Page 1

eMobility Analyser

A 1632

Instruction manual

Version 1.1.4, Code No. 20 752 886

Page 2

Mark on your equipment certifies that it meets requirements of all subjected EU

regulations

.

Distributor:

Manufacturer:

METREL d.d.

Ljubljanska cesta 77

1354 Horjul

Slovenia

web site: http://www.metrel.si

e-mail: metrel@metrel.si

© 2018 METREL

The trade names Metrel®, Smartec®, Eurotest®, Auto Sequence® are trademarks registered in Europe and

other countries.

No part of this publication may be reproduced or utilized in any form or by any means without

permission in writing from METREL.

2

Page 3

A 1632 eMobility Analyser Table of contents

Table of Contents

1 General description ....................................................................................................... 4

1.1 Warnings and notes ................................................................................................ 4

1.1.1 Markings on the instrument: ............................................................................ 5

1.1.2 Notes related to measurement functions ......................................................... 5

1.2 Battery and charging of Li-ion battery pack ............................................................. 6

1.2.1 Battery indication ............................................................................................ 6

1.2.2 Charger ........................................................................................................... 6

1.2.3 Li – ion battery pack guidelines ....................................................................... 6

1.3 Standards applied ................................................................................................... 7

2 Accessories ................................................................................................................... 8

2.1 Standard set ................................................................ ........................................... 8

2.2 Optional accessories .............................................................................................. 8

3 Adapter description ....................................................................................................... 9

3.1 Front panel ............................................................................................................. 9

4 Analyser operation ...................................................................................................... 11

4.1 Power supply consideration .................................................................................. 12

4.2 Operation modes .................................................................................................. 12

4.2.1 How to select or change the operating mode ................................................ 13

4.3 Operation in autonomous mode ............................................................................ 13

4.4 Remote operation ................................................................................................. 13

5 Single tests .................................................................................................................. 14

5.1 Test connections to charging cables / stations ...................................................... 14

5.1.1 Connection of detachable charging cable for Mode 3 EVSE ......................... 14

5.1.2 Connection to Mode 2 charging cable ........................................................... 14

5.1.3 Connection to Mode 3 EVSE ......................................................................... 15

5.2 Safety and functional tests .................................................................................... 15

5.3 Diagnostic test – EV simulator .............................................................................. 16

5.3.1 Remote connection ....................................................................................... 16

5.3.2 Autonomous mode ........................................................................................ 17

5.4 Diagnostic test – Monitor ...................................................................................... 17

5.5 Diagnostic test – CP Errors ................................................................................... 18

5.6 Simulation of mains voltage errors ........................................................................ 19

5.6.1 Simulation of connection of the charging cable to faulty mains ...................... 19

5.6.2 Simulation of a fault that occurs during operation .......................................... 19

6 Upgrading the adapter ................................................................................................ 20

7 Maintenance ................................................................................................................. 21

7.1 Periodic calibration ............................................................................................... 21

7.2 Fuses.................................................................................................................... 21

7.3 Service ................................................................................................................. 21

7.4 Cleaning ............................................................................................................... 21

8 Technical specifications ............................................................................................. 22

8.1 Diagnostic test (EVSE) ......................................................................................... 22

8.2 PP, CP simulator .................................................................................................. 23

8.3 System state ......................................................................................................... 23

8.4 Errors.................................................................................................................... 24

8.5 Other .................................................................................................................... 24

8.6 General data ......................................................................................................... 25

3

Page 4

A 1632 eMobility Analyser General description

1 General description

eMobility Analyser is a multi-function, portable, battery or mains powered test adapter intended

for safety and functional testing of EVSE and charging cables for EV’s.

Available functions and features offered by the eMobility Analyser:

Diagnostic test for verification of proper operation of CP circuit;

Simulation of electrical vehicle’s CP and PP circuits;

Simulation of errors on CP circuit and input mains;

Accessible Inputs/ Outputs for connection of safety testers;

Monitoring of communication between charging station and EV;

Bluetooth communication with Metrel safety testers.

1.1 Warnings and notes

In order to maintain the highest level of operator safety while carrying out various tests and

measurements Metrel recommends keeping your eMobility Analyser adapters in good

condition and undamaged. When using the adapter, consider the following general warnings:

The symbol on the test equipment means »Read the Instruction manual with

special care for safe operation«. The symbol requires an action!

If the test equipment is used in a manner not specified in this Instruction manual,

the protection provided by the equipment could be impaired!

Follow the instructions in Instruction manual carefully, otherwise the use of the

test equipment may be dangerous for the operator, the test equipment itself or for

the tested object!

Do not use the test equipment or any of the accessories if any damage is noticed!

The input / output sockets are intended for test purposes only! Do not connect any

other devices except appropriate test equipment.

Do not connect the test equipment to a mains voltage different from the one

defined on the label adjacent to the mains connector, otherwise it may be

damaged.

