Metso MA050L, MA080L, MA150L, MA200L, MT050J Installation Maintenance And Operating Instructions

...

BALL VALVE

Series MBV

P&P version

Installation, Maintenance and

Operating Instructions

1 MBV 75 en

Issue 5/02

2

Table of Contents

1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Scope of the manual . . . . . . . . . . . . . . . . . . . . 3

1.2 Valve description . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Valve approvals . . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.7 Recycling and disposal of a rejected valve . . . . 4

1.8 Safety precautions . . . . . . . . . . . . . . . . . . . . . . 5

2 TRANSPORTATION, RECEPTION

AND STORAGE . . . . . . . . . . . . . . . . . . . . . 5

3 INSTALLATION AND USE. . . . . . . . . . . . 6

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Installing in the pipeline . . . . . . . . . . . . . . . . . 6

3.3 Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . 6

4 SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Changing the gland packing while

the valve is in the pipeline . . . . . . . . . . . . . . . 7

4.3 Repair of a jammed or stuck valve

while it is in the pipeline . . . . . . . . . . . . . . . . . 8

4.4 Detaching the actuator . . . . . . . . . . . . . . . . . . 8

4.5 Removing the valve from the pipeline . . . . . 8

4.6 Dismantling the valve . . . . . . . . . . . . . . . . . . . 8

4.6.1 Sizes DN 25-40, 65 . . . . . . . . . 8

4.6.2 Sizes DN 50-400 . . . . . . . . . . . 9

4.7 Inspection of removed parts . . . . . . . . . . . . . 9

4.8 Replacing parts. . . . . . . . . . . . . . . . . . . . . . . . . 9

4.9 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.9.1 Sizes DN 25-40, 65 . . . . . . . . 10

4.9.2 Sizes DN 50-400 . . . . . . . . . . 10

5 TESTING THE VALVE. . . . . . . . . . . . . . . 11

6 INSTALLING THE ACTUATOR. . . . . . . 11

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Installing the M-series handwheel operator 11

6.3 Installing the B1C-series actuator. . . . . . . . . 11

6.4 Installing the B1J-series actuator. . . . . . . . . . 12

6.4.1 B1J-type . . . . . . . . . . . . . . . 12

6.4.2 B1JA-type . . . . . . . . . . . . . . 12

6.5 Installing other makes of actuators . . . . . . . 12

7 MALFUNCTIONS . . . . . . . . . . . . . . . . . . . 12

8 TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 ORDERING SPARE PARTS. . . . . . . . . . . . 12

10 EXPLODED VIEW AND PARTS LIST. . . 13

11 DIMENSIONS AND WEIGHTS . . . . . . . . 14

11.1 DN 25-40, 65, PN 40 . . . . . . . . . . . . . . . . . . 14

11.2 DN 50-200, PN 10, 16 . . . . . . . . . . . . . . . . . 14

11.3 DN 25-40, 65 with hand lever LR . . . . . . . . 15

11.4 DN 50-100 with hand lever LR . . . . . . . . . . 15

11.5 With hand wheel operator M. . . . . . . . . . . . . 16

11.6 DN 25-40, 65 with pneumatic actuator B1C 17

11.7 DN 50-300 with pneumatic actuator B1C . 18

11.8 DN 25-40, 65 with pneumatic

spring-return actuator B1J . . . . . . . . . . . . . . . 20

11.9 DN 50-300 with pneumatic

spring-return actuator B1J . . . . . . . . . . . . . . . 21

12 TYPE CODE . . . . . . . . . . . . . . . . . . . . . . . . 23

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the valve.

If you require additional assistance, please contact the manufacturer or manufacturer’s representative.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

1 GENERAL

1.1 Scope of the manual

This installation, operation and maintenance manual provides

essential information on M-series ball valves. The actuators and

instrumentation to be used with M-series valves are also discussed briefly. Refer to the separate actuator and control equipment instruction manuals for further information.

NOTE:

Selection and use of the valve in a specific application requires

close consideration of detailed aspects. Due to the nature of the

product, this manual cannot cover all the individual situations that

may occur when installing, using or servicing the valve.

If you are uncertain about the use of the valve or its suitability for

your intended use, please contact Metso Automation for more

information.

1.2 Valve description

M-series valves are flanged full bore ball valves. The valve body

is in two parts, fastened together by body-joint bolting. In sizes

DN 25-40, 65 the valve body is in one part; the ball and the seats

are fastened behind a screw-on insert

The ball and stem are separate. Stem blow-out is prevented by

a shoulder machined on the stem.

The valve is either soft or metal seated. Stem torque is transmitted to the ball through a spline driver installed in a groove on

the ball surface. In sizes DN 25-40, 65 the stem is installed straight

into a groove on the ball surface.

The valve is tight in both flow directions. Tightness is provided

by a pressure differential which forces the ball up against the

downstream seat.

Construction details of individual valves are included in the type

code shown on the valve identification plate. To interpret the

type code, please refer to the type coding key in this manual.

M-series valves are specially designed for demanding shut-off

applications involving high operation cycles. They can also be

used in flow control applications.

Fig. 2. Construction of an M series, sizes, sizes DN 50-400

1.3 Markings

Body markings are cast or stamped on the body (see Fig. 3).

The identification plate (Fig. 4) is attached to the flange.

ID plate

Nominal size,

Batch no.

N-J mark,

body material

pressure rating

Fig. 3. Valve markings

Identification plate markings are:

1. Body material

2. Shaft material

3. Trim material

4. Seat material

5. Max and min operating temperature

6. Max shut-off pressure differential / temperature

7. Pressure class

8. Type designation

9. Valve manufacturing parts list no.

10. Model

Body

material

3

Fig. 1. Construction of an M series, sizes DN 25-40, 65

(2)

(1)

ATTENTION : READ INSTRUCTIONS BEFORE INSTALLATION OR SERVICING. CONTACT METSO AUTOMATION FOR COPY.

SHAFT

BODY

TRIM

SEAT

(4)

(5)

T max

MAX. OPER. psatRATING TYPE

T min

(6)

(7)

Fig. 4. Identification plate

(8)

MADE BY METSO AUTOMATION

No.

(9)(3)

MOD

(10)

0045

4

1.4 Specifications

Face-to-face length: acc. to ISO 5752

Body rating: DIN PN 10, 16, 25, 40

Max. pressure differential: see Figs. 7 and 8

Temperature range: see Figs. 5 and 6

Flow direction: free

Tightness:

metal seated DIN 3230 rate 2,

ISO 5208 leakage rate D

soft seated ISO 5208 leakage rate A

Dimensions: see tables on pages 15–23

Weights: see tables on pages 15–23

Fig. 7. Allowed differential pressures, soft seated

Fig. 5. Pressure/temperature curve of valve body,

W. no. 1.4408

Fig. 6. Pressure/temperature curve of valve body,

W. no. 1.0619

Fig. 8. Allowed differential pressures for operation, metal

seated, PN 40. Smaller sizes are full rated.

1.5 Valve approvals

M-series ball valves meet the requirements set by DIN 3840 and

BS 5351.

Fire safety characteristics are designed according to API 607 and

BS 6755.

A patent application for the valve design has been filed.

1.6 CE marking

The valve meets the requirements of the European Directive

97/23/EC relating to pressure equipment, and has been marked

according to the Directive.

1.7 Recycling and disposal of a rejected valve

Most valve parts can be recycled if sorted according to material.

Most parts have material marking. A material list is supplied with

the valve. In addition, separate recycling and disposal instructions are

available from the manufacturer. A valve can also be returned to

the manufacturer for recycling and disposal against a fee.

5

1.8 Safety precautions

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations marked on the valve may cause

damage and lead to uncontrolled pressure release.

Damage or personal injury may result.

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

Dismantling or removing a pressurized valve will result in

uncontrolled pressure release. Always isolate the relevant

part of the pipeline, release the pressure from the valve and

remove the medium before dismantling the valve.

Be aware of the type of medium involved. Protect people and

the environment from any harmful or poisonous substances.

Make sure that no medium can enter the pipeline during valve

maintenance.

Failure to do this may result in damage or personal injury.

