Metal Sales Stile Installation

Stile

Installation Guide

STILE

THE APPLICATION AND DETAIL DRAWINGS IN THIS MANUAL ARE STRICTLY FOR ILLUSTRATION

PURPOSES AND MAY NOT BE APPLICABLE TO ALL BUILDING DESIGNS OR PRODUCT INSTALLATIONS.

ALL PROJECTS SHOULD CONFORM TO APPLICABLE BUILDING CODES FOR THAT PARTICULAR AREA. IT

IS RECOMMENDED TO FOLLOW ALL BUILDING REGULATIONS AND STANDARD INDUSTRY PRACTICES.

METAL SALES MANUFACTURING CORPORATION IS NOT RESPONSIBLE FOR THE PERFORMANCE OF

THIS ROOF SYSTEM IF IT IS NOT INSTALLED IN ACCORDANCE WITH THE SUGGESTED INSTRUCTIONS

REFERENCED IN THIS MANUAL. IF THERE IS A CONFLICT BETWEEN THIS MANUAL AND THE ACTUAL

ERECTION DRAWINGS, THE ERECTION DRAWINGS ARE TO TAKE PRECEDENCE.

PRIOR TO ORDERING AND INSTALLING MATERIALS, ALL DIMENSIONS SHOULD BE VERIFIED BY FIELD

MEASUREMENTS.

METAL SALES RESERVES THE RIGHT TO MODIFY, WITHOUT NOTICE, ANY DETAILS, RECOMMENDATIONS

OR SUGGESTIONS. ANY QUESTIONS YOU MAY HAVE REGARDING PROPER INSTALLATION OF THE STILE

ROOFING SYSTEM SHOULD BE DIRECTED TO METAL SALES.

CONSULT METAL SALES FOR ANY ADDITIONAL INFORMATION NOT OUTLINED IN THIS MANUAL.

IMPORTANT INFORMATION

THIS MANUAL IS DESIGNED TO BE UTILIZED AS A GUIDE WHEN INSTALLING THE STILE ROOFING

SYSTEM. IT IS THE RESPONSIBILITY OF THE ERECTOR TO ENSURE THE SAFE INSTALLATION OF THIS

PRODUCT SYSTEM.

SAFETY

STUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFORE FOLLOWING THESE

INSTRUCTIONS.

The installation of metal roof systems is a dangerous procedure and should be supervised by trained

knowledgeable erectors. USE EXTREME CARE WHILE INSTALLING ROOF PANELS. It is not possible for

Metal Sales to be aware of all the possible job site situations that could cause an unsafe condition to

exist. The erector of the roof system is responsible for reading these instructions and determining the

safest way to install the roof system.

These instructions are provided only as a guide to show a knowledgeable, trained erector the correct

parts placement one to another. If following any of the installation steps would endanger a worker, the

erector should stop work and decide upon a corrective action.

Provide required safety railings, netting or safety lines for crew members working on the roof.

Do not use the roof panels as a walking platform. The roof panels will not withstand the weight of a

person standing at the edge of the panel.

Do not stand on the roof panels at the ends until the panels have has been attached.

