Metro Therm METROAIR I 8, METROAIR I 12, METROAIR I 20, METROAIR I 16 Installer Manual

Installer manual

LEK

METROAIR I™

8, 12, 16, 20

Air/water heat pump

IHB EN 1817-2

431544

Table of Contents

41 Important information

4Safety information

6Symbols

6Marking

6Serial number

6Recovery

6Environmental information

6Country specific information

7Inspection of the installation

8Indoor modules

8Control modules

92 Delivery and handling

9Transport and storage

9Assembly

10Compressor heater

10Condensation

13Installation area

13Supplied components

14Removing the side cover and top panel

153 The heat pump design

15General

19Distribution box

367 Control - Introduction

36General

36LED status

36Master control

37Control conditions

38Control - Heat pump EB101

398 Disturbances in comfort

39Troubleshooting

409 Alarm list

4210 Accessories

4311 Technical data

43Dimensions

44Sound pressure levels

45Technical specifications

48Working area

49Heating

51Cooling

52Energy labelling

57Electrical circuit diagram

6512 1 års ekstra garanti

204 Pipe connections

20General

20Pipe coupling heating medium circuit

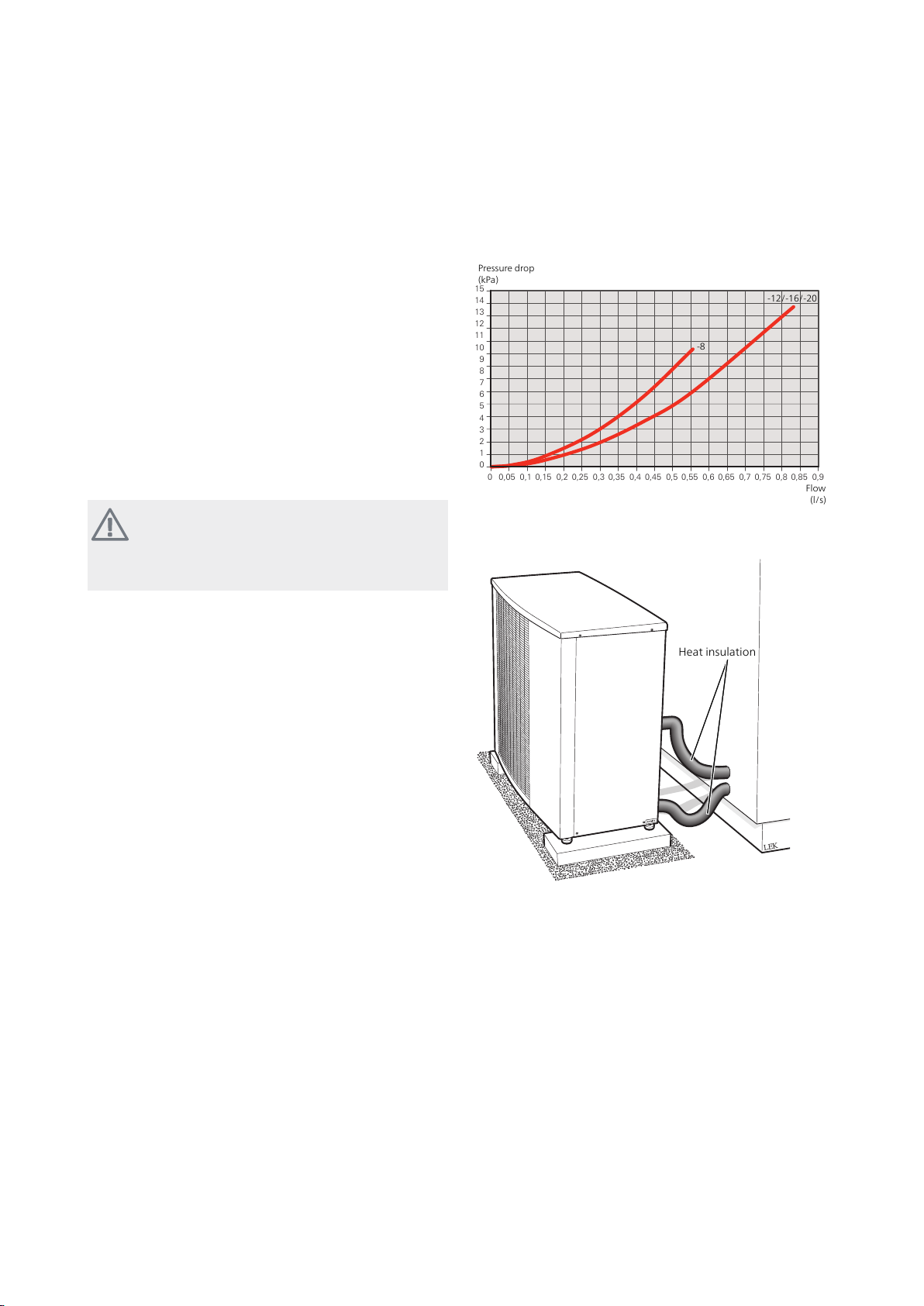

20Pressure drop, heating medium side

20Heat insulation

21Installing flex hoses

65Sådan gør du:

65METRO THERM garantibestemmelser

66Overensstemmelseserklæring

67Item register

225 Electrical connections

22General

23Accessibility, electrical connection

24Configuration using DIP switch

25Connections

29Optional connections

33Connecting accessories

346 Commissioning and adjusting

34Preparations

34Balance temperature

34Filling and venting

34Start-up and inspection

34Readjusting, heating medium side

35Adjustment, charge flow

3Table of Contents |METROAIR I™

1 Important information

Safety information

This manualdescribesinstallation and serviceprocedures

for implementation by specialists.

The manual must be left with the customer.

This appliance can be used by children

aged from 8 years and above and persons with reduced physical, sensory or

mental capabilities or lack of experience

and knowledge if they have been given

supervision or instruction concerninguse

of the appliance in a safeway andunderstand the hazards involved. The product

is intended for use by experts or trained

users in shops, hotels, light industry,

farming and similar environments.

Children must be instructed/supervised

to ensure that they do not play with the

appliance.

Do not allow children to clean or maintain the appliance unsupervised.

This is an original manual. It may not be

translated without the approval of

METROTHERM.

Rights to make any design or technical

modifications are reserved.

Safety precautions

Caution

Install the system in full accordance with this installation

manual.

Incorrect installationcancausebursts, personal injury,waterleaks,

refrigerant leaks, electric shocks and fire.

Pay attention to the measurement values before working on

the cooling system, especially when servicing in small rooms,

so that the limit for the refrigerant’s concentration is not exceeded.

Consult anexpert to interpretthe measurement values. If the refrigerant concentration exceeds the limit, there may be a shortage

of oxygen in the event of any leak, which can cause serious injury.

Use original accessories and the stated components for the

installation.

If parts other than those statedby us are used, water leaks, electric

shocks, fireand personalinjury may occur as theunit maynot work

properly.

Ventilate the working area well – refrigerant leakage may occur

during service work.

If therefrigerant comesinto contact withnaked flames, poisonous

gas is created.

Install the unit in a location with good support.

Unsuitable installationlocations can causethe unit to fall andcause

material damageand personal injury. Installationwithout sufficient

support can also cause vibrations and noise.

Ensure that the unit is stable when installed, so that it can

withstand earthquakes and strong winds.

Unsuitable installationlocations can causethe unit to fall andcause

material damage and personal injury.

The electrical installation must be carried out by a qualified

electrician and the system must be connected as a separate

circuit.

Power supply with insufficient capacity and incorrect function can

cause electric shocks and fire.

Use the stated cables for the electrical connection, tighten the

cables securely in the terminal blocks and relieve the wiring

correctly to prevent overloading the terminal blocks.

Loose connections or cable mountings can cause abnormal heat

production or fire.

Check, after completed installation or service, that no refrigerant leaks from the system in gas form.

If refrigerantgas leaks into thehouse and comes intocontact with

an aerotemp, an oven or other hot surface, poisonous gases are

produced.

Switch off the compressor before opening/breaching the refrigerant circuit.

If therefrigerant circuitis breached /opened whilst thecompressor

is running,air can enterthe processcircuit. This cancause unusually

high pressure in the process circuit, which can cause bursts and

personal injury.

Switch off the power supply in the event of a service or inspection.

If the power supply is not shut off, there is a risk of electric shocks

and damage due to the rotating fan.

Do not run the unit with removed panels or protection.

Touching rotating equipment, hot surfaces or high voltage parts

can cause personal injury due to entrapment, burns or electric

shocks.

Cut the power before starting electrical work.

