INTELLIGENT

VALVE CONTROLLER

ND9200F

Rev. 2.2

Installation, Maintenance and

Operating Instructions

7 ND92F 70 en • 1/2009

2 7 ND92F 70 en

Table of Contents

1 ND9000 PRODUCT FAMILY SUMMARY ....... 3

1.1 Key features........................................... 3

2 ND9200F INTELLIGENT VALVE CONTROLLER WITH

FOUNDATION FIELDBUS COMMUNICATION... 4

2.1 General .................................................. 4

2.2 Technical description ............................ 4

2.3 Markings ................................................ 4

2.4 Technical specifications ........................ 5

2.5 Recycling and disposal ......................... 6

2.6 Safety precautions ................................. 6

3 TRANSPORTATION, RECEPTION AND

STORAGE ....................................................... 6

4 MOUNTING...................................................... 7

4.1 General .................................................. 7

4.2 Mounting on EC and EJ actuators ......... 7

4.3 Mounting on Metso actuators with

VDI/VDE mounting face ......................... 7

4.4 Mounting on linear actuator of

nelesCV Globe....................................... 8

4.5 Mounting on linear actuator with IEC 60534

mounting face ........................................ 8

4.6 Piping..................................................... 9

4.7 Electrical connections.......................... 12

5 LOCAL USER INTERFACE (LUI) ................. 13

5.1 Measurement monitoring ..................... 13

5.2 Guided start-up.................................... 13

5.3 Configuration menu ............................. 14

5.4 Mode menu.......................................... 14

5.5 Configuration parameters .................... 15

5.6 Valve travel calibration......................... 17

5.7 Special displays................................... 18

5.8 Write protection.................................... 19

6 MAINTENANCE............................................. 19

6.1 Prestage............................................... 19

6.2 Spool valve .......................................... 20

6.3 Flame arrestor assembly ..................... 20

6.4 Diaphragms ......................................... 20

6.5 Communication circuit board .............. 20

7 ERROR MESSAGES..................................... 21

7.1 Failsafe errors ...................................... 21

7.2 Alarms.................................................. 21

7.3 Errors ................................................... 22

7.4 Warnings.............................................. 22

7.5 Notifications ......................................... 23

8 TROUBLE SHOOTING.................................. 23

9 ND92_F/K_, ND92_F/I__, ND92_F/B__

(WITH LIMIT SWITCHES) ............................. 24

9.1 Introduction.......................................... 24

9.2 Installing ND92_F/K_, ND92_F/I_ or

ND92_F/B_ on a valve controller 25

9.3 Electrical connections.......................... 25

9.4 Adjustment........................................... 25

9.5 Removal of the limit switches ND92_F/K_,

ND92_F/I_ or ND92_F/B for accessing

the valve controller............................... 26

9.6 Circuit diagrams .................................. 26

9.7 Maintenance ........................................ 26

10 TOOLS........................................................... 26

11 ORDERING SPARE PARTS ......................... 26

12 DRAWINGS AND PARTS LISTS .................. 27

12.1 Exploded view and parts list, ND9200F27

12.2 Exploded view and parts list,

ND92_F/K_, ND92_F/I__, ND92_F/B__... 29

12.3 Mounting parts for EC05-14 actuators,

rising signal opens valve ..................... 31

12.4 Mounting parts for B1C/B1J 6-20 actuators31

12.5 Mounting parts for B1C/B1J 25-50,

B1C 502 and B1J322 actuators........... 32

12.6 Mounting parts for Quadra-Powr®

actuators .............................................. 32

12.7 Mounting parts for linear actuators of

nelesCV Globe..................................... 33

12.8 Mounting parts for linear actuators...... 34

12.9 Connection diagrams .......................... 35

13 DIMENSIONS ................................................ 39

14 EC DECLARATION OF CONFORMITY ........ 40

15 TYPE CODING .............................................. 41

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about the safe handling and operation of the intelligent valve controller.

If you require additional assistance, please contact the manufact urer or manufactu rer's representa tive.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

7 ND92F 70 en 3

1 ND9000 PRODUCT FAMILY SUMMARY

1.1 Key features

❑ Benchmark control performance on rotary and

linear valves

❑ Reliable and robust design

❑ Ease of use

❑ Language selection: English, German and French

❑ Local / remote operation

❑ Expandable architecture

❑ Advanced device diagnostics including

❑ Self-diagnostics

❑ Online diagnostics

❑ Performance diagnostics

❑ Communication diagnostics

❑ Extended off-line tests

❑ Intelligent Valve Diamond

1.1.1 Options

❑ Interchangeable communication options:

❑ FOUNDATION Fieldbus

❑ HART

❑ Profibus PA

❑ Limit switches

❑ Position transmitter (in HART only)

❑ Special corrosion resistant finish

❑ Exhaust adapter

1.1.2 Total cost of ownership

❑ Low energy and air consumption

❑ Future proof design allows further options at a

reduced cost

❑ Optimised spares program. Reduced number of

spares

❑ Retro-fit to existing installations (Neles or 3rd party)

1.1.3 Minimised process variability

❑ Linearisation of the valve flow characteristics

❑ Excellent dynamic and static control performance

❑ High-speed of response

❑ Accurate internal measurements

1.1.4 Easy installation and configuration

❑ Same unit for linear and rotary valves, double

and single-acting actuators

❑ Simple calibration and configuration

❑ using Local User Interface

❑ using FieldCare software in a remote location

❑ Flush mounting capability to avoid tubing and

mounting parts

❑ Low power design enables installation to all com-

mon control systems

1.1.5 Open solution

Metso is committed to delivering products that freely interface with software and hardware from a variety of manufacturers; and the ND9000 is no exception. This open

architecture allows the ND9000 to be integrated with other

field devices to give an unprecedented level of controllability.

❑ FDT based multi-vendor support configuration.

ND9000 DTM download page:

www.metso.com/automation/nd9000

1.1.6 ND9000 in fieldbus networks

❑ Approved interoperability

❑ Host interoperability ensured

❑ FOUNDATION Fieldbus ITK version 5.01 certified

❑ Profibus PA profile version 3.0 PNO certified

❑ Easy to upgrade; can be done by replacing the

HART communication board to fieldbus communication board

❑ Excellent maintainability with firmware download

feature

❑ Advanced communication diagnostics

❑ Digital communication via the fieldbus includes

not only the set point, but also the position feedback signal from the position sensor. No special

supplementary modules for analog or digital

position feedback are needed when using the

fieldbus valve controller.

❑ Back up LAS functionality available in FOUNDA-

TION Fieldbus enviroment

❑ Input selector and output splitter blocks available

in FOUNDATION Fieldbus devices allowing

advanced distributed control

❑ Multipurpose functionality

❑ Standard function blocks enables the freedom

to use ND9000 intelligent valve controller either

in continuous or on-off control applications

❑ Open and close information directly available

via the fieldbus

❑ Open and close detection is based on either

position measurement (soft limit switch) or

mechanical limit switch information

❑ ND9000 download page:

www.metso.com/automation/nd9000

1.1.7 ND9000 mounting on actuators and

valves

❑ Mounted on single and double acting actuators

❑ Both rotary and linear valves

❑ Flush mounting capability

❑ Ability to attach options to electronics and

mechanics later

❑ Possibility to mount also on valves that are in

process with 1-point calibration feature

1.1.8 Product reliability

❑ Designed to operate in harsh environmental con-

ditions

❑ Rugged modular design

❑ Excellent temperature characteristics

❑ Vibration and impact tolerant

❑ IP66 enclosure

❑ Protected against humidity

❑ Maintenance free operation

❑ Resistant to dirty air

❑ Wear resistant and sealed components

❑ Contactless position measurement

1.1.9 Predictive maintenance

❑ Easy access to collected data with FieldCare software

❑ Ingenious Valve Diamond to visualise control

valve performance & diagnostics

❑ Logical trend and histogram collection

❑ Information collected on service conditions

❑ Extensive set of off-line tests with accurate

key figure calculations

❑ Fast notifications using on-line alarms

❑ Condition monitoring tool available

❑ Real time monitoring of valve control parameters.

4 7 ND92F 70 en

2 ND9200F INTELLIGENT VALVE

CONTROLLER WITH FOUNDATION

FIELDBUS COMMUNICATION

2.1 General

This manual incorporates Installation, Maintenance and

Operation Instructions for the Metso ND9200F intelligent

valve controller. The ND9200F may be used with either

cylinder or diaphragm type pneumatic actuators for

rotary or linear valves.

NOTE:

The selection and use of the valve controller in a specific

application requires close consideration of detailed

aspects. Due to the nature of the product, this manual

cannot cover all the likely situations that may occur when

installing, using or servicing the valve controller.

If you are uncertain about the use of the controller or its

suitability for your intended use, please contact Metso’s

Automation business for more information.

2.2 Technical description

The ND9200F is a fieldbus powered microcontrollerbased intelligent valve controller. The ND9200F configuration can be done either using local push buttons or

FOUNDATION Fieldbus configurator.

