Metro Therm METROAIR AQUA HPM User Manual

HEAT PUMPS

Manual

METROAIR AQUA

HEAT PUMP MODULE

DOMESTIC HOT

WATER HEAT PUMP

08:965-1609

EN

2

METROAIR AQUA HEAT

PUMP MODULE (HPM)

METRO article number: 156002601

3

Table of Contents

1 Transport 6

1.1 Delivery mode 6

1.2 Storage 6

1.3 Transport with forklift 6

1.4 Unloading the heat pump 6

2 Dimensions 7

3 About the product 8

3.1 General 8

3.2 Scope of delivery 8

3.3 Product description 8

3.4 Operation of the METROAIR AQUA 8

3.5 Technical data 9

3.6 Performance data 9

3.7 Refrigerant circuit – description 10

3.8 Requirements for the water circuit 11

3.8.1 Water circuit - diagram 12

3.9 Electrical diagram Optima 172 Control 13

3.10 Fan capacity 14

4 Before Installation and start up 15

4.1 Important safety instructions 15

4.1.1 Cooling system – safety instructions 15

4.1.2 Electrical circuit – safety instructions 15

4.1.3 Water circuit – safety instructions 15

4.1.4 Users 15

5 Installation 16

5.1 Location 16

5.2 Set-up sequence 16

5.3 Water connections 17

5.4 Location of connecting pipes 17

5.5 Connection of condensate drain 17

5.6 Air intake, air exhaust and connections 18

4

6 Commissioning 19

6.1 Leak test 19

6.2 Commissioning of the water circuit 19

6.3 Commissioning of the air circuit 19

6.4 Commissioning of the electrical circuit 19

7 Controls and Operations 20

7.1 Control panel Optima 170 20

7.2 Operation 20

7.3 Main Menu 20

7.3.1 Display view (main menu) 22

7.4 Service menu 22

7.4.1 Changing settings in the service menu 22

7.4.2 Service menu points 22

7.5 Table for set points 31

7.6 Table for defrosting 32

7.7 Functional description 32

7.7.1 Controlling Domestic hot water heat pump with Optima 170 33

7.7.2 Performance 33

7.7.3 The function of the heat pump 33

7.7.4 Water heating 34

7.7.5 Fan operation 34

7.7.6 Defrosting 36

7.8 Safety features 36

7.8.1 High pressure switch 36

7.8.2 Safety breakers 36

7.9 Alarms 36

7.9.1 PE: High pressure switch alarm 36

7.9.2 Er6: Atypical evaporator temperatures 36

Table of Contents

5

8 Maintenance 37

8.1 Environmental requirements 37

8.2 Cooling system and fan 37

8.3 Condensation and condensate drain 37

8.4 Water circulation and water tank 37

8.4.1 Pressure relief valve 37

9 Disassembly/decommissioning 38

10 Troubleshooting 39

10.1 The heat pump does not supply hot water 39

11 Warranty provisions 40

12 Declaration of conformity 41

13 Product and installer information 42

6

1 Transport

Immediately upon receipt, examine the Heat Pump Module (HPM) to make sure that it is intact

and undamaged. If not, inform this to the shipping company immediately. All shipments are the

responsibility of the recipient unless otherwise agreed.

1.1 Delivery mode

METROAIR AQUA HPM is delivered without condensate drain tube and the safety equipment for

the water circuit.

1.2 Storage

METROAIR AQUA HPM must be stored and transported upright free of water and within its

packaging.

Transport and storage may take place at temperatures between -10 °C and +50 °C. If the unit

has been transported or stored at sub-zero temperatures leave the unit at room temperatures

for 24 hrs before commissioning.

1.3 Transport with trolley

When transporting the METROAIR AQUA HPM by trolley the unit shall be in its disignated transportation box and transportet upright. The box shall be lifted from the disignated side.

Make sure that the trolley does not damage the cabinet or the various connections.

1.4 Tilting of unit

When carefully and manually transporting the METROAIR AQUA HPM over a short distance to

its final location the unit can be tilted up to 45°. If this limit is exceeded, the METROAIR AQUA

must be left in its normal upright position for at least 1 hour before it is started.

