Metro Therm 15 pipe downwards 905, 15 pipe upwards 906, 30 pipe downwards 907, 30 pipe upwards 910, 35 pipe upwards 909 User Manual

...

TANKS

08:008-1902

ELECTRICAL

WATER HEATERS

Manual

Models 15, 30 and 35

Type 611, 905, 906, 907, 909 and 910

Type 905, 907

Type 906, 910

Model 15 pipe downwards

Type 905

METRO number: 119051004

Plumbing number: 345166200

Model 15 pipe upwards

Type 906

METRO number: 119061004

Plumbing number: 345167200

Model 30 pipe downwards

Type 907

METRO number: 119071004

Plumbing number: 345166400

Model 30 pipe upwards

Type 910

METRO number: 119101004

Plumbing number: 345167400

Model 35 pipe upwards

Type 909

METRO number: 119091001

Plumbing number: 345161034

Type 611

Model 35 pipe downwards

Type 611

METRO number: 116111004

Plumbing number: 345121100

Type 909

2

Contents

Transport 4

Position 4

Diagram 5

Plumbing installation 6

Electrical installation 8

User Guide 10

Maintenance 12

Troubleshooting 14

Guarantee terms 16

Declaration of compliance 18

3

Transport

Inspect the water heater for damage and missing parts immediately upon receipt. Report any

damage or missing parts to the carrier immediately. All carriage is the responsibility of the

recipient unless otherwise agreed.

Position

Installation can only be performed by an authorised plumbing installer, and in accordance

with the Danish Building Code.

Tank and pipes cannot be exposed to freezing. Position the tank close to its water supply and

a floor drain. Ensure that there is sufficient room for service and maintenance.

Important!

Check that the wall can bear the weight of the tank when full of water.

Type 906, 909 and 910 (pipe upwards) must stand on a firm, level surface.

