Page 1

OmegaPAT XA

MI 3360

Instruction manual

Ver. 1.2.2, Code no. 20 752 658

Page 2

Mark on your equipment certifies that it meets European Union requirements for EMC,

LVD, ROHS regulations

Distributor:

Manufacturer:

Metrel d.d.

Ljubljanska cesta 77

SI-1354 Horjul

E-mail: metrel@metrel.si

http://www.metrel.si

© 2017 Metrel

The trade names Metrel, Smartec, Eurotest, Autosequence are trademarks registered or

pending in Europe and other countries

No part of this publication may be reproduced or utilized in any form or by any means without

permission in writing from METREL.

2

Page 3

MI 3360 OmegaPAT XA Table of contents

TABLE OF CONTENTS

1 General description ........................................................................................................... 7

1.1 Warnings and notes ........................................................................................................ 7

1.1.1 Safety warnings ...................................................................................................... 7

1.1.2 Warnings related to safety of measurement functions .......................................... 8

1.1.2.1 Flash HV ............................................................................................................. 8

1.1.2.2 Differential leak., Ipe leak., Touch leak., Ileak (W-PE), Primary leak., Power,

Leak’s & Power, Equipment leak., Applied part leak.__ .................................................... 8

1.1.2.3 Insulation resistance........................................................................................... 8

1.1.3 Markings on the instrument .................................................................................... 8

1.2 Power management ....................................................................................................... 9

1.2.1 230 V / 110 V operation .......................................................................................... 9

1.2.2 Battery and charging, auto power off ..................................................................... 9

1.2.3 Power Off, Restart .................................................................................................. 9

1.3 Standards applied ........................................................................................................... 9

2 Instrument set and accessories ..................................................................................... 11

2.1 Standard set of the instrument ..................................................................................... 11

2.2 Optional accessories .................................................................................................... 11

3 Instrument description .................................................................................................... 12

3.1 Front panel .................................................................................................................... 12

4 Instrument operation ....................................................................................................... 14

4.1 General meaning of keys.............................................................................................. 14

4.2 General meaning of touch gestures ............................................................................. 14

4.3 Virtual keyboard ............................................................................................................ 15

4.4 Safety checks ............................................................................................................... 15

4.5 Symbols and messages ............................................................................................... 16

4.6 Instrument main menu .................................................................................................. 20

4.7 General settings ............................................................................................................ 21

4.7.1 Language .............................................................................................................. 22

4.7.2 Date and time ....................................................................................................... 22

4.7.3 Profiles .................................................................................................................. 22

4.7.4 Workspace Manager ............................................................................................ 22

4.7.5 Auto Sequence® groups ...................................................................................... 22

4.7.6 Settings ................................................................................................................. 23

4.7.7 Initial Settings ....................................................................................................... 24

4.7.8 About ..................................................................................................................... 24

4.7.9 User Accounts ...................................................................................................... 25

4.7.9.1 Signing in .......................................................................................................... 25

4.7.9.2 Changing user password, signing out .............................................................. 26

4.7.9.3 Managing accounts .......................................................................................... 27

4.8 Devices ......................................................................................................................... 29

4.9 Instrument profiles ........................................................................................................ 30

4.10 Workspace Manager .................................................................................................... 31

4.10.1 Workspaces and Exports...................................................................................... 31

4.10.2 Workspace Manager main menu ......................................................................... 31

4.10.2.1 Operations with Workspaces ........................................................................... 32

4.10.2.2 Operations with Exports ................................................................................... 33

4.10.2.3 Adding a new Workspace ................................................................................ 33

4.10.2.4 Opening a Workspace ...................................................................................... 34

3

Page 4

MI 3360 OmegaPAT XA Table of contents

4.10.2.5 Deleting a Workspace / Export ........................................................................ 34

4.10.2.6 Importing a Workspace .................................................................................... 35

4.10.2.7 Exporting a Workspace .................................................................................... 36

4.11 Auto Sequence® groups .............................................................................................. 37

4.11.1 Auto Sequence® groups menu ............................................................................ 37

4.11.1.1 Operations in Auto Sequence® groups menu ................................................. 38

4.11.1.2 Selecting a list of Auto Sequences® ................................................................ 38

4.11.1.3 Deleting a list of Auto Sequences® ................................................................. 39

5 Memory Organizer ........................................................................................................... 40

5.1 Memory Organizer menu .............................................................................................. 40

5.1.1 Measurement statuses ......................................................................................... 40

5.1.2 Structure Objects .................................................................................................. 41

5.1.2.1 Measurement status indication under the Structure object ............................. 41

5.1.3 Selecting an active Workspace in Memory Organizer ......................................... 42

5.1.4 Adding Nodes in Memory Organizer .................................................................... 43

5.1.5 Operations in Tree Menu ...................................................................................... 44

5.1.5.1 Operations on measurements (finished or empty measurements) ................. 44

5.1.5.2 Operations on Structure objects ...................................................................... 45

5.1.5.3 View / Edit parameters and attachments of a Structure object ....................... 47

5.1.5.4 Add a new Structure Object ............................................................................. 49

5.1.5.5 Add a new measurement ................................................................................. 51

5.1.5.6 Clone a Structure object ................................................................................... 53

5.1.5.7 Clone a measurement ...................................................................................... 54

5.1.5.8 Copy & Paste a Structure object ...................................................................... 54

5.1.5.9 Copy & Paste a measurement ......................................................................... 56

5.1.5.10 Delete a Structure object .................................................................................. 57

5.1.5.11 Delete a measurement ..................................................................................... 57

5.1.5.12 Rename a Structure object .............................................................................. 58

5.1.5.13 Recall and Retest selected measurement ....................................................... 59

5.1.6 Searching in Memory Organizer........................................................................... 60

6 Single tests ....................................................................................................................... 63

6.1 Selection modes ........................................................................................................... 63

6.1.1 Single test screens ............................................................................................... 64

6.1.1.1 Single test start screen ..................................................................................... 65

6.1.1.2 Setting parameters and limits of single tests ................................................... 66

6.1.1.3 Single test screen during test ........................................................................... 67

6.1.1.4 Single test result screen ................................................................................... 68

6.1.1.5 Single test memory screen............................................................................... 69

6.1.2 Single test (inspection) screens ........................................................................... 70

6.1.2.1 Single test (inspection) start screen ................................................................. 70

6.1.2.2 Single test (Inspection) screen during test ...................................................... 71

6.1.2.3 Single test (Inspection) result screen ............................................................... 72

6.1.2.4 Single test (inspection) memory screen........................................................... 73

6.1.3 Help screens ......................................................................................................... 74

6.2 Single test measurements ............................................................................................ 75

6.2.1 Visual inspection ................................................................................................... 75

6.2.2 Continuity // Protective earth resistance .............................................................. 76

6.2.2.1 Compensation of test lead / IEC test cable resistance .................................... 78

6.2.3 Flash test .............................................................................................................. 79

6.2.4 Insulation resistance (Riso, Riso-S) ..................................................................... 81

6.2.5 Sub-leakage (Isub, Isub-S) ................................................................................... 82

6.2.6 Differential Leakage .............................................................................................. 84

6.2.7 Ipe Leakage .......................................................................................................... 86

4

Page 5

MI 3360 OmegaPAT XA Table of contents

6.2.8 Touch Leakage ..................................................................................................... 87

6.2.9 Power .................................................................................................................... 89

6.2.10 Leak's & Power ..................................................................................................... 90

6.2.11 PRCD test ............................................................................................................. 91

6.2.12 RCD test ............................................................................................................... 93

6.2.13 PE conductor (PRCD) .......................................................................................... 95

6.2.14 Open conductor (PRCD) ...................................................................................... 96

6.2.15 PRCD PE probe test ............................................................................................. 97

6.2.16 Polarity .................................................................................................................. 99

6.2.17 Clamp current ..................................................................................................... 101

6.2.18 Insulation resistance – Riso (welding equipment) ............................................. 103

6.2.19 Welding Circuit Leakage – I leak (W-PE) ........................................................... 104

6.2.20 Primary Leakage................................................................................................. 105

6.2.21 No-load voltage ................................................................................................... 106

6.2.22 Insulation resistance – Riso (medical equipment) ............................................. 107

6.2.23 Equipment Leakage (medical equipment) ......................................................... 110

6.2.24 Applied Part Leakage (medical equipment) ....................................................... 113

6.2.25 Touch Current (medical equipment) ................................................................... 115

6.2.26 Functional test .................................................................................................... 117

7 Auto Sequences® .......................................................................................................... 118