7

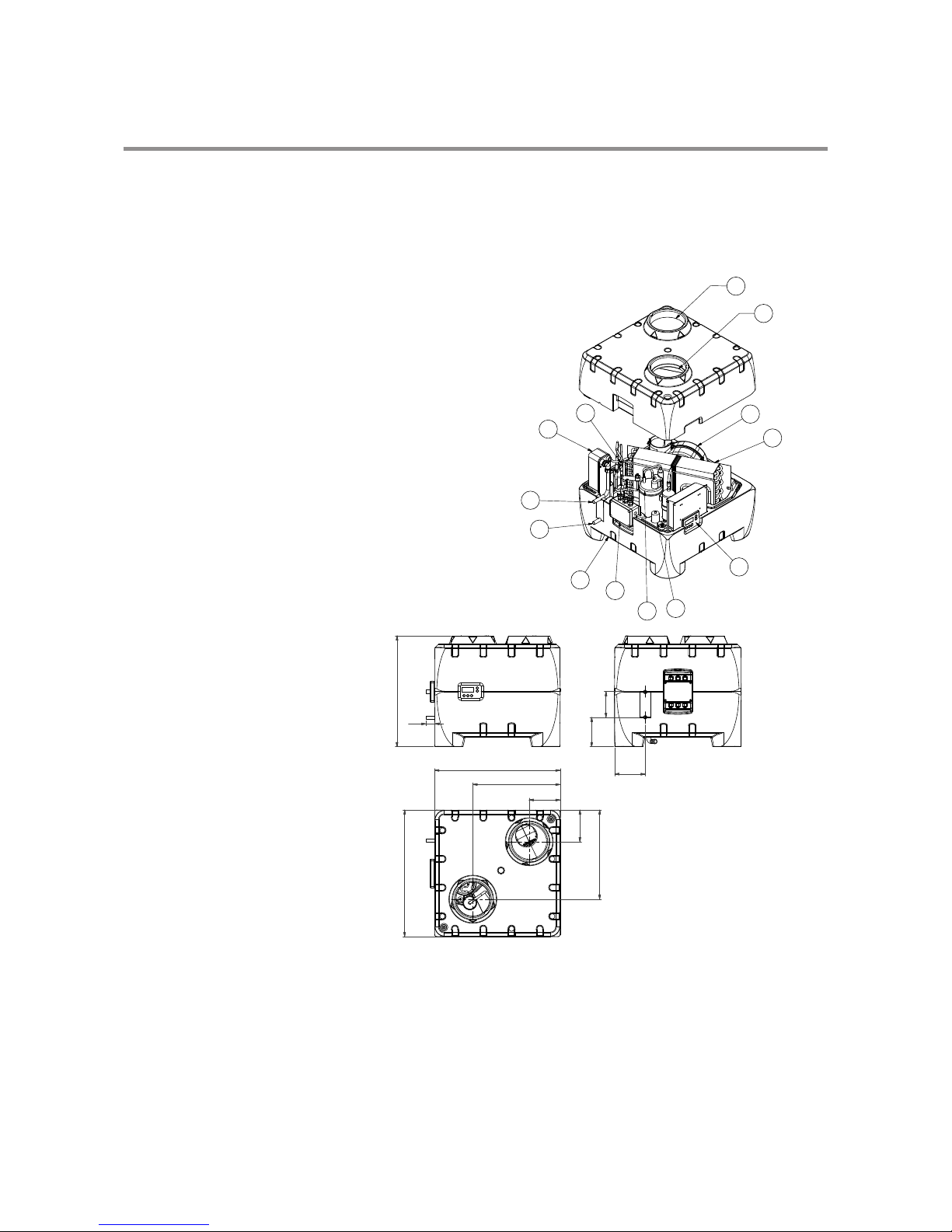

2 Dimensions

1 Inlet air Ø 160 mm

2 Outlet air Ø 160 mm

3 Cold water connection Ø15

4 Hot water connection Ø15

5 Circuit board

6 Electrical junction box

7 Condensate drain 3/4” hose connection

8 Condenser

9 Compressor

10 Capacitor

11 Evaporator

12 Fan

13 Thermostatic expansion valve

General arrangement METROAIR AQUA HPM

All dimensions in mm.

1

2

3

4

5

6

508

140

134

118,5

575

580

142

145

408

400

41

5

12

11

9

8

10

7

6

4

3

1

2

13

8

3 About the product

3.1 General

The heat pump module (HPM) has been designed and produced according to all relevant EU

guidelines (please also refer to the EEC-declaration of conformity).

3.2 Scope of delivery

• Hot water heat pump unit with built-in control.

• External temperature sensors T7 and T8.

• Manual including installation guidelines, operating instructions and technical data.

3.3 Product description

The METROAIR AQUA HPM is a hot water heat pump, ready made for installation. It has

been designed for domestic hot water application but can also be used for e.g. space heating

applications. It consists of cabinet, components for refrigerant, air and water circuits as well as

control panel, and control and monitoring equipment designed for automatic operation.