Failure to cut the power can cause electric shocks, damage and incorrect function of the equipment.

Care

Carry out the electrical installation with care.

Do notconnect the ground leadto the gasline, water line, lightning

conductor or telephone line's ground lead. Incorrect grounding

can cause unit faults such aselectric shocks dueto short-circuiting.

Use main switch with sufficient breaking capacity.

If the switch does not have sufficient breaking capacity, malfunctions and fire can occur.

Always use a fuse with the correct rating in the locations where

fuses are to be used.

Connecting the unit with copper wire or other metal thread can

cause unit breakdown and fire.

Cables must be routed so that they are not damaged by metal

edges or trapped by panels.

Incorrect installation can cause electric shocks, heat generation

and fire.

Do not install the unit in close proximity to locations where

leakage of combustible gases can occur.

If leaking gases collect around the unit, fire may occur.

Do not install the unit where corrosive gas (for example nitrous

fumes) or combustible gas or steam (for example thinner and

petroleum gases) can build up or collect, or where volatile

combustible substances are handled.

Corrosive gas can cause corrosion to the heat exchanger, breaks

in plastic parts etc. and combustible gas or steam can cause fire.

Do not use the unit where water splashes may occur, for example in laundries.

The indoor section is not waterproof and electric shocks and fire

can therefore occur.

Do not use the unit for specialist purposes such as for storing

food, cooling precision instruments, freeze-conservation of

animals, plants or art.

This can damage the items.

METROAIR I™Chapter 1 | Important information4

Do not install and use the system close to equipment that

generates electromagnetic fields or high frequency harmonics.

Equipment such asinverters, standby sets, medicalhigh frequency

equipment andtelecommunications equipmentcan affect theunit

and cause malfunctions and breakdowns. The unit can also affect

medical equipment and telecommunications equipment, so that

it functions incorrectly or not at all.

Do not install the outdoor unit in the locations stated below.

- Locations where leakage of combustible gas can occur.

- Locations where carbon fibre, metal powder or other powder

that can enter the air.

- Locations where substances that canaffect the unit, for example,

sulphide gas, chlorine, acid or alkaline substances can occur.

- Locations with direct exposure to oil mist or steam.

- Vehicles and ships.

- Locationswhere machinesthat generatehigh frequency harmonics are used.

- Locations where cosmetic or special sprays are often used.

- Locations that can be subjected to direct salty atmospheres. In

this case,the outdoor unitmust be protected against directintakes

of salty air.

- Locations where large amounts of snow occur.

- Locations where the system is exposed to chimney smoke.

If the bottom frame of the outdoor section is corroded, or in

any other way damaged, due to long periods of operation, it

must not be used.

Using an old and damaged frame can cause the unit to fall and

cause personal injury.

If soldering near the unit, ensure that solder residue does not

damage the drip tray.

If solder residue enters the unit during soldering, small holes can

appear in the tray resulting in water leakage. To prevent damage,

keep the indoor unit in its packing or cover it.

Do not allow the drainage pipe to exit into channels where

poisonous gases, containing sulphides for example, can occur.

If the pipe exits into such a channel, any poisonous gases will flow

into the room and seriously affect the user's health and safety.

Insulate the unit's connection pipes so that the ambient air

moisture does not condense on them.

Insufficient insulation can cause condensation, which can lead to

moisture damageon theroof, floor,furniture andvaluable personal

property.

Do not install the outdoor unit in a location where insects and

small animals can inhabit.

Insects and small animals can enter the electronic parts and cause

damage and fire. Instruct the user to keep the surrounding equipment clean.

Take care when carrying the unit by hand.

If the unit weights more than 20 kg, it must be carried by two

people. Use gloves to minimize the risk of cuts.

Dispose of any packaging material correctly.

Any remaining packaging material can cause personal injury as it

may contain nails and wood.

Do not touch any buttons with wet hands.

This can cause electric shocks.

Do not touch any refrigerant pipes with your hands when the

system is in operation.

During operation the pipes become extremely hot or extremely

cold, depending on the method of operation. This can cause burn

injuries or frost injuries.

Do not shut off the power supply immediately after operation

has start.

Wait at least 5 minutes, otherwise there is a risk of water leakage

or breakdown.

Do not control the system with the main switch.

This can cause fire or water leakage. In addition, the fan can start

unexpectedly, which can cause personal injury.

5Chapter 1 | Important informationMETROAIR I™

Symbols

!

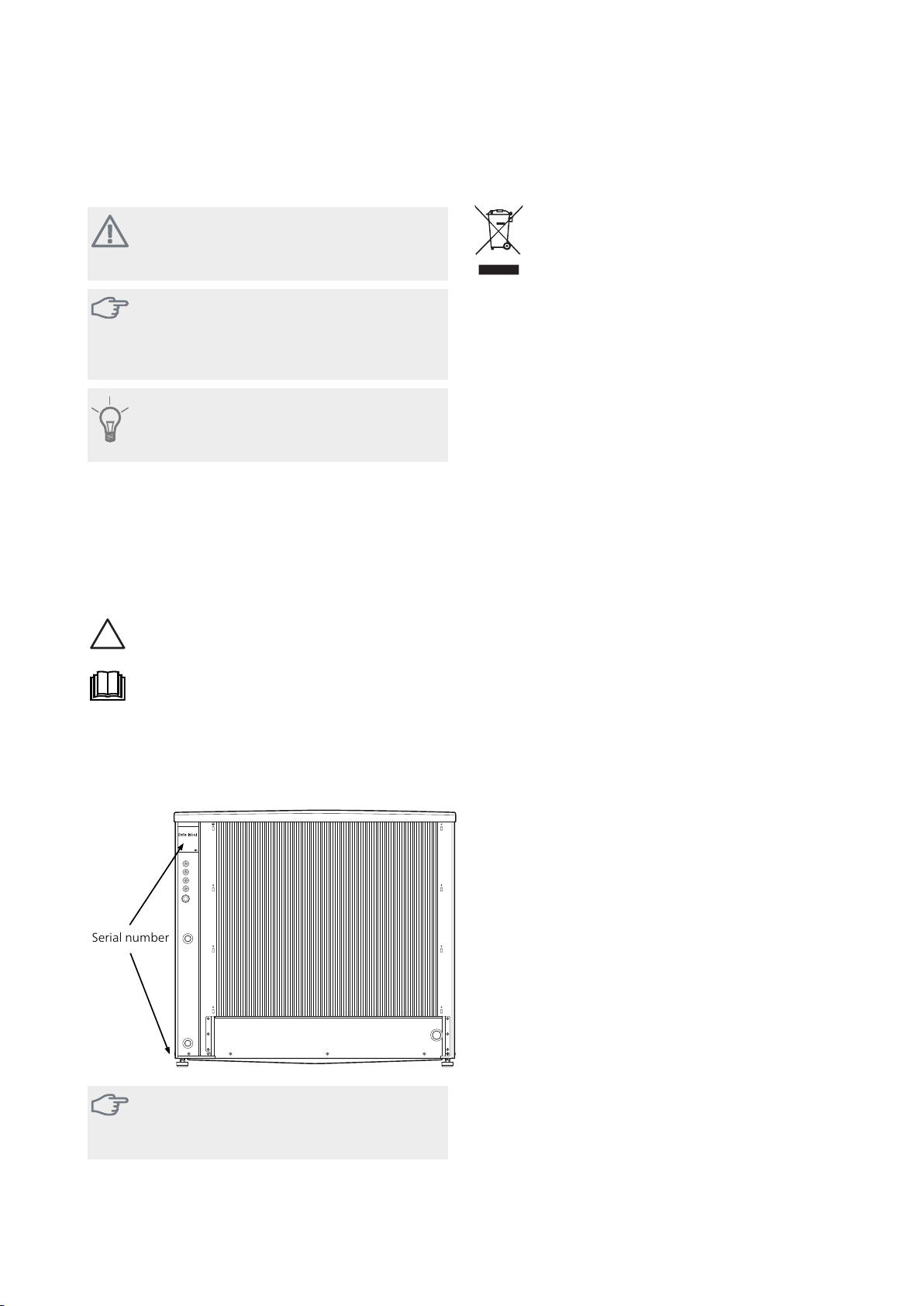

Serial number

Recovery

NOTE

This symbol indicates danger to person or machine .

Caution

This symbol indicates important information

about what you should consider when installing or servicing the installation.

TIP

This symbol indicates tips on how to facilitate

using the product.

Marking

The CE mark is obligatory for most products sold

CE

in the EU, regardless of where they are made.

Classification of enclosure of electro-technical

IP24

equipment.

Danger to person or machine.

