BALL VALVE

Series Top5

®

Installation, Maintenance and

Operating Instructions

1 T5 71 en • 12/2008

2 1 T5 71 en

Table of Contents

1 GENERAL........................................................ 3

1.1 Introduction ............................................3

1.2 Valve structure .......................................3

1.3 Markings................................................. 3

1.4 Valve approvals......................................4

1.5 CE marking ............................................4

1.6 Recycling and disposal .......................... 4

1.7 Safety precautions .................................4

2 TRANSPORTATION, RECEPTION AND

STORAGE........................................................ 5

3 INSTALLATION IN THE PIPELINE ................. 5

4 COMMISSIONING ........................................... 5

5 SERVICING...................................................... 5

5.1 Gland packing ........................................6

5.2 Dismantling the valve.. .... .......................6

5.3 Assembly................................................6

6 TESTING THE VALVE................................... 10

7 INSTALLING THE ACTUATOR .................... 10

7.1 Installing the BC/B1C-series actuator.. 10

7.2 Installing the BJ/B1J-series actuator....11

8 ORDERING SPARE PARTS ......................... 11

9 PARTS LIST .................................................. 13

10 DIMENSIONS AND WEIGHTS ...................... 14

11 TYPE CODING............................................... 20

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the valve.

If you require additional assistance, please contact the manufact urer or manufactu rer's representa tive.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

1 T5 71 en 3

1 GENERAL

1.1 Introduction

These instructions describe the installation, operation

and main-tenance of Top 5

Entry Rotary Control Valve series.

Top 5 is a generic name for a product series group

comprising the following valve series:

❑ T5 — flanged, reduced bore, single seated

❑ T4 — like T5, with weld ends

❑ T25 — full bore, flanged, otherwise like T5

❑ T35 — like T25, with weld ends.

When the valve is equipped with a control ball reducing

the flow rate and thus preventing noise and cavitation, it

is called Q-T5 etc.

Further information on the installation, operation and

maintenan-ce of actuators is given in the individual

manuals for each actuator model.

NOTE:

Selection and use of the valve in a specific application

requires close consideration of detailed aspects. Due

to the nature of the product, this manual cannot cover

all the individual situations that may occur when the

valve is used. If you are uncertain about use of the

valve or its suitability for your intended purpose,

please contact Metso’s Automation business for more

information.

®

, a valve in the Metso Top-

1.2 Valve structure

The Top 5 valve series is intended for either control or

special shut-off applications. It is tight in one direction.

The ball may be equipped with an attenuator element

(Q attenuator). The ball has been mounted on the body

and on the bonnet with bearings.

Thanks to its top entry structure, the valve is also applicable for use as a butt weld end version, because the

valve can be serviced without removing it from the

pipeline.

1.3 Markings

positioner id plate

Note. When the actuator

cover is removed, the ball

position can be checked at

the line stamped at the end

of the stem

actuator id plate

customer’s tag or position

number (if exists)

identification plate,

see fig. 3

manufacturing number

arrow showing the tight

direction, on both sides

of the body

Fig. 2 Valve markings

In addition to the markings shown in Figure 2, the valve

may have directional arrows:

FLOW DIRECTION

TIGHT DIRECTION

When standard seats are used, the arrow on the body

shows the tight direction.

(1) (2) (5) (7) (8)

ATTENTION : READ INSTRUCTIONS BEFORE INSTALLATION OR SERVICING. CONTACT METSO AUTOMATION FOR COPY.

BODY

TRIM

(3) (4) (6) (9) (10)

T max

SHAFT

SEAT

MAX. OPER. psatRATING TYPE

T min

No.

Fig. 3 Identification plate markings

MADE BY METSO AUTOMATION

MOD

XXXX

Fig. 1 The valve bonnet is bolted to the body

Identification plate markings:

1. Body material

2. Stem material

3. Trim material

4. Seat material

5. Maximum and minimum operating temperatures

6. Maximum shut-off pressure differential / temperature

7. Pressure class

8. Type designation

9. Valve manufacturing parts list no.

10. Model

The type designation is explained in Metso standard

S389. An extract of the standard is shown on page 16.

4 1 T5 71 en

1.4 Technical specifications

The identification plate must be checked for the essential safety limits in the extreme range, such as pressure

and temperature resistance and the highest operable

pressure difference.

The selected actuator size or the available instrument

air pressure may place restrictions on the highest operable pressure so that it becomes lower than the limits

determined by the mechanical strength of the valve.

Face-to-face length:

series T5 ANSI/ISA S75.03,

IEC 534-3-3

series T25, T4, T35 API Class 600

Body pressure and

temperature rating: ANSI B16.34*), see Table 1

Ball bearings:

bearings, code E Metal-reinforced PTFE

easy, low Δp use:

max. +230 °C

demanding, high Δp use:

max +200 °C

bearings, code B Cobalt based alloy

+450 °C

max. pressure difference

according to a separate

specification

Dimensions: See pages 14 and 15

Weights: See pages 14 and 15

*) Unless the selected ball bearings or flange standards impose a lower pressure and temperature restriction.

1.5 Valve approvals

The valve is fire safe for hydrocarbon applications

according to API 607 and BS 6755.

1.6 CE marking

The valve meets the requirements of the European

Directive 97/23/EC relating to pressure equipment, and

has been marked according to the Directive.

recycling and disposal instructions are available from

the manufacturer. A valve can also be returned to the

manufacturer for recycling and disposal against a fee.

1.8 Safety precautions

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations marked on the valve may

cause damage and lead to uncontrolled pressure

release. Damage or personal injury may result.

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

Dismantling or removing a pressurized valve will result in

uncontrolled pressure release. Always isolate the relevant part of the pipeline, release the pressure from the

valve and remove the medium before dismantling the

valve. Be aware of the type of medium involved. Protect

yourself and the environment from any harmful or poisonous substances. If the valve is equipped with an

actuator, do not forget to close and detach the actuator

pressure supply pipeline. Failure to do this may result in

damage or personal injury.

CAUTION:

Beware of the cutting movement of the ball!

Keep hands, other parts of the body, tools and other

objects out of the open flow port. Leave no foreign

objects inside the pipeline. When the valve is actuated,

the ball functions as a cutting device. Close and detach

the actuator pressure supply pipeline for valve maintenance. Failure to do this may result in damage or personal injury.

CAUTION:

Protect yourself from noise!

The valve may produce noise in the pipeline. The

noise level depends on the application. It can be

measured or calculated using the Metso Nelprof software. Observe the relevant work environment regulations on noise emission.

1.7 Recycling and disposal

Most valve parts can be recycled if sorted according to

material. Most parts have material marking. A material

list is supplied with the valve. In addition, separate

CAUTION:

Beware of a very cold or hot valve!

The valve body may be very cold or very hot during

use. Protect yourself against cold injuries or burns.

Table 1 Body materials commonly used by Metso and their resistance to pressure and temperature according

ANSI 16.34,

Pressur

e class

1)

ANSI

300

ANSI

600

Flange

code 1)

D A216 gr WCB

F A216 gr WCB

Body material Material

Carbon steel

A351 gr CF8M

Stainless steel

Carbon steel

A351 gr CF8M

Stainless steel

code

D

A

D

A

°C

38 50 100 150 200 250 300 350 400

51,1

49,6

102,1

99,3

50,1

48,1

100,2

96,3

46,4

42,2

92,8

84,4

45,2

38,5

90,5

77,0

43,8

35,7

87,6

71,3

41,7

33,4

83,4

66,8

38,7

31,6

77,5

63,3

37,0

30,4

73,9

60,8

34,5

29,1

69,0

58,2

1) Flange codes according to PN standards, see Chapter 13. Max resistance to pressure and temperature

depending to the flange and its material. Resistance in the middle part of the valve up to size DN 400 (16") according to table A600.

1 T5 71 en 5

2 TRANSPORTATION, RECEPTION

AND STORAGE

Check the valve and the accompanying devices for any

damage that may have occurred during transpor t.

Store the valve carefully before installation, preferably

indoors in a dry place. Do not take the valve to the

intended location and do not remove the flow port protectors until the valve is installed. The valve is delivered

in the open position, with the exception of valve packages where the actuator spring closes the valve.

NOTE:

Valves with a carbon steel body may become badly

corroded on the inside if the inside is left damp during

storing.

CAUTION:

Never lift the valve or valve package by the actuator, positioner, limit switch or their piping. Place

the lifting ropes securely around the valve body.

