Imprint

These operating instructions are published by Conrad Electronic GmbH, KlausConrad-Str. 1,92240 Hirschau/Germany

No reproduction (including translation) is permitted in whole or part e.g.photocopy, microfilming or storage in electronic data processing equipment, without

the express written consent of the publisher.

The operating instructions reflect the current technical specifications at time of

print.We reserve the right to change the technical or physical specifications.

©

Copyright 1998 by Conrad Electronic GmbH. Printed in Germany.

Note de l´éditeur

Cette notice est une publication de la société Conrad Electronic GmbH,Klaus-Conrad-Str. 1, 92240 Hirschau/Allemagne.

Tous droits réservés, y compris traduction. Toute reproduction, quel que soit le

type,par exemple photocopies,microfilms ou saisie dans des traitements de texte

electronique est soumise à une autorisation préalable écrite de l`éditeur.

Impression, même partielle, interdite.

Cette notice est conforme à la règlementation en vigueur lors de l´impression.

Données techniques et conditionnement soumis à modifications sans aucun préalable.

©

Copyright 1998 par Conrad Electronic GmbH. Imprimé en Allemagne.

Impressum

Diese Bedienungsanleitung ist eine Publikation der Conrad Electronic GmbH.

Alle Rechte einschließlich Übersetzung vorbehalten.Reproduktionen jeder Art,z.B.

Fotokopie, Mikroverfilmung,oder die Erfassung in elektronischen Datenverarbeitungsanlagen, bedürfen der schriftlichen Genehmigung des Herausgebers.

Nachdruck, auch auszugsweise, verboten.

Diese Bedienungsanleitung entspricht dem technischen Stand bei Drucklegung.

Änderung in Technik und Ausstattung vorbehalten.

©

Copyright 1998 by Conrad Electronic GmbH. Printed in Germany.

Impressum

Deze gebruiksaanwijzing is een publikatie van Conrad Electronic Ned BV.

Alle rechten, inclusief de vertaling, voorbehouden.Reprodukties van welke aard

dan ook, fotokopie, microfilm of opgeslagen in een geautomatiseerd gegevensbestand, alleen met schriftelijke toestemming van de uitgever.

Nadruk, ook in uittreksel, verboden.

Deze gebruiksaanwijzing voldoet aan de technische eisen bij het ter perse gaan.

Wijzigingen in techniek en uitrusting voorbehouden.

©

Copyright 1998 by Conrad Electronic Ned BV. Printed in Germany.

*185-06-98/30-M

NL

D

F

GB

100% recycling paper.

Bleached

without

chlorine.

100% Recycling-papier.

Chloorvrij

gebleekt.

100% Recycling-Papier.

Chlorfrei

gebleicht.

100%

papier

recyclé.

Blanchi

sans chlore.

p

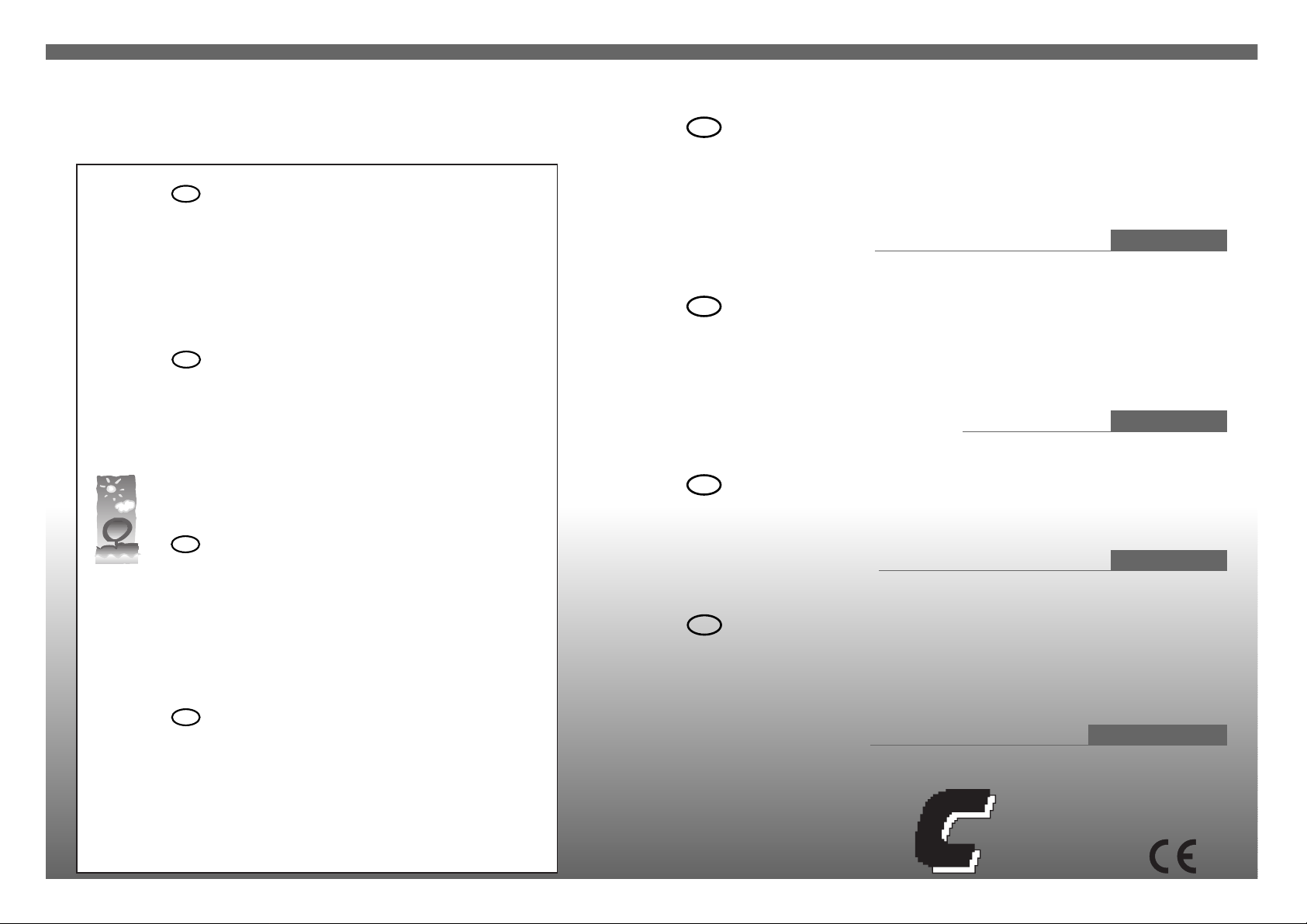

OPERATING INSTRUCTIONS

Multi-Measurement

Station MS-9160

Item-No.: 10 97 70

NOTICE D´EMPLOI

Station Multimètre

MS-9160

No de commande: 10 97 70

BEDIENUNGSANLEITUNG

Multimeßstation MS-9160

Best.-Nr.: 10 97 70

GEBRUIKSAANWIJZING

Universeel Meetsysteem

MS-9160

Best.-Nr.: 10 97 70

NL

D

F

GB

Page 2 - 45

Page 46 - 94

Seite 95 - 140

Pagina 141 - 186

3

digital multimeter

- Measurement of AC voltages to 750 VAC rms max., DC and AC currents

(true rms) to 20 A max. (30 seconds duration max., fused), measurement of resistance to 40 MOhm max., capacity to 400 µF max. and

inductance to 400 mH max., continuity test and logic test.

- Measurements should not be performed under unfavourable ambient

conditions. Unfavourable environmental conditions include:

- Wetness or excessive air humidity,

- Dust and combustible gases, vapours or solvents,

- Thunderstorms or storm conditions such as strong electrostatic fields

etc..

Any use other than as described above may result in damage to the measuring instrument and can cause hazards such as, for example, short-circuits, fire, electric shock, etc... No part of the product should be modified

or converted! Safety instructions must be observed at all times!

2. The MS-9160 Universal System

The MS-9160 Universal System is a compact, powerful measuring instrument for various application areas such as laboratories, service centres,

schools, hobbies etc. This "All in One" instrument contains a function

generator, a frequency counter, a DC voltage power supply with two

fixed and one variable output voltages and a high quality (physically

separate) multimeter.

The instrument in detail:

1. The function generator delivers seven different waveforms: sinusoi-

dal, sawtooth, square, adapted sinusoidal (clockwise, counterclock-

wise), pulse, ramp and TTL level (square). The FG produces these

waveforms in seven steps from 0.2 Hz to 10 MHz.

2. The frequency counter can measure frequencies from 5 Hz to 1300

MHz and display these on the 8-position LED display.

3. The DC voltage power supply delivers two stabilised fixed voltages,

these being 5 V / 2 A and 15 V / 1 A. Additionally a stabilised, adju-

stable DC voltage is available of from 0 to 30 V with a current capaci-

ty of from 0 to 3 A. By means of a link the adjustable power supply

output can be "grounded".

4. The digital multimeter measures voltage to 1000 VDC and 750 VAC,

current to 20 A DC/AC, resistance to 40 MOhm, capacity to 400 uF and

inductance to 400 mH max. It has a built-in logic tester and offers spe-

2

Multi-measurement station MS-9160

Attention! You must read this!

Please read this user manual thoroughly. In the event of damages which

arise due to non-compliance with the user manual, any claim under guarantee will be void. Non-compliance with this manual may also endanger the user! We accept no liability for consequential damage resulting

from such non-compliance! Keep this user manual in a safe place.

List of contents

Page

1. Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Universal Measuring System MS 9160, Introduction . . . . . . . . . . . . . 3

3. Safety requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. Working with the MS 9160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1Working with the frequency counter . . . . . . . . . . . . . . . . . . . . . 12

5.2 Working with the function generator . . . . . . . . . . . . . . . . . . . . 18

5.3 Working with the DC power supply . . . . . . . . . . . . . . . . . . . . . 22

5.4 Working with the digital multimeter . . . . . . . . . . . . . . . . . . . . 24

5.5 Maintenance and calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6. DMM technical data, measurement tolerances,

battery changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.Operation of the multi-measurement station

in accordance with the specification:

- Measurement and display of frequencies up to 1300 MHz max. by

means of the built-in frequency counter

- Production of sinusoidal, square, sawtooth and/or TTL signals up to

10 MHz max.by means of the built-in signal generator

- Conversion of 230V AC voltage to DC voltage 5V/2A, 15V/1A and 0 to

30V/0 to 3A by means of the built-in power supply

- Measurement of DC voltages to 1000 VDC max., TRUE RMS with the

GB

5

3.7 In schools, training facilities, hobby and self-help workshops the

handling of measuring instruments must be responsibly supervised

by trained personnel.

3.8 When opening covers or removing parts, except where this can be

done without tools, live parts can be uncovered. Connection

points may also be live. Prior to adjustment, service, repair or

replacement of components or subassemblies when the instrument is required to be opened, it must be disconnected from all

voltage sources and circuits being measured. If adjustment, maintenance or repair is subsequently required on the opened instrument while it is live, these must only be carried out by a specialist

familiar with the associated hazards and relevant regulations

(VDE-0100, VDE-0701, VDE-0683).

3.9 Capacitors in the instrument may remain charged even when the

instrument has been disconnected from all voltage sources and circuits.

3.10 When effecting replacements, it must be ensured that only fuses

of the specified type and specified current rating are used. The use

of patched fuses or bridging of the fuse socket is not recommended. Before changing fuses, disconnect the measuring instrument

from the circuit being measured, switch it off and disconnect the

entire measuring instrument from the AC supply (pull out the AC

plug). Remove all connected leads and test probes.

To change the DMM protection fuses carefully remove the second

cover from the top (with a medium-bladed screwdriver). Remove

the defective fuse(s) by unscrewing the fuseholder(s) counterclockwise and replace with identical type and specification 0.8 A

quick-acting, 250 V; standard designation: F0.8A/250V and 20 A

quick-acting, 250 V, F20A/250V (Bussmann types). Having successfully replaced the fuse(s) carefully screw the fuseholder(s) with

the fresh, sound fuse(s) clockwise into their respective fuseholder(s). Then carefully close the fuse compartment again.

To change the power supply fuse, with a suitably-bladed screwdriver carefully lever up the cover (noting the notch) of the power

supply voltage switch with the embedded power supply fuse.

Remove the defective fuse and replace with an identical type and

specification. For the 220 to 240 VAC supply the fuse is: 1A slow-

4

cial functions such as an RS 232 interface for connection to a PC, data

hold and min/max value display , reference value measurement (=REL=

relative), 5-location measurement value memory (=MEM), manual

range selection (=R-H), dual display (=EXT) and comparison measurement (=CMP).

3. Safety requirements

3.1 CE identification: The multi-measurement station MS-9160 is EMVapproved and complies with 89/336/EWG directives; in addition it

is tested for safety and complies with 73/23/EWG low-voltage

directives.

3.2 The universal measuring instrument is constructed and tested to

Safety Class 1 per VDE 0411 and VDE 0550 and left the factory in a

perfect, technically-safe condition. To maintain this condition, the

safety instructions and warning notices appearing in these instructions must be observed at all times. It is equipped with a VDEapproved power supply with safety cable and may only be used

with and connected to 230 VAC supplies with safety grounding.

