Mettler Toledo 8142PRO+ Service Manual

1

8142PRO

+

(PR08)

Industrial Terminal

Service Manual

1

1. Introduction

This manual describes the 8142Pro+ dual display scale terminal (PRGN-XXX8), which is tailor designed to

meet the vehicle and floor scale needs.

Installation and service procedure should be performed only by authorized personnel.

1.1 8142Pro+ Features

• Two 7 digits numeric vacuum fluorescent displays

• 24 position keypad

• Input for up to eight 350Ω analog load cells

• The selectable increments from 1000 to 50,000

• A/D internal Resolution: 1,000,000

• Display update rate: 10 updates each second

• Pushbutton and keyboard tare

• Tare interlock function

• The expanded weight display

• Tare and clear tare automatically

• Automatic zero maintenance

• Motion detection and indication

• Center of zero indication

• Real time clock by battery back-up

• 500 truck ID/Tare record (8 digits truck ID)

• 99 cargo ID subtotal (2 digits cargo ID)

• 99 client ID subtotal (2 digits client ID)

• 1000 transactions record ( the information include CN, time and date, truck ID, cargo ID, client ID,

gross, tare and net )

• Accumulators by truck ID, cargo ID or client ID

• Daily report printout

• 4 printout formats

• 2 serial communication interface (continuous output port and host port)

• 1 parallel centronics interface

• Host interface

• High accurate delta-sigma A/D converter

• TraxDSP

TM

vibration rejection

• SMT technology

1.2 8142Pro+ Specifications

1.2.1 Analog Load Cell

• Excitation Voltage: +10VDC, power up to eight 350Ω analog load cells

• Span range: 3 ~ 32mV

• Zero range: 0 ~ 25mV

1.2.2 Power Requirements

2

8142Pro+ is available in four versions. 100V , 120V , 220V and 240V , voltage variation is from –15% to

+10% , frequency is from 49 to 63Hz . Power consumption is 12 Watts maximum . Power is applied through

a modular power plug line cord.

8142Pro+ requires a true earth ground for reliable operation.

The power line for 8142Pro+ must not be shared with equipment such as motors, relays, or heaters that

generate line noise.

1.2.3 Display and Keyboard

The enclosure of 8142Pro+ is cast zinc-aluminum alloy.

The display are two 7 digits numeric vacuum fluorescent display.

The keyboard consists of a flat membrane switch covered with a domed polyster overlay.

1.2.4 Temperature and Humidity

8142Pro+ operates over a temperature range from -10 to 40 °C at 10% to 95% humidity, noncondensing.

Storage temperature range is from -40 to 60 °C at 10% to 95% humidity, noncondensing.

