TABLE

OF

CONTENTS

Servicing

Information:

人

Drawings

Block

A/D

Diagram

Control

Logic

Timer/Display

P/S

-

R/F

Board

A/D

Control

Board

Timer/Display

P/S

-

R/F

Board

Diagram

Logic

Diagram

Schematic

Assembly

Board

Assembly

Assembly

7

2/92

254)

1R6:18

It

is

recommended

706

be

performed

technicians

for

the

this

device.

and

prompt

INTRODUCTION

that

all

at

the

factory

the

appropriate

and

efficient

servicing

where

equipment

repair

and

of

the

Sonicator

experienced

are

available

recalibration

of

Should

factory

guidance

component

parts

at

the

the

entire

This

maintenance

sufficient

to

function

and

the

devices

it

not

for

repair,

to

locate

level.

list

at

the

factory

unit

service

guidance

to

insure

in

performance

listed

Regulations).

The

preventive

procedures

qualified

electronic

This

thoroughly

If

there

in

the

Department

factory

in

as

much

provided

service

measurement

manual

before

is

any

accomplishment

at

with

an

detail

be

possible

this

manual

potential

Major

end

as a secondary

to

the

manual

accordance

components,

of

this

factory.

is

to

that

the

manual,

designed

qualified

Sonicator

with

standards

in

21

CFR

1050.10

and

corrective

herein

personnel

only

equipment.

should

be

read

attempting

doubt

as

to

of

repairs,

the

factory,

explanatory

as

possible.

the

or

to

return

offers

problems

should

alternative

to

service

applicable

for

ultrasound

(Code

maintenance

should

be

using

and

understood

any

servicing

correct

contact

return

note

describing

the

device

the

necessary

to

the

major

as

listed

to

in

be

repaired

returning

provide

technicians

706

continues

specifications

therapy

of

Federal

performed

the

recommended

procedures.

course

the

the

unit

the

of

Service

to

problem

to

the

the

by

action

the

SPECIFICATIONS

Input:

Frequency:

Pulse

Pulse

Temporal

Indication

APPLICATOR:

Ceramic:

Frequency:

Effective

120VAC

Repetition

+

1.0

MHz

Duration:

Peak/Average

Accuracy:

Barium

1.0

MHz + 5%

Radiating

10%,

60Hz,

+

Rate:

2

msec

+

maximum

100

20%

Titanate

Area

.5-amp

5%

Hz

+

+

20%

Intensity

for

(ERA):

20%

Ratio:

any

10

cm?

max.

5

reading

+

20%

+

20%

above

10%

of

the

Type:

Beam

TIMER:

Accuracy:

Maximum

W

W/cm?

CW

msec

ERA

Collimating

Non-uniformity

+0.5

+10%

+1.0

Treatment

-

watts

-

watts

-

continuous

-

milliseconds

Area

-

effective

Ratio:

minutes

for

minutes

5

to

for

10

for

Time:

ABBREVIATIONS

per

square

waveform

radiating

centimeter

6.0

max.

times

minutes

times

29

less

greater

minutes

area

than

than

A/D

Ρ/5

R/F

BNR

Coll

5

minutes

10

minutes

-

analog-to-digital

-

power

-

radio

-

beam

-

collinating

supply

frequency

nonuniformity

ratio

S/N

-

serial

number

MHz

-

megahertz

.

Servicing

qualified

.

This

attempting

.

Use

other

hazardous

.

Line

of

service

manual

of

controls,

than

supply

any service

those

exposure

when connected

power

.

Measure

connection

the

ground

.

Do

than a few

source

ring

not

the

jack

around

pin.

operate

seconds.

automatically

unloaded.

the

Sonicator

technicians

should

be

adjustments,

specified

voltages

to

the

during

ground

and

the

piezoelectric

Results

the

should

unit

The

terminate

PRECAUTIONS

ME

706

only.

read

and

understood

procedures.

or

performance

in

this

manual

to

ultrasonic

are

present

AC

disassembly.

resistance

the

line

with

Sonicator

ultrasonic

inside

outlet.

between

cord

disc

be

one

the

applicator

should

energy.

be

may

the

ME

Disconnect

the

plug

ground

and

the

ohm

or

less.

in

ME

706

is

power

when

performed

thoroughly

of

procedures

result

in

706

enclosure

the unit

auxiliary

pin

and

line

cord

free

air

for

designed

the

applicator

by

before

from

the

between

plug

more

to

is

.

Multimeter

.

Calibrated

.

Hipot

.

Leakage

.

Degassed

.

Dual

the

tested

requirement

tester.

channel

To

assure

Sonicator

annually.

TEST

with

AC/DC

ultrasound

current

water

tester.

(for

35MHz

MAINTENANCE

continued

ME

It

be

performed

EQUIPMENT

volts

power

the

power

oscilloscope.

compliance

706

should

is

recommended

at

REQUIRED

and

ohms

scales.

meter.

meter).

SCHEDULE

with

21

CFR

be

factory-calibrated

that

this

the

factory.

1050.10,

annual

FDA,

and

safety

maintenance

GENERAL:

The

Sonicator

ultrasound

four

printed

panel

control,

subassemblies.

the

end

therapy

circuit

membrane

and

inter/connections.

of

this

EQUIPMENT

ME

706

device

boards,

switch

Refer

manual.

to

DESCRIPTION

is a single

with a built-in

power

assembly,

the

appropriate

unit,

transformer

main

This

section

molded

plastic

applicator.

assembly,

power

drawings

switch,

briefly

describes

in

enclosed

It

consists

control

intensity

the

appendix

of

these

at

MAJOR

SUBASSEMBLIES:

P/S - R/F

circuits,

regulator,

timer

RFI

A/D

pulse

5-volt

Timer

logic,

meter

(CW

Buzzer Board - small

Control

clock

filters.