3.3 Current measurements with the built-in multimeter may only be

performed in current circuits, which are themselves fused at 16 A

and in which no voltages greater than 250 VDC/VAC rms and

powers greater than 4000 VA can occur. The measuring instrument

may not be used in IEC 664 Overvoltage category III installations.

The measuring instrument and instrument leads are not protected

against arcing (IEC 1010-2-031, Section 13.101).

3.4 Care must be taken to ensure that the (yellow/green) ground lead

remains sound in the instrument, in its power lead and in the AC

supply, because a damaged ground lead can result in danger to

life. Care must also be taken to ensure that insulation becomes

neither damaged nor destroyed.

3.5 Measuring instruments and accessories do not belong in children's

hands!

3.6 In industrial facilities the accident prevention regulations of the

Industrial Employers' Liability Association for electrical systems and

equipment must be observed.

7

3.18 The voltage between any digital multimeter socket and ground

must not exceed 500 VDC or VAC rms. The voltage between any

frequency counter socket and ground must not exceed 35 VDC or

VAC rms.

3.19 Never switch the measuring instrument on immediately after it has

been brought from a cold into a warm area. The resulting condensation water could damage the instrument. Allow the instrument to come to room temperature before switching on.

3.20 While working with power supplies, the wearing of metal or other

conducting jewellery such as chains, bracelets, rings, etc. is not

recommended.

3.21 Power supplies are not intended for use with/on people or animals.

3.22 When connecting the outputs of more than one power supply in

series voltages dangerous to life (> 35 VDC) can result. Take particular care when dealing with voltages greater than 35 V AC or

greater than 35 V DC. Even at these voltages a lethal electric shock

can be received if electrical conductors are touched.

3.23 Power supply ventilation holes should not be covered! The instrument is to be placed onto a hard, non-inflammable base, so that

cooling air can enter unhindered. The instrument is cooled by

means of a fan on its right side and by means of convection.

3.24 Power supplies and their connected loads should not be left operating unsupervised. There are measures for the protection and

safety of the connected loads in the face of power supply incidents

(e.g. overvoltages, complete failure) and effects and dangers stemming from the loads themselves (e.g. unduly high current consumption).

3.25 Faulty power supplies can produce voltages over 50 V DC, which

can be dangerous, even when the indicated output voltages of the

instrument are lower than this.

3.26 For power-on work, only tools expressly approved for this should

be used.

6

acting/250 V, standard identification: T1A/250V.

After successfully changing the fuse, snap the cover into the fuseholder. The arrow indication must correspond with the present AC

voltage.

Attention!

Only use the measuring instrument when the housing has been safely

closed and screwed together.

3.11 Do not work with the measuring instrument in environments or

under adverse environmental conditions where inflammable

gases, steam or dust are present or can occur.

For safety reasons, it is essential to avoid the measuring instrument

or test leads becoming damp or wet.

3.12 Take particular care when dealing with voltages greater than 25 V

AC or greater than 35 V DC. Even at these voltages a lethal electric

shock can be received when touching electrical conductors. Therefore, first of all switch off the voltage source current, connect

the measuring instrument to the voltage source points to be measured, set the required measuring range on the measuring instrument and only then switch on the voltage source again.

After the measurement has been completed, switch off the voltage source and remove the test leads from the voltage source.

3.13 Before each voltage measurement ensure that the measuring

instrument (multimeter) is not set to a current measuring range.

3.14 Before each change in measuring range, the test probes must be

removed from the test points.

3.15 Before each measurement check the measuring instrument and

test leads for damage.

3.16 For measurements, use only the test leads which are enclosed with

the measuring instrument. Others should not be used.

3.17 T o avoid electric shock, while measuring take care not to touch the

test probes and the points to be measured (test points), even indirectly.

9

Warning instructions and their symbols!

Within these instructions the following various safety symbols can be

found:

These symbols encourage the user to read the instructions

carefully, to obviate damage to the instrument.

The "lightning strike" represents a dangerous voltage!

The earth/ground symbol indicates a grounding point.

CAT II= Overvoltage category II

Remarks and passages containing these symbols, which are indicated

with "Attention!" or "Note!", must be followed without fail.

4. PUTTING INTO OPERATION

4.1 Unpacking and checking the instrument!

Once the instrument is unpacked, check for the presence of all accessories and check the integrity of the instrument.

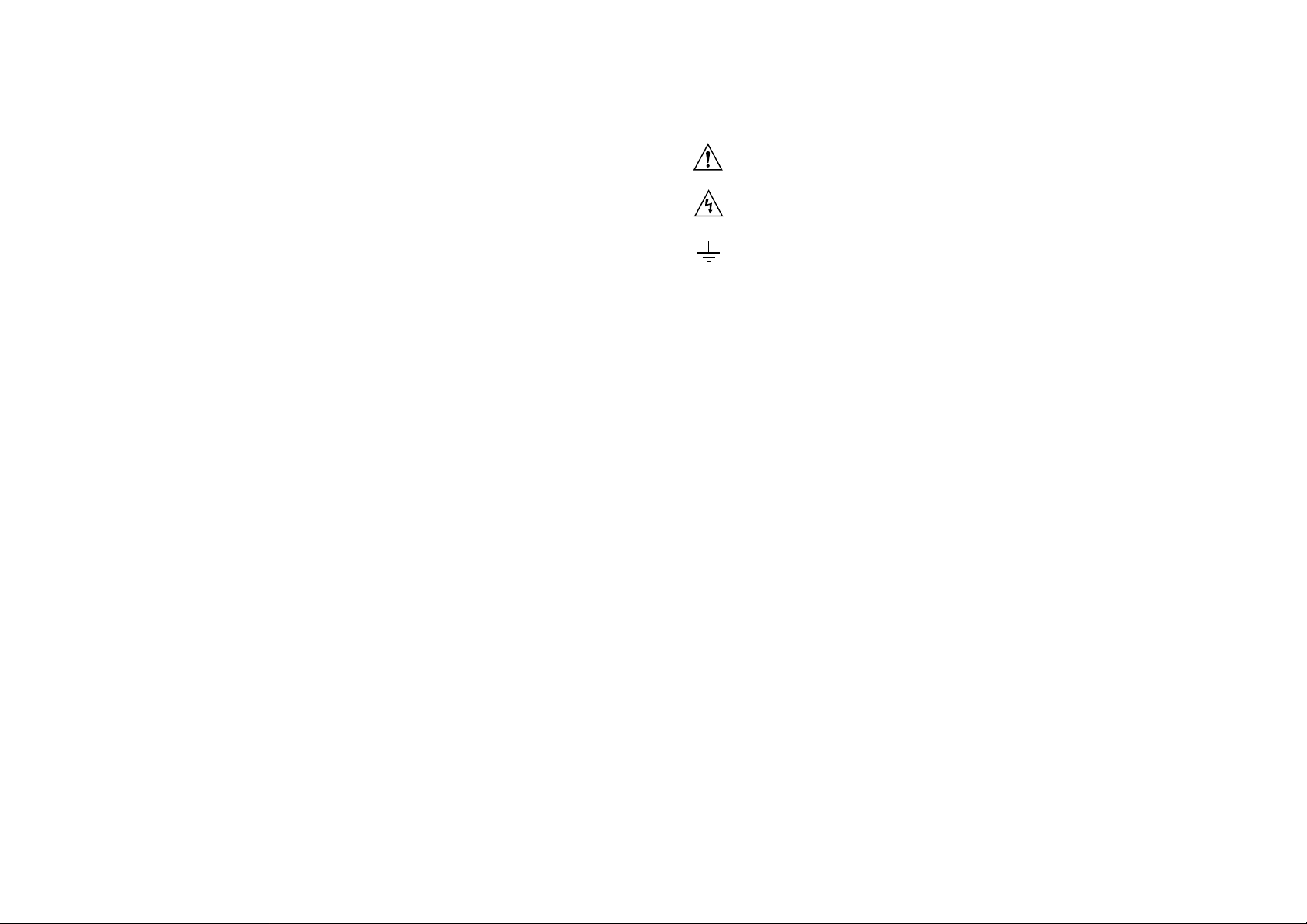

4.2 AC power input

The Euro-socket, the AC fuse and the AC voltage-change switch are

on the rear of the case. Plug the supplied AC power cable into the

measuring instrument and its plug into a grounded AC socket. Ensure firm, safe connection of the AC power cable, both to the measuring instrument and to the AC socket.

4.3 AC power voltage magnitude and type

The instrument operates with voltages from 220 to 240V AC with a

permissible tolerance of ± 10 %, with a frequency of 50 Hz or 60 Hz.

4.4 Changing the AC power voltage setting!

Attention!

Without fail, disconnect the instrument from all circuits being measured

and above all from AC power before changing the setting. Remove the

AC power plug from the socket, disconnect the AC power cable from the

instrument and ensure that the instrument is absolutely free of voltages

and not connected to any circuit.

8

3.27 The power supply outputs and their connecting leads, sockets and

terminals must be protected from direct touch. In addition, the

leads used must be sufficiently insulated and voltage-proof and

the contact points safe from being touched (safety sockets).

3.28 Use of bare metal leads and contacts should be avoided. All these

items are to be covered by suitable, non-inflammable insulation or

other arrangement and thereby protected from being touched.

The electrically-conducting parts of the connected load must also

be appropriately protected from direct touch.

3.29 When safe operation is considered no longer possible, the instrument must be placed out of service and secured against unintended use. It is to be assumed that safe operation is no longer possible, if

- the instrument shows visible signs of damage,

- the instrument no longer functions and

- after prolonged storage under unfavourable conditions or

- after severe transportation stress.

3.30 To reduce the danger of possible electric shock and to guarantee

optimum operation of the measuring instrument, the case and

chassis must be electrically grounded (via a grounded AC socket).

The central ground (safety conductor) connector is in the socket on

the rear of the case. The power cable supplied, equipped with a

grounded plug, must be connected to an approved grounded

socket.

3.31 The frequency counter and function generator BNC sockets are

floating, i.e. they are not connected to ground.

Attention!

Only for use indoors.

While opening or closing the case, the instrument must be disconnected

from all voltage sources. To preclude any risk of additional sources of

danger, never exchange components or subassemblies unaided and

make no supposed improvements to this universal measuring instrument. Otherwise, the instrument can be damaged and thereby all guarantee claims become void.

11

5. Working with the MS 9160

General view of the MS 9160 front panel with controls

Rear view of the MS 9160

Foreword

Before beginning with measurements, read through the operating

instructions carefully. Ensure that the instrument was set up, adjusted

and connected in accordance with para. 4.

The following instructions are divided into four main groups:

5.1 Frequency counter 5.2 Frequency generator

5.3 DC voltage power supply 5.4 Digital multimeter

FREQUENCY COUNTER

OFF ON

FUNCTION GENERATOR

OFF ON

FUSE

220V/2A

FUSE

250V /20A

RS232C

240

100

220

120

POWER FUSE : 250 V / 1A

10

Now remove the fuseholder (levering out with a suitable screwdriver).

Note the arrow indication and replace the fuseholder in its fixture, turned by 90°, the arrow pointing to the desired AC voltage indication.

Then reconnect the measuring instrument to the AC power (also check

the AC voltage source).

4.5 AC power fuse specifications

For an AC voltage of from 220 to 240 VAC, the current rating of the

AC power fuse is 1 A with a voltage rating of 250 V . The melting characteristic of the AC power fuse is "slow-acting" (usual designation:

T 1/250 V or 1 AT / 250 V).

4.6 Digital multimeter fuses

For the 400 mA range (and below), the specified fuse has the following designation: F 0.8A / 250V or 800 mAF / 250V. The 20 A range

requires: F 20A / 250V or 20 AF / 250V. The fuses can be found on the

rear of the case, above the AC power plugs beneath the lockable

cover.

4.7 Setting up the instrument

To be able to view the DMM display and the controls on the front

panel optimally and to avoid reading errors, it is recommended that

both mounting feet under the front panel be hinged out and the

instrument placed at least{216} 30 cm away from the wall (the 30 cm

free space applies also for other set-up locations).

13

Attention !

Check for correct positioning of the AC power voltage switch in the AC

power input module on the rear of the case. Check that the AC power

fuse in the fuse holder is as prescribed, both while observing safety

rules. (pull out the AC power plug!)

Make sure that the correct AC power switch is operated. The instrument

should be warmed up for approx. 20 minutes for completely accurate

operation.

Preparations

a) Initial switch settings

- Check the BNC socket for damage or short-circuit (visible check).

- Set the display selection switch to the FC position (not pressed in).

This switch is in the the function generator controls area at the bottom right (under the round scale).

- Switch on the frequency counter. The switch is located on the rear

of the instrument. Immediately after switch-on, the following self

test occurs relatively quickly:

First, all LEDs, segments and decimal points light up, then

"PASS_ALL" and afterwards "UC 1300" should be seen in the LED

display.

- Set the gate time to 1 s (second) and then press the GATE button

until the LED behind "1" lights.

- Press the CHAN (channel) button, until the LED behind A lights.

