Mettler Toledo 8132 Service Manual

8132

Indicator

Service Manual

TM008132I06

INTRODUCTION

This publication is provided solely as a guide for individuals who have

received METTLER TOLEDO Technical Training in servicing the

METTLER TOLEDO product.

Information regarding METTLER TOLEDO Technical Training may be

obtained by writing to:

METTLER TOLEDO

Training Center

P.O. Box 1705

Columbus, Ohio 43216

(614) 438-4400

METTLER TOLEDO RESERVES THE RIGHT TO MAKE

REFINEMENTS OR CHANGES WITHOUT NOTICE.

i

PRECAUTIONS

CAUTION

• • READ this manual before operating or servicing this

equipment.

• • ALWAYS REMOVE POWER and wait at least 30

seconds BEFORE connecting or disconnecting any

internal harnesses. Failure to observe these

precautions may result in damage to, or destruction of

the equipment.

• • ALWAYS take proper precautions when handling static sensitive devices.

• • DO NOT connect or disconnect a load cell scale base

to the equipment with power connected or damage

will result.

WARNING

DISCONNECT ALL POWER

TO THIS UNIT BEFORE

REMOVING THE FUSE

OR SERVICING.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO

SERVICE THIS EQUIPMENT. EXERCISE CARE

WHEN MAKING CHECKS, TESTS, AND

ADJUSTMENTS THAT MUST BE MADE

WITH POWER ON.

• • SAVE this manual for future reference.

• • DO NOT allow untrained personnel to operate, clean, inspect, maintain, service, or tamper with this

equipment.

• • ALWAYS DISCONNECT this equipment from the power

source before servicing.

OBSERVE PRECAUTIONS

FOR HANDLING

• • CALL METTLER TOLEDO for parts, information, and

service.

ELECTROSTATIC

SENSITIVE DEVICES

ii

Contents

1. GENERAL DESCRIPTION................................ ................................ ................................ ............................. 1

2. SYSTEM DESCRIPTION................................ ................................ ................................ ................................ 2

2.1 THE 8132 CONSISTS OF THREE (3) MAJOR BLOCKS: ................................ ................................ ......... 2

2.2 THE 8132 SETPOINT UNIT RETAINS ALL THE BASIC FUNCTIONS EXCEPT: ................................ ..... 2

3. SPECIFICATIONS................................ ................................ ................................ ................................ .......... 3

3.1 ELECTRICAL AND PHYSICAL SPECIFICATIONS................................ ................................ ................... 3

3.2 INTERNAL FUNCTIONS ................................ ................................ ................................ ........................... 3

3.3 DISPLAY FORMAT................................ ................................ ................................ ................................ .... 3

3.4 DATA INTERFACE................................ ................................ ................................ ................................ .... 4

3.5 FACTORY RAM IDENTIFICATION................................ ................................ ................................ ............ 4

3.6 RFI SPECIFICATIONS................................ ................................ ................................ ............................... 4

3.7 RAMS 9 AND 19 CUTOFF SPECIFICATIONS................................ ................................ ........................... 5

3.8 8132 FACTORY NUMBERS................................ ................................ ................................ ...................... 5

4. INSTALLATION INSTRUCTIONS................................ ................................ ................................ .................. 6

4.1 SET-UP PROCEDURE ................................ ................................ ................................ .............................. 6

4.2 PRECALIBRATION OF THE INSTRUMENT USING A LOAD CELL SIMULATOR................................ . 11

4.3 CALIBRATING THE 8132................................ ................................ ................................ ........................ 12

4.4 PROGRAM SWITCH SUMMARY (INCLUDING OPTION PCB'S)................................ ............................ 13

5. OPERATING INSTRUCTIONS................................ ................................ ................................ ..................... 32

6. PREVENTIVE MAINTENANCE................................ ................................ ................................ ..................... 37

6.1. REQUIRED TOOLS AND SUPPLIES ................................ ................................ ................................ ..... 37

6.2 MAINTENANCE SCHEDULE ................................ ................................ ................................ ................... 37

6.3 CLEANING ................................ ................................ ................................ ................................ .............. 37

6.4 TROUBLESHOOTING................................ ................................ ................................ ............................. 37

6.5 INPUT/OUTPUT CONNECTIONS................................ ................................ ................................ ............ 42

6.6 DATA OUTPUT TABLES ................................ ................................ ................................ ....................... 53

6.7 INTERCONNECT DIAGRAM................................ ................................ ................................ .................. 55

6.8 RECOMMENDED LIST OF SPARE PARTS................................ ................................ ........................... 58

6.9 8132 MAIN PCB CHART................................ ................................ ................................ ......................... 59

7. INTERFACE K.O.P.'S ................................ ................................ ................................ ................................ ... 60

7.1 PARALLEL I/O K.O.P................................. ................................ ................................ ............................. 60

7.2 EIA INTERFACE K.O.P. ................................ ................................ ................................ .......................... 60

7.3 MULTIPLE BUILD K.O.P. (151)................................ ................................ ................................ ............... 60

7.4 8820/30 PRINTER INTERFACE K.O.P.'S................................ ................................ ................................ 61

8. PARTS CATALOG................................ ................................ ................................ ................................ ........ 64

8.1 FRONT PANEL & COVER ASSEMBLY (DESK)................................ ................................ ..................... 64

8.2 MISCELLANEOUS HARDWARE (DESK)................................ ................................ ................................ 65

8.3 TRANSFORMER & HARNESS ASSEMBLIES (DESK)................................ ................................ ........... 66

8.4 INTERNAL HARDWARE (DESK)................................ ................................ ................................ ............. 67

8.5 FRONT PANEL & KEYBOARD (DESK AND WALL)................................ ................................ .............. 68

8.6 DISPLAY PCB & COMPONENTS................................ ................................ ................................ ............ 69

8.7 FRONT PANEL & MISCELLANEOUS HARDWARE (WALL)................................ ................................ . 70

8.8 DISPLAY ASSEMBLY (WALL)................................ ................................ ................................ ................ 72

8.9 OPTIONAL PCB'S & HARNESS (WALL)................................ ................................ ................................ 73

8.10 MISCELLANEOUS HARDWARE (WALL)................................ ................................ .............................. 74

8.11 MAIN PCB’S................................ ................................ ................................ ................................ .......... 75

8.12 COMMON C.O.D. MAIN PCB’S AND ADDITIONAL PARTS................................ ................................ . 76

8.13 INTERFACE K.O.P.’S................................ ................................ ................................ ............................ 77

8.14 SERIAL OUTPUT INTERCONNECTING CABLES................................ ................................ ................ 82

iii

1

1. GENERAL DESCRIPTION

The Model 8132 Electronic Digital Indicator is intended for use with strain gauge load cell scales. The

8132 provides Gross or Net weight and Tare weight displays. The unit is available in Desk and Wall

mount enclosures. Weight information is transmitted to a printer or accessory device using ASCII Code,

20 mA current loop, with even parity. The baud rate is selectable at 300, 1200, 2400, or 4800 Baud. An

8130 type output, Parallel BCD, is also available as an option. Other options include an Analog Over

PCB, an Analog Verification PCB an EIA interface (RS-232-C), setpoint output, and remote input PCB.

FEATURES

-- Selectable increments from 1000, 1500, 1700, 2000, 2500, 3000, 3400, 4000, 5000,

6000, 6800, 8000, 8500, 10,000, 12,000, 16,000, 17,000, and 20,000.

-- Displays Gross, net or Tare weight in pounds (LB) or kilograms (KG).

-- Continuous tare display.

-- Single or double width printing of displayed data, 0.3" high LED tare display.

-- Available in a desk mount enclosure or in a wall mount, NEMA 4, "washdown"

enclosure.

-- Power input is through a separate line cord.

-- Push-button tare or keyboard tare.

-- Computer compatibility.

-- Automatic Zero Maintenance (within ± 2% of scale capacity from zero).

-- Push-button zeroing (within ± 2% of scale capacity from zero).

-- Under capacity blanking at 7% of scale capacity.

-- Over capacity blanking at 5 increments over scale capacity.

Optional version of the 8132 (Rams 9 and 10) will provide TTL level control signals for two different

types of operations: however, both modes cannot be used at the same time. The two operations

include:

-- Either one or two cutoffs complete with dribble, preact and tolerance settings.

-- From one to four setpoints for use a single cutoffs. No dribble, preact or

tolerance values can be set.

The 8132 setpoint control signals will change states when the absolute value of the displayed weight

equals or exceeds the programmed setpoint value. This means that as long as the weighing sequence

starts at zero, the cutoffs can be used in either weigh up or weigh down mode.

With the Setpoint option, any time power is lost, all information is cleared to zero in the registers.

2

2. SYSTEM DESCRIPTION

The instrument provides 15 volts of excitation for strain gauge load cells. The excitation is gated so that

zero drift and temperature change can be compensated. The instrument conditions the microvolt signal

and amplifies it to a maximum level of about 10 volts. It is then filtered and converted to a digital signal

in the integrator.

The excitation voltage is 15 volts DC gated, switchable to 10 volts gated.

The initial range is adjustable from 0 to 30 millivolts.

The span range is adjustable from 3 to 30 millivolts.

The largest increment is 200 LB the smallest is 0.0001 LB.

Excitation current is provided for 6-240 ohm cells or 8-350 ohm cells.

2.1 THE 8132 CONSISTS OF THREE (3) MAJOR BLOCKS:

2.1.1 Control PCB -- Contains the scale logic, regulated strain gauge supply, program selection

switches and data transmission circuitry.

