VALVCON®

V-Series

ELECTRIC ACTUATORS

115 VAC AND 230 VAC

With Iso/Readback Board Installed (Option “U”)

Installation, Maintenance and

Operating Instructions

IMO-I5500 EN • 10/2017

2 IMO-I5500 EN

TABLE OF CONTENTS

1. GENERAL .................................................................. 3

1.1 Scope of the Manual ................................................... 3

1.2 Actuator Markings ........................................................ 3

1.3 Safety Precautions .........................................................3

2. TRANSPORTATION AND STORAGE ........................ 3

3. GENERAL INSTALLATION INFORMATION ............. 3

3.1 Description of Iso/Readback Board ........................ 3

3.2 Operation ......................................................................... 4

3.2.1 High or Low Voltage Control Signal ........................ 4

3.2.2 Position Readback ......................................................... 4

3.3 Operation for ON/OFF or Jogging

Applications (Motor Board only) .............................. 6

3.3.1 Set Up for Operation ................................................... 6

3.3.2 Setting Actuator Stop Positions .............................. 6

3.3.3 Proper Actuator Cover Installation .........................7

3.4 Board Installation ......................................................... 7

3.4.1 Tools Required ................................................................ 7

3.4.2 Installation Instructions .............................................. 7

4. VSERIES STANDARD OPTIONS ............................. 8

4.1 Option “H” – Tropical Heater and Thermostat ..... 8

4.2 Option “I” – ISO 5211 Output ..................................... 8

4.3 Option “K” – Mechanical Brake ..................................9

4.4 Option “P” – Feedback Potentiometer ................... 9

4.5 Option “S2” – Two Auxiliary Limit Switches .......... 9

4.6 Option “T” – Heater and Thermostat ...................... 9

4.7 Option “Y” - Keyed Output ......................................10

4.8 Option “Z” – Handwheel Override .........................10

4.9 Voltage ............................................................................10

5. GENERAL OPERATING INFORMATION ................ 10

5.1 Enclosure Ratings and Product Certications ...10

5.2 Wiring ..............................................................................10

5.3 Duty Cycle and Motor Protection ..........................10

5.4 Operating Temperature Limits ...............................11

5.5 Actuator Mounting .....................................................11

5.6 Manual Override ..........................................................11

5.7 Lubrication .....................................................................11

5.8 Problem Prevention ....................................................11

5.9 Warranty .........................................................................11

5.10 Repair Service/Spare Parts .......................................11

6. SPECIFICATIONS & TECHNICAL INFORMATION . 12

6.1 Dimensions ....................................................................13

6.2 Exploded View ..............................................................14

7. VSERIES ACTUATORS BY MODEL NUMBER ....... 15

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the actuator.

If you require additional assistance, please contact the manufacturer or manufacturer’s representative.

Addresses and phone numbers are printed on the back cover.

See also www.metso.com/electricactuators for the latest documentation.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

IMO 10/17

( 1 )

( 2 )

( 7 )

( 8 )

( 9 )

( 3 )

( 5 )

( 6 )

( 4 )

IMO-I5500 EN 3

1. GENERAL

1.1 Scope of the Manual

This instruction manual contains important information

regarding the installation, operation and maintenance of

the Valvcon V-Series electric actuator. Please read these

instructions carefully and save them for future reference.

1.2 Actuator Markings

WARNING

AS THE USE OF THE ACTUATOR IS APPLICATION SPECIFIC, A

NUMBER OF FACTORS SHOULD BE TAKEN INTO ACCOUNT WHEN

SELECTING AN ACTUATOR FOR A GIVEN APPLICATION. THEREFORE,

SOME OF THE SITUATIONS IN WHICH THE ACTUATORS ARE USED

ARE OUTSIDE THE SCOPE OF THIS MANUAL.

IF YOU HAVE ANY QUESTIONS CONCERNING THE USE, APPLICATION

OR COMPATIBILITY OF THE ACTUATOR WITH THE INTENDED

SERVICE, CONTACT METSO FOR MORE INFORMATION.

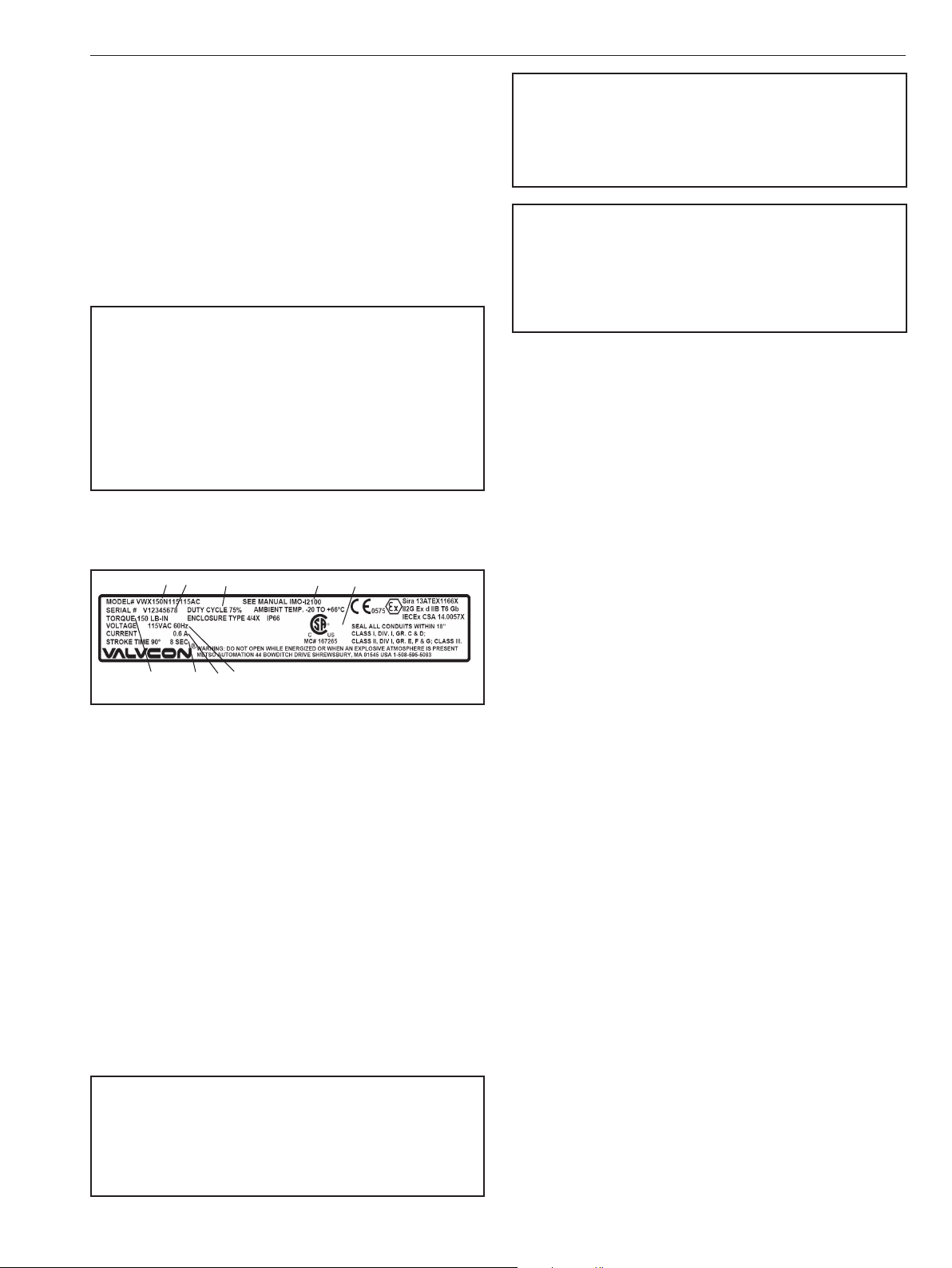

The actuator has an identication label attached to the

base casting (see Figure 1).

WARNING

DO NOT EXCEED THE ACTUATOR ELECTRICAL LIMITATIONS!

EXCEEDING THE ELECTRICAL LIMITATIONS MARKED ON THE

ACTUATOR IDENTIFICATION LABEL MAY CAUSE DAMAGE TO THE

ACTUATOR AND/OR PERSONAL INJURY.

WARNING

BEWARE OF MOVEMENT OF THE FINAL DRIVE ELEMENT AND ANY

LINKAGE BETWEEN IT AND THE ACTUATOR!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS AND OTHER

OBJECTS OUT OF THE WAY OF MOVING PARTS. FAILURE TO DO THIS

MAY RESULT IN DAMAGE OR PERSONAL INJURY!

2. TRANSPORTATION AND STORAGE

Check the actuator and any accompanying devices for any

damage that may have occurred during transport.

Store the actuator carefully. Storage indoors in a dry place is

recommended.

Move the actuator to its intended location just before

installation.

Figure 1 Identication Plate

Identication label markings:

1. Model number

2. Serial number

3. Maximum output torque

4. Voltage

5. Current draw (full-load running)

6. Cycle time

7. Duty cycle

8. Applicable manual

9. Certications marking

1.3 Safety Precautions

WARNING

DO NOT EXCEED THE ACTUATOR PERFORMANCE LIMITATIONS!

EXCEEDING THE TORQUE LIMITATIONS MARKED ON THE ACTUATOR

IDENTIFICATION LABEL MAY CAUSE DAMAGE TO THE ACTUATOR

AND/OR FINAL DRIVE ELEMENT.

The actuator is usually shipped in the full clockwise,

(typically closed) position.

If the actuator(s) will be stored for a period longer than 90

days, follow the recommendations in IMO-S2 to maintain

the actuator’s integrity.