The application area and operating principles of the heat pump are specified in this manual.

3.4 Operation of the METROAIR AQUA HPM

The control starts the compressor when hot water is needed. The compressor operates until the

water in the water tank (T8) reaches the set temperature. Usually, the METROAIR AQUA HPM

can produce enough hot water to cover the need of a household of 4 persons.

If the METROAIR AQUA HPM is not able to produce enough domestic hot water, an electrical

immersion heater can be installed in the adjacent water tank and activated by the HPM.

This way more domestic hot water can be produced. It is possible to set the temperature to

which the electrical immersion heater should heat the water. The electrical immersion heater

should only be used when there is a need, as it consumes significantly more energy that the

compressor.

Any work carried out on

this unit must only be done by

skilled personnel.

Take all necessary precautions to

avoid accidents.

9

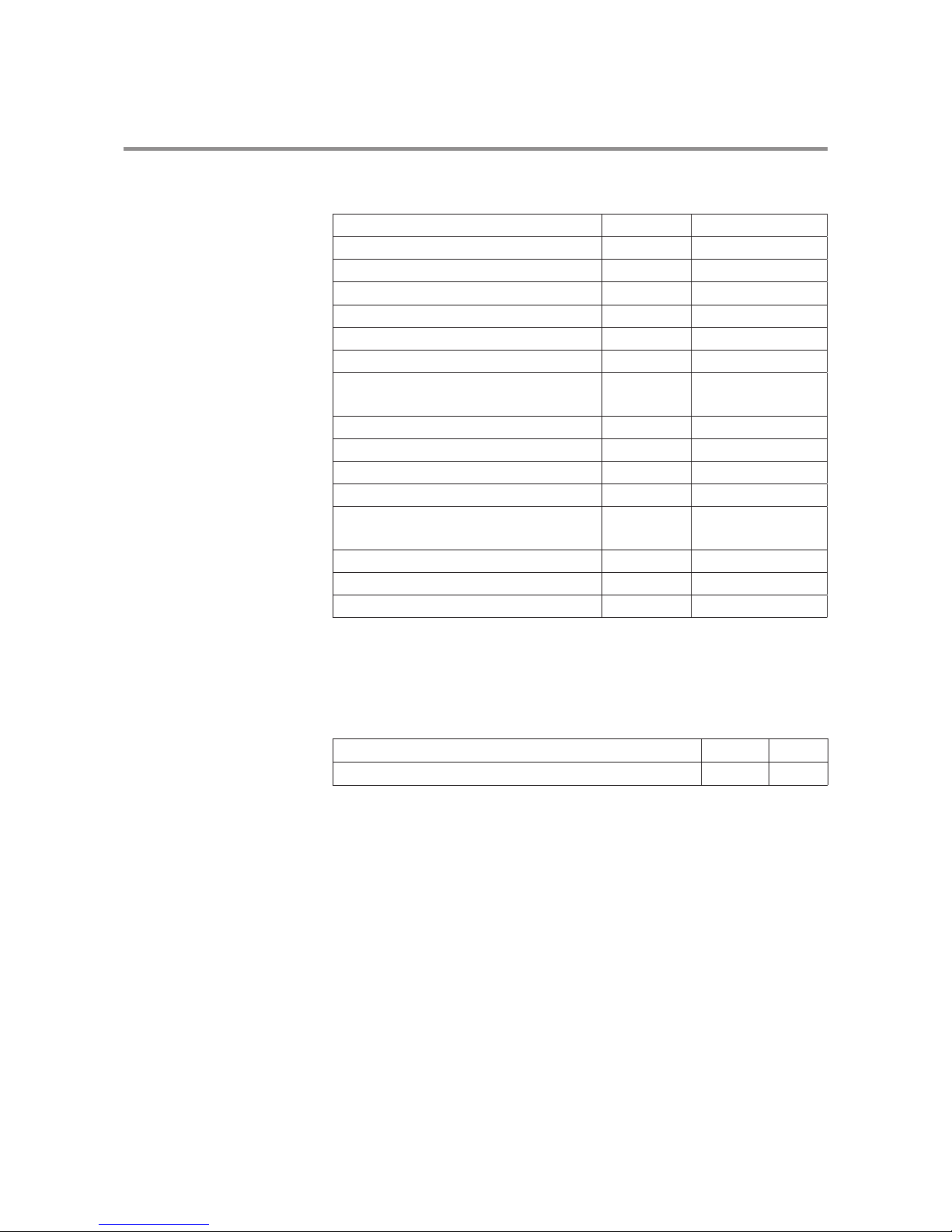

Dimensions (LxWxH) mm 580x575x508

Weight kg 30

Air duct connections mm Ø160

Water connections (compression fittings) mm Ø15

Condensate outlet (hose connection) “ 3/4

Maximum allowed water pressure MPa 1.0

Maximum allowed water temperature in tank °C 90

Allowed flow range external circulation pump

(not included)

