Metso neles ND7000H, neles ND9000F, neles ND9000H, neles ND9000P, ND7000H Operating Instructions Manual

...

INTELLIGENT

VALVE CONTROLLER

ND7000H

ND9000H, ND9000F, ND9000P

Rev. 4.0

Installation, Maintenance and

Operating Instructions

7 ND90 71 en • 5/2019

2 7 ND90 71 en

Table of Contents

1 PRODUCT FAMILY SUMMARY.............................. 3

1.1 ND9000 .......................................................................3

1.2 ND7000 .......................................................................4

2 ND9000 AND ND7000 INTELLIGENT VALVE

CONTROLLER WITH DIFFERENT

COMMUNICATION PROTOCOLS .......................... 4

2.1 General........................................................................4

2.2 Technical description.............................................4

2.3 Markings.....................................................................5

2.4 Technical specifications ........................................5

2.5 Recycling and disposal..........................................9

2.6 Safety precautions ..................................................9

3 TRANSPORTATION, RECEPTION AND

STORAGE ............................................................. 10

4 MOUNTING .......................................................... 10

4.1 General ................................................................... 10

4.2 For mounting parts for Metso actuators, see

12.5–12.10.Mounting on Metso actuators

with VDI/VDE mounting face........................... 10

4.3 Mounting on Neles VC and VD actuators or

linear actuators with IEC 60534 mounting

face ............................................................................ 11

4.4 Piping ....................................................................... 12

4.5 Electrical connections......................................... 16

5 LOCAL USER INTERFACE (LUI)............................ 23

5.1 Measurement monitoring................................. 23

5.2 Guided start-up..................................................... 24

5.3 Configuration menu............................................ 24

5.4 Mode menu............................................................ 24

5.5 Configuration parameters ................................ 26

5.6 Valve travel calibration....................................... 28

5.7 Special displays..................................................... 30

5.8 Write protection ................................................... 31

6 MAINTENANCE.................................................... 32

6.1 Prestage................................................................... 32

6.2 Spool valve ............................................................. 32

6.3 Flame arrestor assembly.................................... 33

6.4 Diaphragms............................................................ 33

6.5 Communication board....................................... 33

7 ERROR MESSAGES............................................... 34

7.1 Failsafe errors......................................................... 34

7.2 Alarms ...................................................................... 34

7.3 Errors......................................................................... 34

7.4 Warnings ................................................................. 35

7.5 Notifications........................................................... 36

8 TROUBLE SHOOTING.......................................... 36

9 ND9000 WITH LIMIT SWITCHES ........................ 37

9.1 Introduction............................................................37

9.2 Installation on a valve controller.....................40

9.3 Electrical connections .........................................41

9.4 Adjustment .............................................................41

9.5 Removal of the limit switches for accessing

the valve controller ..............................................41

9.6 Circuit diagrams ....................................................41

9.7 Maintenance...........................................................41

10 TOOLS.................................................................. 41

11 ORDERING SPARE PARTS................................... 41

12 DRAWINGS AND PARTS LISTS ........................... 42

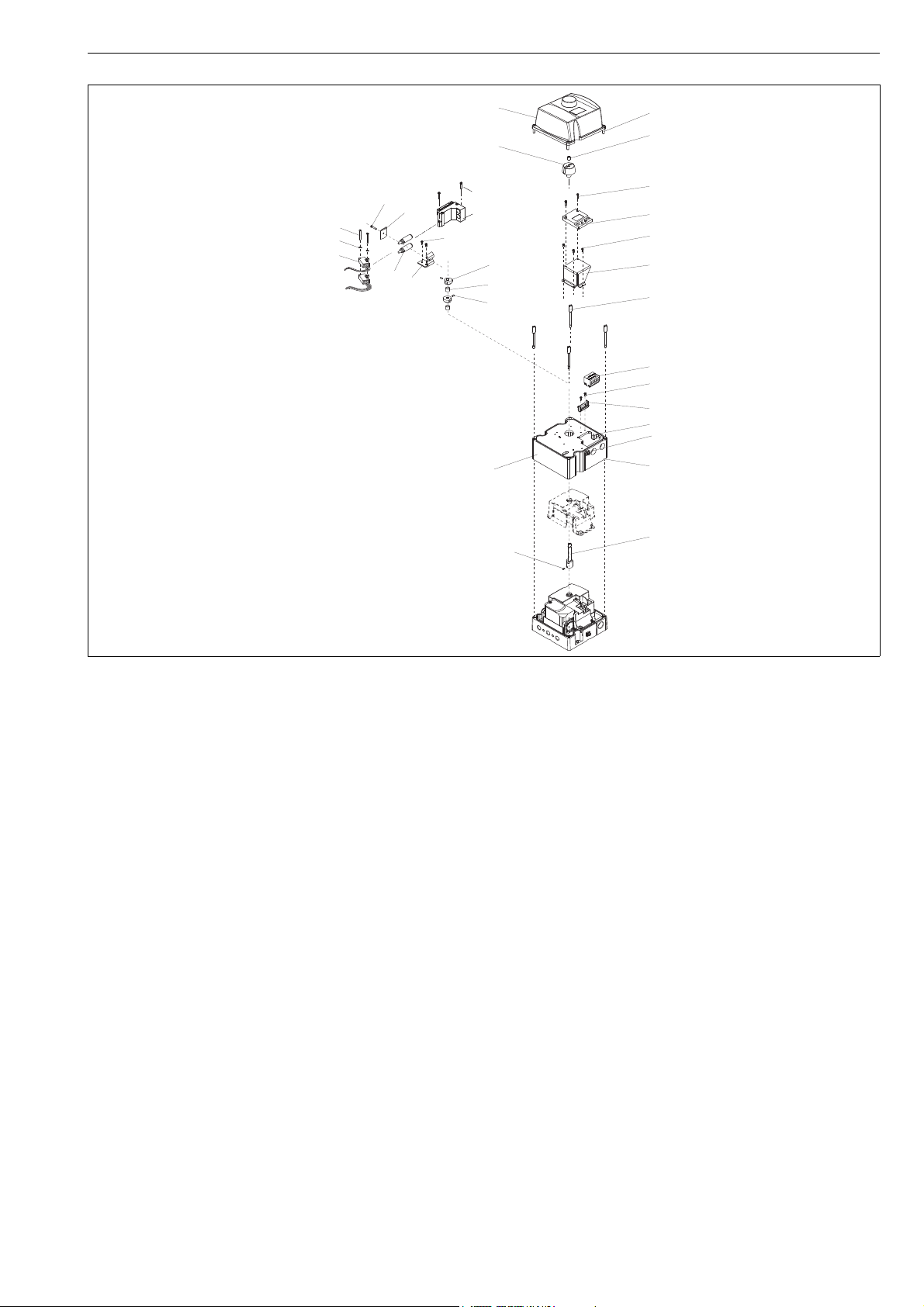

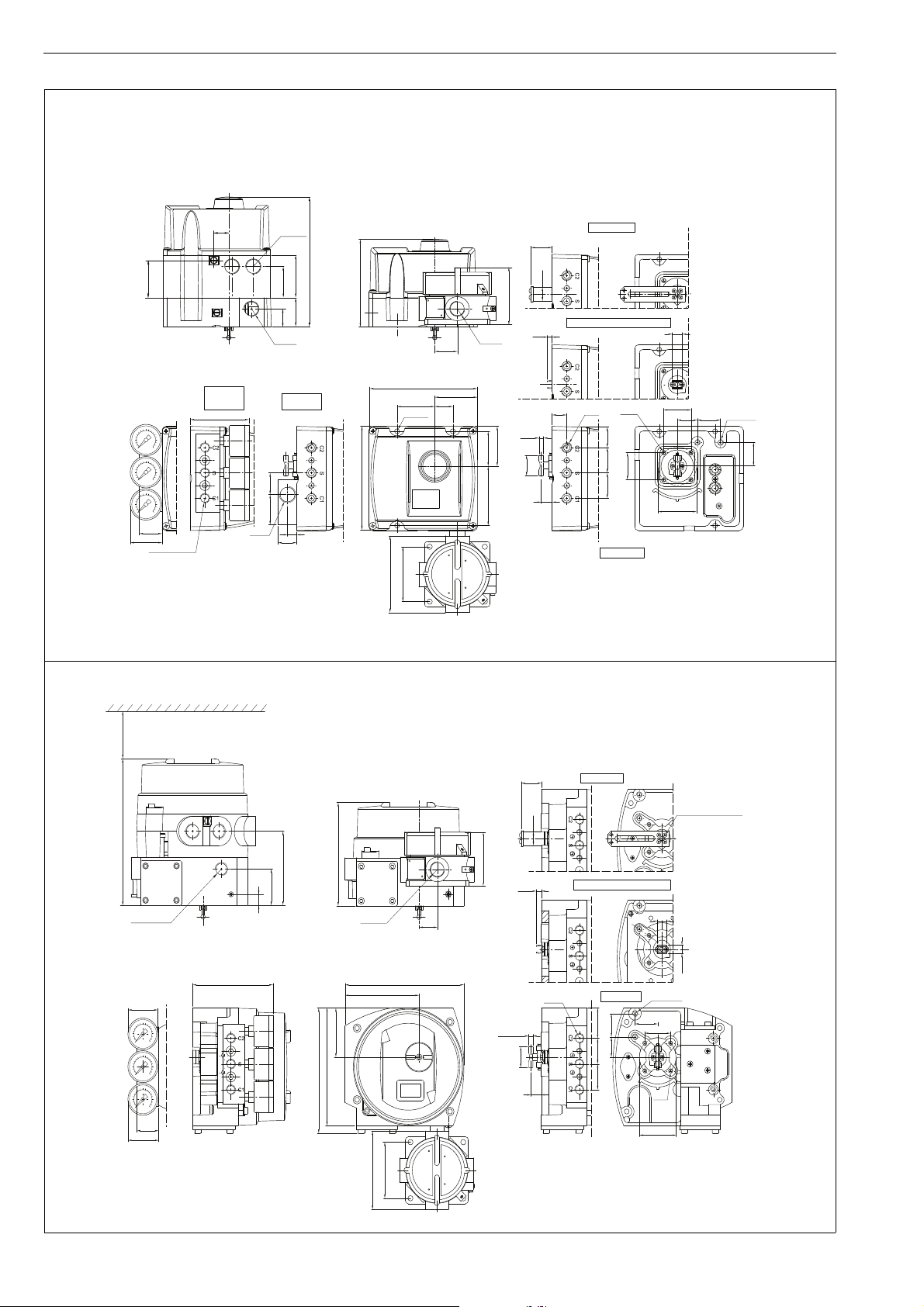

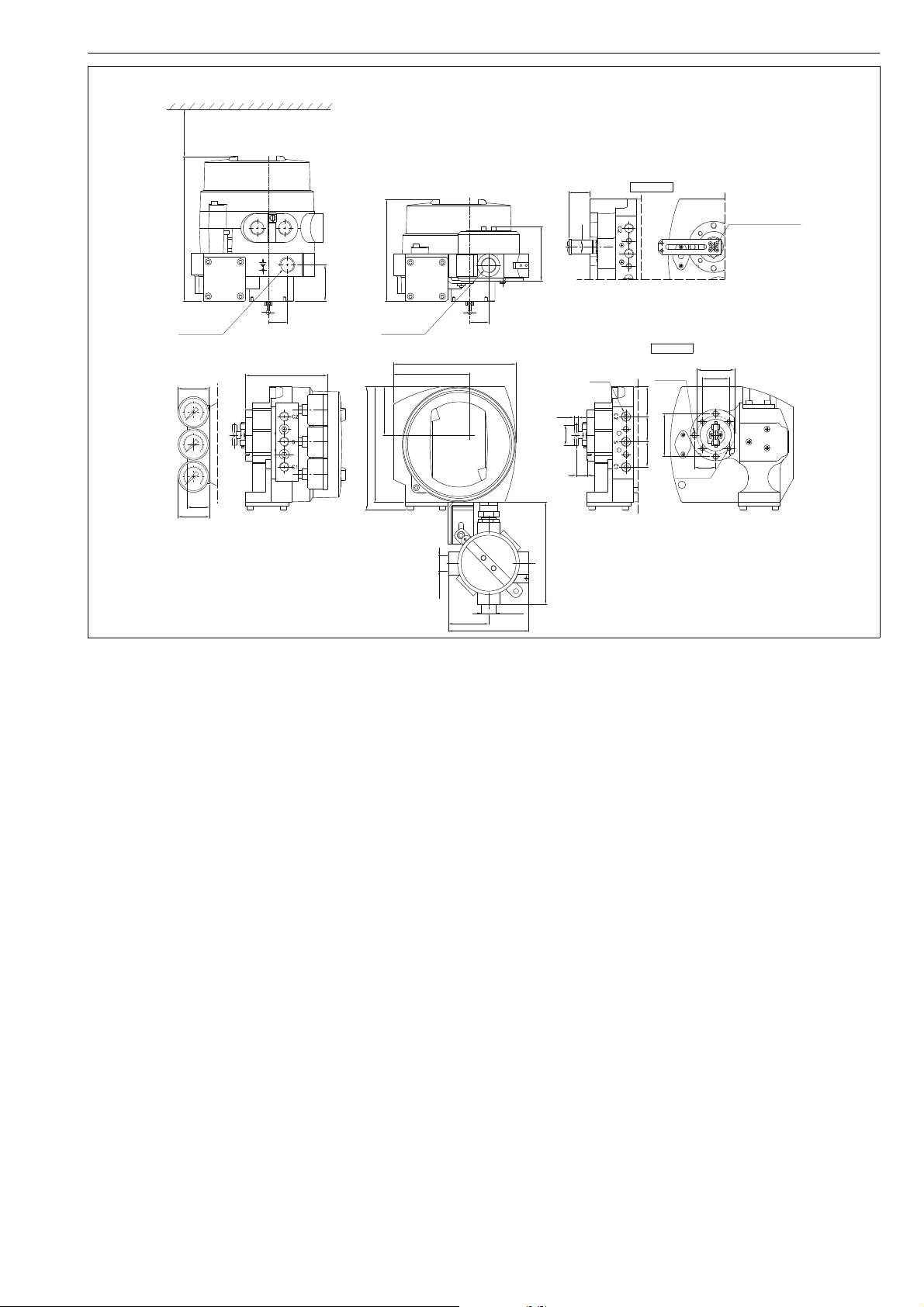

12.1 Exploded view ND9100, ND9400,

ND7100.....................................................................42

12.2 Exploded view ND9100_/D__, ND9100_/I__,

ND9100_/K0_ and ND9100_/B06 ...................43

12.3 Exploded view ND9200, ND9300,

ND7200 ...................................................................44

12.4 Exploded view ND9200_/D__, ND9200_/I__,

ND9200_/K0_, ND9200_/B06,

ND9300_/D__, ND9300_/I__, ND9300_/K0_,

ND9300_/B06_.......................................................46

12.5 Mounting parts for B1C/B1J 6-20

actuators ..................................................................48

12.6 Mounting parts for B1C/B1J 25-50, B1C 502

and B1J322 actuators ..........................................49

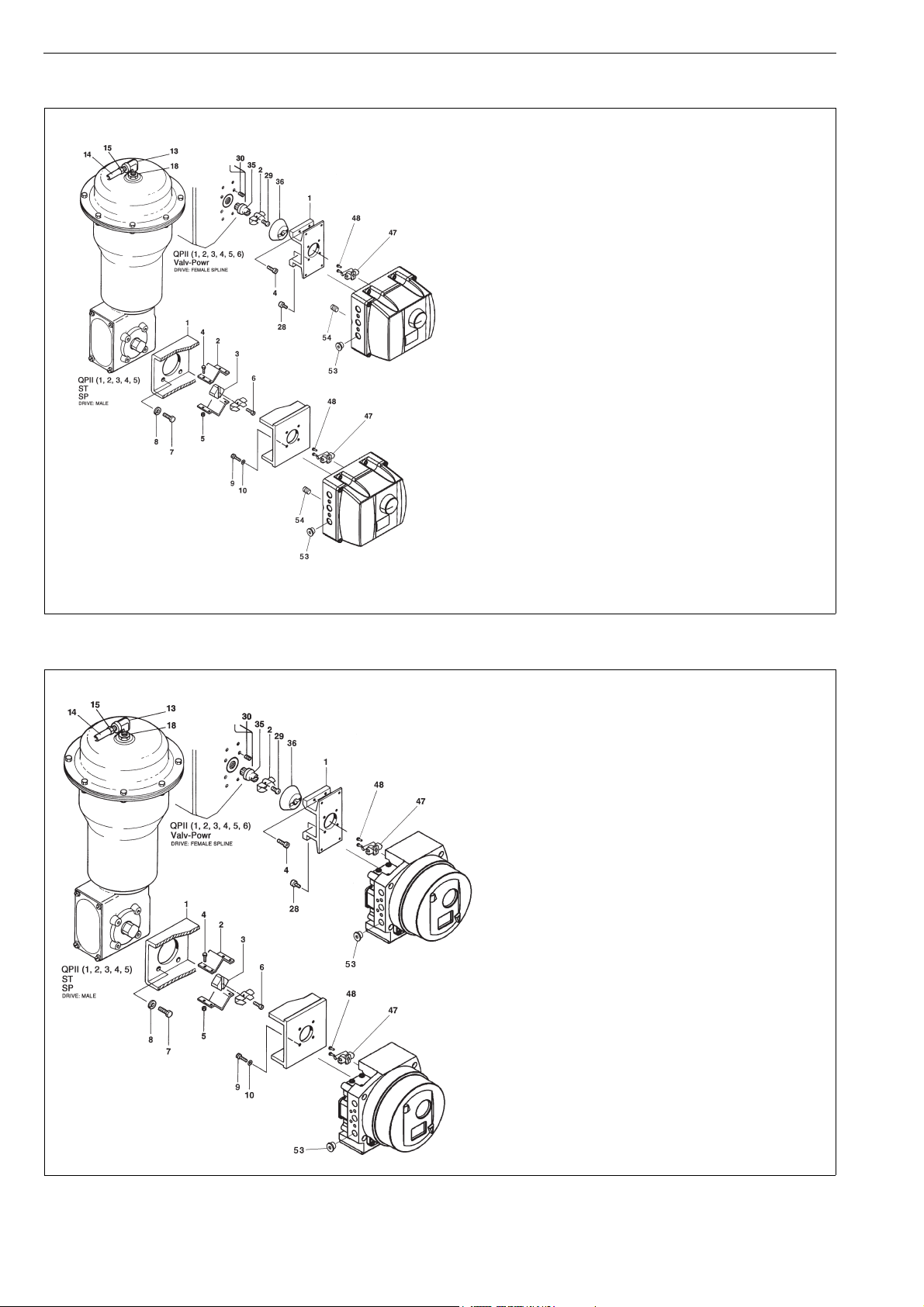

12.7 Mounting parts for Quadra-Powr®

actuators ..................................................................50

12.8 Mounting on Neles VC and VD actuators or

linear actuators with IEC 60534 mounting

face.............................................................................51

12.9 Connection diagrams..........................................53

13 DIMENSIONS ................................................... 58

14 EC DECLARATION OF CONFORMITY ................. 60

15 ID PLATES............................................................ 61

16 TYPE CODING...................................................... 62

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about the safe handling and operation of the intelligent valve controller.