3. GENERAL INSTALLATION

INFORMATION

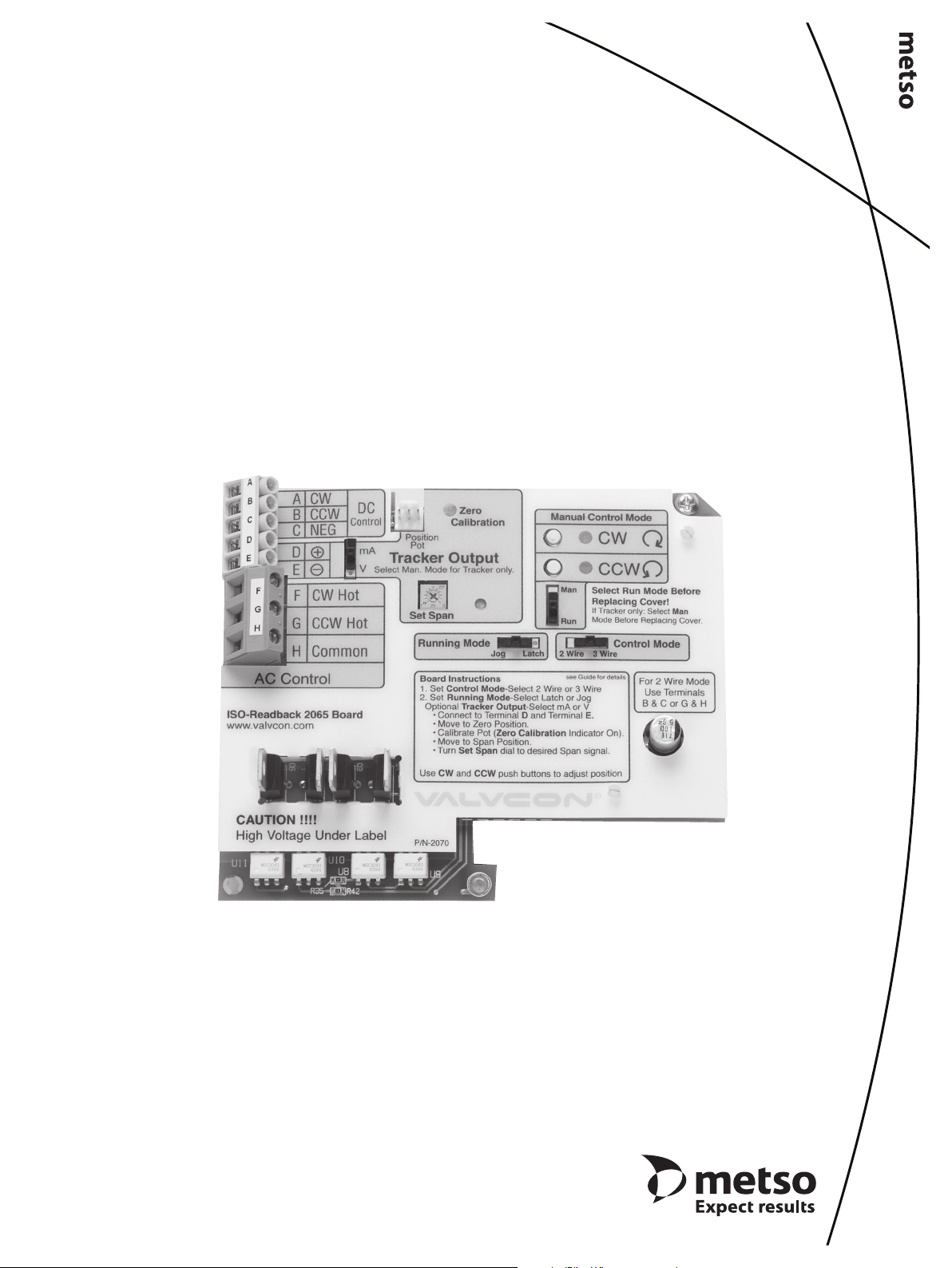

3.1 Description of Iso/Readback Board

The V-Series Iso/Readback Board is a 115/230 VAC option

that provides jogging or latching control from a low voltage

(12 VDC or 24 VDC) or high voltage (115 VAC or 230 VAC)

control signal. It also provides:

• a 4-20 mA or 0-10 DC position “readback” signal

• isolation for the motor, so that multiple actuators may

be wired in parallel

• supervisory control via a mode selector switch and

on-board CW and CCW push buttons. The supervisory

control mode overrides a remote signal for simple and

uninterrupted system set-up.

The isolation feature solves the problem of feedback

voltage interfering with PLC or DCS systems. In standard

electric actuators, the motor acts as an inductive load

and ”steps up” the input voltage, and feeds it back via the

non-powered terminals to the power supply. The Iso/

Readback board isolates the motor from the control signal,

preventing the feedback voltage from reaching the power

supply.

IMO 10/17

4 IMO-I5500 EN

Position indication is available at terminals 5 and 6 on the

Motor Board (for discrete end of travel indication), and at

terminals D and E on the Iso/Readback Board (for analog

position readback).

Note: This option will t all V-Series 115 & 230 VAC actuators

with the letter “N” preceding the voltage designator in the

part number on the product nameplate.

WARNING

DANGEROUS VOLTAGES ARE PRESENT INSIDE THE ACTUATOR

COVER UNLESS THE POWER SUPPLY TO THE ACTUATOR HAS BEEN

SHUT OFF OR DISCONNECTED. USE EXTREME CAUTION WHENEVER

WORKING ON THE ACTUATOR WITH THE COVER REMOVED.

WARNING

ACTUATORS SHOULD BE PROPERLY GROUNDED AND WIRED IN

ACCORDANCE WITH LOCAL ELECTRICAL CODE; SEE NAMEPLATE

FOR MAXIMUM CURRENT DRAW.

3.2 Operation

NOTE: Assumes option is installed; if installing kit, see

Section 3.4 of this manual.

3.2.1 High or Low Voltage Control Signal

The Iso/Readback Board plugs into the Valvcon Motor Board

using standard brackets and mounting screws provided.

Several selector switches are provided on the board for

mode set-up. The matrix below explains the actuator’s

functions for each combination of switch settings:

3.2.2 Position Readback

The Iso/Readback Board provides either a 4-20 mA or 0-10

VDC analog signal for position indication. To initiate this

function, connect to terminals D and E on the Iso/Readback

Board. Then:

1. Calibrate the Zero position (4 mA or 0 VDC) by

selecting the “Man” mode and use the on-board CW

push button to drive to the full clockwise position.

Using the 1/16” Allen wrench provided, loosen the

setscrew on the larger, white nylon gear. Adjust that

gear until the “Zero Calibration” LED turns on. Tighten

the setscrew.

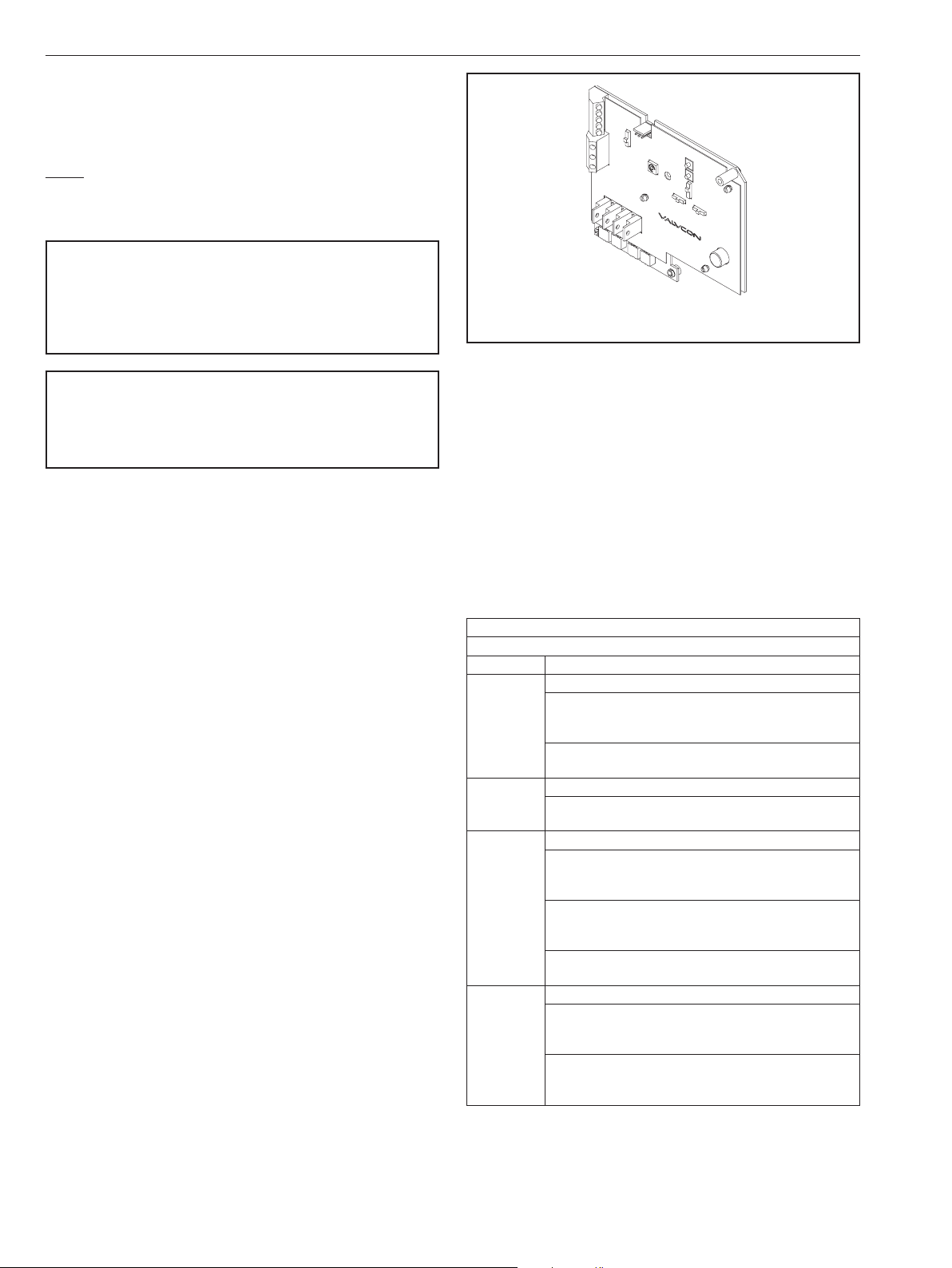

P/N VC002065

Iso/Readback Board

Figure 2

2. Calibrate the Span position by using the on-board

CCW push button to drive to the full counter-clockwise

position. Adjust the “Set Span” potentiometer until

you read the desired Span signal (20 mA or 10 VDC).

3. If you are using the Position Readback signal in

conjunction with a high or low voltage control signal,

return the selector switch to the “Run” mode.

3a. If you are using the Position Readback signal without

the high or low voltage control signal, leave the

selector switch in the “Man” position.

TABLE 1

Selector Switch Modes

Control Running

Jog

When the control signal is maintained at terminals B and

2 Wire

2 Wire

3 Wire

3 Wire

C (DC voltage) or G and H (AC voltage), the actuator will

drive to the full counter-clockwise position

When the control signal is de-energized, the actuator will

drive to the full clockwise position.

Latch

When 2 Wire Mode is selected, the Running Mode must be

set to “Jog”.

Jog

When the control signal is maintained at terminals B and

C (DC voltage) or G and H (AC voltage), the actuator will

drive to the full counter-clockwise position

When the control signal is maintained at terminals A and

C (DC voltage) or F and H (AC voltage), the actuator will

drive to the full clockwise position

When the control signal is de-energized, the actuator will

remain in position.

Latch

When a momentary control signal is applied to terminals

B and C (DC voltage) or G and H (AC voltage), the

actuator will drive to the full counter-clockwise position

When a momentary control signal is applied to terminals

A and C (DC voltage) or F and H (AC voltage), the

actuator will drive to the full clockwise position.

