OPERATING INSTRUCTION MANUAL

MODEL 8760CLP

TOTAL FREE CHLORINE & pH ANALYZER

REV. 0

AquaMetrix Inc.

1245 Maple Hill Ct, Unit 7

Newmarket, ON

Canada, L3Y 9E8

Tel: (800) 742-1413

(905) 954-0841

Fax: (905) 954-0415

www.aquametrix.com

N116-58 R.0

Contents

AQUAMETRIX INC.

Contents ……………………………………………….

8760CLP Menus………………………………………

INTRODUCTION…………………………………….

General …………………………………………

Features………………………………………….

Specifications…………………………………….

INSTALLATION…………………………………….

Analyzer Mounting……………………………….

8760CLP Component Identification……………...

Analyzer Wiring…………………………………..

Sensor Mounting………………………………….

Sensor Wiring……………………………………..

Instrument Shop Test Startup……………………..

STARTUP……………………………………………..

Analyzer Startup Tests………………………….

Easy to use menu………………………………...

Remembers Where You Were…………………...

Home Base: Press Sample……………………….

Display Features…………………………………

Arrow Keys……………………………………...

AUTO and MANUAL Keys………………...……

Standby Mode…………………………………….

Output Hold……………………………………….

Edit Mode…………………………………….…...

Temperature °C or °F………………………….…

Real-Time Clock……………………………..…..

Input Damping…………………………………….

APPLICATION INFORMATION…………………..

Chlorine Chemistry……………………………..

Chlorine and the Effect of pH…………………..

Disinfectant Properties of Chlorine……….…….

8760CLP CHLORINE MEASUREMENT………….

Introduction……………………………………...

Galvanic Measuring Cell…………………….….

CHLORINE SENSOR INSTRUCTIONS………..…

Chlorine Sensor, P/N A2104034, Component

Identification…………………………………...…

Assembly of the Chlorine Sensor………………...

Inserting Chlorine Sensor in the Flow Fitting.……

Removing Chlorine Sensor from Flow Fitting……

Zero Test Technique………………………………

Monthly Maintenance……………………………..

Semi-Annual Maintenance………………………..

Chemical Cleaning………………………………..

Sensor Storage…………………………………….

CHLORINE CALIBRATION……………………….

Standardizing Chlorine……………………………

PH and Temperature impact on Chlorine…………

Manual Temperature Compensation……………...

Manual pH Compensation………………………...

pH SENSOR INSTRUCTIONS……………………...

2

3

6

7

7

8

12

12

12

13

13

13

14

15

15

16

16

16

16

17

17

17

17

18

19

19

19

20

20

20

22

23

23

23

24

24

25

27

27

27

28

28

28

29

30

30

32

32

32

33

Inserting pH Sensor into Flow Fitting…………….

Removing pH Sensor from Flow Fitting…………...

Electrode Maintenance……………………………..

Sensor Storage……………………………………...

Monthly Maintenance………………………………

Yearly Maintenance………………………………..

When to Clean Sensor……………………………...

pH CALIBRATION…………………………………...

Selecting a pH Buffer………………………………

PH Buffer Use and Maintenance…………………...

Standardizing – Single-Buffer Calibration…………

Calibrating – Two-Buffer Calibration……………...

Manual Adjustment of Offset and Slope…………...

ERROR MESSAGES………………………………….

Acknowledging an Error Message…………………

Messages for Chlorine Input……………………….

Messages for Temperature Input…………………...

Messages for pH Input……………………………..

Cautions Messages for Alarms…………………….

DISPLAY PROMPTS…………………………………

GLOSSARY……………………………………………

CONFIGURATION OF PROGRAM………………..

OUTPUT SIGNALS…………………………………..

Reversing the 4 mA to 20 mA Output……………...

Simulated 4 mA to 20 mA Output………………….

Units for Outputs…………………………………...

ALARM FUNTIONS………………………………….

Use of Relay Contacts……………………………...

Alarm Indication……………………………………

Manual Alarm Override……………………………

Delayed Relay Activation………………………….

Unit Selection………………………………………

Wiring and NO/NC Contacts……………………....

High or Low Alarm………………………………...

Deviation Alarm……………………………………

Fault Alarm…………………………………………

Using Alarms for On/Off Control………………….

TROUBLESHOOTING………………………………

Analyzer: Electronic Hardware Alignment………..

Chlorine Sensor…………………………………….

pH Sensor…………………………………………..

APPENDIX A – Enabling Security…………………...

APPENDIX B – Default Settings……………………..

APPENDIX C – Installation…………………………..

DRAWINGS……………………………………………

D4040081: Outline and Mounting Dimensions……

D5030269: Main Board Component Location…….

D5980176: Display Board Component Location…..

D5040276: Wiring Diagram………………………..

INDUSTRIAL PRODUCTS WARRANTY………….

INDEX………………………………………………….

33

33

33

33

34

34

34

36

36

37

38

39

39

40

40

41

41

42

43

44

46

47

49

49

49

49

50

50

50

51

51

51

51

52

52

53

53

54

54

56

57

59

62

63

64

64

65

66

67

68

69

1-800-742-1413 www.aquametrix.com 2

AQUAMETRIX INC.

