Page 1

Case Carts

R

EMOVE ALL PROTECTIVE COVERING FROM

THE EXTERIOR OF THE CART. COVERING

MUST BE REMOVED BEFORE PLACING THE

CART INTO SERVICE.

DOORS

oor Latch

D

1. To open, lift up on latch paddle to open the

door(s) (Fig. 1). On double door units, the right

door must be opened before the left door. To

close, swing door(s) back into cart.

Fig. 1

Optional Passive Lock Security Latch

1. Install Metro Security Seal (sold separately)

into latch hasp as shown in Fig 1A. To gain

to the cart, simply lift latch to break security seal.

Fig. 2A

CASTERS

Grease Zerk Fittings (See Fig. 3)

Under normal usage, the casters should be

1.

regreased at least once a month.

2. When the unit is being cleaned in a cart wash,

it is recommended that the casters be regreased

every second week.

Fig. 3

Foot Operated Wheel Brake Caster

Wheel brake caster can be engaged or

d

isengaged by applying pressure to the black

pedal mounted on the caster (Fig. 4).

INSTRUCTIONS

FOR USE

Fig. 5

Fig. 6

WIRE & SOLID SHELVES

Each shelf is supplied with a left and right

helf slide.

s

To Install Shelf Slides:

1.

Take a shelf slide and position in the cart

with the notched end toward the back. At

the desired height insert the slide’s rear

rivet head into the rear keyhole slot at the

rear of the cart and slide back once

engaged. Align and insert the slide’s front

rivet head with the front keyhole slot and

push down once engaged (Fig. 7, wire

pullout slide; Fig. 8, roller shelf slide).

Repeat for the other side.

Fig. 1A

Side Door Catch

1. T

o lock the door(s) in the open position, simply

push the door(s) in against side of unit (Fig. 2). To

disengage, pull door(s) outward away from unit.

2. To adjust door catch, loosen nuts on backside

of door catch bracket (under cart, Fig 2A). Adjust

bracket/door catch up or down as necessary, and

tighten nuts.

Fig. 2

InterMetro Industries Corporation

North Washington Street, Wilkes-Barre, PA USA 18705

For Product Information Call: 1-800-992-1776

Visit Our Web Site: www.metro.com

Fig. 4

Swivel Lock Caster

On carts equipped with the swivel lock caster,

f

acing the end of the cart which the caster

is mounted, push the arm to the far left for

swivel caster operation (Fig. 5). Push the

arm to the far right to engage the mechanism

for rigid caster operation (Fig.6)

Fig. 7

Fig. 8

INSTRUCTIONS

FOR USE

For Metro Case Carts

Page 2

Case Carts

To Install Wire Pullout Shelves or

Roller Shelves:

2.

Lay the shelf on the shelf slides making

sure the two wire loops or rollers are toward

the rear and on the bottom. Slide shelf back

until loops or rollers fall into shelf slide notches.

Pull shelf forward making sure wire loops/rollers

are undershelf slides (Fig. 9, Fig. 10).

Fig. 9

Fig. 10

3. The shelf can be pulled out for easier

accessibility of contents. Stops are built into the

shelf slides to prevent shelf from being pulled

out too far (Fig 11).

Fig. 11

To Remove Shelves:

Push shelf to rear of cart. Lift the rear of the

shelf until the shelf rollers/wire loops are free

of the shelf slide notches. And then remove

shelf from cart.

To Change Shelf Levels:

Remove shelf from cart. Grasp a shelf slide

front and lift up until free of key slot in side

of cart. Pull slide forward until shelf slide

rivet is free of keyhole slot. Re-position at

desired level, locking shelf slide into slots.

Repeat on other side. Reinstall shelf.