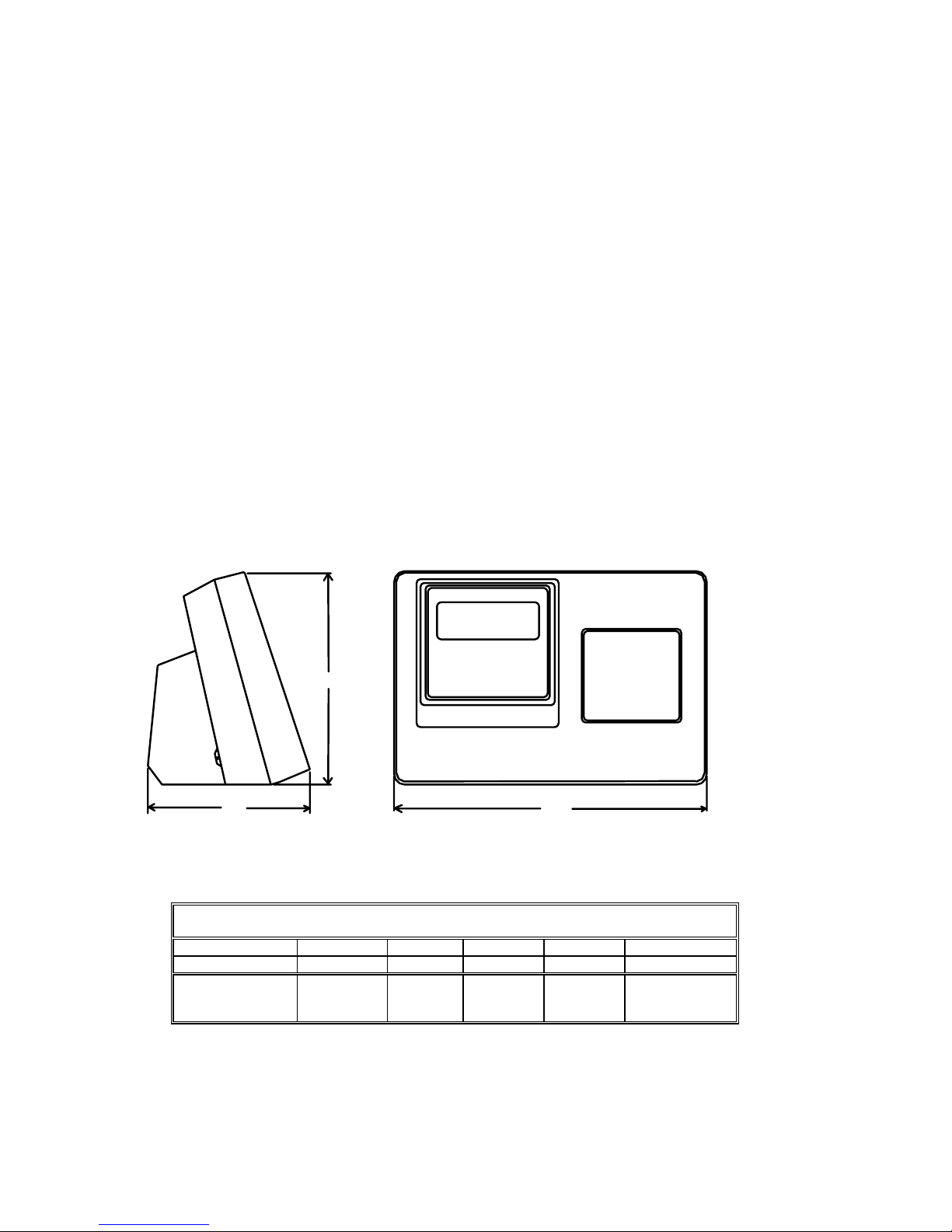

1.2.5 Physical Dimension

324

204

168

METTLER TOLEDO

8142PRO

0

1000

1.3 Ordering Information

8142Pro+ MODEL CONFIGURATION

ex: PRGN-0038-023

PRGN X X X X XXX

MODEL PCB type Reserved Market DISPLAY Country

PR - 8142Pro+

G-General housing

N - Numeric

1 - Analog L/C

2 - HAP

0 3- Export 7 - Single

8 – Dual

023 - CHINA

3

2. Installation

This chapter gives detailed instructions and important information you will need to install 8142Pro+ scale

instrument successfully. Please read this chapter throughly before you begin installation.

2.1 Unpacking and Inspection

Please inspect the package as it is delivered by the carrier. If the shipping container is damaged, check for

internal damage and file a freight claim with the carrier if necessary.

If the container is undamaged, unpack the 8142Pro+ scale instrument from its protective package, noting

how it was packed, and inspect each component for damage.