7.1 Selection of Auto Sequences® .................................................................................. 118

7.1.1 Selecting an active Auto Sequence® group in Auto Sequences® menu .......... 118

7.1.2 Searching in Auto Sequences® menu ............................................................... 119

7.1.3 Organization of Auto Sequences® in Auto Sequences® menu ........................ 121

7.2 Organization of an Auto Sequence®.......................................................................... 122

7.2.1 Auto Sequence® view menu .............................................................................. 122

7.2.1.1 Auto Sequence® view menu (Header is selected) ........................................ 122

7.2.1.2 Auto Sequence® view menu (measurement is selected) ............................. 123

7.2.1.3 Indication of Loops ......................................................................................... 124

7.2.1.4 Managing multiple points ............................................................................... 124

7.2.2 Step by step execution of Auto Sequences® .................................................... 124

7.2.3 Auto Sequence® result screen .......................................................................... 126

7.2.4 Auto Sequence® memory screen ...................................................................... 128

7.2.5 Print label menu .................................................................................................. 129

8 Maintenance ................................................................................................................... 130

8.1 Periodic calibration ..................................................................................................... 130

8.2 Fuses .......................................................................................................................... 130

8.3 Service ........................................................................................................................ 130

8.4 Cleaning ...................................................................................................................... 130

9 Communications ............................................................................................................ 131

9.1 USB and RS232 communication with PC .................................................................. 131

9.2 Bluetooth communication ........................................................................................... 131

9.3 Bluetooth communication with printers and scanners ............................................... 132

9.4 RS232 communication with other external devices ................................................... 132

9.5 Connections to test adapters ...................................................................................... 132

9.5.1 Active 3 Phase Adapter /Plus (A 1322 / A 1422) ............................................... 132

9.5.2 110 V Test Adapter (A 1474) .............................................................................. 133

10 Technical specifications ............................................................................................... 134

10.1 Continuity // Protective earth resistance .................................................................... 134

10.2 Insulation Resistance (Riso, Riso-S) .......................................................................... 134

10.3 Sub-Leakage Current, Substitute Leakage Current - S ............................................. 135

5

Page 6

MI 3360 OmegaPAT XA Table of contents

10.4 Differential Leakage current ....................................................................................... 135

10.5 PE leakage current ..................................................................................................... 135

10.6 Touch leakage current ................................................................................................ 136

10.7 Power .......................................................................................................................... 136

10.8 Leak’s & Power ........................................................................................................... 137

10.9 PRCD test ................................................................................................................... 139

10.10 RCD test ..................................................................................................................... 139

10.11 PE conductor (PRCD) ................................................................................................ 140

10.12 Open conductor (PRCD) ............................................................................................ 140

10.13 PRCD PE probe test ................................................................................................... 140

10.14 Polarity ........................................................................................................................ 141

10.15 Clamp current ............................................................................................................. 141

10.16 Flash test .................................................................................................................... 141

10.17 Insulation resistance Riso (welding equipment) ........................................................ 142

10.18 Welding Circuit leakage (Ileak W-PE) ........................................................................ 142

10.19 Primary Leakage (I diff) .............................................................................................. 142

10.20 No-load voltage ........................................................................................................... 142

10.21 Insulation Resistance (medical equipment) ............................................................... 143

10.22 Equipment leakage ..................................................................................................... 143

10.23 Applied Part leakage .................................................................................................. 144

10.24 Touch current (medical equipment) ........................................................................... 144

10.25 General data ............................................................................................................... 145

Appendix A Structure objects in OmegaPAT XA ............................................................ 146

Appendix B Profile Notes ................................................................................................... 147

Appendix C Print labels and write / read RFID / NFC tags ............................................. 148

C.1 PAT tag format ............................................................................................................ 148

C.2 Generic tag format ...................................................................................................... 150

Appendix D Default list of Auto Sequences® .................................................................. 152

Appendix E Programming of Auto Sequences® on Metrel ES Manager ......................... 153

E.1 Auto Sequence® Editor workspace ........................................................................... 153

E.2 Managing groups of Auto Sequences® ..................................................................... 154

E.2.1 Auto Sequence® Name, Description and Image editing ................................... 156

E.2.2 Search within selected Auto Sequence® group ................................................ 157

E.3 Elements of an Auto Sequence® ............................................................................... 158

E.3.1 Auto Sequence® steps ....................................................................................... 158

E.3.2 Single tests ......................................................................................................... 158

E.3.3 Flow commands .................................................................................................. 158

E.3.4 Number of measurement steps .......................................................................... 158

E.4 Creating / modifying an Auto Sequence® .................................................................. 158

E.5 Description of flow commands ................................................................................... 159

E.6 Custom Inspections programming ............................................................................. 162

E.6.1 Creating and editing Custom Inspections .......................................................... 162

E.6.2 Applying Custom Inspections ............................................................................. 164

6

Page 7

MI 3360 OmegaPAT XA General description

Read before use

1 General description

1.1 Warnings and notes

1.1.1 Safety warnings

In order to reach high level of operator safety while carrying out various measurements using

the OmegaPAT XA instrument, as well as to keep the test equipment undamaged, it is

necessary to consider the following general warnings:

Read this user manual carefully, otherwise use of the instrument may be

dangerous for the operator, for the instrument or for the equipment under test!

Consider warning markings on the instrument!

If the test equipment is used in manner not specified in this user manual the

protection provided by the equipment may be impaired!

Do not use the instrument and accessories if any damage is noticed!

Regularly check the instrument and accessories for correct functioning to avoid

hazard that could occur from misleading results.

Consider all generally known precautions in order to avoid risk of electric shock

while dealing with hazardous voltages!

Use only standard or optional test accessories supplied by your distributor!

Only test equipment provided or approved by Metrel should be connected to 3-

PHASE ADAPTER connector.

Do not connect external voltage to CLAMP inputs. It is intended only for

connection of Clamps approved by Metrel.

Use only earthed mains outlets to supply the instrument!

If working on other than 230 V TN/TT voltage systems refer to chapter 1.2.1 230 V /

110 V operation.

In case a fuse has blown refer to chapter 8.2 Fuses to replace it!

Instrument servicing and calibration is allowed to be carried out only by a

competent authorized person!

LCD screenshots in this document are informative only. Screens on the

instrument may be slightly different.

7

Page 8

MI 3360 OmegaPAT XA General description

1.1.2 Warnings related to safety of measurement functions

1.1.2.1 Flash HV

A voltage of up to 3 kV

between main socket’s LN and PE socket terminals / 1.5 kVAC between FLASH and

mains socket PE terminal is applied to the instrument’s outputs during the test.

Although the current of the HV source is limited to safe level special safety

consideration must be taken when performing this test!

between FLASH and mains socket LN terminals / 1.5 kVAC

AC

1.1.2.2 Differential leak., Ipe leak., Touch leak., Ileak (W-PE), Primary leak., Power, Leak’s & Power, Equipment leak., Applied part leak.__

Load currents higher than 10 A can result in high temperatures of fuse holders! It is

advisable not to run tested devices with load currents above 10 A for more than 15

minutes. Recovery period for cooling is required before proceeding with tests!

Maximum intermittent duty cycle for measurements with load currents higher than 10

A is 50 %.

1.1.2.3 Insulation resistance

Do not touch the test object during the measurement or before it is fully discharged!

Risk of electric shock!

1.1.3 Markings on the instrument

Read the Instruction manual with special care to safety operation«. The

symbol requires an action!

Dangerous high voltage is present on terminals during the test.

Consider all precautions in order to avoid risk of electric shock.

Mark on your equipment certifies that it meets European Union

requirements for EMC, LVD, and ROHS regulations.

This equipment should be recycled as electronic waste.

8

Page 9

MI 3360 OmegaPAT XA General description

1.2 Power management

1.2.1 230 V / 110 V operation

The instrument works on 110 V and 230 V mains. 110 V and 230 V appliances can be fully

tested.

In UK and Aus/Nz models only 110 V mains voltage will be applied to the mains test socket if

the 110 V test adapter (A 1474) is connected to the instrument.

