Page 1

Insulation / Continuity Tester

MI 2123

User Manual

Version 1.1, Code No. 20 750 424

Page 2

Distributor:

COSINUS Computermesstechnik GmbH

Lise-Meitner-Strasse 6

D-85521 Ottobrunn

GERMANY

Tel: 089/665594-0

Fax: 089/665594-30

http://www.cosinus.de

Manufacturer:

METREL d.d.

Ljubljanska cesta 77

1354 Horjul

Slovenia

web site:

http://www.metrel.si

e-mail: metrel@metrel.si

Mark on your equipment certifies that this equipment meets the requirements of the EU

(European Union) concerning safety and electromagnetic compatibility regulations

© 2000..2007 METREL

No part of this publication may be reproduced or utilized in any form or by any means

without permission in writing from METREL.

2

Page 3

MI 2123 Insulation / Continuity Table of contents

1. General introduction--------------------------------------------------------------------------------4

1.1. Features---------------------------------------------------------------------------------------------4

1.2. Applied Standards--------------------------------------------------------------------------------4

2. Instrument description-----------------------------------------------------------------------------5

2.1. Instrument Casing--------------------------------------------------------------------------------5

2.2. Operator’s Panel----------------------------------------------------------------------------------5

2.3. Connectors-----------------------------------------------------------------------------------------6

2.4. Bottom Section------------------------------------------------------------------------------------7

2.5. Accessories ----------------------------------------------------------------------------------------7

3. Warnings and Instrument Messages ----------------------------------------------------------8

3.1. Warnings--------------------------------------------------------------------------------------------8

3.2. Instrument Messages----------------------------------------------------------------------------8

4. Measurements --------------------------------------------------------------------------------------10

4.1. Insulation Resistance--------------------------------------------------------------------------10

4.2. R ±200mA --------------------------------------------------------------------------------------12

4.3. Continuity----------------------------------------------------------------------------------------- 14

5. Operation with Results--------------------------------------------------------------------------- 16

5.1. Storing of Measurement Results ------------------------------------------------------------ 16

5.2. Storage Handling -------------------------------------------------------------------------------17

5.3. Data Transfer------------------------------------------------------------------------------------ 20

6. Maintenance ----------------------------------------------------------------------------------------- 21

6.1. Inspection-----------------------------------------------------------------------------------------21

6.2. Battery Replacement --------------------------------------------------------------------------21

6.3. Fuse replacement ------------------------------------------------------------------------------22

6.4. Cleaning-------------------------------------------------------------------------------------------22

6.5. Service --------------------------------------------------------------------------------------------22

7. Specifications--------------------------------------------------------------------------------------- 23

7.1. Measurements-----------------------------------------------------------------------------------23

7.2. General specifications-------------------------------------------------------------------------24

3

Page 4

MI 2123 Insulation/Continuity Tester General introduction

1. General introduction

1.1. Features

The SMARTEC Insulation / Continuity Tester is a portable hand-held battery powered

test instrument intended for testing of safety measures on mains installations. It

operates on a SIMPLE and CLEAR basis.

The equipment is designed and produced with the extensive knowledge and experience

acquired through many years of dealing with electrical installation test equipment.

General functions of the SMARTEC Insulation / Continuity Tester:

- Insulation Resistance measurement,

- Continuity measurement using test current of 200 mA in accordance with EN 61557

standard,

- Continuity measurement (continuous measurement) using test current of up to

7 mA,

- AC / DC Voltage and Frequency measurement.

Features:

- Wide range of Insulation Resistance test voltages (50 up to 1000 V DC),

- Automatic discharge of tested item after measurement completion,

- Automatic test voltage polarity exchange in Continuity ± 200 mA function,

- Continuity 7 mA function for inductive test items,

- Memories,

- PC connection.

A custom designed LCD offers easy to read results. Operation is simple and clear, the

operator does not need any special training (except reading and understanding this

Users Manual) to operate the instrument.

In order for the operator to be familiar with measurements in general, it is advisable to

read the handbook Measurements on electric installations in theory and practice.

The instrument allows storage of test results. Professional PC SW enables simple

transfer of test results and other parameters in both directions between the tester and

the PC.

1.2. Applied Standards

Instrument operation: IEC / EN 61557-1, IEC / EN 61557-2, IEC / EN 61557-4

DIN VDE 0413-1, DIN VDE 0413-4, DIN VDE 100

BS 7671 – 16th edition

Electromagnetic compatibility (EMC): IEC 61326, Class B

Safety: EN/IEC 61010-1 (instrument),

EN/IEC 61010-2-31 (accessories)

4

Page 5

MI 2123 Insulation/Continuity Tester Instrument description

2. Instrument description

2.1. Instrument Casing

The instrument is housed in a plastic casing, which maintains the protection class

defined in general specifications. The casing consists of a main section, which includes

the operator's panel and connectors and of a flexible cover.

Note! The cover is permanently fixed to the base section and cannot be detached.