IMO 10/17

IMO-I5500 EN 5

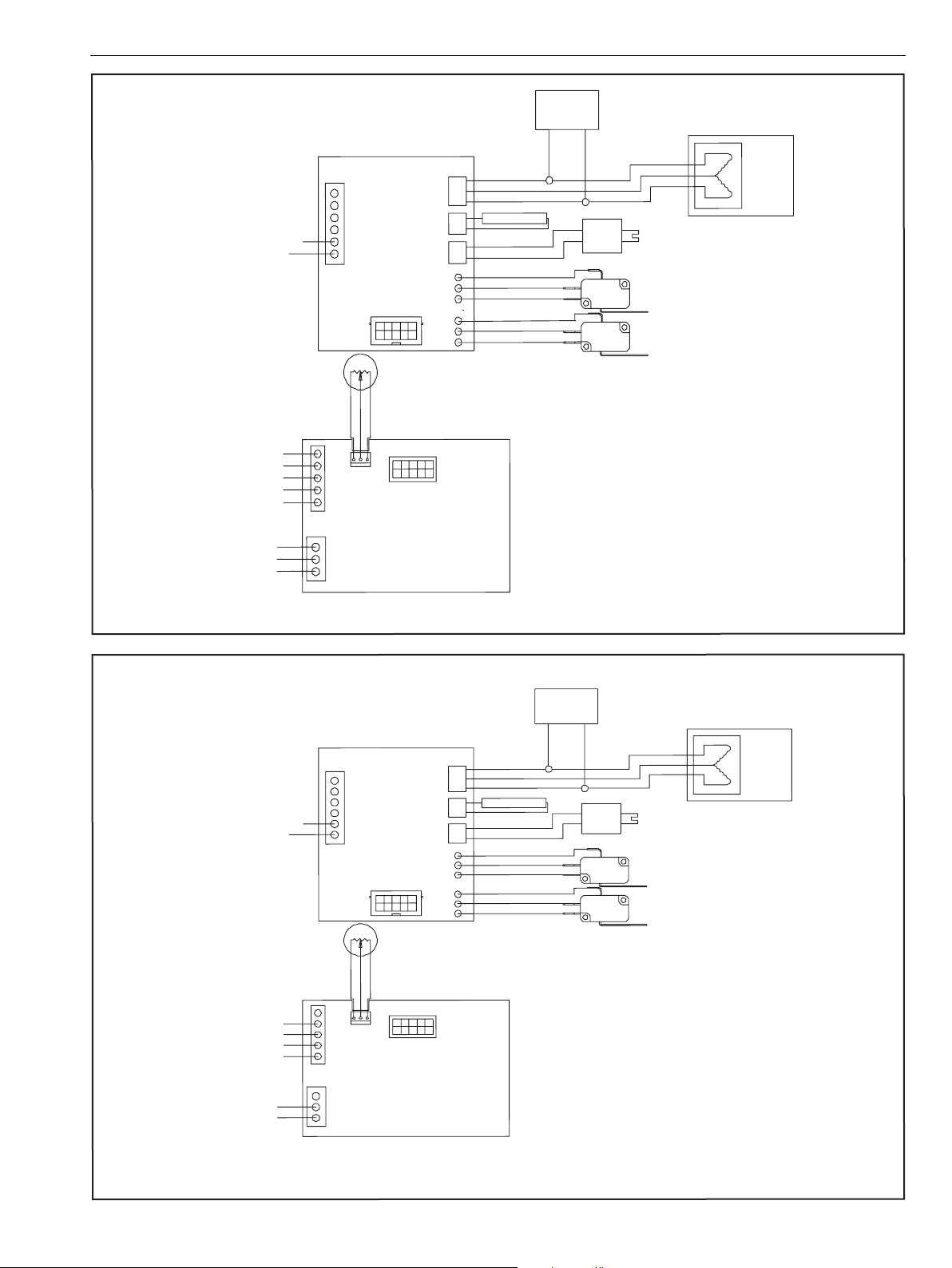

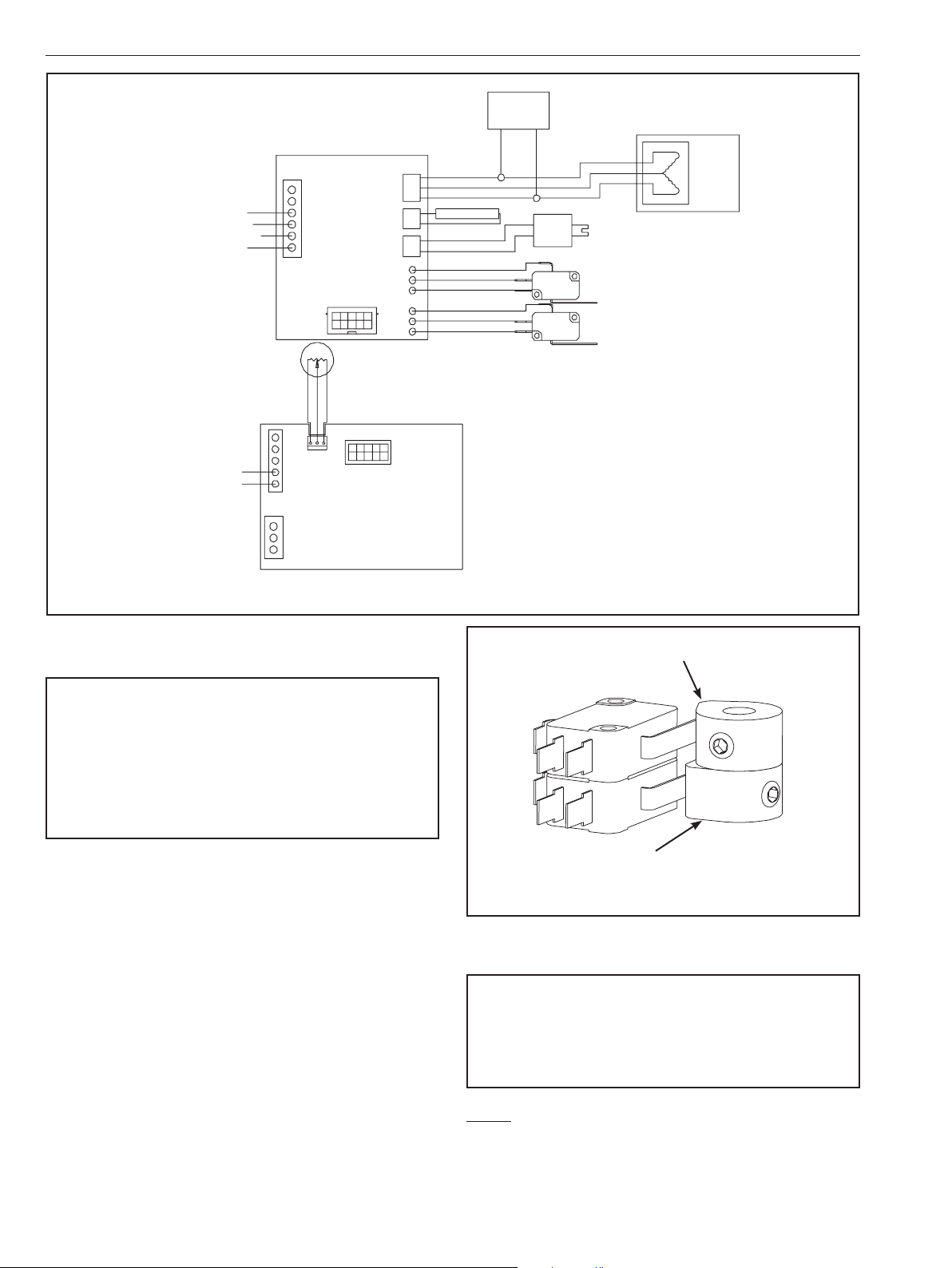

Wiring Diagram – Three Wire Mode

Motor Board

TB1

6

5

Motor

4

L02253

Board

3

2

1

TO OPTION

BOARD

1

2

3

RET. GREEN

SIG. BLACK

+5V RED

TB2

A

B

J1

C

D

G

H

E

F

FROM MOTOR BOARD

Iso/Readback

AC POWER MUST CONNECT

Choose AC or

DC Control

mA or DC

Retransmit

Output is

optional

AC COMMON

AC HOT

DC CONTROL

CW POS

CCW POS

NEG

RETRANSMIT+

OUTPUT –

AC CONTROL

CW HOT

CCW HOT

COMMON

TB1

MOTOR

J2

CONNECTOR

HEATER

J3

OPTION

CONNECTOR

BRAKE

J1

OPTION

CONNECTOR

E10

E11

J4

E12

E13

E14

E15

POSITION FEEDBACK POT.

J3

Board

MOTOR

CAPACITOR

CCW RED

RET BLACK

CW WHITE

HEATER

BROWN

RED

ORANGE

GR AY

VIOLET

BLUE

NO

NC

NO

NC

COM

COM

BRAKE SOLENOID

CLOCKWISE (BOTTOM)

LIMIT SWITCH

COUNTER-CLOCKWISE (UPPER)

LIMIT SWITCH

CAUTION: DOUBLE POLE/NEUTRAL FUSING!

CAUTION: MORE THAN ONE LIVE CIRCUIT!

P/N VC002065 Iso/Readback BOARD

Wiring Diagram – Two Wire Mode

Motor Board

TB1

6

5

L02336

A

B

C

D

E

F

G

H

4

3

2

1

3

+5V RED

TB2

J1

Motor

Board

TO OPTION BOARD

1

2

RET. GREEN

SIG. BLACK

AC POWER MUST

CONNECT

Choose AC or

DC Control

mA or DC

Retransmit

Output is

optional

AC COMMON

AC HOT

DC CONTROL

CCW POS

NEG

RETRANSMIT+

OUTPUT –

AC CONTROL

CCW HOT

COMMON

TB1

MOTOR

CONNECTOR

HEATER

OPTION

CONNECTOR

BRAKE

OPTION

CONNECTOR

J4

POSITION FEEDBACK POT

J3

FROM MOTOR BOARD

Iso/Readback

Board

Figure 3

J2

J3

J1

E10

E11

E12

E13

E14

E15

MOTOR

CAPACITOR

CCW RED

RET BLACK

CW WHITE

HEATER

BROWN

RED

ORANGE

GR AY

VIOLET

BLUE

COM

NO

NC

COM

NO

NC

BRAKE SOLENOID

CLOCKWISE (BOTTOM)

LIMIT SWITCH

COUNTER-CLOCKWISE (UPPER)

LIMIT SWITCH

CAUTION: DOUBLE POLE/NEUTRAL FUSING!

CAUTION: MORE THAN ONE LIVE CIRCUIT!