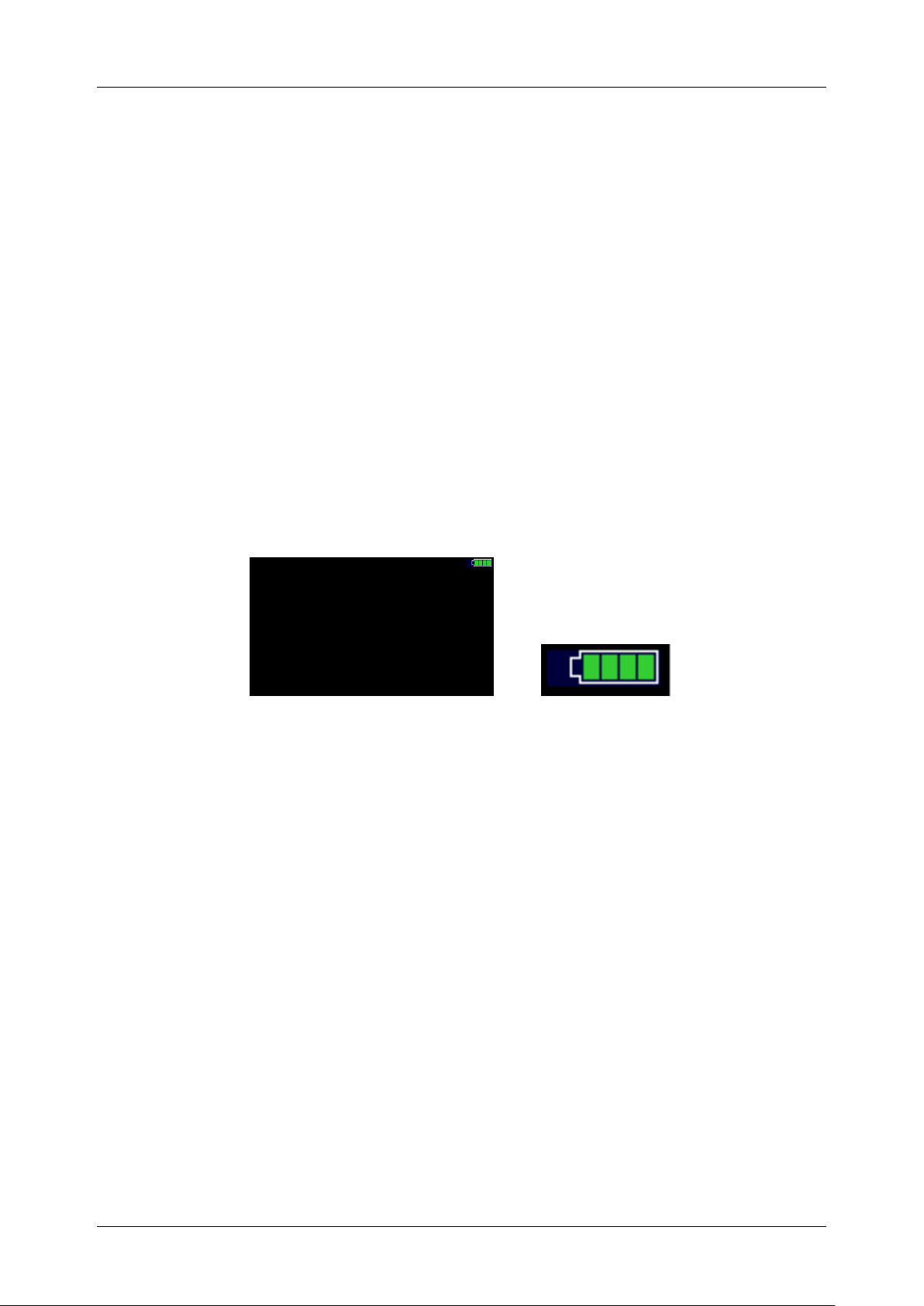

1.2.2 Battery and charging, auto power off

The instrument has an in-built rechargeable battery pack. The battery is charged whenever the

instrument is connected to the mains. When the instrument is disconnected from mains, the

battery provides power to the instrument to stay energized for 1 minute. This is indicated by the

battery symbol in the upper right corner of the LCD. Operation with the instrument is not

possible except the mains was disconnected during the RCD test. As long as the instrument is

energized it will be ready to use immediately after connected to mains voltage again. This

enables faster testing of appliances.

If the instrument is not reconnected to mains within 1 minute it will completely switch off. When

connected to mains again, a normal power up procedure will be taken.

Figure 1.1: Indication of battery status

Notes:

A flat or faulty battery will result in an immediate power off after the instrument is

disconnected from the mains.

Charging time of the battery is about 14 h.

1.2.3 Power Off, Restart

Instrument is powered by battery:

when pressing the ESC key for ca 5 s the instrument will switch off.

Instrument is connected to mains:

when pressing the ESC key for ca 5 s the instrument will restart.

1.3 Standards applied

The OmegaPAT XA instrument is manufactured and tested according to the following

regulations, listed below.

9

Page 10

MI 3360 OmegaPAT XA General description

EN 61326-1

Electrical equipment for measurement, control and laboratory use - EMC

requirements – Part 1: General requirements

Class B (Portable equipment used in controlled EM environments)

EN 61010-1

Safety requirements for electrical equipment for measurement, control, and

laboratory use – Part 1: General requirements

EN 61010-2-030

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 2-030: Particular requirements for testing and

measuring circuits

EN 61010-031

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 031: Safety requirements for hand-held probe

assemblies for electrical measurement and test

EN 61010-2-032

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 2-032: Particular requirements for hand-held and

hand-manipulated current sensors for electrical test and measurement

EN 61557

Electrical safety in low voltage distribution systems up to 1 000 V a.c. and 1

500 V d.c. – Equipment for testing, measuring or monitoring of protective

measures

Instrument complies with all relevant parts of EN 61557 standards.

Code of Practice

Household and similar electrical appliances

VDE 0701-702

Inspection after repair, modification of electrical appliances – Periodic

inspection on electrical appliances

General requirements for electrical safety

IEC/EN 60974-4

Arc welding equipment – Part 4: Periodic inspection and testing

IEC/EN 62353

Medical electrical equipment - Recurrent test and test after repair of

medical electrical equipment

AS/NZS 3760

In-service safety inspection and testing of electrical equipment

Electromagnetic compatibility (EMC)

Safety (LVD)

Functionality

10

Page 11

MI 3360 OmegaPAT XA Instrument set and accessories

2 Instrument set and accessories

2.1 Standard set of the instrument

Instrument MI 3360 OmegaPAT XA

Bag for accessories

Flash test probe (MI 3360 F only)

IEC test cable 3 x 1.5 mm2, 2 m

Test lead (black)

Test tip (black)

Alligator clip (black)

Mains cable, 3 x 1.5 mm2, 2 m

USB cable

Calibration Certificate

Short form instruction manual

CD with instruction manual (full version) and PC SW Metrel ES Manager

2.2 Optional accessories

See the attached sheet for a list of optional accessories that are available on request from your

distributor.

11

Page 12

MI 3360 OmegaPAT XA Instrument description

3 Instrument description

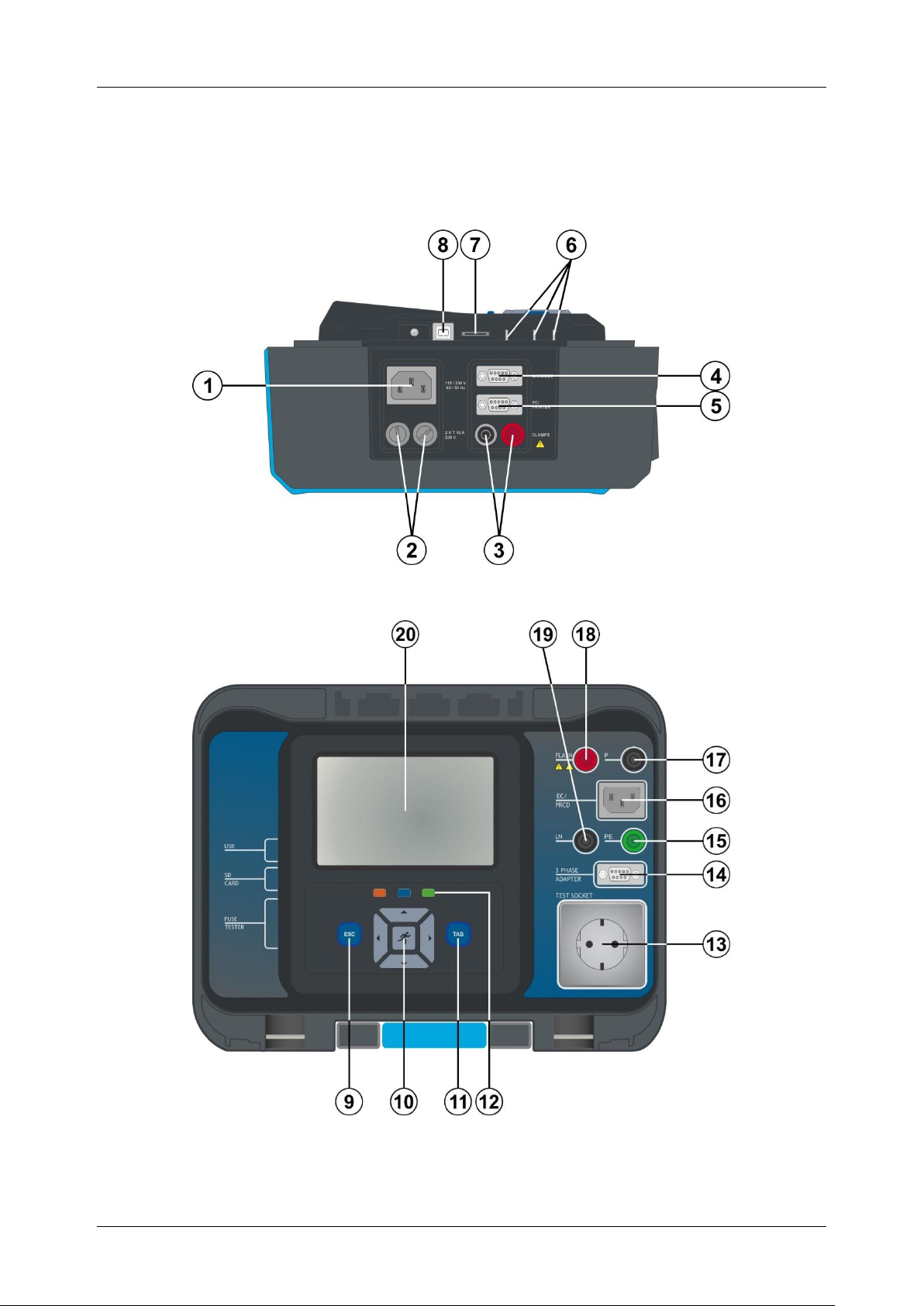

3.1 Front panel

Figure 3.1: Left side panel

Figure 3.2: Front panel

12

Page 13

MI 3360 OmegaPAT XA Instrument description

1

Mains supply connector

2

F1, F2 fuses (T 16 A / 250 V)

