Page 1

Smart Camera (SMC) Series 3 - Hardware

Document Version B

User Manual

Page 2

Intentionally left blank

2 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 3

1 Introduction

1.1 Intended Use

The SMART CAMERA is suitable for inspecting the readability of:

Identification number, lot number, proof of origin, expiry date and variable print on labels, cartons, films

and other printed items.

The optical character reading monitors the most important errors of:

Stamp, hot stamp block, photo plate, thermal transfer, laser or inkjet printers, that render the print

unreadable or result in incorrect recognition, for example:

Reversed characters; blurred characters; worn characters; merged characters or missing character(s).

Typical applications for optical character verification are on:

Brochures, labels, vignettes, cartons, tubes and tins.

Any other use or use that exceeds the aforementioned scope is not in compliance with the intended use. The

manufacturer/supplier is not liable for any damage arising from misuse. Risk is borne solely by the user.

CAUTION

If the smart camera is not used correctly, reliable operation of the system cannot be

guaranteed. The operator of the image processing system is liable for any personal injury

and damage to property caused by incorrect use, not the manufacturer.

1.2 Additional Documents

The table shows which further documents for smart cameras are available.

Further Documents

OCV/OCR and Code Reader Software Manual Describes the functionally and handling of the

camera software which is running on the camera.

JDatatrans Software Manual Describes the functionally and handling of the

service tool JDatatrans which is running on a PC.

SMC-Series Datasheet The datasheet for SMC cameras shows properties of

cameras in compact form.

CE Certificate CE Certificate of Conformity

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 3 / 34

Page 4

2 Safety Notes

Important Safety Note

Read and understand all the safety notes in the following sections as well as

the safety messages in the rest of this manual.

If you do not follow the safety notes and messages, this may lead to property damage

and personal injury up to and including death.

2.1 Safety Labels and Notice Labels

The ISO3864 safety labels are installed at potentially hazardous areas on the equipment. They give special

safety-related notifications. The locations of these labels are given in the drawings supplied with your

equipment. There are three types of safety labels:

• Hazard notifications

• Mandatory procedures

• Prohibitive procedures

Additionally, NOTICE labels may appear on your equipment.

The meanings of the different kinds of labels are explained in the following sections.

Before you transport, install, operate or work on the equipment, find out about the location and meanings of

the labels. Maintain the labels so that they are clear of obstructions and are readable. Do not remove any

labels. Replace any label that is no longer readable.

2.1.1 Hazard Notifications

A hazard notification consists of the following:

• Hazard alert symbol (yellow triangle with black symbol)

• Signal word (DANGER , WARNING , or CAUTION )

• Special notifications related to the hazard (as required)

The signal word labels are attached next to the hazard alert symbol labels on the equipment.

2.1.1.1 Definitions of Signal Words

Signal words describe the level of risk of a particular hazard. The color of the safety label background

indicates the risk, as shown in the following table. The definitions of the signal words are based upon the

ISO3864 definitions..

DANGER (red): This signal word indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING (orange): This signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION (yellow): This signal word indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate injury.

2.1.1.2 Meaning of Hazard Alert Symbols

The following hazard alert symbols may be installed on your equipment.

UV light

Optical radiation

4 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 5

2.1.2 Notice

The word NOTICE does not give safety information. It is still an important word to inform you of activities

that may harm the equipment or other property. The following definition is based upon the ANSIZ535

definition.

NOTICE (blue): This word indicates important information that is not related to

personal injury which, if ignored, could result in damage to the equipment, damage

to property, malfunctions, erroneous results, or loss of data.

2.2 General Protective Procedures

Important Safety Note

Make sure that all personnel who work on or near the equipment are capable

of performing all operations in a safe manner.

• Keep the manual in a convenient location near the equipment. Replace the manual if it becomes lost or

damaged.

• Wear Personal Protective Equipment (PPE) in accordance with your plant's safety procedures.

• Understand the hazards of the equipment and the risks related to those hazards before working on or

near the equipment.

• Obey all safety procedures of the local plant.

• Do not wear loose clothing, jewelry, long hair, or anything that can become entangled with the

equipment.

• Be careful around the equipment to avoid hitting your head, arms, or other body parts against the

equipment. Be careful if the equipment is over your head.

• Be careful not to trip over cables or other parts of the equipment.

• Do not move quickly in the area around the equipment.

• Do not climb, hang onto, or use any of the part of the equipment as a support.

• Obey the lockout tagout (LOTO) procedures of the plant.

• If there is a safety-related malfunction when you are operating the equipment, press the emergency stop

device. Tell the responsible supervisor, and follow the applicable steps approved by your company to fix

the malfunction.

2.3 Safety Notes for Various Activities

Important Safety Note

Read and understand all parts of the manual before using or working on any

equipment.

The following sections list safety notes for particular activities or groups of activities. Refer to the correct

sections in the manual for more detailed instructions.

2.3.1 Transporting and Moving the Equipment

• Only transport or move the equipment if you have the applicable training as defined by your company.

• Your company has sole responsibility for the safe moving and transporting of the equipment.

• Use safe moving procedures during transporting to maintain stability and to prevent the equipment from

tipping or falling.

• Disconnect the electrical supply, the pneumatic supply, and the communication cables before you move

the equipment.

• Use the correct lifting devices. If you use a forklift, lift the equipment at the correct lift points as shown by

the blue lift point labels.

• Blue lift point labels are placed on the equipment to show recommended locations for lifting. These lift

point locations were tested with the manufacturer's forklift trucks. A qualified rigger must make sure that

the lift points are correct for your lifting equipment.

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 5 / 34

Page 6

• When you lift the equipment by hand, obey the safe lifting procedures of your company.

2.3.2 Installing

Only install the equipment if you have the applicable training as defined by your company.

2.3.3 Operating the Equipment and Monitoring the Inspection Process

• Before beginning operation, make sure that the area is safe.

• Know the location and effect of each emergency stop button that controls the equipment.

• Do not operate the equipment without protective guards and doors in place.

• Make sure the safety circuit is working correctly.

• Do regular inspections of the equipment.

• If there is a fault or change in the equipment behavior, stop the equipment and inform responsible

personnel.

2.3.4 Testing and Verifying the Equipment

Only do testing and verifying of the equipment if you have applicable training as defined by your company.