I

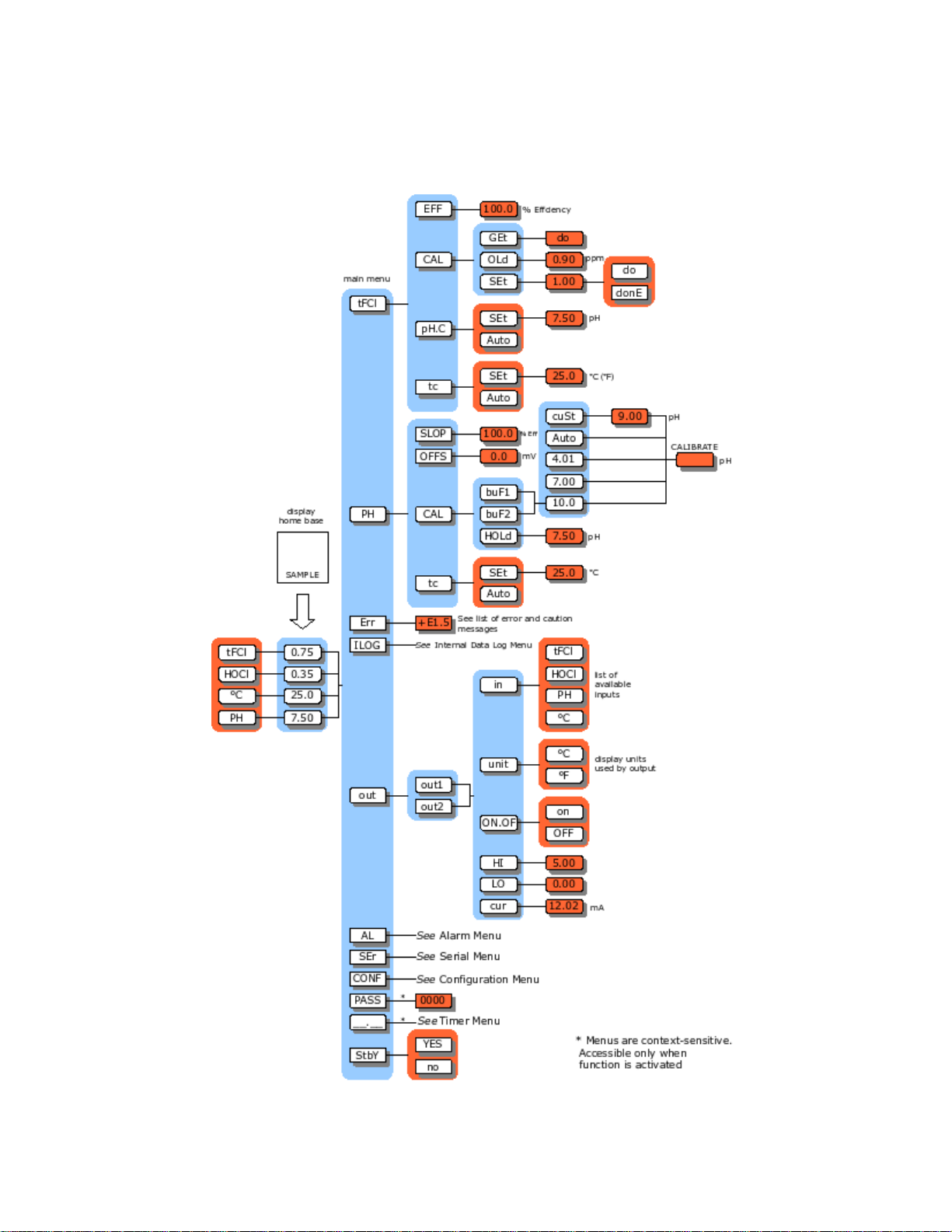

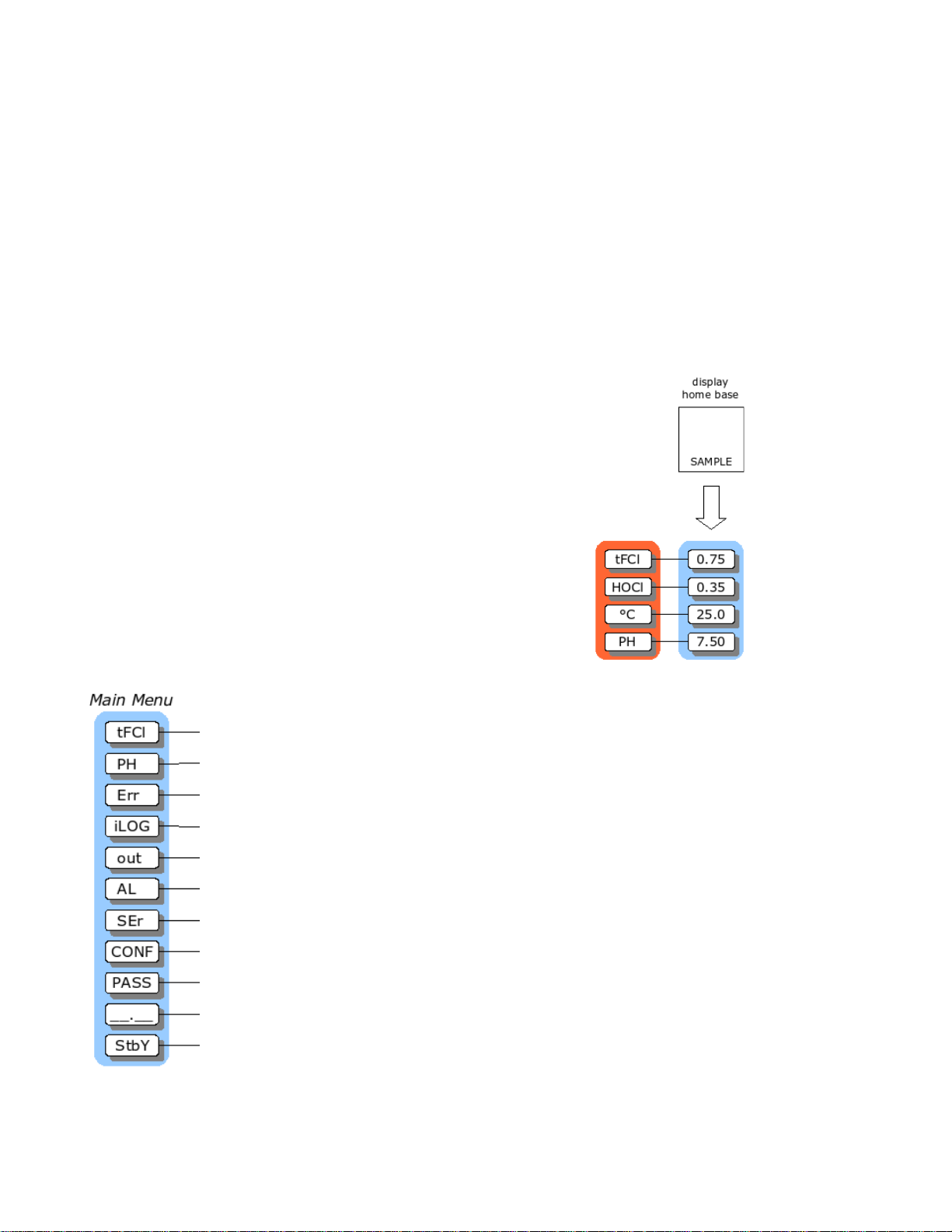

8760CLP Menus

llustration 1: Menu overview

1-800-742-1413 www.aquametrix.com 3

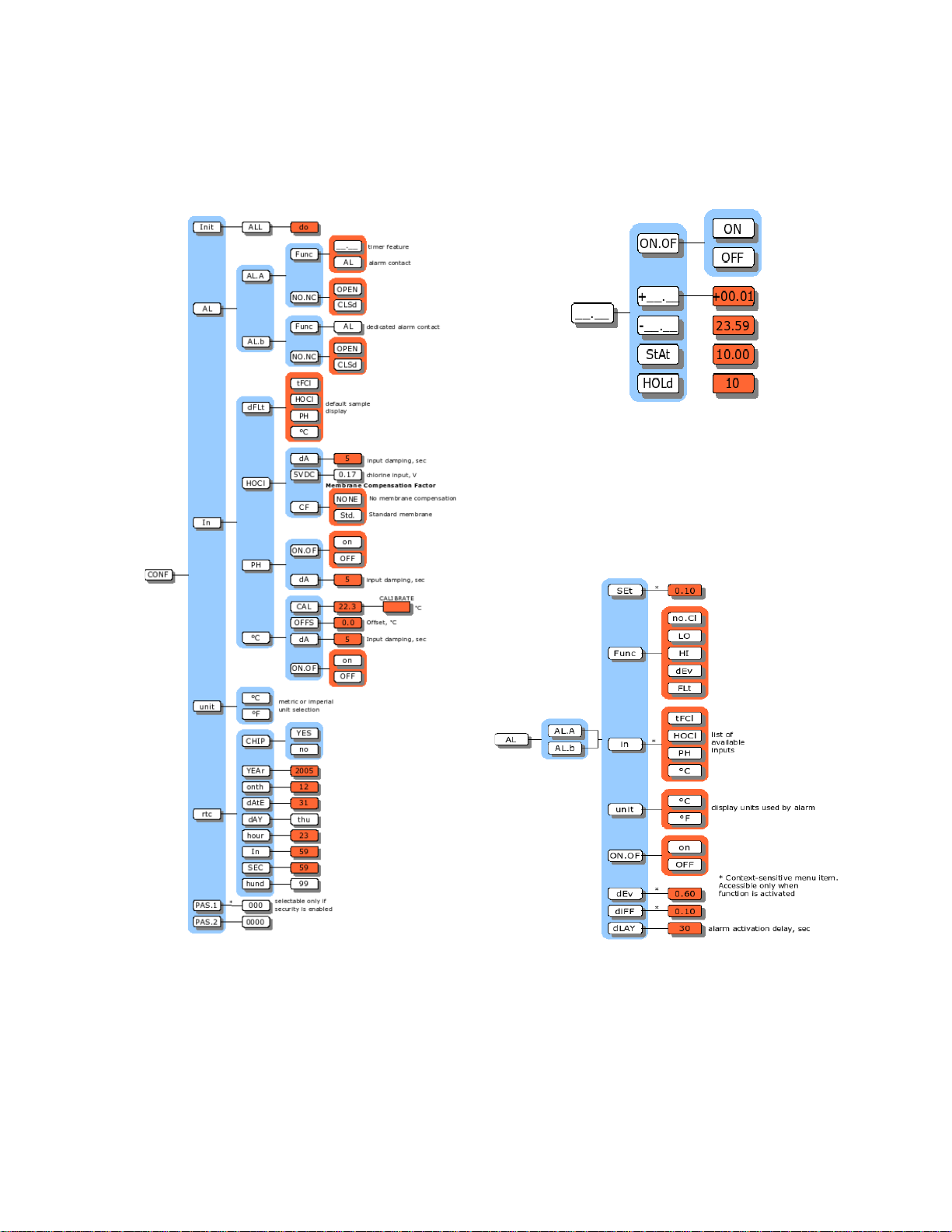

8760CLP Menus

I

I

I

AQUAMETRIX INC.

llustration 3: Timer menu

llustration 2: Configuration menu

1-800-742-1413 www.aquametrix.com

llustration 4 Alarm menu

4

AQUAMETRIX INC.

I

I

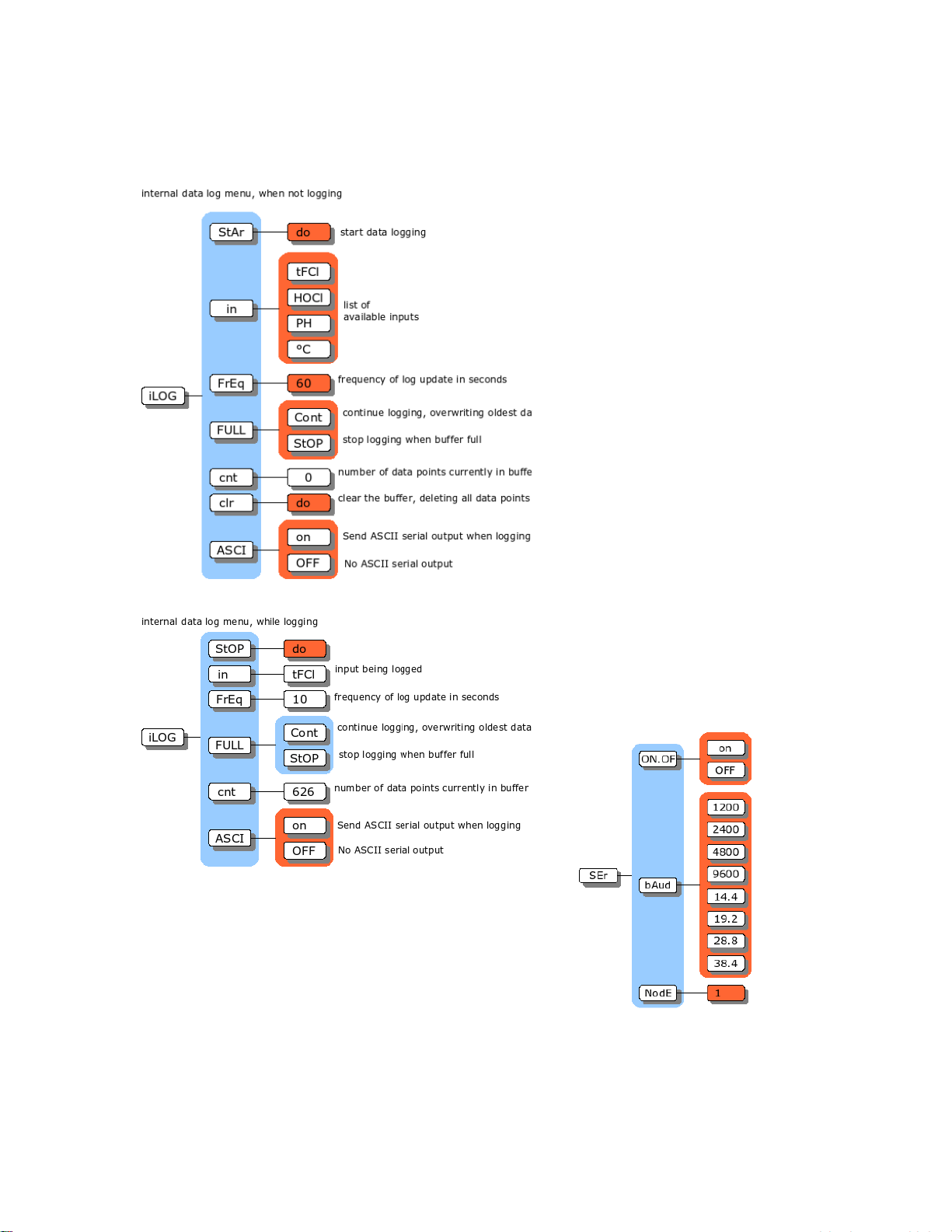

llustration 5: Internal data log menu

llustration 6: Serial menu

1-800-742-1413 www.aquametrix.com

5

AQUAMETRIX INC.

INTRODUCTION

The model 8760CLP is AquaMetrix’s industrial quality remote operational total free chlorine and pH

analyzer, designed to provide maximum flexibility, reliability, and ease-of-use. The model 8760CLP

analyzer has been designed to include a pH input to measure sample pH for continual pH

compensation ― ideal for samples with fluctuating pH values. Temperature compensation is obtained

via a temperature sensor in the chlorine sensor.

The chlorine sensor used with the 8760CLP is a galvanic cell that is separated from the process by a

chlorine permeable membrane. As the hypochlorous acid (HOCl) in the process diffuses through the

membrane, a galvanic reaction occurs which produces a current that is proportional to the free available

chlorine concentration. An advantage of the galvanic cell is that an absolute zero measurement can be

obtained; no chlorine present equals no chlorine produced. Many manufacturers use amperometric

technology as opposed to galvanic. Amperometric cells rely on an induced voltage to produce a current.

Since this residual current is always present, an absolute measurement cannot be obtained and the HOCl

concentration measured may be artificially high. Another disadvantage of the amperometric method,

that does not affect galvanic measurement, pertains to iron coating. Polarization attracts iron ions that

may be in the process water which can cause coating of the membrane; iron deposits on the membrane

can skew the chlorine readings.

NOTICE OF COMPLIANCE

US

This meter may generate radio frequency energy and if not installed and used properly, that is, in strict accordance with

the manufacturer’s instructions, may cause interference to radio and television reception. It has been type-tested and

found to comply with the limits for a Class A computing device in accordance with specifications in Part 15 of FCC

Rules, which are designed to provide reasonable protection against such interference in an industrial installation.

However, there is no guarantee that interference will not occur in a particular installation. If the meter does cause

interference to radio or television reception, which can be determined by turning the unit off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

* Reorient the receiving antenna

* Relocate the meter with respect to the receiver

* Move the meter away from the receiver

* Plug the meter into a different outlet so that the meter and receiver are on different branch

circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful: How to Identify

and Resolve Radio-TV Interference Problems. This booklet is available from the U.S. Government Printing Office,

Washington, D.C., 20402. Stock No. 004-000-00345-4.

CANADA

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numérique n’ émet pas de bruits radioélectriques depassant les limites applicables aux appareils

numériques (de la class A) prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

1-800-742-1413 www.aquametrix.com

6

AQUAMETRIX INC.

