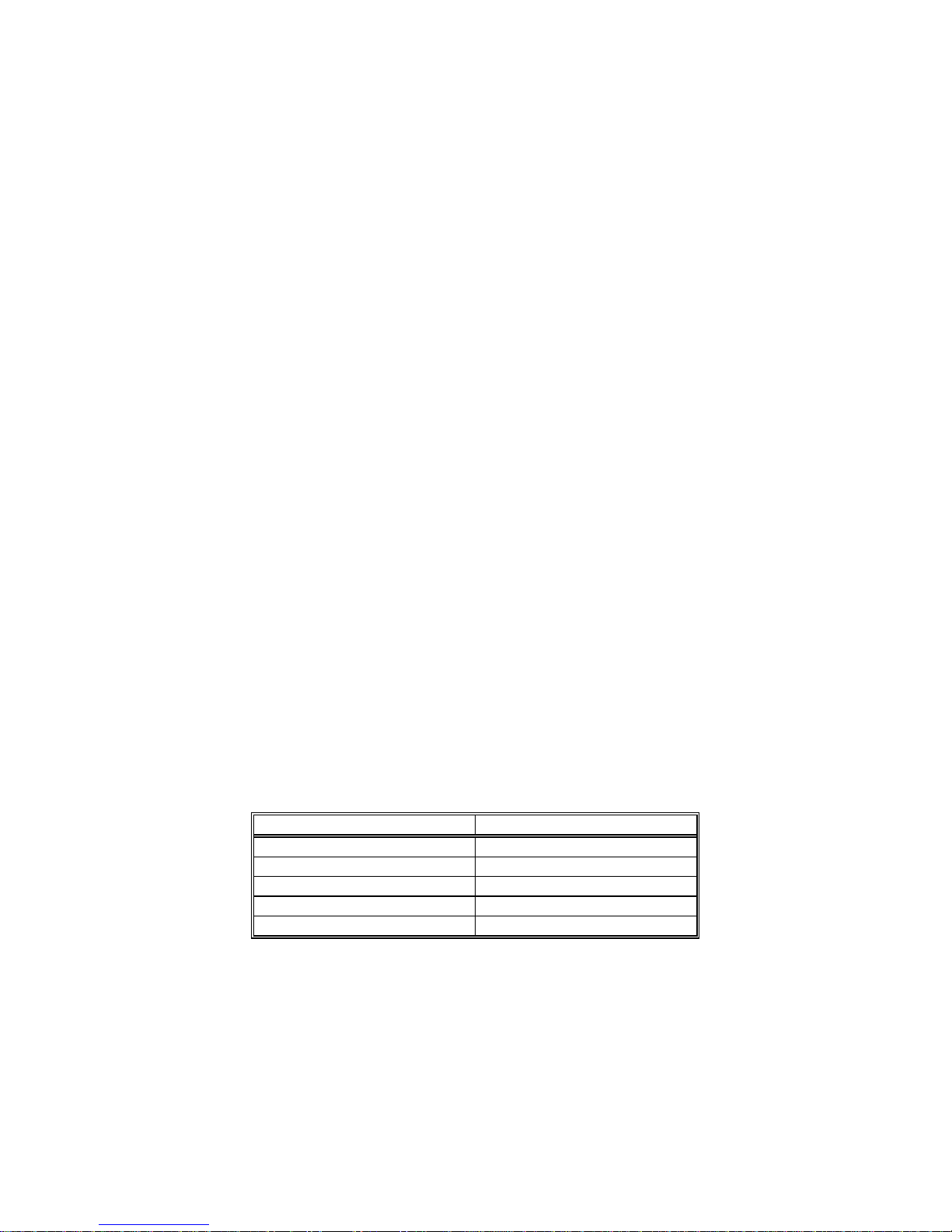

2.3 LOAD CELL EXCITATION (APPLICABLE WITH ANALOG PCB ONLY)

The 8146 uses gated 15 VDC excitation for normal analog load cell excitation.

Each Analog PCB is capable of powering six 350-ohm load cells; however, the 8146 will power a

maximum of eighteen 350-ohm load cells per unit. Refer to the following chart for more information

regarding the maximum number of load cells per unit.

The maximum distance between the 8146 and the load cells is 500 ft using 16-gauge or 300 ft using a 20gauge load cell cable.

Reduced excitation voltage levels are also available for use in hazardous areas. Refer to the following

paragraph for a more detailed description of this reduced excitation voltage.

Per Analog PCB Per System

14-825 ohm cells 42-825 ohm cells

12-700 ohm cell 36-700 ohm cells

6-425 ohm cells 18-425 ohm cells

6-350 ohm cells 18-350 ohm cells

4-240 ohm cells 12-240 ohm cells

Page 9

3

2.4 REDUCED EXCITATION VOLTAGE (APPLICABLE WITH ANALOG PCB ONLY)

Reduced excitation output versions of the Model 8146 are available in all models for us with Toledo

Intrinsic Safety Barriers. Contact Toledo Fast Factory for additional information. Reduced excitation

voltage is limited to +3 volts for plus excitation and -3 volts for minus excitation (6 volts p to p). Also

included in the reduced excitation voltage versions are sense-to-excitation-shunting resistors which

prevent excitation runaway in the event that these line connections open.

NOTE: The lower excitation voltage must be considered when calculating the microvolt per increment

build. This also limits the maximum full scale increments to 40,000 instead of 50,000.

2.5 INITIAL AND SPAN (APPLICABLE WITH ANALOG PCB ONLY)

The initial and span values are calculated during the scale’s calibration procedure.

The initial range is from 0 to 27 millivolts.

The span range is from 3 to 45 millivolts, based upon 15-volt load cell excitation.

2.6 OVERCAPACITY

Individual Scales: The weight display will blank and printing is inhibited when the weight on the scale is

five or more increments above full scale capacity.

Summed Scales: If any of the individual scales reach an overcapacity condition (as described above),

the summed display will show eight asterisks (SUM********lb). This display will also occur when

the summed total is greater than eight digits.

2.7 DIGITAL FILTERING

The 8146 is equipped with a multi-stage digital filter. By selecting the correct level of filtering required

for your installation, changes in weight caused by wind, liquids, or vibration may be filtered out allowing

the indication to stabilize.

As with all filtering, the higher the filtering rate the slower the display will respond to weight changes.

2.8 LINE SYNCHRONIZATION (LINE SYNC) (APPLICABLE WITH ANALOG PCB ONLY)

The line sync feature is used to eliminate any “crosstalk” on the load cell signal wires.

This “crosstalk” is typically caused by two or more load cell cables, operating at different frequencies,

being run side by side, such as in conduit. This normally results in a slowly changing weight display.

The compensation for this is that all excitation voltages may be sync’d to the AC power source by

means of line sync jumpers located on both the Analog PCB’s and the Power Supply PCB.

NOTE: Running load cell cable in a conduit with other cabling is not recommended.

Page 10

4

2.9 LINEARITY CONNECTION (APPLICABLE WITH ANALOG PCB ONLY)

The 8146 has the ability to compensate for nonlinear weight readings. This is done by taking weight

readings at zero, half capacity, and full capacity. (Half capacity is defined as between 30 and 50% of full

capacity.) It is important to note that the closer to full scale capacity the test weights are to the actual

scale capacity, the more accurate the compensation will be.

Linearity correction may be disabled in the setup procedure.

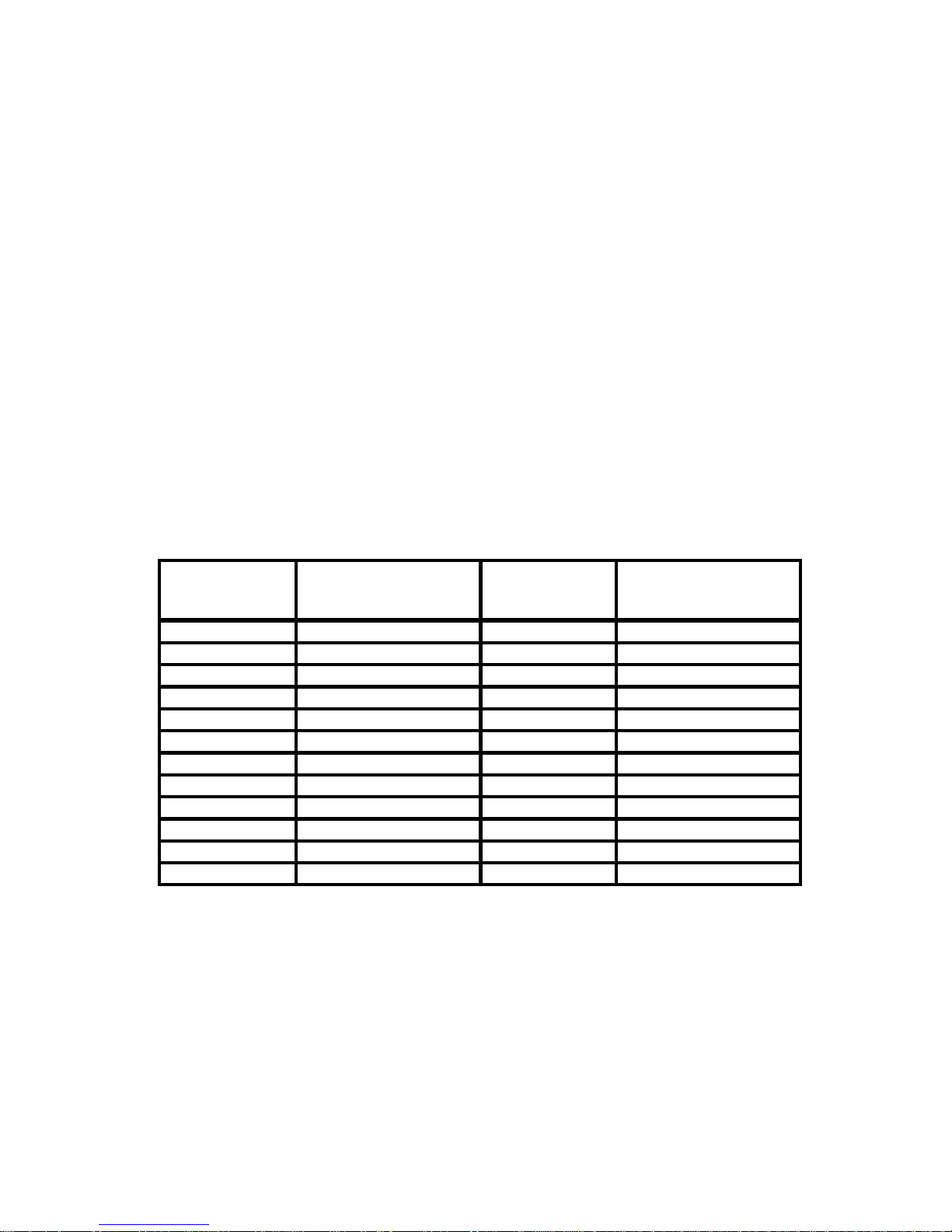

2.10 ANALOG VERIFICATION

Analog verification is a test routine which is used to verify only the indicator’s electronic analog section.

It is not usable on scales which have initial weight values greater than 7.5 millivolts. The AV test is

performed automatically approximately every four hours with the display reading zero. The indicator will

display “AAAAAA” during the test.

The AV process is performed by injecting a known test signal at the output of the pre-amp section. The

resulting data is then compared to a value calculated during calibration. If the test data is within the

tolerance of the calculated value (show in the chart), the test is passed. If the test fails, the indicator

becomes inoperative until corrective action is taken.

Analog verification may be disabled in the setup procedure.