The powerful 32-bit microcontroller controls the valve

position. The measurements include:

❑ Input signal

❑ Valve position with contactless sensor

❑ Actuator pressures, 2 independent measurements

❑ Supply pressure

❑ Spool valve position

❑ Device temperature

Advanced self-diagnostics guarantees that all measurements operate correctly. Failure of one measurement

does not cause the valve to fail if the input signal and

position measurements are operating correctly. After

connections of electric signal and pneumatic supply the

micro controller (µC) reads the input signal, position sensor (α), pressure sensors (Ps, P1, P2) and spool position

sensor (SPS). A difference between input signal and

position sensor (α) measurement is detected by the control algorithm inside the µC. The µC calculates a new

value for prestage (PR) coil current based on the information from the input signal and from the sensors.

Changed current to the PR changes the pilot pressure to

the spool valve. Reduced pilot pressure moves the spool

and the actuator pressures change accordingly. The

spool opens the flow to the driving side of the double

diaphragm actuator and opens the flow out from the

other side of the actuator. The increasing pressure will

move the diaphragm piston. The actuator and feedback

shaft rotate clockwise. The position sensor (α) measures

the rotation for the µC. The µC using control algorithm

modulates the PR-current from the steady state value

until a new position of the actuator according to the input

signal is reached.

Fig. 1 The principle of operation

2.3 Markings

The valve controller is equipped with an identification

plate sticker (Fig. 2).

Fig. 2 Identification plate

Identification plate markings from top to bottom include:

❑ Type designation of the valve controller

❑ Revision number

❑ Enclosure class

❑ Input signal (voltage range)

❑ Input resistance

❑ Maximum supply voltage

❑ Operational temperature

❑ Supply pressure range

❑ Contact details of the manufacturer

❑ CE mark

❑ Manufacturing serial number TTYYWWNNNN*)

*) Manufacturing serial number explained:

TT= device and factory sign

YY= year of manufacturing

WW = week of manufacturing

NNNN = consecutive number

Example: PH08011234 = controller, year 2008, week 1,

consecutive number 1234.

7 ND92F 70 en 5

2.4 Technical specifications

ND9200F INTELLIGENT VALVE CONTROLLER

General

Bus powered, no external power supply required.

Suitable for rotary and sliding-stem valves.

Actuator connections in accordance with VDI/VDE 3845

and IEC 60534-6 standards.

Flush mounting on NelesCV™ control valves

Action: Double or single acting

Trave l range: Linear; 10–120 mm with standard IEC parts.

Larger strokes possible with suitable kits

Rotary; 45–95°.

Measurement range 110° with freely

rotating feedback shaft.

Environmental influence

Standard temperature range:

-40° to +85 °C / -40° to +185 °F

Influence of temperature on valve position:

< 0.5 % / 10 °K

Influence of vibration on valve position:

< 1 % under 2g 5–150 Hz,

1g 150–300 Hz, 0.5g 300–2000 Hz

Enclosure

Material: Anodised aluminium alloy and

polymer composite

Protection class: IP66, NEMA 4X

Pneumatic ports: 1/4 NPT

Electrical connection: max. 2.5 mm

Cable gland thread: M20 x 1.5 (E1), 1/2 NPT (E2)

Weight: 3.4 kg / 7.5 lb

Mechanical and digital position indicator visible

through the main cover

Special corrosion resistant finish available

Pneumatics

Supply pressure: 1.4–8 bar / 20–115 psi

Effect of supply pressure on valve position:

< 0.1 % at 10 % difference in inlet pressure

Air quality: According to ISO 8573-1:2001

Solid particles: Class 5

(3–5 µm filtration is recommended)

Humidity: Class 1

(dew point 10 °C/50 °F below minimum

temperature is recommended)

Oil class: 3 (or <1 ppm)

Capacity with 4 bar / 60 psi supply:

5.5 Nm

12 Nm

38 Nm

3

/h / 3.3 scfm (spool valve 2)

3

/h / 7.1 scfm (spool valve 3)

3

/h / 22.4 scfm (spool valve 6)

Consumption with 4 bar / 60 psi supply

in steady state position:

< 0.6 Nm

< 1.0 Nm

3

/h / 0.35 scfm (spool valves 2 & 3)

3

Electronics

Power supply: taken from bus

Bus voltage: 9 to 32 V DC, reverse polarity protection

2

/h / 0.6 scfm (spool valve 6)

Max basic current: 17.2 mA

Fault current (FDE): 3.9 mA

EEx ia IIC T6: Ui ≤ 24 V

Ii ≤ 380 mA

Pi ≤ 5.32 W

Ci < 5 nF

Li < 10 µH

EEx nL IIC: Ui ≤ 32 V

Ii ≤ 380 mA

Pi ≤ 5.32 W

Ci < 5 nF

Li < 10 µH

(ATEX approval is valid under these conditions)

FOUNDATION Fieldbus function block execution times

AO 20 ms

PID 20 ms

DO 15 ms

DI 15 ms

IS 15 ms

OS 15 ms

Performance with moderate constant-load,

actuators EC05-EC10

Values at 20 °C / 68 °F and without any additional instru-

ments, such as boosters or quick exhaust valves etc.

Dead band acc. to IEC 61514:

≤ 0.1 %

Hysteresis acc. to IEC 61514:

< 0.5 %

Local user interface functions

❑ Local control of the valve

❑ Monitoring of valve position, input signal, temper-

ature, supply and actuator pressure difference

❑ Guided start-up function

❑ LUI may be locked remotely to prevent unauthor-

ised access

❑ Calibration: Automatic / Manual

❑ 1-point calibration

❑ Limit switch state monitoring

❑ Control configuration: aggressive, fast, optimum,

stable, maximum stability

❑ Mode selection: Automatic/Manual

❑ Rotation: valve rotation clockwise or counter-

clockwise to close

❑ Dead angle

❑ Low cut-off, cut-off safety range (default 2 %)

❑ Positioner fail action, open/close

❑ Actuator type, double/single acting

❑ Valve type, rotary/linear IEC/nelesCV Globe/FLI

❑ Language selection: English, German and French

Approvals

Flameproof, explosion proof and dust exclusion

ATEX II 2 G Ex d IIC T4...T6

(EN 60079-0:2006, EN 60079-1:2004)

II 2 D Ex tD A21 IP66 T 100 °C

(EN 61241-0:2006, EN 61241-1:2004)

Certificate KEMA 04ATEX2098 X Issue 2

CSA Explosion proof Class I, II and III,

Division 1 and 2, Groups B, C, D, E, F

Pending

6 7 ND92F 70 en

FM Explosion proof Class I, II and III,

Division 1 and 2, Groups A, B, C, D, E, F

Pending

Electromagnetic protection

Electromagnetic compatibility

Emission acc. to EN 61000-6-4 (2001)

and FCC 47 CFR PART 15,

SUBPART B, CLASS B (1994)

Immunity acc. to EN 61000-6-2 (2001)

CE marking

89/336/EEC

Electromagnetic compatibility

94/9/EC

ATEX

P

OSITION TRANSMITTER (optional)

Output signal: 4–20 mA (galvanic isolation;

600 V DC)

Resolution: 16 bit / 0.244 µA

Linearity: <0.05 % FS

Temperature effect:<0.35 % FS

EEx d IIC T4/T5/T6

Ui ≤ 30 V

Rx= 0–780 Ω

MICRO SWITCHES, 2 PIECES

(OPTIONAL WITH EXTENSION MODULE)

Code B06 Omron D2VW-01 gold plated micro switch,

Bus powered, no external power and cabling needed.

Code I02 P+F NJ2-12GK-SN

Code I09 P+F; NCB2-12GM35-N0

Code I56 IFC 2002-ARKG/UP

Code K05 Omron D2VW-5, micro switch

Code K06 Omron D2VW-01 gold plated, micro switch

CAUTION:

Do not remove or dismantle a pressurized controller!

Removing or dismantling a pressurized prestage or

spool valve of an ND9200F leads to uncontrolled pressure release. Always shut off the supply air and release

the pressure from the pipelines and equipment before

removing or dismantling the controller. Otherwise per-

sonal injury and damage to equipment may result.

WARNING:

During automatic or manual calibration and tuning

the valve operates between open and closed positions. Make sure that the operation does not

endanger people or processes!

WARNING:

Do not operate the device with the cover removed!

Electromagnetic immunity is reduced, valve may stroke.

ATEX WARNING:

Electrostatic charge hazard!

The windows and identification plate are non-conductive. Clean with a damp cloth only!

ATEX WARNING:

The locking screw (part 107) of the cover is essential to explosion protection.

The cover has to be locked in place for Ex d protection. The

screw grounds the cover to the housing.

Ex d WARNING:

Do not open the device when energized!

Ex d WARNING:

Use a cable gland with suitable Ex d certification.

For ambient temperature over 70 °C / 158 °F use a

heat resistant cable and cable gland suitable for at

least 90 °C / 194 °F.