If you require additional assistance, please contact the manufacturer or manufacturer's representative.

Addresses and phone numbers are printed on the back cover.

See also www.metso.com/valves for the latest documentation.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

7 ND90 71 en 3

1 PRODUCT FAMILY SUMMARY

1.1 ND9000

1.1.1 Key features

Benchmark control performance on rotary and linear

valves

Reliable and robust design

Ease of use

Language selection: English, German and French

Local / remote operation

Expandable architecture

Advanced device diagnostics including

Self-diagnostics

- Online diagnostics

- Performance diagnostics

- Communication diagnostics

- Extended off-line tests

- Performance view

- Online Valve Signature

1.1.2 Options

Interchangeable communication options:

HART 6 or 7 (H)

F

OUNDATION fieldbus (F)

Profibus PA (P)

Limit switches

Position transmitter (in HART only)

Stainless steel housing

Exhaust adapter

Remote mounting

Cold version (up to -53 °C)

1.1.3 Total cost of ownership

Low energy and air consumption

Future proof design allows further options at a

reduced cost

Optimised spares program. Reduced number of

spares

Retro-fit to existing installations (Neles or 3rd party)

1.1.4 Minimised process variability

Linearisation of the valve flow characteristics

Excellent dynamic and static control performance

High-speed of response

Accurate internal measurements

1.1.5 Easy installation and configuration

Same unit for linear and rotary valves, double and

single-acting actuators

Simple calibration and configuration

using Local User Interface (H, F, P)

using DTM or EDD in a remote location (H, F)

see 375/475 menu structure from annex 1

using Profibus configurator like Simatic PDM (P)

or DTM

Low power design enables installation to all com-

mon control systems

Ability to attach options to electronics and mechan-

ics later

Possibility to mount also on valves that are in pro-

cess with 1-point calibration feature

1.1.6 Open solution

Metso is committed to delivering products that freely interface with software and hardware from a variety of manufacturers; and the ND9000 is no exception. This open

architecture allows the ND9000 to be integrated with other

field devices to give an unprecedented level of controllability.

FDT based and DD/eEDD multi-vendor support con-

figuration files from download page:

www.metso.com/ND9000

1.1.7 ND9000 in fieldbus networks

Approved interoperability

Host interoperability ensured

F

OUNDATION fieldbus ITK version 6.1.2 certified

Profibus PA profile version 3.0 PNO certified

Easy to upgrade; can be done by replacing the HART

communication board to fieldbus communication

board

Excellent maintainability with firmware download

feature

Advanced communication diagnostics

Digital communication via the fieldbus includes not

only the set point, but also the position feedback signal from the position sensor. No special supplementary modules for analog or digital position feedback

are needed when using the fieldbus valve controller.

Back up LAS functionality available in F

fieldbus enviroment

Input selector and output splitter blocks available in

F

OUNDATION fieldbus devices allowing advanced dis-

tributed control

Multipurpose functionality

Standard function blocks enables the freedom to

use ND9000 intelligent valve controller either in

continuous or on-off control applications

Open and close information directly available via

the fieldbus

Open and close detection is based on either posi-

tion measurement (soft limit switch) or mechanical limit switch information

OUNDATION

1.1.8 Product reliability

Designed to operate in harsh environmental condi-

tions

Rugged modular design

Excellent temperature characteristics

Vibration and impact tolerant

IP66 enclosure

Protected against humidity

Maintenance free operation

Resistant to dirty air

Wear resistant and sealed components

Contactless position measurement

1.1.9 Predictive maintenance

Easy access to collected data with FDT based DTM

Unique Online Valve Signature to detect valve

friction even more accurately.

Performance view with report, which gives

guidelines for recommended actions.

Logical trend and histogram collection

Information collected on service conditions

4 7 ND90 71 en

Extensive set of off-line tests with accurate key

figure calculations

Fast notifications using on-line alarms

Condition monitoring tool available

Real time monitoring of valve control parameters

1.2 ND7000

1.2.1 Key features

Benchmark control performance on rotary and linear

valves

Reliable and robust design

Ease of use

Language selection: English, German and French

Local / remote operation

Expandable architecture

Basic diagnostics including

Self-diagnostics

Online diagnostics

Extended off-line tests

1.2.2 Total cost of ownership

Low energy and air consumption

Retro-fit to existing installations (Neles or 3rd party)

1.2.3 Minimised process variability

Linearisation of the valve flow characteristics

Excellent dynamic and static control performance

High-speed of response

Accurate internal measurements

1.2.4 Easy installation and configuration

Same unit for linear and rotary valves, double and

single-acting actuators

Simple calibration and configuration

using Local User Interface (H)

using DTM or EDD in a remote location (H, F)

see 375/475 menu structure from annex 1

Low power design enables installation to all com-

mon control systems

Possibility to mount also on valves that are in pro-

cess with 1-point calibration feature

1.2.5 Open solution

Metso is committed to delivering products that freely interface

with software and hardware from a variety of manufacturers;

and the ND7000 is no exception. This open architecture allows

the ND7000 to be integrated with other field devices to give an

unprecedented level of controllability.

FDT based multi-vendor support configuration

ND9000 DTM download page:

www.metso.com/ND9000

1.2.6 Product reliability

Designed to operate in harsh environmental condi-

tions

Rugged modular design

Excellent temperature characteristics

Vibration and impact tolerant

IP66 enclosure

Protected against humidity

Maintenance free operation

Resistant to dirty air

Wear resistant and sealed components

Contactless position measurement

2 ND9000 AND ND7000 INTELLIGENT

VALVE CONTROLLER WITH DIFFERENT

COMMUNICATION PROTOCOLS

2.1 General

This manual incorporates Installation, Maintenance and

Operation Instructions for the Metso ND9000 and ND7000

intelligent valve controller. The ND9000 and ND7000 may

be used with either cylinder or diaphragm type pneumatic

actuators for rotary or linear valves.

NOTE:

The selection and use of the valve controller in a specific

application requires close consideration of detailed

aspects. Due to the nature of the product, this manual

cannot cover all the likely situations that may occur when

installing, using or servicing the valve controller.

If you are uncertain about the use of the controller or its

suitability for your intended use, please contact Metso’s

Automation business for more information.

2.2 Technical description

ND9000H and ND7000H

The ND9000H and ND7000H are a 4–20 mA loop-powered

microcontroller-based intelligent valve controllers. The

devices operate even at 3.6 mA input signal and communicates via HART.

ND9000F

The ND9000F is a fieldbus powered microcontroller-based

intelligent valve controller.

ND9000P

The ND9000P is a fieldbus powered microcontroller-based

intelligent valve controller.

All versions

All devices contain a Local User Interface enabling local

configuration.

Independently from the communication protocol, the valve

position is controlled by the powerful 32-bit microcontroller. The measurements include:

Input signal

Valve position with contactless sensor

Actuator pressures, 2 independent measurements

Supply pressure

Spool valve position

Device temperature

Advanced self-diagnostics guarantees that all measurements operate correctly. Failure of one measurement does

not cause the valve to fail if the input signal and position

measurements are operating correctly. After connections of

electric signal and pneumatic supply the micro controller

(µC) reads the input signal, position sensor (α), pressure

sensors (Ps, P1, P2) and spool position sensor (SPS). A difference between input signal and position sensor (α) measurement is detected by the control algorithm inside the µC.

The µC calculates a new value for prestage (PR) coil current

based on the information from the input signal and from

the sensors. Changed current to the PR changes the pilot

pressure to the spool valve. Reduced pilot pressure moves

the spool and the actuator pressures change accordingly.

The spool opens the flow to the driving side of the double

diaphragm actuator and opens the flow out from the other

7 ND90 71 en 5

side of the actuator. The increasing pressure will move the

diaphragm piston. The actuator and feedback shaft rotate

clockwise. The position sensor (α) measures the rotation for

the µC. The µC using control algorithm modulates the PRcurrent from the steady state value until a new position of

the actuator according to the input signal is reached.

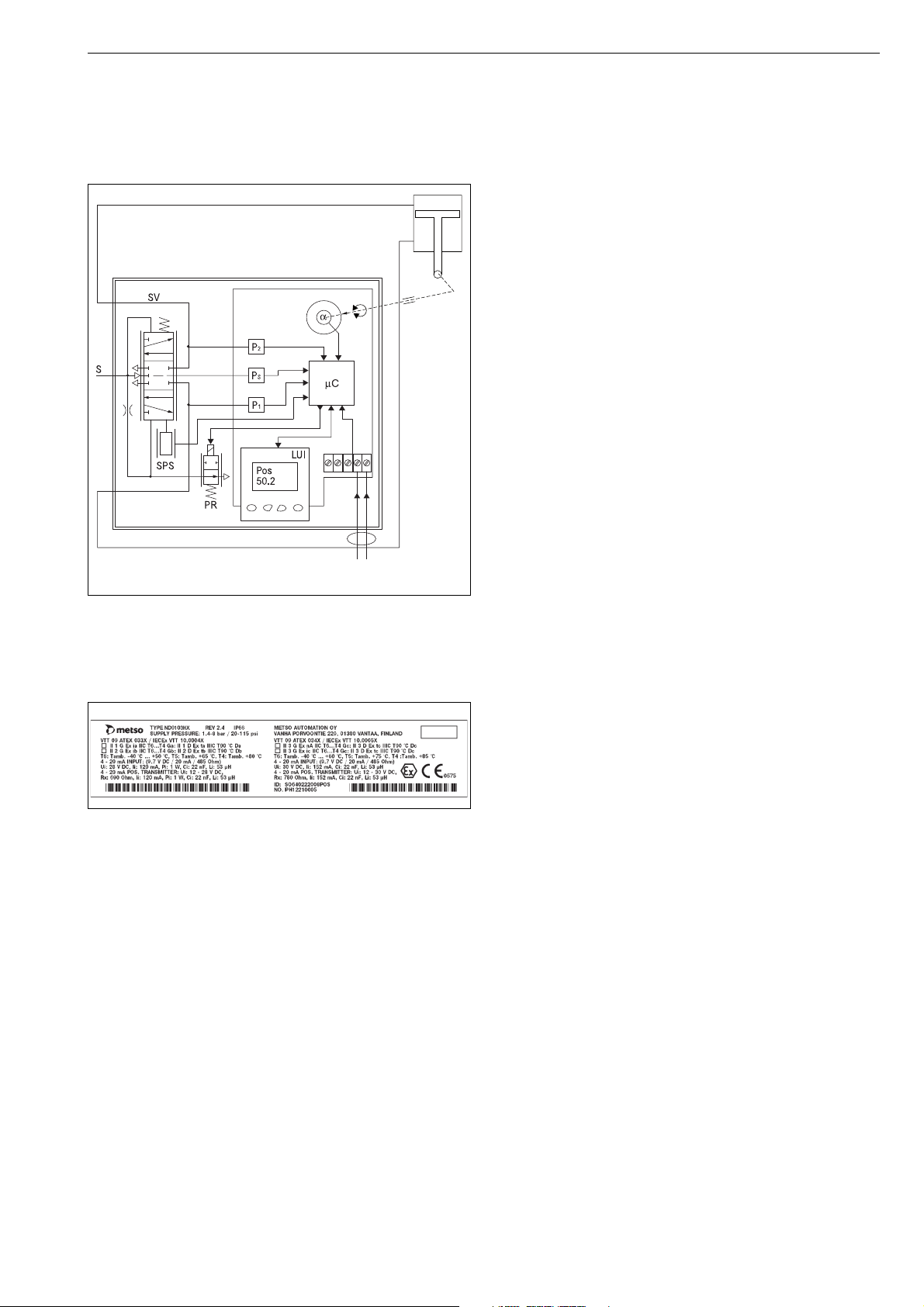

Fig. 1 The principle of operation

2.3 Markings

The valve controller is equipped with an identification plate

(Fig. 2).

Fig. 2 Example of the identification plate

Identification plate markings include:

Type designation of the valve controller

Revision number

Enclosure class

Input signal (voltage range)

Input resistance

Maximum supply voltage

Operational temperature

Supply pressure range

Contact details of the manufacturer

CE mark

Manufacturing serial number TTYYWWNNNN*)

*) Manufacturing serial number explained:

TT= device and factory sign

YY= year of manufacturing

WW = week of manufacturing

NNNN = consecutive number

Example: PH13011234 = controller, year 2013, week 1, consecutive number 1234.

Note, that in ND9200 and ND9300 models there may have

two identification plates if there is double approval (type

ND92_XE1 or ND93_XE1).

When device is installed to Ed i or Ex d area, remove identification plate which is not valid.

If device is installed to Ex d area, it can't be installed to Ex i

area even that identification plate would be changed.

See Chapter 15 for all ID plates.

2.4 Technical specifications

ND9000 AND ND7000 INTELLIGENT VALVE

CONTROLLER

General

Either loop powered (ND9000H and ND7000H) or

bus powered (ND9000F and ND9000P),

no external power supply required.

Suitable for rotary and sliding-stem valves.

Actuator connections in accordance with VDI/VDE 3845

and IEC 60534-6 standards.

Action: Double or single acting

Trave l ran ge: Linear; 10–120 mm with standard IEC parts.

Larger strokes possible with suitable kits

Rotary; 45–95°.

Measurement range 110° with freely

rotating feedback shaft.

Environmental Influence

Standard temperature range:

-40° to +85 °C / -40° to +185 °F

Low temperature option:

-53° to +85 °C / -64° to +185 °F

Influence of temperature on valve position:

< 0.5 % / 10 °C

Influence of vibration on valve position:

< 1 % under 2g 5–150 Hz,

1g 150–300 Hz, 0.5g 300–2000 Hz

Enclosure

ND9100 and ND7100

Material: Anodised aluminium alloy and

polymer composite

Protection class: IP66, NEMA 4X

Pneumatic ports: G 1/4

Electrical connection: max 2.5 mm

Cable gland thread: M20 x 1.5 / 1/2 NPT (U)

Weight: 1.8 kg / 4.0 lb

with extension housing (limit switches) plus 0.8 kg / 1.8 lb

Mechanical and digital position indicator visible through

the main cover

ND9200 and ND7200

Material: Anodised aluminium alloy and

tempered glass

Protection class: IP66, NEMA 4X

Pneumatic ports: 1/4 NPT

Electrical connection: max. 2.5 mm

Cable gland thread: M20 x 1.5, except 1/2 NPT (E2)

Weight: 3.4 kg / 7.5 lb

with extension housing (limit switches) plus 1.0 kg / 2.2 lb

Mechanical and digital position indicator visible through

the main cover (not applicable to ND9200_E2)

2

2

6 7 ND90 71 en

ND9300 and ND9400

Material: Full stainless steel enclosure (ND9300)

Stainless steel housing and polymer

composite cover (ND9400)

Protection class: IP66, NEMA 4X

Pneumatic ports: 1/4 NPT

Electrical connection: max. 2.5 mm

2

Cable gland thread: M20 x 1.5 / 1/2 NPT (U and E2)

Weight: 5.6 kg / 12.4 lbs (ND9400)

8.6 kg / 19.0 lbs (ND9300)

with extension housing (limit switches) plus 3.0 kg / 6.6 lb

Pneumatics

Supply pressure: 1.4–8 bar / 20–115 psi

Effect of supply pressure on valve position:

< 0.1 % at 10 % difference in inlet pressure

Air quality: According to ISO 8573-1:2001

Solid particles: Class 5

(3–5 µm filtration is recommended)

Humidity: Class 1

(dew point 10 °C / 18 °F below minimum

temperature is recommended)

Oil class: 3 (or <1 ppm)

Capacity with 4 bar / 60 psi supply:

5.5 Nm

12 Nm

38 Nm

3

/h / 3.3 scfm (spool valve 2)

3

/h / 7.1 scfm (spool valve 3)

3

/h / 22.4 scfm (spool valve 6)

Consumption with 4 bar / 60 psi supply

in steady state position:

< 0.6 Nm

< 1.0 Nm

3

/h / 0.35 scfm (spool valves 2 & 3)

3

/h / 0.6 scfm (spool valve 6)

Electronics

ND9000H and ND7000H

Supply power: Loop powered, 4–20 mA

Minimum signal: 3.6 mA

Current max : 120 mA

Load voltage: up to 9.7 V DC / 20 mA

(corresponding 485 Ω)

Voltage: max 30 V DC

Polarity protection: -30 V DC

Over current protection:

active over 35 mA

ND9000F and ND9000P

Power supply: Taken from bus

Bus voltage: 9–32 V DC, reverse polarity protection

Quiescent Current

Draw: 16 mA

Max basic current: 17.2 mA

Fault current (FDE): 3.9 mA

F

OUNDATION fieldbus function block execution times

ND9000F

AO 20 ms

AI 20 ms

PID 20 ms

DO 20 ms

DI 15 ms

IS 15 ms

OS 15ms

Performance with moderate constant-load actuators

Values at 20 °C / 68 °F and without any additional instruments, such as boosters or quick exhaust valves etc.

