Servo drive

Mounting Instructions

DIS-2 48/10 FB FS STO

Metronix Meßgeräte und Elektronik GmbH Telefon: +49-(0)531-8668-0

Kocherstraße 3 Telefax: +49-(0)531-8668-555

38120 Braunschweig E-mail: vertrieb@metronix.de

Germany http://www.metronix.de

Original instructions

Copyrights

2013 Metronix Meßgeräte und Elektronik GmbH. All rights reserved.

The information and data in this document have been composed to the best of our knowledge. However,

deviations between the document and the product cannot be excluded entirely. For the devices and the

corresponding software in the version handed out to the customer, Metronix guarantees the contractual

use in accordance with the user documentation. In the case of serious deviations from the user

documentation, Metronix has the right and the obligation to repair, unless it would involve an

unreasonable effort. A possible liability does not include deficiencies caused by deviations from the

operating conditions intended for the device and described in the user documentation.

Metronix does not guarantee that the products meet the buyer’s demands and purposes or that they work

together with other products selected by the buyer. Metronix does not assume any liability for damages

resulting from the combined use of its products with other products or resulting from improper handling of

machines or systems.

Metronix Meßgeräte und Elektronik GmbH reserves the right to modify, amend, or improve the document

or the product without prior notification.

This document may, neither entirely nor in part, be reproduced, translated into any other natural or

machine-readable language nor transferred to electronic, mechanical, optical or any other kind of data

media, without expressive authorisation by the author.

Trademarks

Any product names in this document may be registered trademarks. The sole purpose of any trademarks

in this document is the identification of the corresponding products.

ServoCommander™ is a registered trademark of Metronix Meßgeräte und Elektronik GmbH.

Revision Information

Author: Metronix Meßgeräte und Elektronik GmbH

Manual title: Mounting Instructions “Servo drive DIS-2 48/10 FB FS STO”

File name: MI_DIS-2_48_10_FB-FS-STO_1p0_EN.docx

Version 1.0 July 2013

Page 3

CONTENTS

1 GENERAL .......................................................................................................... 5

1.1 Documentation............................................................................................ 5

1.2 Scope of supply .......................................................................................... 6

2 SAFETY NOTES FOR ELECTRICAL DRIVES AND CONTROLLERS ............. 8

2.1 Used symbols ............................................................................................. 8

2.2 General notes ............................................................................................. 8

2.3 Danger resulting from misuse ................................................................... 10

2.4 Safety notes .............................................................................................. 10

2.4.1 General safety notes .................................................................. 10

2.4.2 Safety notes for assembly and maintenance ............................. 11

2.4.3 Protection against electrical shock by means of

protective extra-low voltage (PELV) .......................................... 13

2.4.4 Protection against dangerous movements ................................. 13

2.4.5 Protection against contact with hot parts ................................... 14

2.4.6 Protection during handling and assembly .................................. 14

3 TECHNICAL DATA .......................................................................................... 15

3.1 Ambient conditions and qualification ......................................................... 15

3.2 Supply [X1] ............................................................................................... 16

3.3 Motor connection [X301-X303] ................................................................. 16

3.4 Angle encoder connector [X2] .................................................................. 17

3.5 Communication interfaces ........................................................................ 18

3.6 STO interface ........................................................................................... 20

3.7 Fieldbus interfaces .................................................................................... 21

4 MECHANICAL INSTALLATION ....................................................................... 22

4.1 Important notes ......................................................................................... 22

4.2 Position and alignment of the connectors ................................................. 23

4.2.1 Connectors on the main board ................................................... 23

4.2.2 Connectors for the fieldbus interfaces and RS232 interface

(CANopen, PROFIBUS or EtherCAT) ........................................ 23

4.3 Dimensions of the housing ....................................................................... 24

4.4 Mounting ................................................................................................... 26

5 ELECTRICAL INSTALLATION ........................................................................ 30

5.1 Connection to power supply, control and motor ........................................ 30

5.2 Connectors on the basic device DIS-2 48/10 FB FS STO ........................ 32

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 4

5.2.1 Connection: Power supply and I/O [X1] .................................... 32

5.2.2 Connection: Motor [X301-X303] ................................................ 34

5.2.3 Connection: Angle encoder [X2] ................................................ 34

5.2.4 Connection: Holding brake [X3] ................................................. 36

5.2.5 Connection: Brake resistor [X304, X305] .................................. 37

5.2.6 Connection: Extension port [X8] ................................................ 38

5.2.7 Connection: Safe Torque Off (STO) [X40] and [X40A] .............. 40

5.3 Connectors field bus modules DIS-2 48/10 FB FS STO .......................... 42

5.3.1 Connection: Serial interface [X5] ............................................... 42

5.3.2 Connection: CANopen [X401] and [X402] ................................. 43

5.3.3 Connection: PROFIBUS [X401] and [X402] .............................. 44

5.3.4 Connection: EtherCAT [X401] and [X402] ................................. 45

6 FUNCTIONAL SAFETY TECHNOLOGY ......................................................... 46

6.1 General, intended use .............................................................................. 46

6.2 Safety indices ........................................................................................... 46

7 EMC-COMPLIANT CABLING .......................................................................... 47

7.1 Connection between the DIS-2 and the motor ......................................... 47

7.2 Connection between DIS-2 and power supply ......................................... 48

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

General Page 5

1 General

1.1 Documentation

This installation information serves the purpose of a safe use of the DIS-2 48/10 FB FS STO servo drive.

It contains safety notes, which must be complied with.

Further information can be found in the following manuals of the DIS-2 product range:

Product Manual “Servo drive DIS-2 48/10 FB FS STO”: Description of the technical data and the

device functionality plus notes concerning the installation and operation of the DIS-2 48/10 FB FS

STO servo drive (German version).

CANopen Manual “Servo drive DIS-2”: Description of the implemented CANopen protocol as per

DSP402.

PROFIBUS Manual “Servo drive DIS-2 48/10 FB”: Description of the implemented PROFIBUS-DP

protocol.

EtherCAT Manual “Servo drive DIS-2 48/10 FB”: Description of the implemented EtherCAT

protocol (Geman version).

User Manual “DIS-2 48/10, DIS-2 48/10 IC, DIS-2 48/10 FB”: Description of the device functionality

and the software functionalities of the firmware including the RS232 communication. Description of

TM

the parameterisation program DIS-2 ServoCommander

DIS-2 series servo drive.

You can find all these documents on our homepage at the download area (http://www.metronix.de

Furthermore, the manuals are part of the CD-ROM DIS-2 ServoCommander™.

Certificates and declarations of conformity for the products described in this manual can be found at

http://www.metronix.de

The functions described in this installation information refer to the firmware version 3.4.

.

with instructions for the commissioning of a

).

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 6 General

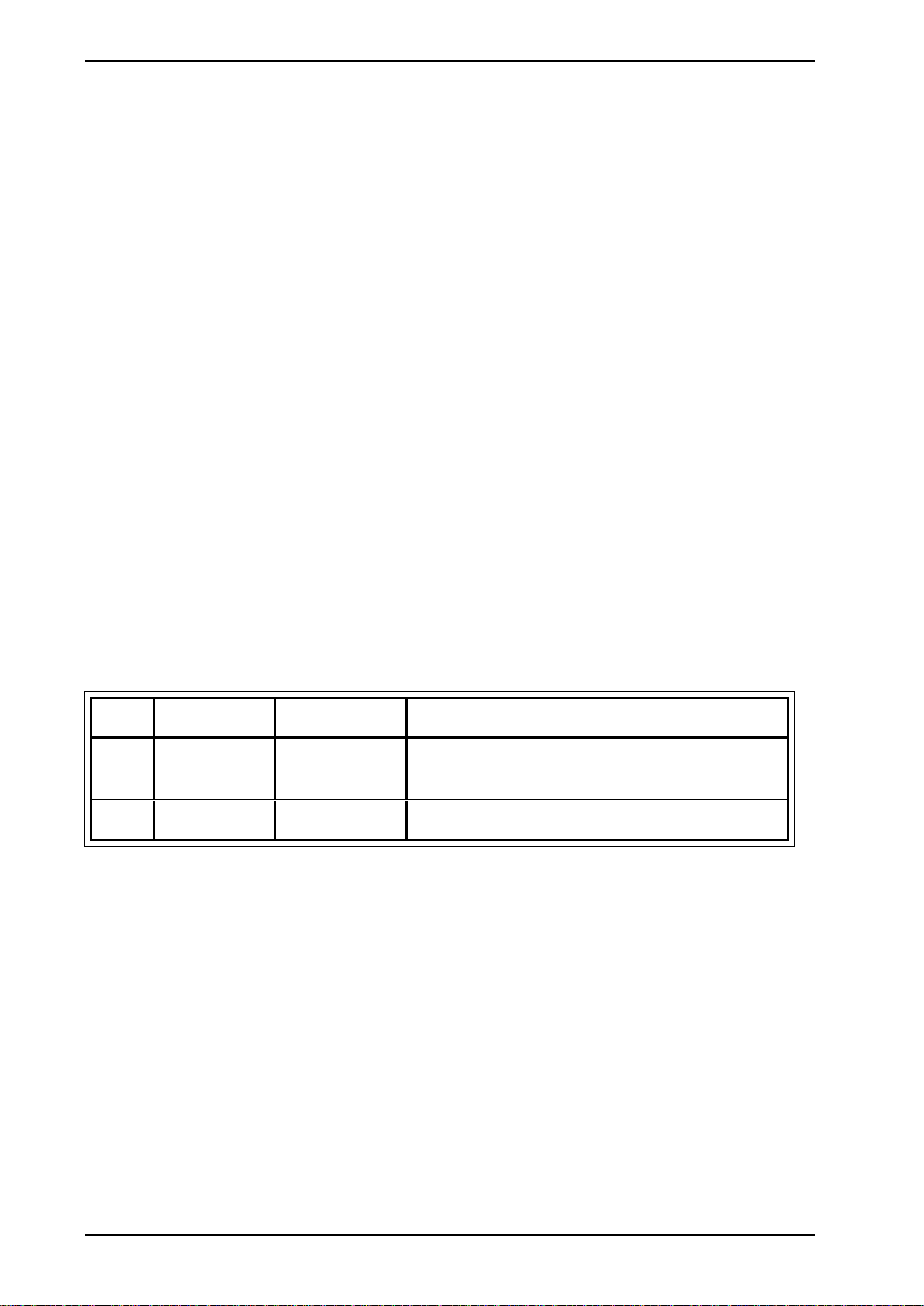

1.2 Scope of supply

The DIS-2 48/10 FB FS STO servo drive is available in the following three versions. The corresponding

technology modules (CAN, PROFIBUS, EtherCAT) are factory-integrated and are not designed for an

exchange by the user.

