OPERATING INSTRUCTION MANUAL

MODEL 2200C

CONDUCTIVITY ANALYZER

REV. 7.0

AquaMetrix Inc.

22-121 Granton Drive

Richmond Hill, ON

Canada, L4B 3N4

Tel: (800) 742-1413

(905) 763-8432

Fax: (905) 763-9480

www.aquametrix.com

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 GENERAL INFORMATION 1

2 SPECIFICATIONS 2

3 INSTALLATION 3

4 DESCRIPTION OF FUNCTIONS 6

5 START-UP AND OPERATION 11

6 OPERATING HINTS 16

7 UTILITY MENU 17

8 DIAGNOSTICS 21

9 TROUBLESHOOTING AND SERVICE 22

Model 2200C Page 1

MODEL 2200C CONDUCTIVITY CONTROLLER

INSTRUCTION MANUAL

1.0 GENERAL INFORMATION

The AquaMetrix Model 2200C conductivity analyzer is a versatile industrial microprocessor based

instrument. Setpoints and outputs are programmed through the menu with push buttons on the face

of the instrument. Calibration is achieved from the front panel menu. The instrument may be used

in conjunction with any AquaMetrix MS series cell.

The instrument provides non-isolated 0-5 Vdc, 0-1 mA and isolated 4-20 mA analog outputs. The

analog output may be programmed to represent any segment of the measuring scale. One control

relay, with fully adjustable deadband, and one high-low alarm relay are provided. The control relay

can be programmed to activate in response to rising or falling conductivity.

The integrity of the system is ensured with a watch-dog timer and system alarm. A password

feature protects the stored values.

The instrument is housed in a NEMA 4X enclosure. The standard unit is provided with mounting

hardware for surface mount applications. Both panel and pipe mount kits can be ordered

separately.

Model 2200C Page 2

2.0 SPECIFICATIONS

DISPLAY:

4 digit LED, 1/2" high digits

MEASURING RANGES:

Eighteen ranges;

The range is set at the factory as ordered, but maybe

changed in the field to any other range through the

Utility Menu.

Temperature: 0°C to 100°C (32°F to 212°F)

POWER REQUIREMENTS:

Standard: 98-132 Vac, 50/60 Hz (less than 5 VA)

Optional: 196-264 Vac, 50/60 Hz (less than 5 VA)

23-26Vdc (nominal current 150mA)

AMBIENT CONDITIONS:

-30 to 50°C (-22 to 122°F)

0 to 90% R.H. non-condensing

CONTROL RELAY:

5A 115/230 Vac, 5A 30 Vdc SPDT

Selectable to activate in response to rising or falling

process

Fully adjustable setpoint and deadband

Manual Override Auto / Off / On

Cycling Feature: On time 0-600sec Off time 0-600sec

Normal or Fail Safe operation

ALARM RELAY:

5A 115/230 Vac, 5A 30 Vdc SPDT

Programmable to activate at high and low alarm

setpoints

Deadband fixed at 2% of Full Scale

Normal or Fail Safe Operation

RELAY INDICATORS:

Three individual LED indicate status of the control

relay and the alarm relay.

ANALOG OUTPUTS:

Non Isolated 0-1mA, 100 ohms maximum load

Non Isolated 0-5Vdc, 1000 ohms minimum load

Isolated 4-20mA, 800 ohms maximum load

Range Expand:

The 4-20 mA analog output can be

made to represent any segment of the measuring

scale. Minimum segment is 10% of full scale.

Output Hold

: The analog outputs are automatically

placed on hold during calibration or other setup

operations.

Temperature Output

: The 0-5 Vdc output can be

programmed to follow the process temperature or

conductivity.

TEMPERATURE COMPENSATION:

Automatic 0°C to 100°C (32°F to 212°F)

SYSTEM ERROR:

A LED indicates a system error. The alarm relay can

be programmed to activate upon system memory loss.

DIAGNOSTICS:

Invalid entries are identified by respective flashing

LEDs. When a system error is indicated, use the CALL

button to display STATUS, to determine the status

code.

TEST:

Display value and analog outputs can be set manually

to any value for testing and diagnostic purposes. This

feature allows the operation of the control relay, alarm

relay, analog outputs to be tested independently of the

process.

SAFETY AND SECURITY:

Non-volatile memory (EPROM)

Password protected if enabled

Watch-dog timer monitors microprocessor

Instrument automatically returns to on line operation if

accidentally left in menu mode. (This feature may be

field disabled if desired.)

SENSITIVITY: 0.1% of span

STABILITY: 0.1% of span per 24 hrs. non-cumulative.

NON-LINEARITY: 0.1% of span

REPEATABILITY: 0.1% of span or better

TEMPERATURE DRIFT:

Zero: 0.01% of span per °C

Span: 0.01% of span per °C

RESPONSE TIME:

0.5 second to 90% of value upon step change

ENCLOSURE:

NEMA 4X molded fiberglass reinforced polyester

enclosure with four 1/2" conduit holes and mounting

feet for surface mount. A NEMA 4 plug is provided for

one hole.

MOUNTING CONFIGURATIONS:

Standard is surface mount

Optional panel mount hardware Part No. C35-68

Optional pipe mount hardware Part No. C35-69

NET WEIGHT: 3 1/2 lb. (1.6 kg)

Approvals: CSA

Model 2200C Page 3

3.0 INSTALLIATION

3.1 Location

3.1.1 Locate the instrument within 3000 feet of where the AquaMetrix MS or MC

conductivity cell is installed.

3.1.2 Select an installation site which is:

• free of mechanical vibrations

• reasonably clean and dry

• protected from falling corrosive fluids within the ambient temperature and humidity

specifications

• remote from high voltage relay and power switches

3.2 Type of Mounting

3.2.1 If the instrument is to be pipe or panel mounted a special hardware kit will be

required. For panel mount order part number C35-68. For pipe mount order part

number C35-69. Instructions for both types of mounting will be included with the

kits.

3.2.2 For surface mounting, four feet brackets, together with fastening screws, are

provided with the instrument. These should be fastened to the back of the

instrument and then it may be screwed or bolted in the selected location.

3.3 Conduit Connections

3.3.1 Four 1/2" conduit holes are provided in the bottom of the enclosure. One of these is

fitted with an approved water tight plug. To maintain NEMA 4 integrity, approved

conduit hubs must be used to connect conduit. The hubs must be connected to the

conduit before being connected to the enclosure. Any unused conduit holes must

be closed with water tight plugs or connectors.