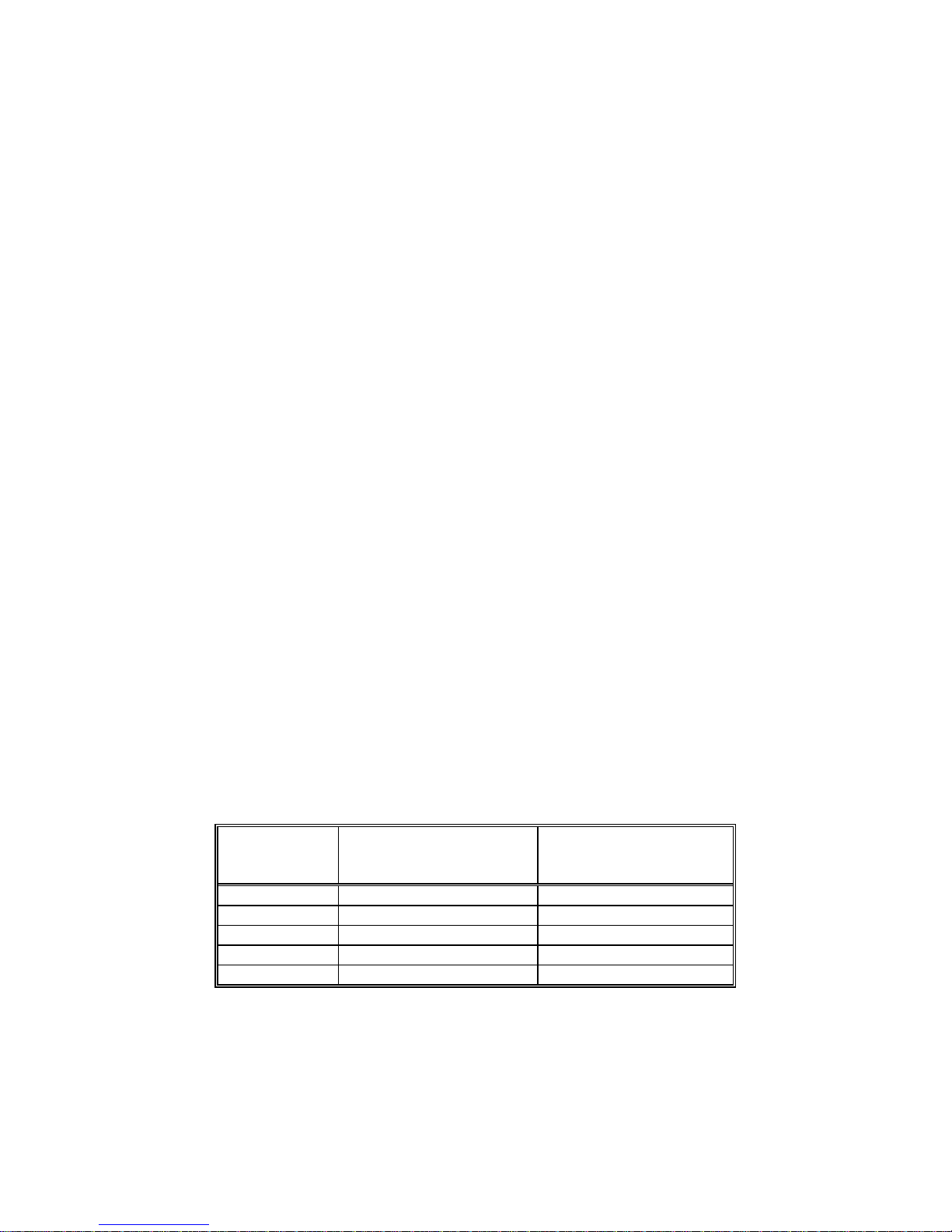

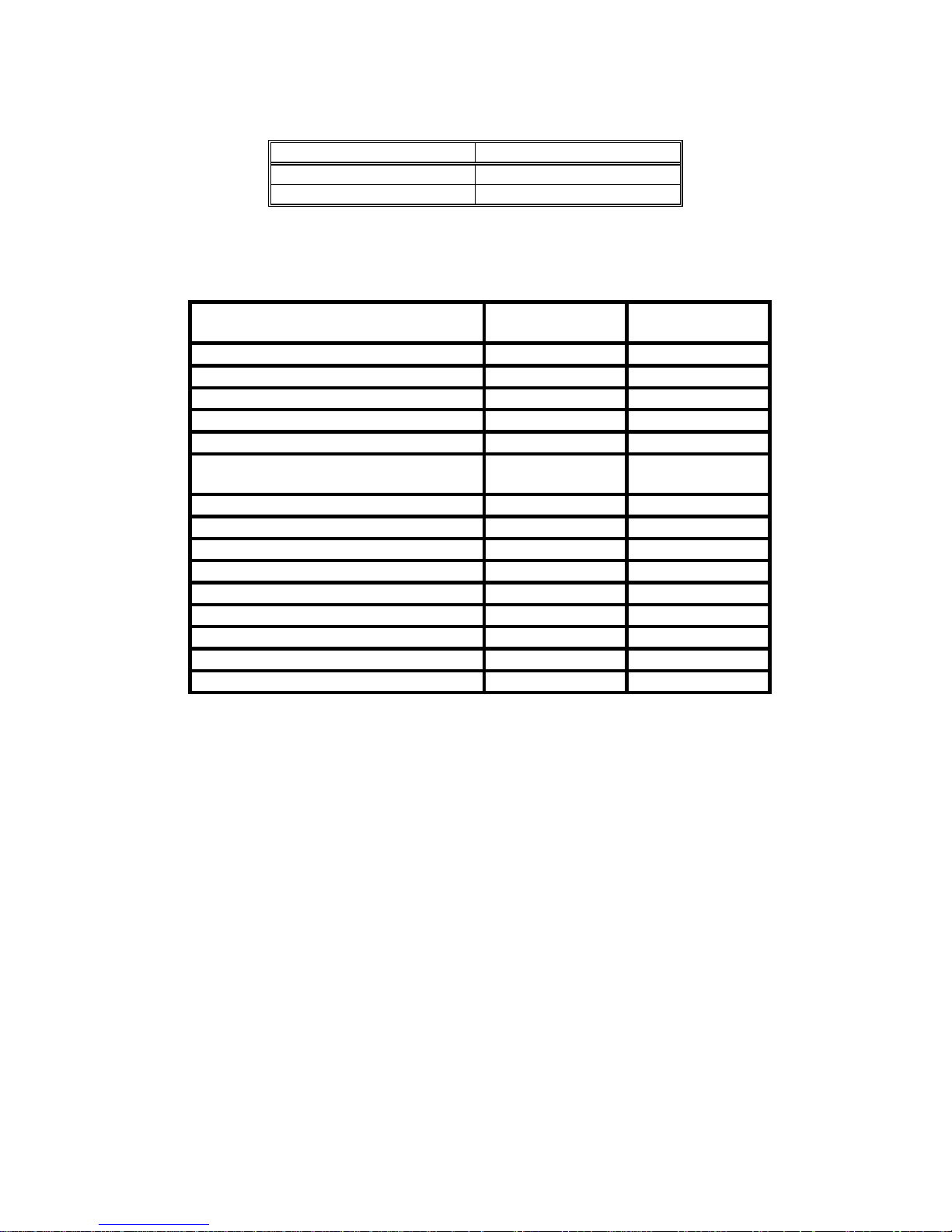

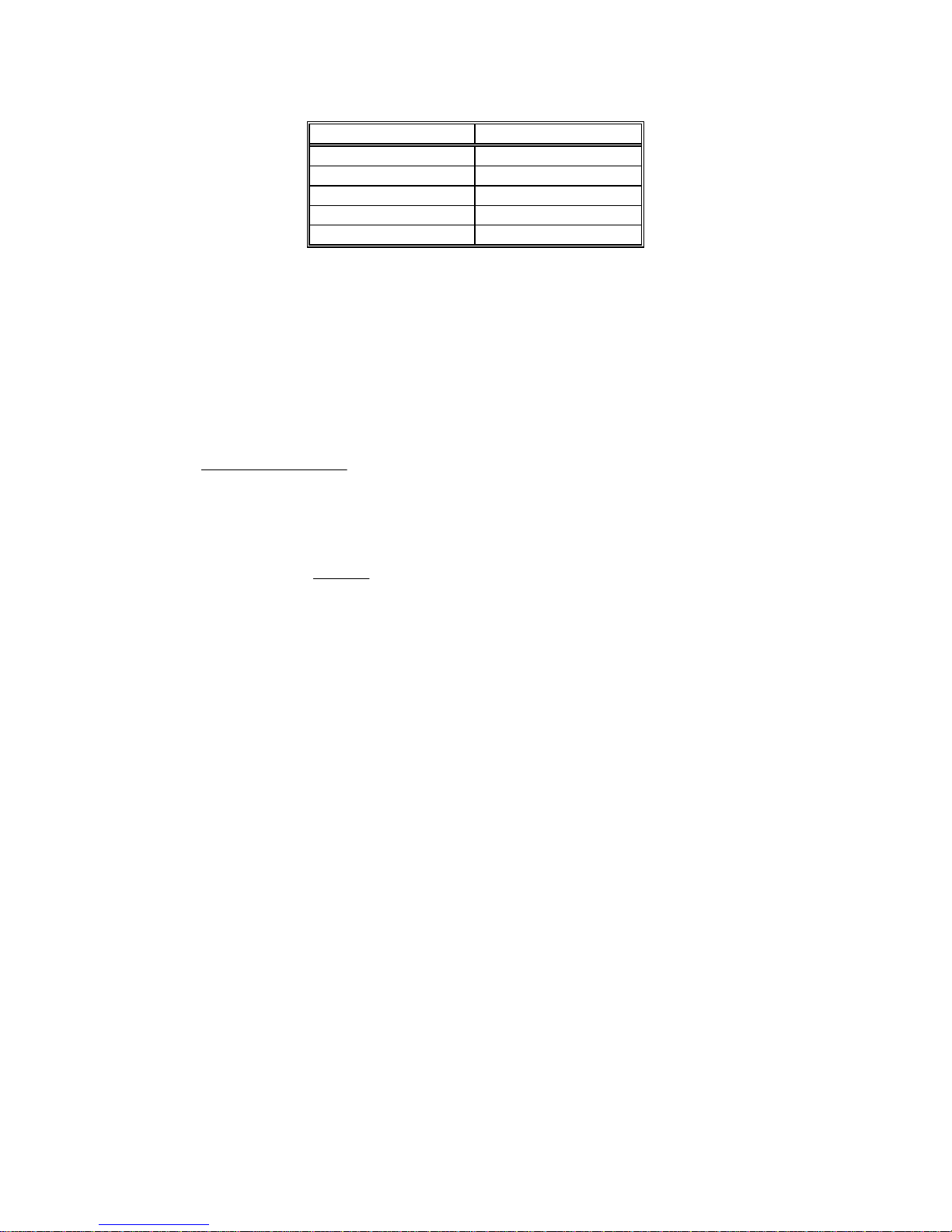

If Full Scale

Increments Are:

1000 ± 1.0 Increment 15000 ± 4.5 Increments

1200 ± 1.0 Increment 16000 ± 4.8 Increments

1500 ± 1.0 Increment 20000 ± 6.0 Increments

2000 ± 1.0 Increment 25000 + 7.5 Increments

2500 ± 1.0 Increment 30000 ± 9.0 Increments

3000 ± 1.0 Increment 32000 ± 9.6 Increments

4000 ± 1.2 Increments 35000 ± 10.5 Increments

5000 ± 1.5 Increments 40000 ± 12.0 Increments

6000 ± 1.8 Increments 45000 ± 13.5 Increments

8000 ± 2.4 Increments 48000 ± 14.4 Increments

10000 ± 3.0 Increments 50000 ± 15.0 Increments

12000 ± 3.6 Increments

Figure 2.1 Analog verification (AV) Test Tolerances

Acceptable

Tolerances

are:

If Full Scale

Increments are:

Acceptable

Tolerances

are:

Page 11

5

2.11 POWER UP SEQUENCE

When the AC power is applied, the 8146 will perform a series of display routines. These routines will

check all display segments and inform the operator as to which software version he has and of any

options that are installed. The series of display are as follows:

WEIGHT DISPLAY - Will count up, starting at 1 and ending at 0.

DATA DISPLAY - Will show a series of numbers and then flash the unit’s configuration.

EXAMPLE - Scales 2

- Host Port

- Software Revision Number

At the end of this routine, the unit will be at the home position and ready to operate.

2.12 DIGITOL ® LOAD CELL CABLE DISTANCES (APPLICABLE TO DWP44 PCB

ONLY)

2.12.1 DigiTOL ® Bench Portable

300 ft. Maximum, 8146 to Scale

2.12.2 DigiTOL ® J-Box and Floor Scale

300 ft. Maximum, 8146 to Scale

2.12.3 DigiTOL ® Power Cells

900 ft. Maximum, 8146 to Scale

NOTE: See chart below for maximum distance the auxiliary power supply can be placed from the scale.

This chart is based on the use of Toledo Scale load cell cable 8 conductor, 20 gauge with

stainless steel sheath for lightning protection.

Cells Per Pit

Power Supply

4 900 ft. 6 ft.

6 775 ft. 125 ft.

8 585 ft. 315 ft.

10 470 ft. 430 ft.

12 390 ft. 510 ft.

NOTE: This chart is a reference to maximum distances, dependent on the number of load cells and the

gauge of cable used.

Maximum Distance

Scale to Auxiliary

Supply

Maximum Distance

Auxiliary Supply to

8146

Page 12

6

3.0 SPECIFICATIONS

3.1 ELECTRICAL AND PHYSICAL SPECIFICATIONS

3.1.1 Environment

The 8146 will operate at temperatures from -10º C (14º F) to +40º C (104º F) with a noncondensing relative

humidity of 0 to 95%. The 8146 has a zero temperature coefficient of 0.1 µV/ºC typical., 0.15 µV/ºC

maximum and a maximum span temperature coefficient of 6 PPM/º C. (Applicable on unit the Analog

PCB installed).

The desk-type enclosure is ventilated and, therefore, restricted to office or light industrial applications.

The wall mount enclosure is rated NEMA 4X and is constructed from stainless steel and designed for

washdown environments.

3.1.2 Power Requirements

The 8146 can operate (by selection) at 120V, 220V or 240V AC. The voltage input tolerance is +10% to 15% of the selected AC voltage with a line frequency of from 49 to 61.5 hertz. Maximum power

consumption is 65 watts. Isolated power is recommended.

CAUTION!

ALL UNITS ARE SHIPPED FOR 120V AC OPERATION.

REFER TO SECTION 4.0 FOR ALTERNATE VOLTAGE

OPERATION.

3.1.3 UL and C.S.A. Standard

Materials, components, and electrical design comply with UL and C.S.A. standards and requirements

including grounding of all metal parts, fusing, etc.

3.1.4 FCC Regulations

The 8146 meets or exceeds the FCC conducted and radiated emissions requirements.

3.1.5 RFI Specifications

In environments where RFI radiation exists, use the stainless steel wall mount enclosure. This model

has been designed to greatly reduce the susceptibility to Radio Frequency Interference.