Table 1: Scope of supply DIS-2 48/10 FB FS STO CANopen

1x Servo drive DIS-2 48/10 FB FS STO CANopen Metronix part number:

9019-0248-13

1x STO connection cable pre-fabricated on both sides with

the device interface M12 (circular connector) for rear panel

installation.

1x Counterplug for the STO interface

Table 2: Scope of supply DIS-2 48/10 FB FS STO PROFIBUS

1x Servo drive DIS-2 48/10 FB FS STO PROFIBUS Metronix part number:

1x STO connection cable pre-fabricated on both sides with

the device interface M12 (circular connector) for rear panel

installation.

1x Counterplug for the STO interface

Table 3: Scope of supply DIS-2 48/10 FB FS STO EtherCAT

1x Servo drive DIS-2 48/10 FB FS STO EtherCAT Metronix part number:

9019-0248-14

9019-0248-15

1x STO connection cable pre-fabricated on both sides with

the device interface M12 (circular connector) for rear panel

installation.

1x Counterplug for the STO interface

Information

In the delivery status [X40] is not connected!

The scope of supply includes an STO connection cable pre-fabricated on both sides with

the device interface M12 (circular connector) for wiring the STO function.

For the case that the function “STO” is not needed, a counterplug for [X40] is included

alternatively. This counterplug allows bypassing pins 1, 3 and 5 to deactivate the STO

function.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

General Page 7

Counterplugs, control panel, mains filter, communication cables, brake resistor and parameterisation

program are not part of the standard scope of supply. They can be ordered as accessories:

Table 4: Accessories DIS-2 48/10 FB FS STO

1x Connector set for motor, encoder, holding brake: Metronix part number:

9019-0210-01

Content: 1x 3 pcs insulated blade receptacles

6,3 mm for motor connection

1x 16-pole counterplug für angle

encoder, incl. crimp contacts

1x 2-pole counterplug for holding

brake, incl. crimp contacts

1x Connector set for power supply and I/Os

1x 2-pole VARICON counterplug

Metronix part number:

9019-3120-01

(for DIS-2 48/10 FB FS STO)

1x 6-pole VARICON counterplug

(for DIS-2 310/2 FB FS STO)

2x 8-pole VARICON counterplug incl. sleeve

frame, sleeve housing and EMC cable gland

1x Control panel DIS-2 FB with Phoenix connector Metronix part number:

9019-0320-00

1x RS232 connection cable for DIS-2 48/10 FB

Pre-fabricated connection cable for the servo drive

Metronix part number:

9019-0221-00

parameterisation, length approximately 150 cm,

M8 circular connector for the connection to the

servo drive, DSUB9 connector for the connection

to the COM-Port of the PC

1x Brake resistor for DIS-2 48/10 FB

Plate resistor, Metallux PLR100.55.43, 5 Ω ±10%,

Metronix part number:

9519-0001-00

30 W continuous power output, dimensions 55 mm

x 43 mm, height: 1,5 mm, in the area of the

connecting cables height 4 mm, with strands

l = 100 mm

1x Parameterisation program

DIS-2 ServoCommander

TM

Metronix part number:

9019-0900-00

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 8 Safety notes for electrical drives and controllers

2 Safety notes for electrical drives

and controllers

2.1 Used symbols

Information

Important information and notes.

Caution!

Nonobservance may result in severe property damages.

DANGER!

Nonobservance may result in property damages and in personal injuries.

Caution! Dangerous voltages.

The safety note indicates a possible perilous voltage.

2.2 General notes

In case of damage resulting from non-compliance with the safety notes in this manual, Metronix

Meßgeräte und Elektronik GmbH will not assume any liability.

Prior to the initial use you must read chapter 2 Safety notes for electrical drives and

controllers, starting on page 8 and chapter 7 EMC-compliant cabli ng, starting on

page 47.

If the documentation in the language at hand is not understood accurately, please contact and inform

your supplier.

Sound and safe operation of the servo drive requires proper and professional transportation, storage,

assembly and installation as well as proper operation and maintenance.

Only trained and qualified personnel is authorised to handle electrical devices and systems:

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Safety notes for electrical drives and controllers Page 9

TRAINED AND QUALIFIED PERSONNEL

in the sense of this product manual or the safety notes on the product itself are persons who are

sufficiently familiar with the project, the setup, assembly, commissioning and operation of the product as

well as all warnings and precautions as per the instructions in this manual and who are sufficiently

qualified in their field of expertise:

Education and instruction or authorisation to switch devices/systems on and off and to ground them

as per the standards of safety engineering and to efficiently label them as per the job demands.

Education and instruction as per the standards of safety engineering regarding the maintenance and

use of adequate safety equipment.

First aid training.

The following notes must be read prior to the initial operation of the system to prevent personal injuries

and/or property damages:

These safety notes must be complied with at all times.

Do not try to install or commission the servo drive before carefully reading all safety

notes for electrical drives and controllers contained in this document. These safety

instructions and all other user notes must be read prior to any work with the servo drive.

In case you do not have any user notes for the servo drive, please contact your sales

representative. Immediately demand these documents to be sent to the person

responsible for the safe operation of the servo drive.

If you sell, rent and/or otherwise make this device available to others, these safety notes

must also be included.

The user must not open the servo drive for safety and warranty reasons.

Professional control process design is a prerequisite for sound functioning of the servo

drive!

DANGER!

Inappropriate handling of the servo drive and non-compliance with the warnings

as well as inappropriate intervention in the safety features may result in property

damage, personal injuries, electric shock or in extreme cases even death.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 10 Safety notes for electrical drives and controllers

2.3 Danger resulting from misuse

DANGER!

High electrical voltages and high load currents!

Danger to life or serious personal injury from electrical shock!

DANGER!

High electrical voltage caused by wrong connections!

Danger to life or serious personal injury from electrical shock!

DANGER!

Surfaces of device housing may be hot!

Risk of injury! Risk of burning!

DANGER!

Dangerous movements!

Danger to life, serious personal injury or property damage due to unintentional

movements of the motors!

2.4 Safety notes

2.4.1 General safety notes

The servo drive corresponds to IP54 degree of protection as well as pollution degree 2.

Make sure that the environment corresponds to this degree of protection and pollution

degree.

Only use replacement parts and accessories approved by the manufacturer.

The devices must be connected to the mains supply as per EN regulations and VDE

regulations, so that they can be cut off the mains supply by means of corresponding

separation devices (for example main switch, contactor, power switch).

Gold contacts or contacts with a high contact pressure should be used to switch the

control contacts.

Preventive interference rejection measures should be taken for control panels, such as

connecting contactors and relays using RC elements or diodes.

The safety rules and regulations of the country in which the device will be operated must

be complied with.

The environment conditions defined in the product documentation must be kept. Safety-

critical applications are not allowed, unless specifically approved by the manufacturer.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Safety notes for electrical drives and controllers Page 11

For notes on installation corresponding to EMC, please refer to chapter 7 EMC-

compliant cabling, starting on page 47. The compliance with the limits required by

national regulations is the responsibility of the manufacturer of the machine or system.

The technical data and the connection and installation conditions for the servo drive are

to be found in this product manual and must be met.

DANGER!

The general setup and safety regulations for work on power installations (for example

DIN, VDE, EN, IEC or other national and international regulations) must be complied

with.

Non-compliance may result in death, personal injury or serious property damages.

Without claiming completeness, the following regulations and others apply:

VDE 0100 Erection of power installations with nominal voltages up to 1000 V

EN 1037 Safety of maschinery - Prevention of unexpected start-up

EN 60204-1 Safety of machinery - Electrical equipment of machines

Part 1: General requirements

EN 61800-3 Adjustable speed electrical power drive systems

Part 3: EMC requirements and specific test methods

EN 61800-5-1 Adjustable speed electrical power drive systems

Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-5-2 Adjustable speed electrical power drive systems

Part 5-2: Safety requirements - Functional

EN ISO 12100 Safety of machinery - General principles for design - Risk assessment and

risk reduction

EN ISO 13849-1 Safety of machinery - Safety-related parts of control systems

Part 1: General principles for design

EN ISO 13849-2 Safety of machinery - Safety-related parts of control systems

Part 2: Validation

2.4.2 Safety notes for assembly and maintenance

The appropriate DIN, VDE, EN and IEC regulations as well as all national and local safety regulations and

rules for the prevention of accidents apply for the assembly and maintenance of the system. The plant

engineer or the operator is responsible for compliance with these regulations:

The servo drive must only be operated, maintained and/or repaired by personnel trained

and qualified for working on or with electrical devices.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 12 Safety notes for electrical drives and controllers

The motor holding brake supplied by default or an external motor holding brake driven by

Prevention of accidents, injuries and/or damages:

Additionally secure vertical axes against falling down or lowering after the motor has

been switched off, for example by means of:

Mechanical locking of the vertical axle,

External braking, catching or clamping devices or

Sufficient balancing of the axle

the servo drive alone is not suitable for personal protection!

Keep the electrical equipment voltage-free using the main switch and protect it from

being switched on again until the DC bus circuit is discharged, in the case of:

Maintenance and repair work

Cleaning

long machine shutdowns

Prior to carrying out maintenance work make sure that the power supply has been

turned off, locked and the DC bus circuit is discharged.

Be careful during the assembly. During the assembly and also later during operation of

the drive, make sure to prevent drill chips, metal dust or assembly parts (screws, nuts,

cable sections) from falling into the servo drive.

Also make sure that the external power supply of the servo drive (24 V) is switched off.

The DC bus circuit or the mains supply must always be switched off prior to switching off

the 24 V servo drive supply.

Carry out work in the machine area only, if AC and/or DC supplies are switched off.

Switched off output stages or servo drive enablings are no suitable means of locking. In

the case of a malfunction the drive may accidentally be put into action.

This does not apply to drives with the “Safe Torque Off” (STO) feature (see chapter 6).

Initial operation must be carried out with idle motors, to prevent mechanical damages for

example due to the wrong direction of rotation.

Electronic devices are never fail-safe. It is the user’s responsibility, in the case an

electrical device fails, to make sure the system is transferred into a secure state.

The servo drive and in particular the brake resistor, externally or internally, can assume

high temperatures, which may cause serious burns.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Safety notes for electrical drives and controllers Page 13

2.4.3 Protection against electrical shock by means of protective extra-low voltage (PELV)

All connections and terminals with voltages of up to 50 Volts at the servo drive are protective extra-low

voltage, which are designed safe from contact in correspondence with the following standards:

International: IEC 60364-4-41

European countries within the EU: EN 61800-5-1

DANGER!