- Now read "0.0000000" on the display and immediately to its right

read the measurement unit MHz.

b) Measurements

- According to in which frequency range measurements are to be carried out, select either channel A, B or C by pressing the CHAN button.

In CHAN A position, frequencies from 10 Hz to 100 MHz will be

measured. This applies also to channel B. Channel C is for frequencies from 100 MHz to 1300 MHz.

- Setting the gate time. To achieve the highest possible resolution,

select a suitable gate time.

- HOLD Function

If the button "HOLD" is pressed, the most-recently read frequency

12

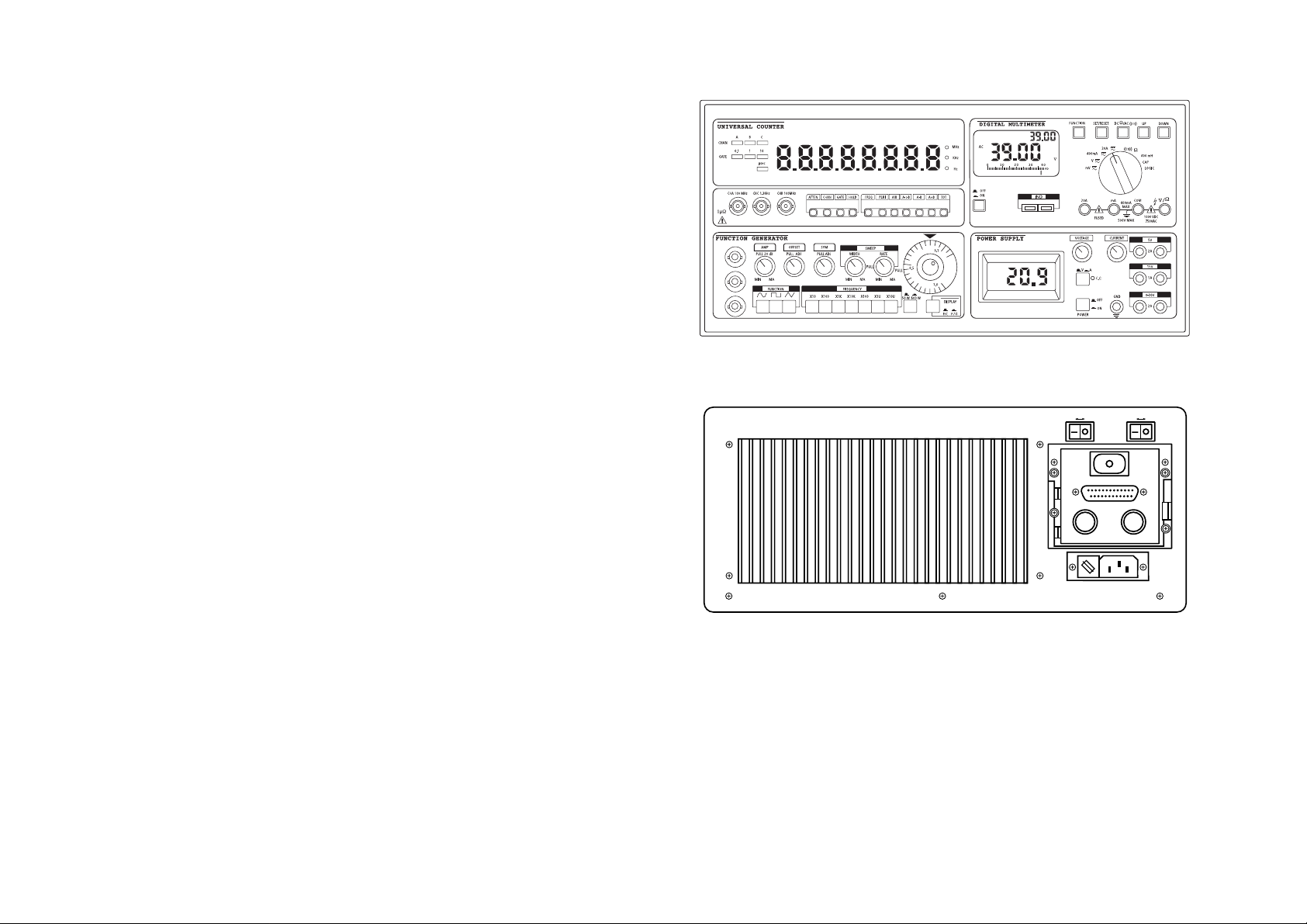

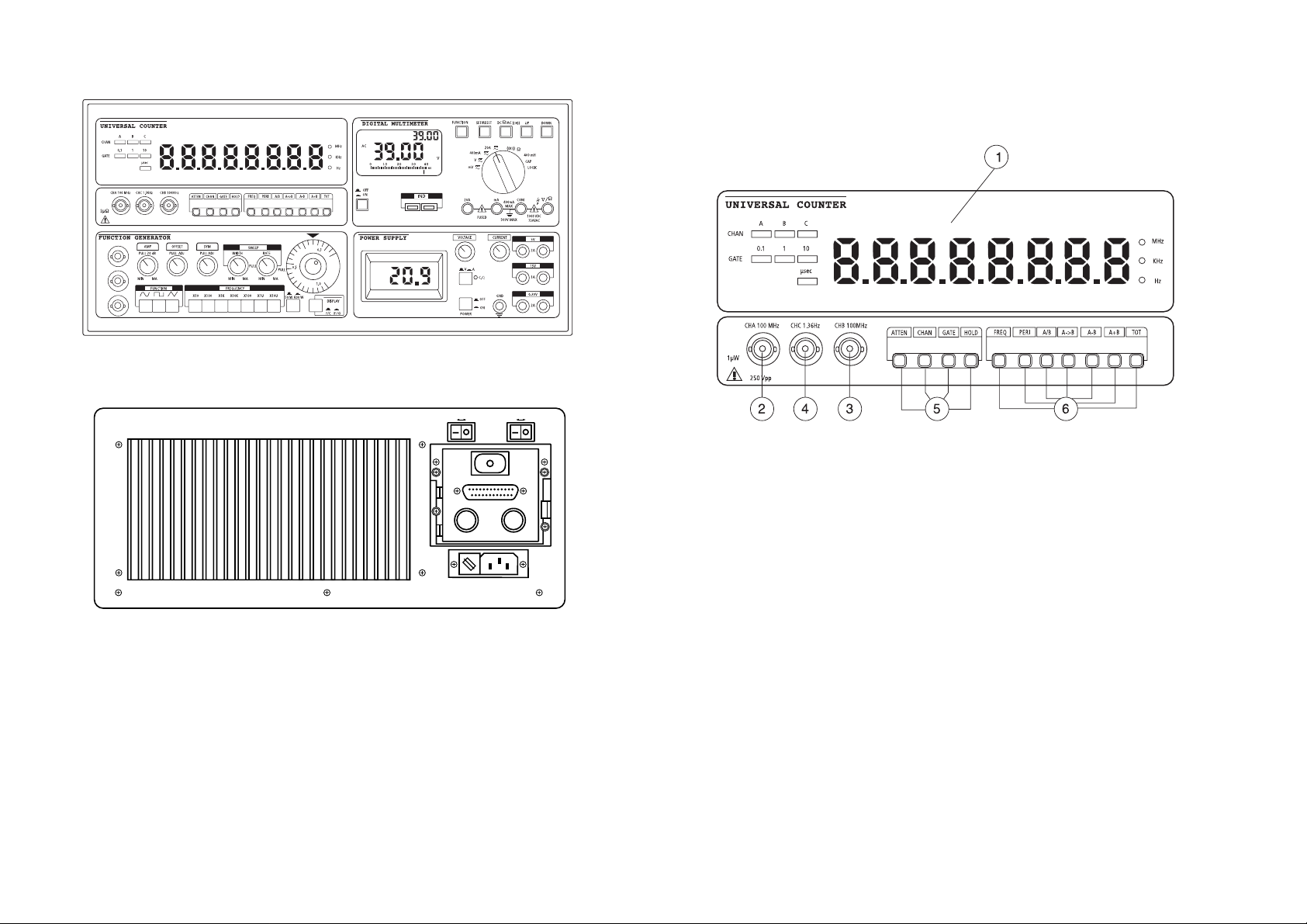

5.1 Working with the frequency counter

Frequency counter controls*

1. LED display

2. Input socket A for 5 Hz to 100 MHz, 1 MOhm

3. Input socket B for 0.2 Hz to 100 MHz, 50 Ohm

4. Input socket C for 100 MHz to 1300 MHz, 50 Ohm

5. Function buttons block I: ATTEN = Incoming signal attenuator

CHAN = A, B and C channel selection

GATE = 0.1sec, 1sec and 10sec gate time

selection

HOLD = Frequency value hold

6. Function buttons block II: FREQ = Display of measured values in

Hz, kHz or MHz

PERI = Display of period in µs

A/B = A/B relationship

A => B = Time interval measurement

A - B = Channel A minus channel B

A + B = Channel A plus channel B

TOT = Total = pulse counter

* The AC power switch ("FREQUENCY COUNTER") for the frequency

counter is at the rear of the MS 9160 case.

15

- While the frequency of the built-in signal generator is being measured, the BNC socket of channel A is inoperative. That is to say even

when an external frequency is introduced into channel A , only the

frequency of the built-in signal generator is measured, provided

that the F/C - F/G switch is pressed (set to F/G).

- Switch the frequency generator on, noting 5.2 without fail.

d) Measurement of external frequencies

1. Switch the measuring instrument and the counter on.

2. Select the channel by pressing the CHAN button.

3. Set a suitable gate time.

4. Connect a screened signal lead with intact BNC plug(s) to the input

socket of the selected channels.

5. Select the correct attenuator (ATTEN) setting. For signals having an

amplitude greater than 300 mV rms, the attenuator should be switched in. In this case the input signal voltage will be reduced by a

factor of 20, to reduce measurement errors (measurement tolerance).

6. Read off the measured frequency and appropriate measurement

units on the LED display.

e) Measurement of period

1. Switch the measuring instrument and the counter on.

2. Select channel A, B or C by pressing the CHAN button.

3. Press the PERI button once.

4. Connect a screened signal lead with intact BNC plug(s) to the BNC

socket of the selected channels.

5. Read the period t of the signal in µs (=microseconds) on the display.

Remember: f = 1/t and t = 1/f

f) Presentation of the relationship of channel A divided by channel

B = A/B

1. Switch the measuring instrument and the frequency counter on.

2. Press the A/B button.

3. Connect two screened signal leads each with intact BNC plug(s) to

the BNC channels A and B sockets.

4. Read the result in the display.

g) MMeasurement of time interval A=>B

A measurement is started by a signal fed into channel A and stopped

by a signal fed into channel B. The time difference is shown in µs. If

14

will be "frozen", i.e. held. This remains so, even when the BNC lead

is disconnected from the item being measured.

- Attenuator (1/20 gain) = ATTEN

If the incoming signal level is higher than 300 mV, this button

should be pressed. For levels lower than 300 mV this button should

not be pressed.

- Resolution

Resolution = decimal places, depends on the gate time (GATE) and

the frequency: Gate time 0.1 sec., up to 5 decimal places; Gate time

1 sec., up to 6 decimal places; Gate time 10 sec., up to 7 decimal places.

- PERI = Period measurement

After pressing the PERI button, frequency is not displayed in kHz,

rather its period (= time for one cycle) in µs (= microsecond = exp.

-6)

- A/B = Relationship measurement

After pressing the A/B button, the relationship of channel A to

channel B is displayed,

e.g.: 100 kHz (from the function generator) is present on channel A.

If the same frequency is present also on channel B, Then "1.000000"

is displayed, provided that both frequencies are absolutely identical.

- A-B = Difference measurement

After pressing the A-B button, the difference A minus B is counted.

- A+B = Addition of A and B

After pressing the A+B button the sum A + B is counted.

- Time interval measurement A ==> B

After pressing the A=>B button the time interval between A and B

in µs (=microsecond) is displayed.

- TOT = "Total measurement" = pulse counter operation

Select this operating mode by means of the TOT button when pulses from electronic switches are to be counted. TOTAL means that

the pulses are summed.

c) Display of signal generator output frequencies on the

LED display

- To be able to read the signal generator frequencies on the LED display, the bottom right switch on the signal generator must be pressed.

- Because the signal generator can generate 10 MHz max., channel A

should be selected, which can count up to 100 MHz.

17

70 MHz to 80 MHz 50 mV rms

80 MHz to 100 MHz 70 mV rms

Channel C:

100 MHz to 1,3 GHz < 25 mV rms

5.2 The function generator

Function generator (FG) operation

1. VCF input socket 8. Switch for frequency range

2. FG output socket 9. SWEEP (band)width control

3. TTL level output 10. SWEEP speed control

4. Amplitude control knob 11. Connection impedance switch

5. Waveform switch 12. Frequency adjustment with scale

6. OFFSET control knob 13. Display counter/generator switch

7. Symmetry control knob

Attention!

Before switching the instrument on, check that both the position of the

AC power voltage selection switch and the AC power fuse are correct.

Ensure that the correct AC power switch on the rear of the case is used

to switch on function generator. So that the generator functions completely accurately a warm up time of approx. 30 minutes is required.