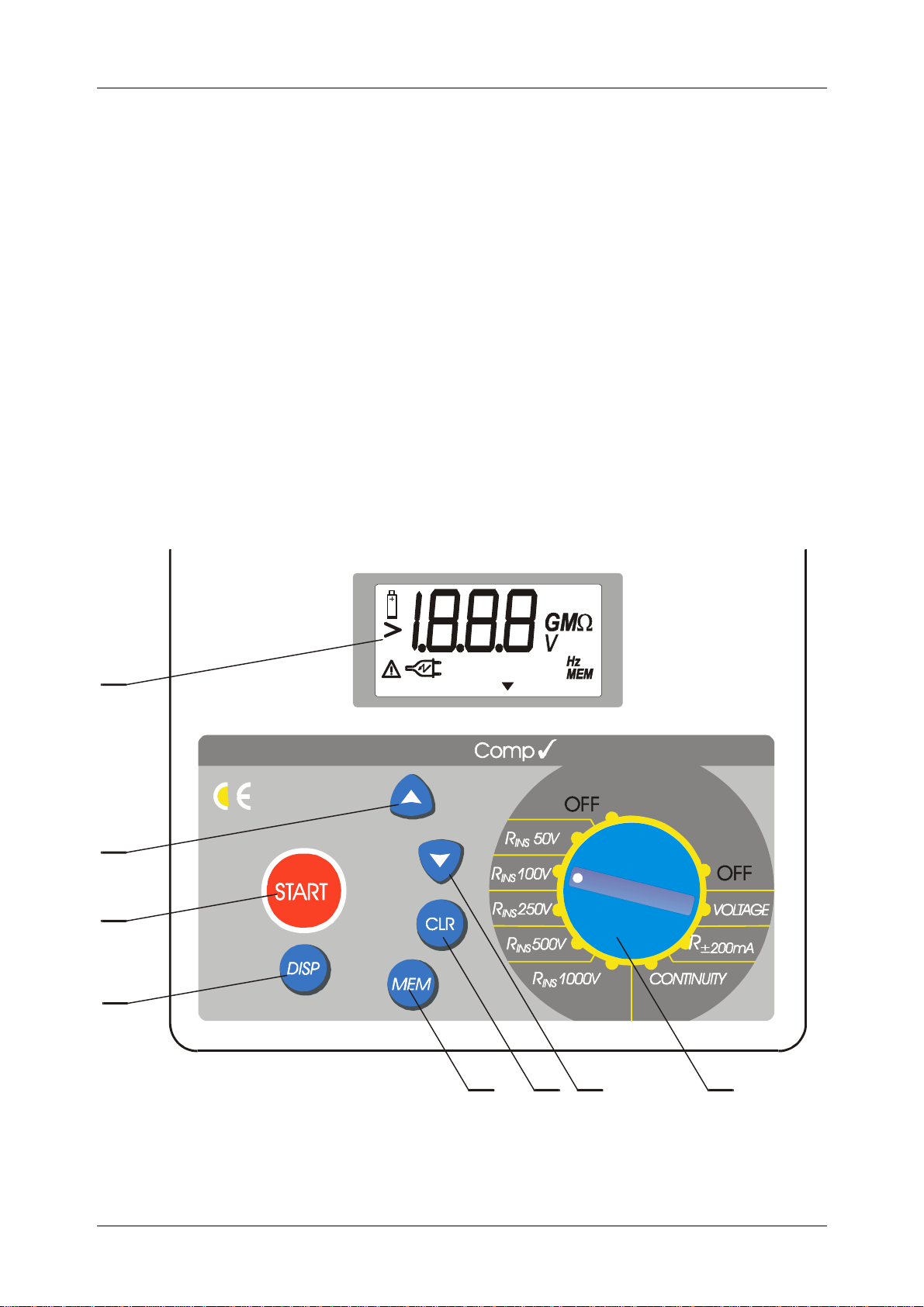

2.2. Operator’s Panel

The operator’s panel consists of a custom LCD, a rotary switch, and a keyboard, see

the figure below.

1

2

3

1

2

3

4

6

5

8

7

4

7865

Fig. 1. Front panel

5

Page 6

MI 2123 Insulation/Continuity Tester Instrument description

Legend:

1..........Custom designed LCD.

2..........Up key to increase storage group.

3..........START key to start any measurement.

4..........DISP key to display subresults of selected function.

5..........MEM key to store and recall results.

6..........CLR key to erase memorized results.

7..........Down key to decrease storage group.

8..........Rotary switch to select measurement function.