2.3.5 Maintaining, Cleaning and Sanitizing the Equipment

• Remove all power from the equipment before doing any work.

• Keep the equipment in good working order.

• Follow a preventative maintenance program.

• Replace parts when needed.

• Obey the lockout tagout (LOTO) procedures of the plant.

• Test (validate) the safety circuit after parts are replaced.

• Only use METTLER TOLEDO approved spare parts and accessories.

• Do not make any unauthorized modifications to the equipment.

• Replace safety labels if damaged, missing, or unreadable.

• Do a visual check of the equipment at least once during a shift to identify any visual damage or faults.

Report any equipment changes to the responsible supervisor immediately.

• When required for a hygienic production environment, do regular sanitizing of the equipment according

to your company's procedures.

• After cleaning or sanitizing, check all cables, connectors, and pneumatic hoses for leakage, loose

connections, rub marks and damage. Tighten, repair, or replace any faulty cables and air tubing, as

necessary.

2.4 Special Hazards

The following sections describe special instructions for equipment that may have special hazards.

2.4.1 Strobe Lights

• Strobe lights can cause seizures in individuals with photosensitive epilepsy.

• Individuals with photosensitive epilepsy must not operate the equipment.

• Do not operate the equipment when excessively fatigued or after consuming alcohol.

• Do not look directly at the lights, especially at close distances.

• Avoid placing the equipment in areas with reduced lighting.

• If lights are inside of an enclosure, do not open the enclosure doors when lights are flashing.

2.4.2 Lights and Laser Sensors

• Do not stare directly at any lights or lasers.

• Avoid prolonged exposure to ultraviolet (UV) light, infrared (IR) light, and lasers.

6 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 7

3 Equipment Overview

3.1 Equipment Components

The smart camera consists of an intelligent camera with integrated signal processor and software which is

able to control different characteristics. Further, the camera hardware contains a memory, network interface,

an optical component and illumination. The illumination is integrated into the camera and external illuminations can be mounted additionally around the camera.

3.1.1 Housing

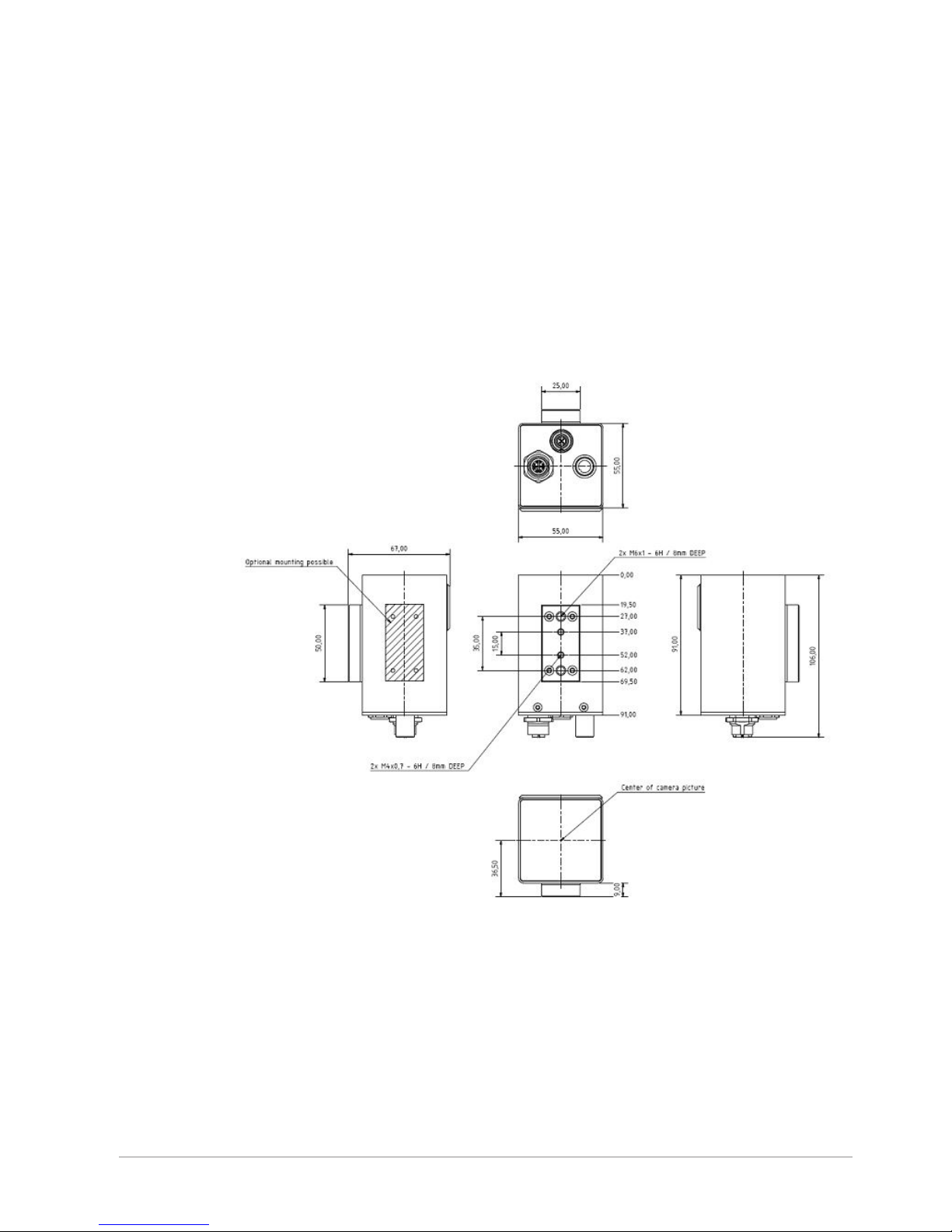

3.1.1.1 Dimensions of Housing Size 21

The image shows the dimension of housing “Size 21”. The image also shows the dimensions of the plastic

mounting block and the positions of the mounting threads 2x M4 with a distance of 15mm and the 2x M6

with a distance of 35mm. The plastic mounting block can also be placed optionally at one side of the

camera, as shown in the image. All dimensions are given in mm.