CAUTION:

Beware of the ball cutting movement!

Keep hands, other parts of the body, tools and other objects

out of the open flow port. Leave no foreign objects inside the

pipeline. When the valve is actuated, the ball functions as a

cutting device. Close and detach the actuator pressure supply

pipeline for valve maintenance. Failure to do this may result

in damage or personal injury.

2 TRANSPORTATION, RECEPTION

AND STORAGE

Check the valve and the accompanying device for any damage

that may have occurred during transport.

Store the valve carefully. We recommend storing indoors in a

dry place.

Fig. 9. Storing the valve

Do not remove the flow port protectors until installing the valve.

Move the valve to its intended location just before installation.

The valve is usually delivered in the open position.

CAUTION:

Beware of noise emission!

The valve may produce noise in the pipeline. The noise level

depends on the application. It can be measured or calculated

using the Metso Automation Nelprof computer program.

Observe the relevant work environment regulations on noise

emission.

CAUTION:

Beware of extreme temperatures!

The valve body may be very hot or very cold during use.

Protect people against cold injuries or burns.

CAUTION:

When handling the valve or the valve package, bear

in mind its weight!

Never lift the valve or valve package by the actuator, positioner, limit switch or their piping.

Place the lifting ropes securely around the valve body (see Fig. 10).

Damage or personal injury may result from falling parts.

The weights are shown on pages 14–22.

CAUTION:

Follow the proper procedures when handling and

servicing oxygen valves.

CORRECT

WRONG

Fig. 10. Lifting the valve

6

3 INSTALLATION AND USE

3.1 General

Remove the flow bore protectors and check that the valve is

clean inside. Clean the valve if necessary.

3.2 Installing in the pipeline

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package!

Flush the pipeline carefully before installing the valve. Make sure

the valve is entirely open when flushing. Foreign particles, such

as sand or pieces of welding electrode, will damage the ball and

seats.

NOTE:

Use screws, nuts, bolts and gaskets equivalent to the fastenings

used elsewhere in the pipeline. Center the flange gaskets

carefully when fitting the valve between flanges.

NOTE:

Do not attempt to correct pipeline misalignment by means of

flange bolting.

The valve may be installed in any position and offers tightness in

both directions. However we do not recommend installing the

valve with the actuator on the underneath side because dirt in

the pipeline may then enter the body cavity and damage the

gland packing. The position to be avoided is shown in Fig. 11.

Fig. 12. Supporting the valve

3.3 Actuator

NOTE:

When installing the actuator on the valve, make sure that the

valve package functions properly. Detailed information on

actuator installation is given in section 6 or in the separate

actuator instructions.

The valve open/closed position is indicated as follows:

by an indicator on the actuator

or

by a groove at the end of the ball stem (parallel to the ball

flow opening).

If there is any uncertainty about the indicator, check the ball

position by the groove.

The actuator should be installed in a manner that allows plenty

of room for its removal.

The upright position is recommended for the actuator cylinder.

The actuator must not touch the pipeline, because pipeline

vibration may interfere with its operation.

Fig. 11. Avoid this mounting position

It may be necessary to firmly support the pipeline in order to

protect the valve from excess stress. Sufficient support will also

reduce pipeline vibration and thus ensures proper functioning of

the positioner.

To facilitate servicing, it is preferable that the valve be supported

by the body, using pipe clamps and supports. Do not fasten

supports to the flange bolting or to the actuator, see Fig. 12.

In certain cases it may be considered advantageous to provide

additional support to the actuator. These cases will normally be

associated with large actuators, extended stems, or where severe

vibration is present. Please contact Metso Automation for advice.

3.4 Commissioning

Ensure that there is no dirt or foreign objects left inside the valve

or pipeline. Flush the pipeline carefully. Make sure that the valve

is entirely open when flushing.

Ensure that all nuts, pipings, and cables are properly fastened.

Check that the actuator, positioner, and switch are correctly

adjusted. Actuator adjustment is explained in section 6. To adjust

the accompanying device refer to the separate control equipment instruction manuals.

7

4SERVICING

4.1 General

CAUTION:

Observe the safety precautions mentioned in section 1.8 before servicing!

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package!

NOTE:

Always use original spare parts to make sure that the valve

functions as intended.

Although M-series ball valves require no regular maintenance, it

is recommended that the gland packing be checked regularly for

tightness. If for some reason the valve should require maintenance, then a few simple service measures should normally

suffice. This section outlines the service operations that can be

carried out by the end user.

The numbers in parentheses refer to the parts list and the exploded

view of the valve on page 13, if not otherwise stated.

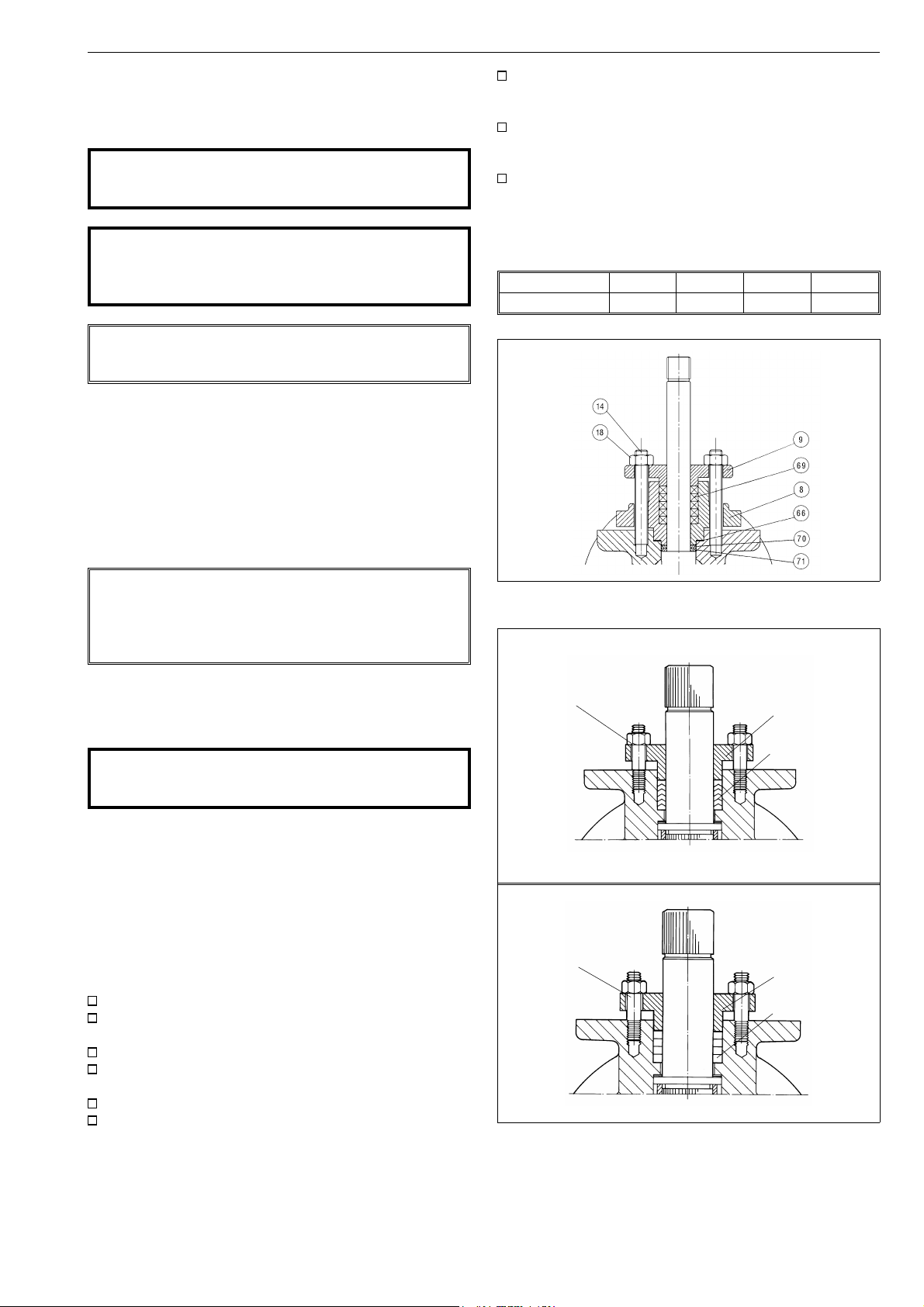

V-ring packings:

Fasten the gland follower (9) and tighten the nuts (18)

with hands at first and then with a tool 1.5–2 turns.