General

The 8760CLP is supplied in a corrosion resistant IP65 (NEMA 4X) watertight, dust-tight case. The

analyzer measures the sensor signal corresponding to the actual chlorine with respect to the sample pH

and temperature. The analyzer digitizes the signal for maximum accuracy, conditions it and then sends

it out as a digital output and/or on 4 mA to 20 mA outputs.

The model 8760CLP comes as a complete sample conditioning system. The analyzer is mounted on a

CPVC panel with a dual flow cell containing the pH and chlorine sensors. The sample conditioning

system includes a pressure regulator valve, head tank, sample point and atmospheric drain. The only

installation requirement of the user is to mount the panel and supply plumbing to the inlet and from the

outlet. A chlorine and pH calibration kits are supplied with the unit.

Features

The model 8760CLP total free chlorine and pH analyzer has the following features:

• No reagents required: reagent based analysis typically require a separate waste outlet. Added

reagents also require time for reaction, therefore, there is usually a lag time in response. No reagents

allow for reduced stock and maintenance costs.

• No mechanical parts: since direct measurement does not require reagents to be added and sample

mixing, there is no need for additional pumps, tubing etc., which also reduces the maintenance

required.

• Immediate response without lag time: the direct measurement method used with the model 8760CLP

gives instantaneous results. By comparison, systems that use reagents require time for the sample to

react with the reagent in the sample chamber, thus introducing a lag time.

• Galvanic technology: for better calibration with absolute zero. Galvanic technology does not attract

iron to the sensor tip, therefore, the sensor requires less cleaning and maintenance.

• Easy to replace membrane.

• pH measurement and compensation for better accuracy.

• Intuitive user-friendly program that is easy to use.

• Grab sample calibration for chlorine.

• Self and sensor diagnostics.

• Two programmable 4 mA to 20 mA outputs.

• Two programmable alarms.

• Serial digital output and remote operation.

• Three level security to protect settings.

1-800-742-1413 www.aquametrix.com

7

AQUAMETRIX INC.

Specifications

Specifications

Analyzer; 8760CL

Physical Data

PROPERTY CHARACTERISTIC

Display Four LCD digits, 1.5 cm (0.6 in) displays for total free available chlorine

(tFC1) and diagnostic information (back –lit display optional)

Display Ranges Total free available chlorine (tFC1): 0.00 mg/L to 5.00 mg/L

Free available chlorine (HOC): 0.00 mg/L to 2.00mg /L

PH: 0 pH to m14 pH units.

Temperature: -5.0 °C to 105 °C (23.0 °F to 221 °F)

Keypad 8 push button entry keys

LED’S 2 alarms (A and B). 1 auto, 1 error

Analyzer

Dimensions

Panel

Dimensions

Weight 9.1 kg (20.0 lb)

Shipping

Weight

Shipping

Dimensions

PROPERTY CHARACTERISITCS

Temperature

Environment

Ratings

Electrical

Ratings

Electrical

Requirements

12.0cm (H) x 20.0 cm (W) x 7.5 cm (D)

[4.7 in (H) x 7.9 in (W) x 3.0 in (D) ]

36 cm (W) x 66cm (H) [14 in (W) x 26 in (H) ]

11.4 kg (25.0 lb)

71 cm x 41 cm x 20 cm

(28 in x 16 in x 8 in)

Environmental Data

Operational: 5.0 °C to 45 °C (41.0 °F to 113 °F)

Storage: -10 °C to 55 °C (14.0 °F to 55 °F)

Relative Humidity: 95% maximum; non-condensing

Housing: IP (Nema 4X)

Pollution Degree: 2

Installation Category: II

115/230 VAC, 0.25 A, 50/60 Hz

115/230 VAC ± 10%, 50 W

1-800-742-1413 www.aquametrix.com

8

Specifications

Analyzer 8760CL

PROPERTY CHARACTERISTIC

AQUAMETRIX INC.

Operational Data

Accuracy

Precision

Response Time 90% within 5 s (default), function of flow and temperature

Temperature

Compensation

Sample Conditions Flow: 50mL/min to500mL/min

Sample Inlet ½ in barb fitting

Chlorine: ±0.02 mg/L

PH: ±0.04 ph units

Temperature: ±0.1 C

Chlorine: ±0.01 mg/L

PH: ±0.02 pH units

Temperature: ± 0.1 °C

Damping adjust: 3 to 99’s

Automatic temperature compensation via 1000 Ω Pt RTD.

Auto: -5 °C to 105 (23.0 °F to 221 °F)

Manual -5 °C to 105 (23.0 °F to 221 °F)

Temperature: 2 °C to 45 °C (35.0 °F to 113°F)

Pressure: <400 kPa (60 psi, 4 bar)

Drain: Atmospheric

Sample Outlet ½ in barb fitting

Security 3 access-levels security; partial and /or all settings may be protected via 3

and /or 4 digit security code.

Alarms Two continuous, assignable, programmable configurable, fail safe,

NO/NC alarm relays: SPDT, Form C, rated 10 A 115 V/5 A 230 V

Outputs Two continuous, assignable, programmable 4 mA to 20 mA, or 0 mA to

20mA outputs; isolated, max. Load 600 Ω; Convertible from 1 VDC to 5

VDC or 0 VDC to 5 VDC.

Communication

Via RS485 bi-directional serial data port; require IC Net™ 2000 software.

1-800-742-1413 www.aquametrix.com

9

AQUAMETRIX INC.

Specifications

AM-A2104033 pH Sensor

Measurement Range.........................................................................................0 pH to 14 pH units

Minimum Temperature.................................................................................................0 °C (32 °F)

Maximum Temperature..........................................................................................100 °C (212 °F)

Maximum Pressure..............................................................................................689 kPa (100 psi)

Minimum Flow Velocity........................................................................................15 cm/s (0.5 ft/s)

Wetted Materials....................................................................................CPVC, PTFE, Viton, Glass

Electrode Dimensions

Diameter.....................................................................................................................2.3 cm (0.9 in)

Length.......................................................................................................................16.5 cm (6.5 in)

Process Connection..............................................................fixed in the flow cell via a 1 in MNPT

CPVC quick connect insertion fitting

Sensor Cable.........................................................................................2 conductor; 1.5 m (5 ft) in

length with BNC connector

Preamplifier.........................................................................................................................Remote

Weight.........................................................................................................................0.5 kg (1.1 lb)

Shipping Weight........................................................................................................0.9 kg (2.0 lb)

Shipping Dimensions.................................................................................30 cm × 23 cm × 23 cm

(12 in × 9 in × 9 in)

1-800-742-1413 www.aquametrix.com

10

AQUAMETRIX INC.

Specifications

AM-A2104034 Chlorine Sensor

Measurement Range

Free Available Chlorine (HOCl)....................................................................0.00 mg/L to 2.00 mg/L

Total Free Available Chlorine (HOCl + OCl⎯)................................................0.00 mg/L to 5.00 mg/L

Minimum Temperature.................................................................................................0 °C (32 °F)

Maximum Temperature............................................................................................80 °C (176 °F)

Maximum Pressure..............................................................................................621 kPa (90 psi)

Principle of Operation.......................................................................................................Galvanic

Electrode Materials

Cathode......................................................................................................................................Gold

Anode.......................................................................................................................................Silver

Minimum Flow Velocity........................................................................................15 cm/s (0.5 ft/s)

Wetted Materials..............................................................................................CPVC, PTFE, Viton

Electrode Dimensions

Diameter.....................................................................................................................2.3 cm (0.9 in)

Length.......................................................................................................................16.5 cm (6.5 in)

Process Connection..............................................................fixed in the flow cell via a 1 in MNPT

CPVC quick connect insertion fitting

Sensor Cable...............................................................................4 conductor; 1.5 m (5 ft) in length

with 5-pin DIN connector

Weight.........................................................................................................................0.5 kg (1.1 lb)

Shipping Weight........................................................................................................0.9 kg (2.0 lb)

Shipping Dimensions.................................................................................30 cm × 23 cm × 23 cm

(12 in × 9 in × 9 in)

1-800-742-1413 www.aquametrix.com 11

AQUAMETRIX INC.

I

INSTALLATION

Analyzer Mounting

The model 8760CLP comes as a complete sample conditioning system. The analyzer is mounted on a

CPVC panel with a dual flow cell containing the pH and chlorine sensors. The sample conditioning

system includes a pressure regulator valve, sample point and atmospheric drain. The only installation

requirement of the user is to mount the panel and supply plumbing to the inlet and from the outlet.

The panel mounts on a wall via four ⅜ inch bolts at 12¼ inch x 24¼-inch centers; refer to drawing

D4040081 for mounting dimensions. Sample inlet and outlet plumbing hookup is via a ½ in barb fitting.

Analyzer Wiring

8760CLP Component

Identification

A) Identification label; indicates complete model

number and serial number

llustration 7: 8760CLP component identification

B) Analyzer, model 8760CL

C) pH sensor, P/N AM-A2104033

D) Chlorine sensor, P/N AM-A2104034

E) Atmospheric drain

F) Flow cell; a cleaning injection port is located

on the underside of the chlorine sensor flow cell

housing (hidden from view by the pressure

gauge)

G) Pressure gauge

H) Pressure regulator

I) Flow control/shut-off valve

J) Inlet

K) Outlet

1-800-742-1413 www.aquametrix.com

12

AQUAMETRIX INC.

ANALYZER WIRING

Please refer to drawing D5040276 and perform the following:

1. The 8760CLP requires 115 VAC or 230 VAC power to be hooked up to TB400. Power consumed is

less than 1 A so generally 16 gauge wire is OK (consult local electrical codes for verification). For

stable operation, the microprocessor needs a good earth ground.

CAUTION: Confirm that the 115/230 VAC switch is correctly set for your feed.

2. If required, connect the two relay contacts; as supplied, they are not powered. They are typically

used as L1 (HOT) circuit ON-OFF switches, in NO (normally open) configuration to control the

chlorine or acid (pump/valve). Best practice uses a separate circuit to isolate the sensitive sensing

circuits from any pump or solenoid inductive surges however, as a convenience for light loads, a 3 A

circuit fuse can be installed at F402 to feed the 8760CL L1 HOT to COM on relay A.

Alarm A contact TB300, closest to AC lines.

Alarm B contact TB301.

3. If required, connect the two-isolated 4 mA to 20 mA outputs, these are 24 VDC.

Output 1, TB303, closest to the relays.

Output 2, TB304.

4. Connect the inputs.

Chlorine sensor is direct connected to the analyzer via a 5-pin DIN connector.

pH sensor is direct connected to the analyzer via a BNC connector.

Sensor Mounting

Optimum sensor performance with minimum user effort is provided through the use of the factory

integrated sample system; 35.5 cm x 66.0 cm (14 in x 26 in) CPVC sample panel with pressure

regulating valve, flow setting valve, atmospheric break, grab sample point, drain, plus dual flow cell

housing the chlorine and pH sensors. The chlorine sensor and pH sensor are fixed in the flow cell via a

1 in MNPT CPVC quick connect insertion fitting.

The sensors are mounted within the sensor lead length, as near as possible to the chlorine analyzer. The

flow cell is arranged so that the sensors are mounted on a 45-degree rising line, with the sensor's tip

down at an angle anywhere from 15 degrees above horizontal to 15 degrees vertical. 45 degrees above

horizontal is best because air bubbles will rise to the top and grit will sink, both bypassing the sensor.