Read the User Manual.

Leave the disposal of the packaging to the installer who installed the product or to special

waste stations.

Do not dispose of used products with normal

household waste. It must be disposed of at a

special wastestation or dealer who providesthis type of

service.

Improper disposal of the product by the user results in

administrative penalties inaccordance with current legislation.

Environmental information

The equipment contains R410A, a fluorinated greenhouse gas witha GWPvalue (Global Warming Potential)

of 2088. Do not release R410A into the atmosphere.

Country specific information

Denmark

Commissioning, setting and annual servicing of the

product has to be entrusted to an authorised service

technician, the manufacturer’s installers or a service

company approved by the manufacturer.

Work on the refrigerant system may only be carried out

by an authorised cooling engineer (at least Certificate

II), the manufacturer’s own installers or a service company approved by themanufacturer.The companymust

be registered/approved by KMO (Kølebranchens

Miljøordning).

Serial number

The serial number can be found at the top left on the

rear cover and at the bottom on the side.

Caution

You needthe product's(14 digit) serialnumber

for servicing and support.

METROAIR I™Chapter 1 | Important information6

Inspection of the installation

✔

Current regulations require the heating installation to be inspected before it is commissioned. The inspection must

be carried out by a suitably qualified person. Fill in the page for information about installation data in the User

manual.

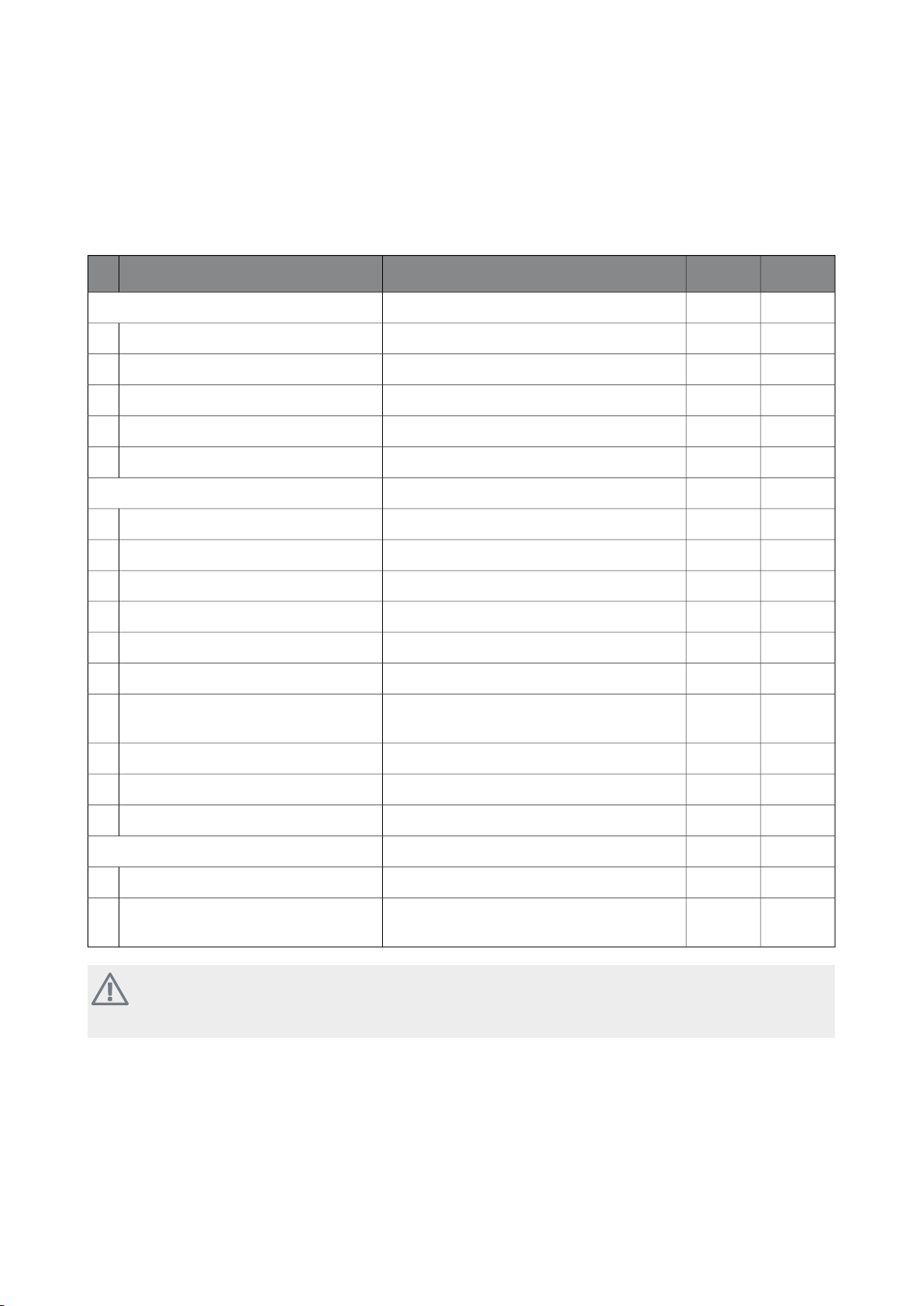

DateSignatureNotesDescription

Heating medium (page 20)

System flushed

System vented

Particle filter

Shut-off and drain valve

Charge flow set

Electricity (page 22)

Fuses property

Safety breaker

Earth circuit-breaker

Heating cable type/effect

Fuse size, heating cable (F3)

Communication cable connected

METROAIR I addressed (only when cascade connection)

Connections

Main voltage

Phase voltage

Miscellaneous

Condensation water pipe

Insulation condensation water pipe,

thickness (if KVR 10 is not used)

NOTE

Check the connections,main voltage and phase voltage before the machine is started, to prevent damage

to the heat pump electronics.

7Chapter 1 | Important informationMETROAIR I™

Indoor modules

Control modules

METROAIR 330

Stainless Steel, 3 x 400 V

Part no. 153 001 605

METROAIR S20

Control module

Part no. 150 209 601

METROAIR S40

Control module

Part no. 150 409 601

METROAIR I™Chapter 1 | Important information8

LEK

F2120

min 300 mm

LEK

F2120

min

70 mm

2 Delivery and handling

Transport and storage

METROAIR I must be transported and stored vertically.

NOTE

Ensure that the heat pump cannot fall over

during transport.

Ensure that the heat pump cannot be damaged during

transportation.

Assembly

■

Place METROAIR I outdoors on a solid level base that

can take theweight, preferablya concrete foundation.

If concrete slabs are used they must rest on asphalt or

shingle.

■

The lower edge of theevaporator must be atthe level

of the average local snow depth. The concrete foundation or concrete plinthsmust therefore beat least 70

mm high.

■

METROAIR I should not be positioned next to noise

sensitive walls, for example, next to a bedroom.

■

Also ensure that the placement does not inconvenience the neighbours.

■

METROAIR I must not be placed so that recirculation

of the outdoorair can occur. This causes lower output

and impaired efficiency.

■

The evaporator must be sheltered from direct wind / ,

which negativelyaffects the defrosting function.Place

METROAIR I protected from wind / against the evaporator.

■

Some water may drip from the drainage hole below

METROAIR I. Make sure that water can run off by selecting a suitable material underneath METROAIR I

(see page 10).

■

Care must be exercised so that the heat pump is not

scratched during installation.

If there is a risk of snow slip from roof, a protective roof

or covermust be erected toprotect the heat pump, pipes

and wiring.

Do not place METROAIR I directly on the lawn or other

non solid surface.

