OPERATING INSTRUCTION MANUAL

MODEL 3200U

ULTRASONIC LEVEL & FLOW MONITOR

AquaMetrix Inc.

22-121 Granton Drive

Richmond Hill, ON

Canada, L4B 3N4

Tel: (800) 742-1413

(905) 763-8432

Fax: (905) 763-9480

www.aquametrix.com

AquaMetrix

Bench Test ·······················································3

Connections·······················································3

Keypad System ····················································4

Menu - Flow Chart ·················································4

Run·····························································6

Totalizer (Flow Mode)··············································6

Password ························································6

Units / Mode ······················································7

Flume Selection ···················································9

Calibration - for Level ·············································10

Calibration - for Open Channel Flow ··································11

4-20mA Current Loop Offset ········································12

Rejection Time ···················································12

Relay Parameters ·················································13

Special Functions ·················································15

Sensor Location - Tank Level········································17

Sensor Mounting/Location - Open Channel ·····························20

Enclosure Installation ··············································23

Error/Warning Messages ···········································24

Field Troubleshooting··············································25

Installation Considerations In Noisy Environments ·······················27

Customer Service ·················································29

Instrument Return Procedure ········································29

Appendix A - Options··············································30

Data Logger ·····················································32

RS232C Serial Output ·············································38

Appendix B - Applications Background································41

Conversion Guide ·················································42

Specifications ····················································43

Calibration Worksheet - Level Mode ··································46

Calibration Worksheet - Flow Mode ··································47

Ultrason

INDEX

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Page 2

AquaMetrix

QUICK BENCH TEST:

Ultrason

Connect Sensor to the

T.DUCER terminals as shown below, then apply Power. When properly connected

a soft clicking can be heard from the sensor and figures will show on the large LCD display. Test

operation of the Ultrason by holding the sensor steadily and aiming at a flat, stable target 12 to 28" (305

to 711 mm) away from the end of the sensor. Allow a few seconds for the Ultrason to lock onto the

target before displaying its distance. The Ultrason will now display distance in ft or cm (factory

calibration).

CONNECTIONS:

POWER INPUT: The standard model requires AC power input between 100-130VAC 50/60Hz (2 amp

fuse is recommended). No adjustments are necessary for any voltage in this range. Optional 230VAC

requires power input between 200-260VAC 50/60Hz. (See OPTIONS section of this manual for

connection of optional 12VDC or 24VDC power input).

IMPORTANT NOTE

: To comply with CSA/NRTL standards, AC power input and relay connection

wires must have conduit entry to the instrument enclosure.

AMqua etrix

C

N.O

RELAY 1

100-130VAC (50/60 Hz)

OPTIONAL:

200-260VAC (50/60 Hz)

N.C

N.O

RELAY 2

C

C

N.O

N.C

N.C

RELAY 3

G

N

L

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 12 AWG CONDUCTOR

4\20

AC

T.DUCER

GND

RX

PU

TX

RS 232

*

N.O

RELAY 4

OPTIONAL

C

N.C

N.O

RELAY 5

C

*

C

N.O

N.C

GROUND STUD

IMPORTANT

ATTACH CABLE

SHIELDS (4-20mA, RS232)

THIS END ONLY

N.C

RELAY 6

:

ALUMINUM CHASSIS

Page 3

AquaMetrix

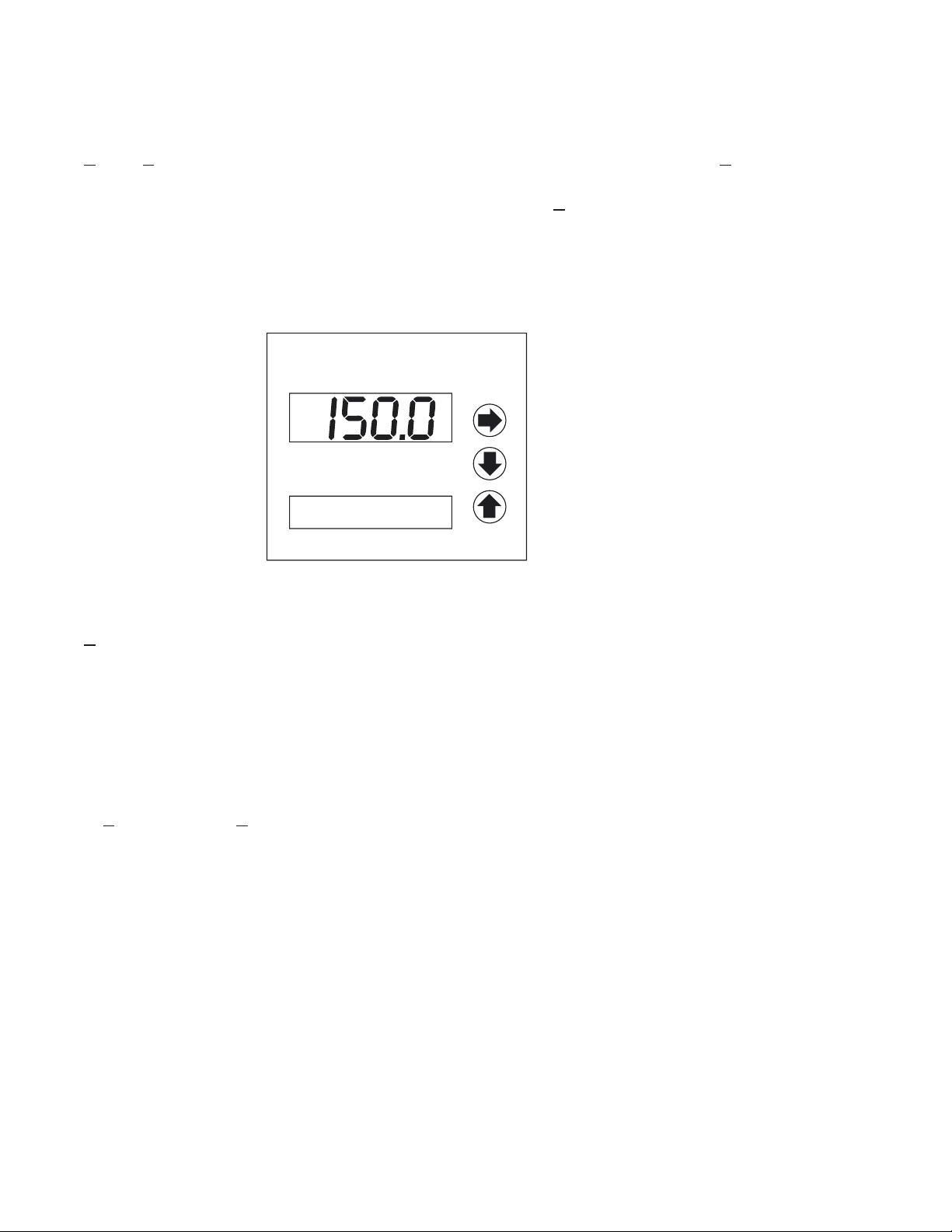

KEYPAD SYSTEM

The Ultrason has a simple 3-button

calibration system. Operating and

calibration modes are shown on the

16-digit alphanumeric display. The

keypad is used to move around the

menu to calibrate the Ultrason, and to

view operating mode and functions. A

beep is sounded as each key is pressed.

If the keypad is not used for 2 minutes,

the Ultrason will automatically go to

RUN mode (scrolling display). Use the

keypad to explore the Menu and

become familiar with its features.