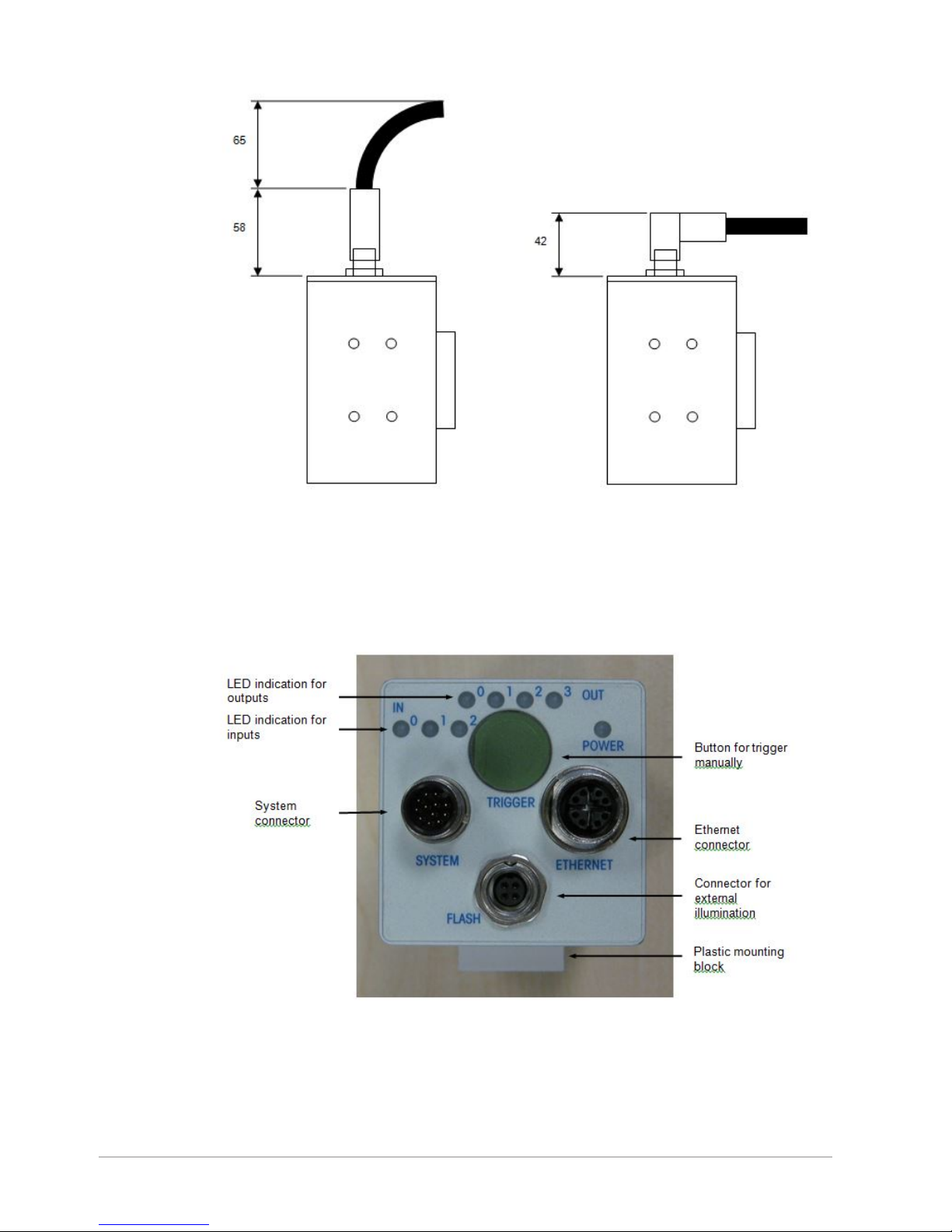

3.1.1.2 Dimensions with Cables and Connectors

The image shows the dimensions of the connectors and the recommended bending radius of cables. The

mounting direction of 90° connectors is only possible in one direction in relationship to housing, as shown

in the image.

All dimensions are given in mm.

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 7 / 34

Page 8

3.1.2 The Backend of the Camera

The following image shows the back side of the camera. The exact allocations are specified in the tables on

the following pages.

With the Push button in the camera’s rear panel, a camera trigger can be released. Thus, the camera starts

recording and evaluating a picture.

The LEDs in the rear panel indicate the input and output signals. The LEDs are arranged in lines. An LED

flashes, if the appropriate signal applies.

8 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 9

Description of the I/O LEDs:

Description Function

IN0 Camera trigger from PLC

IN1 Universal, function belongs to software settings

IN2 Reset signal from PLC

OUT0 Good signal

OUT1 Camera ready signal

OUT2 Second optional good signal

OUT3 Data valid signal

3.2 Accessories for the Camera

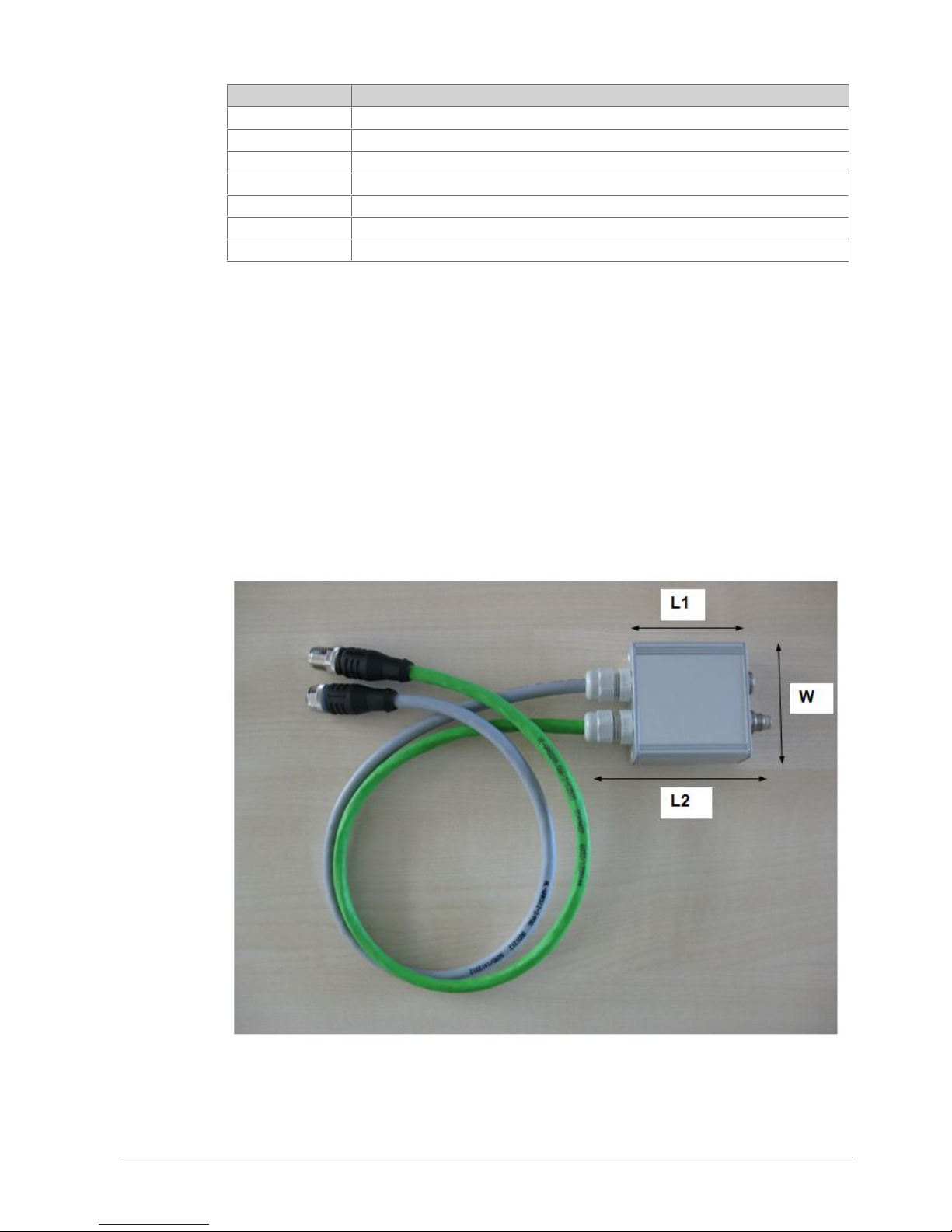

3.2.1 SMC 3 Adapter

The SMC 3 Adapter has been developed for the Smart Camera 3 series because wire assignment differs

between Smart Camera 1 series and Smart Camera 2 series. The adapter offers the possibility to connect an

SMC 3 camera to an existing system. The main use case of the SMC 3 adapter is to replace an SMC 1/

SMC 2 camera with an SMC 3 camera without replacing the SMC 1 / SMC 2 cables. Alternatively, you can

replace the cables and the Patch Panel 2 of SMC 1 / SMC 2 series with cables for Smart Camera 3 and

Patch Panel 3, without using the adapter.

On one side, the adapter has cables with plugs to connect the SMC 3 camera. The length of the cables is

about 0,5m. On the other side the adapter has sockets for plug-in cables for the SMC 1 / SMC 2 camera.

The adapter routes and crosses the wire assignment between SMC 1 / SMC 2 cables and SMC 3 cables to

get the correct wire assignment on both sides.

Dimensions of the SMC 3 Adapter with cables for the SMC 3 series

Dimension

Length, Width and Height: L1=54mm, W=55mm, H=24mm

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 9 / 34

Page 10

Length Including Pull Relief of Cables and Sockets

Length: L2=90mm

SMC 3 Adapter with mounted SMC 1 / SMC 2 cables.

Length Including Pull Relief of Cables and Connectors

Length: L3=120mm

The housing protection is IP54.

All other specifications of the adapter correspond to the camera specifications.