9Chapter 2 | Delivery and handlingMETROAIR I™

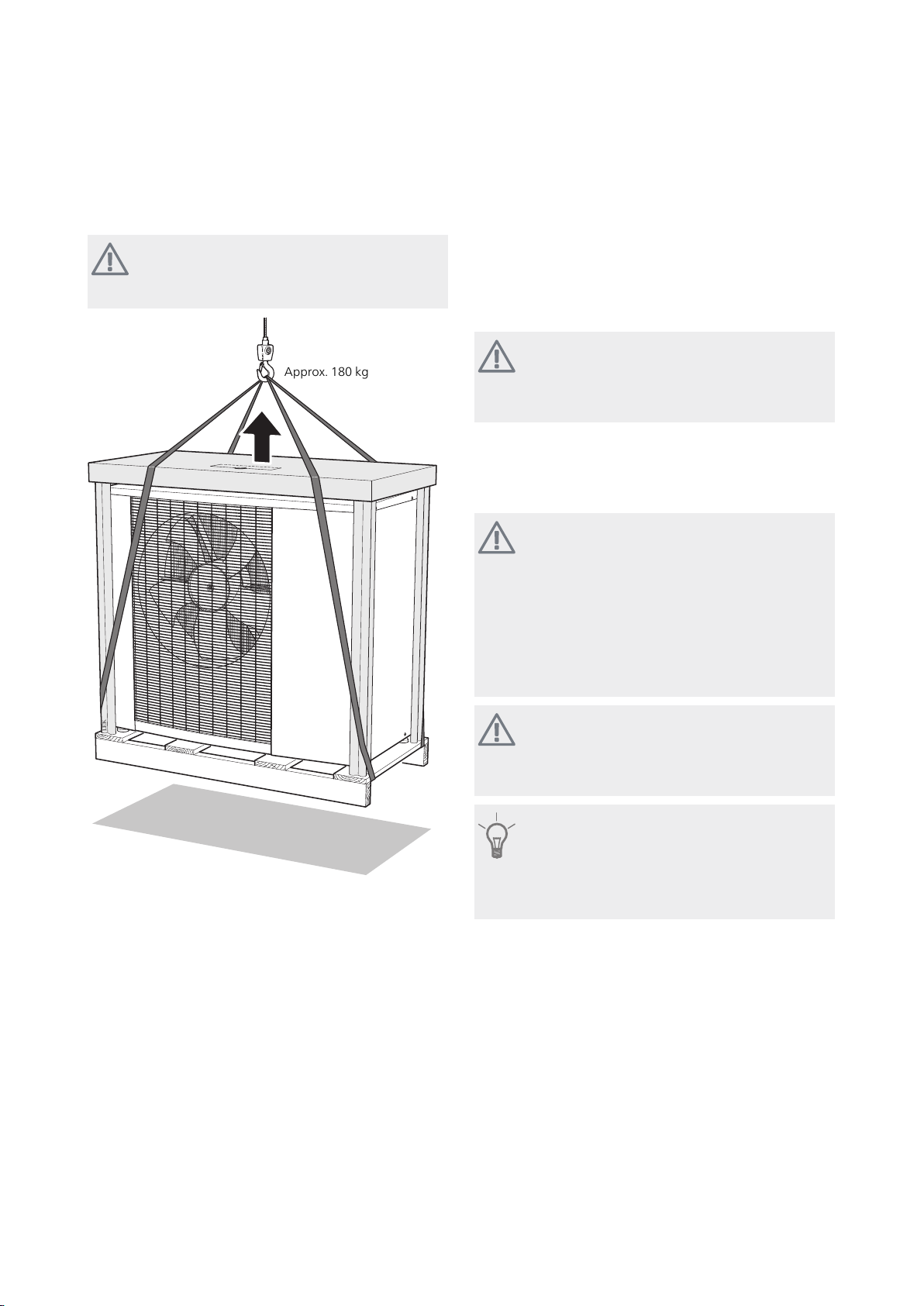

Lift from the street to the set up location

L

E

K

C:a 180 kg

Approx. 180 kg

If the base allows, the simplest thing is to use a pallet

truck to move the METROAIR I to the set up location.

Scrapping

When scrapping, theproduct is removed in reverseorder.

Lift by the bottom panel instead of a pallet!

NOTE

The centre of gravity is offset to one side (see

print on the packaging).

Compressor heater

METROAIR I is equipped with two compressor heaters

that heat the compressor before start-up and when the

compressor is cold.

NOTE

The compressor heater must have been active

for approx. 3 hours before the first start, see

section “Start-up and inspection” on page 34.

Condensation

The condensation water troughcollects and leads away

most of the condensation water from the heat pump.

NOTE

It is important to the heat pump function that

condensation water is led away and that the

drain for the condensation water run offis not

positioned so that it can cause damage to the

house.

Condensation runoff shouldbe checked regularly, especially during the autumn. Clean if

necessary.

NOTE

The electrical installation and wiring must be

carried outunder the supervisionof an authorised electrician.

TIP

Pipe with heating cable for draining the condensation water trough is not included.

To ensure this function the accessory KVR 10

If METROAIR I needs to be transported across soft

ground, such as a lawn, we recommend that a crane is

used that can lift the unit to the installation location.

■

When METROAIR I is lifted with a crane, the packaging

must be undisturbed, see the illustration above.

If a crane vehiclecannot be used the METROAIR I can be

transported on anextended sack truck. METROAIR Imust

■

be taken from its heaviest side and two people are required to lift METROAIR I.

Lift from the pallet to final positioning

Before lifting remove the packaging and the securing

■

■

strap to the pallet.

Place lifting straps around each machine foot. Lifting

from the pallet to the base requires four persons, one

for each lifting strap.

■

■

should be used.

The condensation water (up to 50 litres/24 hrs) that

collects inthe trough should berouted away by apipe

to an appropriate drain, it is recommended that the

shortest outdoor stretch possible is used.

The section of the pipe that can be affected by frost

must be heated by the heating cable to prevent

freezing.

Route the pipe downward from METROAIR I.

The outlet of the condensation water pipe must be at

a depth that is frost free or alternatively indoors (with

reservation for local ordinances and regulations).

Use a water trap for installations where air circulation

may occur in the condensation water pipe.

The insulation must seal against the bottom of the

condensation water trough.

METROAIR I™Chapter 2 | Delivery and handling10

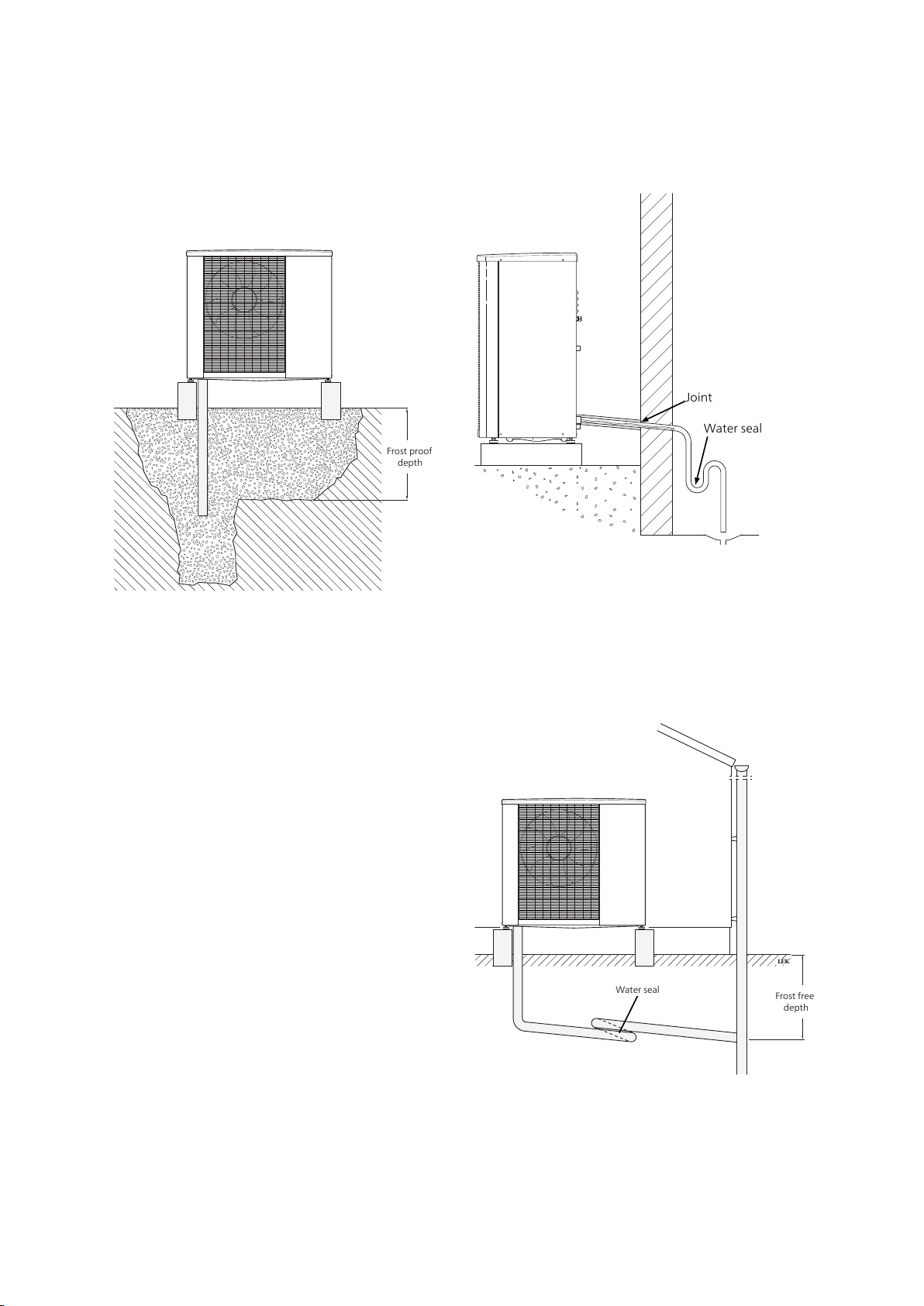

Recommended alternative for leading off

Frostfritt djup

F2120

Frost proof

depth

Water seal

Joint

LEK

F2120

Frostfritt

djup

Frost free

depth

Water seal

condensation water

Stone caisson

If the house has a cellar the stone caisson must be positioned so that condensation water does not affect the

house. Otherwise the stone caisson can be positioned

directly under the heat pump.

