Page 1

TAHI SATINJET SHOWER SYSTEM

INSTALLATION GUIDE

TECHNICAL SPECIFICATIONS

Operating Pressure:

Min 1.5 bar, Max 5 bar.

If supply exceeds 5 bar, a pressure

limiting valve must be installed.

Operating Temperature:

Max 70°C

Page 2

Page 3

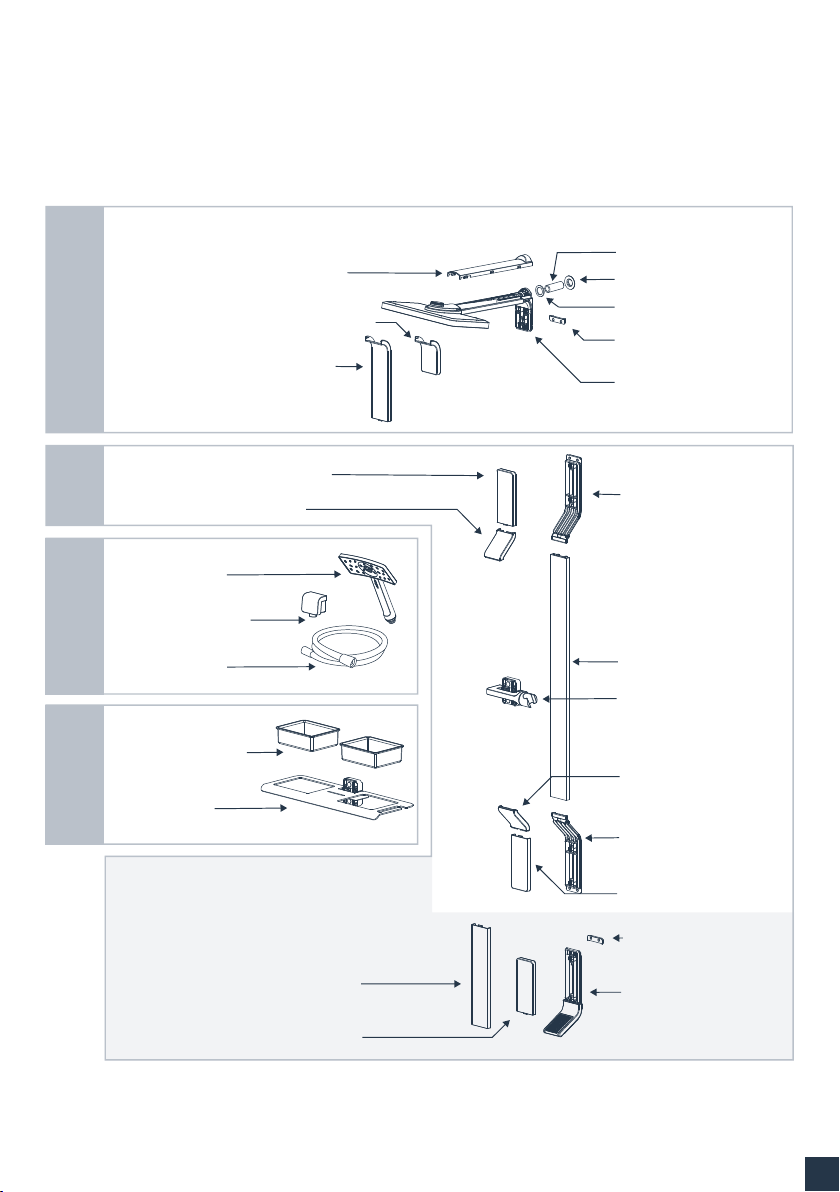

Separate footrest cover

Overhead shower

assembly

Separate overhead

shower spacer

Foam seal

Overhead shower arm cover

Separate overhead shower cover

Rail top bracket cover

Rail top 45° cover

Handset

Hose elbow

Hose

Shelf trays

Shelf

Rail bottom 45° cover

Rail bottom

bracket cover

Attached footrest cover

Rail top bracket

Rail

Rail bottom bracket

Separate footrest

spacer

Footrest assembly

Handset holder

A

B

C

Only included when you

purchase footrest option.