2.5 Recycling and disposal

Most valve controller parts can be recycled if sorted

according to material.

Most parts have material marking. A material list is supplied with the valve controller. In addition, separate recycling and disposal instructions are available from the

manufacturer.

A valve controller may also be returned to the manufacturer for recycling and disposal. There will be a charge

for this.

2.6 Safety precautions

CAUTION:

Do not exceed the permitted values!

Exceeding the permitted values marked on the valve

controller may cause damage to the controller and to

equipment attached to the controller and could lead to

uncontrolled pressure release in the worst case. Damage to the equipment and personal injury may result.

ELECTRICAL SAFETY WARNING:

Use fuses for limit switch installations with

50 V AC/75 V DC or higher.

NOTE:

Avoid earthing a welding machine in close proximity to

an ND9200F valve controller.

Damage to the equipment may result.

3 TRANSPORTATION, RECEPTION

AND STORAGE

The valve controller is a sophisticated instrument, handle it with care.

❑ Check the controller for any damage that may

have occurred during transportation.

❑ Store the uninstalled controller preferably

indoors, keep it away from rain and dust.

❑ Do not unpack the device until installing it.

❑ Do not drop or knock the controller.

❑ Keep the flow ports and cable glands plugged

until installing.

❑ Follow instructions elsewhere in this manual.

7 ND92F 70 en 7

4 MOUNTING

4.1 General

NOTE:

The enclosure of ND9200F intelligent valve controller

meets the IP66 protection class according to EN 60529

in any position when the cable entry is plugged according to IP66.

Based on good mounting practice, the recommended

mounting position is electrical connections placed

downwards. This recommendation is shown in our

mounting position coding for control valves.

If these requirements are not fulfilled, and the cable

gland is leaking and the leakage is damaging valve

controller or other electrical instrumentation, our warranty is not valid.

If the ND9200F is supplied with valve and actuator, the

tubes are mounted and the ND9200F adjusted in

accordance with the customer’s specifications. If the

controller is ordered separately, the mounting parts for

the assembly must be ordered at the same time.

Sample order: (B1CU13)-Z-ND9206FN

The controller is equipped with the Metso flush mounting

face, the old Neles mounting face and for connection

according to VDI/VDE 3845.

Shaft coupling alternatives for the controller for Metso

actuators are shown in Fig. 5.

For mounting parts for Metso actuators, see 12.3 - 12.8.

4.2 Mounting on EC and EJ actuators

See figure in Section 12.3.

❑ Mount the U-shaped coupling (47) to the shaft.

Apply thread-locking compound to the screws

(48) and tighten firmly.

❑ Remove the protective plastic plugs from pneu-

matic connections C2, S and C1. Mount the

metal plugs (53) to the unused controller connections with sealant.

For EC (double acting) actuators, remove the

metal plugs (54, 2 pcs) from the connections at

the bottom of the controller. For EJ (single acting,

spring to close) and EJA (single acting, spring to

open) actuators, leave the metal plug (54) in the

C1 connection at the bottom of the controller and

remove the metal plug from the C2 connection at

the bottom.

❑ Mount the O-rings (38, 4 pcs.) into the air con-

nections in the bottom of the controller and the

mounting plate (64).

❑ Install the mounting plate (64) on the actuator as

shown in 12.3.

❑ Place the valve controller on top of the actuator

so that the pointer is located in the position

shown in Fig.5.

❑ Fasten the screws (4).

Fig. 3 Mounting on EC and EJ actuators

4.3 Mounting on Metso actuators with

VDI/VDE mounting face

See figures in Section 12.4 -12.6.

❑ Mount the H-shaped coupling (47) to the shaft.

Apply the thread-locking compound to the screw

(48) and tighten firmly.

❑ Remove the protective plastic plugs from pneu-

matic connections C2, S and C1. Leave the metal

plugs (54) in the unused connections at the bottom of the controller.

❑ BJ and other single acting actuators: install a

metal plug (53) with sealant to the C1 connection.

❑ Set the direction arrow of the actuator in the direc-

tion of the valve closure member and attach the ear

(2) to the indicator cover in the position shown in

Section 12.4. Secure the screw of the ear using e.g.

Loctite and tighten firmly.

❑ Attach the bracket (1) to the ND9200F.

❑ Attach the bracket (1) to the actuator. The shaft cou-

pling of the ND9200F must fit into the ear (2) so that the

pointer is located in the position shown in Fig.4.

C2

S

C1

Fig. 4 Mounting on Metso actuator with VDI/VDE

mounting face

O-rings

11

The pointer on the coupling must

stay in this sector

8 7 ND92F 70 en

4.4 Mounting on linear actuator of

nelesCV Globe

See figure in Section 12.7

❑ Attach the J-shaped feedback lever (47) to the

valve controller shaft. Apply the thread-locking

compound to the screws and tighten firmly.

❑ Remove the protective plastic plugs from pneu-

matic connections C2, S and C1. Mount the

metal plugs (53) to the unused controller connections with sealant.

❑ Leave metal plug (54) in the connection C1 at the bot-

tom of the controller. Remove the metal plug (54) from

the C2 connection at the bottom. Mount the O-rings

(38, 2 pcs.) to the connections.

❑ Attach the mounting plate (64) to the valve con-

troller with screws (65).

❑ Mount the O-rings (38, 2 pcs.) and attach the

mounting plate (39) to the valve controller with

screws (28).

❑ Mount the conical plug (16) to the lever and select

the position on the scale according to the valve

stroke.

❑ Install the O-ring (31) to the actuator. Place the con-

ical plug into the frame on the stem and tighten the

screws (4).

4.5 Mounting on linear actuator with IEC

60534 mounting face

See figure in Section 12.8

❑ Attach the feedback arm with spacer to the valve

controller shaft. Note the position of the pointer

on the shaft as in 12.8. Apply thread locking

compound to the screws and tighten firmly.

Attach the spring to the feedback arm as shown

in Section 12.8.

❑ Mount the valve controller mounting bracket

loosely to the yoke of the actuator.

❑ Remove the protective plastic plugs from pneu-

matic connections C2, S and C1. Leave the metal

plugs (54) in the unused connections at the bottom of the controller. Single acting actuators:

install a metal plug (53) with sealant to the C1

connection.

❑ Mount the valve controller loosely to the mount-

ing bracket guiding the pin on the actuator stem

to the slot of the feedback arm.

❑ Align the bracket and the valve controller with the

actuator stem and adjust their position so that the

feedback arm is approximately at a 90° angle to

the actuator stem (in the mid-stroke position).

❑ Tighten the valve controller mounting bracket

screws.

❑ Adjust the distance of the valve controller to the

pin on the actuator stem so that the pin stays in

the lever slot at full stroke. Ensure also that the

maximum angle of the lever does not exceed 45°

in either direction. Maximum allowed travel of the

lever is shown in Section 12.8. Best control performance is achieved when the feedback lever

utilises the maximum allowed angle (±45° from

horizontal position). The whole range should be

at least 45°.

❑ Make sure that the valve controller is in right

angle and tighten all the mounting bolts.

❑ Ensure that the valve controller complies with

previous steps. Check that the actuator pin does

not touch the valve controller case throughout

the entire stroke of the actuator. If the actuator

pin is too long it may be cut to size.

❑ Apply grease (Molykote or equivalent) to the con-

tact surfaces of the actuator pin and the feedback arm to reduce wear.

pointer

mark on

housing

pointer

mark on

housing

VDI/VDE 3845 mounting

45°

EC/EJ flush mounting

45°

shaft end

shaft end

pointer

mark on

housing

pointer

mark on

housing

nelesCV Globe mounting

45°

shaft end

2015 30

IEC 60534 mounting

45°

shaft end

Fig. 5 Shaft coupling alternatives

7 ND92F 70 en 9

4.6 Piping

CAUTION:

Do not exceed the permitted supply pressure of

the ND9200F!

Table 2 provides the recommended tube sizes in

accordance with actuator sizes. Tube sizes are the minimum values allowed. Operating times may be tested by

the FieldCare software.

Connect the air supply to S (1/4 NPT).

Connect C1 and C2 (1/4 NPT) to the actuator, see Fig. 6.

ND9200F is connected direct to the EC or EJ actuator.

Connections C1 and C2 (1/4 NPT) must be plugged, see

12.3.

Liquid sealants, such as Loctite 577 are recommended

for the pipe threads.

NOTE:

A valve controller mounted on a spring actuator must

be connected only as single-acting. See Fig. 6.

NOTE:

An excess of sealant may result in faulty operation of

the controller.

Sealing tape is not recommended.

Ensure that the air piping is clean.

The air supply must be clean, dry and oil-free instrument

air, see Section 2.4.

