Page 1

Automation Components of Modular Design

Subject to change without notice / January 2005

1.001

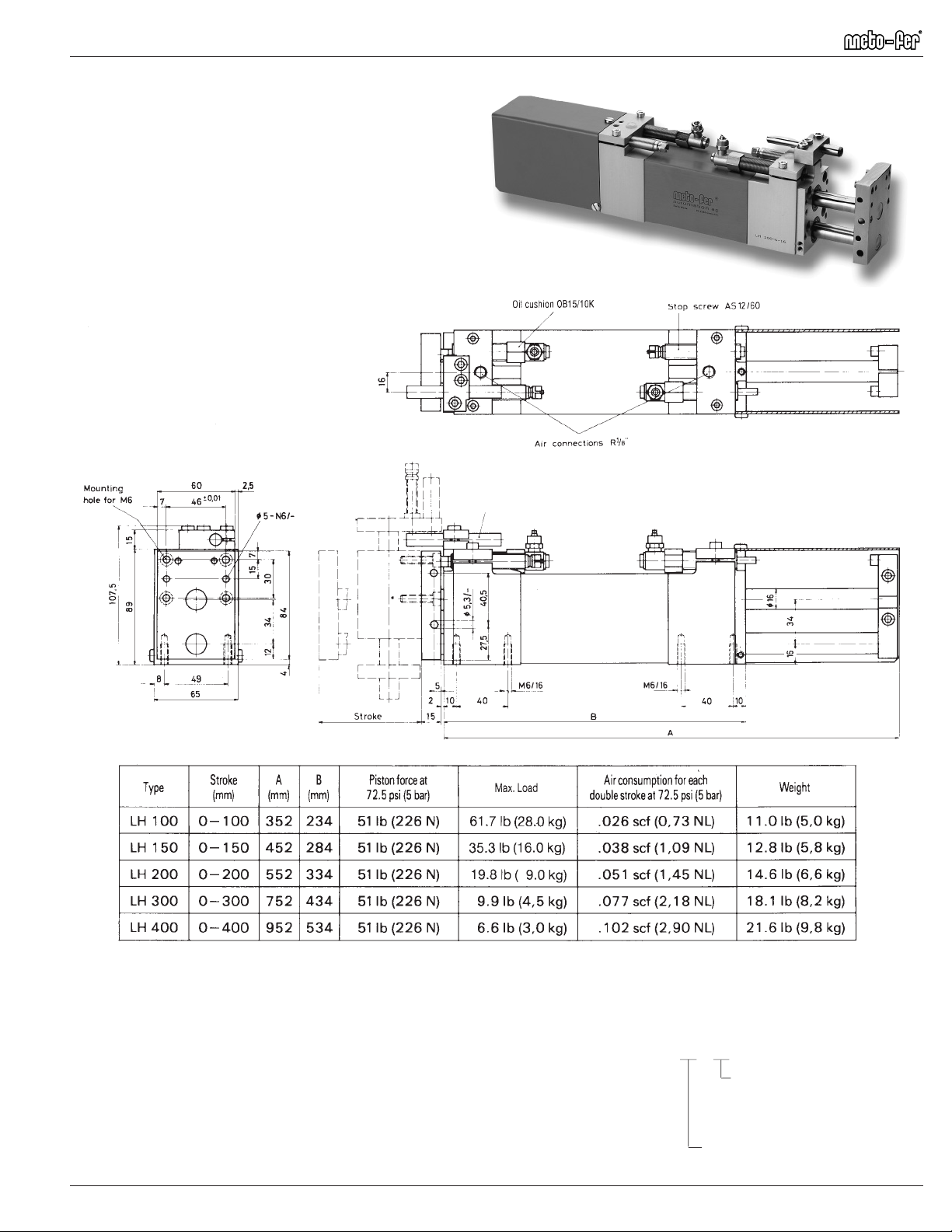

Linear units LH

— Progressive working oil cushions,

includes oil reservoir KOB 50

(see sheet 6.001)

— Patented stop screws with sensing device

— High repeat accuracy

— Many combination possibilities

— Third position stop dowel pin for use with

vertical unit VE *

Stop position dowel pin

for third position *

Technical data:

–Stroke steplessly adjusted bybuilt in patented stop screws with fine threads.

–The stop screws can be fitted with patented sensing elements. (see section "Stop Screws with plug-in sensing elements").

–End position damped with adjustable oil cushions.

–Designed for high operating rates / long life (expected life 20 million cycles)

–Seal repair kits available

–Linear ball bushings.

