Metro Therm Microbooster PS, Microbooster P, Microbooster V, Microbooster VS User Manual

MICROBOOSTER HEAT PUMP

Manual

METRO Microbooster P

METRO Microbooster PS

METRO Microbooster V

METRO Microbooster VS

08:220-1809

2

3

TABLE OF CONTENTS

Introduction .....................................................................4

1. About the product ...............................................................4

2. Transport, Handling and Delivery .............................................13

3. Positioning ....................................................................15

4. Water Circuit ..................................................................17

5. Electric Connections ..........................................................22

6. Optimal operation .............................................................23

7. Control and Operation ........................................................25

8. Maintenance ..................................................................41

9. Disassembly & Decommissioning .............................................43

10. Troubleshooting ...............................................................44

11. Warranty ......................................................................46

12. Declaration of conformity ....................................................48

13. Product and installer information ............................................49

4

INTRODUCTION

The aim of this manual is to give information, instructions and warnings on the Microbooster Domestic Hot Water Heat Pump (MBHP). The manual is to be used by installers and plumbers as well as by end users, since it contains important safety

information. The manual is a part of the Microbooster heat pump and it is to be conserved with care, since it contains important installation and maintenance instructions that can be useful to assure a long lifetime and an efficient operation.

1. ABOUT THE PRODUCT

The product is a Microbooster heat pump that has been designed according to EU

directives. The product is intended for hot water production for domestic use or for

similar applications. The unit has been designed to be ready for installation.

1.1. Safety precautions

• The product must be installed, commissioned, and repaired only by qualified technicians. Incorrect installation can result in damages of properties and personal injuries.

• The unit must be disconnected from the power supply when the cover is off.

• The unit must not be used by children or by people with limited physical or mental

capacity.

• Children should be supervised to ensure that they do not play with the appliance.

• Cleaning and maintenance must not be done by children without supervision.

• Do not place flammable materials in contact or close to the unit.

• The water system should be installed as stated in the manual.

• When in service, the unit should not be placed in subzero temperature areas.

• When not in service, the unit can be placed in subzero temperature areas, but all the

water in the tank or in the condensate drain must be removed beforehand.

• Hot water can cause serious burns if directly connected to the taps. The installation

of a mixing valve is suggested.

• The unit should be used only for its specified purpose. The manufacturer is not liable

for any damages due to failure to observe this manual.

• Take all the possible precautions to avoid incidents.

• The product contains HFC-R134a.

5

1.2. Technical data

1.2.1. General

The unit is composed of a water tank, a refrigerant circuit, a cabinet and a display that

is connected to a control board. The main scope of the appliance is to heat water

stored in a tank.

1.2.2. Operation

The unit is programmed to start heating the water inside the tank when its temperature falls below a predetermined level. The unit stops when the water temperature

reaches a set point that can be regulated by the user. In general, the appliance is

designed to produce enough hot water to cover the need of a household of 4 persons

or more.

There are two main ways in which the unit can heat the water. These are determined by

the temperature of the heat source upon entry:

1) Internal coil operation (Heat source temperature > Domestic hot water tempera-

ture)

This mode of operation only applies to models with internal coil. If the heat source has

a temperature above the domestic hot water temperature upon entry, it can be used

to pre-heat the water in the tank. This is done by directing the heat source through an

internal coil in the water tank, thereby transferring heat from the heat source to the

domestic water. The cooled heat source is then sent through the refrigerant cycle (as

seen in paragraph 1.2.3). Using the heat source to pre-heat the domestic water boosts

the efficiency of the heat pump.

2) Heat pump operation (Heat source temperature < Domestic hot water temperature)

When the heat source enters the unit at a temperature below the domestic hot water

temperature, only the heat pump operation is used. In the operation with heat pump, a

refrigerant cycle utilizes the operation of a compressor and a heat source at low temperature to heat the water in the tank to a higher temperature level.