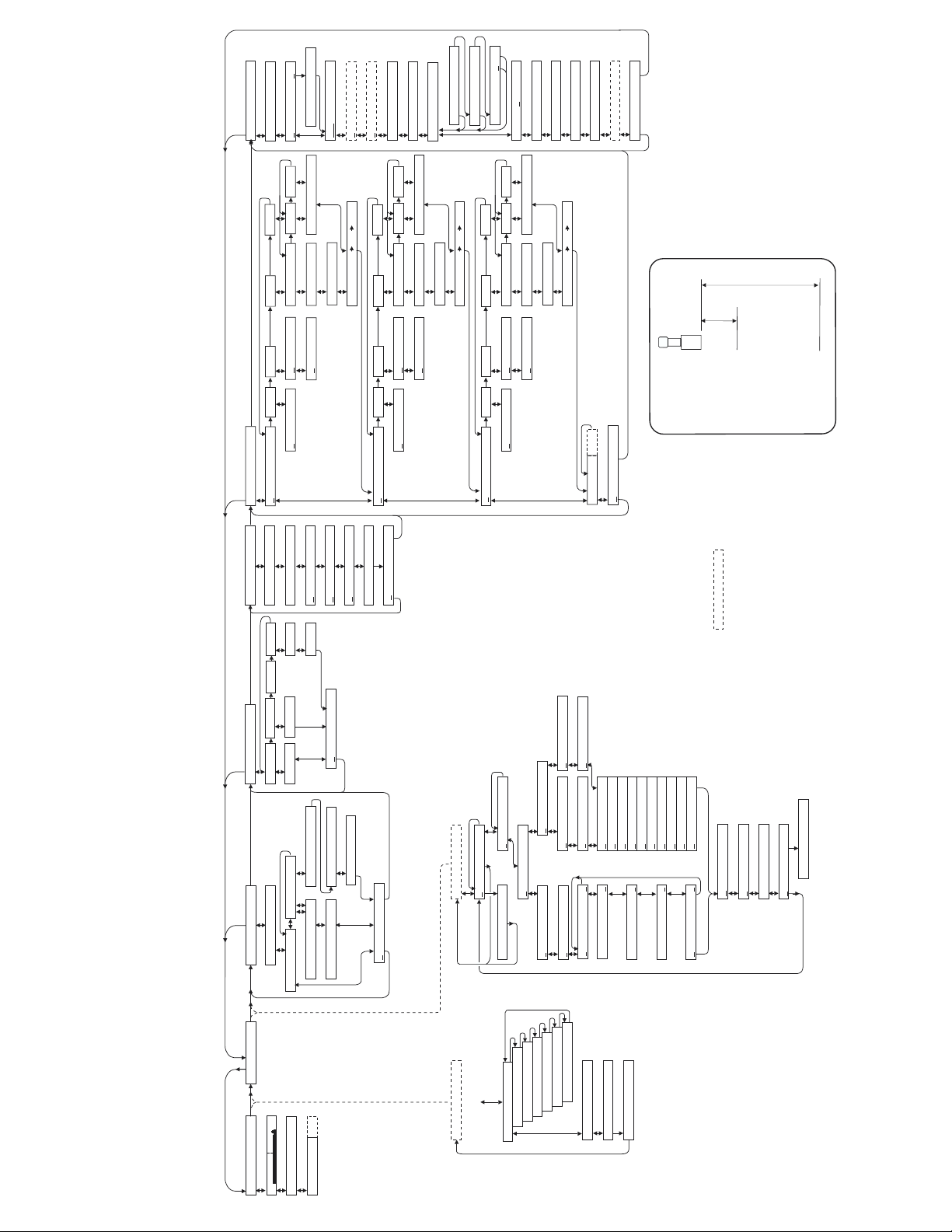

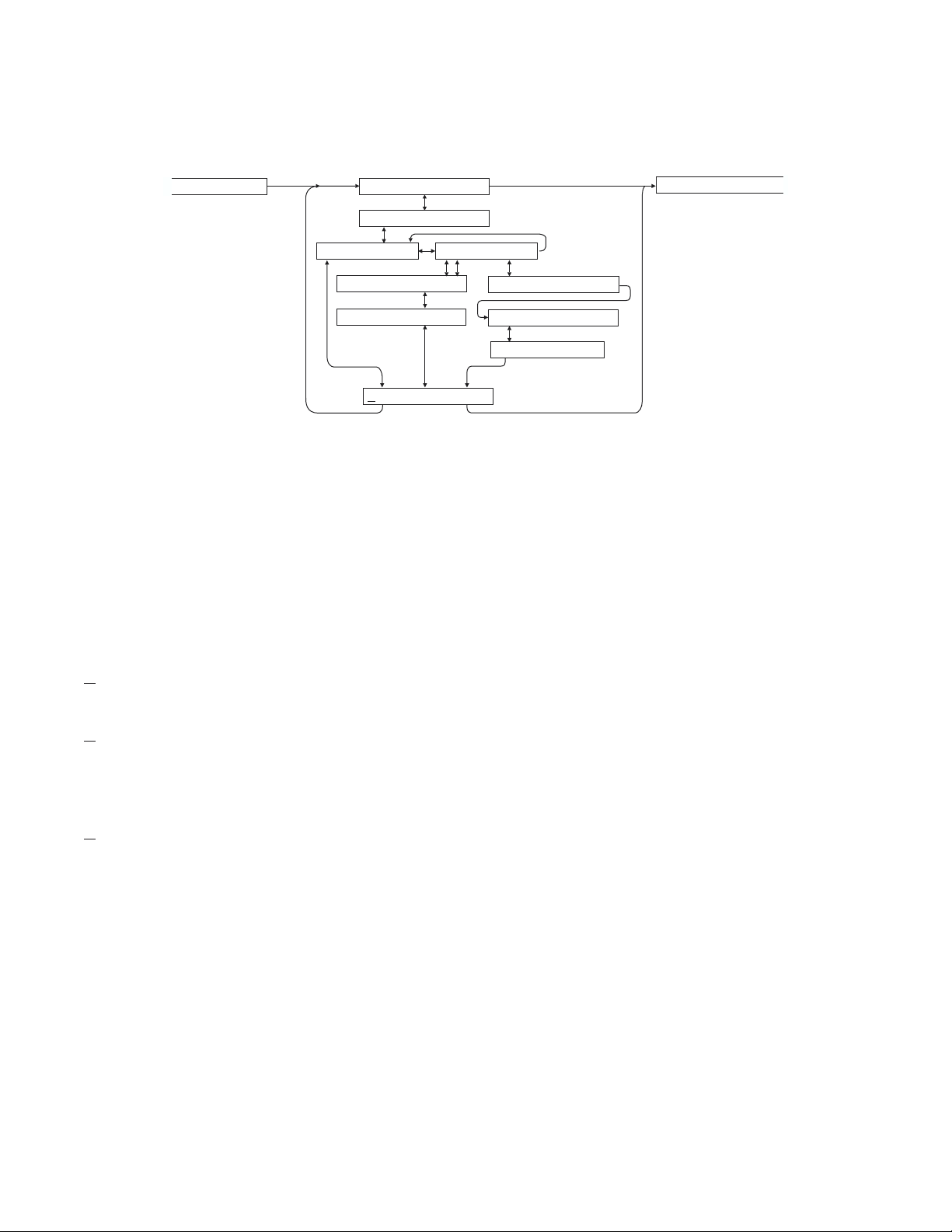

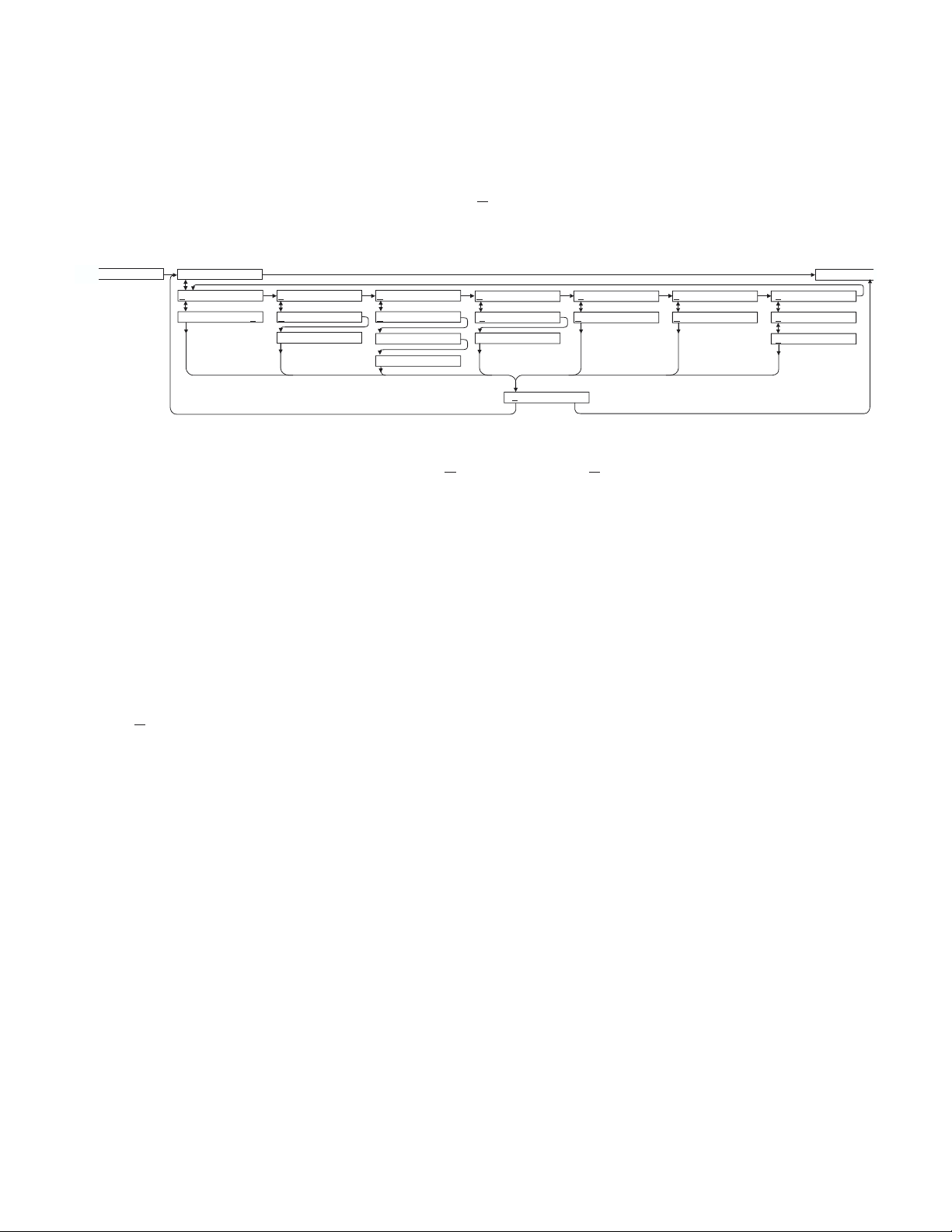

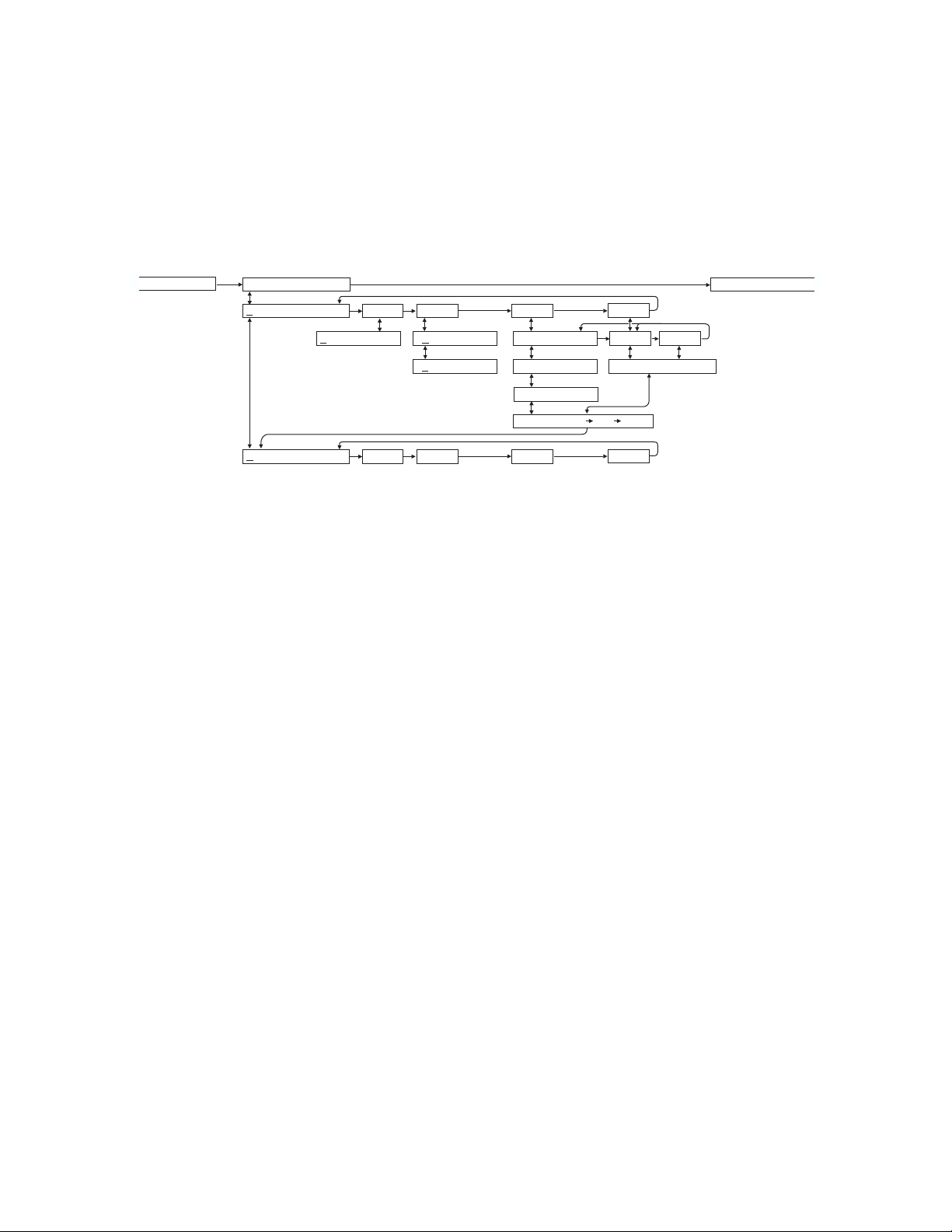

MENU - FLOW CHART

Ultrason

The following diagram shows part of the Ultrason Menu system. Arrows show the three directions to

leave a box. Pressing a corresponding keypad arrow will move to the next box in the direction shown.

Move the cursor (or underline) under numerals to increase or decrease the number with the ÈÇ keys.

At the bottom of each Menu column is a

(even through power failure), move the cursor under

pressed with the cursor under

the Menu column.

Store? no changes will be stored and the system will return to the top of

Store? Yes box. To store the calibration values permanently

Yes and press the È or Ç key. If the È key is

Page 4

V 2.51

O

SLT32

SPECIAL FUNCTION

1234567890123456

Tag 01

VYiew Codes? es

23:39:51

Time

Date May 31/1999

30 s

LOE Time

Yes

Tot?

Reset

Cº

20.3

Temp

Cº

20.0

Min Temp

Cº

23.0

Max Temp

DISPLAY FCºº

0.00%

4.000

20.000

Simul

20mA ADJ

4mA ADJ

ISB?: oYesN

Yes

Store?

New Password: 00

Com 24 48 96 192

N MENU

RELAY PARAMETERS

CALIBRATION

Flow

Level

Temp

Pulse

R1 Function Off

1.333 ft

MinRg

HiAlm

LoAlm

R1 Mode Pump

R1on 0.00 C°

R1on 0.00 ft3

32.00 ft

MaxRg

R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 on 0.00 ft

° C

OFF

R1 0.00

0.00 %

100.00 %

20mA @

4mA @

Hold

On

R1 LOE Off

%

08 s

20

RejTime

Damping

Flow

Level

Temp

Pulse

R2 Function Off

Yes

Store?

HiAlm

LoAlm

R1 Mode Pump

R1on 0.00 C°

R1on 0.00 ft3

R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 on 0.00 ft

° C

OFF

R1 0.00

Hold

On

R1 LOE Off

Flow

Level

Temp

Pulse

Function Off

R3

HiAlm

LoAlm

R1 Mode Pump

R1on 0.00 C°

R1on 0.00 ft3

R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 on 0.00 ft

° C

OFF

R1 0.00

Hold

On

R1 LOE Off

(123456)

ALT

Yes

Store?

MIN

SENSOR

RANGE

OPTIONAL FEATURES

MAX LEVEL

MAX

RANGE

ZERO LEVEL

Ultrason - CALIBRATI

FLOW MODE ONLY

FLUME SELECTION

UNITS / MODE

PASSWORD: 00

K=

Custom

More

Sizes

Parshall

Sizes

V-Notch

cm %

Vol Hrt Flow

m

in

Level

ft

Range

n=

Yes

Store?

L

m3

VSG USMG

IG IMG

ft3

L

USG IG m3

Mx Vol xxxx.x ft3

ft3

123456

LoAlm

5.0 ft3/s

HiAlm

At:

Event

1

Time

Trend

Formatted

StartJan 01/2000

Flow

MAX

AVERAGE

TOTAL

Daily

Daily

Daily

TIME

Flow

MAX

Flow

MIN

Daily

StartJan 01/2000

03:02:16

Start

TIME

Flow

MIN

Log Site ID

Setup

s min hr d

Yes

Store?