2.1.2 Display PCB -- Contains the weight, tare and legend LED's as well as the decoding

circuitry for the LED's and used as an interface for the keyboard.

2.1.3 Keyboard -- The keyboard allows operator interface for functions such as Tare, Print,

Clear,

LB/KG selection, push-button Zero and if ordered, Analog Verify. Test VERIFY and

Setpoint

information.

2.2 THE 8132 SETPOINT UNIT RETAINS ALL THE BASIC FUNCTIONS EXCEPT:

(of a standard 8132)

2.2.1 Keyboard switching from LB to KG is disabled; however, the unit may be powered up in

either KG or LB as determined by an internal programming switch.

2.2.2 Analog Verification is deleted and the program switch that was used for operation of AV

is now used for setpoint mode selection.

2.2.3 Display Verification has also been removed.

2.2.4 Several keys on the keyboard have a dual function such as entering tare and also

setpoint information.

2.2.5 Setpoint may be changed while the scale is in motion.

3

3. SPECIFICATIONS

8 8 8 8 8 8 88888

3.1 ELECTRICAL AND PHYSICAL SPECIFICATIONS

3.1.1 ENVIRONMENT

The Model 8132 operates from -10 C (14 F) to +50 C (122 F) 10 to 05% relative humidity, noncondensing.

Zero Temperature Coefficient -- 0.1 uV/ C Max.

Span Temperature Coefficient - ±12 PPM/ C Max.

3.1.2 POWER INPUT

The Model 8132 can operate (upon selection) at 100V, 120V, 220V and 240 VAC, (+10%, -15%) 49

Hz to 61.2 Hz. Power consumption is about 25 watts.

3.1.3 U.L. & C.S.A. STANDARDS

Materials, components and electrical design comply with U.L. and D.S.A. standards and

requirements, including grounding of all metal parts, fusing, etc.

3.1.4 APPEARANCE AND DIMENSIONS

The color of the Model 8132 is charcoal with a red display lens and color coded function

switches. The desk mount sheet metal enclosure is 8.8 cm tall (3.47"), x 43.2 cm wide (17"), x

23.7 cm deep (9.3"), suitable for rack mounting with adapters. The wall mount Stainless Steel

NEMA 4 enclosure is 33 cm high (13"), x 45.7 cm wide (18"), x 14 cm deep 5.5").

The desk mount model weights approximately 7 KG (15.4 LB), the wall mount unit weighs about

16 KG (35 LB).

Power, load cell and output connections are made via rear mounted connectors on the desk

Model 8132, and via connectors on the bottom of the NEMA 4 enclosure.

3.2 INTERNAL FUNCTIONS

The 8132 contains the necessary electronics, except the load cell (s), to calculate and display

weight, as well as the capability to transmit data to a remote device.

3.3 DISPLAY FORMAT

The weight display is 6 digit including (-) sign, 7 segment LED's.

The tare display is a 5 digit , 7 segment LED display. LED's are also used as a legend indicators.

Sample display:

On rams 9 and 19, the tare display is used to show what information is being entered for

setpoints. Once Setpoint Selection Mode has been entered and a location selected the tare

display will blink on and off displaying the data already stored. If no information is in that

location, the tare display will blink all zeros. When the new data has been entered the display

will return to displaying tare values.

4

3.4 DATA INTERFACE

Data output is provided in bit serial form, ASCII code, 20mA current loop, even parity. The baud rate is

selectable at 300, 1200, 2400, or 4800 baud.

NOTE: The PRINT push-button on the 8132 is NOT active when using the parallel BCD option with a

Model 500, 510 or 8895 Printer.

The 300 baud output is not changed with rams 0 and 19. The 4800 baud rate format changes to include

the status of setpoint, dribble, preact and tolerance.

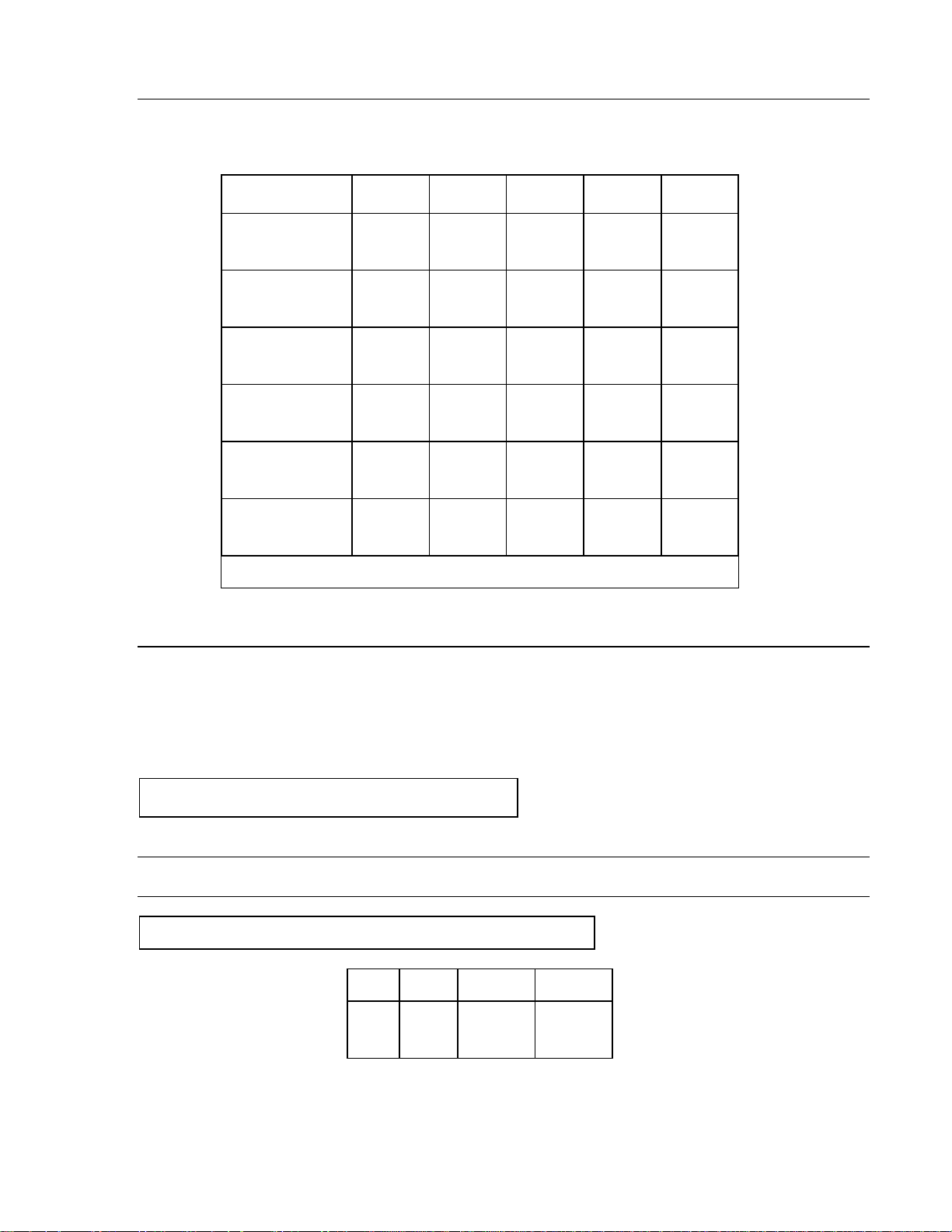

3.5 FACTORY RAM IDENTIFICATION

TYPE RAM NUMBER VERIFIED DESCRIPTION OF MAIN PCB

DESK

TOP

WALL

8132 0001

8132 0002

8132 0003

8132 0004

8132 0007

8132 0008

8132 0009

8132 0010

8132 0201

8132 0202

8132 0203

8132 1009

8132 0011

8132 0012

8132 0013

8132 0014

8132 0017

8132 0018

8132 0019

81320 020

8132 0211

8132 1019

NO

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

NO

NO

NO

NO

NO

NO

NO

Span Temp. Coef. of 12 PPM/ C

Span Temp. Coef. of 6 PPM/ C

Span Temp. Coef. of 3 PPM/ C

Span Temp. Coef. of 6 PPM C

Expanded Zero capture

Print Interlock

Setpoint Mode

Intrinsic Safe

Averaging

Averaging Checkweigh

Averaging legal for Trade

Setpoint w/Intrinsic Safe

Span Temp. Coef. of 12 PPM/ C

Span Temp. Coef. of 6 PPM/ C

Span Temp Coef. of 3 PPM/ C

Span Temp Coef. of 6 PPM/ C

Expanded Zero capture

Print Interlock

Setpoint Mode

Intrinsic Safe

Averaging

Setpoint w/Intrinsic Safe

*NOTES:

Expanded Zero Capture -- Zero will automatically capture when the display returns to within ± 3

increments of zero. Intended for large capacity scales only.

Print Interlock -- After printing, the indication must return to within ±.25 increments of zero before

another print may be made.

Setpoint Mode -- Provides TTL level signals for either two cutoffs, complete with dribble and preact, or

four signal setpoints.

Intrinsic Safety -- Excitation voltage is reduced to ±3 volts.

3.6 RFI SPECIFICATIONS

The Model 8132 has successfully passed FCC regulation regarding the emission of RFI. The

8132 has also passed SMA requirements for susceptibility to RFI. Additional protection may be

required in severe RFI environments.

5

3.7 RAMS 9 AND 19 CUTOFF SPECIFICATIONS

3.7.1 All cutoffs are TTL level negative true and "ON" when the displayed weight is less than

the programmed cutoff value. That is, the output is 0 volts unit the cutoff value. That is,

the output is 0 volts until the cutoff is reached then goes to a + 5 volt level.