3 INSTALLATION IN THE PIPELINE

Remove the protecting plates around the valve and

check that the valve is clean. Flush and blow the pipeline carefully before installing the valve. Foreign particles, such as sand or pieces of welding electrode, will

damage the valve.

Check that the pipeline is supported properly. Do not

attempt to correct any pipeline misalignment by means

of the flange bolting or welding of the valve. Do not support the pipeline using the valve as help.

An arrow pointing at the tight direction of a seat that is

tight in one direction (the most commonly used version)

is cast on both sides of the valve. This is usually the

flow direction. If the flow direction and the tight direction can be opposite to each other, the piping plan must

be checked for the correct position.

Check that the unbroken side of the ball faces the seat

when the valve is in the CLOSED position.

dimensional drawing of the valve.

There should be enough free space around the valve

so that the actuator can be removed and the valve dismantled without detaching the valve from the pipeline.

Check that the indicator arrow on the actuator is parallel to the ball flow opening.

The actuator must not touch the pipeline or any permanent structures, because pipeline vibration may damage it or interfere with its operation. If the pipeline

drawings show a support for the actuator, the support

must be installed.

Make sure that the valve is in the OPEN position when

welding a weld end valve into the pipeline.

Note! A valve equipped with a BJ actuator is in the

CLOSED position when it is not pressurized. Direct

compressed air into the cylinder to turn the valve open.

When welding a valve into a pipeline, protect the valve

from welding spatter, see Fig. 5. Always ground the

welding apparatus on the side of the pipeline.

4 COMMISSIONING

The gland packing may leak after long storage. If the

packing leaks, tighten it steadily until the leaking stops.

Do not tighten the packing unnecessarily as this will

increase the required torque and impair the control

properties. (More information about the gland packing

in section 5.1.).

Check that the valve has been installed correctly in

relation to the flow direction.

Fig. 4 Installation of the valve into the pipeline

Install the valve in the position shown in the piping

installation drawing. The position code shows the installation position that should be used when the actuator

has been installed at the factory. The position code has

been given either on the specification sheet or in the

Fig. 5 Protecting the valve during welding

5 SERVICING

CAUTION:

Observe the safety precautions listed in section

1.8 before starting work.

The valve can be serviced without removing it from the

pipeline. Servicing in a workshop is, however, recommended whenever possible.

If the valve is removed from the pipeline, the body must

be supported for servicing with the stem standing

upright.

The numbers in parentheses refer to the exploded view

and the parts list on pages 12 and 13, unless otherwise

6 1 T5 71 en

indicated.

NOTE:

If you send the valve to the manufacturer for servicing,

do not dismantle it. Clean the valve. If the medium is

dangerous, inform the manufacturer when you send

the valve.

5.1 Gland packing

The gland packing of the valve may be made of graphite with a PTFE finish or it may be a model where the

lowest graphite ring has been replaced with a metallic

O-ring sleeve, see Fig. 6. If the gland packing is tightened too much, the control properties of the valve may

suffer. The need to tighten the packing may be reduced

by means of the O-rings.

Even if the O-rings were damaged, there will be enough

graphite rings to enable tightening of the packing and

to ensure reliable operation.

The standard is a graphite gland packing with a PTFE

finish.

graphite

O-ring

Fig. 7 Using a special tool to remove the gland

packing

5.2 Dismantling the valve

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

❑ Remove the actuator and the actuator mounting

shelf.

❑ Remove the key (10). Check that there are no

burrs on

❑ the edges of the key slot.

❑ Loosen the gland packing by unscrewing the

nuts (18).

❑ Remove the hexagon nuts (16) on the bonnet.

❑ Lift the bonnet. You may use an extractor as help,

see Fig. 8.

Fig. 6 Gland packing

5.1.1 Changing the gland packing

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

❑ Remove the actuator.

❑ Make sure the valve is not pressurized.

❑ Detach the gland (9).

❑ Remove the old packing rings (69), see Fig. 7.

❑ Clean the packing ring counterbore.

❑ Check that there are no burrs on the edges of the

key slot.

❑ Install the new packing rings one by one using

the gland as a tool.

❑ Tighten the gland packings uniformly.

If the packing has O-rings, lubricate them with silicone

grease before installation. Put the outer O-ring on the

bottom of the packing ring counterbore and the inner

O-ring on the gland.

Cover the stem key slot with tape, a plastic bag or other

similar material that protects the O-ring when you push

the gland over the key slot.

Fig. 8 Detaching the bonnet

❑ Turn the valve ball 180 degrees from the

CLOSED position, see Fig. 9.

❑ Lift the ball. Check that the unbroken side of the

ball does not rest on the seat, see Fig. 10.

❑ Remove the seat (7). You may use a tool to pull

out a seat that has been installed by means of Orings, see Fig. 11.

5.3 Assembly

Check all sealing surfaces with care. If necessary, lap

the sealing

surfaces with diamond powder and thereafter with

water sanding

1 T5 71 en 7

Fig. 9 Turning the ball

Fig. 10 Lifting the ball from the body

Fig. 12 Installing the seat

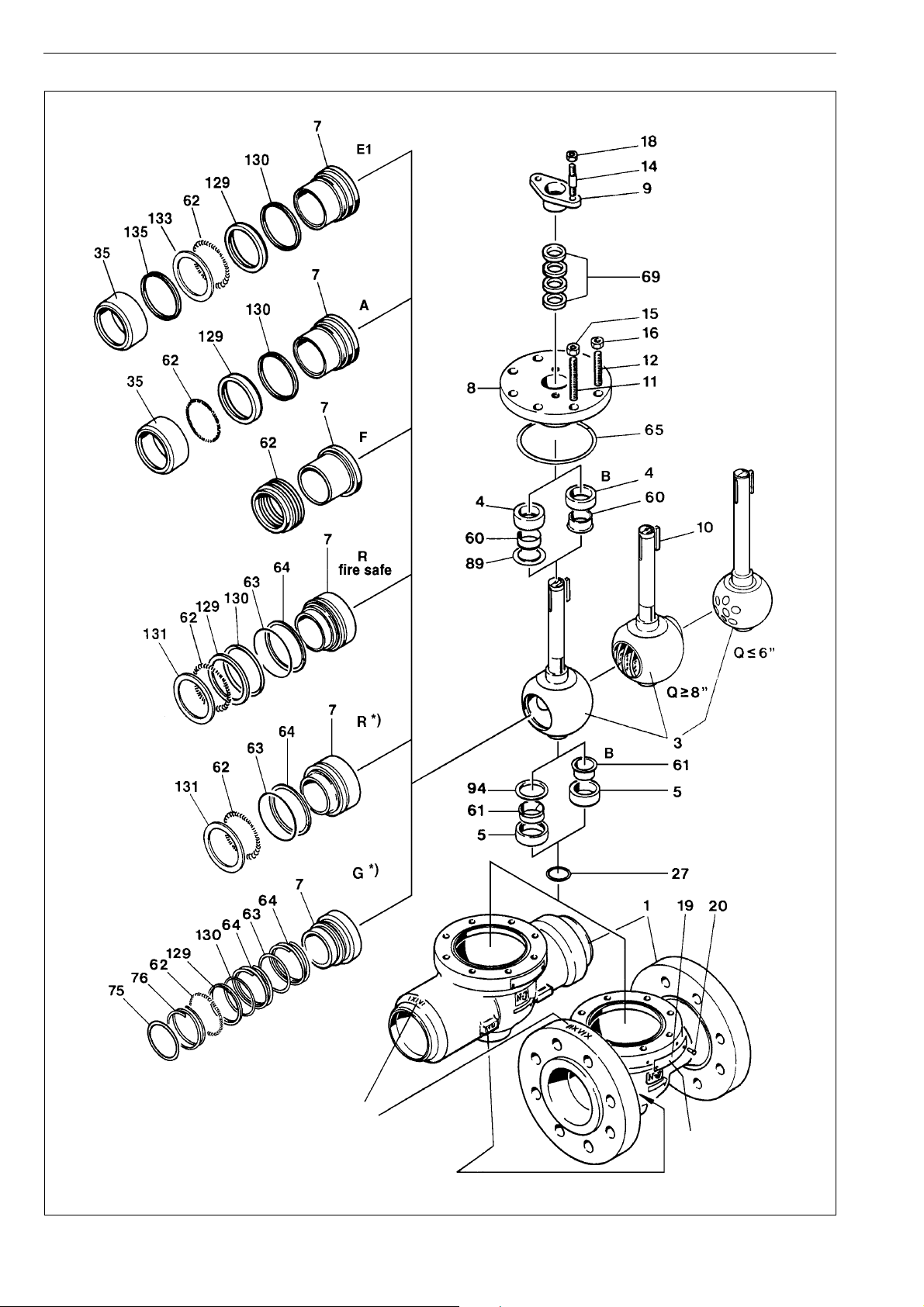

5.3.1.1 A-seat, Figure 13

❑ Check the sealing surfaces.