16

100 kHz for example is fed into channel A from the built-in signal

generator and 10 KHz into channel B, then a "time interval" of 100

µs results.

1.Switch the measuring instrument and the frequency counter on.

2.Press the A=>B button.

3. Connect two test leads with intact BNC plugs to the channel A and

channel B BNC sockets.

4. Read the measured value in the LED display.

h) Measurement of channel A minus channel B

1. Switch the measuring instrument and the counter on.

2. Press the A-B button.

3. Connect two screened signal leads (or test leads) with intact BNC

plugs to channel A and channel B BNC sockets.

4. Read the result of A minus B in the display.

i) Presentation of channel A plus channel B (A+B)

1. Switch the measuring instrument and the counter on.

2. Press the A+B button.

3. Connect two screened signal leads with intact (= undamaged) BNC

plugs to channel A and channel B BNC sockets.

4. Read the result of channel A + channel B in the display.

k) Pulse counter operation = addition of single pulses (TTL) or square

wave signals

1. Switch the measuring instrument MS-9160 and the frequency coun-

ter on.

2. Press the TOT button once, firstly to select the pulse counting ope-

rating mode and secondly to initialise = reset the counter.

3. Connect a screened signal lead with intact BNC plug to channel A

or channel B BNC socket.

4. If the input level is greater than 300 m V rms, press the ATTEN but-

ton, firstly to attentuate the signal by a factor of 20 and secondly

to reduce the possibility of measurement errors.

5. When the pulse-counting operation is completed, press the HOLD

button to "freeze" the display before reading the displayed count.

l) Frequency counter signal input sensitivity

Channel A and B:

100 kHz to 60 MHz < 20 mV rms

60 MHz to 70 MHz 30 mV rms

19

x 100k approx. 10 kHz (1 kHz) to 100 kHz

x 1M approx. 100 kHz (10 kHz) to 1 MHz

x 10M approx. 1 MHz (110 kHz) to 10 MHz

Note!

The values in brackets are achieved when the frequency adjustment

control knob is almost at its left stop. They are dependent on the output amplitude and the load connected to the generator output.

22

- Set the Hi/Lo switch on the frequency counter to Lo and the gate time

to 1 sec. (lower LED row, centre LED).

-Set the display switch (bottom right on the FG) to F/G, in case not yet

done.

- The generator frequency can now be read in the LED display.

d) Voltage controlled Frequency VCF

- The output frequency of the generator can be adjusted by connec-

ting an external voltage to the VCF input (BNC).

- The output frequency can be adjusted by a factor of 1:20 by an

input voltage between 0 and 10 VDC, dependent on the setting of

the frequency range button.

- T o be able to work with the VCF function, it is necessary to place the

frequency adjustment control knob (scale) to its left stop (two graduations next to "0.1" on the right) and to connect the external DC

voltage to the VCF socket (BNC) (observing the inner "+" polarity).

e) Setting the output amplitude

- The amplitude of the output voltage with open output is 20 V p-p.

With 50 Ohm or 600 Ohm load the output voltage approximately

halves, i.e. to 10 V p-p.

- The amplitude of the output voltage is set with the AMP control

knob.

- By pulling this control knob the amplitude is set to -20 dB.

- To guarantee a precise waveform in the range from 1 MHz to

2 MHz, set the "AMP" control knob to 5 V p-p.

18

Preparation

a) Initial settings

- Check the contacts of the BNC sockets for damage and short circuits

- Set the display switch to the position F/G. The switch is located at

the bottom right of the function generator

- Set the function switch to sine function

- Set the frequency selection switch "FREQUENCY" to 1 kHz

- Set the frequency adjustment control knob (scale) to the position

1.0

- Press all buttons such as AMP, OFFSET, SYM, SWEEP (WIDTH and

RATE), until they are latched in

- Set the output impedance to the required value (50 or 600 Ohm)

- If frequency is to be measured, note subclause c) of the function

generator instructions.

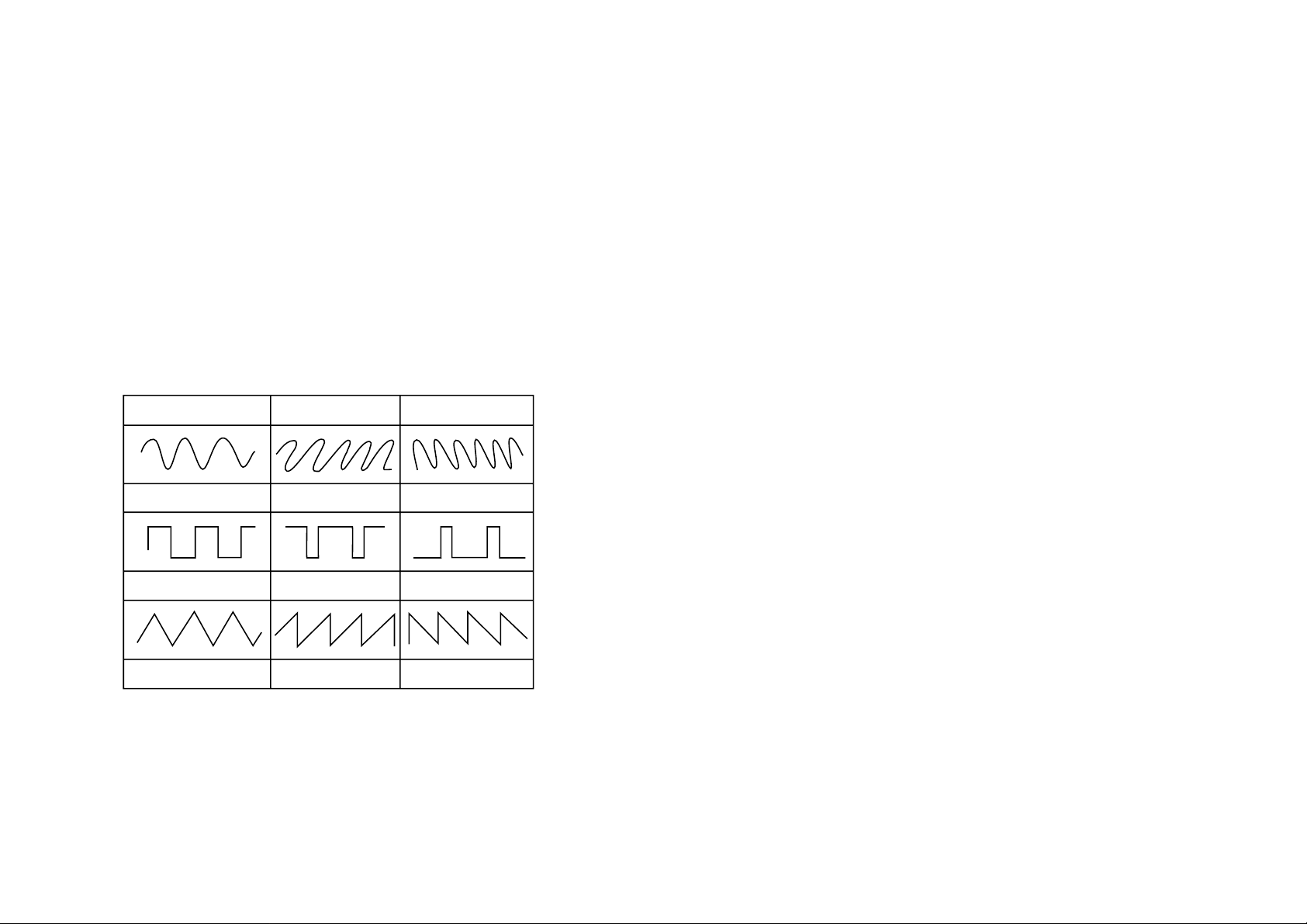

b) Output waveforms

The generator can deliver three standard basic waveforms: SINE,

SQUARE and SAWTOOTH. For these, press one of the switches under

FUNCTION.

c) Frequency range

Press one of the seven buttons under FREQUENCY, to set the desired

frequency range. The selectable ranges are given in the following

table:

Switch position Frequency range

x 10 approx. 1 Hz to 10 Hz

x 100 approx. 10 Hz (2 Hz) to 100 Hz

x 1k approx. 100 Hz (10 Hz) to 1 kHz

x 10k approx. 1 kHz (100 Hz) to 10 kHz

: Sine waveform

: Square waveform

: Sawtooth waveform

21

h) SWEEP adjustment (Wobbler)

- To operate the built-in frequency sweep, pull the SWEEP WIDTH

control knob and use it to adjust the width of the sweep signals in

the range 100 : 1.

- To achieve maximum width, turn the frequency adjustment knob

(with scale) to its left stop and the width control to its right stop.

- To adjust the speed of the sweep signal, turn the SWEEP RATE control knob slowly to the left or right. A linear sweep signal is obtained.

- A logarithmic sweep signal is possible by pulling the SWEEP RATE

control knob.

i) TTL output

- The TTL level is available at the TTL OUT socket (BNC).

A TTL level is an "asymmetric square wave". It is asymmetrical

because, in contrast to the sine or "pure" square waves, the signal

does not cross zero, i.e. it has no negative voltage values (negative

logic excepted).

- The TTL output can drive 20 "unit loads" when HIGH and 15 "unit

loads" when LOW.

- One "unit load" is 40 µA for the HIGH and 1.6 mA for the LOW

state.

j) Output impedance

- The output impedance of the generator output F/G OUT, is 50 Ohm

or 600 Ohm depending on the setting of the 50 / 600 Ohm switch.

20

f) OFFSET adjustment

- The DC voltage level of the output signal can be adjusted with the

OFFSET control knob in the range of +/- 10 V.

- To set the DC voltage level, pull this control knob out. Turning to

the right means positive voltage, turning to the left means negative voltage.

- If the control knob is pressed, the output voltage will have no DC

voltage component.

g) Symmetry adjustment

- The symmetry of the output voltage can be changed in the range of

1:3 and 3:1.

The control knob carries the designation SYM.

- To change the symmetry of the waveforms, pull the SYM control

knob and turn it slowly to the left (ccw) or to the right (cw). Refer

to the table for the resulting waveforms.

Note!

Note that because of this adjustment of symmetry, the frequency can

change and therefore should be readjusted.

BASIC WAVEFORMS CLOCK WISE (CW) COUNTER CLOCKWISE (CCW)

SINE SKEWED SINE SKEWED SINE

SQUARE PULSE PULSE

TRIANGLE SAWTOOTH SAWTOOTH

23

f) Switch the display switch to "V" (voltage) and set the desired

output voltage.

g) Now connect the load to the output terminals "+" and "-" of the

adjustable output. While doing this, observe the polarity of the load.

Attention!

All outputs are floating. Other outputs can either be grounded through

the ground socket (= chassis) on the front panel (bottom right) or

remain floating.

Current limiting characteristics

All 3 outputs are independently protected against overload and short

circuit by means of a separate current limiting circuit.

a) Output 0 to 30 V, 3 A: protected by means of current limiting. If the

output current increases due to a load of more than 3 A, the output

voltage is reduced (with a short circuit to approx. 0.2 V).

b) Fixed voltage output 5 V / 2 A: protected by a fixed current limit

(stabilising circuit).

Should the load current exceed the value of 2.2 A, the output voltage is reduced.

c) Fixed voltage output 15 V / 1 A: protected by a fixed current limit

(stabilising circuit).

Should the load current exceed the value of 1.2 A, the output voltage is reduced.

