GAS GRIDDLE

OFTG 40B

OFTG 40BLC

OFTG 60B

OFTG 60BLC

Installation and Operation Manual

10/31 Gas heated Fry-Tops and sloped Grillplates (FTG/BIG)

GB

INDEX

INSTALLATION INSTRUCTIONS -----------------------------------------------------------------------page ---11

WARNINGS ---------------------------------------------------------------------------------------------------------- page --- 11

INSTALLATION ------------------------------------------------------------------------------------------------------page ---11

Positioning

Assembly

In line union of the 600

Connection to gas piping

CONVERSION TO ANOTHER TYPE OF GAS ------------------------------------------------------------------------ page --- 11

Replacement of burner nozzle

Burner primary air adjustment

Replacement of minimum adjustment screw

Replacement of pilot burner nozzle

Replacement of gas preset adhesive label

START-UP ------------------------------------------------------------------------------------------------------------page --- 11

Function check

Nominal heat input check

Inlet pressure check

ANALYSIS OF SEVERAL FAILURES ---------------------------------------------------------------------------------page --- 11

Difficult or lacking pilot ignition

Extinction of pilot burner flame during operation

Extinction of main burner flame during operation

Difficult or lacking burner ignition

Difficult or lacking temperature adjustment

REPLACEMENT OF PARTS SUBJECT TO CHANGE -----------------------------------------------------------------page --- 12

Burner, Pilotburner, Thermocouple, Ignition spark plug, Safety thermostat

Gas valve, Piezoelectric igniter

USE AND MAINTENANCE ----------------------------------------------------------------------------------page ---12

WARNINGS -----------------------------------------------------------------------------------------------------------page --- 12

Additional safety device

USE ------------------------------------------------------------------------------------------------------------------ page --- 12

Burner ignition on appliances with firm splashguard

Burner ignition on appliances with removable splashguard

Burner extinction

CLEANING AND MAINTENANCE ------------------------------------------------------------------------------------page ---13

LIST OF PARTS SUBJECT TO CHANGE -----------------------------------------------------------------------------page --- 13

Gas heated Fry-Tops and sloped Grillplates (FTG/BIG) 11/31

– Screw down fixing screws and seal them with

red paint.

Replacement of gas cock minimum adjustment

screw (Fig. 1-2)

– Remove control panel of appliance.

– Unscrew the minimum adjustment screw and

replace it with the proper one indicated Table T1.

Replacement of pilot burner nozzle (Fig. 4)

– Remove control panel of appliance.

– Remove the pilot burner support plate SP, loosen

the two screws fastening the plate at the front.

– Unscrew pipe fitting R and replace nozzle B with

the proper one indicated in Table T1.

– Screw down pipe fitting R.

Replacement of gas preset adhesive label

– Apply the correct adhesive label which indicates

the new type of gas for which the appliance is

now set.

START-UP

Function check

– Start-up the appliance according to instructions

for use and check the regularity of the burner

ignition, the absence of gas leaks and the efficiency

of the burnt gas exhaust system.

– If necessary consult paragraph “Analysis of

several failures”.

Nominal heat input check

– After installation or adjustment to another type

of gas and at each maintenance intervention

check the heat input of the appliance.

– The nominal heat input is stated in the “Technical

data” table.

– The appliance operates at the nominal heat

input when the nozzles assembled are suitable

for the type of gas used and the inlet pressure is

the one indicated in Table T1.

– For the measurement of the inlet pressure read

paragrah “Inlet pressure check”.

Inlet pressure check

– For the measurement of the inlet pressure use a

gauge having a minimum definition of 0.2 mbar.

– Remove front panel of appliance, remove seal

screw C from upstream pressure tapping and

connect the gauge pipe.

– Carry out the measurement with appliance on.

– If the value is not within the limits indicated in

Table T3, interrupt the operation of the appliance

and contact the gas delivery body.

– Disconnect the gauge pipe and screw down seal

screw C.