3.3.2 For convenience of internal connections the right conduit hole (viewed from the

front) should be used for power connection; the next hole to the left for relay

outputs; the next hole to the left for analog outputs and finally the fourth hole for

sensor input.

Model 2200C Page 4

3.4 Electrical Connections

CAUTION: The instrument operates from line voltage. This constitutes a possible shock hazard.

Ensure that line power is removed before attempting connections.

Note:

A separate

source of line power may have been connected to the floating relay contacts.

3.4.1 To access the terminal strips open the door of the instrument and then unscrew the

captive retaining screw near the upper right hand corner of the panel. Now swing

open the panel to reveal the terminal strip on the power supply circuit board and the

smaller terminal strip on the back of the main circuit board.

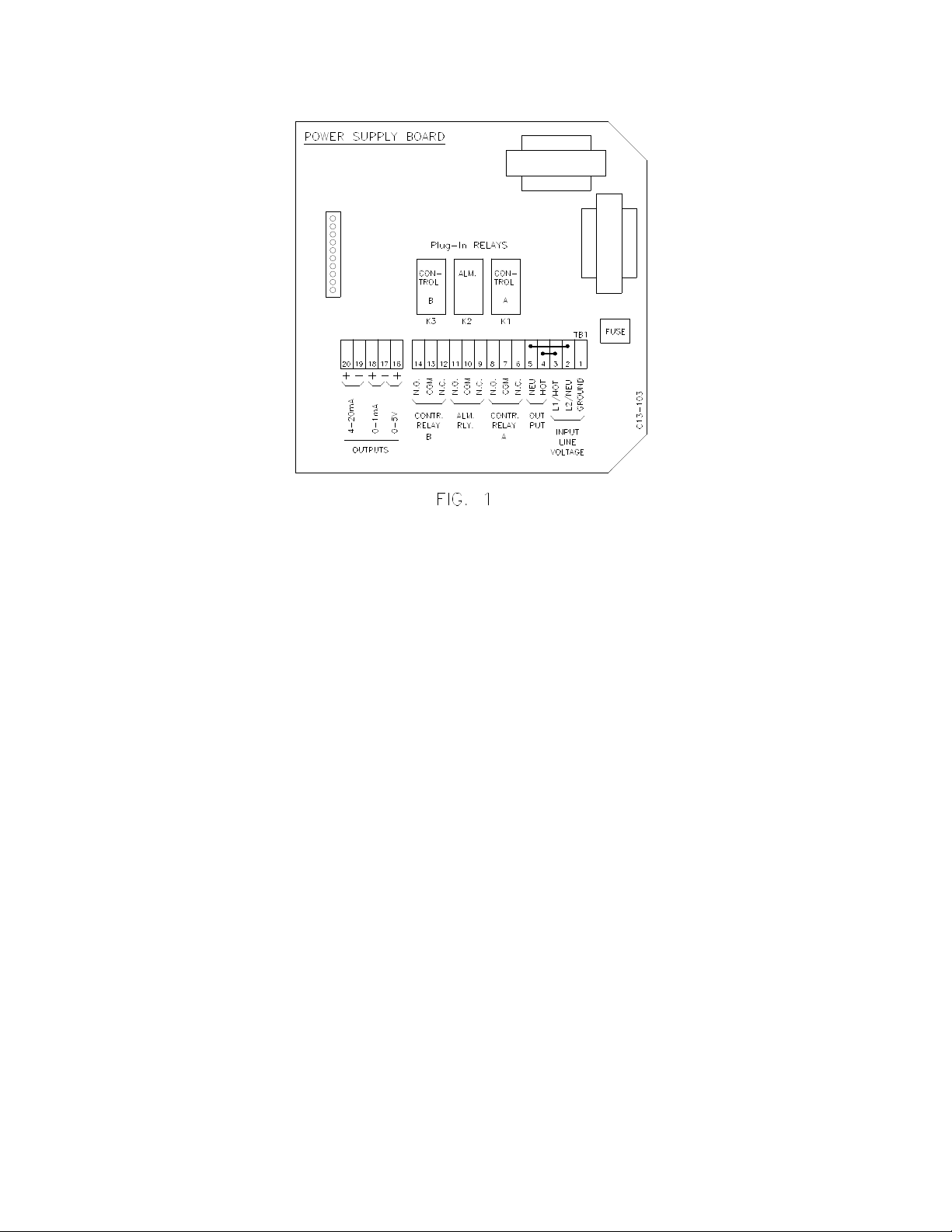

3.4.2 The terminal strip on the power supply board at the back of the instrument is

labeled for line power, relay outputs and analog outputs. Connect the wiring in

accordance with this labeling. (Refer to Fig.1)

Note: Control Relay B is not used in the 2200C.

Terminals 4 and 5 are wired directly to the input line voltage. These terminals can

be used to supply power to the relays. Use the common ground of Terminal 1as the

ground for the auxiliary devices. A separate source of power can also be used to

provide power to the relays. Ensure that the circuit breaker supplying the instrument

is able to supply enough current to the auxiliary devices, to ensure proper operation

of the instrument.

Model 2200C Page 5

CAUTION: Connecting the line voltage to incorrect terminals may cause serious damage.

3.5 Cell Connections

3.5.1 Connect the 4 wires of the cell cable to the TB2 terminal strip on the main circuit

board being sure to match the colors as printed on the TB2 terminal strip. White

and black are the electrode wires; red and green are the temperature sensor wires.

Place switches S41 and S42 in the down “on-line” position. Refer to Fig.2

Model 2200C Page 6

3.5.2 The test resistor R68, is used for the simulation feature. It has a resistance equal to

the equivalent resistance of the cell at mid scale. The resistor that is shipped with

the unit corresponds to the mid scale of the range ordered. If the range is changed,

from the range configured at the factory. Refer to Sec. 9.1.5 for the correct resistor

value.

4.0 Description of Functions

Model 2200C Page 7

4.1 Overview

4.1.1 The Model 2200C is a microprocessor based conductivity analyzer designed for

industrial applications. It is compatible with AquaMetrix’s MS and MC conductivity

cells and offers several measurement ranges. The unit's software makes

maintenance and operation easy.

4.1.2 The outputs include voltage-free relay contacts and industry standard analog

transmission signals. Two programmable relays are provided for process control

and alarm. The status of each relay is indicated on the front by a LED. The analog

output signals transmit low power signals to peripherals such as data recorders or

control systems.