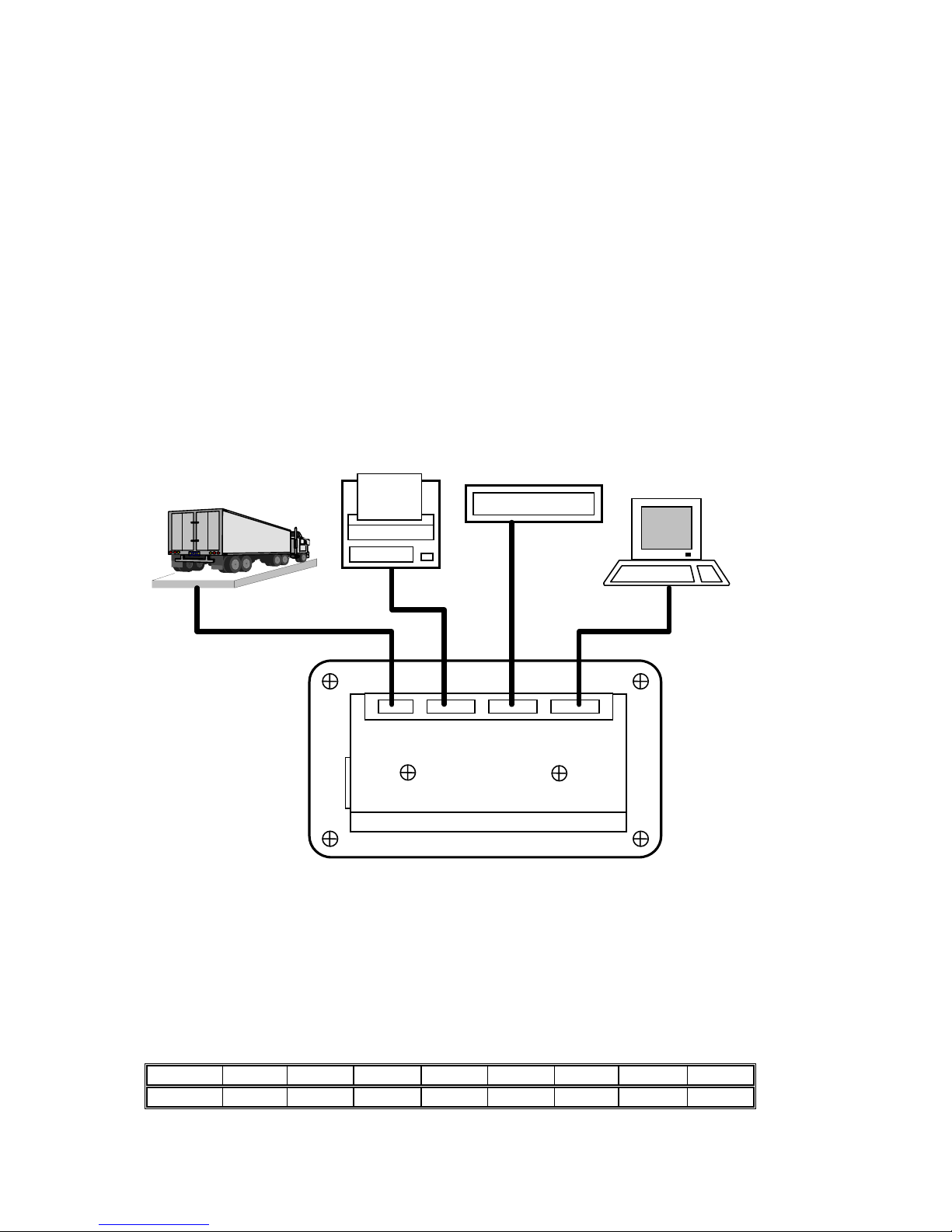

2.2 Electrical Connections

ScaleWin

计 算 机

IBM

LOAD CELL COM1

COM2

PARALLEL

Power Cord

1000 kg

Platform Scale

Scoreboard

Printer

8142PRO PR8 Terminal

1 1500 500 1000

PQ30

1

1

1

1

Computer

2.2.1 Connect the Load Cell

8142Pro+ powers up to eight 350Ω analog load cells.

The wiring between 8142Pro+ and junction box is standard 6-wire cable

The analog load cell connector to the terminal is a 9 pin D-SUB female connector. The following diagram

shows the pins assignments for 9 pin D-SUB connector. (Pin 9 is used to connect to the outer shield layer of

cable)

SIGNAL +EXC +SEN SHLD -SEN -EXC +SIG -SIG GND

PIN 1 2 3 4 5 7 8 9

4

2.2.2 Serial Port COM1 Connection

The serial port COM1 consist of RS-232 and 20 mA current loop.

The maximum recommended cable length for RS-232 interface is 50 feet.

The maximum recommended cable length for 20 mA interface is 1000 feet.

The serial port COM1 connector is a 25 pin D-SUB female connector. The following diagram shows the pins

assignments for COM1 connector.

SIGNAL PIN

SHIELD GROUND 1

TXD (RS-232) 2

RXD (RS-232) 3

SIGNAL GROUND 7, 19, 22, 23

CLRX+ 8, 16

CLTX+ 9

CLRX- 10, 18

Note: The transmitter of 20 mA current loop is active, the receiver is passive.

Below is the pin assignment of 8142Pro+ 8 to the Mettler-Toledo scoreboard .

COM1 at 8142Pro+ 7 Mettler-Toledo Scoreboard

9 1 CLRX+

7 2 CLRX-

If you want to connect your 8142Pro+ 8 to the computer , please refer to the below sheet for pin assignment .

COM1 Computer ( 9 pin ) Computer ( 25 pin )

2 2 3

3 3 2

7 5 7

2.2.3 Serial Port COM2 Connection

The serial port COM2 consist of RS-232 and RS-422.

The maximum recommended cable length for RS-232 interface is 50 feet.