❑ Install the back seal (130) on the seat (7).

❑ Install the ring (129).

❑ Install the spring (62) into the seat body.

❑ Install the support ring (35).

❑ Spread some anticorrosive agent, e.g. Cortec

VCI-369, in the seat recess of a carbon steel

body.

❑ Push the seat into its place.

Fig. 11 Using a tool to pull out the seat

paper no. 1200. Clean all parts carefully.

Spray the sealing surfaces of the ball and the seat

thinly with e.g. Molykote 321R dry lubricant. Wipe the

surfaces with a soft cloth after the lubricant has dried.

Check the gland packing. If it shows any signs of dam-

age, remove it and clean the packing ring counterbore.

Do not install a new gland packing until you have put

the bonnet back.

5.3.1 Installing a seat

The same seat selection is available for all Top 5 series

valves. The dimensions of seat recesses have been

standardized to be of equal sizes since June, 1990.

Push the seat into the body by hand; the final installa-

tion is done using a tool (in the reverse order compared

Fig. 13 A seat

5.3.1.2 F-seat, Figure 14

❑ Check the sealing surfaces.

❑ Check the sealing surfaces at the ends of the

spring (62).

❑ Check the spring countersurface in the body.

❑ Spray both ends of the spring and their counter-

surfaces thinly with dry lubricant.

❑ Install the spring on the seat (7).

❑ Spread some anticorrosive agent, e.g. Cortec

VCI-369, on the countersurface of the spring in a

carbon steel body.

❑ Push the seat into its place.

8 1 T5 71 en

❑ Install the O-ring (63).

❑ Install the support ring (64) into its groove. Cut

the ribbon ends diagonally to make a flexible

seam.

❑ Only in the Fire Safe version:

❑ Install the back seal (130) and the ring (129). See

Fig. 17.

❑ Install the spring (62) into the seat body (7).

❑ Install the spring support ring (131).

Fig. 14 F seat

5.3.1.3 G-seat, Figure 15

❑ Check the sealing surfaces.

❑ Lubricate the O-rings (63, 75) with silicone

grease before installation.

❑ Install the O-ring (63).

❑ Install the support rings (64) into their groove.

Cut the ribbon ends diagonally to make a flexible

seam.

❑ Install the back seal (130) and the ring (129).

❑ Install the spring (62) into the seat body (7).

❑ Install the O-ring (75).

❑ Install the support ring (76) into its groove. Cut

the ribbon ends diagonally to make a flexible

seam. See Fig. 15.

❑ Spread some anticorrosive agent, e.g. Cortec

VCI-369, on the seat recess of a carbon steel

body.

❑ Push the seat into its place.

Fig. 16 R-seat. Delivered after 4/95 only as a spare

part.

The G-seat has been replaced with the A-seat

Deliveries of the G-seat ceased in 1990

Fig. 15 G seat

5.3.1.4 R-seat, Figures 16 and 17

❑ Check the sealing surfaces.

❑ Lubricate the O-ring (63) with silicone grease

before installation.

Fig. 17 R-seat (Fire Safe)

5.3.1.5 E1-seat, Figure 18

❑ Check the sealing surfaces.

❑ Install the back seal (130) on the seat (7).

❑ Install the ring (129).

❑ Install the spring (62) into the seat body.

❑ Install the ring (133).

❑ Install the seal (135).

❑ Install the support ring (35).

❑ Spread some anticorrosive agent, e.g. Cortec

VCI-369, in the seat recess of a carbon steel

body.

❑ Push the seat into its place.

1 T5 71 en 9

using a press-on fit. See Fig. 20.

If the surfaces are badly damaged and cannot be

‘restored’ using an abrasive cloth, the bearings and the

ball must be replaced.

When installing new bearings (4, 5), lock them securely

to the bonnet and the body using a nail punch.

thrust bearing (4)

bearing (60)

sleeves made of

Fig. 18 E1-seat

5.3.2 Installation of bearings

Check the bearings and the bearing surfaces. If neces-

sary, grind the bearing surfaces with an abrasive cloth

and replace worn bearings. Spray the bearing surfaces

special steel have been

installed in the ball

using a press-on fit

Fig. 20 Heat-resistant bearings

5.3.3 Installing the ball

(5, 61)

lightly with dry lubricant.

If the ball surface has deep scratches that cannot be

5.3.2.1 Standard bearings

The bearing material is PTFE reinforced with an acid-

resistant steel

net. If the bearings are so worn that the net is visible on

the wear

surface, you should replace the bearings (60, 61, 89,

94). See Fig. 19.

removed using an abrasive cloth or if it is not completely round, you should send the ball to the manufacturer for repair.

Adjust the seat to the ball by lapping them together with

diamond powder before you install the ball (and the

seat) into the body.

Install the ball into the body with the ‘cut’ side against

the seat. Take care not to damage the bearing and the

seat with the ball. In valves that have PTFE bearings

and have a size of 6" or more, the bearings (94, 61, 5)

are ready-fitted on the ball and locked using a lock ring

bearing (60)

(27).

When the ball is in its place, turn the ball against the

seat and check visually that the ball has enough room

to complete the operating circle and that it turns easily

thrust bearing (89)

(61, 94)

against the seat.

5.3.4 Installing the bonnet

The bonnet is installed in the reverse order compared

to the disassembly, see section 5.2. Spray the bolts

lightly with Molykote 321R dry lubricant.

Fig. 19 Standard bearings

Twist the bonnet gasket (graphite ribbon) around two

times so that the ends overlap for about 25 mm, see

5.3.2.2 Heat-resistant bearings

Fig. 21.

The position of the ball in the direction of the stem is

determined by means of the bearings (4, 60). Pipeline

pressure causes a pressure force towards the cross

section of the ball stem; this force removes the clear-

ances against the bearings (4, 60) supported on the

bonnet.

The bearings (4, 5) are precision-machined cobalt

based alloy sleeves.

The bearing countersurface is a sleeve (60, 61) of spe-

cial steel, which has been installed against the ball

10 1 T5 71 en

Fig. 21 Installing a gasket for the bonnet

Pull at the stem to make the ball perpendicular. The

bonnet settles in the correct position, and the necessary pre-compression between the ball and the seat is

achieved, see Fig. 22.

Table 2 Torques for the bonnet nuts

Val ve sizeDNScrews Stage 1

0,2xM

(Nm)

4

20

20

20

35

80

80

80

165

165

165

01

015

02

03

04

06

08

10

12

14

16

Size

UNC

3/8

5/8

5/8

5/8

3/4

1

1

1

1 1/4

1 1/4

1 1/4

Pcs. Wrench

opening

8

6

6

8

8

8

12

16

16

22

22

1 1/16

1 1/16

1 1/16

1 1/16

1 1/4

1 5/8

1 5/8

1 5/8

2

2

2

6 TESTING THE VALVE

CAUTION:

Pressure testing should be carried out using

equipment conforming to the correct pressure

class!

We recommend that the valve body be pressure tested

after the valve has been assembled.

The pressure test should be carried out in accordance

with an applicable standard using the pressure rating

required by the pressure class or flange bore of the

valve. The valve must be in an open position during the

test.

If you also want to test the tightness of the closure

member, contact the manufacturer.

7 INSTALLING THE ACTUATOR

CAUTION:

Beware of the cutting movement of the ball!

Installation of the actuator must not cause bearing

loads on the valve. The valve has two bearings, and the

actuator serves as the third bearing. They must all be

aligned.

Fig. 22 Adjusting the bonnet by pulling at the ball stem

Tighten the bonnet nuts crosswise as shown in Table 2.

Stages 1 to 4: all bolts are tightened crosswise.

Stage 5: the bolts are tightened in succession along the

circumference.