DATA LOGGING

24 HR LOG

ONLY IF ENABLED

SHOWS 24 Hr FORMAT

STOP

RUN

1

Session No

->

01/2000

Jan

03:02:16

Start

Interval: 30 Sec

Isnterval: 24 Hr

Interval: 12 Hrs

->

31/1999

Days

Dec

255

5 Sec

2 Sec

Interval: 10 Sec

Interval:

Interval:

s

Hr

Interval: 8

-

data

more

no

-

1 Sec

5 Min

Interval:

Interval: 30 Min

Interval: 10 Min

Interval:

s

Hr

Interval: 4

2 Min

1 Min

Interval:

Interval:

Hr

Isnterval: 1

WrapAround? Yes

Yes

Reset Log?

26640 Hrs Left

Yes

*** STORING ***

Store?

RUN

FLOW MODE ONLY

C

RELAYS:

Tot:

E

AquaMetrix

o

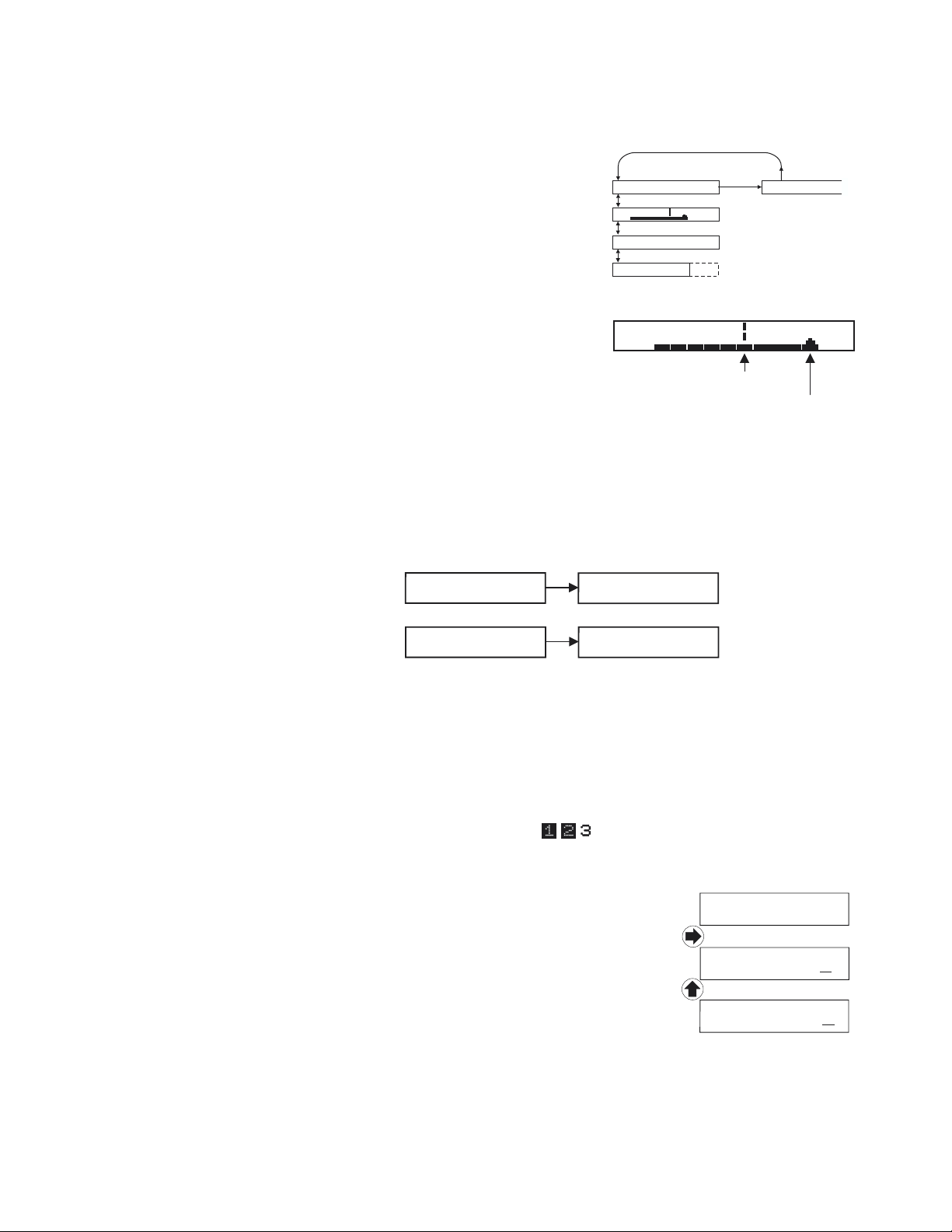

RUN

Ultrason

A scrolling display shows the units selected from the

UNITS/MODE column, the mode of operation (Range, Level or

Flow), the full scale value for the large numeric display, Totalizer

value (in

FLOW mode), and air temperature at the sensor location.

RUN

EC

FLOW MODE ONLY

Tot:

RELAYS:123456

PASSWORD: 00

ECHO CONFIDENCE

EC

Echo Strength is automatically adjusted by the Ultrason in response

to operating conditions in the applications.

From RUN use È to get to the Echo Confidence display,

EC.

Minimum

Marker

Current

Echo Strength

Arr

w

TOTALIZER

The Totalizer display will only be enabled when the Ultrason is calibrated in

FLOW mode. From RUN

use È or Ç keys to display Tot: value. The Totalizer value is updated every 2 seconds with flow

volume > 1 litre (0.264 USG). The display will show up to 10 digits and then restart at 0 automatically.

Units: ft³, USG, IG, L

T: 9999999999

TOT: 0

Units = m³

Press È or Ç keys to return to

RUN.

The totalizer can be reset to zero by going Æ to

T: 0283168470

SPECIAL FUNCTION and È to Reset Tot?.

TOT: 0

RELAY STATUS DISPLAY

Press È from

Engerized relays will be displayed in reverse type

Tot: to RELAYS 1,2,3.

RELAYS:

PASSWORD

The password (a number from

CALIBRATION menu.

From

RUN (scrolling display) press Æ to PASSWORD.

00 to 99) prevents unauthorized access to the

Press Æ to place the cursor under the digits and È or Ç to change the

number and then Æ to proceed to

CALIBRATION.

PASSWORD: 00

PASSWORD: 00

PASSWORD: 01

Factory default Password is

and È to New Password.

00. A new password can be stored by going Æ to SPECIAL FUNCTION

Page 6

AquaMetrix

UNITS / MODE

Ultrason

Press Æ to

DATA LOGGING

Range Level

UNITS/MODE, then È . Press Æ to move the cursor under the required measurement units:

ft - feet

in - inches

m - meters

cm - centimeters

% - percent

UNITS / MODE

ft in m cm %

Vol Hrt Flow

ft3 USG IG m3 L

Mx Vol xxxx.x ft3

Store? Yes

ft3 USG USMG

IG IMG m3 L

s min hr d

FLUME SELECTION

Press È to

Range mode displays distance from the sensor to the target or liquid surface like a tape measure.

Range Level > Vol Hrt Flow.UseÆ to select the operating mode of the Ultrason.

Range mode is useful to measure the exact distance from the sensor to the zero level during

calibration, or to monitor “outage” or free space in a tank.

Level mode can be used to measure tank level in linear units, or “Head” (height of flow) in an open

channel for comparison with a flume manufacturer’s flow tables.

Vol Volume mode displays tank inventory in engineering units like gallons or liters.

Hrt Horizontal Round Tank mode sets the Ultrason to calculate and display volume units in a

horizontal round tank.

Flow mode is for open channel flow through a flume or weir.

From

Vol Hrt or Flow press È to make your selection. (Range or Level mode will bypass the

Volume units selection menu).

Vol Hrt or Flow modes will give you the additional choice of

volumetric units:

ft3 - cubic feet

USG - US gallons

USMG - US million gallons (FLOW only)

IG - Imperial gallons

IMG - Imperial million gallons (FLOW only)

m3 - cubic meters

L - liters

Press Æ to position the cursor underneath your selection and press È to make your selection.

Page 7

AquaMetrix

Vol or Hrt modes will also prompt you to enter a maximum volume. Press È from MxVol to position

Ultrason

the cursor under the first digit. Use È or Ç to change the digits or decimal point to enter the actual

maximum volume you will be measuring. Press Æ to return to

MxVol and È .

You can enter values up to 6 digits (e.g. 150,000 liters). When the measured tank volume exceeds 4

digits, the Ultrason will automatically display a 'multiplier' on the lower alphanumeric display.

AMqua etrix

= 150,000 Liters

UNITS 1000L

FLOW mode will offer the additional selection of time units:

s - seconds

min - minutes

hr - hours

d - day

Note: The Ultrason will display

value of 9,999,999. Use

to

Store and Æ to Yes. Then press È or Ç to store all your UNITS/MODE selections.

US MGD, Imp MGD or m3/d so that Units will be 9,999,999 or less. Press È

Er:ILLEGAL UNITS if your choice of Units exceeds a maximum

Page 8

AquaMetrix

FLUME SELECTION

The

FLUME SELECTION menu will only appear in FLOW mode.

Use È and Æ to select the correct Flume or Weir.

Ultrason

UNITS/MODE

Use È and Æ again to select the Size then È to

Press È or Ç to store flume selection and get to

FLOW MODE ONLY

FLUME SELECTION

V-Notch More> P. Bowlus More> L.Lagco More> Rect. Weir >

22.5 30 45 60 09

Parshall More>

2" 3" 6" 9" >

12" 18" 24" 36">

4" 6" 8" 10">

12" 15" 18">

21" 24" 42">

6" 8" 10" 12" >

18" 24" 30" 36">

Store? Yes

Size 1.000 ft

Store? and Æ to Yes.

CALIBRATION mode.

Rect.Weir w/EC >

Size 1.000 ft

Custom More>

K = 1.0000

N = 1.0000

CUSTOM FLUMES: Experimental or empirical data for any flume or weir can be reduced to an

equation of the form

Q is flow volume

K is as scaling factor which includes flume size and units of flow measurement

n describes the flume non-linearity

H is the level being measured

Use the AquaMetrix Utility program

Select

n: enter an 'n' constant.

CUSTOM for flumes or weirs not listed in the Menu. At the K: prompt enter a 'K' constant. At the

Q=KHn where:

FIND K&n.exe to determine K and n constants from entered data.

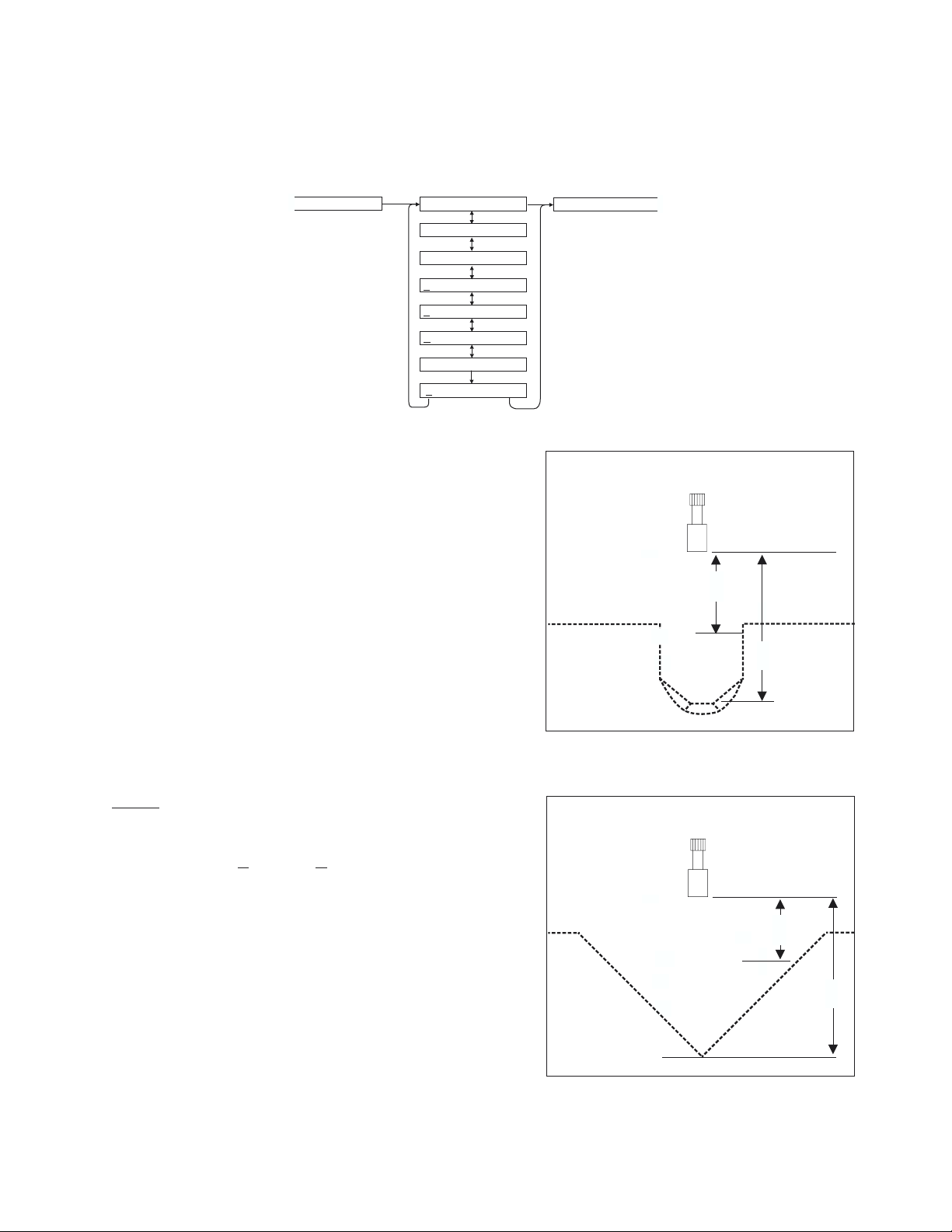

CALIBRATION

Page 9

AquaMetrix

Ultrason

CALIBRATION

- for Level/Inventory Applications

1. Before starting the calibration determine:

a) MAX RANGE = ________________

(Maximum range = distance from Sensor to Zero

level)

b) MAX LEVEL = ________________

(Maximum level of product being measured)

c) MIN RANGE = ________________

(Distance from sensor to Max Level)

Minimum range = MAX RANGE - MAX LEVEL

(must be at least 8" / 203 mm depending on sensor

model)

2. Check the maximum range with the sensor installed by:

a) Use Æ to get to

Range, then Store? Æ Yes

UNITS/MODE then È to get to

(NOTE: liquid must be at zero level)

or

b) Carefully measure distance from sensor to zero

level with tape measure.

