Page 1

TESTING METHOD -

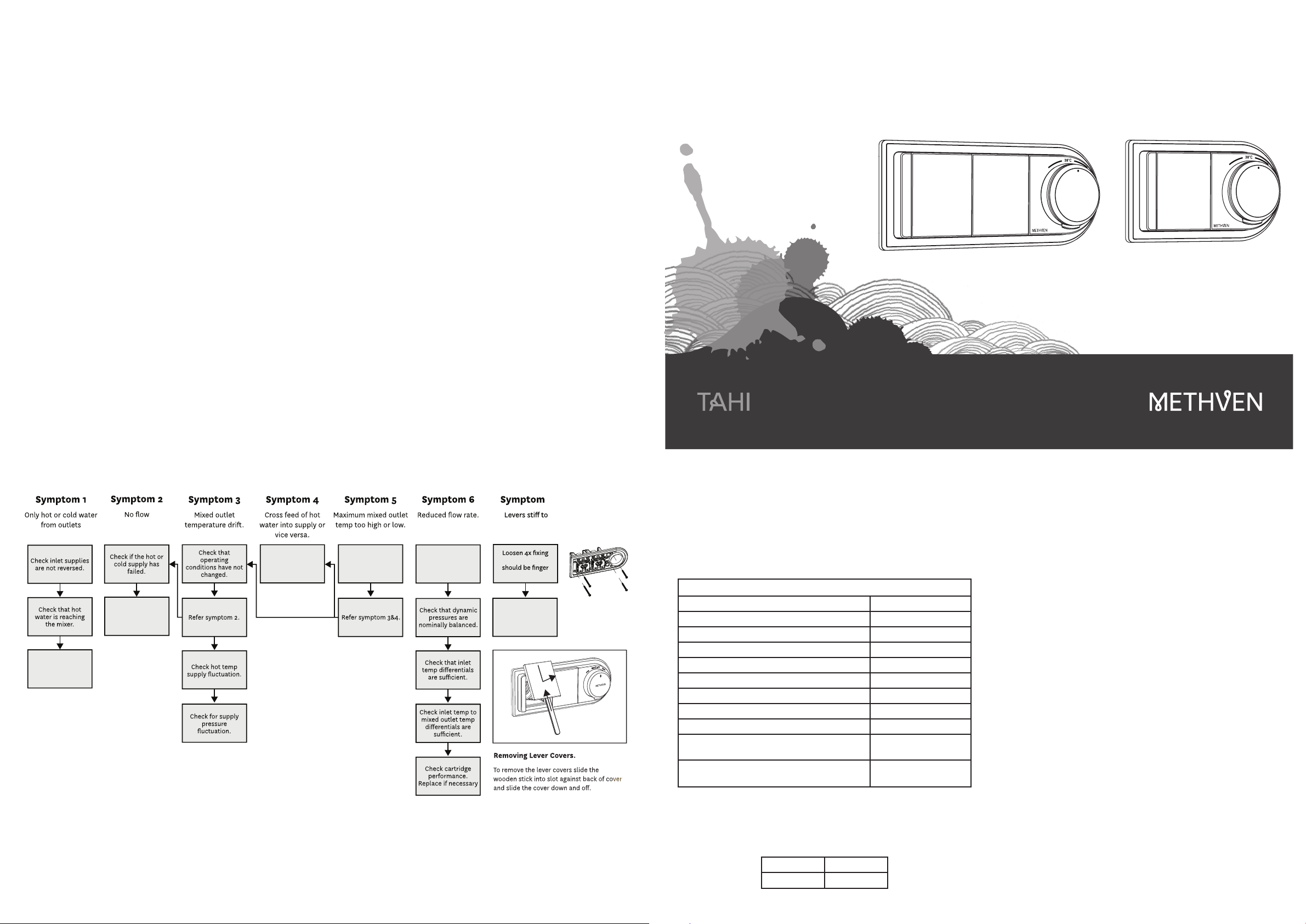

Check non-return

valve function.

Check strainers

around cartridge for

blockage.

Check non-return

valve function.

Check limit

settings (Refer

commissioning).

Check Strainer

around cartridge for

blockage.

7

operate.

screws (A). Screws

tight only

Check installation

depth is within

manufacturers stated

limits (refer step 1)

A.