Use only earthed 1 – phase or 3 – phase mains supply system to power A 1632. PE

must have low impedance to earth!

Some pre-tests that could determine the PE fault on mains are disabled in Mode 2,

to enable operation in IT voltage system. When using Mode 2, this note should be

considered. See chapter 4.2 Operation modes.

All normal safety precautions must be taken in order to avoid risk of electric shock

while working on electrical installations!

Only adequately trained and competent persons may operate the equipment.

Service intervention or adjustment is only allowed to be carried out by competent

authorized personnel!

4

Page 5

A 1632 eMobility Analyser General description

1.1.1 Markings on the instrument:

Read the Instruction manual with special care to safety operation«. The

symbol requires an action!

Mark on your equipment certifies that it meets requirements of all subjected EU

regulations.

This equipment should be recycled as electronic waste.

This equipment is protected by reinforced insulation.

1.1.2 Notes related to measurement functions

R iso

The resistances in OUTPUT area, between terminals L/L1-PE, L2-PE, L3-PE are ca 100

MΩ and between terminals L/L1-N, L2-N, L3-N, Lx-Ly are ca 200 MΩ. This should be

considered if Riso is measured.

The OUTPUT voltage LED indicators can light on during the insulation test. This has no

particular meaning and has no influence on the measurement.

Diagnostic test (EVSE)

Because of capacitive crosstalk between conductors in the three phase Output adapters

a certain voltage U

Do not use A 1631 Monitor adapter cable for charge currents higher than 32 A.

will be displayed on not connected phases.