The maximum recommended cable length for RS-422 interface is 2000 feet.

The serial port COM2 connector is a 25 pin D-SUB female connector. The following diagram shows the pins

assignments for COM2 connector.

SIGNAL PIN

SHIELD GROUND 1

TXD (RS-232) 2

RXD (RS-232) 3

SIGNAL GROUND 7

TXD+ (RS-422) 11

5

TXD- (RS-422) 12

RXD+ (RS-422) 13

RXD- (RS-422) 24

2.2.4 The Parallel Interface

The parallel interface is standard Centronics printer interface. It is used to connect to a printer.

The parallel port connector is a 25 pin D-SUB female connector. The following diagram shows the pins

assignments for connector.

SIGNAL PIN SIGNAL PIN

STRORE 1 BUSY 11

DATA BIT0 2 PAPER EMPTY 12

DATA BIT1 3 SELECT 13

DATA BIT2 4 AUTO FEED 14

DATA BIT3 5 ERROR- 15

DATA BIT4 6 INIT- 16

DATA BIT5 7 SELECT- 17

DATA BIT6 8 SIGNAL GND 18 ~ 25

DATA BIT7 9

ACK- 10

2.3 8142Pro+ Jumper and Switch Settings

Jumper and switches on the main PCB should be set as follows:

• K1-1 is the setup enable switch. This switch should be ON to access all setup parametersand be OFF in

operating mode .

• K1-2 is selection switch for comma. This switch should be ON to display comma (not decimal point).

• K1-3 is used to access factory test mode. This switch is always OFF in the normal operation mode.

• K1-4 is used to access factory test mode. This switch is always OFF in the normal operation.

• W1 jumper should be removed for 3 mV/V, installed for 2 mV/V analog load cell.

2.4 Minimum Increment Size for Analog Scale Input

The minimum increment size selection for an analog scale input is determined by calculating the microvolts

per increment for the desired build.

2.4.1 Solve the following equation for µV per increment.

Increment Size x cell output x excitation voltage (15) x 1000

µV per Increment = ---------------------------------------------------------------------------------

Load Cell Capacity x Number of Cells or Level Ratio

The increment size, scale capacity, and load cell capacity must all be measured in the same weight units, lb

or kg.

6

Load cell output is rated in mV/V (millivolts per volt of excitation), marked on load cell data tag. Mettler

Toledo load cells are typically 2 mV/V. Other load cells can range from 1 mV/V to 4.5 mV/V.

The load cell capacity is the rated capacity marked on load cell data tag. The number of cells is the total

number of load cells in the system , for the electronic –mechanical scale , the level ratio is the total level

ratiop in the system .

2.4.2 Calculate the total number of increments by dividing the calibrated capacity by the

increment size.