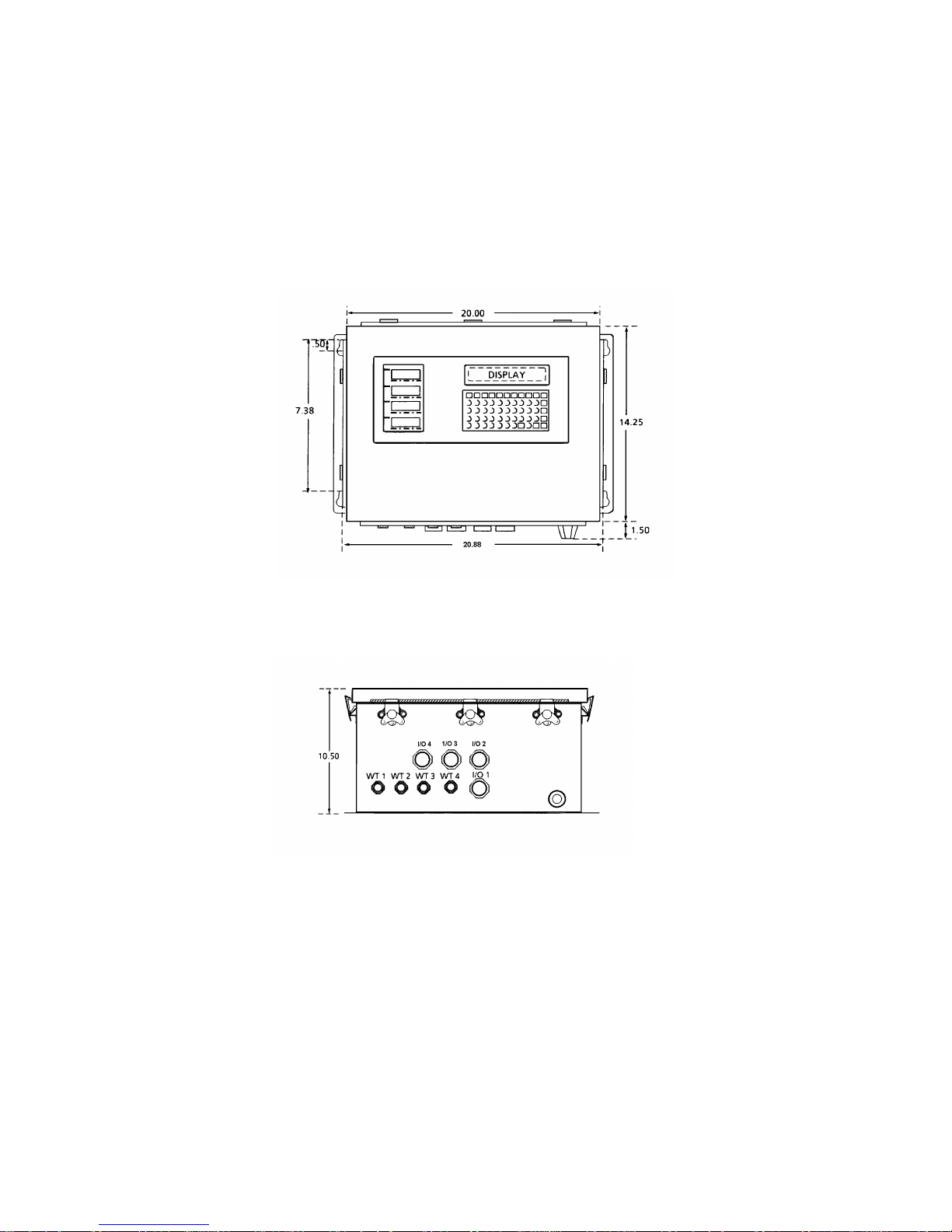

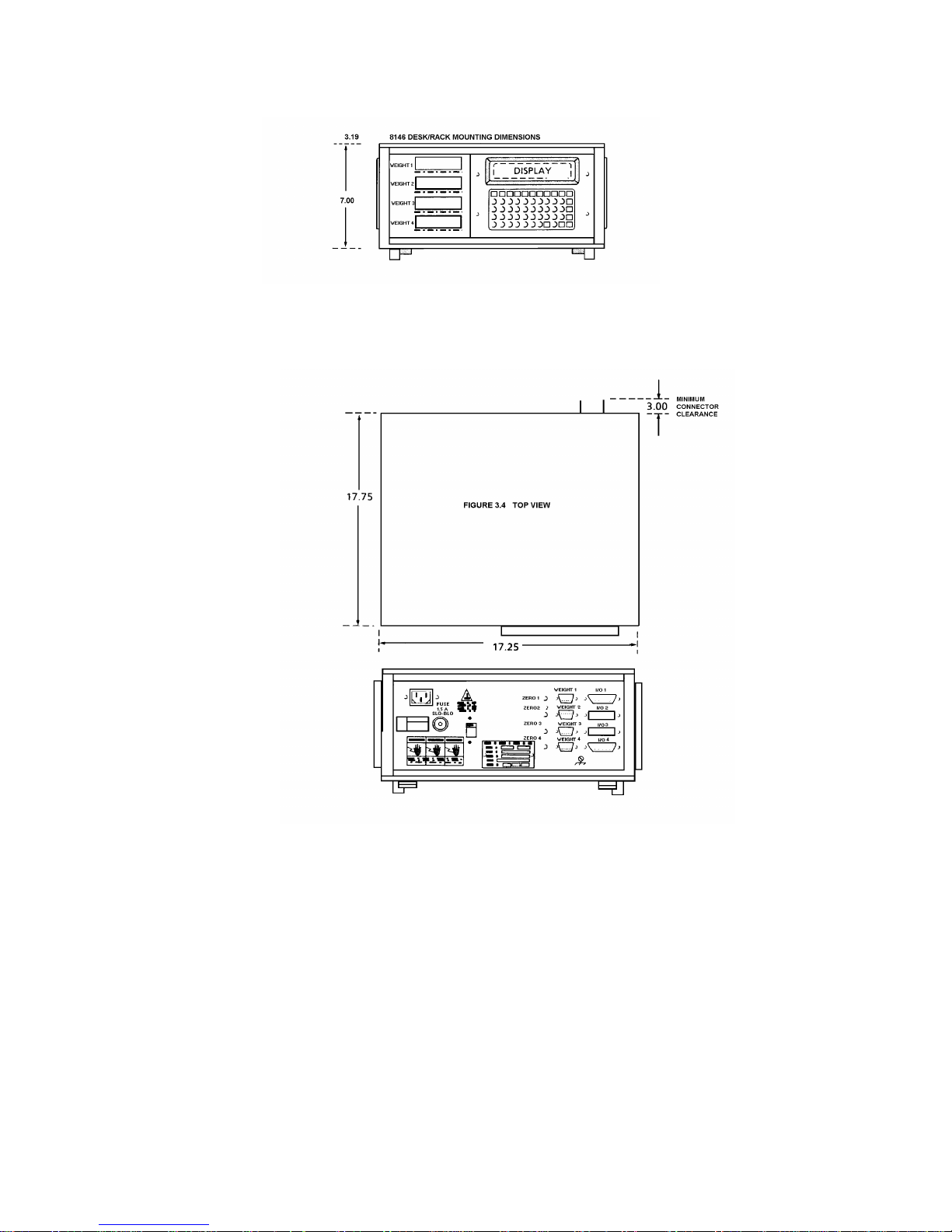

3.1.6 Appearance and Dimensions

Desk Mount - This unit is charcoal black in color with a blue-green display and green display lens. The

unit’s metal case is 7” (17.8 cm) tall, [8.8” tall (22.4 cm) with legs extended] X 17.25” (43.8

cm) wide X 17.75” (45.1 cm) deep.

Wall Mount - This unit is a stainless steel NEMA 4X enclosure with a blue-green display and green

display lens. The enclosure is 14.25” (36.2 cm) tall X 20” (50.8 cm) wide X 10.5” (26.7 cm)

deep.

Page 13

7

3.1.7 Hazardous Areas

In locations classified as hazardous by the National Electrical Code (NED) because of combustible or

explosive atmospheres, special modules are required. Toledo Scale Intrinsic Safety Modules are

designed for use in NEC Class I, or Class II, Division I, Groups C, D, E, F, or G. These Intrinsic Safety

Modules may be used ONLY with specific versions of the 8146. DO NOT CONNECT INTRINSIC SAFETY

MODULE TO ANY OTHER VERSION OF THE 8146. Contact Toledo Fast Factory for additional

information.

3.1.8 8146 Wall Mounting Dimensions

Figure 3.1 Front View

Figure 3.2 Bottom View

Page 14

8

3.1.9 8146 Desk/Rack Mounting Dimensions

Figure 3.3 Front View

3.2 INTERNAL FUNCTIONS

The 8146 contains the necessary electronics to calculate and display weight as well as the capability to

transmit data to a remote device.

Figure 3.5 Back View

Page 15

9

3.3 DISPLAY FORMATS

3.3.1 Weight Displays

The weight display is a 7-digit vacuum fluorescent-type, 0.512 inches high with a lighted decimal point.

A lighted comma may be selected to replace the decimal point by inserting a jumper plug across two

pins located on the Weight Display PCB. (See Section 4.4.6.) The display also includes seven vacuum

fluorescent descriptors which are located underneath the digits. These descriptors are ZERO, LB, KG,

GROSS, NET, TARE, and SELECT. Their functions are as follows:

ZERO When illuminated, this indicates that the scale is on gross zero.

LB or KG Indicates the unit is in the pounds or kilogram mode.

GROSS When illuminated, this indicates that the displayed value is the gross weight.

Gross = Tare + Net

TARE When illuminated, this indicates that the displayed value is the tare weight.

Tare = Gross - Net

SELECT When illuminated, this indicates which scale has been selected for further operations.

The 8146 may have two Weight Display PCB’s installed -- with each Weight Display PCB having two 7digit displays. This allows the 8146 to display the weight on each of the four possible scales at the same

time. With only two scales, it is possible to display the Gross or Net and Tare of each scale.

3.3.2 Data Display

The data display is a 16-character alphanumeric, dot matrix type. The characters are 0.44 inches high.

This display is used to prompt the operator throughout the various operating sequences as well as

display the results of the operation.

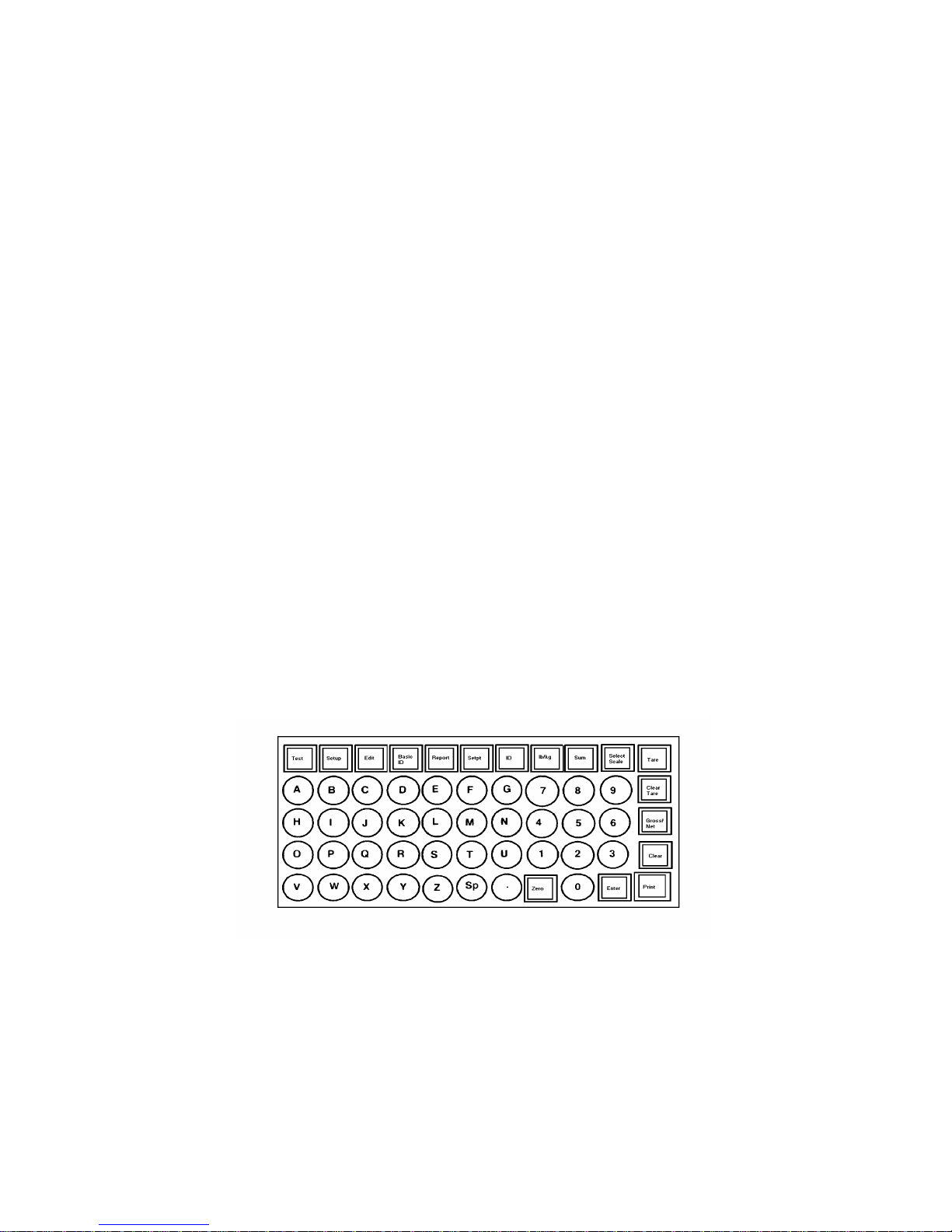

Figure 3.6 Keyboard Layout

Page 16

10

3.4 KEYBOARD SPECIFICATIONS

The keyboard is a 55-position, tactile feedback keyboard with the edge of each key raised. The keys are

arranged as follows:

A-Z Used to enter the appropriate character when prompted for an alphanumeric input.

0-9 Used to enter the appropriate digit when prompted for a numeric value.

Test Initiates the internal self-diagnostics. This routine will continue until the second

depression of the test key

Setup Used to enter setup mode in conjunction with setup lockout switch(es).

Edit This key is used to view or change the contents of the ID, CN, Time, Date, Stored Tare,

Subtotals and Totals data.

Basic ID Used to enter a 16-character identification.

Report Used to initiate report printing sequence

Setpt Used to view or change the value of any of the twelve setpoints.

ID Used to access the tare recall function, for stored weight operation.

lb/kg Used to alternate between the lb and kg display mode. This key may be disabled in the

setup procedure.

Sum Used in conjunction with a numeric key (1-4) to select the scales that are to be summed.

Also used in conjunction with the Select Scale key to select sum display of previously

entered scales.

Select Used in conjunction with a numeric key (1-4) to select a particular scale for subsequent

operations. Also used with the Sum key for recalling the summed weight to the

alphanumeric display.

Tare Used to initiate an autotare.

Clear Clears the tare applied to the selected scale. The operation of this key is dependent upon

the

Tare programming of the tare function.

Gross/Net Alternately selects between the gross and net display modes.

Clear Used to clear any erroneous entry of numeric data.

Print Used to initiate a data transmission through the printer interface.

Enter Used to terminate any entry.

Zero Used to zero the selected scale’s weight display.

3.5 FACTORY NUMBER CONFIGURATION AND OPTIONS

3.5.1 Configuration Chart

Page 17

11

All factory numbers are configured with one Weight Display PCB. Scale interface kits are ordered as

options. (See chart below.)

Factory Number Mounting

8146-0022 Desk

8146-0032 Wall

Figure 3.7 Factory Number Configuration Chart

3.5.2 Options

Descriptions

Service

Part Number

Sales

Part Number

Analog Scale KOP, Desk 127480 00A 0917-0126

Analog Scale KOP, Wall 124781 00A 0917-0127

Dual Serial I/O KOP, Desk 127482 00A 0917-0128

Dual Serial I/O KOP, Wall 127483 00A 0917-0129

Rack Mount KOP, Desk *** 127484 00A 0917-0130

Additional Weight Display KOP,

134367 00A 0917-0174

Desk

Additional Weight Display KOP, Wall 134369 00A 0917-0175

Tool-Operated Zero Pushbutton KOP 128235 00A 0917-0137

Scale Channel KOP (Analog KOP) 134365 00A 0917-0173

Weight Display Lens KOP, Desk* 134373 00A 0917-0176

Weight Display Lens KOP, Wall * 134374 00A 0917-0177

DigiTOL ® Scale KOP, Desk ** 134361 00A 0917-0171

DigiTOL ® Scale KOP, Wall** 134363 00A 0917-0172

DigiTOL ® Scale KOP, Desk ** 0917-0179

DigiTOL ® Scale KOP, Wall ** 0917-0180

Figure 3.8 Factory Options Chart

NOTE(S):

* Weight 1, Tare 1, Weight 2, Tare 2

** DigiTOL ® Power Cells

*** DigiTOL ® Bench Portable and DigiTOL ® J-Box

**** Factory Installed Option - Not Available as Field Installed KOP.

Page 18

12

3.6 DATA INTERFACE

3.6.1 Printer Output

The 8146 is capable of transmitting bit serial, ASCII coded, data stream at 300 to 9600 baud. 20mA

current loop, EIA RS232-C and EIA RS422 are all available as standard circuit types.

3.6.1.1 Demand Operation - 300 to 9600 baud

When a print command is received, either from the print key or an external “Print Demand” signal via the

host port, the 8146 will transmit a message which was formatted during the printer output setup

procedure. Transmission of a checksum character, as well as expanded print, is selectable in the same

setup procedure.

