Ceramic Ball Valves

Series E2 and E6

Installation, Maintenance and

Operating Instructions

1 E2 70 en • 9/2011

2 1 E2 70 en

Table of Contents

1 GENERAL........................................................ 3

1.1 Valve description.................................... 3

1.2 Valve markings....................................... 3

1.3 Technical data................. ... ....................3

1.4 CE marking ............................................ 3

1.5 Recycling and disposal ...... ... .................3

1.6 Safety precautions ................................. 4

2 TRANSPORTATION, RECEPTION AND

STORAGE........................................................ 4

3 INSTALLATION AND USE .............................. 4

3.1 Valve insulation......................................6

4 MAINTENANCE............................................... 6

4.1 General ..................................................6

4.2 Changing the gland packing,

A-construction ........................................6

4.3 Changing the gland packing,

H-construction........................................8

4.4 Changing the gasket of the gland packing... 8

4.5 Changing the bearing,

A-construction and H-construction.........8

4.6 Changing the ceramic parts ................... 8

4.7 Detaching and installing the actuator..... 9

5 MALFUNCTION ............................................. 10

6 TOOLS NEEDED ........................................... 10

7 ORDERING SPARE PARTS ......................... 10

8 EXPLODED VIEWS AND PARTS LIST ........ 11

9 DIMENSIONS AND WEIGHTS ...................... 12

10 TYPE CODE................................................... 15

READ THESE INSTRUCTIONS FIRST!

These instructions provide information needed for safe handling and operation of the valve.

If you require additional assistance, please contact the manufacturer or manufacturer’s representa tive.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

1 E2 70 en 3

1 GENERAL

1.1 Valve description

The E2 ceramic ball valve is a flangeless (wafer type),

and E6 is a single flange (lug type) reduced-bore valve

specially designed for control of erosive media.

The body and shaft are metal, while the trim is ceramic.

There are no separate ball seats; instead, the seating

surfaces are directly ground into the ceramic bushings.

The insert retaining ceramic parts is attached to the

body with threaded joint. The flow medium comes into

contact with the metallic valve body. Note this when the

valve is used for aggressive media.

Rotation transmission between shaft and ball takes

place through a slot head. Axial bearings are located

outside the valve, under the actuator mounting piece.

The valve is usually equipped with an actuator. (For

details, see type-specific instructions.

1.2 Valve markings

The markings stamped on the body indicate the

❑ body material

❑ nominal size

❑ pressure rating

The valve also has an identification plate, the type of

which depends upon the size of the valve. See Figure 1.

1.3 Technical data

Face-to-face length: IEC 534-3-2 / ISA S75.04

Body pressure rating: ASME Class 300

Max. diff. pressure/ temperature:

in control applications

ASME Class 150

in shut-off applications

ASME Class 300,

see Figure 2

For NPS 8/DN 200 the maximum

differential pressure is limited

to 20 bar.

Max. oper. temp.: A-construction: +200 °C (+392 °F)

H-construction: +450 °C (+842 °F)

Direction of flow: insert on upstream side

Characteristic curve: equal percentage

Tightness class: 10 x ISO 5208 Rate D

Media: not for inflammable media

Dimensions: see Section 9

Weights: see Section 9

Temperature °F

900 1000

110 0

100 200 300 400 500 600 700 800

bar

100

80

60

50

40

30

20

10

8

6

5

4

3

2

CF8M Class 150

CF8M Class 300

1200

1300

1400

psi

1500

1200

900

700

600

500

300

150

120

90

70

60

50

30

Fig. 1 Alternatives for identification plate

The different sections of the identification plate give the

following informations:

1. body material

2. trim material

3. shaft material

4. seat material

5. highest operating temperature

6. lowest operating temperature

7. maximum shut-off pressure differential

8. type designation

9. number in manufacturer’s list

10. pressure class

The type designation is defined in the type code, see

Section 10.

1.0

100 200 300 400 500 600 700 800

0

Temperature °C

Fig. 2 Pressure-temperature diagram

1.4 CE marking

The valve meets the requirements of the European

Directive 97/23/EC relating to pressure equipment, and

has been marked according to the Directive.

1.5 Recycling and disposal

Most valve parts can be recycled if sorted according to

material. Most parts have material marking. A material

list is supplied with the valve. In addition, separate

recycling and disposal instructions are available from

the manufacturer. A valve can also be returned to the

manufacturer for recycling and disposal against a fee.

4 1 E2 70 en

1.6 Safety precautions

CAUTION:

Due to the nature of ceramic material used in valve internals, the valve might cause an ignition of explosive gas

mixtures. Valve internals, when operating against each

other may cause sufficient heat to ignite the gaseous mixture inside the valve. Therefore the safe use of the valve

must be assessed when used in potentially explosive and

flammable applications. According to the Hazard Analysis

the valve is not creating an ignition risk to its environment

outside the valve. For further information, please contact

Metso’s Automation business.

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations marked on the valve body may

cause damage and lead to uncontrolled pressure

release.

Damage or personal injury may result.

CAUTION:

Do not dismantle the valve or remove it from the

pipeline if the valve is pressurized!

Damage or personal injury may result. Dismantling a

pressurized valve will cause uncontrolled pressure

release. Always isolate the required part of the pipeline,

release the pressure from the valve and remove the

medium before dismantling the valve. Be aware of the

medium type. Protect people and equipment in the area

from any harmful or poisonous medium. If the valve is

actuator operated, close and detach the actuator pressure supply pipeline.

CAUTION:

Be aware of the ball cutting movement!

When the valve is actuated, the ball functions as a cutting device.