The valve should be tested to ensure correct operation at

commissioning and thereafter at intervals no greater than 12

months.

Notes:

The testing will only require a normal thermometer with a ●

scale greater than 65°C. The temperature sensitive element of

the thermometer should always be fully inserted into the water

flow.

Temperature readings should be taken at the normal flow rate ●

after allowing for the system to stabilise.

If the Tahi thermostatic mixing valve has been adjusted ●

or serviced it must be re-commissioned and re-tested in

accordance with these instructions.

When commissioning/testing is due the following

performance checks shall be carried out:

Measure the mixed water temperature and record. 1.

The testing will only require a normal thermometer with a 2.

scale greater than 65°C. The temperature sensitive element of

the thermometer should always be fully inserted into the water

flow.

Notes:

If there is no significant change to the set outlet temperature ●

(±2°C or less change from the original settings) and the failsafe shut off is functioning, then the valve is working correctly

and no further service work is required.

If the outlet temperature has drifted by more than 2°C, or ●

if the fail/safe function does not work, a full service or recommissioning is required.

If there is a residual flow during the commissioning or the ●

annual verification (cold water supply isolation test), then this

is acceptable providing the temperature of the water seeping

from the valve is no more than 2°C above the designated

maximum mixed water outlet temperature setting of the valve.

Temperature readings should be taken at the normal flow rate ●

after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully ●

submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be ●

re-commissioned and re-tested in accordance with the

manufacturers’ instructions.

Water Supply (Water Fittings) Regulations 1999

TAHI THERMOSTATIC MIXER VALVE (1 and 2 outlets)

INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR

COMPLIANCE TO THE TMV2 SCHEME

Carry out a cold fail/safe shut-off test by using the isolation 3.

valve to shut off the water to the cold supply.

This valve complies with the requirements of the above Regulations

and installation should be carried out in strict compliance with

them.

Wait 5 seconds, if water is still flowing check that the water 4.

temperature is below 46°C. The flow should stop or reduce to

a trickle.

Open cold water isolation valve and measure mixed water 5.

temperature.

FAULT FINDING FLOWCHART

Methven warrants this product against manufacturing defects and that it is suitable for use under the operating conditions specified in this

instruction sheet.

For your warranty please refer to www.methven.com or call Customer Service

New Zealand

0800 804 222

Australia

1300 638 483

0800 195 1602

UK

OPERATING CONDITIONS OF USE -

Before installation the operating conditions of use must be checked. Table

1 contains details of the necessary conditions of operation. If your water

supply cannot meet these conditions then the valve cannot be guaranteed to

operate as a Type 2 valve. This valve is suitable for use in HP (BS 1111) operating

conditions.

Operating pressures above 5.0 Bar will require the installation of a pressure

reducing valve.

Operating Conditions of Use

BS1111

Maximum Static Pressure 10 bar

Flow pressure (Hot & Cold) 0.5 bar – 5 bar*

Hot Supply Temperature 55 - 65 °C

Optimum Hot Supply Temperature 60 - 65 °C

Cold Water Supply Temperature 5 – 25 °C

Pressure Designation of Use HP* S/BT

Maximum Allowable Outlet Temperature 46 °C

Installation Type Concealed

Max Dynamic Pressure Ratio

(Hot to Cold OR Cold to Hot)

Minimum Temperature Differential Between Either

Supply and Outlet Temperature

Table 1. Operating Conditions of use

* If a water supply is fed by gravity then the supply pressure should be verified

to ensure the conditions of use are appropriate for the valve.

3.5 : 1

12 °C

RECOMMENDED OUTLET TEMPERATURES -

Bath Fill 44 °C **

Shower 41 °C

Issue A435027

The mixed water temperature at the terminal fitting must never exceed ●

46 °C

The maximum mixed water temperature can be 2°C above the ●

recommended maximum set outlet temperatures.

** 46°C is the maximum mixed water temperature from the bath tap. The

maximum temperature takes account of the allowable temperature tolerances

inherent in thermostatic mixing valves and temperature losses in metal baths.

It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5°C as a comfortable

bathing temperature for children. In premises covered by the Care Standards

Act 2000, the maximum mixed water outlet temperature is 43°C.