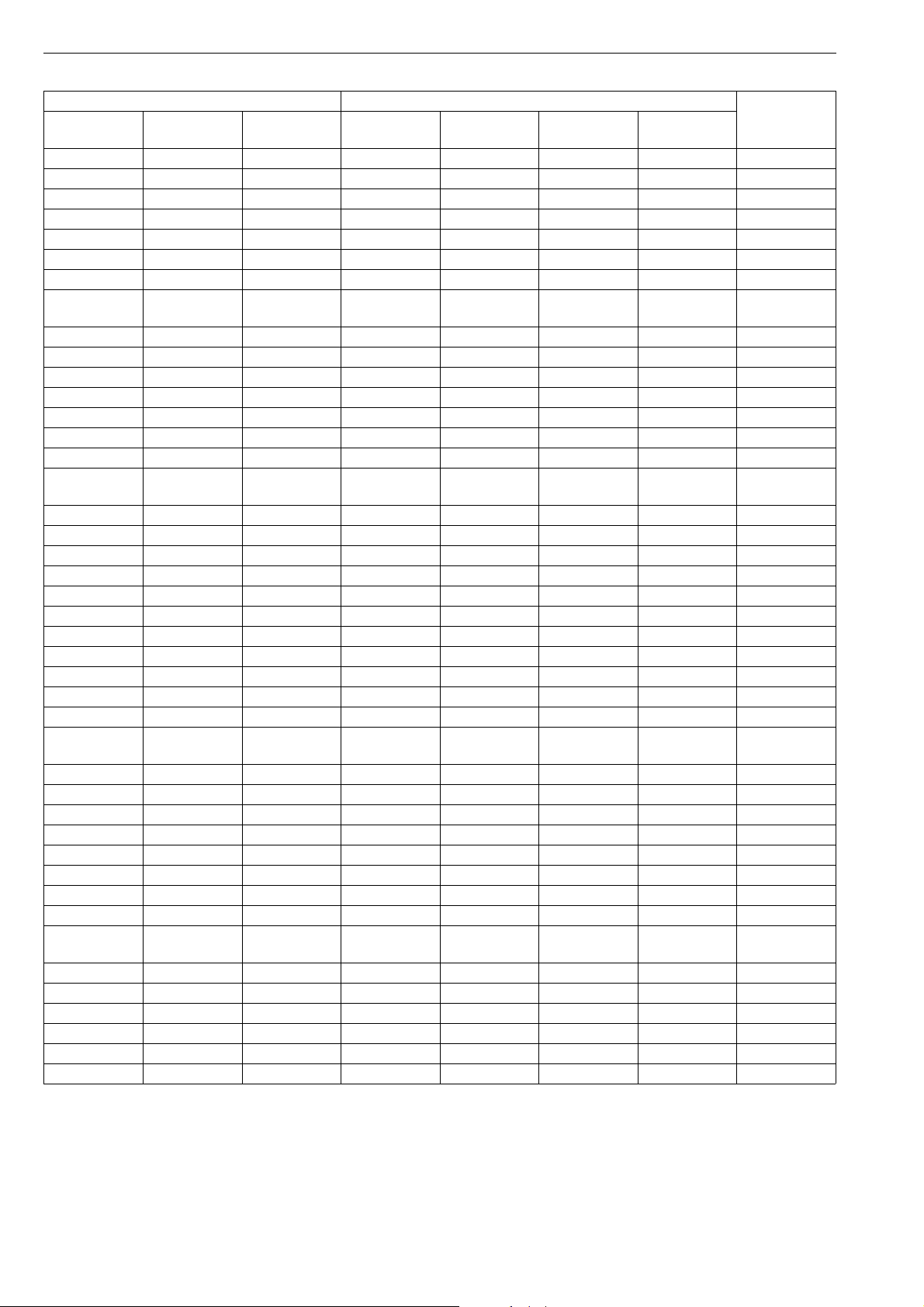

Table 1 Spring rates

Actuator type Spring rate (bar/psi)

B1JK 3 / 43

B1J 4.2 / 61

B1JV 5.5 / 80

QPB 3 / 43

QPC 4.3 / 62

QPD 5.6 / 81

EJK 3 / 43

EJ 4 / 57

EJV 5 / 72

Adjust regulator pressure to a level that is max 1 bar

(14.5 psi) + spring rate.

10 7 ND92F 70 en

Table 2 Piping

EC

Actuator Actuator piping

Stroke vol.

3

/ in

3

dm

G 6 10 1/4 3/8

Spool valve

05 0.09 / 5 1/4 x x 2

07 0.2 / 12 1/4 x x 2

10 0.5 / 31 1/4 x x 3

12 1.2 / 73 1/4 x x 3

14 3.0 / 183 1/4 x x 6

16 7.7 / 470 3/8 x x 6

25 20.5 / 1250 3/8 x x 6

EJ

Stroke vol.

3 / in3

dm

G 6 10 1/4 3/8

Spool valve

05 0.18 / 11 1/4 x x 2

07 0.4 / 24 1/4 x x 2, 3*

10 1 / 61 1/4 x x 3

12 2.4 / 145 1/4 x x 3

14 6 / 366 1/4 x x 6

16 15 / 915 3/8 x x 6

25 41 / 2500 3/8 x x 6

B1C

Stroke vol.

3

3

/ in

dm

NPT 6 10 1/4 3/8

Spool valve

6 0.3 / 18 1/4 x x 2, 3*

9 0.6 / 37 1/4 x x 3

11 1.1 / 67 3/8 (x) x (x) x 3

13 2.3 / 140 3/8 x x 3

17 4.3 / 262 1/2 x x 6

20 5.4 / 330 1/2 x x 6

25 10.5 / 610 1/2 x x 6

32 21 / 1282 3/4 x x 6

40 43 / 2624 3/4 x x 6

50 84 / 5126 1 x x 6

502 195 / 11900 1 x x 6

B1J

B1JA

Stroke vol.

3

3

/ in

dm

NPT 6 10 1/4 3/8

Spool valve

8 0.9 / 55 3/8 (x) x (x) x 3

10 1.8 / 110 3/8 x x 3

12 3.6 / 220 1/2 x x 6

16 6.7 / 409 1/2 x x 6

20 13 / 793 3/4 x x 6

25 27 / 1648 3/4 x x 6

32 53 / 3234 1 x x 6

322 106 / 6468 1 x x 6

QP

Stroke vol.

3

3

/ in

dm

NPT 6 10 1/4 3/8

Spool valve

1 0.62 / 37 3/8 (x) x (x) x 2, 3*

2 1.08 / 66 3/8 (x) x (x) x 3

3 2.18 / 133 3/8 x x 3

4 4.34 / 265 3/8 x x 6

5 8.7 / 531 3/8 x x 6

6 17.5 / 1068 3/4 x x 6

Air supply piping 10 mm or 3/8" for all actuators.

Pipe sizes are nominal, i.e. approximately outer diameter. Inner diameter is typically 2 mm smaller.

x = Standard pipe size used in Neles control valves.

(x) = Minimum pipe size (if smaller than standard).

*) Spool size 2 is preferred for accurate control and standard for Neles control valves.

Spool size 3 can be used if fast full stroke times are required.

7 ND92F 70 en 11

DOUBLE-ACTING ACTUA TOR

Self closing

1.

C2

S

C1

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = CLO

A0, CUTL and VTYP according to valve type

DOUBLE-ACTING ACTUATOR, REVERSED PIPING

Self opening

2.

Default setting:

ROT = cC (close valve to clockwise)

C2

S

C1

ATYP = 2-A

PFA = OPE

A0, CUTL and VTYP according to valve type

SINGLE-ACTING ACTUA TOR, SPRING TO CLOSE

3. Self closing

C2

S

C1

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = CLO (must be in the spring direction)

A0, CUTL and VTYP according to valve type

SINGLE-ACTING ACTUA TOR, SPRING TO OPEN

4. Self opening

C2

S

C1

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = OPE (must be in the spring direction)

A0, CUTL and VTYP according to valve type

Fig. 6 Operation directions and air connections

12 7 ND92F 70 en

4.7 Electrical connections

The ND9200F is powered by FOUNDATION Fieldbus

(IEC 61158-2). The same bus cable is used also for the

fieldbus communication.

The bus cable is led through a M20 x 1.5 (E1)/1/2 NPT

(E2) cable gland. Connect the conductors to the terminal strip as shown in Fig. 7.

Reverse polarity protection permits connection of the

bus cables in any order.

The cable shield can be grounded by connecting the

shield to the earth connection screw. The shield can be

left unconnected by using the empty terminal.

Please note following before mounting the cover of

the valve controller:

❑ Attach the LUI (223) cabling to the sticker on the

reverse side of the LUI.

Check that the cabling does not get squeezed by

the electronics cover (39) or the device cover

(100).

❑ Check using a feeler gauge that the clearance

between the position indicator (109) and the

electronics cover is 1 mm.

Fig. 7 Terminals

HAZARDOUS LOCATION

ND9200F

Entity Parameters:

Ui ≤ 32.0 V

Fig. 8 Control wiring

NONHAZARDOUS LOCATION

Associated

apparatus

Entity Parameters:

Uo ≤ Ui

connect the cable

shield to earth ground

7 ND92F 70 en 13

5 LOCAL USER INTERFACE (LUI)

The local user interface may be used to monitor the

device behaviour as well as configuring and commissioning the controller during installation and normal

operation. The local user interface consists of 2 row LCD

and 4 button keypad interface. There are also custom

graphical characters for special conditions.

user to view all the measurements through the window of

the main cover.