Do not stick your hand or other body parts into the open

flow port. Prevent foreign objects from being left inside

the pipeline. If the valve is actuator operated, close and

detach the actuator pressure supply pipeline.

CAUTION:

Be aware of noise emission!

Depending on the application the valve may cause noise

emission during use. The noise level can be measured

with equipment designed for this purpose or by using

the Metso Nelprof software. Pay attention to work environment legislation concerning noise emission.

CAUTION:

Be aware of extreme temperatures!

During use the valve body may be very cold or very

hot. If extreme temperatures occur, protect people

from frost injuries or burns.

NOTE:

Do not drop, knock or hit the valve!

Internal parts of the valve are made of ceramic material.

Although the material is robust, it will not tolerate impact

as metals do.

NOTE:

Media which may solidify should not be allowed to stand

in the ball valve. Wash such media from the valve using a

suitable arrangement. Cycle a valve few times when

washing.

2 TRANSPORTATION, RECEPTION

AND STORAGE

Valves are delivered in the usual Metso packaging,

unless otherwise agreed with the customer.

Make sure that the valve and any possible accessories

have not been damaged during transport.

Do not remove the bore protectors before installation.

Store the valve with care, preferably indoors and in a

dry environment.

Take the valve to the installation site only just before

installation.

Fig. 3 Storage of the valve

NOTE:

Ceramic valves must be handled with particular care.

3 INSTALLATION AND USE

Remove the bore protectors and check that the valve is

clean. Also ensure that the pipeline is clean.

The pipeline must be firmly supported so that the valve

is not subjected to additional strain.

The valves can be installed between the following

flanges:

❑ EN PN 10, 16, 25, 40

❑ ASME 150, 300

❑ ISO 7005 PN 20, PN 50

❑ JIS 10 K, 16 K, 20 K, 30 K

In some valve sizes the body of the valve has thread fillets for the two flange screws located closest to the shaft.

Size NPS 8 / DN 200 has thread fillets for all flange

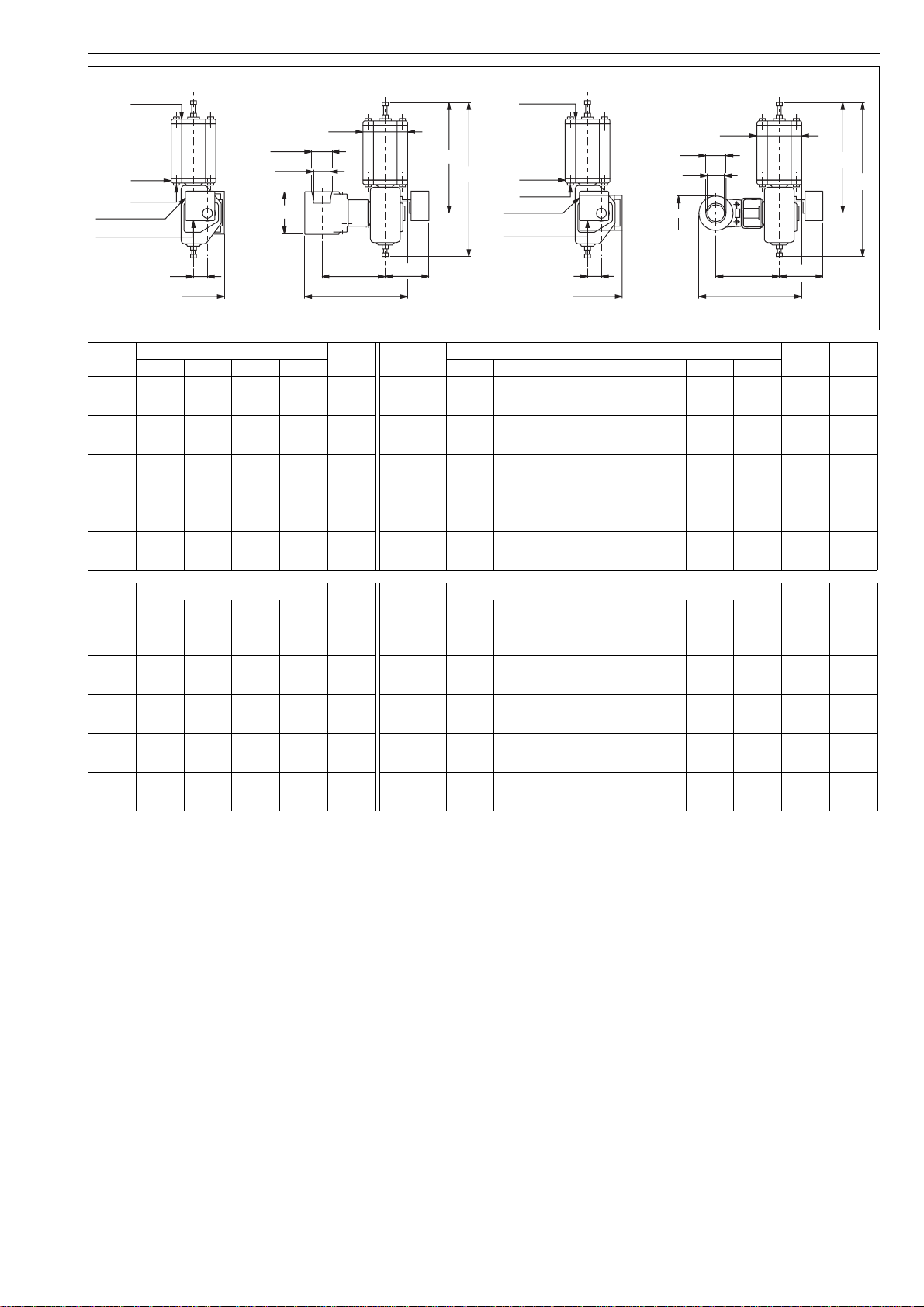

screws. See Figure 4 and Tables 1 to 3. All other dimensions are shown in Section 9.