22

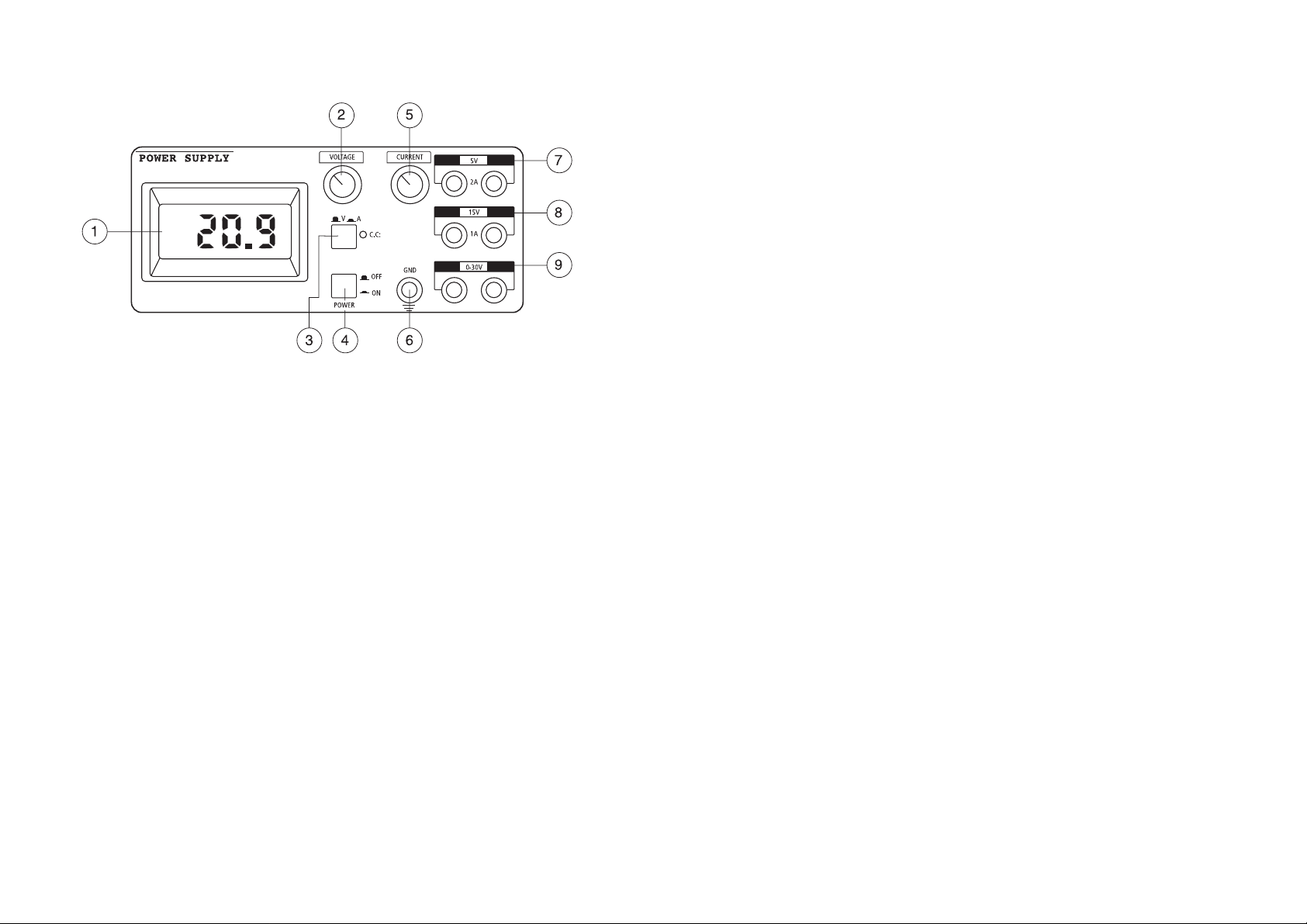

5.3 The DC voltage measuring instrument

Operating elements

1. Illuminated 3 1/2-position 5. Adjustable current limiting

17 mm high LCD display 6. Ground connector

2. Voltage adjustment 7. Fixed voltage output 5 V / 2 A

3. V/A display switch 8. Fixed voltage output 15 V / 1 A

4. AC power main switch 9. Adjustable output 0-30 V / 0-3 A

Attention! Safety measures!

Protect the instrument from being dropped and from external mechanical damage by falling objects.

Do not short circuit the "+" and "-" terminals.

Never go beneath the maximum permitted load of 2.5 Ohm at the 5V/2A

output and 15 Ohm at the 15V/1A output.

Basic settings

a) Before connecting the AC power cable, ensure that no load is pre-

sent on the output terminals of the power supply.

b) Centralise the (CURRENT) current-limiting control knob.

c) Switch the AC power switch (POWER) on.

d) The LEDs under the legends 5 V and 15 V light up.

e) Connect the loads to the 5V and 15V output.

25

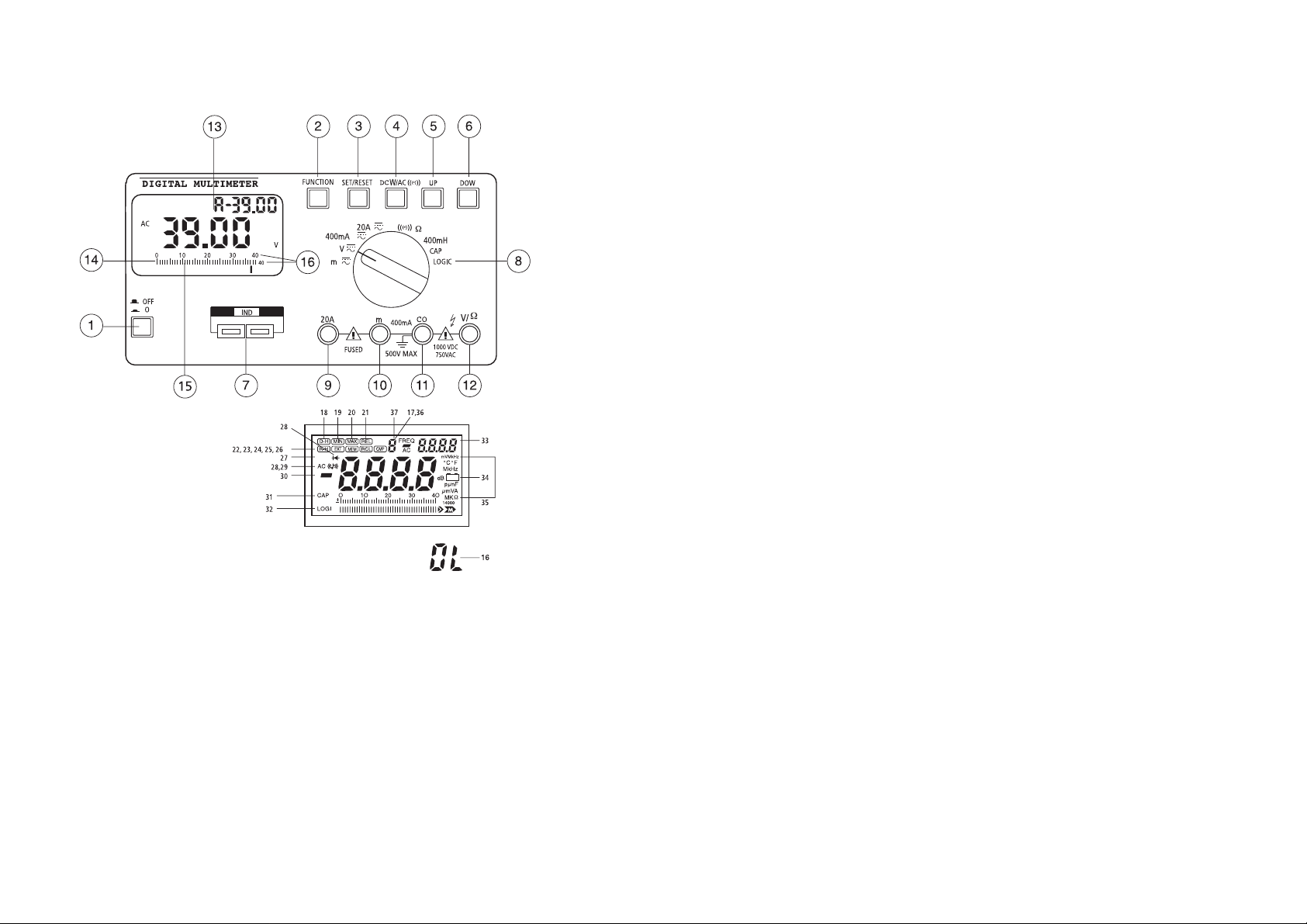

5. Up button ("plus" button)

6. Down button ("minus" button)

7. Capacity and inductance socket

In this socket uncharged capacities and voltage-free inductances

(coils, chokes, transformers, etc.) can be measured.

8. Rotary switch for setting the different operations (voltage measurement, current measurement, etc.)

9. A input socket for the measurement of DC and AC currents to 20 A

max.

10. mA input:

This input is for measuring direct and alternating currents up to 400

mA max. (protected with a quick-acting 800mA fuse).

11. COM (-) input socket (COM or negative connection)

12. V-Ohm (+) input socket (= positive connection)

13. LCD display (3/4-position, highest display value: 3999)

14. Analogue bar graph

15. Bar graph line division

16. Overload "OL" display

If "OL" appears in the display, this means that the range has been

exceeded

Attention!

Observe maximum input levels.

17. Auto Hold "A" in front of the small display

18. Data Hold

Data Hold "freezes" the measured value.

19. MIN = Minimum

As soon as this symbol appears in the display, the lowest-measured

value at any given time is displayed, for example during discharge

of rechargeable cells.

20. MAX = Maximum

As soon as this symbol appears in the display, the highest-measured

value at any given time is displayed, e.g. during overvoltage.

21. REL = Relative

22. MEM = Memory

23. RCL = Recall = of stored measured value

24. R-H = Range Hold = Auto Range switched off, manual range{723}

selection, excluding CAP capacity measuring range.

25. EXT = External

24

5.4 The digital multimeter

5.4.1 Operating elements

1. Device on/off

2. Function pushbutton

The various subfunctions, such as MIN/MAX, REL, DUAL, etc. are set

using this button.

3. Set/Reset button

The instrument is reset into its basic condition with this button.

4. DC Ω / AC (•) button

This button switches the measurement from DC to AC values or,

under resistance measurement, from actual resistance measurement to continuity test

27

power and from all circuits should changing the battery be begun.

Screw out both crosshead screws carefully with a suitable screwdriver

and remove the cover cautiously. Remove the used battery (9 V). It is

connected with a battery clip. Remove this carefully from the old battery and connect the clip to a fresh, unused battery observing the polarity. Push the battery into the battery compartment to the stop and

screw the cover carefully up again.

Attention!

Do not under any circumstances operate the measuring instrument

when it is open! Danger to life!

Leave no used battery in the measuring instrument, because even leakproof batteries can corrode and thereby release chemicals, which can

endanger health and destroy the battery compartment. Used batteries

are to be considered as special waste and must therefor e be disposed of

without putting the environment at risk. Special collection containers

are provided for this purpose by specialist dealers and in scrap yards.

Switch the measuring instrument off when it is no longer required.

B) Connecting the test leads

Always use only the supplied test leads for making measurements.

Before each connection note the condition of the connecting plug and

test probes and check the insulation for damage.

These test leads are intended for voltages up to 1000 V max. The measuring instrument is similarly designed for voltages up to 1000 VDC and

750 VAC rms max. Take particular care when dealing with voltages

greater than 25 V AC or 35 V DC.

Attention!

Never exceed the maximum input amplitudes, because danger to life

can arise under adverse conditions.

C) Putting into service

C.1 Basic settings

Press the ON button (1). The display is now illuminated. T o select a function, rotate the operating mode switch to the desired position. "Normal" measurements can now be performed without additional func-

26

With this function, two different operating modes can be read

simultaneously, e.g. the secondary voltage of a transformer < 125

VAC rms and AC power frequency

26. CMP = Comparison

27. " " = Inductance

28. AC = AC voltage or current

29. (•) = Symbol for acoustic continuity tester

30. "-" = Minus sign and symbol for negative polarity

31. CAP = Capacity ==> measurement of capacitors

32. LOGI = Logic test

When the logic test function is selected, this symbol appears in the

display

33. Second "small" display for the DUAL display function

34. = Battery symbol

If this symbol appears in the display, the battery must be changed.

35. Various measurement units

36. Reference number: indicating the memory location numbering for

the MEM and RCL (=Recall) functions

5.4.2. Using the multimeter

A) Fitting the battery - changing the battery

So that the measuring instrument functions perfectly, it must be fitted

with a 9V battery. When the battery change symbol appears in the display (after approx. 60 hours of operation) the battery must be replaced. To do this, proceed as follows:

The battery compartment is located beneath the upper cover (on the

rear of the case) which is secured with two screws, left and right.

Attention!

Remove the MS-9160 without fail from all circuits being measured before changing the battery.

Always switch off the instrument with the main switch (POWER), which

is located in the control area of the DC voltage power supply.

Only when it is certain that the MS-9150 is disconnected from AC

29

occur.

b) Operating mode switch = measurement function switch (8)

Attention!

The operating mode switch may not be moved during measurements,

because otherwise the measuring instrument can be destroyed and as a

result danger to life can occur.

Arranged in a semi-circle, the various basic measurement ranges selectable by rotating the switch are:

mV = millivolt AC/DC (milli = 10 exp.-3)

V = Volt AC/DC

400mA = milliampere AC/DC

20A = Ampere AC/DC

(@) = Continuity test

W = Resistance measurement

mH = Inductance measurement

CAP = Capacity measurement

LOGIC = Logic test

c) 20 A socket

For DC or AC current measurements up to 20 A max.(!), the red test

lead must be plugged in here.

Attention!

When measuring current,the operating mode switch must never be set

to voltage (mV or V) or to any other switch position other than current

measurement (mA or A).

d) mA socket

The red test lead must be plugged in here for DC or AC current

measurements to 400 mA max!, but only when the operating mode

switch is set to "400mA".

e) COM = common socket

Except for capacity and inductance measurements, the black test

lead must be plugged in here for all measurements (common socket

means minus, "-" or ground socket)

f) V/Ohm socket

28

tions.

To select such an additional function, press the FUNCTION (2) button.

By the repeated pressing of this button the various subfunctions are

displayed in the display . To exit from the menu, press the Set/Reset button twice: once sets the subfunction, twice resets it.

C.2 Button configuration

a) The ON/OFF button switches the measuring instrument both on and

off: if the button is pressed once, the instrument is switched on; if

it is pressed a second time, it is switched off.

After approx. 8 minutes of "zero use", when the display hardly

changes (with open test leads), the Auto Power Off function switches the multimeter off, to save energy. The multimeter must then

be switched off and on again.

b) FUNCTION

The A-H symbol appears in the display as soon as the instrument is

switched on. Press the "FUNCTION" button to call the subfunctions.