Dead band: ≤ 0.1 %

Hysteresis: < 0.5 %

Local user interface functions

Local control of the valve

Monitoring of valve position, input signal, tempera-

ture, supply and actuator pressure difference

Guided start-up function

LUI may be locked remotely to prevent unauthorised

access

Calibration: Automatic/Manual/Linearization

1-point calibration

Control configuration: aggressive, fast, optimum,

stable, maximum stability

Mode selection: Automatic/Manual

Rotation: valve rotation clockwise or counterclock-

wise to close

Dead angle

Low cut-off, cut-off safety range (default 2 %)

Positioner fail action, open/close

Signal direction: Direct/reverse acting

Actuator type, double/single acting

HART version: HART 6 or HART 7

Valve type, rotary/linear IEC/nelesCV Globe/FLI

Language selection: English, German and French

Electromagnetic protection

Electromagnetic compability acc. to

Emission: EN 61000-6-4 (2007) + A1(2011)

Immunity: EN 61000-6-2 (2005)

Safety

IEC 61508 compliant up to and

including SIL 2 by TUV

CE marking

EMC 2014/30/EU

ATEX 94/9/EC (until 19 April 2016)

ATEX 2014/34/EU (from 20 April 2016)

7 ND90 71 en 7

Approvals

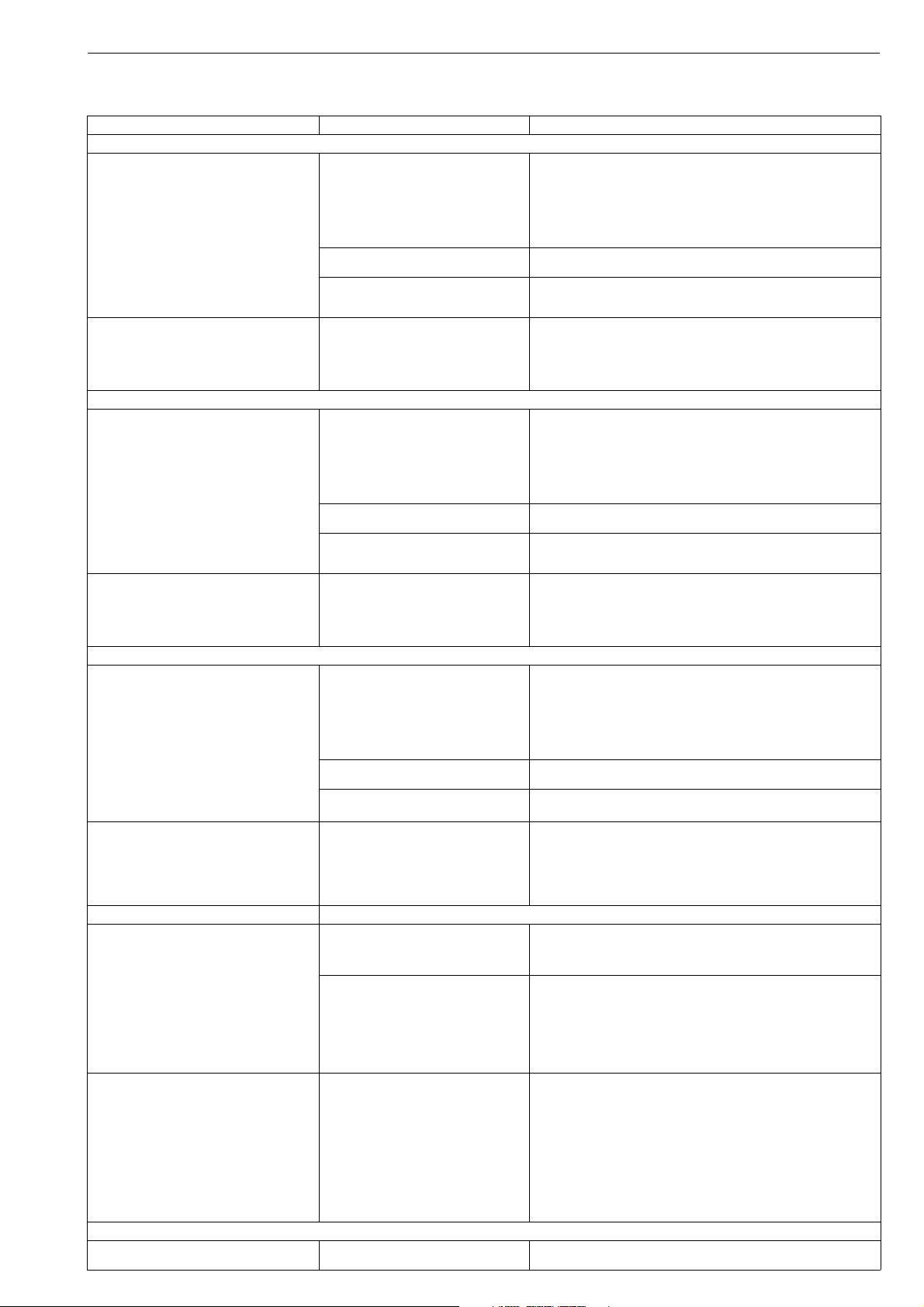

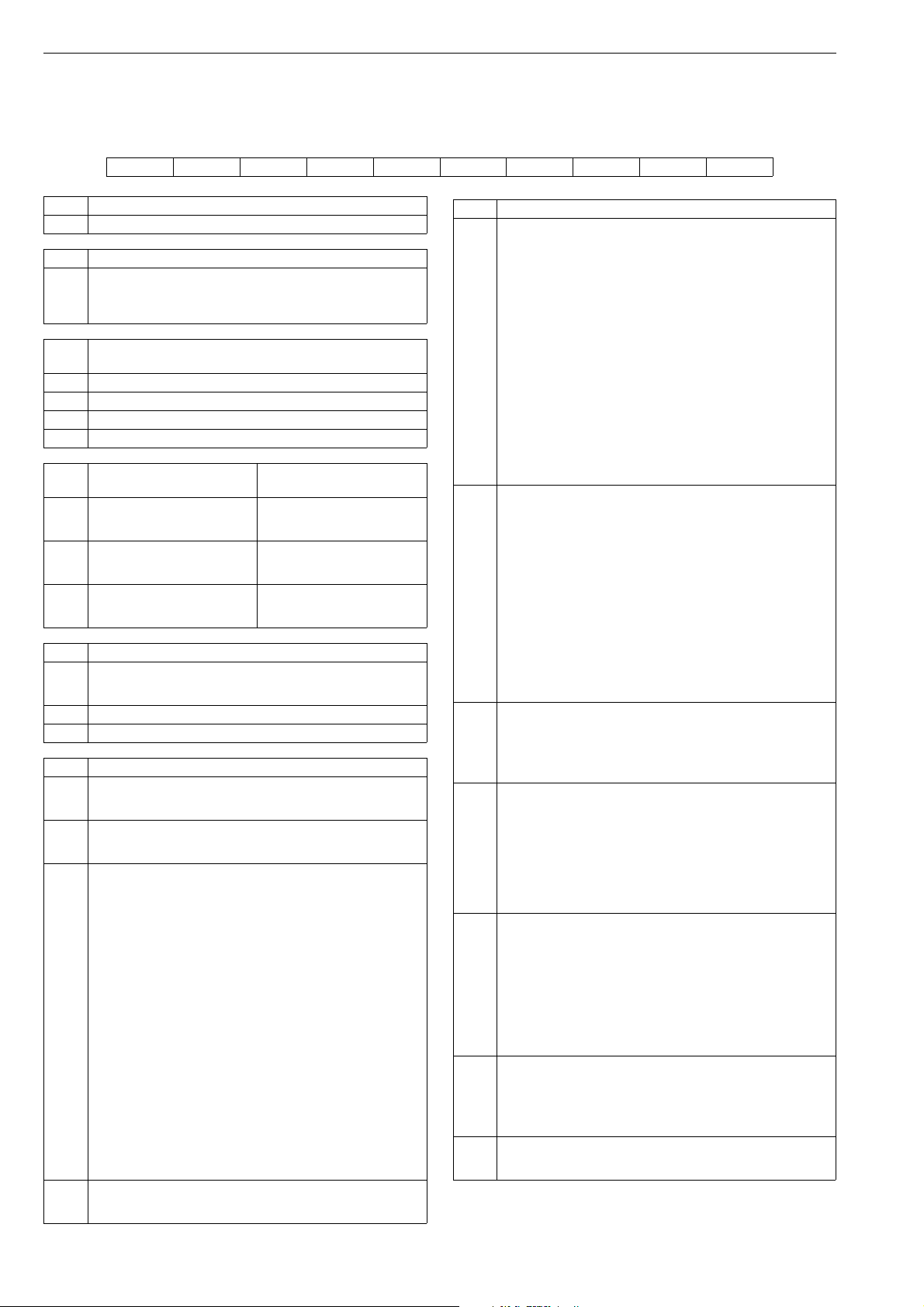

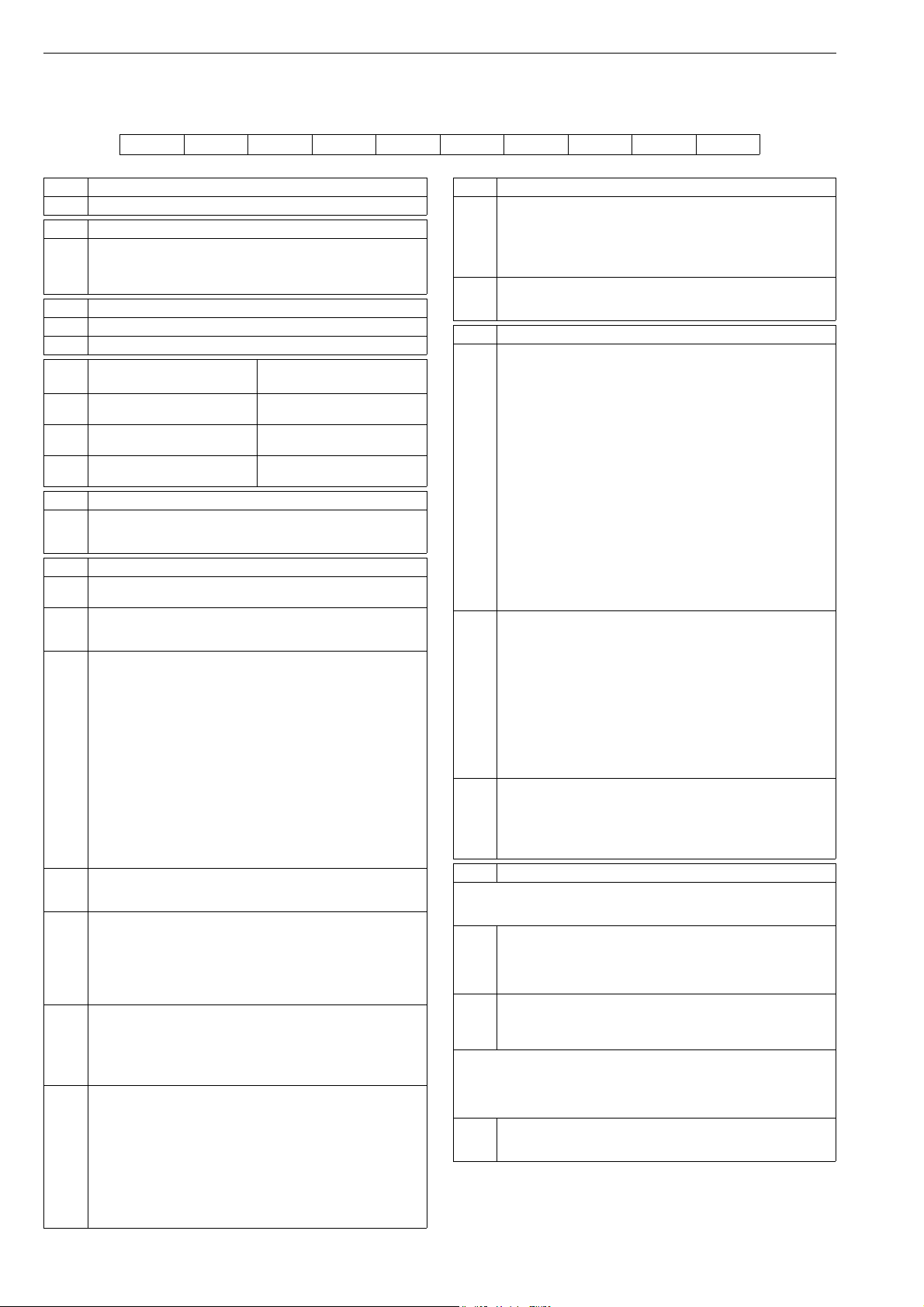

Table 1 Approvals and electrical values, HART

Certificate Approval Electrical values

ATE X

ND_X

VTT 09 ATEX 033X

VTT 09 ATEX 034X

EN 60079-0: 2012

EN 60079-11: 2012

EN 60079-26: 2007

EN 60079-31: 2009

EN 60079-0: 2012

EN 60079-11: 2012

EN 60079-15: 2010

EN 60079-31: 2009

ND_E1

SIRA 11 ATEX 1006X

EN 60079-0:2012

EN 60079-1:2007

EN 60079-31:2009

IECEx

ND_X

IECEx VTT 10.0004X

IECEx VTT 10.0005X

IEC 60079-0: 2007/2011

IEC 60079-11: 2011

IEC 60079-26: 2006

IEC 60079-31: 2008

IEC 60079-0: 2007/2011

IEC 60079-11: 2011

IEC 60079-15: 2010,

IEC 60079-31: 2008

ND_E1

IECEx SIR 11.0001X

IEC 60079-0:2011

IEC 60079-1:2007

IEC 60079-31:2008

INMETRO

ND_Z

NCC 12.0793 X

NCC 12.0794 X

ABNT NBR IEC 60079-0:2013

ABNT NBR IEC 60079-11:2009

ABNT NBR IEC 60079-26:2008 (2009)

ABNT NBR IEC 60079-27:2010

ABNT NBR IEC 60079-0:2013

ABNT NBR IEC 60079-11:2009

IEC 60079-15:2012

ABNT NBR IEC 60079-27:2010

ABNT NBR IEC 60529:2005

ND_E5

NCC 12.0795 X

ABNT NBR IEC 60079-0:2013

ABNT NBR IEC 60079-1:2009 (2011)

ABNT NBR IEC 60079-31:2011

ABNT NBR IEC 60529:2005

cCSAus

ND_U

CSA Std C22.2 No.25-1966, CSA Std

C22.2 No.30-M1986, CAN/CSA-C22.2

No.94-M91, C22.2 No. 142-M1987,

CAN/CSA C22.2 61010-1-04, CAN/CSAC22.2

No 60079-0-07, CAN/CSA-C22.2

No 60079-1-07, CAN/ CSA C22.2 No

60079-31-12, CAN/CSA-C22.2 No.

60529-05, FM 3600 (1998), FM 3615

(2006), FM 3810 (2005), ANSI/ NEMA

250-1991, ISA 60079-0-07, ISA 60079-107, ISA 60079-31-2009, ANSI/IEC

60529:2004

ND_E2

CSA Std C22.2 No.25-1966, CSA Std

C22.2 No.30-M1986, CAN/CSA-C22.2

No.94-M91, C22.2 No. 142-M1987,

CAN/CSA C22.2 61010-1-04, CAN/CSAC22.2

No 60079-0-07, CAN/CSA-C22.2

No 60079-1-07, CAN/ CSA C22.2 No

60079-31-12, CAN/CSA-C22.2 No.

60529-05, FM 3600 (1998), FM 3615

(2006), FM 3810 (2005), ANSI/ NEMA

250-1991, ISA 60079-0-07, ISA 60079-107, ISA 60079-31-2009, ANSI/IEC

60529:2004

Japanese Ex-d Certification:

ND_E4 II 2 G Ex d IIC T6 Gb

II 1G Ex ia IIC T6...T4 Ga

II 1D Ex ta IIIC T90 °C Da

II 2 G Ex ib IIC T6...T4 Gb

II 2 D Ex tb IIIC T90 °C Db

II 3 G Ex nA IIC T6...T4 Gc

II 3 D Ex tc IIIC T90 °C Dc

II 3 G Ex ic IIC T6...T4 Gc

II 3 D Ex tc IIIC T90 °C Dc

II 2 G Ex d IIC T6...T4 Gb

II 2 D Ex tb IIIC T80 °C...T105 °C Db IP66

Ex ia IIC T6...T4 Ga

Ex ta IIIC T90 °C Da

Ex ib IIC T6...T4 Gb

Ex tb IIIC T90 °C Db

Ex nA IIC T6...T4 Gc

Ex tc IIIC T90 °C Dc

Ex ic IIC T6...T4 Gc

Ex tc IIIC T90 °C Dc

Ex d IIC T6...T4 Gb

Ex tb IIIC T80 °C...T105 °C Db IP66

Ex ia IIC T4/T5/T6 Ga

Ex ia IIC T4/T5/T6 Gb

Ex nA IIC T4/T5/T6 Gc Input: Ui ≤ 30 V, Ii ≤ 152 mA

Ex ic IIC T4/T5/T6 Gc Input: Ui ≤ 30 V, Ii ≤ 152 mA, Pmax = device limits itself, Ci ≤ 22 nF, Li ≤ 53 H.

Ex d IIC T4/T5/T6 Gb

Ex tb IIIC T100 °C Db IP66

IS Class I, Division 1, Groups A, B, C, and D;

T4/T5/T6

Ex ia IIC T4/T5/T6 Ga

IS Class I, Zone 0 AEx ia IIC T4/T5/T6 Ga

Class I, Division 2, Groups A, B, C, and D; T4/

T5/T6

Ex nA IIC T4/T5/T6 Gc or Ex nA ia IIC T4/T5/T6

Gc Ga

Class I, Zone 2 AEx nA IIC T4/T5/T6 Gc or Ex

nA ia IIC T4/T5/T6 Gc Ga

Class I, Div 1, Groups B, C, D; Class II, Div 1,

Groups E,F,G; Class III; T4…T6, Enclosure type

4X

Ex d IIC T4…T6

AEx d IIC T4…T6

Ex tb IIIC T100 °C IP66

AEx tb IIIC T100 °C IP66

II 2 D Ex tb IIIC T80°C Db

Input: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H.

Output: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H.

Input: Ui ≤ 30 V, Ii ≤ 152 mA

Output: Ui ≤ 30 V, Ii ≤ 152 mA

Input: Ui ≤ 30 V, Ii ≤ 152 mA, Pmax = device limits itself, Ci ≤ 22 nF, Li ≤ 53 H.

Output: Ui ≤ 30 V, Ii ≤ 152 mA, Pmax = device limits itself, Ci ≤ 22 nF,

Li ≤ 53 H.

Input: Ui ≤ 30 V

Output: Ui ≤ 30 V, Pmax = device limits itself.

Input: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H

Output: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H.

Input: Ui ≤ 30 V, Ii ≤ 152 mA

Output: Ui ≤ 30 V, Ii ≤ 152 mA

Input: Ui ≤ 30 V, Ii ≤ 152 mA, Pmax = device limits itself, Ci ≤ 22 nF, Li ≤ 53 H

Output: Ui ≤ 30 V, Ii ≤ 152 mA, Pmax = device limits itself, Ci ≤ 22 nF,

Li ≤ 53 H.

Input: Ui ≤ 30 V

Output: Ui ≤ 30 V, Pmax = device limits itself.

Input: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H

Output: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H.

Output: Ui ≤ 30 V, Ii ≤ 152 mA

Output: Ui ≤ 30 V, Ii ≤ 152 mA, Pmax = device limits itself, Ci ≤ 22 nF, Li ≤ 53 H.

Input: Ui ≤ 30 V

Output: Ui ≤ 30 V, Pmax = device limits itself.