The valve is tight in both directions and may be

installed in any position. It must not, however, be

installed in such a way that the actuator is below the

valve (see Figure 5).

The actuator must not come into contact with the pipeline, as vibrations in the pipeline might damage the

actuator and its performance.

1 E2 70 en 5

S

R

Lmin.

A

S

Lmin.

R

TYPE E2

S

R

Lmin.

S

R

Lmin.

A

TYPE E6

Fig. 4 Flange drilling / neck bolting

Table 1 Flange drilling / neck bolting, dimensions in mm. ASME 150 / ISO 7005 PN 20. ASME 300 / ISO 7005 PN 50

ASME 150 / ISO 7005 PN 20 ASME 300 / ISO 7005 PN 50

TYPE

E2_025/E2_01 102 4 - - - - 4 - - - -

E2_040/E2_1H 114 4 - - - - 4 - - - -

E2_050/E2_02 124 4 - - - - 8 2 5/8" UNC / M16 17.0 70

E2_080/E2_03 165 4 - - - - 8 2 3/4" UNC / M20 20.0 85

E2_100/E2_04 194 8 2 5/8" UNC / M16 17.0 75 8 2 3/4" UNC / M20 20.0 90

E6_025/E6_01 102 4 - 1/2" UNC / M12 - - 4 - 5/8" UNC / M16 - -

E6_040/E6_1H 114 4 - 1/2" UNC / M12 - - 4 - 3/4" UNC / M20 - -

E6_050/E6_02 124 4 - 5/8" UNC / M16 - - 8 2 5/8" UNC / M16 28.5 75

E6_080/E6_03 165 4 - 5/8" UNC / M16 - - 8 2 3/4" UNC / M20 28.5 85

E6_100/E6_04 194 8 2 5/8" UNC / M16 29.5 80 8 2 3/4" UNC / M20 29.5 90

E6_150/E6_06 229 8 2 3/4" UNC / M20 28.5 80 12 2 3/4" UNC / M20 28.5 95

E6_200/E6_08 243 8 8 3/4" UNC / M20 28.5 80 12 12 7/8" UNC / M24 28.5 95

*) total number / flange

**) number of neck bolts / flange

Face-to-face A

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Table 2 Flange drilling / neck bolting, dimensions in mm. EN PN 10, 16, 25, 40

EN PN 10 EN PN 16 EN PN 25 EN PN 40

TYPE

E2_025/E2_01 102 4 - - - - 4 - - - - 4 - - - - 4 ----

E2_040/E2_1H 114 4 - - - - 4 - - - - 4 - - - - 4 ----

E2_050/E2_021244----4----4----4----

E2_080/E2_03 165 8 2 M16 17.0 65 8 2 M16 17.0 65 8 2 M16 17.0 70 8 2 M16 17.0 70

E2_100/E2_04 194 8 2 M16 17.0 65 8 2 M16 17.0 65 8 2 M20 20.0 75 8 2 M20 20.0 75

E6_025/E6_01 102 4 - M12 - - 4 - M12 - - 4 - M12 - - 4 - M12 - -

E6_040/E6_1H 114 4 - M16 - - 4 - M16 - - 4 - M16 - - 4 - M16 - -

E6_050/E6_02 124 4 - M16 - - 4 - M16 - - 4 - M16 - - 4 - M16 - -

E6_080/E6_03 165 8 2 M16 28.5 70 8 2 M16 28.5 70 8 2 M16 28.5 75 8 2 M16 28.5 75

E6_100/E6_04 194 8 2 M16 29.5 70 8 2 M16 29.5 70 8 2 M20 29.5 80 8 2 M20 29.5 80

E6_150/E6_06 229 8 2 M20 28.5 75 8 2 M20 28.5 75 8 2 M24 28.5 85 8 2 M24 28.5 85

E6_200/E6_08 243 8 8 M20 28.5 75 12 12 M20 28.5 75 12 12 M24 28.5 85 12 12 M27 28.5 85

*) total number / flange

**) number of neck bolts / flange

Face-to-face A

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

6 1 E2 70 en

Table 3 Flange drilling / neck bolting, dimensions in mm. JIS 16 K, 20 K, 30 K

JIS 10 K JIS 16 K - 20 K JIS 30 K

TYPE

E2_025/E2_011024----4----4- --

E2_040/E2_1H 114 4 - - - - 4 - - - - 4 - - - -

E2_050/E2_02 124 4 - - - - 8 2 M16 17.0 65 8 2 M16 17.0 70

E2_080/E2_03 165 8 2 M16 17.0 65 8 2 M20 20.0 75 8 2 M20 20.0 80

E2_100/E2_04 194 8 2 M16 17.0 65 8 2 M20 20.0 75 8 2 M22 22.0 90

E6_025/E6_01 102 4 - M16 - - 4 - M16 - - 4 - M16 - -

E6_040/E6_1H 114 4 - M16 - - 4 - M16 - - 4 - M20 - -

E6_050/E6_02 124 4 - M16 - - 8 2 M16 28.5 70 8 2 M16 28.5 70

E6_080/E6_03 165 8 2 M16 28.5 70 8 2 M20 28.5 75 8 2 M20 28.5 80

E6_100/E6_04 194 8 2 M16 29.5 70 8 2 M20 29.5 80 8 2 M22 29.5 90

E6_150/E6_06 229 8 2 M20 28.5 75 12 2 M22 28.5 85 12 2 M24 28.5 95

E6_200/E6_08 243 12 12 M20 28.5 75 12 12 M22 28.5 85 12 12 M24 28.5 95

*) total number / flange

**) number of neck bolts / flange

Face-to-face A

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

Number of flange bolts *)

Number of neck bolts **)

Bolt size R

Depth of neck bolt drilling S

Length of neck bolts Lmin

3.1 Valve insulation

If necessary, the valve may be insulated. Insulation

must not continue above the upper level of the valve

body, see Figure 6.