3

Clamp inputs

4

Barcode scanner and RFID / NFC reader / writer device serial port

5

PC / Printer serial port

6

Fuse checker

7

MicroSD card slot

8

USB communication port

9

Escape key / reset key

10

Keypad

11

TAB key

12

Shortcut keys

13

Mains test socket

14

Data connection 3 phase adapter

15

PE connector

16

IEC test connector

17

P/S (probe) connector,

P/AP (probe / applied part) connector

18

FLASH output connector

19

LN connector

20

Colour TFT display with touch screen

13

Page 14

MI 3360 OmegaPAT XA Instrument operation

Cursor keys are used to:

- select appropriate option

RUN key is used to:

- confirm selected option

- start and stop measurements

Escape key is used to:

- return to previous menu without changes

- abort measurements

- reset instrument (long press >5 sec)

- switch OFF instrument from standby mode (long press >5 sec)

Option key is used to:

- expand column in control panel

- show detailed view of options

Shortcut keys for immediate access to the Memory Organizer, Auto

Sequences® menu and Single Tests menu.

Tap (briefly touch surface with fingertip) is used to:

- select appropriate option

- confirm selected option

- start and stop measurements

Swipe (press, move, lift) up/ down is used to:

- scroll content in same level

- navigate between views in same level

long

Long press (touch surface with fingertip for at least 1 s) is used to:

- select additional keys (virtual keyboard)

- enter cross selector from single test screens

Tap Escape icon is used to:

- return to previous menu without changes;

- abort / stop measurements

4 Instrument operation

The instrument can be manipulated via a keypad or touch screen.

4.1 General meaning of keys

4.2 General meaning of touch gestures

14

Page 15

MI 3360 OmegaPAT XA Instrument operation

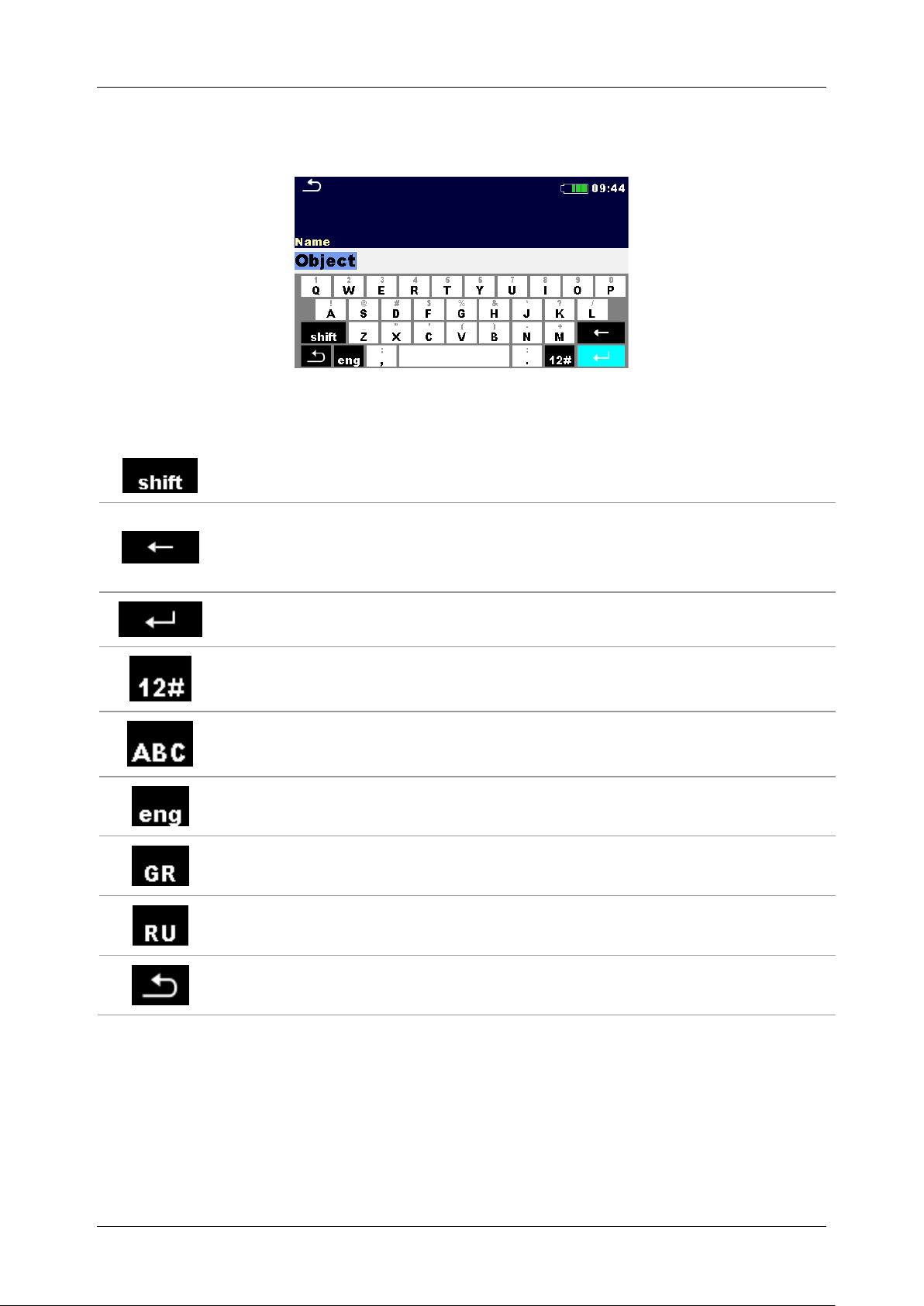

Figure 4.1: Virtual keyboard

Toggle case between lowercase and uppercase.

Active only when alphabetic characters’ keyboard layout selected.

Backspace

Clears last character or all characters if selected.

(If held for 2 s, all characters are selected).

Enter confirms new text.

Activates numeric / symbols layout.

Activates alphabetic characters.

English keyboard layout.

Greek keyboard layout.

Russian keyboard layout.

Returns to the previous menu without changes.

4.3 Virtual keyboard

Options:

4.4 Safety checks

At start up and during operation the instrument performs various safety checks to ensure

safety and to prevent any damage. These safety pre-tests are checking for:

Correct input mains voltage

Presence of input PE connection,

15

Page 16

MI 3360 OmegaPAT XA Instrument operation

Supply voltage warning

Possible causes:

No earth connection.

Instrument is connected to an IT earthing

system. Press YES to continue normally or NO

to continue in a limited mode (measurements are

disabled).

Warning:

The instrument must be earthed properly to work

safely!

Resistance L-N > 30 kΩ

In pre-test a high input resistance was measured.

Possible causes:

Device under test is not connected or switched

on

Input fuse of device under test is blown.

Select YES to proceed with or NO to cancel

measurement.

Resistance L-N < 10 Ω

In pre-test a very low resistance of the device under test

supply input was measured. This can result in a high

current after applying power to the device under test. If

the too high current is only of short duration (caused by

a short inrush current) the test can be performed

otherwise not.

Select YES to proceed with or NO to cancel

measurement

Resistance L-N < 30 Ω

In pre-test a low input resistance of the device under

test was measured. This can result in a high current

after applying power to the device. If the high current is

only of short duration (caused by a short inrush current)

the test can be performed, otherwise not.

Any external voltage against earth on mains test socket

Excessive leakage currents through measuring I/O’s,

Too low resistance between L and N of tested device,

Proper operation of safety relevant internal electronic circuits

If a safety check fails, an appropriate warning message will be displayed and safety

measures will be taken. The warnings and safety measures are described in chapter 4.5

Symbols and messages.