TANK INVENTORY

LEVEL MODE

0%

0%

MIN RANGE

MIN RANGE

100%

TANK INVENTORY

RANGE MODE

SENSOR

MAX RANGE

SENSOR

MAX RANGE

MAX LEVEL

MAX

VOLUME

ZERO LEVEL

MAX LEVEL

MINIMUM RANGE:

CALIBRATION

At

- Press È to get to MinRg

- Press Æ to move the cursor under the digits

-UseÈ or Ç to set the minimum range

MinRg must be ³12" (30.5 cm) for US2-1A1A

Note:

sensors and ³ 16" (40.6 cm) for US2-2A1B sensors except

in

Hrt mode. For correct tank volume calculation in Hrt

mode MinRg must be the actual distance from the end of

the sensor to the top of the tank (any value ³0). In

Level

or Range modes the Ultrason will only accept MinRg

values ³ 8" (20.3 cm).

- Press Æ to return to

MinRg

MAXIMUM RANGE:

Press È to get to

MaxRg

Repeat as for MinRg

100%

TANK INVENTORY

HORIZONTAL ROUND TANK (HRT) MODE

MIN RANGE

MAX

VOLUME

MAX RANGE

ZERO LEVEL

Page 10

AquaMetrix

CALIBRATION

- for Open Channel Flow

Ultrason

FLUME SELECTION

CALIBRATION

MinRg 1.333 ft

MaxRg 32.00 ft

4mA @ 0.00 %

20mA @ 100.00 %

Damping 20 %

RejTime 08 s

Store? Yes

1. Before starting the calibration determine:

a) MAX RANGE = ____________________

(Maximum range = distance from the Sensor to Zero

level point)

b) MAX LEVEL = ____________________

(Maximum level of flow through flume or weir)

c) MIN RANGE = __________________

(Distance from sensor to Max Level)

Minimum range = MAX RANGE - MAX LEVEL

(must be at least 8" / 20.3 cm depending on sensor

model).

RELAY PARAMETERS

PALMER BOWLUS

SENSOR

MAX LEVEL

MIN

RANGE

MAX

RANGE

ZERO LEVEL

2. Check

a) Use Æ to get to

the maximum range with the sensor installed by:

UNITS/MODE then È to get to

Range, then Store? Yes

(NOTE: flow must be at zero flow)

or

b) Carefully measure distance from sensor to zero level

with tape measure.

Page 11

V-NOTCH

SENSOR

MIN

RANGE

MAX LEVEL

MAX

RANGE

ZERO LEVEL

AquaMetrix

4-20mA CURRENT LOOP OFFSET

Some applications may require the 4-20mA output to be offset so that 4mA or 20mA corresponds to a

Level, Range or Flow other than Zero and Full Scale.

4mA at - use Ç and È to set % output for 4mA. It is adjustable from -5% (3.8mA) up to 15% lower

than the 20mA setting. Adjustment resolution is 0.05% (0.01mA).

20mA at - use Ç and È to set % output for 20mA (down to 15% greater than the 4mA setting and up

to 300%). Adjustment resolution is 0.05% (0.01mA).

DAMPING

Minimum damping allows fast response to level changes. Increasing damping slows the Ultrason's

response to level changes and is ideal to smooth the display and outputs in turbulent conditions.

Damping value is shown in percent (0-99%). Some experimentation may be required to select the

optimum damping value. A value of 20% is recommended for most applications. For fast level changes

(up to ½ inch/sec - 13 mm/sec), a

Damping value of 1% is recommended. Maximum is 99%.

Ultrason

If the Ultrason is unable to obtain repeated echoes the Damping setting will be automatically set to 1%

by the instrument.

REJECTION TIME (RejTime)

Rejection Time adjustment is a powerful Ultrason feature to suppress false echoes and the effects of

transient targets such as agitators, splashing, or turbulence. Rejection Time is shown in seconds. The

time value represents the number of seconds the Ultrason must receive repeated echoes from a new

target before indicating its level on the display and outputs. The factory default is 8 seconds and should

be ideal for most applications. Decreasing this value allows the Ultrason to respond more quickly to fast

level changes, and increasing the time value allows the Ultrason to reject false echoes from slow

sweeping agitators, tank filling streams, splashing, severe turbulence and steam. Minimum setting is 1

second (for fast level changes up to 1/2 inch/sec - 13 mm/sec). Maximum setting is 85 seconds. If the

Ultrason is unable to obtain repeated echoes the

by the instrument.

RejTime setting will be automatically set to 1 second

Page 12

AquaMetrix

RELAY PARAMETERS

Ultrason

Each relay can be individually calibrated. Press È to

ÆTemp Æ Level Æ Flow.

Off

Pulse

CALIBRATION

mode means the relay will not be energized

Appears in Flow mode only. Press È and set digits to the flow volume increment required

RELAY PARAMETERS

R1on 0.00 ft3

R2 Function Off

Pulse

Pulse

TempR1 Function Off

R1on 0.00 C°

R1 0.00

OFF

Temp

between relay pulses. Use this feature for remote samplers, chlorinators or totalizers.

Minimum time between pulses is 1 second and pulse duration is 350 milliseconds.

R Function and Æ to select: Off Æ Pulse

SPECIAL FUNCTION

Level Flow

R1 Mode Pump LoAlm

° C

R1 on 0.00 ft R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 LOE Off

Level Flow

On

HiAlm

Hold

Temp References temperature reading from the Ultrason's ultrasonic sensor (air temperature at

the sensor location). Press È and Æ and set the relay On and Off set points.

Level

Range

Volume

Appears in Level, Range, Volume or HRT modes only. Press È to R Function and Æ

to select

Pump mode - press È and Æ and set relay On and Off set points.

LoAlm mode - press È and set relay On point. Relay will be On with levels below

Pump, LoAlm (low alarm) or HiAlm (high alarm).

this point.

HiAlm mode - press È and set relay On point. Relay will be On with levels above

this point.

LOE - press Æ to select Off ÆOn Æ Hold. In a loss of echo condition, the

(Loss Of Echo) relay will turn Off (de-energize), On (energize) or Hold its current state.

Each relay can be individually configured. Press È.

To calibrate a relay for echo loss alarm only, set the relay On and Off set points to exactly

the same value, and then set

LOE to On mode. The relay will now energize only when an

echo loss condition occurs.

Page 13

AquaMetrix

Ultrason

Flow

Appears in Flow mode only. Press È to R Function and Æ to select Pump, LoAlm

(low alarm) or HiAlm (high alarm).

Pump mode - press È and Æ and set relay On and Off set point.

LoAlm mode - press È and set relay On point. Relay will be energized with levels

below the On point and de-energized with levels above the On point.

HiAlm mode - press È and set relay On point. Relay will be energized with levels

above the On point and de-energized with levels below the On point.

LOE - press Æ to select Off ÆOn Æ Hold. In a loss of echo condition, the

(Loss Of Echo) relay will turn Off (de-energize), On (energize) or Hold its current state.

Each relay can be individually configured. Press È.

ALT permits relays calibrated in Pump mode to be

alternated automatically. Pump alternation

allows even pump wear in pumping station

applications.

ALT (-None-) indicates that no relays have

been programmed in Pump mode.

ALT 123 - Press Æ to place cursor (underline)

under the relay number to be programmed for

alternation and press Ç or È to highlight.

Repeat until all relays to be alternated are

highlighted.

PUMP ALTERNATION (R1, R2, R3)

LAG

PUMP 1

2

3

1

1st CYCLE

2nd CYCLE

3rd CYCLE

...ETC

LEAD

PUMP

1

2

3

LAG

PUMP 2

3

1

2

Press È to

Store? Yes and Æ to Yes. Press Ç or È to save your Relay settings.

Page 14

AquaMetrix

SPECIAL FUNCTIONS

SLT32 V2.26 shows software version installed

Ultrason

View Codes? Yes

Select Yes and then È to display an

instrument performance code. Faults detected

by the instrument are stored in the code and

will be requested by AquaMetrix if you call

for service or assistance.

Tag Enter Instrument Tag number (0-9999)

Date MM DD/YYYY

(with optional Data Logger) Press Æand Ç or

È to change Month, Day Year.

Time HH:MM:SS

(with optional Data Logger) Press Æ and Ç or

È to change Hours, Minutes, Seconds

LOE TIME

Press Æ and Ç or È to change the number of

seconds without receiving an echo before the

Ultrason displays

ECHO LOSS, and Control

relays change state as calibrated under Relay

Parameters.

Factory default is 30 seconds and is

recommended for most applications,

Minimum is 10 seconds and maximum is 60

seconds.

SPECIAL FUNCTION

SLT32 V 2.26

VYiew Codes? es

1234567890123456

Tag 01

Date May 31/1999

Time 23:39:51

LOE Time 30 s

Reset Tot? Yes

Temp 20.3 Cº

Min Temp 20.0 Cº

Max Temp 23.0 Cº

DISPLAY FCºº

ISB?: N Yeso

Simul 0.00%

Reset Tot? Yes (FLOW mode only) Position the cursor under

Yes to reset the totalizer. Store this selection

at the

Store? Yes prompt.

Temp 25.0°C Indicates current temperature at the sensor

head. Press Æ to

Temp

to display the minimum and maximum

Min Temp and Æ to Max

temperatures the Ultrason has sensed. Press Æ

to Display °

C °F. Position the cursor under °C

4mA ADJ 4.000

20mA ADJ 20.000

New Password: 00

Com 24 48 96 192

Store? Yes

for celcuis display or °F for Farenheight

display. Press È to return to

ISB?: No Yes Select Yes only when the instrument is equipped with an optional Intrinsic

Temp.

Safety Barrier for sensor mounting in hazardous locations. This setting

compensates for the electrical characteristics of an Intrinsic Safety Barrier.

Page 15

AquaMetrix

Simul The Output simulation function controls the 4-20mA output, digital display

and control relays. Use it to simplify calibration of remote devices such as

chart recorders or remote displays, and to test Relay set-points. Simulation

digits are shown as a percentage of full scale. Use the Çand ÈArrow keys to

simulate

Increments will automatically accelerate when the Çor È is continuously

pressed.

0% (4mA), 100% (20mA), and increments of .05% (.008mA).

Ultrason

4mA ADJ

20mA ADJ

New Password position cursor under digits and set new number between 00 and 99.

Com 24 48 96 192 Optional (with Data Logger) Speed of RS-232C transmission. Select 2400,

Use to fine tune the 4mA and 20mA calibration of the 4-20mA output.

Adjustment range is +1mA to –1mA in 0.002mA steps

Important

during these adjustments.

4800, 9600 or 19200 baud rate (must be set to match baud rate in

‘AquaMetrix Logger’ software and any modems used for serial

communication).

: The 4-20mA output will be forced to 4mA and 20mA respectively

Page 16

AquaMetrix

OO

Ultrason

INSTALLATION - SENSOR LOCATION

- Tank Level/Inventory Applications

Each Ultrason Level Transmitter includes a

non-contacting ultrasonic sensor. The sensor must be

installed in a position to obtain unobstructed echoes

from the liquid or material being measured.