P/N VC002065 Iso/Readback BOARD

Figure 4

IMO 10/17

6 IMO-I5500 EN

Wiring Diagram – Retransmit Only

Motor Board

TB1

6

Terminal 4 CW Hot (Must Connect)

Terminal 3 CCW Hot (Must Connect)

Terminal 2 AC Common (Must Connect)

Terminal 1 AC Hot (Must Connect)

4-20 mA or 0-10 VDC

Retransmit Output

Terminal D POS (+)

Terminal E NEG (–)

CW HOT

CCW HOT

AC COMMON

AC HOT

RETRANSMIT+

OUTPUT –

5

Motor

4

Board

3

2

1

TO OPTION BOARD

L02337

123

RET. GREEN

SIG. BLACK

+5V RED

TB2

A

B

J1

C

D

E

TB1

F

G

H

FROM MOTOR BOARD

Iso/Readback

MOTOR

J2

CONNECTOR

HEATER

J3

OPTION

CONNECTOR

BRAKE

J1

OPTION

CONNECTOR

E10

J4

E11

E12

E13

E14

E15

POSITION FEEDBACK POT.

J3

Board

MOTOR

CAPACITOR

CCW RED

RET BLACK

CW WHITE

HEATER

BRAKE SOLENOID

BROWN

RED

ORANGE

GR AY

VIOLET

BLUE

COM

NO

NC

NO

NC

COM

CLOCKWISE (BOTTOM)

LIMIT SWITCH

COUNTER-CLOCKWISE (UPPER)

LIMIT SWITCH

CAUTION: DOUBLE POLE/NEUTRAL FUSING!

CAUTION: MORE THAN ONE LIVE CIRCUIT!

P/N VC002065 Iso/Readback BOARD

Figure 5

3.3 Operation for ON/OFF or Jogging

Applications (Motor Board only)

WARNING

VALVCON AC VOLTAGE ACTUATORS USE REVERSING INDUCTION

MOTORS WHICH CAUSE HIGH VOLTAGES. DEVICES CONNECTED

TO TERMINAL 3 AND TO TERMINAL 4 MUST BE RATED FOR

MINIMUM 250 VAC 440 VAC FOR 230 VAC APPLICATIONS. DUE

TO THE INDUCED FEEDBACK VOLTAGE, MULTIPLE ACTUATORS

CANNOT BE WIRED IN PARALLEL. SEPARATE ISOLATED CONTACTS

MUST BE PROVIDED FOR EACH ACTUATOR.

3.3.1 Set Up for Operation

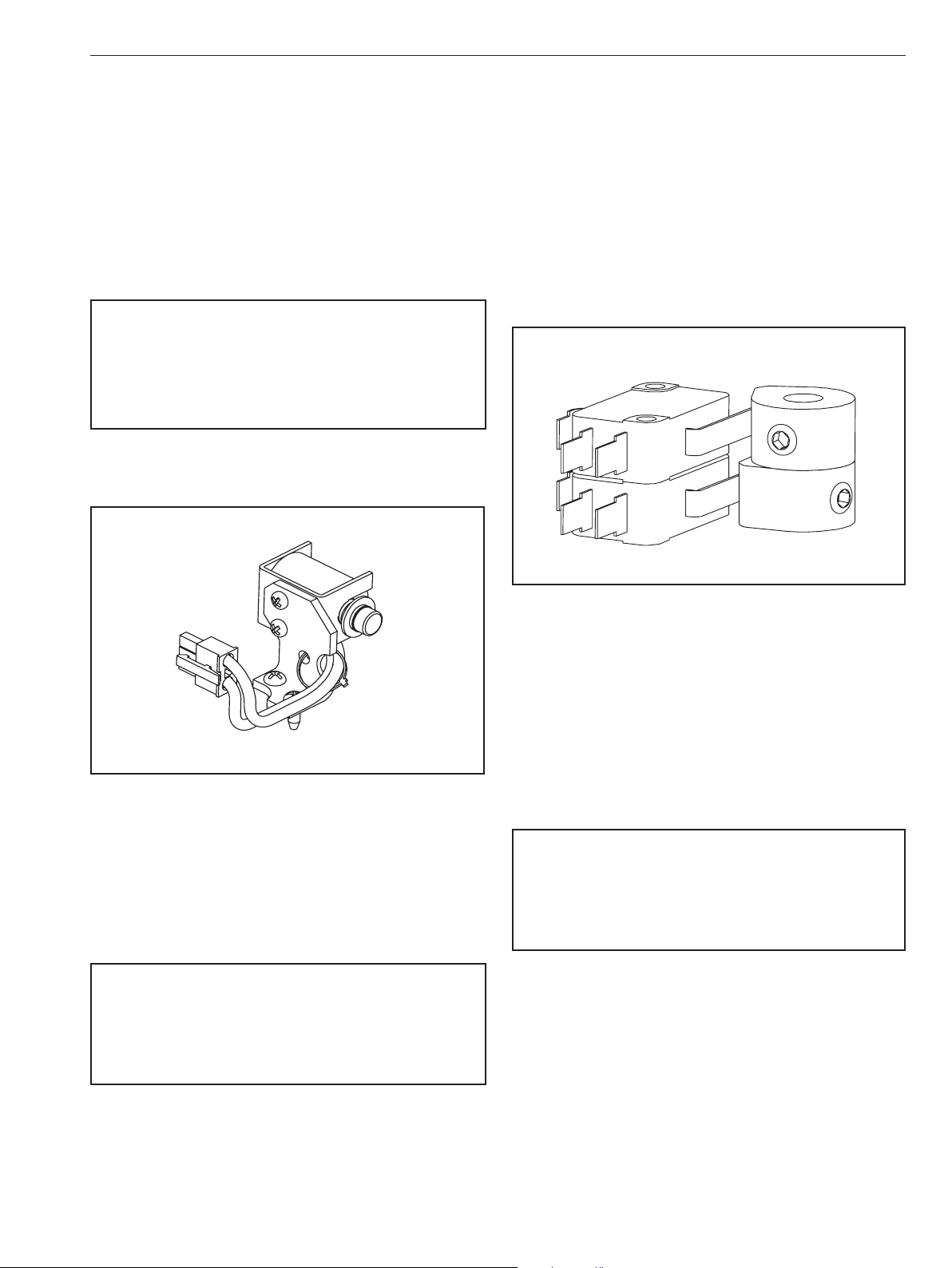

Two limit switches operated by the cams on the output shaft

determine the exact positions where the actuator will stop

at each end of travel. The bottom limit switch determines

the clockwise stop position. The next limit switch up

from the bottom determines the counter-clockwise stop

position. The end of travel limit switches can be adjusted to

provide from 5 to 320 degrees of actuator rotation.

The two standard limit switches may be used to indicate

the open and closed status of the actuator. Terminals 5

(counter-clockwise) and 6 (clockwise) provide the position

indication at line voltage. If dry contacts or intermediate

position indication are needed, additional limit switches

and cams may be installed in the actuator. When additional

limit switches are installed, they can be set in any position

and are wired to a separate terminal block provided with

the option. See (Section 4), V-Series Standard Options.

Counter-Clockwise (CCW) CAM and SWITCH

Clockwise (CW) CAM and SWITCH

Figure 6

3.3.2 Setting Actuator Stop Positions

WARNING

DANGEROUS VOLTAGES ARE PRESENT INSIDE THE ACTUATOR

COVER UNLESS THE POWER SUPPLY TO THE ACTUATOR HAS BEEN

SHUT OFF OR DISCONNECTED. USE EXTREME CAUTION WHENEVER

WORKING ON THE ACTUATOR WITH THE COVER REMOVED.

NOTE: To gain more access to cams, move the capacitor

and terminal strip, if installed.

1. Loosen the set screw in the cam using a 1/16” hex

wrench. The bottom cam controls the clockwise end-of-

IMO 10/17

IMO-I5500 EN 7

travel, and the second cam, (from the bottom) controls

the counter-clockwise end-of-tavel (See Figure 3).

2. Move the actuator to the desired STOP position

3. Apply power according to desired mode of operation

or use the manual override. (See Figures 4, 5 & 6)

4. Remove the power and rotate cam in the direction of

travel to the exact point the switch “clicks” closed.

5. Tighten the set screw.

6. Repeat this procedure to set the opposite end of the

travel limit.

3.3.3 Proper Actuator Cover Installation

1. Remove the override shaft from the actuator cover

bushing; if the actuator is equipped with a handwheel,

remove the handwheel before removing the top piece

of the “two-piece” shaft form the cover bushing.

2. Install the override shaft on the square motor shaft; if

the actuator is equipped with a handwheel, install the

bottom piece of the “two-piece” shaft on the motor

shaft and then install the top piece of the shaft onto

the bottom piece of the shaft.

3. Align cover so that the override shaft will pass through

the override bushing and carefully push it down so

that the cover ange contacts the base ange.