Control

oscillator,

regulated

Display

timer

selection

or

two

PULSE),

Applicator - an

piezoelectric

cable,

to

strain-relief

the

RF

generator

Board - contains

regulated

overload

reference,

Board - contains

power

power

12-volt

sensor,

AC

indicator

supply.

Board - contains

logic,

output

timer

indicators

power

pcb

containing

integrated

ceramic

disc

and

connector.

at

the

unit

display,

(W

on reset

in a molded

P/S - R/F

enclosure.

the

power

power

RF

power

input

the

the

or

consisting

supplies,

level

line

fuses,

analog-to-digital

scaling

timer

power

W/cm?),

indicator

and

overload

buzzer

of a glass-coated

plastic

It

is

connected

board

supply,

switching

sensor

and

input

converter,

adjustment,

keyboard

mode

signal

entry

display,

indicators

controller.

control

handle

directly

within

the

RF

circuit,

line

and

a

circuit.

with

OTHER

The

and

generator

COMPONENTS:

membrane

power

front

SUBASSEMBLY

All

subassemblies

connectors.

plugs

interlock

without

keys

switch,

transformer

housing.

CONNECTIONS:

are

interconnected

The

connectors

excessive

are

provided

intensity

are

all

mounted

control,

cannot

force,

or

where

on

with

be

connected

obvious

necessary.

power

and

cable

error.

switch

under

the

assemblies

to

the

wrong

Connector

and

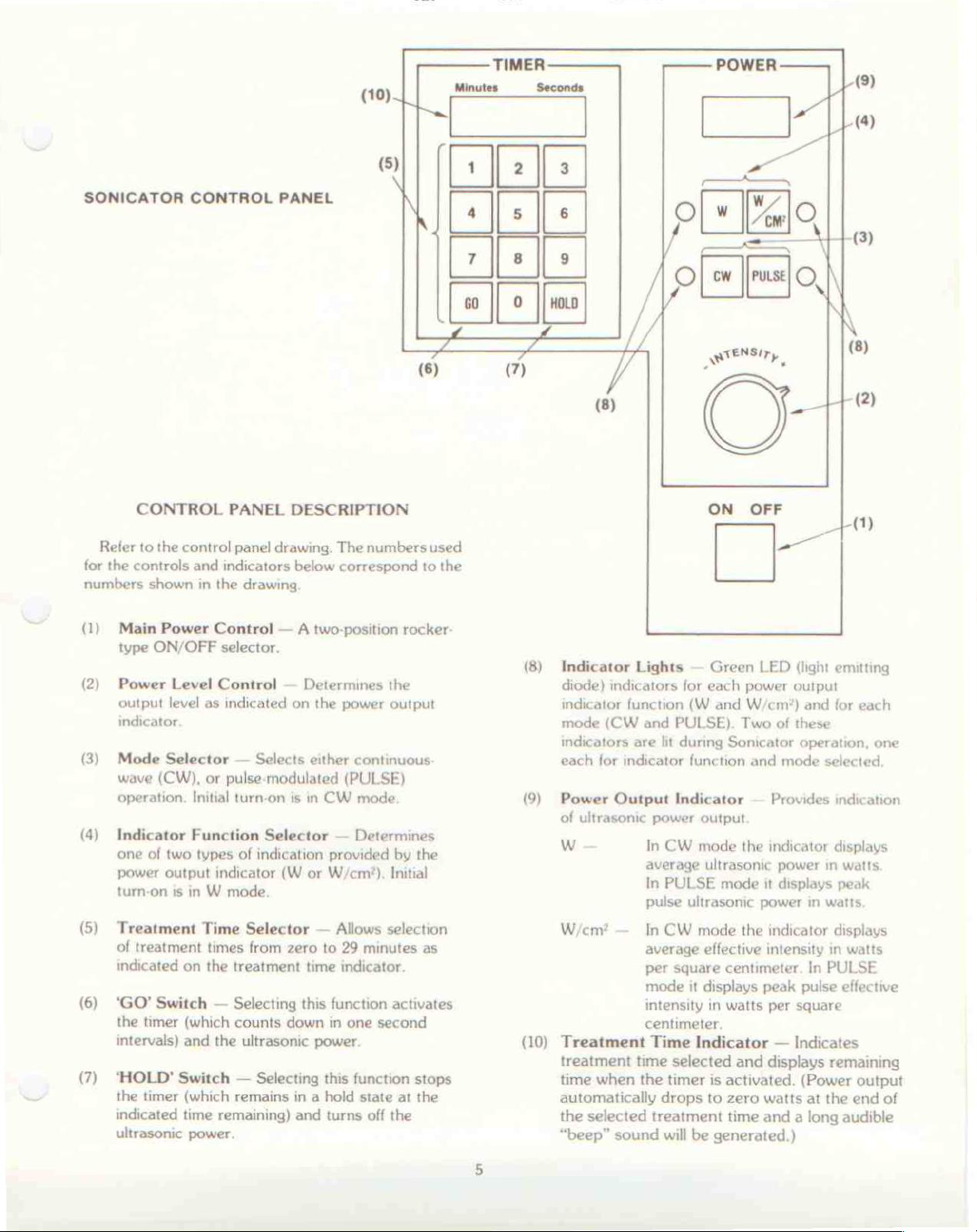

SONICATOR

CONTROL

PANEL

(10)

| 4

(>

(5)

Nile

Minutes

는

7

co

(6)

TIMER

Seconds

İzle

ls

o]

8 9

(|

O

(7)

ies

но

/

Ol

/

POWER

[n

w

ew

RENS,

o

<

м

WO

=

PMSE

.

A

À

n

Lo

=

(8)

©

(3)

CONTROL

Reler

to

the

for

the

controls

numbers shown

(1)

Main

Power

type

ON/OFF

(2)

Power

output

indicator.

(3)

Mode

wave

operation.

(4)

Indicator

one

power

turn-on

Level

level as

Selector — Selects

(CW),

of

two

output

is

PANEL

control

panel

and

indicators

in

the

Control — A

selector.