High electrical voltages due to wrong connections!

Danger to life, risk of injury due to electrical shock!

Only devices and electrical components and wires with a protective extra low voltage (PELV) may be

connected to connectors and terminals with voltages between 0 to 50 Volts.

Only connect voltages and circuits with protection against dangerous voltages. Such protection may be

achieved by means of isolation transformers, safe optocouplers or battery operation.

2.4.4 Protection against dangerous movements

Dangerous movements can be caused by faulty control of connected motors, for different reasons:

Improper or faulty wiring or cabling

Error in handling of components

Error in sensor or transducer

Defective or non-EMC-compliant components

Software error in superordinated control system

These errors can occur directly after switching on the device or after an indeterminate time of operation.

The monitors in the drive components for the most part rule out malfunctions in the connected drives. In

view of personal protection, particularly the danger of personal injury and/or property damage, this may

not be relied on exclusively.

Until the built-in monitors come into effect, faulty drive movements must be taken into account; their

magnitude depends on the type of control and on the operating state.

DANGER!

Dangerous movements!

Danger to life, risk of injury, serious personal injuries or property damage!

For the reasons mentioned above, personal protection must be ensured by means of monitoring or

superordinated measures on the device. These are installed in accordance with the specific data of the

system and a danger and error analysis by the manufacturer. The safety regulations applying to the

system are also taken into consideration. Random movements or other malfunctions may be caused by

switching the safety installations off, by bypassing them or by not activating them.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 14 Safety notes for electrical drives and controllers

2.4.5 Protection against contact with hot parts

DANGER!

Housing surfaces may be hot!

Risk of injury! Risk of burning!

Do not touch housing surfaces in the vicinity of heat sources! Danger of burning!

Before accessing devices let them cool down for 10 minutes after switching them off.

Touching hot parts of the equipment such as the housing, which contain heat sinks and

resistors, may cause burns!

2.4.6 Protection during handling and assembly

Handling and assembly of certain parts and components in an unsuitable manner may under adverse

conditions cause injuries.

DANGER!

Risk of injury due to improper handling!

Personal injury due to pinching, shearing, cutting, crushing!

The following general safety notes apply:

Comply with the general setup and safety regulations on handling and assembly.

Use suitable assembly and transportation devices.

Prevent incarcerations and contusions by means of suitable protective measures.

Use suitable tools only. If specified, use special tools.

Use lifting devices and tools appropriately.

If necessary, use suitable protective equipment (for example goggles, protective

footwear, protective gloves).

Do not stand underneath hanging loads.

Remove leaking liquids on the floor immediately to prevent slipping.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Technical data Page 15

3 Technical data

3.1 Ambient conditions and qualification

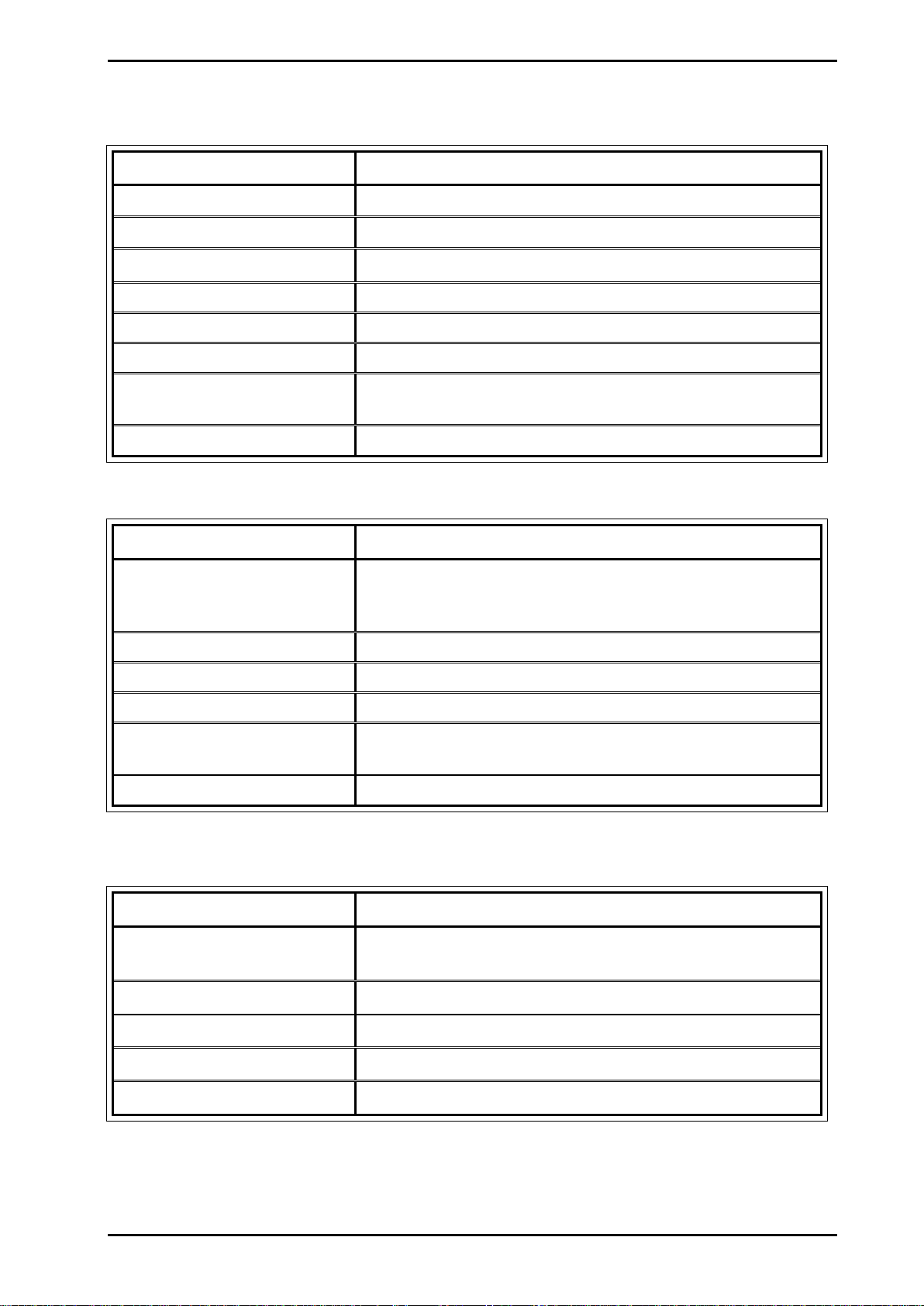

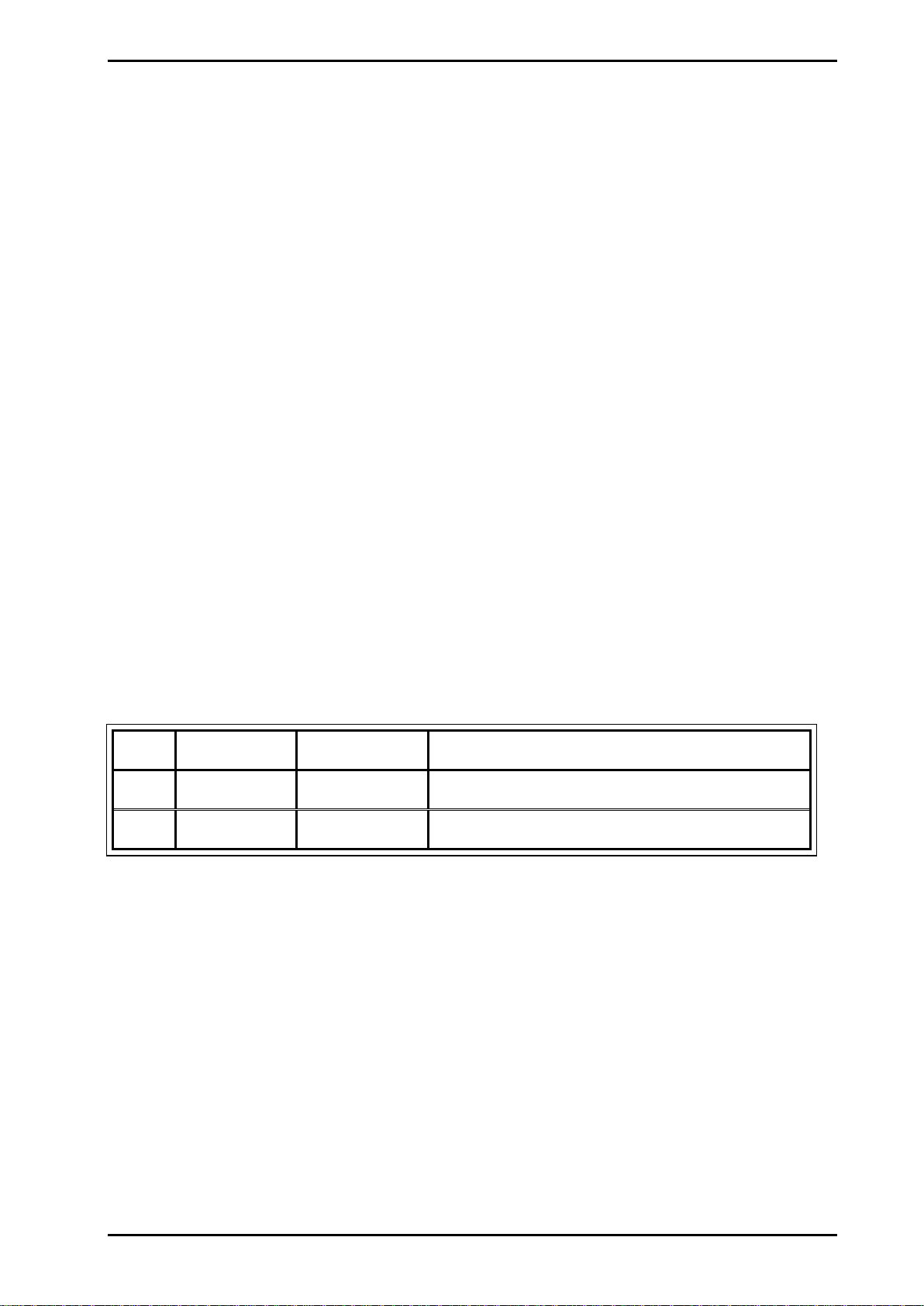

Table 5: Technical data: Ambient conditions and qualification

Range Values

Admissible temperature ranges Storage temperature: -25°C to +70°C

Operating temperature: 0°C to +50°C

+50°C to +70°C

at reduced power 2%/K

Temperature switch-off at approx. 80°C

Admissible installation height Mounting height maximum 2000 m above msl, above 1000 m

above msl with power reduction 1% per 100 m

Humidity Relative humidity up to 90%, no bedewing

Protection degree IP54, dependent on mounting IP67 may be achieved

Protection class

Pollution degree 2

EC type-examination for

integrated safety function

„Safe Torque Off (STO)“

CE conformity:

Low-voltage directive:

EMC directive:

Interference emission:

Interference immunity:

Table 6: Technical data: Dimensions and weight

Parameter Values

Dimensions basic device (H*W*D)

(without counterplug und mounting plate)

Weight approx. 0,5 kg

III

See chapter 6 Functional safety technology.

not applicable

Directive 2004/108/EG (Standard DIN EN 61800–3)

First environment category C2

Second environment

56 x 80 x 112 mm

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 16 Technical data

25

KTY81-1x0; KTY81-2x0

R25 ≈ 1000 Ω

KTY83-1xx

R

25

≈ 1000 Ω

100

3.2 Supply [X1]

Table 7: Technical data: Performance data power supply [X1]

Parameter Values

DC bus voltage 0 V... 60 V DC (48 V DC nominal / 15 A nominal) 1)

24 V logic supply

24 V DC [± 20%] / approx. 200 mA 2)

+ 700 mA

+ 100 mA

internally protected with poly-switch, triggered at approx. 1 A

Brake chopper

switching threshold ON:

switching threshold OFF:

U

CHOP_ON

U

CHOP_OFF

= 60 V [± 5%]

= 55 V [± 5%]

External brake resistor possible mounting on mounting plate

(Type: PLR of Metallux, Metronix order no: 9519-0001-00)

Resistance 5 Ω

Continuous power / pulse power 30 W / 750 W

1)

An external fuse 15A is recommended.

2)

Current consumption of the DIS-2 48/10 without additional wiring

3)

Maximum admissible current consumption of an optional holding brake

4)

Maximum current consumption when DOUT0 to DOUT2 and the CAN bus are active

3.3 Motor connection [X301-X303]

Table 8: Technical data: Motor connection specifications [X301-X303]

3)

4)

Parameter Values

Specifications for operation with 48 V / T

Housing max.

= 50°C

Output power 500 VA

Max. output power for 2 s 1500 VA

Output current 15 A

10 A

Max. output current for 2 s 40 A

32 A

rms

rms

rms

rms

@ T

@ T

@ T

@ T

PowerStage

PowerStage

PowerStage

PowerStage

≤ 50°C

≤ 70°C

≤ 50°C

≤ 70°C

PWM frequency 10 kHz / 20 kHz

Table 9: Technical data: Motor temperature monitoring [X2]

Parameter Values

Digital sensor Normally closed contact: R

< 500 Ω R

cold

Analogue sensor Silicon temperature sensors, KTY series

KTY81-2x0; KTY82-2x0 R

≈ 2000 Ω

> 100 kΩ

hot

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

KTY84-1xx R

≈ 1000 Ω

Technical data Page 17

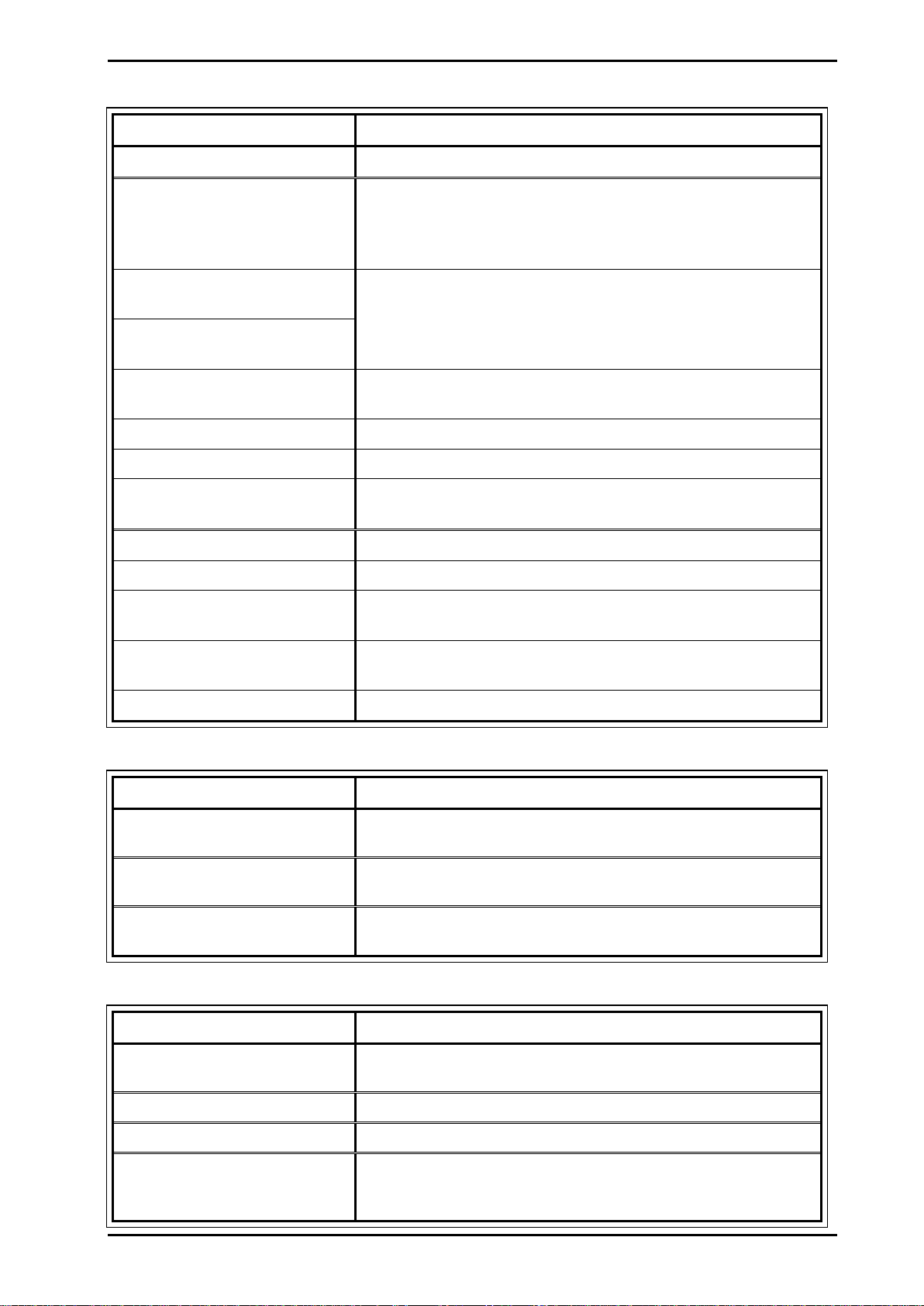

3.4 Angle encoder connector [X2]

Table 10: Technical data: Resolver evaluation [X2]

Parameter Values

Suitable resolvers

Transformation ratio

Carrier frequency

Industry standard

0.5

10 kHz

Resolution > 12 Bit ( typ. 15 Bit)

Delay time signal detection < 200 µs

Speed resolution ca. 4 min-1

Absolute accuracy of angle

< 10´

detection

Max. rotational speed 16.000 min-1

Table 11: Technical data: Evaluation of analogue Hall sensor signals [X2]

Parameter Values

Suitable Hall sensors

HAL400 (Micronas), SS495A (Honeywell) and others

Type: differential analogue output, V

Signal amplitude: max. 4,8 V

differential

ss

= 2.0 V...3.0 V

CM

1)

Resolution > 12 Bit ( typ. 15 Bit)

Delay time signal detection < 200 µs

Speed resolution approx. 10 min-1

Absolute accuracy of angle

< 30´

detection

Max. rotational speed 16.000 min-1

1)

Other Signal levels on request as customer specific version, please contact your local supplier.

Table 12: Evaluation of Six-Step-Sensors (Hall) and block commutation mode [X2]

Parameter Values

Suitable Hall sensors Hall sensors with +5V supply, 120° phase shift between phases,

open collector or push-pull output; i

> 5 mA

out

Resolution 6 steps per electric turn

Delay time signal detection < 200 µs

Speed resolution Depends on number of poles of the motor

Max. rotational speed 3.000 min

-1

on motors with two pole pairs

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 18 Technical data

Table 13: Technical data: Evaluation of Incremental encoder [X2]

Parameter Values

Pulse counts Programmable 32 to 1024 lines per revolution,

equivalent to 128 to 4096 increments / revolution

Input signal level 5 V differential inputs / RS422 standard

Power supply for encoder +5 V / 100 mA max.

Input impedance Ri ≈ 1600 Ω

Max. input frequency f

> 100 kHz (pulses/s)

max

Table 14: Technical data: Evaluation of HIPERFACE® Encoders [X2]

Parameter Values

Suitable encoders

Stegmann HIPERFACE®;

SCS60/70, SCM60/70;

SRS50/60, SRM50/60;

SNS50/60;

SKS36 / SKM36;

SEK 34/37/52, SEL 34/37/52;

for other types, please contact your supplier.

Resolution Up to 16 Bit (depends on number of increments)

Delay time signal detection < 200 µs

Speed resolution approx. 4 min-1

Absolute accuracy of angle

< 5´

detection

Max. rotational speed 6.000 min

-1

/ 3.000 min

-1

at 1024 increments / revolution

3.5 Communication interfaces

Table 15: Technical data: RS232 [X5]

Parameter Values

RS232 as per RS232 specification, 9600 Baud to 115,2 kBaud

Table 16: Technical data: Analogue inputs and outputs [X1]

Parameter Values

High resolution

analogue inputs

Analogue input:

AIN0 / #AIN0

Analogue input:

AIN1 / #AIN1

Analogue output:

AMON0

±10V input range, 12 Bit resolution, differential,

< 250µs delay time, Input protection up to 30V

Analogue input, usable as input for current or speed setpoint.

(Pins shared with DIN0 and DIN1)

Analogue input, usable as input for current or speed setpoint.