Calibrated Capacity

# Increments = ----------------------------

Increment Size

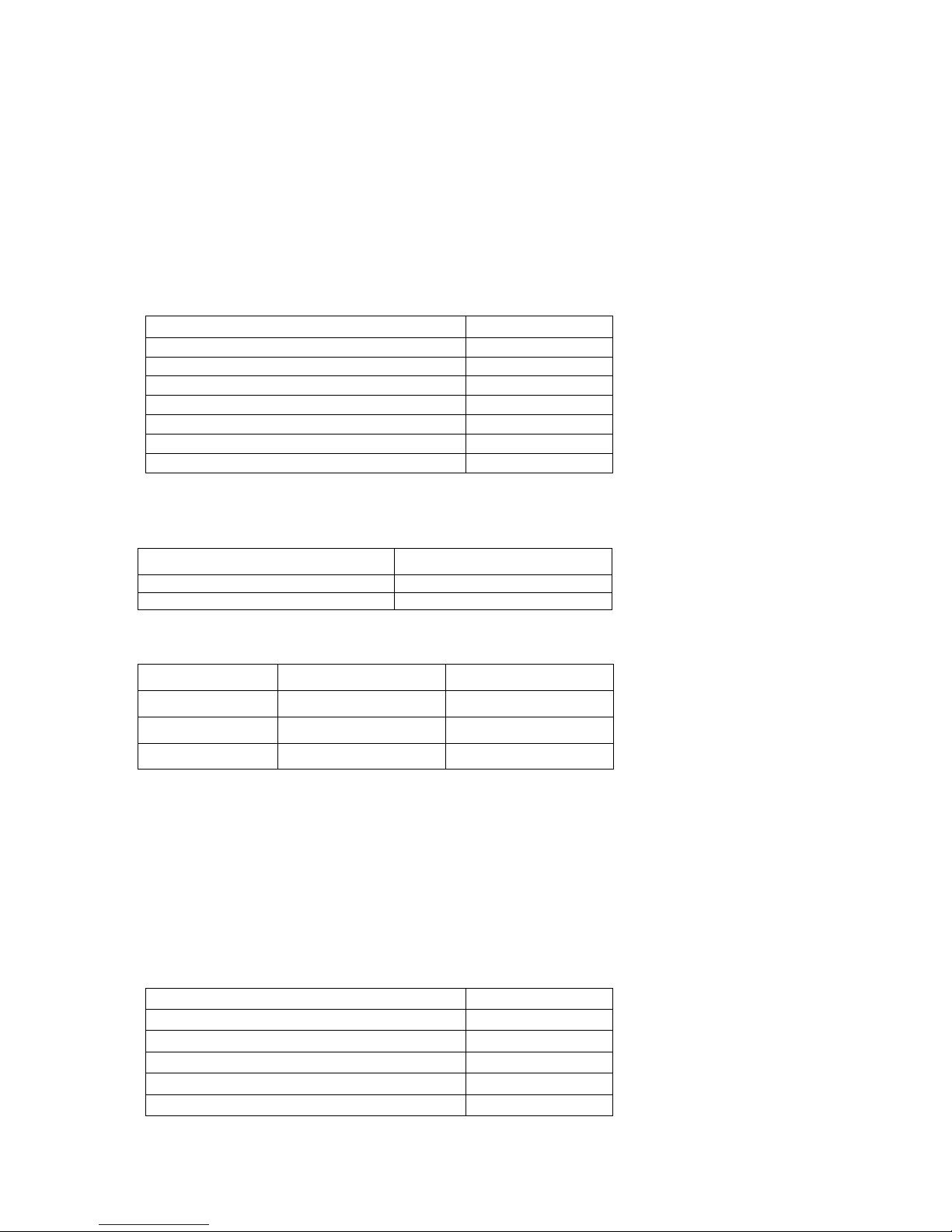

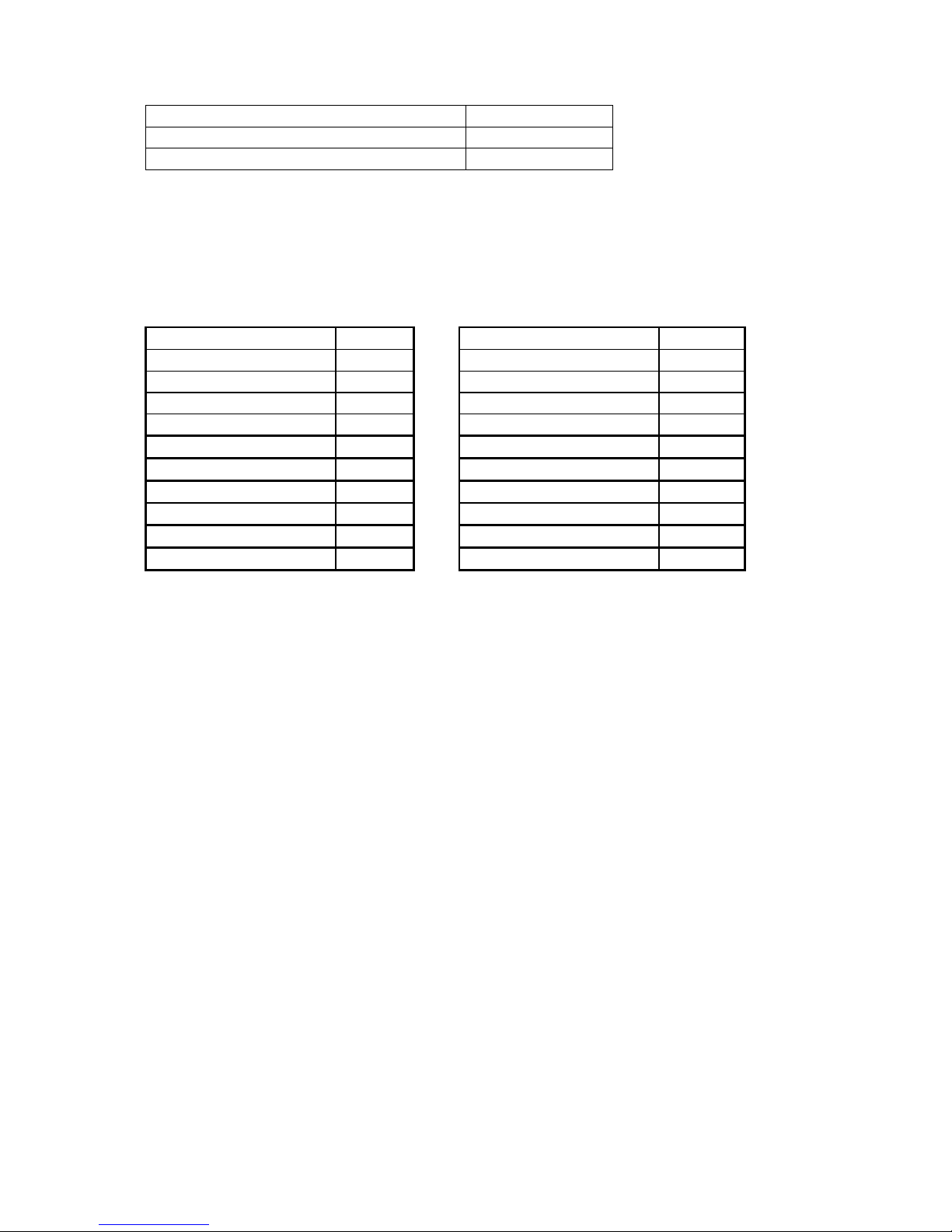

2.4.3 Microvolt build table

Use the following microvolt build table to determine if the µV per increment calculated in step 1 is within

the range allowed for the total number of increments calculated in step 2. These parameters have

demonstrated stable builds but smaller minimum µV per increment and larger total number of increments are

possible.

Microvolt Build Table

Total

Number of

Increment

Minimum

µV per

Increment

Maximum mV per Increment

2 mV/V 3 mV/V

1,000 3.0 26.0 38.0

2,000 1.5 13.0 19.0

2,500 1.2 10.4 15.2

3,000 1.0 8.7 12.7

4,000 0.75 6.5 9.5

5,000 0.6 5.2 7.6

6,000 0.5 4.4 6.4

8,000 0.375 3.3 4.8

10,000 0.3 2.6 3.8

20,000 0.15 1.3 1.9

50,000 0.1 0.52 0.76

Note: 8142Pro+ should never be programmed for least than 0.5 µV per increment when used with single

load cell applications and never less than 0.1 µV per increment when used with multiple load cell

applications. 8142Pro+ cannot be calibrated for builds that exceed the maximum µV per increment listed in

the microvolt build rate.

3. 8142Pro+ Operations

This chapter provides information that an operator will need to become fimiliar with the terminal and to

perform its functions.