Install the gland packing as explained in section 5.1.

final

Stage 2

0,5xM

(Nm)

10

50

50

50

90

200

200

200

415

415

415

final

Stage 3

0,8xM

(Nm)

16

80

80

80

145

320

320

320

665

665

665

final

Stage 4

1xM

final

(Nm)

20

100

100

100

180

400

400

400

830

830

830

Stage 5

1xM

final

(Nm)

20

100

100

100

180

400

400

400

830

830

830

If the actuator causes extra torsion on the stem, it is

seen as increased need for torque and impaired control properties.

More detailed information on actuators can be obtained

from the installation, operation and maintenance

instructions for each actuator type.

7.1 Installing the BC/B1C-series

actuator

❑ Drive the actuator piston to the extreme outward

end and turn the valve into the closed position.

❑ Clean the stem bore and file off any burrs.

❑ If a coupling is needed between the actuator and

the valve stem, install it into the stem bore. Lubricate the coupling and stem bore. Note the correct position. The line at the end of the stem

indicates the direction of the ball flow bore.

❑ Fasten the bracket loosely to the valve.

❑ Push the actuator carefully onto the valve stem.

Avoid forcing it, since this may damage the ball

and seats. We recommend mounting the actuator so that the cylinder is pointing upwards.

❑ Align the actuator as accurately as possible

using the valve as help. Lubricate the mounting

1 T5 71 en 11

screws. Install the washers and tighten all

screws. Final tightening may not change the

position of the fixture.

❑ Adjust the ball open and closed positions (limits

to piston movement) by means of the actuator

stop screws (see Fig. 23). An accurate open

position can be seen in the body flow bore.

Check that the yellow arrow indicates the direction of the ball flow bore. "Times"Keep your fin-

gers out of the flow bore!

There is no need to adjust the stop screw if the actuator

is re-installed in the same valve. Drive the actuator piston to the housing end (open position). Turn the actuator by hand until the valve is in the open position

(unless it is already open). Fasten the actuator in this

position.

❑ Check the tightness of the stop screw at the end

of the cylinder during cylinder operation. An O-

ring is used for sealing.

❑ Check that the actuator is functioning correctly.

Check the ball flow bore position and the actua-

tor movement relative to the valve (clockwise:

close, counterclockwise: open) after installing

the actuator. The valve should be closed when

the piston is in the extreme outward position.

❑ Check that the yellow arrow indicates the direc-

tion of the flow bore. If necessary, change the

position of the arrow.

7.2.1 BJ/B1J-type

Install the actuator so that the piston is in the extreme

outward position. The cylinder must not be pressurized

and air supply connections must be open. The valve

must be in the closed position.

7.2.2 BJA/B1JA-type

Install the actuator so that the piston is in the cylinderend position at housing side. The cylinder must not be

pressurized and the air supply connection must be

open. The valve must be in the open position.

The rest of the installation procedure is the same as for

the BC/B1C actuator.

8 ORDERING SPARE PARTS

When ordering spare parts, always include the following information:

❑ type code, sales order number, serial number

(stamped on a valve body)

❑ number of the parts list, part number, name of

the part and quantity required

This information can be found from the identification

plate or documents.

Limiting screw for the

CLOSED position

Limiting screw for the

OPEN position

Fig. 23 Open and closed position in a B1 actuator

7.2 Installing the BJ/B1J-series actuator

Spring-return actuators are used in applications where

valve opening or closing movement is needed in case

the air supply is interrupted. The BJ/B1J type is used

for spring-to-close operation; the spring pushes the piston towards the cylinder end, the extreme outward

position. In turn, the BJA/B1JA type is used for springto-open operation; the spring is between the piston and

the cylinder end and pushes the piston towards the

housing.

Spring-return actuators are installed in a manner similar

to BC/B1C-series actuators, taking into account the following.

12 1 T5 71 en

9 EXPLODED VIEW

1 T5 71 en 13

10 PARTS LIST

Item Qty. Description Spare part category

1 1 Body

3 1 Ball 3

4 1 Thrust bearing 3

5 1 Trunnion bearing 3

7 1 Seat 2

8 1 Bonnet

9 1 Gland

10 1 Key 3

11 Stud

12 Stud

14 Stud

15 Hexagon nut

16 Hexagon nut

18 Hexagon nut

19 1 Identification plate

20 2 Screw

27 1 Lock ring

35 1 Support ring 2

60 1 Bearing 3

61 1 Bearing 3

62 1 Spring 2

63 1 O-ring

64 1 (G-seat: 2) Support ring

65 1 Gasket 1

69 Gland packing 1

75 1 O-ring

76 1 ( 4") Support ring

89 1 Thrust bearing 1***

94 1 Thrust bearing 1***

125 1 O-ring sleeve

129 1 Ring 2

130 1 Back seal 2

131 1 Spring retainer

133 1 Ring

135 1 Seal

Spare part category 1: Recommended soft parts, always needed for the repair. Delivered as a set.

***) Bearing set

Spare part category 2: Parts for replacing of the seat. Delivered as a set.

Spare part category 3: Parts for replacing of the closing element.