I/hr 200-600

Refrigerant/quantity -/kg 134a/0.65

Electrical connections V/Hz 230/50 (L1, N, G)

Fuse size A 10 (13)

Max. water temperature (heat pump only) °C 60

Max. water temperature (heat pump and immersion heater)

°C 65

Air flow range (@100 Pa) m3/h 100-330

Temperature range for compressor operation °C -5 – + 35

Sound level 2 m in front om unit at 100% air flow dB(A) 44

COP acc. to EN-16147 class L , 7°C inlet air - 2.4

COP acc. to EN-16147 class L , 20°C inlet air - 3.3

3.6 Performance data

Performance specified for heating of domestic water from 10°C (cold water) to 52.5°C (domestic water) in a connected water tank of 300 l and extract air temperature 7°C:

3.5 Technical data

10

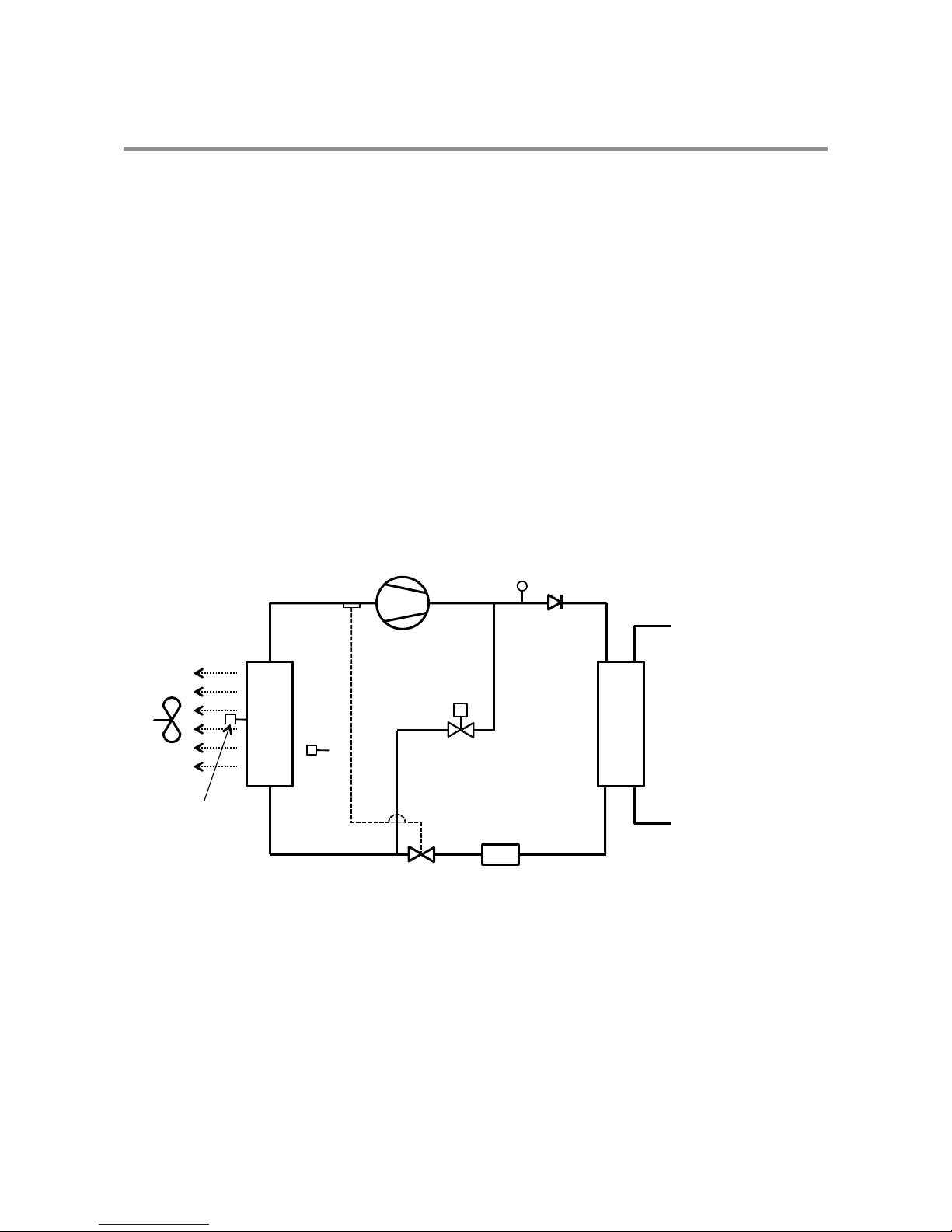

3.7 Refrigerant circuit – description

The cooling system is optimized for extracting the heat from the inlet air. Via the cooling system