© Metal Sales Manufacturing Corporation/ Subject to change without notice

1

STILE

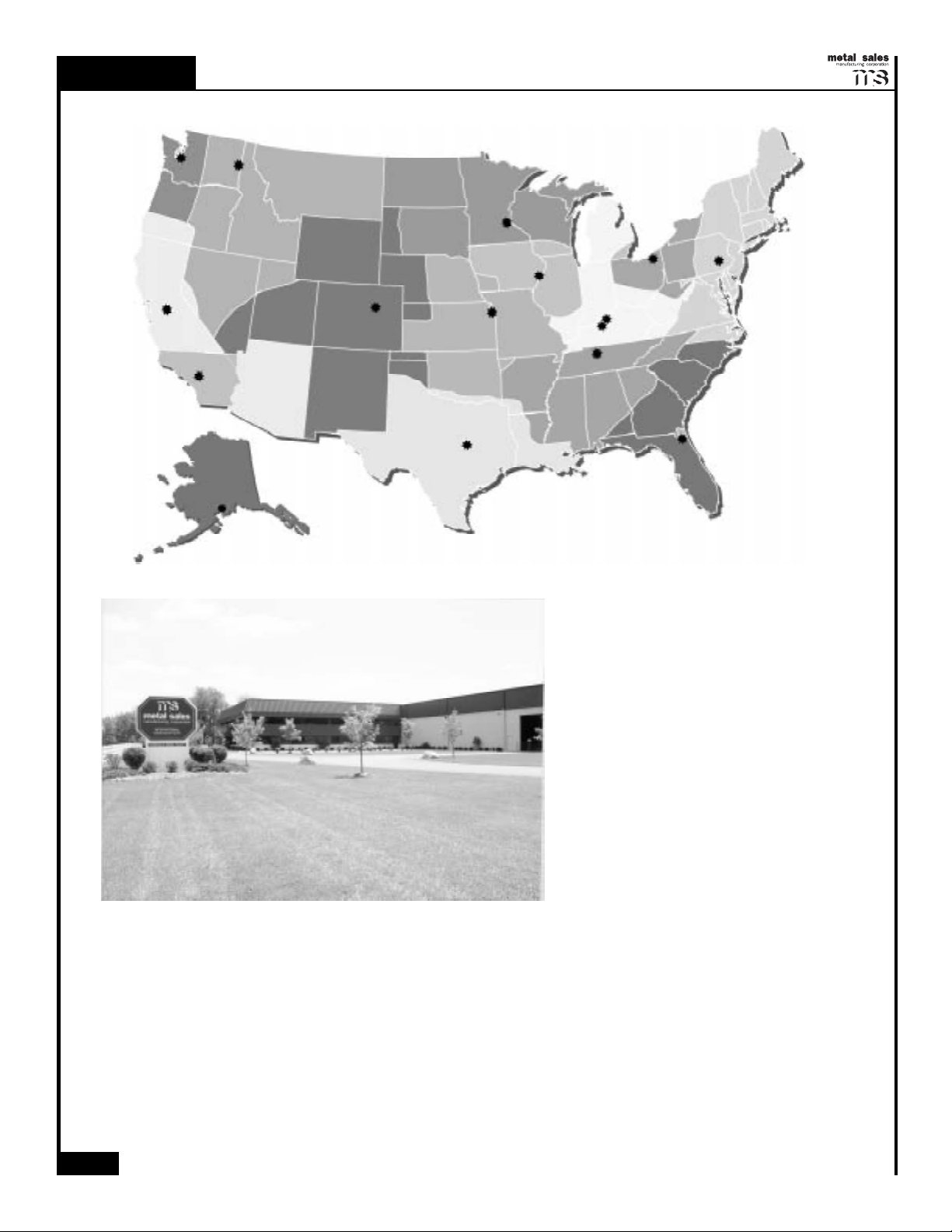

METAL SALES' LOCATIONS

*METAL SALES LOCATIONS

Note: Shaded areas represent regions

served by each location.

Arizona is served bt Fontana and

Longmont branches.

CORPORATE OFFICE

SELLERSBURG, INDIANA

Metal Sales offers a complete line of metal roof, wall, and fascia panel systems for the commercial,

architectural, industrial, residential, and agricultural markets. Metal Sales offers over 30 profiles with a

wide selection of widths, colors, and gauges - new construction or retrofit.