Connection bar

Attached overhead shower

cover (Discard if installing

stand-alone overhead shower)

½" Backnut

Overhead Shower

EXPLODED DIAGRAM

1

Page 4

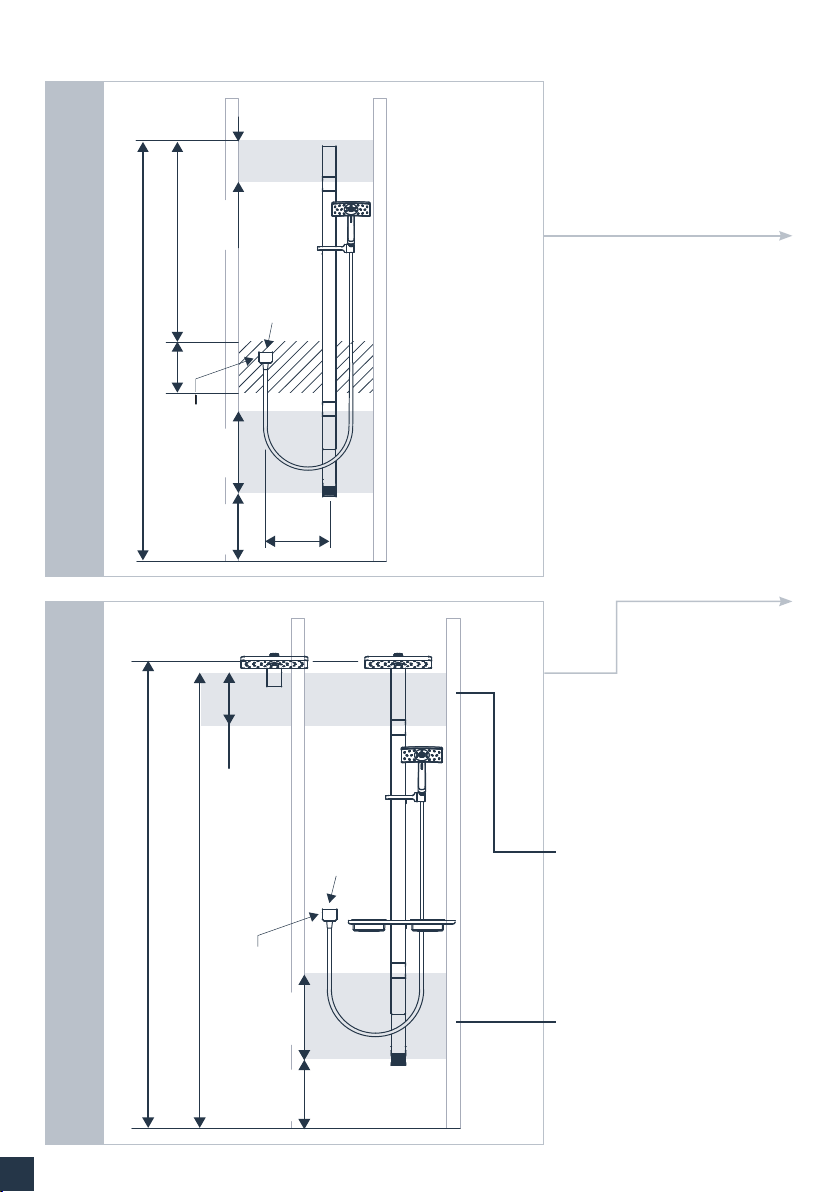

380mm360mm

Hole

Ø25mm

2100mm

Recommended

outlet height

2070mm

240mm

Floor

Elbow height at

installer’s discretion

PRE WALL LINING REQUIREMENTS

Standard Rail

Fastening Zone

-load bearing

support required

Shower Kit

Fastening Zone

-load bearing

support required

Fastening Zone

-load bearing

support required

2020mm

930mm

180mm

180mm

Floor

300mm

Min.