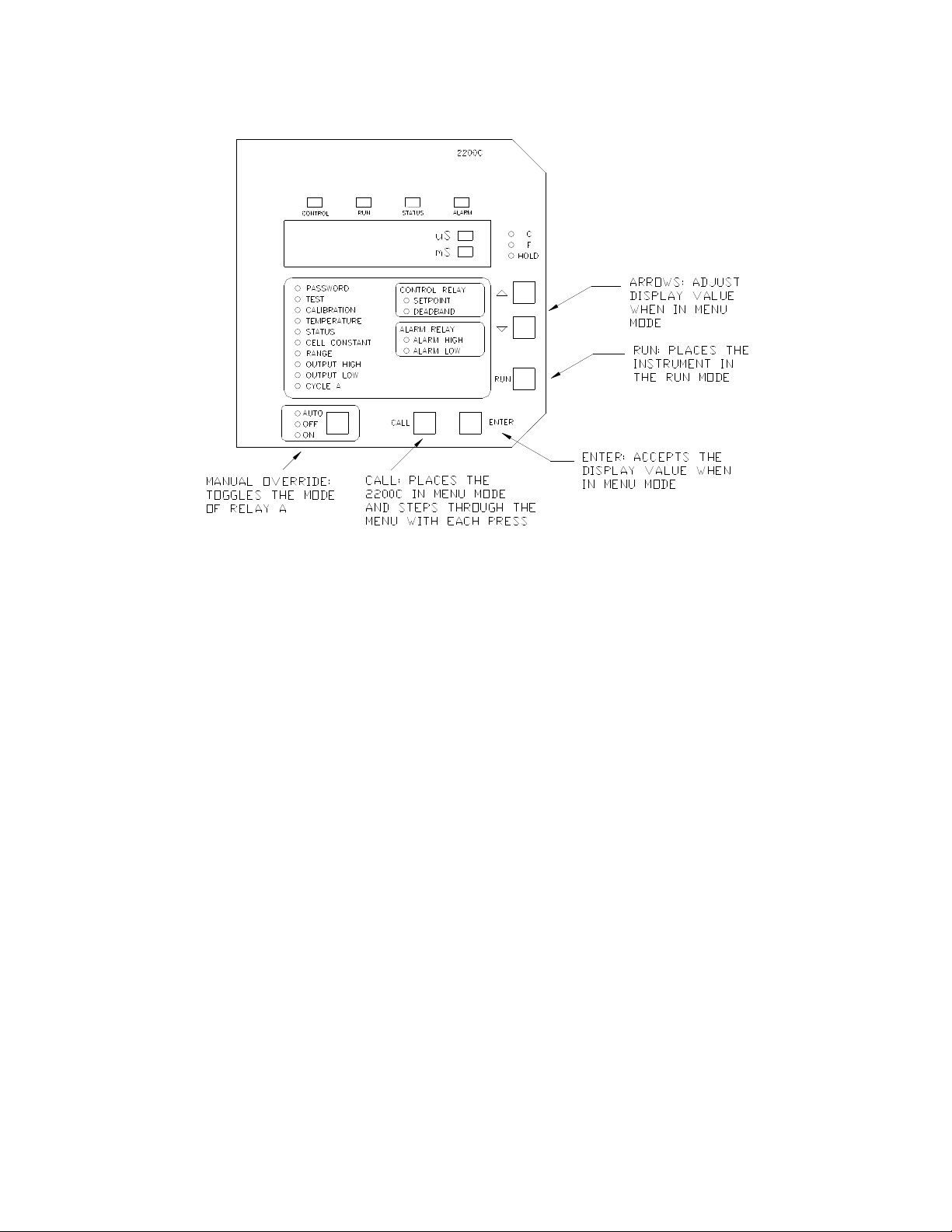

4.1.3 The software is designed for ease of operation. It uses a simple menu with all items

indicated on the panel. The user interface consists of six buttons on the front panel.

The buttons are scanned and responded continuously. In addition, an extensive

system checking for values and parameters is performed by the software. All of the

operating parameters are stored in non-volatile memory, without the need of a

battery.

4.1.4 The Model 2200C operates like a normal analog converter with a number of

additional functions made possible by the microprocessor in the instrument.

Some of these are:

• Recall and easy adjustment of relay and output parameters

• Push button calibration

• A HOLD function for outputs

• Continuous sensor check during measurement

• Continuous self check and watch-dog timer to ensure correct operation

• Password protection of stored values

• Temperature Output

Model 2200C Page 8

4.2 Calibration

4.2.1 All conductivity systems need to be calibrated when first placed in service and

thereafter from time to time. The frequency of calibration can only be found by the

operator’s experience with each process. Calibration must always be performed

when a new sensor is placed in service.

4.2.2 Calibration is accomplished by using buffer solutions, of known conductivity, and

adjusting the instrument to show the known value. Buffers are available in 500 mL

bottles and in 20 L packs from AquaMetrix. The procedure for performing

calibration is very simple and is given in Sections 5.2.

4.3 Temperature Compensation

4.3.1 Temperature compensation is an essential component of conductivity

measuring instruments. Specific conductivity increases with temperature even

though there has been no addition of dissolved solids. It is therefore the industry

standard to compensate for temperature change as if the temperature were

constant at 25°C. The 2200C compensates for a 2% increase in specific

conductivity per °C.

4.4 Relay Outputs

4.4.1 Two SPDT (Single Pole Double Throw) relays are provided. The normally open

contacts, NO, are open when no alarm or control is active.

4.4.2 The control relay can be programmed to close on either rising or falling conductivity.

It is normally used to control a valve, pump or auxiliary device. It may be set to

close at any point on the scale. The deadband, sometimes termed hysteresis,

defines the point at which the relays open.

4.4.3 Refer to Sections 5.4, to 5.6.

4.4.4 The second relay functions as a high-low alarm. It has two programmable

Setpoints (high and low). The deadband is fixed at 2% of full span. The alarm

contact can be programmed to also signal memory loss in the controller. See

Sections 4.7, 5.7, and 5.8.

4.4.5 All relays can be programmed for "fail-safe" operation which reverses the normal

operation of the relay. In fail safe mode the Normally Closed contact functions as

the Normally Open contact. In the event of power loss to the unit, the relay will deenergize and the device connected to the Normally closed contact will be turned on.

This option is selected with the DIP switches on the swing out board. See Section

4.7.