Graphite packings:

Fasten the gland follower (9); place the nuts (18) on the

studs (14) and tighten them to torques shown in Table 1.

Check leakage when the valve is pressurized and retighten the nuts carefully if necessary.

Table 1. Recommended tightening torques of the packing nuts

Valve size, DN 25-40, 65 50-100 150 200-400

Torque, Nm 10 20 50 90

NOTE:

If you choose to send the valve to the manufacturer for

servicing, do not dismantle it. Instead, clean the valve carefully

of all medium and inform the manufacturer of any dangerous

medium involved.

4.2 Changing the gland packing while the

valve is in the pipeline

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

The V-ring gland packing requires no regular tightening. The gland

packing tightness is provided by the pipeline pressure together

with gland pressure against the packing rings. In graphite gland

packings, tightness is ensured by contact between the gland

follower and the packing rings.

The gland packing (69) must be changed if leakage occurs even

after the hex nuts (18) have been tightened. The V-ring gland

packing must be tightened with care because excess force may

damage the V-rings.

Make sure that the valve is not pressurized.

Detach the actuator, coupling, and bracket according to

the instructions in section 4.4.

Remove the gland follower (9).

Remove the packing rings (69) from around the stem using

a knife or some other pointed instrument.

Clean the packing ring counterbore.

Place the new packing rings (69) over the stem (5). The

gland follower may be used for pushing the rings into the

counterbore. Do not damage packing rings in the stem

splines. See Figs. 13 and 14 for proper orientation.

Fig. 13. Gland packing, sizes DN 25-40, 65

hex nut (18)

hex nut (18)

Fig. 14. Gland packing, sizes DN 50-400

gland follower (9)

gland packing (69)

(V-rings)

gland follower (9)

gland packing (69)

(graphite)

8

4.3 Repair of a jammed or stuck valve

while it is in the pipeline

Jamming may be due to the ball (3) and seats (7) becoming

clogged with flow medium. They may be cleaned by turning the

ball to the partly open position and flushing the pipeline. If this

does not help, follow the instructions in the following sections.

4.4 Detaching the actuator

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package!

NOTE:

Before dismantling, carefully observe the position of the valve

with respect to the actuator and positioner/limit switch so as

to make sure that the package can be properly re-assembled.

It is generally most convenient to detach the actuator before

removing the valve from the pipeline. If the valve is small or if it

is difficult to access, it may be more practical to remove the entire

package at the same time.

Note that the seats can be replaced without detaching the

actuator.

Close and detach the actuator pressure supply pipeline

and remove control cables.

Unscrew the bracket screws.

Detach the actuator. The actuator can be removed by

hand or with a special tool made for this purpose. The

tool can be ordered from the manufacturer (see section

"Tools").

Remove the bracket and coupling.

4.5 Removing the valve from the pipeline

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

Make sure that the valve is not pressurized and that the

pipeline is empty. Make sure that the medium cannot flow

into the section where servicing is to take place.

Support the valve carefully with a hoist. Place ropes

carefully and unscrew the pipe flange bolts. See that the

ropes are positioned correctly, see Fig. 10. Lift valve

down.

4.6 Dismantling the valve

4.6.1 Sizes DN 25-40, 65

Place the valve in a standing position on the pipe flange

end so that the body cap points upwards. Use a level

surface that will not scratch the pipe flanges.

Unfasten the gland follower (9) nuts. Remove the gland

follower and the packing rings (69).

Unfasten the bolts of the stem retainer (8). Remove the

gland, the stem retainer seal (66), the stem (5) and the

thrust bearings (70, 71).

Unscrew the insert (2) using a suitable tool. See section 8

"Tools". Remove the ball (3) and seats.

Remove the locked seat (7) using a special tool that can

be ordered from the manufacturer, see Fig. 16.

Fig. 15. Removing the actuator with an extractor

Fig. 16. Removing the locked seat

9

4.6.2 Sizes DN 50-400

Place the valve in a standing position on the pipe flange

end. Use a level surface that will not scratch the flanges.

See that the body stud nuts (16) are facing upward.

Mark the the body halves for correct orientation during

re-assembly.

Turn the ball to the closed position.

Unscrew the body stud nuts (16).

Remove the body cap (2). If the seat (7) is not lying on

the ball (3), prevent the seat from falling from the body

cap and detach it later. Don’t leave your fingers

between the body cap and the surface!

Stand the removed body cap on its pipe flange. See Fig. 17.

Lift the ball (3) from the body (1) by gripping by the flow

bore (small sizes) or by passing a rope through the flow

bore and turning it at the same time around the flow bore

axis. Handle the ball carefully and place it on a soft surface.

See Fig. 19.

Pull the spline driver (4) from the stem (5) and remove

the seat (7) from the lower body half (1).

Remove the gland follower (9).

Push the stem into the body and remove it.

Remove thrust bearing(s) (70), secondary stem seal (71),

packing rings (69) and body gasket (65). Also remove back

seals (63) in ball seats.

Fig. 17. Lifting the body cap

Remove the seat from body cap if it is still in place. If the

seat is locked, it must be removed using a special tool (see

Fig. 18 and section "Tools").

Fig. 18. Removing the locked seat

Fig. 19. Removing of the ball

4.7 Inspection of removed parts

Clean removed parts.

See if the stem (5) or thrust bearings (70) are damaged.

See if the ball (3) or seats (7) are damaged (scratched) by

examining them under bright light. The ball and the seat

can be replaced if necessary.

See if the body joint flanges are damaged.

4.8 Replacing parts

We recommend that soft material parts be replaced whenever

the valve is dismantled for servicing. Other parts may be replaced

if necessary. Always use genuine spare parts to ensure proper

functioning of the valve (see section "Ordering spare parts").

10

4.9 Assembly

4.9.1 Sizes DN 25-40, 65

Place the valve in a standing position on the pipe flange

end so that the insert thread points upwards. Use a level

surface that will not scratch the flanges.

Screw the insert (2) into the body by itself. Tighten the

insert slightly to ensure that it has gone all the way in. Mark

the position, for example by tapping a screwdriver lightly

against the body at the point of the mark in the insert.

Unscrew the insert and remove it from the body.

H seat: Place the back seal (63) into the seat (7), see Fig. 20,

and then both parts all the way into the body counterbore.

H seat: Lock the seat into the body using a special tool

that can be ordered from the manufacturer. The tool is

accompanied by operating instructions.

T / M seat: Place the seat (7) into the body counterbore.

62

63

7

Fig. 20. Mounting the back seal, H seat

25

Push the packing rings (69) into their place in the stem

retainer (8).

Tighten the studs (14). Place the gland follower (9) on the

packing rings (69). Lightly screw the nuts (18) onto the

studs (14).

Cycle the valve slowly a couple of times to ensure that

the ball’s position between the seats is correct.

Tighten the gland follower nuts (10 Nm), see also section 4.2.

Check the gland packing for leakage when the valve is

pressurized and re-tighten the nuts carefully if necessary.

Install the valve in the pipeline as carefully and accurately as

when you removed it. Note the instructions given in section 3.

4.9.2 Sizes DN 50-400

Place the valve body on the pipe flange end. Use a level

surface that will not scratch the flanges.

S / K seat: Place the back seals (63) into the seats (7) as

shown in Fig. 22. Place one of the seats into the body

counterbore.

75

76

H seat: Place the back seal (63), Fig. 22, and the seat (7)

into body counterbore.

K / H seat: Lock the seat (7) using a special locking tool.

The tool is accompanied by operating instructions.

T / M seat: Place the seat (7) into body counterbore.

Slip the thrust bearing(s) (70) and secondary stem seal (71)

onto the stem (5). See exploded view for proper orientation.