The following symbols appear in the display as a result: D-H -> MIN

-> MAX -> REL -> CMP -> R-{783}H -> EXT -> MEM -> RCL

c) Set/Reset

To activate, i.e. switch on, a selected subfunction, press this button

once.

Press the button once to return to the basic setting again (Reset).

d) DC/Ohm/AC (•)

When the operating mode switch is set to voltage or current measurement, press this button to switch from DC voltage measurement

to AC voltage measurement. When the measurement function

switch is set to (•), this button must also be pressed to switch from

acoustic continuity test to resistance measurement.

e) UP / DOWN

Press one of these buttons to set the reference value in the REL or

CMP subfunctions and to address the stored value in the MEM or

RCL (Recall Memory) subfunctions.

C.3 Connector and socket configuration

a) Sockets for capacity or inductance measurement

Insert the (discharged!) capacitor observing polarity or the voltagefree inductance (coil) into the sockets. Ensure that the connections

are long enough, because otherwise incorrect measurements can

31

Press the Set/Reset button once: the highest measured value is now

displayed on the second display , while measurements continue with

the large display.

g) REL (= Relative)

This setting permits the comparison of a reference value with a subsequent measured value. Proceed as follows:

1. First press the "Function" button until "REL" appears in the

display.

2. Now set the polarity of the reference value, the reference value

and the measurement range with the "UP" and "DOWN" buttons. After each input the SET/RESET button must be pressed

once in confirmation.

Button operation sequence:

=> Function => Display "REL" =>

=> Setting ± (with UP-/DOWN buttons) => SET/RESET =>

=> Setting first position => SET/RESET =>

=> Setting 2

nd

position => SET/RESET =>

=> Setting 3rdposition => SET/RESET =>

=> Setting 4thposition => SET/RESET =>

=> Setting the measurement range (no automatic range change)

=> SET/RESET =>

=> The small display displays the reference value

The measuring instrument will now show the difference between the

stored value and the subsequently-measured value on the small display,

while the actual value presently being measured can be read on the

large display.

Example:The reference value is 100.0 V; the present (large display) rea-

ding shows 90 V. On the small display the difference of

-10 V can be read. Should the next measured value be 100.0 V,

the differ. will be "0". The small display then reads 0000. The

display can display 3999 max.

Attention!

With the REL function, RESET using the SET/RESET button is not possible. To exit this function, press either the measurement function switch

or the FUNCTION button or one of the other buttons.

30

The red test lead must be plugged into this socket when voltage or

resistance measurements, continuity check or logic tests are performed.

C.4 Explanation of display and symbols

a) Digital display

The display can show up to "3999" and the polarity (-) is automatically displayed (for negative voltages and reversed polarity). Additionally there are three decimal point positions.

b) Analogue bar graph

The analogue bar graph consists of 43 segments. It has a higher

speed of measurement than the digital display. Measured value

trends are thus more easily recognised. If the measurement range is

exceeded, "OL", for Overload will be displayed and the display

"flashes" in warning.

c) Auto Hold and Dual Display "d"

The Auto Hold function is active for DC voltage, current, resistance,

and capacity (CAP) measurements and continuity test. The measured value, visible in the "large" display 4 - 5 sec. beforehand, is displayed in the small display. The Auto Hold function itself is indicated with the letter "A" in front of the small display. "d" for Dual

Display appears left in front of the small display, when an AC voltage (ACV) or logic (LOGIC) measurement is carried out. The following

table shows which measurements / indications are possible:

d) Data-Hold "D-H"

With D-H a measured value is frozen (held).

e) MIN (= Minimum)

Press this button once: the smallest measured value is displayed on

the second-(DUAL)display, while measurements continue with the

"normal" display.

f) MAX (= Maximum)

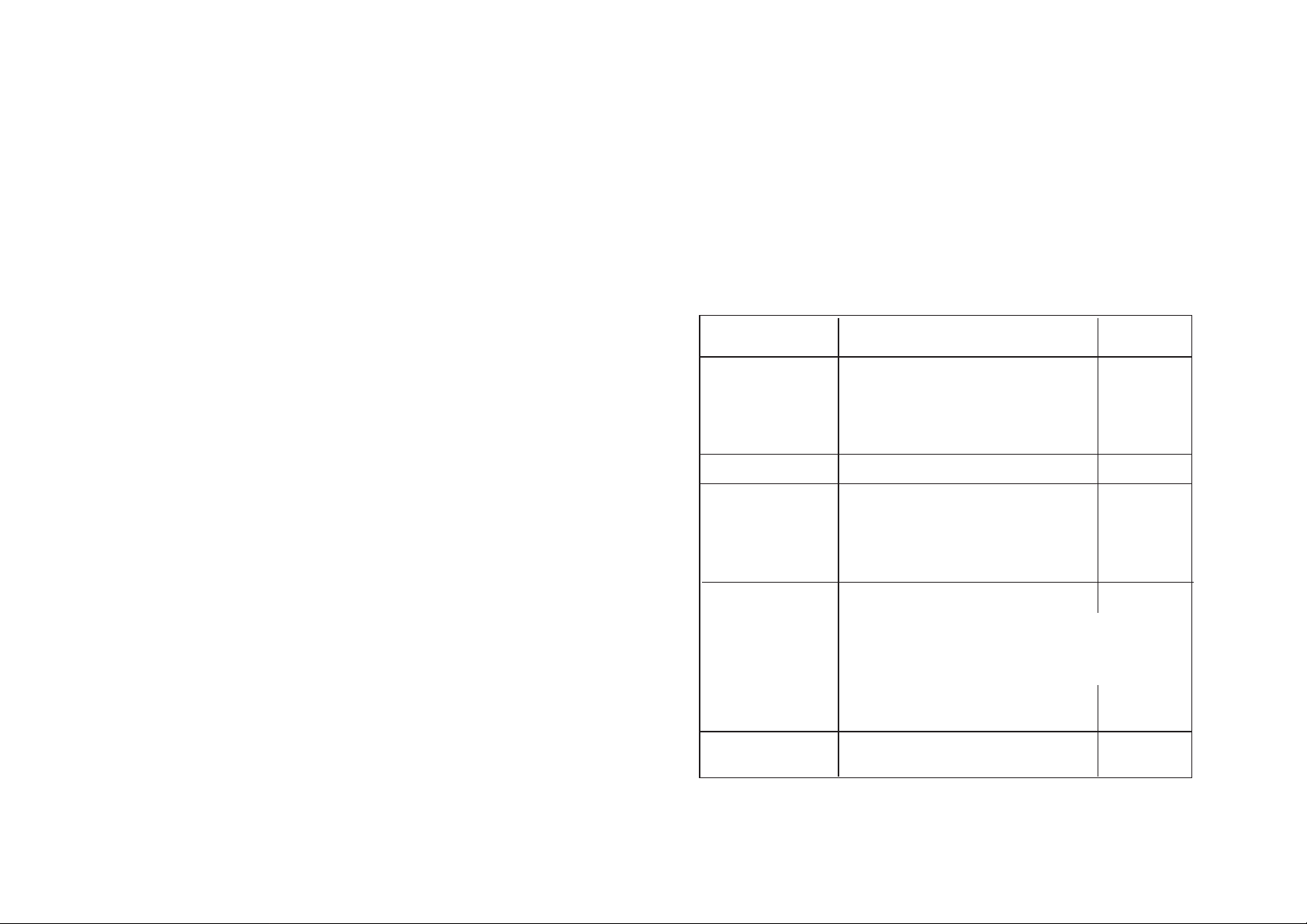

Measuring function Main display Subdisplay

(Large display) (Small display)

AC voltage AC voltage dB(m)

Logic measurement Hi/Lo DC voltage

33

=> FUNCTION => display "CMP" and "MIN" =>

=> set polarity +/- (Up/Down) => SET/RESET =>

=> set 1stposition => SET/RESET =>

=> set 2ndposition => SET/RESET =>

=> set 3rdposition => SET/RESET =>

=> set 4thposition => SET/RESET =>

=> display "CMP" and "MAX" =>

=> set +/- => SET/RESET =>

=> set 1stposition => SET/RESET =>

=> set 2ndposition => SET/RESET =>

=> set 3rdposition => SET/RESET =>

=> set 4

th

position => SET/RESET =>

=> display of "CMP", "MIN" or "MAX" and "LO" or "HI" or "PASS"

in the small display

=> the instrument is ready for comparison measurement.

Note!

With the High/Low logic function the CMP function is inoperable.

n) Display for the reference number

The reference number is applicable to the MEM and RCL functions.

The numbers are called by pressing the UP (+1) or DOWN (-1) buttons.

C.5 Display information and symbols about operating modes

a) " " Inductance measurement

The measurement range covers from 0.01 mH to 400 mH max.

b) (•) Continuity test

The continuity of voltage-free wiring, plug connections or fuses can

be checked with this function acoustically and optically (display of

measured value).

c) "-" Negative polarity

With reversed test leads and with negative polarity, a "-" sign

appears in front of the measured value.

d) CAP Capacity measurement

The capacity measurement range enables measurements of discharged capacitors from 4 nF to 400 µF

e) LOGIC logic test

All logic levels can be measured and displayed with this function.

f) Battery change indicator

An alkaline 9 V battery has an average life of approx. 60 hours in

this measuring instrument. About 8 hours before the battery end of

32

h) MEM (= Memory)

With this special function up to 8 reference values can be stored,

except under temperature measurement. For this, proceed as follows:

1. Press the function button until MEM appears in the display,

2. Press the UP/DOWN button, to set a reference number between 0

and 4,

3. Press the Set/Reset button, to store the value.

When several reference values are "filed" under the same reference number, the previous value will be overwritten in each case.

i) RCL (= Memory Recall)

This function reads the stored reference value from the memory.

Proceed as follows:

1. Press the UP or DOWN button to select the desired reference number,

2. Now press the Set/Reset button to read out the stored value. The

read-out value is shown on the small display.

k) R-H = Range Hold

With this function it is possible to exit the Auto Range mode and to

set/determine the measurement range in the selected operating

mode (voltage, current, resistance, etc. measurement) by pressing

the UP and DOWN buttons manually. This function is not available

while measuring capacity (CAP).

l) EXT (= External)

With this function two different operating modes can be read

simultaneously, one on the large display, one on the small display.

Note the following table in this connection:

m)CMP (= Comparison)

In this subfunction a high/low comparison can be made, in which

the highest and lowest stored reference values can be compared

with the presently-measured value. T o exit from this function, briefly press the operating mode switch. First set the desired measurement range. Then proceed according to the following examples:

Button operation sequence

Operation mode Main display Subdisplay

AC voltage AC voltage Frequency change-over

Logic measurement Hi/Lo Frequency change-over

35

Each of the five voltage ranges, whether AC or DC, has an input impedance of 10 MOhm in parallel with 100 pF. The AC voltage input is ACcoupled. As soon as a "-"-sign appears in front of the measured value

under DC voltage measurements, the measured voltage is negative

(or the test leads reversed).

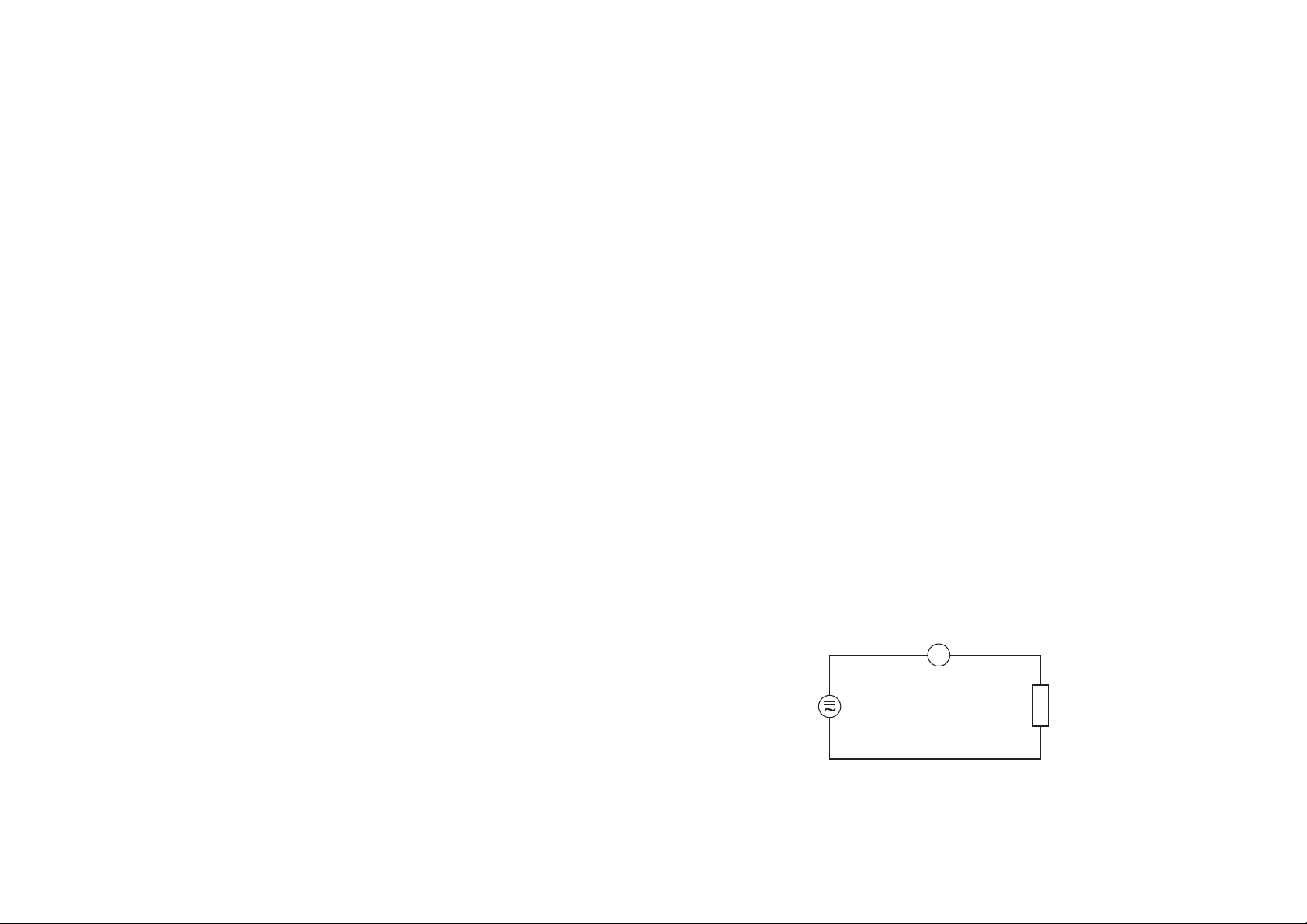

B) Current measurement

To measure direct or alternating currents, procedure is as follows:

1. Set the rotary switch to current measurement (400mA or 20A).

2. Connect the red test lead to the mA socket when currents up to 400

mA max. are to be measured and to the A socket for currents up to

20 A max.

3. Press the DC/AC button according to whether DC or AC current is

now to be measured.

As soon as "AC" appears in the display, the AC current measurement range is set.

4. Connect the instrument leads in series with the test object (see figure below).

Attention!

Do not measure any currents in circuits in which voltages greater than

250 VDC or VAC rms can occur. Under no circumstances should currents

over 20 A be measured. Measurements should only be made in 16Afused current circuits or those in which powers greater than 4000 VA

cannot occur. Measurements of currents equal to 20 A must only be

measured for a maximum of 30s duration and must only be performed

at intervals of 15 minutes (cooling down phase for the shunt).

A

DMM

Consuming

device,

load, circuit

Current

source

34

life, the battery change symbol appears in the display.

A battery check is carried out each time between individual measurement cycles.

g) all other symbols, which stand for the various measurement units:

AC = AC units

DC = DC units

mV = millivolt (exp.-3)

V = Volt

mA = milliampere (exp.-3)

A = Ampere

kHz = kilohertz (exp.3)

uF = microfarad (exp.-6)

nF = nanofarad (exp.-9)

mH = milliHenry (exp.-3)

uH = mikroHenry (exp.-6)

W = Ohm

kW = kiloohm (exp.3)

MW = Megaohm (exp.6)

5.4.3 Performing measurements

A) Voltage measurement

Attention!

Under no circumstances exceed the maximum permitted input amplitude. 1000 VDC max. and 750 VAC rms max.

Touch no circuits or components when voltages greater than 25 V AC rms

or 35 VDC are present.

To measure DC or AC voltages, proceed as follows:

1. Set the rotary switch to the desired position (mV or V)

2. Connect the red test lead to the V/Ohm socket (+) and the black

test lead to the COM socket (-)

3. Press the DC/AC button according to whether DC or AC voltage is

to be measured. As soon as "AC" appears in the display , the AC voltage measurement range is set.

4. Connect the test probes to the points of measurement (load, circuit, etc.).

37

With resistances greater than approx. 4 MOhm the display can

require some time to become stabilised.

As soon as "OL" appears in the display and the bar graph flashes,

the measurement range has been exceeded and the measurement

path is interrupted.

E) Inductance measurement

For the measurement of inductance proceed as follows:

1. Set the rotary switch to "400 mH".

2. Measurements can now be performed with the test socket on the

measuring instrument. The "R-H" function can be used to switch to

and fro manually between two measurement ranges. If the "R-H"

function is not set, the measuring instrument automatically sets itself to Auto Range.

Attention!

With inductance measurements, make sure without fail that the coil and

the circuit, to which it may be connected, is absolutely voltage-free. Any

capacitors present must be discharged.

F) Capacity measurement

For the measurement of capacities proceed as follows:

1. Discharge each capacitor before connecting it to the measuring

instrument.

Attention!

When short-circuiting capacitors, high-energy discharges can occur.

Caution: danger to life!! Do not touch capacitor connections with voltages greater than 35 VDC and 25 V AC. Take care in environments in which

dust, inflammable gas, steam or liquids are present or can occur. ==>

Danger of explosion!

2. Set the measurement function switch (8) to "CAP".

3. Measurements can now be performed with the test socket on the

measuring instrument.

With polarised capacitors, observe the correct polarity.

G) Using the analogue bar graph

The bar graph is easy to operate and understand. It is comparable with

36

C) Continuity test

With this function voltage-free leads, fuses, circuits etc. can be acoustically checked for continuity. This measurement is performed as follows:

1. Position the rotary switch to (•).

2. Connect the red test lead to the V/Ohm socket (+) and the black test

lead to the COM socket (-).

3. Then connect the test probes to the points of measurement.

Attention!

Measure no charged capacitors, because otherwise the measuring

instrument can be destroyed by a possible discharge.

D) Resistance measurement

Attention!

Ensure that all components, circuits, chips and other objects to be measured, are completely voltage-free.

1. Set the measurement function switch to resistance measurement

(OHM).

2. Connect the red test lead to the V/Ohm socket (+) and the black test

lead to the COM socket (-).

3. Now connect the measuring probes with the test object.

The resistance of the test leads can normally be ignored (approx. 0.1

to 0.2 Ohm). However, this low value can lead to inaccuracies in the

lowest measurement range.

Using the "REL" function, this resistance can be "subtracted" to

compensate for these "measurement errors", i.e. the display referenced and set to "0".

When a resistance measurement is performed, ensure that the test

points which you touch with the test probes during measurement

are free from dirt, oil, solder flux or similar. Such conditions can falsify the measured value.

39

b) Using the software

This multimeter operates with any computer with an RS-232 interface, but the software is only suitable for IBM-compatible computers. Using the software is described as follows:

1. Insert the floppy disk into the drive. Copy the files either onto the

hard drive or make a back-up copy of the floppy.

2. Press the "Enter" key.

3. To stop or interrupt the program during execution, press CRTL +

BREAK on the computer keyboard.

Data transfer

SAs soon as the multimeter is switched on, the interface is ready. Data

transfer is started by command [D] from the computer.

The following should be noted, when software other than that provided is used.:

The data format is 14 bits in length. It is composed as follows:

BYTE 1 2 3 4 5 6 7 8 9 A B C D E

Example 1 DC - 3 , 9 9 9 V CR

Example 2 OHM 3 , 9 9 9 M o h m CR

Program example in BASIC for easy reading of the multimeter:

10 OPEN "COM1:1200,N,7,2,RS,CS,DS,CD" AS#2

20 A$="D"

30 PRINT #2,A$;

40 IN$=INPUT$(14,#2)

50 PRINT IN$

60 CLOSE #2

70 END

Specific data transfer characteristics (communication parameters):

Transfer rate : 1200 baud

Character code : 7-bit ASCII

Parityt : none

Stop bits : 2

5.5 Maintenance and calibration

38

the pointer of an analogue measuring instrument but without its

mechanical disadvantages. It is particularly suitable for quickly-changing signals, for which the digital display is too "slow". Trends in a

changing measurement value can thereby be quickly recognised and

evaluated. During overrun or when the measurement range is exceeded, all bar graph display segments flash.

H) Logic test

This measurement function indicates logic levels in digital circuits.

1. Switch the measuring instrument on.

2. Set the measurement function switch (8) to HIGH/LOW. "rdY"

(ready) appears in the display.

3. Connect the test leads to the COM socket (black lead) and to the

V/Ω socket (red lead).

4. Now connect the other end of the black test lead to the digital circuit"ground" = "-" (normally). The red test probe must be connected to the positive supply voltage (V+ or Vcc).

5. When the connections are made, press the Set/Reset button once.

6. While the black test lead remains connected to ground, the red test

probe can be removed from the positive supply. The test points

under consideration can now be touched with the red test probe; as

a result the multimeter will display three possibilities.

- If the level is more than 70 % of the stored supply voltage, "Hi"

will be displayed;

- If the level is less than 30 % of the stored supply{1215} voltage,

"Lo" will be displayed;

- If the level on the contrary is between = 31 % and 69 % of the sto-

red supply voltage (e.g. 5 V), "---" will be displayed.

In the "LOGIC" operating mode, it is not possible to use the subfunctions

"MAX", "MIN" and Data Hold = "D-H". Before using the measurement

range switch when leaving the logic function, -the SET/RESET button

must be pressed, so that "rdY appears" in the- display.

I) Using the multimeter in connection with a computer

a) Connection

Connect the RS-232 interface cable (null modem cable) to the multimeter (rear of the case under the lower cover) and to a serial interface of the computer.

Now switch on the measuring instrument.

41

Max. input levels: Channels A, B and C 3V rms

Resolution (of the display): 1 Hz, 10 Hz, 100 Hz

| | |

Gate Time: 10 sec., 1 sec., 100ms = 0.1 sec.

Standard time basis: Frequency 10 MHz; Stability 5 ppm (0°C

to +40°C)

LED display: 8 digit LED with units of measurement

Period measurement: Channels A and B; 0.1 sec. to 10 sec.

min. Resolution 1 µs to 0.1 ps, depen-

dent on gate time Channel C;

0.1 sec. to 10 sec.; Resolution 0.1 ps

min., dependent on gate time

Difference measurement A-B: Resolution 100 Hz to 100 µHz min.

according to gate time and input sig-

nal

Addition of A+B: Resolution 100 Hz to 10 nHz min. ac-

cording to gate time and input signal

Time interval A=>B: Range 100 ns to 10 sec.

Resolution 100 ns min.

Overrun indicator: "OVER"

C) Function generator

Waveforms: sine, square, sawtooth,

"skewed" sine, ramp, pulse,

TTL level (square)

Frequency: 1 Hz to 10 MHz in 7 ranges

VCF voltage level: 0 to 10 VDC (but max.: ±15VDC)

Output impedance: 50W ± 10 %, 600 W ± 10%

Connectors: BNC

Amplitude: 2 V p-p to 20 V p-p unloaded

1 V p-p to 10 V p-p into 50 Ohm

Attentuator: - 20 dB

Variable frequency range: 20 to 1 or more

Variable symmetry range:: 3 to 1 or more

Variable offset range: max. ±10 VDC

Sine function

- Harmonic distortion: lower than 1 % (at 100 kHz)

- Amplitude errors: ± 0.3 dB

40

To guarantee the accuracy of the multimeter over a prolonged period of

time, it should be calibrated annually. Fuse replacement is under 3.

(Safety requirements). Battery replacement can be found under 4.4.1.

To clean the instrument or the display window, take a clean, lint-free,

anti-static, dry cleaning cloth.

Attention!

Use no carbonaceous cleaners or petrols, alcohols or similar for cleaning.

Otherwise the surface of the measuring instrument will be attacked. In

addition, the vapours are damaging to health and explosive.. Also use

no sharp-edged tools, screwdrivers or metal brushes or similar for cleaning.

6.Technical data (general and DMM) and

DMM measurement tolerances

6.1 Technical Data

A) Measuring instrument in general

Input voltage: 100/120/220 or 240 VAC / 50 or 60Hz,

according to the position of the voltage selection "switch" (= fuseholder

cap)

Power consumption: approx. 120 VA

AC power fuse: for voltages from 220 to 240 VAC, 1 A

slow-acting 250 V.