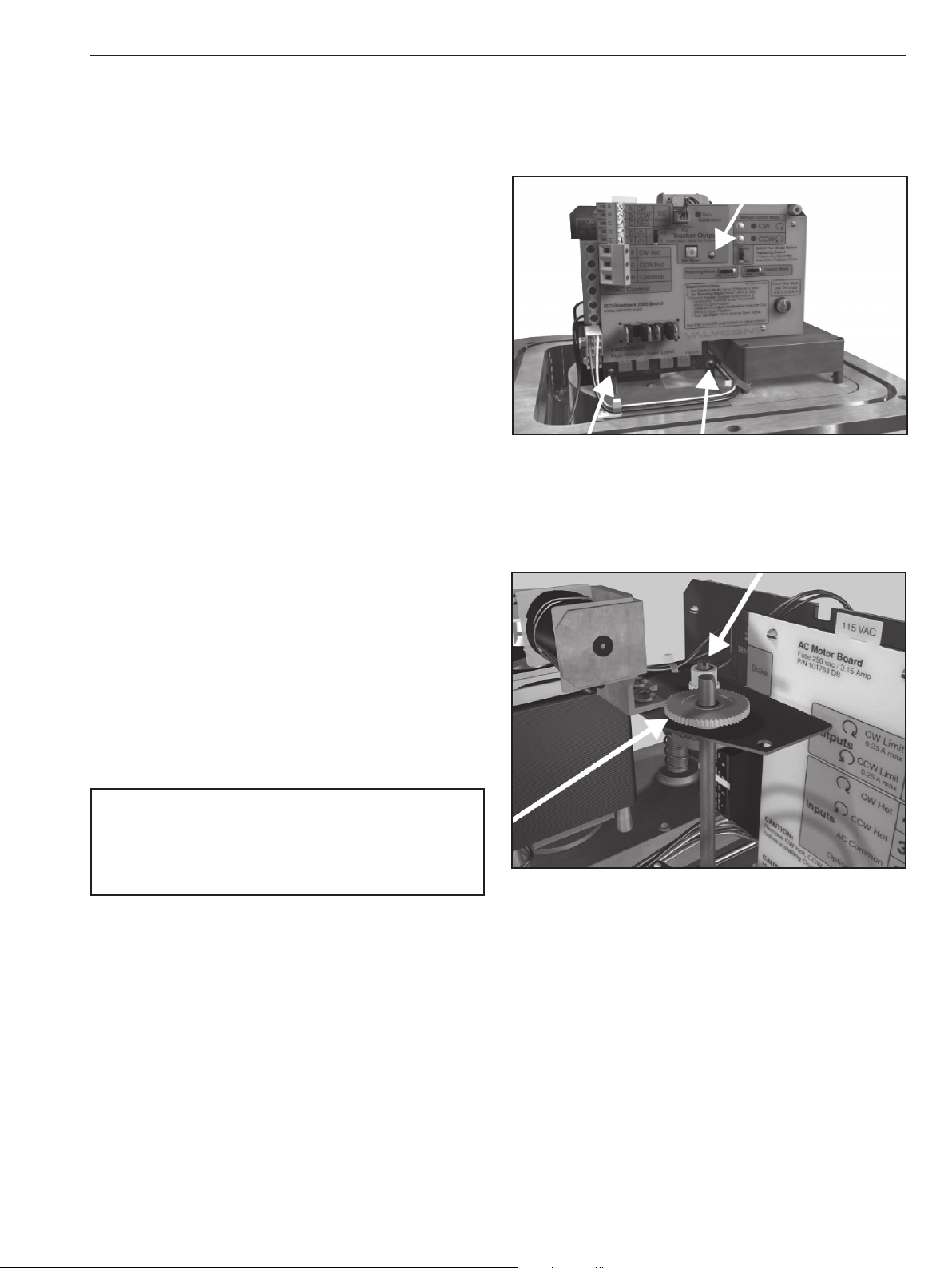

3. Plug Pot connector into the 3-pin connector on the front

of the Iso/Readback Board (“J1”). Plug Iso/Readback

Board into Motor Board (P/N VC002015) via 10-pin

connector and secure to the existing bracket with

three mounting screws. (See Figure 7).

Figure 7

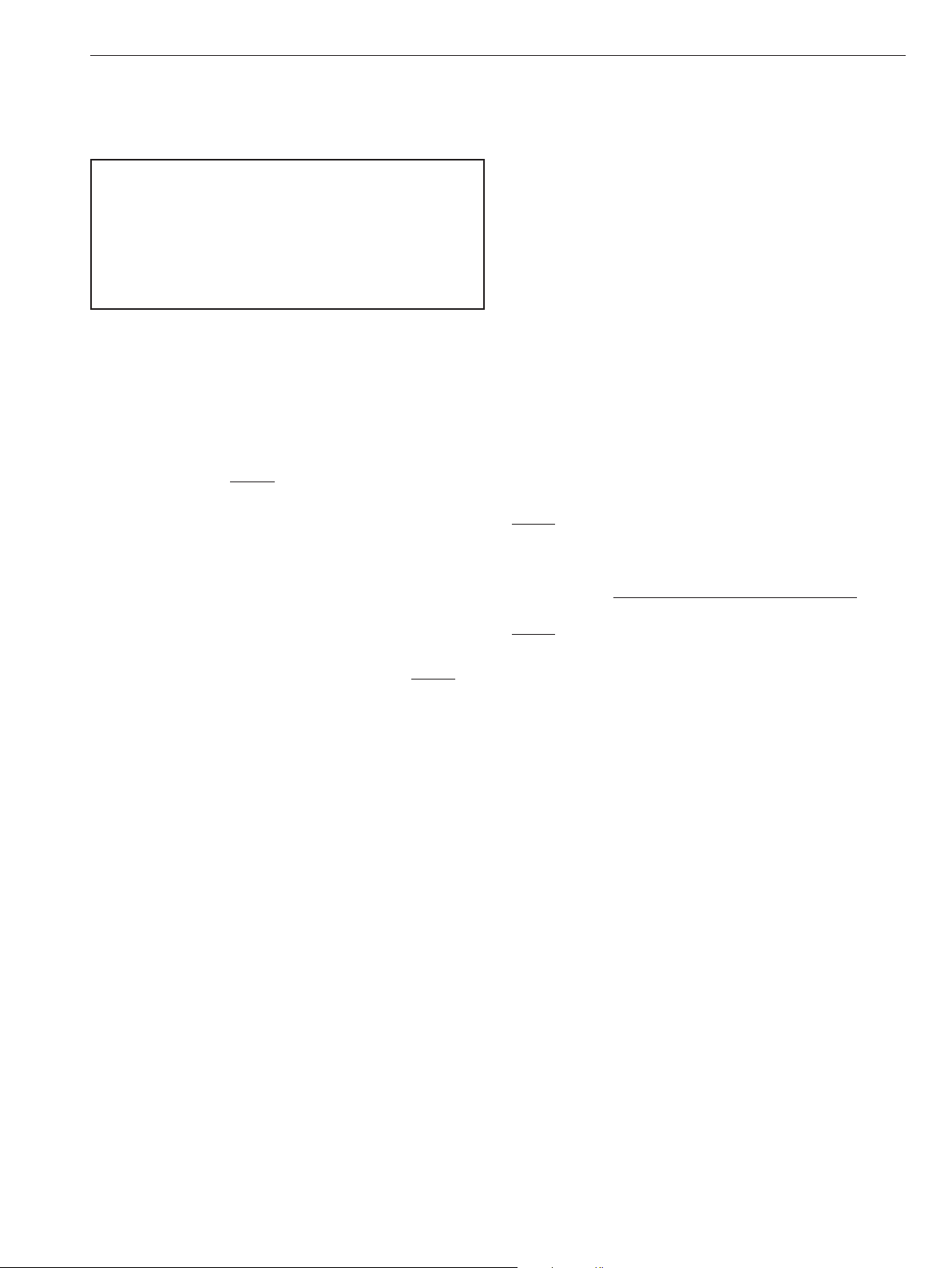

4. Place small (20-tooth) gear on Pot shaft and tighten.

Place spacer on Camshaft then place large (60-tooth)

gear on Camshaft. Properly positioned, gears should

mesh evenly. (See Figure 8).

4. Once the cover is properly seated, tighten the screws

to secure the cover; a cross pattern is recommended

for uniform distribution of load.

5. If the position indicator is not seated to the output/

cam shaft, turn until it drops into place in order to

ensure accurate visual position indication.

3.4 Board Installation

WARNING

DANGEROUS VOLTAGES ARE PRESENT INSIDE THE ACTUATOR

COVER UNLESS THE POWER SUPPLY TO THE ACTUATOR HAS BEEN

SHUT OFF OR DISCONNECTED. USE EXTREME CAUTION WHENEVER

WORKING ON THE ACTUATOR WITH THE COVER REMOVED.

3.4.1 Tools Required

• 1/16” Hex wrench

• #1 or #0 Philips Screwdriver

• 1/2” Wrench/Nut driver

3.4.2 Installation Instructions

!Disconnect Power!

1. Remove and discard screw that secures Motor Board

to the upper bracket. (See Figure 9).

2. Remove 1/2” nut and lockwasher from potentiometer

(Pot) shaft and insert, “Pot shaft up” through hole in

upper support bracket. Align lockwasher and nut and

tighten.

Figure 8

5. Loosen setscrew in CW or CCW cam. (1/16 hex wrench)

CW = bottom cam

CCW = next cam up from bottom cam

6. Connect AC Power to terminal 1 (Hot) and 2 (Common)

of Motor Board P/N VC002015. Select Manual Mode

and drive to desired STOP position. Remove power.

7. Rotate cam in the direction of travel to the exact point

that the switch “clicks” open. Tighten setscrew

8. Repeat procedure 5, 6 and 7 to set opposite end of

travel limit.

9. Connect AC or DC Control Signals to AC or DC Control

terminals to achieve desired operation, as indicated in

wiring diagrams on previous pages.

IMO 10/17

8 IMO-I5500 EN

Exploded View

DC Control Signal

Terminals - A, B & C

AC Control Signal

Terminals - F, G & H

P/N VC002065

Board

Selector Switch for

Jogging or Latching

Mode

Mounting Screw

Optional Retransmit

Terminals - Connect D&E

Locations

1 (AC Hot), 2 (Neutral)

Pot Connector

Selector Switch for

Manual or Run Mode

Optional Locking

Brake Assembly

Motor Board

Terminals 1 & 2

To install P/N VC002065

board, discard this screw

10 Pin

Connector

Selector Switch for 2

Wire or 3 Wire Mode

Figure 9

4. VSERIES STANDARD OPTIONS

All V-Series options are designed to be easily installed in the

eld. Options for all standard V-Series actuators are universal

and completely interchangeable with each enclosure size.

For additional V-Series Options, see (Table3). Voltage is not

eld changeable.

4.1 Option “H” – Tropical Heater and

Thermostat P/N VC099716, VC099723

The tropical heater and thermostat option is a self-adhesive,

resistance heater strip which is applied to the primary

gearbox. It installs with a plug-in connector and is

recommended in high-humidity applications. The tropical

heater option is also recommended in installations that

experience wide temperature swings in order to evaporate

any condensation. Thermostat is pre-set to activate at or

below 90˚F (32˚C) and deactivate at or above 110˚F (43˚C).

The tropical heater draws 15 watts at 115 VAC; 40 watts at

230 VAC (see IMO-I9500 for additional reference).

WARNING

WHENEVER WORKING INSIDE THE ACTUATOR BE SURE TO FOLLOW

ALL GUIDELINES, AND HEED ALL WARNINGS IN THIS MANUAL. IF

INSTALLING AN OPTION KIT, BE SURE TO READ AND FOLLOW THE

SUPPLIED INSTRUCTIONS CAREFULLY AND HEED ANY ADDITIONAL

WARNINGS.

Option “H” Tropical Heater and Thermostat

Option “T” Standard Heater and Thermostat

Figure 10

4.2 Option “I” – ISO 5211 Output

150 – 600 lb•in (12 - 25 lb•ft; 17 - 68 Nm) models are

supplied with a 3/4” female square output coupling; when

the “I” option is selected they are supplied with a 14 mm

female square.

1000 – 3000 lb•in (83 - 250 lb•ft; 113 - 339 Nm) models are

supplied with a 1” female square output coupling; when the

“I” option is selected, 1000 lb•in (83 lb•ft; 113 Nm) models

are supplied with a 19 mm female square and 1500 – 3000

lb•in (125 - 250 lb•ft; 169 - 339 Nm) models are supplied

with a 22 mm female square.

This option can be installed in the eld; for 115 VAC

applications, order kit P/N VC099716 and for 230 VAC

applications, order kit P/N VC099723.

IMO 10/17

This option is factory installed only.