the extracted heat is transferred to the water. The process is only possible with the addition of

additional external energy in the compressor. The cooling system is a closed system where the

HCFC-free refrigerant R134a is the energy carrier.

In the evaporator, heat is absorbed from the air and transferred to the refrigerant at low evaporation temperature. Refrigerant in gaseous form is fed to the compressor, in which it is raised up

to a higher pressure and temperature level and transported to the condenser. In the condenser

the refrigerant condense and the heat absorbed in the evaporator plus some of the compressor

energy is transferred to the water.

Finally the high condensing pressure is throttled to the evaporating pressure using an expansion

valve and the refrigerant can again absorb heat from the extract air in the evaporator.

3.7.1 Refrigerant circuit – diagram

3 About the product

Air temp

sensor

(T5)

Evaporating temp

sensor (T6)

Evapo

rator

Filter drier

Compressor

Thermostatic

expansion

valve

HP-switch

Condenser

Cold water

inlet

Hot water

outlet

Solonoid valve

Checkvalve

Fan

Hot water outlet

11

3.8 Requirements for the water circuit

The water circuit must be constructed in accordance with local norms and standards. The water

used must be of drinking water quality when charged to the system. Material compatibility in

the whole system must be ensured.

The pipe sizes for on-site installation shall be defined based on the available water pressure

as well as the expected pressure loss in the pipe system. The water circuit shall be designed

according to the drinking water installation regulative in force. Incorrect material combinations

in the water circuit can lead to corrosion damage due to galva-nic corrosion. This requires special

attention when using galvanized components and components that contain copper.

As for all pressurized vessels the heat pump associated water tank has to have an approved

safety valve (pressure setting depending on local rules and regulations) and a non return/

check valve on the cold water inlet. Max. working pressure is 1.0 MPa (10 bar) and max. inlet

temperature is 65°C. Dirt must be avoided in the pipe system (if necessary flush the pipes before

the heat pump is connected)!