Usual designation: T1A/250V;

Fuse dimensions: 6 x 30 mm

Weight: approx. 12.5kg

Dimensions (W x H x D): 380 x 185 x 370 mm (without leads and

with feet hinged back)

B) Frequency counter

Channel A: 5 Hz to 100 MHz

Channel B: 5 Hz to 100 MHz

Channel C: 100 MHz bis 1.3 GHz (= 1300 MHz)

Input impedances: Channels A and B: 1MΩ (in parallel

with 100 pF); Channel C: 50 Ω

Input sensitivities: 70 mV rms for channels A and B,

35 mV rms for channel C

43

less than 75%, non-condensing

Storage temperature: -10°C to +50°C, with relative humidity

less than 80%, non-condensing

Temperature for guaranteed

accuracy: +23°C ± 5K

Battery type: NEDA 1604 9V or 6F22 9V , alkaline type

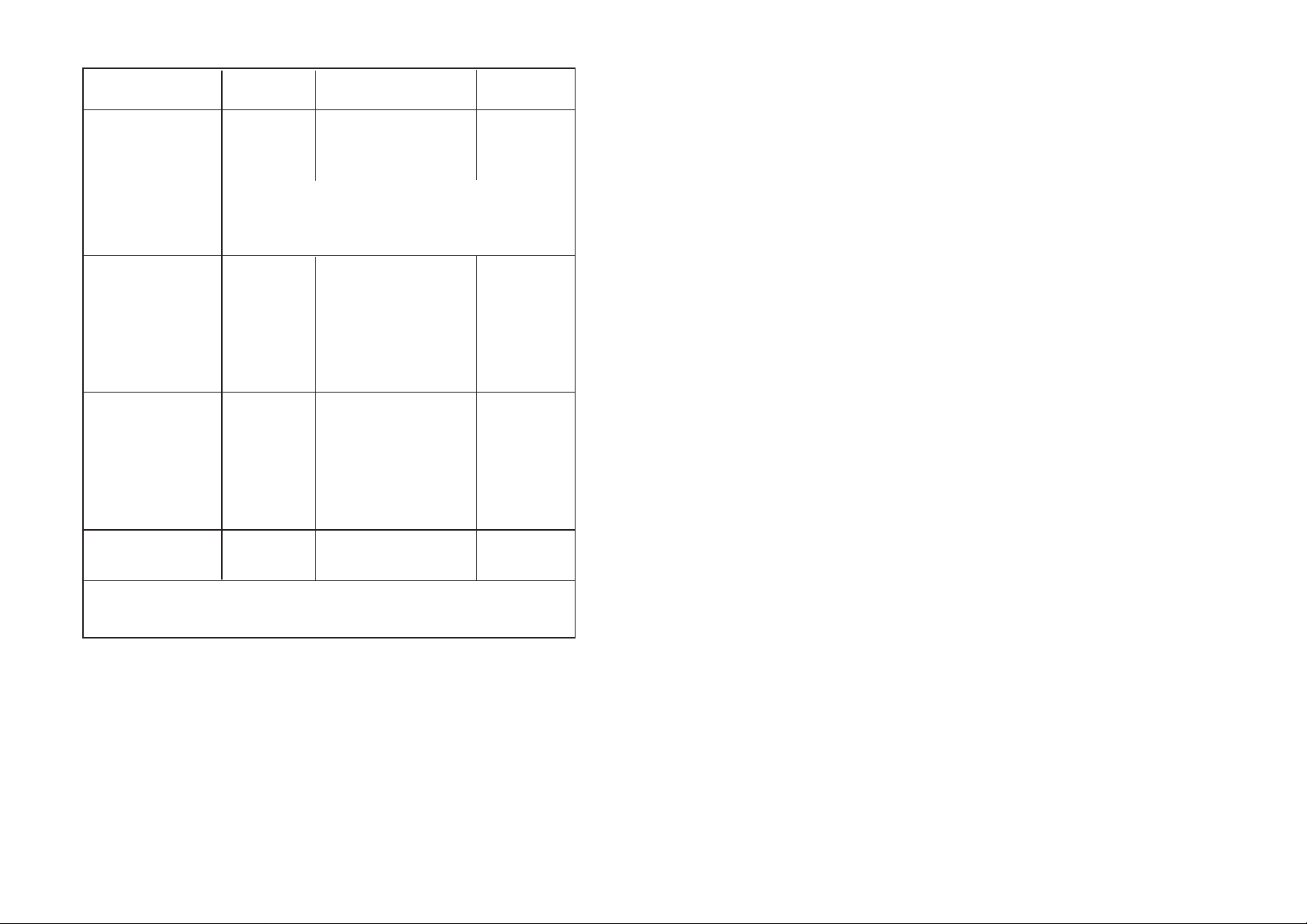

6.2 Multimeter measurement tolerance

Accuracy specified in ±(% of reading + number of digits); accuracy over

one year at a temperature of +23°C ±5K, with relative humidity of less

than 75 %. Warm-up time, 1 minute.

Operating mode Measuring range Accuracy Resolution

DC voltage 400 mV ±(0.3%+1dgt) 100 uV

4 V ±(0.3%+1dgt) 1mV

40 V ±(0.3%+1dgt) 10 mV

400 V ±(0.3%+1dgt) 100 mV

1000 V ±(0.5%+1dgt) 1 V

AC voltage 400 mV ±(2.5%+5dgts) 100 uV

True RMS = 4 V ±(2.5%+5dgts) 1 mV

effective value 40 V ±(2.5%+5dgts) 10 mV

crest factor 3 400 V ±(1.0%+3dgts) 100 mV

750 V ±(1.0%+3dgts) 1 V

Frequency of DC voltage:

from 40 to 10 kHz of the mV range up to 40 V

from 40 Hz to 1 kHz from 400 to the 750 V range

DC current 40 mA ±(0.8%+1dgt) 10 uA

400 mA ±(0.8%+1dgt) 100 uA

4 A ±(1.5%+5dgts) 1 mA

20 A ±(1.5%+5dgts) 10 mA

42

Square function

Symmetry: < ± 3 % (at 1 kHz)

Risetime/falltime: < 150 ns (at 1 kHz)

Sawtooth function

Linearity: < 1 % (at 100 kHz)

< 5 % (100 kHz to 2 MHz)

< 10 % (2MHz to 10 MHz)

TTL level

Risetime/falltime: < 30 ns (at 1 kHz)

Output level: > 3 V

Sweep frequency (Wobbel)

Sweep time: 20 ms to 2 s

Deviation: Linear/logarithmic (switchable)

Bandwidth: > 100 to 1

Sweep output (ext.) = VCF input

D) DC voltage power supply

Output A Output B Output C

Output voltage: 0 - 30 V 5 V (fixed) 15 V (fixed)

Output current: 0 - 3 A 2 A -"- 1 A -"Ripple voltage: 1 mV max. 2 mV max. 2 mV max.

Load stabilisation: 0.1%+5mV 0.1%+70mV 0.1%+35 mV

Stabilisation for

AC power variation: 0.1%+5mV 0.1%+30mV 0.1%+30mV

Current limiting: to 3.2 A 2.2 A (typ.) 1.2 A (typ.)

Fold Back Fold Back

Display: 3 1/2-position --- ---

LCD display

for V and A

illuminated

LED display: LED for LED for "ON" LED for "ON"

current limiting

E) Digital multimeter

Technical data, general

Display: 3

3

/4-position LCD display up to 3999,

with automatic polarity indicator

Measurement rate: 10 measurements per second

Input resistance: 10 MΩ

Input current AC/DC: 20 A

Operating temperature: 0°C to +40°C, with relative humidity

45

6.3 Maximum input levels, overload protection

(Multimeter)

Voltage measurement:1000 VDC and 750 VAC

Current measurement: 400mA AC/DC in mA range

20 A AC/DC in 20A range, 30 sec. max. duration

with a subsequent cooling phase of at least

15 minutes, 250 VDC/VAC rms max.

Resistance

measurement: 40 MOhm, Overload protection 250 VDC/AC

Continuity test: Overload protection 250 VDC/AC

Logic measurement: Overload protection 250 VDC/AC

Capacity

measurement: 400 uF

Inductance

measurement: 400 mH

Attention!

The capacity and inductance measurement functions are not protected

against overload or excessive input voltage(s). Exceeding the maximum

permitted input will result in damage to the measuring instrument or

can endanger the user's life.

44

AC voltage 40 mA ±(2.5%+3dgts) 10 uA

True RMS = 400 mA ±(2.5%+3dgts) 100 uA

effective value

crest factor 3 4 A ±(2%+5dgts) 1 mA

20 A ±(2%+5dgts) 10 mA

Frequency of DC voltage:

from 40 Hz to 10 kHz of 40 mA and 400 mA range

from 40 Hz to 1 kHz of 4A and 20 A range

Resistance 400 Ω ±(0.5%+1dgt) 0,1 Ω

4 kΩ ±(0.5%+1dgt) 1 Ω

40 kΩ ±(0.5%+1dgt) 10 Ω

400 kΩ ±(0.5%+1dgt) 100 Ω

4 MΩ ±(0.5%+1dgt) 1 k Ω

40 MΩ ±(1%+2dgts) 10 kΩ

Capacity 4nF ±(2%+3dgts) 1pF

40nF ±(2%+3dgts) 10pF

400nF ±(2%+3dgts) 100pF

4uF ±(3%+5dgts) 1nF

40uF ±(3%+5dgts) 10nF

400uF ±(3%+5dgts) 100nF

Inductance 40 mH ±(3%+20dgts) 10 uH

400 mH ±(3%+10dgts) 100 uH

Continuity tester: acoustic signal in case of resistances smaller

than 30 Ohm, measuring tension 2.0 VDC max.

47

- T ransformation d'une tension de courant alternatif de 230V en tension

de courant continu de 5V/2A, 15V/1A et de 0 à 30V/0 jusqu'à 3A à l'aide de l'appareil de secteur intégré

- A l'aide du multimètre numérique, mesure de tensions de courant continu jusqu'à un maximum de1000 VDC, TRUE RMS (=valeur effective)

- Mesure de tensions de courant alternatif jusqu'à un maximum 750

VACrms, mesure de courants continus et alternatifs (True rms) jusqu'à

un maximum de 20 A, longueur maximale de 30 s (protégé par fusible),

mesure de résistances jusqu'à un maximum de 40 MOhm, mesure de

capacités jusqu'à un maximum de 400 uF, mesure d'inductances jusqu'à

un maximum de 400 mH, contrôle de circulation électrique et test de

logique.

- Il est interdit de pratiquer des mesures dans un environnement aux

conditions défavorables. Des conditions défavorables se définissent

comme suit:

- toute forme d'humidité (air trop humide, par exemple),

- la poussière, les gaz inflammables, les vapeurs et solvants,

- l'orage et les très puissants champs électrostatiques créés par un

climat orageux.

Toute autre utilisation provoque des dégâts dans le système de mesure ;

l'utilisateur, en outre, est exposé aux risques électriques (court-circuit,

incendie, électrocution etc...). Il est interdit de modifier ou de reconstruire cet appareil dans son intégralité ! Respecter obligatoirement les

consignes de sécurité!

2. Le système universel MS-9160

Le système universel MS-9160 est un système de mesure compact et de

haut rendement adapté à des domaines d'application comme les laboratoires, les ateliers de réparation, les écoles, les amateurs de bricolage

etc... Cet instrument de type "Tout en un" (All In One) comporte un

générateur de fonctions, un compteur de fréquence, un appareil de secteur pour tension de courant continu avec tensions de sortie stable et

variable et un multimètre pour toutes fonctions (isolé galvaniquement).

Les appareils contenus en un seul sont composés de la façon suivante:

1. Le générateur de fonctions délivre sept (7) formes de courbes dif-

férentes: Sinusoïde, triangle, rectangle, courbe chutant (dans le sens

des aiguilles d'une montre, contre le sens des aiguilles d'une montre),

impulsion, rampe et niveau de Logique Transistor Transistors (rec-

tangle). Le générateur de fonctions réalise des formes de courbes en

46

Station Multimètre MS-9160

Attention! A lire absolument!

Veuillez lire avec la plus grande attention la présente notice d'emploi.

En cas de dommages qui seraient la conséquence du non-respect de la

présente notice d'emploi, vous perdez tout droit à dédommagement, la

garantie n'étant plus applicable; vous courez, en outre, un danger de

mort en cas de non-respect de la notice d'emploi! Pour tous dommages

consécutifs, nous n'assumons aucune responsabilité. Veuillez conserver

cette notice d'emploi avec soin.

Sommaire

Page

1. Utilisation conforme à la destination . . . . . . . . . . . . . . . . . . . . . . . 46

2. Le système de mesure universel MS 9160, Présentation . . . . . . . . . 47

3. Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4. Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5. Travailler avec MS 9160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.1 Travailler avec le compteur de fréquence . . . . . . . . . . . . . . . . . 57

5.2 Travailler avec le générateur de fonctions . . . . . . . . . . . . . . . . 63

5.3 Travailler avec l'appareil de secteur (DC) . . . . . . . . . . . . . . . . . 68

5.4 Travailler avec le multimètre numérique . . . . . . . . . . . . . . . . . 71

5.5 Entretien et calibrage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6. Données techniques, tolérance des mesures,

changement de batterie du DMM . . . . . . . . . . . . . . . . . . . . . . . . . 89

1.Utilisation conforme à la destination de la station

multimètre:

- Mesure et affichage des fréquences jusqu'à un maximum de 1300 MHz

à l'aide du compteur de fréquence intégré

- Création de signaux sinusoïdaux, rectangulaires, triangulaires et de sig-

naux Logique Transistor Transistors à l'aide du générateur de signaux

jusqu'à un maximum de 10 MHz

F

49

effectuées que sur des circuits électriques qui sont protégés par

fusible de 16 A ou bien dans lesquels ne se rencontre aucune tension supérieure à 250 VDC/VACrms ou aucune charge dépassant

4000 VA. Cet appareil de mesure ne doit pas être utilisé dans des

installations de la Catégorie III de surtension d'après la norme IEC.

Ni l'appareil ni ses câbles de mesure ne sont protégés contre les

explosions de l'arc électrique (Norme IEC 13-101-031, Paragraphe

13.101).