4

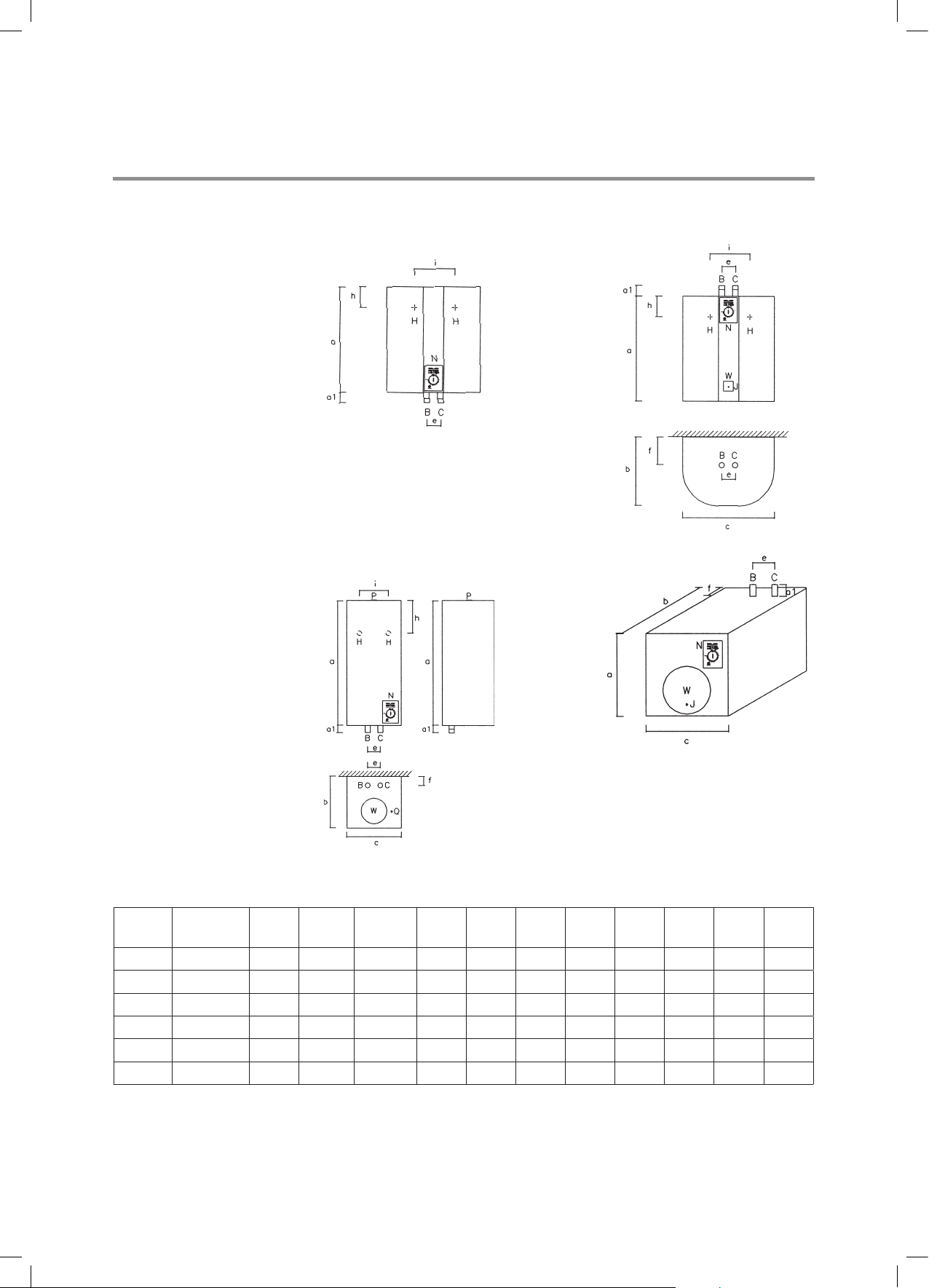

Diagram

B Hot water outlet

C Cold water inlet

H Holes in mounting plate

J Drain spout

N Control box

O Indicator light

Q Electrical connection

W Removable plate

I CC measurements for mounting plate

Models 15-30 (type 905, 907) Models 15-30 (type 906, 910)

Model 35 (type 611)

Model 35 (type 909)

Dimensioned diagram

All dimensions are in mm.

Type no. Pipe

connection

905

906

907

909

910

611

i

h

i

h

h

i

Model Volume

(litres)

Net

weight

a a1 b c e f h i

15 14 16 450 35 300 390 70 110 103 255

15 14 16 450 35 300 390 70 110 103 255

30 26 22 525 65 345 460 70 138 103 255

35 33 25 380 25 540 380 100 105 -

30 26 22 525 65 345 460 70 138 103 255

35 33 23 700 30 300 300 70 50 183 160

-

5

Plumbing installation

Note following for installation

Installation can only be performed by an authorised plumbing/electrical installer, and in

accordance with the Danish Building Code.

• Installations shall comply with the Danish Building Code and all other relevant regulations

and provisions, including those for electrical and water installations.

• Check all technical data and information on the type plate.

• Check that all accessories are removed from the packaging.

• Check that there is easy access to the hot water tank.

• Flush all water pipes carefully before connection.

• Always perform pressure testing at water pressure of 10 bar when replacing a water heater

or service has been performed on pressurised parts.

• Never expose the heater to water pressure exceeding 1 MPa (10 bar).

• The heater is fitted with nylon bushings for the cold water connection and PEX pipes for the

hot water connection. These parts protect the enamel coating and must not be removed.

The installer shall instruct the user of the heater’s function, care and disposal.

Approvals

VA no. 3.23/DK 19559

Approved by DEMKO

Hot water tank

Test pressure 13.5 bar

Operating pressure 10 bar

Energy labels at www.METROTHERM.dk

Risk of corrosion

METRO THERM hot water tanks are made of enamelled steel, and protected by a magnesium

anode. If connections and pipes are copper or stainless steel, there can be risk of galvanic

corrosion at the point of connection.

The risk can be mitigated by using a PEX pipe adapter between tank and pipe installation.

Using softened water in a METRO THERM tank

Water softened using salt can be used in a METRO THERM hot water tank. Conductivity must

be kept under 100 mS/m (millisimiens per m), to be able to use the anode. Water pH value

must be between 6 and 9, and chloride content must be under 250mg Cl/l.

If this level of conductivity is exceeded, the anode current will be too high, degrading the

anode too rapidly. That will cause the water to smell. It may be necessary to remove the anode

to remedy this, which will invalidate the METRO THERM 5-year corrosion guarantee on the

inner tank.

Do not use demineralised water (double ion exchange), which will rapidly corrode the tank.

Demineralised water is also referred to as totally desalinated or deionised water.

6

Loading...

Loading...