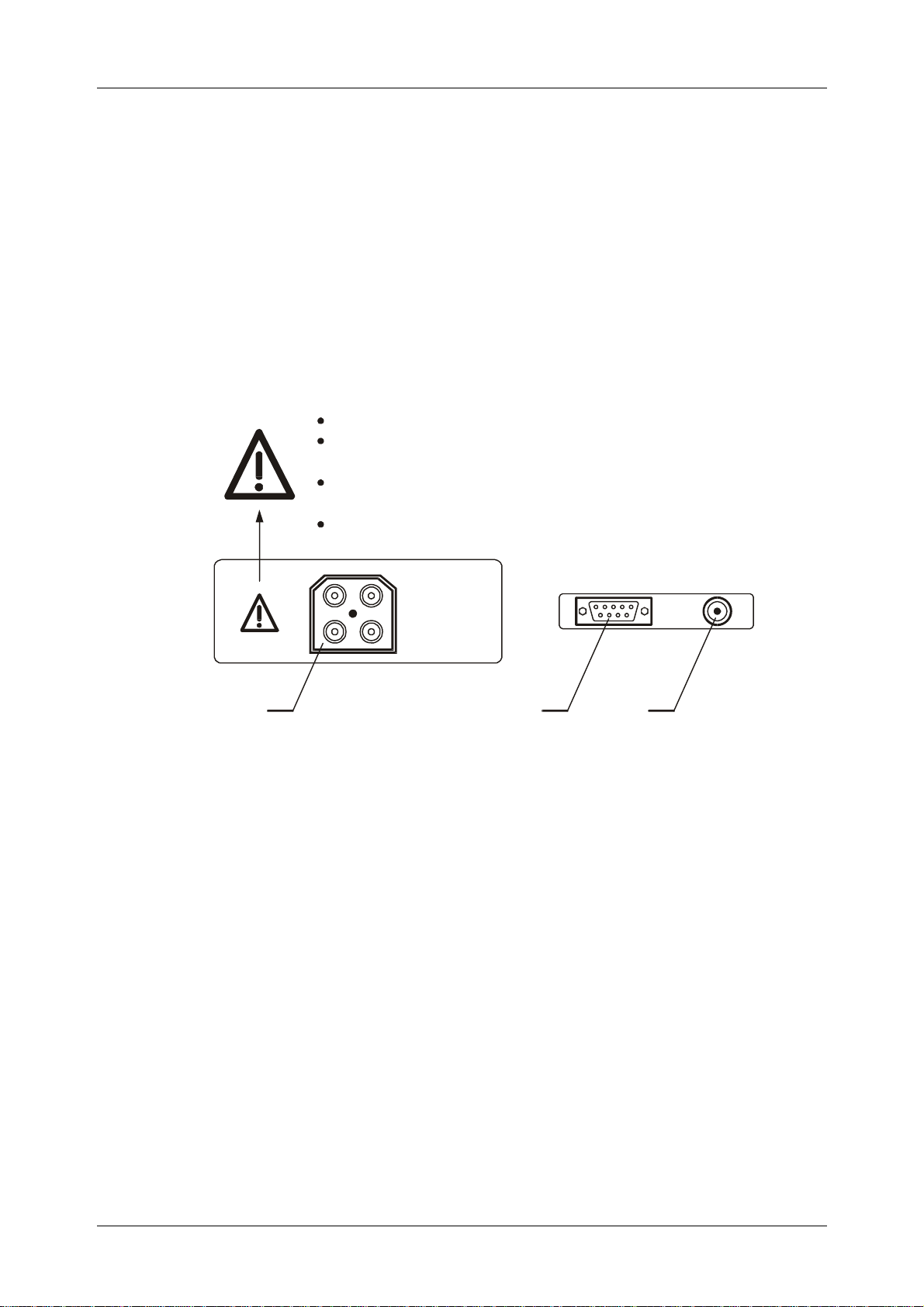

2.3. Connectors

Use originl test accessories only!

Max. allowed voltage between mains test terminals

and ground is 300 V!

Max. allowed voltage between mains test terminals

is 600 V!

Max. output voltage between test terminals is 1100 V!

1

123

Fig. 2. Connectors

Legend:

1..........Test connector.

2..........RS 232 connector to connect the instrument to PC.

3..........Battery charger connector.

Test connector is intended for connection of the test cable and is accessible only when

the instrument cover is lifted up. RS 232 and battery charger connectors are accessible

only when the cover of the instrument is closed. For safety reasons both connector

fields cannot be accessible at the same time, the cover of the instrument selects the

accessible one.