The pressure-regulating valve installed before the flow cell functions to control and stabilize flow. The

atmospheric drain allows for the collection of representative samples without disturbing sample

conditions and acts as a vent for bubbles. The drain line should be larger than the sample line to allow

for purging of sediments, bubbles, biologicals and other debris.

Sensor Wiring

The basic wiring scheme for AquaMetrix chlorine sensor and pH sensor is shown in drawing D5040276.

This wiring scheme is intended for cable lengths less than 20 meters (65 feet) where electrical

interference is low. The chlorine sensor has a 5-pin DIN connector and the pH sensor has a BNC

connector. This allows the sensors to be connected and disconnected easily at the analyzer.

Take care to route all signal wiring away from AC power lines, to minimize unwanted electrical

interference. Avoid twisting the sensor lead, to minimize possibilities for broken wire. Make sure that

the sensor connections are clean and tight.

1-800-742-1413 www.aquametrix.com

13

AQUAMETRIX INC.

I

k

Instrument Shop Test Startup

1. Apply 115/230 VAC power to the analyzer.

2. Hook up the chlorine sensor to bottom of analyzer via 5-pin DIN connector. Ensure that the shorting strap on

the sensor connector is removed (refer to illustration 8). Keep shorting jack for future use.

3. With the chlorine sensor in air, the 8760CL analyzer should come up reading 0.0 ppm ± 0.05 ppm.

4. Run an “air” zero check; use wires to be field installed and allow 30 minutes warm-up time for the electronics

to stabilize.

5. Run a “span” check. In the [tFCl] menu, change to these settings: [tc] [SEt] [25.0] and [pH.C] [SEt] [7.50].

A fairly accurate 1 ppm chlorine standard can be made from commercially available bleach; use a fresh 5.25%

solution.

a. Pipet 0.1 mL of bleach into a 1.0 L volumetric flask.

b. Fill to mark with deionized water. This will produce a 5 ppm standardizing solution.

c. Pipet 20 mL of the 5 ppm solution into a 100 mL volumetric flask.

d. Fill to mark with deionized water. This solution should be used immediately after prepared

and then discarded after 2 hours.

e. Fill a plastic beaker with the 1-ppm chlorine standard and place the chlorine sensor into the

beaker and stir.

f. Wait 10 minutes; the 8760CL should read 1.0-ppm ± 0.3 ppm.

Return the [tc] and [pH.C] settings back to [Auto].

6. To check for general performance, place the chlorine sensor in running tap water (chlorinated tap water should

be between 0.2 ppm and 1.0 ppm). The display should read in that range.

7. Hook up the pH sensor via the BNC connector on the underside of the 8760CL analyzer and remove orange

protective cap from sensor tip. Keep the cap for future use.

8. With the pH sensor in pH 7 buffer, the pH analyzer should display a reading of 7.0 ± 0.5 pH.

9. Run a “zero” calibration; 7 pH is equivalent to 0.0 mV so use pH 7 buffer.

10. Run a “span” calibration by placing the sensor in pH 4 buffer. The display should read approximately

4.01 ± 0.05 pH.

11. To check for general performance, place the pH sensor in pH 7 buffer again. It should now read approximately

7.0 ± 0.05 pH.

12. The sensor is now ready for field installation.

13. If the application will be in the caustic region, repeat steps 10 & 11 using pH 10 buffers so that the sensor is

tested in the region of use.

14. Before placing the 8760CL analyzer into operation, verify

the settings to ensure that they agree with the intended

setup. Factory defaults are listed in Appendix B. For the 4

mA to 20 mA output, set high limit and low limit.

Set preference for temperature units, ° C or ° F in [CONF]

15.

[unit]; default is ° C.

16. Set desired input signal damping, if known; default is

5 seconds.

17. The analyzer is now ready for field installation.

llustration 8: Pin location for chlorine sensor shorting jac

1-800-742-1413 www.aquametrix.com

14

AQUAMETRIX INC.

STARTUP

If the analyzer is new and has not been installed, follow the procedures described in Installation and

Configuration of Program before mounting. Mounting and wiring procedures for new installations vary

with equipment options — see drawing section for instructions. If the analyzer has been previously

installed, all that is required is to attach the electrode to the analyzer and then to turn on the power.

The analyzer will go through its automatic startup procedure any time power to the analyzer was lost for

more than a few seconds. The startup procedure initializes the analyzer program, performs error

checking, and then proceeds to display the chlorine and operate the analyzer normally.

All program settings, calibration settings, and the analyzer will have remembered defaults, as the

memory is none volatile.

Analyzer Startup Tests

The startup procedure will begin by alternately flashing [tESt] and [——] and blinking the top LED

while performing the memory tests. The analyzer will then display in sequence the analyzer number, in

this case [8760CL], any software option numbers, and the program version number, eg.[2.10]. The

program then proceeds to the display test that will light each of the implemented display segments in

turn. At the same time each of the LEDs will be lighted. If the analyzer passes all the tests, then the

hardware is functioning properly and the analyzer will proceed to display total free chlorine.

If the analyzer displays +Err or -Err, this indicates that the input is off-scale. The error LED will be

lighted as long as any input is off-scale. An off-scale error can indicate that the electrode is not in

solution, is off-scale, or is not connected properly. If the error LED remains lighted, go to the error

display section (select [Err] from main menu) to see what errors the analyzer has detected.

Calibration Settings Retained

If the analyzer was calibrated previously then the analyzer will use the calibration settings from the last

successful calibration, otherwise default settings are used. Error and caution messages generated during

the last calibration will remain in effect. AquaMetrix recommends a full chemical calibration of

chlorine after initial startup. Refer to the Chlorine Calibration section.

Analyzer settings and parameters can be viewed and/or changed at any time. Refer to the menus on

pages 3 to 5; the areas shaded in dark gray indicate program settings.

1-800-742-1413 www.aquametrix.com

15

AQUAMETRIX INC.

I

Easy to use Menu

The layout of the program is shown in the menus starting on page 3.

Remembers Where You Were

The analyzer remembers where SAMPLE is. The sample display is

home base for the program. The program also remembers which menu

selections were used last and loops around the columns. The menu can

be accessed using the arrow keys to find any parameter then press

SAMPLE to return to the displayed reading. Then, using the Right

arrow key return to exactly where you were.

Home Base: Press Sample

From anywhere in the menu, the SAMPLE key can be used to return to

displaying tFCl. The program will safely abort whatever it was doing at

the time and return to displaying the tFCl reading.

The tFCl display is the default sample display for the analyzer. The

analyzer's inputs, tFCl, HOCl, pH and temperature, are arranged

underneath each other at the left-hand side of the menu. Use the Up or

Down arrow key to display each of the readings in turn.

Display Features

1. The analyzer has a built-in timer, which returns the program to

displaying tFCl if no key is pressed for 15 minutes. This time-out has

the same effect as pressing the SAMPLE key. If security has been

enabled, then the time-out will change the access level back to 0 or 1

automatically, which gives the user read-only access. The user will

have to enter an appropriate password to go to a higher access level.

2. When the sample value is displayed, pressing the Left arrow key will

show which of tFCL, HOCl, pH or temperature is displayed. Pressing

Right arrow key displays the sample reading again.

3. The main sample, i.e. the input that is displayed first when the SAMPLE

key is pressed, can be changed. By default the main input is [tFCl].

Change the default in [CONF] [in] [dFLt]. Refer to the Configuration

of Program section for further details.

llustration 10: Main menu

Illustration 9: Home base

1-800-742-1413 www.aquametrix.com

16

AQUAMETRIX INC.

I

d

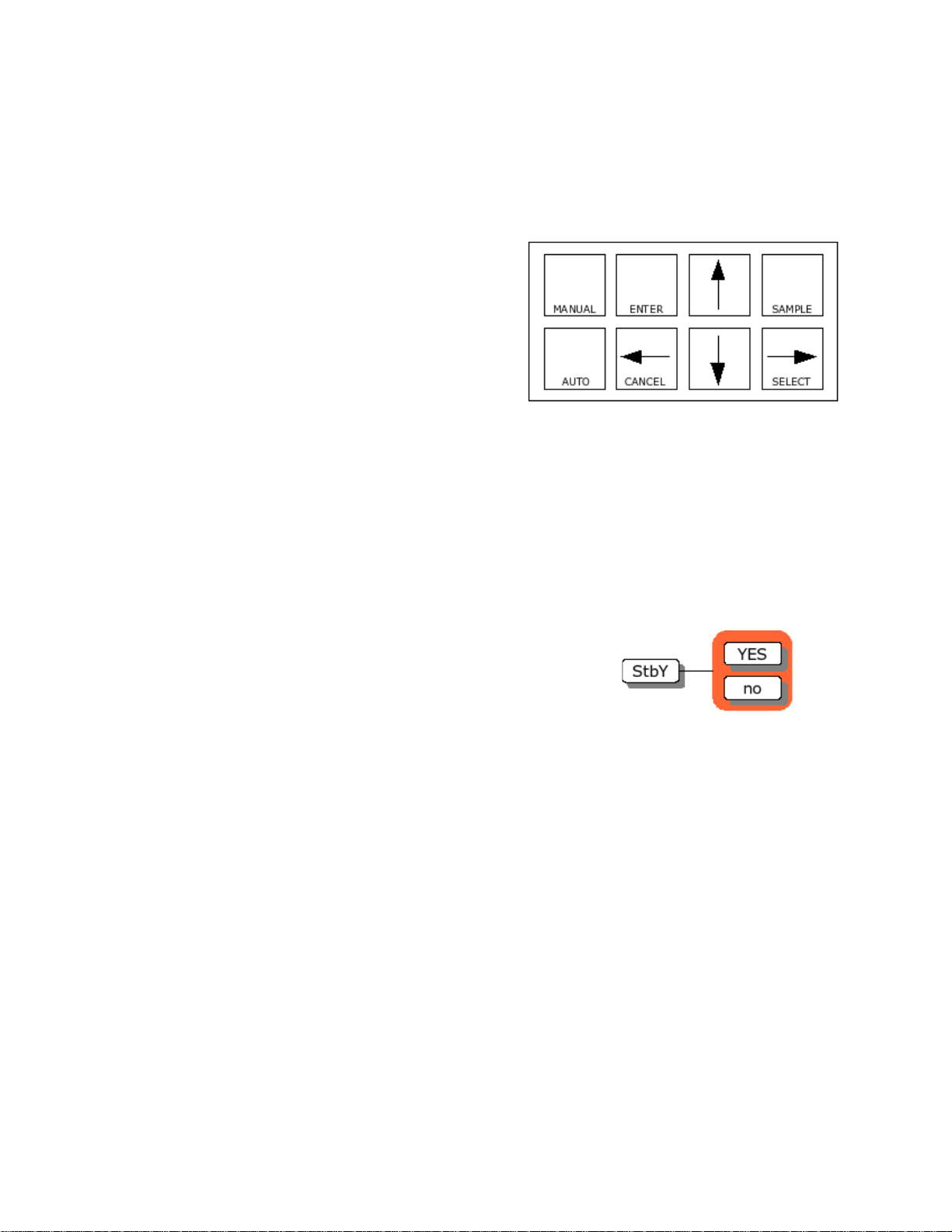

Arrow Keys

The four arrow keys on the keypad are used to move around in the menu.

Example:

Press SAMPLE to make sure that display is at home

base. Press the Right arrow key. One of the prompts

in the column starting with [out] will be displayed.