The outlet of the condensation water pipe must be at

frost free depth.

Drain indoors

The condensation water is lead to an indoor drain (subject to local rules and regulations).

Route the pipe downward from METROAIR I.

The condensation water pipe must have a water seal to

prevent air circulation in the pipe.

KVR 10 spliced as illustrated. Pipe routing inside house

not included.

Gutter drainage

The outlet of the condensation water pipe must be at

frost free depth.

Route the pipe downward from METROAIR I.

The condensation water pipe must have a water seal to

prevent air circulation in the pipe.

11Chapter 2 | Delivery and handlingMETROAIR I™

Caution

If none of the recommended alternatives is

used goodlead off of condensationwater must

be assured.

METROAIR I™Chapter 2 | Delivery and handling12

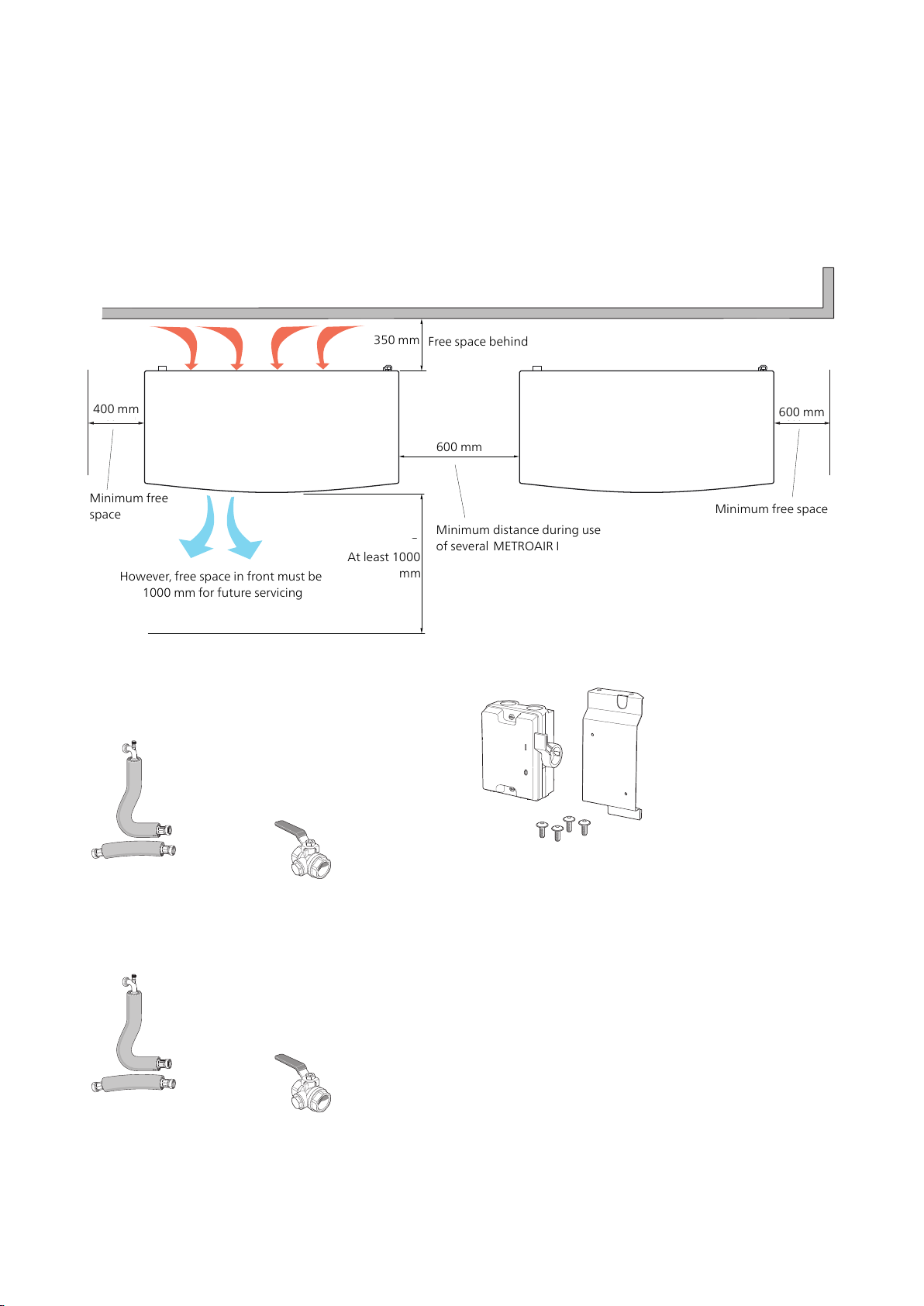

Installation area

350 mm

Fritt utrymme bakom

Fritt utrymme framför

dock 1000 mm för ev. framtida service

Min. avstånd

vid användning

av flera F2300

600 mm

1000 mm

400 mm

Minimalt

fritt utrymme

600mm

Minimalt

fritt utrymme

Minimum free

space

However, free space in front must be

1000 mm for future servicing

Minimum free space

Minimum distance during use

of several METROAIRI

600 mm

600 mm

At least 1000

mm

Free space behind

350 mm

400 mm

LEK

LEK

The distance between METROAIR I and the house wall

must be at least 350 mm. The free space above METROAIR I must be at least 1,000 mm. The free space in

front must be at least 1,000 mm for future servicing.

Supplied components

METROAIR I 8, METROAIR I 12

2 xflexible pipes(DN25, G1")

with 4 x gaskets.

METROAIR I 16, METROAIR I 20

2 x flexible pipes (DN25, G1

1/4") with 4 x gaskets.

Filterball (G1").

Filterball (G1 1/4").