3.7.2 The output consists of TTL open collector lines with 10K ohm pull-up resistors.

3.7.3 Each output will support 30 TTL loads of 7406 or similar gates.

3.8 8132 FACTORY NUMBERS

TYPE PART NUMBER VERIFIED DESCRIPTION OF MAIN PCB

DESK TOP

WALL

8132 0001

8132 0002

8132 0003

8132 0004

8132 0007

8132 0008

8132 0009

8132 0010

8132 0201

8132 0202

8132 0203

8132 1009

8132 0011

8132 0012

8132 0013

8132 0014

8132 0017

8132 0018

8132 0019

8132 0020

8132 0211

8132 1019

NO

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

UES

UES

NO

NO

NO

NO

NO

NO

NO

Span Temp. Coef. of 12 PPM/ ºC

Span Temp. Coef. of 6 PPM/ ºC

Span Temp. Coef. of 3 PPM/ ºC

Span Temp. Coef. of 6 PPM/ ºC

Expanded Zero Capture

Print Interlock

Setpoint Mode

Intrinsic Safe

Averaging

Averaging Checkweigh

Averaging Legal for Trade

Setpoint w/Intrinsic Safe

Span Temp. Coef. of 12 PPM/ ºC

Span Temp. Coef. of 6 PPM/ ºC

Span Temp. Coef. of 3 PPM/ ºC

Span Temp. Coef. of 6 PPM/ ºC

Expanded Zero Capture

Print Interlock

Setpoint Mode

Intrinsic Safe

Averaging

Setpoint w/Intrinsic Safe

6

4. INSTALLATION INSTRUCTIONS

4.1 SET-UP PROCEDURE

4.1.1 Inspect the indicator for loose or damaged parts.

4.1.2 Open the indicator and remove the top cover and continue the inspection, noting that all

the interconnecting harnesses are securely fastened.

4.1.3 Check the line filter/fuse holder assembly to insure that the proper voltage and fuse size

are selected for use in your area.

CAUTION: All units are shipped for 120 VAC operation. See below for alternate voltage

operation.

The following photos will assist you in checking or changing the voltage selection.

This step MUST be performed prior to applying power to the unit

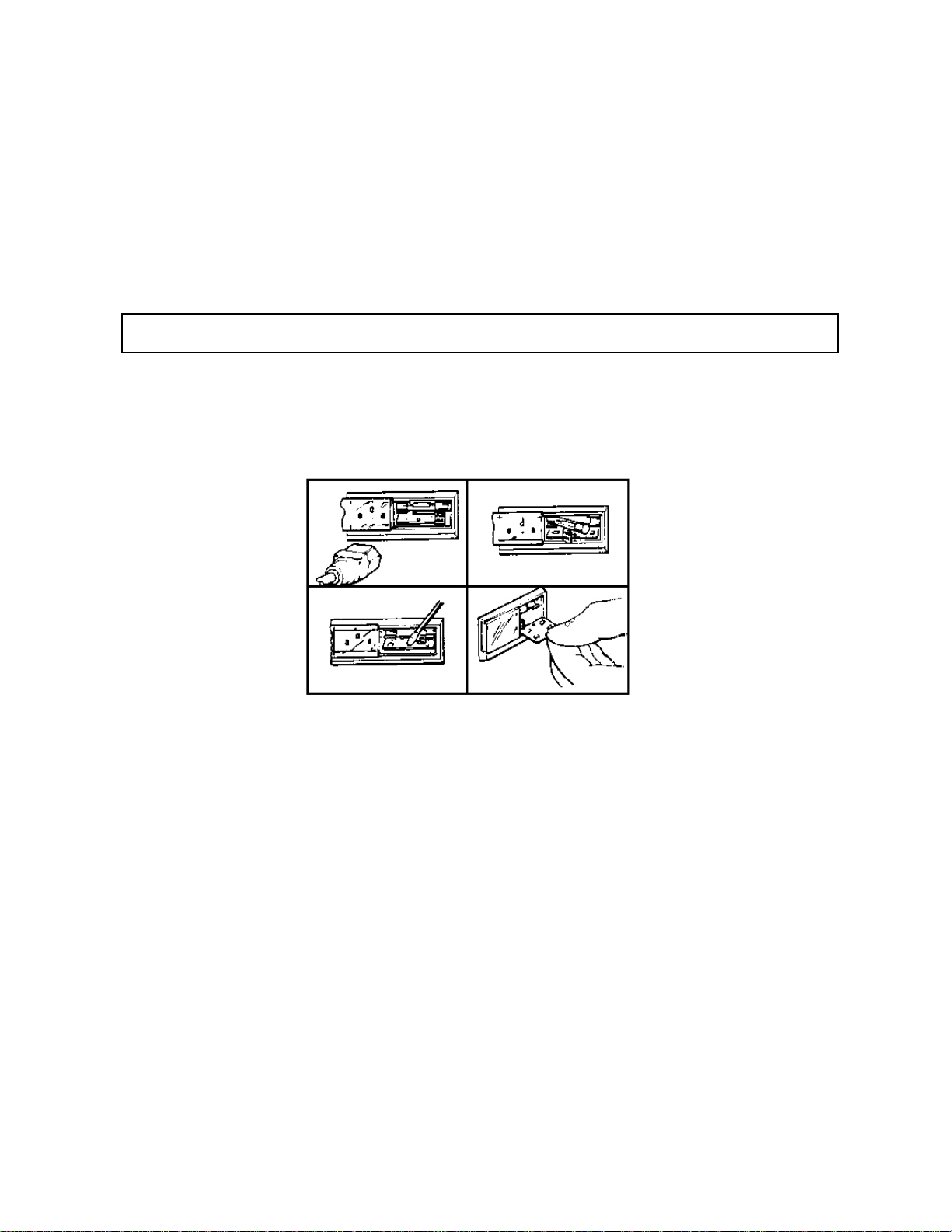

1. This photo shows the line cord 2. In this photo the fuse is

detached and the fuse cover removed by pulling the handle

moved to the left. labeled “FUSE PULL”

3. With the fuse removed, 4. Once you have determined

use a small screwdriver or the proper voltage, return the

similar object and gently pry card to the slot. The voltage

the card from the assembly. desired will be on the left side

A hole in the card is provided of the card in a readable position.

to assist removal. In the photo, the voltage selected

is 120V. Replace the fuse with

one of the correct rating. Slide

fuse cover back into place.

7

4.1.4 Preliminary Calculations

Before any calibration is done it should be determined if the load cell (s) are of a size that

will work correctly with the instrument and platform. If it is a standard build, go ahead

and install the scale. However, if it is a special build or if it is a conversion of an existing

mechanical scale, it should be checked by determining the microvolts per increment then

checking it with the cart to make sure the proposed load cell (s) are the correct size.

HOW TO DETERMINE MICROVOLTS PER INCREMENT

FIRST FIND:

- Scale capacity*.

- Increment Size*.

- Number of load cells or total lever ratio.

- Size of load cell(s)*.

- Cell output rating in mV/V --millivolts per volt of excitation.

* In LB or KG depending on how scale is to be calibrated and used.

THEN:

1. Divide the scale capacity by the increment size to get the number of increments that the

indicator is to be programmed for.

2. Multiply the cell size by the number of cells or the lever ration (depending on the type of

scale). This will be the overall scale capacity (disregard initial at this time).

3. Divide the overall scale capacity by the increment size. This will be the overall number of

increments.

4. Multiply cell output in millivolts by 1,000 to get cell output in microvolts.

5. Divide cell output in microvolts by the overall number of increments to get microvolts per

increment.

NOTE: Load Cells built by Toledo are 2 mV/V. Load Cells built by BLH are usually 2 mV/V or 3 mV/V.

Load Cells built by HBM that are used on the Toledo 7200 are 1.8 mV/V. The Model 2300 is 1mV/V.

