OPERATING MANUAL

®

METO-FER

COMPACT GRIPPER TYPE KZL 12

AUTOMATION AG

SERIES FROM 2-16

KZL 20

KZL 25

KZL 32

KZL 50

1. PRODUCT DESCRIPTION

1.1 Introduction

1.1.1. Utilization

The compact grippers are able to execute grip movements in any position. The

fingers (Pos.5) make a parallel movement. .

1.1.2. Safety Precautions

Before starting to operate the compact gripper KZL (KZL…D), it is

necessary to check that no body parts are within the working range of the element.

The maximum supply pressure of 8 bar must not be surpassed.

1.1.3. Danger Area

Any body parts are to be kept out of the working area (stroke area) of the unit in

order to avoid mangling.

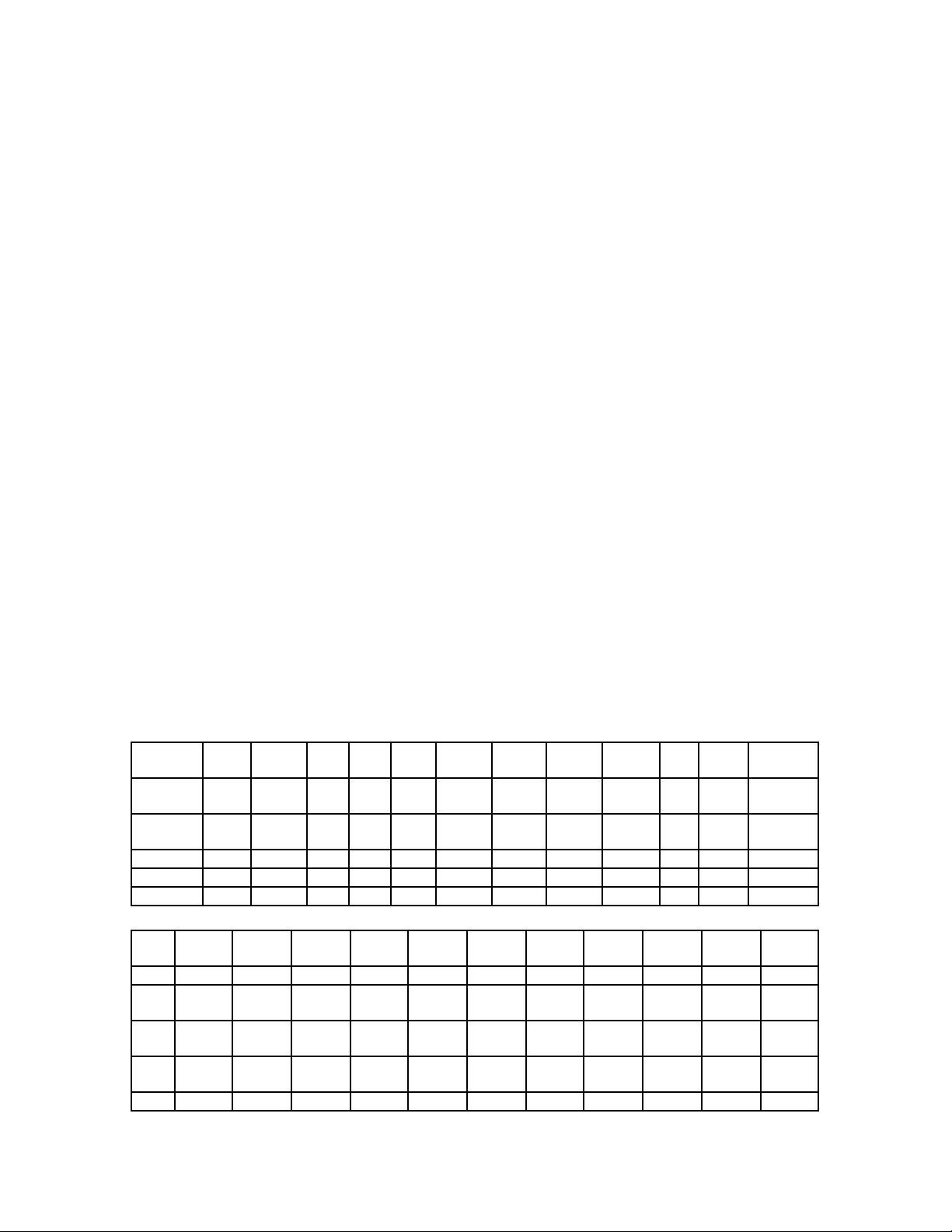

1.2 Technical Data

1.2.1 Weights and Measurements

See also Sheet 5

Type A B C D E F G H

min.Hmax

KZL 12 28 49.5 40 20 4 7.5

7.5

KZL 20 35 55.5 56 24

5.5

KZL 25 40 65.5 60 30 5 4 7 10 20 8 4.5 10-H7

KZL 32 60 87.5 90 40 10 8 8 15 31 10 5.5 12-H7

KZL 50 70 102.0 107 50 10 16 16 20 40 11 6.6 15-H7

M N O P Q R S min S

17 5.5 M4/8 1.2 3.2 10 28 35 M3 25 20 6.2

21 5.5 M4/1

2

26 5.2 M5/1

5

28 14 M6/1

5

40 132 M8/1 2.5 6.2 25 70 90 M6 50 39 6.2

1.5 4.2 13 35.5 43.5 M4 25 19.5 8

1.5 4.2 15 40 50 M5 30 22.5 8

2.5 5.2 22.5 60 76 M6 35 26.5 6.2

3 6 9.5

8 15 6 3.5 6-H7

17.5

T U V W

max

JK L

8 4.5 8-H7

1

273

OPERATING MANUAL (KZL)