Input: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H

Output: Ui ≤ 28 V, Ii ≤ 120 mA, Pi ≤ 1 W, Ci ≤ 22 nF, Li ≤ 53 H.

Input: Ui ≤ 30 V.

Output: Ui ≤ 30 V.

Input: Ui ≤ 30 V

Output: Ui ≤ 30 V, Pmax = device limits itself.

Input: Ui ≤ 30 V

Output: Ui ≤ 30 V, Pmax = device limits itself.

8 7 ND90 71 en

Table 2 Approvals and electrical values, FOUNDATION fieldbus and Profibus PA

Certificate Approval Electrical values

ATE X

ND_X

VTT 09 ATEX 033X

VTT 09 ATEX 034X

EN 60079-0: 2012

EN 60079-11: 2012

EN 60079-26: 2007

EN 60079-31: 2009

EN 60079-0: 2012

EN 60079-11: 2012

EN 60079-15: 2010

EN 60079-31: 2009

ND_E1

SIRA 11 ATEX 1006X

EN 60079-0:2012

EN 60079-1:2007

EN 60079-31:2009

IECEx

ND_X

IECEx VTT 10.0004X

IECEx VTT 10.0005X

IEC 60079-0: 2007/2011

IEC 60079-11: 2011

IEC 60079-26: 2006

IEC 60079-31: 2008

IEC 60079-0: 2007/2011

IEC 60079-11: 2011

IEC 60079-15: 2010,

IEC 60079-31: 2008

ND_E1

IECEx SIR 11.0001X

IEC 60079-0:2011

IEC 60079-1:2007

IEC 60079-31:2008

ND_Z

NCC 12.0793 X

NCC 12.0794 X

ABNT NBR IEC 60079-0:2008 (2011)

ABNT NBR IEC 60079-11:2009

ABNT NBR IEC 60079-26:2008 (2009)

ABNT NBR IEC 60079-27:2010

ABNT NBR IEC 60079-0:2008 (2011)

ABNT NBR IEC 60079-11:2009

IEC 60079-15:2010

ABNT NBR IEC 60079-27:2010

ABNT NBR IEC 60529:2009

ND_E5

NCC 12.0795 X

ABNT NBR IEC 60079-0:2008 (2011)

ABNT NBR IEC 60079-1:2009 (2011)

ABNT NBR IEC 60079-31:2011

ABNT NBR IEC 60529:2009

ND_U

CSA C22.2 No. 0-M91, CSA C22.2 No.

94-M91, CSA C22.2 No. 142-M1987,

CSA C22.2 No. 157-92, CSA C22.2 No.

213-M1987, CSA C22.2 No. 60079-0:11,

CSA C22.2 No. 60079-11:11, CSA C22.2

No. 60079-15:12, CSA C22.2 No.

60529:05, ANSI/ISA 60079-0: 2009,

ANSI/ISA 60079-11: 2012, ANSI/ISA

60079-15: 2012, FM 3600 November

1998, FM 3610 October 1999, FM 3611

October 1999, FM 3810-2005, ANSI/

NEMA 250:1991, ANSI/IEC 60529:2004

ND_E2

CSA Std C22.2 No.25-1966, CSA Std

C22.2 No.30-M1986, CAN/CSA-C22.2

No.94-M91, C22.2 No. 142-M1987,

CAN/CSA C22.2 61010-1-04, CAN/CSAC22.2

No 60079-0-07, CAN/CSA-C22.2

No 60079-1-07, CAN/ CSA C22.2 No

60079-31-12, CAN/CSA-C22.2 No.

60529-05, FM 3600 (1998), FM 3615

(2006), FM 3810 (2005), ANSI/ NEMA

250-1991, ISA 60079-0-07, ISA 60079-107, ISA 60079-31-2009, ANSI/IEC

60529:2004

ND_E4 II 2 G Ex d IIC T6 Gb

INMETRO

cCSAus

Japanese Ex-d Certification:

II 1G Ex ia IIC T6...T4 Ga

II 1D Ex ta IIIC T90 °C Da

II 2 G Ex ib IIC T6...T4 Gb

II 2 D Ex tb IIIC T90 °C Db

II 1 D Ex ia IIIC T90 °C...T120 °C Da

II 2 D Ex ib IIIC T90 °C...T120 °C Db

II 3 G Ex nA IIC T6...T4 Gc

II 3 D Ex tc IIIC T90 °C Dc

II 3 D Ex ic IIIC T90 °C...T120 °C Dc

II 3 G Ex ic IIC T6...T4 Gc

II 3 D Ex tc IIIC T90 °C Dc

II 3 D Ex ic IIIC T90 °C...T120 °C Dc

II 2 G Ex d IIC T6...T4 Gb

II 2 D Ex tb IIIC T80 °C...T105 °C Db IP66

Ex ia IIC T6...T4 Ga

Ex ta IIIC T90 °C Da

Ex ib IIC T6...T4 Gb

Ex tb IIIC T90 °C Db

Ex ia IIIC T90 °C...T120 °C Da

Ex ib IIIC T90 °C...T120 °C Db

Ex nA IIC T6...T4 Gc

Ex tc IIIC T90 °C Dc

Ex ic IIIC T90 °C...T120 °C Dc

Ex ic IIC T6...T4 Gc

Ex tc IIIC T90 °C Dc

Ex ic IIIC T90 °C...T120 °C Dc

Ex d IIC T6...T4 Gb

Ex tb IIIC T80 °C...T105 °C Db IP66

Ex ia IIC T4/T5/T6 Ga

Ex ia IIC T4/T5/T6 Gb

Ex nA IIC T4/T5/T6 Gc Ui ≤ 24 V

Ex ic IIC T4/T5/T6 Gc Ui ≤ 32 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Ex d IIC T4/T5/T6 Gb

Ex tb IIIC T100 °C Db IP66

Class I, Division 1, Groups A, B, C, and D; T4/

T5/T6

Ex ia IIC T4/T5/T6 Ga

Class I, Zone 0 AEx ia IIC T4/T5/T6 Ga

Class I, Division 2, Groups A, B, C, and D; T4/

T5/T6

Ex ic IIC T4/T5/T6 Gc

Class I, Zone 2 AEx ic IIC T4/T5/T6 Gc

Class I, Div 1, Groups B, C, D; Class II, Div 1,

Groups E, F, G; Class III; T4…T6, Enclosure

type 4X

Ex d IIC T4…T6

AEx d IIC T4…T6

Ex tb IIIC T100 °C IP66

AEx tb IIIC T100 °C IP66

II 2 D Ex tb IIIC T80°C Db

Ui ≤ 24 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO field device

Ui ≤ 24 V

Ui ≤ 32 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO Ex ic field device

Ui ≤ 32 V

Ui ≤ 24 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO field device

Ui ≤ 24 V

Ui ≤ 32 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO Ex ic field device

Ui ≤ 32 V

Ui ≤ 24 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO field device

Comply with the requirements for FISCO Ex ic field device

Ui ≤ 32 V

Ui ≤ 24 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO field device

Ui ≤ 32 V, Ii ≤ 380 mA, Pi ≤ 5.32 W, Ci ≤ 5 nF, Li ≤ 10 H.

Comply with the requirements for FISCO Model Ex ic field device

Ui ≤ 32 V

Input: Ui ≤ 30 V

Output: Ui ≤ 30 V, Pmax = device limits itself.

7 ND90 71 en 9

Optional parts

ND9000H and ND7000H

Position transmitter

Output signal: 4–20 mA (galvanic isolation;

600 V DC)

Supply voltage: 12–30 V

Resolution: 16 bit / 0.244 µA

Linearity: < 0.05 % FS

Temperature effect: < 0.35 % FS

External load: max 0–780 Ω

max 0–690 Ω for intrinsically safe

ND9000/H, ND9000/F, ND9000/P,

ND9000F/B06, ND9000P/B06

Proximity sensors and micro switches, 2 pieces

(with extension module)

Code D33 SST Sensor Dual Module

Code D44 Namur Sensor Dual Module

Code I02 P+F NJ2-12GK-SN

Code I09 P+F NCB2-12GM35-N0

Code I32 Omron E2E-X2Y1

Code I41 P+F NJ4-12GK-SN

Code I45 P+F NJ3-18GK-S1N

Code I56 IFC 2002-ARKG/UP

Code K05 Omron D2VW-5

Code K06 Omron D2VW-01

Code B06 Omron D2VW-01 (ND9100F/P, ND9200F/P

and ND9300F/P only)

2.5 Recycling and disposal

Most valve controller parts can be recycled if sorted according to material.

Most parts have material marking. A material list is supplied

with the valve controller. In addition, separate recycling and

disposal instructions are available from the manufacturer.

A valve controller may also be returned to the manufacturer

for recycling and disposal. There will be a charge for this.

2.6 Safety precautions

NOTE (ND9000, ND7000):

Avoid earthing a welding machine in close proximity to an

ND valve controller.

Damage to the equipment may result.

CAUTION (ND9000, ND7000):

Do not exceed the permitted values!

Exceeding the permitted values marked on the valve

controller may cause damage to the controller and to

equipment attached to the controller and could lead to

uncontrolled pressure release in the worst case. Damage

to the equipment and personal injury may result.

CAUTION (ND9000, ND7000):

Do not remove or dismantle a pressurized controller!

Removing or dismantling a pressurized prestage or

spool valve of an ND leads to uncontrolled pressure

release. Always shut off the supply air and release the

pressure from the pipelines and equipment before removing or dismantling the controller. Otherwise personal

injury and damage to equipment may result.

WAR NI NG (ND9000, ND7000):

During automatic or manual calibration the valve

operates between open and closed positions. Make

sure that the operation does not endanger people or

processes!

WARNING (ND9000, ND7000):

Do not operate the device with electronics cover (39)

removed!

Electromagnetic immunity is reduced, valve may stroke.

Explosion protection may be impaired.

Ex d WARNING (ND9200, ND7200, ND9300):

Do not open the device when energized!

Explosion protection is lost.

ELECTRICAL SAFETY WARNING (ND9200, ND7200,

ND9300):

Use fuses for limit switch installations with

50 V AC / 75 V DC or higher.

Ex WARNING (ND9100, ND7100):

Electrostatic charge hazard!

The cover is non-conductive. Clean with a damp cloth

only!

Spark hazard!

Protect the aluminium housing from impacts and friction!

Ex WARNING (ND9100, ND9200, ND9300 and ND7100):

For use in the presence of combustible dust.

Ignition protection relies on the enclosure. Protect the

cover of the valve controller from impacts. When temperature is higher than 70 °C / 158 °F the temperature rating of

the cable shall be higher than the ambient temperature.

Ex WARNING (ND9200, ND7200, ND9300):

The locking screw (part 107) of the cover is essential to

explosion protection.

The cover has to be locked in place for Ex d protection.

The screw grounds the cover to the housing.

10 7 ND90 71 en

Intrinsic Safety (Ex i) WARNING (ND9100, ND9200,

ND9300 and ND7100):

Ensure that the complete installation and wiring is

intrinsically safe before operating the device!

The equipment must be connected via a certified Zener

barrier placed outside the hazardous area.

Ex WARNING (ND9200, ND7200):

Electrostatic charge hazard!

The windows and identification plate are non-conductive.

Clean with a damp cloth only!

Ex WARNING (ND9100, ND7100):

For use in the presence of combustible dust.

Device shall not be subjected to a prolific charge generating mechanism.

Ex WARNING (ND9000, ND7000):

Accumulation of dust shall be avoided!

Ex d WARNING (ND9200, ND7200, ND9300):

Use a cable gland and blind plug with suitable Ex d

certification.

For ambient temperature over 70 °C / 158 °F use a heat

resistant cable and cable gland suitable for at least

90 °C / 194 °F.

Ex n WARNING (ND9100, ND9200, ND9300 and ND7100):

At an ambient temperature ≥ +70 °C / 158 °F, the temperature rating of selected connection cable shall be

in accordance with the maximum ambient temperature range.

Selected cable gland shall not invalidate the type of

protection.

Ex i WARNING (ND9100, ND9200, ND9300 and ND7100):

At an ambient temperature ≥ +70 °C / 158 °F, the temperature rating of selected connection cable shall be

in accordance with the maximum ambient temperature range.

Ex NOTE:

Follow the standards EN/IEC 60079-14 when installing the

equipment and and EN/IEC 60079-25 when connecting

Ex i interfaces.

3 TRANSPORTATION, RECEPTION AND

STORAGE

The valve controller is a sophisticated instrument, handle it

with care.

Check the controller for any damage that may have

occurred during transportation.

Store the uninstalled controller preferably indoors,

keep it away from rain and dust.

Do not unpack the device until installing it.

Do not drop or knock the controller.

Keep the flow ports and cable glands plugged until

installing.

Follow instructions elsewhere in this manual.

4 MOUNTING

4.1 General

NOTE:

The enclosure of ND9000 and ND7000 intelligent valve

controller meets the IP66 protection class according to

EN 60529 in any position when the cable entry is plugged

according to IP66.

Based on good mounting practice, the recommended

mounting position is electrical connections placed downwards. This recommendation is shown in our mounting

position coding for control valves.

If these requirements are not fulfilled, and the cable gland

is leaking and the leakage is damaging valve controller or

other electrical instrumentation, our warranty is not valid.

NOTE:

Make sure the mounting of the device and the valve

assembly is suitable for the weight of the assembly.

If the ND is supplied with valve and actuator, the tubes are

mounted and the ND adjusted in accordance with the customer’s specifications. If the controller is ordered separately,

the mounting parts for the assembly must be ordered at

the same time.

Sample order: (B1CU13)-Z-ND9_06HN

Shaft coupling alternatives for the controller for Metso

actuators are shown in Fig. 6.

4.2 For mounting parts for Metso actuators,

see 12.5–12.10.Mounting on Metso

actuators

with VDI/VDE mounting face

See figures in Section 12.6–12.7.

ND9100, ND9400, ND7100

Mount the H-shaped coupling (47) to the shaft.

Apply the thread-locking compound to the screw

(48) and tighten firmly.

Remove all protective plastic plugs from the pneu-

matic connections (5 pcs.). Mount the metal plugs

(54) with sealant to the unused controller connections at the bottom of the controller.

BJ and other single acting actuators: mount a

metal plug (53) with sealant to the C1 connection.

Set the direction arrow of the actuator in the direc-

tion of the valve closure member and attach the ear

(2) to the indicator cover in the position shown in

Section 12.6-12.7. Secure the screw of the ear using

e.g. Loctite and tighten firmly.

Attach the bracket (1) to the ND.

Attach the bracket (1) to the actuator. The shaft cou-

pling of the ND must fit into the ear (2) so that the

pointer of the shaft washer (16) is located in the position shown in Fig. 5.

7 ND90 71 en 11

C2

S

C1

The pointer on the coupling must

stay in this sector

11

ND9200, ND7200, ND9300

Make sure the mounting bracket is suitable for the

weight of the controller. See detailed weight information in Section 2.4.

ND9300: Extra mounting holes exist in the housing

for additional support. See dimension drawings for

ND9300 in Chapter 13. The use of this extra support

is mandatory in addition to the standard face.

ND9300: Due to the extra weight of stainless steel

version and/or possible heavy vibration, make sure

there are proper supports in the pipeline to hold the

weight of the valve assembly.

Mount the H-shaped coupling (47) to the shaft.

Apply the thread-locking compound to the screw

(48) and tighten firmly.

Remove the protective plastic plugs from pneumatic

connections C2, S and C1. Leave the metal plugs (54)

in the unused connections at the bottom of the controller.

BJ and other single acting actuators: install a

metal plug (53) with sealant to the C1 connection.

Set the direction arrow of the actuator in the direc-

tion of the valve closure member and attach the ear

(2) to the indicator cover in the position shown in

Section 12.6-12.7. Secure the screw of the ear using

e.g. Loctite and tighten firmly.

Attach the bracket (1) to the controller.

Attach the bracket (1) to the actuator. The shaft cou-

pling of the controller must fit into the ear (2) so that

the pointer is located in the position shown in Fig. 5.

Fig. 3 Mounting on Metso actuator with

VDI/VDE mounting face

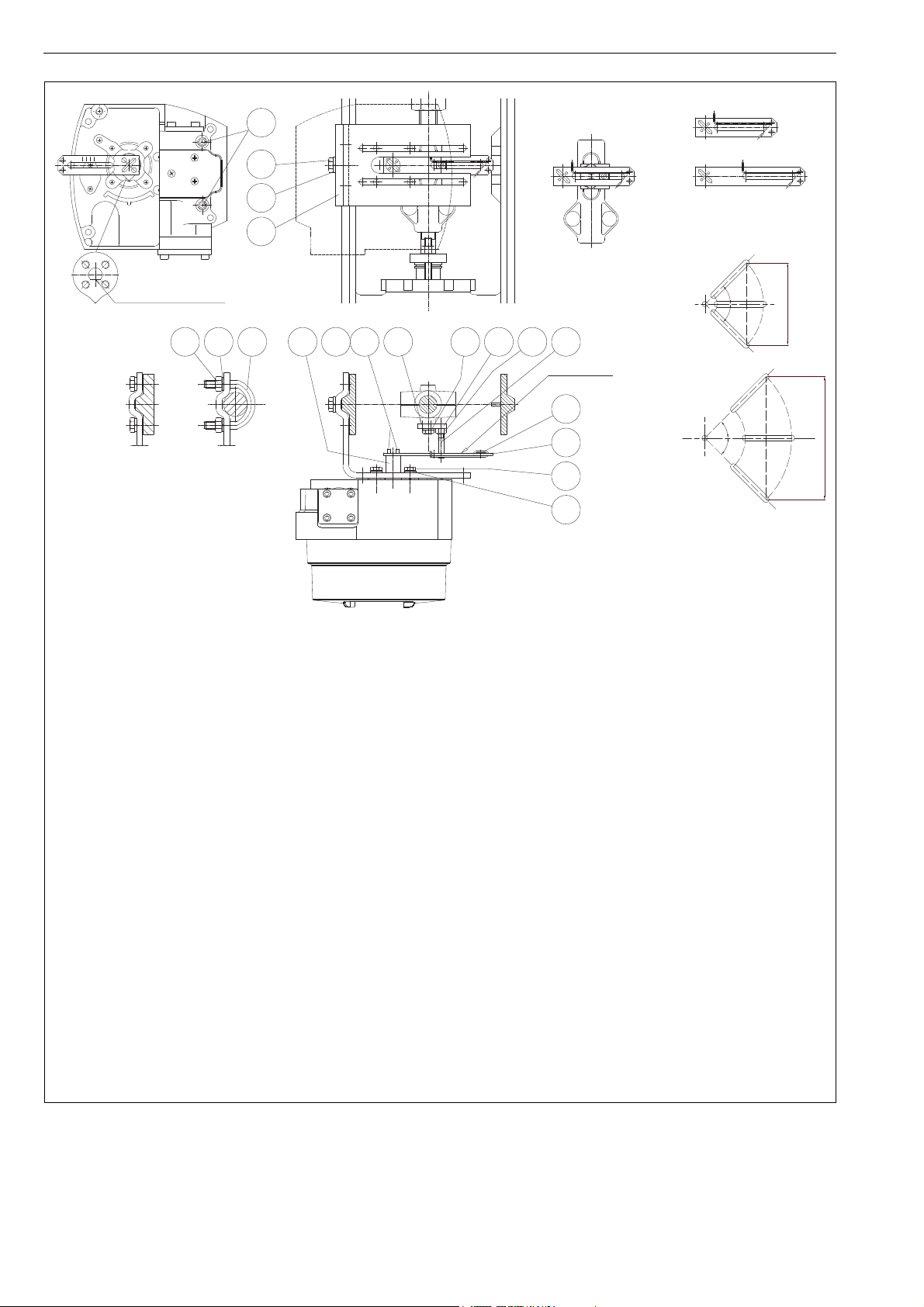

4.3 Mounting on Neles VC and VD actuators

or linear actuators with IEC 60534

mounting face

See figure in Section 12.10

ND9100, ND9400, ND7100

Attach the feedback arm with spacer to the valve

controller shaft. Note the position of the mark on the

shaft as in 12.10. Apply thread locking compound to

the screws and tighten firmly. Attach the spring to

the feedback arm as shown in Section 12.10.