6

Page 7

MI 2123 Insulation/Continuity Tester Instrument description

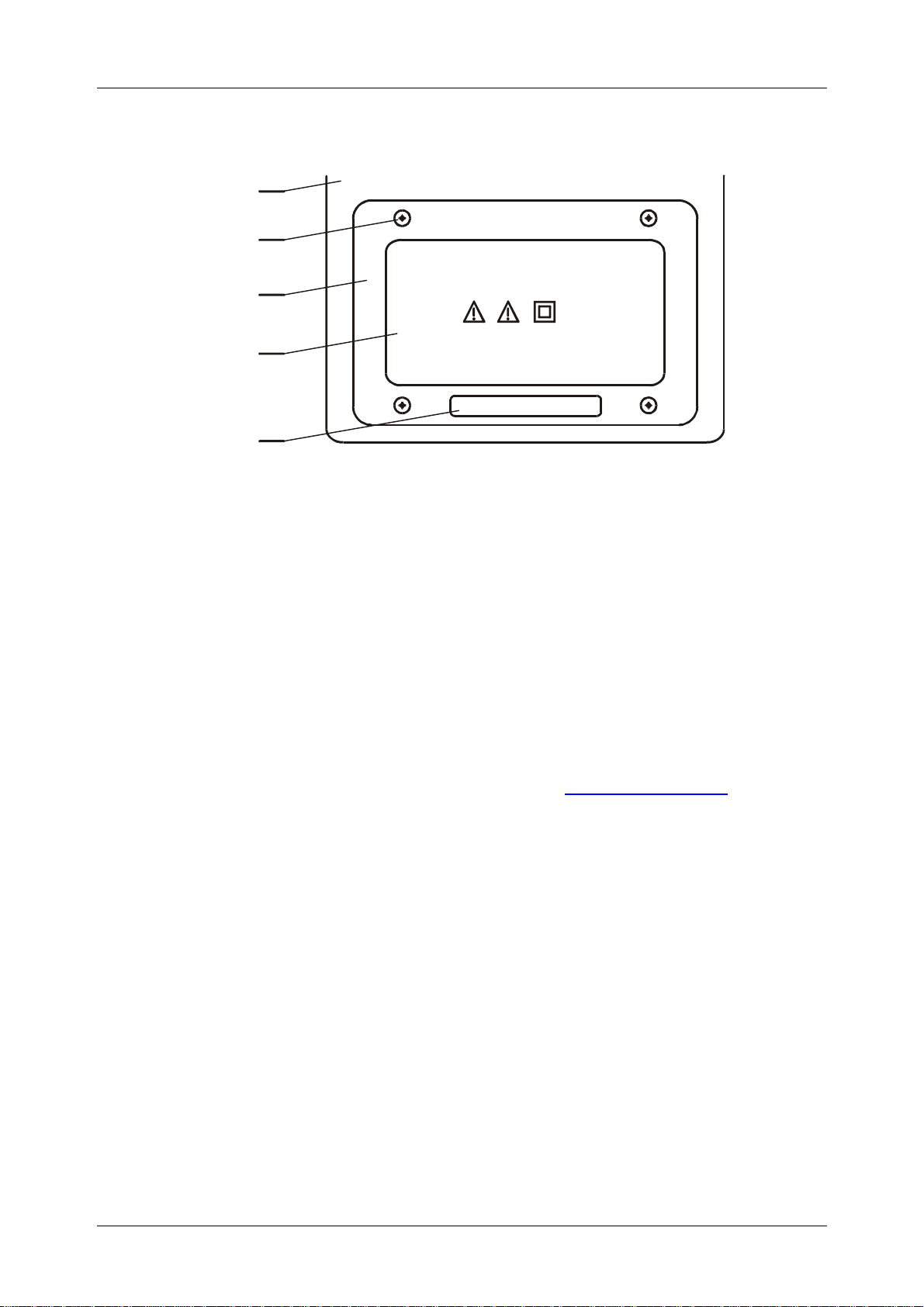

2.4. Bottom Section

1

2

DISCONNECT ALL TEST LEADS AND SWITCH OFF THE INSTRUMENT

BEFORE REMOVING THE BATTERY COVER - HAZARDOUS VOLTAGE!

DO NOT CHARGE IF BATTERY COMPARTMENT CONTAINS ALKALINE CELLS!

3

4

5

Legend:

1..........Plastic housing.

2..........Screw (4 pieces) to fix the battery cover.

3..........Battery compartment cover.

4..........Battery cover warnings.

5..........Trade mark label.

POWER SUPPLY: 4 × 1,2 V - NiCd, NiMH RECHARGEABLE (IEC LR 14)

or 4 × 1,5 V ALKALINE BATTERIES (IEC LR 14)

VOR OFNEN DES BATTERIEFACHS ALLE ZULEITUNGEN VOM GERAT

ENTFERNEN UND DAS GERAT AUSSCHALTEN - GEFAHRLICHE SPANNUNG!

NICHT AUFLADEN WENN ALKALZELLEN VERWENDET SIND!

STROMVERSORGUNG:

oder 4×1,5V - ALKALZELLEN (IEC LR 14)

4×1,2V - NiCd, NiMH AUFLADBAR (IEC LR 14)

Fig. 3. Bottom section

2.5. Accessories

The instrument consists of standard and optional accessories. Optional accessories can

be delivered upon request. See attached list for standard configuration and options or

contact your distributor or see the METREL home page:

http://www.metrel.si .

7

Page 8

MI 2123 Insulation/Continuity Tester Warnings and Messages

3. Warnings and Instrument Messages

3.1. Warnings

In order to reach highest level of operator’s safety while carrying out various

measurements and tests using the SMARTEC Insulation / Continuity Tester, as well

as to ensure the test equipment remains undamaged, it is necessary to consider the

following general warnings:

• If the test equipment is used in a manner not specified in this Users Manual,

the protection provided by the equipment may be impaired!

• Do not use the instrument and accessories if any damage is noticed!

• In case of blown fuse, follow the instructions in this Instruction Manual to

replace it!

• Service intervention or calibration procedure is allowed to be carried out

only by a competent, authorised person!

• Consider all generally known precautions, in order to avoid risk of electric

shock while dealing with electrical installations!

• Use only standard or optional test accessories supplied by your distributor!

•

•

• Disconnect all test leads and switch power off before opening Battery cover!

• Do not charge when alkaline batteries are fitted!

!

symbol at the instrument means “Read the Users Manual with special

care!” The symbol requires an action!

symbol on LCD indicates that the measurement results show an irregular

!

condition of the item under test which may present a hazardous live voltage.