Type Dimension for Air Connection Weight

Lb.(kg)

A1 B1 C1 D1

KZL 12 18.25 9.75 14.5 6 0.3 (0.15)

KZL 20 23.50 11.5 17.5 6 0.4 (0.20)

KZL 25 26 14 19.5 5 0.8 (0.35)

KZL 32 30 30 34 8 2.1 (0.95)

KZL 50 35 35 33 8 3.3 (1.50)

1.2.2. Performance Characteristics

Type Clamping force at 72.5PSI (5 Bar)Air consumption for each double stroke at 72.5

PSI (5 Bar)

KZL 12 7 lb. ( 31 N) .0002 scf (0.004 NL)

KZL 20 20 lb. ( 88 N) .0005 scf (0.014 NL)

KZL 25 31 lb. ( 137 N) .0010 scf (0.027 NL)

KZL 32 51 lb. ( 225 N) .0025 scf (0.072 NL)

KZL 50 124 lb. ( 550 N) .0079 scf (0.224 NL)

1.2.3 Operating Source

40mm filtered, unoiled or oiled air (dew point 6oC)

Operating pressure P

1.2.4 Connections

Air connections M5 (see sheet 6)

1.2.5 Environment

Temperature 50

Relative humidity 95% (without condensation of water)

Purity of the environment air regular working place atmosphere

NL: Normal Liter

3 bar

min

P

o

F to 122oF (+ 10oC to + 50oC)

max

8 bar

OPERATING MANUAL (KZL)

1.3 Features

1.3.1 Standard Features

The compact gripper KZL (KZL…D) includes a sensor bracket for checking the

end position. It is possible to add this sensor bracket later on by ordering

KZL…Q. The inductive proximity sensors are not included.

1.3.2 Special Equipment

The compact grippers KZL (KZL…D) can be equipped with proximity switches

(see Meto-Fer® Electronic Catalog Page 15) so you will be able to check open

and closed positions.

Gripper Inductive Proximity Switches

KZL 12 D IM-004-…-…

KZL 20 D IM-004-…-…

KZL 25 D IM-004-…-…

KZL 32 D IM-006-…-…

KZL 50 D IM-006-…-…

2. SAFETY REGULATIONS

2.1 In general

See chapters 1.1.1

1.1.2

1.1.3

2.2 Specifically

Do not make any changes or modifications to the unit (voids warranty).

3. CONSTRUCTION AND FUNCTION

To check the end position, the compact gripper can be equipped with inductive

proximity switches. The stroke (clamp) cannot be adjusted.

4

OPERATING MANUAL (KZL)

4. INITIAL OPERATION

4.1 Compressed Air

Remove the safety caps from the air connections. In order to regulate the velocity

of the movement, we recommend our flow controls DV-M5 (see sheet 5.021).

5. MAINTENANCE

5.1 Introduction

The compact gripper unit does not require any special maintenance procedure

Never use any type of solvents in order to clean the unit.

5.2 Air Supply

The mini linear unit is equipped with oil-free seals and can be operated with dry

and non-oiled compressed air. If oiled compressed air is used, we recommend:

- Airpress compound SAE 5 (Klueber Order No. 063027)

6. REPAIR

6.1 Introduction

If the unit no longer meets the requirements (leakage, wear, etc.) the

defective parts must be replaced.

6.2 Safety Precautions

Before dismounting the unit, it is necessary to check that the compressed air

supply is turned off. It is best to disconnect the compressed air supply from the

unit.

When repair work is done, only the original spare parts and lubrication must be

used.

5

OPERATING MANUAL (KZL)

6.3 Replacing the Seals

- Remove the housing (Pos.1) by loosening the screws (Pos.206).

- Loosen the screw (Pos.207) and extract the piston (Pos.2).

- Replace the O-Rings (Pos.201 and 202) and the piston seal (Pos.203).

- Grease the cylinder bore and piston rod. (See Chapter 7.2.)

- The parts are then assembled in reverse order as above described.

7. SPARE PARTS LIST

7.1 Spare Parts

When ordering spare parts, the type and serial number of the unit must be

supplied.

Seal Kit Order Number 460.100.0302

Type Position Order

Description Quantity

Number

201 025.100.0320 O-Ring 1 Piece

KZL 12 202 025.100.0160 O-Ring 1 Piece

203 025.150.0500 Piston Seal 1 Piece

Seal Kit Order Number 460.100.0304

Type Position Order

Description Quantity

Number

201 025.100.0520 O-Ring 1 Piece

KZL 20 202 025.100.0230 O-Ring 1 Piece

203 025.150.0550 Piston Seal 1 Piece

Seal Kit Order Number 460.100.0306

Type Position Order

Description Quantity

Number

201 025.100.0580 O-Ring 1 Piece

KZL 25 202 025.100.0270 O-Ring 1 Piece

6

203 025.150.0600 Piston Seal 1 Piece

7

OPERATING MANUAL (KZL)

Seal Kit Order Number 460.100.0308

Type Position Order

Description Quantity

Number

201 025.100.0660 O-Ring 1 Piece

KZL 32 202 025.100.0310 O-Ring 1 Piece

203 025.150.0650 Piston Seal 1 Piece

Seal Kit Order Number 460.100.0309

Type Position Order

Description Quantity

Number

201 025.100.0795 O-Ring 1 Piece

KZL 50 202 025.100.0420 O-Ring 1 Piece

204 025.150.0700 Piston Seal 1 Piece

7.2 Lubrication

Grease for seals Staburag NBU 4 Atemp.

(Klueber Order No. 005 040)

8

Loading...

Loading...