Control — Determines

indicated

or

pulse-modulated

Initial

turn-on

Function

types

of

A

indicator

+

in W mode.

DESCRIPTION

drawing.

below

drawing,

on

is

in

Selector — Determines

indication

(W

or

The

numbers

correspond

two-position

the

the

power

output

either

continuous-

(PULSE)

CW

mode

provided

W/cm?).

by

Initial

used

to

the

rocker-

the

2

(8)

(9)

(8)

Indicator

diode)

indicator

mode

indicators

each

Power

of

M

indicators

(CW

for

indicator

Output

ultrasonic

ON

Lights — Green

for

each

function

are

(W

and

and

PULSE).

lit

during

Indicator — Provides

power

In

CW

average

In

PULSE

pulse

Sonicator

function

output

mode

ultrasonic

mode

ultrasonic

OFF

LED

power

W/cm®*)

Two

of

and

mode

the

indicator

power

it

displays

power

ATO

+

ンー

(light

emitting

output

and

for

these

operation,

selected,

indication

displays

in

in

watts.

(1)

each

one

watts

peak

(5)

(6)

(7)

Treatment

of

treatment

indicated

‘GO’

the

timer

intervals)

‘HOLD’

the

timer

indicated

ultrasonic

Time

times

on

the

Switch — Selecting

(which

and

the

Switch — Selecting

(which

time

remaining)

power.

Selector — Allows

from

zero

to

29

treatment

counts

ultrasonic

remains

time

this

function

down

in

power.

this

in a hold

and

turns

indicator.

one

function

state

selection

minutes

activates

second

at

off

the

as

stops

the

W/cm?

(10)

Treatment

treatment

time

automatically

the

“beep”

—

In

average

per

mode

intensity

centimeter.

time

when

the

selected

sound

CW

mode

the

indicator

effective intensity

square

Time

selected

timer

drops

treatment

will

centimeter.

it

displays

in

Indicator — Indicates

is

to

be

generated.)

peak

watts

per

and

displays

activated.

zero

watts

time

and a long

displays

in

In

PULSE

pulse

square

remaining

(Power

at

the

watts

effective

output

end

of

audible

OPERATING

INSTRUCTIONS

Refer

to

operating

indicator

1.

Connect

60Hz

number

receptacle.

Energize

Enter

the

SELECTOR

a.

For

Example:

b.

For

Example:

c.İf

an

POWER

Select

by

pressing

the

control

procedures,

the

unit

the

unit

treatment

(5).

times

10

up

For 9 minutes,

to

29

For

incorrect

panel

for

shown

to

an

by

pressing

time

The

to 9 minutes,

minutes,

15

minutes,

time

CONTROL

continuous-wave

the

appropriate

drawing.

example

in

the

appropriately

(1),

drawing.

the

using

treatment

the

time

enter

enter

enter a ‘1’

enter a ‘1’

is

entered

(1)

and

reselect

(CW)

or

pulse-modulated

MODE

Numbers

indicate

grounded

MAIN

in

the

POWER

the

TREATMENT

must

‘0’

a ‘0’

or

accidentally,

be

entered

followed

then a ‘9’.

‘2’

followed

the a ‘5°.

by

cycle

the

desired

SELECTOR

following

control

120

VAC,

CONTROL

TIME

using

the

second

by

the

the

treatment

(PULSE)

(3)

function.

or

(1).

two

second

MAIN

mode

to

digits.

digit.

digit.

time.

the

left.

Select

the

desired

appropriate

(W

or

W/cm’).

Immerse

Press

power

a.

Treatment

pressing

the

the

‘GO’

output.

the

INDICATOR

b.

Restart

will

c.A

treatment

d.

If

the

applicator

time

Adjust

power

the

commence

buzzer

treatment

is

remaining.

the

POWER

output

INDICATOR

power

INDICATOR

ultrasound

applicator

SWITCH

time

(and

power

‘HOLD’

(10)

unit

will

by

pressing

SWITCH

indicate

countdown

automatically

time.

is

interrupted

head,

the

The

buzzer

output

LEVEL

level as

indicated

(9).

output

indication

FUNCTION

(6)

to

initiate

output)

(7).

the

the

from

sounds

at

due

will

sound

power

CONTROL

on

SELECTOR

head

treatment

can

The

time

‘GO’

the

time

the

to

to

will

the

POWER

by

pressing

in

water.

be

stopped

TREATMENT

remaining.

SWITCH

remaining.

end

of

the

lack

of

four

or

five

then

drop

(2)

to

the

OUTPUT

the

(4)

switch

time

and

by

(6).

The

selected

coupling

times

to

zero

desired

TIME

timer

at

the

indicating

watts.

that

GENERAL:

The

remainder

calibration

Sonicator

with

the

beginning

For

the

appropriate

manual.

procedures,

ME

descriptions

of

theory

drawings

SERVICING

of

706.

this

manual

of

operation

the

manual

and

The

technician

and

located

INFORMATION

contains

troubleshooting

should

operating

before

and

in

instructions

attempting

calibration

the

appendix

the

theory

guidelines

be

thoroughly

presented

to

service

sections,

at

the

of

operation,

for

the

familiar

at

the

device.

refer

to

end

of

this

the

the

THEORY

Timer

Power

OF

OPERATION

Display

programmed

entry

digits

timer

to

(as

output

Enable

the

timer

discussed

TREATMENT

timer,

SWITCH.

‘HOLD’

coupling

selected

the

treatment

The

SWITCH,

at

the

treatment

INDICATOR

timer,

the

approximately

treatment

the

power

output

panel

maintain

turned

timer

PULSE

the

and

‘GO’

SWITCH.

Supply

voltage

output

is

controlled

power

the

on

is

running

MODE

100

Hz

treatment,

time.