3.2. Instrument Messages

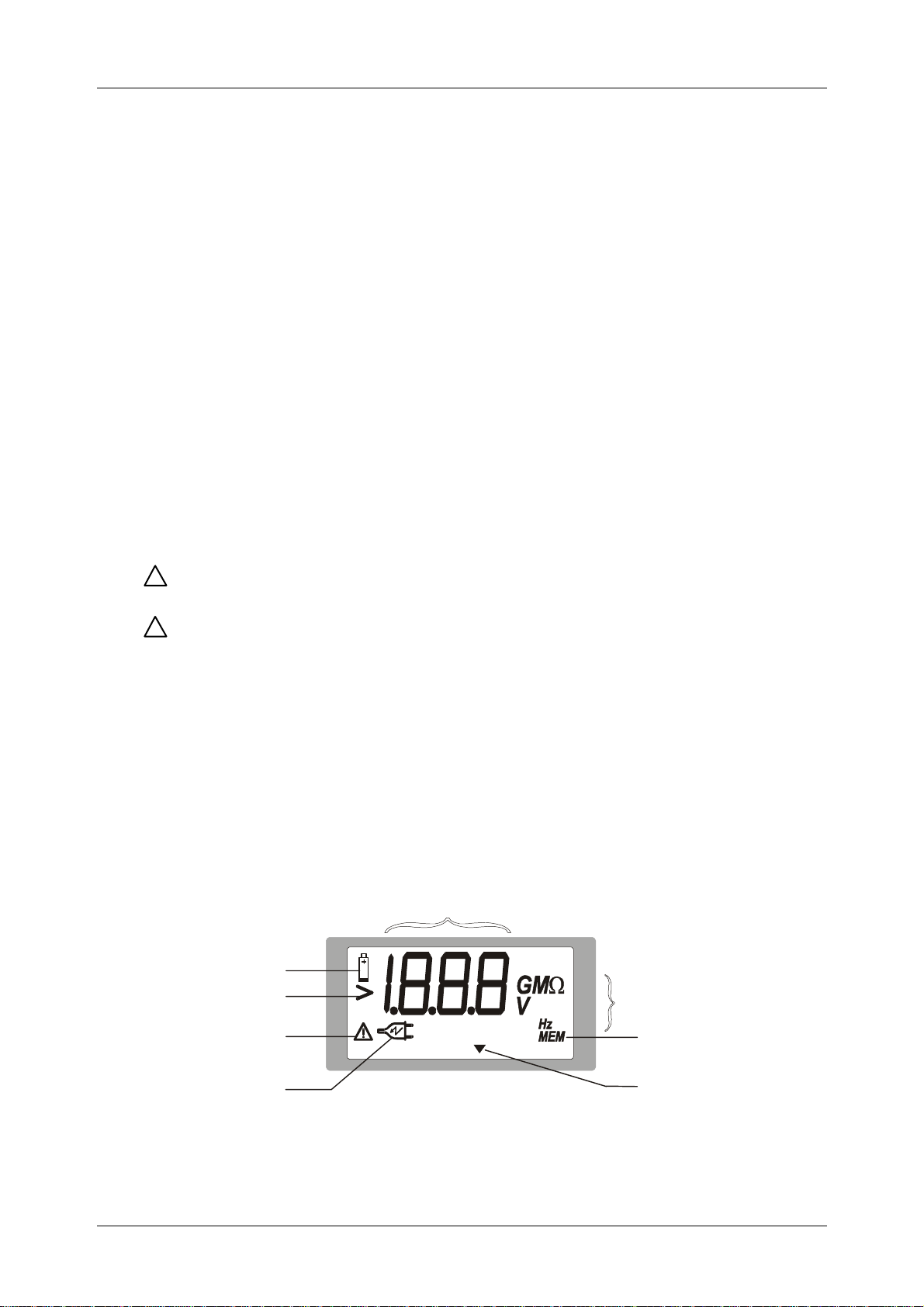

Messages are generated on the LCD using special symbols and numeric segment

combinations. The next figure shows all possible display segments and the table under

the figure describes the messages.

Result value

Low battery

Higher than

Warning!

Mains voltage present

at test terminals

Fig. 4. Display segments

Unit of displayed result

Operation with storage

Cursor to indicate

compensated test leads

8

Page 9

MI 2123 Insulation/Continuity Tester Warnings and Messages

Description of possible display messages:

>1999

FUS

SEr

rES

End MEM

MEM

no MEM

rCL

Clr flashing

Clr / ALL alternating

Result over range.

Blown fuse in Continuity functions only.

Active serial communication.

*Reset of the instrument (erased memories).

All storage locations occupied.

Operation with storage (store or recall).

No result to be stored or no stored result to be recalled.

Recall function is entered.

Confirm or abort clearing of last stored result?

Confirm or abort clearing of all stored results?

Table 1. Messages

Note!

• * This indication appears after the first insertion of batteries, i.e. when there were no

batteries in the battery compartment for a specific period of time (a few hours), or if

the microprocessor detects an irregular state in its memory or if reset of the

instrument has been performed.

9

Page 10

MI 2123 Insulation/Continuity Tester Measurements

4. Measurements

4.1. Insulation Resistance

Warnings!

• Make sure that the item to be tested is disconnected (mains voltage

disconnected) before starting the Insulation Resistance measurement!

• When measuring Insulation Resistance between conductors, all loads must

be disconnected and all switches closed!

• Do not touch tested item while the test is in operation, risk of electric shock!

• Do not connect test terminals to an external voltage higher than 600 V AC or

DC in order not to damage the test instrument!

• In case of capacitive test item (capacitive compensation of reactive power,

long tested cable etc.), automatic discharge of the item may not be done

immediately after finishing the measurement. Falling voltage will be displayed

in that case – do not disconnect test leads until the voltage drops below 50 V!

The following figure shows connection of the instrument to tested item for testing of

Insulation Resistance on electric installations. The measurement should be carried out

between all conductor

s.

RCD

L1

L2

L3

N

PE

PE N L3 L2 L1

Fig. 5. Connection of the instrument to item under test

There may be also other items to be tested such as motor windings, ground cables,

antistatic floor coatings, walls etc., see the booklet

installations in theory and practice

Measurements on electric

10

Page 11

MI 2123 Insulation/Continuity Tester Measurements

How to carry out the measurement:

- Connect test leads to item to be tested in accordance with figure 5.

- Select Insulation resistance function using appropriate test voltage by means of

rotary switch knob.

- Press the

release the key. With pressing the

measurement starts to run.

- Read displayed result (Insulation Resistance).

- Check subresult (Actual test voltage) by pressing the

- The result can optionally be saved using the

instructions in paragraph 5.2. Storage handling.

START key and keep it pressed until the result has stabilised then

START key twice successively, continuous

DISP key.

MEM, Up and Down keys, see

M

Ω

V

Example of displayed

Insulation Resistance

Fig. 6. Example of displayed result

Notes!

• If an external voltage higher than 30 V AC/DC is present at test terminals, the

Insulation Resistance measurement will not be carried out after pressing START

key but the voltage will be displayed marked with

• Tested item is discharged automatically after finishing the measurement and the

actual voltage is displayed during discharge operation (only if high capacity is

present).