Mount the sensor away from pipes, ladders, or

structural members which might cause continuous

false echoes.

SOLIDS AND POWDERS

SENSOR MOUNTED

AWAY FROM MATERIAL

PATH. COARSE SOLIDS

WILL USUALLY RETURN

AN ECHO EVEN IF AT

AN ANGLE

BAD G

D

90°

FINE POWDERS

MAY NEED SENSOR

TILTED NORMAL TO

SURFACE TO OBTAIN

GOOD ECHOES

Page 17

AquaMetrix

A

0

SENSOR MOUNTING LOCATION

- Tank Level/Inventory Applications

1 FT (30 cm) HORIZONTAL

FROM SIDEWALL FOR

EVERY 10' (3 m) VERTICAL

NOTE: 2 FT (60 cm) FOR

EVERY 10' (3 m) DEPTH ON

PPLICATIONS WITH ROUGH

SIDEWALLS, LADDERS,

REINFORCING RINGS ETC.

PREFERRED SENSOR

LOCATION

SENSOR FACE MUST

BE HORIZONTAL ±1°

Ultrason

6" SCHEDULE 4

STAND PIPE IF

EXTENSION

REQUIRED

MAX. LIQUID LEVEL

SENSOR MOUNTING

Each sensor is equipped with a 3/4 inch “isolation coupling” which MUST be used in your installation.

A threaded nipple or length of conduit may be used to position the sensor at the desired height.

The sensor should be hand-tightened (like a light bulb) by turning the sensor stem only. DO NOT use a

wrench and do not over tighten. DO NOT clamp the sensor below the isolation coupling.

Page 18

AquaMetrix

Notes:

1. Use the ¾" NPT "Isolation Coupling"

supplied and only. Do

not clamp sensor body or stem.

2. Locate the sensor 1 ft (30 cm) from

the sidewall or obstruction for every

10 ft (3 m) depth.

3. mount in direct sunlight.

Do not

4. Extend sensor cable up to 500 ft

(150 m) with RG62AU coaxial only.

CROSS BAR MOUNT

CLAMP

DO NOT

CLAMP IN

THIS AREA

hand tighten

3/4"

CONDUIT

ISOLATION

COUPLING

(SUPPLIED)

MUST BE

USED

FLANGE MOUNT

4" OR 6" BLIND FLANGE

TAPPED ¾" NPT

¾" NPT

NIPPLE

DO NOT

CLAMP IN

THIS AREA

FLEXIBLE

CONDUIT

ISOLATION

COUPLING

(SUPPLIED)

MUST BE

USED

CONDUIT MOUNT

Ultrason

JUNCTION

BOX

(OPTION JB)

3/4"

CONDUIT

STANDPIPE LENGTH

AS SHORT AS POSSIBLE

STANDPIPE DIAMETER

AS LARGE AS POSSIBLE

TYPICAL STANDPIPE:

4” / 100 mm DIAMETER

12” / 300 mm LENGTH

NARROW DIAMETER

STANDPIPES (<4” / 100 mm)

MAY AFFECT ACCURACY

OF READING

STAND PIPE MOUNT

SMOOTH

GRIND OR FILE

PIPE EDGE

DO NOT

CLAMP IN

THIS AREA

3/4" NPT

DO NOT

CLAMP IN

THIS AREA

ISOLATION

COUPLING

(SUPPLIED)

MUST BE

USED

ANGLE MOUNT

NIPPLE

ISOLATION

COUPLING

(SUPPLIED)

MUST BE

USED

Page 19

AquaMetrix

Ultrason

SENSOR MOUNTING/LOCATION

- Open Channel Flow Applications

Each sensor is equipped with a 3/4 inch isolation coupling which MUST be used in your installation. A

threaded nipple or length of conduit may be used to position the sensor at the desired height. The

sensor should be hand-tightened by turning the sensor stem only. DO NOT use a wrench and do not

over tighten.

IMPORTANT: Follow the flume manufacturer’s directions for transducer location. The transducer

should be centered above the flume approach section and mounted ³ 12"/30.5 cm (minimum) above the

maximum liquid level (depending on sensor model).

The transducer should be protected from physical damage and the transducer cable should be routed in

a separate metal conduit.

Because the sensor is equipped with a temperature sensor, it should be shielded from direct sunlight.

Use the PVC “isolation coupling” supplied with the sensor and hand-tighten

assembly onto your mounting stand. Do not

12"

305

clamp directly to the sensor or to the isolation coupling.

12"/305

the sensor/coupling

METAL

CONDUIT

TO ULTRASON

ENCLOSURE

Page 20

AquaMetrix

Ultrason

TYPICAL TRANSDUCER POSITIONING

FOR FLUMES AND WEIRS

Always refer to the flume or weir manufacturer’s instructions for correct measurement point upstream

from the flume or weir. Location of the sensor is critical for accurate flow measurement.

If manufacturer’s instructions are not available, the following guidelines are generally accepted.

1.PARSHALL FLUME:

Position the sensor at 2/3 Approach

as illustrated above. Sensor height

must be 12" (30.5 cm) or more

above the highest water level.

2. PALMER BOWLUS FLUMES:

Position the sensor at 1/2 the flume

Diameter upstream from the throat

of the flume. Sensor height must be

12" / 30.5 cm (depending on sensor

model) or more above the highest

water level.

3. V-NOTCH WEIRS

Position the sensor at 3 x maximum Head upstream from

the weir plate. Sensor height must be 12" / 30.5 cm

(depending on sensor model) or more above the highest

water level.

SENSOR

POSITION

D

3x MAX. HEAD

FLOW

WEIR

PLATE

STILLING WELLS

Stilling wells are recommended to reduce the effects of turbulence as water flows through the flume or

weir. The Ultrason sensor is centered over the stilling well. Sensor height must be 12" (30.5 cm) or more

above the highest water level. The well must be kept clean of sediments and deposits on the side walls.

Page 21

AquaMetrix

ZERO POSITIONING OF SENSOR

- Open Channel Flow Applications

Locate the sensor at the positionupstream from the throat of the flume or weir plate as recommended by

the manufacturer.

A technique for accurate sensor height adjustment is shown:

Ultrason

Page 22

AquaMetrix

Ultrason

ENCLOSURE INSTALLATION

Locate the enclosure within 500 ft (150 m) of the sensor. It can be wall mounted with four mounting

screws (supplied) or panel mounted with Option PM Panel Mounting Kit from AquaMetrix. Avoid

mounting the enclosure in direct sunlight to protect the electronics from damage due to overheating and

condensate. In high humidity atmospheres, or where temperatures fall below freezing, Option TH

Enclosure Heater and Thermostat is recommended. Seal conduit entries to prevent moisture from

entering enclosure.

NEMA4X (IP66) WITH CLEAR COVER

COVER

1. Open hinged enclosure cover.

2. Insert #8 screws and washers through the four enclosure

ENCLOSURE

MOUNTING

HOLES

mounting holes to secure enclosure to wall or mounting stand.

3. Close cover.

Additional conduit holes can be cut in the end of the enclosure

ENCLOSURE

when required. Use a hole saw or Greenlee-type hole cutter to cut

the required holes.

END VIEW

Note: This non-metallic enclosure does not automatically provide grounding between conduit

connections. Grounding must be provided as part of the installation. Ground in accordance with the

requirements of the National Electrical Code. System grounding is provided by connecting grounding

wires from all conduit entries to the steel mounting plate or another point which provides continuity.

Page 23

AquaMetrix

Ultrason

ERROR/WARNING MESSAGES

! LOSING ECHO ! No valid echoes for half LOE TIME (SPECIAL FUNCTION menu).

"ECHO LOSS"(flashing) No valid echoes received within the LOE TIME setting. See FIELD

TROUBLESHOOTING (F). In

Level mode the Ultrason will hold the

display and outputs at the last reading until a new echo is received. In

FLOW mode it will display 0.00 and totalization will stop until an echo

is received.

Er: ILLEGAL MinRg The value entered for MinRg (Minimum Range) is less than 8"(20.3 cm).

MinRg must be greater than or equal to 8" (20.3 cm) for US12-1A1A

sensors. Minimum Range for US2-1A1A sensors must be ³ 12" / 30.5

cm and for optional US2-2A1B sensor must be greater than or equal to

16" (40.6 cm).

Er: ILLEGAL UNITS Your choice of UNITS exceeds a maximum value of 9,999,999. Use US

MGD, Imp MGD or m3/d so that UNITS will be 9,999,999 or less.

Err:ILLEGAL SPAN 1. The value entered for MaxRg is the same or less than MinRg +2".

Maximum range must

be greater than minimum range and less than

102 ft. (31.09 m). (Note: to invert the scale and outputs, choose

Level instead of Range selection in the UNITS/MODE menu.)

2. For Rectangular Weirs with End Contractions, the SPAN (

MinRg

) must be less than 1/2 the weir size (eg: 12" crest width,

MaxRg -

SPAN must be 6" or less).

-or- Your choice of Units exceeds 9,999,999. Use USMG/d, IMG/d or m3/d

so that Units will be 9,999,999 or less

ERR: ILLEGAL

SETPOINTS

NORMAL / REVERSED

SET POINTS MIXED!

ON or OFF setpoint is < MinRg or > MaxRg

Relays have been selected for Pump Alternation and have been calibrated

in opposite modes. Any alternating relays must be calibrated in the same

mode:

1. with ON setpoint > OFF setpoint, or

2. with OFF setpoint > ON setpoint

TEMP * 23.5 C

ECHO TOO CLOSE Indicates that the target is less than MinRg distance from the sensor

* Indicates Temperature Compensation fault. Check sensor connections.

(too close to the sensor)

!! SENSOR OPEN ! Instrument has detected sensor connection/cable Open.

! SENSOR SHORTED ! Instrument has detected sensor connection/cable Shorted.

Page 24

AquaMetrix

FIELD TROUBLESHOOTING

Ultrason

SYMPTOMS

Display - full scale A

- zero B

- erratic - random C

- drifting up D

- drifting down E

ECHO LOSS prompt - flashing F

Calibration Non-Linear H

SYMPTOMS

Unit “See’s” Wrong Target Due To:

A,C,D,F - sensor not aimed correctly

A,F,D - condensation/dust/dirt buildup on

A,D - sensor mounting stand pipe - Lower Sensor below stand pipe intrusion

C,E - very turbulent flow in open channel - Increase

C,E - very turbulent level in tank

FAULTS SOLUTIONS

sensor

- too long / - too narrow

- dirty / - gasket intruding

CHECK

- Clean carefully (do not scratch sensor face)

RejTime (CALIBRATION menu)

- install stilling well on flume or weir

- Increase

- change tank fill method

RejTime (CALIBRATION menu)

Unit Picks-Up Interference Due To:

A,C - noise from high pressure fill - Install submerged fill pipe

A,D - sensor coupling over tightened - Hand tighten only (like a light bulb)

A,D - sensor coupling not used - Use coupling supplied

C - other ultrasonic unit in close proximity - Synchronize

Electrical interference:

C - sensor cable connections reversed

C,G - through sensor cable - Use properly grounded metal conduit

C - sensor cable extended and junction not

insulated

C,G - through enclosure - Use metal enclosure

C,G - through 4-20mA output cable - Use shielded twisted pair (shielded to AC

C,G - wiring or installation close to variable

speed drive or inverter

Page 25

- Use metal Junction Box

ground)

- Use grounded metal conduit

- Follow V.S.D. manufacturer’s instructions

for Drive grounding, wiring and shielding

AquaMetrix

Unit Receives No Return Echo Due To:

C,F,E - foam on liquid surface - Use stilling well (open channel flow)

B - target beyond

E - calibration error -

G - sensor damaged

Wiring Problems Due To Sensor Cable:

A,C,F, - open circuit - Measure continuity (5K Ohms max.)

B,F - short circuit - Check connections

F - too long (max 500 ft., 150 m)

C - bundled/run in conduit with power

cable

C - sensor ground shorted to

conduit/enclosure

A - extended with wrong type of wire - Use RG62A/U coaxial only

C - close to high voltage/large motors

G - AC chassis/ground missing on

instrument power connections

MAX RG - Recalibrate

ISB No selected in SPECIAL FUNCTIONS

and instrument has an optional ISB

- Insulate

Ultrason

Non-Linearity Due To:

H - Vapour - Dissipate fumes, Calibration in-situ

H - zero not set accurately - See “Zero Positioning of Sensor”

H - wrong flume, or K&n selected (

mode)

D,E - calibration error -

FUSE REPLACEMENT

1. Turn OFF power

2. Loosen 2 Phillips corner screws and remove power module from the chassis.

3. Locate fuse on Power Board

4. Replace fuse with 2 Amp/250V, 5 x 20mm fuse

5. Reinstall power module in the chassis.

FLOW

- Select correct flume

ISB Yes selected in SPECIAL FUNCTIONS

menu and instrument does not have an ISB

POWER MODULE

Page 26

AquaMetrix

INSTALLATION CONSIDERATIONS IN NOISY ENVIRONMENTS

AquaMetrix’s instruments are designed with a high degree of noise immunity for use in industrial

environments. Noise interference can still occur if certain minimal considerations are not adhered to

when installing the equipment.