2

© Metal Sales Manufacturing Corporation/ Subject to change without notice

STILE

METAL SALES LOCATIONS

CUSTOMER SERVICE

DENVER BRANCH

7990 E. I-25 Frontage Rd

Longmont, CO 80504

(303) 702-5440

(800) 289-7663

(800) 289-1617 /FAX

JACKSONVILLE BRANCH

7110 Stuart Avenue

Jacksonville, FL 32254

(904) 783-3660

(800) 394-4419

(904) 783-9175 /FAX

JEFFERSON BRANCH

352 East Erie Street

Jefferson, OH 44047

(440) 576-9070

(800) 321-5833

(440) 576-9242 /FAX

(800) 233-5719 /FAX

INDEPENDENCE BRANCH

1306 S. Powell Road

Independence, MO 64057

(816) 796-0900

(800) 747-0012

(816) 796-0906 /FAX

WOODLAND BRANCH

1326 Paddock Place

Woodland, CA 95776

(530) 668-5690

(800) 759-6019

(530) 668-0901 /FAX

CLARKSVILLE BRANCH

7800 State Road 60

Sellersburg, IN 47172

(812) 246-1866

(800) 999-7777

(812) 246-0893 /FAX

(800) 477-9318 /FAX

MINNEAPOLIS BRANCH

22651 Industrial Blvd.

Rogers, MN 55374

(763) 428-8080

(800) 328-9316

(763) 428-8525 /FAX

(800) 938-9119 /FAX

NASHVILLE BRANCH

4314 Hurricane Creek Blvd.

Antioch, TN 37013

(615) 641-7100

(800) 251-8508

(615) 641-7118 /FAX

SPOKANE BRANCH

East 2727 Trent Avenue

Spokane, WA 99202

(509) 536-6000

(800) 572-6565

(509) 534-4427 /FAX

SEATTLE BRANCH

20213 84th Avenue, South

Kent, WA 98032

(253) 872-5750

(800) 431-3470 (outside WA)

(800) 742-7900 (inside WA)

(253) 872-2008 /FAX

ROCK ISLAND BRANCH

8111 West 29th Street

Rock Island, IL 61201

(309) 787-1200

(800) 747-1206

(309) 787-1833 /FAX

DEER LAKE BRANCH

29 Pinedale Industrial Rd

Orwigsburg, PA 17961

(570) 366-2020

(800) 544-2577

(570) 366-1648 /FAX

(800) 544-2574 /FAX

TEMPLE BRANCH

3838 North General Bruce Dr.

Temple, TX 76501

(254) 791-6650

(800) 543-4415

(254) 791-6655 /FAX

(800) 543-4473 /FAX

FONTANA BRANCH

14213 Whittram Avenue

Fontana, CA 92335

(909) 829-8618

(800) 782-7953

(909) 829-9083 /FAX

ANCHORAGE BRANCH

4637 Old Seward Hwy.

Anchorage, AK 99503

(907) 646-7663

(907) 646-7664 /FAX

TECHNICAL SUPPORT

TECHNICAL SERVICES

7800 State Road 60

Sellersburg, IN 47172

(812) 246-0819 (800) 406-7387

(812) 246-0829 /FAX (800) 944-6884 /FAX

pserv@aye.net

© Metal Sales Manufacturing Corporation/ Subject to change without notice

3

STILE

TABLE OF CONTENTS

PAGE NO.

Panel Overview

Slope ............................................................................................................ 6

Substructures

Coverage

Length

Applications

Panel Fastening System

Fasteners

Materials

Finishes

Stile Isometric Panel Profiles

Flashing Overview ..................................................................................................7

Flashing and Accessory Profiles ....................................................................... 8-10

Fastener Selection Guide ..................................................................................... 11

Design / Installation Considerations

General ....................................................................................................... 12

Condition of Substructure

Ventilation

Flashing Angle Specifier Chart

Roof Slope Factor

................................................................................................ 6

....................................................................................................... 6

.......................................................................................................... 6

.................................................................................................. 6

.................................................................................. 6

...................................................................................................... 6

....................................................................................................... 6

........................................................................................................ 6

.......................................................................... 6

............................................................................. 12

................................................................................................... 13

....................................................................... 13

........................................................................................ 14

Packaging ............................................................................................................. 15

Handling Material

Receiving Material........................................................................................ 16

General Handling

Mechanical Handling

Manual Handling

......................................................................................... 16

.................................................................................... 16

.......................................................................................... 17

Storage

General ....................................................................................................... 18

Foot Traffic

.................................................................................................. 18

Field Cutting and Touch-up

Field Cutting ................................................................................................ 19

Touch-up Paint

............................................................................................ 19

Installation Techniques

Installation of Eave or Gutter ......................................................................... 20

Installation of Rake Starter

Installation of Stile C-Closure

Installation of Valley

Installation of Panels

Installation of Formed Rake

Installation of Formed Ridge

Installation of Chimney

Installation of Rubber Roof Jack

Installation of Stile Roof Vent

............................................................................ 21

........................................................................ 22

..................................................................................... 23

............................................................................... 24-28

........................................................................... 29

.................................................................... 30-31

................................................................................. 32

.................................................................... 33

........................................................................ 34

4

© Metal Sales Manufacturing Corporation/ Subject to change without notice

STILE

TABLE OF CONTENTS

PAGE NO.