IMO-I5500 EN 9

4.3 Option “K” – Mechanical Brake

P/NVC099715

The brake option prevents back-driving; it is required

on all buttery valve and damper applications. It is also

recommended on PVC ball valves and resilient seated

valves. The brake option draws 4 watts and is universal to

all standard V-Series actuators. It is simple to install with a

plug-in connector and two philips head mounting screws.

No additional brackets are required (see IMO-I9715 for

additional reference).

WARNING

WHENEVER WORKING INSIDE THE ACTUATOR BE SURE TO FOLLOW

ALL GUIDELINES, AND HEED ALL WARNINGS IN THIS MANUAL. IF

INSTALLING AN OPTION KIT, BE SURE TO READ AND FOLLOW THE

SUPPLIED INSTRUCTIONS CAREFULLY AND HEED ANY ADDITIONAL

WARNINGS.

This option can be installed in the eld; order kit P/N

VC099715.

Option “K” – Mechanical Brake

4.5 Option “S2” – Two Auxiliary Limit

Switches P/N VC099000

The extra switches and stainless steel cams provide dry

contacts and are fully adjustable to trip at any position. They

are often used for position indication or to interlock other

devices (such as in sequencing operations). The switches

are single pole, double throw switches rated for 11A 1/2HP

250 VAC, CSA certied. Auxiliary switch kit P/N VC099000

is universal to all standard V-Series actuators and includes

“ying wiring leads” for termination inside of the actuator

enclosure using the supplied 6 position terminal block (see

IMO-I9000 for additonal reference).

Option “S2” – Two Auxiliary Limit Switches

Figure 11

4.4 Option “P” – Feedback Potentiometer

P/N VC099200

The Feedback Potentiometer option provides 0 – 1000 Ohm

resistance feedback and includes a 12 position terminal

block for internal wiring (see IMO-I9200 for additional

reference).

WARNING

WHENEVER WORKING INSIDE THE ACTUATOR BE SURE TO FOLLOW

ALL GUIDELINES, AND HEED ALL WARNINGS IN THIS MANUAL. IF

INSTALLING AN OPTION KIT, BE SURE TO READ AND FOLLOW THE

SUPPLIED INSTRUCTIONS CAREFULLY AND HEED ANY ADDITIONAL

WARNINGS.

Figure 12

4.6 Option “T” – Heater and Thermostat

P/N VC099515, P/N VC099523

The heater and thermostat option is a self-adhesive,

resistance heater strip which is applied to the primary

gearbox. It installs with a plug-in connector and is

recommended in installations where the ambient

temperatures drop below 32˚F (0˚C). Thermostat is pre-set

to activate at or below 40˚F (4˚C) and deactivate at or above

60˚F (15˚C). The heater draws 15 watts at 115 VAC; 40 watts

at 230 VAC (see IMO-I9500 for additional reference).

WARNING

WHENEVER WORKING INSIDE THE ACTUATOR BE SURE TO FOLLOW

ALL GUIDELINES, AND HEED ALL WARNINGS IN THIS MANUAL. IF

INSTALLING AN OPTION KIT, BE SURE TO READ AND FOLLOW THE

SUPPLIED INSTRUCTIONS CAREFULLY AND HEED ANY ADDITIONAL

WARNINGS.

This option can be installed in the eld; for 115 VAC

applications, order kit P/N VC099515 and for 230 VAC

applications, order kit P/N VC099523. (see Figure 10)

This option can be installed in the eld; order kit P/N

VC099000.

IMO 10/17

10 IMO-I5500 EN

4.7 Option “Y” - Keyed Output

150 – 600 lb•in (12 - 25 lb•ft; 17 - 68 Nm) actuators are

supplied with a 3/4” female square output coupling; when

the “Y” option is selected they are supplied with a 15mm

female keyed output.

1000 – 3000 lb•in (83 - 250 lb•ft; 113 - 339 Nm) models are

supplied with a 1” female square output coupling; when the

“Y” option is selected they are supplied with a 20mm female

keyed output.

This option is factory installed only.

4.8 Option “Z” – Handwheel Override

P/N VC009097, P/N VC009098

All V-Series actuators are supplied with a wrench-operated

manual override shaft. If the Handwheel Override option is

selected the shaft is replaced by a declucthable shaft and a

six-inch handwheel (see IMO-I9090 for additional reference).

WARNING

WHENEVER WORKING INSIDE THE ACTUATOR BE SURE TO FOLLOW

ALL GUIDELINES, AND HEED ALL WARNINGS IN THIS MANUAL. IF

INSTALLING AN OPTION KIT, BE SURE TO READ AND FOLLOW THE

SUPPLIED INSTRUCTIONS CAREFULLY AND HEED ANY ADDITIONAL

WARNINGS.

This option can also be installed in the eld; for 150 –

600 lb•in (12 - 25 lb•ft; 17 - 68 Nm) models order kit P/N

VC009097 and for 1000 – 3000 lb•in (83 - 250 lb•ft; 113 - 339

Nm) models order kit P/N VC009098.

4.9 Voltage

5.2 Wiring

WARNING

VALVCON AC VOLTAGE ACTUATORS USE REVERSING INDUCTION

MOTORS WHICH CAUSE HIGH VOLTAGES. DEVICES CONNECTED

TO TERMINAL 3 AND TO TERMINAL 4 MUST BE RATED FOR

MINIMUM 250 VAC 440 VAC FOR 230 VAC APPLICATIONS.

CONTROLLERS WITH SOLID STATE OUTPUTS MUST BE RATED

FOR MORE THAN 250 VAC. WE STRONGLY RECOMMEND THAT

RELAY OUTPUTS BE USED ON CONNECTED DEVICES. DUE TO THE

INDUCTION FEEDBACK VOLTAGE, MULTIPLE ACTUATORS CAN NOT

BE WIRED IN PARALLEL. SEPARATE ISOLATED CONTACTS MUST BE

PROVIDED FOR EACH ACTUATOR. IF THE ACTUATOR IS DRIVEN BY

CONTACTS ON A PC OR PLC, MAKE SURE THE CONTACTS HAVE THE

PROPER RATINGS.

5.3 Duty Cycle and Motor Protection

V-Series actuators can operate continuously for up to 15

minutes at 104˚F (40˚C). After 15 minutes of continuous

operation they are rated for 75% duty cycle operation at

104˚F and for 30 starts per minute. Duty cycles decrease at

temperatures in excess of 104˚F. Duty cycle is the maximum

proportion of “on” time and the minimum required “o” time

to prevent thermal overloading. Actuators with cycle times

of 30 seconds must rest at least 10 seconds between cycles.

Higher temperature applications decrease duty cycle.

AC motors contain thermal overload protection. Exceeding

the rated duty cycle may cause the thermal overload switch

to temporarily remove power to the motor and cause it to

stall. After the motor cools, the actuator will resume normal

operation. The thermal protector is a safety device, designed

for infrequent use. Constant tripping of the thermal overload

protector may cause premature motor failure.

115 VAC or 230 VAC. V-Series actuators are rated for full

torque at +/- 10% of the nominal voltage at 60 Hz. Note:

operation at 50 Hz will proportionally decrease the duty

cycle and increase the cycle time. V-Series actuators are

rated for a minimum of 75%* duty cycle at 60 Hz at 104˚F

(40˚C).

* 55% duty cycle for 3000 lb•in actuators.

5. GENERAL OPERATING INFORMATION

For enclosure specications and dimensions, see (Tables

1-2 and Figure 13).

5.1 Enclosure Ratings and Product

Certications

Metso oers two versions of V-Series actuator enclosures:

the “W” enclosure is weathertight, and the “WX” enclosure

which is weathertight and explosion-proof.

IMO 10/17

5.4 Operating Temperature Limits

V-Series actuators are designed to operate in ambient

environments between -40˚F (-40˚C) and 150˚F (65˚C). In

outdoor applications where ambient temperatures exceed

80˚F, actuators should be shielded from direct sunlight.

In applications with high media temperatures, insulating

blankets, heat shields and/or extended mounting shafts

should be used to maintain ambient temperatures at the

actuator within normal operating limits.

Heaters and thermostats are recommended for all outdoor

applications and may also be used to dry condensation in

high humidity environments.

5.5 Actuator Mounting

The actuator may be mounted in any position including

upside-down. It must be rmly secured to a direct mount

ange or sturdy mounting bracket. A minimum of four bolts

with lock washers should be used to secure the actuator to the

bracket. Flexibility in the bracket is not allowed, and backlash,

IMO-I5500 EN 11

or “play”, in the coupling should be minimized. The actuator

output shaft must be in line (centered) with the valve shaft to

avoid side-loading the shaft. See (Figure 13) for output drive

dimensions and mounting hardware specications.

WARNING

FAILURE TO USE MANUAL OVERRIDE PROPERLY COULD RESULT

IN DAMAGE TO THE ACTUATOR GEARING. ENSURE THAT THE

OVERRIDE IS FULLY DISENGAGED AND DO NOT USE EXCESSIVE

FORCE WHEN MANUALLY POSITIONING ACTUATOR. DO NOT DRIVE

THE ACTUATOR BEYOND THE TRAVEL LIMIT SETTINGS. FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN DAMAGE TO THE

ACTUATOR AND/OR FINAL DRIVE ELEMENT.

5.6 Manual Override

To use the manual override, push the override shaft down

approximately 1/4 inch to disengage the motor from the

gear train. Failure to disengage motor prior to turning

override will cause damage to the actuator. While holding

the shaft down, turn the shaft with a wrench or handle to

the desired position. NOTE: The override shaft on actuators

below 1000 lb•in must be rotated in the opposite direction

of the desired direction of the output shaft. In actuators

1000 lb•in and above, the override and the output shaft

turn in the same direction.

Do not drive the actuator beyond the limit switch settings;

it is possible to damage installed options such as a feedback

potentiometer. The manual override shaft must be returned

to its fully upward position before the motor is re-engaged.

Rotate the shaft slightly to align the spur gears until the

shaft “springs” back to its re-engaged position. NOTE: The

rotation direction of the output may not be the same as the

rotation of the override shaft!

5.9 Warranty

All V-Series actuators are backed by a 2-year warranty that

covers materials and workmanship. The warranty expires

24 months from installation or 30 months from delivery;

whichever comes rst.

To request a Return Authorization for an actuator within the

warranty period, please consult your local Metso distributor.

5.10 Repair Service/Spare Parts

We recommend that electric actuators be directed to our

Northeast Service Center for maintenance. The Service

Center is equipped to provide rapid turn-around at

reasonable cost and oer new product warranty with all

reconditioned electric actuators.

For electric actuators outside of the warranty period,

request a Return Authorization by calling the Northeast

Service Center at (508) 595-5195; or by sending an e-mail to

valvconservice@metso.com.

NOTE: When sending electric actuators to the Service

Center for repair, do not disassemble them! The actuator

should be relatively clean upon return. For further

information on spare parts and service or assistance, visit

our Web site at www.metso.com/electricactuators.