Noise

When relay contacts are used to switch inductive loads, such a auxiliary relays or solenoids, extremely

large voltage spikes can be generated when the relay contact opens producing what is known as

Radio-Frequency Interference or “RFI” or just “noise”.

These voltage spikes can also be coupled from power lines that are powering equipment that contains

S.C.R. circuitry such as VSD controllers, or lines that are actuating AC or DC solenoids or actuators.

There are three major ways that noise spikes can enter the instrument.

1. Via the AC power input lines.

2. Via the Sensor input line.

3. Via the output lines (relay connections and 4-20mA output)

Ultrason

Symptoms of RFI produced by relay activation

If the instrument shows the following symptoms suspect RFI.

- The Alphanumeric display (bottom display) blinks continuously as if power was being turn

off and on (i.e instrument resets continuously).

- Keypad does not respond or instrument resets to run mode from inside the menu.

- The instrument calibration is lost.

- The message "

- Relays trip erratically.

- Both digital displays go blank as if power was OFF.

Symptoms of noise on sensor input and/or 4-20mA lines

- Instruments readings are erratic or high when actual value is low

- The Alphanumeric display (bottom display) blinks continuously as if power was being turned

off and on i.e instrument resets continuously.

- Instrument “beebs” intermittently even if the Keypad is not pressed.

MEM CORRUPTED" is shown.

Page 27

AquaMetrix

Ultrason

Avoiding noise problems

1. It is recommended that electronic instruments be connected to a relatively clean AC power source.

Use an AC power filter or isolation transformer if necessary.

2. The sensor input line and the control lines (AC or DC) should not be run in the same conduit . The

sensor input should be separated from wires going to inductive loads such as motors, solenoids, relays

and contactors. For best results run the sensor wire in a separate metal conduit. A two-conductor

shielded cable is recommended for the 4-20mA output, the shield should be connected to chassis ground

at the instrument only.

3. For the relay connections, one of most overlooked sources of trouble, noise suppressors are

recommended. Also known as “snubbers” these devices will limit the large spikes produced when the

relay opens, stopping the RFI and also protecting the relay contacts from degrading.

ULTRASON

NOISESUPPRESSIONON RELAYOUTPUT

SNUBBER

AQUAMETRIX PART # SNUB

C

NO

NOISE

SUPPRESSED

AT INSTRUMENT

POWER

240VAC (MAX)

28VDC

SNUBBER

NOISE

SUPPRESSED

AT LOAD

(

B

E

LOAD

S

T)

Page 28

AquaMetrix

Ultrason

CUSTOMER SERVICE

If a problem cannot be resolved with the foregoing procedures or application assistance is required,

frequently a telephone consultation with your AquaMetrix representative or directly with AquaMetrix

will provide the answer. To contact the factory, call, fax or write to:

AquaMetrix Telephone: (905) 946-1064

4-30 Royal Crest Court Fax: (905) 946-8064

Markham, Ontario

Canada

L3R 9W8

INSTRUMENT RETURN PROCEDURE

If you are returning the instrument for service please enclose a written description of the problem and a

purchase order to cover the repair. If, in AquaMetrix judgement, the repair is to be covered under

warranty, there will be no charge against the purchase order. Be sure to pack the instruments adequately

because AquaMetrix cannot be responsible for shipping damage. For safety reasons, AquaMetrix cannot

accept instruments and sensors for repair that have not been thoroughtly cleaned to remove all process

material.

When you contact AquaMetrix please have the following information available:

1. Model number / Software Version

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

USA

WARNING:This equipment generates, uses and can

radiate radio frequency energy and if not installed and used

in accordance with the instructions manual, may cause

interference to radio communications. It has been tested

and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection

against such interference when operated in a commercial

environment.

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the

radio interference regulations of the Canadian Department of

Communicatons.

Le présent appareil numérique n'émet pas de bruits

radioélectriques dépassant les limites applicables aux

appareils numériques de la Classe A prescrites dans le

Réglement sur le brouillage radioélectriques éicter par le

ministére des Communications du Canada.

Canada

Page 29

AquaMetrix

Ultrason

APPENDIX A - OPTIONS

EXTRA SENSOR CABLE

(OPTION XC)

Each AquaMetrix Ultrason includes 25 ft. (7.6m) RG62AU coaxial cable. Additional RG62AU coaxial

cable and Cable Junction Box (Option JB) may be ordered with the Flow Monitor, or the cable may be

spliced and extended up to 500 ft (152m) as required during installation. No adjustment is required when

the sensor cable is extended or shortened. Use only

RG62AU (or RG62U) coaxial cable which is

available from AquaMetrix or your local distributor. Nominal impedance of RG62AU cable is 93 ohms.

Extended sensor cable must be installed in metal conduit to prevent interference. Do not use BNC

coaxial connectors (TV cable type). Recommended installation with a metal junction box is illustrated

below:

SENSOR CABLE

25 ft (7.6 m)

RG62AU COAXIAL

Note: Optional Watertight steel NEMA4 Junction Boxes with terminal strips (Option JB) are available

from AquaMetrix.

Page 30

AquaMetrix

Ultrason

SENSOR INTRINSIC SAFETY - OPTION ISB

Ultrason Sensors (with built-in temperature compensation)

When connected through an Intrinsic Safety Barrier, the AquaMetrix Ultrason sensors are CSA certified

for installation in a hazardous location rated:

Class I, Groups C,D

Class II, Groups E, F and G

Class III

Intrinsic Safety Barriers may be ordered with the AquaMetrix instrument and are supplied mounted in

the AquaMetrix instrument enclosure. Replacement barrier fuses (Part No. ISB-011239) may be

purchased separately. Barriers must be installed in the sensor cable between the safe and hazardous

locations, and must be mounted in either the safe or Div. 2 area. Barriers may be plate, busbar or rail

mounted.

Intrinsic Safety Barrier Specifications: Certified, rated 17.5V max, 95 ohms min. (Recommended: Stahl

Model 9001/02-175-200-10).

N.O

RELAY 1

2

1

N.O

RELAY 2

N.O

C

N.C

RELAY 3

C

N.C

L

NOTE:

BARRIER-EQUIPPED UNITS

ARE FACTORY-WIRED WITH

GROUND THROUGH THE

INSTRUMENT CHASSIS.

POWER INPUT GROUND

MUST BE

GOOD GROUND (<1 Ohm) WITH

A 12 AWG CONDUCTOR

REPLACEMENT FUSE ASSEMBLY

ORDER PART NO. ISB-011239 (160mA)

INTRINSIC SAFETY BARRIER

AMqua etrix

C

N.C

4-20

G

AC

N

CONNECTED TO A

4

3

T.DUCER

GND

RX

PU

TX

C

C

N.C

N.C

RS 232

N.O

N.O

RELAY 5

RELAY 4

OPTIONAL

NON-HAZARDOUS LOCATION

HAZARDOUS LOCATION

CLASS I, GROUPS C,D

CLASS II, GROUPS E,F,G

CLASS III

N.O

RELAY 6

N.C

C

Page 31

SENSOR

AquaMetrix

Ultrason

POWER INPUT OPTION

12VDC OR 24VDC

Ultrason Level & Flow Monitors may be ordered factory-configured for 12VDC, or 24VDC power

input.

QUICK BENCH TEST:

Connect Sensor as shown below, then Power. When properly connected a soft clicking can be heard

from the sensor and figures will show on the large LCD display. Test operation of the Ultrason by

holding the sensor steadily and aiming at a flat, stable target 12 to 28" (305 to 711 mm) away from the

end of the sensor. Allow a few seconds for the Ultrason to lock onto the target before displaying its

distance. The Ultrason will now display Range in ft or cm (factory calibration).

CONNECTIONS:

POWER INPUT: Connect only 12VDC/0.5 Amps to the + and - terminals for units marked 12V, or

24VDC/0.5 Amps for units marked 24VDC. The Power Input GND must be connected to the nearest

Ground pole. A 1 amp fuse in line is recommended. Power Consumption is 6.5 W continuous.

12V or

24VDC

1 AMP FUSE

12 AWG

MAX

OPTIONAL 24VDC

OPTIONAL 12VDC

POWER INPUT

GND

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 12 AWG CONDUCTOR

Page 32

AquaMetrix

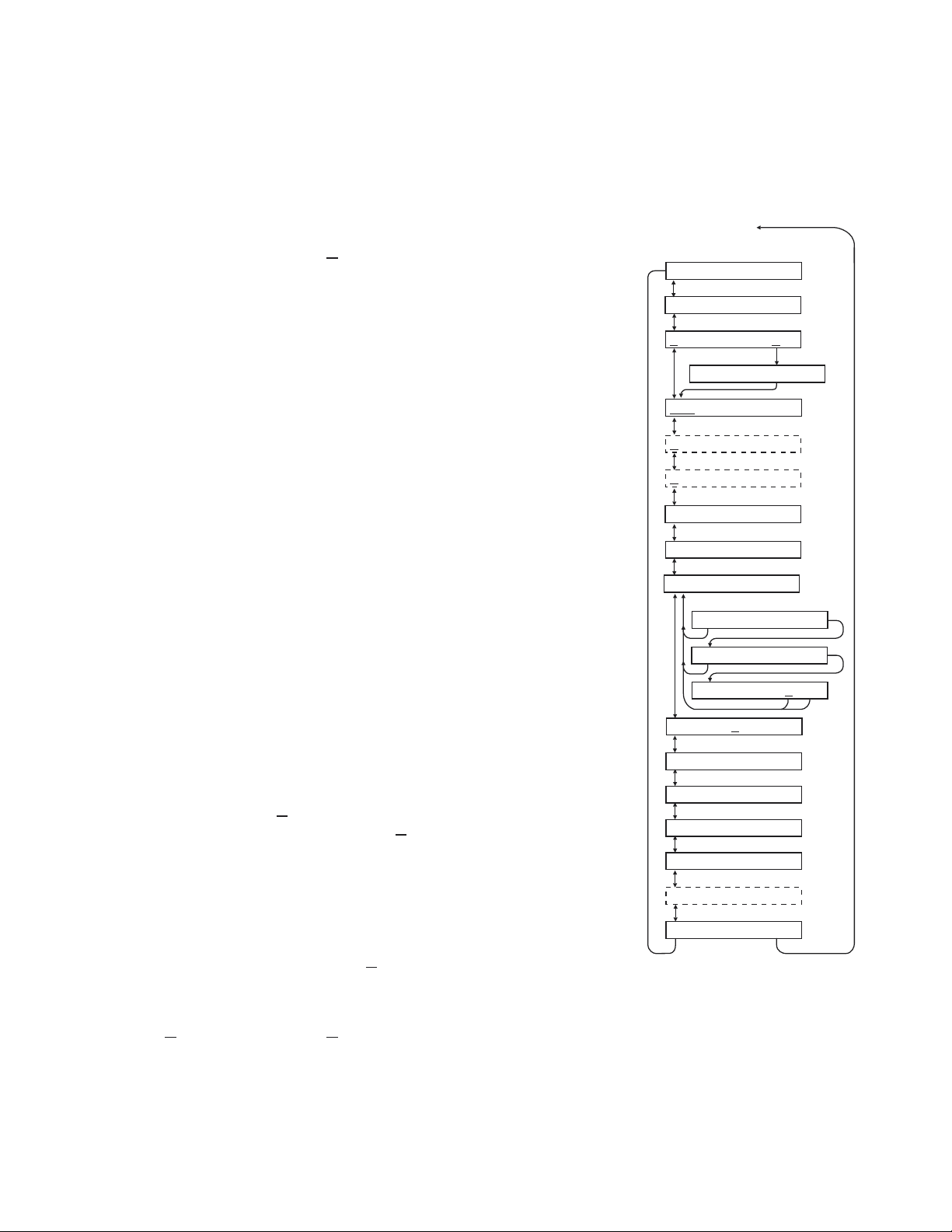

DATA LOGGER MENU (Optional)

Ultrason

PASSWORD: 00 UNITS / MODE

Session No 1

StartJan 01/2000

Start 03:02:16

Isnterval: 24 Hr

Interval: 12 Hrs

Interval: 8 Hrs

Interval: 4 Hrs

Isnterval: 1 Hr

DATA LOGGING

RUN STOP Setup

Log Site ID 1

Formatted Trend

Time Event

StartJan 01/2000

Start 03:02:16

Interval: 30 Sec

Interval: 10 Sec

Interval: 5 Sec

Interval: 2 Sec

Interval: 1 Sec

Interval: 30 Min

Interval: 10 Min

Interval: 5 Min

Interval: 2 Min

Interval: 1 Min

HiAlm LoAlm

At: 5.0 ft3/s

WrapAround? Yes

Reset Log? Yes

26640 Hrs Left

Store? Yes

*** STORING ***

Page 33

AquaMetrix

Ultrason

DATA LOGGING (Optional)

Setup

From

RUN STOP SETUP press Æ to SETUP and then È to Log Site ID 0. Press Æ to position the

cursor under the numeral and È or Ç to change the numerals. The “Site ID” number is retained with

data logging sessions to identify logs stored from different locations.