Spares for the full overhaul: All parts from the categories 1, 2 and 3

14 1 T5 71 en

11 DIMENSIONS AND WEIGHTS

T5D-BC, B1C

Type DN A _B _D F G H I J V X NPT kg

T5D01 - B1C6 25 197 124 25 400 260 335 215 191 36 90 1/4 14

T5D01 - B1C9 25 197 124 25 455 315 330 220 192 43 110 1/4 20

T5D015 - B1C6 40 235 155.4 38 400 260 380 215 223 36 90 1/4 19

T5D015 - B1C9 40 235 155.4 38 455 315 380 220 225 43 110 1/4 25

T5D015 - B1C11 40 235 155.4 38 540 375 390 225 230 51 135 3/8 31

T5D02 - B1C6 50 267 165.1 38 400 260 385 215 223 36 90 1/4 23

T5D02 - B1C9 50 267 165.1 38 455 315 385 220 225 43 110 1/4 29

T5D02 - B1C11 50 267 165.1 38 540 375 395 225 230 51 135 3/8 35

T5D03 - B1C11 80 317 209.5 50 540 375 430 225 245 51 135 3/8 48

T5D03 - B1C13 80 317 209.5 50 635 445 460 235 260 65 175 3/8 63

T5D04 - B1C13 100 368 254 76 635 445 525 235 303 65 175 3/8 87

T5D04 - B1C17 100 368 254 76 770 545 555 255 315 78 215 1/2 110

T5D04 - B1C20 100 368 254 76 840 575 590 270 337 97 215 1/2 129

T5D06 - B1C17 150 473 317.5 102 770 545 645 255 375 78 215 1/2 169

T5D06 - B1C20 150 473 317.5 102 840 575 680 270 397 97 215 1/2 188

T5D06 - B1C25 150 473 317.5 102 1040 710 735 310 415 121 265 1/2 245

T5D08 - B1C20 200 568 381 125 840 575 755 270 440 97 215 1/2 312

T5D08 - B1C25 200 568 381 125 1040 710 815 310 465 121 265 1/2 369

T5D08 - B1C32 200 568 381 125 1330 910 895 350 505 153 395 3/4 489

T5D10 - B1C25 250 708 444.5 152 1040 710 865 310 480 121 265 1/2 445

T5D10 - B1C32 250 708 444.5 152 1330 910 940 350 515 153 395 3/4 565

T5D10 - B1C40 250 708 444.5 152 1660 1150 1040 370 565 194 505 3/4 760

T5D12 - B1C25 300 775 520.7 202 1040 710 960 310 539 121 265 1/2 660

T5D12 - B1C32 300 775 520.7 202 1330 910 1040 350 576 153 395 3/4 780

T5D12 - B1C40 300 775 520.7 202 1660 1150 1140 370 626 194 505 3/4 975

T5D14 - B1C32 350 927 584.2 254 1330 910 1250 350 755 153 395 3/4 1300

T5D14 - B1C40 350 927 584.2 254 1660 1150 1350 370 805 194 505 3/4 1495

T5D14 - B1C50 350 927 584.2 254 1970 1350 1455 415 855 242 610 1 1880

T5D16 - B1C32 400 1057 647.7 254 1330 910 1280 350 755 153 395 3/4 1350

T5D16 - B1C40 400 1057 647.7 254 1660 1150 1385 370 805 194 505 3/4 1545

T5D16 - B1C50 400 1057 647.7 254 1970 1350 1485 415 855 242 610 1 1930

1 T5 71 en 15

T5F-BC, B1C

Type DN A _B _D F G H I J V X NPT kg

T5F01 - B1C6 25 210 124 25 400 260 298 215 191 36 90 1/4 15

T5F01 - B1C9 25 210 124 25 455 315 309 220 192 43 110 1/4 21

T5F015 - B1C6 40 251 155.4 38 400 260 350 215 223 36 90 1/4 21

T5F015 - B1C9 40 251 155.4 38 455 315 380 220 225 43 110 1/4 27

T5F015 - B1C11 40 251 155.4 38 540 375 390 225 230 51 135 3/8 33

T5F02 - B1C6 50 286 165.1 38 400 260 385 215 223 36 90 1/4 25

T5F02 - B1C9 50 286 165.1 38 455 315 385 220 225 43 110 3/8 31

T5F02 - B1C11 50 286 165.1 38 540 375 395 225 230 51 135 3/8 37

T5F03 - B1C11 80 337 209.5 50 540 375 430 225 245 51 135 3/8 52

T5F03 - B1C13 80 337 209.5 50 635 445 460 235 260 65 175 3/8 67

T5F04 - B1C13 100 394 273.1 76 635 445 535 235 303 65 175 3/8 100

T5F04 - B1C17 100 394 273.1 76 770 545 565 255 315 78 215 1/2 123

T5F04 - B1C20 100 394 273.1 76 840 575 600 270 337 97 215 1/2 142

T5F06 - B1C17 150 508 355.6 102 770 545 665 255 375 78 215 1/2 201

T5F06 - B1C20 150 508 355.6 102 840 575 700 270 397 97 215 1/2 220

T5F06 - B1C25 150 508 355.6 102 1040 710 755 310 415 121 265 1/2 277

T5F08 - B1C20 200 610 419.1 125 840 575 775 270 440 97 215 1/2 360

T5F08 - B1C25 200 610 419.1 125 1040 710 835 310 465 121 265 1/2 417

T5F08 - B1C32 200 610 419.1 125 1330 910 915 350 505 153 395 3/4 537

T5F10 - B1C25 250 752 508 152 1040 710 895 310 480 121 265 1/2 533

T5F10 - B1C32 250 752 508 152 1330 910 970 350 515 153 395 3/4 653

T5F10 - B1C40 250 752 508 152 1660 1150 1075 370 565 194 505 3/4 848

T5F12 - B1C25 300 819 558.8 202 1040 710 980 310 539 121 265 1/2 743

T5F12 - B1C32 300 819 558.8 202 1330 910 1060 350 576 153 395 3/4 863

T5F12 - B1C40 300 819 558.8 202 1660 1150 1160 370 626 194 505 3/4 1058

T5F14 - B1C32 350 972 603.3 254 1330 910 1260 350 755 153 395 3/4 1373

T5F14 - B1C40 350 972 603.3 254 1660 1150 1360 370 805 194 505 3/4 1568

T5F14 - B1C50 350 972 603.3 254 1970 1350 1465 415 855 242 610 1 1953

T5F16 - B1C32 400 1108 685.8 254 1330 910 1300 350 755 153 395 3/4 1478

T5F16 - B1C40 400 1108 685.8 254 1660 1150 1400 370 805 194 505 3/4 1673

T5F16 - B1C50 400 1108 685.8 254 1970 1350 1505 415 855 242 610 1 2058

T5D-BJ/BJA, B1J/B1JA

Type DN A _B _D F G H I J V X NPT kg

T5D01 - B1J/B1JA8 25 197 124 25 560 420 320 220 192 43 135 3/8 27

T5D01 - B1J10 25 197 124 25 650 490 350 225 198 51 175 3/8 40

T5D015 - B1J/B1JA8 40 235 155.4 38 560 420 380 220 225 43 135 3/8 32

T5D015 - B1J/B1JA10 40 235 155.4 38 650 490 395 225 230 51 175 3/8 45

T5D015 - B1J12 40 235 155.4 38 800 620 440 235 255 65 215 1/2 72

T5D02 - B1J/B1JA8 50 267 165.1 38 560 420 385 220 225 43 135 3/8 36

T5D02 - B1J/B1JA10 50 267 165.1 38 650 490 400 225 230 51 175 3/8 49

T5D02 - B1J12 50 267 165.1 38 800 620 445 235 255 65 215 1/2 76

T5D03 - B1J/B1JA10 80 317 209.5 50 650 490 440 225 245 51 175 3/8 62

T5D03 - B1J/B1JA12 80 317 209.5 50 800 620 475 235 260 65 215 1/2 89

T5D03 - B1J/B1JA16 80 317 209.5 50 990 760 515 255 275 78 265 1/2 132

T5D04 - B1J/B1JA12 100 368 254 76 800 620 540 235 303 65 215 1/2 113

T5D04 - B1J/B1JA16 100 368 254 76 990 760 575 255 315 78 265 1/2 156

T5D04 - B1J/B1JA20 100 368 254 76 1200 935 660 270 337 97 395 3/4 231

T5D06 - B1J/B1JA16 150 473 317.5 102 990 760 670 255 378 78 265 1/2 215

T5D06 - B1J/B1JA20 150 473 317.5 102 1200 935 755 270 395 97 395 3/4 290

T5D06 - B1J/B1JA25 150 473 317.5 102 1530 1200 830 310 415 121 505 3/4 465

T5D08 - B1J/B1JA20 200 568 381 125 1200 935 830 270 440 97 395 3/4 414

T5D08 - B1J/B1JA25 200 568 381 125 1530 1200 910 310 465 121 505 3/4 589

T5D08 - B1J/B1JA32 200 568 381 125 1830 1410 965 350 505 153 540 1 909

T5D10 - B1J/B1JA20 250 708 444.5 152 1200 935 865 270 445 97 395 3/4 490

T5D10 - B1J/B1JA25 250 708 444.5 152 1530 1200 955 310 480 121 505 3/4 665