Mount the valve controller mounting bracket loosely

to the yoke of the actuator.

Remove all plastic plugs from all actuator connec-

tions. Mount the metal plugs (54) with sealant to the

unused controller connections at the bottom of the

controller.

Mount the valve controller loosely to the mounting

bracket guiding the pin on the actuator stem to the

slot of the feedback arm.

Align the bracket and the valve controller with the

actuator stem and adjust their position so that the

feedback arm is approximately at a 90° angle to the

actuator stem (in the mid-stroke position).

Tighten the valve controller mounting bracket

screws.

Adjust the distance of the valve controller to the pin

on the actuator stem so that the pin stays in the lever

slot at full stroke. Ensure also that the maximum

angle of the lever does not exceed 45° in either

direction. Maximum allowed travel of the lever is

shown in Section 12.10. Best control performance is

achieved when the feedback lever utilises the maximum allowed angle (±45° from horizontal position).

The whole range should be at least 45°.

Make sure that the valve controller is in right angle

and tighten all the mounting bolts.

Ensure that the valve controller complies with previ-

ous steps. Check that the actuator pin does not

touch the valve controller case throughout the

entire stroke of the actuator. If the actuator pin is too

long it may be cut to size.

Apply grease (Molykote or equivalent) to the contact

surfaces of the actuator pin and the feedback arm to

reduce wear.

ND9200, ND7200, ND9300

Make sure the mounting bracket is suitable for the

weight of the controller. See detailed weight information in Section 2.4.

ND9300: Extra mounting holes exist in the housing

for additional support. See dimension drawings for

ND9300 in Chapter 13. The use of this extra support

is mandatory in addition to the standard face.

ND9300: Due to the extra weight of stainless steel

version and/or possible heavy vibration, make sure

there are proper supports in the pipeline to hold the

weight of the valve assembly.

12 7 ND90 71 en

45°

45°

45°

45°

45°

45°

ND9100

ND7100

ND9300

ND9200

ND7200

VDI/VDE 3845 mounting Neles VC/VD actuators and

IEC 60534 mounting

pointer

pointer

pointer

marks on

housing

marks on

housing

marks on

housing

Attach the feedback arm with spacer to the valve

controller shaft. Note the position of the pointer on

the shaft as in 12.10. Apply thread locking compound to the screws and tighten firmly. Attach the

spring to the feedback arm as shown in Section

12.10.

Mount the valve controller mounting bracket loosely

to the yoke of the actuator.

Remove the protective plastic plugs from pneumatic

connections C2, S and C1. Leave the metal plugs (54)

in the unused connections at the bottom of the controller. Single acting actuators: install a metal plug

(53) with sealant to the C1 connection.

Mount the valve controller loosely to the mounting

bracket guiding the pin on the actuator stem to the

slot of the feedback arm.

Align the bracket and the valve controller with the

actuator stem and adjust their position so that the

feedback arm is approximately at a 90° angle to the

actuator stem (in the mid-stroke position).

Tighten the valve controller mounting bracket

screws.

Adjust the distance of the valve controller to the pin

on the actuator stem so that the pin stays in the lever

slot at full stroke. Ensure also that the maximum

angle of the lever does not exceed 45° in either

direction. Maximum allowed travel of the lever is

shown in Section 12.10. Best control performance is

achieved when the feedback lever utilises the maximum allowed angle (±45° from horizontal position).

The whole range should be at least 45°.

Make sure that the valve controller is in right angle

and tighten all the mounting bolts.

Ensure that the valve controller complies with previ-

ous steps. Check that the actuator pin does not

touch the valve controller case throughout the

entire stroke of the actuator. If the actuator pin is too

long it may be cut to size.

Apply grease (Molykote or equivalent) to the contact

surfaces of the actuator pin and the feedback arm to

reduce wear.

4.4 Piping

CAUTION:

Do not exceed the permitted supply pressure (8 bar /

115 psi) of the ND9000 and ND7000!

Table 4 provides the recommended tube sizes in accordance with actuator sizes. Tube sizes are the minimum values

allowed. Operating times may be tested by the offline tests

in DTM / EDD.

Connect the air supply to S.

Connect C1 and C2 to the actuator, see Fig. 7 and 8.

Air connections are as follows

ND9100, ND7100: G 1/4

ND9200, ND9300, ND9400, ND7200, : 1/4 NPT

Liquid sealants, such as Loctite 577 are recommended for

the pipe threads.

NOTE:

A valve controller mounted on a spring actuator must be

connected only as single-acting. See Fig. 7 and 8.

NOTE:

An excess of sealant may result in faulty operation of the

controller when accessed to pneumatic components.

Sealing tape is not recommended.

Ensure that the air piping is clean.

When pneumatic connector is removed, clean threads

carefully from dry sealant particles before mounting connector back.

The air supply must be clean, dry and oil-free instrument air,

see Section 2.4.

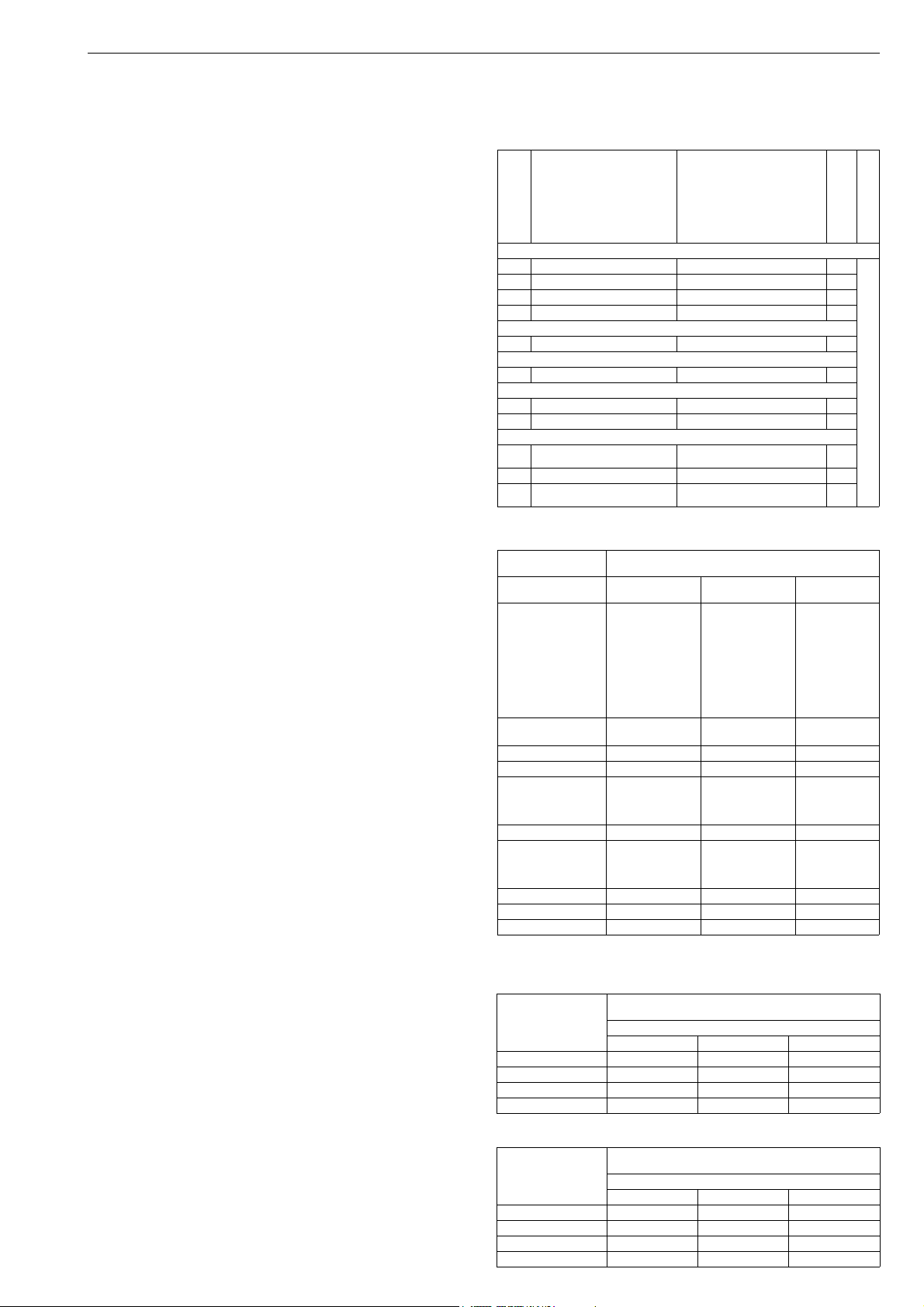

Table 3 Spring rates

Actuator type Spring rate (bar/psi)

B1JK 3 / 43

B1J 4.2 / 61

B1JV 5.5 / 80

QPB 3 / 43

QPC 4.3 / 62

QPD 5.6 / 81

Adjust regulator pressure to a level that is max 1 bar (14.5 psi)

+ spring rate.

Fig. 4 Shaft coupling alternatives

7 ND90 71 en 13

Table 4 Piping and stroke times

ND_2_

Supply 1/4" NPT

Actuator 1/4" NPT

(s)

Close

(s)

Piping Open

B1C

Actuat or

Stroke volume

3

3

/ in

dm

NPT Piping Open

6 0.3 18 1/4 6 mm or 1/4" 1.6* 1.6* 6 mm or 1/4" 1.0* 1.0* – – –

9 0.6 37 1/4 – – – 6 mm or 1/4" 2.0 2.0 – – –

11 1.1 67 3/8 – – –

10 mm or 3/8"

[6 mm or 1/4" (x)]

13 2.3 140 3/8 – – – 10 mm or 3/8" – – – – –

17 4.3 262 1/2 – – – – – – 10 mm or 3/8" 3.6 3.6

20 5.4 330 1/2 – – – – – – 10 mm or 3/8" 5.0 5.0

25 10.5 610 1/2 – – – – – – 10 mm or 3/8" 9.5 9.5

32 21 1282 3/4 – – – – – – 10 mm or 3/8" 18.0 18.0

40 43 2624 3/4 – – – – – – 10 mm or 3/8" 35.0 35.0

50 84 5126 1 – – – – – – 10 mm or 3/8" 67.0 67.0

60 121 7380 1 – – – – – – 10 mm or 3/8" – –

75 189 11500 1 – – – – – – 10 mm or 3/8" – –

502 195 11900 1 – – – – – – 10 mm or 3/8" 130.0 130.0

602 282 17200 1 – – – – – – 10 mm or 3/8" – –

752 441 26900 1 – – – – – – 10 mm or 3/8" – –

B1J

B1JA

Stroke volume

3

3

/ in

dm

6 0.47 28.7 3/8

8 0.9 55 3/8

NPT Piping Air

10 mm or 3/8"

[6 mm or 1/4" (x)]

10 mm or 3/8"

[6 mm or 1/4" (x)]

Spring

(s)

––

––

(s)

[6 mm or 1/4" (x)]

[6 mm or 1/4" (x)]

Piping Ai r

10 mm or 3/8"

10 mm or 3/8"

10 1.8 110 3/8 – – – 10 mm or 3/8" – – –

12 3.6 220 1/2 – – – – – – 10 mm or 3/8" 3.0 5.2

16 6.7 409 1/2 – – – – – – 10 mm or 3/8" 5.8 7.7

20 13 793 3/4 – – – – – – 10 mm or 3/8" 9.0 14.0

25 27 2048 3/4 – – – – – – 10 mm or 3/8" 19.0 25.0

32 53 3234 1 – – – – – – 10 mm or 3/8" 36.0 50.0

322 106 6468 1 – – – – – – 10 mm or 3/8" 70.0 100.0

QP

Stroke volume

3

3

/ in

dm

NPT Piping Air

1C 0.62 37 3/8

10 mm or 3/8"

[6 mm or 1/4" (x)]

Spring

(s)

–* –*

(s)

Piping Ai r

10 mm or 3/8"

[6 mm or 1/4" (x)]

2C 1.08 66 3/8 – – – 10 mm or 3/8" 2.4 3.0 – – –

3C 2.18 133 3/8 – – – 10 mm or 3/8" 4.8 5.2 – – –

4C 4.34 265 3/8 – – – – – – 10 mm or 3/8" 3.2 3.7

5C 8.7 531 3/8 – – – – – – 10 mm or 3/8" 7.5 11.0

6C 17.5 1068 3/4 – – – – – – 10 mm or 3/8" 12.0 20.0

Air supply piping 10 mm or 3/8" for all actuators.

Pipe sizes are nominal, i.e. approximately outer diameter. Inner diameter is typically 2 mm smaller.

x = Standard pipe size used in Neles control valves.

(x) = Minimum pipe size (if smaller than standard).

*) Spool size 2 is preferred for accurate control and standard for Neles control valves.

Spool size 3 can be used if fast full stroke times are required.

Stroking times have been measured without valve.

Tests have been done with supply pressure of 5 bar.

ND_3_

Supply 1/4" NPT

Actuator 1/4" NPT

(s)

4.1 4.1 – – –

(s)

–––––

–––––

(s)

1.2* 2.1* – – –

Close

(s)

Spring

(s)

Spring

(s)

ND_6_

Supply 1/2" NPT

Actuator 1/2" NPT

Piping Open

Piping Air

Piping Air

(s)

(s)

(s)

Close

(s)

Spring

(s)

Spring

(s)

Table 5. VD & VC stroking time table

Act'r

Series

Stroke

length

Controller

Series

Stroking time

(Sec.)

Loa d Ve nt Loa d Ve nt Loa d Ve nt

VD_25 20mm NDX 3 3 VD_25 20mm

VD_29

VD_37

20mm

40mm 3 4 40mm 8 10

NDX

20mm

40mm 3.5 4 40mm 11 16 120mm 11 12

NDX

33

33.5

50mm 4 5 50mm ND9206 7 8

20mm

34

40mm 3.5 5 40mm 9 11 140mm 17 16

VD_48

50mm 4 6 50mm 10 12

NDX

60mm 5 6.5 60mm 11 13 140mm 21 19

70mm 6 7.5 70mm 12 14 180mm 25 21

20mm

36

40mm 4 7 40mm 12 15 180mm 24 22

VD_55

50mm 5 8 50mm 14 17 240mm 28 27

60mm 6 9 60mm 16 19

NDX

70mm 7 10 70mm 18 21 240mm 35 31

80mm 8 11 80mm 20 23 280mm 39 34

Note:

- Mounted with ND9 / NDX smart positioners and B72G-2AS-980 AFR only.

- VD model / spring range : VDR / 0.8 ~ 2.6 bar

- Stroking time accuracy: ± 10 %

- Supply pressure for VD_25/29/37 is 3.2 bar and VD_48&55 is 3.5 bar.

- VC model air supply pressue : 6.0 barg

Act'r

Series

VD_29

VD_37

VD_48

VD_55

Stroke

length

20mm

20mm

20mm

20mm

Controller

Series

Stroking time

(Sec.)

ND9202 5 7

ND9203 4 5 80mm 8 8

ND9203

ND9203

5 7 100mm 10 10

9 11 100mm 10 11

Act'r

Series

VC_30

VC_40

Stroke

length

60mm

80mm

Controller

Series

ND9206

ND9206

100mm

ND9203

ND9206

ND9206

16 19 120mm 15 14

VC_50

120mm

VC_60

911

140mm

VC_70

180mm

VC_80

ND9206

ND9206

ND9206

ND9206

Stroking time

(Sec.)