Formatted Data

Press È from

Formatted” data stores a summary of flow readings over a user-selectable time period. The

“

Log Site ID and press È from Formatted .

summary includes:

DATE and TIME

Interval TOTAL

Interval AVERAGE

Interval MAX FLOW

Interval MAX FLOW TIME

Interval MIN FLOW

Interval MIN FLOW TIME

From

Formatted press È to Start MMM DD/YYYY (eg: Jan 01/2000). Press Æ to position the

cursor and then È or Ç to set the Month, Day and Year that logging will Start. Press Æ to return to

Start.

Press È to

clock in Hours/minutes/seconds, eg:

Æ to return to

Start (time) and Æ to position the cursor under the time column HH/MM/SS (24 hour

23:02:16) and then È or Ç to set the logging start Time. Press

Start .

Press È to

Interval and Æ to the Hrs column. Press È or Ç to select the flow logging interval.

Choose from:

24 Hrs,or 12 Hrs,or 8 Hrs,or 4 Hrs,or 1 Hrs

Press Æ to return to Interval. Press È and the Ultrason will report xxxxx Hrs Left indicating

the amount of logging time available with your current set-up. You can also press Ç to return to

previous menu items and make changes.

Press È to

WrapAround mode the oldest

WrapAround Yes?. Press Æto Yes? and È to enable the logging wrap function. In

data will be overwritten by the newest. If WrapAround is not enabled the

logger will stop when its memory becomes full.

Press È to

sessions and stored values. Or press È from

Ultrason will display “

Reset Log? Yes. Press Æ to Yes and then È to reset the Log and erase all previous

Reset Log? to retain existing data in the Log. The

xxxxx Hrs/Days Left.

Page 34

AquaMetrix

Ultrason

From the xxxxx Hrs Left display press È to Store? Yes. Press Æ to Yes and then È to save

your Data Logging setup, or press È from

Store? to cancel changes made above and exit without

storing changes.

From the Data Logging

position the cursor under

and Time. The Ultrason will display

Store? Yes prompt the menu will return to RUN STOP SETUP. Press Æ to

RUN and press È to activate the Data Logger to start at your selected start Date

SESSION NO. x. Press È to return to DATA LOGGING.

Viewing FORMATTED Data Logs on the Ultrason Display

24 Hour Formatted logs can be viewed directly on the Ultrason display. From

LOG

. This function is available only if 24 Hour Formatted logging has been Stored from the DATA

RUN press Æ to 24 HR

LOGGING menu.

The 24 Hour Log Report is designed to be read one line at time using the Æ key. Using the È or Ç

keys will return the display to the Date column.

TODAYS DATE DAILY TOTAL DAILY AVERAGE MAX FLOW MAX FLOW TIME MIN FLOW MIN FLOW TIME

PREVIOUS DATE “ “ ““““

PREVIOUS DATE “ “ ““““

PREVIOUS DATE “ “ ““““

PREVIOUS DATE “ “ ““““

PREVIOUS DATE “ “ ““““

The current day plus the past 255 days of data can be displayed. (Logger software will display up to

1300 days of data.)

Trend Data Logging - Setup

From

RUN STOP SETUP press Æ to SETUP and then È to Log Site ID 0. Press Æ to position the

cursor under the numeral and È or Ç to change the numerals. The “Site ID” number is retained with

data logging sessions to identify logs stored from different locations.

From

Log Site ID press È to Formatted Trend and press Æ to position the cursor under

Trend. Then press È to select Time based logging.

‘Time’ based Trend Logging

Time based logging allows you to choose Start and Stop times and a logging interval.

From

Time press È to Start MMM DD/YYYY (eg: Jan 01/2000). Press Æ to position the cursor

and then È or Ç to set the Month, Day and Year that logging will Start. Press Æ to return to

Start.

Page 35

AquaMetrix

Ultrason

Press È to Start (time) and Æ to position the cursor under the time column HH/MM/SS (24 hour

clock in Hours/minutes/seconds, eg:

Æ to return to

Start .

23:02:16) and then È or Ç to set the logging start Time. Press

Press È to Interval and Æ to the

Sec/Min column. Press È or Ç to set the logging time interval.

Choose:

30 Sec

10 Sec

5 Sec

2 Sec

1 Sec

30 Min

10 Min

5 Min

2 Min

1 Min

Press Æ to return to to Interval and È to Reset Log? To erase all existing data in the log press Æ

to

Yes and È. To keep existing data in the Log press È from Reset Log? If you have made changes

to the Start Date, Time or Interval, the data logger will automatically start a new “session”. The Ultrason

will display “

From the

Data Logging setup, or press È from

xxxxx Hrs/Days Left”.

xxxxx Hrs Left display press È to Store? Yes. Press Æ to Yes and then È to save your

Store? to cancel changes made above and exit without storing

changes.

From the Data Logging

position the cursor under

and Time. The Ultrason will display

Store? Yes prompt the menu will return to RUN STOP SETUP. Press Æ to

RUN and press È to activate the Data Logger to start at your selected start Date

SESSION NO. x. Press È to return to DATA LOGGING.

‘Event’ based Trend Logging

Event based logging stores data points only when a High or Low flow set point has been reached.

With cursor under

rate, while

LoAlm and press È to the At: prompt. Press Æ to the numerals column and press È or Ç to set flow

LoAlm will log points below a selectable flow rate. Position the cursor under HiAlm or

alarm logging set point. Press Æ to return to

Event press È to HiAlm LoAlm . HiAlm will log points above a selectable flow

At:

Page 36

AquaMetrix

Ultrason

Press È to Interval and Æ to the Sec/Min column. Press È or Ç to set the logging time interval.

Choose:

30 Sec

10 Sec

5 Sec

2 Sec

1 Sec

30 Min

10 Min

5 Min

2 Min

1 Min

Press Æ to return to Interval and press È to Reset Log? To erase all existing data in the log press

Æ to

Yes and È. To keep existing data in the Log press È from Reset Log? If you have made

changes to the Start Date, Time or Interval, the data logger will automatically start a new “session”. The

Ultrason will display “

xxxxx Hrs/Days Left”.

From the

your Data Logging setup, or press È from

xxxxx Hrs Left display press È to Store? Yes. Press Æ to Yes and then È to save

Store? to cancel changes made above and exit without

storing changes.

From the Data Logging

position the cursor under

display

SESSION NO. x. Press È to return to DATA LOGGING.

Store? Yes prompt the menu will return to RUN STOP SETUP. Press Æ to

RUN and press È to activate the Data Logger to start. The Ultrason will

Logging "Sessions"

Each time you select

memory as a "

selecting

NO xx

". When you download the logger files to your PC using AquaMetrix Logger software, each

SESSION NO" automatically numbered from "1"to"10". If you resume logging by

RUN, the Data Logger will report that a new logging session is started and titled "SESSION

STOP in the DATA LOGGING menu, the Data Logger stores the current data in

Session will open as a separate graph/table titled "AquaMetrix Data Log xx".

Important:

If you

STORE instrument calibration changes under the UNITS/MODE or CALIBRATON menus, STOP

the data logger and select RUN again to start a new logging Session with your new calibration values.

Page 37

AquaMetrix

PublicTeleph

RS232C SERIAL OUTPUT (with optional Data Logger)

Ultrason

Format: 8 Bits, 1 Stop Bit, No Parity. (Baud rate may be changed under the

SPECIAL FUNCTIONS

menu. Factory default is 19200 baud).

Output Connector is DB9-Female. Use the cable supplied for connection to a PC Computer. Use the

cable plus the “NULL MODEM” (supplied) for connection to modem.

oneLines

Modem

Computer

AquaMetrix

Ultrason

INCLUDED

RS232

20' (6 m) cable

included

Detail

GND

RX

PU

RS 232

(BLK)

(WHT)

(GREEN)

TX

(RED)

DB9F

ADAPTOR

9M

B

D

DB25F

6

7

8

9

Detail

L

L

U

N

DB25M

1

2

3

4

5

M

E

D

O

DB25M

M

Wired as DCE

(Data Communication Equipment)

PIN2-RX

PIN3-TX

PIN 4 - DTR (PU)

PIN 5 - GND

SHIELD - CASE

(PU = PULL-UP)

Modem

DB25F

DB25M

Computer

DB9M

Page 38

AquaMetrix

Ultrason

RS485 SERIAL OUTPUT

(Replaces standard RS232 Output with Data Logger option.)

Permits transfer of optional Data Logger reports on long wire lengths up to 4000 ft. (1220 m). Use for

Ultrason to PC communication only (not for multidrop RS485 networking).

Format: 8 Bits, 1 Stop Bit, No Parity. (Baud rate may be changed under the

SPECIAL FUNCTIONS

menu. Factory default is 19200 baud).

Use shielded, 4-conductor cable (cable option SC-18AWG recommended). Connect the cable shield to

Ground at the Ultrason electronics enclosure and do not connect to Ground at the other end.

AMqua etrix

Transmitter

with

RS485 Output

RS485

18AWG, 4-conductor, shielded

<4000 ft (1220 m)

Option: SC-18AWG

Detail

GND

RX

PU

TX

RS485

(BLK)

(RED)

(WHT)

(GREEN)

RS232/485 Converter

Option: 485OICR-12V

TX

RX

PU

GND

RS485

RS232

DB25F

RS232 Cable

Option: DB25M/DB9F

DB25M

6ft(2m)

DB9F

Configure the Logger software program for RS485 communications. Under the Communications /

Connection Setup menu, select 'Connected to a 485OICR-12V adaptor.

485OICR-12V

RS232/RS485 Converter

Use with optional RS485 putput for connection to a PC computer

or modem.

•

Optically isolates and protects your computer's RS232 port

•

Terminal block for RS485 connections

•

Operates from 2400 up to19.2K baud

DB25M/DB9F - RS232 Cable

Connects RS232/485 Converter to a PC

Cable length 6 ft.(2 m) with DB25M and DB9F connectors.

Page 39

AquaMetrix

m

ENCLOSURE SUNSCREEN - OPTION SSM

Note:

Ultrason

11" / 280 mm

Exposure to direct sunlight can cause

overheating and moisture condensation

which will reduce the operating life of

electronics.

Protect Instruments from direct sunlight

with this iridite finished aluminum sun

screen (AquaMetrix Option SSM).

Seal conduit entries with caulking

compound to further reduce moisture

condensation.

SENSOR SUNSCREEN - OPTION SSP

11"

280 mm

5"

127 m

Page 40

AquaMetrix

APPENDIX B - APPLICATIONS BACKGROUND

Conditions in the tank or channel where the ultrasonic sensor is installed can affect the performance,

range and accuracy of the system. The following notes are for general reference. Contact AquaMetrix or

your local representative for specific information on your application.

Ultrason

FOAM

ultrasonic level measuring system. Foam acts as a sound insulator and may eliminate, or reduce the

strength of an echo. Measurement range may be reduced in a system where foam is present. Ultrasonics

are not recommended where thick dense foam is continually present. Intermittent or thin layers of light

foam (1/8 in. or less) can generally be disregarded. Use a stilling well in open channel applications.

LIQUIDS

viscous liquids can be monitored without contacting the liquid.

SOLIDS - The Ultrason will measure most granular material and powders as well as liquids. Powders

will not generally provide the same echo strength as liquids. Therefore maximum expected range should

be reduced to approximately 20 feet (6 m) for powders. There are many exceptions to this rule and

installation of a test system is recommended when in doubt.

DUST

concentrations of dust are expected ultrasonics may not work. Where moderate dust is encountered

care should be taken to mount the sensor in a position where dust accumulation will be minimized and

where the sensor can be cleaned if necessary.

SENSOR TEMPERATURE - The standard sensor model US2 supplied with each Level & Flow

Monitor includes a built-in temperature sensor. The Ultrason automatically compensates for temperature

fluctuations to retain high accuracy. Note the operating temperature ranges listed in the product

specifications section. Do not exceed the sensor temperature ratings or damage may occur.