8

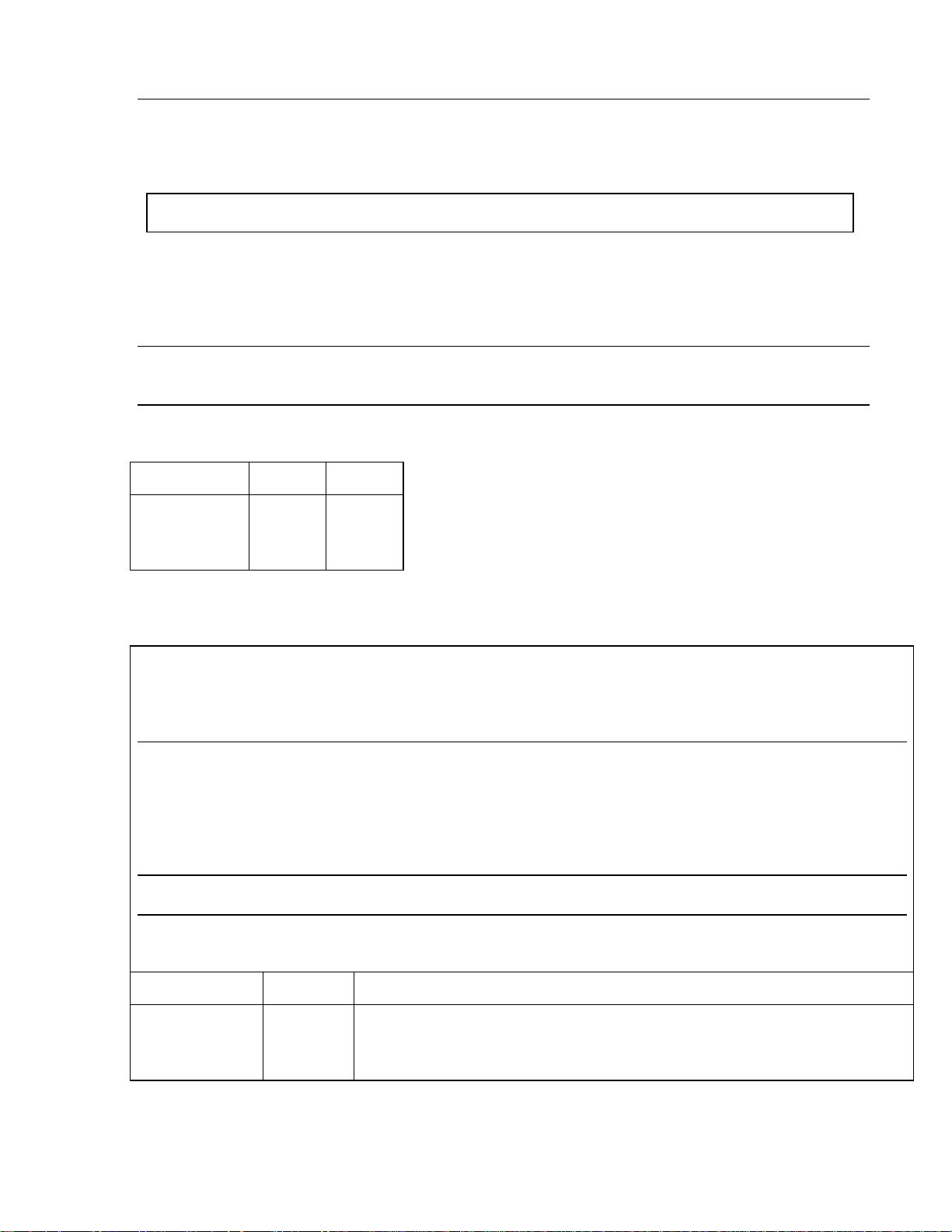

The chart below shows the limits in microvolts for each available number of increments.

MICROVOLT CHART

Number of Increments

Programmed

20,000

17,000

16,000

12,000

10,000

8,500

8,000

6,800

6,000

5,000

4,000

3,400

3,000

2,500

2,000

1,700

1,500

1,000

Maximum*

uV/ Increment

1.5

1.7

1.8

2.5

3

3.5

3.7

4.4

5

6

7.5

8.8

10

12

15

17

20

30

Minimum**

uV/ Increment

0.3

0.3

0.3

0.3

.0.3

0.35

0.37

0.44

0.5

0.6

0.75

0.8

1.7

2.0

3.0

1.7

2.0

3.0

NOTE: *the 8132 cannot be adjusted on builds that are greater than the voltage shown for maximum

V/ Increment.

NOTE: **the instrument should never be programmed to less than .3uV/ Increment for multiple cell

scales (4 or more) and no less than 1.5 V/Increment for single cell scales.

If these limits are exceeded, the scale will not be stable.

EXAMPLE 1

60 x 10 Bridgemaster

Scale Capacity in pounds......................................................................100,000 LB

Increment Size in pounds...............................................................................20 LB

Number of Load Cells..........................................................................................4

Size of Load Cells in pounds...................................................................100,000 LB

Cell Output Rating.......................................................................................2 mV/V

STEP 1

100,000 LB capacity -- 20 LB increments

100,000 ÷ 20 = 5,000 increments

STEP 2

4 load cells - 100,000 LB capacity

4 x 100K = 400,000 LB overall scale capacity

STEP 3

400,000 LB overall scale capacity -- 20 LB increments

400,000 ÷ 20 = 20,000 overall number of increments

9

STEP 4

2 mV/V cell output rating

STEP 5

30 mV x 1,000 = 30, 000 millivolts at full capacity

STEP 6

30,000 ÷ 20,000 = 3 ÷ 3 = 1.4 microvolt per increment

Check the Microvolt Chart to see if the V/Increment fits in the range listed for 5,000 increments.

The range listed is .6 to 6uV/Increment and 1.5 is inside this range, therefore, it will be a

satisfactory build.

Scale Capacity in pounds.......................................................................100,000 LB

Increment Size in pounds...............................................................................20 LB

Lever Ration..............................................................................................800 to 1

Size of Load Cells in pounds ..........................................................................200 LB

Cell Output Rating.........................................................................................mV/V

STEP 1

100,000 LB Capacity 0020 LB increments

2 mV/V x 15 - 30 millivolt cell output at full capacity

EXAMPLE 2

60 x 10 Lectrolever Scale

100,000 ÷ 20 = 5,000 increments

STEP 2

800 lever ratio -200 LB load cell

800 x 200 = 160,000 LB overall scale capacity

STEP 3

160,000 LB overall scale capacity - 20 LB increments

160,000 ÷ 20 = 8,000 overall number of increments

STEP 4

2mV/V output rating

2mM.V x 15 = 30 millivolt cell output at full capacity

STEP 5

30 mV x 1,000 = 30,000 microvolts at full capacity

STEP 6

30,000 ÷ 8,000 = 30 ÷8 =3.75 microvolts per increment

Check the Microvolt Chart to see if the V/ increments fits in the range listed for 5,000

increments. The range listed is .6 to 6 V/Increment and 3.75 V/Increment is inside the is range,

therefore, it will be a satisfactory build.

10

EXAMPLE 3

Model 2184

Scale Capacity in pounds...............................................................................300 LB

Increment Size in pounds..............................................................................0.01 LB

Lever Ratio............................................................................................... ..8.1 to 1

Size of Cell in pounds....................................................................................100 LB

Cell Output Rating........................................................................................2 mV/V

STEP 1

300 LB scale capacity --0.1 LB increments

300 ÷0.1 = 3.000 increments

STEP 2

8.1 lever ratio -100 LB load cell

8.1 x 100 - 810 LB overall scale capacity

STEP 3

810 overall scale capacity -0.1 LB increments

810 ÷ 0.1 - 8, 100 overall number of increments

STEP 4

2mV/V cell output rating

2mV/V x 15 = 30 millivolts at full capacity

STEP 5

30 mV x 1,000 = 30,000 microvolts at full capacity

STEP 6

30,000 ÷ 8.100 = 300 ÷ 81 = 3.7 microvolts per increment

Check the Microvolt Chart to see if the V/ Increment fits in the range listed for 3,000 increments.

The range listed is 1 to 10 V/Increment and 3.7 V/Increment is inside this range therefore, it will

be a satisfactory build.

4.1.5 Programming the 8132

a. Select the proper number of increments to match the capacity of the platform and

the load cell(s). Select with switches SW4-1 through SW4-5.

b. Select the proper increment size using switches SW5-2 and SW5-3.

c. Select the proper decimal point and/ or dummy zero (if used) with switches SW5-

9, SW 6-1, and SW6-2.

d. Select the proper functions for tare, KG/LB, printing and blanking with switches

remaining on SW5, SW6, and SW7.

11

4.2 PRECALIBRATION OF THE INSTRUMENT USING A LOAD CELL SIMULATOR

NOTE: Precalibration of the 8132 is not a required step; however, it can reduce the number of times

test weights need to be applied to the scale platform.

FIRST FIND:

- Number of cells used.

- Capacity of one cell*.

- Total level ration (if required).

- Millivolt output of the cell(s).

* In LB or KG depending on how the scale is to be calibrated and used.

THEN:

1. Multiply the cell capacity by the number of cells used. Multiply this number by the lever

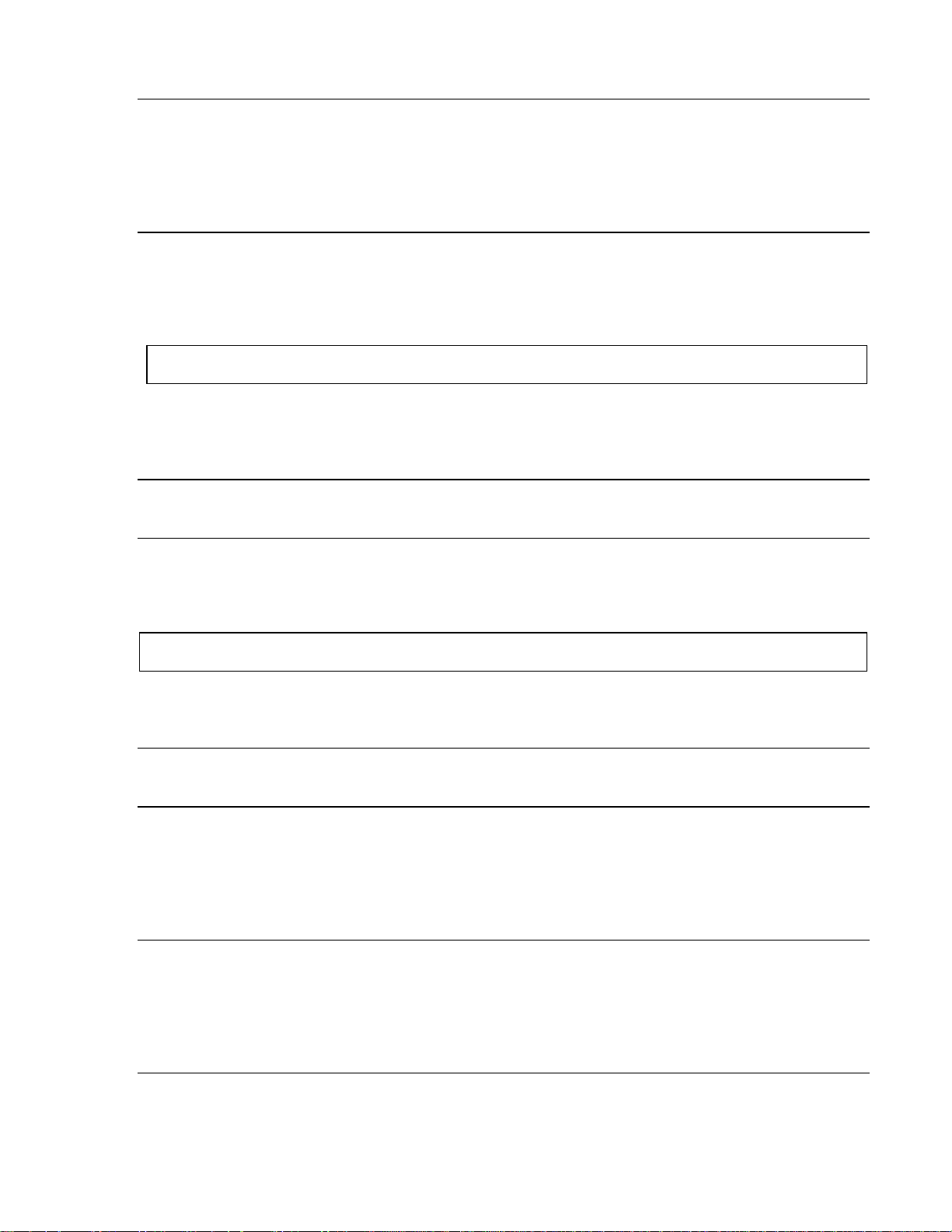

ratio, if required, to find the Total Cell Capacity.

2. Divide the Total Cell Capacity by the correct division number to find LB or KG per step on

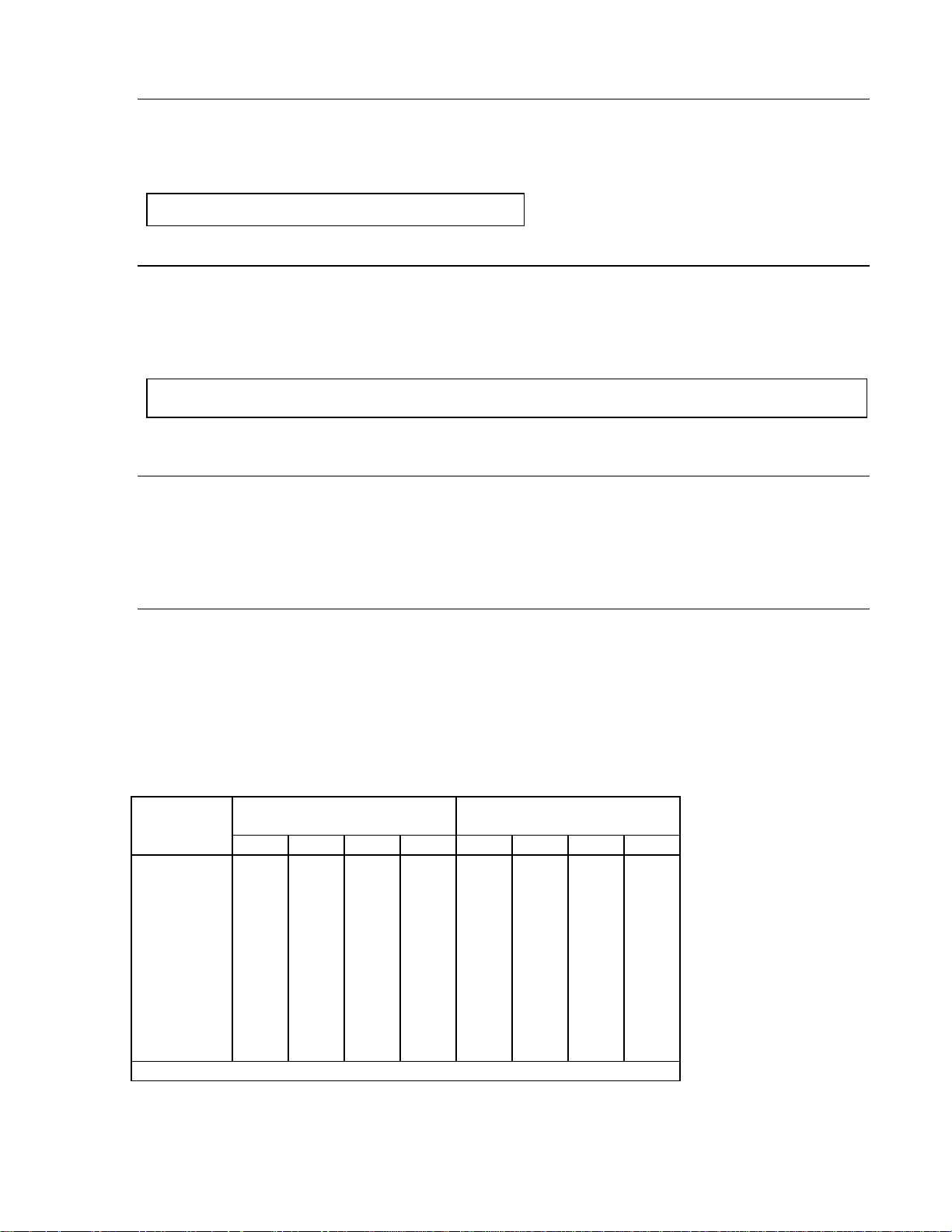

the simulator. Refer to the following chart for this number.

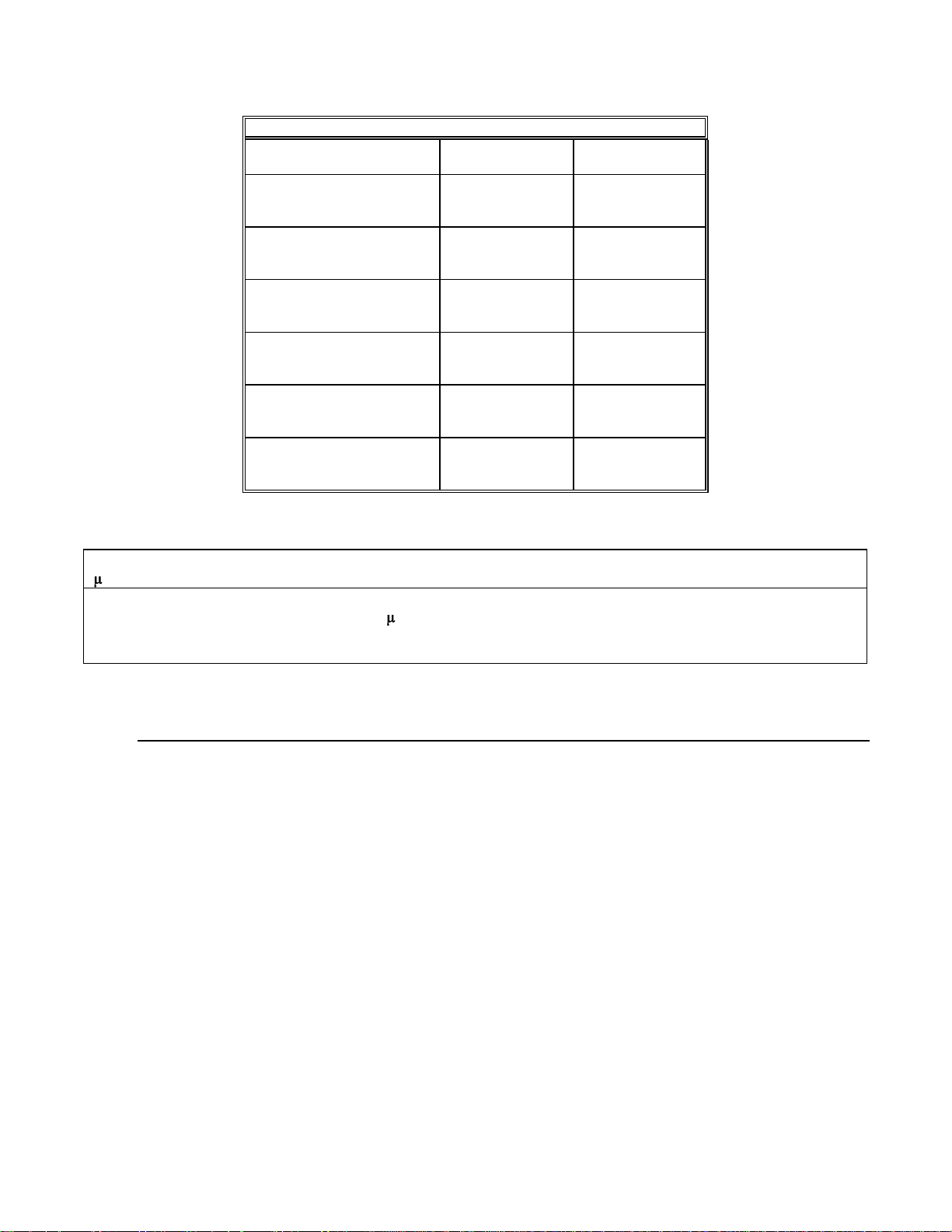

MILLIVOLTS/VOLT

CELL OUTPUT

1

1.8

2

3

3. At this time, connect the simulator to the instrument.

4. Connect to the power line.

5. Turn the simulator switch to the zero position and set the instrument to zero using the

initial switches and potentiometer.