67

810

13 13

18 16

20 19

31 30

14 7 ND90 71 en

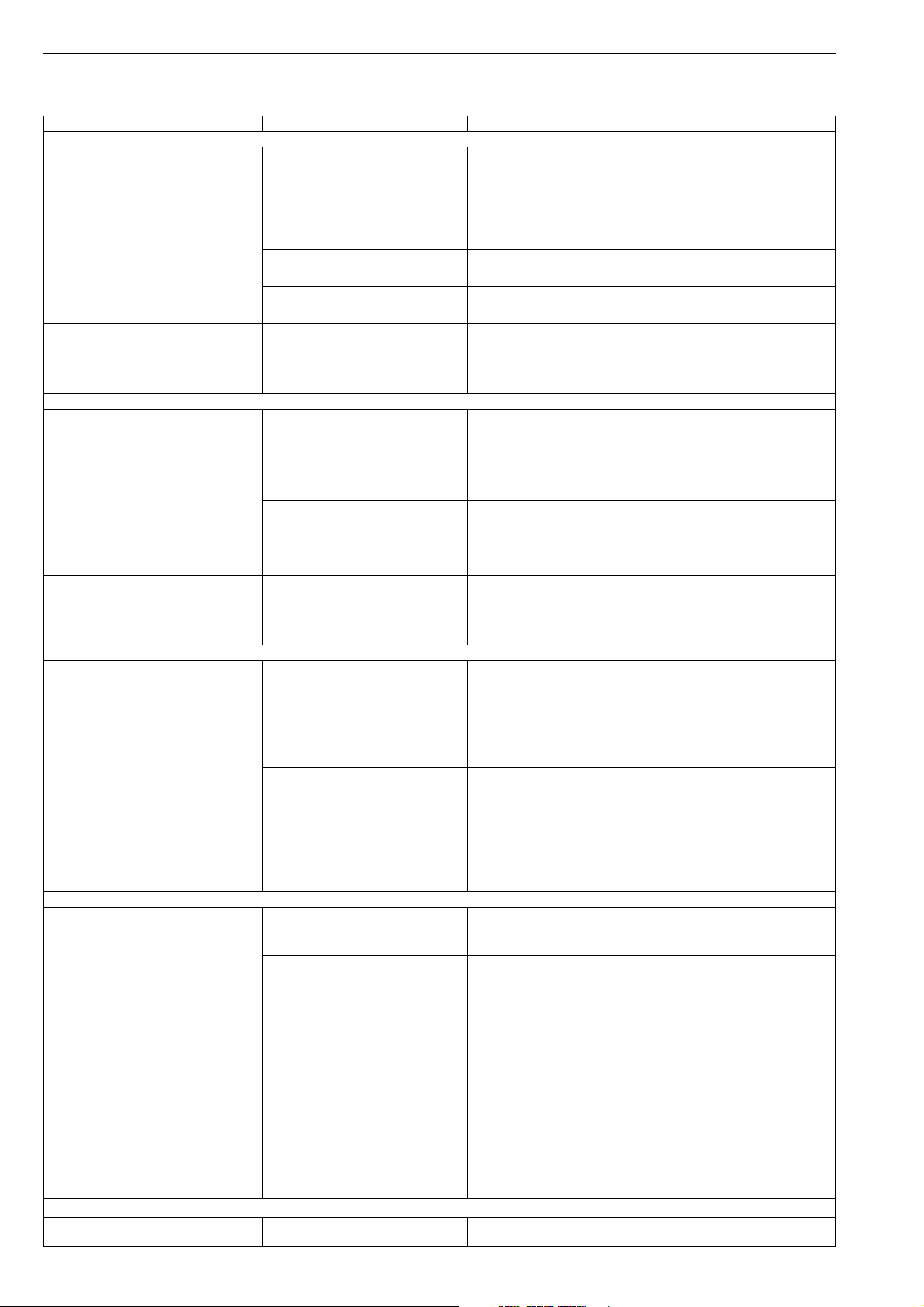

SINGLE-ACTING ACTUATOR, SPRING TO OPEN

SINGLE-ACTING ACTUATOR, SPRING TO CLOSE

DOUBLE-ACTING ACTUATOR, REVERSED PIPING

Increasing input signal to open valve (not recommended)

Default setting:

DIR = OPE

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = OPE

A0, CUTL and VTYP according to valve type

5. Increasing input signal to open valve (shown)

Default setting:

DIR = OPE

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = CLO (must be in the spring direction)

A0, CUTL and VTYP according to valve type

7. Increasing input signal to close valve (shown)

Default setting:

DIR = CLO

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = OPE (must be in the spring direction)

A0, CUTL and VTYP according to valve type

6. Increasing input signal to close valve (not recommended)

Default setting:

DIR = CLO

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = CLO (must be in the spring direction)

A0, CUTL and VTYP according to valve type

4. Increasing input signal to close valve (shown)

Default setting:

DIR = CLO

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = OPE

A0, CUTL and VTYP according to valve type

.

3.

8. Increasing input signal to open valve (not recommended)

Default setting:

DIR = OPE

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = OPE (must be in the spring direction)

A0, CUTL and VTYP according to valve type

DOUBLE-ACTING ACTUATOR

Increasing input signal to open valve (shown)

Default setting:

DIR = OPE

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = CLO

A0, CUTL and VTYP according to valve type

2. Increasing input signal to close valve (not recommended)

Default setting:

DIR = CLO

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = CLO

A0, CUTL and VTYP according to valve type

.

1.

7 ND90 71 en 15

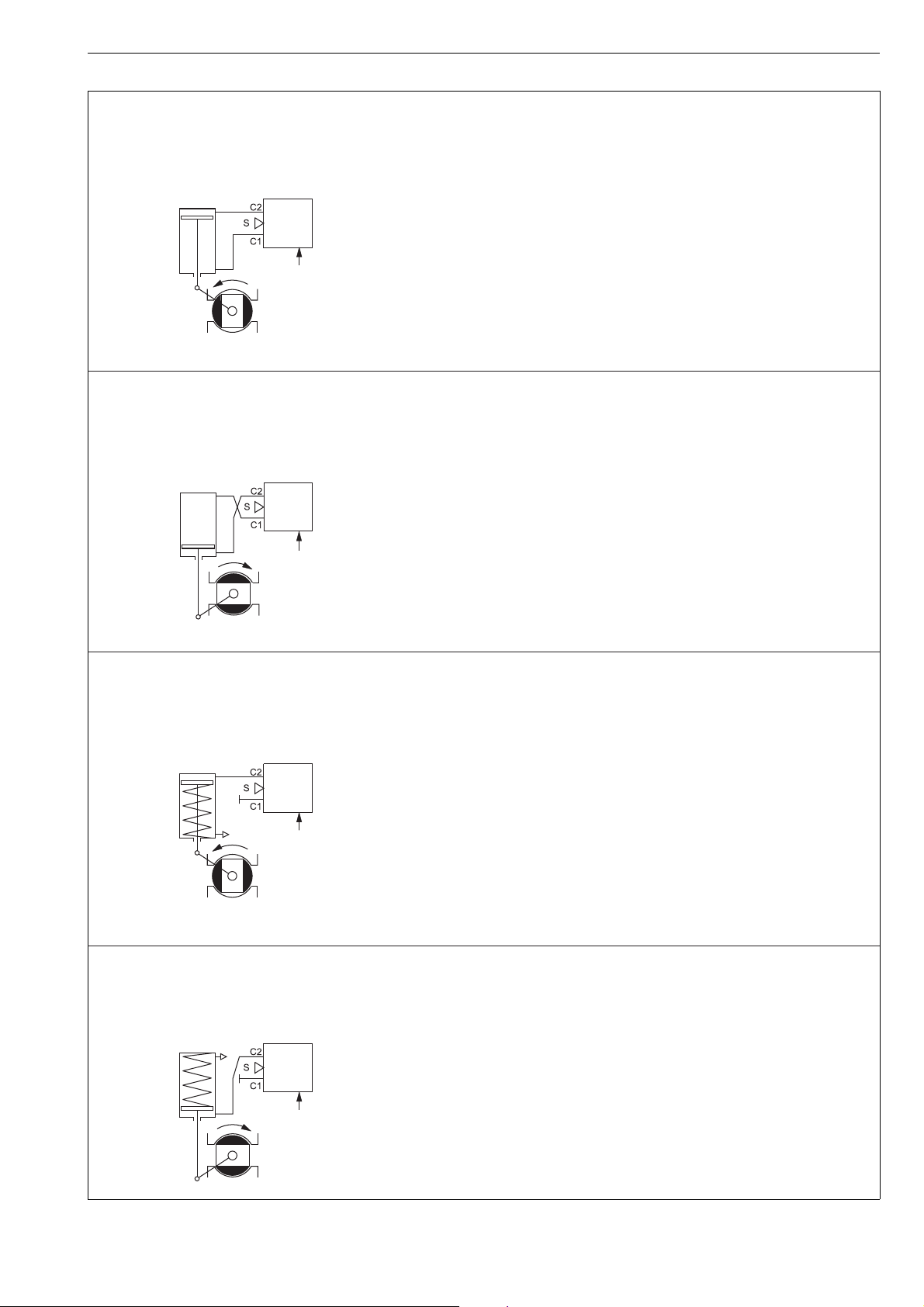

SINGLE-ACTING ACTUATOR, SPRING TO OPEN

SINGLE-ACTING ACTUATOR, SPRING TO CLOSE

DOUBLE-ACTING ACTUATOR

Self closing

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = CLO

A0, CUTL and VTYP according to valve type

3. Self closing

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = CLO (must be in the spring direction)

A0, CUTL and VTYP according to valve type

4. Self opening

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 1-A

PFA = OPE (must be in the spring direction)

A0, CUTL and VTYP according to valve t

ype

1.

DOUBLE-ACTING ACTUATOR, REVERSED PIPING

Self opening

Default setting:

ROT = cC (close valve to clockwise)

ATYP = 2-A

PFA = OPE

A0, CUTL and VTYP according to valve t

ype

2

.

Fig. 6 Operation directions and air connections, ND9000F and ND9000P

16 7 ND90 71 en

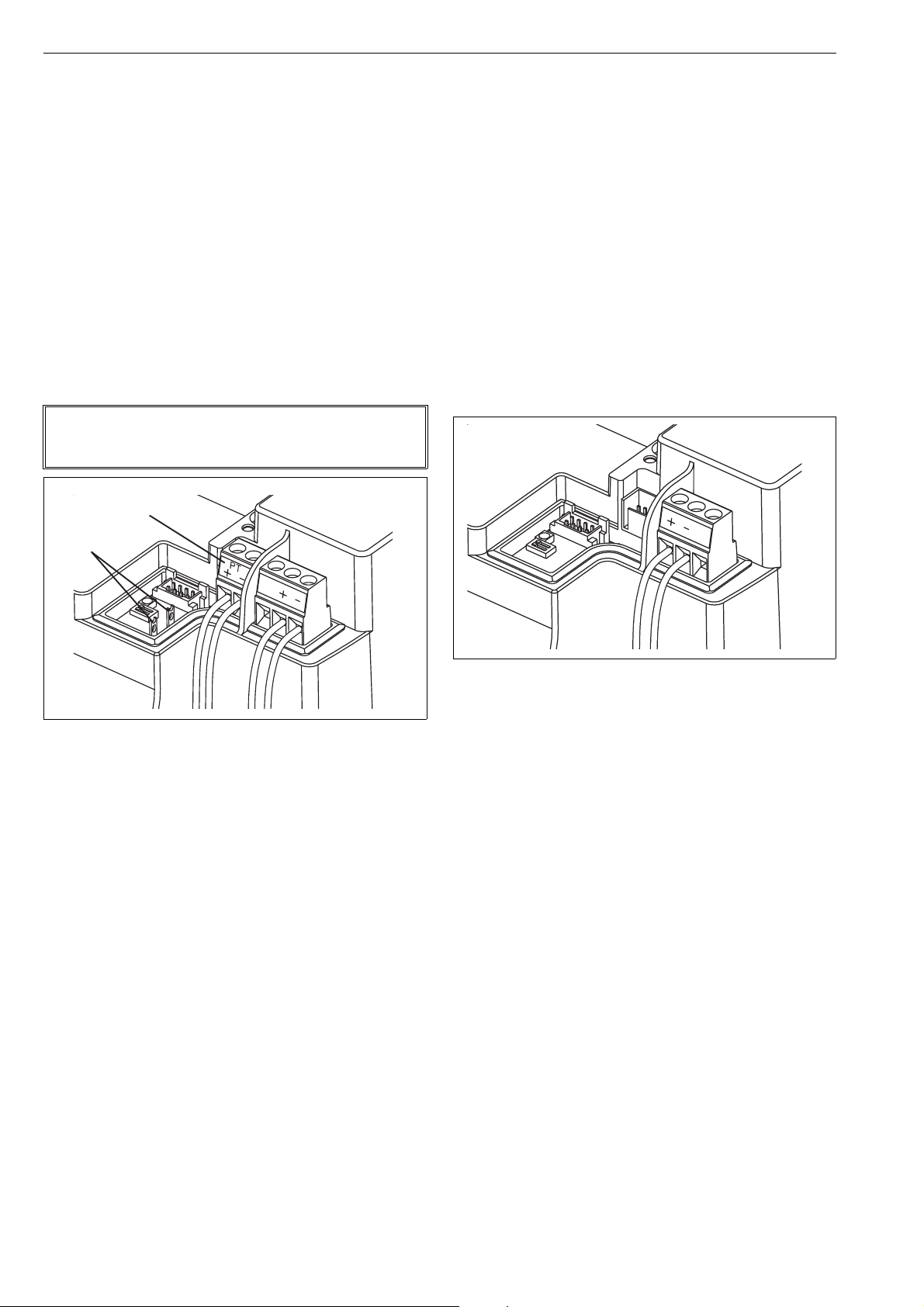

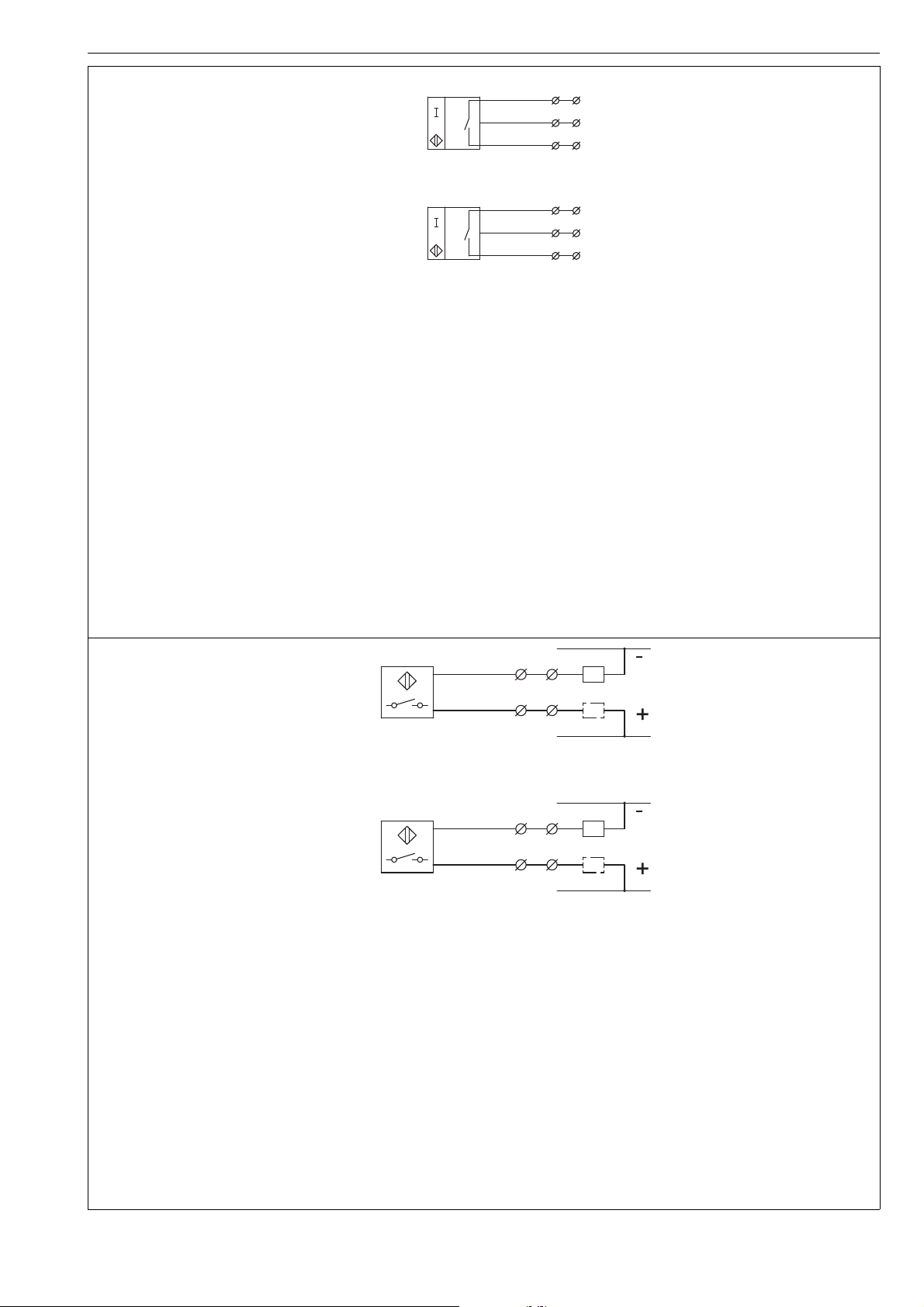

HART connection

position transmitter

connection (optional)

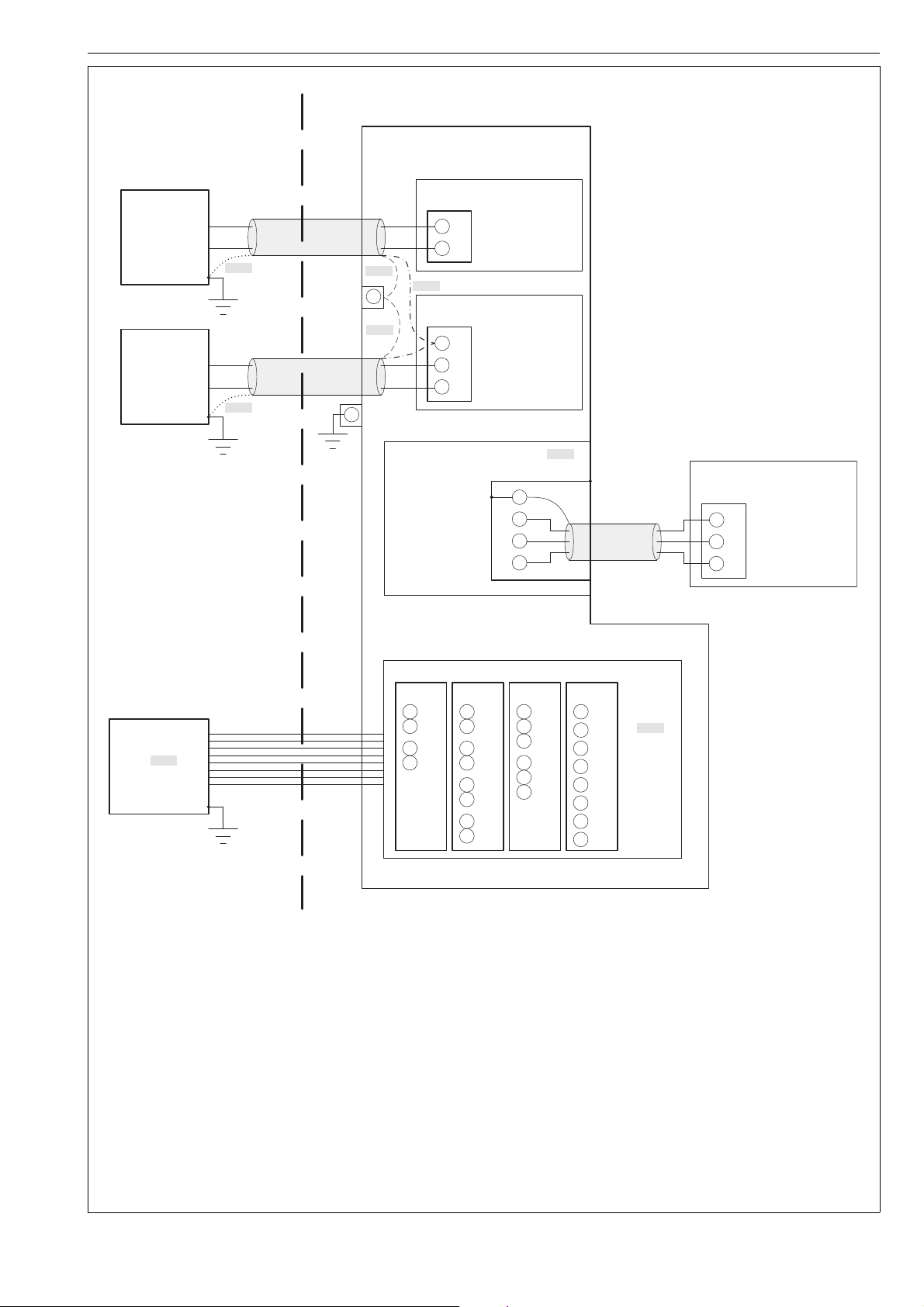

4.5 Electrical connections

ND9000H, ND7000H

The ND9000H and ND7000H is powered by a standard 4–20

mA current loop that also functions as a carrier to the HART

communication.