1 xcircuit breakersincl. screw

and plate

13Chapter 2 | Delivery and handlingMETROAIR I™

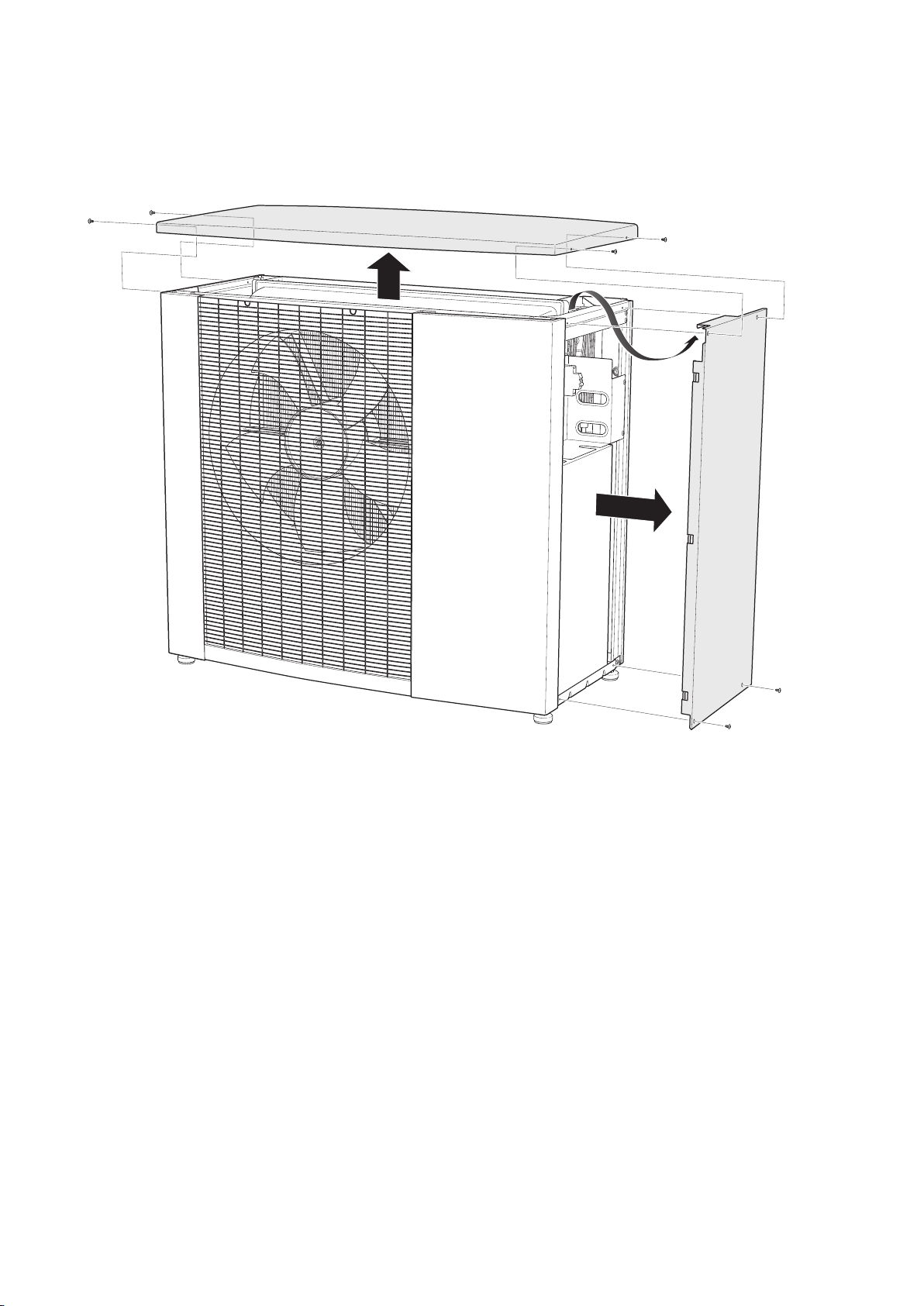

Removing the side cover and top panel

L

EK

METROAIR I™Chapter 2 | Delivery and handling14

LEK

GQ1

AA2

UB1

BT12

EP2

XL1

BT3

XL2

HS1

XL21

BT84

QN1

QN4

RM1

QN2

BP11

QN34

BT15

BT14

EB10

QA40 GQ10

BT17

RA1

BP9

BP1

BP2

BP8

XL20

BT81

HQ9

CA1

X6

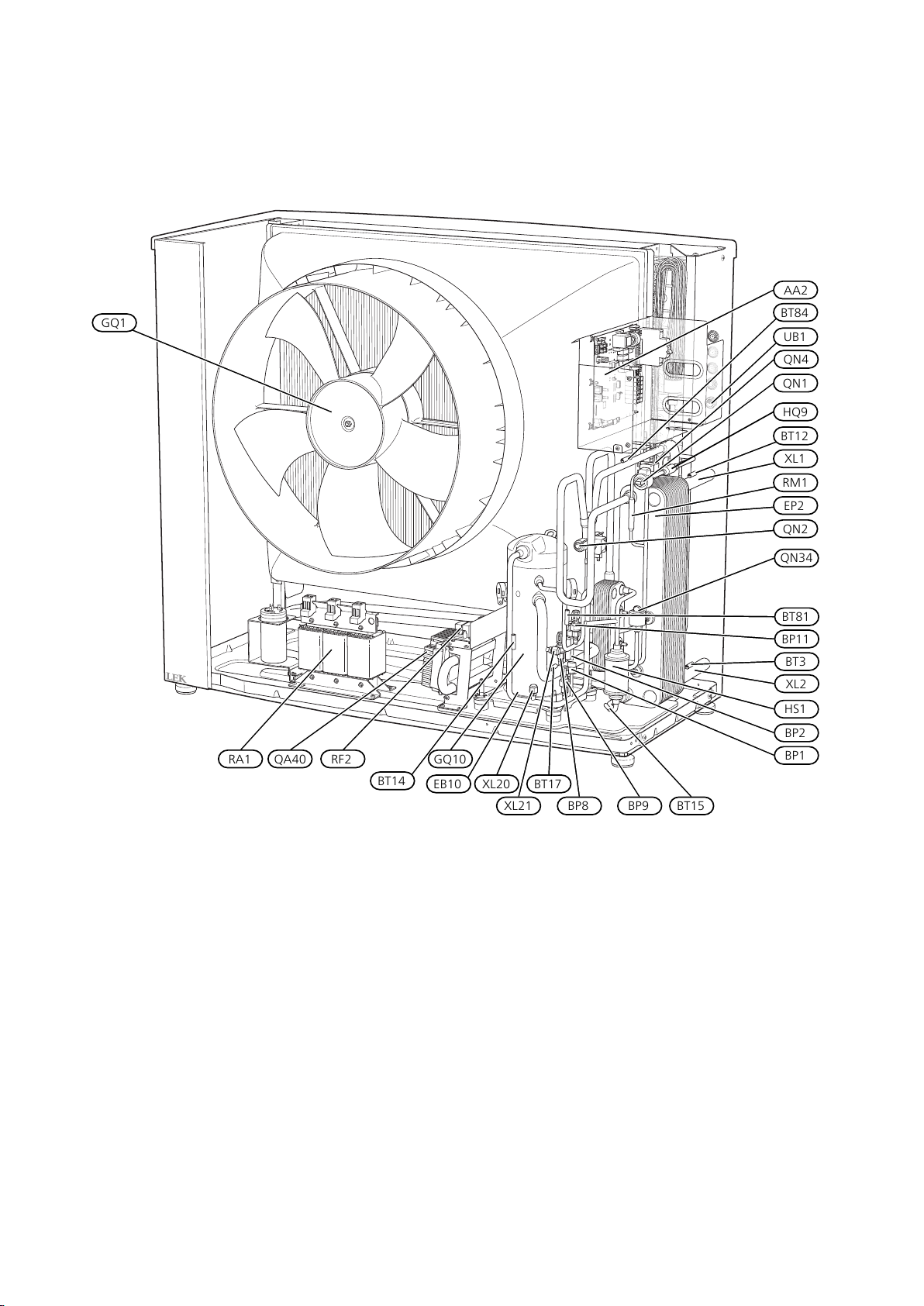

3 The heat pump design

General

METROAIR I (1x230V)

15Chapter 3 | The heat pump designMETROAIR I™

METROAIR I (3x400V)

