Page 1

- Non-fouling insertion or submersion

- No wetted metal parts

- Excellent chemical resistance

- 0/4 to 20 mA outputs for

Conductivity & Temperature

- Four relays

- PID Control

THORNTON

Leading Pure Water Analytics

7100E

Inductive Conductivity System

Page 2

7100E Inductive Conductivity System

2

Features

Advantages at a glance. A striking feature of the Mettler-Toledo Thornton 7100E inductive conductivity transmitter is

its extremely wide measuring range of 0 - 2000 mS/cm. The unit also provides simultaneous readings of the measured value (conductivity, concentration or salinity) and temperature clearly portrayed in a well-arranged LC display, with

analog outputs for both. Status annunciators indicate the mode of operation. The AC/DC universal power capability

allows the transmitter to be connected to almost any power source.

Process safety - in the foreground. SensoCheck®continuously monitors the sender coil and wiring for short circuits,

and the receiver coil for any disruptions. GainCheck®allows a manual functional check of the transmitter at any time.

In addition, an installed background program carries out an independent, periodic check of all instrument functions. A

red LED in the front panel optically signals any alarm condition. A 22 mA alarm signal can be set in the event of a

malfunction.

Rapid connection and start-up. Plug-in terminals and front panel access allow rapid installation of sensors and output wiring. Instrument mounting configurations include wall, pipe or panel mounting. The robust plastic enclosure can

withstand the harshest process conditions with a rating of IP65, NEMA 4X.

Simple calibration. Calibration of the transmitter and sensor is carried out either through direct entry of the factory calibrated cell constant or through manual validation of the cell constant using a standard calibration solution.

Temperature may also be calibrated to provide more precise automatic temperature compensation of the measured

conductivity values.

Variety of process adaptions. The sensors can be inserted into a process pipe by means of a threaded bushing or

submerged using a support pipe and coupling.

PID proportional, integral, derivative control. Built in control enables complete loop autonomy where desired. Control

output is through relays based on pulse frequency for metering pumps or pulse duration for solenoid valves. Analog

outputs are still available for conductivity and temperature.

Applications

Semiconductor processes can be monitored with sensors of glass-filled PEEK or polypropylene and no wetted metal

parts. Process purity requirements are protected.

Waste water monitoring reliability is assured with non-fouling inductive sensors even at high conductivity and sus-

pended solids levels. Inductive sensors measure even in concentrated, zero-discharge applications.

Deionization Regeneration acid and base concentrations can be controlled reliably and accurately with inductive

conductivity measurement. Direct temperature-compensated, % by weight readout is provided for all chemicals used

for deionizer and softener regeneration.

Pharmaceutical clean-in-place (CIP) processes requiring control of chemical concentrations can use inductive

conductivity measurement. It can also be used to validate concentrations at the return end of the line and for waste

treatment.