4.5 Symbols and messages

16

Page 17

MI 3360 OmegaPAT XA Instrument operation

Select YES to proceed with or NO to cancel

measurement.

Warning for proper connection in some PRCD

measurements. Connection of PRCD’s plug must be

changed in order to proceed.

Select YES to retry after reconnection with or NO to

cancel measurement.

Warning for improper supply voltage condition. If

pressing OK instrument will continue to work in a limited

mode (measurements are disabled).

In pre-test a too high external voltage was detected

between P and PE terminals. The measurement was

cancelled. Press OK to continue.

In pre-test a too high external voltage was detected

between LN and PE terminals. The measurement was

cancelled. Press OK to continue.

The set Unom differs too much from the measured

mains voltage. Parameter or mains voltage must be

changed.

In pre-test a possible high leakage current was

detected. It is likely that a dangerous leakage current

(higher than 3.5 mA) will flow after applying power to the

device under test.

Select YES to proceed with or NO to cancel

measurement.

The measured leakage (Idiff, Ipe, Itouch) current was

higher than 20 mA. Measurement was aborted. Press

OK to continue.

17

Page 18

MI 3360 OmegaPAT XA Instrument operation

The load current higher than 16 A is detected.

Measurement is aborted. Press OK to continue.

The average load current higher than 10 A over the last

5 min test interval is detected. Measurement is stopped.

Recovery period for cooling is required before

proceeding with tests! Press OK to continue.

The polarity pre-test of the cable / PRCD has failed.

Press OK to continue.

Instrument prohibits the test because 115 V adapter is

connected to the instrument and the instrument is

powered with 230 V.

The instrument is overheated. The measurement can’t

be carried out until the icon disappears. Press OK to

continue.

The device under test should be switched on (to ensure

that the complete circuit is tested).

In case of simultaneously measuring of Riso, Riso-S or

Isub, Isub-S. If the voltage has dropped because of one

measurement the other measurement is also

compromised.

Red dot indicates phase of measurement where higher

leakage was measured. Applicable only if phase

reversal is enabled during the measurement.

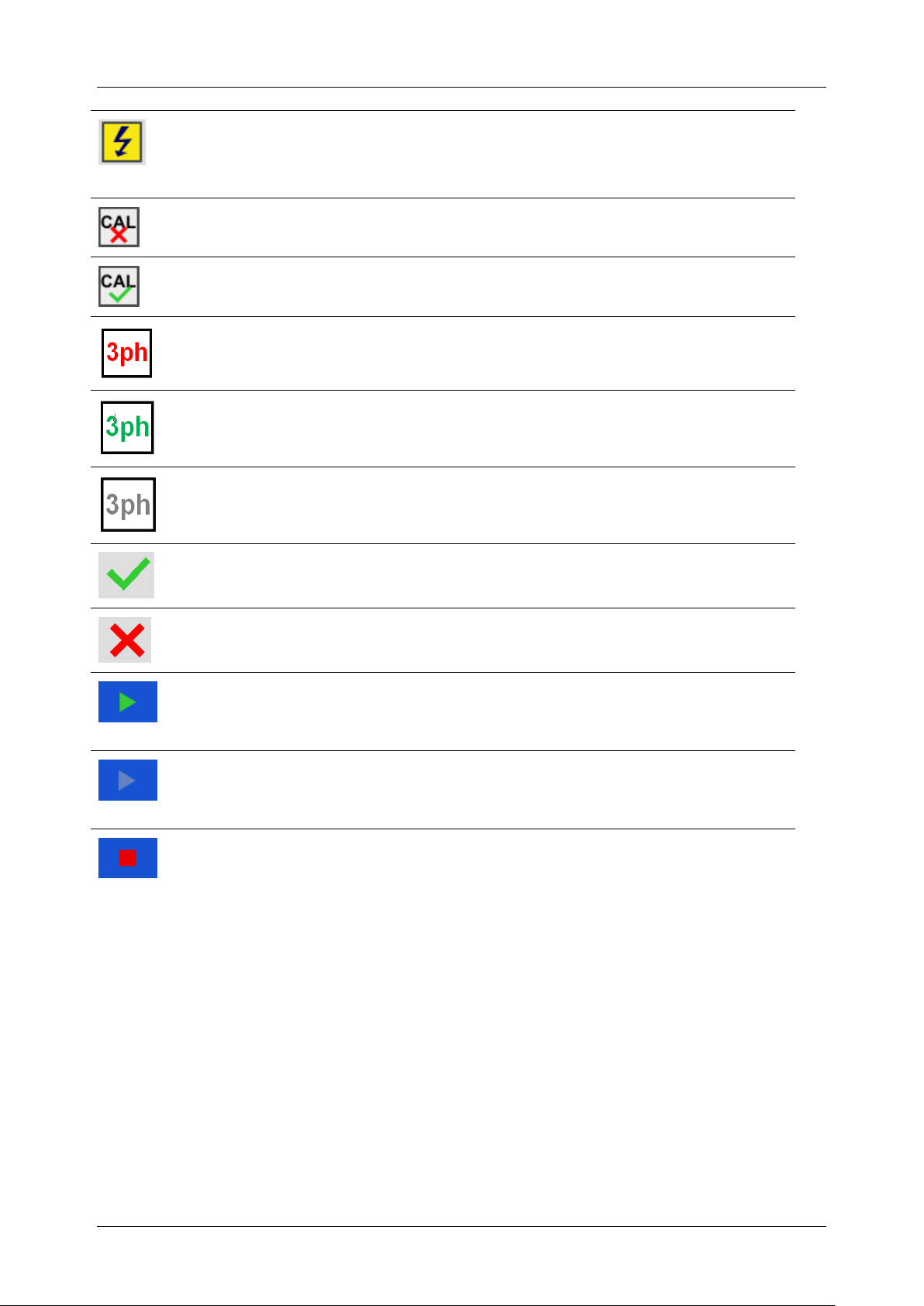

Warning!

A high voltage is / will be present on the instrument

output! (Withstanding test voltage, Insulation test

voltage, or mains voltage).

18

Page 19

MI 3360 OmegaPAT XA Instrument operation

Warning!

A very high voltage is / will be present on the instrument

output! (Flash test voltage).

Test leads resistance in Continuity / Protective Earth

measurement is not compensated.

Test leads resistance in Continuity / Protective Earth

measurement is compensated.

Measurement can’t be started. 3 phase adapter should

be disconnected from the instrument.

Measurement in combination with appropriate 3 phase

adapter can be carried out.

The measurement can be carried out only in

combination with appropriate 3 phase adapter.

Test passed.

Test failed.

Conditions on the input terminals allow starting the

measurement; consider other displayed warnings and

messages.

Conditions on the input terminals do not allow starting

the measurement, consider displayed warnings and

messages.

Stop the measurement.

19

Page 20

MI 3360 OmegaPAT XA Instrument operation

Figure 4.2: Main menu

Single Tests

Menu with single tests, see chapter 0 Error! Not a valid result for

able..

Auto Sequences®

Menu with customized test sequences, see chapter 7 Auto

Sequences®.

Memory Organizer

Menu for working with and documentation of test data, see chapter 5

Memory Organizer.

General Settings

Menu for setup of the instrument, see chapter 4.7 General settings.

4.6 Instrument main menu

From the instrument Main Menu different main operation menus can be selected.

Options

20

Page 21

MI 3360 OmegaPAT XA Instrument operation

Figure 4.3: Setup menu

Language

Instrument language selection.

Date / Time

Instruments Date and time.

Workspace Manager

Manipulation with project files. Refer to chapter 4.10 Workspace Manager for

more information.

Auto Sequence® groups

Manipulation with lists of Auto Sequences®. Refer to chapter 4.11 Auto

Sequence® groups for more information.

User accounts

User account settings.

Profiles

Selection of available instrument profiles.

Settings

Setting of different system / measuring parameters.

Devices

Setting of external devices.

Initial Settings

Factory settings.

About

Basic instrument data.

4.7 General settings

In the General Settings menu general parameters and settings of the instrument can be viewed

or set.

Options in General Settings menu

21

Page 22

MI 3360 OmegaPAT XA Instrument operation

4.7.1 Language

In this menu the language of the instrument can be set.

Figure 4.4: Select language menu

4.7.2 Date and time

In this menu date and time of the instrument can be set.

Figure 4.5: Setting data and time menu

4.7.3 Profiles

Refer to Chapter 4.9 Instrument profiles for more information.

4.7.4 Workspace Manager

Refer to Chapter 4.10 Workspace Manager for more information.

4.7.5 Auto Sequence® groups

Refer to Chapter 4.11 Auto Sequence® groups for more information.

22

Page 23

MI 3360 OmegaPAT XA Instrument operation

Description

Touch screen

ON – touch screen is active.

OFF – touch screen is deactivated.

Keys & touch sound

ON – sound is active.

OFF – sound is deactivated.

Equipment ID

Increment – offered ID will be incremented +1.

