Page 1

NEFNEF

CONTROLLED PRESSURE WATER HEATER: DOMESTIC BUILDING

CONTROLLED

PRESSURE

WATER HEATER

- Valve fitted at the Heater -

Cold Water Outlets

Mains

Supply

(1) Pressure

Limiting Valve

(2) Pressure

Limiting Valve

Line

Strainer

Non Return

Isolating

Valve

Inlet Control Valves

Expansion

Control Valve

Tempering Valve

Tempered Water (50°C Maximum to Bathroom)

Hot Water (60°C Minimum to Kitchen & Laundry)

In a domestic installation it is recommended that one Nefa pressure-limiting valve is used at the property boundary (1) to limit

pressure to the whole

site.

Where there is no Pressure Limiting Valve controlling the whole installation (1), it is recommended that the cold supply to the water

heater & tempering valve be controlled by a Nefa Pressure Limiting Valve (2)

Flush line thoroughly before fitting.

Pressure &

Temperature

Relief Valve

Fig 4

CONTROLLED PRESSURE WATER HEATER: DOMESTIC BUILDING

CONTROLLED

PRESSURE

WATER HEATER

Pressure

Limiting Valve

Line

Strainer

Non Return

Isolating

Valve

Line

Strainer

In a domestic installation it is recommended that one Nefa pressurelimiting valve is used at the property boundary to limit pressure to the

whole site. Where there is no Pressure Limiting Valve controlling the

whole installation (1), it is recommended that the cold supply to the

tempering valvebe controlledby a PressureLimiting Valve(2) ofthe same

pressure setting as the valve supplying the water heater. Flush line

thoroughly beforefitting.

- Valve fitted remotely from the Heater -

Expansion

Control Valve

Tempering Valve

(2) Pressure

Limiting Valve

Mains

Supply

(1) Pressure

Limiting Valve

Cold Water Outlets

Hot Water

(60°C Minimum to

Kitchen & Laundry)

Tempered Water

(50°C Maximum

to Bathroom)

Inlet Control Valves

Pressure &

Temperature

Relief

Valve

Fig 5

Pressure

Limiting Valve

HEAT EXCHANGE WATER HEATER: DOMESTIC BUILDING

Tempered Water

(50°C Maximum

to Bathroom)

Pressure Expansion

&

Non Return

Valve

Line

Strainer

Mains

Supply

Cold Water Outlets

Non Return

Isolating Valve

Hot Water

(60°C Minimum to

Kitchen & Laundry)

Tempering Valve

Schematic shows valve fitted at the heater. It is possible to mount the valve remote from the heater.

Flush line thoroughly before fitting.

HEAT

EXCHANGE

WATER HEATER

Fig 6

PUMPED SUPPLIES, MULTIPLE VALVES: COMMERCIAL BUILDING

It is recommended that Pressure Limiting Valves are installed for each valve to ensure any pressure fluctuations

from the pumped supply or other source are minimised prior to supplying water to the tempering valves.

There MUST be non-return valves fitted to BOTH hot and cold inlets for this type of installation.

Easily accessed, fully serviceable strainers (in addition to the strainers supplied with the Tempering Valve)

should be installed on each floor or circuit.

Flush line thoroughly before fitting

Pumped

Cold Supply

50°C Maximum to Room 1

Tempered Water Tempered Water Tempered Water

Strainer

P

umped

Hot Supply

Hot Return

50°C Maximum to Room 2

Strainer

50°C Maximum to Room 3

Fig 8

557$ 557$

/0/3&563/

7"-7&

'*-5&3

4&"-03*/(

'JH

4&"-8"4)&3

'*-5&3/0/3&563/

"44&.#-:*/6/*0/

A NEW INSTA NEW INST

NEF

A NEW INST

NEFNEF

A NEW INSTA NEW INST

WARRANTY RETURN FORMWARRANTY RETURN FORM

WARRANTY RETURN FORM

WARRANTY RETURN FORMWARRANTY RETURN FORM

ALLAALLA

ALLA

ALLAALLA

TION ANDTION AND

TION AND

TION ANDTION AND

THIS FORM MUST BE FILLED OUT IN FULL AND RETURNED TO NEFA WITH THE

FAULTY VALVE OR YOUR CLAIM WILL NOT BE PROCESSED.