Insulation limit

Fig. 5 Avoid this mounting position

To facilitate easy maintenance, the actuator should be

installed in such a way that there is plenty of room for

removing it.

The screws, nuts and washers used should be equivalent to the fastenings used elsewhere in the pipeline.

Pay particular attention when centring the flange gasket.

The inside diameter of the gasket should be acc. to the

nominal size of the valve, i.e. the gasket covers the insert (6)

and the rim of the ceramic bushing (3).

NOTE:

An eccentric flange gasket may cause premature body

wear, par ticularly with media containing particles.

The pipeline should be flushed carefully before use.

The valve should be kept entirely open during flushing.

Fig. 6 Insulation of the valve

4 MAINTENANCE

CAUTION:

Observe the safety precautions mentioned in 1.6

before you start work!

4.1 General

The valve does not require regular maintenance. Its operation should, however, be checked at regular intervals.

The end use may carry out the following maintenance

tasks himself.

4.2 Changing the gland packing,

A-construction

The component numbers given in brackets refer to the

diagram and component list given in Section 8.1. See

also Figure 7.

1 E2 70 en 7

4.2.1 Disassembly

CAUTION:

Do not detach or disassemble a pressurized valve!

This warning also applies to individual components (13).

1. Detach the air supply conduit from the actuator. Also

detach any cables preventing the removal of the actuator.

2. Remove the actuator from the bracket (5) by

unscrewing the fixing screws. Pull the actuator from

the shaft (4). Detaching the actuator is described in

more detail in Section 4.7.1.

3. Detach the key (20) from the shaft.

4. Detach the bracket (5) from the body (1) by opening

the screws (13) M12 or M16.

5. Detach the bearing (8), the axial bearing (7) and the

lock ring (19).

6. Loosen the strain ring (9) with a special tool, see

Table 4.

7. Pull the shaft (4), and lift it and gland bushing (10)

and parts (11, 12, 17) out of the valve body.

8. Pull the gland bushing off the shaft while rotating.

Now the gland packing may be disassembled.

9. Remove the gasket (16) between the gland bushing

and the body from the valve body.

4.2.2 Replacing parts

The gland packing set includes the V-ring set (11) and

the spring (12). Replace both parts at the same time.

NOTE:

Replace the gasket (16) between the gland bushing (10)

and the body (1) whenever the strain ring has been loosened. Leakage of the V-ring set (11) and leakage of the

gasket (16) may cause similar symptoms.

The O-ring (17) should be replaced if it is damaged.

The main purpose of the O-ring is to protect the shaft

from erosive media, such as sludge, and it therefore

does not need to be changed regularly.

4.2.3 Assembly

1. Apply silicon grease to the O-ring (17) and install it

into the gland bushing (10) cavity.

NOTE:

Make sure you do not damage the O-ring with the shaft

keyway and the shaft shoulder.

2. Slip the gland bushing (10) onto the shaft (4).

3. Install the spring (12) into the bottom of the gland

bushing (10). Before installation, the spiral should

be completely compressed once, for example in a

vice. This will make installation of the strain ring easier, since the working height of the spiral is roughly

0.6 x the free height of the spring.

4. Once the spiral is in place, slip the sheet ring (15)

into position. After this, install the V-ring (11) onto the

shaft, one by one.

NOTE:

Make sure you do not damage the gland packing rings

with the shaft keyway or shaft shoulder.

The order from bottom to top of the different rings is as

follows:

❑ base ring

❑ angle rings

❑ saddle ring

5. Place the gasket (16) into the valve body.

6. Insert the shaft together with the gland bushing

back into the valve body.

7. The shaft joint on the ball has been shaped in such

a way that the shaft only fits seat when it is in the

correct position. Check the direction of the bore by

observing the indicator line at the top of the shaft,

and take the position of the keyway into account

when you install the actuator.

8. Lubricate the thread of the strain ring with, for example, Molykote. Then fasten the strain ring (9). When

correctly fastened, the ring shoulder must be at least

on a level with the body, or 0.1 mm below it. The tightening torques are given in Table 4. The shoulder of the

strain ring must not remain above the surface level of

the body.

Table 4 Tightening torques of strain ring

Nominal

size

DN

25/20 M39 x 1.5 190 34-36 F14096_01

40/32 M45 x 1.5 250 40-42 F14096_1H

50/40 M50 x 2 320 45-50 F14096_02

80/65 M64 x 2 340 58-62 F14096_03

100/80 M75 x 2 560 68-75 F14096_04

150/100 M95 x 2 1330 80-90 F14096_06

200 M95 x 2 1330 80-90 F14096_06

Thread

Torque

Nm

Tool

DIN 1810A

Special

tool

9. Make sure that the bracket (5) is not carrying the

weight of the valve because this would have an

immediate effect on the bearing clearance.

10.Install the lock ring (19), the axial bearing (7) and

the bearing (8) onto the shaft.

11.Attach the bracket to the valve body. While fastening

the screws, make sure that the hole in the bracket is

properly centered in relation to the shaft. For the

correct tightening torques, see Table 5.

12.Install the actuator. See Section 4.7.2.