Condition Detail Explanation ................................................................................ 35

Formed Ridge/Hip Detail

Ridge/Hip Detail

Formed Rake Detail

Rake Detail

Eave Detail

Extended Eave Detail

Gutter Detail

Rake Parapet Counter Detail

Rake Parapet Siding Detail

High Side Counter Detail

High Side Reglet Detail

Valley with Cover Detail

High Side Parapet Detail

Slope Change Detail

Stile Roof Vent Detail

........................................................................................... 37

.................................................................................................. 39

.................................................................................................. 40

................................................................................................ 42

Care and Maintenance ......................................................................................... 51

............................................................................... 36

...................................................................................... 38

.................................................................................... 41

.......................................................................... 43

............................................................................ 44

............................................................................... 45

................................................................................. 46

................................................................................ 47

............................................................................... 48

..................................................................................... 49

....................................................................................

50

© Metal Sales Manufacturing Corporation/ Subject to change without notice

5

STILE

SLOPE

SUBSTRUCTURE

COVERAGE

LENGTH

APPLICATION

FASTENING SYSTEM

PANEL OVERVIEW

The minimum recommended slope for any Stile roofing panel is 3:12.

The recommended substrate is 5/8" plywood with a #30 felt moisture barrier. To

avoid panel distortion, use a properly aligned and uniform substructure.

If your application is over a substrate other than 5/8" plywood, please contact the

Metal Sales location servicing you (refer to page 2).

Each panel has a coverage of 39.4" (1 meter).

Minimum factory cut length is 3'-0". Maximum panel length is 20'-0". Lengths

between 3'-0" and 20'-0" will be cut at 1'-0" increments.

Architectural panel.

Direct Fasten (exposed).

FASTENERS

MATERIALS

FINISHES

PANEL ISOMETRIC

The Fastener Selection Guide (see page 11) should be consulted for choosing

proper fasteners for specific applications. Quantity and type of fastener must meet

necessary loading and code requirements.

Stile panels are available in 26 Gauge Galvanized (G-90) coating.

Stile panels are available in limited Fluorocarbon (PVF2)* finishes. See Stile

brochure for color selection.

*Meets both Kynar 500 and Hylar 5000 specifications.