— A switching

to

adjustment

proper

by the

pulse

Circuits — The

by

the

front

circuit.

in

is

displayed

TIME

timer

INDICATOR.

is

can

or

applicator

time.

displays

The

two

seconds

the

RF

from

the

by a feedback

power

enable

and

the

the

power

frequency

panel

Time

the

operating

on

started

be

by

an

head,

The

the

remaining

can

then

timer

power

stage

unit.

with

level.

signal

unit

supply

membrane

must

the

front

After

by

pressing

stopped

overload

or

at

TREATMENT

be

resumed

activates

at

the

end

supply

which

The

in

power

comparing

an

RF

The

which

is

in

the

is

pulsed

by

the

enable

digital

be

timer

switch

entered

as

procedures).

panel

by

the

programming

the

‘GO’

by

pushing

due

to

the

end

the

of

the

lack

the

TIME

treatment

the

of

the

is

turn

supply

time.

by

pressing

buzzer

selected

used

to

controls

voltage

the

power

power

is

present

CW

monitor

supply

when

MODE.

on

and

signal.

is

signal

two

The

of

The

for

control

the

front

to

is

the

In

the

off

at

the

RF

Oscillator

circuit

output

coupling

from

to

which

voltage

the

be

compared

— The

RF

operates

is

present.

transformer

applicator

circuit

to a reference

oscillator

when

to

the

The

output

the

applicator. A feedback

is

fed

is a push-pull

switching

back

for

power

is

to

power

fed

the

output

transistor

supply

through

output

power

supply

control.

a

SERVICING

INFORMATION

When

and

fed

stops

tuned

maximum

the

to

Applicator

transmitted

shielded

connected

The

face

connected

shields

stainless

Power

Meter — The

squared

proportional

output

converter

The

meter

decimal

watts

or

the

applicator

back

to

enable

timer

the

— The

coaxial

electrode,

are

steel

in a squaring

is

converted

point

watts

and

piezoelectric

power

transfer.

RF

to

the

cable.

to

the silver

to

ground

connected

cup

to

the

which

function

in

position

per

is

unloaded

the

hold

power

output

piezoelectric

The

output.

ceramic

from

the

ceramic

center

electrode

transducer

through

to

the

used

to

analog

voltage

circuit

ultrasound

to a digital

turn

drives

controls

to

provide

square

cup,

the

face

mount

to

power

output

the

(W

centimeter.

the

overload

condition

The

RF

disc

frequency

RF

section

disc by a double-

wire

of

on

the

back

and

coax

ground

electrode

the

disc.

input

provide

to

an

output.

in

the

power

or

W/cm?)

an

output

is

sensed

which

oscillator

in

is

the

coax

of

the

shield

system.

through

the

RF

circuits

analog

The

A/D

meter

display.

enable

reading

turn

is

for

is

disc.

are

Both

the

is

voltage

analog

the

in

CALIBRATION

CAUTION:

1.

Place

Note:

2.

Connect

3.

Check

is

obtain

4.

Energize

Select

SELECTOR

the

Correct

required.

directions

reading,

applicator

source.

the

not

the

the

‘W’

applicator

the

the

PROCEDURES:

Calibration

nicians

equipment

voltage

AC

required

proper

and

familiar

and

present.

in

orientation

With

as

required

then

proceed

in

this

Sonicator

line

voltage

level,

line

Sonicator

‘CW’

on

and

MODE

should

the

the

be

performed

with

the

the

adjustment

ultrasound

of

the

applicator

power

on,

to

obtain

with

position.

to a 120VAC

with a multimeter.

an

autotransformer

voltage.

and

program

the

INDICATOR

SELECTOR

by

operation

of

equipment

power

tip

the

the

calibration

+

10%,

meter.

in

the

applicator

highest

60Hz

must

29

minutes

FUNCTION

respectively.

qualified

of

the

required

the

power

possible

keeping

line

If

the

line

be

on

the

tech-

with

meter

in

all

the

voltage

voltage

used

to

timer.

test

line

is

8

SERVICING

INFORMATION

Check

levels.

the

Low

Desired

High

With

the

If

the

Sonicator

Level

Level

Level

AC

power

Reconnect

HIGH

Repeat

Adjust

as

obtain

is

meter

POWER

VOLTAGES

step

the

indicated

20

located

should

LEVEL

Sonicator

measured

indicated

4W

5W

6W

disconnected,

the

Sonicator

4.

Sonicator

on

the

watts

on

on

the

A/D

also

CONTROL

indicate

output

values

values

“8W

10W

“12W

to

ARE

PRESENT

POWER

ultrasound

the

POWER

Control

20

at

the

are

more

proceed

12W

15W

18W

remove

the

line

LEVEL

power

OUTPUT

Board.)

watts.

as

necessary.

5,

10, 15,

than

to

16W

20W

24W

the

source.

INSIDE

CONTROL

meter.

The

Readjust

and

20

watt

20%

different

recalibrate

back

cover.

(CAUTION:

THE

UNIT.)

to

Adjust

INDICATOR.

ultrasound

the

R109

Sonicator

the

20

watts

(R109

power

from

unit.

LIVE

to

10.

Adjust

watts

(P/S — R/F

INDICATOR.

11.

Return

indication

between

step 5 are

12.

Adjust

on

observe

OUTPUT

Select

13.

the

14.

Select

INDICATOR

power

the

as

the

the

POWER

‘W’

POWER

PULSE

meter

front

panel

indicated

Board)

to

step 9 and

is

correct

steps 9 and

satisfied,

Sonicator

OUTPUT

that

the

W/cm?

INDICATOR

and

observe

OUTPUT

MODE

reads

reads

POWER

on

the

ultrasound

for

10

readjust

at

both

10 as

proceed

POWER

indicator

reads

that

INDICATOR

and

approximately

approximately 4 watts.

LEVEL

watts

on

as

necessary

levels

needed.

with

the

the

(10

When

LEVEL

INDICATOR.

lights

2.0

W/cm?.

the

‘W’

indicator

observe

that

20

CONTROL

power

and

following

CONTROL

reads

watts

meter. Adjust

POWER

20

the

Select

and

until

the

watts).

checks

steps.