0...0,1 mm bellow the

top level of the bracket

sheet ring

(15)

spring

(12)

gland

bushing

(10)

gasket (16)shaft (4)

bracket (5)

strain ring

(9)

saddle ring

(11)

angle ring

(11)

base rings

(11)

O-ring

(17)

Fig. 7 Sealing of the shaft, A-construction

8 1 E2 70 en

Table 5 Tightening torques of bracket screws

Nominal size

DN

25/20, 40/32, 50/40 M12 80 19

80/65, 100/80, 150/100, 200 M16 190 24

Thread

Torque

Nm

Tool size

4.3 Changing the gland packing,

H-construction

CAUTION:

Do not detach or disassemble a pressurized valve!

This warning also applies to individual components (13).

The part numbers in this section refer to the diagram

and part list in Section 8.2 .

1. Unfasten the nuts (24) of the gland (22) and lift up

the gland.

2. Remove the old packing rings (11) by using, for

example, a sharp pricker.

3. Install the new packing rings.

4. Place the nuts on the studs and tighten the gland

packings while the valve is not pressurized, see

Table 6.

5. Retighten if necessary.

Table 6 Tightening torques of gland nuts

Nominal size

DN

25 M12 40 19

40 M12 50 19

50 M12 80 19

80 M16 55 24

100 M16 90 24

150, 200 M16 105 24

Thread

Torque

Nm

Tool size

4.4 Changing the gasket of the gland

packing

In an H-construction valve, changing the gland packing

does not require unfastening the strain ring, and this

does not entail changing the gasket (16).

When the gasket (16) needs to be changed, this can be done

by following the same instructions that were given for the Aconstruction. Note that there is no O-ring in the H-construction.

4.5 Changing the bearing,

A-construction and H-construction

1. Detach the actuator from the bracket, see Section

4.7.1.

2. Detach the bracket (5) from the valve body (1) by

unscrewing fixing screws (13) M12 or M16 and

detach the key from the shaft.

3. Detach and change the bearing (8).

4. Attach the bracket to the valve, see Table 5.

5. Install the actuator, see Section 4.7.2.

4.6 Changing the ceramic parts

Changing the ceramic parts, ball (2) and bushings (3)

requires special tools. It is highly recommended that

this work is done by the Metso service organisation.

4.6.1 Disassembly

1. Detach the actuator from the valve, see Section

4.7.1.

2. Detach the key (20), fixing screws (13), bracket (5),

axial bearing (7), bearing (8) and lock ring (19).

3. Fasten the valve firmly into a vice the insert (6) pointing upwards.

4. Fasten the special tool, Table 7, to the insert and

turn it open without removing it.

5. Remove the strain ring (9) with a special tool,

Table 4. See also Sections 4.2.1, 4.3 and 4.4.

6. Pull the shaft (4) with gland bushing (10) out of the

body.

7. Remove the insert (6) and detach the ceramic parts,

bushing (3), ball (2) and bushing (3), from the body.

8. Remove the gasket (25) between the insert and

body (8"/DN 200 only).

NOTE:

Replace the gasket (25) between the insert (6) and the

body (1) whenever the insert has been loosened.

4.6.2 Assembly

1. Apply Molykote 312R lubricant to the threads of the

insert (6).

2. Turn the insert into metal-to-metal contact with the

body (without ceramic parts) and draw a mark with

a felt tip pen to the body and insert seam.

3. Remove the insert.

4. Install the sheet rings (14) on the bushings (3).

5. Place the ball (2) between the bushings (3).

6. Push the ceramic parts as a package into the body.

Please note the position of the shaft slot.

7. Install the gasket (25) on the body (1) (8"/DN 200 only).

8. Turn the insert (6) lightly into the body.

9. Push a assembly guide tool, Table 7, through the

gland bore into the slot of the ball. Make sure that

the tool is properly engaged with the ball. The tool

will keep the bushings (3) in place during the tightening of the insert (6).

Table 7 Assembly guide tool

Nominal size Tool

1" / DN 25 280139

1.5" / DN 40 280140

2" / DN 50 280141

3" / DN 80 280142

4" / DN 100 280143

6" / DN 150 280529

8" / DN 200 F33977

10.Fasten the valve firmly into a vice the insert (6) pointing

upwards and tighten the insert evenly using a special

tool 1...2 mm past the mark made earlier. See Table 8.

1 E2 70 en 9

Table 8 Tightening torques of insert

Nominal size

DN

25/20 M52 x 1,5 60 C279922

40/32 M70 x 2 120 C279921

50/40 M85 x 2 240 C279921

80/65 M115 x 2 440 C279920

100/80 M140 x 2 770 C279920

150/100 M200 x 3 1450 F05016

200 M250 x 3 2000 F33976

*) Graphite lubricant applied to the threads

Thread

Max. torque

Nm *

Tool

11.Remove the assembly guide tool from the gland

bore and mount the shaft (4). See Sections 4.2.3,

4.3 and 4.4 for details of gland packing assembly.

Tighten the strain ring (9) according to Table 4.

4.7 Detaching and installing the actuator

4.7.1 Detaching from the valve

1. Detach the air supply tube from the actuator. Also detach

any cables preventing the removal of the actuator.

2. Detach the actuator from the bracket (5) by

unscrewing the fixing screws.

3. Pull the actuator off the shaft by using a special extraction tool, Figure 8. Prevent the shaft from pressing the

ceramic ball when removing, e.g. by gripping the shaft

with self-locking pliers (don’t damage the shaft) .

NOTE:

Make a note of the mutual position of the valve and the

actuator. This will enable you to keep the operating direction unchanged during reassembly. Also make a note of

the position of the actuator (valve open/closed).