The input signal cable is led through a

M20 x 1.5 cable gland, or

1/2 NPT cable gland (U, E2)

Connect the conductors to the terminal strip as shown in

Fig. 9. It is recommended that the earthing of the input

cable shield be carried out from the DCS end only.

The position transmitter is connected to 2-pole terminal PT

as shown in Fig. 9. The position transmitter needs an external power supply. The ND9000H / ND7000H and the position transmitter circuits are galvanically isolated and

withstand a 600 V AC voltage.

NOTE:

The ND9000H and ND700H equal a load of 485 Ω in the

current loop.

ND9000F, ND9000P

The ND9000F is powered by F

OUNDATION fieldbus

(IEC 61158-2).

The ND9000P is powered by Profibus PA (IEC 61158-2).

The same bus cable is used also for the fieldbus communication.

The bus cable is led through a

M20 x 1.5 cable gland, or

1/2 NPT cable gland (U, E2)

Connect the conductors to the terminal strip as shown in

Fig. 10.

Reverse polarity protection permits connection of the bus

cables in any order.

The cable shield can be grounded by connecting the shield

to the earth connection screw. The shield can be left unconnected by using the empty terminal.

Fig. 7 Terminals, ND9000H and ND7000H

Fig. 8 Terminals, ND9000F and ND9000P

Please note following before mounting the cover of the

valve controller:

Attach the LUI (223) cabling to the sticker on the

reverse side of the LUI.

Check that the cabling does not get squeezed by the

electronics cover (39) or the device cover (100).

Check using a feeler gauge that the clearance

between the position indicator (109) and the electronics cover is 1 mm.

7 ND90 71 en 17

Notes

1. By default, the screen of the cable is connected to earth either at the barrier (dotted line) or at the earthing terminal inside ND9000H enclosure

(dash line). If the screen is connected to earth at both ends of the cable, the potential equalization of the system shall conform to requirements

of IEC 6007914:2013 Clause 16.2.3.

2. X102 terminal 1 (SHD) does not have any electrical connection. If wanted, cable screens can be connected to this terminal for floating

termination of screen at ND9000H end (dashdot line). Shrink tubes are recommended to avoid short circuits.

3. For installation in accordance with this figure, the intrinsically safe barrier must be certified by an accredited agency.

4. The following conditions must be satisfied:

Uo (Voc) <= Ui (Vmax) Co (Ca) >= Ci + Ccable

Io (Isc) <= Ii (Imax) Lo (La) >= Li + Lcable

Po <= Pi (Pmax)

5. Maximum nonhazardous area voltage must not exceed 250 V.

6. Canadian installations should be in accordance with Canadian Electrical Code, Part I. U.S. installations should be in accordance with Article 504

in the National Electrical Code, ANSI/NFPA 70.

7. See user manual for installation conditions.

8. See documents F41446 and F41476 for the approved switches and their entity parameters.

9. Remote Mount (option R) is only available for ND91_ (standard enclosure) variants.

NOITACOLSUODRAZAHNOITACOLSUODRAZAHNON

ND9000HValvePositioner

PositionTransmitter

ExiBarrier

Uo(Voc)≤28V

Io(Isc)≤120mA

Po≤1W

ExiBarrier

Uo(Voc)≤28V

Io(Isc)≤120mA

Po≤1W

NOTE1NOTE1

NOTE1

Earthing

terminal

(internal)

NOTE1

NOTE1

X300

1

2

NOTE2

X102

1

2

3

Ui(Vmax)=28V

Ii(Imax)=120mA

+

Pi(Pmax)=1W

Li=53uH

Ci=22nF

AnalogmAInput

SHD

Ui(Vmax)=28V

Ii(Imax)=120mA

+

Pi(Pmax)=1W

Li=53uH

Ci=22nF

ExiBarrier

NOTE8

Uo(Voc)≤Ui(Vmax)

Io(Isc)≤Ii(Imax)

Po≤Pi(Pmax)

Earthing

terminal

(external)

RemoteMount

PositionSensorInterface

Uo(Voc)=3.53V

Io(Isc)=12.6mA

Po=11.1mW

Lo(La)=10uH

Co(Ca)=10nF

SHD

+

CNT

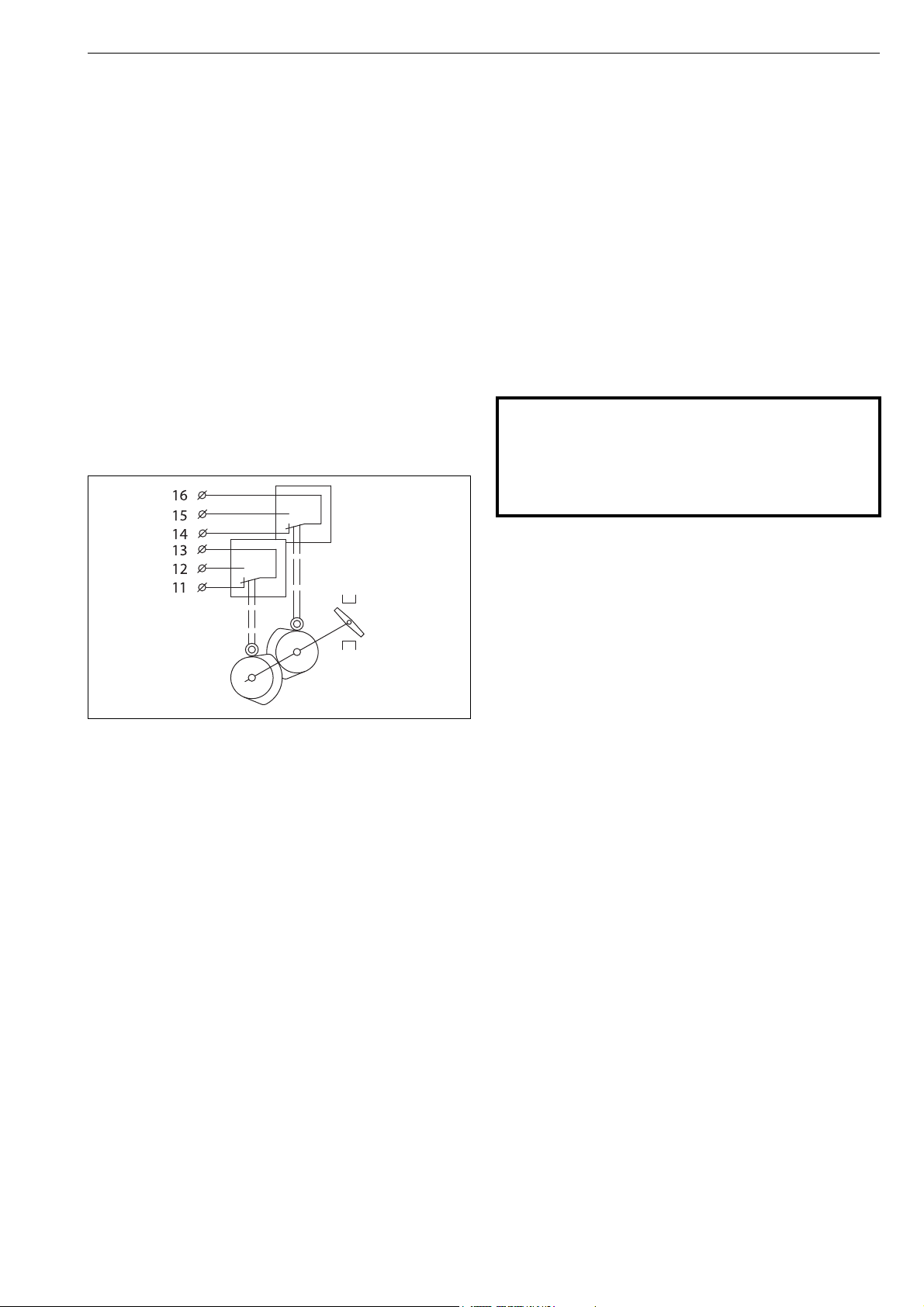

LimitSwitches

I02,I09,

I57,I60

11

13

14

16

I41,I58

L

11

L+

L

L+

L

L+

12

L

13

L+

14

L

15

L+

16

17

L

L+

18

1

2

3

4

I45

11

12

13 L+

14

15

16 L+

NOTE9

RemoteMount

PositionSensor

1

Ui(Vmax)≥3.53V

+

Ii(Imax)≥12.6mA

CNT

2

Pi(Pmax)≥11.1mW

3

D44

L

L

(SOL1)

(SOL2)

(SOL

PWR1)

(SOL

PWR2)

TOP

SW+

TOP

SW

BTM

SW+

BTM

SW

NOTE8

Ui(Vmax)

Ii(Imax)

Pi(Pmax)

Li

Ci

Fig. 9 Control wiring, ND9000H and ND7000H, Ex i

18 7 ND90 71 en

Notes

1. By default, the screen of the cable is connected to earth either at the barrier (dotted line) or at the earthing terminal inside ND9000F/P

enclosure (dash line). If the screen is connected to earth at both ends of the cable, the potential equalization of the system shall conform to

requirements of IEC 6007914:2013 Clause 16.2.3.

2. X102 terminal 3 (SHD) does not have any electrical connection. If wanted, cable screen can be connected to this terminal for floating

termination of screen at ND9000F/P end (dashdot line). Shrink tube is recommended to avoid short circuits.

3. For installation in accordance with this figure, the intrinsically safe barrier must be certified by an accredited agency.

4. The following conditions must be satisfied:

Uo (Voc) <= Ui (Vmax) Co (Ca) >= Ci + Ccable

Io (Isc) <= Ii (Imax) Lo (La) >= Li + Lcable

Po <= Pi (Pmax)

5. Maximum nonhazardous area voltage must not exceed 250 V.

6. Canadian installations should be in accordance with Canadian Electrical Code, Part I. U.S. installations should be in accordance with Article 504

in the National Electrical Code, ANSI/NFPA 70.

7. See user manual for installation conditions.

8. See documents F41446 and F41476 for the approved switches and their entity parameters.

9. Remote Mount (option R) is only available for ND91_ (standard enclosure) variants.

NOITACOLSUODRAZAHNOITACOLSUODRAZAHNON

FISCO’ia’

PowerSupply/

Barrier

Uo(Voc)≤24V

Io(Isc)≤380mA

Po≤5.32W

ND9000F/PValvePositioner

FieldbusInput

X102

Ui(Vmax)=24V

Ii(Imax)=380mA

Pi(Pmax)=5.32W

Li=10uH

Ci=5nF

1

2

+

3

SHD

Earthing

terminal

(internal)

Earthing

terminal

(external)

NOTE1NOTE1

NOTE1

LimitSwitches

Ui(Vmax)

Ii(Imax)

Pi(Pmax)

Li

Ci

ExiBarrier

Uo(Voc)≤Ui(Vmax)

Io(Isc)≤Ii(Imax)

Po≤Pi(Pmax)

11

13

14

16

L

L+

L

L+

12

L

11

13 L+

15

L

14

16 L+

I02,I09,

I57,I60

I45

NOTE8

NOTE8

NOTE2

(SOL1)

(SOL2)

(SOL

PWR1)

(SOL

PWR2)

TOP

SW+

TOP

SW

BTM

SW+

BTM

SW

D44

11

12

13

14

15

16

17

18

L

L+

L

L+

L

L+

L

L+

I41,I58

RemoteMount

PositionSensorInterface

Uo(Voc)=5.0V

Io(Isc)=17.8mA

Po=22.2mW

Lo(La)=10uH

Co(Ca)=10nF

SHD

+

CNT

1

2

3

4

RemoteMount

PositionSensor

Ui(Vmax)≥5.0V

Ii(Imax)≥17.8mA

Pi(Pmax)≥22.2mW

2

3

CNT

1

+

NOTE9

Fig. 10 Control wiring, ND9000F/P, Ex ’ia’ for Zone 0 / Division 1

7 ND90 71 en 19

NOITACOLSUODRAZAHNOITACOLSUODRAZAHNON

FISCO’ic’

PowerSupply/

Barrier

Uo(Voc)≤32V

Io(Isc)≤380mA

Po≤5.32W

ND9000F/PValvePositioner

FieldbusInput

X102

Ui(Vmax)=32V

Ii(Imax)=380mA

Pi(Pmax)=5.32W

Li=10uH

Ci=5nF

1

2

+

3

SHD

Earthing

terminal

(internal)

Earthing

terminal

(external)

NOTE1NOTE1

NOTE1

LimitSwitches

Ui(Vmax)

Ii(Imax)

Pi(Pmax)

Li

Ci

ExiBarrier

Uo(Voc)≤Ui(Vmax)

Io(Isc)≤Ii(Imax)

Po≤Pi(Pmax)

11

13

14

16

L

L+

L

L+

12

L

11

13 L+

15

L

14

16 L+

I02,I09,

I57,I60

I45

NOTE8

NOTE8

NOTE2

(SOL1)

(SOL2)

(SOL

PWR1)

(SOL

PWR2)

TOP

SW+

TOP

SW

BTM

SW+

BTM

SW

D44

11

12

13

14

15

16

17

18

L

L+

L

L+

L

L+

L

L+

I41,I58

RemoteMount

PositionSensorInterface

Uo(Voc)=5.0V

Io(Isc)=17.8mA

Po=22.2mW

Lo(La)=10uH

Co(Ca)=10nF

SHD

+

CNT

1

2

3

4

RemoteMount

PositionSensor

Ui(Vmax)≥5.0V

Ii(Imax)≥17.8mA

Pi(Pmax)≥22.2mW

2

3

CNT

1

+

NOTE9

Notes

1. By default, the screen of the cable is connected to earth either at the barrier (dotted line) or at the earthing terminal inside ND9000F/P

enclosure (dash line). If the screen is connected to earth at both ends of the cable, the potential equalization of the system shall conform to

requirements of IEC 6007914:2013 Clause 16.2.3.

2. X102 terminal 3 (SHD) does not have any electrical connection. If wanted, cable screen can be connected to this terminal for floating

termination of screen at ND9000F/P end (dashdot line). Shrink tube is recommended to avoid short circuits.

3. For installation in accordance with this figure, the intrinsically safe barrier must be certified by an accredited agency.

4. The following conditions must be satisfied:

Uo (Voc) <= Ui (Vmax) Co (Ca) >= Ci + Ccable

Io (Isc) <= Ii (Imax) Lo (La) >= Li + Lcable

Po <= Pi (Pmax)

5. Maximum nonhazardous area voltage must not exceed 250 V.

6. Canadian installations should be in accordance with Canadian Electrical Code, Part I. U.S. installations should be in accordance with Article 504

in the National Electrical Code, ANSI/NFPA 70.

7. See user manual for installation conditions.

8. See documents F41446 and F41476 for the approved switches and their entity parameters.

9. Remote Mount (option R) is only available for ND91_ (standard enclosure) variants.

Fig. 11 Control wiring, ND9000F/P, Ex ’ic’ for Zone 2 / Division 2

20 7 ND90 71 en

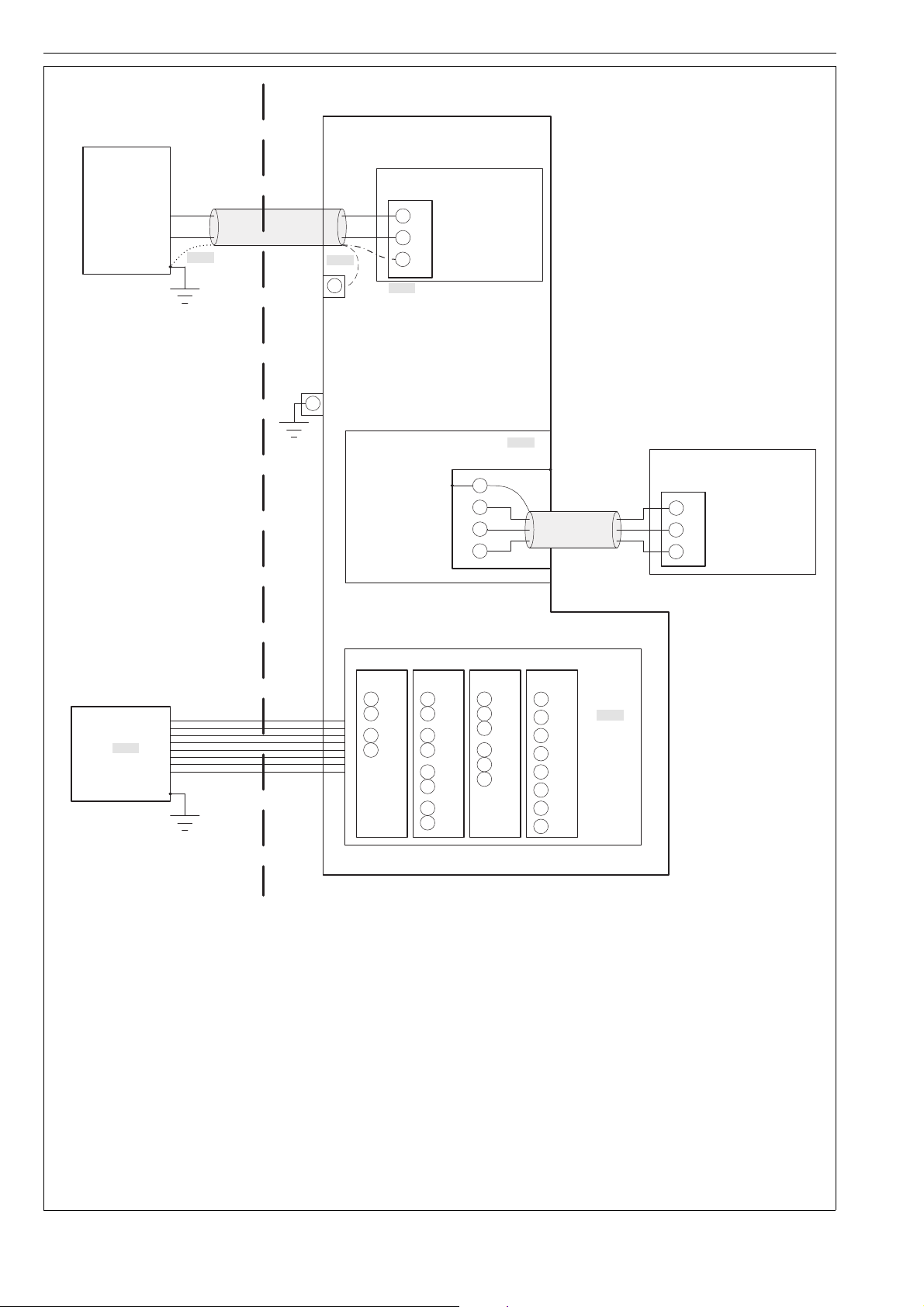

HAZARDOUS LOCATION

Control

system

Uout max 30 V

Control

system

Uout max 30 V

ND9200H_T

ND7200H_T

Position Transmitter

NONHAZARDOUS LOCATION

HAZARDOUS LOCATION

ND9200F

ND9200P

NONHAZARDOUS LOCATION

Entity Parameters:

Ui ≤ 32.0 V

Entity Parameters:

Uo ≤ Ui

connect the cable

shield to earth ground

Associated

apparatus

Fig. 12 Control wiring, ND9000 and ND7000, Ex d

Fig. 13 Control wiring, ND9000F and ND9000P, Ex d

7 ND90 71 en 21

4.5.1 Remote mounting

ND9100H,ND9100F, ND9100P, ND7100H

For applications if there is e.g. heavy vibrations, environment temperature is very high or access is difficult, there is

available remote position measurement option. In this kind

of applications position sensor is attached to actuator and

ND9000 can be installed further away. Pneumatic piping

between ND9000 and actuator is done as explained in

chapter 4.6 and wiring between position sensor and

ND9000 according to Fig. 13.