Push the stem into body (1) from the inside and assemble the

gland packing (69) from the outside. Place the gland follower (9)

over the stem (5). Tighten the gland nuts (18) with fingers.

1, 2

7

grooves towards

the ball

Fig. 21. Mounting the T / M seat

Place the ball on the locked seat so that the groove faces

the stem entrance opening. Push the stem into the valve

from the outside. Make sure that the end of the stem (5)

fits into the ball groove.

H seat: Assemble the seat (25), spring (62), back seals (75)

and back-up ring (76), Fig. 20, and place the assembly on

the insert (2).

T / M seat: Place the seat (7) on the ball (3), see Fig. 21.

Slip the thrust bearings (70, 71), part (70) first, onto the

stem and push them against the stem shoulder.

Put the stem retainer seal (66) in its groove, replace the

stem retainer (8) and tighten the studs (13).

Tighten the nuts (17) of the studs (13) evenly to achieve

uniform compression of the seal (66). The torque is 25

Nm when the threads have been lubricated.

Place the body gasket (65) into the body, on the shoulder

at the foot of the threads.

Screw the insert and seat assembly into the body. This is

easier to do if the valve is horizontal. Tighten the insert

using a spanner wrench until the cap reaches 5-10 mm

past the mark made earlier. The torque is 160 Nm for

DN 25 and 200 Nm for DN 40.

1

S / K seat

63

7

H seat

63

62

76

75

Fig. 22. Mounting the back seal, S / K and H seats

Slip the spline driver (4) onto the stem. Note the correct

orientation. Place the ball into the body (1) carefully.

K seat: Place another seat (with the back seal) into the

body cap (2) as described above. Lock the seat

S seat: Place the seat on the top of the ball.

H seat: Place the back seal (75), back-up ring (76), spring (62),

Fig. 21, and the seat (7) into body cap.

T / M seat: Place the seat (7) onthe ball.

Install the body gasket (65) in the body groove.

Place the body cap (2) carefully over body studs (12) and

body (1). See that flange holes are aligned acc. to the mark

made during the dismantling.

Fasten the body nuts (16). Tighten the nuts gradually,

always switching to other side of the valve after every nut.

The recommended torques are given in Table 2.

2

11

Table 2. Recommended tightening torques of the body stud nuts

Recommended tightening torques (Nm)

Thread Stainless steel Carbon steel

M14 55-63 55-63

M16 114-133 118-140

M20 173-203 184-214

M22 214-251 280-329

M24 310-360 490-580

M30 388-454 626-738

NOTE: Threads must be well lubricated. If studs and nuts are

unlubricated and have been used before, torques must be

about 50% higher.

Cycle the valve slowly a couple of times to insure correct

position of the ball between the two seats. The spline

driver should move correctly too.

Tighten the gland nuts (18) with fingers at first and then

with a tool 1.5–2 turns. Check for leakage once the valve

is pressurized and re-tighten the nuts carefully if necessary.

Install the valve in the pipeline as carefully and accurately

as when removing it. Follow the instructions given in

Section 3.

5 TESTING THE VALVE

Bracket with ISO

5211 mounting

surface

Stem

Coupling

Fig. 23. Bracket and coupling mounted on valve

Adjust the circular movement of the ball with the hexagon

screws located at the side of the housing (see figure 24).

The stop-screw for the open position is nearest to the

handwheel on the side of the housing and the screw for

the closed position is at the opposite end. The turning

directions for the handwheel are marked on the wheel.

Check the handwheel by turning the valve to the extreme

positions. The yellow arrow should indicate the direction

of the ball flow bore.

CAUTION:

Pressure testing should be carried out using equipment conforming to the correct pressure class!

We recommend that the valve body be pressure tested after

the valve has been assembled.

The pressure test should be carried out in accordance with an

applicable standard using the pressure rating required by the

pressure class or flange bore of the valve. The valve must be in

an open position during the test.

If you also want to test the tightness of the closure member,

contact the manufacturer.

6 INSTALLING THE ACTUATOR

6.1 General

Different Metso Automation actuators can be mounted using

suitable brackets and couplings. The valve can be actuated by an

M-series handwheel operator or B1-series actuators.

6. 2 Installing the M-series handwheel operator

The mark at the end of the stem indicates the direction

of the ball flow bore. Turn the valve to the closed position.

Lubricate the grooves of the actuator and the couplings.

Place the coupling on the stem and lock it. Place the bracket

on the valve and turn the lubricated screws a few times.

Turn the actuator to the closed position and push it

carefully onto the valve stem on which the coupling has

been mounted. Please note the marks on the handwheel

and the coupling.

Lubricate the actuator screws. Tighten all screws.

stop-screw for CLOSED position

stop-screw for OPEN position

Fig. 24. Open and closed positions of the M-series actuator

6.3 Installing the B1C-series actuator

CAUTION:

Beware of ball cutting movement!

Turn the valve to the closed position and drive actuator

piston to the extreme outward position.

File off any burrs and clean the stem bore .

Place the coupling over the stem (see Fig. 23). Note the

correct position. The line at the end of the stem and

coupling indicates the direction of the ball flow bore.

Lubricate the coupling and stem bore. Fasten the bracket

loosely to the valve.

Slip the actuator carefully onto the coupling. Avoid forcing

it since this may damage the ball and seats. We recommend mounting the actuator so that the cylinder is pointing upwards.

Position the actuator parallel or vertical to the pipeline as

accurately as possible. Lubricate the actuator mounting

screws and then fasten all screws.

12

Adjust the ball open and closed positions by means of the

actuator stop screws located at both ends (see Fig 24).

An accurate open position can be seen in the body flow

bore. Check that the yellow arrow on the actuator indicates the ball flow opening position. Keep fingers out

of the flow bore!

There is no need for stop screw adjustment if the actuator is

re-installed in the same valve. Drive actuator piston to the

housing end (open position). Turn the actuator by hand until the

valve is in the open position. Fasten the actuator in this position

as explained above.

Check the stop screw thread tightness. The threads must

be sealed using an appropriate non-hardening sealant, e.g

Loctite 225.

Check that the actuator is functioning correctly. Drive the

actuator piston to both cylinder ends and check the ball

position and its movement with respect to the actuator

(close: clockwise; open: counterclockwise). The valve

should be closed when the piston is in the extreme

outward position.

If necessary, change the position of the actuator pointing

cover to correctly indicate the valve open/closed position.

6.4 Installing the B1J-series actuator

Spring-return actuators are used in applications where valve

opening or closing movement is needed in case the air supply is

interrupted. The B1J type is used for spring-to-close operation;

the spring pushes the piston towards the cylinder end, the

extreme outward position. In turn, the B1JA type is used for

spring-to-open operation; the spring pushes the piston towards

the housing.

Spring-return actuators are installed in a manner similar to

B1C-series actuators, taking into account the following.

6.4.1 B1J-type

Install the actuator so that the piston is in the extreme

outward position. The cylinder must not be pressurized

and air supply connections must be open. The valve must

be in the closed position.

6.5 Installing other makes of actuators

NOTE:

Metso Automation accepts no responsibility for compatibility

of actuators not installed by Metso Automation.

Other actuators can be installed only if they have an ISO 5211

actuator connection.

7 MALFUNCTIONS

The following Table 3 lists malfunctions that might occur after

prolonged use.

8 TOOLS

In addition to standard tools, the following special tools are

needed.

For removal of the actuator:

- extractor

For removal of the insert:

- removal tool

For removal of the locked seats:

- detaching tool

For locking of the seats:

- locking tool

These tools can be ordered from the manufacturer. Always give

the valve type designation when ordering.

9 ORDERING SPARE PARTS

When ordering spare parts, always include the following information:

valve type designation (from the name plate or documents)

number of the parts list (or number of this manual), part

number, name of the part and number of pieces required.

6.4.2 B1JA-type

Install the actuator so that the piston is in the cylinder end

position at housing side. The cylinder must not be pressurized and air supply connections must be open. The

valve must be in the open position.

The rest of the installation procedure is the same as in section 6.3.