(Pins shared with DIN2 / DIN3)

0... 10V output range, 8 Bit resolution, f

Limit

≈ 1kHz

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Technical data Page 19

Table 17: Technical data: Digital inputs and outputs [X1]

Parameter Values

Signal level 24V (14V … 30V) active high

DIN0

DIN1

DIN2

DIN3

DIN4 (usable as incremental

input A-signal)

DIN5 (usable as incremental

input B-signal)

DIN6 (usable as incremental

Bit 0 \

Bit 1, \ Target selection for positioning

Bit 2, / 16 targets selectable from target table

Bit 3 /

Bit 4 \

\ Target selection for positioning

/ 4 target groups with separate positioning parameter

Bit 5 / selectable (e.g. speed, acceleration)

Control signal start positioning

input N-signal)

DIN7 End switch input 0

DIN8 End switch input 1

DIN9 Servo drive enable at high signal,

acknowledge error with falling edge

Logic outputs general 24V (8V... 30V) active high, short circuit rated to GND

DOUT0 Operational state / Ready 24 V, max. 20 mA

DOUT1 Freely configurable, usable as

24 V, max. 20 mA

Encoder output A-signal

DOUT2 Freely configurable, usable as

24 V, max. 20 mA

Encoder output B-Signal

DOUT3 (on [X3]) Holding brake 24 V, max. 700 mA

Table 18: Technical data: Incremental encoder input [X1] (DIN4, DIN5, DIN6):

Parameter Values

Number of lines Programmable to 32 / 64 / 128 / 256 / 512 / 1024 lines per

revolution

Connection level 24 V single ended / 24V (8V...30V) active high,

following DIN EN 61131-2

Max. input frequency F

= 50 kHz (lines/s); f

Limit

data measured with R

depending on input filter,

Limit

= 13,3 kΩ and C

Input

= 470 pF

Input

Table 19: Technical data: Incremental encoder output [X1] (DOUT1, DOUT2):

Parameter Values

Number of lines Programmable to 32 / 64 / 128 / 256 / 512 / 1024 lines per

revolution

Connection level 24V / max. 20 mA

Output impedance

Limit frequency F

≈ 300 Ω

R

a

> 100 kHz (lines/s); f

Limit

data measured with R

depending on cable length,

Limit

= 1 kΩ and C

Load

= 1 nF (which

Load

corresponds to a cable length of 5m)

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 20 Technical data

3.6 STO interface

Table 20: Technical data: Control ports [X40] (STO1, STO2):

Parameter Values

Nominal voltage 24 V (related to GND)

Voltage range 19,2 ... 28,8V

Permissible residual ripple 2 % (related to nominal voltage 24 V)

Input current STO1 0,5 mA (typical; maximum 1 mA)

Input current STO2 25 mA (typical; maximum 30 mA)

Input voltage threshold

Switching on

Switching off

Switch-on time STO1 from Low

to High (t

STO1-ON

)

Switch-on time STO2 from Low

to High (t

STO1-ON

)

Switch-off time STO1 from High

to Low (t

STO1-OFF

)

Switch-off time STO2 from High

to Low (t

STO2-OFF

)

Maximum test impulse length

STO1/2 for OSSD signals

approx. 17 V

approx. 15,5 V

5 ms (typical; maximum 10 ms)

10 ms (typical; maximum 15 ms)

5 ms (typical; maximum 10 ms)

70 ms (typical; maximum 75 ms)

19,2 V 24 V 28,8 V

max. 2,5 ms max. 4 ms max. 4 ms

Table 21: Technical data: Feedback contact [X40] (REL1, REL 2 ):

Parameter Values

Version Floating relay contact, normally open

Voltage range contacts < 30 V (overvoltage-proof up to 60 V DC)

Nominal current < 200 mA (not short circuit proof)

Voltage drop < 200 mV

Residual current

< 1µA

(contact opened)

Switching time closing < 1ms

Switching time opening < 0,5 ms

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Technical data Page 21

3.7 Fieldbus interfaces

Table 22: Technical data: CA N-Bu s [X401] / [X402]

Communication interface Values

CAN controller TJA 1050, Full-CAN-Controller, 1MBit/s; adjustable max.

500kBit/s

CANopen protocol as per DS301 and DSP402

Current consumption of the

activated CAN technology

module

Table 23: Technical data: PR O FIBUS [X401] / [X402]

Communication interface Values

Controller PROFIBUS-controller VPC3+C, max. 12 MBaud

Protocol PROFIBUS DP, 32 byte telegrams with mode-dependent

Current consumption of the

activated PROFIBUS technology

module

Table 24: Technical data: EtherCAT [X401] / [X402]

Communication interface Values

5 mA

structure

20 mA

Controller ESC10, slave

EtherCAT protocol CoE, CANopen over EtherCAT

Signal level 0 ... 2,5 VDC

Differential voltage 1,9 ... 2,1 VDC

Current consumption of the

activated EtherCAT technology

module

35 mA

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 22 Mechanical installation

Power supply

Power supply

U,V,W,

brake

Inputs/Outputs

Communication

DIS-2

DIS-2

Motor

Motor

feedback

a)

b)

Inputs/Outputs

Communication

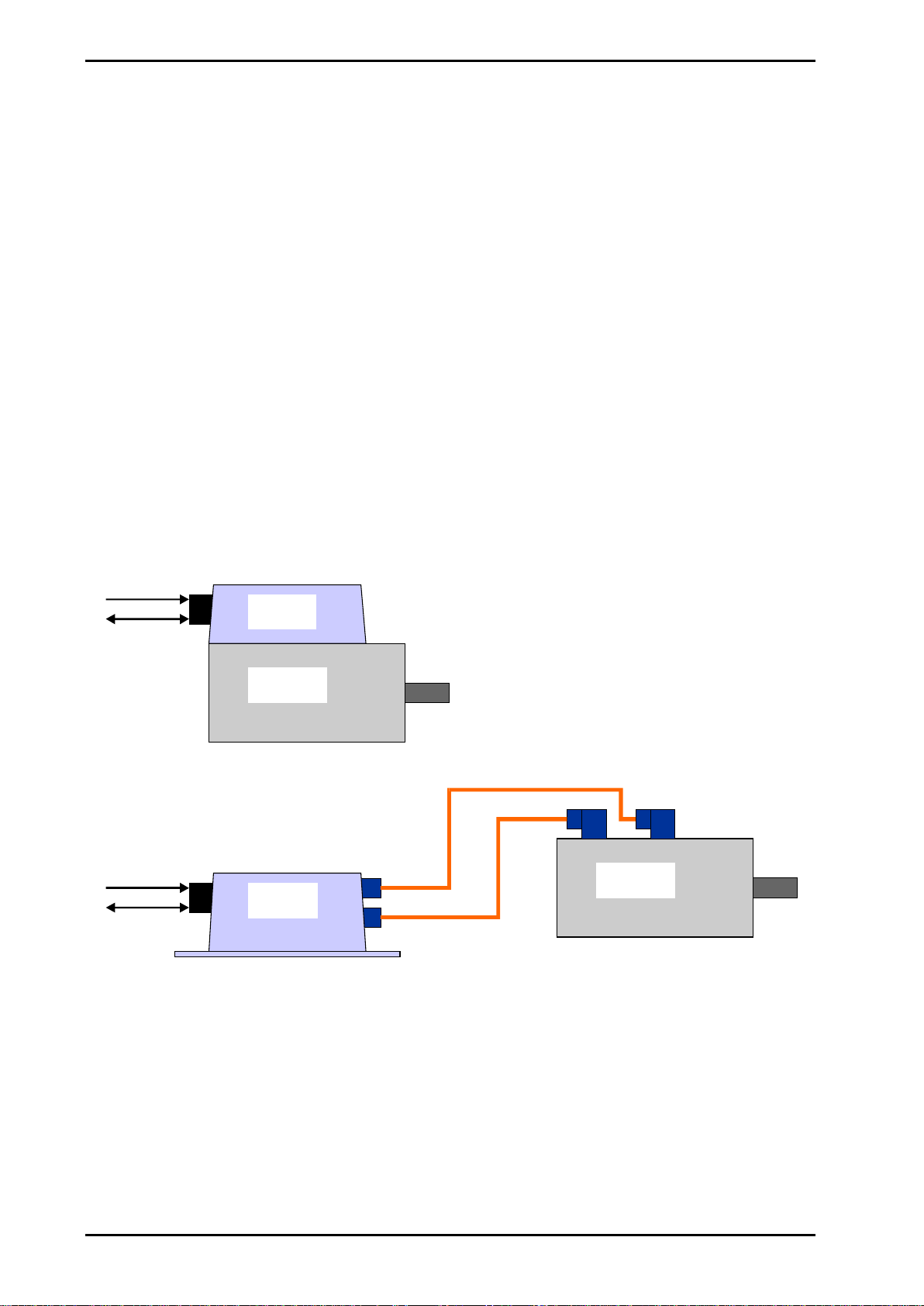

4 Mechanical installation

4.1 Important notes

The DIS-2 48/10 FB FS STO servo drive was designed for direct installation on the motor.

Optionally, it is possible to use it separately from the motor. In this case, additional connecting cables

between the motor and the DIS-2 servo drive are required. These cables should be as short as

possible. The maximum length is 1 m.

Optimum cooling can be ensured when the DIS-2 48/10 FB FS STO servo drive is mounted in a

vertical position. This means that connector [X1] is located on top or at the bottom.

The maximum permissible temperature of the housing is 70°C to guarantee the specified service life

of the electronic system.

Connect the connecting cable for [X1] as closely as possible to the DIS-2 48/10 FB FS STO servo

drive to increase the reliability of the cabling.

Installation spaces:

Keep a minimum distance of 100 mm to other components each underneath and above the device to

ensure sufficient venting.

Figure 1: a) Mounted directly on the motor – standard,

b) Separated from the motor – Please contact your local distributor to check whether

this option is available.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Mechanical installation Page 23

4.2 Position and alignment of the connectors

The DIS-2 48/10 FB FS STO has the following connections:

Figure 2: Arrangement of the connectors DIS-2 48/10 FB FS STO – Top view of the device

4.2.1 Connectors on the main board

[X1]: The only connector on the main board that is led to the outside. It includes digital and analogue

inputs and outputs and the power supply.

[X2]: Connector of the angle encoder.

[X3]: Connector of the holding brake.

[X304, X305]: Connector for the brake resistor that is mounted on the mounting plate.

[X301, X302, X303]: Connectors for the three motor phases U, V and W.

[X8]: Expansion interface for technology modules (fieldbuses).

[X40]: Connector of the STO interface. This interface is led to the outside via a 5-pole M12 circular

connector. The circular connector normally is fixed on the mounting plate.