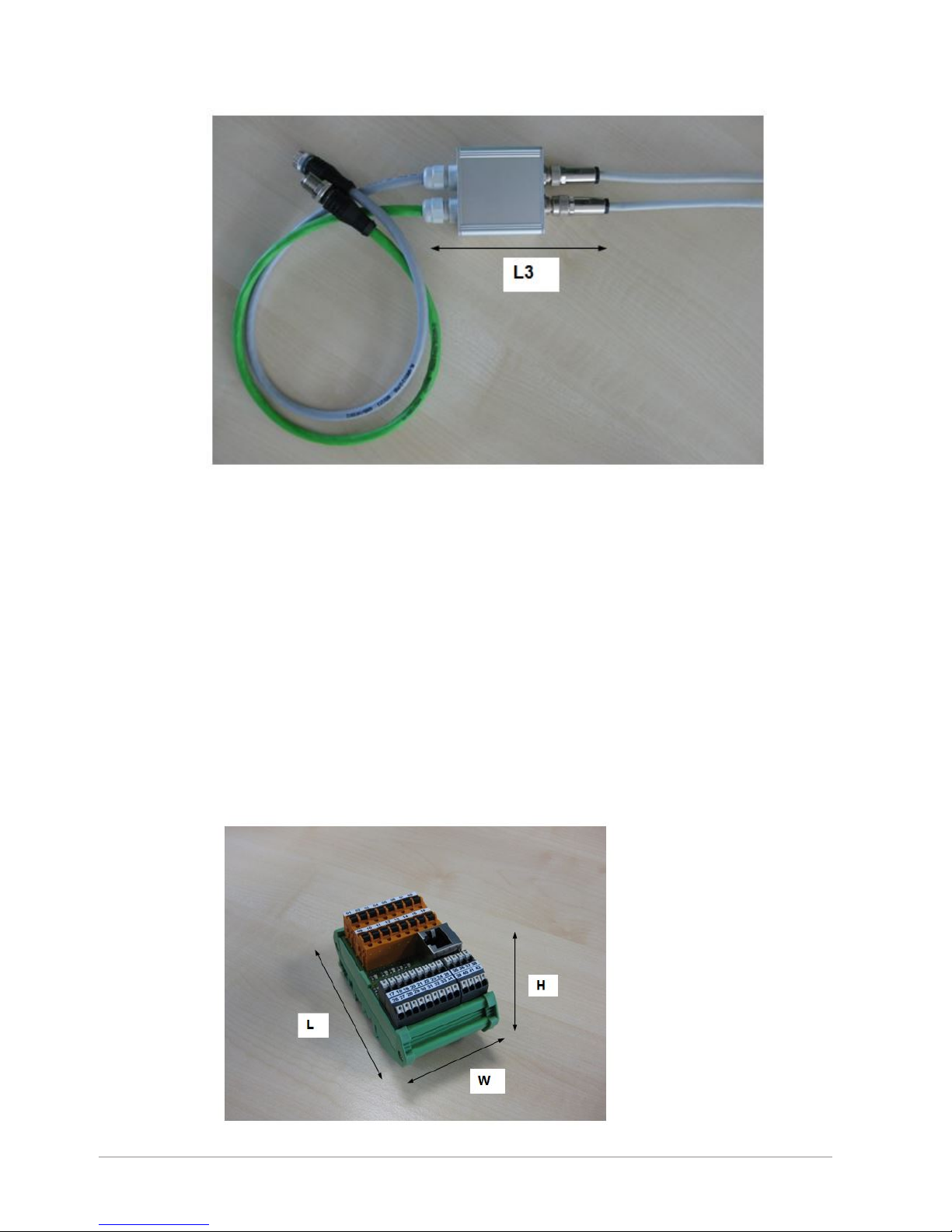

3.2.2 Patch Panel

3.2.2.1 Patch Panel Description

The Patch Panel 3.0 has been developed for the Smart Camera 3 Series. The Patch Panel is an easy

connection board for connecting cameras and scanners to a switching cabinet. Patch Panel 3.0 must be

used for Smart Camera 3 Series but is also compatible with Smart Camera 1 Series, Smart Camera 2 Series

and the comparison module VGL V7 and VGL V8 which will be used in combination with scanners.

Therefore Patch Panel 3.0 can be used in exchange for Patch Panel 1 and Patch Panel 2.

3.2.2.1.1 View and Dimensions

View and dimensions of Patch Panel 3.0 with printed circuit board L1173-0.

10 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 11

Side view on camera clamps.

Dimension

Length, Width and Height: L=90mm, W=52mm, H=54mm

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 11 / 34

Page 12

LED Display

The patch panel offers some LEDs to easy identify if a signal is present. If the signal has a high status,

normally 24V, the corresponding LED gives light.

The following signals are displayed:

3.2.2.1.2 Connectivity

Each camera is connected to a patch panel inside the switching cabinet.

During installation of the camera system the length of the camera cables can be adapted to the machine.

Standard wiring of a Smart Camera System.

3.2.2.2 Overview of Camera Types and Camera Series

The smart cameras series are also named SMC 1 (or only SMC), SMC 2 and SMC 3.

12 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 13

3.2.2.2.1 Camera Type No. of Camera 1 Series

Camera 1 series is used with patch panel 1 and can also be used with patch panel 3.0.

Smart Camera 1 Series - SMC 1

Smart Camera Type Resolution [Pixel] Status

200 640x480, B/W Replaced since 2013.10.29, by

type 205

202 1024x768, B/W Replaced since 2013.10.29, by

type 215

203 1024x768, B/W Replaced since 2013.10.29, by

type 215

204 1550x1200, B/W Replaced since 2013.10.29, by

type 215

220 640x480, Color Replaced since 2014.05.16, by

type 207

201 640x480, B/W Active

222 768x582, Color Active

223 1600x1200, Color Active

3.2.2.2.2 Camera Type No. of Camera 2 Series

Camera 2 series is used with patch panel 2 and can also be used with patch panel 3.0.

Smart Camera 2 Series - SMC 2

Smart Camera Type Resolution [Pixel] Status

150 752x480, B/W Active

205 752x480, B/W Active

215 1600x1200, B/W Active

216 1600x1200, B/W Active

240 2048x2048, B/W Active

207 752x480, Color Active

217 1600x1200, Color Active

247 2048x2048, Color Active

3.2.2.2.3 Camera Type No. of Camera 3 Series

Smart Camera 3 Series - SMC 3

Smart Camera Type Resolution [Pixel] Status

320 1600x1200, B/W Active

3.2.2.3 Description of I/O and Interfaces of Camera Series

3.2.2.3.1 Camera 1 Series

The table shows a description of inputs, outputs and interfaces offered by smart camera 1 series:

Description Description, Function Notes

IN0 Camera trigger E.g. signal from trigger sensor or PLC

IN1 Manually trigger Signal of the pushbutton at camera backside or

external signal e.g. push button

IN2 Reset Signal Only necessary with good signal = latch mode E.g.

signal from push button or PLC

IN3 Not connected Not used by camera

OUT0 Good Signal E.g. signal to PLC

OUT1 Camera Ready Signal E.g. signal to PLC

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 13 / 34

Page 14

Description Description, Function Notes

OUT2 Second Good Signal Optional, control windows can be separated into two

groups E.g. signal to PLC

OUT3 Data Valid Signal or External

illumination On/Off

Usually used for Data Valid e.g. signal to PLC

OUT4 Not connected Not used by camera

OUT5 Not connected Not used by camera

OUT6 Not connected Not used by camera

TxD+ Ethernet – TxD 100 MBit/s Transmit signal of camera

TxD-

RxD+ Ethernet – RxD 100 MBit/s Receive signal of camera

RxD-

TxD RS-232 – TxD Transmit signal of camera

RxD RS-232 – RxD Receive signal of camera

3.2.2.3.2 Camera 2 Series

The table shows a description of inputs, outputs and interfaces offered by smart camera 2 series:

Description Description, Function Notes

IN0 Camera trigger E.g. signal from trigger sensor or PLC

IN1 Universal Function belongs to software settings

IN2 Reset Signal Only necessary with good signal = latch mode E.g.

signal from push button or PLC

IN3 Not connected Not used by camera

OUT0 Good Signal E.g. signal to PLC

OUT1 Camera Ready Signal E.g. signal to PLC

OUT2 Second Good Signal Optional, control windows can be separated into two

groups E.g. signal to PLC

OUT3 Data Valid Signal E.g. signal to PLC

OUT4 Universal Function belongs to software settings

OUT5 Universal Function belongs to software settings

OUT6 External illumination On/Off Can switch an external illumination On/Off

TxD+ Ethernet – TxD 100 MBit/s Transmit signal of camera

TxD-

RxD+ Ethernet – RxD 100 MBit/s Receive signal of camera

RxD-

3.2.2.3.3 Camera 3 Series

The table shows a description of inputs, outputs and interfaces offered by smart camera 3 series:

Description Description, Function Notes

IN0 Camera trigger E.g. signal from trigger sensor or PLC

IN1 Universal Function belongs to software settings

IN2 Reset Signal Only necessary with good signal = latch mode E.g.

signal from push button or PLC

IN3 Not connected Not used by camera

OUT0 Good Signal E.g. signal to PLC

OUT1 Camera Ready Signal E.g. signal to PLC

OUT2 Second Good Signal Optional, control windows can be separated into two

groups E.g. signal to PLC

OUT3 Data Valid Signal E.g. signal to PLC

OUT4 Not connected Not used by camera

14 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 15

Description Description, Function Notes

OUT5 Not connected Not used by camera

OUT6 Not connected Not used by camera

D1+, TxD+ Ethernet – TxD or Bi-directional 100/1000 MBit/s Transmit signal of camera

D1-, TxD-

D2+, RxD+ Ethernet – RxD or Bi-directional 100/1000 MBit/s Receive signal of camera

D2-, RxD-

D3+ Ethernet – Bi-directional 100/1000 MBit/s Bi-directional data signal of camera

D3-

D4+ Ethernet – Bi-directional 100/1000 MBit/s Bi-directional data signal of camera

D4-

TxD RS-232 – TxD Transmit signal of camera

RxD RS-232 – RxD Receive signal of camera

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 15 / 34

Page 16

3.2.2.4 Assigning Wires to Patch Panel Clamps

3.2.2.4.1 Overview of Patch Panel Clamps

The following image shows the assignment of clamps to the machine signals. You can use the machine

clamps to connect the inputs and outputs of the PLC or a trigger sensor or optocouplers and the power

supply.

Graphical top view on patch panel

The next chapters show the wire-to-clamp-assignments for connecting different cameras and comparator

boxes to the patch panel.

16 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 17

3.2.2.4.2 Clamp Assignment for SMC 1, VGL V7 and VGL V8

The follwoing tables show the Patch Panel 3.0-clamp-assignment for SMC 1 (SMC) and the clamp

assignment for comparator VGL V7 and VGL V8.

Power supply Input RS232 Interface Shield

Clamp

number

17 18 19 20 21 22 23 24 25

Clamp

function

+24V Minus In0 In1 In2 In3 RS232

TxD

RS232

RxD

Shield

Assignm

ent

cable

and wire

System

cable

whiteblue

System

cable

blue

System

cable

brown

I/O cable

brown

I/O cable

yellow

I/O cable

orange

I/O cable

blue

I/O cable

violet

System

cable

Output Shield

Clamp

number

26 27 28 29 30 31 32 33 34

Clamp

function

Out0 Out1 Out2 Out3 Out4 Out5 Out6 Not used Shield

Assignm

ent

cable

and wire

System

cable

whitebrown

I/O cable

black

I/O cable

green

I/O cable

red

- - - - I/O cable

Ethernet Interface

Clamp number 35 36 37 38

Clamp function TxD+

D1+

TxDD1-

RxD+

D2+

RxDD2-

Assignment cable

and wire

System cable

white-orange

System cable

orange

System cable

white-green

System cable

green

Ethernet Interface

Clamp number 39 40 41 42

Clamp function D3- D3+ D4+ D4-

Assignment cable

and wire

- - - -

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 17 / 34

Page 18

3.2.2.4.3 Clamp Assignment for SMC 2

The following tables show the Patch Panel 3.0-clamp-assignment for SMC 2.

Power supply Input RS232 Interface Shield

Clamp

number

17 18 19 20 21 22 23 24 25

Clamp

function

+24V Minus In0 In1 In2 In3 RS232

TxD

RS232

RxD

Shield

Assignm

ent

cable

and wire

System

cable

whiteblue

System

cable

blue

System

cable

brown

I/On

cable

brown

I/O cable

yellow

- - - System

cable

Output Shield

Clamp

number

26 27 28 29 30 31 32 33 34

Clamp

function

Out0 Out1 Out2 Out3 Out4 Out5 Out6 Not used Shield

Assignm

ent

cable

and wire

System

cable

whitebrown

I/O cable

black

I/O cable

green

I/O cable

red

I/O cable

blue

I/O cable

violet

I/O cable

orange

- I/O cable

Ethernet Interface

Clamp number 35 36 37 38

Clamp function TxD+

D1+

TxDD1-

RxD+

D2+

RxDD2-

Assignment cable

and wire

System cable

white-orange

System cable

orange

System cable

white-green

System cable

green

Ethernet Interface

Clamp number 39 40 41 42

Clamp function D3- D3+ D4+ D4-

Assignment cable

and wire

- - - -

18 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 19

3.2.2.4.4 Clamp Assignment for SMC 3

The following tables show the Patch Panel 3.0-clamp-assignment for SMC 3:

Power supply Input RS232 Interface Shield

Clamp

number

17 18 19 20 21 22 23 24 25

Clamp

function

+24V Minus In0 In1 In2 In3 RS232

TxD

RS232

RxD

Shield

Assignm

ent

cable

and wire

System

cable

brown

System

cable

blue

System

cable

white

System

cable

green

System

cable

pink

- System

cable

greypink

System

cable

red-blue

System

cable

Output Shield

Clamp

number

26 27 28 29 30 31 32 33 34

Clamp

function

Out0 Out1 Out2 Out3 Out4 Out5 Out6 Not used Shield

Assignm

ent

cable

and wire

System

cable

yellow

System

cable

black

System

cable

grey

System

cable

red

- - - System

cable

violet

Ethernet

cable

Ethernet Interface

Clamp number 35 36 37 38

Clamp function TxD+

D1+

TxDD1-

RxD+

D2+

RxDD2-

Assignment cable

and wire

Ethernet cable

white-orange

Ethernet cable

orange

Ethernet cable

white-green

Ethernet cable

green

Ethernet Interface

Clamp number 39 40 41 42

Clamp function D3- D3+ D4+ D4-

Assignment cable

and wire

Ethernet cable

white-blue

Ethernet cable

blue

Ethernet cable

white-brown

Ethernet cable

brown

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 19 / 34

Page 20

3.3 Assignment of Plugs and Cables

With the 12-pin-system-plug the camera is supplied with 24V and can be connected with input and output

signal to e.g. a PLC or to optocouplers. The camera establishes a connection to the network with the

Ethernet cable.