ANALYSIS OF SEVERAL FAILURES

Difficult or lacking pilot ignition

– Insufficient gas inlet pressure.

– Obstructed nozzle or main.

– Defective gas cock.

INSTALLATION INSTRUCTIONS

WARNINGS

Installation, adjustments and maintenance of the

appliances must be done by authorized installers,

in accordance with the safety standards in force.

The manufacturer declines any responsibility

if such obligation is not observed.

INSTALLATION

Positioning

– The overall/connection dimensions and the tech-

nical data are stated in the pages in the appendix.

– Install the appliances only in sufficiently aired

rooms.

– Fry-tops are type “A” appliances and for this

reason the rooms must be ventilated in

accordance with the technical standards in force.

– Position appliances at least 10 cm from the

nearby walls. Such distance can be less when

the walls are incombustible or protected by a

thermal insulator.

– The appliances are not suitable for built-in

installation.

Assembly

– Remove the film which protects the external

panels. Any glue remaining on these is to be

removed with a suitable solvent.

In line union of the 600 series appliances

– Put the appliances next to eachother and level

them at the same height.

– Unite the appliances using the special union

joint-coverings supplied upon request.

Connection to the gas piping

– Before carrying out the connection consult the

gas delivery body.

– Install a fast-closing cut-off cock upstream from

the appliance in an easily accessible place.

– Check if the appliance is set for the type of gas

with which it will be fed. If it is not, read

paragraph “Adaptation to another type of gas”.

– Check for any leaks in the connection points.

CONVERSION TO ANOTHER TYPE OF GAS

To adapt appliances to work with other tyes of gas

carry out all the operations stated below.

Nozzles, minimum adjustment screws and adhesive

labels are in the bag supplied with the appliance.

Replacement of burner nozzles (Fig. 3)

– Remove front panel of appliance.

– Remove the nozzle-support manifold RU.

– Unscrew nozzles and change them with the

proper ones according to Table T1.

Burner primary air adjustment (Fig. 3)

– Remove front panel of appliance.

– Operating on the shutters adjust primary air inlet

at the distance “A” indicated on Table T1.

12/31 Gas heated Fry-Tops and sloped Grillplates (FTG/BIG)

– Defective piezoelectric igniter, ignition spark

plug or cable.

Extinction of pilot burner flame during operation

– Gas inlet pressure drop

– Defective or insufficiently heated thermocouple,

or poorly connected to the gas cock.

– Defective gas cock.

– Defective or intervention of safety thermostat

(models with chromed plate).

Extinction of main burner flame during operation

– Gas inlet pressure drop

– Defective or insufficiently heated thermocouple,

or poorly connected to the gas cock.

– Defective gas cock.

– Defective or intervention of safety thermostat

(models with chromed plate).

Difficult or lacking burner ignition

– Insufficinet gas inlet pressure.

– Obstructed nozzle.

– Defective or intervention of safety thermostat

(models with chromed plate).

– Defective gas cock.

Difficult or lacking temperature adjustment

– Defective gas cock.

REPLACEMENT OF PARTS SUBJECT TO CHANGE

Sealed components must not be tampered

with.

After each intervention, if necessary, check

for the absence of gas leaks.

Burner, Pilotburner, Thermocouple, Ignition spark

plug, Safety thermostat

– Remove control panel of appliance and replace

the component.

Gas cock, Piezoelectric igniter

– Remove control panel of appliance and replace

the component.

USE AND MAINTENANCE

WARNINGS

The appliance is for professional use and must be

used by trained personnel. The appliance has to be

used only for direct cooking of food, laying the food

to be cooked (meat, hamburger, fish, vegetables,

etc.) directly on the hot surface of the plate. Any

other use of the appliance is considered improper.

It is absolutely forbidden to use the plate for

indirect cooking of food, laying pots casseroles

or pans containing food on the plate.

The installation and adaptation to other types of gas

must be done by qualified and authorized installers.

In case of breakdown close the gas cut-off cock

upstream from the appliance.