6

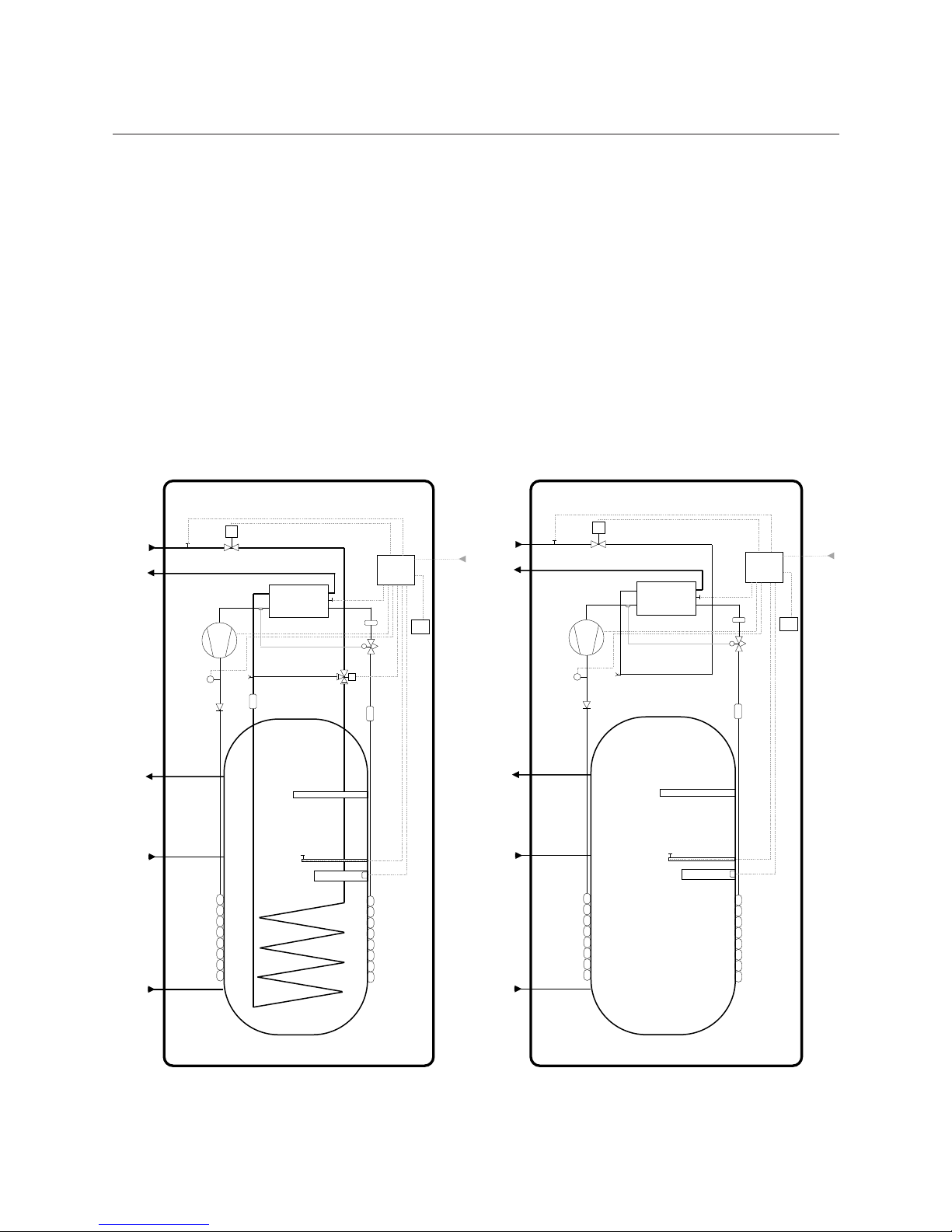

1.2.3. Refrigerant circuit

As depicted in Figure 1 and 2, the heat pump cycle can be divided in four main processes: compression (1-2), condensation (2-3), expansion (3-4), evaporation (4-1)

described below:

• At the suction of the compressor (1) the superheated refrigerant gas enters the

compressor at low pressure.

• In the compressor, the refrigerant is compressed to a higher pressure and temperature level (2).

• The refrigerant is cooled and condensed in the condenser exchanging heat with the

water stored in the tank.

• The refrigerant exits the condenser in a subcooled, liquid form (3)

• Through a thermostatic expansion valve the pressure of the refrigerant is lowered

to allow its evaporation at lower temperatures (4).

• The refrigerant is evaporated in the flat plate heat exchanger that uses a liquid as

heat source (1).

• The process goes on until the power supply to the compressor is stopped.