Model 2200C Page 9

4.5 Analog Outputs

4.5.1 The analog output signals consist of a non-isolated 0-1 mA, 0-5 Vdc, and isolated 420 mA signals.

4.5.2 From the factory all of the analog outputs have a linear range corresponding to the

full range of the instrument. The analog outputs can be programmed to another

linear range by entering two values:

• Output High: This is the conductivity value at which you wish to have 100%

output.

• Output Low: This is the conductivity value at which you wish to have 0% output.

4.5.3 When programming, you must ensure that the output range has a span of at least

10% of the full range of the instrument. For applications that require the output to

decrease as the process value increases, i.e. an inverted output, the Output High

value will be less than the Output Low. See Section 5.3.

4.5.4 The instrument may be used to measure the temperature of the process either in °C

or in °F. The 2200C does not control temperature but the 0-5 Vdc and 0-1 mA

analog outputs can be dedicated to follow the process temperature. See Section

5.10.

4.6 Operation Menu

4.6.1 The operation menu allows the user to recall and to adjust the parameters, required

by the analyzer functions.

4.6.2 When the analyzer is powered up, the program will display the conductivity reading.

None of the LED’s in the operation's menu will be illuminated.

4.6.3 Five buttons on the panel are used to operate the menu. Use the CALL button to

step through the items in the menu. The red LED beside each item makes it very

easy to follow the menu. The function of the RUN button is to return to the on-line

conductivity display from anywhere in the menu. The analyzer has a built-in timer,

which returns the unit to the online mode if no button has been pressed for 10

minutes. This time-out has the same effect as pressing the RUN button.

4.6.4 When in the menu mode, the display will shows the current value of the parameter,

such as the Setpoint of the control relay. The two arrow buttons are used to adjust

the display value up or down. To accept the new value press ENTER twice. While

in the operations menu, the relay outputs and the analog outputs remain on hold.

Model 2200C Page 10

The items that appear in the operations menu are:

• Password

• Test

• Calibration

• Temperature

• Status

• Cell Constant

• Range

• Output High

• Output Low

• Cycle On / Off

• Control Relay Setpoint

• Control Relay Deadband

• Alarm Relay High

• Alarm Relay Low

4.7 DIP Switches

4.7.1 The controls which are frequently used in the normal operation of the instrument are

all accessible on the control panel. Some switches, which are infrequently used,

are located on the back of the main circuit board.

4.7.2 The DIP switches are scanned only on power-up and every time the instrument is

taken out of the menu mode. Therefore, after changes to the DIP switch settings,

you must bring up the menu by pressing CALL, and then return the instrument to

the online mode by pressing RUN, in order for the instrument to scan the new DIP

values.

4.7.3 The following table describes the use of the 16 DIP switches:

Bank S1

Dip Switch

Description

ON

OFF

1

Selects temperature unit

°C

°F

2

Password Feature

Disabled

Enabled

3

Fail-Safe mode for Relay A

Enabled

Disabled

4

Direction of Control for Relay A

Falling

Rising

5

Alarm Relay to be activated for memory loss

Disabled

Enabled

6

Fail-Safe mode for Alarm Relay

Enabled

Disabled

7

Auto return from menu

Enabled

Disabled

8

0-5V / 0-1mA Select

Conductivity

Temperature

Bank S2

Dip Switch

Description

ON

OFF

1

Cycling Control for Relay A

Enabled

Disabled

2

Reserved

3

Reserved

4

Reserved

5

Reserved

Model 2200C Page 11

6

Reserved

7

Reserved

8

Reserved

Note: Items in “BOLD” are the factory settings that the unit will be shipped with.

4.8 Output Hold

4.8.1 Output hold, is a function which freezes all output signals at the last value to

prevent the occurrence of wild distortions during programming and maintenance.

4.8.2 When the Operations Menu is entered by pressing CALL, the relays and the analog

outputs are automatically placed on hold and remain on hold until the instrument

returns to on line. The output hold will remain for a maximum of 10 minutes after

the last button was pressed, if this feature has been enabled. See Section 4.7.

4.9 Parameter and Operation Checking

4.9.1 The instrument continuously checks all parameters in its memory, while measuring

the conductivity. When it detects an invalid value, it flashes the LED in the

operation menu to indicate the parameter that is at fault. You must then access the

operations menu to take corrective actions.

4.10 Simulated Input for Testing

4.10.1 TEST is function that can be used to check the setup of the 2200C. When in the

test mode the display will show a value between 0 and the max range the unit has

been configured for. The arrow keys are used to change the display. The relays and

analog outputs will react to the changes of the display as if it were monitoring the

conductivity. This feature enables the user to verify that the controller has been

configured correctly, and that it will correctly react to the process. Of course, the

relays and outputs are no longer on hold once the arrow buttons are used in TEST

mode.

4.11 Control Relay AUTO/OFF/ON Switch

4.11.1 The AUTO/OFF/ON button is used to set the operating mode of Relay A. This

useful feature allows the operator to check the operation of the device controlled by

the relay. On power up the control relay always returns to the AUTO setting. Be

sure to return to AUTO after completing your test if you wish to work automatically.

4.12 Utility Menu

4.12.1 The Utility Menu is provided to enable authorized personnel to change the range

and to fine tune the analog outputs. Refer to Section 8.0.

4.13 Watchdog Timer and Self Diagnostics

4.13.1 The 2200C continuously monitors the condition of all key components of the

measuring system to ensure that the measurements are reliable. Invalid entries and

memory loss are indicated on the panel. Refer to Section 8.0.

Model 2200C Page 12

5.0 START-UP AND OPERATION

5.1 Password

5.1.1 To enter the menu press CALL and the PASSWORD LED will illuminate. If the

password feature has been disabled by the dip switch, TEST will be the first menu

item illuminated when the CALL button is pressed. With each press of CALL button

you will step through the menu. When the last item, ALARM LOW is reached the

menu wraps around to TEST. If you have enabled PASSWORD by placing DIP

Switch No. 2 of Bank S1 in the off position you must enter the password “6” when

PASSWORD is indicated, if you wish to change any stored value. If the password

is enabled and you do not enter the correct password. All the items in the menu will

be read only.