• Positive pole of test voltage is attached to red test terminal.

Actual test voltage

!

symbol.

11

Page 12

MI 2123 Insulation/Continuity Tester Measurements

4.2. R ±200mA

Continuity of protection conductors is to be measured, before mains voltage is

connected to tested installation (new or adapted installation). Max. allowed resistance

value depends on power of connected loads, used installation system (TN, TT) etc.

Test current of at least 200 mA is required by the EN 61557 regulation which is why this

function is to be used whenever tests are to be done in accordance with this standard.

For additional general information concerning Continuity measurement, refer to the

handbook

Warning!

• Make sure that the tested item is de-energised (mains voltage disconnected)

before starting the measurement! Fuse will blow if test probes are connected

to mains voltage during the test.

How to carry out the measurement:

- Connect test leads to tested item in accordance with the figure below.

- Select R ±200mA function by means of rotary switch knob.

- Make sure test leads are compensated, see the instructions in the next chapter.

- Press the

function enables individual measurements (the START key should be pressed for

each measurement).

- Read displayed result (Continuity), see figure 8.

- The result can optionally be saved using the

instructions in paragraph 5.2. Storage handling.

Measurements on electric installations in practice and theory.

START key and release it. To ensure the instrument’s protection this

MEM, Up and Down keys, see

RCD

L1

L2

L3

N

PE

PE N L3 L2 L1

Fig. 7. Connection of test leads

12

Page 13

MI 2123 Insulation/Continuity Tester Measurements

Ω

Comp

>

Fig. 8. Example of R

±

200mA

test result, test leads are compensated

Notes!

• If an external voltage higher than 10 V AC/DC is present at test terminals, the

R ±200mA

voltage will be displayed, marked with

measurement will not be carried out after pressing START key, but the

symbol.

!

• If test result is out of measurement range (open test leads), >1999 Ω message will

be displayed!

• If indication FUS appears, replace blown fuse with new one. See the paragraph 6.3.

Fuse replacement.

Compensation of test leads’ resistance

In order to achieve high accuracy of test results it is advised to compensate resistance

of the test leads before carrying out Continuity measurement. Especially it is advised to

compensate test leads whenever the leads are changed for different ones.

How to compensate test leads:

- Select R ±200mA function.

- Short out test leads.

- Press the START key twice successively, total value of measured resistance

(resistance of test leads + internal resistance) is displayed for a while then

displayed. Cursor symbol on display (see the fig. 4) shows compensation state.

Resistance of test leads is therefore compensated and the instrument is ready for

Continuity measurements.

Notes!

• Max. resistance that can be compensated is 5 Ω. If total measured resistance is

higher than 5

Ω (e.g. open test leads) then any compensation previously stored is

ignored (compensation indicator disappears).

• Compensation of test leads’ resistance can be done only in the R±200mA

• The indicator for compensation of test leads appears only after compensation has

been performed and remains until the compensation is cancelled (e.g. by performing

the compensation at open test leads).

• Compensation of test leads’ resistance is stored and is used for both R ±200mA

Continuity functions.

0.00 Ω is

function.

and

13

Page 14

MI 2123 Insulation/Continuity Tester Measurements

4.3. Continuity

Continuity function is intended to be used when there are inductive loads to be tested,

for example motor windings, transformers etc. or if there is no need to follow prescribed

standards. It can be used also as an ordinary multi-meter (resistance range). This

function enables continuous measurements (the measurement is running continuously

after pressing the START key).

Test current of only up to 7 mA is used in order to save the battery energy.

For additional general information concerning Continuity measurement, refer to the

handbook

Warning!

• Make sure tested item is de-energised (mains voltage disconnected) before

How to carry out the measurement:

- Connect test leads to tested item.

- Select Continuity function by means of rotary switch knob.

- Make sure test leads are compensated.

- Press the START key and release it, measurement starts to run continuously.

- Press the START key again to stop the measurement.

- Read displayed result (Continuity), see the figure below.

- The result can optionally be saved using the

instructions in paragraph 5.2. Storage handling.

Measurements on electric installations in practice and theory.

starting the measurement! Fuse will blow if test probes are connected to

mains voltage during the test.

MEM, Up and Down keys, see

symbol.

!

14

>

Comp

Fig. 9. Example of Continuity test result, test leads are compensated

Notes!

• If an external voltage higher than 10 V AC/DC is present at test terminals, the

Continuity measurement will not be carried out after pressing START key, but the

voltage will be displayed marked with

• Compensation of test leads’ resistance can be carried out in R ±200mA function only.

• If test result is out of measurement range (open test leads), >1999 Ω message will

be displayed!

• If indication FUS appears, replace blown fuse. See paragraph 6.3. Fuse

replacement.

Positive pole of test voltage is attached to red test terminal.

Page 15

MI 2123 Insulation/Continuity Tester Measurements

4.4. Voltage Measurement

How to carry out the measurement:

- Connect test leads to equipment under test.

- Select

- Press the

- Read displayed result (Voltage), see the figure below. Displayed voltage may be

exchanged with frequency by simply pressing the

the measurement is running.

- Press the

- Check subresult (Frequency of displayed voltage) by pressing the DISP key.

- The result can optionally be saved using the MEM, Up and Down keys, see

instructions in paragraph 5.2. Storage handling.

VOLTAGE function by means of rotary switch knob.

START key, continuous measurement starts to run.

DISP key at any time, even whilst

START key again to stop the measurement.

V

Hz

Displayed result Frequency

Fig. 10. Example of voltage measurement result

Note!