LxN

5

Page 6

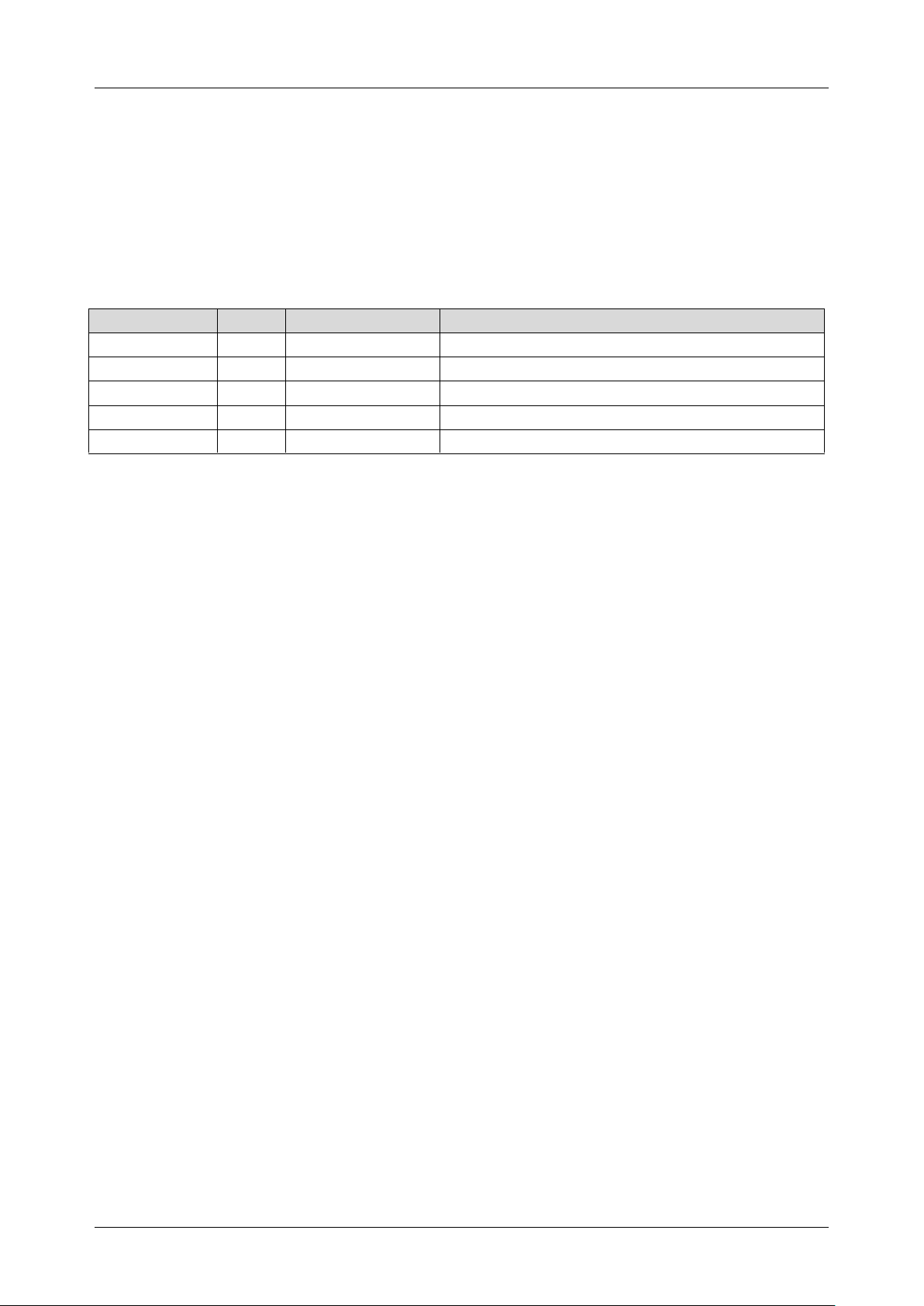

A 1632 eMobility Analyser General description

Mains

Power

ON LED

Connected

Off

blinking white

Analyser is charging

Connected

On

green

Analyser is switched on and charging

Not connected

On

green

Analyser is switched on, Ubat > 20% capacity

Not connected

On

red

Analyser is switched on, Ubat < 20% capacity

blinking red- blue

Battery error or battery is completely empty

1.2 Battery and charging of Li-ion battery pack

The A 1632 adapter is powered with rechargeable Li-ion battery pack or with Mains supply.

1.2.1 Battery indication

The ON LED indicates the charge condition of battery.

1.2.2 Charger

The battery is charged whenever the Mains power supply is connected to the A 1632 adapter.

The intelligent charging system assures appropriate protection and maximal life time of the Li-ion

battery. Typical charging time is 4 h and autonomous operation is >18 h.

1.2.3 Li – ion battery pack guidelines

Li–ion rechargeable battery pack requires routine maintenance and care in their use and

handling. In order to achieve the maximum battery life time please consider:

Use:

Do not leave batteries unused for extended periods of time – more than 6 months (self –

discharge).

Do not leave a battery on prolonged charge when not in use.

Storage:

Charge or discharge the adapter’s battery pack to approximately 50% of capacity before

storage.

Charge the adapter’s battery pack to approximately 50% of capacity at least once every

6 months.

Transportation:

Always check all applicable local, national, and international regulations before

transporting a Li – ion battery pack.

6

Page 7

A 1632 eMobility Analyser General description

Electromagnetic compatibility (EMC)

EN 61326

Electrical equipment for measurement, control and laboratory

use – EMC requirements Class A

Safety (LVD)

EN 61010 - 1

Safety requirements for electrical equipment for measurement, control

and laboratory use – Part 1: General requirements

EN 61010 - 2 – 030

Safety requirements for electrical equipment for measurement, control

and laboratory use – Part 2-030: Particular requirements for testing and

measuring circuits

EN 61010 - 031

Safety requirements for hand-held probe assemblies for electrical

measurement and test

Functional

EN 61557 series

Electrical safety in low voltage distribution systems up to 1000 V a.c.

and 1500 V d.c. - Equipment for testing, measuring or monitoring of

protective measures

EN 61851 – 1

Electric vehicle conductive charging system Part 1: General

requirements

Li – ion battery pack

IEC 62133

Secondary cells and batteries containing alkaline or other non-acid

electrolytes - Safety requirements for portable sealed secondary cells,

and for batteries made from them, for use in portable applications

1.3 Standards applied

The A 1632 adapter is manufactured and tested in accordance with the following regulations:

Note about EN and IEC standards:

Text of this manual contains references to European standards. All standards of EN

6XXXX (e.g. EN 61010) series are equivalent to IEC standards with the same number

(e.g. IEC 61010) and differ only in amended parts required by European harmonization

procedure.

7

Page 8

A 1632 eMobility Analyser Accessories

2 Accessories

The accessories consist of standard and optional accessories. Optional accessories can be

delivered upon request. See attached list for standard configuration and options or contact your

distributor or see the METREL home page: http://www.metrel.si.

2.1 Standard set

eMobility Analyser A 1632

Mains supply cord 1 phase 10 A plug to 3 phase 16 A plug adapter A 1633

Test cable with Type 2 male plug connector, length 2 m, A 1634

Test lead 2 mm / 4 mm safety banana plug adapter, red, length 1 m, A 1635

Bag for accessories A 1271

Instruction manual

Calibration certificate

2.2 Optional accessories

See the attached sheet for a list of optional accessories and licence keys that are available on

request from your distributor.

8

Page 9

A 1632 eMobility Analyser Adapter description

Figure 3.1: Front panel

1

Mains power supply inlet (CEE 16 A).

2

Mains red LED indicates connection to mains (set operation mode).

See chapter 4.1 Power supply consideration for more information.

3

Input fuses (see chapter 7.2 Fuses for more information)

4

Lx/ N/ PE/ CP/ PP safety INPUT sockets for connection of a safety tester

5

Current loop for connection of leakage current clamp for measuring IPE

6

U

INPUT

key

Toggle to apply / not apply voltage to the INPUT connectors (1 phase socket, Type 2

connector, 3 phase socket, 4 mm/ 2 mm safety sockets)

7

U

INPUT

LED indicator

ON = voltage applied, OFF = voltage not applied

3 Adapter description

3.1 Front panel

The operator’s panel is shown on Figure 3.1 below.