Table 3. Possible malfunctions

Symptom Possible fault Toimenpiteet

Leakage through a closed valve Wrong stop screw adjustment of the actuator Adjust the stop screw for closed position

Damaged ball surface Turn the ball by 180°

Damaged seat(s) Replace seat(s)

Ball cannot move freely Clean the inside of the valve

Irregular valve movement Impurities between the ball and seats Flush the valve from the inside

Clean the sealing surfaces and seats mechanically

Leakage through gland packing Loose packing Tighten the nuts

Worn-out or damaged packing Replace the gland packing

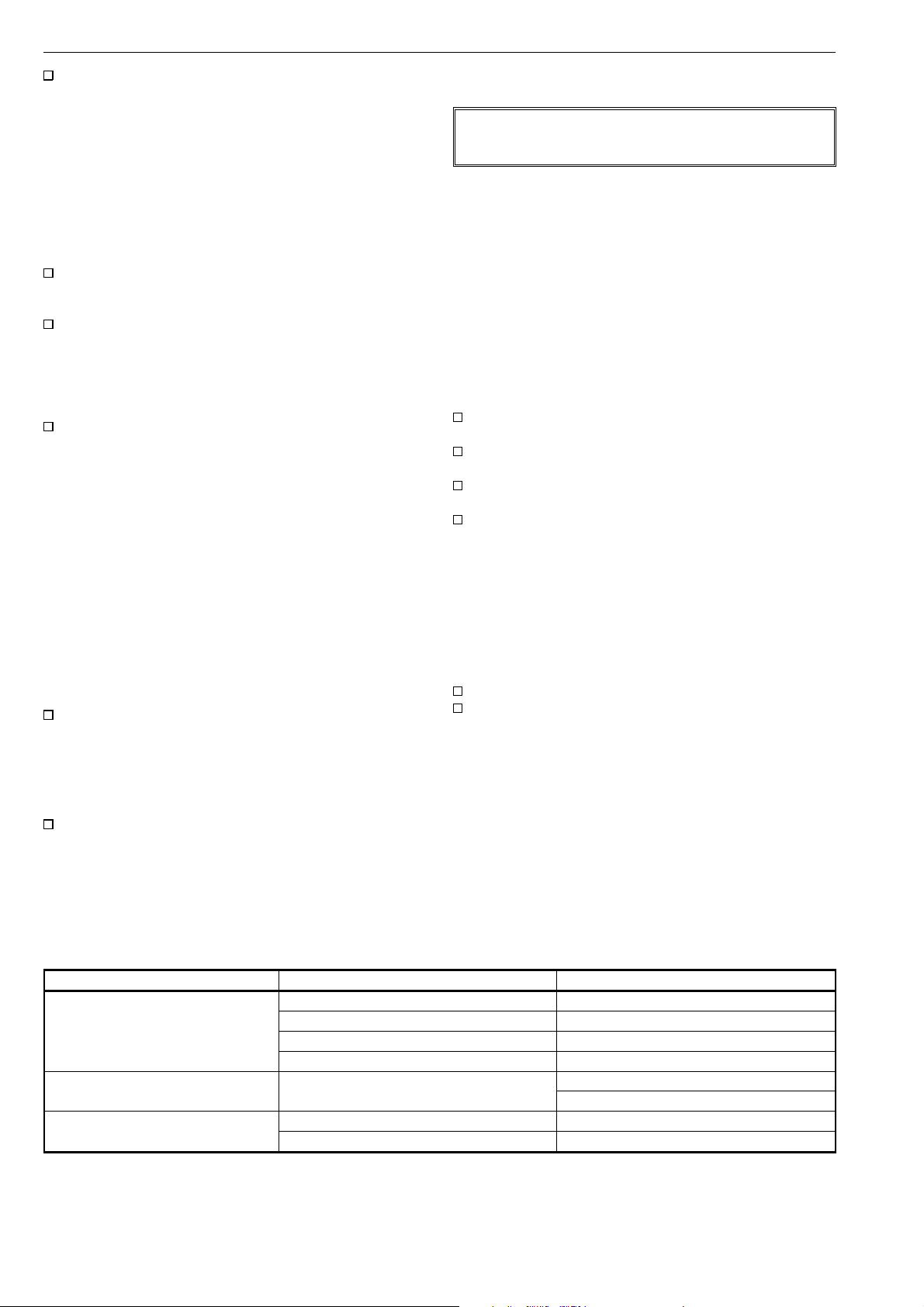

10 EXPLODED VIEW AND PARTS LIST

13

DN 25, 40, 65 DN 50 ... 400

Item Qty Description Available spare parts Recommended spare parts

11 Body

2 1 Body cap (DN 50...400)