• Do not connect test leads to a voltage higher than 600 V AC, to avoid possible

damage to the instrument!

15

Page 16

MI 2123 Insulation/Continuity Tester Operation with Results

5. Operation with Results

5.1. Storing of Measurement Results

The memory for storing of measurement results has a stacking group organisation. The

operator has the possibility to organise 1999 groups. Each group has the possibility to

stack any measured result. In ‘storing result’ mode the operator selects a group and

then the result is stacked together with all its parameters into the selected group. The

figure below shows a graphic presentation of result grouping.

Rm

Ri

R2

R1

G1 G2 G3 Gn G1999..... .....

Fig. 11. Storage locations organisation

A set of information stored on location Ri (main result, sub-results and parameters)

depends on selected function. There can be many results stored on the same location.

Practical Example of Storage Organization

For example: There is a standard house installation that has to be verified with regard to

various electrical characteristics. The test plan should be prepared before any

measurement is taken. The plan is based on wiring schematics and contains group

definitions e.g. floor, room, wall socket and the related measurements in each group.

The groups are assigned with numbers from 1 to 1999. When the test plan is defined

the operator starts to run the measurements from group to group. The instrument asks

every time for the group when storing test results. The result can be simply stored into

the appropriate group if the group number already corresponds to selected

measurement place in test plan, or the group number can be changed first and then the

result stored.

All results can be stored under a single group, e.g. No.: 1, if there is no need for

grouping.

16

Page 17

MI 2123 Insulation/Continuity Tester Operation with Results

5.2. Storage Handling

The following keys are intended to be used for storage handling:

There are the following possibilities of handling:

To store

result (result

is displayed):

a) Press the

MEM key after completing the measurement. Last used

group will be offered automatically, see the figure below.

b) Use

c) Press the

↑ and ↓ keys to change group number.

MEM key again to store result.

MEM, ↑, ↓ and CLR.

To recall

stored

results:

MEM

Offered group number

Once stored -

no possibility

MEM

to store the same result again

Fig. 12. Group code and reaction to double storing of the same result

Notes!

- Press the START key or change rotary switch position to cancel

store procedure.

- Each result can only be stored once.

a) Press the MEM key just after changing rotary switch position, MEM

mark will appear on LCD and

rCL for a moment followed by the last

accessed group number.

b) If there is no stored data

no and MEM will flash for a second

followed by selected function idle state display.

c) Use the

d) Press the

recall stored result. If there is no result stored in selected group

and

e) Use the

↑ and ↓ keys to change the group number.

MEM key again once appropriate group is selected to

no

MEM will flash followed by the group number.

DISP key to check sub-results and parameters.

f) To see previous or next stored results inside selected group press ↑

↓ key. Every entry is followed by the function code and then the

or

result.

g) Press the

MEM key to change group number and go to b).

Note!

- Press the START key or change rotary switch position to cancel

recall procedure.

17

Page 18

MI 2123 Insulation/Continuity Tester Operation with Results

Indication when entering recall

procedure

MEM

Last accessed group is offered

Storage buffer empty

Code of stored function (rotary

switch position 7 = R

MEM

Ω

Stored result (R±200mA)

MEM

Fig. 13. Displayed information during recall procedure

To clear

complete

Memory:

a) Exit storage operation (storing or recalling), press the CLR key and

keep it pressed until

release it.

b) Press the

Clr and ALL messages start to alternate then

CLR key again to erase all stored results.

MEM

±200mA)

MEM

Fig. 14. Waiting for confirmation

Note!

Press the

procedure.

START key or change rotary switch position to cancel clear

18

MEM

Page 19

MI 2123 Insulation/Continuity Tester Operation with Results

To clear only

last stored

result:

a) Exit storage operation (storing or recalling), press the CLR key, Clr

message appears, then release the key.

b) Press the

CLR key again to erase last stored result.

MEM

Fig. 15. Waiting for confirmation

Note!

- Press the START key or change rotary switch position to cancel

clear procedure.

Stored Parameters

The following is a list of results, sub-results and parameters stored for each function.

Function No Stored data Function No Parameters

RINS 50 V

1 Function code

Insulation resistance

Actual test voltage

RINS 1000 V

5 Function code

Insulation resistance

Actual test voltage

RINS 100 V

RINS 250 V

RINS 500 V

2 Function code

Insulation resistance

Actual test voltage

3 Function code

Insulation resistance

Actual test voltage

4 Function code

Insulation resistance

Actual test voltage

CONTINUITY

R±200mA

VOLTAGE

6 Function code

Resistance

7 Function code

Resistance

8 Function code

Voltage

Frequency

19

Page 20

MI 2123 Insulation/Continuity Tester Operation with Results

5.3. Data Transfer

Stored results can be transferred to a PC. A special communication program has the

ability to identify the instrument and download the data.

How to transfer stored data:

- Connect PC COM port to the instrument with the serial communication cable.

- Turn power on to the PC and the instrument.

- Run the

- The PC and the instrument automatically recognise each other.

- The program on the PC enables the following possibilities:

-- download data;

-- clear storage;

-- change and download user data;

-- prepare a simple report form;

-- prepare a file to import to a spreadsheet.

The program

README.TXT for instructions on installing and running the program.

smartlink.exe. program

smartlink.exe is a Windows 95/98 based PC software. Read file

20

Page 21

MI 2123 Insulation/Continuity Tester Maintenance

5

6. Maintenance

6.1. Inspection

To maintain operator’s safety and ensure reliability of the instrument it is good practice

to inspect the instrument on a regular basis. Check that the instrument and accessories

are not damaged. If any defect is found please consult service centre, distributor or

manufacturer.