Sealed components must not be tampered with.

For repairs consult only authorized service centres

and ask for original spare parts only.

The manufacturer declines any responsability

if such obligations are not observed.

Carefully read this booklet and keep it in a safe place.

Before using the appliance carefully clean all the

surfaces that will come in contact with food.

Additional safety device

Appliances with chromed plate are provided with

an additional safety thermostat which operates

shutting off the outflow of gas when, for any

failure, the cooking plate exceeds maximum temperature allowed. If this event occurs close the gas

cut-off cock and call for a authorized technician.

USE

Burner ignition on appliances with firm splashguard

(Mod. BIG-40/60)

The gas cock knob has following references

● off

pilotburner

maximum flame

minimum flame

– Push down the knob and turn it to position .

– Maintain the knob pushed down and operate on

piezoelectric igniter push-button to light the

flame. Hold knob in for about 20 seconds then

release it and check that the flame stays alight

(if the pilot flame turns off repeat the operation).

– Turn the knob to the desired cooking tempera-

ture.

– The burner flame can be seen through the peep

hole on the front panel.

Burner ignition on appliances with removable

splashguard and appliances with chromed plate

(Mod. FTG-40B/60B/60BR/80B/80BR/40BLC/

60BLC)

The thermostatic gas cock knob has following

references

● off

pilotburner

1 Minimum temperature

2 - 6 Intermediate temperature

7 Maximum temperature

– Push down the knob and turn it to position .

– Maintain the knob pushed down and operate on

piezoelectric igniter push-button to light the

Gas heated Fry-Tops and sloped Grillplates (FTG/BIG) 13/31

flame. Hold knob in for about 20 seconds then

release it and check that the flame stays alight

(if the pilot flame turns off repeat the operation).

– Turn the knob to the desired cooking tempera-

ture.

– The burner flame can be seen through the peep

hole on the front panel.

Burner extinction

– Turn knob to position .

– To extinguish pilot burner turn it to position ●.

CLEANING AND MAINTENANCE

– Before any cleaning operation disconnect the

electrical supply (if present).

– Clean stainless steel surfaces daily with water

and non abrasive common detergents, rinse

well and dry thoroughly.

– Do not use iron scouring pads or chlorate

products.

– Do not use sharp objects which can scratch and

ruin the steel surface.

– Do not use corrosive products to clean the floor

under the appliance.

– Do not wash the appliance with water jets.

– Before a long period of inactivity close the gas

cut-off cock upstream from the appliance.

Proceed to its thorough cleaning.

– At least twice a year, ask for the intervention of

an authorized technician authorized for checking

the appliance and the cleaning of the burnt gas

discharge duct. It is advisable in any case to

stipulate a maintenance contract.

LIST OF PARTS SUBJECT TO REPLACEMENT

– Gas cock

– Thermostatic gas cock

– Main burner

– Pilot burner

– Thermocouple

– Pilot ignition spark plug

– Safety thermostat (on models with chromed

plate)

TECHNICAL DATA

T1

GAS

P

mbar

OFTG-40B.. OFTG-60B..