3.6.1.2 Continuous Operation - 300 to 9600 baud

Setpoint status is transmitted via serial port in an ASCII coded format. This format is compatible with a

Reliance Electric AUTOMATE 15 TM programmable controller. This allows a standard AUTOMATE 15 to

be used as a setpoint output controller. Communications are via a standard ASCII RS232 serial link, at

9600 baud, 8 data bits, 1 stop, no parity into the programming port on the AUTOMATE 15. The first 12

bits in the first I/O rail [0.00 through 0.13 (octal)] are assigned to setpoint outputs 1-12. The last output

rail (0.17) is assigned as a toggling watchdog bit, with state complimenting at each I/O update. The

other bits in the rail (0.14, 0.15, and 0.16) are allocated, but of indeterminate state. The AUTOMATE 15

may be programmed to use the setpoint bits as internal points, but MUST NOT ALTER THE OUTPUT

STATES. All other available I/O points (1.00 through 3.17) are usable to the AUTOMATE 15. Any digital

output module usable with the standard AUTOMATE 15 head may be used for setpoint control.

Automate head must have an address of 01, i.e., PCID = 1. Refer to Section 6.9 for a detailed description

of this output.

3.6.3 Bar Code I/O - Optional

This port provides a bi-directional, bar code interface. 20ma current loop and EIA RS232-C circuit types

are supported. Baud rates are selectable from 300 to 9600 baud. Refer to Section 6.8 for a more detailed

description. Bar Code output is available for use with the 8860 Thermal Label Printer.

3.6.4 Computer I/O - Optional

This port provides a bi-directional interactive computer interface. EIA RS232-C and 20 mA Current Loop

are available at 300 to 9600 baud. Refer to Section 6.7 for message format, content and protocol.

Page 19

13

4.0 INSTALLATION INSTRUCTIONS

4.1 PRELIMINARY INSPECTION

4.1.1 Inspection of Outer Case

Inspect the outer case for loose or damaged parts. If any damage is found, immediately notify the

freight carrier.

4.1.2 Inspection of Instrument

Open the instrument and continue the inspection noting that all interconnecting harnesses are securely

fastened.

4.1.2.1 The desk unit is opened by removing the four screws (two on the top cover plate and two on

the rear panel) and slide the top cover plate towards the rear of the unit.

4.1.2.2 The wall mount is opened by flipping the wing-type handle of each fastener up and turning

them 180 degrees counter-clockwise. Loosen the hinge fasteners of the bottom of the unit last.

4.2 OPERATING VOLTAGE SELECTOR

The operating voltage selector is located on the rear panel for the desk mount and inside the enclosure

on the wall mount. Locate this selection switch and verify that the correct operating voltage is selected

for installation.

! CAUTION

DO NOT APPLY POWER TO UNIT UNTIL VOLTAGE

HAS BEEN VERIFIED AND POWER SELECTION HAS

BEEN MADE.

! CAUTION

BE CERTAIN POWER IS DISCONNECTED BEFORE

MAKING ANY ADJUSTMENT TO THE

TRANSFORMER FOR VOLTAGE CHANGES.

Page 20

14

4.2.1 To adjust the voltage selection switch, loosen the two screws and slide the locking plate until the

correct voltage level is showing. Possible selections are: 120, 220, and 240 volts AC.

! CAUTION

IF THE OPERATING VOLTAGE IS CHANGED, BE

SURE THE FUSE IS REPLACED WITH A FUSE OF

THE CORRECT RATING.

120 VAC operation requires a 1.5 amp Slo-Blo Fuse

220 VAC operation requires a .75 amp Slo-Blo Fuse

240 VAC operation requires a .75 amp Slo-Blo Fuse

4.3 PRELIMINARY CALCULATIONS (APPLICABLE WITH ANALOG PCB ONLY)

Before connecting the 8146 to an understructure, it should be determined if the load cell(s) are of a size

that will work correctly with the instrument and platform. If it is a standard build, proceed with

installation of the scale. However, if it is a special build or a conversion of an existing mechanical scale,

the microvolt per increment should be calculated. After calculating the microvolt per increment build,

refer to the build charts to verify that the 8146 will operate correctly with this build.

4.3.1 To find the microvolt per increment build, you must first find the following items:

a) Scale capacity*

b) Increment size *

c) Number of load cells or total lever ratio

d) Load cell capacity

e) Load cell output rating in mV/V (millivolts per volt of excitation)

* in lb or kg depending on how the scale is to be calibrated and used.

4.3.2 Find the total load cell output in millivolts by multiplying the cell output rating* by the 8146

excitation voltage, 6 or 15 volts.*

NOTE: Toledo Scale load cells are 2mV/V. Other manufacturers’ load cells may be 1, 1.75, or

3mV/V. Standard excitation is 15 VDC, reduced excitation is 6 VDC.

4.3.3 Use the formula shown to calculate the microvolt per increment ratio.

IncrementSize TotalLoadCellOutput mV x

LoadCellCapacityxNumberofCells orLeverRate

4.3.4 Divide scale capacity by the increment size to determine the number of increments which will be

used.

4.3.5 The following microvolt chart shows the limits, in microvolts, for the number of increments used.

& ( )

( )

1000

The 8146 Analog PCB’s are designed to operate with a maximum microvolt input of either 30 or

45uV*. This selection is determined by the position of the W3 jumper located on the Analog PCB.

Verify the position of this jumper on all Analog PCB’s installed in your unit. It may be necessary

to change this jumper position to reach an acceptable microvolt per increment build on your

unit.

* The maximum microvolt input is found by multiplying the excitation times the millivolt

output rating of the load cell.

Page 21

15

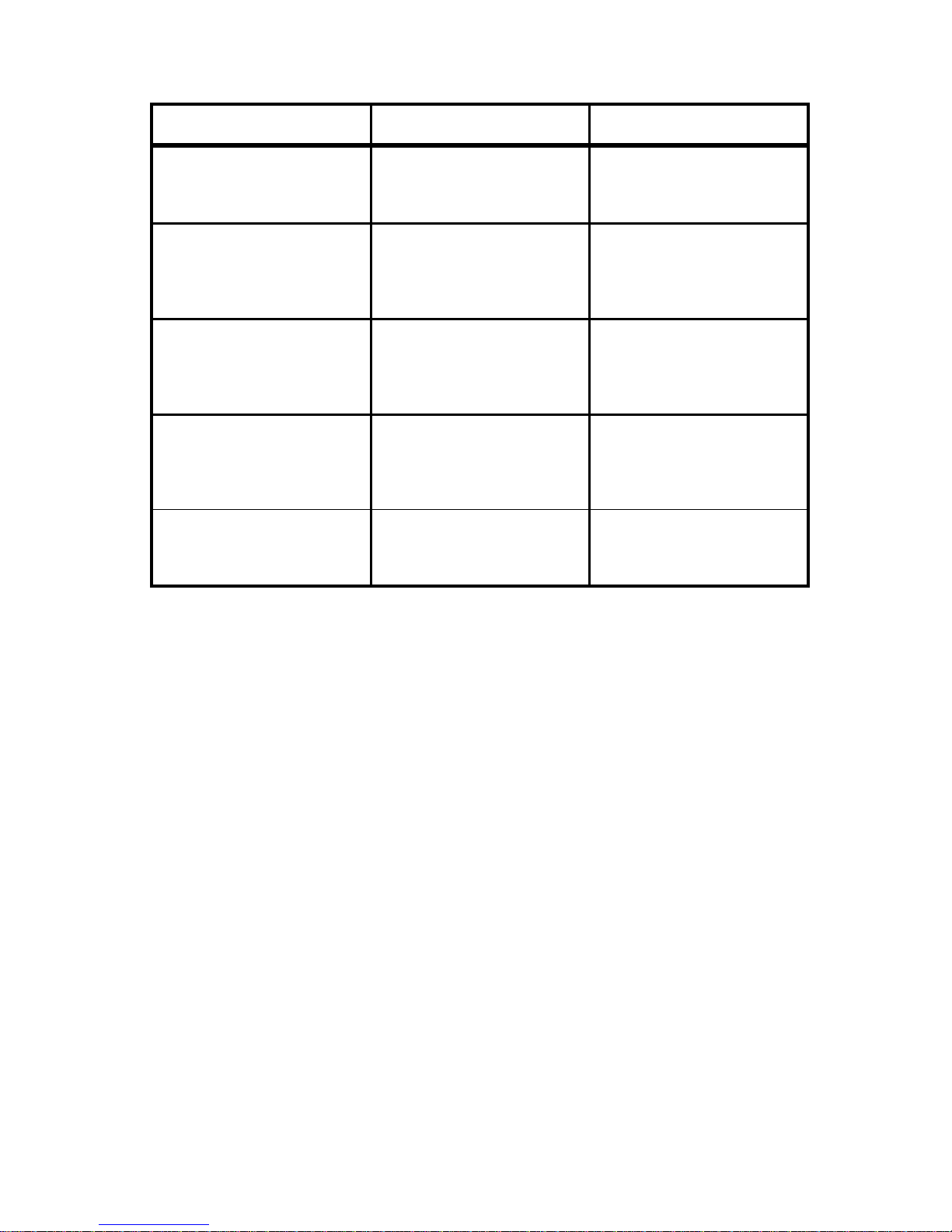

Number of Increments*** Minimum µV/INC** Maximum µ/V/INC*

1,000

1,200

1,500

2,000

2,500

3,000

4,000

5,000

6,000

8,000

10,000

12,000

15,000

16,000

20,000

25,000

30,000

32,000

35,000

40,000

45,000

48,000

50,000

3.0

2.5

2.0

1.5

1.2

1.0

0.75

0.6

0.5

0.375

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

38.0

31.7

25.3

19.0

15.2

12.7

9.5

7.6

6.4

4.8

3.8

3.2

2.5

2.4

1.9

1.5

1.3

1.2

1.1

0.95

0.84

0.80

0.76

* The 8146 cannot be calibrated on builds that are greater than shown for the maximum

µV/Increment.

** The 8146 should never be programmed to less than .3uV/Increment for multiple cell scales

(4 or more) and no less than 1.0uV/Increment for single cell scales.

*** The number of increments shown are the only selections which should be made. If these

limits are exceeded, the scale may not be stable.

Page 22

16

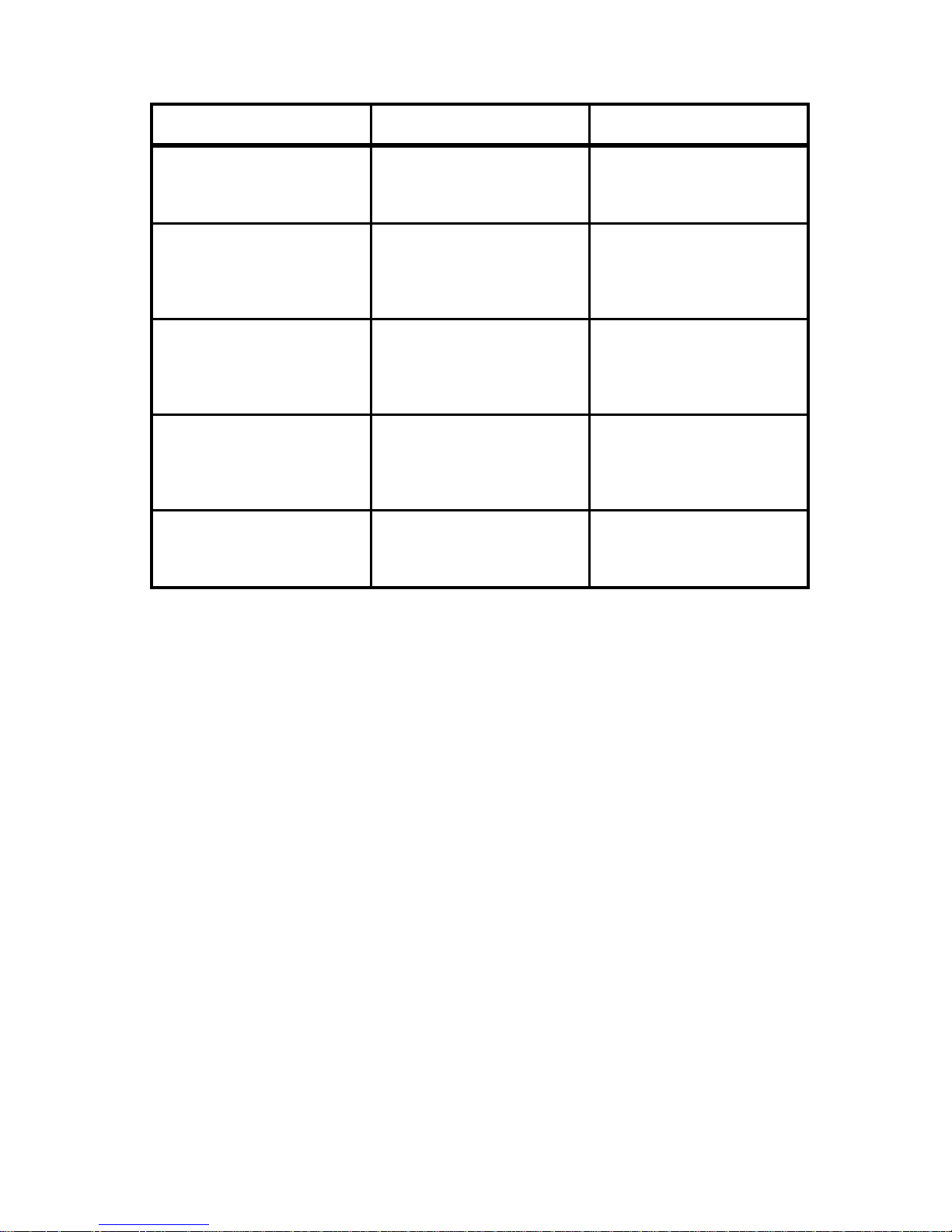

Number of Increments*** Minimum µV/INC** Maximum µ/V/INC*

1,000

1,200

1,500

2,000

2,500

3,000

4,000

5,000

6,000

8,000

10,000

12,000

15,000

16,000

20,000

25,000

30,000

32,000

35,000

40,000

45,000

48,000

50,000

3.0

2.5

2.0

1.5

1.2

1.0

0.75

0.6

0.5

0.375

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

Figure 4.2 Microvolt Chart for Analog PCB With

Jumper W3 Set Between Pins 2 and 3 (30mV)

26.0

21.7

17.3

13.0

10.4

8.7

6.5

5.2

4.4

3.3

2.6

2.2

1.7

1.6

1,3

1.0

0.87

0.81

0.74

0.65

0.58

0.54

0.52

* The 8146 cannot be calibrated on builds that are greater than shown for the maximum

µV/Increment.

** The 8146 should never be programmed to less than .3 µV/Increment for multiple cell scales (4

or more) and not less than 1.0 µV/Increment for single cell scales.

*** The number of increments shown are the only selections which should be made. If these limits

are exceeded, the scale may not be stable.