9

Page 10

A 1632 eMobility Analyser Adapter description

8

Type 2 INPUT socket for connection of a 3 phase Mode 3 charging cable

9

1 phase INPUT socket for connection of a 1 phase Mode 2 charging cable

22

3 phase INPUT socket for connection of a 3 phase Mode 2 charging cable

10

RS232 connection port (intended for firmware upgrade and service purposes)

11

ON multicolour LED

See chapter 1.2.1 Battery indication for more information.

12

ON / OFF key

Switches the eMobility Analyser On (short press) or Off ( 2 s press).

Auto-off after 20 minutes of no-activity.

13

Remote LED indicates that the adapter is controlled by Metrel safety tester (inclusive

CP, PP and Error state)

14

Rotary switch for selection of different simulated errors:

See chapter 8.4 Errors for more information.

15

Error ON key

Switching On/Off the selected error.

16

Error ON LED

ON = Error applied, OFF = Error not applied

17

Rotary switch for setting Control Pilot state (CP on OUTPUT side)

Position

Description

D

EV charged and ventilation

B

EV connected

A

no EV connected

B

EV connected

C

EV charged

18

Rotary switch for setting Proximity Pilot current rating resistor (PP on OUTPUT side)

[NC, 13 A, 20 A, 32 A, 63 A, 80 A]

19

Lx/ N/ PE/ CP/ PP/ CP MON safety OUTPUT sockets for connection of a safety tester

20

L/L1, L2, L3 OUTPUT LED’s

ON = mains voltage at the OUTPUT test connection present,

OFF = mains voltage at the OUTPUT test connection not present.

21

OUTPUT connectors for test cable connection to the output of charging cable or

EVSE

Note:

On INPUT side, the L/L1, L2, L3, N, PE, CP and PP safety sockets (4) are connected in parallel

with Type 2 socket (8), 1 phase socket (9) and 3 phase socket (22).

10

Page 11

A 1632 eMobility Analyser Analyser operation

Keys, switches, LEDs

Relates to

Test condition

UINPUT On/Off = Off

INPUT

L/L1,L2,L3,N,PE

No voltage on the input of charging

cable, input is disconnected from mains

UINPUT On/Off = On

Error ON = Off

INPUT

L/L1,L2,L3,N,PE

Mains voltage NORMAL condition on

the input of charging cable

UINPUT On/Off = On

Error ON = On

ERRORS INPUT is set

INPUT

L/L1,L2,L3,N,PE

Mains voltage ERROR condition on the

input of charging cable (selected by

ERRORS switch position).

See chapter 5.6 Simulation of mains

voltage errors for more information.

PP STATE

OUTPUT

PP

EV simulation, charging cable current

rating

CP STATE

Error ON = Off

OUTPUT

CP

EV simulation, normal operation

modes:

A, B, C no ventilation,

A, B, D ventilation required during

charging

Error ON = On

ERRORS OUTPUT is set

OUTPUT

CP

EV simulation, fault on CP simulated:

– Diode short,

– CP_PE short,

– PE open

Any combination

OUTPUT

L/L1,L2,L3,N,PE

Connection at the output of charging

cable / station. The condition depends

on the set state of the instrument.

4 Analyser operation

The eMobility Analyser can operate autonomously or it can be remote controlled via Bluetooth

communication link with Metrel Instrument. Following test conditions can be set:

11

Page 12

A 1632 eMobility Analyser Analyser operation

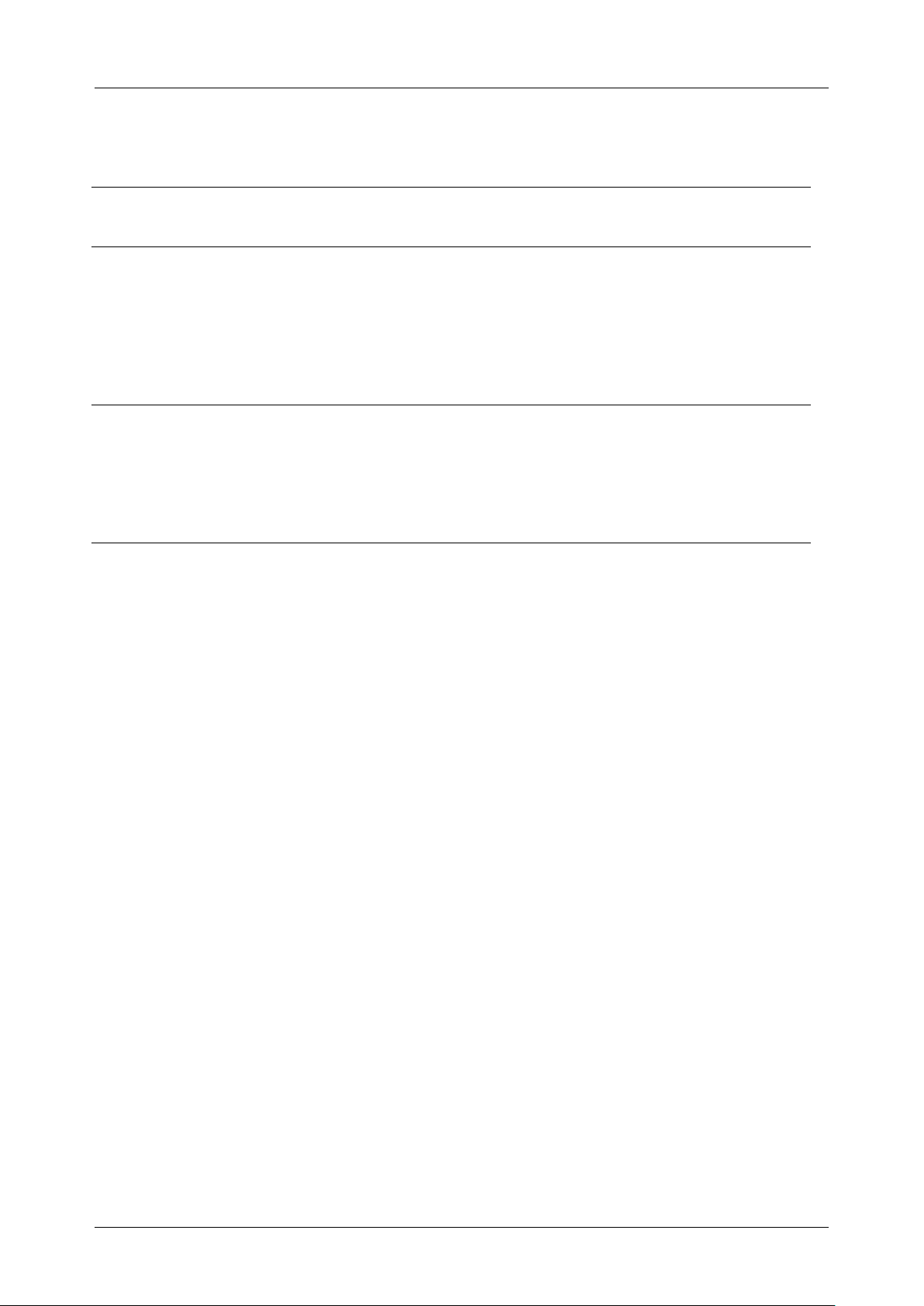

Operation

mode

Symbol

LED indication

Description

Mode 1

ON

Correct connection

Mode 2

Blinking (5 s cycle)

Correct connection

Blinking (~0.3 s cycle)

L – N crossed or wrong voltage

system

4.1 Power supply consideration

The 3-phase 16 A CEE inlet is intended for connection to Single and 3-phase Mains supply.

Single phase connection

1 phase 10 A plug to 3 phase 16 A CEE cable connector adapter A 1633 should be used for

single phase connection. It is suitable for internal battery charging and for single phase supply to

INPUT section for testing of Single phase Mode 2 Charging cables.

3-phase connection

Testing of 3 phase Mode 2 Charging cables requires 3 phase Mains power supply to the

eMobility Analyser and its INPUT section, neutral N wire connection is mandatory. Ordinary 3phase CEE 16 A 5-wire extension cord can be used for Mains power supply.

Note:

If mains voltage is out of standard levels for 115 V~, 230 V~ and 230 V / 400 V 3~, the

MAINS LED is fast blinking, eMobility Analyser cannot be switched ON and operation

with the adapter is not possible.

4.2 Operation modes

The analyser has two operation modes.

Mode 1

Mode 1 is the preferred operating mode. It is indicated by one short beep when mains voltage is

applied. In this mode the PE connection of the INPUT connectors is connected to the

installation’s N conductor. This prevents from nuisance tripping of the RCD when RCD or

impedance tests are carried out.

This operation mode 1 is suitable for TN and TT voltage systems. The mains LED will show an

error and the analyser cannot be switched on if connected to an IT voltage system.

Mode 2

Mode 2 is indicated by three beeps when mains voltage is applied. In this mode the PE

connection of the INPUT connectors is connected to the installation’s PE conductor. This

operation mode is suitable for any voltage system.

Note:

In Mode 2 the RCDs in the installation can trip if they are more sensitive than the PRCD

in the tested charging cable. Nuisance tripping of the RCD can be avoided if appropriate

alternative connection for the RCD tests is used.

12

Page 13

A 1632 eMobility Analyser Analyser operation

Switch OFF the eMobility Analyser.

Press and hold U

INPUT

key for at least 5 s while switching ON the adapter (ON/OFF

key). (Alternatively apply Mains supply while pressing and holding U

INPUT

key for at

least 5 s.)