Identify Problem (Please Tick)

R Valve leaks R Water hammer R Noisy valves R Valve failed

R Insufficient water flow (measure flow of valve litres/minute)

R Pressure Limiting Valve is not limiting pressure (state outlet pressure kPa)

○○○○○

○○○

R Tempering Valve does not regulate temperature between 40°C and 50°C.

R Tempering Valve does not limit temperature to 50°C.

Further Details

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Was faulty valve replaced?

Did this fix the problem? R Yes R No

Commissioning sticker details:

Installation date: ___ / _____ / 20 ____

Commissioned temp: ____________ °C

R Yes R No If yes: Brand

Model

○○○○○○○○○○○○

○○○○○○○○○○○○

Date checked: ___________ Temp: ______ °C

Date checked: ___________ Temp: ______ °C

Date checked: ___________ Temp: ______ °C

Date checked: ___________ Temp: ______ °C

Date checked: ___________ Temp: ______ °C

Warranty Statement

The following warranty statement shall apply to all NEFA valve products supplied by NEFA Australia.

Where NEFA valves are installed in a suitable, commercial or domestic application, in addition to any other right or

remedy which the purchaser or end user may have under any relevant consumer protection legislation, Methven

Australia, or any of its subsidiaries, undertake to replace any NEFA brand valve deemed to be faulty by a licensed

plumber.

Further, if any NEFA valve submitted for warranty is found to contain a material defect which arose in the course

of manufacture or does not satisfy the relevant Australian Standards and/or New Zealand Standards product

requirements upon testing, the claimant (licensed plumber) will be reimbursed $50 (See Note 1.)

These undertakings will only apply if:

1. The product was installed by a licensed plumber

2. The warranty claim form is completed in its entirety

3. The product was installed as described in the installation instructions supplied with every NEFA product

4. The product is installed in accordance with the relevant Australian Standards and Plumbing Codes

5. The product was installed as described within the limits of the product specifications supplied with every NEFA product

6. The product has not been tampered with or repaired in any way

7. The product has not been damaged by misuse, accident or neglect

8. The product does not contain excessive debris

9. The product is installed in the specific Country where the original purchase was made

10. The product is submitted to NEFA Australia within 5 years from the date of manufacture.

(See Note 2)