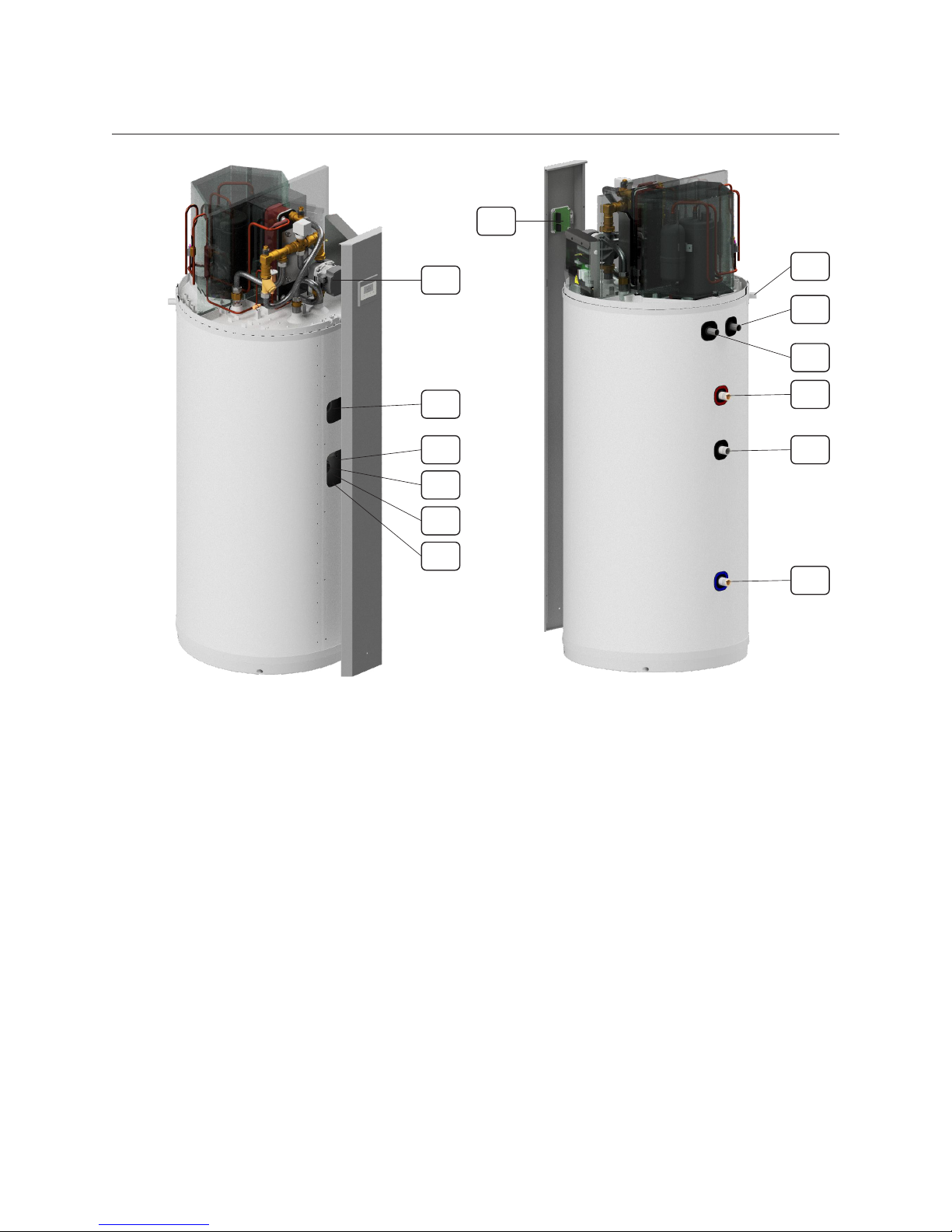

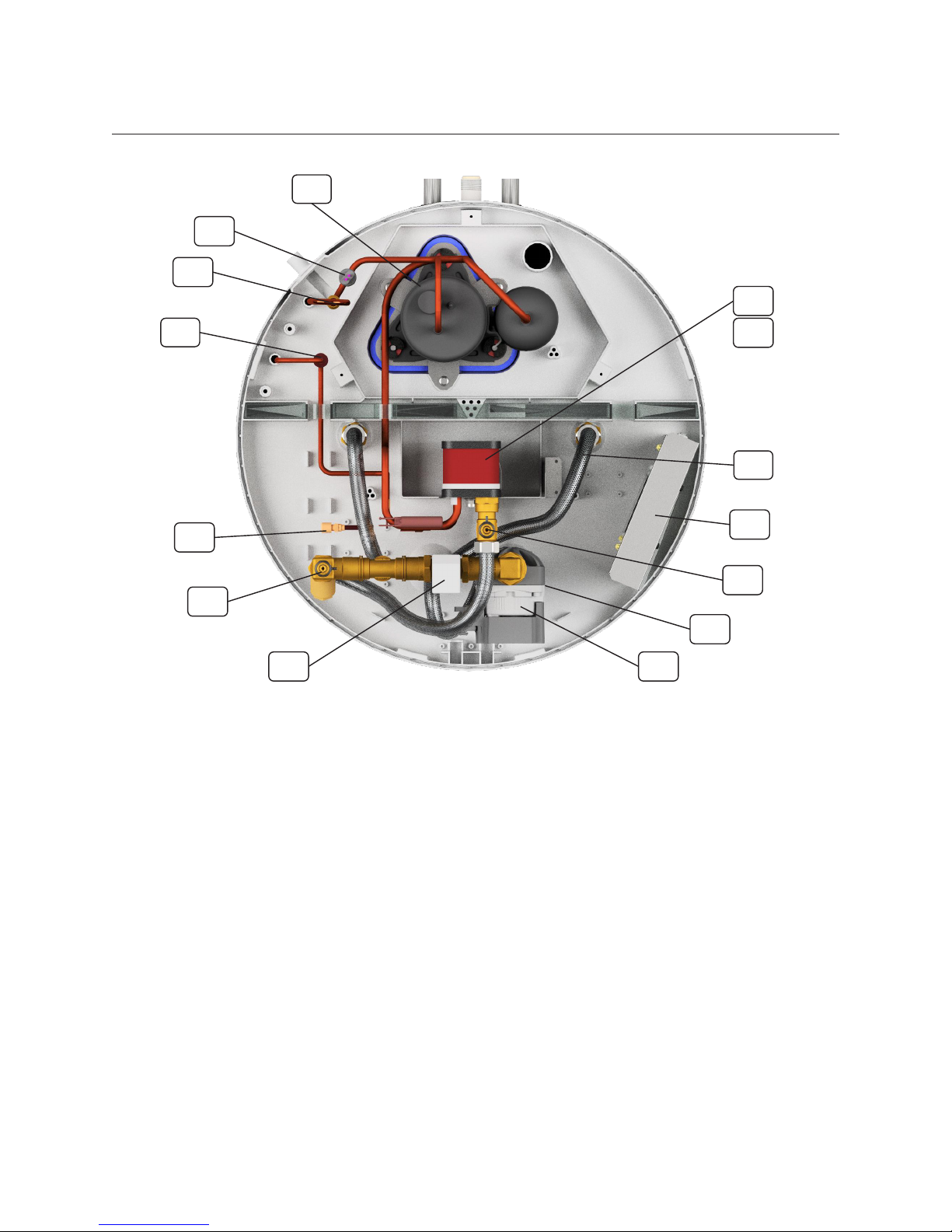

A deeper description of the refrigerant circuit and all components used for its design

can be found in Figure 3, 4 and 5.

3 2

14

• Gas

• Low Temperature

• Low Pressure

• Gas

• High Temperature

• High Pressure

1

23

4

Figure 1 – Heat pump principle Figure 2 – Pressure-Enthalpy diagram

7

Figure 3 – Process and Instrumentation Diagram with coil (left) and without coil (right)

½

M

AA1

AA2

GP1

EP1

GQ1

BP1

RM1

XL2

QN1

BT2

BT1

BT3

EB1

WG1

XL1

XL3

XL4

EP2

HZ1

QN2

XL6

XL5

FR1

FN1

c

½

M

AA1

AA2

GP1

EP1

GQ1

BP1

RM1

XL2

GQ2

QN1

BT2

BT1

BT3

EB1

XL1

XL3

XL4

EP3

EP2

HZ1

HZ2

QN2

XL6

XL5

FR1

FN1

c

WG1

½

M

AA1

AA2

GP1

EP1

GQ1

BP1

RM1

XL2

QN1

BT2

BT1

BT3

EB1

WG1

XL1

XL3

XL4

EP2

HZ1

QN2

XL6

XL5

FR1

FN1

c

1.2.4. Safety instructions – Refrigerant circuit

• Only skilled and trained technicians shall carry out repair and service of the heat

pump circuit.

• Before opening the refrigerant circuit, discharge the heat source to a level that

allows safe working conditions.

• Special attention should be given if the maintenance of the unit is carried out with