When releasing the U

INPUT

key, beep sound indicates the newly set mode:

Single beep

Mode 1 selected

3 - beeps

Mode 2 selected

eMobility Analyser is now ready to operate in new operating mode.

4.2.1 How to select or change the operating mode

Setup procedure

Note:

Repeat upper procedure to toggle between operating modes.

4.3 Operation in autonomous mode

In this operation mode there is no need for data connection with master instruments. The

Remote LED is switched OFF. The eMobility Analyser test condition can be set with the switches

and keys on the analyser’s front panel.

4.4 Remote operation

For remote setting of test condition, the eMobility Analyser must be connected via Bluetooth with

the Metrel safety tester first. See Supported Instruments Selection Table and instrument’s

Instruction manual, chapter Settings for more information. The Analyser Remote LED is lit ON

and indicates that it is controlled by the Instrument. While in remote mode the analyser’s keys

are not operating (except the On/Off key) and the state of rotary switches is irrelevant. The test

parameters are set by the instrument that controls the analyser.

Analyser Remote LED is lit ON only when associated Diagnostic test (EVSE) is selected on the

Instrument. When other Instrument safety test is selected, Analyser cannot be remote controlled

and Remote LED is lit OFF.

13

Page 14

A 1632 eMobility Analyser Single tests

5 Single tests

5.1 Test connections to charging cables / stations

5.1.1 Connection of detachable charging cable for Mode 3 EVSE

Figure 5.1: Connection of detachable charging cable for Mode 3 EVSE

5.1.2 Connection to Mode 2 charging cable

Figure 5.2: Connection of a 1 phase Mode 2 charging cable

Figure 5.3: Connection of a 3 phase Mode 2 charging cable

14

Page 15

A 1632 eMobility Analyser Single tests

5.1.3 Connection to Mode 3 EVSE

Figure 5.4: Connection of a Mode 3 EVSE

5.2 Safety and functional tests

In general the safety single tests and inspections can be carried out in combination with any

safety testers. For more information how to carry out single tests and inspections refer to

Instruction manual of the safety tester.

Test circuit examples

Figure 5.5: Example of RISO tests on a Mode 2 charging cable

Figure 5.6: Example of Zline test on a Mode 3 EVSE

15

Page 16

A 1632 eMobility Analyser Single tests

Measurement procedure

Connect the charging cable /station to the eMobility Analyser (see test circuits above).

Select the measurement or inspection on the safety tester.

Set test parameters / limits of the selected measurement on the test instrument.

Put the charging cable / station into proper operating mode by setting the eMobility Analyser.

Connect the instrument test leads to the Analyser sockets (optional), see test circuits above

and Instruction manual of test instrument.

Carry out the measurement or inspection.

Save results (optional).

5.3 Diagnostic test – EV simulator

This test is intended for simulation of an electrical vehicle with eMobility Analyser. The CP and

PP states can be set in order to put the charging cable/ station into proper operation mode. The

CP signal is analysed and the presence of voltage at the output of the charging cable / station is

monitored.

5.3.1 Remote connection

The test is performed in combination with an external (master) instrument. The results are

transmitted via Bluetooth communication link and displayed on the master instrument.

Test connections

Figure 5.7: Diagnostic test - EV simulator test connection to the Mode 3 EVSE

Figure 5.8: Diagnostic test - EV simulator test connection to the Mode 2 charging cable - Remote

connection

16

Page 17

A 1632 eMobility Analyser Single tests

Measurement procedure

Connect the charging cable /station to the eMobility Analyser (see test circuits above).

Select Diagnostic test – EV simulator on the master instrument.

Set test parameters on the master instrument.

Check that the eMobility Analyser is in Remote mode (Bluetooth communication between

eMobility Analyser and the master instrument is established).

Carry out the Diagnostic test.

Manually set status of the test (Optional).

Save results (optional).

For information about test parameters and displayed results refer to Instruction manual of the

master instrument.

5.3.2 Autonomous mode

The eMobility Analyser test condition can be set with the switches and keys on the analyser’s

front panel. Only Mode 2 single and 3-phase charging cables can be tested in this mode.

Figure 5.9: Diagnostic test - EVsimulator test connection to the Mode 2 charging cables -

Autonomous mode

5.4 Diagnostic test – Monitor

This test monitors and analyses the CP signal and voltages between the charging cable / station

and the electrical vehicle. For this test a monitor adapter cable (A 1631) is needed

The test is performed in combination with eMobility Analyser and an external (master)

instrument. The results are transmitted via Bluetooth and displayed on the master instrument.

17

Page 18

A 1632 eMobility Analyser Single tests

Test connection

Figure 5.10: Example of a Diagnostic test - Monitor

Measurement procedure

Connect the A 1631 cable adapter between the charging cable /station and the electrical

vehicle.

Connect test probes to A 1632 eMobility Analyser.

Select the Diagnostic test – Monitor on the master instrument.