3.3.1 System Cable

The images below show the M12x1 female connector with “A” encoding of the system cable.

The cross section is 12x0,14mm² (AWG26). Protection rating is IP67.

View on the front side of female inserts.

The table shows the assignment and function of the system cable.

Pin No. Color Description Function Notes

1 Brown +24V Power supply

+24V

-

2 Blue GND Power supply

minus, GND

-

3 White IN0 Trigger signal Default: Trigger signal from trigger

sensor or PLC

Optional: -

4 Green IN1 Universal Default: No setting

Optional: Function belongs to software

settings

5 Pink IN2 Reset signal /

universal

Default: Reset of different camera stop

or error functions, e.g. signal from

push button or PLC.

Optional: Function belongs to software

settings

6 Yellow OUT0 Good signal Default: Good signal, e.g. signal for

PLC

Optional: -

7 Black OUT1 Ready signal Default: Ready signal, e.g. signal for

PLC

Optional: Function belongs to software

settings

20 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 21

Pin No. Color Description Function Notes

8 Grey Out2 Second good

signal

Default: Second good signal, e.g.

signal for PLC

Optional: Function belongs to software

settings

9 Red Out3 Data valid signal Default: Data valid signal, e.g. signal

for PLC

Optional: Function belongs to software

settings

10 Violet Not connected - -

11 Grey/Pink RS-232 RS-232 - TxD RS-232 interface, transmit signal of

camera

12 Red/Blue RS-232 RS-232 - RxD RS-232 interface, receive signal of

camera

3.3.2 Ethernet Cable

The images below show the M12x1 male connector with “X” encoding of the Ethernet cable.

The cross section is 4x2x0,14mm² (AWG26). Protection rating is IP67.

View on the front side of male inserts.

The table shows the assignment and function of the Ethernet cable.

Pin No. Color Description Function Notes

1 White (Orange) D1+, TxD+ Ethernet – TxD or

Bi-directional

10/100/1000Mbit

Ethernet network,

e.g. connected to

an Ethernet switch.

2 Orange D1-, TxD-

3 White (Green) D2+, RxD+ Ethernet – RxD or

Bi-directional

4 Green D2-, RxD-

5 White (Brown) D4+ Ethernet – Bi-direc-

tional

6 Brown D4-

7 White (Blue) D3+ Ethernet – Bi-direc-

tional

8 Blue D3-

3.3.3 Illumination Cable

The images below show the M9x0,5 male connector of the illumination cable.

The cross section is 3x0,25mm² (AWG24). Protection rating is IP67.

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 21 / 34

Page 22

Back side of male inserts

The table shows the assignment and function of the illumination cable.

Pin No. Color Description Function Notes

1 Not connected - - -

2 Green +24V Power supply

+24V

-

3 Brown Trigger Trigger signal Default: Trigger

signal from camera

to illumination

Optional: -

4 White GND Power supply

Minus, GND

-

22 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 23

4 Installation and Integration

4.1 Installing the Camera

To install your SMC 3 camera:

1 You can mount the camera in horizontal, vertical or any other position.

NOTICE

If the camera housing is mounted in rotated positions, also the image of camera is

rotated. Use the software settings to rotate the image back to horizontal.

2 Use the plastic block at the bottom of the camera to mount the camera with 2 x M4 or 2 x M6 screws.

3 Mount the camera in the correct distance to the object, e.g. 135 mm as default value.

NOTICE

The distances can differ depending on camera types or applications.

4 Check that the positive edge of the trigger signal is sent to the camera in the moment in which the print

of your product is in the middle of the camera's view field.

4.2 Mounting the Patch Panel in a Control Cabinet

The images show the stripping of the two camera cables, system cable and ethernet cable. The stripped

length of the cables should be short as possible.

The image shows the preparation of the system cable with the stripping length.

The image shows the preparation of the ethernet cable with the stripping length.

It is recommended to leave the aluminium foil about 35mm around the ethernet pairs and strip only about

35mm. The insulation of about 15mm prevents a division of the shielding. The length of about 15mm is a

good choice if the distance between screen bus bar (grounding bus bar) and patch panel is about 25mm.

If the distance exceeds 25mm, also the length of insulation should be longer than 15mm.

The image shows the patch panel on a mounting rail and a screen bus bar. Mount the shielding of cables

to a screen bus bar. Connect the screen bus bar to protected earth PE.

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 23 / 34

Page 24

The image shows an example for installation of Patch Panel 3.0 with camera cables (grey and green),

ethernet patch cable (white) and wiring of switching cabinet (blue) with power, inputs and outputs and

protecting earth wire (green/yellow).

4.3 Standard Network Address

The standard network address configuration is as follows:

Device Standard IP-Address

Panel PC with touch (e.g. VCU)

VCU 15,6” 2.0

192.168.100.200

24 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 25

Device Standard IP-Address

Smart Camera 192.168.100.215

Comparator box VGL V7 with scanner LAS1000 192.168.100.221

The standard subnet mask is 255.255.255.0 for all devices.

4.4 Example of Wiring a System

The following example consists of a control cabinet, a VCU (=a monitor with integrated PC), an Ethernet

switch, a smart camera, a patch panel and a PLC. The graphic shows the components and the wiring:

Wiring diagram example

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 25 / 34

Page 26

5 Operation

The camera is handled with a cable-bound network LAN (Local Area Network). A PC must be present in this

network for the operation of the camera. The PCE Line Manager and Inspection Manager are suitable

software, in order to operate the camera comfortably: Descriptive visualizations indicate the adjusting

options on the touch display and ensure comfortable operation by means of large-sized touch buttons.

The PC software (PLM, IM or SMC Client) offers all the necessary functions to handle the camera. The

screen shows e.g. buttons and a keyboard to send commands and characters. For mounting the camera

and for setting up the system, a live image can be displayed on the screen.

5.1 Optical Parameters

5.1.1 Orientation of Field of View to Camera Housing

The image shows the orientation of the field of view in relation to the camera housing.

5.1.2 Center of Image to Camera Housing

The image below shows the center of the camera image in relation to the camera housing.

All dimensions are given in mm.