4.2.2 Connectors for the fieldbus interfaces and RS232 interface (CANopen, PROFIBUS or EtherCAT)

[X5]: Connector for the RS232 communication, for example to parameterise the DIS-2 48/10 FB FS

STO

[X401]: Fieldbus connector for bus IN or bus OUT

[X402]: Second fieldbus connector for bus IN or bus OUT

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 24 Mechanical installation

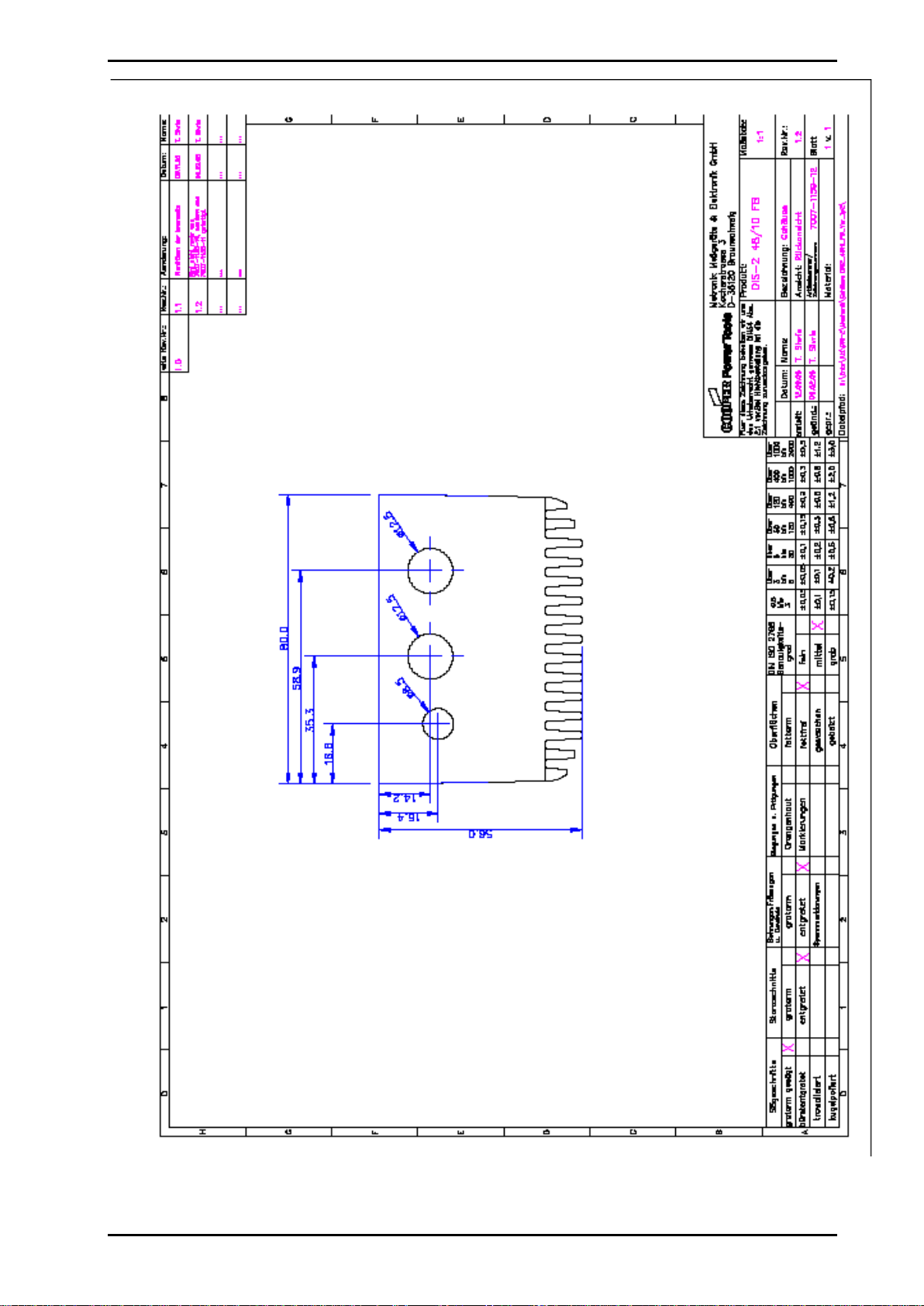

4.3 Dimensions of the housing

Figure 3: Dimensions of the housing - 1

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Mechanical installation Page 25

Figure 4: Dimensions of the housing - 2

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 26 Mechanical installation

4.4 Mounting

The servo drive DIS-2 48/10 FB FS STO will be mounted directly to the motor using a seal. The mounting

flange at the motor should have a smooth surface with a circular slot to achieve the highest protection

against water. Achieving the protection degree of IP67 is possible by using a good mechanical

construction.

Figure 5: DIS-2 mounting example without STO

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Mechanical installation Page 27

The following two figures show a mounting example of an STO application. In this case, the mounting

plate must be milled deeper so that the M12 circular connector [X40A] can be integrated.

Figure 6: DIS-2 48/10 FB FS STO mounting example with STO – synchronous servo motor,

mounting plate with brake resistor and servo drive

Mounting Instructions „Servo drive DIS-2 48/10 FB

FS STO

“

Version 1.0

Page 28 Mechanical installation

Right side view

Top view

Rear view

The green hatched area is reserved for

is about 3mm high!

the optional brake resistor and therefore

must not be blocked! The brake resistor

Figure 7: DIS-2-FB FS STO Example of a mounting plate universal

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Mechanical installation Page 29

Right side view

Top view

Rear view

The green hatched area is reserved for the

be blocked! The brake resistor is about 3mm

optional brake resistor and therefore must not

Figure 8: DIS-2-FB FS STO Example of a realised mounting plate

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 30 Electrical installation

X301

X302

X303

X304 X304

X3.1

X3.2

X2.12

X2.2

X2.x

X2.y

+

PM synchro nous machine

holding

brake

Resolv er / Encoder

T

6...10

....

DIS-2-48/10-FB

Power Supply

(PELV)

48 V DC

> 20 A

+

-

Power Supply

(PELV)

Controller / PLC

24 V DC

> 2 A

+

-

+24V

0V

other DIS-2-48/10 FB

central GND-point

X301

X302

X303

X3.1

X3.2

X2.12

X2.2

X2.x

X2.y

+

PM synchro nous machine

holding

brake

Resolv er / Encoder

T

6...10

....

DIS-2-48/10 FB

(U_ZK)

(+24V)

(GND)

(AMON0)

(RxD)

(TxD)

(CANHI)

(AIN0)

(CANLO)

(#AIN0)

(U_ZK)

(+24V)

(GND)

(GND)

(AMON0)

(RxD)

(TxD)

(CANHI)

(AIN0)

(CANLO)

(DINx)

(DOUT x)

(#AIN0)

AOUT

0V

connected

internal

120R

120R

CANH

CANL

DOUTx

DINx

Each drive:

fuse 15 A

C-char acteristic

15 A

C-char acteristic

X1

X1

X1

X5

X401

X402

R

Brake

5 Electrical installation

5.1 Connection to power supply, control and motor

The following figure shows a typical application with two or more DIS-2 servo drives with a connection to

an 48V intermediate circuit supply, to a 24 V DC logic supply and to a control or to a PLC without STO

functionality.

The connector [X40] for the integrated safety function “Safe Torque Off (STO)” is not shown in this figure.

For further information concerning the safety function please refer to chapter 6 Functional safety

technology and the Product Manual “Servo drive DIS-2 48/10 FB FS STO”, chapter 6.

Figure 9: Connection to power supply, control and motor

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 31

The servo drive is connected to the 48 V intermediate circuit supply and to the 24 V logic supply. A

shared reference potential (GND) is used. A central star point near the power supply units for all GND

connections reduces the "ground bouncing" effects between the servo drives.

The motor has to be connected through the FASTONs [X301] to [X303] on the circuit board of the

DIS-2. The DIS-2 controls an optional holding brake through connector [X3]. The encoder and the

temperature sensor have to be connected through the recessed connector [X2] on the circuit board.

The DIS-2-48/10 FB has an additional integrated brake chopper. It is therefore possible to connect the

braking resistor through the FASTONs [X304] and [X305] on the circuit board as shown in Figure 9 on the

bottom right. Normally, the braking resistor is installed on the mounting plate for the electronics housing.

DANGER!

Only use the brake resistor that is approved by the manufacturer. The used brake

resistor must have a high pulse loading capacity to be able to permanently withstand the

short peak loads. Unsuitable brake resistors will fail prematurely; they can cause fires

and even electrical hazards! Consecutively, the user is at risk of being harmed, too.

If the analogue inputs are used to assign setpoints, we recommend using shielded and twisted cables for

AINx / #AINx, even if the control does not provide any differential signal. Connection of #AINx to the 0V

reference potential at the control system prevents common-mode interferences which are caused by high

currents flowing through the power stage and the external cables. The shield prevents the penetration of

interferences and should be connected on both ends (to the housing of the DIS-2 48/10 FB FS STO servo

drive and to the housing of the control system).

The wiring of the fieldbus should be done in the same way as the wiring of the analogue inputs. At both

ends of the network, for example for the CAN bus (120 Ω / 1%), a termination resistor is needed.

The fieldbus is looped through the DIS-2 48/10 FB FS STO via the fieldbus connectors [X401] und

[X402].

The DIS-2 48/10 FB FS STO has a separate connector, [X5], for the serial service interface to be

TM

connected to a PC. This enables the parameterisation and analysis using the DIS-2 ServoCommander

or the control of the servo drive. [X5] is part of the fieldbus module and is looped through to the basic

device.

The signals for the digital IOs, DINx and DOUTx, do not need a shield to protect them against

interferences, but a shielded cable between the DIS-2 servo drive and the control system improves the

EMC behaviour throughout the entire system, particularly in view of radiated interferences. At least the

control signals DIN9 (servo drive enable) and DOUT0 (ready for operation) have to be connected

between the PLC and the servo drive.

For synchronization, DIN4, 5 and 6 are used as incremental encoder inputs and DOUT1 and DOUT2 are

used as incremental encoder outputs.

Make sure that the servo drive is completely wired prior to switching on the power supply for the

intermediate circuit (DC bus) and the logic system. If the 24 V DC power supply connections are

reversed, if the power supply is too high or if the connections of the intermediate supply and the logic

supply are mixed up, the DIS-2 48/10 FB FS STO servo drive may be permanently damaged.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 32 Electrical installation

2 1

C

8 7

6

5 8 7 6 5

4 3 2 1 4 3 2 1

B A

Verify that the power supply used for the power and for the logic part fulfil the

specifications for the DIS-2 48/10 FB FS STO and are correspondingly resistant:

see Table 7: Technical data: Performance data power supply [X1]

All power supply units must have PELV (Protective Extra Low Voltage).

Intermediate supply: 48 V DC (PELV)

Logic supply: : 24 V DC (PELV)

DANGER!

Wrong connections around the power supply can destroy the servo drive DIS-2 48/10 FB

FS STO when the power is switched on. This is particularly true for the connection of the

mains, the protection earth, the motor phases and the brake resistor.