TAHI THERMOSTATIC MIXER VALVE INSTALLATION -

The Tahi thermostatic mixer valve is precision engineered and will give ●

continuous safe and controlled performance providing it is installed,

commissioned and maintained according to the instructions contained in

this document.

The valve must be so installed that it is readily accessible for ●

commissioning and maintenance when being installed in accordance with

TMV2.

The valve is fitted with integral “listed” single check valve cartridges ●

which command the water supply; therefore the thermostatic valve is

protected against cross-flow due to unbalanced line pressures as required

by the Water Supply (Water Fittings) Regulations 1999.

The valve must be installed with isolation valves on both the hot and cold ●

water supplies as close as possible to the valve; so as to allow the valve to

be commissioned and tested correctly.

The fitting of strainers is recommended as close as is practicable to the ●

water supply inlets of the thermostatic mixing valve. (Recommended

maximum mesh aperture of 0.02”).

Page 2

1

MOUNT MIXER BODY IN WALL CAVITY

Wall lining

VERTICAL

5

PARALLEL

=

=

MOUNT

PARALLEL TO

WALL LINING

=

Wall lining

96-116mm

=

OPTIMUM = 106mm

Rotate temperature A.

stop fully anticlockwise

If temp ≤ 46°CB.

If temp > 46°C

Adjust (see

commissioning)

Maximum temperature stop

8

CHECK MAX OUTLET TEMPERATURE

ASSEMBLE DIAL GUIDE AND DIAL

Dial

guide

Dial

10

FIT DIAL CAP

HOLD DIAL TO STOP

ROTATION WHILST

TIGHTENING.

Insert and tighten A.

screw using

2.5mm Allen

key (finger tight

only) to fix dial

position.

Fit cap (force B.

required)

Tip: Insert dot end

of cap first

NOTE - Use of supply

line or zone strainers is

strongly recomended.

CHECK WATERTIGHTNESS

2

P < 1000 kPa/10 bar

(Test pressure must not

exceed 1000 kPa/10 bar)

FIT WALL LINING AND REMOVE DUST COVER

3

6mm

MAX

6

FIT TRIM COMPONENTS

x 2 (long screws)

NOTE - Levers to be

inserted from bottom

as shown in diagrams

A and B

x 2 (short screws)

A. B.

x 2 (Allen screws)

9

ASSEMBLE HEIGHT ADJUSTOR

Hold dial A.

hard against

faceplate.

Wind depth B.

adjustor into

dial. Stop when

you feel dial

starting to push

away from the

faceplate

NOTE - Locating

feature

Dial

DOWNWARD ORIENTIATION

OF BUTTON CRITICAL

Faceplate

Depth adjustor

Note: Dot orientation on dial

cap is at top (opposite dial

button).

COMMISSIONING -

The Tahi thermostatic mixer valve is factory set to the required temperature.

Check the valve after installation to ensure it operates at the correct outlet

temperature.

Prior to commissioning the Tahi thermostatic mixing valve check the following:

The designation of the thermostatic mixing valve matches the application. ●

The supply pressures are within the valves operating range. ●

The supply temperatures are within the valves operating range. ●

Isolating valves (and strainers preferred) are installed. ●

1

REMOVE MAXIMUM TEMPERATURE STOP

Remove screw.

Do not discard.

Maximum temperature stop

4

6mm MAX

USE PROVIDED

TEMPLATE FOR

ACCURATE HOLE

DIMENSIONS.

TRIM FLUSH AND SEAL WITH SILICON

Wall lining

Tiles

7

SET WATER TEMP TO 38°C

Remove screw. A.

Do not discard.

Rotate clockwise B.

until water temp

= 38°C

If depth adjustor C.

protrudes past

the front face of

the dial; Remove

the depth

adjustor and

trim at midpoint

(cut in half).

Reassemble as

per steps 9: A

and B

Depth Adjustor

Dial

8mm Allen key

Trim

2

3

ADJUST TEMPERATURE TO

DESIRED MAXIMUM.

TEMPERATURE

MUST NOT

EXCEED 46°C

Cartridge control knob

REASSEMBLE MAXIMUM

TEMPERATURE STOP

Assemble with faces

aligned as shown

Note: Do not Rotate

cartridge control knob

while assembling

Maximum temperature

stop

Loading...

Loading...