an open flame.

1.2.5. Process and Instrumentation Diagram

8

Refrigerant circuit

GQ1: Compressor

RM1: Check valve

EP1: Evaporator

EP2: Condenser

HZ1: Filter drier

QN2: Thermostatic

expansion valve

XL7: Service valve

Water circuit

XL1: Water inlet

XL2: Water outlet

XL3: Heat source inlet

XL4: Heat source outlet

XL5: Water recirculation

XL6: Condensate outlet

EP3*: Coil

EB1: Electric heater

FR1: Anode

GQ2*: Three-way valve

QN2: Air vent

HZ2*: Strainer

FN1: Thermal protection

Figure 4 – Design of the refrigerant circuit and the main components

XL2

XL4

XL3

XL1

XL5

XL6

BT3

EB1

FR1

FN1

AA2

GP1

EP2

9

GQ1

EP1

HZ1

QN2

HZ2

AA1

BT2

BT1

XL7

GP1GQ2

RM1

EP3

GP1

Sensors

BT1: Heat source inlet temperature

BT2: Heat source outlet temperature

BT3: Tank water temperature

BP1: High pressure switch

Electric components

AA1: Main printed circuit board

AA2: Display circuit board

GC1: Solar (PV) 0-10V (fig. 13)

QA1: SG-ready port (fig. 13)

GP1: Pump OR

flow control valve

The items with * are only found on models

with internal coil.

Nomenclature according to standard

IEC 81346-1 and 81346-2.