Page 23

17

4.3.6 Example of finding the µV/Increment build

Scale Capacity 5000 lb

Increment Size 1 lb

Number of Cells 4

Size of Cells 2000 lb

Cell Output Rating 2 µV/V

8146 Excitation 15 V

MODEL 2155

Step 1 Find the total load cell output in millivolts (mV).

2mV/V x 15V = 30mV

Step 2. Use the formula to find µV/Increment

1 lb x 30mV x 1000

2000 lb x 4

Step 3 Divide scale capacity by increment size to determine number of increments to be

programmed.*

= 3.75 µV/Inc.

50001lb

lb

Step 4 Check the Microvolt per Increment Chart to see if this build fits into the 5000 increment range.

If it does, this will be a satisfactory build and you can continue with the installation.

If it does not, do not continue with this installation until the problem is corrected.

= 5000 Increments

*

select the closest range from the chart, as only the values in the chart are legitimate builds.

Page 24

18

4.4 JUMPER DESCRIPTION AND RECOMMENDED SETTINGS

This section of the manual describes the function of the onboard jumpers and program switches as well

as their recommended settings for use in the Model 8146. Refer to the following paragraphs by

individual PCB to determine how the jumpers or switches are to be positioned. Selections shown are

the required settings for correct operation of the 8146 indicator.

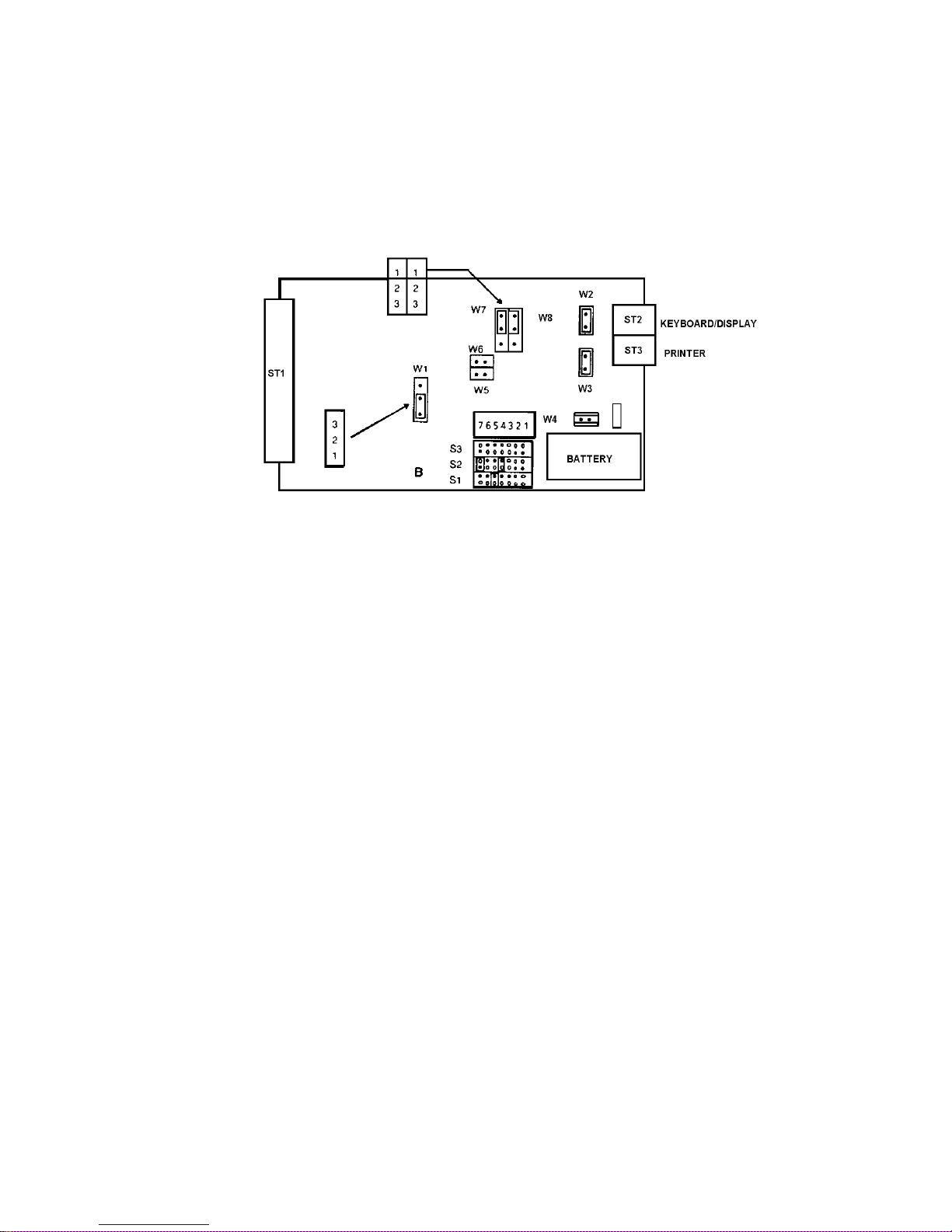

4.4.1 CPU PCB

W1 - RAM Size

Pins 1 to 2 = 8K RAM

W2 - CTS Level for Connector ST2

Pins Connected = Inactive CTS

W3 - CTS Level for Connector ST3

Pins Not Connected = Active CTS

*Pins Connected = Inactive CTS

W4 - Battery Backup

Pins Connected = Battery Active

W5 and W6 - On-board Address Selection

Both of these jumpers must be set so that the pins are not connected.

W7 and W8 - Off-board Address Selection

Both of these jumpers should be installed between Pins 1 and 2.

S1-5

Pins connected = Clock Interrupt

S2-4

Pins Connected = Host/Bar Code Serial Receive Interrupt

S2-7

Pins Connected = Printer Serial Receive Interrupt

*Factory Setting

Page 25

19

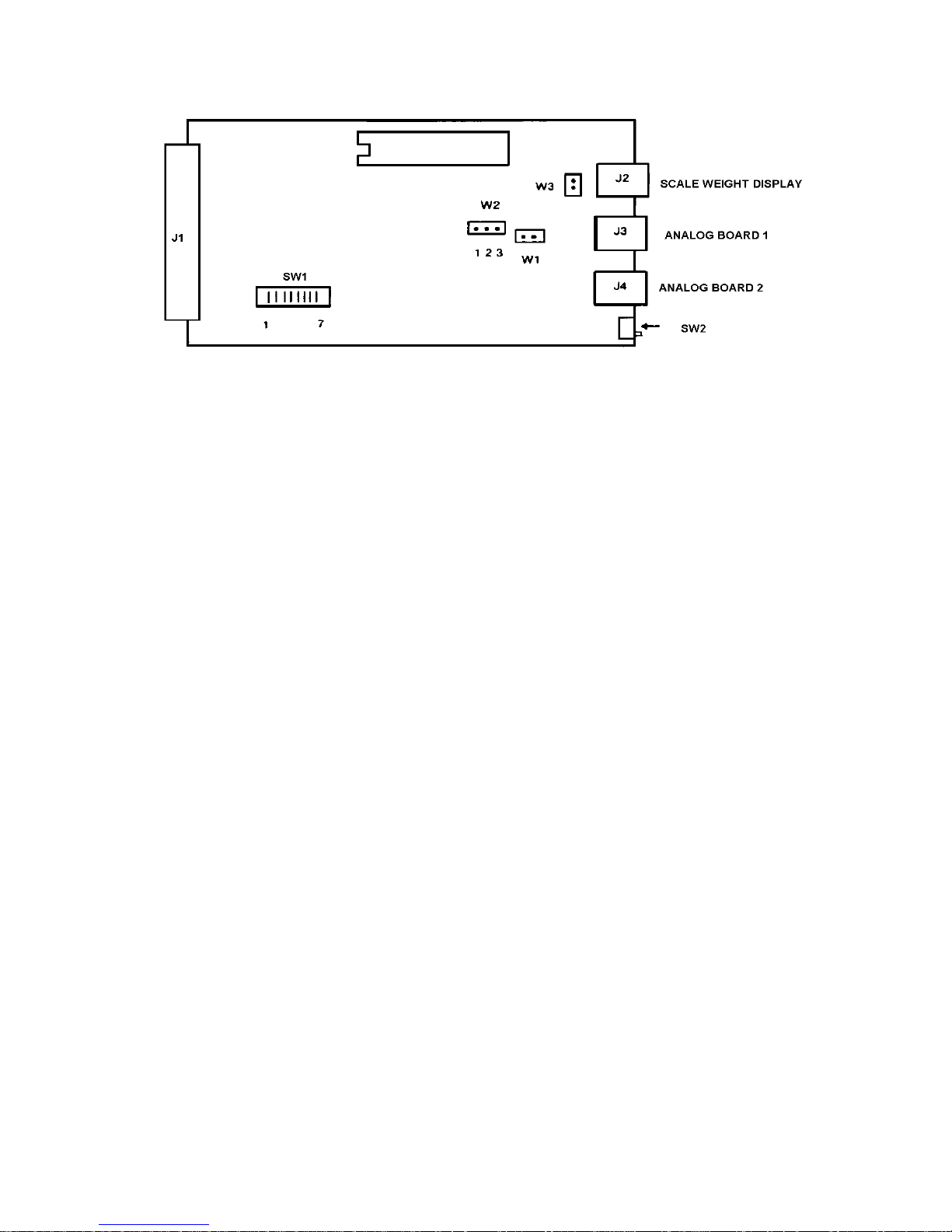

SWITCH 1-1 ON - For the first Scale Channel PCB in the unit

OFF - For the second Scale Channel PCB in the unit

1-2 MUST BE ON

1-3 MUST BE ON

1-4 MUST BE ON

1-5 MUST BE OFF

1-6 MUST BE ON

1-7 MUST BE OFF

SWITCH 2 ON (towards J4)

This switch on the first Scale Channel PCB will allow the setup

procedure to be accessed and calibration of the scales connected to

this PCB. This switch on the second Scale Channel PCB must be

turned ON to access the calibration procedure of any scales connected

to it.

OFF (away from J4)

W1 - PSEN

This jumper must be set so that the pins are connected.

W2 - EPROM Select

Pins 2 to 3 = High Memory Size

W# - CTS Enable

Pins are not connected = CTS Inactive

Prevents access to the setup and calibration procedures.

Page 26

20

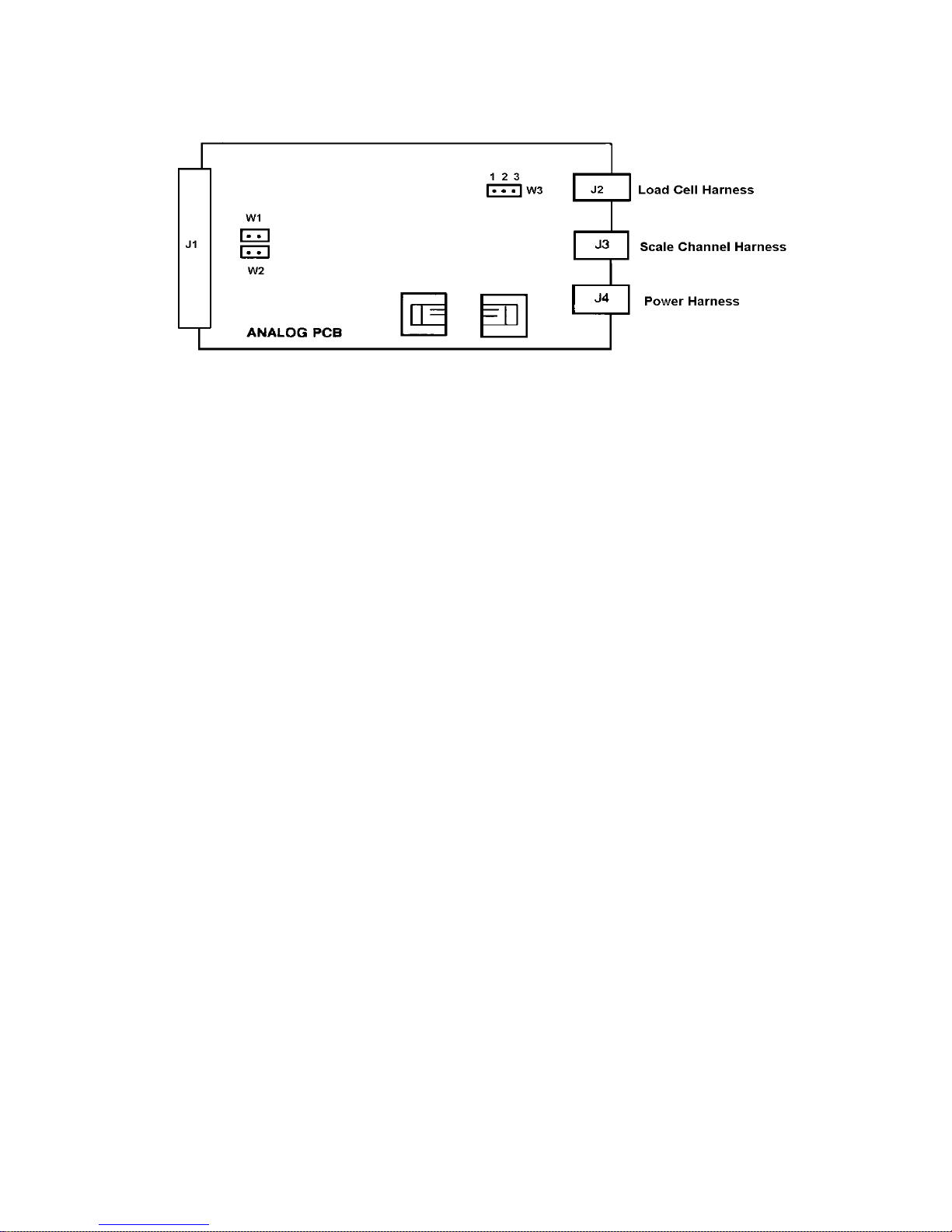

4.4.3 Analog PCB

W1 and W2 - Line Sync

* Pins Connected = AC Line Sync

NOTE: These jumpers must be positioned the same as Jumper W1

Pins not connected = Internal Sync

located on the Power Supply PCB.

W3 - Load Cell Output Selection

3mV/V - For use with 3mV/V load cell(s). This jumper must connect Pins 1 and 2.

2mV/V - For use with 2mV/V load cell(s). This jumper must connect Pins 2 and 3.