Fig. 9 Local user interface (LUI)

5.1 Measurement monitoring

When the device is powered, it enters the measurement

monitoring view. The following measurements may be

viewed from the display. The Table 3 identifies the default

unit and also optional unit of the measurement.

Table 3 Default / optional units of measurements

Measurement Default unit Optional unit

valve position Percentage of full

target position Percentage of full

current loop

setpoint

actuator

pressure

difference

supply pressure bar psi

device

temperature

scale

scale

Percentage of full

scale

bar psi

° Celcius ° Fahrenheit

If the unit selection is altered from the FieldCare software

to US units, the pressure default unit will automatically be

changed to psi and temperature unit to Fahrenheit.

The active unit may be changed by pressing the ? key

constantly. The display shows the current unit selection

on the top row of the display. You may change the selection by pressing + or - while keeping the ? key

pressed down. When the buttons are released the current selection will be activated.

If the device has been idle for 1 hour, and there is no

user activity on the local user interface, the measurements will start scrolling on the display. This enables the

Angle, where 0 %

refers to 0 (angle)

none

— continuous push

— brief push

Fig. 10 Measurement unit change

5.2 Guided start-up

Guided startup offers a fast view of the most critical

parameters of the ND9200F controller, actuator and

valve configuration. After verifying the parameters the

valve travel calibration is recommended. The guided

start-up is entered by pressing the = and ? keys

simultaneously.

The configuration parameters are listed in following

order, see explanation from 5.5:

Valve type VTYP

Actuator type ATYP

Positioner fail action PFA

Valve rotation direction ROT

Valve dead angle A0

If you modify any of the parameters you will also need to

calibrate and tune the device. See 5.6 for detailed

description.

14 7 ND92F 70 en

— brief push

Fig. 11 Guided start-up

NOTE:

You may cancel any action by pressing the = button.

Cancelling of operation returns user interface view one

level up in menu hierarchy.

5.3 Configuration menu

The local user interface is organised in a menu structure. To enter the menus press + and - simultaneously

in the measurement monitoring view panel. To move to

the next or previous selection by pressing + or accordingly.

5.4 Mode menu

If the user wants to change the valve operating mode,

press the ? key at the MODE selection. The mode will

start to flash and by pressing + or - you may alter the

operation mode selection. User accepts the current

selection by pressing the ? key.

There are two options for the operating mode.

5.4.1 AUTO

During the auto mode, the controller controls the valve

position according to the incoming setpoint signal from

the bus. This mode is used during the normal process

control service.

— brief push

Fig. 12 Configuration

5.4.2 MAN

During this mode the valve position may be controlled

manually by using the keyboard and pressing the + or buttons. The position of the manually driven valve is not

saved in the memory of the controller, i.e. the valve will not

return to the same position after signal failure. However, the

valve may be driven back into position after signal failure

by using + and - keys.The manual control starts from

the current position of the valve after the MAN-mode is

activated. In order to change the manual setpoint return to

the measurement monitoring view and go to target position

measurement. Press the ? key shortly to activate the target position editing, text TPOS starts to blink and now you

are able to edit the setpoint by pressing + or - button.

The setpoint changes in 0.1 % increments/decrements in

spite of the selected unit and the valve starts to move

immediately. A continuous push changes the setpoint

faster. In order to view other measurements, press the ?

or = keys and select a measurement. Repeat the previous steps if you would like to alter the setpoint value again.

7 ND92F 70 en 15

❑ Modify the parameter value by pressing + or -

keys alternately until the desired value appears

on the display.

❑ After the desired value is displayed, press the

key ? to conclude the operation.

5.5.3 Valve type, VTYP

To compensate for nonlinearity of the position feedback

caused by the actuator linkage mechanism of a linear

Fig. 13 Setpoint change in MAN mode

5.5 Configuration parameters

When PAR is on the display you may enter the configuration menu by pressing the ? key. In this menu the most

important configuration and signal modification parameters are viewable. You may view the current value and edit

them by pressing the ? key at the relevant parameter.

The name of the parameter will appear on the upper row

of the display and the current value is on the lower row.

5.5.1 Performance level, PERF

If you want to change the tuning of the valve position

control, the PERF selection is available. The default factory value is C.

❑ Once PERF is displayed press the ? key to

enter the edit state and PERF starts to blink.

❑ Select between five values by pressing the + or

- key.

Table 4 Performance level

Selection Meaning Description

Aggressive Immediate response to

A

Fast Fast response to signal

b

Optimum Very small overshoot with

C

Stable No overshooting, slow

d

Maximum stability No overshooting, deadband

E

For use with volume boosters and/or very fast actuators,

additional performance levels A1 to D1 can be used.

Characteristics of these extended levels are the same as

those in the table above. However, with performance level

settings A1 to D1, adaptive properties of the ND9000 control

algorithm are disabled.

❑ After the desired value is displayed, press the

key ? to conclude the operation.

signal changes, overshoots

changes, small overshooting

minimum step response

time

response to input signal

changes

may increase, slow but

stable behaviour

5.5.2 Low cut-off, CUTL

Low cut-off safety range CUTL ensures the valve closing

against mechanical travel stops. The factory default

value is 2 %.

❑ Once CUTL is displayed press the ? key to

enter the edit state and the CUTL will start to

blink. The currently selected value appears as a

percentage (%) on the display.

control valve, the appropriate selection must be made on

the VTYP display.

❑ After selecting VTYP on the display, press the ? key

to enter the edit state and the VTYP starts to blink.

❑ Select between four values rot, LIn, nCG or FLI

using the + and - keys. The value rot indicates a rotary valve and LIn a linear valve. Use

nCG only for nelesCV Globe valves to accommodate special linkage geometry. Use FLI only for

linear valves when linkage geometry is not needed

to be corrected by valve controller firmware.

❑ To conclude press the ? key when the desired

value is shown on the display.

NOTE:

Perform valve calibration and tuning always when

VTYP has been changed.

5.5.4 Actuator type, ATYP

In order to optimise the control performance the device

needs to be informed about the actuator type.

❑ After selecting ATYP on the display, press the ?

key to enter the edit state and ATYP starts to blink.

❑ Select between two values 2-A or 1-A using the +

and - keys. The value 2-A indicates a double

acting actuator and 1-A a single acting actuator.

❑ To conclude press the ? key when the desired

value is shown on the display.

NOTE:

Perform valve calibration and tuning always when

ATYP has been changed.

5.5.5 Positioner fail action, PFA

Positioner fail action will take place in case of signal

failure or when the controller software discovers a fatal

device failure. For single acting actuators set value in

the spring direction. For double acting actuators see

Fig. 6 for correct settings.

❑ Once PFA is displayed, press the ? key to enter

the edit state and the PFA will star t blinking.

❑ You may select between two values by pressing

the + or - key. The CLO value indicates that the

valve ought to be closed in fail action situations.

The OPE value indicates the valve to be opened in

fail action situations.

❑ After the desired value is displayed, press the

key ? to conclude the operation.

16 7 ND92F 70 en

NOTE:

Perform valve calibration and tuning always when controller fail action parameter has been changed.

5.5.6 Valve rotation direction, ROT

The application-specific parameter ROT defines the relationship between position sensor rotation and valve

action.

❑ Once ROT is displayed press the ? key to enter

the edit state and ROT starts to blink.

❑ Now you may select between two values by

pressing the + or - key. The value cC indicates

clockwise rotation for closing the valve and ccC

means counterclockwise to close.

❑ After the desired value is displayed, press the

key ? to conclude the operation.

NOTE:

Perform valve calibration and tuning always when ROT

has been changed.

5.5.7 Valve dead angle, A0

The α0 setting is made for Metso segment and ball valves.

This setting takes into account the "dead angle" α

ball valves. The entire signal range is then used for effective valve opening 90° - α

. Use 0 % as the "dead angle"

0

for the valves not mentioned in Table 5.