6. Calibrate the instrument. Use the maximum number of steps on the simulator without

exceeding the instrument's capacity.

7. Remove power, disconnect the simulator from the instrument and connect the load

cell(s). Reconnect to power. At this time the display will indicate the initial weight. Rest

to zero using the initial switches and potentiometer. Make final calibration test with test

weights.

8. Record the indication at all steps on the simulator along with the simulator's serial

number. Attach this record to the instrument housing for future troubleshooting

assistance.

DIVISION

NUMBER

5

9

10

15

12

4.3 CALIBRATING THE 8132

4.3.1 Make sure the load cells are connected properly.

4.3.2 Turn SW7-1 ON before applying power or the indication will flash with the following

display. the zero pushbutton will not operate with SW7-1 ON.

E E E E E E

4.3.3 Turn initial potentiometer R-23 fully clockwise and span potentiometer R-24 fully

clockwise.

4.3.4 Start with SW1-1 through SW1-8 OFF, SW2-1 through SW2-7 ON and SW3-1 through

SW3-4 ON.

4.3.5 Zero the indication with the front panel zero adjustment.

4.3.6 Set span switch SW2-1 to the OFF position.

4.3.7 INITIAL -- To set initial, start with all SW1 switches OFF, then turn them ON, one at a time

starting with SW1- noting if it takes the indication below zero. If it does, turn OFF that

switch again and go to the next switch. Try turning SW1-2 through SW1-8 ON, one at a

time, only leaving the switches ON that do not take the indication below zero. SW1-1 will

be the largest step and will be used only on scales with very high initial. Make the final

initial adjustment with the fine initial potentiometer R-24.

4.3.8 SPAN-- When setting Span start with all SW2 and SW3 switches in the OFF position and

the indication reading zero. Place test weights on the platform. (Approximately 10% of

scale capacity.) Try turning SW2-1 ON. If the indication is too low, turn, that switch back

OFF and go the next switch. Turning On this switch will have 1/2 the effect of the

previous switch. Continue turning ON only the switches that do not take the indication

below the correct reading. Make the final span adjustment with the span potentiometer

R-24.

4.3.9 Remove test weights and check zero.

4.3.10 Repeat

steps 8 and 9

until scale is

calibrated

properly. The

display can be

expanded by

SW6-6 to allow

more accurate

calibration.

4.3.11 Remove

test weights

from the

understructure

and turn SW7-1

OFF. Capture

zero with the

zero button.

13

4.4 PROGRAM SWITCH SUMMARY (INCLUDING OPTION PCB'S)

It is important that you check the Technical Manual of the printer (if a printer is to be used), for program

switch settings that may affect printer operations and formats, prior to connecting your 8132 Digital

Indicator to the printer.

NOTE: The 8132 should never be programmed for a greater number of increments or a smaller

increment size than the scale understructure will allow. Each understructure has a list of standard

configurations (capacity and increment sizes) which should determine how the 8132 is to be

programmed.

4.4.1 ANALOG FILTER

An Analog Filter is provided with selectable response of 2 seconds and 3 seconds settling time.

The resistor pack (R72) can be inserted into its socket either of two ways- thus controlling the

Analog Filtering. R72 is located on the right edge of the PCB, (facing the instrument) about halfway back on the desk mount unit and the left for the wall mount unit.

For maximum filtering (3 seconds response) install resistor pack with number one pin or dot

away from load cell connector (J2).

For minimum filtering (2 seconds response) install resistor pack with number one pin or dot

toward the load cell connector (J2).

1 second and 5 second update rates are available by replacing the R72 resistor pack with the

specific resistor pack designated for either update rate. Refer to the 8132 Parts Catalog,

PC008132 I05, for the part numbers.

14

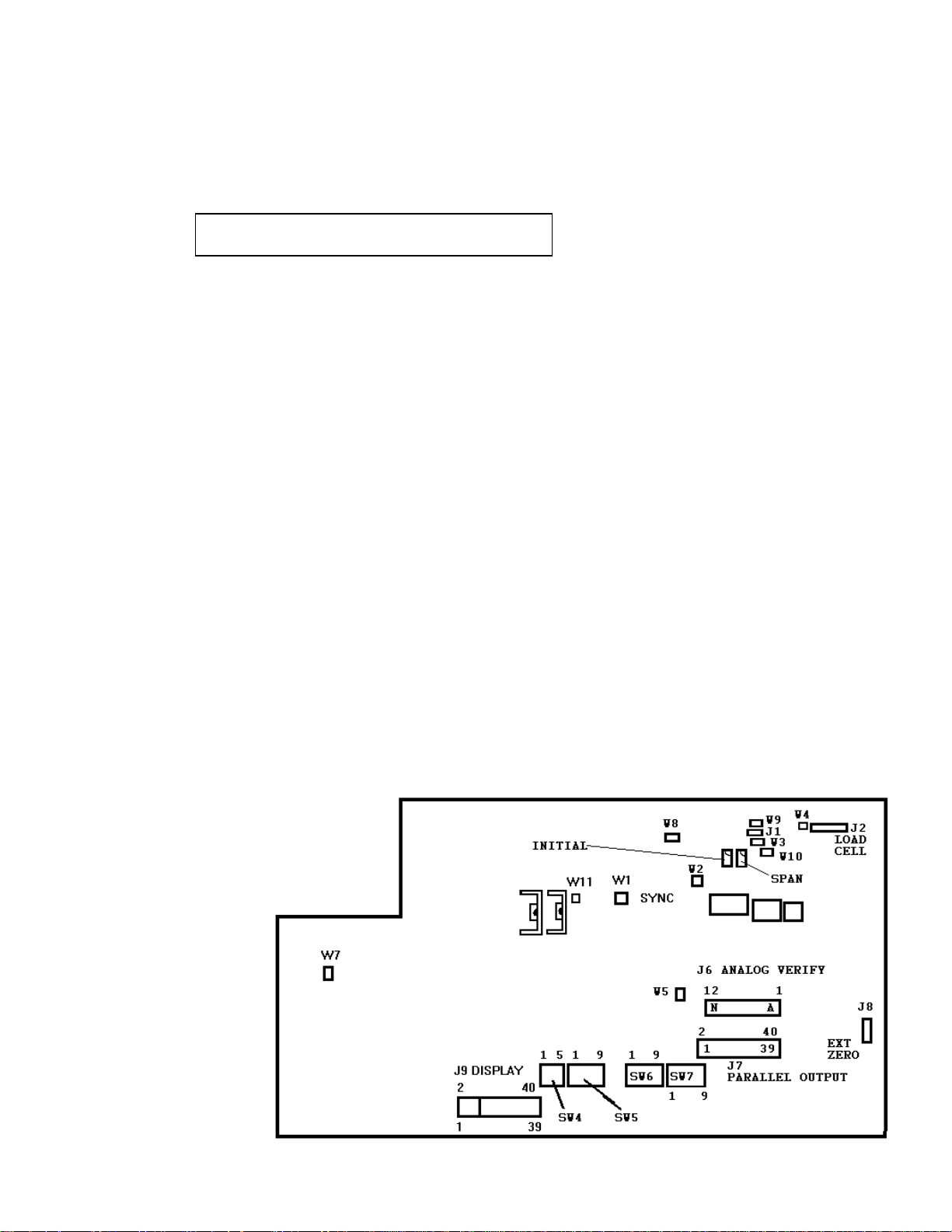

4.4.2 CONTROL PCB PROGRAM SWITCHES

TURNING ON ANY OF SW1 INITIAL SWITCHES WILL INCREASE THE INITIAL COMPENSATION.

SW1-2 HAS 1/2 THE EFFECT OF SW1-1.

SW1-3 HAS 1/2 THE EFFECT OF SW1-2, AND SO ON DOWN TO SW1-8.

SW1 --INITIAL

SW1-1 --LARGEST STEP

SW1-2 -SW1-3 -SW1-4 -SW1-5 -SW1-6 -SW1-7 -SW1-8 --SMALLEST STEP

SW1-9 --NOT USED

TURNING ON ANY OF SW2 AND SW3 SPAN SWITCHES WILL DECREASE THE WEIGHT

INDICATION.

SW2-2 HAS 1/2 THE EFFECT OF SW2-1.

SW2-3 HAS 1/2 THE EFFECT OF SW2-2 AND SO ON DOWN TO SW3-4.