LEK

GQ1

AA2

UB1

BT12

EP2

XL1

BT3

XL2

HS1

XL21

BT84

QN1

QN4

RM1

QN2

BP11

QN34

BT15

BT14

EB10

QA40 GQ10

BT17

RF2RA1

BP9

BP1

BP2

BP8

XL20

BT81

HQ9

METROAIR I™Chapter 3 | The heat pump design16

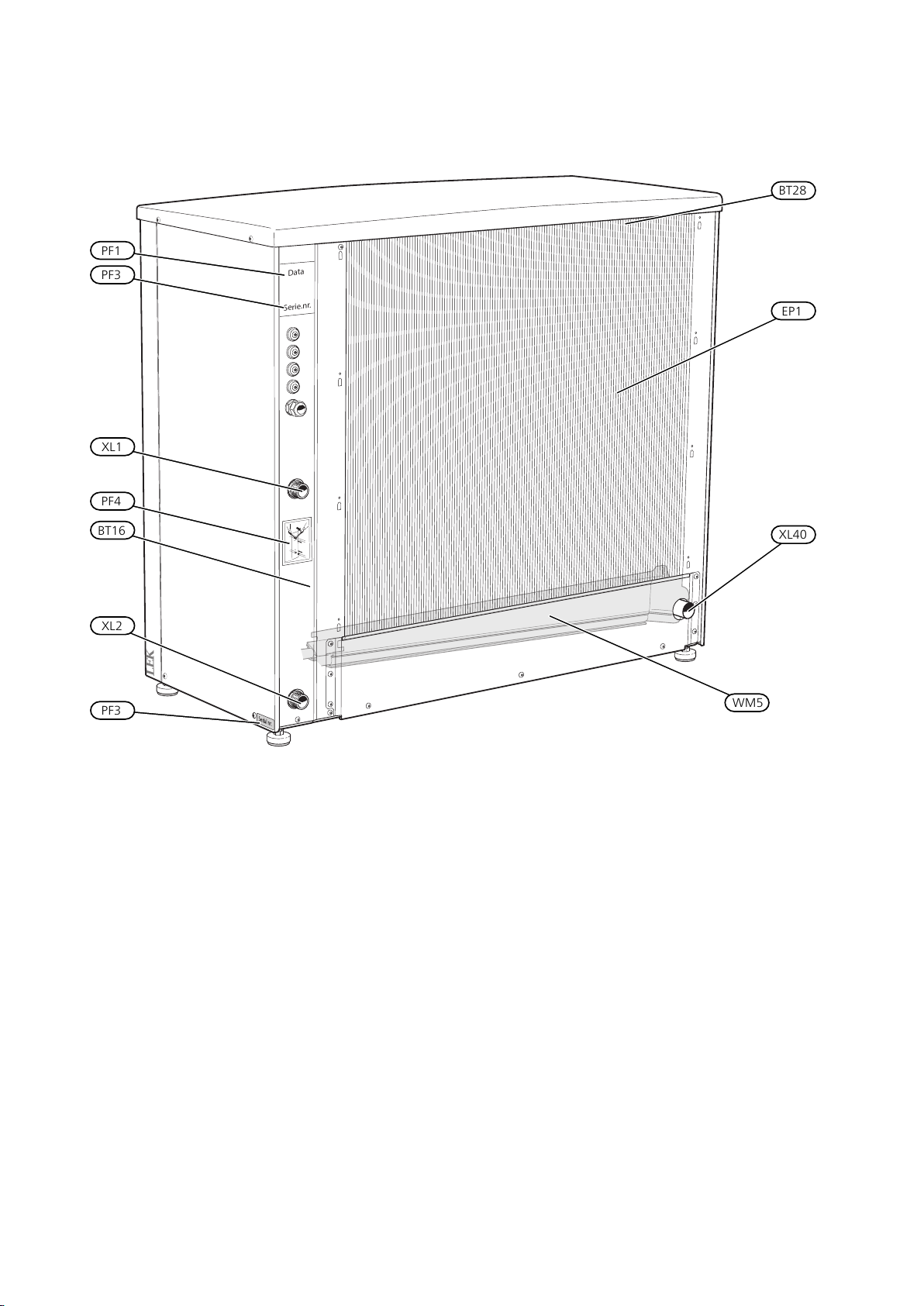

LEK

Data

Serie.nr.

Art.nr.

711453

O

UT

IN

PF4

BT16

PF1

BT28

EP1

WM5

XL40

XL1

XL2

PF3

PF3

17Chapter 3 | The heat pump designMETROAIR I™

Pipe connections

Connection, heating medium out of METROAIR IXL1

Connection, heating medium in to METROAIR I,XL2

Service connection, high pressureXL20

Service connection, low pressureXL21

Connection, drain condensation water troughXL40

Sensors etc.

High pressure pressostatBP1

Low pressure pressostatBP2

Low pressure transmitterBP8

High pressure sensorBP9

Pressure sensor, injectionBP11

Temperature sensor, returnBT3

Temperature sensor, condenser supply lineBT12

Temperature sensor, hot gasBT14

Temperature sensor, fluid pipeBT15

Temperature sensor, evaporatorBT16

Temperature sensor, suction gasBT17

Temperature sensor, ambientBT28

Temperature sensor, injection, EVI compressorBT81

Temperature sensor, suction gas evaporatorBT84

Miscellaneous

Type platePF1

Serial numberPF3

Sign, pipe connectionsPF4

Cable gland, incoming supplyUB1

Condensation water troughWM5

Electrical components

Base cardAA2

Capacitor (1x230V)CA1

Compressor heaterEB10

FanGQ1

InverterQA40

Harmonic filter (3x400V)RA1

Choke (1x230V)RA1

EMC filter (3x400V)RF2

Terminal block (1x230V)X6

Cooling components

EvaporatorEP1

CondenserEP2

CompressorGQ10

Particle filterHQ9

Drying filterHS1

Expansion valveQN1

Bypass valveQN4

4-way valveQN2

Expansion valve, subcoolingQN34

Non-return valveRM1

Designations in component locations according to standard IEC 81346-2.

METROAIR I™Chapter 3 | The heat pump design18

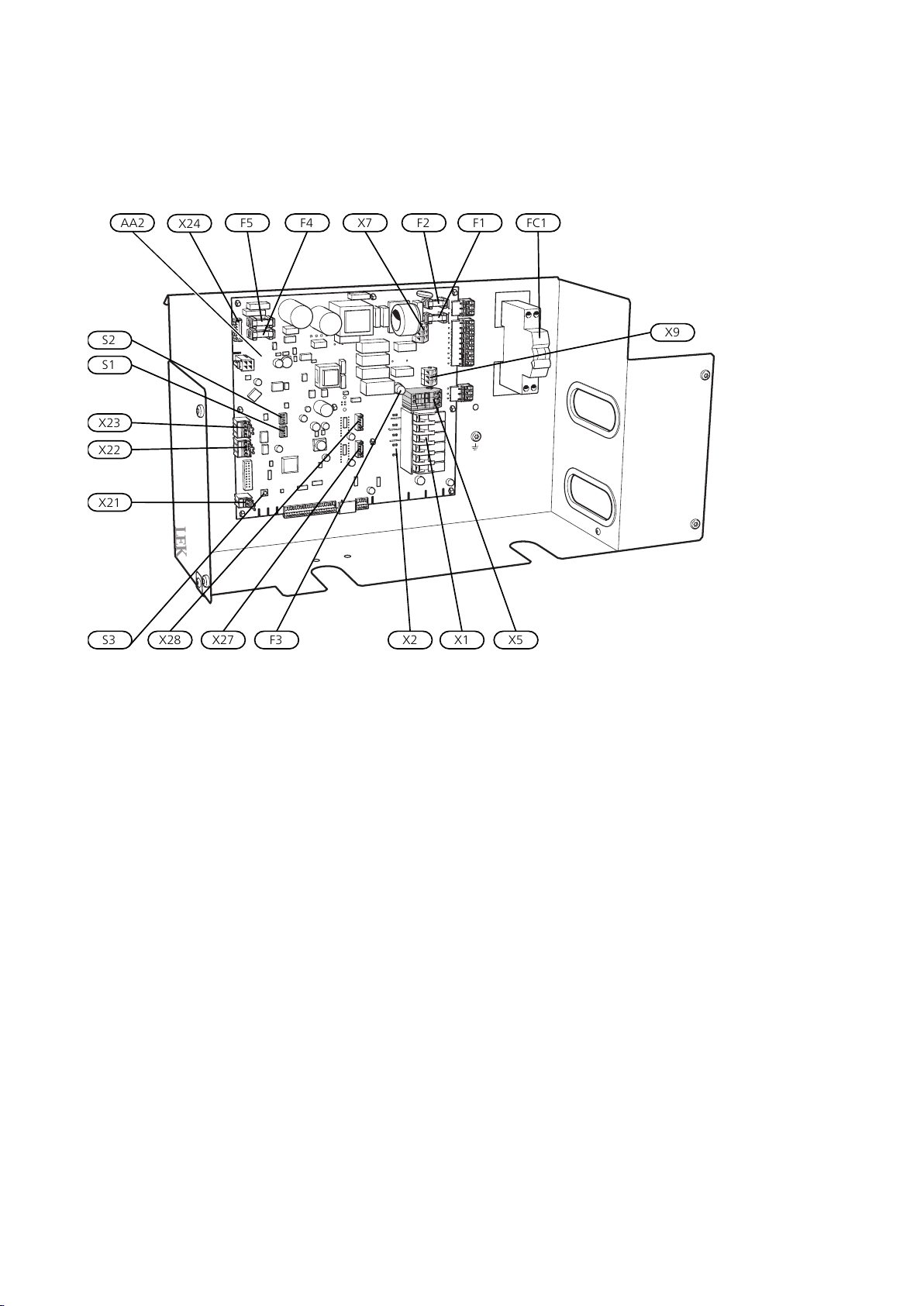

Distribution box

LEK

AA2 FC1

X24

F5 F4 X7 F2 F1

S2

S1

X23

X22

X21

X28 X27 F3 X2 X1 X5

X9

S3

Electrical components

Base cardAA2

Terminal block, incoming supplyX1

Terminal block, compressor supplyX2

Terminalblock, external control voltageX5

Terminal block, 230V~X7

Terminal block, connection KVRX9

X21

Fuse, operating 230V~F1

Fuse, operating 230V~F2

Fuse for external heating cable KVRF3

Fuse, fanF4

FC1

Fuse, fanF5

Miniature circuit breaker (Replacedwith automat-

ic protection (FB1) when installing accessory

KVR 10.)

S1

DIP switch, addressing heat pump during multi

operation

DIP switch, different optionsS2

Reset buttonS3

Terminal block, Compressor blocking,

Tariff

Terminal block, communicationsX22

Terminal block, communicationsX23

Terminal block, fanX24

Terminal block, expansion valve QN1X27

Terminal block, subcooling QN34X28

Designations in component locations according to

standard IEC 81346-2.