There are three different cable lengths available between

ND9000 and remote position sensor: 1.2m, 3m and 30m.

If position sensor is remote mounted to linear actuator,

there are some parameters which have to be defined as following:

valve acting type ( VTYP) have to be defined as rotary

valve rotation direction (ROT) have to be defined as

Clockwise to Close (CC)

Remote position sensor for rotary actuators is available also

with limit switch.

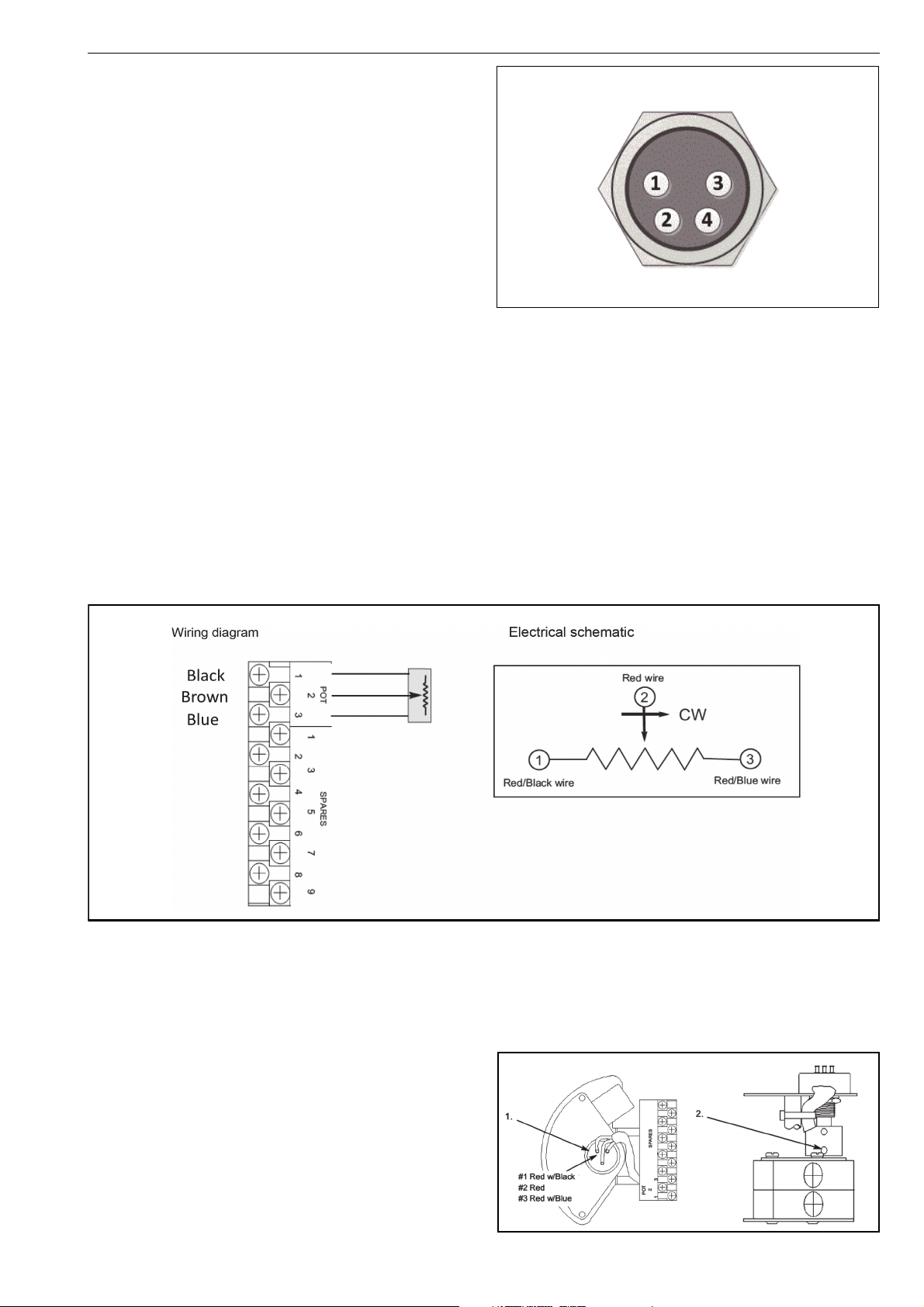

Fig. 14 Pin assignment in female connector view (connec-

tor in device)

Pin assignement

Pin# Function

1 Cable Shield Ground (Ground)

2 Potentiometer Plus (Blue)

3 Potentiometer Center (Brown)

4 Potentiometer Minus (Black)

4.5.2 Quartz position sensor connections and calibration

Potentiometer Calibration

1. Operate the actuator to the desired “zero” position.

Connect an ohm meter across the terminals POT 1 &

POT 2 to measure the potentiometer output.

2. Loosen the bottom set screw and rotate the coupling

until the ohm meter reads approximately 5k Ohms

(assuming a 10K Ohm potentiometer). Retighten the

set screw and verify the ohm meter still reads

approximately 5k Ohms.

3. Operate the actuator to the desired “100 %” position

(assuming 90 degree rotation) and verify the ohm

meter reads (2.7K Ohms or 7.7K Ohms +/- 10 %,

depending on rotation direction).

4. Remove all test equipment.

5. Connect the position sensor cable to the terminal

strip as shown in the above wiring diagram.

6. Connect the connector end of the position sensor

cable to the ND9000 female connector shown in

Fig. 13.

22 7 ND90 71 en

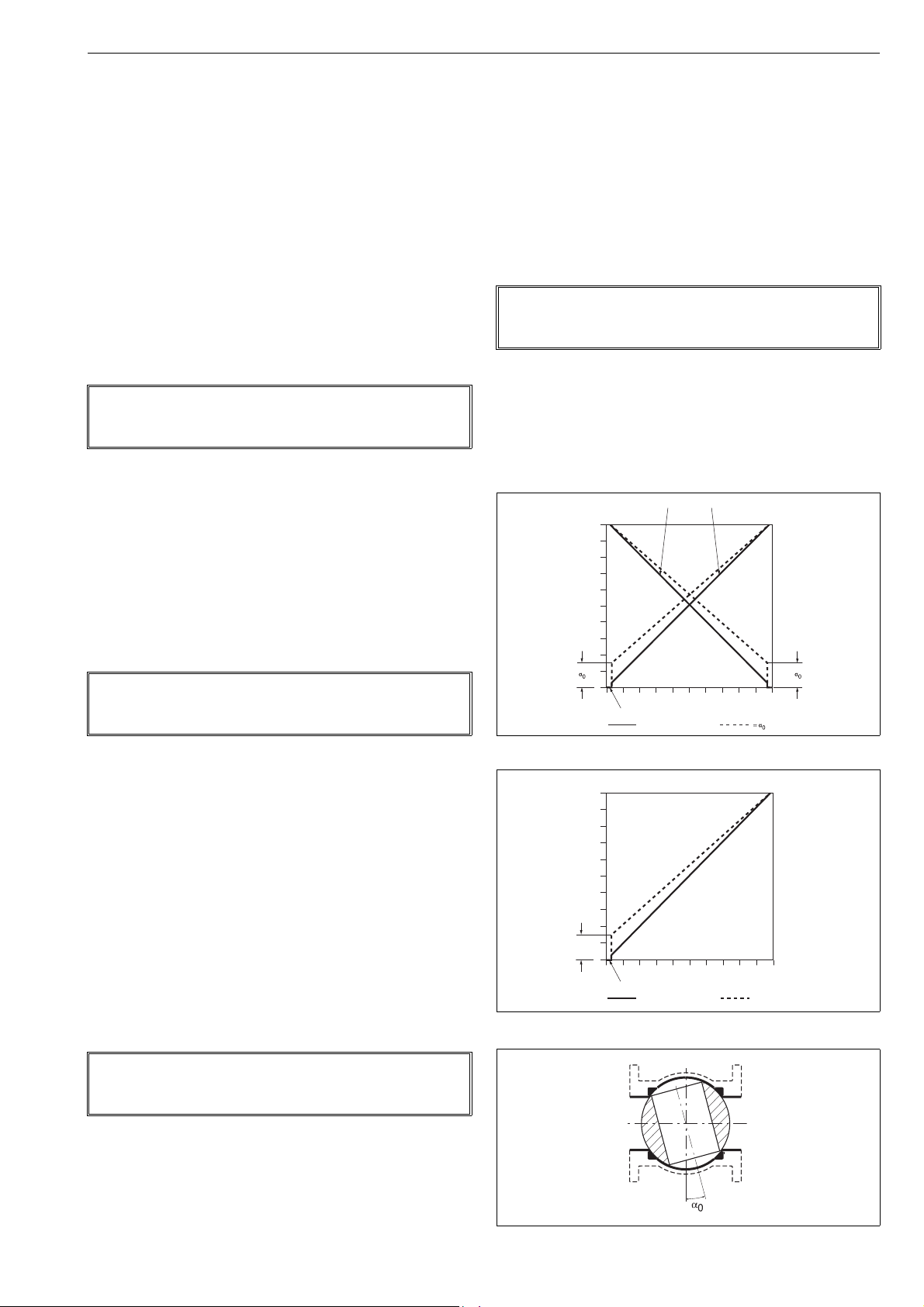

Connection terminals in Rec adapter

4.5.3 Remote mounting by using Metso ReC

If there is 4-20mA output from the position sensor, that

can’t be connected directly to ND9100R. This kind of cases

there have to be ReC adapter which converts position signal suitable for ND9100 like shown in schematic picture

Connection terminals in Rec adapter:

NOTES:

1. Cut the ND9 cable (RC01, RC02 or RC03) and the

Position sensor cable to optimal length for your

application. Then connect the individual wires as

shown in connection diagram.

2. Connect positioner control (4…20mA) signal directly

to ND or alternatively to Pass through terminals IN+/

IN-, and Metso ND9 control input cable to OUT+/

OUT-.

• 4-20mA Pass Through connectors positive (+) ter-

minals are internally shorted, and negative (-) terminals are internally shorted.

3. Connector with “+24V” and “GND” shall be supplied

from external 24V (nominal 24 VDC, range is 18-30

VDC) voltage supply. This supply is powering the

converter and the external position sensor.

4. Use proper cable cland or blind plug for each cable

entry.

7 ND90 71 en 23

5 LOCAL USER INTERFACE (LUI)

The local user interface may be used to monitor the device

behaviour as well as configuring and commissioning the

controller during installation and normal operation. The

local user interface consists of 2 row LCD and 4 button keypad interface. There are also custom graphical characters

for special conditions.

Fig. 15 Local user interface (LUI)

5.1 Measurement monitoring

When the device is powered, it enters the measurement

monitoring view. The following measurements may be

viewed from the display. The Table 5 identify the default

unit and also optional unit of the measurement.

Table 6 Default / optional units of measurements

Measurement Default unit Optional unit

valve position Percentage

target position Percentage

current loop setpoint (ND9000H,

ND7000H)

setpoint

(ND9000F, P)

actuator pressure

difference

supply pressure bar psi

device

temperature

(of full scale)

(of full scale)

mA Percentage

Perce ntage

(of full scale)

bar psi

degree Celsius degree Fahrenheit

If the unit selection is altered from the FieldCare software to

US units, the pressure default unit will automatically be

changed to psi and temperature unit to Fahrenheit.

The active unit may be changed by pressing the ? key

constantly. The display shows the current unit selection on

the top row of the display. You may change the selection by

pressing + or - key while keeping the ? key pressed

down. When the buttons are released the current selection

will be activated.

If the device has been idle for 1 hour, and there is no user

activity on the local user interface, the measurements will

start scrolling on the display. This enables the user to view

all the measurements through the window of the main

cover.

Angle, where 0 % refers

to 0 deg.

none

(of full scale)

— continuous push

— brief push

Fig. 16 Measurement unit change, ND9000H and ND7000H

— continuous push

— brief push

Fig. 17 Measurement unit change, ND9000F and ND9000P

24 7 ND90 71 en

— brief push

5.2 Guided start-up

Guided startup offers a fast view of the most critical parameters of the ND controller, actuator and valve configuration.

After verifying the parameters the valve travel calibration is

recommended. The guided start-up is entered by pressing

the = and ? keys simultaneously.

The configuration parameters are listed in following order,

see explanation from 5.5:

Valve type VT YP

Actuator type ATYP

Positioner fail action PFA

Valve rotation direction ROT

Valve dead angle A0

PA address ADR (ND9000P only)

If you modify any of the parameters you will also need to

calibrate the device. See 5.6 for detailed description.

NOTE:

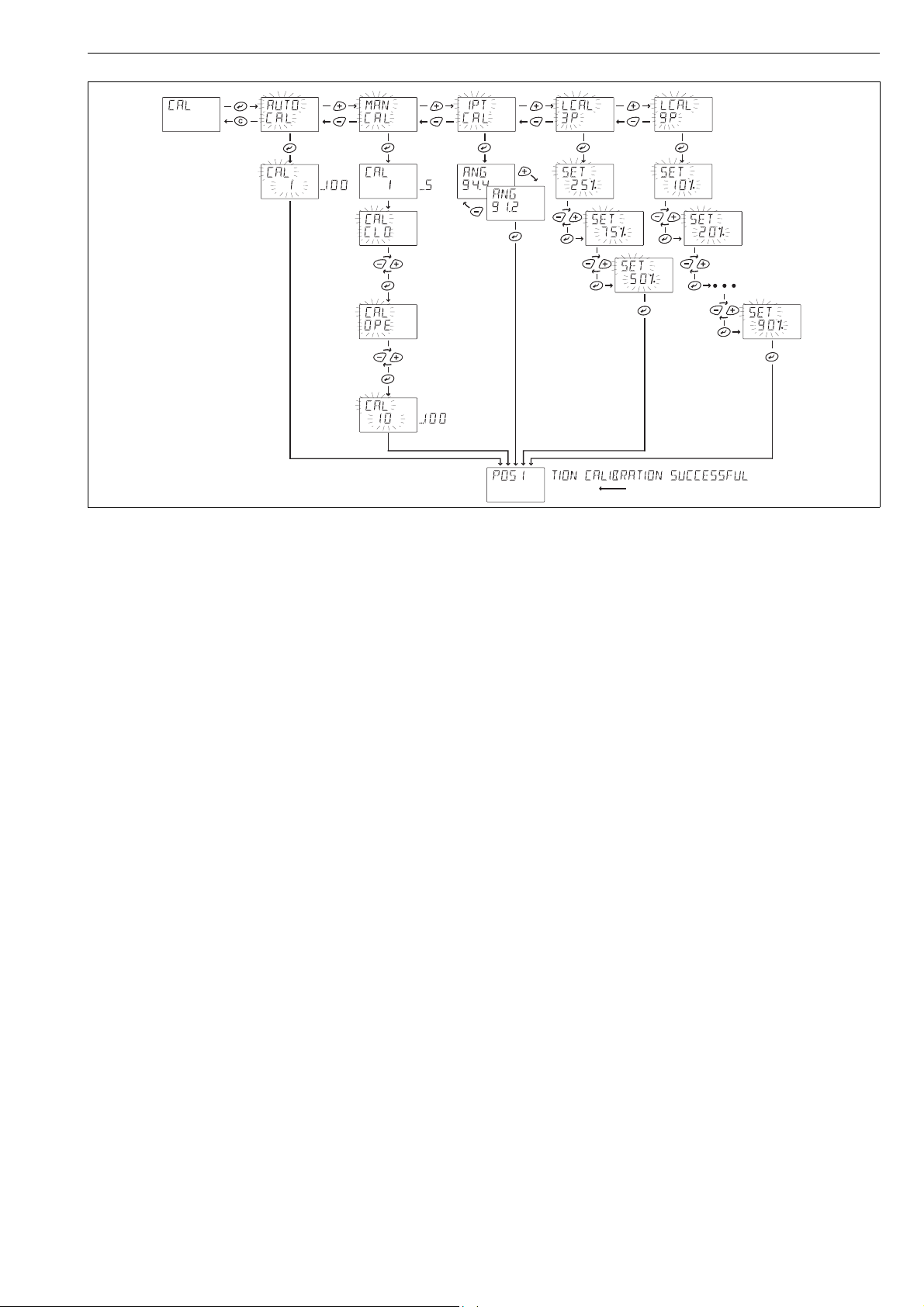

You may cancel any action by pressing the = button.