Taulukko 5 Dead angle in percentage

Valve

size

mm in Dead angle, %

15 1/2 15

20 3/4 15

25 1 14 - - 25.5 19.5 - - 15 25.5 27 12.5

25/1 1/1 14.5 11

25/2 1/2 8 11

25/3 1/3 8 10

25/4 8

40 1 1/2 12 - - 24.5 12.5 - - 12 16 21 12.5

50 2 10 9 13.5 24.5 12.5 18 8 17 20.5 23 12.5

65 2 1/2 9 - - - - - - 13 - 18

8031081218816.58.598.515.5

100 4 10 8 12 16.5 8.5 16 9 8 7 14.5

125 5 12 - - - - 12 6.5 8 -

150 6 10 8 11.5 16 9 13.5 8 13.5 13

200 8 9 7 8.5 12 6.5 9.5 7 11.5

250 10 9 7 7.5 13.5 9.5 7 10.5

300 12 8 6 6.5 9.5 7.5 6 9.5

350 14 6 6 - 5 9.5

400 16 5 5.5 9.5

450 18 6 7.5

500 20 6 4.5

600 24 5.5 6

650 26 7

700 28 7 6

750 30 6

800 32 -

900 36 5.5

1) Seat supported 2) Trunnion 3) Soft seated R-valve 4) Low Cv Finetrol

MBV

QMBV

1)

MBV

QMBV

2)

D,

P,

QT5

C

(14")

(16")

T5,

Valve series

QX-T5T25,

QT25

QXT25R,QR

ER-

59.5

SOFT

3)FL4)

of the

0

ZX

Position

100

80

60

40

20

α

0

0

0 20 40 60 80 100

low cut-off safety range 2 ± 0.5 %

Basic setting α

Input signal

setting

0

Fig. 14 Principle of setting

Fig. 15 Dead angle

❑ After selecting A0 on the display, press the ?

key to enter the edit state and A0 starts to blink.

The value currently selected appears as a percentage (%) on the display.

❑ Modify the parameter value by pressing + or -

keys alternately until the desired value appears

on the display.

❑ Press the ? key to make your selection and

return to the setting state.

5.5.8 Language selection, LANG

❑ Select between three languages EnG, GEr or FrE

using the + and - keys.

❑ To conclude press the ? key when the desired

value is shown on the display.

5.5.9 Low cut-off, low limit, high cut-off,

high limit

ND9200F supports signal cut-off and limiting in both

ends of the operating range. The configuration parameters are; low cut-off, low limit, high cut-off and high limit.

❑ If the input signal is smaller than low cut-off

(TRANSDUCER_BLOCK.FINAL_VALUE_CUTOFF_LO),

the valve will be fully closed.

❑ If the input signal is smaller than low limit

(TRANSDUCER_BLOCK.FINAL_VALUE_RANGE.LO),

the valve stays in the low limit.

❑ If the input signal is greater than high cut-off

(TRANSDUCER_BLOCK.FINAL_VALUE_CUTOFF_HI),

the valve will be fully opened.

❑ If the input signal is greater than high limit

(TRANSDUCER_BLOCK.FINAL_VALUE_RANGE.HIGH),

the valve stays in the high limit.

The cut-off overrides the limit as follows:

7 ND92F 70 en 17

❑ If the low cut-off > low limit, the low limit is not

active.

❑ If the low cut-off < low limit, both low cut-off and

limit are active.

❑ If the low cut-off is set to zero, the low cut-off is

not active.

❑ If the high cut-off < high limit, the high limit is not

active.

❑ If the high cut-off > high limit, both high cut-off

and limit are active.

❑ If the high cut-off is set to 100%, the high cut-off

is not active.

Only the low cut-off is adjustable using the LUI. Low

limit, high cut-off and high limit are configurable via

fieldbus.

5.6 Valve travel calibration

NOTE:

If AUTO CAL or MAN CAL is selected, the valve controller

must be in AUTO mode. 1-point calibration may run in

both AUTO and MAN mode.

Select CAL from the menu by using + or - keys and

press the ? key. Define the calibration type AUTO, MAN

or TUNE. You may also select TUNE after AUTO and MAN

calibration separately as seen in Fig.16.

Fig. 16 Calibration selection

WARNING:

Automatic calibration drives the valve against the

mechanical open and closed travel limits of the

valve-actuator assembly and a tuning procedure is

performed. Make sure that these procedures can

be safely executed.

5.6.1 AUTO calibration function

During the calibration process the display will show the

following text: CALrun. After calibration the ND9200F

scrolls CALIBRATION SUCCESSFUL text. You may inter-

rupt the calibration sequences at any time by pressing

the = key.

After the calibration sequence is finished, press the =

key twice to get back to the measurement view.

Please refer to Chapter 7 if this sequence has failed and

an error message is displayed.

If you cannot drive the valve into a fully open position or if

there is no mechanical limit stop, a manual calibration is

required.

the + or - keys drive the valve manually to the closed

(0 %) position and then press the ? key. If you cancel

the operation, the old values of the previous calibration

will be restored. Drive the valve into the desired maximum opening position (100 %) with the + and - keys

and press the ? key.

If this sequence has failed and an error message is

shown, see Chapter 7.

5.6.3 TUNE function

During the tuning the ND9200F controller searches for

optimum internal control parameters for the valve position control. At any time you may interrupt the tuning

sequence by pressing the = key. The tuning will not

alter the PERF parameter.

If calibration and tuning are performed in sequence, the

cancelling of tuning does not restore the old calibration

values.

5.6.4 1-Point Calibration

1-point calibration is useful in cases in which the valve

controller needs to be changed but it is not possible to

run the normal calibration and the valve is not allowed

to change position (the valve is active, for example).

This procedure does not ensure the best possible

control performance, and it is always recommended

to run either AUTO or MAN calibration and tuning,

as soon as possible. The primary way to calibrate

valve position is to use either AUTO or MAN calibration.

Before starting 1-point calibration, read the warnings

and notes below and check that the valve is mechan-

ically locked. Before starting 1-point calibration,

adjust the TPOS value in the MAN mode (see section 5.4.2) to correspond with the physical position

of the valve.

Once the 1-point calibration is started, the first view

shows ANG above and NN.N below (see Fig. 16). NN.N

presents the maximum turning angle (in degrees) that

the valve can perform.

To change the value:

❑ Press ?, NN.N begins blink

❑ Press + and - -buttons to change the value

After the correct valve operation angle is set, press ?

button.

During the calibration process the display will show the

following text: CALrun. After calibration the ND9200F

scrolls CALIBRATION SUCCESSFUL text. You may inter-

rupt the calibration sequences at any time by pressing

the = key.

After the calibration sequence is finished, press the =

key twice to get back to the measurement view.

Please refer to Chapter 7 if this sequence has failed

and an error message is displayed.

5.6.2 MAN calibration function

After selecting the MAN calibration function from the

menu press the ? key to activate the procedure. With

18 7 ND92F 70 en

The valve can now be unlocked.

WARNING:

Supply pressure can be connected to the valve

controller only after 1-point calibration is successfully completed. If supply pressure is connected to

the valve controller before successful 1-point calibration, the valve may move and cause danger.

NOTE:

If an incorrect valve operation angle is given to the

valve controller during 1-point calibration, valve operation will be incorrect. In this case, you must perform

1-point calibration again with correct valve operation

angle value.

NOTE:

If the valve position is not stable (due to heavy vibration etc) during 1-point calibration, the calibration will

not end successfully. Check that the valve position is

fully stable during this operation.

5.6.5 LS status

LS shows the status of limit switches:

--- No LS active

CLO LS "Closed" active

OPE LS "Open" active

LSE LS Error, both switches activated

at the same time

Fig. 18 Online alarm message

keys simultaneously in the measurement monitoring

view. The message is scrolled on the top row of the display twice. You may stop the scrolling by pressing the ?

key. By pressing the = key, the message will disappear.

For the list of events see Chapter 7.

5.7.4 Fail-safe active

When the ND9200F detects serious device failure (setpoint, valve position and control signals) it enters failsafe mode, which drives the control valve into the position defined in the parameter controller fail action (PFA).

Fail-safe mode is indicated by the display as seen in

Fig. 19. The error message is displayed until the cause

of error is eliminated and the ND9200F unit is restarted,

i.e. the power loop is momentarily disconnected.

scrolling text

5.7 Special displays

5.7.1 User interface locked

In order to prevent unauthorised access, the Local User

Interface may be locked. In this mode measurements

may be viewed but configurations and calibrations are

prohibited. You may lock and unlock the device only via

dip switch, see Fig.21. When the Local User Interface is

locked the lock symbol will be activated on the display.

Fig. 17 LUI locked

5.7.2 Online-alarm active

If an online alarm has been detected the solid & symbol

is activated. This symbol will disappear after the recovery from online alarm. You may view the reason for the

alarm by viewing the latest event while pushing the =

and - keys simultaneously or by using FieldCare software where all events may be viewed.

scrolling text

Fig. 19 Failsafe display

5.7.5 Reduced Performance

When the ND9200F detects spool valve measurement

failure, it enters reduced performance mode. This is

indicated by the blinking & in the display, see Fig. 20.

In reduced performance mode valve control can not be

optimized. To correct the problem replace the spool

valve assembly and perform auto calibration.

Fig. 20 Reduced performance display

5.7.3 Viewing of latest event

You may view the latest event by pressing the = and -

7 ND92F 70 en 19

5.8 Write protection

The ND9200F is delivered from the factory with HW

write protection OFF as the default setting. Reading

and changing parameters is thus allowed. Write protection can be enabled with the switch (DIP1) located on

the circuit board (Fig. 21).

Write protection protects all write access to all writeable

parameters of the device. Changing the parameters

from the LUI or Fieldbus configurator is thus not

allowed.