12

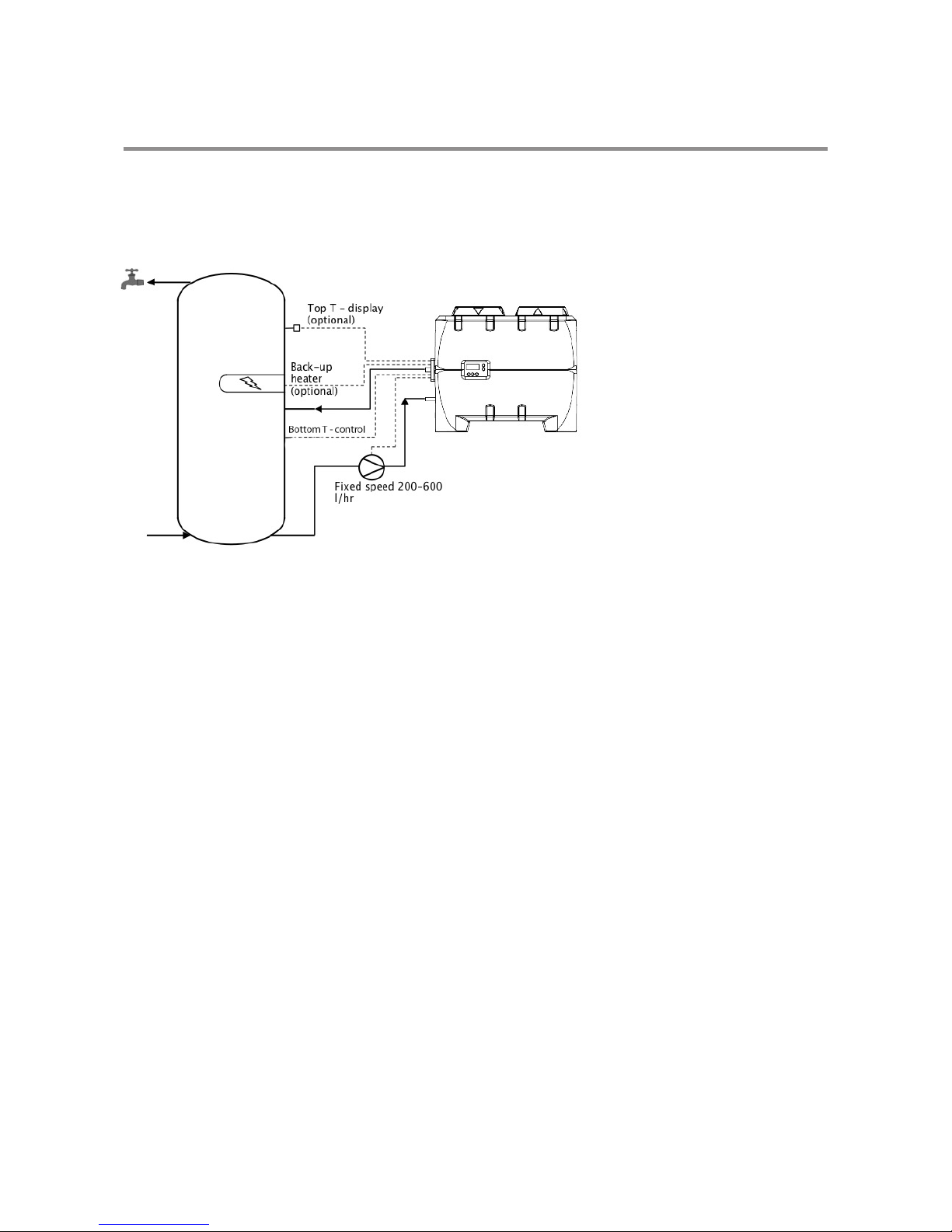

3.8.1 Water circuit - diagram

3 About the product

The HPM heats up the water by the principle of repeatable circulations to reach set point temperature, typically, 5-15 passes to fully heat op a water tank starting with cold water.

Therefore the following should be observed during installation:

- The hot water inlet from the heat pump shall be placed, e.g., 1/3 down from the top to ensure

that hot water is available for use while the heat pumpe heats up the lower 2/3 of the water

tank.

- The heat pump control sensor, T8, shall be located around the how water inlet from the heat

pump. If a higher readyness of hot water is required the sensor location can be lowered.

- Sensor T7 can be used for optional display of temperature in the top of the tank.

- If an optional electrical heater is controlled by the HPM sensor T7 shall be installed ABOVE the

electrical heating element sensor sensor T7 is controling sensor for the electrical heater. It is

recommended to use a safety breaker which will disengage at 80°C.

- A fixed speed pump shall be installed on the cold water return to the HPM. A pump rate

between 200-600 l/h is advisable. Higher pump rates gives better HPM performance but also

consumes more circulation pump power.