Figure 5 – Design of tank, condenser and related components

10

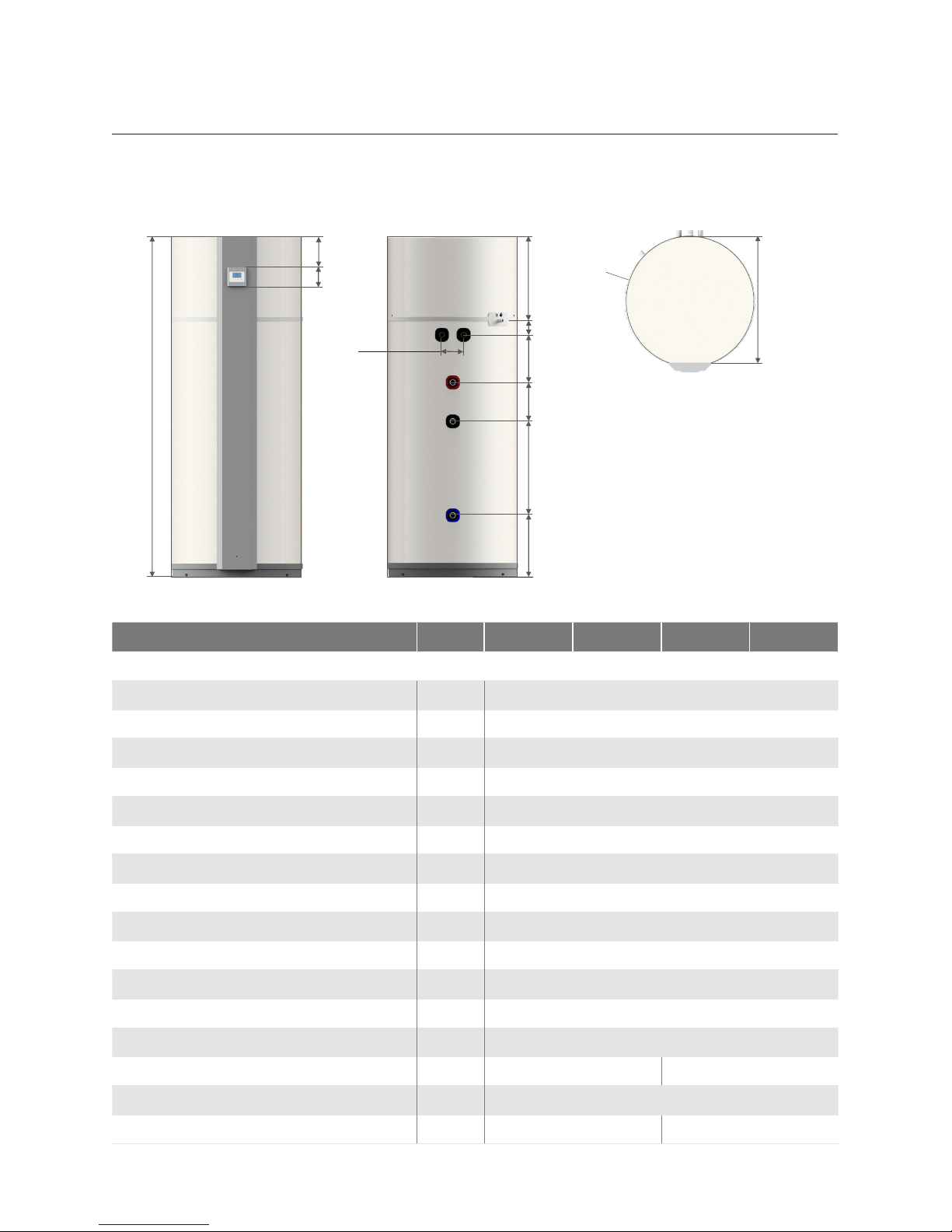

1.2.6. Main Technical Data

The main technical data are collected in the following figures and table.