5.2 Calibration

5.2.1 To calibrate the instrument you will need:

• a buffer solutions of known conductivity

• a beaker of clean water

The 2200C requires a one point calibration, using a conductivity buffer solution. It is

possible to calibrate the unit to the process conductivity. This can only be done

when a sample is taken and measured with a certified lab unit. The process of

calibrating is the same for both methods. If you are calibrating using the sample

method, substitute the certified lab units reading for the know conductivity, and

leave the cell installed in the process. The recommended calibration procedure is

with a certified lab meter.

To calibrate the 2200C in Manual Calibration Mode proceed as follows:

a) Enter the menu by pressing CALL. Proceed by pressing CALL until the

CALIBRATION LED illuminates.

b) Remove the protective cap from the cell, rinse it in clean water, and place it in

the buffer solution. The display will change as the controller measures the

conductivity and the temperature of the buffer solution. The display may flash

which indicates that the instrument is receiving an unstable signal from the cell.

The display will come to a rest and should display a value close to the buffer

solution. If the value on the display is greatly different from the value of the

buffer solution, this indicates that the current calibration is not very close to the

actual value, or the buffer solution is contaminated. If you are confident in your

buffer solution proceed by using the arrow keys to correct the display to read

the actual value of the buffer. Press ENTER. The display will flash until

ENTER is pressed again to confirm the value.

Model 2200C Page 13

c) The system is now calibrated. Press RUN to place the instrument on line or

use the CALL key to proceed to other menu items.

5.3 Analog Output Range Expand

5.3.1 To increase the resolution of the analog outputs, the range may spread over any

section of the scale. As long as it spans at least 10% of full scale. The best way to

describe this setup is by example. Suppose you wish the outputs to span from

400uS to 600uS. Proceed as follows:

a) Enter the menu by pressing CALL until the OUTPUT HIGH LED is illuminated.

Use the arrows keys to make the display read 600. Press ENTER. The display

will flash until ENTER is pressed again to confirm the value.

b) Press CALL and the OUTPUT LOW LED will illuminate. Use the arrow keys to

make the display read 400. Press ENTER. The display will flash until ENTER is

pressed again to confirm the value.

c) The analog output will now be at 0% when the conductivity of the solution is

400 µS and will increase to 100% when the conductivity of the solution is 600

µS.

d) Press RUN to place the instrument on line or press CALL for another menu

selection.

NOTE: A range expand of less than 10% of full scale is an invalid entry which will

be indicated by the LED flashing when you return to RUN. To correct,

return to the menu and correct the output settings.

5.4 Control Relay Setpoint

5.5.1 The Control Relays are configured by programming the Setpoint and Deadband.

•Setpoint: is the value at which the relay will energize

•Deadband: is the value at which the relay will de-energize

As shipped from the factory, Control Relay, is configured to control rising

conductivity. However, you may change the direction of the relay by changing the

position of the DIP switch. (Refer to Section 4.7)

5.5.2 The relay setpoint may be set at any point on the scale.

To program the setpoint. Proceed as follows:

a) Enter the menu by pressing CALL, proceed by pressing CALL until the RELAY

SETPOINT LED is illuminated. Now use the arrow keys to make the display

read the desired value. Press ENTER. The display will flash until ENTER is

pressed again to confirm the value.

Model 2200C Page 14

b) Press RUN, to place the instrument on line, or press CALL for another menu

selection.

5.5 Control Relay Deadband

5.5.1 If you have configured the relay to control decreasing conductivity, the deadband

will be higher than the setpoint. i.e. the auxiliary device connected to the relay will

increase the conductivity. If you have configured the instrument to control

increasing conductivity, the deadband will be lower than the setpoint. i.e. the

auxiliary device connected to the relay will decrease the conductivity.

a) Enter the menu by pressing CALL, proceed by pressing CALL until the RELAY

DEADBAND LED is illuminated. Now use the arrow keys to make the display

read the desired value. Press ENTER. The display will flash until ENTER is

pressed again to confirm the value.

b) Press RUN, to place the instrument on line, or press CALL for another menu

selection.

5.6 Cycle Feature for Control Relay

5.6.1 The 2200C has a cycling feature for the control relay. This feature if enabled will

cause the relays to cycle based on the on and off times selected. This useful

feature can help eliminate overshooting, saving expensive chemicals.

a) If you wish to have cycling control for the Control Relay , you must put DIP

switch NO. 1 of Bank S2 in “ON” position. (See Section 4.7). If the dip switch is

in the “OFF” position, the Relay will act in a simple ON-OFF manner.

b) The following example describes how to enter the ON and OFF times for the

Control Relay cycling control.

i) Enter the menu by pressing Call, proceed by pressing CALL until the

CYCLE LED illuminates.

ii) With the arrow buttons make the display read the number of seconds

(maximum 600) you wish the relay to be activated. Example 30. Press

ENTER. The display will flash until ENTER is pressed again to confirm

entry.

iii) Press CALL. The LED will flash. Now make the display read the

number of seconds (maximum 600) you wish the relay to be

deactivated. Example 60. Press ENTER. Press ENTER again as

above.

Model 2200C Page 15

iv) With this configuration when the process reaches the Control Relay

Setpoint the relay will cycle continuously 30 seconds activated, 60

seconds deactivated until the Deadband Relay A setting is passed.

NOTE: As shipped from the factory the OFF time is set at 10 seconds and the

ON time is set at 5 seconds.

5.7 Alarm High

5.7.1 The instrument is fitted with a relay, which is set to activate on both high and low

alarm conditions. The deadband is factory set. To set the ALARM HIGH proceed

as follows.

a) Press CALL to enter the menu, proceed by pressing CALL until the ALARM

HIGH LED is illuminated. Use the arrow keys make the display read the desired

value. Press ENTER. The display will flash until ENTER is pressed again to

confirm the value.

b) Press RUN to place the instrument on line, or press CALL, for another menu

selection.

5.8 Alarm Low

5.8.1 To set the ALARM LOW proceed as follows:

a) Press CALL to enter the menu, proceed by pressing CALL until the ALARM

LOW LED is illuminated. With the arrows make the display read the desired

value. Press ENTER. The display will flash until ENTER is pressed again to

confirm entry.

b) Press RUN to place the instrument on line, or press CALL, for another menu

selection.

NOTE: A low alarm point higher than the high alarm point is an invalid entry, which

is indicated by the LED flashing when you return to RUN. To correct, return

to the menu and reset the alarm points.

5.9 Test

5.9.1 To check the setup of the 2200C, the TEST feature can be used. The test feature

will allow the user to use the arrow keys to change the display. By changing the

display value the analog outputs and relay outputs will react, as if the process was

actually changing. This feature enables the user to simulate the process and test is

the auxiliary devices connected to the relays are functioning properly.