G20

G20+G25

20

20/25

ugelli bruciatore •

2x120 4x120

ugelli pilota ▲

4 2x4

A = mm

3 3

vite minimo**

100 100

G25

20

ugelli bruciatore •

2x135 4x135

ugelli pilota ▲

4 2x4

A = mm

3 3

vite minimo**

100 100

G25

25

ugelli bruciatore •

2x120 4x120

ugelli pilota ▲

4 2x4

A = mm

3 3

vite minimo**

100 100

G30+G31

G30 G31

29/37

29 29

ugelli bruciatore •

2x80 4x80

ugelli pilota ▲

3 2x3

A = mm

4 4

vite minimo**

70 70

G30

G3

1

50

50

ugelli bruciatore •

2x70 4x70

ugelli pilota ▲

2 2x2

A = mm

4 4

vite minimo**

70 70

G110

8

ugelli bruciatore •

2x290 4x290

ugelli pilota ▲

1 2x1

A = mm

35 35

vite minimo**

REG. • • REG. ••

G120

8

ugelli bruciatore •

2x230 4x230

ugelli pilota ▲

1 2x1

A = mm

35 35

vite minimo**

REG. • • REG. ••

G20

25

ugelli bruciatore •

2x115 4x115

ugelli pilota ▲

4 2x4

A = mm

3 3

vite minimo**

100 100

G25.1

25

ugelli bruciatore •

2x130 4x130

ugelli pilota ▲

4 2x4

A = mm

3 3

vite minimo**

100 100

• Burner nozzle

▲ Pilot burner nozzle

** Minimum adjusting screw

• • Adjustable

29/37

20

20/25

29/37

29

29

20

8

20

8

20

50

50

25

50

50

20

20

29

29

29

29

20

8

8

29

29

25

30

30

25

50

50

20

28-30/37

G30+G31

G20

G20+G25

G30+G31

G30

G31

G20

G110

G20

G110

G20+G25

G30

G31

G25

G30

G31

G20

G20

G30

G31

G30

G31

G20

G110

G120

G30

G31

G20/G25.1

G30

G31

G20/G25.1

G30

G31

G20

G30+G31

Category

II 2H 3+

II 2E+ 3+

III 1a 2H 3B/P

II 1a 2H

II 2ELL 3B/P

I 2L

II 2H 3B/P

II 2H 3B/P

III 1ab 2H 3B/P

I 3B/P

II2HS3B/P

II2HS3B/P

I2E

I3+

Country

IT GR

IE SK

PT

ES

GB

FR

BE

DK

ES IT

CH

DE

NL

AT

CH

FI BG

EE LV

SI LT

CZ

SE

NO CY

MT NL

HU

HU

LU

LU

T4

GAS P mbar

TECHNICAL DATA

T3

P mbar

G20

G25.1

G20 G25 G25 G30 G31

G30-G31 G110 G120

nom.

25 25 20 20 25

29 37

50

8

8

min 18

18 17 18

20 25 30

42,5

6

6

max 33 33 25 25 30 35

45

57,5

15 15

T5

OFTG-40B.. OFTG-60B. .

MAX. MIN. MAX. MIN.