A

B

C

D1

E

D3

D2

I

H

F

G

D4

Figure 6 – Dimensional data

Parameter Unit P V PS VS

Dimensional data

A – Height mm 1570

B mm 385

C mm 65

D1 mm 220

D2 mm 180

D3 mm 435

D4 mm 100

E mm 285

F mm 140

G mm 86

H - Diameter mm Ø603

I - Max diameter mm Ø620

Height required for installation mm 1730

Weight (dry) kg 98 104

Nominal insulation thickness mm 50

Nominal volume, storage tank l 190 180

11

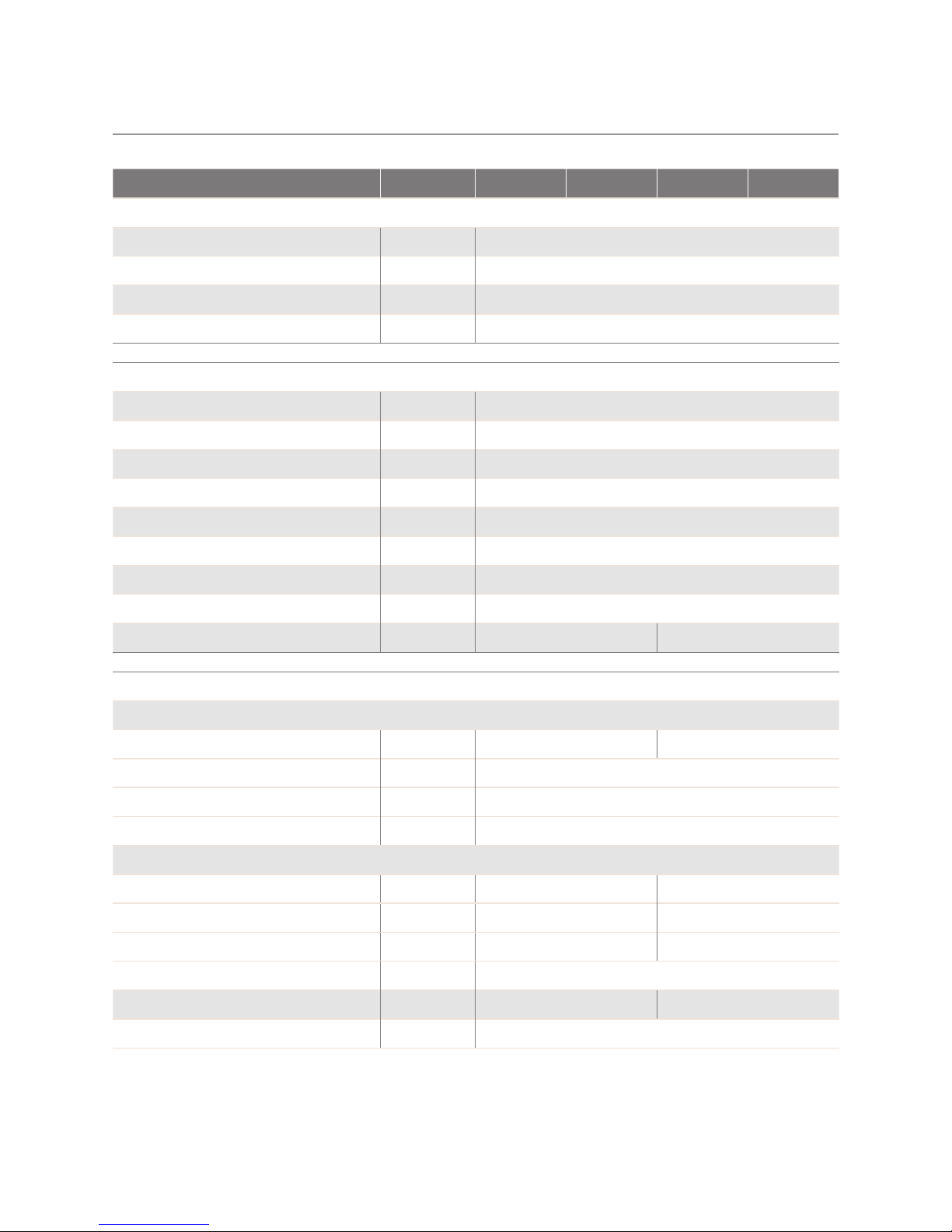

Parameter Unit P V PS VS

Electrical data

Power supply V/Hz 230/50

Fuse A 13 (10)

Electric connections - L1, N, G

Electric heater power W 1500

Refrigerant and water circuit

Refrigerant type - R134a

Refrigerant quantity g 1220

GWP - 1430

CO2 equivalent ton 1,7

Refrigerant circuit - Hermetically sealed

Protection rating - IP21

Water connections in ¾ - BSPT (ISO 7-1)

Heat source connections mm 22 – Compression fittings

Heat source temperature range °C 5 (10*) - 55 5 (10*) - 60

Performance data

Heat source at 25°C, domestic hot water at 10-53,5°C (EN16147, L)

COP - 5,3 5,2

Heat up time hh:mm 04:30

Heating capacity W 2100

Stand-by heat losses W 12

Heat source at 40°C, domestic hot water at 10-53,5°C (EN16147, L)

COP - 6,0 8,5

Heat up time hh:mm 02:50 03:45

Heating capacity W 2700 3200

Stand-by heat losses W 9

Volume at 40°C L 247 234

Sound power dB(A) 46

All data are to be subjected to 3rd party test.

*If brine is used as heat source the minimum temperature is 5 °C.

If uninhibited water is used the minimum temperature is 10 °C.

12

Parameter Unit P V PS VS

Operating limits

Max. compressor power W 600

Max. water temperature (heat pump only) °C 65

Max. water temperature (heat pump and

electric water heater)

°C 65

Min. required heat source flow l/h 100

Max. domestic hot water pressure MPa 1,0

Max. allowed heat source pressure MPa 0,3 1,0 0,3 1,0

Max. available pressure difference kPa 20 600 20 600

13

2. TRANSPORT, HANDLING AND DELIVERY

Immediately upon receipt, the domestic hot water heater pump must be examined to

make sure that it is intact and undamaged. If not, the shipping company must be

informed immediately. The recipient has the responsibility for all the shipments unless

otherwise agreed.

2.1. Delivery Mode

The appliance is delivered without condensate drain tube and the safety equipment

for the water circuit.

2.2. Storage

The unit must be stored and preferably transported upright, free of water and within

its packaging.

Transport and storage may take place at temperatures between -10 °C and +50 °C. If

the unit has been transported or stored at sub-zero temperatures the unit should be

left at room temperatures for 24 hours before commissioning.

2.3. Transport with Forklift

For transport with a forklift, the unit must stand on the associated transport frame.