T5D10 - B1J/B1JA32 250 708 444.5 152 1830 1410 1010 350 515 153 540 1 985

T5D12 - B1J/B1JA25 300 775 520.7 202 1530 1410 1055 270 539 121 505 3/4 880

T5D12 - B1J/B1JA32 300 775 520.7 202 1830 1410 1110 350 576 153 540 1 1200

T5D14 - B1J/B1JA32 350 927 584.2 254 1830 1410 1320 350 755 153 540 1 1720

T5D16 - B1J/B1JA32 400 1057 647.7 254 1830 1410 1350 350 755 153 540 1 1770

16 1 T5 71 en

T5F-BJ/BJA, B1J/B1JA

Type DN A _B _D F G H I J V X NPT kg

T5F01 - B1J/B1JA8 25 210 124 25 560 420 320 220 192 43 135 3/8 28

T5F01 - B1J10 25 210 124 25 650 490 350 225 198 51 175 3/8 41

T5F015 - B1J/B1JA8 40 251 155.4 38 560 420 380 220 225 43 135 3/8 34

T5F015 - B1J/B1JA10 40 251 155.4 38 650 490 395 225 230 51 175 3/8 47

T5F015 - B1J12 40 251 155.4 38 800 620 440 235 255 65 215 1/2 74

T5F02 - B1J/B1JA8 50 286 165.1 38 560 420 385 220 225 43 135 3/8 38

T5F02 - B1J/B1JA10 50 286 165.1 38 650 490 400 225 230 51 175 3/8 51

T5F02 - B1J12 50 286 165.1 38 800 620 445 235 255 65 215 1/2 78

T5F03 - B1J/B1JA10 80 337 209.5 50 650 490 440 225 245 51 175 3/8 66

T5F03 - B1J/B1JA12 80 337 209.5 50 800 620 475 235 260 65 215 1/2 93

T5F03 - B1J/B1JA16 80 337 209.5 50 990 760 515 255 275 78 265 1/2 136

T5F04 - B1J/B1JA12 100 394 273.1 76 800 620 550 235 303 65 215 1/2 126

T5F04 - B1J/B1JA16 100 394 273.1 76 990 760 585 255 315 78 265 1/2 169

T5F04 - B1J/B1JA20 100 394 273.1 76 1200 935 670 270 337 97 395 3/4 244

T5F06 - B1J/B1JA16 150 508 355.6 102 990 760 690 255 378 78 265 1/2 247

T5F06 - B1J/B1JA20 150 508 355.6 102 1200 935 770 270 395 97 395 3/4 322

T5F06 - B1J/B1JA25 150 508 355.6 102 1530 1200 845 310 415 121 505 3/4 497

T5F08 - B1J/B1JA20 200 610 419.1 125 1200 935 850 270 440 97 395 3/4 467

T5F08 - B1J/B1JA25 200 610 419.1 125 1530 1200 930 310 465 121 505 3/4 637

T5F08 - B1J/B1JA32 200 610 419.1 125 1830 1410 985 350 505 153 540 1 957

T5F10 - B1J/B1JA20 250 752 508 152 1200 935 900 270 445 97 395 3/4 578

T5F10 - B1J/B1JA25 250 752 508 152 1530 1200 990 310 480 121 505 3/4 753

T5F10 - B1J/B1JA32 250 752 508 152 1830 1410 1040 350 515 153 540 1 1073

T5F12 - B1J/B1JA25 300 819 558.8 202 1530 1200 1070 310 539 121 505 3/4 963

T5F12 - B1J/B1JA32 300 819 558.8 202 1830 1410 1125 350 576 153 540 1 1283

T5F14 - B1J/B1JA32 350 927 603.3 254 1830 1410 1330 350 755 153 540 1 1793

T5F16 - B1J/B1JA32 400 1108 685.8 254 1830 1410 1370 350 755 153 540 1 1898

T25F-BC, B1C

Type DN A _B _D F G H I J V X NPT kg

T25F02 - B1C11 50 292 165.1 50 540 375 410 225 245 51 135 3/8 53

T25F02 - B1C13 50 292 165.1 50 635 445 440 235 260 65 175 3/8 68

T25F03 - B1C13 80 356 209.5 76 635 445 500 235 300 65 175 3/8 107

T25F03 - B1C17 80 356 209.5 76 770 545 530 255 315 78 215 1/2 130

T25F03 - B1C20 80 356 209.5 76 840 575 570 270 337 97 215 1/2 145

T25F04 - B1C17 100 432 273.1 102 770 545 625 255 375 78 215 1/2 205

T25F04 - B1C20 100 432 273.1 102 840 575 660 270 397 97 215 1/2 218

T25F04 - B1C25 100 432 273.1 102 1040 710 715 310 415 121 265 1/2 285

T25F06 - B1C25 150 559 355.6 152 1040 710 820 310 480 121 265 1/2 445

T25F06 - B1C32 150 559 355.6 152 1330 910 895 350 515 153 395 3/4 565

T25F06 - B1C40 150 559 355.6 152 1660 1150 995 370 565 194 505 3/4 760

T25F08 - B1C25 200 660 419.1 202 1040 710 910 310 539 121 265 1/2 630

T25F08 - B1C32 200 660 419.1 202 1330 910 990 350 576 153 395 3/4 770

T25F08 - B1C40 200 660 419.1 202 1660 1150 1090 370 626 194 505 3/4 970

T25F10 - B1C32 250 787 508.0 254 1330 910 1210 350 755 153 395 3/4 1080

T25F10 - B1C40 250 787 508.0 254 1660 1150 1315 370 805 194 505 3/4 1270

T25F10 - B1C50 250 787 508.0 254 1970 1350 1415 415 855 242 610 1 1660

T25F-BJ/BJA, B1J/B1JA

Type DN A _B _D F G H I J V X NPT kg

T25F02 - B1J/B1JA10 50 292 165.1 50 650 490 415 225 245 51 175 3/8 67

T25F02 - B1J/B1JA12 50 292 165.1 50 800 620 450 235 260 65 215 1/2 95

T25F02 - B1J/B1JA16 50 292 165.1 50 990 760 490 255 275 78 265 1/2 140

T25F03 - B1J/B1JA12 80 356 209.5 76 800 620 515 235 303 65 215 1/2 129

T25F03 - B1J/B1JA16 80 356 209.5 76 990 760 555 255 315 78 265 1/2 175

T25F03 - B1J/B1JA20 80 356 209.5 76 1200 935 640 270 335 97 395 3/4 250

T25F04 - B1J/B1JA16 100 432 273.1 102 990 760 650 255 378 78 265 1/2 245

T25F04 - B1J/B1JA20 100 432 273.1 102 1200 935 730 270 395 97 395 3/4 330

T25F04 - B1J/B1JA25 100 432 273.1 102 1530 1200 805 310 415 121 505 3/4 500

T25F06 - B1J/B1JA20 150 559 355.6 152 1200 935 820 270 445 97 395 3/4 480

T25F06 - B1J/B1JA25 150 559 355.6 152 1530 1200 910 310 480 121 505 3/4 660

T25F06 - B1J/B1JA32 150 559 355.6 152 1830 1410 965 350 515 153 540 1 980

T25F08 - B1J/B1JA25 200 660 419.1 202 1530 1200 1005 310 539 121 505 3/4 860

T25F08 - B1J/B1JA32 200 660 419.1 202 1830 1410 1060 350 576 153 540 1 1180

T25F10 - B1J/B1JA32 250 787 508 254 1830 1410 1280 350 755 153 540 1 1490

1 T5 71 en 17

T4D-BC, B1C

Type DN A _B C _D _E F G H I J V X NPT kg

T4D01 - B1C6 25 210 36 38 25 26.6 400 260 275 215 191 36 90 1/4 20

T4D01 - B1C9 25 210 36 38 25 26.6 455 315 365 220 192 43 110 1/4 26

T4D015 - B1C6 40 251 52 60 38 40.6 400 260 365 215 223 51 135 1/4 22

T4D015 - B1C9 40 251 52 60 38 40.6 455 315 360 220 225 43 110 1/4 27

T4D015 - B1C11 40 251 52 60 38 40.6 540 375 370 225 230 51 135 3/8 33

T4D02 - B1C6 50 292 62 60 38 52.5 400 260 365 215 223 43 110 1/4 22

T4D02 - B1C9 50 292 62 60 38 52.5 455 315 360 220 225 43 110 1/4 30

T4D02 - B1C11 50 292 62 60 38 52.5 540 375 370 225 230 51 135 3/8 36

T4D03 - B1C11 80 356 91 68 50 77.9 540 375 395 225 245 51 135 3/8 50

T4D03 - B1C13 80 356 91 68 50 77.9 635 445 425 235 260 65 175 3/8 65

T4D04 - B1C13 100 432 117 90 76 102.3 635 445 425 235 300 65 175 3/8 100

T4D04 - B1C17 100 432 117 90 76 102.3 770 545 515 255 315 78 215 1/2 125

T4D04 - B1C20 100 432 117 90 76 102.3 840 575 552 270 337 97 215 1/2 205

T4D06 - B1C17 150 559 172 122 102 154.1 770 545 610 255 375 78 215 1/2 185

T4D06 - B1C20 150 559 172 122 102 154.1 840 575 645 270 397 97 215 1/2 198

T4D06 - B1C25 150 559 172 122 102 154.1 1040 710 700 310 415 121 265 1/2 265

T4D08 - B1C20 200 660 223 140 125 202.7 840 575 705 270 440 97 265 1/2 283