26 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 27

5.1.3 Adjusting Focus and Aperture at the Lens

The image below shows the removed cap of the camera housing for lens adjustment. With the focus ring of

the ens, you can adjust the image for best sharpness of the image. Adjusting the focus is necessary if the

distance between the camera and the object changes. With the aperture ring you can adjust the brightness

of the image.

Adjusting focus and lens of the camera

By default, the reading distance of the camera is 135 mm; as a general rule, the reading distances are set

during the installation of the system. Adjust the image sharpness yourself, if you need different reading

distances for smaller letters or larger labels.

With the software parameter shutter value, you can set the main brightness of the image. Adjusting

the aperture is necessary to fine-tune the brightness of the camera image. For example, the adjustment is

necessary for barcode- and DM-Code grading to get valid results. Therefore, use a calibration card as

reference object in front of the camera.

To adjust the focus and aperture use available software functions. To see and evaluate the best sharpness

in the software, set the image transfer quality parameter to 1 and use the software zoom

functions to increase the image:

1 Increase the size of the displayed details either by turning on the Zoom mode in the Main menu and / or

by switching the image quality to 1 in Config. image transfer in the System parameter menu.

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 27 / 34

Page 28

2 Switch the camera to the Live image mode.

3 Adjust the distance between the object and the camera until the image displayed on the PLM screen is

the size that you want.

4 Turn the ring for the focal distance using a suitable tool such as a small pointed screwdriver until you

see a clear, sharp image on the screen.

5 Change the software parameter quality of image transfer back to the pre-set value of 2

and/ or turn off the Zoom mode.

NOTICE

Some cameras have an electronically adjustable lens. If the software detects the presence

of an electronically adjustable lens, it will display the buttons Focus and Autofocus in the

menu Optical Settings menu. If your camera provides an electronically adjustable lens,

make all the adjustments via the software using the Focus or Autofocus buttons and

sliders.

28 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 29

6 Maintenance

The device has been specially designed for industrial requirements. As a result, reliable operation is

guaranteed under the normal conditions existing in production plants, provided that trained personnel have

installed the device.

For perfect operation, it is necessary to clean the glass plate of the camera housing at regular intervals. For

cleaning, only use the cleaning cloths and agents intended specially for this purpose.

NOTE

The device itself has no mechanical wearing parts and therefore requires no

maintenance.

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 29 / 34

Page 30

7 Disposal

In conformance with the European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment. If you have any questions, please

contact the responsible authority or the distributor from which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

30 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 31

8 Technical Data

8.1 Technical Data Smart Camera 3.0

The following specifications apply to the Smart Camera 3 series.

Housing Aluminum,

Dimensions as example for camera type no. 320 and housing size 21:

LxWxH: 91 mm x 55 mm x 55 mm

Protection of housing IP65: dust-tight and protection against water jets. No ingress of dust. Water-

protected by a nozzle against enclosure from any direction.

Power supply 24V DC, min. 20V, max. 28V,

Current during start up: max. about 1A,

Current during operation: about 150mA

Image processing Internally, with special machine vision processor.

Inputs 3 inputs 24 V DC, max. 28V permanent, response threshold: High: about

>13V, Low: about <7V

Outputs 4 Outputs 24V DC, type PNP, max. 100mA permanent, max. 400mA peak

short-circuit-proof, protected against overload and protected against external

voltage

Interface Ethernet 100/1000 Mbit/s, LAN

Interface RS-232

Illumination White LEDs in flash operation

Standard lens (1) C-Mount, 12 mm focal length

Standard distance

between object and

camera housing (1)

135 mm

Standard visible area (1) LxW: 95 mm x 71 mm

Camera inclination angle 0-10 degrees in relation to vertical and product horizontal

Environmental

conditions at transport

and storage

-20°C (-4°F) to +80°C (+176°F),

Max. humidity 90%, non-condensing

Environmental

conditions at operation

0°C (+32°F) to +50°C (+122°F),

Max. humidity 80%, non-condensing

Weight 430g

(1) Other configurations are available.

8.2 Technical Data Patch Panel

The following specifications apply to the Patch Panel.

Dimensions

Length, Width and Height: L=90mm, W=52mm, H=54mm

Power supply +24V DC, approx. 10mA

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 31 / 34

Page 32

Orange clamps

Wiring inside the

switching cabinet

Screwdriver blade e.g. 0,6 x 3,5mm

Clamping range min. 0,12mm², AWG 26

Clamping range max. 2,5mm², AWG 12

Single solid wire min. 0,2mm², AWG 24

Single solid wire max. 2,5mm², AWG 12

Single flexible wire min. 0,2mm², AWG 24

Single flexible wire max. 2,5mm², AWG 12

Wire with plastic collar ferrule min. 0,14mm², AWG 25

Wire with plastic collar ferrule max. 2,0mm², AWG 14

Strip of insulation 10mm

Sleeve length of ferrule >= 8mm to 10mm

Black clamps

Wires of camera / VGL

Screwdriver blade e.g. 0,6 x 3,5mm

Clamping range min. 0,13mm², AWG 25

Clamping range max. 1,5mm², AWG 16

Single solid wire min. 0,2mm², AWG 24

Single solid wire max. 1,5mm², AWG 16

Single flexible wire min. 0,2mm², AWG 24

Single flexible wire max.1,5mm², AWG 16

Wire with plastic collar ferrule min. 0,14mm², AWG 25

Wire with plastic collar ferrule max. 0,75mm², AWG 18

Strip of insulation 8mm

Sleeve length of ferrule 8mm

Environmental

conditions at transport

and storage

-20°C (-4°F) to +80°C (176°F),

max. humidity 90%, non condensing

Environmental

conditions at operation

0°C (32°F) to +50°C (122°F),

max. humidity 80%, non condensing

Weight 90g

32 / 34 Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

Page 33

Intentionally left blank

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B 33 / 34

Page 34

Pharmacontrol Electronic GmbH

Gernsheimer Strasse 2

64673 Zwingenberg, Germany

Tel. +49 6251 8545-0

Fax +49 6251 8545-111

www.mt.com

Subject to technical changes.

© Pharmacontrol Electronic GmbH 04/2017

Smart Camera - SMC Series 3 - Hardware - User Manual - Document Version B

For more information

www.mt.com/pce

Loading...

Loading...