Always lift the unit slowly. Due to the high center of gravity, the appliance must be

secured against tipping during transportation.

2.4. Unloading the Heat Pump

In order to avoid damages, the unit must be unloaded on a flat surface.

14

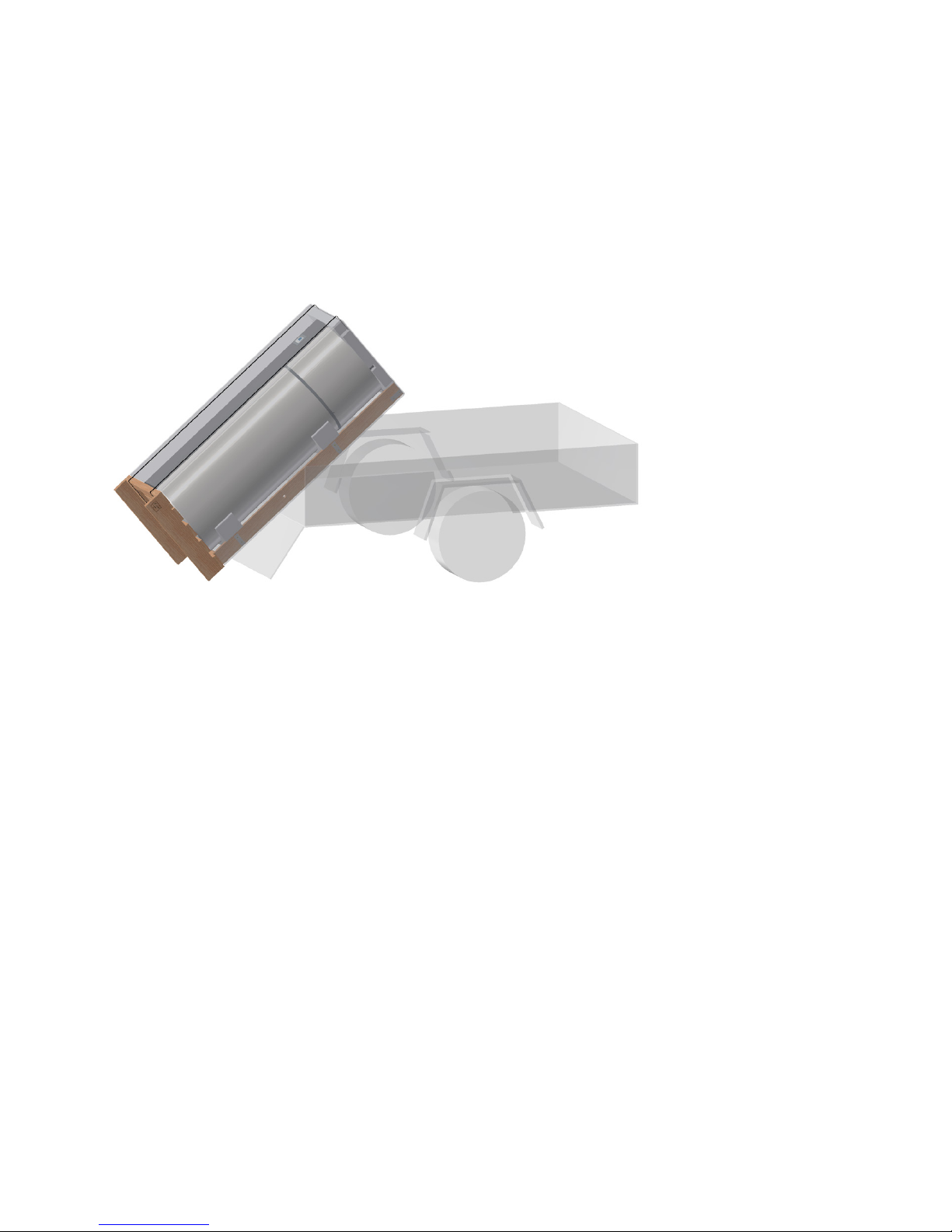

2.5. Transport with Trailer

The unit must only be transported on the associated transport frame. This also

applies to transport on stairs (figure 7).

The unit must be secured against sliding on the trailer.

Water connections etc. shall not be used for transportation purposes.

It should be made sure that the trailer does not damage the cabinet or the

various connections.

Figure 7 - Transport with trailer

2.6 Horizontal transport

When carefully transporting the unit over a short distance to its final location, the unit

can be transported horizontally in its packaging on the dedicated side. If the unit has

been tilted more than 45°, the unit must be left in its normal upright position for at

least 24 hours before it is started.

15

3. POSITIONING

The installation site should be equipped with a power supply of 220-240V and 50 Hz.

The power supply and the hydraulic system must comply with the local regulations.

The unit should be placed vertically, with a maximum inclination of 1°. The unit must be

well balanced and stable on the ground surface. Use the built-in adjustable pads to

level the unit.

The unit must be installed as close as possible to the hydraulic system in order to minimize heat losses in the water pipes. The water pipe outlet should be insulated for the

same reason.