The simulation switch is OFF as the default setting. A0

block simulation is thus disabled. The simulation can be

enabled with the switch (DIP2) located on the circuit

board (Fig 21).

12

ON

6 MAINTENANCE

Ex d WARNING:

Service of the cylindrical flameproof joints is not

allowed.

This includes the diaphragm cover (part 171), flame

arrester plunger (part 200), their mating surfaces in

the housing (part 2) and the shaft assembly fixed in

the housing.

The maintenance requirements of the ND9200F valve

controller depend on the service conditions, for

instance, the quality of instrument air. Under normal

service conditions there is no requirement for regular

maintenance.

When maintaining the ND9200F ensure that the supply

air is shut off and pressure is released. In the following

text the numbers in brackets ( ) correspond to the part

numbers in the exploded view as shown in Chapter 11,

unless otherwise stated.

The ND9200F valve controller includes the following

interchangeable modules: prestage unit (120), spool

valve (193), communication circuit board with optional

position transmitter (215).

The spool valve is located on the bottom side of the

device while the other modules are located below the

covers (100) and (39). In the event of failure the whole

module must be changed. The module retrofit must be

assembled in a clean, dry environment. In reassembly

apply a thread-locking compound (for instance, Loctite

243) and tighten the screws firmly.

Fig. 21 Write protection

6.1 Prestage

NOTE:

The prestage must be handled carefully. In particular

the moving parts of the prestage should not be

touched when the inner cover (39) is not in place.

6.1.1 Removal

❑ Loosen the M8 stop screw (110) in the position

indicator (109) and turn the position indicator

from the shaft (11). Remove the inner cover (39)

attached with M3 screws (42, 3 pcs).

❑ Unplug the prestage wire connector from the

spool sensor board (180). Unscrew the M4

screws (139, 2 pcs.) and lift up the prestage

module. Remove the O-ring (140).

6.1.2 Installation

❑ Place a new O-ring (140) into the groove in the

housing and press the prestage into place. Make

sure the nozzle is guided into the O-ring properly.

The screws guide the prestage body into the correct position. Tighten the screws (139) evenly.

❑ Push the prestage 2-pole wire connector into the

socket on the spool sensor board. The wire connector can only be fitted in the correct position.

Replace the inner cover (39) and tighten the M3

screws.

20 7 ND92F 70 en

6.2 Spool valve

6.2.1 Removal

For spool valve removal it is usually necessary to

unmount the valve controller from the actuator.

❑ Working from the bottom side of the valve con-

troller, unscrew the M4 screws (47, 3 pcs.).

Remove the spool valve cover (61) and the spool

valve (193) with gasket (174). Hold the ends of

the body with your fingers to avoid dropping the

spool from the body.

❑ Spool valve removal is only possible in the

spring-forced failsafe position of the spool. In the

case of a stuck spool it might be necessary to

remove the secondary diaphragm cover (167),

the spool spring (166) with its disc (164) and the

secondary diaphragm (162) with its plate. After

the removal of these parts it is possible to use a

punch to force the spool to the failsafe position.

❑ The spool valve may be cleaned if special atten-

tion is paid to a clean environment and proper

procedure.

❑ Clean the spool and the bore of the body with

care. Do not leave any fibres from cleaning materials in the bore or on the spool. Do not scratch

the mating surfaces of the spool and body.

NOTE:

Each spool valve body has an individual corresponding spool which cannot be replaced by any other

spool. Never alter the orientation of the spool. The orientation of the spool is marked on the device, see

Fig. 22.

6.2.2 Installation

❑ Ensure that the gaskets (174) and (63) are prop-

erly located in their grooves on the bottom of the

housing. Mount the spool valve and the spool

valve cover (61) to the housing, and tighten M4

screws evenly.

195 174 194

6.3 Flame arrestor assembly

The flame arrestor and the restrictor are fit into the same

plug which is located under the diaphragm cover (171).

This assembly can not be disassembled and should be

replaced if clogged.

❑ To remove the flame arrestor assembly, unscrew

the screws (173, 4 pcs.) and remove the diaphragm cover (171) with its O-ring. Turn a M3

screw into the threaded hole of the flame arrestor

assembly to extract it from the housing. Installation is the reversal of removal. Place the O-rings

carefully.

6.4 Diaphragms

The diaphragms (169, 162) may be replaced by removing the respective covers (171, 167). The unit should be

unmounted from the actuator and the side to be worked

on turned upwards in order to avoid loss of small parts.

When replacing the secondary diaphragm (162), the

spool spring (166) with its guide (164) has to be

removed first. When reassembling, pay special attention to the installation of the diaphragms and O-rings.

6.5 Communication circuit board

6.5.1 Removal

❑ Loosen the M8 stop screw (110) in the position

indicator (109) and turn the position indicator

from the shaft (11). Remove the inner cover (39)

attached with M3 screws (42, 3 pcs.).

NOTE:

Ground yourself on the body of the device before

touching the circuit board.

❑ Remove the M3 screws (217, 4 pcs.). Hold the

sides of the circuit board and lift it directly

upwards and outwards. Handle the board carefully, touching only the sides.

NOTE:

Do not remove the Valve Controller Board (210)!

Removing the board will void the warranty.

63 61

Sticker

Fig. 22 Spool valve assembly

7 ND92F 70 en 21

6.5.2 Installation

❑ Mount the new communication circuit board

carefully.

❑ Locate the pins with the matching connector on

the board. Tighten the M3 screws (217) evenly.

❑ Install the inner cover (39).

❑ Mount the position indicator (109) on the shaft

and tighten the M8 stop screw (110) temporarily.

The final orientation and locking of the position

indicator should be done after installation of the

valve controller to the actuator.

ATEX WARNING:

Grounding of the circuit board is essential to

explosion protection.

The board is grounded to the housing by the mounting screw next to the terminal blocks.

215

Fig. 23 Communication board

7 ERROR MESSAGES

7.1 Failsafe errors

Display message Description

POSITION SENSOR FAILURE Position sensor measurement

PRESTAGE SHORTCUT

ERROR

FAE nnn Fatal malfunction in the device.

failed. Change the ND9000

device to a new one.

Shortcut in the prestage unit.

nnn is a number between 001 -

004. Change the ND9000

device to a new one.

7.2 Alarms

Display message Description

DEVIATION ALARM Valve deviation out of limits.

STICTION LOW ALARM Stiction has exceeded the

STICTION HIGH ALARM Stiction has exceeded the

LOAD FOR OPENING LOW

ALARM

LOAD FOR OPENING HIGH

ALARM

SPOOL VALVE PROBLEM Spool valve problem in the

PNEUMATICS PROBLEM Inconsistent actuator

FRICTION PROBLEM Valve is not moving correctly.

low limit.

high limit.

Load for opening has

exceeded the low limit.

Load for opening has

exceeded the high limit.

controller. Check the spool

valve unit and replace if

necessary.

pressures. Check pneumatic

connections and actuator

leakage.

Check load factor.

22 7 ND92F 70 en

7.3 Errors 7.4 Warnings

Display message Description

PRESTAGE CUT ERROR Prestage wire is cut or

PRESSURE SENSOR 1

FA ILU RE

PRESSURE SENSOR 2

FA ILU RE

PRESSURE SENSOR 3

FA ILU RE

SPOOL VALVE SENSOR

FA ILU RE

TEMPERATURE SENSOR

FA ILU RE

STATISTICS DATABASE

ERROR

EVENT DATABASE ERROR Failed to store events. The

POSITION CALIBRATION

FA IL ED

TUNING FAILED Tuning procedure failed.

POSITION SENSOR RANGE

ERROR

CALIBRATION TIMEOUT Calibration timeout occurred.

CALIBRATION START

FA IL ED

TUNING RANGE ERROR Tuning procedure failed.

SPOOL SENSOR RANGE

ERROR

connector is loose.

Actuator pressure sensor has

failed. The device

performance level is reduced.

Change the ND9000 device to

a new one during next

maintenance activity.

Actuator pressure sensor has

failed. The device

performance level is reduced.

Change the ND9000 device to

a new one during next

maintenance activity.

Supply pressure sensor has

failed. This does not affect

the performance level.

Spool valve sensor failed.

Check the sensor

connections. The device

performance level is reduced.

Change the ND9000 device to

a new one during next

maintenance activity.

Temperature measurement

failed. The accuracy of the

measurements is reduced.

Change the ND9000 device

to a new one during next

maintenance activity.

Failed to store statistics. New

measurements will be lost.

new events will be lost.

Travel calibration failed.

Check the configuration

parameters and controller

mounting. Check that the

controller shaft is correctly

aligned.

Check that the valve is

moving properly. Check the

prestage and spool valve

unit.

Position sensor range failed

during calibration. Valve

controller shaft failed to

rotate minimum 45 degrees.

Check the configuration

parameters and controller

mounting. Check that the

controller shaft is correctly

aligned.

Check configuration and

installation.

The calibration starting

conditions are not met.

Check the supply pressure.

Check the prestage and

spool valve unit.

Spool sensor range failed

during position calibration.