Also high voltages lead to the destruction of the device. A high power can occur if the

neutral conductor is not loadable, or a neutral conductor interruption occurs in the wiring

cabinet or externally!

5.2 Connectors on the basic device DIS-2 48/10 FB FS STO

5.2.1 Connection: Power supply and I/O [X1]

Configuration on the device [X1]: Phoenix PLUSCON – VARIOCON with a total of 18 contacts

Counterplug [X1]: Phoenix PLUSCON – VARIOCON kit,

consisting of: 1x VC-TFS2

2x VC-TFS8

1x VC-TR2/3M

1x VC-MEMV-T2-Z

1x VC-EMV-KV-PG21-(11,5-15,5/13,5)

Dimensions approximately

H x W x DH = 86 mm x 80 mm x 32 mm

Figure 10: Connection and pin numbering [X1]

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 33

Table 25: Pin assignm ent [X1]

Pin No. Denomination Values Specification

A1

DOUT0 /

READY

0 V / 24 V Ready for operation

A2 DIN8 0 V...24 V Digital input: Limit switch 1 (blocks n > 0)

A3 DIN5 0 V...24 V

A4 #AIN1(DIN3)

-10 V...10 V

(0 V...24 V)

Digital input: Positioning group selector Bit 1 /

Incremental encoder input track B

Inverted analogue input 1: Differential analogue

input with AIN1 or

(Digital input: Positioning destination selector Bit 3)

A5 DIN9 0 V...24 V Digital input: Power stage activation

A6 DIN7 0 V...24 V

A7 DIN4 0 V...24 V

A8

B1

AIN1

(DIN2)

#AIN0

(DIN1)

-10 V...10 V

(0 V...24 V)

-10 V...10 V

Digital input: Limit switch 0 (blocks n < 0)

Digital input: Positioning group selector Bit 0 /

Incremental encoder input track A

Analogue input 1: Differential analogue input with

#AIN1 or

(Digital input: Positioning destination selector Bit 2)

Inverted analogue input 0: Differential analogue

input with AIN0 or

(Digital input: Positioning destination selector Bit 1)

B2 DOUT2 0 V...24 V

B3 AMON0

0 V...10 V;

2 mA

Digital output programmable /

encoder output track B

Analogue output 0

B4 GND 0 V Reference potential for the control signals

Analogue input 0: Differential analogue input with

#AIN0 or

(Digital input: Positioning destination selector Bit 0)

Digital output programmable /

encoder output track A#

Digital input: Positioning start /

Incremental encoder track N

24 V power supply for the internal logic and the IOs.

B5

AIN0

(DIN0)

-10 V...10 V

B6 DOUT1 0 V...24 V

B7 DIN6 0 V...24 V

B8 +24V Logik

+24 V / I

200 mA...1000

Logik

=

mA

Shared ground potential for the intermediate

C1

GND 0 V

circuit voltage (DC bus voltage) and the 24V

logic supply.

C2 ZK+ +48 V / 15 A

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Intermediate circuit supply (DC bus)

nom.

Page 34 Electrical installation

15 16

13

14

11 12

9

10

7

8

5

6

3 4

1 2

X2

5.2.2 Connection: Motor [X301-X303]

Configuration on the device [X301 – X303]: 6.3 mm FAST-ON male

Counterplug [X301 – X303]: 6.3 mm FAST-ON female (insulated externally)

Figure 11: Position and connection motor cable

Table 26: Pin assignm ent [X301 – X303]

[X30x] Denomination Values Specification

[X301] PHASE_U

[X302] PHASE_V

[X303] PHASE_W

3 x 0 V...48 V

15 A

RMS,nom

40 A

RMS,max

0 Hz...200 Hz

Connection of the three motor phases

5.2.3 Connection: Angle encoder [X2]

Configuration on the device [X2]: JST No. B16B-PHDSS

Counterplug [X2]: JST No. PHDR-16VS / contacts: JST No. SPHD-002T-P0.5

Figure 12: Position and connection angle encoder

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 35

Table 27: Pin assignm ent [X2]

Pin No. Denomination Values Specification

Reference potential for incremental encoder /

1 GND 0 V

analogue Hall sensors / Stegmann HIPERFACE

encoder

2 GND 0 V

3 +5V +5 V / 100 mA

Reference potential for Hall sensors and / or motor

temperature sensor

+5 V supply for linear Hall sensors or incremental

encoder

4 +5V +5 V / 100 mA +5 V supply for Hall sensors

5 COS A

6 HALL_U

7 #COS #A

8 HALL_V

1.5 V

R

> 10 kΩ

i

0 V / 5 V

R

= 5 kΩ

i

1.5 V

R

> 10 kΩ

i

0 V / 5 V

R

= 5 kΩ

i

RMS,diff

RMS,diff

/

/

Connection to resolver signal S1 or

connection to incremental encoder track A

Phase U Hall sensor for commutation

Input with 4,7 kΩ pull-up at +5 V

Connection to resolver signal S3 or

connection to incremental encoder track #A

Phase V Hall sensor for commutation

Input with 4,7 kΩ pull-up at +5 V

®

9 SIN B

10 HALL_W

11 #SIN #B

12 MTEMP

13 REF N

1.5 V

R

> 10 kΩ

i

0 V / 5 V

R

= 5 kΩ

i

1.5 V

R

> 10 kΩ

i

0 V / 3.3 V

R

= 2 kΩ

i

3 V

RMS,diff.

max. 50 mA

RMS,diff

RMS,diff

/

/

RMS

14 +12V +12 V / 100 mA

15 #REF #N

3 V

max. 50 mA

RMS,diff.

RMS

16 n.c. - -

Connection to resolver signal S2 or

connection to incremental encoder track B

Phase W Hall sensor for the commutation

Input with 4,7 kΩ pull-up at +5 V

Connection to resolver signal S4 or

connection to incremental encoder track #B

Motor temperature sensor, normally-closed contact,

PTC, or analogue sensor of KTY series; connected to

GND

Connection to resolver signal R1 or

connection to incremental encoder track N / DATA

+12 V power supply for Stegmann HIPERFACE

®

encoder

Connection to resolver signal R2 or

connection to incremental encoder track #N / #DATA

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 36 Electrical installation

5.2.4 Connection: Holding brake [X3]

Configuration on the device [X3]: JST No. BH02B-XASK-BN (High Box Type)

Counterplug [X3]: JST No. XAP-02V-1 with 2 contacts

JST No. SXA-001T-P0.6

Figure 13: Position and connection holding brake

Table 28: Pin assignm ent [X3]

Pin No. Denomination Values Specification

1 DOUT3 0 V / 24 V

max. 500 mA

2 GND 0 V Reference potential for the holding brake

Digital output: (high active) for the holding brake,

internal supply via the 24 V logic supply.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 37

5.2.5 Connection: Brake resistor [X304, X305]

Configuration on the device [X304, X305]: 2.8 mm FAST-ON male

Counterplug [X304, X305]: 2.8 mm FAST-ON female (insulated externally)

Configuration brake resistor: see chapter 1.2,

Table 4: Accessories DIS-2 48/10 FB FS STO.

Figure 14: Position and connection brake resistor

Table 29: Pin assignm ent [X 304, X305]

[X30x[ Denomination Values Specification

[X304[ ZK+ +48 V / 10 A

Intermediate circuit supply (DC bus)

nom.

[X305] BR-CHOP 0 V / 48 V Connection to brake resistance transistor

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 38 Electrical installation

5.2.6 Connection: Extension port [X8]

Configuration on the device [X8]: 2 x 26 RM 1.27 mm pin row with protective collar

Counterplug [X8]: 2 x 26 RM 1.27 mm socket row

Figure 15: Position and connection technology module interface

Table 30: Pin assignm ent [X8]

Pin No. Denomination Values Specification

All signals with

1 n.b.

3,3 V CMOS

Not used

logic level

2

3

4

5

6

7

8

+24 V

DIN8

DIN7

GND

GND

RxD

TxD

+ 24 V /

max. 100 mA

0 V / 24 V Digital 24 V input for limit switches, parallel to [X1]

0 V / 24 V Digital 24 V input for limit switches, parallel to [X1]

0 V Reference potential

0 V Reference potential

+/- 10 V Serial interface signal RxD

+/- 10 V Serial interface signal TxD

Withdrawal of the protected logic supply of + 24 V for

future applications / device variants

9

10

11

12

CANHI_NDR

CANLO_NDR

+3.3 V

+5 V

0 V / 5 V Field bus signal CAN_H before „filter“

0 V / 5 V Field bus signal CAN_L before „filter“

3,3 V +/- 2%

5,0 V +/- 5%

Technology module power supply

100 mA max. (together with 5 V)

Technology module power supply

100 mA max. (together with mit 3.3 V)

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 39

Pin No.

13

D14

14

D15

15

D12

16

D13

17

D10

18

D11

19

D8

20

D9

21

D6

22

D7

23

D4

24

D5

25

D2

26

D3

27 D0

28

D1

29

A11

30

A12

31

A9

32

A10

33

A7

35

A5

36

A6

37

A3

38

A4

39

A1

40

A2

41

#DS

42

A0

43

#RD

44

#WR

45

#IRQB (SYNC)

46

#IRQA

47

MOSI

48

SCLK

49

MISO

50

#SS

51

GND

0 V

Reference potential

52

GND

0 V

Reference potential

Continuation of the table: Pin assignment [X8]

Denomination Values Specification

All signals with

3,3 V CMOS

16-bit parallel interface data bus

logic level

34

A8

All signals with

3,3 V CMOS

logic level

All signals with

3,3 V CMOS

logic level

16-bit parallel interface – address bus

Bus control signals for access to technology modules

via the data and address bus,

and

synchronous-serial interface for access to technology

modules with an SSIO interface

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 40 Electrical installation

6 5

4 3

2 1

X40

5.2.7 Connection: Safe Torque Off (STO) [X40] and [X40A]

For further information concerning the safety function please refer to chapter 6 Functional safety

technology and the Product Manual “Servo drive DIS-2 48/10 FB FS STO”, chapter 6.

Configuration on the device [X40]: Molex No. 87832-0614

Counterplug [X40]: Molex No. 51110-0660 with up to 6 contacts

Molex No. 50394-8051

Configuration on the mounting plate [X40A]: for example: PhoenixContact M12 socket

(SACC-DSI-FS-5P-PG 9/0,5 SCO 0,25), rear panel

5-pin-type A-coded

Counterplug [X40A]: for example: M12 plug with xx m cable length:

SAC-5P-MS/xx-PUR SAC

Length in metres Order number

1,5 1518960

5,0 1518986

10.0 1518999

Example for

[X40A]:

The counterplug

Molex

No. 51110-0660

mentioned above is

attached to the free

cable ends.

