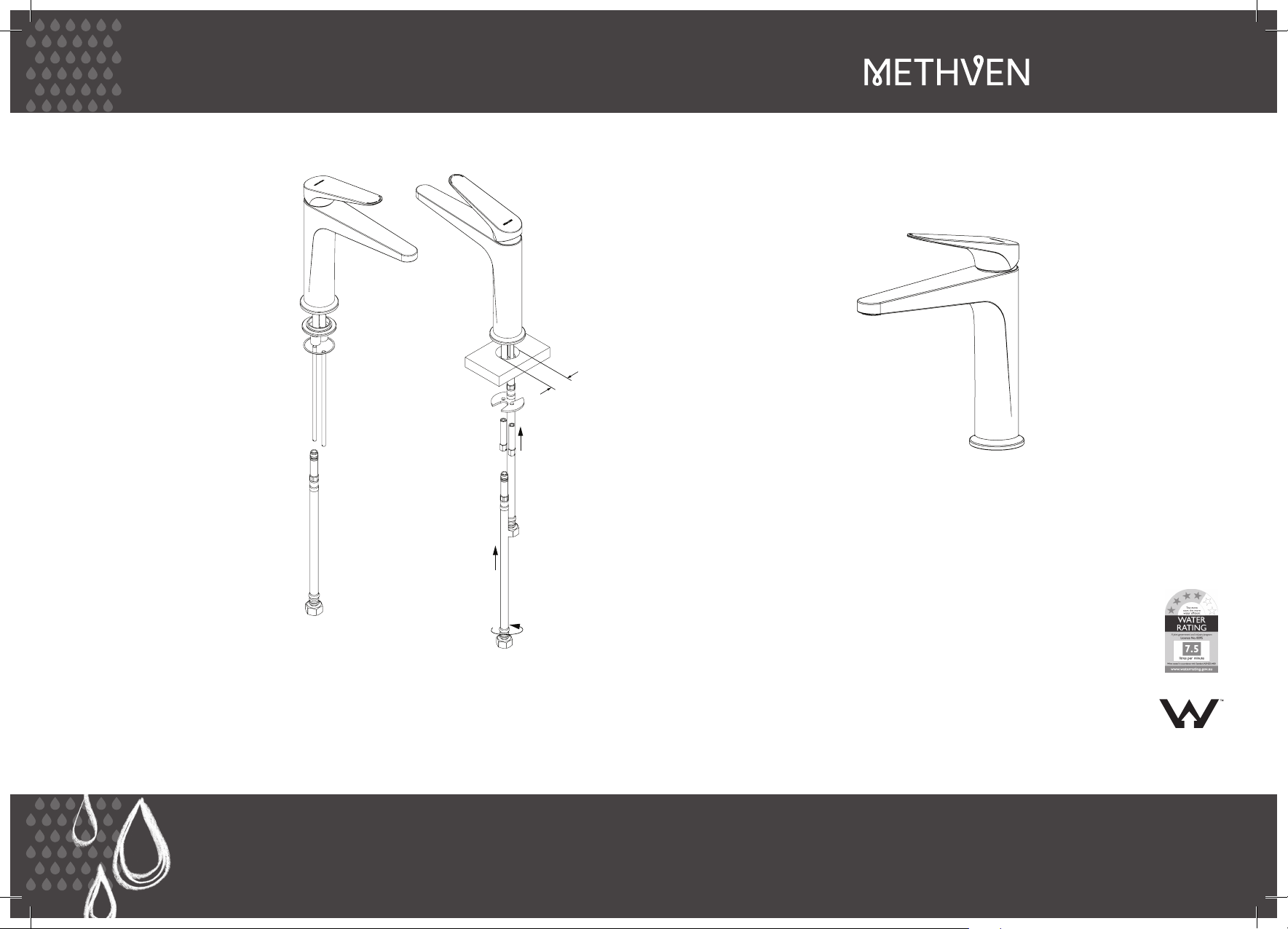

Page 1

Installation

Tip: Install product on bench before

connecting second hose to mixer.

1. Cut a single 35mm diameter hole into the

mounting surface.

2. Insert o-ring into the groove in the

underside of the base ring and fit to base

of mixer.

3. Feed the mixer’s tails and the one fitted

hose through the hole cut in the mounting

surface.

4. Screw in all-thread studs and second

supply hose into the base of the mixer.

5. Fit triangular spacer (optional) followed

by clamp plate.

6. Secure in place with brass mounting nuts.

7. Connect the flexible hoses to the hot

and cold supplies (Hot on left, Cold on

right).

Maku Sink Mixer

01-8628

Ø35mm min

Ø42mm max

Installation Guide

Note: Ensure that the in-line filter

washers supplied are fitted during

this connection.

JUNE 2012

Methven Australia Pty Ltd

ABN 15 104 813 390

Melbourne, Australia

www.methven.com

Hot

Cold

MA018628

IMPORTANT

Please read all of the instructions before installation

Use of this product is recommended for domestic and commercial applications.

All pipework must be thoroughly flushed prior to the installation of the mixer.

Inline filter washers must be installed on both hot and cold supplies to prevent foreign particles

damaging the ceramic cartridge.

Do not remove the ceramic cartridge from the mixer when installing.

Methven recommends a licensed plumber carry out all installations in compliance with

the requirements of AS/NZS 3500. This product complies with AS/NZS 3718 regulations.

www.methven.com

Customer Care Hotline: 1300 METHVEN (638 483)

Email: info@au.methven.com

WMKA21005

Page 2

Technical Specification

Inlet Connections: All 1/2" BSP

Operating Pressure: 150kPa - 500kPa

For optimum performance hot and cold water pressures should be equal.