* Factory Setting

Page 27

21

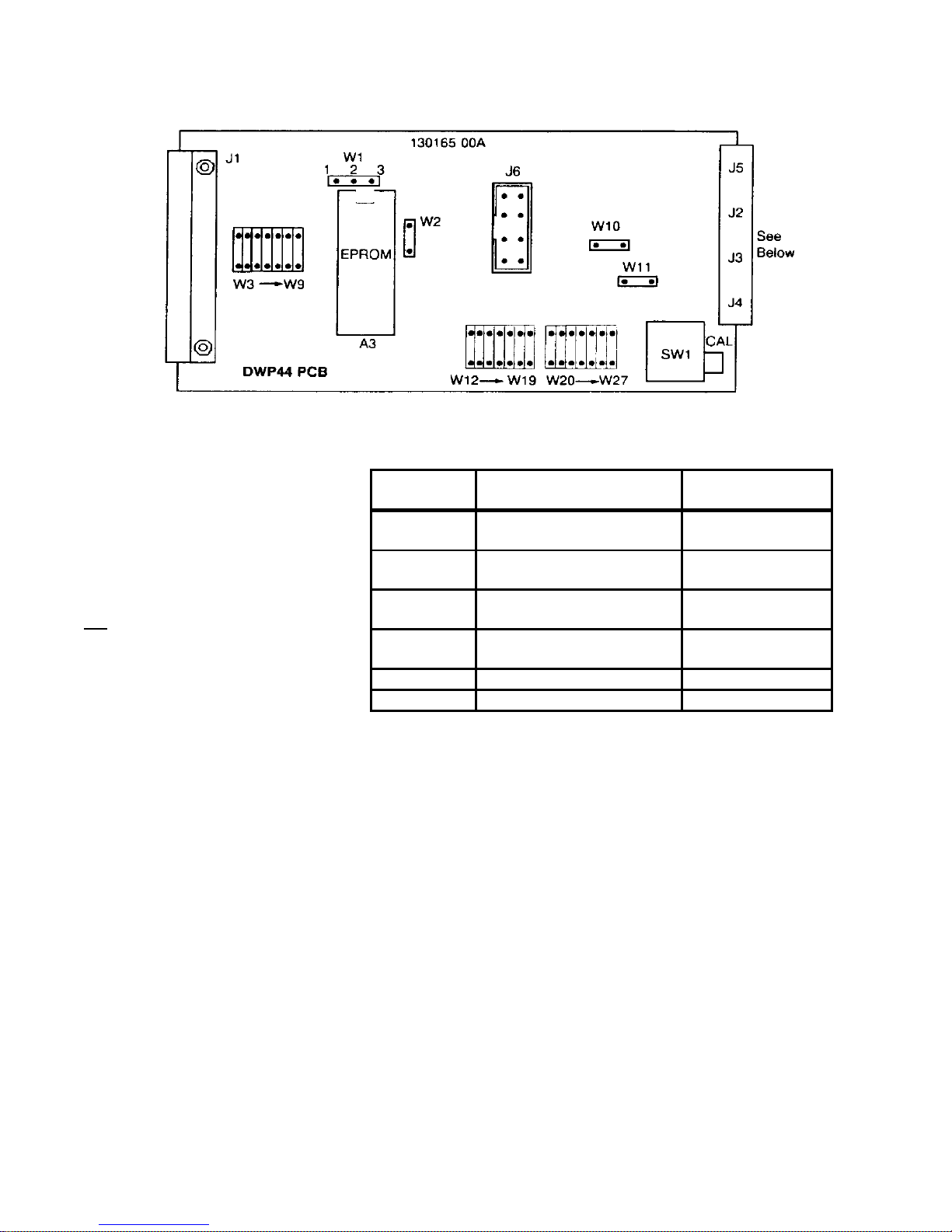

4.4.4 DWP44 PCB

Jumpers installed as follows:

W1 = OVER Pins 2 & 3

W2 = IN (shorting pins together)

W3 = IN for DWP44 #1

W3 = OUT for DWP44 #2

W4, W5, W6 & W8 = IN

NO Jumpers installed

W7, W9 thru W17 = OUT

W19 thru W27 = OU

Connector Usage Internal Harness

Part Numbers

J1 32 Pin TSM Bus Interface

TSM Back Plane

J2 T-LAN & High Speed

Multidrop DLC

J3 Single DLC or DigiTOL ®

J-Box

J4 Single DLC or DigiTOL ®

J-Box

134360 00A Desk

134375 00A Wall

134383 00A Desk

134384 00A Wall

134383 00A Desk

134384 00A Wall

J5 Dual Weight Display 128236 00A

J6 Auxiliary Power Input 118521 00A

Page 28

22

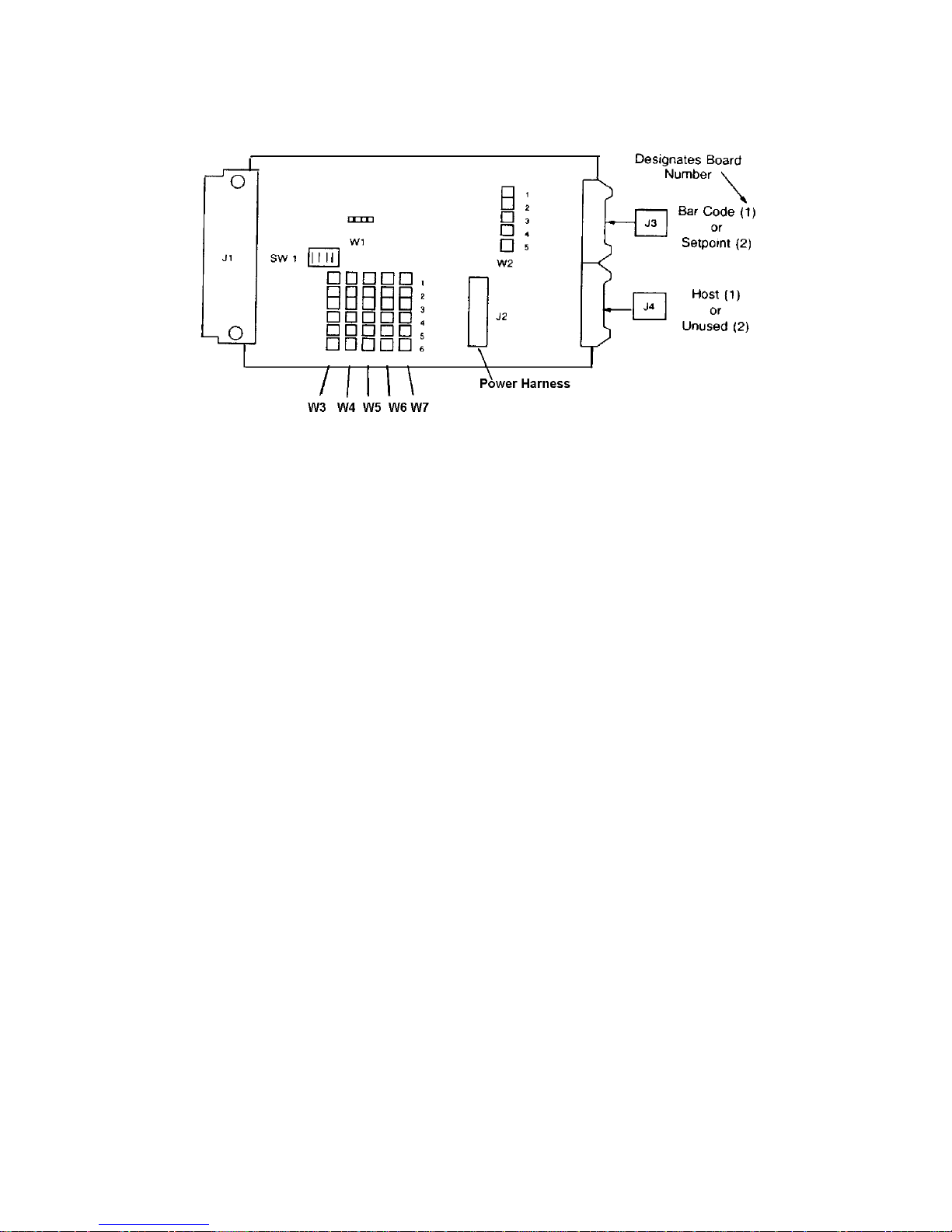

4.4.5 Serial I/O PCB

W3 = Not Used

W4 = 1-2 All Options

W5 = 1-2 Host/Bar Code Only

W6 = Not Used

W7 = Not Used

Switch 1 for the Host and Bar Code Option (1), set switches as follows:

SW1- 1 OFF

SW1- 2 ON

SW1- 3 OFF

SW1-4ON

For the Setpoint Option (2), set switches as follows:

SW1- 1 ON

SW1- 2 OFF

SW1- 3 OFF

SW1-4ON

W1 - Timing Clock

This jumper should be installed between Pins 2 and 3.

W2 - External Device Interfacing (CTS and DSR)

For normal operation this should have two jumpers installed. These jumpers

should be installed across pins 1 and 2, and pins 4 and 5. Pin number 3 should

not be connected.

NOTE: 8146’s may contain 0, 1, or 2 Serial I/O PCB’s. Board (1) is used for the Host and

Bar Code options. Board (2) is used for the Setpoint option. Both are ordered as 917-0128 KOP, for desk units, or 0917-0129, for wall units, then configured using

SW1 as shown.

Page 29

23

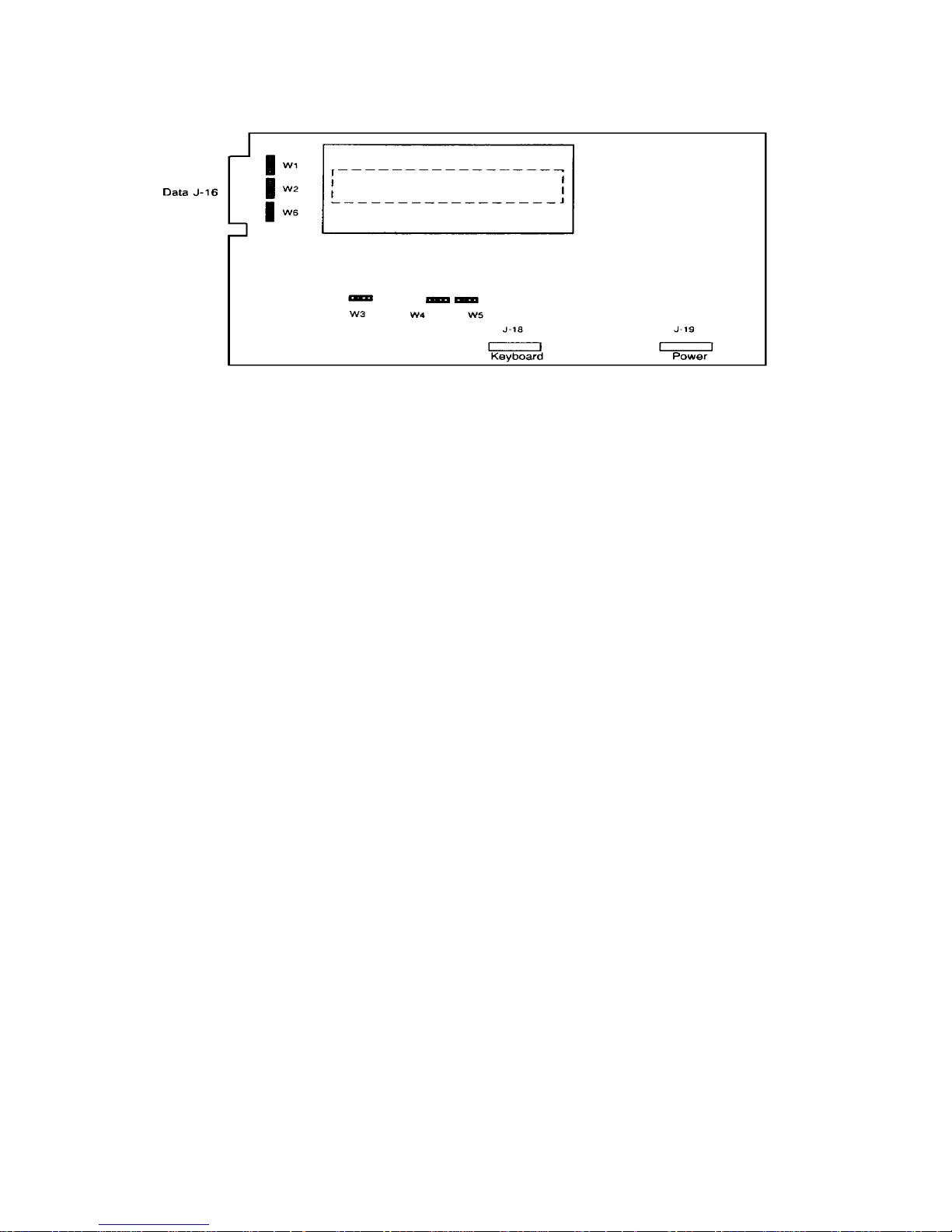

4.4.6 Dot Matrix Display PCB

W1 - Data Output Circuit Type

W2 - CTS Circuit Type

W3 - Test

Pins 2 to 3 = RS232-C Output

Pins 2 to 3 = RS232-C Output

Used to start the self test of the Display PCB. During this test any key

pressed will advance across the display. The pins should not be

connected for normal operation.

W4 - On-board ROM Enable

Pins Not Connected = On-board ROM

W5 - Chip Select

These pins must be connected

W6 - DSR Circuit Type

Pins 2 to 3 = RS232-C Input

Page 30

24

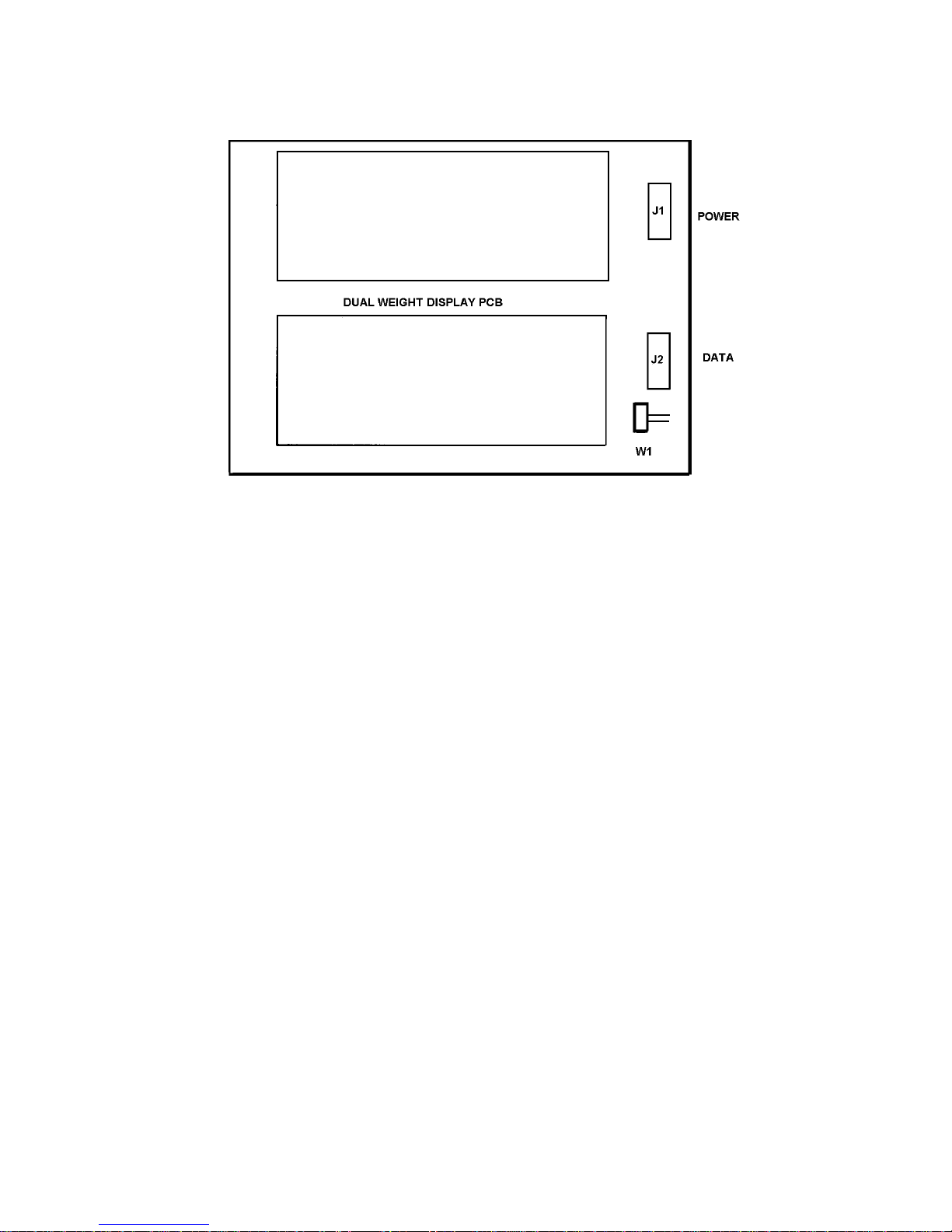

4.4.7 Dual Weight Display PCB

W1 - Comma

Pins not connected = Decimal point on the display

Pins connected = Comma on the display

(Later versions have solder pads only).