4.7.2 Installation onto the valve

Clean the shaft boring of the actuator. Lubricate the

shaft boring and the valve shaft with, for example,

Cortec® VCI 369 anticorrosive agent.

The installation position of the actuator is determined as

follows:

❑ The B1C-actuator is installed in such a way that

the piston is in the extreme outward position

when the valve is closed.

❑ The B1J/B1JA-actuator is installed in one of two

positions, depending on the function required

(spring opens/spring closes).

❑ The actuator mounted the valve before is

installed in the same position.

❑ Carefully insert the actuator over the valve shaft

and make sure the shaft does not press the

ceramic ball, use e.g. self-locking pliers (don’t

damage the shaft).

NOTE:

Do not strike at the actuator during installation because

this might damage the ceramic parts.

❑ Make sure that the actuator is straight in relation

to the valve.

❑ Insert and tighten the fixing screws.

❑ Check to see that the limiter screws of the open

and closed position are properly adjusted.

NOTE:

The actuator has an arrow indicating the flow direction.

Make sure that this arrow is in the correct position in relation

to the bore.

NOTE:

The position of the ball is indicated by means of a groove at

the top of the shaft, which shows the direction of the bore.

Fig. 8 Removal of the actuator with an extractor

More information concerning the actuator is available in

the installation, operation and maintenance instructions

given for the model in question.

10 1 E2 70 en

5 MALFUNCTION

Table 9 shows malfunctions that might appear after prolonged use.

Table 9 Malfunctions

Symptom Possible fault Recommended action

Valve can not be opened/closed Impurities on the ball surface Clean the ball surface mechanically

through the flow ports

Leakage at the base of the shaft Gland packing leaks Check tightening of the strain ring/gland.

Change the gland packing, if needed

Gasket (16) leaks Check tightening of the strain ring.

Change the gasket, if needed

Valve is not tight Excessive wearing Contact manufacturer

Shaft presses ceramic parts Pull the shaft up

6 TOOLS NEEDED

In addition to the usual standard tools, the following

special tools are needed:

❑ Unfastening/tightening the strain ring:

- special tool, see Table 4

❑ Removing the actuator:

- extraction tool 303821 (BC 6)

- extraction tool H797 (BC/BJ 8-10)

- extraction tool H798 (BC/BJ 12-16)

❑ Unfastening/tightening the insert:

- special tool, see Table 7

❑ Assembling the ceramic parts:

- assembly guide, see Table 8

The special tools are available from the manufacturer.

7 ORDERING SPARE PARTS

When ordering spare parts, always include the following information:

❑ type code, sales order number, serial number

(stamped on a valve body)

❑ number of the parts list, part number, name of

the part and quantity required

This information can be found from the identification

plate or documents.

1 E2 70 en 11

8 EXPLODED VIEWS AND PARTS LIST

A-construction H-construction

Item Qty Description Spare part category

11Body

21Ball 3

3 2 Bushing 2

41Shaft 3

51Bracket

6 1 Insert

7 1 Axial bearing 3

81Bearing 1

9 1 Strain ring

10 1 Gland bushing

11 1 V-ring set 1

12 1 Spring (A-construction only)

13 4 Hexagon screw

14 2 Sheet ring 1

15 1 Sheet ring (A-construction only) 3

16 2 Gasket 1

17 1 O-ring (A-construction only) 1

19 1 Lock ring

20 1 Key

21 1 Identification plate

22 1 Gland (H-construction only)

23 2 Stud (H-construction only)

24 2 Hexagon nut (H-construction only)

25 1 Plate ring (8" / DN 200 only) 1

Spare part category 1: Recommended soft parts, always needed for the repair. Delivered as a set.

Spare part category 2: Parts for replacing of the seat. Delivered as a set.

Spare part category 3: Parts for replacing of the closing element.

Spares for the full overhaul: All parts from the categories 1, 2 and 3.

12 1 E2 70 en

9 DIMENSIONS AND WEIGHTS

Dimensions of

mounting level acc. to

ISO 5211

DN

P

O

øD

A

E2 DN25-100

Valve is in open position

Key acc. to ANSI B17.1

mounting level acc. to

M

R

( L )

øB

Dimensions of

ISO 5211

E

DN

øD

P

O

A

E6 DN25-200

Valve is in open position

Key acc. to ANSI B17.1

M

R

( L )

øB

E

Dimensions, mm

DN A

E2 E6

ø B ø B E2 E6

Eø DL O P R M

Mounting

face

Weight, kg

25 102 63.5 130 181 20 8 15 16.9 25 4.76 F07 5 7

40 114 82 160 186 32 8 20 22 35 4.76 F07 7 11

50 124 100 165 202 40 8 25 27.7 46 6.35 F07/F10 10 14

80 165 132 210 256 65 10 35 39 58 9.53 F12 19 27

100 194 157 254 282 80 10 40 44.5 68 9.53 F12/F14 30 45

150 229 - 325 363 100 12 55 60.5 90 12.7 F14 - 105

200 243 - 380 391 135 12 55 60.5 90 12.7 F16 - 330

Dimensions, inch

NPS A

E2 E6

Ø B Ø B E2 E6

EØ DL O P R M

Mounting

face

Weight, lb

1 4.02 2.50 5.12 7.13 0.79 0.31 0.59 0.67 0.98 3/16 F07 11 15

1 1/2 4.49 3.23 6.30 7.32 1.26 0.31 0.79 0.87 1.38 3/16 F07 15 24

2 4.88 3.94 6.50 7.95 1.57 0.31 0.98 1.09 1.81 1/4 F07/F10 22 31

3 6.50 5.20 8.27 10.08 2.56 0.39 1.38 1.54 2.28 3/8 F12 42 60

4 7.64 6.18 10.00 11.10 3.15 0.39 1.57 1.75 2.68 3/8 F12/F14 66 99

6 9.02 - 12.80 14.29 3.94 0.47 2.17 2.38 3.54 1/2 F14 - 231

8 9.57 - 14.96 15.39 5.31 0.47 2.17 2.38 3.54 1/2 F16 - 728

1 E2 70 en 13

I

NPT *) **)