7

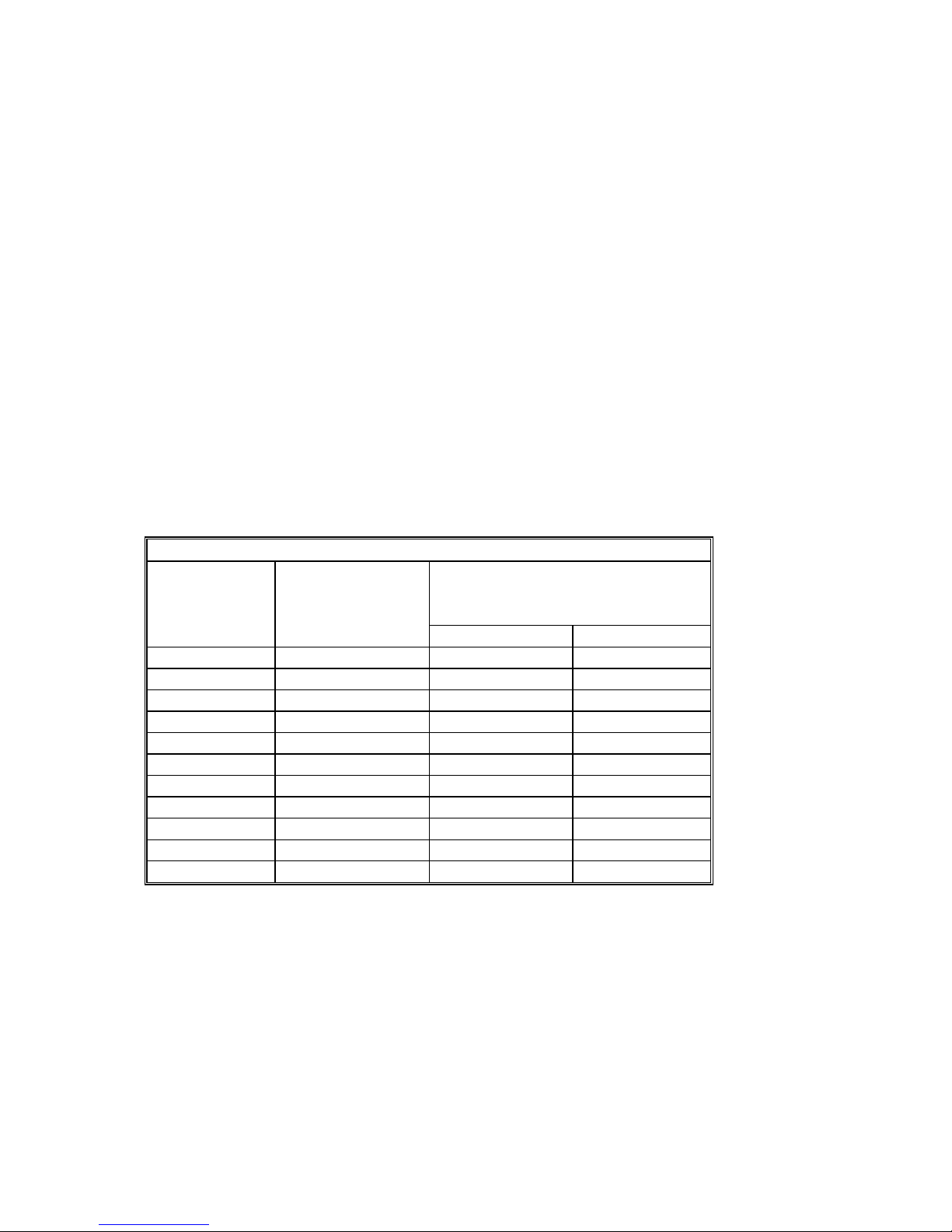

3.1 8142Pro+ Display and Keyboard

8142Pro+ dual display version has two displays where scale data and operational message are presented. These are

pictured below:

The two displays are same. The display is a numeric display. This area can display up to seven numbers each

with a decimal point, comma, and annunciators. The annuniciators are:

• Center-of-zero (→ o ← )

The center-of-zero annunciator indicates that the scale is within ± ¼ increment of gross zero.

• Scale in-motion ( ~ )

The scale instability annunciator indicates that the scale is in motion. The annuniciator will turn off when the

scale is stable. The motion sensitivity of motion detection is adjustable in setup.

• Weighing mode ( Gross or NET)

The 8142Pro+ will be in Net mode when a tare is active. Tare can be entered as a Preset tare value or tare

may be automatically acquired when the operator presses the TARE key.

• Consecutive Number ( CN )

The consecutive number annunciator indicates CN has been recalled and displayed. You can exit the recall

mode of CN by pressing EXIT key.

• Truck ID

The truck ID annunciator indicates that you are entering a truck identification.

• TARE

The tare annunciator indicates a pushbutton tare or keyboard tare is active.

• TIME/DATE

The time annunciator indicates TIME has been displayed. The date annunciator indicates DATE has been

displayed.

• Accumulator (Accum.)

The accumulator annunciator indicates accumulation has been recalled and displayed. You can exit the

recall mode of accumulation by pressing EXIT key.

ID

Cargo C lient

ID

Accum. ReportDate

Time

Tare

ID

GNetCN

Truck

0

~

Kg

8

• Cargo ID

The cargo ID annunciator indicates that you are entering a cargo identification.

• Client ID

The client ID annunciator indicates that you are entering a client identification.

• Report

The report annunciator indicates that the scale is in report mode.