Use the Up or Down arrow keys to display the prompt

above or below. If the prompt at the top or the bottom

is displayed, the program will loop around. Press the

Up or Down key until [AL] is displayed. Press the

Left key to return to the sample display. Press the

Right key again and [AL] will be displayed.

llustration11: Analyzer keypa

AUTO and MANUAL Keys

The AUTO and MANUAL keys are used to implement the alarm override feature. Refer to the heading

Manual Alarm Override in the Alarm Functions section.

Standby Mode

Standby mode can be selected from the main menu. In standby mode the alarms will not function and

the 4 mA to 20 mA outputs will go to 4.00 mA. When SAMPLE is pressed, all the inputs will show

[StbY] instead of the normal input measurement.

The analyzer will not resume normal operation until the analyzer is

taken out of standby mode. While in standby mode, the entire

menu and all of the settings are accessible to the operator as before.

None of the settings will take effect until the analyzer is returned to

normal operation.

The standby feature is protected by security level 2.

Illustration 12: Standby menu

Output Hold

The 8760CLP features an automatic output hold for the pH input only. Output hold goes into effect as

soon as SELECT is pressed when [CAL] is displayed. The output hold feature avoids false alarms and

erratic signal output that would be caused by a routine calibration. Output hold is not necessary for the

chlorine input as chlorine calibration is performed by grab sample calibration only.

Output hold for the pH input has the following effect:

• 4 mA to 20 mA output signal for pH is frozen at it's current level

• Alarms for pH are temporarily disabled

If the output signal for pH is not acceptable at the value found, it can be changed for the duration of the

calibration. Select [Hold] from the pH menu to display the pH value used by the analyzer to determine

the output signal. Use the normal editing procedure to change the pH value used for output hold.

The output hold remains in effect for the duration of the calibration, that is, the output hold is disabled

when the [CAL] prompt is displayed, the SAMPLE key is pressed, or after no key has been pressed for

15 minutes.

1-800-742-1413 www.aquametrix.com

17

AQUAMETRIX INC.

Edit Mode

Edit mode is used to change a numeric value or to select between different options. Values and settings

that can be edited are identified by the darker shading in the menu. Any frame, which has a white

background, cannot be modified.

Editing by Selecting a Setting

Editing a value is like picking an option from a list; only one item on the list can be seen at a time. To

change the setting, press ENTER to go into edit mode. The display will start blinking. Use the Up or

Down arrow key to switch between the possible options and then press ENTER again to accept the new

setting and leave edit mode.

Example: Turn alarm A off.

From the menu, select [AL] [AL.A] [ON.OF]. The analyzer will now display either [ON] or [OFF],

which are the two choices. To change the setting, press ENTER to go into edit mode. The display will

start blinking. Use the Up or Down arrow key to switch between the possible options. When [ON] is

displayed, press ENTER again to accept the new setting and leave edit mode.

Summary of Key Functions in Edit Mode

Enters edit mode. The entire display or a single digit will blink to indicate that the

analyzer is in edit mode. Press the ENTER key again to leave edit mode and accept the

new value.

Adjusts blinking digit upward or selects the previous item from the list. If a 9 is displayed

then the digit will loop around to show 0.

Adjusts blinking digit downward or selects the next item from the list. If a 0 is displayed

then the digit will loop around to show 9.

Numeric values only: move to the right one digit. If blinking is already at last digit, the

display will loop to the ± sign on the left.

Numeric values: move left one digit. If blinking is at the ± sign then blinking goes to last

character.

Settings: restore the initial value if it was changed. Otherwise leaves edit mode without

doing anything.

Illustration 13: Edit keys

1-800-742-1413 www.aquametrix.com

18

AQUAMETRIX INC.

Temperature °C or °F

By default, the analyzer will use metric units. This means that temperature will be displayed using

degrees Celsius and that the prompt for the temperature input will be [°C]. The analyzer can also use

imperial units. For imperial units, temperature will be displayed using degrees Fahrenheit and the

prompt for the first temperature input will be [°F] instead of [°C].

In this instruction manual, the temperature input is always identified as [°C] throughout the menus.

To select imperial units for the analyzer, select [unit] from the configuration menu, then go into edit

mode and change the [°C] setting to [°F].

Real-Time Clock

The analyzer clock is used for internal date/time stamping of system events and the internal data log.

Both the system events and the internal data log are accessed using the IC Net Intelligent Access

Program, which is available as option -2. Analyzers purchased with option -B have a real-time clock

which will maintain the correct time and date even when the analyzer power is turned off.

Input Damping

The chlorine, pH and temperature measurements can be damped to provide the user with a means to

stabilize rapidly varying or noisy signals. Damping range is 3 s to 99 s. With 0 seconds, there would be

no damping and each reading the analyzer made would be used to directly update the display and 4 mA

to 20 mA output. The factory default of 5 seconds adds the next four seconds of readings to the first and

divides by five ― this gives fast response. Selecting 99 seconds adds the readings for 99 seconds and

divides by 99, providing smooth damping out of turbulent readings. Any selection between 3 s and 99 s

can be made.

Select [CONF] [in] from the menu. Use the Up or down arrow key to select the input to be adjusted,

then select the [dA] frame. Press ENTER, then change the input damping to the new number of seconds.

Press ENTER again to leave edit mode.

1-800-742-1413 www.aquametrix.com

19

AQUAMETRIX INC.

H

q

q

q

q

q

q

q

q

q

I

APPLICATION INFORMATION

Chlorine Chemistry

When chlorine gas is dissolved in water, it hydrolyzes rapidly according to equation 1. This reaction

occurs very rapidly, in only a few tenths of a second at 18 °C.

1)

Cl

2 g

2Oaq

— HOC

l aq

HCl

aq

Since HCl (hydrochloric acid) is a strong acid, the addition of gaseous chlorine to water results in a

lowering of the pH due to the acidic HCl by-product.

The important product of reaction (1) is HOCl or hypochlorous acid. Hypochlorous acid is the

disinfectant form of chlorine in water. Hypochlorous acid is unstable because the chlorine molecule is

weakly bonded and as a result will react quickly.

Hypochlorous acid is also referred to as free available chlorine, or free chlorine. It is taste free and

aggressive against germs and organic compounds.

Chlorine supplied as sodium hypochlorite, calcium hypochlorite, or bleach is in a basic form. When a

base is present, a different reaction sequence occurs:

2)

3)

In any hypochlorite solution, the active ingredient is always hypochlorous acid. Then once HOCl and

OH

4)

NaOCl

Ca OCl

-

are formed an additional reaction occurs:

HOCl

H2O

a

2 a

OH

a

a

2 H2O

1

— OCl

— HOCl

— 2 HOCl

a

1

Na1OH

a

H2O

Ca22 OH

a

a

1

1

The proportion of chlorine, hypochlorous acid, and hypochlorite ion in solution depends primarily on

pH and somewhat on temperature. The different forms of chlorine are named as follows:

Cl2chlorine

HOCl hypochlorousacid

OCl1hypochlorite ion

At atmospheric pressure and 20 °C, the maximum solubility of chlorine is about 7,395 mg per liter or

7.395 ppm.

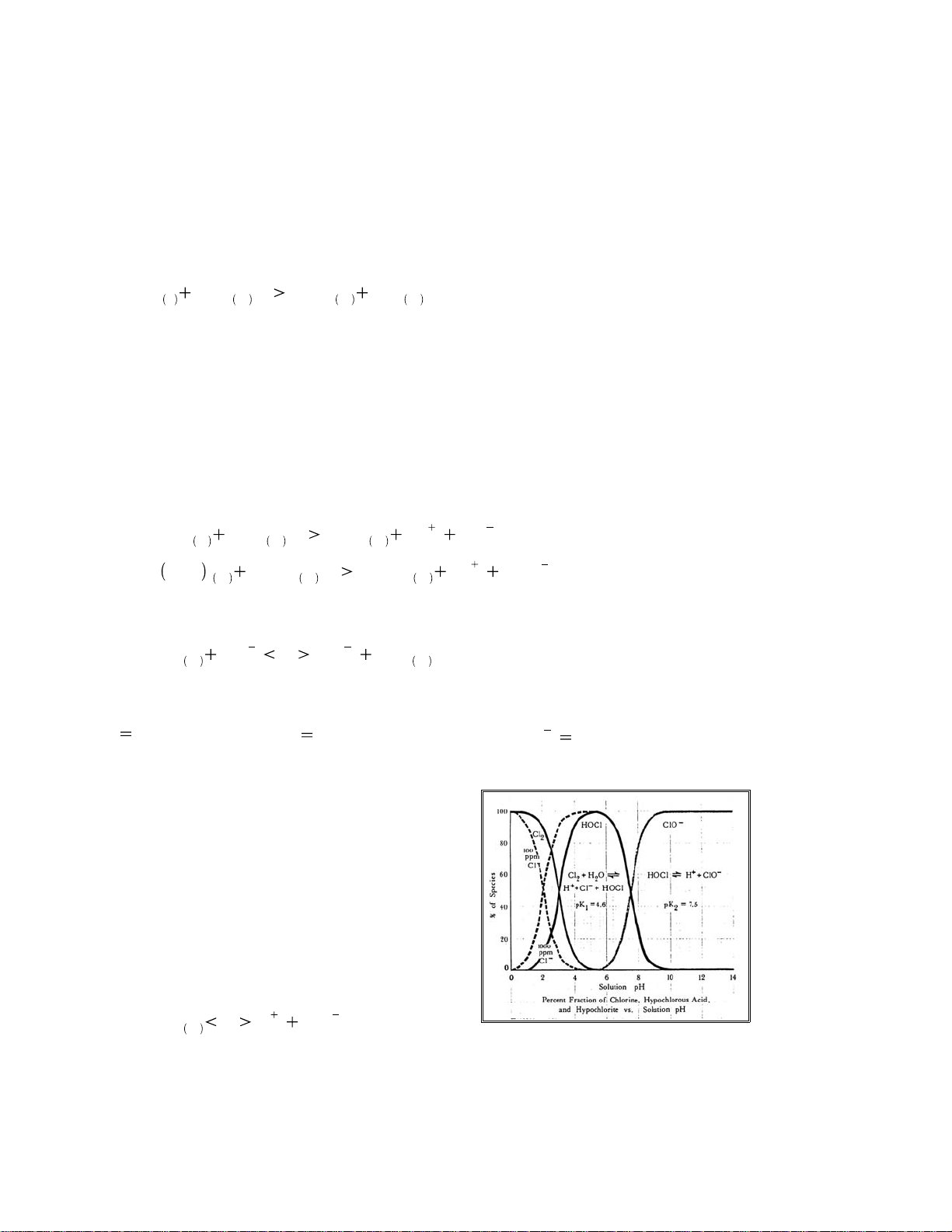

Chlorine and the effect of pH

The most important reaction in the chlorination of an

aqueous solution is the formation of hypochlorous acid.

The hypochlorous acid form of chlorine is very

effective for killing germs. Hypochlorous acid is a

‘weak’ acid, meaning that it tends to undergo partial

dissociation to form a hydrogen ion and a hypochlorite

ion. Once in a water environment, HOCl tends to

dissociate into H

5)

HOCl

1-800-742-1413 www.aquametrix.com

+

and OCl- ions.

— H

a

1

OCl

1

llustration 14: Chlorine species change vs. pH

20

AQUAMETRIX INC.