Check the configuration

parameters. Check the

prestage and spool valve

unit.

Display message Description

TOTAL OPERATION TIME

WARNING

VALVE FULL STROKES

WARNING

VALVE REVERSALS

WARNING

ACTUATOR FULL STROKES

WARNING

ACTUATOR REVERSALS

WARNING

SPOOL FULL STROKES

WARNING

SPOOL REVERSALS

WARNING

STEADY STATE DEVIATION

WARNING

DYNAMIC STATE DEVIATION

WARNING

STICTION LOW WARNING Warning that stiction has

STICTION HIGH WARNING Warning that stiction has

LOAD FOR OPENING TOO

LOW

LOAD FOR OPENING TOO

HIGH

SUPPLY PRESSURE OUT OF

LIMITS

TEMPERATURE OUT OF

LIMITS

HUNTING DETECTION

WARNING

REDUCED PERFORMANCE

ACTIVATED

TOO LOW SUPPLY PRESS

FOR 1-ACT ACTUATOR

VALVE REVERSALS TREND

WARNING

SETPOINT REVERSALS

TREND WARNING

VALVE TRAVEL TREND

WARNING

VALVE REVERSALS WH

STABLE SETP WARNING

Operating time exceeded

limit.

Valve stroke counter limit

reached.

Valve reversals counter limit

reached.

Actuator stroke counter limit

reached.

Actuator stroke counter limit

reached.

Spool stroke counter limit

reached.

Spool reversals counter limit

reached.

Warning that steady state

deviation has increased.

Warning that dynamic state

deviation has increased.

exceeded the low limit.

exceeded the high limit.

Warning that load for

opening has exceeded the

low limit.

Warning that load for

opening is has exceeded the

high limit.

Supply pressure has

exceeded the specified

operating conditions.

Temperature has exceeded

the specified operating

conditions.

Valve hunting detected.

Change performance level to

less aggressive to stabilize

valve. Check that the spool

valve capacity is suitable for

the actuator.

Valve controller performance

is reduced due to defective

spool valve sensor. Change

the spool valve assembly.

Too low supply pressure level

for 1-acting actuator.

Warning that valve reversals

per day has exceeded the

limit.

Warning that setpoint

reversals per day has

exceeded the limit.

Warning that valve travel per

day has exceeded the limit.

Warning that valve reversals

while setpoint is stable, per

day, has exceeded the limit

7 ND92F 70 en 23

7.5 Notifications 8 TROUBLE SHOOTING

Mechanical/electrical defects

Display message Description

CALIBRATION

SUCCESSFULL

TEST CANCELLED Off-line test has been

TEST DONE Off-line test has been

TEST FAILED Off-line test failed. Repeat

CALIBRATION CANCELLED Calibration has been

PARAMETERS BACKUP

RESTORED

PT NOT ACTIVATED (Only with position

1PT CAL FAILED 1-point calibration failed.

TUNE OK Tuning has been

REDUCED PERFORMANCE

DEACTIVATED

Position calibration

successfully performed.

cancelled.

successfully performed.

the test sequence.

cancelled.

Parameter backup database

has been activated.

transmitter option).

The position transmitter is not

energized.

Check the mounting of the

valve controller. Verify input

parameter (range) value.

Check rotation parameter

(ROT).

successfully performed.

Spool valve measurement

and normal valve control is

recovered.

1. A change in the valve position setpoint will not affect

the position of the actuator

❑ Supply pressure too low

❑ Spool valve sticks

❑ Incorrect configuration parameters

❑ Actuator and/or valve jammed

❑ Signal wires incorrectly connected, no value on

display

❑ Circuit boards are defective

❑ Calibration and tuning has not been carried out

❑ Device is in manual mode

❑ Prestage is defective

❑ Device is in fail-safe mode

2. The actuator goes to the end position with a small

change of input signal

❑ Tubes between controller and actuator are incor-

rect, see Fig. 6

❑ The parameter settings PFA and ROT are incor-

rectly selected.

3. Inaccurate positioning

❑ Spool valve dirty

❑ Too high actuator load

❑ Supply pressure too low

❑ Spool or pressure sensors are defective

❑ Actuator leakage

4. Overshooting or positioning too slow

❑ Change PERF value

❑ Spool valve dirty

❑ Supply air tube too small or supply air filter dirty

❑ Valve sticks

❑ Check leakages in tubes between controller and

actuator

❑ Check leakages in mechanical stop screws

5. Error during valve travel calibration

❑ Valve controller is in MAN mode

❑ Check the coupling alignment with the pointer,

see Fig. 5.

❑ The parameter settings PFA and ROT are incor-

rectly selected

❑ The actuator or valve did not move or was stuck

during calibration

❑ Supply pressure too low

❑ Spool valve dirty

24 7 ND92F 70 en

9 ND92_F/K_, ND92_F/I__, ND92_F/B__

(WITH LIMIT SWITCHES)

2 micro switches

2 cams

9.1 Introduction

9.1.1 General description

ND9200F can be equipped with limit switches.

ND9200F/K2_ has two microswitches, ND9200F/I__ has

two inductive proximity switches and ND92_F/B_ has two

bus powered mechanical micro switches. Limit switches

are used for electrical position indication of the valves

and other devices.

The switching points may be chosen freely.

2 micro switches

potential

equalization

Fig. 24 ND92_F/K_ layout

2 cams

terminals

ground

M20 x 1.5

terminals

ground

potential

equalization

Fig. 26 ND92_F/B_ layout

M20 x 1.5

9.1.2 Markings

The limit switch is provided with an identification plate

sticker, see Fig. 27. Identification plate markings from

top to bottom are:

❑ Type designation

❑ Electrical values

❑ Temperature range

❑ Enclosure class

❑ Conduit entry

❑ Manufacturing serial number

The type designation is described in Chapter 14.

2 proximity

switches

potential

equalization

Fig. 25 ND92_F/I__ layout

2 cams

M20 x 1.5

terminals

ground

Fig. 27 Identification plate

9.1.3 Technical specifications

9.1.3.1 ND92_F/K_

Microswitch type: OMRON D2VW-5 (K05)

OMRON D2VW-01 (K06)

(gold-plated contacts)

Protection class IP67

Resistive load: 3A: 250 V AC (K05)

5A: 30 V DC

0.4A: 125 V DC

100 mA: 30 V DC / 125 V AC (K06)

Switch accuracy: < 2°

Number of switches: 2 (K05 or K06)

Protection class of cover: IP66 (DIN 40050, IEC 60529)

Conduit entry: M20 x 1.5

Ambient temperature: -20° to +80 °C / -4° to +176 °F

Weight: Approx. 1.0 kg / 2.2 lb

(limit switches only)

7 ND92F 70 en 25

9.1.3.2 ND92_F/I_

Proximity switch: Inductive, diameter 8–14 mm

(0.31–0.55 in)

Sensing range 2 mm / 0.08 in

Protection class IP67

P+F NJ2-12GK-SN (02)

ifm IFC2002-ARKG/UP (56)

Other switch types on special

order

Electrical values: According to switch type

Switch accuracy: < 1°

Number of switches: 2

Protection class of housing:IP66 (DIN 40050, IEC 60529)

Conduit entry: M20 x 1.5

Ambient t emperature: -20° to +51 °C /-4° to +124 °F (02)

-20° to +80 °C / -4° to +176 °F(56)

Weight: Approx. 1.0 kg / 2.2 lb

(limit switches only)

9.1.3.3 ND92_F/B_

Microswitch type: OMRON D2VW-01 (06)

(gold-plated contacts)

Protection class IP67

Resistive load: 100 mA: 30 V DC/125 V AC (06)

Switch accuracy: < 2°

Number of switches: 2

Protection class of cover: IP66 (DIN 40050, IEC 60529)

Conduit entry: M20 x 1.5

Ambient temperature: -20° to +80 °C / -4° to +176 °F

Weight: Approx. 1.0 kg / 2.2 lb

(limit switches only)

Materials:

Body: Aluminium alloy, epoxy-coated

Internal parts: Stainless steel and polymer

Sealing: Nitrile and neoprene rubber

❑ Replace the plastic plugs with metal ones in con-

duit entries which will not be used.

❑ Mount the pointer (109) on the shaft (311). Adjust

the limit switch according to 9.4.

9.3 Electrical connections

Before connecting the power, make sure that the electrical specifications and the wiring meet the installation

conditions. See the diagrams in 12.9. Refer to the information on the identification plate.

ND9200/I: Observe the functioning of the proximity

switch; activated when the active face is either covered

or free.

9.4 Adjustment

The pointer (109) need not be removed for adjustment.

When the limit switch is ordered together with the valve

and the actuator, the valve controller switches are factory-adjusted. The limits may be adjusted by altering

the position of the cam discs (313) on the shaft. The

lower switch is activated at the closed limit and the

upper switch at the open limit.

❑ With the actuator in the open or closed position,

locate the switching point by turning the cam

disc so that the switch state changes approx. 5°–6°

before the limit.

16