Page 3

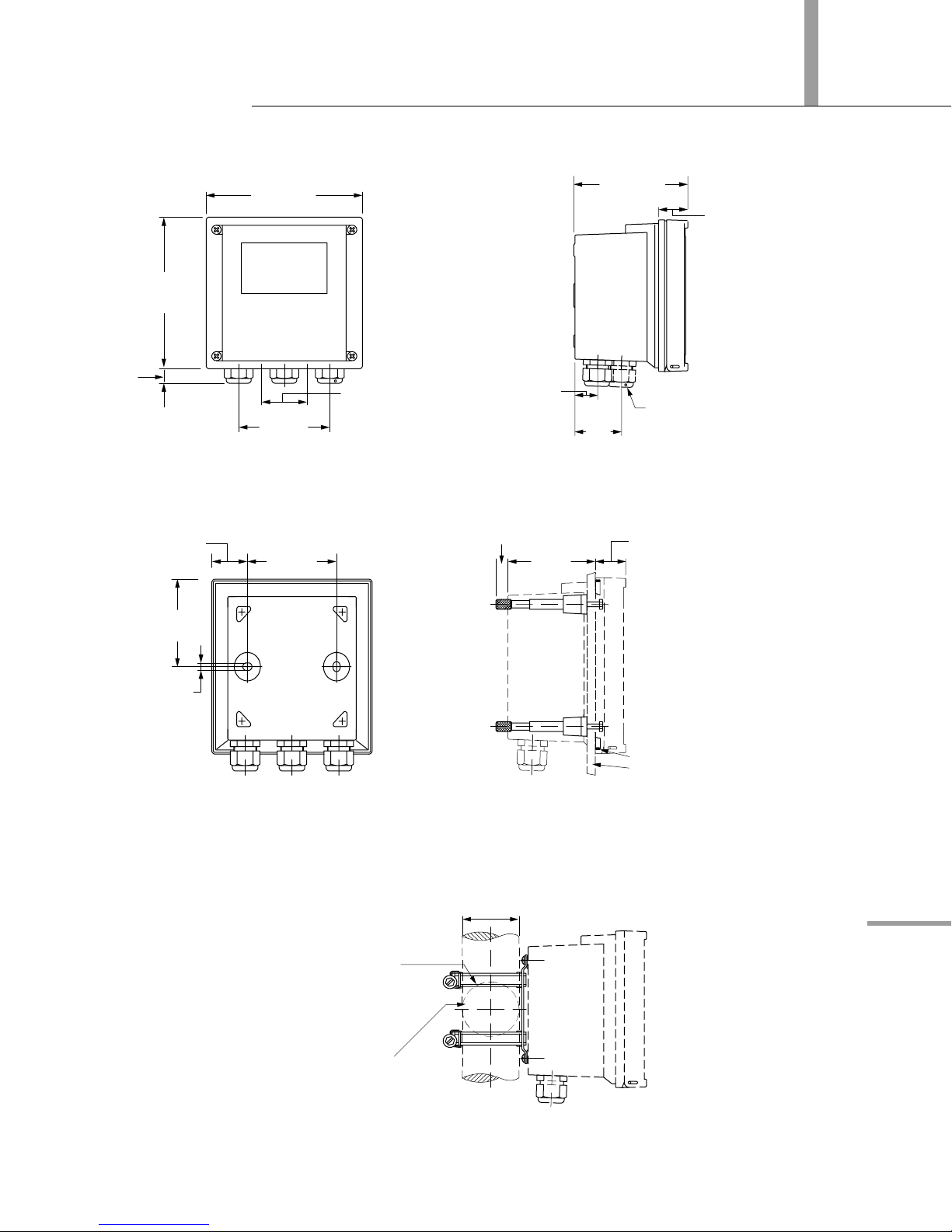

7100E Inductive Conductivity Transmitter Dimensions

3

3.15

(80 mm)

1.26

(32 mm)

0.24

(6.2 mm)

2.83

(72 mm)

Control panel cutout

5.433 x 5.433 (138 x 138 mm)

(DIN 43700)

Seal

Control panel 0.866 (1- 22 mm)

0.98

(25 mm)

1.06

(27 mm)

3.07

(78 mm)

Pg 13,5 (3 x)

0.55

(14 mm)

3.31

(84 mm)

1.65 (42 mm)

5.67

(144 mm)

5.67

(144 mm)

Pg 13,5 or conduit 1/2"

0.83

(21 mm)

1.69

(43 mm)

1.06

(27 mm)

4.13

(105 mm)

Hose clamp with

worm drive to DIN 3017

1-1/4 to 2" Pipe

φ 40 to φ 60 mm

For vertical or horizontal

posts or pipes

With 52 120 740 Panel Mounting Kit

With 52 120 741 Pipe Mounting Kit

Dimensions: Inches (mm)

Page 4

7100E Inductive Conductivity Transmitter Specifications

4

Conductivity input: Mettler-Toledo Thornton 720X Series inductive sensors

Conductivity ranges: 0.000 to 9.999 mS/cm -

00.00 to 99.99 mS/cm 0.000 to 9.999 S/m

000.0 to 999.9 mS/cm 00.00 to 99.99 S/m

0000 to 1999 mS/cm -

Concentration ranges: NaCI 0 to 26% (0 to 60 °C)

HCI 0 to 18% (-20 to 50 °C)