NPT *)

NPT ***)

SUPPLY 1/4 NPT

SIGNAL PG 11

Valve

type

V

DN ø D A ø B F G H I J V X

MOUNTING POSITION A (STANDARD)

ØB

Dimensions, mm

X

DN

ØD

A

WeightkgActuator

E2 025 25 20 102 64 5

E2 040 40 32 114 82 7

E2 050 50 40 124 100 10

E2 080 80 65 165 132 19

E2 100 100 80 194 157 30

H

IJ

type

B1C 6/15

B1J 8/15

B1JA 8/15

B1C 6/20

B1J 8/20

B1JA 8/20

B1C 9/25

B1J 10/25

B1JA 8/25

B1C 13/35

B1J 12/35

B1JA 12/35

B1C 13/40

B1J 16/40

B1JA 16/40

NPT *) **)

G

F

NPT *)

NPT ***)

SUPPLY 1/4 NPT

SIGNAL PG 11

V

A

Dimensions, mm

400

560

560

400

560

560

455

650

560

635

800

800

635

990

990

260

420

420

260

420

420

315

490

420

445

620

620

445

760

760

290

314

314

295

319

319

320

359

333

432

452

452

461

521

521

220

215

215

220

215

215

215

220

215

230

235

235

230

250

250

MOUNTING POSITION B

DN

ØD

ØB

213

214

214

209

210

210

215

221

215

279

279

279

295

310

310

36

43

43

36

43

43

43

51

43

65

65

65

65

78

78

X

G

F

J

H

Weight

90

135

135

90

135

135

110

175

135

175

215

215

175

265

265

NPT

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

3/8*

1/2**

1/2***

3/8*

1/2**

1/2***

kg

22

22

11

24

24

20

40

27

50

76

76

61

130

130

9

Valve

type

E2 0 1 0.79 4.02 2.52 11

E2 1H 1 1/2 1.26 4.49 3.23 15

E2 02 2 1.57 4.88 3.94 22

E2 03 3 2.56 6.50 5.20 42

E2 04 4 3.15 7.64 6.18 66

Dimensions, inch

WeightlbActuator

Size ø D A ø B F G H I J V X

B1C 6/15

B1J 8/15

B1JA 8/15

B1C 6/20

B1J 8/20

B1JA 8/20

B1C 9/25

B1J 10/25

B1JA 8/25

B1C 13/35

B1J 12/35

B1JA 12/35

B1C 13/40

B1J 16/40

B1JA 16/40

See Tables 1 to 3 for flange bolting dimensions

type

15.75

22.05

22.05

15.75

22.05

22.05

17.91

25.59

22.05

25.00

31.50

31.50

25.00

38.98

38.98

10.24

16.54

16.54

10.24

16.54

16.54

12.40

19.29

16.54

17.52

24.41

24.41

17.52

29.92

29.92

Dimensions, inch

11.42

12.36

12.36

11.61

12.56

12.56

12.60

14.13

13.11

17.01

17.80

17.80

18.15

20.51

20.51

8.66

8.46

8.46

8.66

8.46

8.46

8.46

8.66

8.46

9.06

9.25

9.25

9.06

9.84

9.84

8.39

8.43

8.43

8.23

8.27

8.27

8.46

8.70

8.46

10.98

10.98

10.98

11.61

12.20

12.20

1.42

1.69

1.69

1.42

1.69

1.69

1.69

2.01

1.69

2.56

2.56

2.56

2.56

3.07

3.07

3.54

5.31

5.31

3.54

5.31

5.31

4.33

6.89

5.31

6.89

8.46

8.46

6.89

10.43

10.43

NPT

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

3/8*

1/2**

1/2***

3/8*

1/2**

1/2***

Weight

lb

20

48

48

24

53

53

44

88

59

110

167

167

134

286

286

14 1 E2 70 en

MOUNTING POSITION A (STANDARD)

ØB

Dimensions, mm

DN

X

ØD

A

WeightkgActuator

SUPPLY 1/4 NPT

SIGNAL PG 11

Val ve

type

NPT *) **)

NPT *)

NPT ***)

V

DN ø D A ø B F G H I J V X

E6 025 25 20 102 130 7

E6 040 40 32 114 160 11

E6 050 50 40 124 165 14

E6 080 80 65 165 210 27

E6 100 100 80 194 254 45

E6 150 150 100 229 325 105

E6 200 200 135 243 380 330

H

IJ

type

B1C 6/15

B1J 8/15

B1JA 8/15

B1C 6/20

B1J 8/20

B1JA 8/20

B1C 9/25

B1J 10/25

B1JA 8/25

B1C 13/35

B1J 12/35

B1JA 12/35

B1C 13/40

B1J 16/40

B1JA 16/40

B1C 20/55

B1J 20/55

B1JA 20/55

B1C 25/55

B1J 25/55

B1JA 25/55

NPT *) **)

G

F

NPT *)

NPT ***)