Figure 16: Position and connection STO signals [X40] and [X40A]

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 41

Table 31: Pin assignm ent [X40]

Pin No. Denomination Values Specification

1 STO1 0 V / 24 V Control input 1 for STO function

2 GND Corresponding GND for STO1 and STO2

3 +24V +24 V / +/-20% Internal logic supply +24V

4

REL1 Normally open contact for feedback STO to an

external control system

5 STO2 0 V / 24 V Control input 2 for STO function

6

REL2

Normally open contact for feedback STO to an

external control system

Table 32: Pin assignm ent [X40A]

Pin No. Denomination Values Specification

1 STO1 0 V / 24 V Control input 1 for STO function

2 STO2 0 V / 24 V Control input 2 for STO function

3 REL1 Normally open contact for feedback STO

4 REL2 Normally open contact for feedback STO

5 GND Corresponding GND for STO1 and STO2

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 42 Electrical installation

5.3 Connectors field bus modules DIS-2 48/10 FB FS STO

The following types of technology modules can be integrated into the basic device DIS-2 48/10 FB FS

STO. The modules are factory assembled according to the order. The RS232 interface is integrated in

each technology module.

5.3.1 Connection: Serial interface [X5]

Configuration on the device: M8 flush-type socket, 3-pin type

Counterplug [X5]: M8 counterplug for free configuration, for example

Phoenix, order number 1506901 or

see chapter 1.2, Table 4: Accessories DIS-2 48/10 FB FS STO

Figure 17: Position and connection RS232 interface

Table 33: Pin assignm ent [X5]

Pin No. Denomination Values Specification

1 RxD +/-10 V Receive signal, RS232 specification

3 TxD +/-10 V Transmit signal, RS232 specification

Reference potential for the serial interface,

4 GND 0 V

Table 34: Pin assignm ent to s et up an RS232 adapter cable for connection to a PC/notebook

[X5] pin assignment at

DIS-2 48/10-FB

Pin No. Denomination Pin No. Denomination Specification

1 RxD 3 TxD_PC Transmit signal, RS232 specification

D-SUB 9 connector (pin)

for connection to a PC

internally connected with the common reference

potential for the logic system

Specification

3 TxD 2 RxD_PC Receive signal, RS232 specification

Reference potential for the serial interface,

4 GND 5 GND

- Shield Shield

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

internally connected with the common

reference potential for the logic system

Connect the cable shield on both sides of

the connector housing

Electrical installation Page 43

5.3.2 Connection: CANopen [X401] and [X402]

Configuration on the device: [X401] M12 flush-type plug, 5-pin type, A-coded

[X402] M12 flush-type socket, 5-pin type, A-coded

Counterplug: Assembled M12 bus cable, for example made by Phoenix,

one end male connector, one end female connector, pre-

fabricated lengths, order name: SAC-5P-MS/xxx-920/FS SCO

xxx defines the length in [m]. The following lengths are available:

xxx = 0,3 / 0,5 / 1,0 / 2,0 / 5,0 / 10,0 / 15,0

Length in metres Order number

Length in metres Order number

0,3 1518258

0,5 1518261

1,0 1518274

2,0 1518287

5 1518290

10 1518300

15 1518813

Terminating resistor CANopen M12: Order number: 1507816

Figure 18: Position and connection CAN interface

Table 35: Pin assignm ent [X401] and [X402]

Pin No. Denomination Values Specification

1 Shield PE

Contact for cable shield, in the DIS-2 48/10 FB FS

STO connected with the housing

2 -- - Not used

Reference potential for the CAN bus, internally

3 CAN_GND 0 V

connected with the common reference potential for

the logic system

4 CANHI 0 V 5 V Signal CAN_H according to CAN-Bus specification

5 CANLO 0 V 5 V Signal CAN_L according to CAN-Bus specification

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 44 Electrical installation

5.3.3 Connection: PROFIBUS [X401] and [X402]

The PROFIBUS interface at the servo drive DIS-2 48/10 FB FS STO is configured according to EN 50170

as a 5-pole M12 plug, B-coded at the technology module as plug and socket.

Configuration on the device: [X401] M12 flush-type plug, 5-pin type, B-coded

[X402] M12 flush-type plug, 5-pin type, B-coded

Counterplug: Assembled M12 bus cable, for example made by Phoenix,

one end female connector straight, shielded M12-B-coded, 2-pin

type, other end male connector straight, shielded M12-B-coded,

2-pin type, pre-fabricated lengths, order name:

SAC-5P-MS/xxx-920/FS SCO

xxx defines the length in [m]. The following lengths are available:

xxx = 0.3 / 0.5 / 1.0 / 2.0 / 5.0 / 10.0 / 15.0

Length in metres Order number

Length in metres Order number

0,3 1518106

0,5 1518119

1,0 1518122

2,0 1518135

5 1518148

10 1518151

15 1518164

Terminating resistor PROFIBUS M12: 1507803

Figure 19: Position and connection PROFIBUS interface

Table 36: Pin assignm ent [X401] and [X402]

Pin No. Denomination Values Specification

1 +5V +5V

2 A-line green Signal A according to the PROFIBUS specification

3 0V 0 V

Internally connected with the common reference

potential for the logic system

4 B-line red Signal B according to the PROFIBUS specification

5 Shield PE

Contact for cable shield, in the DIS-2 48/10 FB FS

STO connected with the housing

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Electrical installation Page 45

5.3.4 Connection: EtherCAT [X401] and [X402]

The EtherCAT interface at the servo drive DIS-2 48/10 FB FS STO is configured according to

IEC 61076-2-101 as a 4-pole M12 socket, shielded and D-coded at the technology module.

Configuration on the device: [X401] M12 flush-type plug, 4-pin type, D-coded

[X402] M12 flush-type plug, 4-pin type, D-coded

Position: [X401] front – middle

[X402] front – left

Counterplug: Assembled M12 Bus cable for example made by Phoenix

Contact, shielded M12, D-coded, 4-pin type cable

pre-fabricated lengths, order number:

Length in metres Order number

Length in metres Order number

0,3 1523065

0,5 1523078

1,0 1523081

2,0 1521533

5 1524051

10 1524064

15 1524077

Figure 20: Position and connection EtherCAT interface

Table 37: Pin assignm ent [X401] and [X402]

Pin No. Denomination Values Specification

1 TX+ 0 ... 2,5 VDC Transmission Data +

2 RX+ 0 ... 2,5 VDC Receive Data +

3 TX- 0 ... 2,5 VDC Transmission Data -

4 RX- 0 ... 2,5 VDC Receive Data -

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 46 Functional safety technology

6 Functional safety technology

6.1 General, intended use

The DIS-2 48/10 FB FS STO servo drives support the integrated safety function “Safe Torque Off” (STO)

according to the requirements of the standard EN ISO 13849-1.

Furthermore, the principles for testing “Additional requirements for electrical power drive systems

according to EN 61800-5-2” have been considered.

6.2 Safety indices

Category / Performance level: Category 3, Performance level e

PFH value

-8

(probability of dangerous failure per hour): PFH = 4,29 · 10

/h

Information

The indicated values are only reached under the following condition:

Regular testing of the STO function by a superordinated control system (at least once a

week), if such process-related testing is not provided anyway, and test at every switch-

on of the machine / system.

For further information concerning the safety function please refer to the Product Manual

“Servo drive DIS-2 48/10 FB FS STO”, chapter 6.

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

EMC-compliant cabling Page 47

the motor separately, make sure to mount them on the same (metal) part of the machine.

7 EMC-compliant cabling

The following must be considered for an EMC-compliant setup of the drive system:

7.1 Connection between the DIS-2 and the motor

If the DIS-2 servo drive is mounted directly on the motor, the cables are located inside the housing. They

are only a few cm long. In this case, shielding is not necessary.

If you want to mount the motor and the DIS-2 separately, please observe the following wiring instructions:

Use shielded cables only. The encoder cables should have an internal and an external shield.

Use separate cables for the motor phases and the angle encoder.

Alternative: Use a combined cable for the motor and the angle encoder, but with separate shields.

Connect all (external) shields with the housing of the DIS-2 servo drive.

Connect the shield of the motor cable with the motor housing.

Connect the internal shield of the encoder cable to PIN 1 of [X2].

Make sure to set up a "good" PE connection between the motor and the DIS-2 servo drive.

A "good" PE connection only has a low impedance even in the case of very high

interference frequencies. An optimum PE connection can be obtained by mounting the

DIS-2 servo drive directly on the motor. If you want to mount the DIS-2 servo drive and

In this case, the surface of the machine part should be made of uncoated aluminium or

galvanized sheet metal!

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Page 48 EMC-compliant cabling

7.2 Connection between DIS-2 and power supply

Use cable with a sufficient cross-section to reduce "ground bouncing" effects on the DC bus supply

(intermediate circuit supply):

2.5 mm² (AWG13) should be sufficient for a cable length of up to 5 m between the power supply unit

and the DIS-2 servo drive.

Use a star-shaped cable layout (see chapter 5.1 Connection to power supply, control and motor) if

you want to connect several DIS-2 servo drives to one power supply unit. The star point of the

reference potential should be as close as possible to the power supply unit.

The power supply unit should have Y-capacitors of at least 100 nF between the DC bus voltage

(intermediate circuit voltage) and PE as well as between GND and PE.

Make sure to set up a "good" PE connection between the DIS-2 servo drive and the power supply

unit. It is important to ensure a good feedback of the high-frequency leakage currents generated by

the clocked power stage in the DIS-2 servo drive combined with the winding capacity between the

motor phase and PE in the motor.

To make sure that the radiation limits are complied with, use a shielded cable.

The device variants DIS-2 48/10 FB use Pluscon Variocon connectors made by Phoenix for [X1]. If the

recommended metal connector housings (see also chapter 5.2.1) are used, a good PE connection is

ensured by the design of the housing. It is sufficient to connect the shield to the connector housing of the

counterplug.

A "good" PE connection only has a low impedance even in the case of very high

interference frequencies. Mounting the DIS-2 servo drive and the power supply unit to

the same (metal) part of the machine is sufficient for most cases. If not, use a flexible

copper strip (width approx. 10 mm) or a connecting cable with a Cu cross-section of at

least 6 mm2 to set up a PE connection.

DANGER!

For safety reasons, all PE ground conductors must be connected prior to initial

operation.

The regulations of EN 61800-5-1 concerning protective grounding must be complied with

during installation!

Mounting Instructions „Servo drive DIS-2 48/10 FB FS STO“ Version 1.0

Loading...

Loading...