W/cm?

that

OUTPUT

the

lights

20

watts.

the

POWER

and

the

for

10

R37

Sonicator

Alternate

listed

for

POWER

and

20

watts

and

that

in

OUTPUT

ultrasound

15.

Select

meter

CW

MODE

reading

and

changes

observe

to

20

watts, + 20%.

9

that

the

ultrasound

power

16.

Install

the

SERVICING

back

housing

INFORMATION

and

four

rubber

feet.

17. A safety

high

voltage

Calibration

FUSE

the

in

housing.

against

be

REPLACEMENT:

Two

line

fuses

P/S — R/F

the

appendix).

Use

fire

hazard.

If

it

becomes

recalibrated

manual.

CLEANING:

To

clean

generator

damp

not

warranted

soft

the

housing

cloth.

check

for

breakdown

is

complete.

are

used

Board

Fuse

only

1/2-amp,

necessary

using

the

molded

or

applicator

Use

of

or

recommended.

ground

(see

resistance,

is

recommended.

in

the

Sonicator.

the

P/S — R/F

replacement

“slo-blo”

to

replace

procedures

plastic

any

enclosure

handle,

other

requires

fuses

for

the

line

presented

of

use a mild

cleaning

leakage

They

Board

current,

are

assembly

removal

replacement

fuses,

the

agents

the

in

this

Sonicator

detergent

or

and

located

drawing

of

the

back

to

protect

unit

must

service

ME

with

solvents

on

706

a

is

10

TROUBLESHOOTING

GUIDE

SYMPTOM

Will

not

turn

Upon

indicates

Will

‘GO’

unit.

‘HOLD

Timer

turn-on,

EE.EE.

not

accept

will

not

will

display

on.

timer

timer

activate

not

activate.

does

not

display

input.

the

light.

POSSIBLE

Check

cord,

fuses

CAUSE/ACTION

input

power

and

SWITCH.

Replace

Check

connections,

Timer/Display

the

membrane

Timer/Display

and P/S — R/F

Check

board

Display

Same

Check

Timer/Display

P/S — R/F

the

membrane

connections,

board.

as

4.

inter-board

board

supply,

the

MAIN

board.

switch

board

12V

switch,

and

the

connections,

board,

12V

and

supply.

power

POWER

and

board,

supply.

inter-

Timer/

the

Buzzer

the

Will

CW/PULSE

indicating.

10.

Will

W/cm?.

11,

W

or

indicating.

12.

Power

13.

No

will

end

of

treatment

not

change

not

change W to

W/cm?

meter

output

power.

not

operate

mode.

display

display

will

not

at

time.

not

not

light.

Check

the

buzzer,

Timer/Display

P/S — R/F

Check

board

Display

Same

Same

Same

as

as

as

Check

P/S — R/F

connections.

Check

‘GO’

SWITCH,

and

Timer/Display

board

the

membrane

connections,

board.

8.

8.

8.

Timer/Display

board,

the

applicator

buzzer

board,

and

12V

switch,

and

and

and

P/S — R/F

board.

board,

supply.

inter-

Timer/

board,

inter-

plug,

board

n

TROUBLESHOOTING

GUIDE

14.

15.

Part

7001*

QH1-10

XH1-05

SYMPTOM

No

control

Unit

shuts

turn-on.

Number

of

intensity.

off

shortly

POSSIBLE

Check

potentiometer

board.

after

No

the

applicator

board.

PARTS

LIST

Description

Transducer

Power

A/D

Transformer

Control

CAUSE/ACTION

the

power

and

load

on

the

applicator.

P/S

—

R/F

board,

Timer/Display

and

(applicator)

Assembly

and

Board

control

the

Cable

R/F

—

P/S

Check

Assembly

XH1-04

XH1-06

HG1-03

EC4-08

HH2-01

BD5-02

XH1-16

"Factory

echange

only

You

must

sub

Timer/Display

P/S

—

R/F

Membrane

Cable

Flat

Main

Power

Power

Main

the

complete

Level

Power

unt

for

Board

Control

Switch

Assembly

Switch

Control

Switch

talibration

Board

Assembly

(white)

(blue)

12

I

SONICATOR

706

APPENDIX

DRAWINGS

II

III

Block

A/D

Diagram

Control

Timer/Display

P/S

-

R/F

A/D

Control

Timer/Display

P/S

-

R/F

SONICATOR

SONICATOR

Logic

Borad

Board

Board

706

706

Diagram

Logic

Board

Diagram

Schematic

Assembly

Assembly

Assembly

TRANSDUCER

COMPLETE

INSTALLTION

SERVICE

PARTS

ADJUSTMENT

LIST

PROCEDURE

13

APPENDIX

PART

II

SONICATOR

TEST

.

ㆍ

ㆍ

ㆍ

CAUTION

Measurement

EQUIPMENT

VARIAC

Ultrasound

lent).

Degassed

AC

line

requirements

NOTE:

706

REQUIRED

capable

water

ammeter

equipment

to

Prior

replace

plastic

old

coil.

TRANSDUCER

of

watt

meter

(for

for

assure

to

a

transducer

the

bolt

115

must

valid

L6

and

INSTALLATION

VAC/60

(Ohmic

the

ultrasound

0

to 1 AMP.

be

calibrated

results.

coil

on

nut.

Hz

+

UPM-30,

replacement

the

power

Discard

ADJUSTMENT

10%.

UPM-DT-10,

watt

per

on

board.

metal

PROCEDURE

or

meter).

manufacturer's

the

706

Mount

coil

clamp

equiva-

units,

with

if on

the

EQUIPMENT

Oscilloscope.

Note:

Channel

ground

Channel

attached

AMP/DIV

Time/DIV

Place

filled

A

clip

B

to

controls:

control

the

with

EQUIPMENT

1

Rotate

clockwise)

CONNECTIONS

R.F.