13

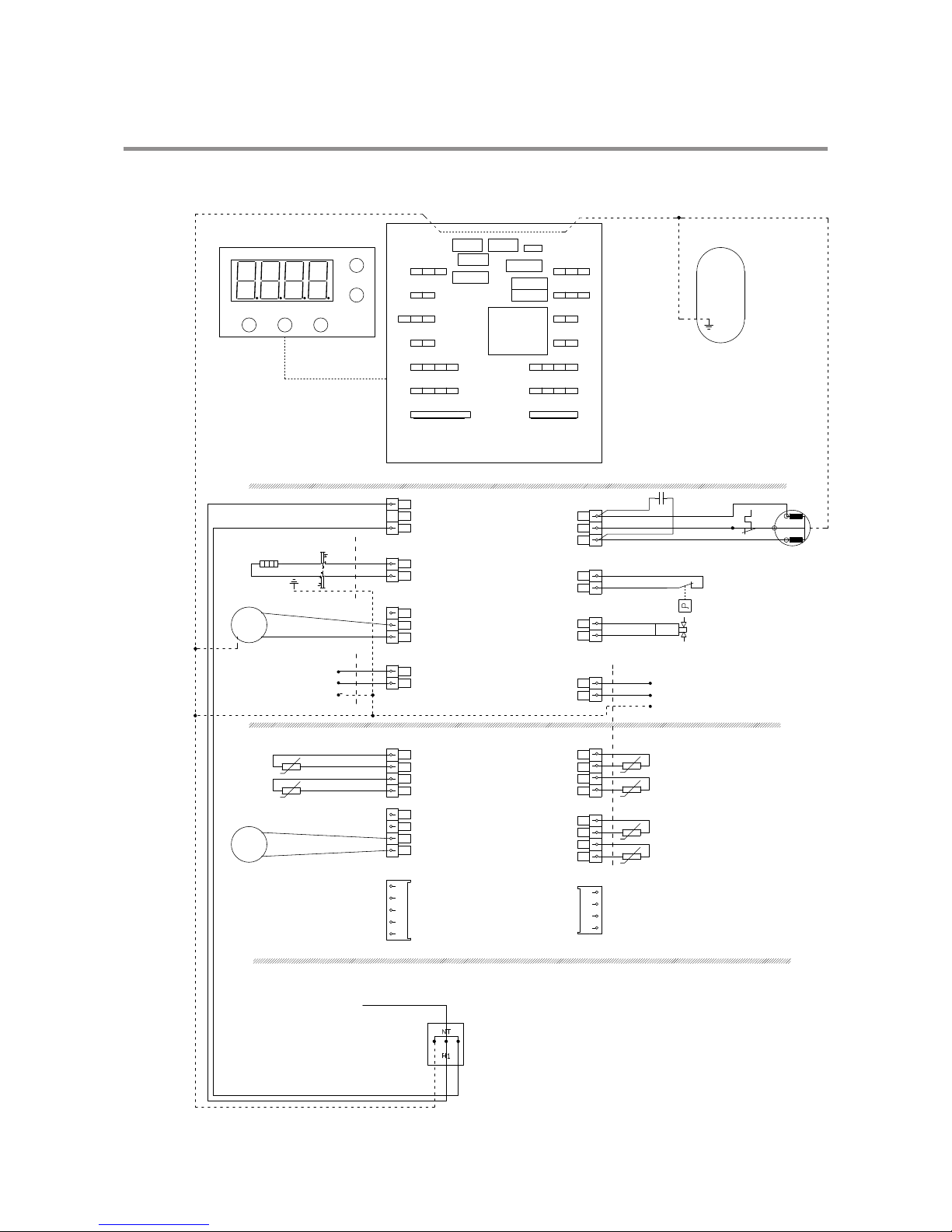

EP

M1

KP

NT

Skal jordforbindes jvt. stærkstrøms reglementet

Must have earth connection

Muss erdung haben

Tilslutning Datalog

Connection Datalog

Anschluss Datalog

MA4-

NT-

EP-

P-

T5-

T6-

T7-

T8-

T9-

T10-

80°C

Føler før køleflade

Sensor before the evaporator

Fühler bevor die kühlfläche

Føler Køleflade

Sensor on the evaporator

Kühlfläche fühler

Føler tank top

Sensor in the top of the tank

Oberer speicher fühler

Føler tank bund

Sensor in the bottom of the tank

Unterer Speicherfühler

Ekstra funktion

Ekstra Funktion

Extra Funktion

Føler start/stop

Sensor start/stop

Fühler start/stop

Tilslutning Datalog

Connection Datalog

Anschluss Datalog

T5-

T6-

T7-

T8-

T9-

T10-

Magnetventil afrimning

Magnetventile Abtau

Solonoid valve Defrost

Nettilslutning 1x230V 50Hz

sikring max. 13 Amp

end main: 1x230V 50Hz

fuse mx. 13 Amp

Netzende: 1x230V 50Hz

sicherung max 13 Amp

El-patron 1,5kW

Electric heating element 1,5kW

Heizstab 1,5kW

Højtrykspressostat

High pressure switch

Hochdruckpressostat

12 12

H1

12 12

H2

12

12

H6

1212

H7

1212

H8

12341234

L4

12341234

L5

12 3

12 3

H3