1 Body insert (DN 25, 40, 65)

31 Ball X

4 1 Spline driver (DN 50...400) X

5 1 Stem X

7 1-2 Seat X

8 1 Stem retainer (DN 25, 40, 65) X

91 Gland X

12 Stud X

13 Stud X

14 Stud X

16 Hexagon nut X

17 Hexagon nut X

18 Hexagon nut X

25 1 Seat X

36 1 Anti-static spring X

62 1 Seat spring X

63 1-2 Back seal X X

65 1 Body gasket X X

66 1 Gasket X X

69 1 Packing X X

70 2 Thrust bearing X

71 1 Stem seal X

75 1 Back-up ring X X

76 1 Seat seal X

14

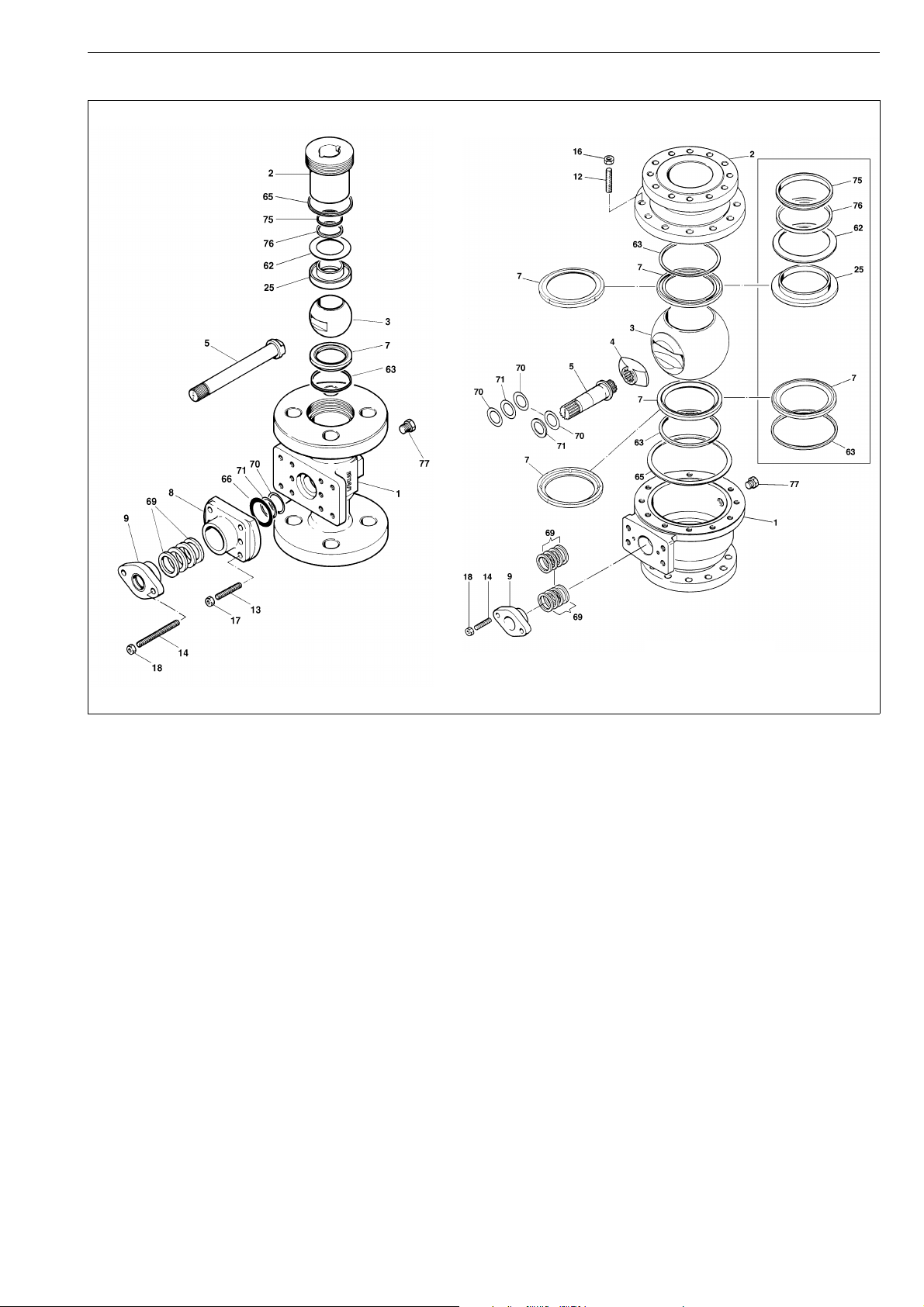

11 DIMENSIONS AND WEIGHTS

11.1 DN 25-40, 65, PN 40

DN 25-40, 65, PN 40

Type Dimensions in mm NPTFU1Kg

DN A A1 ØB ØD K

MA025M 25 160 80 115 25,4 145 1/4 6

MA040M 40 200 87 150 38,1 167 1/4 10,5

MD065M 65 290 95 185 58,7 176 1/2 21

11.2 DN 50-200, PN 10, 16

DN 50-200, PN 25

Type Dimensions in mm NPTFU1Kg

DN A A1 ØB ØB1 ØD K

MA050L 50 216 90 165 146 50,8 168 1/2 16

MA080L 80 282 120 200 203 76,2 229 1/2 34

MA100L 100 305 137 235 254 101,6 264 1/2 62

MA150L 150 403 179 300 367 152,4 342 3/4 146

MA200L 200 502 226 360 467 203,2 440 3/4 264

PN 10, 16

Type Dimensions in mm NPTFU1Kg

DN A A1 ØB ØB1 ØD K

MT050J/K 50 178 79 165 153 50,8 168 1/2 13

MT080J/K 80 203 99 200 194 76,2 189 1/2 23

MT100J/K 100 229 114,5 220 2 52 101,6 250 1/2 42

MT150J/K 150 394 184 285 364 152,4 342 3/4 120

MT200J/K 200 457 229 340 460 203,2 440 3/4 212

PN 40

Type Dimensions in mm NPTFU1Kg

DN A A1 ØB ØB1 ØD K

MA050M 50 216 90 165 146 50,8 168 1/2 16

MA080M 80 282 120 200 203 76,2 229 1/2 34

MA100M 100 305 137 235 254 101,6 264 1/2 62

MA150M 150 403 179 300 367 152,4 342 3/4 14 6

MA200M 200 502 226 375 467 203,2 440 3/4 26 4

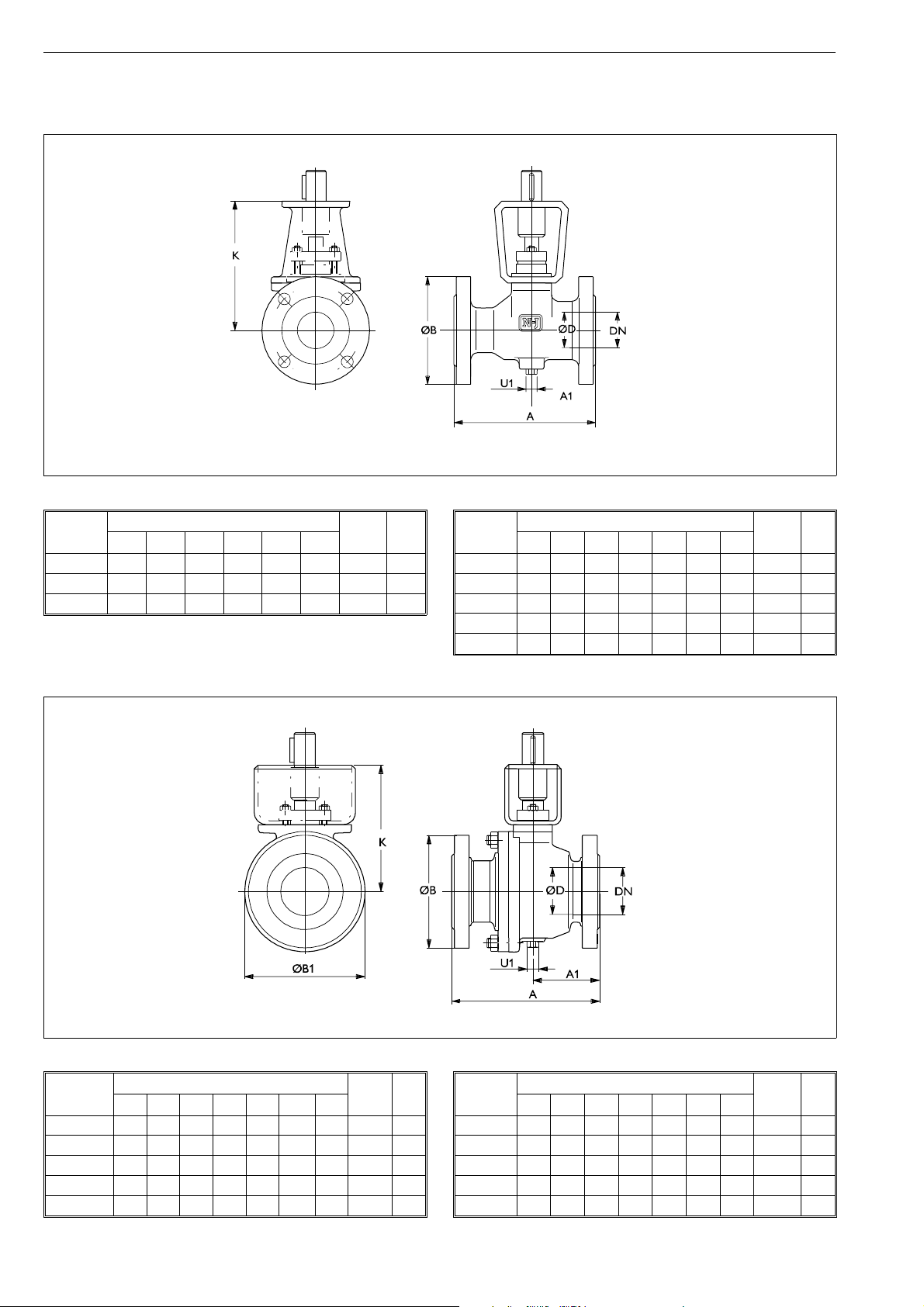

11.3 DN 25-40, 65 with hand lever LR

PN 40

Type Dimensions in mm Kg

DN A A1 ØBH J L

MA025M-

LR220

MA040M-

LR220

MD065M-

LR350

25 165,1 80 124 255 193 220 7,5

40 190,5 87 155 293 215 220 12,5

65 290 95 185 320 228 350 25

15

11.4 DN 50-100 with hand lever LR

PN 10, 16

Type Dimensions in mm Kg

DN A A1 ØB ØB1 H J L

MT50J/K-

LR350

MT080J/K-

LR350

MT100J/K-

LR450

50 178 79 165 153 297 220 350 16

80 203 99 200 194 338 241 350 26

100 2 29 114,5 220 2 52 4 28 3 02 4 50 45

PN 25, 40

Type Dimensions in mm Kg

DN A A1 ØB ØB1 H J L

MA050L/M-

LR350

MA080L/M

LR450

MA100L/M-

LR450

50 216 90 165 146 303 220 350 19

-

80 282 120 200 203 383 281 450 37

100 305 137 235 254 443 316 450 65

16

11.5 With hand wheel operator M

G

F

ø Z

V

ØB1

Type Dimensions in mm Kg

FGJ VØZ

M07 196 152 58 39 125 3

M10 297 239 67 52 200 5

M12 357 282 81 67 250 10

M14 435 345 94 90 457 18

M15 532 406 106 123 457 31

M16 642 466 127 154 610 45

K*

J

11.6 DN 25-40, 65 with pneumatic actuator

B1C

17

PN 40

Type Dimensions in mm NPT Kg

DN A A1 ØBF G H I J V X

MA025M-B1C6 25 165,1 80 124 400 260 310 220 203 36 90 1/4 13

MA040M-B1C6 40 190,5 87 155 400 260 350 220 225 36 90 1/4 17

MA040M-B1C9 40 190,5 87 155 455 315 360 215 226 43 110 1/4 22

MD065M-B1C9 65 290 95 185 455 315 382,5 215 235 43 110 1/4 37

MD065M-B1C11 65 290 95 185 540 375 401 225 241 51 135 3/8 43

18

11.7 DN 50-300 with pneumatic actuator B1C

PN 10, 16

Type Dimensions in mm NPT Kg

DN A A1 ØB ØB1 F G H I J V X

MT050J/K - B1C6 50 178 79 165 153 400 260 390 225 226 36 90 1/4 20

MT050J/K - B1C9 50 178 79 165 153 455 315 385 220 227 43 110 1/4 25

MT050J/K - B1C11 50 178 79 165 153 540 375 395 225 233 51 135 3/8 30

MT080J/K - B1C9 80 203 99 200 194 455 315 425 220 248 43 110 1/4 35

MT080J/K - B1C11 80 203 99 200 194 540 375 435 225 254 51 135 3/8 43

MT080J/K - B1C13 80 203 99 200 194 635 445 465 235 270 65 175 3/8 58

MT080J/K - B1C17 80 203 99 200 194 770 495 495 255 285 78 215 1/2 80

MT100J/K - B1C11 100 229 114,5 220 252 540 375 520 225 315 51 135 3/8 62

MT100J/K - B1C13 100 229 114,5 220 252 635 445 555 235 331 65 175 3/8 78

MT100J/K - B1C17 100 229 114,5 220 252 770 545 585 255 346 78 215 1/2 100

MT150J/K - B1C17 150 394 184 285 364 770 545 730 255 438 78 215 1/2 180

MT150J/K - B1C20 150 394 184 285 364 840 575 765 270 457 97 215 1/2 198

MT150J/K - B1C25 150 394 184 285 364 1040 710 825 310 480 121 265 1/2 255

MT150J/K - B1C32 150 394 184 285 364 1330 910 900 350 517 153 395 3/4 370

MT200J/K - B1C20 200 457 229 340 460 840 575 910 270 555 97 215 1/2 290

MT200J/K - B1C25 200 457 229 340 460 1040 710 970 310 578 121 265 1/2 348

MT200J/K - B1C32 200 457 229 340 460 1330 910 1045 350 615 153 395 3/4 470

MT200J/K - B1C40 200 457 229 340 460 1660 1150 1150 370 665 194 505 3/4 660

MT250J/K - B1C25 250 533 267 395/405 548 1040 710 1095 310 658 121 265 1/2 500

MT250J/K - B1C32 250 533 267 395/405 548 1330 910 1170 350 695 153 395 3/4 620