G20 25 mbar k W

5 1,75 10 3,5

G25.1 25 mbar k W

5 1,5 10 3

Qn kW

G20

20 mbar kW

5 1,75 10 3,5

G25 (NL) 25 mbar kW 4,75

1,75 9,5 3,5

G25 (DE) 20 mbar kW

5 1,5 10 3

G30 29 mbar k W

5 1,9 10 3,8

G30 50 mbar k W

5 2,3 10 4,6

G110 8 mbar k W

5 2,1 10 4,2

G120 8 mbar k W

5 2,3 10 4,6

G20 2 5 mbar m3/h 0,5 3

0,18

1,06 0,37

G25.1 25 mbar m3/h 0,61

0,18

1,23 0,37

Kaasun

G20

20 mbar m3/h

0,53

0,18

1,06 0,37

kulutus G2 5 (NL) 25 mbar m3/h 0,58

0,22

1,17 0,43

G25 (DE) 20 mbar m3/h 0,62

0,18

1,23 0,37

G30 29 mbar k g/h 0,39

0,15

0,79 0,30

G30 50 mbar k g/h 0,39

0,18

0,79 0,36

G110 8 mbar m3/h 1,29

0,54

2,58 1,08

G120 8 mbar m3/h 1,15

0,53

2,29 1,06

Gas

consumption

GAS

60

3,6 3,6

G

G

60

G

40

40

3,6 3,6

G

5,3

60

5,4

G

5,92

1142,5

6,5

2

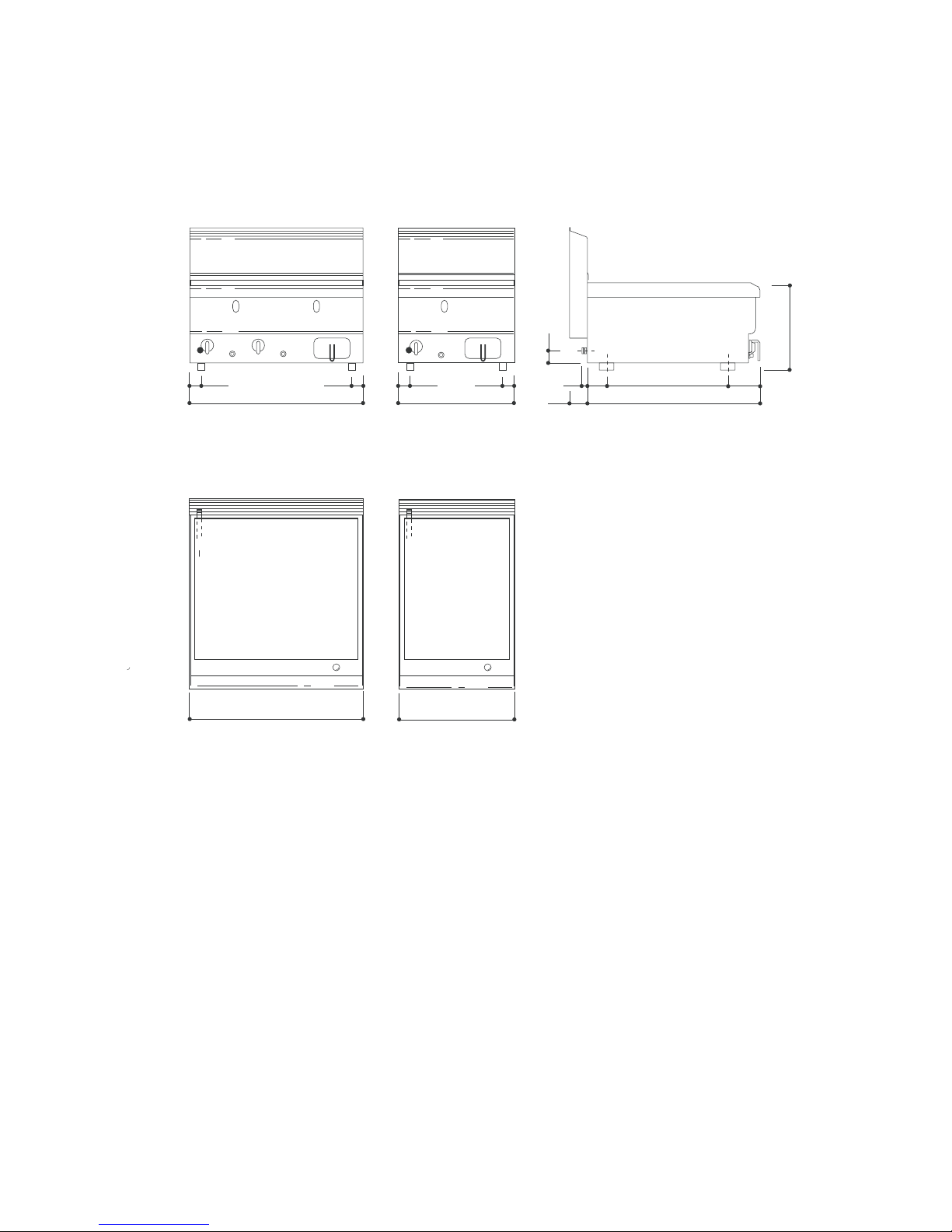

OFTG-40B... OFTG-60B...

ASENNUSKUVA - INSTALLATIONSBILD - INSTALLATION DIAGRAM

(Mitat cm - Mått cm - Measurements cm)

G Kaasuliitäntä - Gasanslutning - Gas connection ISO 7/1 R1/2

OFTG-60B.. OFTG-40B..

Loading...

Loading...