19Chapter 3 | The heat pump designMETROAIR I™

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

0

0,05

0,1 0,15 0,2 0,25 0,3 0,35 0,4 0,45 0,5 0,55 0,6 0,65 0,7 0,75 0,8 0,85 0,9

Tryckfall

[kPa]

Tryckfall F2120

Pressure drop

(kPa)

Flow

(l/s)

-12/-16/-20

-8

LEK

Heat insulation

4 Pipe connections

General

Pipe installation must be carried out in accordance with

current norms and directives.

METROAIR Ican only operate up toa return temperature

of about 55 °C and an outgoing temperature of about

65 °C from the heat pump.

METROAIR Iis not equipped withexternal shut offvalves

on the water side; these must be installed to facilitate

any future servicing. The return temperature is limited

by the return line sensor.

Water volumes

Depending onthe size of METROAIR I,an available water

volume isrequired to prevent shortoperating times and

to enable defrosting. For optimal operation of METROAIR I, a minimum available water volume of 10 litres

times the size number is recommended. E.g. METROAIR I-12: 10 litres x 12 = 120 litres.

NOTE

The pipework must beflushed beforethe heat

pump is connected, so that any contaminants

do not damage the components.

Pipe coupling heating medium

Pressure drop, heating medium side

METROAIR I-8, -12, -16, -20

Heat insulation

circuit

■

The heat pump must be vented by the upper connection (XL1) using the venting nipple on the enclosed

flexible hose.

■

Install the enclosed particle filter before the inlet, i.e.

the lower connection (XL2) on METROAIR I.

■

All outdoor pipes must be thermally insulated with at

least 19 mm thick pipe insulation.

■

Install shutoffand drainvalves sothat METROAIR I can

be emptied in the event of prolonged power failures.

■

The supplied flexible hoses act as vibration dampers.

The flexible pipes are fitted so an elbow is created,

thus acting as vibration damping.

Charge pump

The charge pump (not included in the product) is

powered and controlled fromthe indoormodule/control

module. Ithas a built-inanti-freezing function andmust

therefore not be switched off when there is a risk of

freezing.

At temperatures below +2 °C the charge pump runs

periodically, to prevent the water from freezing in the

charge circuit. The function also protects against excess

temperatures in the charge circuit.

METROAIR I™Chapter 4 | Pipe connections20

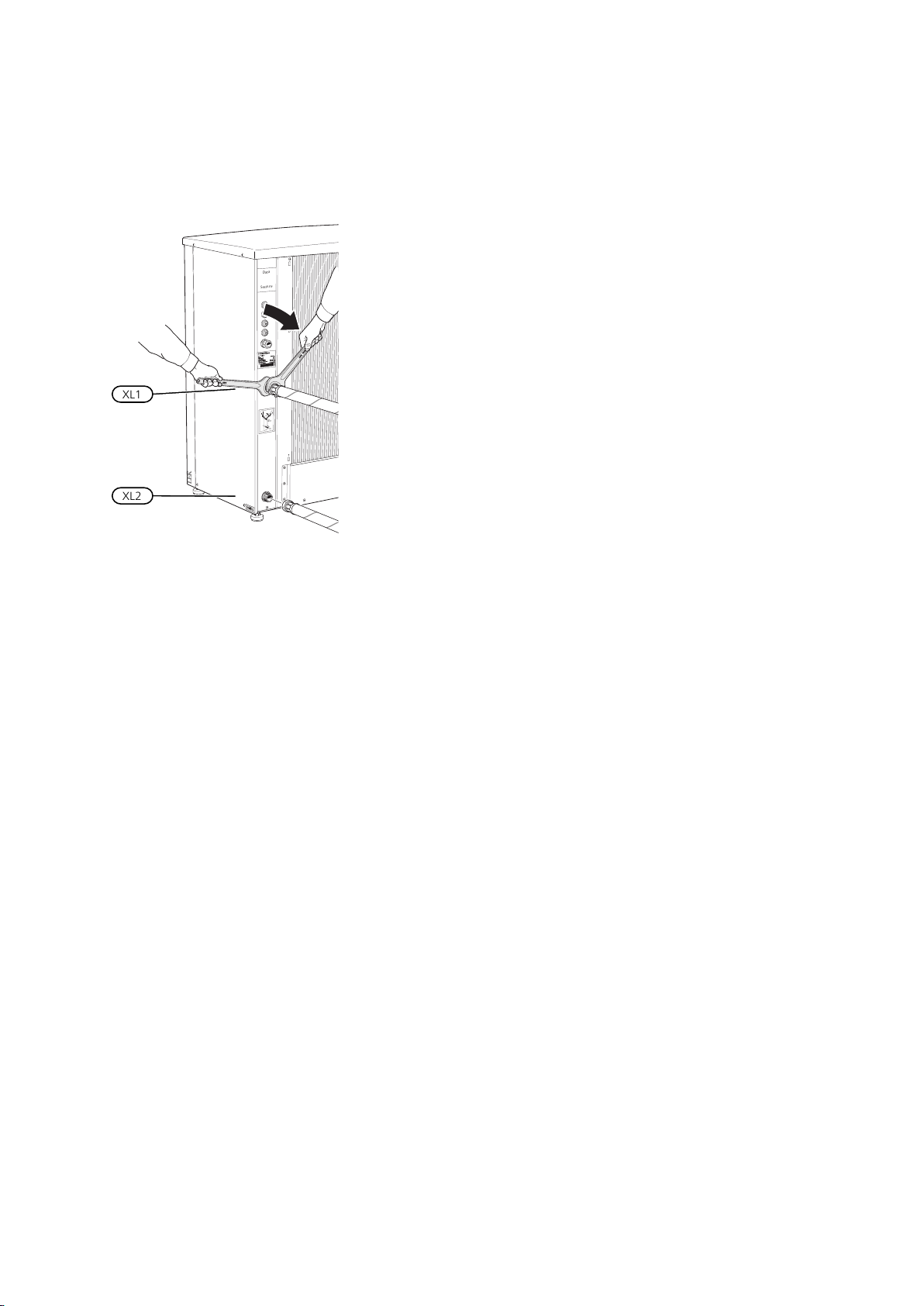

Installing flex hoses

LEK

Data

Serie.nr.

A

rt

.

nr

. 711453

OUT

IN

XL1

XL2

21Chapter 4 | Pipe connectionsMETROAIR I™

5 Electrical connections

General

■

The heat pump must not be connected without the

permission of the electricity supplier and must be

connected underthe supervisionof a qualified electrician.

■

If METROAIRI is fused witha miniature circuit breaker,

it must have at least motor characteristic ”C”. For MCB

size see "Technical Specifications".

■

METROAIR I does not include an omnipolar circuit

breaker on the incoming power supply. The heat

pump’s supply cable must be connected to a circuit

breaker with at least a 3 mm breaking gap. When the

building is equipped with an earth-fault breaker, the

heat pump should be equipped with a separate one.

The earth-fault breaker shouldhave a nominaltripping

current of nomore than30 mA.Incoming supply must

be 400V3N~ 50Hz viaelectrical distribution unitswith

fuses.

For 230V~ 50Hz, the incoming supply must be 230V~

50Hz via distribution box with fuses.

■

If an insulation test is to be carried outin the building,

disconnect the heat pump.

■

If the control is to be supplied separately from other

components in the heat pump (e.g. for tariff connection), a separate operating cable must be connected

to terminal block (X5).

■

The routing of cables for heavy current and signals

should be made out through the cable glands on the

heat pump's right-hand side, seen from the front.

■

The communication cable must be a three core,

screened cable andbe connectedbetween METROAIR I

terminal block X22 and the indoor module/control

module.

■

Connect the charge pumpto the indoor module/control module. See where the charge pump must be

connected in the installation manual for your indoor

module/control module.

NOTE

If the supply cable is damaged, only METROTHERM, its service representative or similar

authorised person may replace it to prevent

any danger and damage.

NOTE

Electrical installation and any servicing must

be carried out under the supervision of a qualified electrician. Disconnect the current with

the circuit breaker before carrying out any servicing. Electrical installation and wiring must

be carried out in accordance with the national

stipulations in force.

NOTE

Check theconnections, main voltage andphase

voltage before startingthe machine toprevent

damage tothe air/water heat pump’s electronics.

NOTE

The live external control must be taken into

consideration when connecting.

METROAIR I™Chapter 5 | Electrical connections22

Loading...

Loading...