Place

to

cover

for

J3

(transducer

attached

to

CR13

a

suitable

transducer

degassed

ADJUSTMENT

the

706

.

must

adjustment.

to a suitable

anode

on

ground

(main

TB):

into

water.

PROCEDURE

intensity

be

installed

jack)

the

power board

point.

1V/DIV

0.2

the U/S

control

with

on

the

ground

usec/DIV

watt

meter

to

at

least

power board

point.

with

the

well,

minimum

(fully

1

screw

with

ground

partially

Counter-

in

the

clip

2.

Turn

on

the

706

by

pressing

the

MAIN

POWER

SWITCH.

Select

twice

minutes.

22

and

minutes

check

on

that

the

the

706

timer

timer

indicator

by

pressing

shows

the

'2'

'22.00'

pad

Press

down

in

Adjust

fast,

ty

Control

less

than

external

Your

oscilloscope

below:

After

power,

in:

a)

An

b)

An

the

or

'GO'

one

L4

for

you may

second

as

500

meter.

reaching

a

slight

improvement

improved

pad and

intervals.

minimum

blow

you

tune.

MA

of

AC

display

the

minimum

adjustment

in

squaring

observe

line

the

When

line

the

of

current.

fuse

fully

current

should

current

of

L4 is

pulse

the

that

or

the

L6.

tuned

with

look like

point,

allowable

envelope.

square

706

This

Increase

wave.

timer

should

you

20w.

the

NOTE:

will

for

be

the

should

output

picture

square

same

any

if it

counts

done

Intensi-

have

on

shown

Sine

&

waves

not

be

the

amplitude.

level

of

results

10.

The two

should

C17

on

While

706

intensity.

the

intensity

without

Shift

malities

Change

similar

This

intensity

will

waveform

change.)

wave

be

in

the

power

watching

waveform

to

PULSE

from

the

time/DIV

to

that

control

forms

phase

the

to

(sine

for

the

board

for

oscilloscope

If

the

display

regain normal

abnormalities.

mode

minimum

should retain

and

control

shown

throughout

to

below:

and

Sonicator

the

check

maximum

to 1 MS/DIV

its

its

square

proper

display,

starts

display

the

shape

full

waves),

706.

phase

to

and

pulse

intensity.

waveform

to

as

range.

as

If

condition.

slowly

break

re-adjust

get

you

rotate

shown

not,

increase

up,

for

the

(The

above,

adjust

the

decrease

L4

abnor-

picture

the

706

amplitude

INDICATOR

ADJUSTMENT

PROCEDURE

1.

2.

3.

4.

5.

6.

Rs

Put the

Adjust

the

706

'0.0'.

Start

control

R37

indicator.

Turn

be

R54

value

Adjust

adjust

output

Decrease

1.0

Repeat

While

between

the

the

5

the

on

the

between

pot.

of

watts

in

wattmeter.

output

short

Sonicator

R39,

the

the

R109

indicator.

steps

maximum

beeps,

on

power

Just

slightly

706

adjusted

power

power

20W

For

R15

needs

intensity

on

the

the

intensity

on

the U/S

2, 3,

CW

indicator

706

on

the

power

output

indicator,

past

by

pressing

for 5.0

board

control

&

21W

for

to

on

older units

to

be

control

the

control

to

wattmeter

4

and

mode,

and

(The

rotate

minimum

706

drops

and

the

timer

hold

board,

first

'GO'

watts

5.0

maximum.

the

where

changed

board

minimum

5

until

should

to

by

test

for

the

and

0.0,

stops

pressing

for

some

and

then

'0.0'

pad.

on

the U/S

watts

The

wattmeter.

R54

and

lift

cut off

is

between

20

watts

for

and

on

all

intensity

a

counting).

point.

With

on

the

output

not

20.0

check

the

are

satisfied.

the

transducer

in

buzzer

'HOLD'

numerical

back

the

wattmeter,

it

706

pad.

value

down

intensity

output

power

If

not,

installed

2K

and

5.6K.

on

the

wattmeter

watts

706

on

for

less

indicator.

the

control midway

about

sounds

6

seconds,

at

to

adjust

should

adjust

the

than

out

least

on

706

of

NOTE:

8.

9.

If

cut-off

Press

current

AUTOMATIC

1.

Hook

chassis

de

Turn

resistor

and

3.

4.

Turn

Place

On

some

the

timer

"Auto

the

condition

adjustment

'GO'

must

CUT

OFF

scope

ground.

R26

full

replace

substitute

the

unit

the

older

display

Cut

Off".

and

increase

be

below

ADJUSTMENT

probe

clockwise

a

on

transducer

units

of

step

procedure.

or

DVM

with

decade

and

program

face

without

board,

7

the

500ma.

PROCEDURE

to

(max

a

trim

box

end

is

power

pin

R).

pot,

for

for

the

not

7

the

under

the

buzzer

buzzer

met,

to

20W.

of

U4 - ground

Note:

20K

or

following

12

minutes.

water.

will

follow

The

If

clip

board

not

the

output

of

R26

is a fixed

one

adjustment.

in

U8

on

sound

on

automatic

line

probe

end

of

to

R26

Press

the

go

water.

and

observe

Set

the

the

output

timer

counting

to 4 watts.

down

and

output

in

10.

Lift

R26

state

Turn

observe

If

more

more

results.

Lock

If a decade

the

(ccw)

(approx.

the

the

conditions

counter

counterclockwise

R26

indicated

transducer

until

10V).

intensity

voltage

of

clockwise

with

torque

box was

value.

the

steps

out

of

voltage

knob

to

at

pin

6 & 7 are not

and

than

seal

used

or

for

water

at

increase

7

check

necessary

pin

of

U4

other

the

and

again.

above,

decrease

7

of

the

remains

met

to

non

permanent

replace

U4

changes

power

high

turn

Do

not

achieve

the

to

R26

adjust

the

R26

value

to a high

max

and

(about

slightly

above

"glue".

with

of

10V).