NOTE: When ordering spare parts, always include the

following information:

a. Actuator model number from the product nameplate.

b. Serial number from the product nameplate.

5.7 Lubrication

All rotating power train components are permanently

lubricated with multi-purpose Lithium grease suitable for

the operating temperature range of the actuator. Additional

lubrication is not required in normal operation.

5.8 Problem Prevention

Most actuator problems result from improper installation.

• Incorrect Wiring and Set Up Make certain the actuator is

wired correctly and travel stops are properly set before

power is applied.

• Coupling, Alignment, and Mounting Do not add extra

torque! Make certain that the mounting arrangement is

sturdy, centered, properly aligned, and that all mounting

hardware is secure and properly tightened.

• Moisture Replace the cover tightly and make certain

conduit entry holes are sealed properly to prevent

moisture inltration.

c. Part number and/or description of the part required.

d. Required quantity.

IMO 10/17

12 IMO-I5500 EN

6. SPECIFICATIONS & TECHNICAL INFORMATION

Table 1 - Torque & VA Ratings

Torque

Output at

breakaway

150 lb•in;

12 lb•ft; 17 Nm

300 lb•in;

25 lb•ft; 34 Nm

600 lb•in

50 lb•ft; 68 Nm

1000 lb•in

83 lb•ft; 113 Nm

1500 lb•in

125 lb•ft; 169 Nm

2000 lb•in

167 lb•ft; 226 Nm

2500 lb•in

208 lb•ft; 282 Nm

3000 lb•in

250 lb•ft; 339 Nm

Temperature Range -40°F to 150°F (-40°C to 65°C)

Conduit Connections

Output

Duty Cycle

Voltage

Limit Switches

Motor Split phase, capacitor driven motor with Class B or better insulation; sub-fractional horsepower

Lubrication Permanently lubricated gear train and bearings

Gear Train Hardened steel spur gears

Approximate Weight

Enclosure Die cast aluminum

Speed

(seconds

per 90˚

rotation)

8 75% 70 vA 115 vA 0.6 amps 0.5 amps 1.25 amps 0.924 amps

15 75% 70 vA 115 vA 0.6 amps 0.5 amps 1.25 amps 0.924 amps

30 75% 70 vA 115 vA 0.6 amps 0.5 amps 1.25 amps 0.924 amps

25 75% 92 vA 161 vA 0.8 amps 0.7 amps 1.66 amps 1.29 amps

40 75% 92 vA 161 vA 0.8 amps 0.7 amps 1.66 amps 1.29 amps

55 75% 92 vA 161 vA 0.8 amps 0.7 amps 1.66 amps 1.29 amps

70 75% 92 vA 161 vA 0.8 amps 0.7 amps 1.66 amps 1.29 amps

75 55% 92 vA 161 vA 0.8 amps 0.7 amps 1.66 amps 1.29 amps

Duty

Cycle

VA Rating

115 VAC 230 VAC 115VAC 230 VAC 115 VAC 230 VAC

Max Running

Current at Full Load

(True MS)

Max Eective Peak

Inrush Current (= .66 x)

Peak rush

Table 2 - Specications

(2) 3/4” NPT in sizes up to 600 lb•in (3/4” to 1/2” reducing bushings included)

(2) 3/4” NPT in sizes 1000 lb•in and above (3/4” to 1/2” reducing bushings included)

150 to 600 lb•in (12 - 25 lb•ft; 17 - 68 Nm) ISO 5211 F05 and F07 bolt circles, 3/4” female square (14mm female square w/ “I”

Option; 15mm female keyed output w/ “Y” Option).

1000 to 3000 lb•in (83 - 250 lb•ft; 113 - 339 Nm): ISO 5211 F07 and F10 bolt circles, 1” female square (1000 lb•in (83 lb•ft; 113

Nm): 19mm female square w/ “I” Option; 1500 - 3000 lb•in (125 - 250 lb•ft; 169 - 339 Nm) : 22mm female square w/ “I” Option;

1000 to 3000 lb•in (83 - 250 lb•ft; 113 - 339 Nm): 20mm female keyed output w/ “Y” Option)

The actuator may run continuously at temperatures below 104° F for up to 15 minutes. After that 15 minutes, the actuators

may run up to 75% duty cycle (between each full cycle), the actuator must rest for 1/3 of the 90 degree cycle time. NOTE: At

50 Hz, the duty cycle is ~60% at 104° F (40°C).

115 VAC: 103.5 to 126.5 VAC, 60 Hz

230 VAC: 207 to 253 VAC, 60 Hz

(2) Single pole, double throw switches rated for 11A 1/2HP 250 VAC, CSA certied, fuse protected.

Two standard switches are used for end of travel control, and for pilot or position indication at terminal 5 and terminal 6.

Indication outputs are protected by 0.25 AMP permanent auto reset polyfuses – reset time approximately 3 mins.

17 lbs (8 kg) for sizes up to 600 lb•in (50 lb•ft; 68 Nm)

31 lbs (14 kg) for sizes 1000 lb•in (83 lb•ft; 113 Nm) and above

IMO 10/17

3/4 NPT Standard

1/2 NPT with Bushing

6.000

6.1

3.1

4.1

5.8

1.7

*12.8

11.1

10.3

Optional

Handwheel

Shown

10.8

9.8

7.5

4.6

3.3

Female Square Drive

Mounting Flange, ISO 5211

All Dimensions in inches unless otherwise

0.787 (20mm)

TO REMOVE COVER REQUIRES AN ADDITIONAL 5.75"

LV-SERIES ENCLOSURES

1.50 (38.1mm)

stated

LV-Series

*11.7 WITHOUT HANDWHEEL

F07/F10

Female Keyed Drive

Actuator SizeDrive Option Drive Type Drive Size Depth

1000-3000 lb-inStandardSquare1.000 (25mm) 1.20 (30.5mm)

1000 lb-in Option "I" Square 0.748 (19mm) 1.20 (30.5mm)

1500-3000 lb-in Option "I" Square 0.866 (22mm) 1.20 (30.5mm)

1000-3000 lb-in Option "Y" Keyed

Approximate Weight 31 lb

4.6

0.75" MIN.

ON

4 X M8-1.25

2.756" B. C. ON

4 X M10-1.5

0.75" MIN.

SEE TABLE

20 mm

22.4 mm

4.8 mm

4.016" B. C.

IMO-I5500 EN 13

6.1 Dimensions

LVSERIES

Actuator Size Drive Option Drive Type Drive Size Depth

1000-3000 lb-in (83-250 lb-ft; 113-339 Nm) Standard Square 1.000 (25mm) 1.20 (30.5mm)

1000 lb-in (83 lb-ft; 113 Nm) Option “I” Square 0.748 (19mm) 1.20 (30.5mm)

1500-3000 lb-in (125-250 lb-ft; 169-339 Nm) Option “I” Square 0.866 (22mm) 1.20 (30.5mm)

1000-3000 lb-in (83-250 lb-ft; 113-339 Nm) Option ”Y” Keyed 0.787 (20mm) 1.50 (38.1mm)

VSERIES

Approximate Weight 31 lb / 14 kg

150-600 lb-in (12-50 lb-ft; 17-68 Nm) Standard Square 0.750 (19mm) 0.90 (22.9mm)

150-600 lb-in (12-50 lb-ft; 17-68 Nm) Option “I” Square 0.551 (14mm) 0.90 (22.9mm)

150-600 lb-in (12-50 lb-ft; 17-68 Nm) Option ”Y” Keyed 0.591 (15mm) 1.40 (35.6mm)

Actuator Size Drive Option Drive Type Drive Size Depth

V-Series

Figure 13

Approximate Weight 17 lb / 8 kg

IMO 10/17

14 IMO-I5500 EN

V-Series spare Parts List

6.2 Exploded View

Optional

Brake Kit

Optional

Feedback Pot Kit

Optional Extra Switch Kit

Optional

Heater Kit

Item No. Part No. Description

1 N/A Cover

Cover screw

VCK00012 Small enclosure

2 (150 – 600 lb•in)

VCK00013 Large enclosure (1000 – 3000 lb•in)

Potentiometer/Cam Shaft Gears

3 VC099090 90 degree Operation

VC099180 180 degree Operation

VC099270 270 degree Operation

Override shaft (replacement only)

4 VC091244 Small enclosure (150 – 600 lb•in)

VC093023 Large enclosure (1000 – 3000 lb•in)

Motor Gearbox

VC090101 115 VAC, 150 – 300 lb•in

VC090102 115 VAC, 600 lb•in

5 VC090201 115 VAC, 1000 – 3000 lb•in

VC090103 230 VAC, 150 – 300 lb•in

VC090104 230 VAC, 600 lb•in

VC090202 230 VAC, 1000 – 3000 lb•in

6 VC001020 Limit Switch

7 VC091352 Cam with set screw

Capacitor

VC093041 115 VAC, 150 – 600 lb•in

8 VC093061 115 VAC, 1000 – 3000 lb•in

VC093051 230 VAC, 150 – 600 lb•in

VC093071 230 VAC, 1000 – 3000 lb•in

Bracket, mounting, motor board w/screws

9 VC091695 Small enclosure (150 – 600 lb•in)

VC091698 Large enclosure (1000 – 3000 lb•in)

Bracket, motor board, upper

10 VC091684 Small enclosure (150 – 600 lb•in)

VC091688 Large enclosure (1000 – 3000 lb•in)

Motor board with screws

VC092015 115 VAC

VC092030 230 VAC

IMO 10/17

Motor Board

Optional

Control Board

Shown

V-Series option kits

Item No. Part No. Description

VC099715 Brake (ALL)

VC099200 Feedback pot (ALL)

VC099000 Extra limit switch (ALL)

VC099515 Heater Thermostat 115 VAC (ALL)

VC099523 Heater Thermostat 230 VAC (ALL)

VC099642 Control Board (ALL)

VC092065 Iso/Readback Board

Hand-wheel Override

VC009097 Small enclosure (150 – 600 lb•in)

VC009098 Large enclosure (1000 – 3000 lb•in)

VC099716 Tropical Heater/Thermostat 115 VAC

VC099723 Tropical Heater/Thermostat 230 VAC

Figure 14

IMO-I5500 EN 15

7. VSERIES ACTUATORS BY MODEL NUMBER

Table 3

Standard V/LV-Series Actuators (with “N” in model number before the voltage code)

Series Enclosure Type Torque Board Options

Code Description Cod e Description Co de Description Code Description Code Description

V W Weathertight 150 150 lb•in; C Control Board H2Tropical Heater/Thermostat N115AC 115 VAC

NEMA 4/4X 12 lb•ft; 17 Nm J Speed Control/Timer Board I3aISO 5211 Output N230AC 230 VAC

300 300 lb•in; U Iso/Readback Board K Brake

WX Weathertight & Explosionproof 25 lb•ft; 34 Nm P Feedback Potentiometer

NEMA 4/4X/7&9 600 600 lb•in; S2 Two Auxiliar y Limit Switches

50 lb•ft; 68 Nm T4Heater/Thermostat

LV W Weathertight 1000 1000 lb•in C Control Board H2Tropical Heater/Thermostat N115AC 115 VAC

NEMA 4/4X 83 lb•ft; 113 Nm J Speed Control/Timer Board I3bISO 5211 Output N230AC 230 VAC

1500 1500 lb•in U Iso/Readback Board K Brake

WX Weathertight & Explosionproof 125 lb-ft; 169 Nm P Feedback Potentiometer

NEMA 4/4X/7&9 2000 2000 lb•in S2 Two Auxiliary Limit Switches

167 lb-ft; 226 Nm T4Heater/Thermostat

2500 2500 lb•in Y5bKeyed Output

208 lb-ft; 282 Nm Z Handwheel

3000 3000 lb•in

250 lb-ft; 339 Nm

Notes: 1. Select only one board option, as needed.