AS/NZS 3500 stipulates a 500kPa maximum operating pressure at any outlet

within a building. Where normal pressure exceeds 500kPa, a pressure limiting

valve must be installed.

This sink mixer is rated at 7.5l/m. If limited water flow is experienced, locate

stream shaper flow restricting device and filter washers and clean away foreign

material as required.

Operating Temperature: Recommended hot water supply 50°C, maximum 70°C. AS/NZS 3500 requires all

hot water supplies to any sanitary fitting to be tempered to 50°C.

Ceramic cartridges: The ceramic cartridge can be damaged due to the presence of the following within

the water supply:

Copper tube pieces

Plastic pieces

Sand, dirt or stones

Thread tape

Other objects not normally present in the potable water supplies

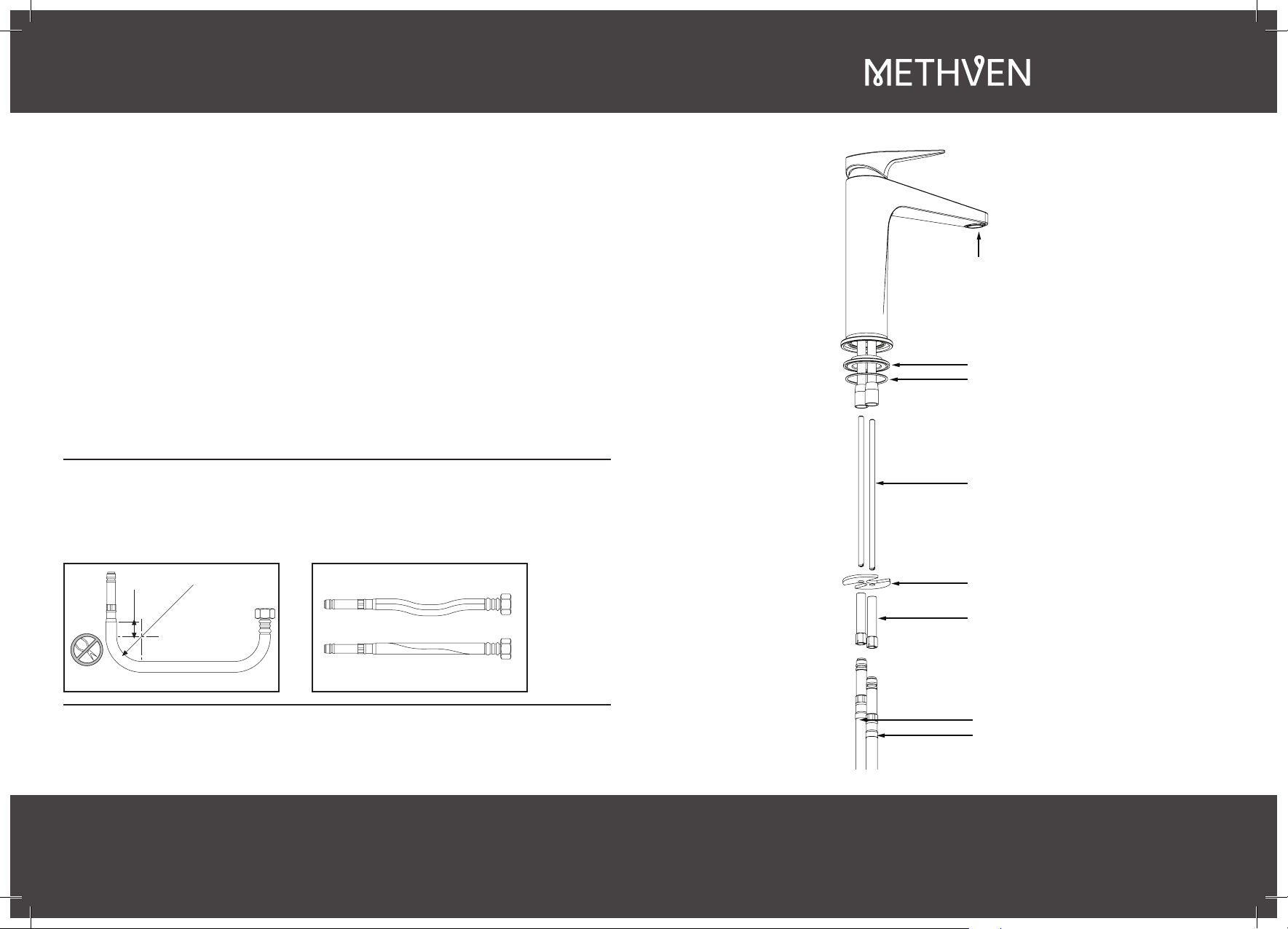

Stream Shaper

Base Ring

O-Ring

Hose Requirement for Mixers

Do not hydrostatic test* the installation with this mixer installed. Damage to the ceramic cartridge may occur.

*Hydrostatic testing refers to placing the system under pressure, above the recommended operating pressure, to

determine water tightness and to uncover leaks or weak joints within the system.

DO NOT CRUSH

HOSE OR SWAGED ENDS

20mm

R35mm Min

DO NOT STRETCH OR TWIST HOSES

CORRECT

INCORRECT

Care and Cleaning

Never use abrasives to clean this product. Clean regularly with contamination free warm soapy water and a damp

soft cloth.

www.methven.com

Customer Care Hotline: 1300 METHVEN (638 483)

Email: info@au.methven.com

Twin Stud Fixing System

Clamping Plate

Mounting Nuts

Flexible Inlet Hose:

Cold

Hot

Loading...

Loading...