R26

the

PARTS

LOCATION

MISCELLANEOUS

Ti

R16

SONICATOR

DESCRIPTION

PARTS

FRONT

BACK

HANDLE

706

TIMER

706

A-D

706

POWER

706

POWER

AC

POWER

BLUE

AC

POWER

POWER

POWER

MEMBRANE

INTENSITY

KNOB

INTENSITY

RIBBON

RUBBER

HEX

STAND

TRANSDUCER

BLACK

4

POINT

LABEL

APPENDIX

&

ASSEMBLIES

HOUSING

COVER

DISPLAY

BOARD

BOARD

BUZZER

CORD

SWITCH

SWITCH

SWITCH

SWITCH

TRANSFORMER

SWITCH

CONTROL

FOR

ABOVE

CONTROL

(FLAT)

FEET

OFFS

GROUND

GROUND

706

METTLER

PART

706

SERVICE

COMPLETE

WITH

ASSEMBLY

(7001)

STUD

BOARD

BOARD

(WITH

TOP

(ONLY)

(WHITE

CABLE ASSLY

&

(FRONT PANEL)

POT

CABLE ASSLY

CABLE

JACK

TERMINAL

III

W/MEMBRANE

BLUE

TOP)

CABLE

5K

ASSY

PARTS

TOP)

LIST

SWITCH

PART

NUMBER

XH1-10

XH1-15

WKR2-03

XH1-04

XH1-05

XH1-06

XH1-09

QH1-05

XH1-16

KD1-09

HH2-01

QH1-07

QH1-10

HG1-03

BD5-02

KD1-06

QH1-08

EC4-08

KA1-03

KL1-02

XH1-02

ED3-11

EB3-03

PA2-01

706

POWER

CR11

CR1-6,9,25

CR14-20,23

CR10

CR12,13

CR7,8

CR24

01,6

BOARD

PARTS

DIODE

DIODE

DIODE

DIODE

DIODE

DIODE

MR851

1N4002

1N4148

1N4737

1N4935

1N5392

DIODE-ZENER

TRANS

TRANS

2N2222A

2M2907A

TRANSISTOR

TRANS

TRANS,

REGULATOR

REGULATOR

TRANSZORB

RES

RES

RES

RES 24K

RES

D45H10

2N4351

2K

OHM

750

OHM

12K

27K

OHM

VOLTAGE

VOLT

SA75A,SA78A

1/4W

1/4W

1N4753

D44C11

PNP

TO-72

7912CT

1/2W

1/4W

5%

5%

5%

1/4W

5%

NPN

AA1-05

AA1-06

AA1-07

AA1-08

AA1-09

AA1-10

AA3-02

AB1-01

AB2-05

AB5-05

AB5-06

AB6-05

AD1-07

AD2-01

AD3-01

BB3-09

BC2-14

BC22-01

BC22-04

BC22-05

PARTS

LOCATION

706

POWER BOARD

SONICATOR

DESCRIPTION

PARTS

(CONT'D)

706

SERVICE

PARTS

LIST

PART

NUMBER

R41,33

R34,35

R38

R42,52

R24

R36

R27

R5,17-19,40,47

R21,22

R12

R51

R29

R13

R49

R10

R6-9,44,45

R4,14

R53

R31

R20

R11

R43,48

R1,3,28

R26

R54

R37

R39

c18

C20,24-26

C14,33

0273

es

c21

c19

c7

C27,28,29

C23,31,32

c16

09

015

010

034

Ce

05

ei

c12

C4

c8,22,30

c17

RES

43K

1/4W

RES

51K

OHM

RES

62K

OHM

RES

100K

RES

RES

RES

200K

240K

290K

OHM

OHM

OHM

RES 1 MEG

RES

20

OHM

RES

33

OHM

RES

RES

RES

RES

RES

RES

RES

RES

RES

RES

RES

RES

RES

RES

POT

POT

100

OHM

160

OHM

200

OHM

300

OHM

510

OHM

1K

OHM

2K

OHM

10

OHM

3.3K

3.6K

4.3K

OHM

OHM

1/4W

5.1K 1/4W

10K

OHM

7.5K

5K

20K

OHM

1/2W

1/2W

POT 1 MEG

CAP

CAP

CAP

CAP

CAP

CAP

CAP

CAP „001

CAP

CAP

CAPACITOR

CAP

1500

.1

PF

MF

2000PF

470

PF

.02

MF

.022

MF

.01 MF

MF

.1

MFD

150

PF

.47

MF

.22

MFD

„01

MF

„005

1.0

ALUM-ELEC

10

3300

33

10

BÉSRSRRRE

ACTTOR

È

MF

MF

MF

MF

MF

MF

5%

1/4W

1/4W

OHM

1/4W

1/4W

1/4W

1/4W

1/4W

1%

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

5%

5%

1/4W

1/4W

MULTITURN

PCMT

1/2W

PCMT

100V

100V

CER

500V

3KV

CER

600V

50V

500V

50V

50V

50V

22V

100V

400V

35V

50V

50V

35V

TRMR

(C)

.022

250V

50V

TANT

680UF,

AX

50V

(A)

(A)

VRBLE

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

"F"

(M)

DISC

CER

(C)

MFD

(MY)

(C)

EL

(A)

"W"

"F"

EL

35V

BC22-06

BC22-07

BC22-08

BC22-10

BC22-13

BC22-14

BC22-16

BC22-18

BC22-20

BC22-21

BC22-22

BC22-23

BC22-24

BC22-25

BC22-26

BC22-28

BC22-30

BC22-31

BC22-35

BC22-36

BC22-38

BC22-40

BC22-42

BC22-43

BD2-05

BD3-03

BD3-05

CA1-10

CA1-11

CA1-12

CB1-03

CB2-01

CB2-02

CB2-05

CB2-16

CB2-18

CB2-19

CC2-14

CC2-15

CC2-16

CC2-17

CC2-18

CD1-01

CD2-16

CD2-27

CD2-28

CD2-29

CD2-30

CE2-01

PARTS

LOCATION

706

POWER BOARD

SONICATOR

DESCRIPTION

PARTS

(CONT'D)