Set test parameters on the master instrument

Check that the eMobility Analyser is in Remote mode (Bluetooth communication between

eMobility Analyser and the master instrument is established).

Carry out the Diagnostic test.

Manually set status of the test (optional).

Save results (optional).

For information about test parameters and displayed results refer to Instruction manual of the

master instrument.

5.5 Diagnostic test – CP Errors

This test can simulate typical errors (diode shorted, CP – PE shorted, PE open) on the CP

signal. The disconnection time of the charging cable / station, as a reaction to the simulated

fault on the CP signal, is measured.

The test is performed in combination with an external (master) instrument. The results are

transmitted via Bluetooth and displayed on the master instrument.

Test connections

Refer to Figure 5.7 and Figure 5.8 for test connections.

Measurement procedure

Connect the charging cable /station to the eMobility Analyser (see Figure 5.7 and Figure

5.8).

Select the Diagnostic test – CP Error on the master instrument.

Set test parameters (CP error) on the master instrument.

Check that the eMobility Analyser is in Remote mode (Bluetooth communication between

eMobility Analyser and the master instrument is established).

Carry out the Diagnostic test.

Manually set status of the test (optional).

Save results (optional).

For information about test parameters and displayed results refer to Instruction manual of the

master instrument.

18

Page 19

A 1632 eMobility Analyser Single tests

5.6 Simulation of mains voltage errors

Mode 2 charging cables have different means for testing the mains condition:

some tests are carried out when connected to the mains (at powerup),

some tests are monitoring the mains condition all time.

Therefore eMobility Analyser has two options for simulating input mains errors.

5.6.1 Simulation of connection of the charging cable to faulty mains

A faulty mains voltage is applied to INPUT terminals / sockets of eMobility Analyser.

Measurement procedure

Connect the charging cable to the eMobility Analyser (see Figure 5.8).

Select the error with ERRORS rotary switch.

U

Press the Error ON key to set error and power the charging cable.

Check the response of the tested charging cable.

must be OFF. (If not already, set U

INPUT

INPUT

to OFF.)

5.6.2 Simulation of a fault that occurs during operation

The Error is activated after mains voltage (normal condition) is applied to INPUT terminals /

sockets of eMobility Analyser.

Measurement procedure

Connect the charging cable to the eMobility Analyser (see Figure 5.8).

Select the error with ERRORS rotary switch.

U

Press the ERROR ON key to set error.

Check the response of the tested charging cable.

Note:

It is possible to carry out this simulation for following errors: L open (any phase), N open

and PE open.

must be ON. (If not already, set U

INPUT

INPUT

to ON.)

19

Page 20

A 1632 eMobility Analyser Upgrading the adapter

6 Upgrading the adapter

The A 1632 eMobility Analyser can be upgraded from a PC via the RS 232 communication port.

This enables to keep the A 1632 eMobility Analyser up to date even if the standards or

regulations change. Download the latest firmware on the Metrel download centre:

https://www.metrel.si/en/downloads/

Figure 6.1: Upgrading the adapter

Procedure

Unscrew two screws (as indicated in Figure 6.1) and remove RS 232 connector

protection cover.

Connect standard DB9 RS232 interface cable on A 1632 and PC. (USB to RS232

adapter should be used if serial PC port is not available.)

Special upgrading software - FlashMe will guide you through the upgrading procedure.

When upgrade is finished, insert the RS 232 connector protection cover back.

Notes:

Contact your dealer for more information.

Upgrading the firmware over Bluetooth communication is not possible.

20

Page 21

A 1632 eMobility Analyser Maintenance

7 Maintenance

7.1 Periodic calibration

It is essential that all measuring instruments are regularly calibrated in order for the technical

specification listed in this manual to be guaranteed. We recommend an annual calibration.

7.2 Fuses

F1, F2, F3: F 5 A / 500 V / (32 6.3) mm (Breaking capacity: 50 kA)

Mains fuses intended for adapter protection.

Warnings!

Switch off the adapter and disconnect all test accessories and mains cord

before replacing the fuses.

Replace blown fuses with the same type as defined in this document.

7.3 Service

For repairs under or out of warranty please contact your distributor for further information.

Unauthorized person is not allowed to open the analyser. There are no user replaceable parts

inside the instrument.

7.4 Cleaning

Use a soft, slightly moistened cloth with soap water or alcohol to clean the surface of analyser.

Leave the instrument to dry totally before using it.

Notes:

Do not use liquids based on petrol or hydrocarbons!

Do not spill cleaning liquid over the instrument!