–Operating medium Compressed air oiled / not oiled

–Operating pressure 43.5 – 116 psi (3 – 8 bar)

–Repeatability ± 0.01mm (0.0004")

–Air connection R 1/8” (adapter see sheet 5.032)

Order No. LH - . . . - . . .

O=Without cushions

A=Elastomer cushions (KB08)

B=Oil cushions and KOB50

(OB15/10K)

Stroke / mm

Page 2

1.002

Subject to change without notice / January 2005

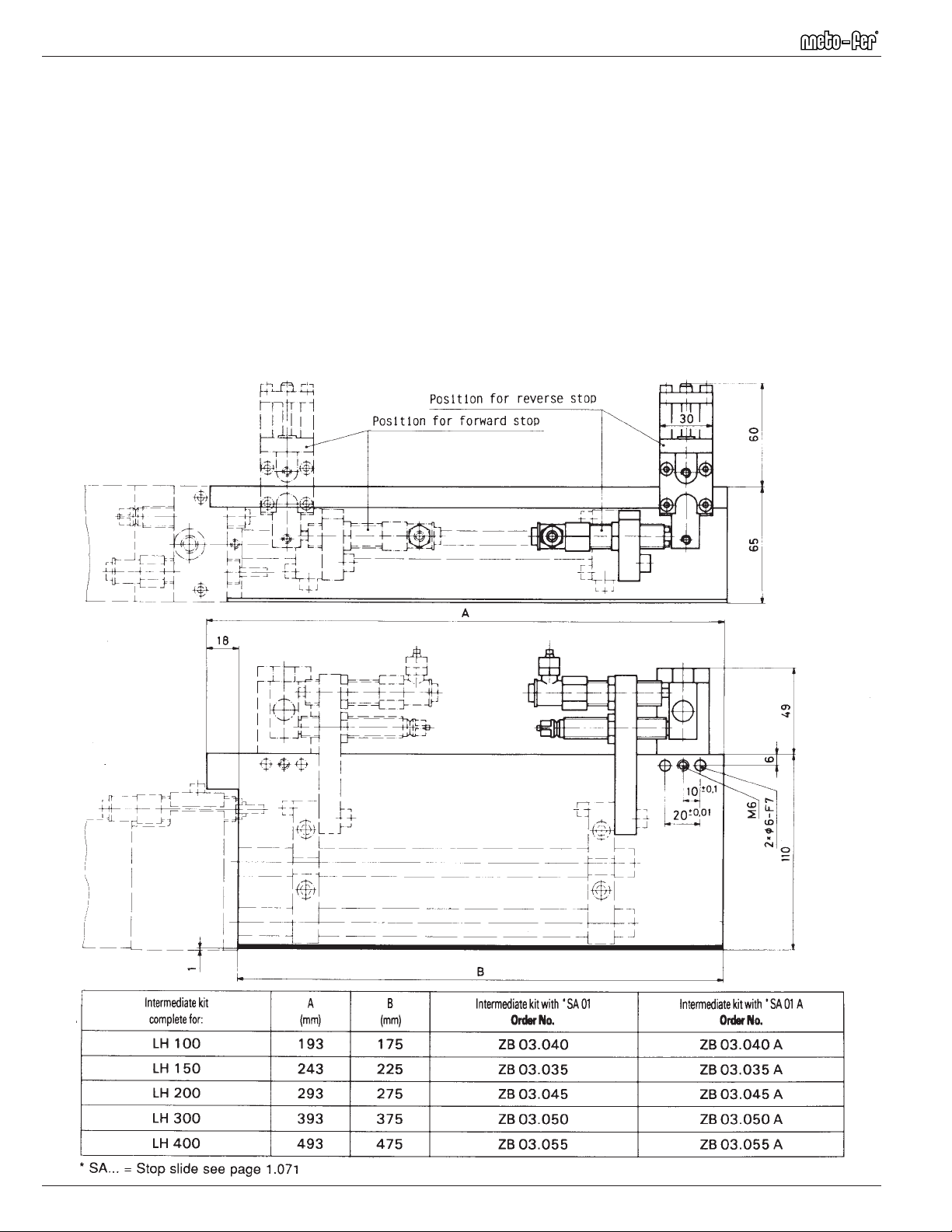

Intermediate position kit for LH

Automation Components of Modular Design

Description:

The intermediate stop operates via a cylinder introducing a robust

stop slide into the path of the horizontal units rear adjustable flange

bracket to that is attached the stop screw and oil cushions. This

stop assembly can be reversed to operate in either the forward or

reverse mode. More than on intermediate stop may be fitted, minimum distance between them 30 mm. They must all operate in the

same direction.

The intermediate position can be utilized both in forward or

reverse modes.

Loading...

Loading...