T4D08 - B1C25 200 660 223 140 125 202.7 1040 710 765 310 465 121 265 1/2 350

T4D08 - B1C32 200 660 223 140 125 202.7 1330 910 845 350 505 153 395 3/4 480

T4D10 - B1C25 250 787 278 170 152 254.4 1040 710 810 310 480 121 265 1/2 425

T4D10 - B1C32 250 787 278 170 152 254.4 1330 910 885 350 515 153 395 3/4 545

T4D10 - B1C40 250 787 278 170 152 254.4 1660 1150 995 370 565 194 505 3/4 735

T4D12 - B1C25 300 838 329 210 202 303.2 1040 710 960 310 539 121 265 1/2 605

T4D12 - B1C32 300 838 329 210 202 303.2 1330 910 990 350 576 153 395 3/4 745

T4D12 - B1C40 300 838 329 210 202 303.2 1660 1150 1090 370 626 194 505 3/4 945

T4D14 - B1C32 350 889 362 275 254 333.4 1330 910 1230 350 755 153 395 3/4 1210

T4D14 - B1C40 350 889 362 275 254 333.4 1660 1150 1335 370 805 194 505 3/4 1400

T4D14 - B1C50 350 889 362 275 254 333.4 1970 1350 1435 415 855 242 610 1 1790

T4D16 - B1C32 400 991 413 275 254 381.0 1330 910 1230 350 755 153 395 3/4 1260

T4D16 - B1C40 400 991 413 275 254 381.0 1660 1150 1335 370 805 194 505 3/4 1450

T4D16 - B1C50 400 991 413 275 254 381.0 1970 1350 1435 415 855 242 610 1 1840

18 1 T5 71 en

T4F-BC, B1C

Type DN A _B C _D _E F G H I J V X NPT kg

T4F01 - B1C6 25 210 36 38 25 24.4 400 260 275 215 191 36 90 1/4 20

T4F01 - B1C9 25 210 36 38 25 24.4 455 315 365 220 192 43 110 1/4 26

T4F015 - B1C6 40 251 52 60 38 37.8 400 260 365 225 223 51 135 1/4 22

T4F015 - B1C9 40 251 52 60 38 37.8 455 315 360 220 225 43 110 1/4 27

T4F015 - B1C11 40 251 52 60 38 37.8 540 375 370 225 230 51 135 3/8 33

T4F02 - B1C6 50 292 62 60 38 49.3 400 260 365 225 223 51 135 1/4 22

T4F02 - B1C9 50 292 62 60 38 49.3 455 315 360 220 225 43 110 1/4 30

T4F02 - B1C11 50 292 62 60 38 49.3 540 375 370 225 230 51 135 3/8 36

T4F03 - B1C11 80 356 91 68 50 73.7 540 375 395 225 245 51 135 3/8 50

T4F03 - B1C13 80 356 91 68 50 73.7 635 445 425 235 260 65 175 3/8 65

T4F04 - B1C13 100 432 117 90 76 97.1 635 445 425 235 303 65 175 3/8 100

T4F04 - B1C17 100 432 117 90 76 97.1 770 545 515 255 315 78 215 1/2 125

T4F04 - B1C20 100 432 117 90 76 97.1 840 575 552 270 337 97 215 1/2 205

T4F06 - B1C17 150 559 172 122 102 146.3 770 545 610 255 375 78 215 1/2 185

T4F06 - B1C20 150 559 172 122 102 146.3 840 575 645 270 397 97 215 1/2 198

T4F06 - B1C25 150 559 172 122 102 146.3 1040 710 700 310 415 121 265 1/2 265

T4F08 - B1C20 200 660 223 140 125 188.9 840 575 705 270 440 97 265 1/2 283

T4F08 - B1C25 200 660 223 140 125 188.9 1040 710 765 310 465 121 265 1/2 350

T4F08 - B1C32 200 660 223 140 125 188.9 1330 910 845 350 505 153 395 3/4 480

T4F10 - B1C25 250 787 278 170 152 242.8 1040 710 810 310 480 121 265 1/2 425

T4F10 - B1C32 250 787 278 170 152 242.8 1330 910 885 350 515 153 395 3/4 545

T4F10 - B1C40 250 787 278 170 152 242.8 1660 1150 955 370 565 194 505 3/4 735

T4F12 - B1C25 300 838 329 210 202 288.8 1040 710 960 310 539 121 265 1/2 605

T4F12 - B1C32 300 838 329 210 202 288.8 1330 910 990 350 576 153 395 3/4 745

T4F12 - B1C40 300 838 329 210 202 288.8 1660 1150 1090 370 626 194 505 3/4 945

T4F14 - B1C32 350 889 362 275 254 317.6 1330 910 1230 350 755 153 395 3/4 1210

T4F14 - B1C40 350 889 362 275 254 317.6 1660 1150 1335 370 805 194 505 3/4 1400

T4F14 - B1C50 350 889 362 275 254 317.6 1970 1350 1435 415 855 242 610 1 1790

T4F16 - B1C32 400 991 413 275 254 363.6 1330 910 1230 350 755 153 395 3/4 1260

T4F16 - B1C40 400 991 413 275 254 363.6 1660 1150 1335 370 805 194 505 3/4 1450

T4F16 - B1C50 400 991 413 275 254 363.6 1970 1350 1435 415 855 242 610 1 1840

T4D-BJ/BJA, B1J/B1JA

Type DN A _B C _D _E F G H I J V X NPT kg

T4D01 - B1J/B1JA8 25 210 36 38 25 26.6 560 420 305 220 192 51 175 3/8 33

T4D01 - B1J10 25 210 36 38 25 26.6 650 490 325 225 198 65 215 3/8 45

T4D015 - B1J/B1JA8 40 251 52 60 38 40.6 560 420 360 220 225 43 135 3/8 34

T4D015 - B1J/B1JA10 40 251 52 60 38 40.6 650 490 380 225 230 51 175 3/8 47

T4D015 - B1J12 40 251 52 60 38 40.6 800 620 425 235 255 65 215 1/2 74

T4D02 - B1J/B1JA8 50 292 62 60 38 52.5 560 420 360 220 225 43 135 3/8 37

T4D02 - B1J/B1JA10 50 292 62 60 38 52.5 650 490 380 225 230 51 175 3/8 50

T4D02 - B1J12 50 292 62 60 38 52.5 800 620 425 235 255 65 215 1/2 78

T4D03 - B1J/B1JA10 80 356 91 68 50 77.9 650 490 400 225 245 51 175 3/8 64

T4D03 - B1J/B1JA12 80 356 91 68 50 77.9 800 620 435 235 260 65 215 1/2 92

T4D03 - B1J/B1JA16 80 356 91 68 50 77.9 990 760 475 255 275 78 265 1/2 137

T4D04 - B1J/B1JA12 100 432 117 90 76 102.3 800 620 500 235 303 65 215 1/2 122

T4D04 - B1J/B1JA16 100 432 117 90 76 102.3 990 760 540 255 315 78 265 1/2 175

T4D04 - B1J/B1JA20 100 432 117 90 76 102.3 1200 935 625 270 337 97 395 3/4 245

T4D06 - B1J/B1JA16 150 559 172 122 102 154.1 990 760 635 255 378 78 265 1/2 225

T4D06 - B1J/B1JA20 150 559 172 122 102 154.1 1200 935 715 270 395 97 395 3/4 300

T4D06 - B1J/B1JA25 150 559 172 122 102 154.1 1530 1200 790 310 415 121 505 3/4 485

T4D08 - B1J/B1JA20 200 660 223 140 125 202.7 1200 935 765 270 425 97 395 3/4 395

T4D08 - B1J/B1JA25 200 660 223 140 125 202.7 1530 1200 860 310 465 121 505 3/4 570

T4D08 - B1J/B1JA32 200 660 223 140 125 202.7 1830 1410 915 350 505 153 540 1 890

T4D10 - B1J/B1JA20 250 787 278 170 152 254.4 1200 935 815 270 445 97 395 3/4 450

T4D10 - B1J/B1JA25 250 787 278 170 152 254.4 1530 1200 905 310 480 121 505 3/4 645

T4D10 - B1J/B1JA32 250 787 278 170 152 254.4 1830 1410 955 350 515 153 540 1 965

T4D12 - B1J/B1JA25 300 838 329 210 202 303.2 1530 1200 1005 310 539 121 505 3/4 845

T4D12 - B1J/B1JA32 300 838 329 210 202 303.2 1830 1410 1060 350 576 153 540 1 1165

T4D14 - B1J/B1JA32 350 889 362 275 254 333.4 1830 1410 1300 350 755 153 540 1 1530

T4D16 - B1J/B1JA32 400 991 413 275 254 381.0 1830 1410 1300 350 755 153 540 1 1680

1 T5 71 en 19

T4F-BJ/BJA, B1J/B1JA

Type DN A _B C _D _E F G H I J V X NPT kg

T4F01 - B1J/B1JA8 25 210 36 38 25 24.4 560 420 305 220 192 43 135 3/8 33

T4F01 - B1J10 25 210 36 38 25 24.4 650 490 325 225 198 51 175 3/8 45

T4F015 - B1J/B1JA8 40 251 52 60 38 37.8 560 420 360 220 225 43 135 3/8 34

T4F015 - B1J/B1JA10 40 251 52 60 38 37.8 650 490 380 225 230 51 175 3/8 47