TEMPERINGTEMPERING

TEMPERING

TEMPERINGTEMPERING

VV

ALAL

AL

ALAL

VEVE

VE

VEVE

V

VV

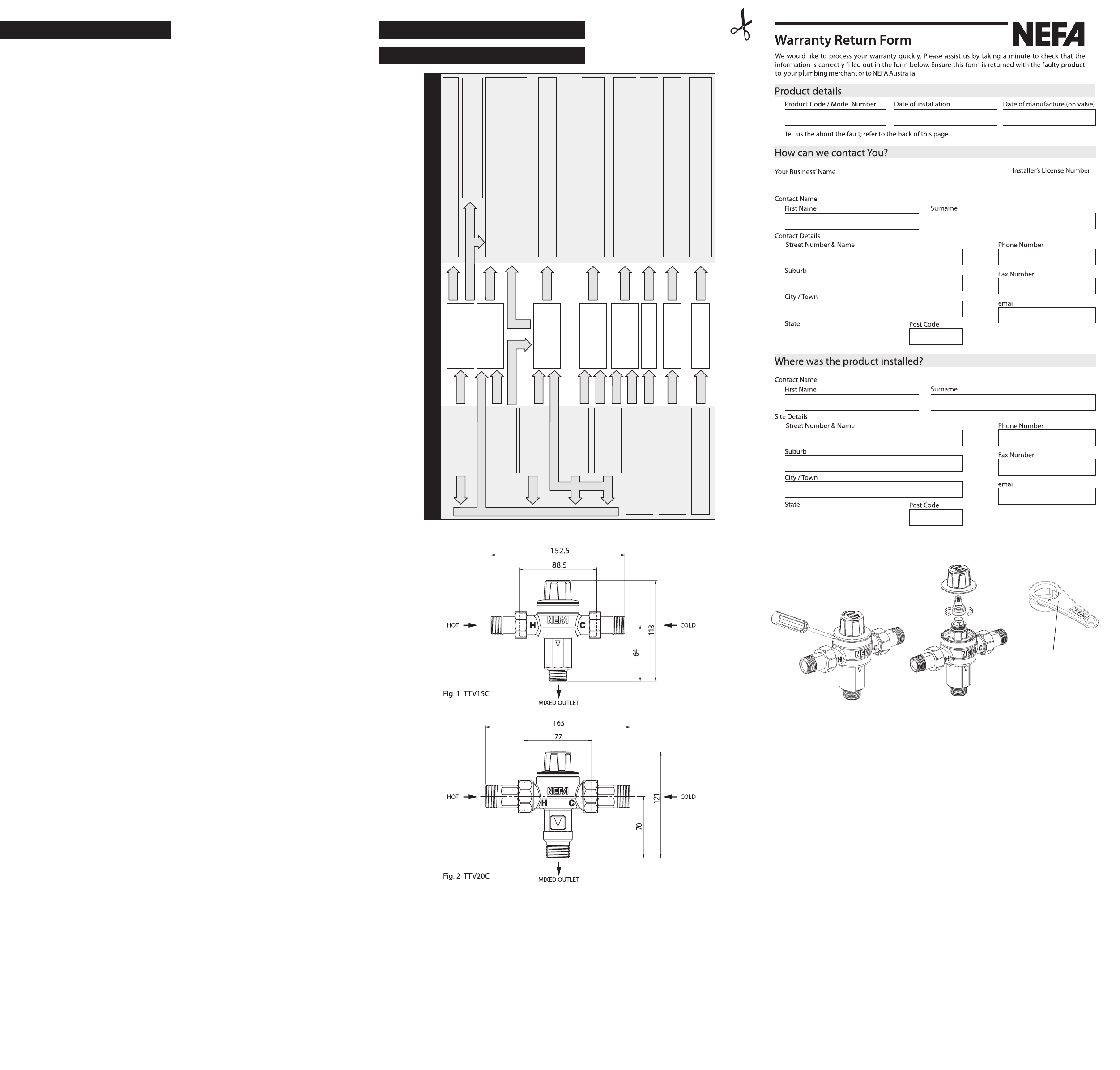

TTV15C

Note 1. Upon submitting a NEFA valve to NEFA Australia for warranty claim purposes, the valve will be tested by

Methven Ltd in accordance with the relevant AS/NZS product standard. If the valve does not meet the requirements

of the product standard, the claimant (licensed plumber) will be reimbursed to a maximum of $50 (incl. GST).

Note 2 The date of manufacture is marked on the valve, represented by a five digit number. The first two digits of

the date of manufacture refer to the last two digits of the year of manufacture. The remaining three digits refer to

the numerical day of the year in which the valve was manufactured (example: 30th June 2007 would be

represented as 07181).

Methven shall in no way be liable to the purchaser or end user of any NEFA valves for any loss, damage (direct,

indirect or consequential), cost or expense suffered or incurred by that person (including, without limitation, any

damage and/or labour charges incurred in installation, repair or replacement), other than as provided in the above

provisions, under any relevant consumer protection legislation or as consented to by Methven in writing in

advance.

CUSTOMER SERVICECUSTOMER SERVICE

CUSTOMER SERVICE

CUSTOMER SERVICECUSTOMER SERVICE

AUSTRALIA

Phone 1300 638 483

Website: www.nefa.com.au

CUSTOMER SERVICECUSTOMER SERVICE

CUSTOMER SERVICE

CUSTOMER SERVICECUSTOMER SERVICE

NEW ZEALAND

Phone 0800 804 222

Website: www.methven.com

Designed, distributed and warranted

by Methven Limited,

Private Bag 19996, Avondale, Auckland, NZ.