I

In waters between 5 pH and 8.5 pH, the reaction is incomplete and both species are present to some

degree. Since H

+

is one of the ions that is formed and it's concentration is expressed as pH, it follows

that changing pH levels will influence the balance of this reaction and with it the availability of

hypochlorous acid for reaction.

In a water environment, the water pH will affect the chemistry of chlorine due to it's pH sensitivity.

This becomes important as pH rises.

1

6)

H2O —H1OH

(preference is right-to-left)

Three things follow from this form of ionization:

1. Since the tendency of these two ions to react and form

2O is much stronger than the tendency of water to

H

break down into the ions, it follows that as the pH rises

there are fewer H

+

2. The H

released by the breakdown of HOCl (equation

5) react to form water (equation 6) and leave behind

residual OCl

+

ions and more OH- ions.

-

(hypochlorite) ions. Hypochlorite does

not react readily, so the chlorine is weaker.

+

3. If the pH goes down and H

available again, the OCl

-

ions revert to HOCl, which is

ions become readily

the killing form of chlorine. This pH change has been

known to cause surprise downstream fish kills.

Terminology

In the industry, there are a number of terms used to

indicate the various forms of chlorine that are of interest. These terms tend to be used rather loosely and

not necessarily consistently. For that reason, AquaMetrix will define the following terms for purposes

of this instruction manual and the 8760CLP system:

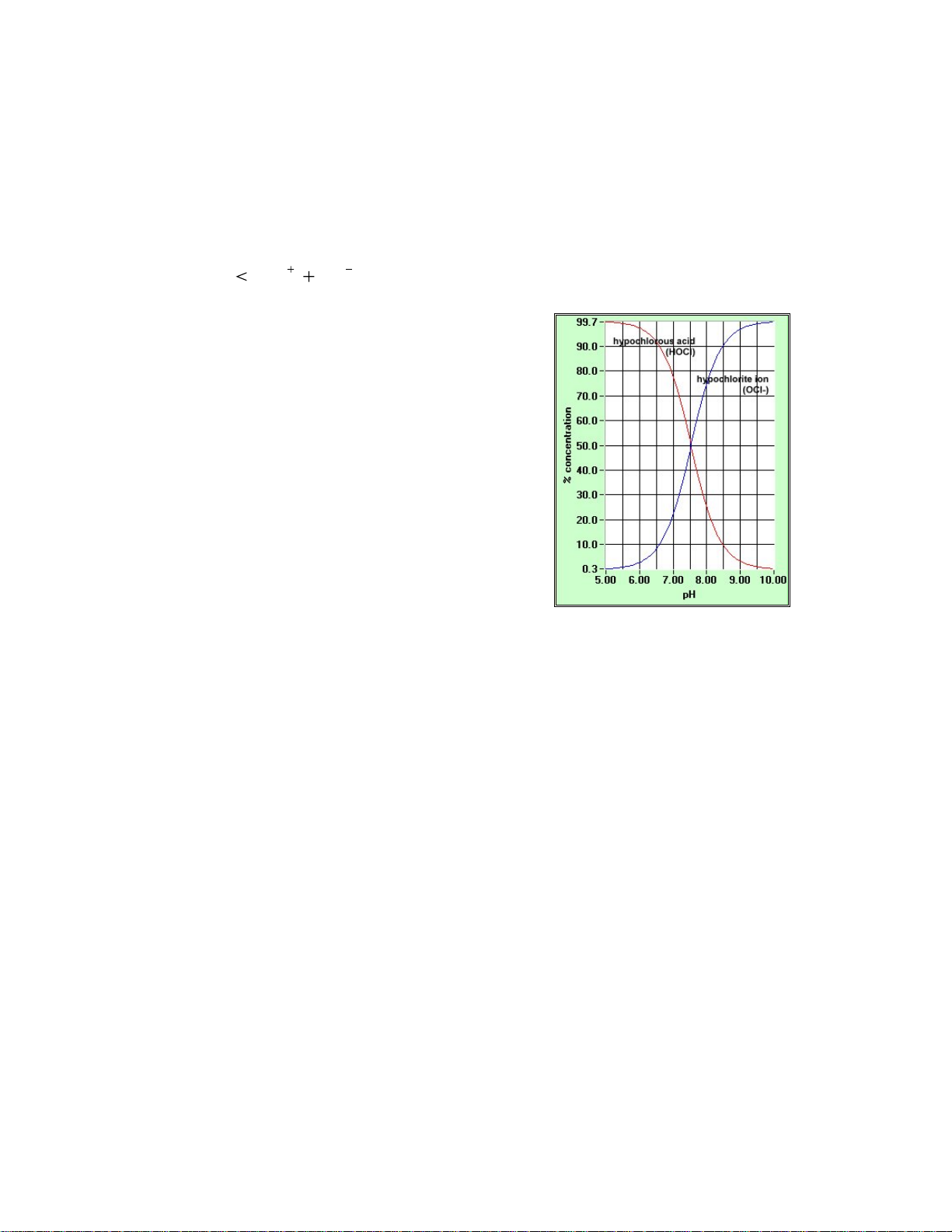

llustration 15: Chlorine concentration vs. pH

FREE AVAILABLE CHLORINE refers to the hypochlorous acid (HOCl) form of chlorine only. It is

said to be free available because it is the free, uncombined form of chlorine that is effective for killing.

TOTAL FREE CHLORINE refers to the sum of hypochlorous acid (HOCl) and hypochlorite ion

-

). The hypochlorite ion is not effective for killing, but it is in a free form. All of the total free

(OCl

chlorine would be in the form of hypochlorous acid if the pH is low enough.

COMBINED CHLORINE refers to chlorine which is not readily available, is not an effective

disinfectant and will not readily convert to hypochlorous acid or hypochlorite ion. For example,

chlorine combined as chloramines or organic nitrogen.

TOTAL RESIDUAL CHLORINE refers to the sum of total free chlorine and combined chlorine. In

environmental studies low total residual chlorine is of particular interest to ensure no downstream

consequences for aquatic life. Total residual chlorine is commonly monitored for final effluent.

1-800-742-1413 www.aquametrix.com

21

AQUAMETRIX INC.

Disinfectant Properties of Chlorine

Chlorine is known to be a good disinfectant; it is able to kill living matter in water such as bacteria,

cysts, and spores. Exactly how chlorine works to kill is not known. Studies do agree, however, that

certain forms of chlorine are more effective disinfectants than others. Whatever the chemical reaction, it

is also generally agreed that the relative efficiency of various disinfecting compounds is a function of

the rate of diffusion of the active agent through the cell wall. Factors which affect the efficiency of

destruction are:

• Nature of disinfectant (type of chlorine residual fraction)

• Concentration of disinfectant

• Length of contact time with disinfectant

• Temperature

• Type and concentration of organisms

• pH

HOCl is the most effective disinfectant of all the chlorine forms and is similar in structure to water. The

germicidal efficiency of HOCl is due to the relative ease with which it can penetrate cell walls. This

penetration is comparable to that of water, and can be attributed to both it's modest size and to it's

electrical neutrality.

The concentration of hypochlorous acid is dependent on the pH, which establishes the amount of

dissociation of HOCl to H

+

and OCl

-

ions. Lowering the temperature of the reacting solution suppresses

the dissociation; conversely raising the temperature increases the amount of dissociation.

-

The rate of dissociation of HOCl is so rapid that equilibrium between HOCl and the OCl

ion is

maintained, even though the HOCl is being continuously used up.

-

The hypochlorite ion (OCl

) form of chlorine is a relatively poor disinfectant because of it's inability to

diffuse through the cell wall of microorganisms. The obstacle is the negative electrical charge.

1-800-742-1413 www.aquametrix.com

22

AQUAMETRIX INC.

g

I

r

8760CLP CHLORINE MEASUREMENT

Introduction

Chlorine in water is a measure of the amount of chlorine, usually thought of as a gas, that is dissolved in

the liquid. Chlorine is widely respected as a leading chemical for the treatment of water to make it

potable or safe to drink. In addition, free available chlorine is often used to control biological agent

growth in water filled industrial systems. The 8760CLP directly measures free available chlorine using

a model (P/N AM-A2104034) galvanic chlorine sensor.

Galvanic Measuring Cell

The chlorine measuring sensor, P/N AM-A2104034, is an electrochemical cell similar to a battery that

produces a current when chlorine is present. By using carefully selected electrodes, in contact with an

appropriate electrolyte, a chemical reaction occurs that uses electrons gained from chlorine molecules to

produce a galvanic current directly proportional to the concentration of chlorine present. Illustration 16

shows how such an electrode system works in a simple laboratory test. Illustration 17 shows how these

scientific principles can be implemented into a working chlorine electrode. Also, unlike an electrolytic

cell in which a flow of current produces the chemical reaction, there is no zero-current as galvanic

current is naturally zero when zero chlorine is present.

The chlorine sensor uses a galvanic cell separated from the sample by a chlorine permeable PTFE

membrane. The cell has a gold cathode in close contact with the PTFE membrane where chlorine gains

electrons (is reduced) to become chloride ions, and a silver anode that produces a fixed potential and

completes the reaction with the chloride to form silver chloride.

The chemical reactions within the cell are;

At the cathode:

At the anode:

Overall:

Cl22 e12 Cl

2 Ag2 A

Cl22 Ag 2 AgCl

1

1

2 e

1

Illustration 2: Basic galvanic cell

llustration 3: Galvanic chlorine senso

1-800-742-1413 www.aquametrix.com

23

AQUAMETRIX INC.

I

CHLORINE SENSOR INSTRUCTIONS

The chlorine sensor is designed for simple maintenance. The sensor is robust and will withstand

difficult applications when properly applied and maintained. Follow the instructions in this section to

promote proper operation.

Chlorine Sensor, P/N A2104034,

Component Identification

A) Membrane

Retainer ring

B)

O-ring

C)

Sensor body

D)

Sensor cable

E)

Silver coils

F)

Gold sensing tip

G)

llustration 18: Chlorine sensor, P/N AM-A2104034, component identificatio n

1-800-742-1413 www.aquametrix.com

24

AQUAMETRIX INC.

I

I

p

I

Assembly of the Chlorine Sensor

This procedure should be done over a sink. Protective eye-wear and plastic or rubber gloves are

recommended when handling the electrolyte, a salt solution. Wash hands with water if the electrolyte

comes in contact with the skin.

1. Galvanic chlorine sensors should have a current drain at all times. Assemble sensor while powered

to analyzer OR with a short; coax center to shield. The chlorine sensor has a 5-pin DIN connector

and the sensor is shipped with a shorting strap across two pins (refer to illustration 8). Remove this

shorting strap prior to connecting to analyzer. Note the location of the pins requiring short for future

sensor storage.

2. Disassemble the chlorine sensor by removing the CPVC membrane retainer (see illustration 20) at

the sensor tip. Pull straight down on the retainer. The retainer holds the membrane in place and

removing the retainer will release the fill solution and expose the silver coils and gold sensing tip.

The fill solution is not hazardous so if any gets on the skin simply rinse with water.

3. Discard the used membrane and rinse the retainer and fill solution cavity thoroughly with deionized

water.