SUPPLY 1/4 NPT

SIGNAL PG 11

V

A

Dimensions, mm

400

560

560

400

560

560

455

650

560

635

800

800

635

990

990

840

1200

1200

1075

1490

1490

260

420

420

260

420

420

315

490

420

445

620

620

445

760

760

575

935

935

725

1140

1140

323

347

347

334

358

358

353

391

365

472

492

492

510

570

570

658

748

748

762

882

882

220

215

215

220

215

215

215

220

215

230

235

235

230

250

250

270

270

270

327

327

327

MOUNTING POSITION

DN

ØD

ØB

213

214

214

209

210

210

215

221

215

279

279

279

295

310

310

388

388

388

439

439

439

36

43

43

36

43

43

43

51

43

65

65

65

65

78

78

97

97

97

121

121

121

B

X

G

F

J

H

90

135

135

90

135

135

110

175

135

175

215

215

175

265

265

215

395

395

265

505

505

I

NPT

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

3/8*

1/2**

1/2***

3/8*

1/2**

1/2***

1/2*

3/4**

3/4***

1/2*

3/4**

3/4***

Weight

kg

11

24

24

15

28

28

24

44

31

58

84

84

76

145

145

178

280

280

461

680

680

Val ve

type

E6 01 1 0.79 4.02 5.12 15

E6 1H 1 1/2 1.26 4.49 6.30 24

E6 02 2 1.57 4.88 6.50 31

E6 03 3 2.56 6.50 8.27 59

E6 04 4 3.15 7.64 10.00 99

E6 06 6 3.94 9.02 12.80 231

E6 08 8 5.31 9.57 14.96 728

Dimensions, inch

WeightlbActuator

Size ø D A ø B F G H I J V X

B1C 6/15

B1J 8/15

B1JA 8/15

B1C 6/20

B1J 8/20

B1JA 8/20

B1C 9/25

B1J 10/25

B1JA 8/25

B1C 13/35

B1J 12/35

B1JA 12/35

B1C 13/40

B1J 16/40

B1JA 16/40

B1C 20/55

B1J 20/55

B1JA 20/55

B1C 25/55

B1J 25/55

B1JA 25/55

See Tables 1 to 3 for flange bolting dimensions

type

15.75

22.05

22.05

15.75

22.05

22.05

17.91

25.59

22.05

25.00

31.50

31.50

25.00

38.98

38.98

33.07

47.24

47.24

42.30

58.70

58.70

10.24

16.54

16.54

10.24

16.54

16.54

12.40

19.29

16.54

17.52

24.41

24.41

17.52

29.92

29.92

22.64

36.81

36.81

28.50

44.90

44.90

Dimensions, inch

12.72

13.66

13.66

13.15

14.09

14.09

13.90

15.39

14.37

18.58

19.37

19.37

20.08

22.44

22.44

25.91

29.45

29.45

29.98

34.70

34.70

10.63

10.63

10.63

12.87

12.87

12.87

8.66

8.46

8.46

8.66

8.46

8.46

8.46

8.66

8.46

9.06

9.25

9.25

9.06

9.84

9.84

8.39

8.43

8.43

8.23

8.27

8.27

8.46

8.70

8.46

10.98

10.98

10.98

11.61

12.20

12.20

15.28

15.28

15.28

17.28

17.28

17.28

1.42

1.69

1.69

1.42

1.69

1.69

1.69

2.01

1.69

2.56

2.56

2.56

2.56

3.07

3.07

3.82

3.82

3.82

4.76

4.76

4.76

3.54

5.31

5.31

3.54

5.31

5.31

4.33

6.89

5.31

6.89

8.46

8.46

6.89

10.43

10.43

8.46

15.55

15.55

10.43

19.88

19.88

NPT

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

1/4*

3/8**

3/8***

3/8*

1/2**

1/2***

3/8*

1/2**

1/2***

1/2*

3/4**

3/4***

1/2*

3/4**

3/4***

Weight

lb

24

53

53

33

62

62

53

97

68

128

185

185

167

319

319

392

616

616

1016

1499

1499

1 E2 70 en 15

10 TYPE CODE

CERAMIC BALL VALVE, series E2

1. 2. 3. 4. 5. 6. 7.

E2 L A 100 X Z

1. CV-VALUE OF THE VALVE DN 25

- Standard, without sign

C05- Maximum C

C15- Maximum C

2. SERIES / CHARACTERISTICS

End entry, wafer type, reduced bore,

E2

seat supported

E6 End entry, lug type, reduced bore, seat supported

3. PRESSURE RATING

C ASME Class 150

D ASME Class 300

J PN 10

K PN 16

L PN 25

M PN 40

R JIS 10K

S JIS 16K

T JIS 20K

X ISO PN 20

Z ISO PN 50

5

v

15

v

5.

01 1" 25 mm 25

1H 1 1/2" 40 mm 040

02 2" 50 mm 050

03 3" 80 mm 080

04 4" 100 mm 100

06* 6" 150 mm 150*

08* 8" 200 mm 200*

6.

X CF8M XM-19 A2-70 316SS

7.

Z

ASME EN and JIS

Body Shaft Screws Other

Zirkoniumoxide, PSZ

+450 °C

T

max

SIZE

METAL PARTS

CERAMIC PARTS

BALL + SEATS

*) E6 only

5.

4. CONSTRUCTION

A Standard, V-ring gland packing

High temperature (over +200 °C / +392 °F),

H

graphite gland packing (max. +450 °C)

16 1 E2 70 en

Metso Automation Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 3235 9700. Fax +55 15 3235 9748/49

Asia Pacific, 20 Kallang Avenue, Lobby B, #06-00, PICO Creative Centre, Singapore 339411, Singapore. Tel. +65 6511 1011. Fax +65 6250 0830

China, 19/F, the Exchange Beijing, No. 118, Jianguo Lu Yi, Chaoyang Dist, 100022 Beijing, China. Tel. +86-10-6566-6600. Fax +86-10-6566-2575

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

Loading...

Loading...