285019 Issue E

• Provides accurate safe controlled

temperature water for sanitaty

outlets.

• Hot water shut-off on cold water

supply failure.

• Tamper-proof adjustment.

• Advanced polymers give greater

resistance to calcium deposits.

• Union connections for easy

installation with integral Line

Strainers and Non- Return valves.

• Integral Non Return Valves.

• WaterMark certified.

• Conforms to AS4032.2

TTV20C

WMKA02729

AS4032.2

www.nefa.com.au

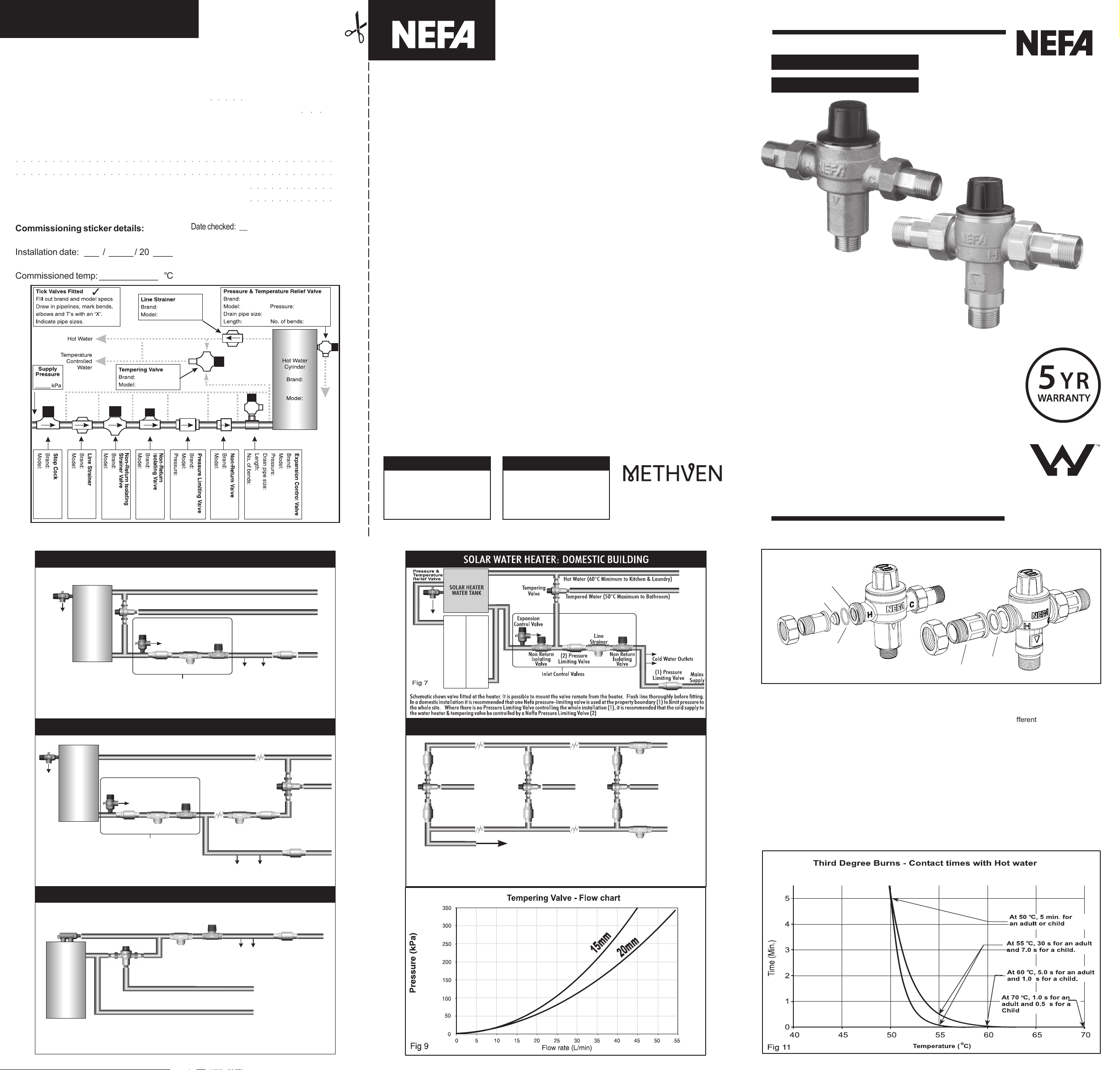

(IMPORTANT) Scalds From Hot Water

The following aims to provide information on the risk of Hot water scalds at different water temperatures

and contact time.

The seriousness of a hot water scald burn is directly dependent on the temperature of the liquid and the

length of contact time.

Medical research has demonstrated that there is a significant difference in the time that it takes to get a

serious, third degree scald at different temperatures. A third degree burn is one that goes through the full

thickness of skin and is likely to require surgery.

For water temperatures less than 50ºC, there is a substantial safe contact time before third degree burns

occur. At 50ºC the safe contact time for an adult and a child is 5 minutes. At higher temperatures, the safe

contact time particularly for children and the elderly, is substantially reduced as shown in (Figure 10.) below.

Children and elderly people are more likely to suffer injury than other age groups because their skin tends

to be softer, they are also more susceptible to falls and are less likely to be able to protect themselves.

Extract from AS 4032.2

Page 2

No flow from outlet

Fluctuating or Low

flow rate

Outlet temperature

changes over time

Unstable outlet

temperature

Outlet temperature

not adjustable

Hot or Cold supply from outlet only