NaOH 0 to 14% (0 to 100 °C)

H

2SO4

0 to 30% (-17 to 110 °C)

HNO

3

0 to 30% (-20 to 50 °C)

H

2SO4

92 to 99% (-17 to 115 °C)

HCI 22 to 39% (-20 to 50 °C)

HNO

3

35 to 96% (-20 to 50 °C)

H

2SO4

32 to 84% (-17 to 115 °C)

NaOH 18 to 50% (0 to 100 °C)

Salinity range: 0.0 to 45.0% (0 to 35 °C)

Measurement error: < 1 % measuring range, ± 1 digit

Temp. Input: * Pt100 / Pt1000 / NTC 100 kΩ

Measuring range: Pt: -20 to +200 °C / -4 to +392 °FNTC: -20 to +130 °C / -4 to +266 °F

Resolution: 0.1 °C / 1 °F

Measurement error: ± 0.5 K; ± 1K with Pt100

Temp. compensation: Linear: 00.00 to 19.99 %/K (Reference temp. 25 °C)

Non-Linear: natural water to EN 27888 (0 to 35 °C)

Display: 3-1/2 digit liquid crystal display with alarm LED

Current outputs: * Two, 0 to 20 mA or 4 to 20 mA, max. 10 V, isolated, 22 mA for error message, can be

disabled; dedicated to conductivity and temperature

Current Characteristic: * Linear or logarithmic

Current error: <0.3 % of current value ± 0.05 mA

Start/end scale: * Selectable within the measurement range for mS, S, % by wt, salinity, temperature

Min. measurement span: Linear: 5% of selected measurement range; Logarithmic: 1 decade

*Configurable

Page 5

5

7100E Inductive Conductivity Transmitter Specifications

*Configurable

Cell factor range: 00.100 to 19.999

Monitoring of cell: Sensocheck

®

: monitoring of sender coil and leads for short circuits, and of the receiver

coil for disruption (can be disabled).

Relays: * 4 SPST relay switching contacts, isolated

- Relays 1 & 2 for limits, with adjustable NO/NC, hysteresis and delay

- Optionally, relays 1 & 2 for PID control

- Relay 3 for system alarm

- Relay 4 for sensor wash

Relay ratings: AC: <250 V / <3 A / <750 VA; DC: <30 V / <3 A / <90 W

PID process controller: * Output via relay contacts

Proportional action: Controller gain K

C

: 0010 ... 9999 %

Integral action: Reset time T

R

: 0000 ... 9999 S

Derivative action: Rate time T

D

: 0000 ... 9999 S

Controller type: Pulse length or pulse frequency controller

Pulse period: 0001 ... 0600 s, min. ON time 0.5 s (pulse length controller)

Max. pulse frequency: 0001 ... 0180 min

-1

(pulse frequency controller)

Power supply: 20 to 253 VAC/DC, AC: 45 to 65 Hz, approx. 5 VA , 2.5 W Overvoltage category II;

Protection class II

Ambient conditions: Operating/ambient temperature -20 to +55 °C;

Transport and storage temperature -20 to +70 °C

Relative humidity 10 to 95% non-condensing

Enclosure: Polymer case, PBTP (polybutyleneterephthalate)

Installation: - Wall-mounting hardware, standard

- Pipe/bracket for 1-1/4 to 2” pipe, φ 40 to 60 mm, with kit ordered separately

- Control panel, cutout to DIN 43700, with kit ordered separately

Dimensions: 144 x 144 x 105 mm (5.67 x 5.67 x 4.13 in.)

Protection: IP 65, NEMA 4X

Cable entry: 5 ports for cable glands M20 x 1.5 or 1/2” conduit

Weight: Approx. 1 kg (0.5lb)

FM/CSA: NI, Class I, Div 2, Group A, B, C, D; T4

EMC: EN 61326

EN 61326/A1

EN 61000-4-5, Installation Class 2

Description Part No.