5.9.2 To use the TEST feature proceed as follows:

Model 2200C Page 16

a) To enter the menu press CALL, the TEST LED will be illuminated. Use the

arrow keys to change the display. The outputs will react to the changes in

the display, as if the unit was online and the process was actually changing.

b) Press RUN to place the instrument on line, or press CALL, for another

menu selection.

5.10 Temperature

5.10.1 The temperature of the process can be read at any time by entering the menu and

scrolling through the menu until TEMPERATURE LED is illuminated. Either °C or

°F will be indicated depending on the position of DIP switch No.1 of Bank S1. If the

temperature is suspected of being incorrect, place the S41 switch on the back of the

main circuit board, in the up position, (this places a 3000 ohm across the RD and

GN terminals) the temperature should read 25°C or 77°F.

5.10.2 The 0-5 Vdc and 0-1 mA analog outputs can be dedicated to follow the process

temperature by simply placing DIP switch No. 8 of Bank S1. in the OFF position.

The temperature span of the output is set to the utility menu. Refer to Section 7.4.

5.11 Status

5.11.1 The 2200C continuously checks the integrity of all stored data and monitors the

condition of the measuring system. If a fault is detected, the FAIL LED above the

display will turn red. The STATUS in the operation menu will provide a numerical

code, giving a possible cause and a suggested remedy.

CODE

POSSIBLE CAUSE

SUGGESTED REMEDY

0

Normal Condition

No action required

1

Reserved

2

Temperature Sensor off Scale

Check for open or short

connections of temperature sensor

input (Terminals RD & GN on TB2)

3

Conductivity reading off Scale

Verify process. Check for open or

short connections. WH and BL

wires

4*

Memory Loss

Call your AquaMetrix Rep. Or

AquaMetrix directly

5

Calibration out of limit

Check scale setting (See range

change in Utility Menu)

NOTE: Code 4 could be a serious failure so the alarm relay will activate in addition to the red

illumination of the FAIL LED if Dip Switch No. 5 of Bank S1 is off.

Model 2200C Page 17

5.12 Range

5.12.1 This menu item is read only, it displays the maximum range of the instrument as

currently configured. You may change the range in the Utility Menu. Refer to

Section 7.3.

5.13 Cell Constant

5.13.1 This menu item is read only, it displays the cell constant required for the range, as it

is currently configured.

6.0 OPERATING HINTS

6.1 Cell Care

6.1.1 Keep the cell clean using the procedure recommended in the cell manual. The

frequency of cleaning depends on the solution being monitored.

6.1.2 Be sure the cell cable is well protected. The cell cable should run in conduit but

never in the same conduit with line power. Excess cable should be cut off and

never coiled.

6.2 Calibration

6.2.1 The system will only be as accurate as your calibration technique. With a clean cell

you will need to calibrate only with a change in conditions or after installing a new

cell.

6.2.2 Be sure of the value of your calibration solution. Conductivity solutions are

available from AquaMetrix.

6.3 Reset

6.3.1 The instrument can be reset without losing calibration or any of the stored values by

pressing and releasing the S9 reset button (located at the bottom of the board near

the center) This action is equivalent to turning the power off and on.

6.4 Ground Loop Errors

6.4.1 If there is a conductive pathway from the sensor connections to earth, ground loop

errors will occur. To avoid this condition keep all terminal connections in the

instrument or in a junction box dry and free of corrosion.

6.5 Output Hold

Model 2200C Page 18

6.5.1 It may be useful during some system maintenance procedures to place the relay

and analog outputs on hold. To accomplish this simply press CALL. To return to

on line operation press RUN. (If the instrument is in TEST the outputs will not be in

HOLD if the arrow buttons are touched.)

NOTE: To safeguard against the operator forgetting to press RUN the instrument

will automatically go back on line ten minutes after the last button was

pressed provided this feature has been enabled by placing DIP switch No.7

in the ON position.

7.0 UTILITY MENU

7.1 Utility Menu Functions

7.1.1 The Utility Menu enables authorized personnel to perform the following:

• Change the range

• Adjust the temperature output range

• Adjust the offset and span of the 0-1 mA/ 0-5 Vdc output

• Adjust the offset and span of the 4-20 mA output

7.2 Access to Utility Menu

7.2.1 The Utility Menu is protected by password. To access the Utility Menu press and

hold both RUN and ENTER for five seconds until the PASSWORD LED illuminates.

The RUN LED will flash to warn that Utility Menu is in use. Now with the arrow keys

make the display read the password, "7". Press ENTER.

7.2.2 The Utility Menu is entirely separate from the Operations Menu but uses the same

LED display. Press CALL to step through the menu items.

Below is the cross-reference between menu items:

Operations Menu

Utility Menu

Range

Range Change

Output High

Temperature Output 100% (5Vdc)

Output Low

Temperature Output 0% (0Vdc)

Control Relay Setpoint

0-1mA / 0-5Vdc Adjust low

Control Relay Deadband

0-1mA / 0-5Vdc Adjust high

Alarm High

4-20 mA Output Adjust Low

Model 2200C Page 19

Alarm Low

4-20 mA Output Adjust High

7.3 Range Selection

7.3.1 The table below shows the ranges which are available for the 2200C together with

the relevant cell constant for each range.

Range uS

Required Cell Constant

0-2uS

0.01

0-5 uS

0.01

0-10 uS

0.05

0-20 uS

0.05

0-50 uS

0.05

0-100 uS

0.05

0-200 uS

0.5

0-500 uS

0.5

0-1000 uS

0.5

0-2000 uS

1.0

0-5000 uS

1.0

Range mS

Required Cell Constant

0-10 mS

10

0-20 mS

10

0-50 mS

10

0-100 mS

20

0-500 mS

50

0-1000 mS

50

Model 2200C Page 20

7.3.2 To change the range of your instrument to any range shown above proceed as

described below. (Note that changing the range may require a change of

conductivity cell.)

a) Enter the Utility Menu as described in 7.2.1.

b) Press CALL until the RANGE LED illuminates, which is “Range Change” in the

Utility Menu. See table in 7.2.2.

c) The display will now show the range as currently configured. Use the arrow

buttons until the display shows the desired range. Press ENTER. The display

will flash until ENTER is pressed again to confirm entry.

d) Return to the Operation Menu and press CALL until the CELL CONSTANT LED

illuminates. The display will show the cell constant required by the new range.