Hot or Cold water leaking through

to other supply

Noise

Hot or Cold supply

pressure failure

Line strainers blocked

Fluctuating or incorrect

supply pressures

Hot water supply

temperature fluctuating

or set too low

Valve inlets reversed

Valve incorrectly set

Non-return valves fouled

High water velocity

See AS3500.1

Restore inlet supply pressures and check outlet

Remove valve and inlet connections. Inspect for

blockages and flush if necessary

Remove and clean strainers. If strainers continue to block

additional Nefa line strainers should be fitted to the system

Fit Nefa pressure limiting valves to Hot and Cold supplies

Adjust hot water supply temperature if necessary

See notes 1 and 3. Valve specifications

Re-fit the valve to the correct inlet connections

Re-adjust outlet temperature as required

Re-adjust outlet temperature as required

Clean non-return valves and flush debris from valve

Reduce water velocity.

Achieved via fitting Nefa pressure limiting valves

What is wrong!

Causes How to fix it

SPECIFICASPECIFICA

SPECIFICA

SPECIFICASPECIFICA

TIONSTIONS

TIONS

TIONSTIONS

TROUBLESHOOTING FORTROUBLESHOOTING FOR

TROUBLESHOOTING FORTROUBLESHOOTING FOR

TROUBLESHOOTING FOR

TROUBLESHOOTING FOR

TROUBLESHOOTING FORTROUBLESHOOTING FOR

TROUBLESHOOTING FORTROUBLESHOOTING FOR

• Connections TTV15C 15mm (½" BSP) Male compression

TTV20C 20mm (¾" BSP) Male compression

• Recommended Outlet Temperature range: 40°C - 50°C

• Factory setting: 50°C nominal

(Must be commissioned on site)

• Accuracy of mixed outlet temperature: ±3° - Tested to AS 4032.2

• Cold water supply: 5°C -25°C

• Hot water supply:

TTV15C & TTV20C: (Gas & Electric Storage) 55°C - 90°C

TTV15CHP & TTV20CHP: (Solar Installations) 55°C - 99°C

• Hot water / mixed water temperature differential: 15°C minimum.