Inductive Conductivity Transmitter with wall mounting hardware 7100E

Panel Mounting Kit for 7100E 52 120 740

Pipe Mounting Kit for 7100E (1-1/4” to 2” Pipe) 52 120 741

Page 6

7100E Inductive Conductivity Sensors

6

Features

- Chemically resistant PEEK (polyetheretherketone) or polypropylene

- No metal wetted parts

- High-Temperature to 200 °C (392 °F)

- Wide measuring range to 2000 mS/cm

- Unaffected by severe fouling

- Simple installation of sensors and accessories

- Variety of process insertion fittings

- Submersion installation for wastewater treatment

- Robust sensor design for maintenance-free operation

- Integrated temperature probe for direct temperature compensation

Operation

The inductive conductivity sensor consists of two high-grade toroids (coils)

which are incorporated concentrically and adjacent to one another in a

polymer body. These coils form a current transformer. The sensor is

designed so part of the liquid media forms a closed conductive current path

passing through the toroids. The primary coil is activated with a sinusoidal

alternating voltage, which induces an alternating voltage in the liquid loop

(sample medium). In liquids which conduct electricity, this causes a current flow which is proportional to the conductivity of the sample medium.

The liquid loop is also acting as the primary winding of the secondary coil

which functions as a current transformer. This current is rectified to the correct phase and amplified. If the toroid of the sensor is mounted in a relatively small (<3”) pipe, the field around the toroid, and therefore the effective

cell factor, will be influenced. In that case, calibration in the pipe is needed

to achieve rated accuracy.

6 m Cable

Locknut

Bushing

4.72

(120 mm)

2" Tri-Clamp

4.55

(115.6 mm)

3/4" NPT Thread

1.42

(36 mm)

2.00

(51 mm)

4.72

(120 mm)

0.52

(13.1 mm)

0.83

(21 mm)

For Submersion

With 52 401 950

Insertion Bushing

With 53 600 066

Tri-Clamp Adapter

Page 7

7

7100E Inductive Conductivity Sensors & Accessories

1) A combination of high pressure, high temperature and/or an aggressive process medium can reduce sensor life.

2) Insertion adapters are available.

Insertion Adapters

7200 Series Sensors

Measuring range: 0 to 2000 mS/cm

Cell Factor: 2.15

Installation

2:

3/4” NPT thread

Cable length: 6 m (20 ft)

Weight: 0.9 kg (2 lb.)

Require user-supplied junction box with 7 terminals

Extension Cables

EPR

EPR

EPR

7200

7201

7202

Polyolefin

PTFE

Polyolefin

NTC 100k Ω

Pt 100

Pt 100

PEEK, glass-filled

PEEK, glass-filled

Polypropylene

Description Temperature Pressure

-5 to +120 °C (23-248 °F)

17.5 bar (250 psi)

-5 to +200 °C (23-392 °F)

17.5 bar (250 psi)

-5 to +200 °C (23-392 °F)

17.5 bar (250 psi)

Temp SensorCable JacketSeal Part No.

Although bushings allow installation through smaller ports, if the toroid itself is in a pipe size smaller

than 3”, then in-place calibration is recommended to accommodate “wall effects” on the cell factor.

52 401 948

52 401 950

53 600 066

Threaded bushing 1-1/2” NPT

Threaded bushing 2” NPT

2” Tri-Clamp Adapter

Description Material

PVDF

PVDF

316L SS

Part No.

10 m (33 ft)

20 m (65 ft)

52 300 221

52 300 223

Part No.Length

Page 8

www.thorntoninc.com

For the most current product information visit:

email: info@thorntoninc.com

www.thorntoninc.com

ML0080 Rev.B 09/03

Mettler-Toledo Thornton, Inc.

36 Middlesex Turnpike

Bedford, MA 01730 USA

Telephone: +1-781-301-8600

Toll-Free: 1-800-510-PURE

Customer/Technical Service

Telephone: +1-781-301-8690

Toll-Free: 1-800-642-4418

Cust Service Fax: +1-781-271-0214

Tech Service Fax: +1-781-271-0675

Mettler-Toledo Thornton, Inc. – Subject to Technical Changes

Thornton 7100E Inductive Conductivity System

ISO

9001

certified

APPROVED

FM

Loading...

Loading...