4. Replace the membrane using one of the following procedures:

A. Assembly with Membrane Replacement

Toolkit

Required Materials

i. P/N AM-A2104035 Membrane replacement toolkit

ii. P/N AM-A2104036 Membrane kit

iii. P/N AM-A1100239 Chlorine sensor fill solution

Membrane Replacement Procedure

a) The membrane replacement toolkit, P/N AM-A2104035, consists of two

pieces which fit together into one unit; separate the toolkit into it's

individual components (refer to illustration 19). One piece will be a

cylindrical shape (A) and the other will resemble a "T" (B).

b) Place the membrane retainer, tapered side up, into the larger diameter hole

of the cylindrical component of the membrane

replacement toolkit.

c) Place one membrane from P/N AM-A2104036,

shiny side up, over the membrane retainer.

d) Place the narrow end of the second component

from the membrane toolkit onto the membrane containing component (refer

to illustration 21). Press firmly on top of the second component until the

llustration 21:Step d) of

membrane replacement

rocedure

two components fit together securely.

llustration 19: Membrane toolkit

llustration 20: Membrane

retainer

1-800-742-1413 www.aquametrix.com

25

AQUAMETRIX INC.

Illustration 22: Step f) of membrane replacement

procedure

e) Take the sensor and rinse the fill solution cavity

with fresh fill solution, P/N AM-A1100239. Hold

the sensor in an upright position with the fill solution

cavity facing upwards and fill with P/N

AM-A1100239 so that the gold tip is completely

covered with liquid. Ensure that there are no air

bubbles in the solution.

f) Take the assembled toolkit with the larger

diameter hole and place over top of the fluid filled

sensor tip (refer to illustration 22). Press down

firmly until a stop is felt and a click is heard. Some

fluid will escape; this is normal and to be expected.

g)Remove the toolkit from sensor tip.

h)Dry the chlorine sensor and blot the tip. Examine

the tip — the membrane should be smooth with no

wrinkles or cuts and the surface contours of the gold

electrode should be clear. There should be no lines

from trapped bubbles between the membrane and the

gold electrode. If there are no visible problems as

described here, then the chlorine sensor is ready to be

put into service.

B. Assembly without Membrane Replacement Toolkit

Required Materials

i. P/N AM-A2104036 Membrane kit

ii. P/N AM-A1100239 Chlorine sensor fill solution

Membrane Replacement Procedure

NOTE: Successful membrane replacement without toolkit P/N AM-A2104035 can be difficult. It is

strongly suggested that the toolkit be purchased for ease-of-use.

a) Take the sensor and rinse the fill solution cavity with fresh fill solution, P/N AM-A1100239. Hold

the sensor in an upright position with the fill solution cavity facing upwards and fill with P/N

AM-A1100239 so that the gold tip is completely covered with liquid. Ensure that there are no air

bubbles in the solution.

b) Place one membrane from P/N AM-A2104036, centered and shiny side down, over the filled sensor

tip.

c) Take the membrane retainer (refer to illustration 20) and carefully slide down over the membrane

until a stop is felt. Some fluid will escape; this is normal and to be expected.

d) Dry the chlorine sensor and blot the tip. Examine the tip — the membrane should be smooth with no

wrinkles or cuts and the surface contours of the gold electrode should be clear. There should be no

lines from trapped bubbles between the membrane and the gold electrode. If there are no visible

problems as described here, then the chlorine sensor is ready to be put into service.

1-800-742-1413 www.aquametrix.com

26

AQUAMETRIX INC.

s

I

Inserting Chlorine Sensor in the Flow Fitting

1. Inspect the inside of the quick union fitting for any foreign matter and wipe out any dirt which may

be inside. It should appear clean, shiny and bright.

2. Install the union ring-nut and push sleeve on the assembled chlorine sensor by sliding it down the

lead wire.

3. Check that the sealing O-ring is on the electrode body, on the sensing tip side of the ledge, or in the

O-ring groove of the flow cell.

4. Insert the chlorine sensor into the fitting. Rock the sensor back and forth to pass the O-ring and press

firmly all the way down so that the O-ring firmly seats in its groove.

5. By hand, turn the union-nut until finger tight. For higher pressures it may be necessary to use a

wrench; however, the components are plastic and care is needed to avoid breakage.

CAUTION: Do not use a large wrench to turn the sensor. The plastic components of the chlorine

sensor could be broken or deformed.

Removing Chlorine Sensor from Flow Fitting

1. Stop the sample flow and allow system to drain. Remove the pH sensor as per instructions on

page 33. Removing the pH sensor will reduce the vacuum effect within the flow cell.

CAUTION: Removal of the chlorine sensor from a sealed flow cell will vacuum stretch the thin

ensing membrane. Stretching the membrane will cause slow response and higher readings at low

levels. Parting the membrane will cause chlorine sensor failure.

2. By hand, turn the union-nut until free. For higher pressures it may be necessary to use a wrench to

start turning the nut.

3. Gently rock and pull the chlorine sensor back and forth to ease the O-ring seals back up the

compression throat.

4. When the chlorine sensor has been fully removed, wipe the sensor clean and then proceed to the

calibration procedure or monthly/yearly maintenance, as necessary.

Zero Test Technique

The best way to zero check at the point of use, where all water and even the air contains some chlorine,

is to use a zero chlorine solution available from AquaMetrix as P/N AM-A1100225 in a 500 mL bottle.

CAUTION: If zero standard gets on hands, wash with running water.

Protective eye-wear and gloves are suggested.

1. Pour some of the zero chlorine solution, P/N AM-A1100225, into a clean beaker.

2. Immerse the chlorine sensor into the beaker so that it is about 3 inches below the

surface of the zero check liquid; refer to illustration 23. Provide slow gentle

movement to ensure the chlorine present is consumed. The chlorine sensor

should rapidly fall below 0.1 ppm, thus confirming operation of the sensor.

Make sure that the zero check solution is used within 8 hours because the

scavenger will be used up with exposure to air by also absorbing oxygen. The

remaining zero check solution should be stored tightly capped in it's bottle. The

llustration 23: Zero

check

1-800-742-1413 www.aquametrix.com

zero solution is “single use”, so discard the used zero solution.

27

AQUAMETRIX INC.

I

g

Monthly Maintenance

Certain applications may require occasional sensor cleaning. A monthly maintenance check is

recommended by visual examination of the sensor cell area. If needed, a soft wipe can be used to blot,

plus detergent and water to remove any deposits. Rinse thoroughly after cleaning with water. Run a

calibration and return to service if sensor efficiency is above 50 percent..

White silt inside the sensor cap may not cause problems. However, if after calibration the sensor

response is slow, replace the electrolyte and wipe the coils and surface lightly using a soft wipe, or a

little more vigorous cleaning can be done using a toothbrush. Recharge with fresh electrolyte. Calibrate

and return the sensor to service.

Semi-Annual Maintenance

Replace the membrane, P/N AM-A2104036, and electrolyte solution, P/N AM-A1100239, following the

appropriate membrane replacement procedure in Assembly of the Chlorine Sensor section in Chlorine

Sensor Instructions. Examine the coils for any discoloration or heavy coating. Such coatings should be

removed for best performance (caution the silver coils are soft metal, never use force in cleaning). To

clean the coils, refer to the Chemical Cleaning section for further instructions.

Remove the old membrane from the cell and replace with a new one. Re-assemble the cell, calibrate,

check efficiency and if above 50 percent, place in service.

Chemical Cleaning

Chlorine sensors can be refreshed with AquaMetrix P/N AM-A1100227, chlorine sensor renew solution.

This solution is only available in 30 mL bottles. Due to the acidic nature of this solution, the 30 mL

bottle is packaged in a baking soda packer for non-hazardous shipment.

NOTE: This procedure should be done over a sink. Wear plastic or rubber gloves and protective eye-

wear as the solution is acidic. Wash hands thoroughly with lots of water if the solution comes in contact

with the skin.

1. Disassemble the chlorine sensor to expose the silver coils and gold tip.

2. Immerse in cleaning solution as shown in illustration 24

for about 10 minutes, or until deposits disappear.

3. Remove and rinse in distilled or deionized water; use a

small toothbrush to scrub coils to speed removal, if

necessary.

4. Repeat steps 2 and 3 until coils and tip look clean and have

a shine; re-assemble chlorine sensor with new membrane

and fill solution, calibrate and verify efficiency is above

50%.

5. Repeat steps 2 to 4 as necessary to get at least 50%

efficiency. If not possible, the chlorine sensor should be

replaced.

1-800-742-1413 www.aquametrix.com

llustration 24: Chemical cleanin

28

AQUAMETRIX INC.

Sensor Storage

Short Term: Immerse the sensor tip in tap water. Wet storage can be used up to two weeks. If the

sensor is not connected to the analyzer, the sensor needs to be shorted. Place the shorting strap across

the appropriate pins of the sensor connector (refer to illustration 8).

CAUTION: If a wet sensor dries out in storage, it may become damaged beyond repair.

Long Term: Disassemble the chlorine sensor tip and pour out the fill solution. Rinse the coils, gold

tip, and membrane retainer with deionized water and blot dry with a paper towel. Re-assemble the

chlorine sensor dry, and store dry with the tip covered.

Dry storage can be used for a year or more.

NOTE: The sensor needs to be shorted only when it is charged (filled with electrolyte) and not

connected to a powered analyzer.

1-800-742-1413 www.aquametrix.com

29

AQUAMETRIX INC.

I

I

d

CHLORINE CALIBRATION

The 8760CLP chlorine system is calibrated by grab sample; an easy method of standardizing the

chlorine measurement without taking the electrode out of the sample. Grab sample standardization

method requires the user to determine the actual total free chlorine concentration of the sample using an

alternative method.

When grab sample calibration is used, it

is the responsibility of the user to ensure

that the grab sample taken and the total

free chlorine value recorded for it are

accurate.

A chlorine calibration kit, P/N

AM-A7010001, is supplied with the

model 8760CLP. The calibration kit

uses a reagent which develops a violet

color which is proportional to the

amount of total free chlorine in the

sample. The kit contains 30 ampoules,

sample cup, and low & high range

comparators to measure total free

chlorine in the 0 ppm to 1 ppm and 1

ppm to 5 ppm concentration ranges respectively.

Illustration 25: Chlorine menu

NOTE: Keep the kit closed when not in use. The comparators need

to be stored in the dark.

Standardizing Chlorine

NOTE: The pH input should be calibrated first, prior to chlorine

standardization. Refer to the pH Calibration section.

1. Press SAMPLE to display the [tFCl] reading. Press SELECT to

reach the first menu, then use the Up or Down arrow key to display

[tFCl].

2. Press SELECT then the Up or Down arrow key to display [CAL].

llustration 26 Chlorine calibration

kit, P/N AM-A7010001

4. From the analyzer outlet, obtain a representative grab sample cup full of water, then immediately go

and press ENTER on the analyzer.

5. Take an ampoule from the kit and place the ampoule’s tapered tip into

one of the four depressions in the bottom of the sample cup. Snap the

tip by pressing the ampoule towards the side of the cup. The sample

will fill the ampoule and begin to mix with the reagent. A small bubble

of inert gas will remain in the ampoule to facilitate mixing.

3. Press SELECT then the Up or Down arrow key to [Get]. Then

press SELECT again to display a flashing [do]. LEAVE

ANALYZER FLASHING!

CAUTION: Do not break the tip of the ampoule unless it is completely

immersed in your sample. Accidentally breaking the tip in the atmosphere

1-800-742-1413 www.aquametrix.com

may produce a “jack-hammer” effect, shattering the ampoule. Wear eye

protection when working with these ampoules.

llustration 27: Metho

for breaking the ampoule

30

AQUAMETRIX INC.