Replicate – offered ID will be the same as last used.

Blank – equipment ID will not be offered.

Equipment name

Replicate – offered name will be the same as last used.

Blank – equipment name will not be offered.

Retest period

Replicate – offered retest period will be the same as last used.

Blank– retest period will not be offered.

Unom

Nominal Line to earth voltage [100 V, 110 V, 120 V, 220 V, 230 V or 240

V] (is used for normalization of leakage current results if testing medical

equipment).

RCD Standard

Selection of appropriate standard for RCD tests.

PRCD Standard

Selection of appropriate standard for PRCD tests.

Ch_1 clamp type

Setting of current clamp type.

Result

In case the measurement consists of multiple measurements taken

successively, the worst or the last result can be displayed at the end.

Worst – the worst result will be displayed at the end of test.

Last – last result will be displayed at the end of test.

Notes:

In general the worst result(s) of the main result is considered.

Sub-result(s) taken at the same time as the worst case of the

main result are displayed.

In the function Leak's & Power the worst case of Idiff and I touch

4.7.6 Settings

Figure 4.6: Settings menu

Setting options:

23

Page 24

MI 3360 OmegaPAT XA Instrument operation

are considered. The Power result measured at the time of worst

Idiff is displayed.

In the function Riso, Riso-S the worst case of Riso and Riso-S

are considered. The Um result measured at the time of worst

Riso is displayed.

For the Power measurement the last result is considered

regardless of the Result setting.

Limit Uc

Conventional touch voltage limit [25 V, 50 V]

Figure 4.7: Initial settings menu

4.7.7 Initial Settings

In this menu internal Bluetooth module can be initialized and the instrument settings,

measurement parameters and limits can be set to initial (factory) values.

Warning!

Following customized settings will be lost when setting the instruments to initial settings:

Measurement limits and parameters

Global parameters, System settings and Devices in General settings menu

Opened Workspace and Auto Sequence® group will be deselected.

User will be signed out.

Note:

Following customized settings will stay:

Profile settings

Data in memory (Data in Memory organizer, Workspaces, Auto Sequence® groups

and Auto Sequences®)

User accounts

4.7.8 About

In this menu instrument data (name, serial number, FW and HW version and date of calibration)

can be viewed.

24

Page 25

MI 3360 OmegaPAT XA Instrument operation

Figure 4.8: Instrument info screen

Note:

Adapter info is also displayed if connected.

4.7.9 User Accounts

The demand to sign in can prevent from unauthorized persons to work with the instrument.

In this menu user accounts can be managed:

Setting if signing in to work with the instrument is required or not.

Adding and deleting new users, setting their user names and passwords.

The user accounts can be managed by the administrator.

Factory set administrator password: ADMIN

It is recommended to change factory set administrator password afer first use. If the custom

password is forgotten the second administrator password can be used. This password always

unlock the Account manager and is delivered with the instrument.

If an user account is set and the user is signed in the user's name will be stored in memory for

each measurement.

Individual users can change their passwords.

4.7.9.1 Signing in

If signing in is demanded the user must enter the password in order to work with the instrument.

Figure 4.9: Sign in menu

25

Page 26

MI 3360 OmegaPAT XA Instrument operation

The user should be selected first. The last used user is

displayed in the first row.

Goes to Password entry menu.

To sign in, the selected user password must be entered and

confirmed.

The user password consist of a up to 4 digit number.

Enters Account manager menu.

The administrator password must be entered and confirmed

first.

Administrator password consists of letters and/or numbers.

Letters are case sensitive.

Signs out the set user.

Options

User signing in

Administrator signing in

4.7.9.2 Changing user password, signing out

Figure 4.10: User profile menu

Options

26

Page 27

MI 3360 OmegaPAT XA Instrument operation

Enters procedure for changing the user’s password.

The actual password must be entered first followed by the

new password.

Enters the Account manager menu.

The Account manager menu is accessed by selecting

Account Manager in Sign in menu or User profile menu. The

administrator password must be entered and confirmed first.

The factory set default administrator password is: ADMIN

Field for setting if signing in is required to work with the

instrument.

Field for setting if signing is required once or at each power

on of the instrument.

Enters procedure for changing the administrator password.

4.7.9.3 Managing accounts

Figure 4.11: Account manager menu

Options

27

Page 28

MI 3360 OmegaPAT XA Instrument operation

The actual password must be entered first followed by the

new password.

Enters menu for editing user accounts.

Opens the window for adding a new user account.

In the Add New window the name and initial password of

the new user account are to be set. ‘Add’ confirms the new

user account.

Changes password of the selected user account.

Deletes all user accounts.

Deletes the selected user account.

Figure 4.12: Edit accounts menu

Options

28

Page 29

MI 3360 OmegaPAT XA Instrument operation

Writing devices

Type

Sets appropriate writing device (Serial printer, Bluetooth printer), RFID

writer).

Port

Sets/views communication port of selected writing device.

Bluetooth device

name

Goes to menu for pairing with selected Bluetooth device.

Bluetooth dongle

Initializes Bluetooth Dongle.

Print labels

Selects label form size. See for details.

Printed date

Selects date printed on label text area, Options: [Test date, Retest

date]. See Appendix C Print labels and write / read RFID / NFC tags for

details.

Auto save

Sets simultaneous saving of finished Auto Sequence when label is

printed or RFID / NFC tag is written. Options: [On print, On write, OFF]

See chapter 7.2.3 Auto Sequence® result screen for details.

Tag format

Sets PAT tag / label format or generic tag /label format. See Appendix

C Print labels and write / read RFID / NFC tags for details.

Reading devices

Type

Sets appropriate reading device (QR or barcode scanner, RFID reader,

android device via aMESM application).

Port

Sets/views communication port of selected reading device.

Bluetooth device

name

Goes to menu for pairing with selected Bluetooth device.

4.8 Devices

In this menu operation with external devices is configured.

Figure 4.13: Devices settings menu

29

Page 30

MI 3360 OmegaPAT XA Instrument operation

Loads the selected profile. The instrument will restart

automatically with new profile loaded.

Enters option for deleting a profile.

Before deleting the selected profile user is asked for

confirmation.

4.9 Instrument profiles

In this menu the instrument profile can be selected from the available ones.

Figure 4.14: Instrument profile menu

The instrument uses different specific system and measuring settings in regard to the scope of

work or country it is used. These specific settings are stored in instrument profiles.

By default each instrument has at least one profile activated. Proper licence keys must be

obtained to add more profiles to the instrument.

If different profiles are available they can be selected in this menu.

Refer to Appendix B Profile Notes for more information about functions specified by profiles.

Options

30

Page 31

MI 3360 OmegaPAT XA Instrument operation

4.10 Workspace Manager

The Workspace Manager is intended to manage with different Workspaces and Exports stored

on the microSD card.

4.10.1 Workspaces and Exports

The works with OmegaPAT XA MI 3360 can be organized with help of Workspaces and

Exports. Exports and Workspaces contain all relevant data (measurements, parameters, limits,

structure objects) of an individual work.

Figure 4.15: Organization of Workspaces and Exports on microSD card

Workspaces are stored on microSD card on directory WORKSPACES, while Exports are stored

on directory EXPORTS. Export files can be read by Metrel applications that run on other

devices. Exports are suitable for making backups of important works or can be used for storage

of works if the removable microSD card is used as a mass storage device. To work on the

instrument an Export should be imported first from the list of Exports and converted to a

Workspace. To be stored as Export data a Workspace should be exported first from the list of

Workspaces and converted to an Export.

4.10.2 Workspace Manager main menu

In Workspace manager Workspaces and Exports are displayed in two separated lists.

Figure 4.16: Workspace manager main menu

31

Page 32

MI 3360 OmegaPAT XA Instrument operation

List of Workspaces.

Displays a list of Exports.

Adds a new Workspace.

Refer to Chapter 4.10.2.3 Adding a new

Workspace for more information.

List of Exports.

Displays a list of Workspaces.

Marks the opened Workspace in Memory Organizer.

Opens the selected Workspace in Memory Organizer.

Refer to chapters 5 Memory Organizer and 4.10.2.4 Opening a Workspace for

more information.

Deletes the selected Workspace.

Refer to chapter 4.10.2.5 Deleting a Workspace / Export for more information.

Adds a new Workspace.

Refer to chapter 4.10.2.3 Adding a new Workspace for more information.

Exports a Workspace to an Export.

Refer to chapter 4.10.2.7 Exporting a Workspace for more information.

Opens options in control panel / expands column.

Options

4.10.2.1 Operations with Workspaces

Only one Workspace can be opened in the instrument at the same time. The Workspace

selected in the Workspace Manager will be opened in the Memory Organizer.

Options

Figure 4.17: Workspaces menu

32

Page 33

MI 3360 OmegaPAT XA Instrument operation

Deletes the selected Export.