T4F015 - B1J12 40 251 52 60 38 37.8 800 620 425 235 255 65 215 1/2 74

T4F02 - B1J/B1JA8 50 292 62 60 38 49.3 560 420 360 220 225 43 135 3/8 37

T4F02 - B1J/B1JA10 50 292 62 60 38 49.3 650 490 380 225 230 51 175 3/8 50

T4F02 - B1J12 50 292 62 60 38 49.3 800 620 425 235 255 65 215 1/2 78

T4F03 - B1J/B1JA10 80 356 91 68 50 73.7 650 490 400 225 245 51 175 3/8 64

T4F03 - B1J/B1JA12 80 356 91 68 50 73.7 800 620 435 235 260 65 215 1/2 92

T4F03 - B1J/B1JA16 80 356 91 68 50 73.7 990 760 475 255 275 78 265 1/2 137

T4F04 - B1J/B1JA12 100 432 117 90 76 97.1 800 620 500 235 303 65 215 1/2 122

T4F04 - B1J/B1JA16 100 432 117 90 76 97.1 990 760 540 255 315 78 265 1/2 175

T4F04 - B1J/B1JA20 100 432 117 90 76 97.1 1200 935 625 270 337 97 395 3/4 245

T4F06 - B1J/B1JA16 150 559 172 122 102 146.3 990 760 635 255 378 78 265 1/2 225

T4F06 - B1J/B1JA20 150 559 172 122 102 146.3 1200 935 715 270 395 97 395 3/4 300

T4F06 - B1J/B1JA25 150 559 172 122 102 146.3 1530 1200 790 310 415 121 505 3/4 485

T4F08 - B1J/B1JA20 200 660 223 140 125 188.9 1200 935 765 270 425 97 395 3/4 395

T4F08 - B1J/B1JA25 200 660 223 140 125 188.9 1530 1200 860 310 465 121 505 3/4 570

T4F08 - B1J/B1JA32 200 660 223 140 125 188.9 1830 1410 915 350 505 153 540 1 890

T4F10 - B1J/B1JA20 250 787 278 170 152 242.8 1200 935 815 270 445 97 395 3/4 450

T4F10 - B1J/B1JA25 250 787 278 170 152 242.8 1530 1200 905 310 480 121 505 3/4 645

T4F10 - B1J/B1JA32 250 787 278 170 152 242.8 1830 1410 955 350 515 153 540 1 965

T4F12 - B1J/B1JA25 300 838 329 210 202 288.8 1530 1200 1005 310 539 121 505 3/4 845

T4F12 - B1J/B1JA32 300 838 329 210 202 288.8 1830 1410 1060 350 576 153 540 1 1165

T4F14 - B1J/B1JA32 350 889 362 275 254 317.6 1830 1410 1300 350 755 153 540 1 1530

T4F16 - B1J/B1JA32 400 991 413 275 254 363.6 1830 1410 1300 350 755 153 540 1 1680

T35F-BC, B1C

Type DN A _B C _D _E F G H I J V X NPT kg

T35F02 - B1C11 50 292 91 68 50 73.7 540 375 375 225 245 51 135 3/8 49

T35F02 - B1C13 50 292 91 68 50 73.7 635 445 425 235 260 65 175 3/8 63

T35F03 - B1C13 80 356 117 90 76 97.1 635 445 485 235 300 65 175 3/8 97

T35F03 - B1C17 80 356 117 90 76 97.1 770 545 515 255 315 78 215 1/2 120

T35F03 - B1C20 80 356 117 90 76 97.1 840 575 550 270 337 97 215 1/2 135

T35F04 - B1C17 100 432 172 122 102 146.3 770 545 610 255 375 78 215 1/2 185

T35F04 - B1C20 100 432 172 122 102 146.3 840 575 645 270 397 97 215 1/2 203

T35F04 - B1C25 100 432 172 122 102 146.3 1040 710 700 310 415 121 265 1/2 265

T35F06 - B1C25 150 559 278 170 152 242.8 1040 710 810 310 480 121 265 1/2 415

T35F06 - B1C32 150 559 278 170 152 242.8 1330 910 885 350 515 153 395 3/4 535

T35F06 - B1C40 150 559 278 170 152 242.8 1660 1150 990 370 565 194 505 3/4 730

T35F08 - B1C25 200 660 329 210 202 288.8 1040 710 910 310 539 121 265 1/2 595

T35F08 - B1C32 200 660 329 210 202 288.8 1330 910 990 350 576 153 395 3/4 725

T35F08 - B1C40 200 660 329 210 202 288.8 1660 1150 1090 370 626 194 505 3/4 920

T35F10 - B1C32 250 787 362 275 254 317.6 1330 910 1230 350 755 153 395 3/4 1010

T35F10 - B1C40 250 787 362 275 254 317.6 1660 1150 1335 370 805 194 505 3/4 1205

T35F10 - B1C50 250 787 362 275 254 317.6 1970 1350 1435 415 855 242 610 1 1590

T35F-BJ/BJA, B1J/B1JA

Type DN A _B C _D _E F G H I J V X NPT kg

T35F02 - B1J/B1JA10 50 292 91 68 50 73.7 650 490 400 225 245 51 175 3/8 63

T35F02 - B1J/B1JA12 50 292 91 68 50 73.7 800 620 435 235 260 65 215 1/2 92

T35F02 - B1J/B1JA16 50 292 91 68 50 73.7 990 760 475 255 275 78 265 1/2 135

T35F03 - B1J/B1JA12 80 356 117 90 76 97.1 800 620 500 235 303 65 215 1/2 119

T35F03 - B1J/B1JA16 80 356 117 90 76 97.1 990 760 540 255 315 78 265 1/2 165

T35F03 - B1J/B1JA20 80 356 117 90 76 97.1 1200 935 625 270 335 97 395 3/4 240

T35F04 - B1J/B1JA16 100 432 172 122 102 146.3 990 760 635 255 378 78 265 1/2 230

T35F04 - B1J/B1JA20 100 432 172 122 102 146.3 1200 935 715 270 395 97 395 3/4 315

T35F04 - B1J/B1JA25 100 432 172 122 102 146.3 1530 1200 790 310 415 121 505 3/4 485

T35F06 - B1J/B1JA20 150 559 278 170 152 242.8 1200 935 815 270 445 97 395 3/4 445

T35F06 - B1J/B1JA25 150 559 278 170 152 242.8 1530 1200 905 310 480 121 505 3/4 635

T35F06- B1J/B1JA32 150 559 278 170 152 242.8 1830 1410 955 350 515 153 540 1 945

T35F08 - B1J/B1JA25 200 660 329 210 202 288.8 1530 1200 1005 310 539 121 505 3/4 825

T35F08 - B1J/B1JA32 200 660 329 210 202 288.8 1830 1410 1060 350 576 153 540 1 1145

T35F10 - B1J/B1JA32 250 787 362 275 254 317.6 1830 1410 1300 350 755 153 540 1 1430

20 1 T5 71 en

12 TYPE CODING

TOP ENTRY BALL VALVE, Series Top 5

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

TS F B 04 A A F 03 / 01

1. TRIM OPTIONS, V-PORT, Q-TRIM

2. SERIES

T5 Reduced bore, flanged

T4 Reduced bore, weld ends

T25 Full bore, flanged

T35 Full bore, weld ends

3. PRESSURE RATING

D ASME class 300

F ASME class 600

4. CONSTRUCTION

E General, PTFE bearings

High and low temperature, metal bearings.

B

Temperature range -50 °C...+450 °C.

5. SIZE

01, 015, 02, 03, 04, 06, 08, 10, 12, 14, 16

6. BODY SCREWS

A CF8M B8M

D WCB L7M

7. BALL

A CF8M + hard chrome with metal seats

D CF8M + NiBo

8. SEAT

A, F, E1 Standard metal seat

R Standard soft seat

9.

Seat

seal

Bonnet

gasket

Gland

packing

Seat

Graphite Graphite Graphite A, F E or C

Graphite Graphite Graphite A, F B or C

Viton GF Graphite Graphite R E

10. FLANGE FACING

- Stock Finish (Ra 10-12.5), without sign (standard)

01 Smooth Finish (Ra 3,2-6,3)

05 Ring Joint

Constru

ction

Metso Automation Inc.

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

Latin America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 3235 9700. Fax +55 15 3235 9748/49

Asia Pacific, 238A Thomson Road, #25-09 Novena Square Tower A, 307684 Singapore. Tel. +65 6511 1011. Fax +65 6250 0830

China, 19/F, the Exchange Beijing, No. 118, Jianguo Lu Yi, Chaoyang Dist, 100022 Beijing, China. Tel. +86-10-6566-6600. Fax +86-10-6566-2575

Europe, Levytie 6, P.O. Box 310, 00811 Helsinki, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates.

Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/automation

Loading...

Loading...