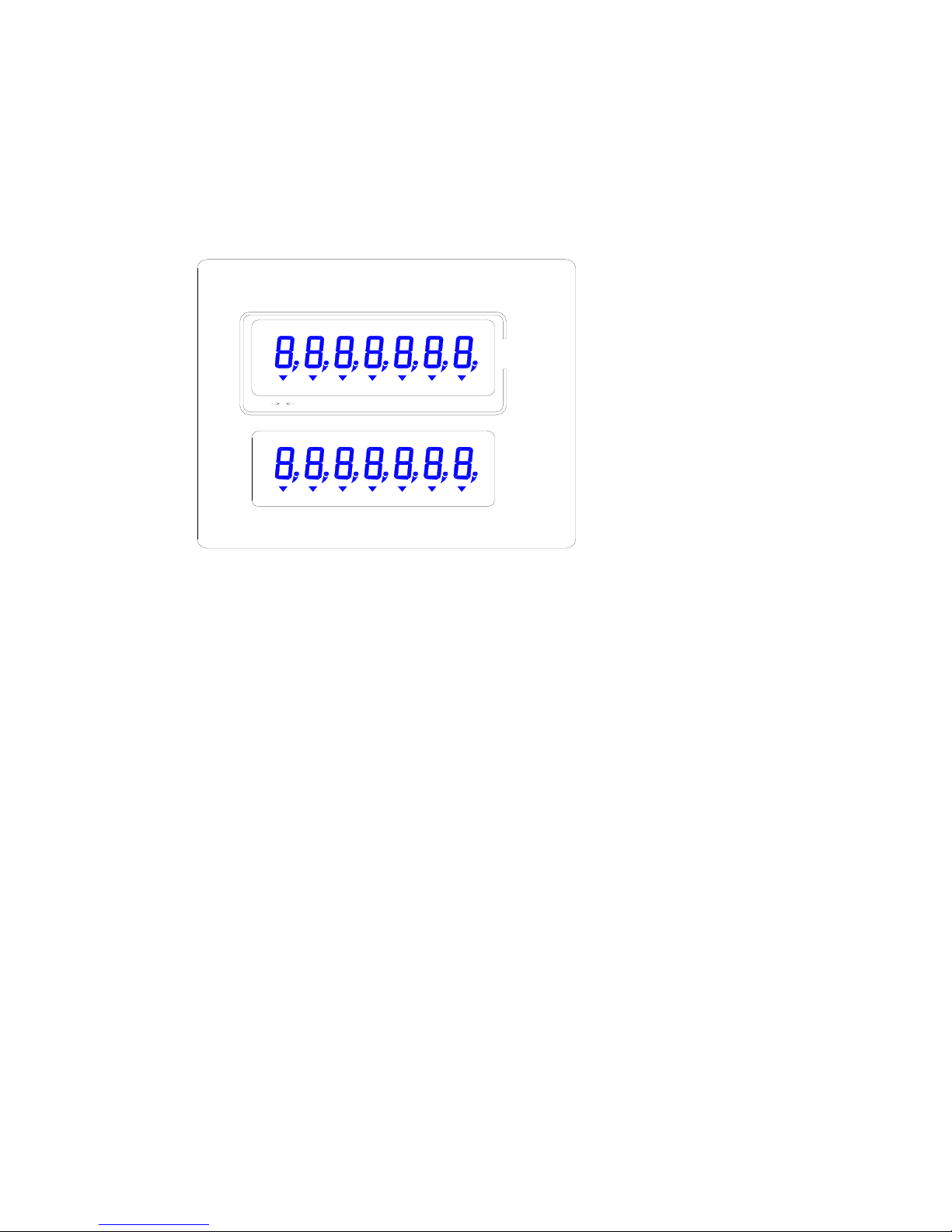

8142Pro+ dual display version is equipped with a 24-key keypad as seen below:

The keypad consists of numeric keys 0 through 9 and fourteen function keys.

The keys perform the following functions:

• NUMERIC keys are used to input numbers.

• ZERO zeros the scale. The ZERO key also functions as backspace when entering data from the keypad.

• TARE performs a pushbutton tare or keyboard tare if enabled in setup.

• CLEAR clears a tare value and returns the scale to gross mode. The CLEAR key also functions as

delete when entering data from the keypad.

• Truck ID acknowledges a prompt and accepts data as truck ID entered from the keypad.

• Cargo ID acknowledges a prompt and accepts data as cargo ID entered from the keypad.

• Client ID acknowledges a prompt and accepts data as client ID entered from the keypad.

• CN key is used to recall consecutive number.

• RECALL is used to recall consecutive number or accumulations.

• TIME/DATE key is used to enter or recall the clock and the date.

• REPORT can generate and print truck-related, cargo-related and client-related reports.

• RECORD key is used to store a weighing transaction.

• ENTER/PRINT acknowledges a prompt and accepts data entered from the keypad. It also initiates a

demand print output.

Loading...

Loading...