21

Page 22

A 1632 eMobility Analyser Technical specifications

Measuring range (V)

Resolution (V)

Accuracy

0 ... 440

1

(2 % of reading + 2 digits)

Measuring range (V)

Resolution (V)

Accuracy

-19.9 V ...19.9 V

0.1

(2 % of reading + 2 digits)

Measuring range (Hz)

Resolution (Hz)

Accuracy

500.0 ... 1500.0

0.1

1 % of reading

Measuring range (%)

Resolution (%)

Accuracy

0.1 … 99.9

0.1

10 digits

Displayed range (A)

Resolution (A)

Accuracy

0.0 … 99.9

0.1

Calculated value*

Measuring range (ms)

Resolution (ms)

Accuracy

0 … 399

1

(1 % of reading + 5 digit)

8 Technical specifications

8.1 Diagnostic test (EVSE)

U1N, U2N, U3N – Mains voltage

Nominal frequency range ....................... 0 Hz, 14 Hz ... 500 Hz

Field – Phase rotation

Result displayed ..................................... 1.2.3 or 3.2.1

UCP+, UCP- – Voltage

Result..................................................... positive, negative peak value (8 μs interval)

Freq – Frequency

D – Duty cycle

Ievse – Charging current available by charging cable / EVSE

*According to Table A.8 in IEC/EN 61851-1

toff – Disconnection time

Note:

For t

the L1-N channel is measured.

off

22

Page 23

A 1632 eMobility Analyser Technical specifications

State

Resistance

N.C.

> 300 kΩ

13 A

1.5 kΩ ± 1.5 %

20 A

680 Ω ± 1.5 %

32 A

220 Ω ± 1.5 %

63 A

100 Ω ± 1.5 %

80 A

56 Ω ± 5 %

State

Resistance

A

> 300 kΩ

B

2.74 kΩ ± 1.5 %

C

882 Ω ± 1.5 %

D

246 Ω ± 1.5 %

State

Meaning

A1

no EV connected

A2

no EV connected / PWM

B1

EV connected

B2

EV connected / PWM

C1

EV charged

C2

EV charged / PWM

D1

EV charged and ventilation

D2

EV charged and ventilation / PWM

E

Error

F

Failure

Invalid

CP signal can’t be classified

8.2 PP, CP simulator

PP simulation

CP simulation

8.3 System state

Possible systems states (measured interpreted by the Analyser*)

* According to Table A.4 in IEC/EN 61851-1.

If more states are displayed as result, all states can be considered as valid according to IEC/EN

61851-1.

23

Page 24

A 1632 eMobility Analyser Technical specifications

Errors

Applied to:

Parameter

Description

L/L1op

INPUT

L/L1 conductor opened

L/L2op

L/L2 conductor opened

L/L3op

L/L3 conductor opened

Nop

N conductor opened

PEop

PE conductor opened

L PE

L/L1and PE conductors crossed*

U

EXT

(PE)

External voltage on PE (on input side)*

OUTPUT

E1

CP diode shorted

E2

CP - PE shorted

E3

PE opened

8.4 Errors

*mains voltage is connected to PE via a 1MΩ resistor

8.5 Other

Output voltage LED………………………………………………………ON: ULx-N > 50 V

24

Page 25

A 1632 eMobility Analyser Technical specifications

8.6 General data

Battery power supply .............................. 7.2 V d.c. (4.4 Ah Li-ion)

Battery charging time ............................. typical 4 h (deep discharge)

Mains power supply ............................... 115 V ~ ± 10 %

230 V ~ ± 10 %

230 V / 400 V 3~ ± 10 %

50 Hz - 60 Hz, 60 VA

Protection category ................................ 300 V CAT II

Battery operation time:

Idle state ................................................ > 32 h

Diagnostic test ....................................... > 18 h

Protection classification .......................... reinforced insulation

Measuring category ................................ 300 V CAT II

Pollution degree ..................................... 2

Degree of protection ............................... IP 65 (case closed), IP 40 (case open)

............................................................... IP 20 (mains test socket)

Dimensions (w h d)........................... 36 cm x 16 cm x 33 cm

Weight ................................................... 5.2 kg, (without accessories)

Sound / Visual warnings ........................ yes

Reference conditions:

Reference temperature range ................ 25 C ± 5 C

Reference humidity range ...................... 40 %RH … 60 %RH

Operation conditions:

Working temperature range .................... -10 °C … 50 °C

Maximum relative humidity ..................... 90 %RH (0 °C … 40 °C), non-condensing

Working nominal altitude ........................ up to 3000 m

Storage conditions:

Temperature range ................................ -10 °C … 70 °C

Maximum relative humidity ..................... 90 %RH (-10 C … 40 C)

............................................................... 80 %RH (40 C … 60 C)

RS 232 communication:

RS 232 serial communication ................. galvanic separated

Baud rate: ........................................ ...... 115200 baud rate, 1 stop bit, no parity

Connector: ............................................. standard RS232 9-pin D female

Bluetooth communication:

Bluetooth module ................................... class 2

Specifications are quoted at a coverage factor of k = 2, equivalent to a confidence level of

approximately 95 %.

Accuracies apply for 1 year in reference conditions. Temperature coefficient outside these limits

is 0.2 % of measured value per °C, and 1 digit.

25

Loading...

Loading...