Hole

Ø25mm

380mm360mm

Elbow height at

installer’s discretion

2

Rail ShowerShower System and Overhead Shower

Fastening Zone

– load-bearing

support required

Fastening Zone

– load-bearing

support required

Page 5

1 2 3

(Recommended) 2010mm

Backnut (Supplied)

Connection bar

FLOW

25mm (Max.)

Finished wall lining

ø 25 ±3mm

Elbow outlet 8.5 ±1.5mm

Overhead outlet 16 ±3mm

Deeper precision

bored end

3

Ensure edge is plumb, mark plumb

line to floor and mark screw holes

Set bracket aside, drill clearance

into lining then pre-drill support

Ensure the deeper precision bored end connects to the overhead arm of

shower. This forms a watertight seal with the ‘O’ ring on the shower arm

as per illustration on Page 4. Install backnut and adjust dimension to suit

connection type as shown above. Seal the wall lining with silicone sealant

Seal holes. Drive in screws (and

wall plugs where appropriate). Clip

on covers

Page 6

Go to 12 on page 6

4

4 5 6

Fit foam seal around connection

bar. Insert waterway and loosely

screw nut on to bar

Overhead shower only

Slip spacer under bracket

Slip top rail bracket under

overhead shower bracket

Ensure edge of bracket is plumb

then mark bottom screw hole

Ensure edge is plumb, mark plumb

line to floor and mark screw holes

Swing aside. Drill clearance into

lining then pre-drill support

Page 7

7 8 9

5

Swing aside. Drill clearance into

lining then pre-drill support

Seal hole and drive in screw (and

wall plug if appropriate)

Seal holes and drive in screws (and

wall plugs if appropriate)

Tighten using a lever until bracket

is pulled flat against wall

Tighten using a lever until bracket

is pulled flat against wall

Run water to ensure the unit is

sealed

Page 8

10 11 12

1

2

6

Run water to ensure the unit is

sealed, then clip on covers

Clip on covers

Push rail and bottom rail bracket

hard on to mounted top bracket

Ensure edge aligns with plumb line.

Mark holes. Set aside, drill clearance

into lining and pre-drill support

Page 9

13 14 15

575mm

7

Go to 19 on

page 8

Clip on cover

No footrest

Release lever and slide shelf (if

included) and handset holder on to

top of rail

Push rail and bracket back on to

top bracket and clip on angled

cover

Seal holes. To ensure correct

alignment, hold rail firmly in place

whilst driving screws in (use wall

plugs where appropriate). Check

alignment with plumb line

Separate footrest

Mark holes

Page 10

16 17 18

8

Place footrest and mark holes.

Drill clearance in lining and predrill support

Set footrest aside, drill clearance

into lining then pre-drill support

Seal holes. Drive in screws

(and wall plugs if appropriate).

Clip on cover with the tab at top

as shown

Seal holes. Attach footrest cap.

Drive in screws (and wall plugs if

appropriate). Clip on cover

Attach hose & insert trays. Adjust

shelf position & handset tension,

see overleaf for instructions

Page 11

Clean filter baskets periodically

Do not use any

sharp objects to

clean nozzles

LOCK

UN-LOCK

Located at the

back of slider

Thumb screw

ADJUSTMENT

Shelf adjustment

CLEANING

Water contains lime which remains on the surface after

the water has evaporated. These lime deposits can be

prevented from forming by wiping immediately after use.

Handset holder tension adjustment

Adjust the tension on the handset holder by rotating the

thumb screw.

To clean the chrome-plated surfaces use a soft cloth,

soap and warm water. Never use cleaning agents that

contain a corrosive acid or a scouring additive.

Page 12

Methven warrants this product against manufacturing defects and that it is suitable for use

under the operating conditions specified in this instruction sheet.

For your warranty please refer to www.methven.com or call Customer Service

290369

New Zealand

0800 804 222

Australia

1300 638 483

UK

0800 195 1602

Issue B

Loading...

Loading...