SW2-1 --LARGEST STEP

SW2-2 -SW2-3 -SW2-4 -SW2-5 -SW2-6 -SW2-7 --

SW3

SW3-1 -SW3-2 -SW3-3 -SW3-4 --SMALLEST STEP

15

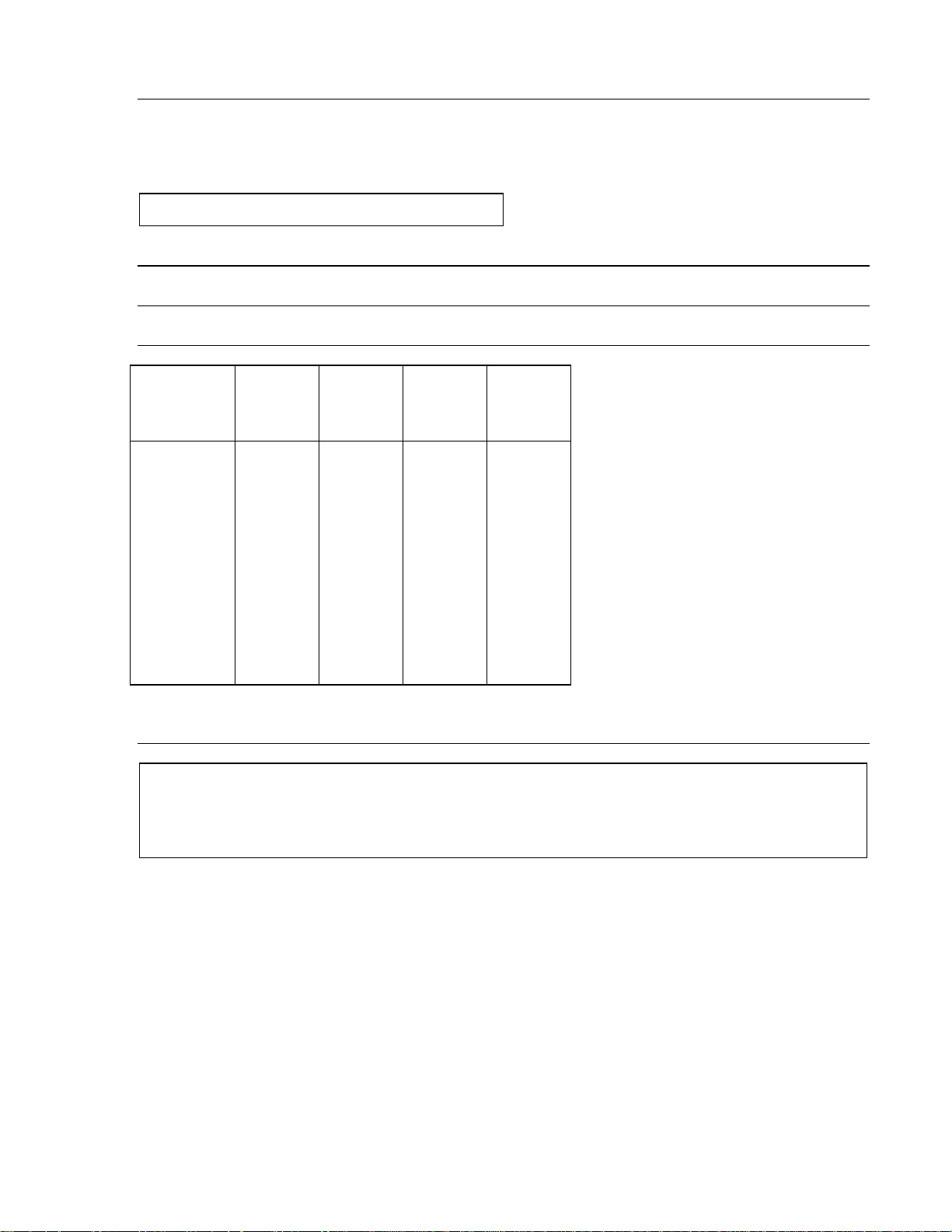

SW4-1 THRU SW4-5

After you have determined the required number of increments, use the chart to find the

appropriate switch settings.

NO. OF

INCREMENTS SW4-1 SW4-2 SW4-3 SW4-4 SW4-5

1000

1500

1700

2000

2500

3000

3400

4000

5000

6000

6800

8000

8500

10000

12000

16000

17000

20000

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

NOTE: Use only the above switch settings.

SW5-1 LB/KG SELECTION INHIBIT

ON -The display will remain in either LB or KG, as selected by SW6-9 and cannot be changed

from one to the other.

OFF -The display may be changed from LB to KG and back again as desired.

RAMS 9 AND 19 ONLY

SW4-1 - Not Used - Should be OFF

SW5-2 INCREMENT SIZE

SW5-3 INCREMENT SIZE

NOTE: DO NOT LEAVE SW5-2 AND SW5-3 BOTH OFF.

LB. KG. SW5-2 SW5-3

X1

X2

X5

X0.5

X1

X3

OFF

ON

ON

ON

OFF

ON

16

SW5-4 TARE DISPLAY

ON -The Tare Display is OFF and Tare is inoperative.

OFF -The Tare Display is ON and the keys affecting tare are operative.

NOTE: SW5-4 must be OFF with Rams 9 & 19.

SW5-5 AUTO CLEAR

ON -Tare must be cleared by the use of the C (Clear) pushbutton.

OFF - Tare will automatically clear when the indication returns to zero. (The scale must first

settle at some weight value greater than 10 increments up scale.)

NOTE: SW5-4 must be OFF for this function to operate. Also see SW5-7 for possible

interaction.

SW5-6 MULTIPLE LINE PRINTING

ON -Single line printing.

OFF -The printer will print multiple lines -- Gross, Tare, and Net.

SW5-7 TARE INTERLOCK

ON -Tare may be cleared or changed at any positive weight indication. Keyboard entries

(both tare and setpoint) are rounded to the nearest increment size.

OFF -The indication must be at true zero before the tare can be removed. (True zero is

actually ZERO minus the tare value.) The least significant digit of keyboard entry (tare

and/or setpoint information) must correspond to the increments size or the entry will not

be accepted.

LSD OF

TARE WITH SW5-7 OFF WITH SW5-7 ON

ENTERED X1 X2 X5 X10 X1 X2 X5 X10

0

1

2

3

4

5

6

7

8

9

10

0

1

2

3

4

5

6

7

8

9

10

0

2

4

6

8

10

0

-

-

-

-

-

-

-

5

-

-

-

-

-

-

10

0

10

0

-

-

-

-

-

-

-

-

-

1

2

3

4

5

6

7

8

9

10

10

10

0

2

2

4

4

6

6

8

8

0

0

0

5

5

5

5

5

10

10

10

0

0

0

0

0

10

10

10

10

10

10

( - ) Tare not accepted.

17

SW5-8 TARE ENTRY

ON -Digital Tare will not work, pushbutton Tare does work.

OFF -Digital Tare and pushbutton Tare both work.

NOTE: SW5-8 must be OFF with Rams 9 & 19.

SW5-9 DECIMAL POINT

SW6-1 DECIMAL POINT

SW6-2 DECIMAL POINT

LB KG

X5

X2

X1

XXXX00

XXXXX0

XXXXXX

XXXXX.X

XXXX.XX

XXX.XXX

XX.XXXX

X.XXXXX

KG

X2

X1 KG.

X5 SW5-9 SW6-1 SW6-2

XXXXX0

XXXXXX

XXXXX.

X

XXXX.X

X

XXX.XX

X

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

XX.XXX

X

X.XXXX

X

----

SW6-3 AUTO ANALOG VERIFY/SETPOINT MODE SELECT

NOTE: In order for Analog Verification to operate, an Analog Verification PCB must be in

place in J6 on the 8132 Main PCB.

NOTE: Auto Analog Verify (SW6-3) must be OFF and Analog Verify (SW6-4 must also be on).

Analog Verification

ON -The Analog Verify will operate only when AV button is pressed. (SW6-4 must also be

On).

OFF -The Analog Verify will operate automatically every time the indicator reruns to

true zero. (The scale must firs settle at some weight value greater than 10

increments up scale.) The Analog Verify will also operate manually by pressing the AV

button while at true zero.

18

RAMS 9 AND 19 ONLY

SETPOINT MODE SELECT

If Rams 9 or 19 are used, SW6-3 is used to select the mode of operation.

ON -The four setpoint mode is selected with no dribble, preact or tolerance settings.

OFF -Two setpoints with dribble, preact and tolerances are selected.

NOTE: All setpoint information must be checked after changing

SW6-3.

SW6-4 ANALOG VERIFY

ON -Analog Verify will operate.

OFF -Analog Verify will not operate.

RAMS 9 AND 19 ONLY

SW6-4 -- Not Used -- Should be OFF

SW6-5 DEMAND MODE

ON -Normal mode, internal update is used.

OFF -Demand mode, the Demand Input line, (refer to Serial Connector Diagram) must be held

low, then pulsed positive at +5V for 50 ms, forcing an A/D cycle.

SW6-6 EXPAND (For Calibration Only)

ON -The display will be expanded for calibration.

INCREMENT

SIZE

1

2

5

OFF -Normal Mode.

NOTE: The AZM (Automatic Zero Maintenance) will be disabled in the expand mode. Check

zero after switching to expand.

SW6-7 MOTION SENSITIVITY

ON -2 increments or less of movement is not detected.

DISPLAY

EXPANDED BY

X10

X5

X2

OFF -1/2 increment or less of movement is not detected.

19

SW6-8 MOTION BLANKING

ON -Motion on the scale will NOT cause the display to blank.

OFF -Motion on the scale will blank the display. (Sensitivity is determined by SW6-7.)

SW6-9 POWER UP KG

ON -The display will be in KG when power is first applied. The Analog Verify option will

operate only in the Kg mode.

OFF -The display will be in LB when power is first applied The Analog Verify option will

operate in the LB mode only.

NOTE: This switch MUST be set BEFORE power is applied. Selection of LB or KG may be

made at the keyboard. (See SW5-1).

SW7-1 AUTOMATIC ZERO MAINTENANCE (AZM)

ON -AZM and the Z (Zero) pushbutton are disabled. The display will not blink on power up.

OFF -AZM will operate to keep the instrument on zero in spite of small changes on the

platform. (Less than 1 increment.) The Z (Zero) pushbutton will also operate.

SW7-2 CHECKSUM

ON -No Checksum character transmitted.

OFF -A Checksum character is transmitted to a device requiring checksum.

NOTE: Checksum is defined as the 2’s complement of the sum of the bits 0-6 of all characters

preceding the checksum character.

SW7-3 PRINT GROSS, TARE, NET

ON -The printer will print the Gross, Tare, and Net weight information.