MT250J/K - B1C40 250 533 267 395/405 548 1660 1150 1275 370 745 194 505 3/4 815

MT300J/K - B1C25 300 610 305 445/460 624 1040 710 1175 310 699 121 265 1/2 675

MT300J/K - B1C32 300 610 305 445/460 624 1330 910 1250 350 736 153 395 3/4 795

MT300J/K - B1C40 300 610 305 445/460 624 1660 1150 1350 370 786 194 505 3/4 990

MT300J/K - B1C50 300 610 305 445/460 624 1970 1350 1455 415 836 242 610 1 1380

PN 25

Type Dimensions in mm NPT Kg

DN A A1 ØB ØB1 F G H I J V X

MA050L - B1C6 50 216 90 165 146 400 260 390 225 226 36 90 1/4 22

MA050L - B1C9 50 216 90 165 146 455 315 385 220 227 43 110 1/4 27

MA050L - B1C11 50 216 90 165 146 540 375 475 225 233 51 135 3/8 33

MA080L - B1C9 80 282 120 200 203 455 315 465 220 288 43 110 1/4 46

MA080L - B1C11 80 282 120 200 203 540 375 480 225 295 51 135 3/8 52

MA080L - B1C13 80 282 120 200 203 635 445 510 235 310 65 175 3/8 67

MA080L - B1C17 80 282 120 200 203 770 545 540 255 325 78 215 1/2 90

MA100L - B1C11 100 305 137 235 254 540 375 540 225 329 51 135 3/8 80

MA100L - B1C13 100 305 137 235 254 635 445 560 235 335 65 175 3/8 95

MA100L - B1C17 100 305 137 235 254 770 545 590 255 350 78 215 1/2 120

MA150L - B1C17 150 403 179 300 367 770 545 735 255 440 78 215 1/2 205

MA150L - B1C20 150 403 179 300 367 840 575 770 270 460 97 215 1/2 224

MA150L - B1C25 150 403 179 300 367 1040 710 825 310 480 121 265 1/2 280

MA150L - B1C32 150 403 179 300 367 1330 910 900 350 517 153 395 3/4 400

MA200L - B1C25 200 502 226 360 467 1040 710 975 310 580 121 265 1/2 400

MA200L - B1C32 200 502 226 360 467 1330 910 1050 350 615 153 395 3/4 520

MA250L - B1C25 250 568 285 425 580 1040 710 1110 310 658 121 265 1/2 515

MA250L - B1C32 250 568 285 425 580 1330 910 1185 350 695 153 395 3/4 630

MA250L - B1C40 250 568 285 425 580 1660 1150 1290 370 745 194 505 3/4 825

MA300L - B1C25 300 648 324 485 652 1040 710 1185 310 699 121 265 1/2 660

MA300L - B1C32 300 648 324 485 652 1330 910 1265 350 736 153 395 3/4 780

MA300L - B1C40 300 648 324 485 652 1660 1150 1365 370 786 194 505 3/4 975

MA300L - B1C50 300 648 324 485 652 1970 1350 1470 415 836 242 610 1 1360

19

PN 40

Type Dimensions in mm NPT Kg

DN A A1 ØB ØB1 F G H I J V X

MA050M - B1C6 50 216 90 165 146 400 260 390 225 226 36 90 1/4 22

MA050M - B1C9 50 216 90 165 146 455 315 385 220 227 43 110 1/4 27

MA050M - B1C11 50 216 90 165 146 540 375 475 225 233 51 135 3/8 33

MA080M - B1C9 80 282 120 200 203 455 315 465 220 288 43 110 1/4 46

MA080L - B1C11 80 282 120 200 203 540 375 480 225 295 51 135 3/8 52

MA080L - B1C13 80 282 120 200 203 635 445 510 235 310 65 175 3/8 67

MA080L - B1C17 80 282 120 200 203 770 545 540 255 325 78 215 1/2 90

MA100L - B1C11 100 305 137 235 254 540 375 540 225 329 51 135 3/8 80

MA100L - B1C13 100 305 137 235 254 635 445 560 235 335 65 175 3/8 95

MA100L - B1C17 100 305 137 235 254 770 545 590 255 350 78 215 1/2 120

MA100L - B1C20 100 305 137 235 254 840 575 625 270 370 97 215 1/2 140

MA100L - B1C25 100 305 137 235 254 1040 710 685 310 395 121 265 1/2 200

MA150L - B1C17 150 403 179 300 367 770 545 735 255 440 78 215 1/2 205

MA150L - B1C20 150 403 179 300 367 840 575 770 270 460 97 215 1/2 224

MA150L - B1C25 150 403 179 300 367 1040 710 825 310 480 121 265 1/2 280

MA150L - B1C32 150 403 179 300 367 1330 910 900 350 517 153 395 3/4 400

MA200L - B1C25 200 502 226 375 467 1040 710 975 310 580 121 265 1/2 400

MA200L - B1C32 200 502 226 375 467 1330 910 1050 350 615 153 395 3/4 520

MA250L - B1C25 250 568 285 450 580 1040 710 1110 310 658 121 265 1/2 515

MA250L - B1C32 250 568 285 450 580 1330 910 1185 350 695 153 395 3/4 630

MA250L - B1C40 250 568 285 450 580 1660 1150 1290 370 745 194 505 3/4 825

MA300L - B1C25 300 648 324 515 652 1040 710 1185 310 699 121 265 1/2 660

MA300L - B1C32 300 648 324 515 652 1330 910 1265 350 736 153 395 3/4 780

MA300L - B1C40 300 648 324 515 652 1660 1150 1365 370 786 194 505 3/4 975

MA300L - B1C50 300 648 324 515 652 1970 1350 1470 415 836 242 610 1 1360

20

11.8 DN 25-40, 65 with pneumatic

spring-return actuator B1J

PN 40

Type Dimensions in mm NPT Kg

DN A A1 ØBF G H I J V X

MA025M-B1J8 25 165,1 80 124 560 420 335 220 204 43 135 3/8 24

MA040M-B1J8 40 190,5 87 155 560 420 385 220 225 43 135 3/8 29

MA040M-B1J10 40 190,5 87 155 650 490 400 225 231 51 175 3/8 42

MD065M-B1J10 65 290 95 185 650 490 425 225 241 51 175 3/8 39

MD065M-B1J12 65 290 95 185 800 620 460 235 257 65 215 1/2 66

11.9 DN 50-300 with pneumatic

spring-return actuator B1J

21

PN 10, 16

Type Dimensions in mm NPT Kg

DN A A1 ØB ØB1 F G H I J V X

MT050J/K - B1J8 50 178 79 165 153 560 420 371 220 227 43 135 3/8 31

MT050J/K - B1J10 50 178 79 165 153 650 490 336 225 233 51 175 3/8 44

MT050J/K - B1J12 50 178 79 165 153 800 620 435 235 249 65 215 1/2 72