• Supply Pressure - Static: 1600kPa maximum

• Supply Pressure - Dynamic: 500kPa maximum

• Maximum permitted pressure variation at inlets: ±10% maximum

(From supply pressure at commissioning)

• Pressure supply differential - Dynamic: 3:1 maximum

(At time of commissioning)

• Minimum flow rate:

For solar installations and applications where fluctuating supply pressures may occur such as

instantaneous water heaters Nefa recommend the installation of a High Performance Tempering Valve.

4 Litres/min

2

1,3

1,3

3

5,6

4

Notes:

1. The minimum hot water storage temperature stated in AS3500.4 Clause1.9 shall

be not less than 60°C to inhibit the growth of legionella bacteria.

NEFNEF

NEF

NEFNEF

A HOA HO

A HO

A HOA HO

T WT W

T W

T WT W

AA

TER SYSTEMSTER SYSTEMS

A

TER SYSTEMS

AA

TER SYSTEMSTER SYSTEMS

2. The valve can be set as low as 35°C or as high as 58°C, depending on site conditions.

These temperatures are outside the optimum working range of the valve and the

requirements of AS 4032.2 and AS3500.

3. This is the minimum temperature differential required between the Hot inlet water

temperature and the Mixed outlet of the valve, to achieve outlet isolation in

accordance with AS 4032.2 in the event of cold water supply failure, providing the

valve is set between the specified adjustable temperature range 40°C to 50°C.

4. The maximum ratio permitted between supply pressures, under dynamic flow

operation. It is recommended at time of commissioning that Hot and Cold pressures

be as equal as possible.

5. The maximum permitted pressure variation in either supply from commissioning

pressures in order to maintain the outlet temperature to ±3°.

6. Note: Steps should be taken to eliminate any causes of rapid changes in supply

pressures, as this may result in an outlet temperature spike greater than ±3° from

commissioned temperature. If a spike occurs it may take a few seconds for the

temperature to stabilize back to within ±3°.

Checks

• Be sure to check site installation parameters (Temperature, Pressure etc.) against the working

specifications of the valve. If these parameters are outside of the stated specifications, they must

be rectified prior to installation.

• Never expose valves to a torch flame or heat. Heat will destroy the seals and sealing parts.

• Never expose valves to freezing conditions. If installed where freezing conditions may occur,

then suitable insulation must be used to prevent damage to the valve.

• Not to be used on Steam supplied systems.

• Not to be used on low–pressure systems.

• The use of excess thread sealant (liquid, tape or any other form) must be avoided as this may

cause the valve to fail.

• A copy of these instructions should be left with the householder for future reference.

The Installation details sticker, should be completed by the installer and attached to the water

heater or other prominent position near the valve or as specified by the local Authority

requirements.

Valve Adjustment

Adjusting tool is marked

to indicate direction for

Hot & Cold temperature

adjustment.

Fig. 3

Operation

• The NEFA Tempering valve is designed to accurately provide safe controlled temperature water

• The Tempering valve will effectively mix to 50

• If the cold water supply to the valve fails then the valve will automatically shut off the hot water

• For installations outside the requirements of AS 4032.2 and AS/NZS 3500.4, the valve can be set

• Strainers are integral to prevent debris entering the Tempering valve that could prevent it working

• Non return valves (NRV’s) are integral to prevent cross feeding of unbalanced supply pressures.

• All working components and critical shut-off faces of the Tempering valve are manufactured from

for outlets primarily used for personal hygiene. The Tempering valve will maintain the outlet

mixed temperature to ± 3

NB: AS/NZS 3500.4 requires hot water to be stored at 60

growth.

supply preventing scalding. 15

set temperature is required to ensure effective hot water shut off in accordance with AS 4032.2.

°C - 58°C. This will depend on site conditions.

to 35

effectively. Installations with poor quality water that could cause the strainers to continually block

should have separate line strainers fitted.

These NRV’s are crucial for the complete hot water system to function effectively and MUST be

fitted to both inlets.

high spec engineering polymers to resist scale build-up. Deposits to similar metal components

would cause them to seize preventing effective and safe operation.