6

© Metal Sales Manufacturing Corporation/ Subject to change without notice

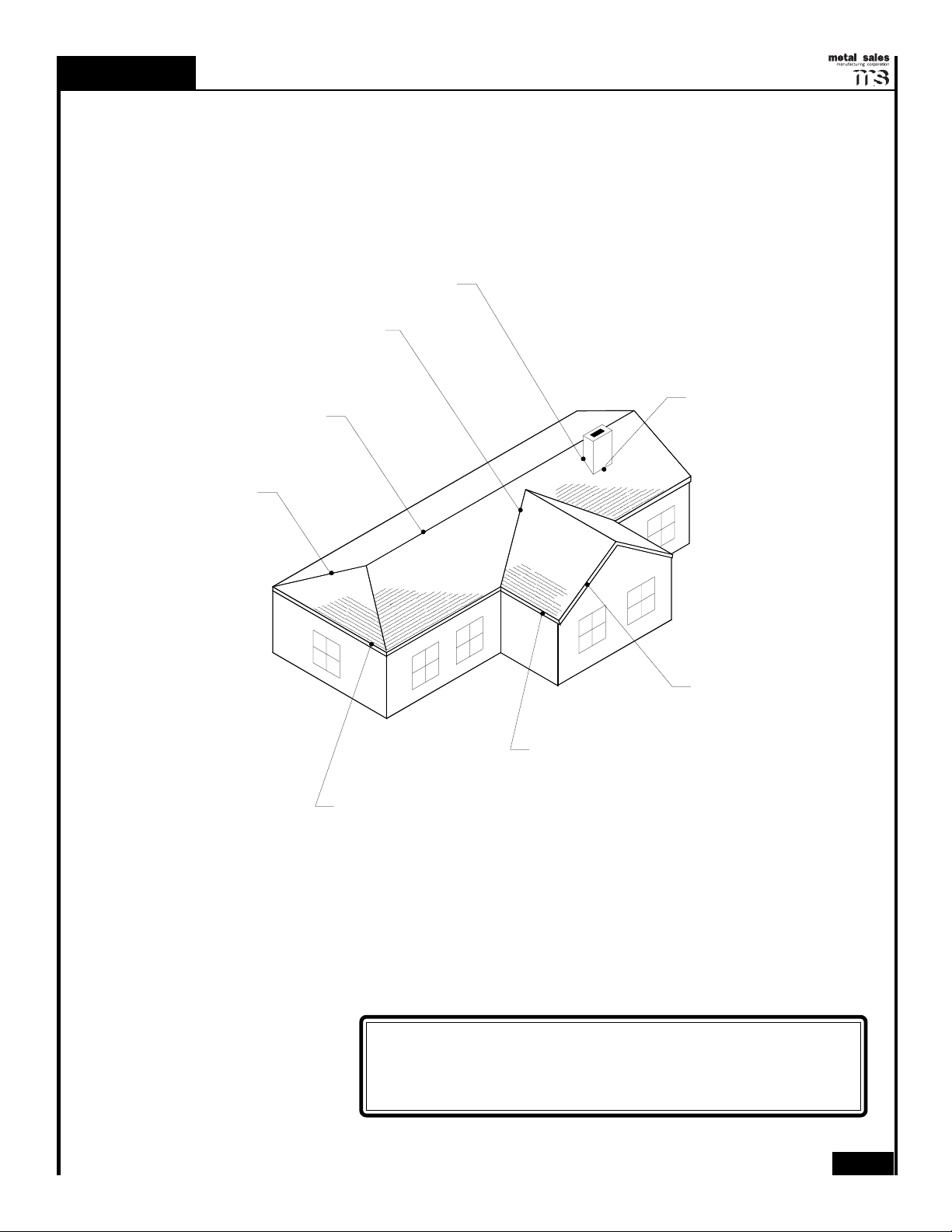

STILE

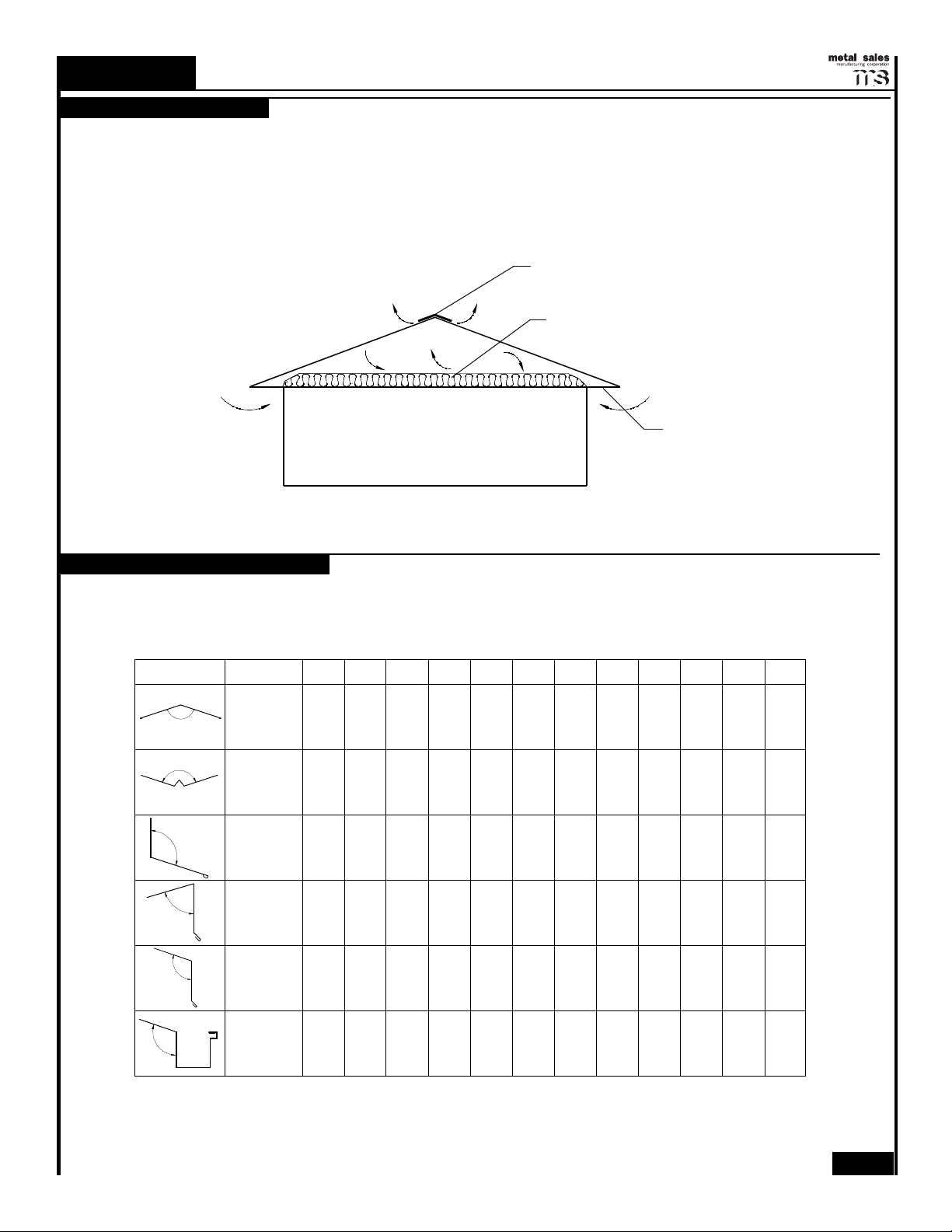

FLASHING OVERVIEW

HIGH SIDE PARAPET

(SEE DETAIL PAGE 48)

(SEE DETAIL PAGE 47)

RIDGE/HIP OR

FORMED RIDGE/HIP

(SEE DETAILS PAGE 36,37)

FORMED RIDGE/HIP

AT HIP CONDITION

(SEE DETAILS PAGE 36,37)

VALLEY

HIGH SIDE

PITCH BREAK

(SEE DETAILS PAGE 45,46)

RAKE OR

FORMED RAKE

(SEE DETAILS PAGE 38,39)

SIMPLE EAVE OR

EXTENDED EAVE

(SEE DETAILS PAGES 40,41)

GUTTER

(SEE DETAIL PAGE 42)

The above building represents the most common conditions of a

residental metal roof. For information on installation of flashings

refer to details on pages 36-50.