12 312 3

H5

12341234

L6

T7

T8

VL1

MA4

BUBNPE BUBNPE

M1

C

PE

R

S

C

PE

R

S

PE

121

2

1

2

1

2

1

1

1

1

1

1 1

1

1

1

1

1

11

2 2

2

2

2

2

2

2

2

2

2

2

2 2

3

3

3

3

3

3

3

3

344

4

4

4

4

5

PE PEPE PEPE PEPE PE

Q1=1,6A Q2=5A

H1

H2

H3

H4

H5

H6

H7

H8

L1

L2

L4

L5

L3 L6

F

F

F

F

F

F

F

N

N

N

N

N

N

1

1

1

1

1

1 1

1

1

1

1

1

11

2 2

2

2

2

2

2

2

2

2

2

2

2 2

3

3

3

3

3

3

3

3

344

4

4

4

4

5

PE PEPE PEPE PEPE PE

1234 1234

L2

BuBu

-M2

YeYe

1234 1234

L1

12345 12345

L3

T5

T6

M1-

EC blæser forsyning

EC fan supply

EC Lüfter strom

M2-

EC blæser kontrol

EC fan control

EC Lüfter regeln

T10

T9

Aux relæ

Aux Relay

Aux Relais

PEPE

1122

H4

PEPE

Pumpe

Pump

Pumpe

Included

Excluded

Excluded

Included

Included

Excluded

3.9 Electrical diagram Optima 172 Control

14

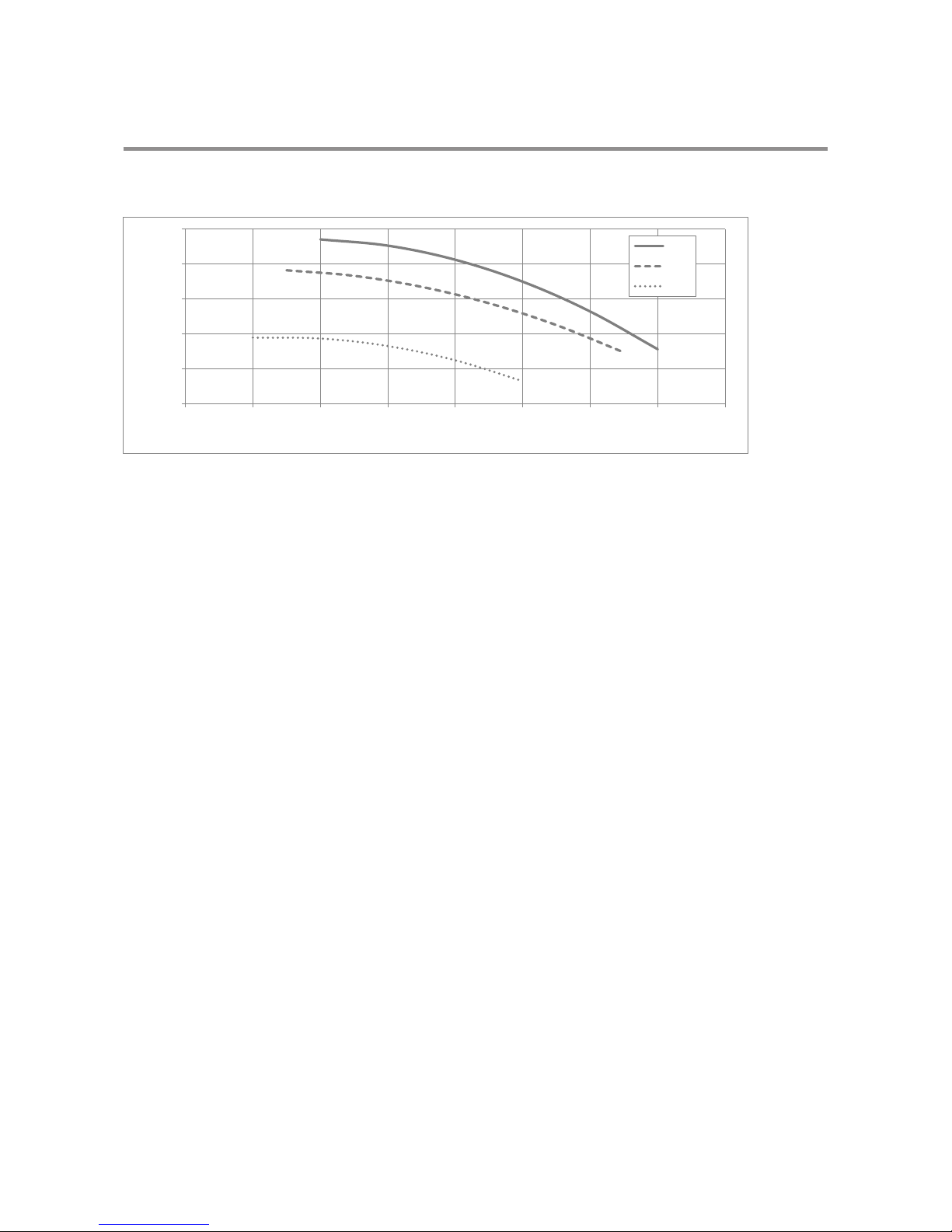

0,0

50,0

100,0

150,0

200,0

250,0

0 50 100 150 200 250 300 350 400

Pressure [Pa]

Air volume flow [m3/h]

100%

75%

50%

3.10 Fan capacity

It is recommended to keep the external pressure loss below 100 Pa.

3 About the product

Loading...

Loading...