°C from set temperature in accordance with AS 4032.2.

°C when supplied with 55°C hot water.

°C minimum to inhibit legionella bacteria

°C differential between the hot inlet water temperature and outlet

Systems supply pressures.

• Optimum performance of the valve is obtained when Hot and Cold dynamic (flowing) supply

pressures are equal.

• Static supply pressures (non-flowing) will not give a true indication of dynamic pressures.

• In commercial installations it is recommend that separate Nefa pressure-limiting valves be fitted

to both inlets of the Nefa tempering valve for optimum performance.

• In a domestic installation it is recommended that one Nefa pressure-limiting valve is used at the

property boundary to limit pressure to the whole site.

• It is recommended that both Hot and Cold supplies to the valve should be controlled with their

own pressure limiting valves.

Installation

• NEFA Valves shall always be installed by a licensed plumber, in accordance with the NEFA installation

instructions, and the National Plumbing and Drainage Code AS/NZS 3500.4. The installation must also

comply with any Local Authority requirements.

• Before fitting a Tempering valve ensure all debris is thoroughly flushed from the pipe-work prior to

installing. Contaminants and debris are the most common causes of system difficulties.

• A separate un-tempered hot water line to the kitchen and laundry is recommended.

• Do not install a Tempering valve directly onto a hot water cylinder. It is recommended that the valve be

installed as close to the Hot water source as possible for optimum performance.

• The Tempering valve shall be installed where it can be easily accessed for strainer checking and

cleaning, or temperature adjustment.

• The valve must be installed in accordance with the installation diagrams shown in (Figs.4-8).

• If installed at an outlet fixture, 1m of pipe must be installed between the Tempering valve and the outlet.

• Ensure both hot and cold water supplies are connected to the correct sides of the Tempering valve as

marked on the valve body.

Once, installed, EVERY valve must be commissioned by adjusting the valve and measuring the mixed

water temperature at the outlet closest to the Tempering valve. A thermometer must be used.

• Before setting the valve ensure the hot water source is switched on and supplying water within

the specified hot water temperature limits. It is recommended the water heater, if controlled by an

adjustable thermostat should be set to the required 15

thermal shut-off. (See Note.3 of valve specifications).

• Allow the water to flow 1-2 minutes to ensure the mixed water temperature has stabilized.

• A thermometer must be used to test the hot water at the nearest outlet to the installed valve to

ensure the correct mixed water temperature is supplied. Test at a flow rate of not less than 4

litres/minute.

• To adjust the set temperature of the valve you must remove the cap allowing access to the

adjusting spindle.

• Using the adjusting tool supplied, simply rotate the spindle shown in (fig.3) in the direction (H)

hot or (C) Cold as indicated on the tool until the required set temperature is achieved.

• Once the set temperature has been reached and tested with a thermometer the cap must be

snapped back onto the valve to protect the spindle from accidental adjustment, damage or

debris.

° differential temperature necessary for

Servicing and checking requirements:

• It is recommended the NEFA tempering valve be checked annually by a certified plumber to

ensure correct functionality of valve. Space has been provided on the commissioning sticker to

record the date & set temperature of the valve.

• Where the water supply is of poor quality or any other supply variations are likely, it maybe

necessary to check the NEFA valve at more frequent intervals.

• Any temperature checks should be performed at the same outlet at which the valve was first

commissioned. (See installation details sticker details). If the temperature varies more than 2

from the commissioned temperature stated on the installation sticker or is outside of the

requirements of AS3500.4, refer to the NEFA Trouble shooting guide.

• Line strainers and non-return valves are easily accessible through the union connectors for

quick cleaning.

• Where the line strainers continue to block it may be necessary to fit an additional filter or line

strainer into the system.

• This valve is a safety valve and cannot be serviced. If the valve fails to operate it is to be

replaced. No attempt should be made to dismantle the valve. Any attempt to dismantle the valve

(other than union connectors and adjustment cap) will void all warranties.

°C

Loading...

Loading...