- Solid or dense surfaces such as a smooth liquid surface will give the best echos in an

- The Ultrason is ideal to monitor tank liquid level or inventory. Caustic, corrosive or very

- Any obstructions to the sound will affect performance of the system. In silo’s where heavy

ELECTRONICS TEMPERATURE

specifications. Temperatures higher than the maximum shown can reduce the operating life of the

electronics. Moisture condensation from those temperatures below the range shown can also damage

electronics components. In cold or outdoor environments the optional factory-installed enclosure heater

and thermostat is recommended.

NOISE

vibration will not affect the system. Sensors installed in close proximity to one another in the same tank

may “cross-talk” and should be synchronized.

VAPOUR

can cause false echoes. Variable vapour cannot be compensated.

CHEMICAL COMPATIBILITY

compatabilities. Tank contents should be checked for their compatibility with PVC. An all-teflon

sensor is available for corrosive applications.

- Because the Ultrason’s sensor operates at high sound frequency, regular process noise or

- May affect but it can be compensated for by calibration in-situ. Severe vapour stratification

- Note operating temperature ranges listed in the product

- The Ultrason is constructed of very durable materials with broad

Page 41

AquaMetrix

FROM TO MULTIPLY BY

US GALLONS CUBIC FEET 0.1337

US GALLONS IMPERIAL GALS 0.8327

US GALLONS LITRES 3.785

US GALLONS CUBIC METERS 0.003785

LITRES/SEC GPM 15.85

LITRES CUBIC METERS 0.001

BARRELS US GALLONS 42

BARRELS IMPERIAL GALS 34.9726

BARRELS LITRES 158.9886

INCHES MM 25.4

DEGREES F DEGREES C

POUNDS KILOGRAMS 0.453

PSI BAR 0.0676

FOOT² METER² 0.0929

Ultrason

CONVERSION

GUIDE

(°F-32) x 0.556

VOLUME CALCULATION FOR ROUND TANKS: 3.142 x R² x H

R = TANK RADIUS (1/2 TANK DIAMETER)

H = TANK HEIGHT

Page 42

AquaMetrix

U

Ultrason

SPECIFICATIONS

7.4 / 188 mm"

6.46 / 164 mm"

5.12 / 130 mm"

Electronics Enclosure: NEMA4X (IP 66), watertight

and dust tight, fiberglass with

clear, shatterproof

hinged Lexan cover

Accuracy: 0.25% F.S., Repeatability:

0.1% F.S., Linearity:

0.1%F.S.

Display: Flow/Level Values: ¾” / 19

AMqua etrix

Ultrason

10 / 254 mm"

10.94"/278mm

mm high, 4 digit LCD

Menu/Status/Totalizer:

16 digit LCD alphanumeric

Programming: 3-button keypad with Menu

selection. Calibration

CONDUIT ENTRY

LOCATION

SIDE VIEW

ENCLOSURE

parameters are permanent

when Stored (even through

power interruptions)

Power Input: 100-130VAC 50/60 Hz, (7.2 W max.)

Optional: 200-260VAC 50/60 Hz,(7.2 W max.)

Optional: 12VDC, or 24VDC (6.5 W max)

Output: Isolated 4-20mA, 1000 ohm

load maximum

Control Relay: Qty 3, rated 5 ampere SPDT

Temperature Compensation: Automatic, temperature probe built in to level Sensor

Lightning/Surge Protection: Sensor, 4-20mA, AC power input

Operating Temperature (electronics): -5 to 140°F (-20 to 60°C). Optional Enclosure Heater recommended for

condensation protection below 32°F (-1°C)

Standard Sensor US2-1-A-1-A

Maximum Range: 32 ft. (10 m)

Deadband (blanking): Programmable, minimum 12” (305 mm)

Beam Angle: 8° at3DB

Temperature Compensation: Automatic, continuous

Operating Frequency: 42 KHz

Exposed Materials: PVC and Teflon

Operating Temperature: -40° to 150°F (-40° to 65°C)

Operating Pressure: 20 psi (1.35 Bar) maximum

Hazardous Rating: with optional Intrinsic Safety Barrier: CSA,

Mounting: ¾” NPT (PVC isolation coupling supplied)

Sensor Cable: RG62AU coaxial, 25 ft. (7.6 m) standard

Class I,II,III, Div. I,II, Groups C,D,E,F,G

Note: Max Range reduced to 25 ft (7.6 m) with

ISB option.

Page 43

3/4"

NPT

ISOLATION

COUPLING

(SUPPLIED)

3/4"

NPT

SIDE

VIEW

END

VIEW

PVC

PVC

1-3/4 "

44.5mm

L

TEFLON

O

TEF

25' (7.6 m) RG62A

COAXIAL CABLE

3-7/8 "

98mm

(127 mm)

OVERALL

5"

AquaMetrix

Optional Sensor US2-1-B-1-A

Ultrason

Maximum Range: 32 ft. (10 m)

Deadband (blanking): Programmable, minimum 12” (305 mm)

Beam Angle: 8° at 3 DB

Temperature Compensation: Automatic, continuous

Operating Frequency: 42 KHz

Exposed Materials: Teflon

Operating Temperature: -40° to 170°F (-40° to 76°C)

Operating Pressure: 20 psi (1.35 Bar) maximum

Mounting: ¾” NPT (Teflon isolation coupling

supplied)

Sensor Cable: RG62AU coaxial, 25 ft. (7.6 m) standard

Hazardous Rating: with optional Intrinsic Safety Barrier:

CSA, Class I,II,III, Div. I,II, Groups

C,D,E,F,G,

Note: Max Range reduced to 25 ft (7.6

m) with ISB option.

3/4"

NPT

TEFLON

ISOLATION

COUPLING

(SUPPLIED)

3/4"

NPT

SIDE

VIEW

END

VIEW

TEFLON

TEFLON

1-3/4 "

44.5mm

L

TEFLON

O

T

EF

25' (7.6 m) RG62AU

COAXIAL CABLE

3-7/8 "

98mm

5"

(127 mm)

OVERALL

Optional US2-2-A-1-B

Maximum Range: 50 ft. (15.6 m)

Deadband (blanking): Programmable, minimum 16"(406mm)

Beam Angle: 8º at 3 DB

Temperature Compensation: Automatic, continuous

Operating Frequency: 40 KHz

Exposed Materials: PVC and Teflon

Operating Temperature: -40 to 150ºF (-40 to 65ºC)

Operating Pressure: 20 psi (1.35 Bar) maximum

Sensor Cable: RG62Au coaxial, 50 ft. (15 m) standard

Hazardous Rating: with optional Intrinsic Safety Barrier:

PVC

Mounting: ¾” NPT (Isolation Coupling supplied)

PVC

CSA, Class I,II,III, Div. I,II, Groups

C,D,E,F,G,

Note: Max Range reduced to 32 ft (10

m) with ISB option.

Page 44

AquaMetrix

Optional US12-1-A-1-A

Maximum Range: 12 ft (3.66 m)

Minimum Range (Deadband): 8" (203.2 mm)

Operating Frequency: 92 KHz

Beam Angle: 8°

Operating Temperature: -40° to 150° (-40° to 65°C)

Temperature Compensation: Automatic, continuous

Max. Operating Pressure: 20 psi (1.35 bar)

Sensor Face: PVC

Sensor Body: PVC

Mounting: ¾" NPT

Cable Length: 25 ft. (7.6 m) continuous

RG62AU coaxial. Optional 50

ft. (15 m) continuous

Max. Cable Length: 500 ft. (152 m) RG62AU

coaxial (splice)

Hazardous Rating: CSA rated Intrinsically Safe

Class I, Groups C,D, Class II,

Groups E,F,G with Optional

Intrinsic Safety Barrier.

~3.9"

(99 mm)

OVERALL

2.75"

70 mm

25 ft (7.6 m) RG62AU

COAXIAL CABLE

(50 ft 15 m OPTIONAL)

3/4“ NPT

3/4" NPT

2.75" (70 mm)

Ultrason

ISOLATION

COUPLING

(SUPPLIED)

1"

(25.4 mm)

Optional US12T_F

Maximum Range: 12 ft (3.66 m)

Minimum Range (Deadband): 8"(203.2 mm)

Operating Frequency: 92 KHz

Beam Angle: 8°

Operating Temperature: -40° to 150° (-40° to 65°C)

Temperature Compensation: Automatic, continuous

Max. Operating Pressure: 20 psi (1.35 bar)

Sensor Face: Teflon

Sensor Body: PVC

Mounting: ¾" NPT

Cable Length: 25 ft. (7.6 m) continuous RG62AU coaxial. Optional 50 ft. (15 m)

continuous

Max. Cable Length: 500 ft. (152 m) RG62AU coaxial (splice)

Hazardous Rating: CSA rated Intrinsically Safe Class I, Groups C,D, Class II, Groups E,F,G

with optional Intrinsic Safety Barrier.

25 ft (7.6 m) RG62AU

COAXIAL CABLE

(50 ft 15 m OPTIONAL)

3/4“ NPT

ISOLATION

COUPLING

(SUPPLIED)

~ 4.5"

(114 mm)

OVERALL

82.5 mm

3.25"

3/4 " NPT

TEFLON FACE 0.01" / 0.25mm

BOLT CIRCLE DIAMETER

FLANGE DIAMETER

Page 45

1"

(25.4 mm)

AquaMetrix

CALIBRATION WORKSHEET - Level Mode

for Horizontal Round Tanks (HRT) and Vertical Tanks

(Ultrason reads) A = ______________

Ultrason

Program Ultrason to show RANGE via:

CALIBRATION

MODE

RANGE

LINEAR

STORE

RUN

(DIP STICK) B = ____________

MIN RANGE

MUST BE

12 in (305 mm)

OR MORE

A

C

B

(INSIDE DIA.) C = ____________

A + B = MAX RANGE

___ + ___ = ___________

A+B-C =MINRANGE

___ + ___ - ___ = ___________

Program MIN RANGE then

Use

VOLUME

for Vertical

Tanks

MAX RANGE via:

CALIBRATION

MODE

LEVEL

HRT

MAX. VOL

MIN RG

MAX RG

STORE

RUN

Page 46

AquaMetrix

n

P

CALIBRATION WORKSHEET - Flow Mode

for Open Channel Flow through Flume and Weirs

MAX RANGE

(Ultrason READS)

rogramUltrason to show

RANGE via:

A=______________

SENSOR

Ultrason

MIN RANGE

MUST BE

12 in. (305 mm)

OR MORE

UNITS

SELECTION

ftinmcm%

RANGE

STORE? YES

MAX HEAD

(Height at MAX Flow)

B=______________

A

B

Program MIN RANGE the

MAX RANGE via:

CALIBRATION

MODE

A - B = MIN RANGE

______ - ______ = __________

MIN RANGE

MAX RANGE

STORE? YES

Page 47

V 2.26

SLT32

SPECIAL FUNCTION

1234567890123456

Tag 01

VYiew Codes? es

23:39:51

Date May 31/1999

Time

30 s

LOE Time

Yes

Tot?

Reset

Cº

20.3

Temp

Cº

20.0

Min Temp

Cº

23.0

Max Temp

DISPLAY FCºº

ISB?: No Yes

0.00%

Simul

4.000

4mA ADJ

20.000

20mA ADJ

Yes

Store?

New Password: 00

Com 24 48 96 192

HiAlm

Flow

LoAlm

Level

R1 Mode Pump

R1on 0.00 C°

Temp

Pulse

R1on 0.00 ft3

RELAY PARAMETERS

R1 Function Off

32.00 ft

1.333 ft

CALIBRATION

MinRg

MaxRg

R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 on 0.00 ft

° C

OFF

R1 0.00

0.00 %

100.00 %

@

20mA @

4mA

Hold

On

R1 LOE Off

%

08 s

20

RejTime

Damping

Flow

Level

Temp

Pulse

R2 Function Off

Yes

Store?

HiAlm

LoAlm

R1 Mode Pump

R1on 0.00 C°

R1on 0.00 ft3

R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 on 0.00 ft

° C

OFF

R1 0.00

Hold

On

R1 LOE Off

Flow

Level

Temp

Pulse

Function Off

R3

HiAlm

LoAlm

R1 Mode Pump

R1on 0.00 C°

R1on 0.00 ft3

R1 on 0.00ft3/s

R1 OFF 0.00 ft

R1 on 0.00 ft

° C

OFF

R1 0.00

Hold

On

R1 LOE Off

(123456)

ALT

Yes

Store?

SENSOR

MIN

OPTIONAL FEATURES

RANGE

MAX LEVEL

MAX

RANGE

ZERO LEVEL

K=

Custom

More

Sizes

Parshall

FLOW MODE ONLY

Ultrason - CALIBRATION RECORD

FLUME SELECTION

V-Notch

cm %

m

in

UNITS / MODE

ft

PASSWORD: 00

Sizes

Vol Hrt Flow

Level

Range

n=

Yes

Store?

L

USMG