Page 31

25

4.4.8 Dual Serial Converter PCB

W1 - Data Input Circuit Type (Keyboard/Display)

W2 and W3 - Data Handling Selection

Pins 2 to 3 = RS232-C Input

Both of these jumpers must have the pins not connected.

W4 - Data Input Circuit Type (Printer)

* Pins 2 to 3 = RS232C Input

W5 Through W8 - Data Handling Selection

All of these jumpers must not have the pins connected.

* Factory Setting

Pins 1 to 2 = RS422 Input

Page 32

26

4.4.9 Power Supply PCB

W1 - Line Sync

Pins not connected = Internal Sync

Pins Connected = AC Line Sync

NOTE: This jumper must be positioned the same as Jumpers W1 and W2 located on the Analog PCB’s.

POWER SUPPLY PCB

!WARNING

THE POWER SUPPLY PCB CONTAINS VOLTAGES IN EXCESS

OF 400 VOLTS. USE CARE WHEN TESTING VOLTAGES.

Page 33

27

5.0 PROGRAMMING PROCEDURE

This section of the manual describes the programming of the indicators’ operating modes and features

as well as the self-calibrating procedure.

The procedure consists of two major groups which deal with the overall setup and calibration of the

indicator. Each major group contains a description of the setup and calibration procedure. Section 5.1

details the procedure for the analog type units and Sections 5.2 thru 5.6 detail the procedure for the

DigiTOL ® type units.

All question prompts and their current status, which affect the overall operation of the indicator, are

displayed on the 16-character alphanumeric display. Questions which deal with the operation of a

specific scale will be displayed on the associated scale’s weight display.

Five front panel keys are used throughout this procedure. The keys’ names and their functions are as

follows:

KEY NAME DESCRIPTION

SETUP This key is used to enter into the setup procedure. It is also used to exit this procedure at

any point in the procedure except during calibration.

ZERO This key is used to back up to the previous question.

ENTER This is used to accept the currently displayed answer to the question prompt.

1 This key is used as a “YES” response to the question prompt and will enable the displayed

function.

0 This key is used as a “NO” response to the question prompt and will disable the displayed

function. It is also used to increment to the next possible selection if the question consists

of several possible choices.

TO ENTER INTO THE SETUP PROCEDURE YOU MUST FIRST TURN “ON” THE SETUP LOCKOUT

SWITCH(ES) -- (SWITCH “2” ON THE ADP-51, SWITCH “1” ON THE DWP-44) LOCATED ON THE SCALE

CHANNEL PCB(S) OR THE DWP44 PCB(S). If there are two PCB’s installed in your unit, both switches

must be turned “ON” to access the setup prompts. The ON position is when the switch handle is toward

the J4 connector. (Switch “2” on the ADP-51, Switch “1” on the DWP-44).

The following chart can be used as a quick reference for programming descriptions. Also listed is the

recommended selection for each step as a beginning point of initial setup. Verify each selection to be

certain that it is correct for actual usage.

Page 34

28

5.1 ANALOG SETUP AND CALIBRATION PROCEDURE

(for use with Analog type load cells)

8146 PROGRAM FUNCTIONS

STEP DESCRIPTION INITIAL

SETUP/CALIBRATE SCALES

F2.0 TARE FUNCTIONS

F2.1 TARE ACTIVE 1

F2.2 TARE INTERLOCK 0

F2.3 AUTO CLEAR TARE 0

F2.4 TARE DISPLAY ACTIVE 1

F3.0 POWER-UP FUNCTIONS

F3.1 POWER-UP TIME 0

F3.2 POWER-UP POUNDS 1

F3.3 LB/KG SWITCHING 1

F3.4 EXPAND MODE 0

F3.5 SPAN ADJUST 0

F4.0 AVERAGING, ZERO, AND AZM FUNCTIONS

F4.1 AUTO ZERO MAINTENANCE 3

F4.2 EXPANDED ZERO CAPTURE 0

F4.3 PUSHBUTTON ZERO 1

F4.4 ZERO CAPTURE RANGE 2

F4.5 MOTION SENSITIVITY 07

F4.6 MOTION DETECTION 03

F4.7 DIGITAL FILTERING 1

F4.8 ANALOG VERIFICATION 0

SETUP

CAL ACCESS CALIBRATION

5.1 ANALOG SETUP AND CALIBRATION PROCEDURE

(FOR USE WITH ANALOG TYPE LOAD CELLS)(CONTINUED)

Displayed Prompts Descriptions

[Setup Scale X] SETUP/CALIBRATE SCALES?

This is the first prompt after entering the setup procedure and is displayed on the alphanumeric display.

If you want to setup, calibrate or make any changes which deal with any one of the four possible scales

connected, simply enter that scale’s number (1-4) and the routine will advance to F2.0. All prompts

which deal with the selected scale will be displayed on that scale’s weight display. If you do not want to

enter into this routine, enter a 0 and the procedure will skip to F5.0.

NOTE: This prompt will remain on the display throughout this routine. At the end of each scale’s

setup, the weight display will return to normal. At this time, the unit is asking for the next

scale number or a 0 to continue. The routines that deal with each scale are: F2.0, F3.0, F4.0,

and CAL.

[F2.0 ] ACCESS TARE FUNCTIONS? Press:

1 To enter into the setup of all tare functions.

0 To skip the tare setup. The procedure will advance to step F3.0.

[F2.1 ?] TARE ACTIVE. Press:

1 To enable both the hand entered and auto tare function.

Page 35

29

0 To disable the tare function.

[F2.2 ?] TARE INTERLOCK. Press:

1 The indication must be at true zero before tare can be removed. (True Zero is actually zero

minus the tare value). Previous tare must be cleared before a second tare may be entered.

This also disables a weight display on power up. The display will flash EEE until zero is

captured.

0 The tare value may be cleared or changed at any weight indication. Multiple tare will be

accepted. The indication will power up with a non-flashing weight display.

[F2.3 ?] AUTO CLEAR TARE. Press:

1 The tare value will automatically clear when the indication returns to zero after settling to a

no-motion condition at a weight greater than 10 minor increments.

0 Tare must be cleared manually by using the Clear key.

[F2.4 ?] TARE DISPLAY ACTIVE. Press:

1 The tare value will be displayed on the lower weight display. This is only usable when the

8146 is configured as a dual display unit.

0 The tare value will not be displayed.

[F3.0 ] ACCESS POWER UP AND lb/kg SELECTION? Press

1 To enter into the setup of the power up and lb/kg selections

0 To skip these setup selections. The procedure will advance to step F4.0.

[F3.1 ?] POWER UP TIMER (Approx. 30 seconds). Press:

1 The weight display(s) will remain blank and the legend indicators will blink until the time-

out period has elapsed.

0 The weight display(s) will illuminate as soon as power is applied.

[F3.2 ?] POWER UP POUNDS. Press:

1 The 8146 will power up in the lb mode.

0 The 8146 will power up in the kg mode.

[F3.3 ?] lb/kg SWITCHING. Press:

1 To enable the switching between the lb and kg modes via the keyboard.

0 To disable lb/kg switching. The unit will operate in the selected power up mode.

Page 36

30

[F3.4 ?] EXPAND MODE. Press:

1 The weight display will be expanded (showing minor increments).

0 The weight display will not be expanded (showing major increments).

NOTE: The 8146 should not be left in the expand mode for weighing. This mode is for

installation evaluation and troubleshooting only. The Print, AZM, and Zero keys are

disabled in this mode.

[F3.5 ] SPAN ADJUST. Press:

1 To enter into the span adjust. The standard calibration must be completed to provide a

reference point before attempting to use this step. Refer to section 5.1.1 for a detailed

description of the span adjustment feature.

0 A “0” will be displayed on the right of the display and the span adjust mode will not be

accessed.

[F4.0 ] ACCESS SCALE PARAMETER SELECTIONS: Press:

1 To enter into the setup of the scale parameter selections.

0 To skip the scale parameter selections. The procedure will advance to step CAL.

[F4.1 ?] AUTO ZERO MAINTENANCE

This selection allows for different AZM band and rate selections. The band size is the

maximum amount of increments which can be adjusted for, and the rate is the amount of

adjustment per cycle. Key in the appropriate selection from the chart below and then press

“ENTER”.

AZM Selection AZM Range

0 AZM Disabled

1 ± 0.5 increment with 0.1 rate

2 ± 1.0 increment with a 0.2 rate

3 ± 3.0 increments with a 0.4 rate

[F4.2 ?] EXPANDED AZM CAPTURE RANGE. Press:

1 To increase the AZM range from ± 2% up to ± 10% of the scale capacity.

0 The AZM range will not be increased.

[F4.3 ?] PUSHBUTTON ZERO. Press:

1 To enable the front panel Zero pushbutton.

0 To disable the front panel Zero pushbutton.

Page 37

31

[F4.4 ?} PUSHBUTTON ZERO CAPTURE RANGE

This prompt is requesting the percent of the scale capacity that can be captured by using the

Zero pushbutton. This entry is selectable from 2 to 20% of scale capacity.

[F4.5 07] MOTION SENSITIVITY SELECTION

The detection of motion disables printing, tare, and pushbutton zeroing. Steps F4.5 and F4.6

program the sensitivity of motion detection. Changes in weight greater than F4.5 (minor

increments) over the time required to perform F4.6 (A/D cycles) are detected as motion. The

“in motion” signal is provided as a status bit in the output data when the continuous output

mode is selected.

Sensitivity of motion is the amount of change in weight allowed before motion is detected.

The sensitivity can be programmed in a range from 0.1 to 3 major increments in steps 0.1

increment.

To determine what number to enter in this step, use the following procedure. Valid

selections are 0* through 30 with 07 recommended as a beginning value.

* Determine the number of increments (or part of an increment) that the sensitivity should be.

For example, 0.5, 1 or 0.7 increment. Multiply this number by 10. Example: If the number

selected is 0.7, multiply this by 10 to get 7. This result (7) is the number to be entered for

step F4.5.

NOTE: If a value of “0” is entered there will be no motion detection and prompt F4.6 will be

skipped.

[F4.6 03] MOTION DETECTION RANGE

This step programs the number of A/.D cycles over which the 8146 will monitor weight

changes. The changes in weight must be less than the value programmed in step F4.5 to

obtain a “no motion” signal. Numeric values between 1 and 20 A/D cycles are selectable with

a beginning value of 3 recommended. The “ENTER” key must be pressed to proceed to step

F4.7.

NOTE(S):

1 The update rate of the 8146 (A/D cycles per second) is dependent upon the number of

full scale increments and the amount of initial weight. It varies from approximately 11 (at

1,000 total increments) to 4 (at 50,000 total increments).

2 The smaller this number is, the greater the probability will be for detecting “no motion”

since it checks for motion over a shorter length of time.

Page 38

32

[F4.7 1] DIGITAL FILTERING SELECTION

This allows selection of different quantities of A/D cycles to be filtered before a display

update. The higher the number, the slower the update. Key in the appropriate selection from

the chart below and then press “ENTER”.

FILTERING SELECTION FILTERING RATE

0 NONE

1 LIGHT

2 MEDIUM

3 HEAVY

4 VERY HEAVY

[f4.8 ?] ANALOG VERIFICATION. Press:

1 To enable analog verification.

0 To disable analog verification.

[CAL] ACCESS CALIBRATION MODE? Press:

1 To enter the calibration mode.

0 To skip the calibration mode. (The procedure will return to the Setup Scale prompt.)

NOTE: Error codes that may be displayed during calibration are described in the

troubleshooting section of this manual.

[C1 ] FULL SCALE CAPACITY

[XXXXXX]

This display is showing yhou the programmed scale capacity. If this capacity is correct, press

the “ENTER” Key.

If the displayed capacity is not correct for your scale, enter the desired scale capacity and

press the “ENTER” Key.

[C2 ] INCREMENT SIZE

[XXXXXX]

At this time the unit is asking you to enter the displayed increment size.

If the displayed increment size is not correct for your scale, enter the desired size and press

the “ENTER” key. This entry must include the decimal point or trailing zero if required.

Maximum increment size is 500.

Page 39

33

[C3 X] LINEARITY CORRECTION. Press:

1 To select the two-stage linearity correction

0 To disable the two-stage linearity correction.

NOTE: This step will normally not be required. If after calibration, the indication appears to

be nonlinear, this step may be used to correct this. The use of this step requires that

test weights of 60% of the scale’s capacity be available for calibration.

[SC ] CALIBRATION SHORT CUT

This allows bypassing the actual test weight calibration by entering in previously calculated initial

and span values. These values are determined AFTER the actual test weight calibration has been

completed. To obtain these values, answer YES to the PRINT SETUP prompt at the end of the

setup procedure. The initial and span values needed will be included in the printout of the setup

parameters. Press:

1 If the short cut initial and span values are to be used for calibration, the standard test weight

calibration will be bypassed.

2 If the initial and span values are not to be used, the 8146 will proceed with the standard test

weight calibration procedure.

NOTE: At this time the calibration sequence will follow one of four possible procedures. The

procedure this sequence takes depends on how you answered the “Linearity Correction”

and “Calibration Short Cut” prompts. Use the following chart to determine which

procedure you should follow.