2. This heater option activates at or below 90˚F and deactivates at 110˚F; it is recommended in high-humidity applications.

3a. 150 – 600 lb•in (12 - 25 lb•ft; 17 - 68 Nm) models with “I” option are supplied with a 14 mm female square (note that without option “I”

the female square is 3/4”)

3b. 1000 lb•in (83 lb•ft; 113 Nm) models with “I” option are supplied with a 19 mm female square and 1500 – 3000 lb•in (125 - 250 lb•ft;

169 - 339 Nm) models are supplied with a 22 mm female square (note that without option “I” the female square is 1”)

4. This heater option activates at or below 40˚F and deactivates at 60˚F; it is recommended in applications where the temperature may

drop below 32˚F.

5a. 150 - 600 lb•in (12 - 25 lb•ft; 17 - 68 Nm) models with “Y” option are supplied with a 15mm female keyed output.

5b. 1000 - 3000 lb•in (83 - 250 lb•ft; 113 - 339 Nm) models with “Y” option are supplied with a 20mm female keyed output.

1

Other Options Operating Voltage

Y5aKeyed Output

Z Handwheel

For enclosure specications and dimensions see (Tables1-2

and Figure 13).

• Enclosure “W” (weathertight) is certied by CSA

to meet specications for NEMA 4/4X; IP 66 for

weathertight and dust-tight, environments and is CE

compliant. It is intended for non-hazardous locations;

indoor or outdoor use.

• Enclosure “WX” (weathertight & explosionproof) is

certied by CSA to meet specications for NEMA 7&9,

hazardous locations, (Class I, Division 1, Groups C, and

D; Class II, Division 1, Groups E, F, and G; Class III) as well

as to meet NEMA 4/4X and IP 66 specications. The

enclosure is CE compliant, certied to ATEX directive

94/9/EC: Ex d IIB T6 Gb, and IECEx CSA 14.0057X.

Sample Model Code: LVW1500CHIKS2N230AC

Actuator Series LV

Enclosure Type W

Torque 1500

Board Option C

Other Options (if applicable) H

I

K

S2

Operating Voltage N230AC

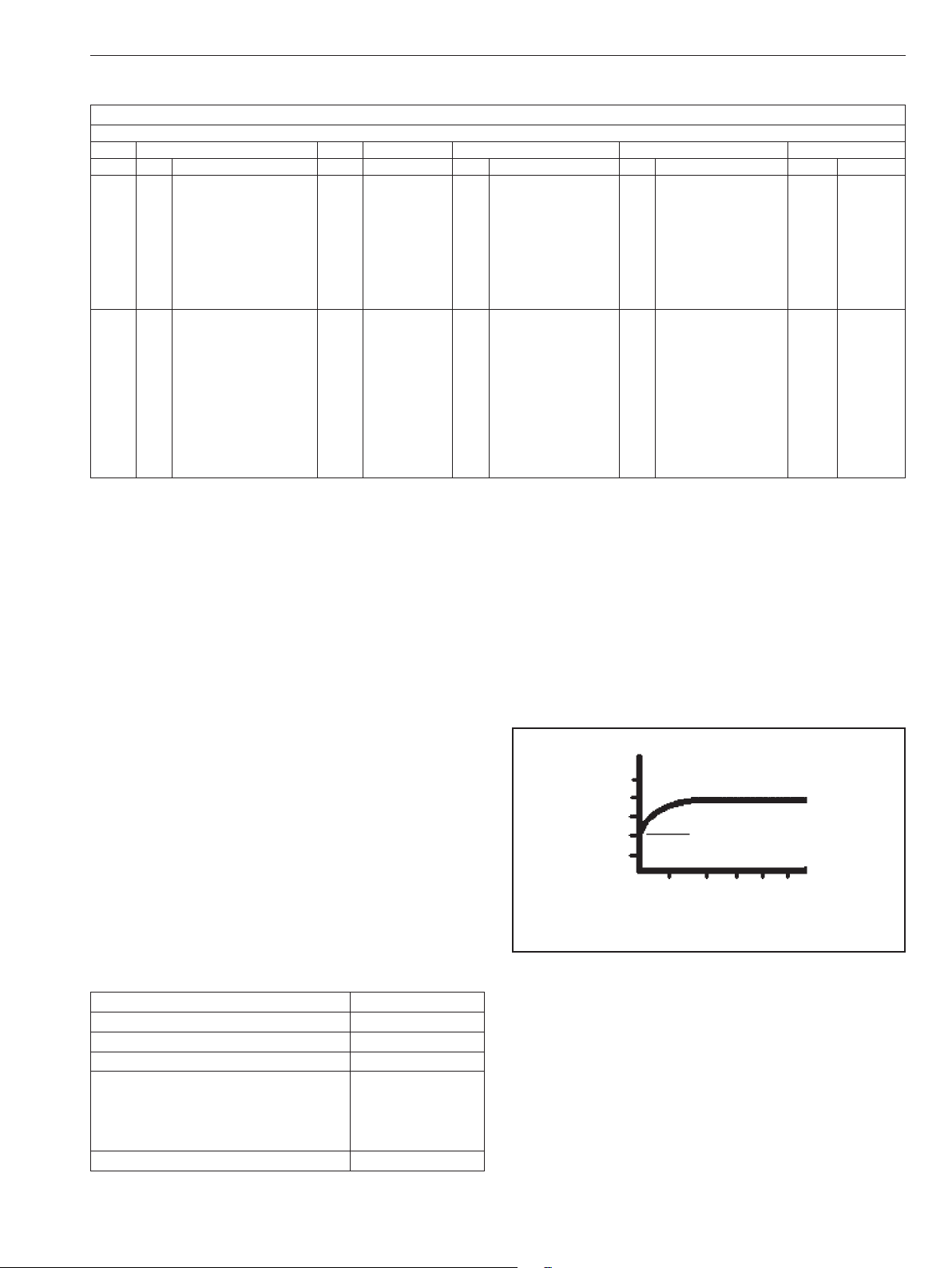

• Torque = Breakaway Torque Valvcon electric actuators

are rated at breakaway torque. This is the torque required

to move a full load immediately upon power-up.

Actuator

Torque

Breakaway

Running

Time

Figure 15

IMO 10/17

16 IMO-I5500 EN

8. ADDITIONAL ACTUATOR PRODUCTS AND ACCESSORIES FROM METSO

ADC-Series

• Universal Control Board for On/O and Modulating

applications

• Up to 3000 inch pounds (250 lb•ft; 339 Nm)

• Optional Internal Battery Back-Up

• Continuous Duty Cycle

• Universal Input Power: 115VAC, 230VAC, 24VAC, 12VDC or

24VDC

• NEMA 4/4X and NEMA 4/4X/7&9 enclosures

• CSA (C US) Certied

• CE Compliant

• Certied to ATEX Directive 94/9/EC: Ex d IIB T6 Gb, and IECEx

CSA 14.0057X (“WX” models only)

• IP 66

• Standard Features: auxiliary limit switches, heater/

thermostat, manual override and visual position indicator

• Available Options: metric and “keyed” female outputs, and

handwheel override

ESR-Series

• Up to 600 inch pounds (50 lb•ft; 68 Nm) for true “Two-Wire”

On/O applications

• 80% Duty Cycle

• 115VAC and 230VAC voltages

• NEMA 4/4X and NEMA 4/4X/7&9 enclosures

• Available Options: dynamic brake, extra limit switches,

heater/thermostats and metric and “keyed” female outputs

I-Series Network Capable

• MODBUS®

• AS-Interface

• DeviceNet™

• Foundation Fieldbus

• Other eldbus protocols (consult factory)

• CSA Certied to Canadian and U.S. standards

QX-Series

• Up to 3000 inch pounds (250 lb-ft; 339 Nm) for On/O

applications

• Economical NEMA 4/4X/7&9 solution

• 12VDC & 24VDC voltages

• 80% Duty Cycle

• CSA (C US) Certied

• Standard Features: auxiliary limit switches, dynamic brake,

manual override and visual position indicator

• Available Options: metric and “keyed” female outputs,

heater/thermostats and handwheel override

LCR Series

• Up to 600 inch pounds (50 lb-ft; 68 Nm)

• Economical actuators for Reversing applications

• 25% duty cycle (80% on 12VDC or 24VDC models)

• NEMA 4/4X enclosure

• 115VAC, 230VAC, 24VAC, 12 VDC and 24VDC voltages

• Options include extra limit switches and heater/thermostats

• Male output (standard) or female output (optional)

LCU Series

• Up to 600 inch pounds (50 lb-ft; 68 Nm)

• Economical actuators for Unidirectional applications

• 25% duty cycle (80% on 12VDC or 24VDC models)

• NEMA 4/4X enclosure

• 115VAC, 230VAC, 24VAC, 12 VDC and 24VDC voltages

• Options include extra limit switches and heater/thermostats

• Male output (standard) or female output (optional)

Q6-Series for Remote Solar Applications

• 600 inch pounds (50 lb•ft; 68 Nm)

• 12VDC

• Low current draw

• 80% Duty Cycle

• NEMA 4/4X/7&9

• CSA (C US) Certied

Subject to change without prior notice.

Metso Flow Control Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P. O. Box 8044, Shrewsbury, M A 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Te l. +55 15 2102 9700. Fax +55 15 2102 9748

China, 11/F, China Youth Plaza, No.19 North Rd of East 3rd Ring Rd, Chaoyang District, Beijing 100020, China. Te l. +86 10 6566 6600. Fax +86 10 6566 2583

Middle East, Roundabout 8, Unit AB-07, P. O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

Asia Pacic, 238B Thomson Road, #17-01 Novena Square Tower B, Singapore 307685. Tel. +65 6511 1011. Fax +65 6250 0830

www.metso.com/electricactuators

Loading...

Loading...