OFF -Only the displayed weight is printed. (Gross or Net - Not Tare.)

SW7-4 -NEGATIVE WEIGH PRINTING

ON -Below “0” weights may be printed.

OFF -The printer will not print as long as the indication is below “0”.

20

SW7-5 PRINT TONS

ON -A symbol “t” for tons is printed in place of the LB or KG symbol.

OFF -Only the LB or KG units is printed.

NOTE: No conversion from LB or KG to tons is made. The scale MUST be calibrated in

tons.

The 8805 printer will not print a "t" for tons. The space for the weight symbol will be left blank if

SW7-5 is ON.

SW7-6 BAUD RATE SELECT

SW7-7 BAUD RATE SELECT

The setting of SW7-6 and SW7-7 will determine the output baud rate.

BAUD RATE SW7-6 SW7-7

300

1200

2400

4800

NOTE: At 300, 1200, and 2400 baud, activation of the PRINT pushbutton or a remote print

command is required to generate a transmission. At 4800 baud the output is continuous.

THE 8132 WILL OPERATE AT 300 BAUD OR 4800 BAUD ONLY!. WHEN INSTALLING

SW7-6 BAUD RATE SELECT (20 mA OUTPUT)

ON -The weight information is continuously transmitted at the 4800 Baud rate.

OFF -The weight information is transmitted at the 300 Baud rate. Activation of the PRINT

pushbutton or remote print command is required.

SW7-7 MINIMUM PRINT

SW7-8 MINIMUM PRINT

The setting of SW7-7 and SW7-8 determines how many increments must be displayed before a print

may be made.

INCREMENTS SW7-7 SW7-8

OFF

OFF

ON

ON

ONE OF THESE RAMS, THE SWITCH SETTINGS ARE AS FOLLOWS.

OFF

ON

OFF

ON

RAMS 9 AND 19 ONLY

0

10

20

50

OFF

OFF

ON

ON

OFF

ON

OFF

ON

21

SW7-8 MINIMUM PRINT

ON -There must be at least 20 increments displayed before a transmission will occur.

OFF -No Minimum

SW7-9 DOUBLE WIDTH PRINT

ON -Normal print width selected.

OFF -The printer will print the GROSS or NET weight and symbol at twice the normal width.

(The weight printed at double width is the LAST weight field to be printed.)

NOTE: This function is NOT active for the 500, 510, 8810, 8820 or 8830 printers. This switch

must be ON when printing Gross, Tare, and Net on a single line.

4.4.3 CONTROL PCB JUMPER SETTINGS

W1 SYNC

W2 SYNC

IN -Line Sync (50 Hz or 60Hz as determined by local power.)

OUT -Internal Sync (217 Hz)

NOTE Both Line Sync jumpers, W1 and W2, must be set the same way. Either they are both in

or both are out!

W3 LOAD CELL EXCITATION REDUCTION

W4 LOAD CELL EXCITATION REDUCTION

IN -Load cell excitation reduced to ± 5V.

OUT -Normal mode, load cell excitation ± 7.5V.

W5 ANALOG OUTPUT

IN -Normal mode - Must be in place to allow output of filter to the A/D section.

OUT -Factory Test purposes only.

W6 THIS DESIGNATION IS NOT USED

22

W7 EXTERNAL ROM SELECT

IN -Normal operation.

OUT -Factory Test purposes only.

Used in conjunction with TJ1 and TJ2.

W8 COMMON MODE

Jumper between Pins 1 and 2

Common mode enable

Use this setup except with Rams 10 and 20.

Jumper between Pins 2 and 3

Common mode disable

Use this setup with Rams 10 and 20.

W9 INTRINSIC SAFETY

W10 INTRINSIC SAFETY

IN -Intrinsic Safety. These pins must be shorted with Rams 10 and 20.

OUT -Normal Operation.

WARNING

With Rams 10 and 20 the following jumpers must be as stated for Intrinsically Safe

Operation.

W3, W4, W9, W10 and W11 must all be shorted from one pin to the other.

W8 must be from Pin 2 to Pin 3.

J1-1 LINEARITY (UNITS WITH ANALOG VERIFY OPTION ONLY)

J1-1 to J1-2 + Linearity correction.

J1-2 to J1-3 - Linearity correction.

Potentiometer R6 on the Analog Verify PCB is used, in conjunction this jumper, for fine

adjustment of linearity.

23

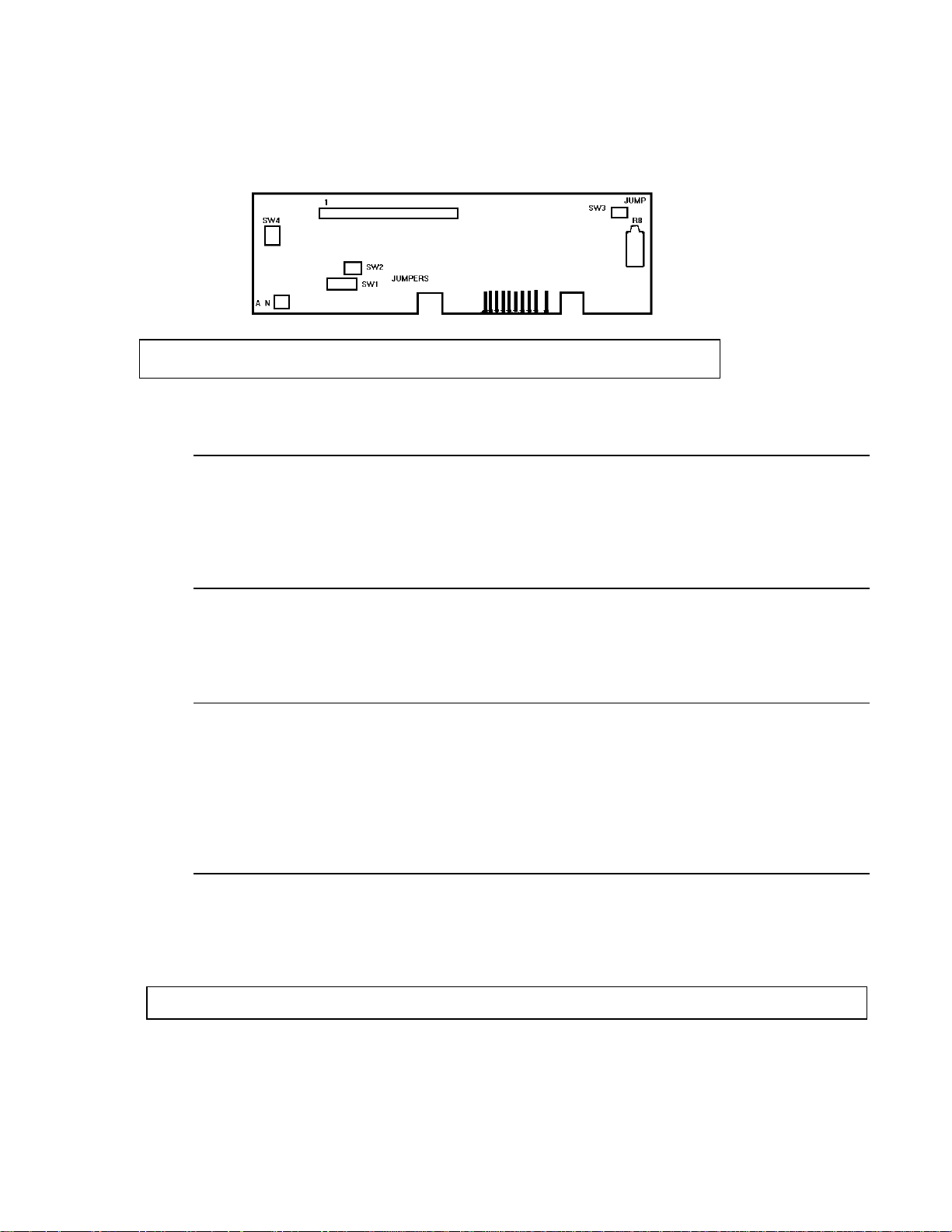

4.4.4 PARALLEL OUTPU T PCB/ANALOG OVER PCB JUMPER SETTINGS

These PCB's fit into J7 on the 8132 Main PCB.

A. Parallel I/O PCB - Part Number 108614 00A.

NOTE: The PRINT pushbutton on the 8132 is ONT active when using the

parallel BCD option with a Model 500 or 510 Printer.

JUMPER SETTINGS

SW1 MOTION SYNC (PARALLEL OUTPUT PCB ONLY)

ON -Jumper between pins 1 and 2, sync pulse is enabled at all times.

OFF -Jumper between pins 2 and 3, sync pulse is disabled when scale motion is

detected.

SW2 PARITY (PARALLEL OUTPUT PCB ONLY)

ON -(Jumper Connected) Odd parity selected.

OFF -(Jumper Disconnected) Even parity selected.

SW3 ANALOG OVER (PARALLEL OUTPUT AND ANALOG OVER PCB).

ON -(Jumper Connected) An analog over signal is present at J22-43. The adjustment

for this signal is through the variable resistor R8 located on the Parallel Output

and Analog Over PCB's.

OFF -(Jumper Disconnected) No analog over signal available at J22-43.

SW4 DIGITAL OVER (PARALLEL OUTPUT PCB ONLY).

ON -(Jumper connected) A digital over signal is present at J22-43 when the indicator

reaches 105% of selected capacity.

OFF -(Jumper Disconnected) No digital over signal available J22-43.

NOTE: Do NOT attempt to have both SW3 and SW4 ON at the same time, as errors may occur.

Loading...

Loading...