You can also check the new range by calling RANGE. If the required cell

constant is other than the one used with the previous range it will be necessary

to purchase a cell with the correct constant.

e) Recalibrate. Refer to Section 5.2.

f) Press RUN to return to on line or press CALL to proceed to another item in the

Utility Menu.

7.4 Temperature Output

7.4.1 The 0-5 Vdc and 0-1 mA outputs may be programmed to track the temperature of

the process. The factory outputs have a linear range corresponding to 0°C to

100°C, (or 32°F to 212°F.) Suppose you wish the output to span 10°C to 45°C.

Proceed as follows:

a) Enter the Utility Menu as described in 7.2.1.

b) Press CALL until the OUTPUT HIGH LED illuminates, which is “Temperature

output, 100% point” in the Utility Menu (See table in 7.2.2). Use the arrow keys

to make the display read 45.0. Press ENTER. The display will flash until

ENTER is pressed again to confirm entry.

c) Press CALL and the OUTPUT LOW LED will illuminate, which is “Temperature

output, 0% point” in the Utility Menu (See table in 7.2.2). Use the arrow keys to

show 10.0 on the display. Press ENTER twice as above.

d) Press RUN to return to on line or press CALL to proceed to another item in the

Utility Menu.

7.5 Adjust 0-1 mA / 0-5 Vdc Output

7.5.1 It may be desirable to fine tune the 0-1 mA / 0-5 Vdc output to take into account the

characteristics of your particular loop. The following method involves a high and

low calibration and requires the use of a digital multi-meter. (DMM). Proceed as

follows ignoring the instrument display:

Model 2200C Page 21

a) Turn off the power to the instrument. Connect your DVM in parallel with the 0-5

Vdc output terminals on the power supply board.

b) Turn on the power. Enter the Utility Menu as described in 7.2.1.

c) Press CALL until the CONTROL RELAY SETPOINT LED illuminates, which is

"0-1 mA/ 0-5 Vdc output adjust, low" in the Utility Menu (See table in 7.2.2).

Use the arrow keys to make your DMM read 1.25V. Press ENTER twice to

confirm.

d) Press CALL and the CONTROL RELAY DEADBAND LED will illuminate, which

is "0-1 mA / 0-5 Vdc Output adjust, high" in the Utility Menu (See table in 7.2.2.)

Use the arrow keys to make your DMM read 3.75V. Press ENTER twice to

confirm.

e) Press RUN to return to on line or press CALL to proceed to another item in the

Utility Menu.

7.6 Adjust 4-20 mA Output

7.6.1 It may be desirable to fine tune the 4-20 mA isolated output to take into account the

characteristics of your particular loop. Before deciding that the adjustment is

necessary, be aware of the "Output High" and "Output Low" settings you may have

programmed as described in Section 5.4. The following method involves a high and

low calibration and requires the use of a Digital Multimeter (DMM). Proceed as

follows ignoring the instrument display.

a) Turn off the power to the instrument. Connect your DVM in series with the 4-20

mA output terminals on the power supply board.

b) Turn on the power. Enter the Utility Menu as described in 7.2.1.

c) Press CALL until the ALARM HIGH LED illuminates, which is "4-20 mA Output

adjust, low" in the Utility Menu (See table in 7.2.2.) Now use the arrow keys to

make your DMM read 8 mA. Press ENTER twice to confirm.

d) Press CALL and the ALARM LOW LED illuminates, which is "4-20 mA Output

adjust, high" in the Utility Menu (See table in 7.2.2). Now use the arrow keys to

make your DMM read 16 mA. Press ENTER twice to confirm.

e) Press RUN to return to on line or press MENU to proceed to another item in the

Utility Menu.

Model 2200C Page 22

8.0 DIAGNOSTICS

8.1 Description

8.1.1 The 2200C has diagnostic features which alerts the operator to invalid entries and

memory loss. Invalid entries are indicated by the flashing of the appropriate menu

LED. The flashing will commence after RUN is pressed and will continue until the

errors are corrected. Memory loss is indicated by the flashing of TEST and by the

alarm relay if enabled by DIP Switch No. 5 of Bank S1. See Section 4.7.3.

8.2 Invalid Calibration

8.2.1 Invalid calibration will be indicated when the input is out of range. This could occur

if you had attempted to calibrate with a solution which was outside the range of the

instrument.

8.3 Invalid Output

8.3.1 Invalid output will be indicated if the expanded range is less than 10% of full scale.

To correct, refer to Section 5.3.

8.4 Invalid Alarm Points

Model 2200C Page 23

8.4.1 Invalid Alarm will be indicated if the Low Alarm is set higher than the High Alarm.

To correct, refer to Section 5.6 and 5.7.

8.5 Invalid Setpoint

8.5.1 The deadband setting must be lower than the Setpoint if you are controlling rising

conductivity, and higher than the Setpoint if you are controlling falling conductivity.

If you have not made these settings correctly, invalid entry will be indicated by a

flashing LED. To correct, refer to Section 5.4 and 5.5.

9.0 TROUBLESHOOTING AND SERVICE

9.1 Isolate the cause

9.1.1 When a measurement problem occurs, the first step is to try to isolate the cause. If

the 2200C is powered, go through the menu and check your settings. A convenient

way to do this is to call TEST. See Section 5.7

9.1.2 If your 2200C appears dead or intermittent, check the breaker, make sure that the

instrument is set up for the available line voltage and make sure the line voltage is

actually available at the terminals. Now measure that sufficient voltage is available

at all times; it should be 98 Vac to 132 Vac or 187 Vac to 243 Vac respectively.

Shut line power off, making sure it is off.

CAUTION

:

Power to the relays may be

supplied from a separate source, shut it off too

. Check and if necessary replace the

internal 0.25A fuse. Push the connector of the ribbon cable firmly into its socket. If

these steps do not solve the problem it may be necessary to replace the power

supply board. See Section 9.3.1 below.

9.1.3 Should your process control element e.g. pump, valve or alarm not be activating,

check that the correct power is supplied to the "floating” relay contacts, jumped over

Model 2200C Page 24

from the line voltage terminals or perhaps from a separate breaker or DC supply.

Use the TEST menu feature to simulate the input values to observe the switching

points.

Check that your process control elements can function independently of the 2200C.

Next check with a test light or an Ohmmeter (power off to the relay contacts, wires

to the control elements disconnected) that the contacts of the respective relay are

making contact when actuated. If a relay is malfunctioning, it may be necessary to

change it. See Section below.