Refer to chapter 4.10.2.5 Deleting a Workspace / Export for more information.

Imports a new Workspace from Export.

Refer to chapter 4.10.2.6 Importing a Workspace for more information.

Opens options in control panel / expands column.

New workspaces can be added from the

Workspace manager screen.

Enters option for adding new Workspace.

Keypad for entering name of a new Workspace

is displayed after selecting New.

4.10.2.2 Operations with Exports

Figure 4.18: Workspace manager File menu

Options

4.10.2.3 Adding a new Workspace

33

Page 34

MI 3360 OmegaPAT XA Instrument operation

After confirmation a new Workspace is added in

the list in Main Workspace Manager menu.

Workspace can be selected from a list in

Workspace manager screen.

Opens a Workspace in Workspace manager.

The opened Workspace is marked with a blue

dot. The previously opened Workspace will close

automatically.

Workspace / Export to be deleted should be

selected from the list of Workspaces / Exports.

Opened workspace can’t be deleted.

Enters option for deleting a Workspace / Export.

4.10.2.4 Opening a Workspace

4.10.2.5 Deleting a Workspace / Export

34

Page 35

MI 3360 OmegaPAT XA Instrument operation

Before deleting the selected Workspace / Export

the user is asked for confirmation.

Workspace / Export is removed from the

Workspace / Export list.

Select an Export file to be imported from

Workspace Manager Export list.

Enters option Import.

Before the import of the selected file the user is

asked for confirmation.

The Imported Export file is added to the list of

Workspaces.

Note:

If a Workspace with the same name already exists

the name of the imported Workspace will be

changed (name_001, name_002, name_003…).

4.10.2.6 Importing a Workspace

35

Page 36

MI 3360 OmegaPAT XA Instrument operation

Select a Workspace from Workspace manager

list to be exported to an Export file.

Enters option Export.

Before exporting the selected Workspace, the

user is asked for confirmation.

Workspace is exported to Export file and is

added to the list of Exports.

Note:

If an Export file with the same name already

exists the name of the Export file will be changed

(name_001, name_002, name_003, …).

4.10.2.7 Exporting a Workspace

36

Page 37

MI 3360 OmegaPAT XA Instrument operation

4.11 Auto Sequence® groups

The Auto Sequences® in OmegaPAT XA MI 3360 can be organized by using lists. In a list a

group of similar Auto Sequences® is stored. The Auto Sequence® groups menu is intended to

manage with different lists of Auto Sequences® that are stored on the microSD card.

Figure 4.19: Organization of Auto Sequences® on microSD card

Folders with lists of Auto Sequences® are stored in Root\__MOS__\AT on the microSD card.

4.11.1 Auto Sequence® groups menu

In Auto Sequence® groups menu lists of Auto Sequences® are displayed. Only one list can be

opened in the instrument at the same time. The list selected in the Auto Sequence® groups

menu will be opened in the Auto Sequences® main menu.

Figure 4.20: Auto Sequence® groups menu

37

Page 38

MI 3360 OmegaPAT XA Instrument operation

Opens the selected list of Auto Sequences®. Previously selected list of Auto

Sequences® will be closed automatically.

Refer to chapter 4.11.1.2 Selecting a list of Auto Sequences® for more

information.

Deletes the selected list of Auto Sequences.

Refer to chapter 4.11.1.3 Deleting a list of Auto Sequences® for more

information.

Opens options in control panel / expands column.

A list of Auto Sequences® can be selected

from the Auto Sequence® groups menu.

Enters option for selecting a list.

Selected list of Auto Sequences® is marked

with a blue dot.

Note:

Previously selected list of Auto Sequences®

is closed automatically.

4.11.1.1 Operations in Auto Sequence® groups menu

Options

4.11.1.2 Selecting a list of Auto Sequences®

38

Page 39

MI 3360 OmegaPAT XA Instrument operation

A list of Auto Sequences® to be deleted can

be selected from the Auto Sequence® groups

menu.

Enters option for deleting a list.

+ Before deleting the selected list of Auto

Sequences® the user is asked for

confirmation.

A list of Auto Sequences® is removed.

4.11.1.3 Deleting a list of Auto Sequences®

39

Page 40

MI 3360 OmegaPAT XA Memory Organizer

passed finished single test with test results

failed finished single test with test results

finished single test with test results and no status

empty single test without test results

or

at least one single test in the Auto

sequence passed and no single test

failed

or

at least one single test in the Auto

sequence failed

5 Memory Organizer

Memory Organizer is a tool for storing and working with test data.

5.1 Memory Organizer menu

The data is organized in a tree structure with Structure objects and Measurements. OmegaPAT

XA has a multi-level structure. The hierarchy of Structure objects in the tree is shown on Figure

5.1. In Appendix A Structure objects in

OmegaPAT XA is a list of available structure objects.

Figure 5.1: Tree structure and its hierarchy

5.1.1 Measurement statuses

Each measurement has:

a status (Pass or Fail or no status)

a name

results

limits and parameters

A measurement can be a Single test or an Auto Sequence.

For more information, refer to chapters 6 Single tests and 7 Auto Sequences®.

Statuses of Single tests

Overall statuses of Auto Sequence

40

Page 41

MI 3360 OmegaPAT XA Memory Organizer

or

at least one single test in the Auto

sequence was carried out and there

were no other passed or failed single

tests

or

empty Auto sequence with empty single

tests

There are no measurement result(s)

under selected structure object.

Measurements should be made.

Figure 5.3: Example of status - No

measurement result(s)

5.1.2 Structure Objects

Each Structure object has:

an icon

a name

parameters

Optionally they can have:

an indication of the status of the measurements under the Structure object

a comment or a file attached

Structure objects supported are described in Appendix A Structure objects in

OmegaPAT XA.

Figure 5.2: Structure object in tree menu

5.1.2.1 Measurement status indication under the Structure object

Overall status of measurements under each structure element / sub-element can be seen

without spreading tree menu. This feature is useful for quick evaluation of test status and as

guidance for measurements.

Options

41

Page 42

MI 3360 OmegaPAT XA Memory Organizer

One or more measurement result(s)

under selected structure object has

failed. Not all measurements under

selected structure object have been

made yet.

Figure 5.4: Example of status -

Measurements not completed with fail

result(s)

All measurements under selected

structure object are completed but one

or more measurement result(s) has

failed.

Figure 5.5: Status - Measurements

completed with fail result(s)

Press the active Workspace in Memory Organizer

Menu.

Select List of Workspaces in Control panel.

Note:

There is no status indication if all measurement results under each structure element /

sub-element have passed or if there is an empty structure element / sub-element

(without measurements).

5.1.3 Selecting an active Workspace in Memory Organizer

Memory Organizer and Workspace Manager are interconnected so an active Workspace can be

selected also in the Memory Organizer menu.

Procedure

42

Page 43

MI 3360 OmegaPAT XA Memory Organizer

Choose desired Workspace from a list of

Workspaces.

Use Select button to confirm selection.

New Workspace is selected and displayed on the

screen.

Press the active Workspace in Memory

Organizer Menu.

Select Add New Structure Element in Control

panel.

5.1.4 Adding Nodes in Memory Organizer

Structural Elements (Nodes) are used to ease organization of data in the Memory Organizer.

One Node is a must; others are optional and can be created or deleted freely.

Procedure

43

Page 44

MI 3360 OmegaPAT XA Memory Organizer

Change name of the Node if necessary and

press Add to confirm.

New Structure Element (Node) will be added.

Views results of measurement.

The instrument goes to the measurement memory screen. Refer to chapters

6.1.1.5 Single test memory screen and 7.2.4 Auto Sequence® memory screen

Auto Sequence® memory screen for more information.

5.1.5 Operations in Tree Menu

In the Memory organizer different actions can be taken with help of the control panel at the right

side of the display. Possible actions depend on the selected element in the organizer.

5.1.5.1 Operations on measurements (finished or empty measurements)

The measurement must be selected first. Operation options can be selected from the menu on

the right side of the screen. Menu options are adopted to measurement status, empty, finished,

finished and saved, as presented on Figure 5.6.

Figure 5.6: A measurement is selected in the tree menu

Options

44

Page 45

MI 3360 OmegaPAT XA Memory Organizer

Starts a new measurement.

The instrument goes to the measurement start screen. Refer to chapters

6.1.1.1 Single test start screen and 7.2.1 Auto Sequence® view menu for more

information.

Saves a measurement.

Saving of measurement on a position after the selected (empty or finished)

measurement.

Clones the measurement.

The selected measurement can be copied as an empty measurement under

the same Structure object. Refer to Chapter 5.1.5.7 Clone a measurement for

more information.

Copies & Paste a measurement.

The selected measurement can be copied and pasted as an empty

measurement to any location in structure tree. Multiple “Paste” is allowed.

Refer to Chapter 5.1.5.9 Copy & Paste a measurement for more information.

Adds a new measurement.