Linearity Correction Calibration Shortcut Follow

NO NO Procedure A

YES NO Procedure B

NO YES Procedure C

YES YES Procedure D

PROCEDURE A: Normal Calibration without linearity correction

[EP SCL] EMPTY SCALE Remove all weight from the scale platform. Press the

“ENTER” key to continue.

[15 CAL] TIME OUT The display will count down from 15 to 0 while initial is

being set.

[Add Ld] ADD LOAD Place the selected test weights on the scale platform. This

should be at least 10% of the scale’s capacity. Press the

“ENTER” key to continue.

[XXXXXX] TEST WEIGHT The value of the test weights used must be entered.

Fractional or decimal values are not acceptable - only whole

numbers. Press the “ENTER” key to continue.

[15 CAL] TIME OUT The display will count down from 15 to 0 while span is being

set.

[EP SCL] EMPTY SCALE Remove all weight from the scale platform. Press the

“ENTER” key to continue.

Page 40

34

[15 CAL] TIME OUT The display will count down from 15 to 0 while initial is

being reset.

[CAL A] CALIBRATION COMPLETE This display will appear after calibration is complete and will

be displayed for approximately three seconds. At the end of

this time the display will show S FILE for approximately two

seconds. The weight display will then return to normal.

PROCEDURE B: Normal Calibration with linearity correction

[EP SCL] EMPTY SCALE Remove all weight from the scale platform. Press the

“ENTER” key to continue.

[15 CAL] TIME OUT The display will count down from 15 to 0 while initial is

being set.

[Add A] ADD HIGH WEIGHT Place the selected test weights on the platform. This MUST

be greater than 60%, but less than 100% of scale capacity.

Press the “ENTER” key to continue.

[XXXXXX] TEST WEIGHT The value of the test weights must be entered. Fractional or

decimal weights are not acceptable - only whole numbers.

Press the “ENTER” key to continue.

[15 CAL] TIME OUT The display will count down from 15 to 0 while high span is

being set.

[Add B] ADD LOW WEIGHT Place the selected test weights on the platform. This MUST

be greater than 30%, but less than 50% of scale capacity.

Press the “ENTER” key to continue.

[XXXXXX] TEST WEIGHT The value of the test weights must be entered. Fractional or

decimal weights are not acceptable - only whole numbers.

Press the “ENTER” key to continue.

[15 CAL] TIME OUT The display will count down from 15 to 0 while low span is

being set.

[EP SCL] EMPTY SCALE Remove all weight from the scale platform. Press the

“ENTER” key to continue.

[15 CAL] TIME OUT The display will count down from 15 to 0 while initial is

being reset.

[CAL A] CALIBRATION COMPLETE This display will appear after calibration is complete and will

be displayed for approximately three seconds. At the end of

this time the display will show S FILE for approximately two

seconds. The weight display will then return to normal.

PROCEDURE C: Shortcut Calibration without linearity correction

[0 ] “TO” ENTRY Enter the time value obtained for “TO”

[1 ] “T1” ENTRY Enter the time value obtained for “T1”

[FS A] FINE SPAN - HIGH Enter the value obtained for the high order of the fine

Page 41

35

span adjustment

[FS b] FINE SPAN - LOW Enter the value obtained for the low order of the fine span

adjustment

[F0 A] FINE ZERO - HIGH Enter the value obtained for the low order of the fine zero

adjustment

[F0 b] FINE ZERO - LOW Enter the value obtained for the low order of the fine zero

adjustment

[CAL A] CALIBRATION COMPLETE This display will appear after calibration is complete and will

be displayed for approximately three seconds. At the end of

this time the display will show S FILE for approximately two

seconds. The weight display will then return to normal.

PROCEDURE D: Shortcut Calibration with linearity correction

[0 ] “TO” ENTRY Enter the time value obtained for “TO”

[1 ] “T1” ENTRY Enter the time value obtained for “T1”

[FS A] FINE SPAN - HIGH Enter the value obtained for the high order of the fine span

adjustment

[FS b] FINE SPAN - LOW Enter the value obtained for the low order of the fine span

adjustment.

[F0 A] FINE ZERO - HIGH Enter the value obtained for the high order of the fine zero

adjustment

[F0 b] FINE ZERO - LOW Enter the value obtained for the low order of the fine zero

adjustment

[LF - ?] LINEARITY This prompt is asking you in which direction the linearity

factor should be. Enter the value obtained from the printout:

1 A negative linearity factor

0 A positive linearity factor

[LF A] LINEARITY FACTOR - HIGH Enter the value obtained for the high order of the linearity

factor

[LF b] LINEARITY FACTOR - LOW Enter the value obtained for the low order of the linearity

factor

[SF A] SPAN FACTOR - HIGH Enter the value obtained for the high order of the span factor

[SF b] SPAN FACTOR - LOW Enter the value obtained for the low order of the span factor

[S FILE] The display will show S FILE for approximately two

5.1.1 Span Adjustment

The span adjust feature of the 8146 is used to make adjustments to the span without repeating the entire

calibration procedure. This is especially useful on large capacity scales, tank scales and hopper scales

seconds. The weight display will then return to normal.

Page 42

36

where a “build-up” procedure is used for calibration. The procedure for using the span adjust feature is

as follows.

5.1.2

Before span adjust can be used, the standard calibration, as specified in the setup section, must be

performed. It is suggested that as much weight as is practical be used for calibration.

5.1.3

Apply known test weights to the scale. If any adjustment is necessary proceed to the next step.

5.1.4

Enter the setup procedure. Select the correct scale and advance to prompt F3.5. Change the setting of

this prompt to a 1 (yes).

5.1.5

Exit the setup procedure.

5.1.6

Enter the setup procedure and select the correct scale. The data display will now show [Cal Adj 000000].

5.1.7

To make a span adjustment, enter the correct test weight value. Enter all digits including those to the

right of the decimal point. (See Note c below.) Press the “ENTER” key and the normal setup procedure

will begin.

5.1.8

Exit the setup procedure. The weight display should now show the correct weight value. This

procedure may be repeated several times during a “build-up” calibration.

5.1.9

After all adjustments are completed. reenter the setup procedure and change prompt F3.5 to a 0 (NO).

Exit the setup procedure. The indicator is now ready for normal operation.

Page 43

37

NOTES OF INTEREST:

a. This procedure will work correctly once when in the net mode. This is useful if a device to hold the

test weights is required. Simply attach the holding device, then press Tare. Add the test weights,

then follow the span adjustment procedure. After one adjustment, tare must be cleared and then

reentered if required again.

b. Weights that are entered in values other than multiples of the increment size will not be accepted. For

example, entering the 103 pounds when the increment size is 2 lbs.

c. The entire weight value must be entered including numbers to the right of the decimal point. This is

different from the standard calibration where only the numbers to the left of the decimal point may be

entered.

5.2 DIGITOL ® SETUP AND CALIBRATION PROCEDURE

(For Use With DigiTOL® J-Boxes)

00 CELL SELECTION

01 Select Cell Type

02 Load Cell Operation (T-LAN Only)

03 Number of Cells (T-LAN/DigiTOL ® J-Box)

04 Load Cell Address (T-LAN Only)

05 Second Scale Select (T-LAN Only)

06 Reset DigiTOL ® J-Box Shift Constants (DigiTOL ® J-Box Only)

10 CALIBRATION SELECT

11 Calibrate in lb/kg

12 Future

13 Future

14 Scale Capacity

15 Increment Size

16 Future

17 Future

18 Shift Compensation (T-LAN/DigiTOL ® J-Box)

19 Zero and Span Calibration

20 FILTERING AND AZM (All DigiTOL ® types)

21 Zero Adjust

22 Span Adjust

23 AZM Range

24 Auto Zero Capture at Power-Up

25 Push Button Zero

26 Motion Detection

27 Filter Selection

28 Overload Blanking

Page 44

38

30 TARE SELECTION (All DigiTOL ® types)

31 Tare Enable

32 Tare Interlock

33 Future

34 Auto Clear Tare

35 Gross/Net Switching

36 Tare Display Active

80 POWER UP AND UNIT SWITCHING (All DigiTOL ® types)

81 Analog Verify

82 lb/kg Switching

83 lb/kg Power Up

90 LOAD CELL REPLACEMENT (T-LAN Only)

91 Re-Addressing A Load Cell

92 Replacing a Load Cell

93 Shift Adjustment

94 Set Shift Constants

95 Expanded Display Mode

96 Manual Shift Adjust

97 Span/Zero Shift Constants

99 Display Load Cell Output

5.3 SETUP AND CALIBRATION PROCEDURE FOR SINGLE CELL DIGITAL LOAD CELL

SYSTEMS

This procedure describes the setup and calibration for digital load cells used in single cell scales. For

setup and calibration for multiple digital load cell systems, proceed to Section 5.4 (Calibration of

multiple digital load cell systems) or Section 5.5 for DigiTOL ® J-Box.

NOTE: To enter the setup mode when the main display is showing [SCL 1 TR 000000] (8146 Standard

Mode) first move SW1 on the DWP44 PCB toward connector J4. If two DWP44 PCB(s) are

installed, both SW1(s) must be moved to gain entry to all setup parameters for all scales being

used. Press the “SETUP” key. The display will now show [SETUP SCALE?] key in the scale

number to be setup (1 thru 4). The weight display for the scale chosen will show [- - ].

Calibration groups for that scale can now be assessed.

5.3.1 Access Load Cell Type Selection Group 00

[00 ]

With the display prompt at [-- ], enter “00” followed by pressing the “ENTER” key to select GROUP 00

setup parameters. The display will increment to parameter 01.

[01 ]

Press “0” to select the Single, High Resolution DLC mode.

NOTE: If this parameter is being changed from 1 to 0, the indicator must be powered down then back up

before continuing with calibration so that the DWP44 card gets initialized properly for the type of

operation selected.

[01 ] DLC TYPE SELECTION

Page 45

39

0 - Single DLC

1 - Power Cells

2 - DigiTOL ® J-Box

The selection entered for scale One will be forced into the scale Two parameters and this step will be

skipped when setting up scale Two.

Press “0” to select the Single DLC configuration.

The display will return to the [-- ], prompt.

5.3.2 Access Calibration Sequence Group 10

[10 ]

With the display prompt at [-- ], enter “10” followed by pressing the “ENTER” key to select GROUP 10

calibration parameters. Parameters 11 - 19 will be prompted in sequence.

[11 ] CALIBRATE IN LB/KG

Enter the units in which the scale is to be calibrated in.

0 - To calibrate in kg.

1 - To calibrate in lb.

[14 ] ENTER FULL SCALE CAPACITY

The display will show the currently entered full scale capacity. If the capacity is correct, press the

“ENTER” key.

If the displayed capacity is not correct for your application, enter the desired full scale capacity followed

by the “ENTER” key.

[15 ] ENTER INCREMENT SIZE

The display will show the currently entered increment size. If the increment size is correct, press the

“ENTER” key.

If the increment size is not correct, press the “0” key. The display will display zeros. Continue pressing

the “0” key until the decimal point is in the correct position or until the correct number of fixed zeros ar

displayed. Now press the “1”, “2” or “5” key to select the proper increment size. This entry will replace

the “-” character on the display.

[19 ] ZERO AND SPAN CALIBRATION

Press “0” to return to [-- ], prompt, or press “1” to proceed.

The display will show [Add Ld ]. Press the “ENTER” key. The display will blank. Place test weight on

the scale and enter this value using the keyboard followed by the “ENTER” key. The display will count

down from

[16 CAL ] to [ 09 CAL ]. A check is now made to see if enough counts are received from the DLC.. If

not, new T0 and T1 values are calculated and sent to the DLC. The display will then continue to count

down to [ 01 CAL].

If new T0 and T1 counts were sent, then the display will show [E SCL ], otherwise it will proceed to

calibration done. Remove the test weight from the scale and press the “ENTER” key. The display will

count down from

Page 46

40

[16 CAL ] to [01 CAL ].

When calibration is completed, the display will show {CAL ] for two seconds indicating the zero and

span calibration has been successfully completed. The display will then return to the [-- ] prompt.

The remainder of the setup parameters may be directly addressed by entering their two digit code.

However, by entering the group number first, the unit will automatically increment through some or all of

the parameters in that group.

5.3.3 Access Load Cell Replacement Group 90

[90 ]

With the display prompt at [-- ], enter the parameter number and press the “ENTER” key to select the

parameter.

[97 ] DISPLAY AND ENTRY OF SPAN AND ZERO CONSTANTS

With the display at [-- ], enter “97” followed by pressing “ENTER” key to select this parameter. This

parameter allows the operator to view or alter the values stored for span and zero.

0 = To return to [-- ] prompt.

1 = To proceed with the display of these values.

A) The display will show [97A ] for a 1/2 second then display the current span value. Press the

“ENTER” key to retain the current value or enter a new value followed by pressing the “ENTER” key.

B) The display will show [97b ] for a 1/2 second then display the current zero value. Press the

“ENTER” key to retain the current value or enter a new value followed by pressing the “ENTER” key.

C) The display will show [SA ] to save the new values permanently. If you want to save the new values

permanently, press the “1” key. The original values will be replaced by the new ones. If you want to

return to the original values, press the “0” key. The display will return to the [-- ] prompt.

Page 47

41

5.4 SETUP AND CALIBRATION PROCEDURE FOR T-LAN MULTIPLE DIGITAL LOAD

CELL SYSTEMS

This procedure describes the setup and calibration for digital load cell(s) which are interfaced to the

8146 via a T-LAN network.

5.4.1 Access Load Type Selection Group 00

[00 ]

With the display prompt at [-- ], enter 00 followed by pressing the “ENTER” key to select GROUP 00

setup parameters. The display will increment to parameter 01.

[01 ] DLC TYPE SELECTION

0 - Single DLC

1 - Power Cells

2 - DigiTOL ®

The selection entered for scale One will be forced into the scale Two parameters and this step will be

skipped when setting up scale Two.

Press “1” to select the T-LAN network configuration.

NOTE: If this parameter is being changed from 0 to 1, the indicator must be powered down then back up

after group 00 parameters have been set before continuing with calibration so DWP44 card and

the 8146 CPU will get initialized properly for the type of operation selected.

[02 ] LOAD CELL OPERATION

This parameter selects whether the load cells are to operate independently or in sectional pairs. The

independent mode is intended for applications such as tank or hopper scales where there is an odd

number of load cells connected, or floor scales where corner adjustments will be made. The sectional

pair mode is intended for applications such as floor and truck scales where section adjustments are

made. For the load cells to operate in the sectional pair mode, an even number of load cells must be

used.

0 - Independent cell operation

1 - Sectional pair operation

[03 ] NUMBER OF LOAD CELLS

Enter the number of load cells to be addressed for the scale being calibrated. (i.e., if calibrating scale 1,

enter the number of load cells in scale 1.) If independent cell operation was selected, then only numbers

from 1 to 16 will be accepted. If sectional pair operation was selected, then only even numbers from 2 to