Page 1

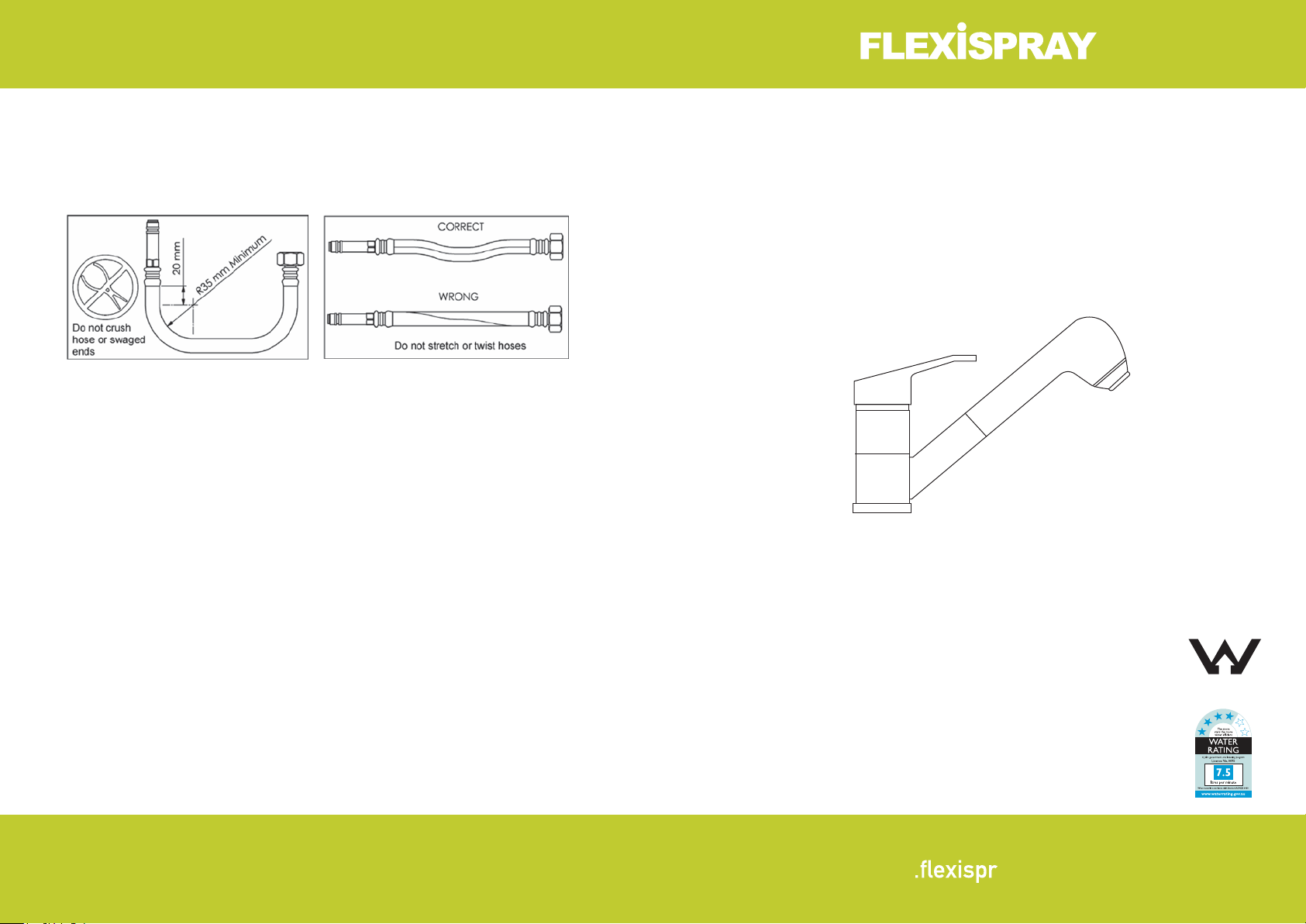

Hose requirements for mixers

“In situ” testing

The maximum working pressure of the ceramic cartridge is 1000kPa. Do not

hydrostatic test the installation with this mixer installed. Damage to the ceramic

cartridge may occur, voiding our warranty.

Echo Sink Mixers

with Pullout Spray

CIRCA 03-3355

STRATA 03-2358

Installation Guide

MAY 2010 MA432032

Methven Australia Pty Ltd

ABN 15 104 813 390

Melbourne, Australia

www.methven.com

IMPORTANT

Please read all of the instructions before installation

Use of this product in non-domestic applications voids warranty.

All pipe work must be thoroughly flushed prior to the installation of the mixer.

NEFA inline filters must be installed on both hot and cold supplies.

Do not remove the ceramic cartridge from the mixer when installing.

Damage caused by hydrostatic testing is not covered by our warranty.