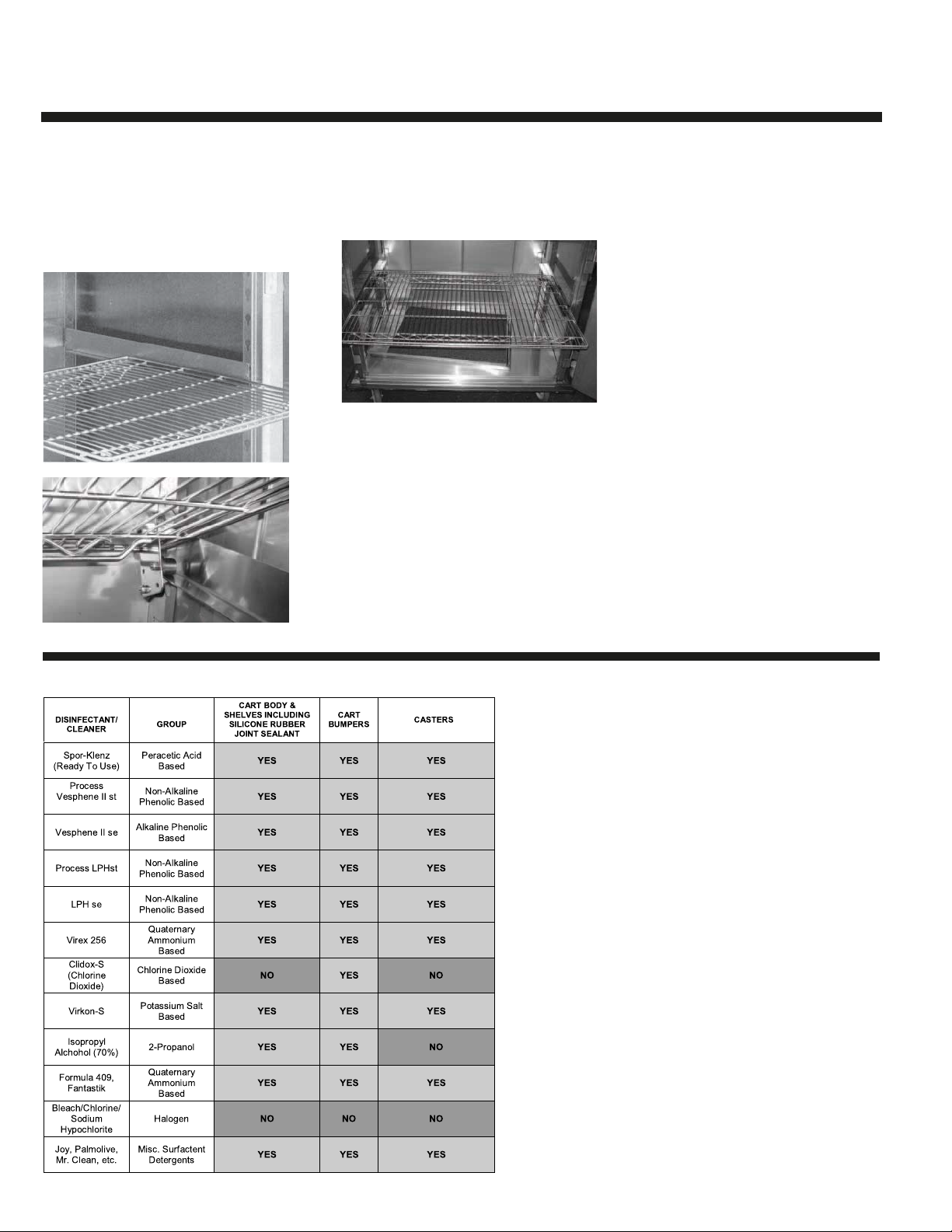

CASE CART CLEANING/STERILIZATION GUIDE FOR MANUAL CLEANING

YES ratings are based on adherence to the manufacturer’s

recommended dilution ratio for the cleaner/disinfectant

concentrate being used (where applicable), at ambient

temperatures not exceeding 72° F (22.2° C), and with

intermittent exposure times not exceeding15 minutes

each exposure.

Page 3

Case Carts

CASE CART AUTOMATED CART WASH PARAMETERS

1. The Cart Wash Chamber must be non-pressurized.

2. Water temperatures in the range of 140°F (60°C) to 180°F (82.2°C) are allowed with an exposure period not to exceed 30 minutes.

3. Hot air drying is allowed with the temperatures not to exceed 200°F (93.3°C) and an exposure period not to exceed 15 minutes.

4. Steam sanitation is allowed with the temperature not to exceed 212°F (100°C) and an exposure period not to exceed 15 minutes.

5. Phosphoric acid based sanitation is allowed with the concentration of phosphoric acid not to exceed 10% by volume.

6. Sodium hydroxide based sanitation is allowed with the concentration of sodium hydroxide not to exceed 10% by volume.

7. Potassium hydroxide based sanitation is allowed with the concentration of sodium hydroxide not to exceed 10% by volume.

8. Sodium hypochorite, chlorine, chlorine dioxide and/or bleach based sanitation MUST be avoided.

CASTER/ CART MAINTENANCE RECOMMENDATIONS

As a general guideline, if cart washing is frequent and/or prolonged, it is suggested to start by re-greasing the casters once a week

with a high temperature non-EP or silicone grease designated for use with anti-friction bearings and capable of withstanding

temperature ranges of between 0° F (17.7°C) to 325° F (162.7°C). The f requency of caster re-greasing can then be adjusted as

required. Casters should be periodically inspected for worn treads, loose bolts, excessive play and/or caster wheel/tread degradation

and repaired or replaced as required.

Additionally, if cart washing is frequent and/or prolonged, the silicone sealed joints should also be periodically inspected to insure that

the integrity and adhesion of the silicon seal to the metal substrate is acceptable and remains capable of maintaining a watertight seal.

If visible degradation of the silicone seal becomes apparent, the existing sealant should be removed and replaced with

Dow Corning® 732 Multi-Purpose Sealant or equivalent.

*Save this document for future application, load rating and/or safety reference.

InterMetro Industries Corporation

North Washington Street, Wilkes-Barre, PA USA 18705

For Product Information Call: 1-800-992-1776

Visit Our Web Site: www.metro.com

L01-232 Rev.D

01/13

Loading...

Loading...