9.1.4 If the process value seems wrong, clean the cell as described in the cell manual.

Inspect the cell, wire and interconnections. Calibrate and resume operation.

9.1.5 To find out whether the problem is in the sensor, or in the analyzer, use the selftesting features. Leave the instrument in RUN mode and proceed as follows:

a) Move the slide switches S41 and S42 on the back of the swing-out panel from

position "ON LINE" to position "TEST."

b) Connect a test resistor R68 to the TB3 terminal strip on the swing-out

board according to the following table:

Range uS

Required Cell Constant

R68 Value

0-2uS

0.01

10,000

0-5 uS

0.01

4000

0-10 uS

0.05

10000

0-20 uS

0.05

5000

0-50 uS

0.05

2000

0-100 uS

0.05

1000

0-200 uS

0.5

5000

Model 2200C Page 25

0-500 uS

0.5

2000

0-1000 uS

0.5

1000

0-2000 uS

1.0

1000

0-5000 uS

1.0

400

Range mS

Required Cell Constant

R68 Value

0-10 mS102000

0-20 mS101000

0-50 mS10400

0-500 mS50200

0-1000 mS50100

c) Set the temperature simulation DIP switch No. 1, S43 ON and Switch No. 2

OFF. This is to simulate 25°C. Set the conductivity simulation DIP switch No. 1,

S44 ON and switch No. 2 OFF. The display should indicate mid-range ±5%.

(For example, for range 5000 µS, cell constant is 1 and R68 = 400 Ohms

display should be 2500 µS ±5%.)

d) Now set the conductivity simulation DIP switch No. 1, S44 OFF and switch No.

2 ON. The display should show full range ±5%.

NOTE: Do not use this mode for calibration if both c) and d) are satisfied the

analyzer is in order and the problem is with the probe.

9.2 Escape

9.2.1 If the instrument appears to be "DEAD", for example not responding to the buttons,

or not performing on line measurement and control, always try the reset feature

first, as described in 6.3.1.

9.2.2 a) The "ESCAPE" procedure is to be used normally at the factory only, when the

unit is powered with a new processor. As a result, the internal non-volatile

memory (EPROM) is "FORMATTED" and the factory values are loaded into it.

b) The "ESCAPE" procedure is to be used if a unit is serviced for a new processor,

or in case of a memory loss problem, when so advised by AquaMetrix service

support.

9.2.3 Before performing the "ESCAPE" procedure it is important to know that this

procedure provides the option to erase all programmed values and replace them

Model 2200C Page 26

with the factory set default values. This means that the range selection and the

conductivity calibration must be performed after an "ESCAPE" procedure. After

that, all the control, alarm and scaling parameters mentioned above must be set to

the user values.

9.2.4 To perform the ""ESCAPE"" proceed as follows.

a) Turn off the power.

b) Press and hold the RUN button for about 3 seconds, while turning on t he

power. The FAIL LED will turn red and status code 7 will be obtained to show

that the "ESCAPE" procedure was just performed.

9.2.5 After the "ESCAPE" procedure it is necessary to do the following:

a) Tune the analog outputs and the temperature output span to suit your particular

application and loop. See Sections 7.4, 7.5, and 7.6.

b) Calibrate the system, as described in Section 5.2.

c) Set up the user values for:

• Output High and Low - See Section 5.3.

• Control Relay - See Sections 5.4 and 5.5.

• Alarm Relay - See Sections 5.7 and 5.8.

d) After all the above operations are performed the FAIL LED will turn

"green” and status "0" should be obtained.

e) The unit may be tested now, using the TEST menu item (See Section

5.8.), or the built-in self-testing feature, (See Section 9.1.5.)

e) Bring the unit on line for measurement and control.

9.3 Printed Circuit Board Replacement

9.3.1 a) To replace printed circuit boards, shut off all power to the 2200C, including any

independent power to the relay contacts. Make a record of the external wiring,

then disconnect the wires. Unplug the ribbon cable connector.

b) The power supply circuit board is fastened to the back of the enclosure by four

screws, remove the screws and the board is free. Reverse the procedure to

mount a replacement board.

c) The microprocessor circuit board is located on the swing-out assembly behind

the door. Swing the assembly out, lift it up to unseat the lower hinge pin (the

upper hinge pin is spring loaded.) The assembly is now free. The circuit board

Model 2200C Page 27

is fastened to the front panel by five screws. Remove the screws to release the

circuit board.

9.4 Customer Service

9.4.1 If a problem has not been resolved with the above procedures, a telephone

consultation with your AquaMetrix representative, or directly with AquaMetrix will

provide the answer.

AquaMetrix Inc. Tel: (800) 742-1413

22-121 Granton Drive (905) 763-8432

Richmond Hill, Ontario Fax: (905) 763-9480

L4B 3N4 Canada Email: support@aquametrix.com

9.6 Parts and Accessories

9.6.1 The major parts are listed below. When ordering parts please use the complete

part number.

Description Part #

Fuse, 0.25A Quantity of 5 A35-72

Power Supply Circuit Board Assembly, 120 Vac C13-103A

Power Supply Circuit Board Assembly, 240 Vac C13-103B

Microprocessor Circuit Board Assembly C13-2200C

(Includes front plate and hinge.)

500 ml Conductivity Solutions, Part No. varies with value

9.7 Instrument Return

9.7.1 If you are returning the instrument for service, please call an obtain an “Return

Material Authorization” (RMA) number. The box must be clearly marked with the

RMA number. Be sure to pack the instruments adequately because AquaMetrix will

not be responsible for shipping damage. For safety reasons, AquaMetrix cannot

accept instruments and sensors for repair that have not been thoroughly cleaned of

process materials.

Model 2200C Page 28

STATEMENTS OF CONFORMITY FROM THE MANUFACTURER

U.S.A.

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instructions manual, may

cause interference to radio communications. It has been

tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable

protection against such interference when operated in a

commercial environment.

Canada

This digital apparatus does not exceed the Class A limits

for radio noise emissions from digital apparatus set out in

the radio interference regulations of the Canadian

Department of Communications.

Le presént appareil numérique n’émet pas de bruits

radioélectriques dépassant les limites applicables aux

appareils numériques de la classe A prescrites dans le

Réglement sur le brouillage radioélectrique édicté par le

ministére des Communications du Canada.

Loading...

Loading...