The instrument goes to the Menu for adding measurements. Refer to Chapter

5.1.5.5 Add a new measurement for more information.

Views and edit comments.

The instrument displays comment attached to the selected measurement or

opens keypad for entering a new comment.

Deletes a measurement.

Selected Measurement can be deleted. User is asked for confirmation before

the deleting. Refer to Chapter 5.1.5.11 Delete a measurement for more

information.

Starts a new measurement.

First type of measurement (single test or Auto sequence®) should be selected.

After proper type is selected the instrument goes to single test or Auto

5.1.5.2 Operations on Structure objects

The structure object must be selected first.

Figure 5.7: A structure object is selected in the tree menu

Options

45

Page 46

MI 3360 OmegaPAT XA Memory Organizer

Sequence® selection screen. Refer to Chapters 6.1 Selection modes and 7.1

Selection of Auto Sequences® for more information.

Saves a measurement.

Saving of measurement under the selected Structure object.

View / edit parameters and attachments.

Parameters and attachments of the Structure object can be viewed or edited.

Refer to Chapter 5.1.5.3 View / Edit parameters and attachments of a Structure

object for more information.

Adds a new measurement.

The instrument goes to the Menu for adding measurement into structure. Refer

to Chapter 5.1.5.5 Add a new measurement for more information.

Adds a new Structure object.

A new Structure object can be added. Refer to Chapter 5.1.5.4 Add a new

Structure Object for more information.

Attachments.

Name and link of attachment is displayed.

Clones a Structure object.

Selected Structure object can be copied to same level in structure tree (clone).

Refer to Chapter 5.1.5.6 Clone a Structure object for more information.

Copies & Paste a Structure object.

Selected Structure object can be copied and pasted to any allowed location in

structure tree. Multiple “Paste” is allowed. Refer to Chapter 5.1.5.8 Copy & Paste

a Structure object for more information.

Views and edit comments.

The instrument displays comment attached to the selected Structure object or

opens keypad for entering a new comment.

Deletes a Structure object.

Selected Structure object and sub-elements can be deleted. User is asked for

confirmation before the deleting. Refer to Chapter 5.1.5.10 Delete a Structure

object for more information.

Renames a Structure object.

Selected Structure object can be renamed via keypad. Refer to Chapter 5.1.5.12

Rename a Structure object for more information.

46

Page 47

MI 3360 OmegaPAT XA Memory Organizer

Parameters

Figure 5.8: Example of View / Edit parameters menu

Select structure object to be edited.

Select Parameters in Control panel.

Example of Parameters menu.

In menu for editing parameters the parameter’s

value can be selected from a dropdown list or

entered via keypad. Refer to chapter 4 Instrument

operation for more information about keypad

operation.

5.1.5.3 View / Edit parameters and attachments of a Structure object

The parameters and their content are displayed in this menu. To edit the selected parameter tap

on it or press RUN key to enter menu for editing parameters.

Procedure and options

47

Page 48

MI 3360 OmegaPAT XA Memory Organizer

a

Select Attachments in Control panel.

a

Attachments

The name of attachment can be seen. Operation

with attachments is not supported in the

instrument.

b

Select Comments in Control panel.

b

View or edit comments

Complete comment (if exists) attached to the

structure object can be seen on this screen.

Press RUN key or tap on screen to open keypad

for entering a new comment.

48

Page 49

MI 3360 OmegaPAT XA Memory Organizer

Add Structure

Figure 5.9: Add a new Structure Object menu

Default initial structure.

Select Add Structure in Control panel.

Add a new structure object menu.

a

The type of structure object to be added can be

selected first from dropdown menu.

Only structure objects that can be used in the

same level or next sub-level are offered.

b

The name of structure object can be edited.

5.1.5.4 Add a new Structure Object

This menu is intended to add new structure objects in the tree menu. A new structure object can

be selected and then added in the tree menu.

Procedure and options

49

Page 50

MI 3360 OmegaPAT XA Memory Organizer

c

Parameters of the Structure object can be edited.

Adds the selected structure object in the tree

menu.

Returns to the tree menu without changes.

New object added.

50

Page 51

MI 3360 OmegaPAT XA Memory Organizer

Add Measurement

Figure 5.10: Add a new measurement menu

Select level in structure where measurement will

be added.

Select Add measurement in Control panel.

Add new measurement menu.

a

Type of test can be selected from this field.

Options: (Single Tests, Auto Sequences)

Tap on field or press the RUN key to modify.

b

Last added measurement is offered by default.

To select another measurement tap on filed or

press the RUN to open menu for selecting

measurements. Refer to Chapters 6.1 Selection

modes and 7.1 Selection of Auto Sequences for

more information.

5.1.5.5 Add a new measurement

In this menu new empty measurements can be set and then added in the structure tree. The

type of measurement, measurement function and its parameters are first selected and then

added under the selected Structure object.

Procedure and options

51

Page 52

MI 3360 OmegaPAT XA Memory Organizer

c

Select parameter and modify it as described

earlier.

Refer to Chapter 6.1.1.2 Setting parameters and

limits of single tests for more information.

Adds the measurement under the selected

Structure object in the tree menu.

Returns to the structure tree menu without

changes.

New empty measurement is added under the

selected Structure object.

52

Page 53

MI 3360 OmegaPAT XA Memory Organizer

Clone

Figure 5.11: Clone Structure Object menu

Select the structure object to be cloned.

Clone

Select Clone option from control panel.

The Clone Structure object menu is displayed.

Sub-elements of the selected structure object

can be marked or un-marked for cloning.

Refer to Chapter 5.1.5.8 Copy & Paste a

Structure object for more information.

a

Selected structure object is copied (cloned) to

same level in the structure tree.

b

Cloning is cancelled. No changes in the

Structure tree.

The new structure object is displayed.

5.1.5.6 Clone a Structure object

In this menu selected structure object can be copied (cloned) to same level in the structure tree.

Cloned structure object have same name as original.

Procedure and options

53

Page 54

MI 3360 OmegaPAT XA Memory Organizer

Select the measurement to be cloned.

Clone

Select Clone option from control panel.

The new empty measurement is displayed.

Select the structure object to be copied.

Copy

Select Copy option from control panel.

Select location where structure element

should be copied.

5.1.5.7 Clone a measurement

By using this function a selected empty or finished measurement can be copied (cloned) as an

empty measurement to the same level in the structure tree.

Procedure and options

5.1.5.8 Copy & Paste a Structure object

In this menu selected Structure object can be copied and pasted to any allowed location in the

structure tree.

Procedure and options

54

Page 55

MI 3360 OmegaPAT XA Memory Organizer

Paste

Select Paste option from control panel.

The Paste structure object menu is

displayed. Before copying it can be set which

sub-elements of the selected structure object

will be copied too. For more details see

options below.

a

The selected structure object and elements

are copied (pasted) to selected position in

the tree structure.

b

Returns to the tree menu without changes.

The new structure object is displayed.

Note:

The Paste command can be executed one or

more times.

Parameters of selected structure object will

be copied too.

Attachments of selected structure object will

be copied too.

Structure objects in sub-levels of selected

structure object will be copied too.

Measurements in selected structure object

and sub-levels will be copied too.

Options

55

Page 56

MI 3360 OmegaPAT XA Memory Organizer

Select the measurement to be copied.

Copy

Select Copy option from control panel.

Select location where measurement should be

pasted.

Paste

Select Paste option from control panel.

The new (empty) measurement is displayed in

selected Structure object.

Note:

The Paste command can be executed one or

more times.

5.1.5.9 Copy & Paste a measurement

In this menu selected measurement can be copied to any allowed location in the structure tree.

Procedure

56

Page 57

MI 3360 OmegaPAT XA Memory Organizer

Select the structure object to be deleted.

Delete

Select Delete option from control panel.

A confirmation window will appear.

a

Selected structure object and its sub-elements

are deleted.

b

Returns to the tree menu without changes.

Select a measurement to be deleted.

5.1.5.10 Delete a Structure object

In this menu selected Structure object can be deleted.

Procedure

5.1.5.11 Delete a measurement

In this menu selected measurement can be deleted.

Procedure

57

Page 58

MI 3360 OmegaPAT XA Memory Organizer

Delete

Select Delete option from control panel.

A confirmation window will appear.

a

Selected measurement is deleted.

b

Returns to the tree menu without changes.

Select the structure object to be renamed.

Rename

Select Rename option from control panel.

Virtual keypad will appear on screen. Enter new

text and confirm.

5.1.5.12 Rename a Structure object

In this menu selected Structure object can be renamed.

Procedure

58

Page 59

MI 3360 OmegaPAT XA Memory Organizer

Select the measurement to be recalled.

Recall results

Select Recall results in control panel.

Measurement is recalled.

Parameters and limits can be viewed but

cannot be edited.

Retest

Select Retest in control panel.

Measurement retest starting screen is

displayed.

a