www ay.com.au

SPE C 001

LN: WMKA2 1005

Page 2

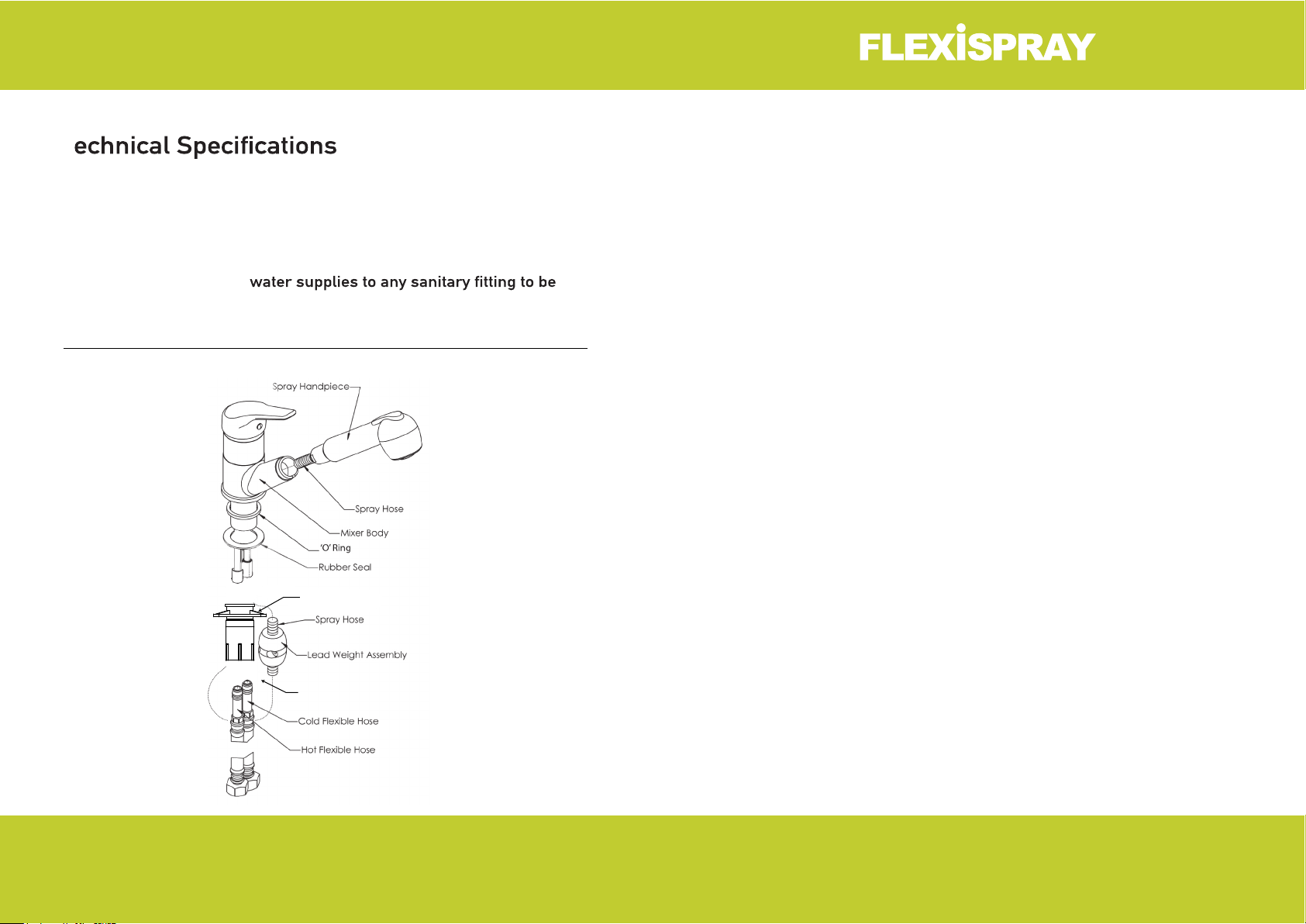

T

Inlet Connections: All 1/2’ BSP

Operating Pressure: 150kPa - 500kPa

Operating Temperatures: Recommended hot water supply 50°C,

maximum 70°C. AS 3500 requires all hot

tempered to 50°C.

Optional PVC Triangle Spacer

Fast-fit Tube

INSTALLATION

1. Cut a 40mm diameter hole through the bench top. Ensure the thickness of the

bench top does not exceed 30mm.

2. Remove the rubber seal washer.

3. Fit the ‘o’ ring sealing washers (provided in a separate bag) over the tail pipes and

push it up to fit against the underside of the sink faucet.

4. Place the mixer body through the hole cut in the bench top.

5. Secure the ‘hot’ hose into the port marked H. Secure the ‘cold’ hose into the other

port.

Note: Optional hose connection tails are available as spare part (04-8434).

6. Place the rubber seal washer over the hoses to form a seal on the underside of the

bench. If required also use PVC triangle spacer.

7. Secure the faucet in place using the Fast-Fit Tube, against the underside of the

bench.

8. Screw the pull out spray handpiece into the conical end of the spray hose, ensuring

firm seal is made with the sealing washer within the hose’s conical end fitting.

9. Place the smaller threaded end of the pull out spray hose through the faucet spout

opening. Push the hose down the spout and through the faucet body until it exits

out the bottom of the faucet next to the hot and cold hoses. Continue pushing the

hose through the faucet body until the pull out spray handpiece engages in the

spout opening.

10. Screw the spray hose connection into the remaining pipe connection, ensuring the

small rubber sealing washer provided in the bag is fitted in the remaining pipe

connection to form a water tight seal.

11. Attach the lead weight to the spray hose using the screws provided. The screws are

used to assemlbe the two halves of the lead weight around the hose. The optimum

position for the lead weight is at the bottom of the front loop of the spray hose

12. Flush pipework thoroughly.

13. Connect the hoses to their respective water supplies (see over page). Two rubber

washers are provided for the flexible hose supply connections. Machined nipple

ends are required to ensure a seal to the flexible hose nuts and the rubber washers.

We recommend that this product is installed by a licensed plumber.

THE METHVEN GUARANTEE

The warranty statement shall apply to all tapware & showers supplied by Methven

For more information visit www.methven.com

THIS WARRANTY ISSUED BY: Methven Australia Pty Ltd, Melbourne Australia

Loading...

Loading...