MT080J/K - B1J10 80 203 120 200 194 650 490 440 225 254 51 175 3/8 55

MT080J/K - B1J12 80 203 120 200 194 800 620 475 235 270 65 215 1/2 82

MT080J/K - B1J16 80 203 120 200 194 990 760 515 255 285 78 265 1/2 125

MT100J/K - B1J12 100 229 137 220 252 800 620 565 235 331 65 215 1/2 102

MT100J/K - B1J16 100 229 137 220 252 990 760 605 255 346 78 265 1/2 145

MT150J/K - B1J16 150 394 179 285 364 990 760 755 255 438 78 265 1/2 235

MT150J/K - B1J20 150 394 179 285 364 1200 935 840 270 457 97 395 3/4 300

MT150J/K - B1J25 150 394 179 285 364 1530 1200 915 310 480 121 505 3/4 475

MT200J/K- B1J20 200 457 226 340 460 1200 935 985 270 555 97 395 3/4 392

MT200J/K- B1J25 200 457 226 340 460 1530 1200 1060 310 578 121 505 3/4 565

MT200J/K - B1J32 200 457 226 340 460 1830 1410 1115 350 615 153 540 1 890

MT250K - B1J25 250 533 267 395 548 1530 1200 1185 310 658 121 505 3/4 720

MT250K - B1J32 250 533 267 395 548 1830 1410 1240 350 695 153 540 1 1050

MT300K - B1J32 300 610 305 445 624 1830 1410 1250 350 736 153 540 1 1225

22

PN 25

Type Dimensions in mm NPT Kg

DN A A1 ØB ØB1 F G H I J V X

MA050L - B1J8 50 216 90 165 146 560 420 375 220 227 43 135 3/8 35

MA050L - B1J10 50 216 90 165 146 650 490 405 225 233 51 175 3/8 48

MA050L - B1J12 50 216 90 165 146 800 620 440 235 249 65 215 1/2 75

MA080L - B1J10 80 282 120 200 203 650 490 485 225 294 51 175 3/8 66

MA080L - B1J12 80 282 120 200 203 800 620 520 235 310 65 215 1/2 93

MA080L - B1J16 80 282 120 200 203 990 760 560 255 325 78 265 1/2 136

MA100L - B1J12 100 305 137 235 254 800 620 570 235 335 65 215 1/2 122

MA100L - B1J16 100 305 137 235 254 990 760 610 255 350 78 265 1/2 165

MA100L - B1J20 100 305 137 235 254 1200 935 695 270 369 97 395 3/4 240

MA150L - B1J16 150 403 179 300 367 990 760 755 255 438 78 265 1/2 250

MA150L - B1J20 150 403 179 300 367 1200 935 840 270 457 97 395 3/4 325

MA150L - B1J25 150 403 179 300 367 1530 1200 915 310 480 121 505 3/4 500

MA150L - B1J32 150 403 179 300 367 1830 1410 970 350 517 153 540 1 820

MA200L- B1J20 200 502 226 360 467 1200 935 985 270 555 97 395 3/4 445

MA200L- B1J25 200 502 226 360 467 1530 1200 1065 310 578 121 505 3/4 620

MA200L - B1J32 200 502 226 360 467 1830 1410 1120 350 615 153 540 1 940

MA250L - B1J25 250 568 285 425 580 1530 1200 1200 310 658 121 505 3/4 730

MA250L - B1J32 250 568 285 425 580 1830 1410 1255 350 695 153 540 1 1050

MA300L - B1J25 300 648 324 485 652 1530 1200 1280 310 699 121 505 3/4 880

MA300L - B1J32 300 648 324 485 652 1830 1410 1335 350 736 153 540 1 1200

PN 40

Type Dimensions in mm NPT Kg

DN A A1 ØB ØB1 F G H I J V X

MA050M - B1J8 50 216 90 165 146 560 420 375 220 227 43 135 3/8 35

MA050M - B1J10 50 216 90 165 146 650 490 405 225 233 51 175 3/8 48

MA050M - B1J12 50 216 90 165 146 800 620 440 235 249 65 215 1/2 75

MA080M - B1J10 80 282 120 200 203 650 490 485 225 294 51 175 3/8 66

MA080M - B1J12 80 282 120 200 203 800 620 520 235 310 65 215 1/2 93

MA080M - B1J16 80 282 120 200 203 990 760 560 255 325 78 265 1/2 136

MA100M - B1J12 100 305 137 235 254 800 620 570 235 335 65 215 1/2 122

MA100M - B1J16 100 305 137 235 254 990 760 610 255 350 78 265 1/2 165

MA100M - B1J20 100 305 137 235 254 1200 935 695 270 369 97 395 3/4 240

MA100M - B1J25 100 305 137 235 254 1530 1200 770 310 392 121 505 3/4 415

MA150M - B1J16 150 403 179 300 367 990 760 755 255 438 78 265 1/2 250

MA150M - B1J20 150 403 179 300 367 1200 935 840 270 457 97 395 3/4 325

MA150M - B1J25 150 403 179 300 367 1530 1200 915 310 480 121 505 3/4 500

MA150M - B1J32 150 403 179 300 367 1830 1410 970 350 517 153 540 1 820

MA200M- B1J20 200 502 226 375 467 1200 935 985 270 555 97 395 3/4 445

MA200M- B1J25 200 502 226 375 467 1530 1200 1065 310 578 121 505 3/4 620

MA200M - B1J32 200 502 226 375 467 1830 1410 1120 350 615 153 540 1 940

MA250M - B1J25 250 568 285 450 580 1530 1200 1200 310 658 121 505 3/4 730

MA250M - B1J32 250 568 285 450 580 1830 1410 1255 350 695 153 540 1 1050

MA300M - B1J25 300 648 324 515 652 1530 1200 1280 310 699 121 505 3/4 880

MA300M - B1J32 300 648 324 515 652 1830 1410 1335 350 736 153 540 1 1200

12 TYPE CODE

23

24

Metso Automation Inc.

Europe, Levytie 6, P.O. Box 310, 00811 Helsinki, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

Latin America, Av. Independéncia, 2500- Iporanga, 18087-101, Sorocaba-São Paulo, Brazil.

Tel. +55 15 3235 9700. Fax +55 15 3235 9748/49

Asia Pacific, 501 Orchard Road, #05-09 Wheelock Place, 238880 Singapore. Tel. +65 673 552 00. Fax +65 673 545 66

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates.

Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metsoautomation.com

en

Loading...

Loading...