706

SERVICE

PARTS

LIST

PART

NUMBER

L1,2

T2

L3

L5

L6

T3

τά

L4

L7

L8

SPK1

INDUCTOR

TOROID

INDUCTOR

TOROIDAL

INDUCTOR,

TRANSFORMER

TRANSFORMER

INDUCTOR

CHOKE

FERRITE

JACK,

SOCKET

SOCKET,

HEADER

HEADER

HEADER

HEADER

FUSE

FUSE

CABLE

INSULATOR,

INSULATOR,

INSULATING

HEATSINK

HEATSINK,

HEATSINK,

IC

VOL

IC

CA3280E

IC

LM324N

BUZZER

10717

33

RCA

IC

3

11

5

(ENC.)

.5

CLIP

SUPPORT

REG

CMB12

1.2MH

TOROID

INDCTR

CP

TUNEABLE

MH

CORE WIRE

FEM.

14

IC

PIN

PIN

PIN

AMP

PC

FUSE

TRANSISTOR

WASHER,

6025

LONG

SHORT

LM723CN

QD

TOROID

CORE

CP

CORE

CP

CORE

9360-09

COAX

PIN

16

PIN

11

250V

MNT

POST

BIT

10706

OP

500MH

12MH

ASSLY

PIN

SLO-BLO

1/4"

TRANS

10707B

AMP

MYLAR

DA1-03

DA1-10

DA1-11

DA1-12

XH1-12

XH1-14

XH1-13

DB2-01

DI2-01

QH1-17

EC2-07

EC7-02

EC7-03

ED4-02

ED4-03

ED4-04

ED4-12

FA1-04

FC2-02

GG1-07

KN1-06

K01-01

K01-02

L11-02

LI1-03

LI1-04

RC1-01

RD1-01

RF1-04

SA1-01

706

TIMER

CR1-8

Q1

R11,12,14-17

R1,2

R3-9

R10,18-21

R13,22

c7

C3-6,8

σε

co

U8

(FOR

BUZZER

BOARD)

J2

J3

31

DISPLAY

BOARD

DIODE

TRANS

RES

RES

RES

RES

RES

CAP

CAP

CAP

CAP

SOCKET

HEADER

HEADER

HEADER

22K

100K

510

1K

10K

.001

150

1.0

10

PARTS

1N4148

2N2222A

OHM

1/4W

OHM

1/4W

OHM

1/4W

OHM

1/4W

OHM

1/4W

MF

50V

PF

50V

MF

35V

MF

50V

IC

14

PIN

12

PIN

CONNECTOR

11

PIN

5%

5%

5%

5%

(C)

TANT

EL

RD

26

5%

EL

PIN

AA1-07

AB1-01

BC22-03

BC22-10

BC22-26

BC22-28

BC22-42

CB2-16

CB2-19

CD1-01

CD2-32

EC7-09

ED4-06

ED4-08

ED4-12

PARTS

LOCATION

706

TIMER

FOR

LED

DS

U2,10

U3,9

DS1-7

1-4

1-7

U4,7

U6

U5

U1

DISPLAY

SONICATOR

DESCRIPTION

BOARD

SPACER

DIODE,

DISPLAY

IC

4081

IC

4001

IC,

IC

COUNTER

IC

KEY

IJC

PARTS,

DISPLAY

LIGHT

7

QUAD

QUAD

DISPL DRIVR

ENCODER

4013

SEG

TIME

DUAL

706

(CONT'D)

10716

EMIT

DIGITAL

1INPT

1INPUT

MM74C922N

F-FLOP

SERVICE

SBG5633

AND

NOR

MC1416P

MK50396N

RED

PARTS

LIST

PART

NUMBER

KK1-08

NB1-03

NB2-01

RA1-01

RA1-02

RB1-01

RD1-02

RD1-05

RE1-03

NOTE:

706

A

CR101-103

R111,123

R110,116-122

R114,115

C104,107

6105,106

U8

TO

U102

R103

R102

R107

R101

R112

R108

R113

R109

C108

C102

で

103

C101

P3

U101

U103

D

PC

706

BUZZER

IT IS

NEEDED

BOARD

DIODE

REGULATOR

RES 68K

RES

RES

RES

RES

RES

RES

RES

RES

RES

POT

CAP

CAP

CAP

CAPACITOR

CAP

CAP

CONN,

IC

IC

BOARD

RECOMMENDED

AND NOT

PARTS

1N4148

OHM

100K

240K

300K

1

160

200

510

1K

5.1K

200

250

.1

1

.47

10

4001

DVM

MEG

OHM

MFD

MF

MF

26

ADD

OHM

OHM

OHM

OHM

OHM

OHM

1/4W

OHM

PF

50V

MF

PIN

OUAD

PARTS

THAT

REPAIRED...SEE

VOL

78L05A

1/4W

5%

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

5%

5%

5%

5%

5%

5%

1/2W

OCMT

50V

50V

RDL

EL

220V

.022MFD

100V

50V

EL RD

DUAL

2

INPUT

3701CCN

5%

5%

5%

HSG

THE

"F"

NOR

BUZZER

MISCELANEOUS

BOARD

BE

REPLACED

PARTS.

AA1-07

AD1-06

BC22-09

BC22-10

BC22-14

BC22-15

BC22-19

BC22-23

BC22-24

BC22-26

BC22-28

BC22-40

BD3-04

CB2-17

CB2-18

CC1-01

CC2-14

CC2-04

CD2-32

EC7-05

RA1-02

RD1-04

IF

Loading...

Loading...