I

I

6. Remove the fluid-filled ampoule from the cup. Mix the contents of the ampoule by inverting it several

times, allowing the bubble to travel from end to end each time.

7. Wipe all liquid from the exterior of the ampoule and wait 1 minute.

8. After 1 minute, use the appropriate comparator to determine the level of chlorine in the sample. Write

down the chlorine value.

Low-range Comparator:

0 ppm to 1 ppm

The ampoule is placed in the center tube, flat

end downward. The top of the cylinder is then

directed toward a source of bright light while

viewing from the bottom. Hold the

comparator in a nearly horizontal position and

rotate it until the standard below the ampoule

shows the closest match.

llustration: 28 Using the low-range

comparator

Table 1: How to use the comparators

High-range Comparator:

1 ppm to 5 ppm

The comparator should be illuminated by a

strong white light directly above the

comparator. The filled ampoule should be

placed between the color standards for

viewing. It is very important that the ampoule

be compared by placing it on both sides of the

standard tube before concluding that it is

darker, lighter, or equal to the standard.

llustration 29: Using the high-range

comparator

9. Install the chlorine calibration value, determined in step 8, into the 8760CL as follows:

Press SAMPLE then SELECT to display [tFCl]. Press SELECT to display [CAL], then press SELECT to

display [Get], then press Up arrow to display [SEt]. Press SELECT to display numeric value, then press

ENTER to get the numeric value to flash. Edit the numeric value to the new value determined from step

8. When the flashing value is the chlorine value from step 8, press ENTER to get the analyzer to accept

the value, then press SELECT to display flashing [do]. Press ENTER to get the 8760CL to accept the

chlorine calibration by displaying [Done].

10. Press SAMPLE to display the [tFCl] or total available chlorine reading in mg/L or ppm . Write down this

value.

11. Press Down arrow key to display [HOCl] or free available chlorine in mg/L or ppm. Write down this

value.

12. Press SELECT to display [tFCl], then press SELECT, then the Up arrow key to display [EFF]. Press

SELECT to display the sensor efficiency in percent. Write down this value.

NOTE: Keeping a written calibration record will show how your unit trends over time.

The 8760CL analyzer is now reading chlorine and tracking chlorine changes in the water sample.

1-800-742-1413 www.aquametrix.com

31

AQUAMETRIX INC.

pH and Temperature impact on Chlorine

The measurement of the chlorine concentration is done by the galvanic sensing electrode. However, the

chlorine chemistry of the sample will change with both temperature and pH. Illustration 15 shows how

the relative concentrations of hypochlorous acid and hypochlorite ion shift with a change in the water

pH. This same relationship is also dependent on the temperature of the solution, as the curves will shift

with changes in the temperature. The 8760CLP includes a temperature input and pH input to

compensate for these changes. A pH sensor is provided to measure the pH of the sample and

temperature compensation is provided via a temperature sensor in the chlorine electrode.

A method has been provided in the analyzer program to change the compensation method for

temperature compensation and pH compensation from automatic to manual. Providing a method of

manual temperature compensation and/or manual pH compensation allows the analyzer to continue

measuring free available chlorine and total free chlorine in the event that the temperature sensor and/or

pH sensor are malfunctioning or absent.

Manual Temperature Compensation

From the main menu, select [tFCl] [tc]. At this point either [Auto] (for automatic temperature

compensation), or [SEt] (for manual temperature compensation set-point) will be displayed. To change

the setting from [Auto] to [SEt] press ENTER to edit the current setting. The display will start blinking,

indicating that a selection needs to be made. Use the Up or Down arrow key to display [SEt]. Press

ENTER to select manual temperature compensation.

With [SEt] as the current display, press SELECT to display the temperature setting for manual

temperature compensation. If the current value needs to be changed, press ENTER to edit the current

setting. The display will start blinking. Use the Up or Down arrow keys to display the desired

temperature for manual temperature compensation. Press ENTER to accept the currently displayed

value.

Manual pH Compensation

From the menu select [tFCl] [PH.C]. At this point either [Auto] (for automatic pH compensation), or

[SEt] (for manual pH compensation set-point) will be displayed. To change the setting from [Auto] to

[SEt] press ENTER to edit the current setting. The display will start blinking, indicating that a selection

needs to be made. Use the Up or Down arrow key to display [SEt]. Press ENTER to select manual pH

compensation.

With [SEt] as the current display, press SELECT to display the pH setting for manual pH compensation.

If the current value needs to be changed, press ENTER to edit the current setting. The display will start

blinking. Use the Up or Down arrow keys to display the desired pH value for manual pH compensation.

Press ENTER to accept the currently displayed value.

1-800-742-1413 www.aquametrix.com

32

AQUAMETRIX INC.

pH SENSOR INSTRUCTIONS

Preparation for Use

1. Moisten the pH sensor body with tap water and carefully remove the tape and orange plastic storage

cap. Caution should be used in removing this cap; pull straight down. Do not bend the body of the

pH sensor. This can result in damage to the internal element.

NOTE: Save the lower cap for later use in storage of the pH sensor.

2. Rinse away any deposits on the exposed pH bulb and junction area with tap water.

3. For first time use, or after long term storage, immerse the pH electrode in 4 pH buffer for 30 minutes.

This hydrates the pH bulb and prepares the reference junction for contact with test solutions.

4. If air bubbles are visible inside the pH bulb, shake the electrode downward to fill the bulb with

solution.

5. AquaMetrix electrodes are shipped in a pH electrode storage solution buffered to approximately 7

pH. These electrodes are often ready for use immediately with typical accuracy of ± 0.2 pH without

buffering; however, it is strongly recommended that buffered calibration be performed.

6. The pH sensor is ready to be placed in service.

Inserting pH Sensor into Flow Fitting

Insertion sensors should be examined for good clean sealing surfaces and installed carefully. Clean

seals such as O-rings should be lubricated with silicone grease to ensure liquid tight performance.

Remove the storage cap then carefully push the sensor into the insertion fitting until it is seated against

the stop. Tighten the retainer nut to hold the sensor firmly in place. Let the vessel fill with liquid. The

pH sensor should now read the liquid pH.

Removing pH Sensor from Flow Fitting

Simply turn off the sample flow and allow the pressure to drop to zero, then undo the retaining nut and

carefully remove the pH sensor from the flow cell.

Electrode Maintenance

The pH sensor needs to be calibrated periodically to maintain accurate measurements. AquaMetrix

recommends that the electrode be calibrated every 30 days. Depending on the process, it may need to be

calibrated more frequently, eg. weekly or even daily. Frequent calibration is especially important if

accurate measurements are required.

Over time, electrode performance will degrade. The glass bulb becomes less responsive to pH and the

reference electrode becomes depleted. The electrodes will need to be replaced after several years of use

or, depending on the harshness of the process, after several months.

Sensor Storage

Short Term: Rinse the pH sensor in demineralized water then store in a plastic shipping cap of 4.0 pH

buffer solution.

Long term: Clean the pH sensor in electrode wash solution, AM-A1100091, rinse in demineralized

water, then store in a plastic shipping cap of pH electrode storage solution, AM-A1100090.

1-800-742-1413 www.aquametrix.com

33

AQUAMETRIX INC.

Monthly Maintenance

Remove the sensor from the flow cell, rinse in water, remove any significant deposits, and then check by

calibration in 7 pH for offset and then 4 pH or 10 pH buffer for slope.

If the calibration turns up a caution or error message in the 8760CL analyzer, then follow the

appropriate solution. Also, refer to Troubleshooting section.

If the calibration is good, keep a log of the pH offset and slope at each monthly calibration.

The pH sensor is now ready to return to service.

Yearly Maintenance

Check the pH offset log. If the pH offset has changed more than 30 mV over the past year, it may need

to be chemically cleaned – follow the Chemical Cleaning of Sensor procedure.

Check the pH slope (efficiency) log. If the efficiency has dropped below 85%, it may need to be

chemically cleaned and restored – see Chemical Cleaning of Sensor and/or Restoring Electrode

Response in the Troubleshooting section.

After all the above checks, plus chemical cleaning and/or restoring procedures, follow the monthly

maintenance procedure. Start a new log with the improved values.

When to Clean Sensors

Various factors can affect the pH reading; scale, biological growth, oil, wax, gum, etc., all reduce the

area for hydrogen ion to react with the glass. Biological microbe growths can also produce local pH

environments inside their growth deposit, which can be quite different from the true process pH.

Periodic cleaning of pH sensors will remove these deposits, restore the pH glass surface, reference

junction and thus the pH accuracy.

Mechanical Cleaning of Sensor

The sensor will require cleaning if sludge, slime, or other deposits build up in the internal cavities of the

sensor.

Wherever possible, clean with a soft brush and detergents. General debris, oils, films, biological

growths, and non-tenacious deposits can be removed in this way.

Use a soft flat brush and a beaker or bucket of water with a good liquid detergent. Take care not to

scratch the pH electrode glass surface; it is thin, fragile and easily broken.

All the wetted surfaces of plastic body sensors should be washed with a soft cloth. This will return their

appearance to like-new condition and remove sites for buildups to occur.

When to Chemical Cleaning

After mechanical cleaning, as above, check the sensor against a pH buffer. If the sensor is still not

developing the pH reading properly in the pH buffer, proceed to the Chemical Cleaning procedure;

otherwise return the sensor to the process.

1-800-742-1413 www.aquametrix.com

34

AQUAMETRIX INC.

Chemical Cleaning of Sensor

AquaMetrix offers a pH sensor chemical cleaning kit containing solutions and necessary cleaning items as

P/N AM-A1600054.

NOTE 1: A suitable place to do chemical cleaning is at a counter or bench with a laboratory sink, with a

chemical drain where waste is contained and treated before release.

NOTE 2: AquaMetrix kits are kept small and portable so that they can be taken to installation sites,

together with a plastic bucket of water (for rinsing) and a rag/towel (for drying). Waste materials

(particularly acid leftovers) should be returned to the laboratory for disposal.

CAUTION: Use extra care when handling the cleaning solution as it contains acid. Wear rubber gloves

and adequate facial protection when handling acid. Follow all P/N AM-A1100091 & P/N AM-A1100094

MSDS safety procedures.

a) Set up the cleaning supplies where cleaning is to be performed. Lay out the sensor cleaning brush,

syringe, cleaning solutions and rinse solutions, plus the beakers and sensor.

NOTE: Ensure your cleaning solution beaker is on a firm flat surface since it will contain acid.

b) First remove the pH sensor from the process and examine it for deposits. Use the sensor cleaning brush

and tap water to loosen and flush away any deposits within the measurement area. Detergent can be

added to remove oil films and non-tenacious deposits. Hard scales and other tenacious deposits may

require chemical cleaning.

c) CHEMICAL CLEANING: Fill a beaker ¾ full of pH electrode wash solution, P/N AM-A1100091.

d) Lower the pH sensor into the center of the beaker until the entire tip is submerged.

e) Allow the sensor to sit in this solution for a few minutes and then check to see if the pH electrode and

reference junction appear clean. If not entirely clean, allow sensor to sit in solution until clean. Stubborn

deposits can be removed with the brush and syringe, to squirt wash solution into hard to reach areas.

CAUTION: Use great care when brushing and squirting acid. Wear rubber gloves and facial protection.

f) Rinse the cleaned sensor thoroughly in tap water and then with deionized water for a second rinse prior to

calibration.

g) Check the sensor against a pH buffer close to the application pH. If the sensor is still not reading properly