6.2. Battery Replacement

The battery symbol on the upper left corner of the LCD indicates the battery state (Ubat

< 4.2 V).

If a low battery state is indicated the batteries must be replaced to ensure accurate

measurements.

The instrument is switched off automatically when battery voltage drops down to 4.0 V;

bat indication is displayed before switching off.

Notes!

• All four cells shall be replaced each time.

!

•

Nominal power supply voltage is 6 V DC. Use four 1.5 V alkaline cells, type IEC LR14

(dimensions: diameter = 26 mm, height = 50 mm).

Turn power off and disconnect any measurement accessory connected to

the instrument before opening battery cover.

M0.31

+

+

+

21

+

Fig. 16. Correct polarity of inserted batteries and fuse position

One set of full-capacity alkaline cells can supply the instrument for approx. 150

hours.

Page 22

MI 2123 Insulation/Continuity Tester Maintenance

Rechargeable NiCd or NiMH battery can be used instead of alkaline. The instrument

contains an additional connector for charging the batteries.

Notes!

• Insert cells correctly, otherwise test instrument will not operate and battery could be

discharged, see the figure above for correct battery polarity!

• If the instrument is not to be used for a long period of time remove all batteries from

the battery compartment.

• To ensure the integrity of the stored results do not leave battery compartment empty

for more than 1 minute.

Warnings!

• Do not charge when alkaline batteries are fitted!

• Take into account handling, maintenance and recycling requirements as

defined by related standards and manufacturer of alkaline or rechargeable

batteries.

6.3. Fuse replacement

The instrument contains a fuse to protect R

can blow if an external voltage is connected to test terminals during the measurement.

See the fig. 16. for fuse location.

Warning!

Replace blown fuse with prescribed one only (M0.315A) otherwise the instrument may

be damaged.

±200mA and Continuity functions. The fuse

6.4. Cleaning

Use a soft cloth slightly moistened with soapy water or spirit to clean the surface of the

instrument and leave the instrument to dry totally, before using it.

Notes!

• Do not use liquids based on petrol or hydrocarbons!

• Do not spill cleaning liquid over the instrument!

6.5. Service

Repairs under or out of warranty time: Please contact your distributor for further

information.

Note!

• Unauthorised person is not allowed to open the instrument!

22

Page 23

MI 2123 Insulation/Continuity Tester Specifications

7. Specifications

7.1. Measurements

Insulation resistance

Measuring range Riso (Un ≥ 500V): 0.12MΩ ÷ 20GΩ

Display range Riso

Ω)

(M

Un: 500V, 1000V

0.00 ÷ 19.99

20.0 ÷ 199.9

200 ÷ 1999

2.00k ÷ 19.99k

Measuring range Riso (Un

Display range Riso

Ω)

(M

Un: 50V, 100V, 250V

0.000 ÷ 1.999

2.00 ÷ 19.99

20.0 ÷ 199.9

Nominal output voltages: 50V, 100V, 250V, 500V, 1000V

Output voltage tolerance: +20%, -0%

Nominal output current:

Short circuit current: < 3mA

R±200mA

Measuring range R: 0.08 Ω ÷ 2000 Ω

Display range R

(

Ω)

0.00 ÷ 19.99

20.0 ÷ 199.9

200 ÷ 1999

Open-terminal test voltage: 4 - 7 Vd.c.

Test current for R

Compensation of test leads (up to 5

Automatic polarity exchange: yes

Measurement mode: single measurement

≤ 2Ω: > 200 mA

Resolution

(MΩ)

0.01

0.1

1

10

< 500V): 0.012MΩ ÷ 200MΩ

Resolution

(MΩ)

0.001

0.01

0.1

≥1mA

Resolution

(Ω)

0.01

0.1

1

Ω): yes

±(3% of reading + 3 Digits)

±(10% of reading)

±(5% of reading + 3 Digits)

±(2% of reading + 2 Digits)

Accuracy

Accuracy

Accuracy

±3% of reading

23

Page 24

MI 2123 Insulation/Continuity Tester Specifications

Continuity

Display range R

(

Ω)

0.0 ÷ 199.9

200 ÷ 2000

Resolution

(Ω)

0.1

1

Accuracy

±(5% of reading + 3 Digits)

Open-terminal test voltage: 4 - 7 V DC

Short-circuit test current: up to 7 mA

Measurement mode: continuous measurement

Voltage U

Display range U

(V)

0 ÷ 600

Resolution

(V)

1

Accuracy

±(3% of reading + 3 Digits)

Nominal frequency range DC, 45 – 65 Hz

7.2. General specifications

Power supply 6V DC (4 × 1.5V alkaline battery IEC LR14)

or 4.8V DC (4 × 1.2V NiCd, NiMH rechargeable

battery IEC LR14)

Battery charging 1.5 hours for full charge (using fast charger)

Auto power off yes, approximately 10 min of no activity

Dimensions (w × h × d) 15.5 × 9.5 × 19 cm

Weight (without accessory, with battery) 1.3 kg

Display custom LCD

Memory approx. 1000 measurements

Computer connection RS 232 (9600 baud, no parity, 8 bit data,

1 stop bit)

Protection classification Class II (double insulation)

Over-voltage category CATIII 300V

Pollution degree 2

Protection degree IP 54

Working temperature range 0

Reference temperature range 10

Max. humidity 85 % RH (0

Reference humidity range 40

÷ 40 °C

÷ 30 °C

÷ 40°C)

÷ 60 % RH

24

Loading...

Loading...