The unit should not be placed in direct contact with the sunlight.

The unit can only be installed in a frost-free room and it should follow the criteria:

• Room temperature between 5°C and 35°C.

• Drain possibility for condensate and floor drain.

• Solid base (approx. 500 kg / m2).

• It is necessary to ensure that there is sufficient space around the unit for mainte-

nance and service. A clearance of 0,5 m around the unit is recommended.

Once the appliance is located in the right position, remove the packaging and remove

the unit from the pallet.

16

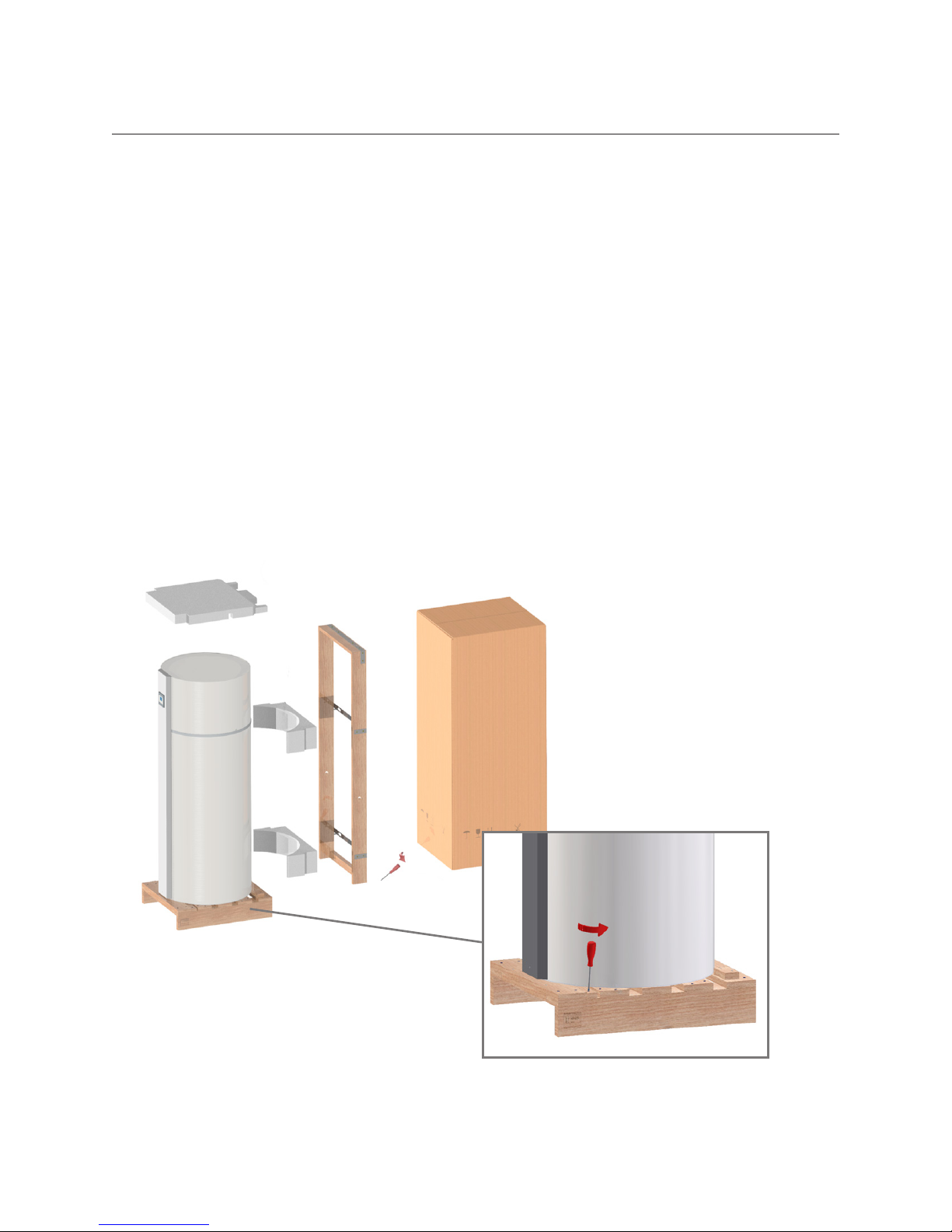

3.1. Set-up sequence

Once the unit is placed in a room with characteristics as specified in the previous

paragraph, then it can be prepared following the sequence described below:

1. Remove the packaging from the pallet.

2. Remove the transport fittings from the pallet.

3. Remove the unit off the pallet and place it on the floor.

4. Adjust the unit vertically by adjusting the feet.

5. Check that the unit has no damages.

6. Set up the water circuit (See chapter 4) and fill the tank with water.

7. Set up the electric connections (See chapter 6).

When the unit is supplied with electricity, it automatically starts running in its

standard operation according to the factory settings as described in Chapter 7.

Figure 8 - Set-up sequence

Loading...

Loading...