© Metal Sales Manufacturing Corporation/ Subject to change without notice

7

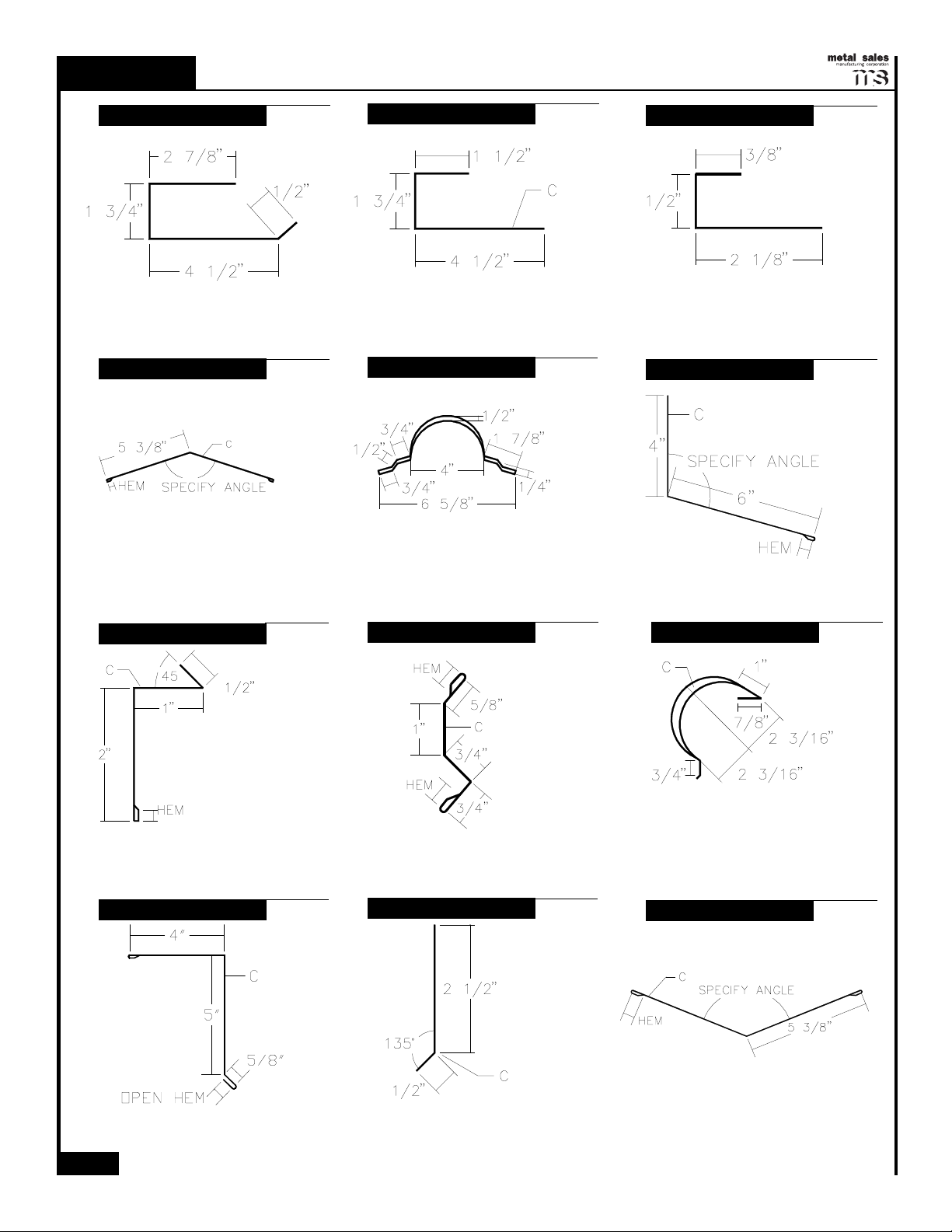

STILE

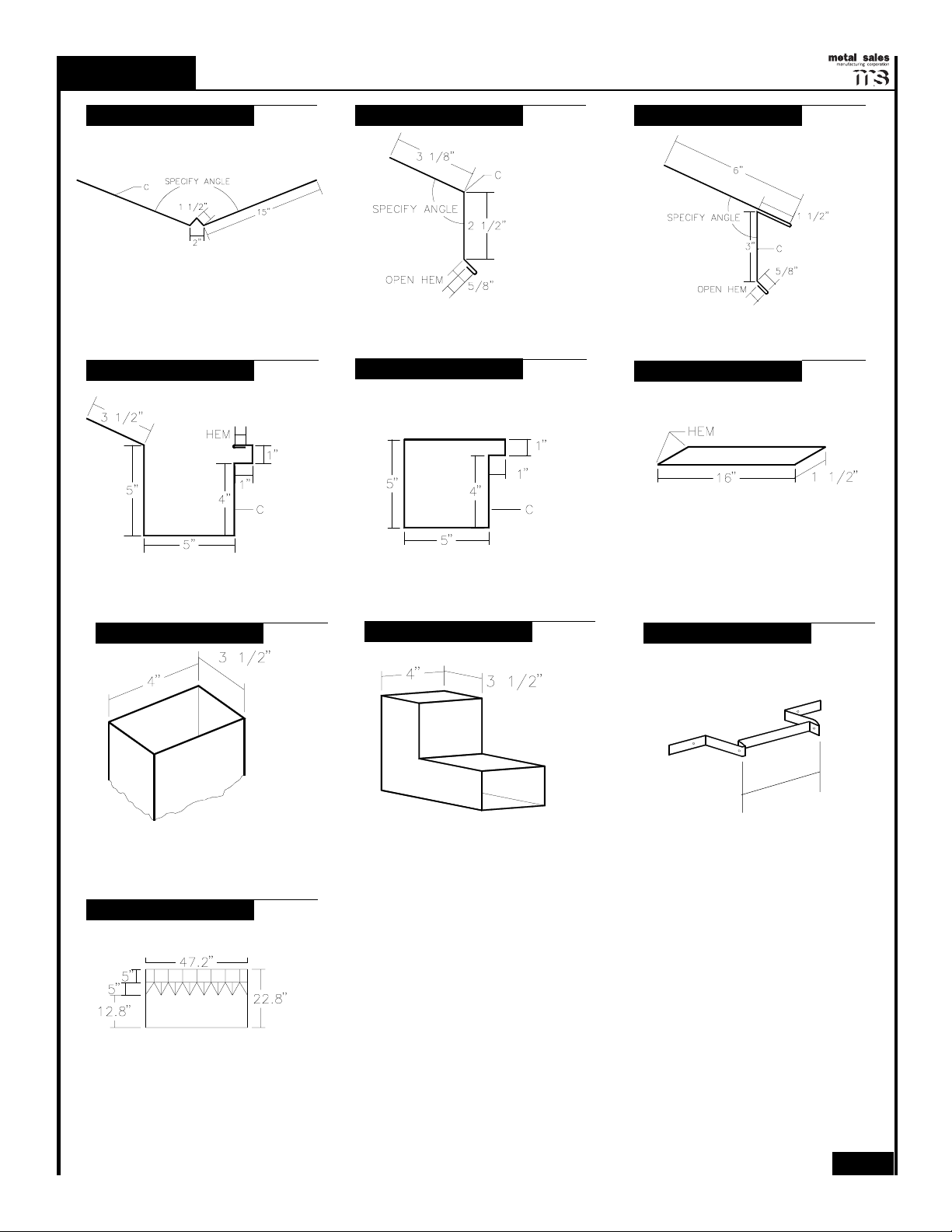

FLASHING PROFILES

RAKE STARTER

LENGTH 10'-2"

26 GA. GALVALUME

RIDGE/HIP COVER

STILE C-CLOSURE

LENGTH 10'-2"

26 GA. PAINTED

FORMED RIDGE

STILE STARTER

LENGTH 10'-2"

26 GA.

PITCH BREAK

LENGTH 10'-2"

26 GA. PAINTED

REGLET FLASHING

LENGTH 10'-2"

26 GA. PAINTED

RAKE

LENGTH 3'-6"

26 GA. PAINTED

COUNTER FLASHING

LENGTH 10'-2"

26 GA. PAINTED

CLEAT

LENGTH 10'-2"

26 GA. PAINTED

FORMED RAKE

LENGTH 3'-6"

26 GA. PAINTED

VALLEY COVER

LENGTH 10'-2"

26 GA. PAINTED

8

© Metal Sales Manufacturing Corporation/ Subject to change without notice

LENGTH 10'-2"

26 GA. PAINTED

LENGTH 10'-2"

26 GA. PAINTED

STILE

FLASHING PROFILES (CONT)

VALLEY

LENGTH 10'-2"

26 GA. PAINTED

BOX GUTTER

EXTENDED EAVE

LENGTH 10'-2"

26 GA. PAINTED

BOX GUTTER END

EAVE

LENGTH 10'-2"

26 GA. PAINTED

UNIVERSAL GUTTER/

DOWNSPOUT STRAP

LENGTH 10'-2"

26 GA. PAINTED

DOWNSPOUT

LENGTH 10'-2"

26 GA. PAINTED

JUNCTION SHEET

26 GA. PAINTED

95O ELBOW

26 GA. PAINTED

LENGTH 1'-4"

26 GA. PAINTED

DOWNSPOUT BRACKET

4"

26 GA. PAINTED

LENGTH 1'-11"

26 GA. PAINTED

© Metal Sales Manufacturing Corporation/ Subject to change without notice

9

STILE

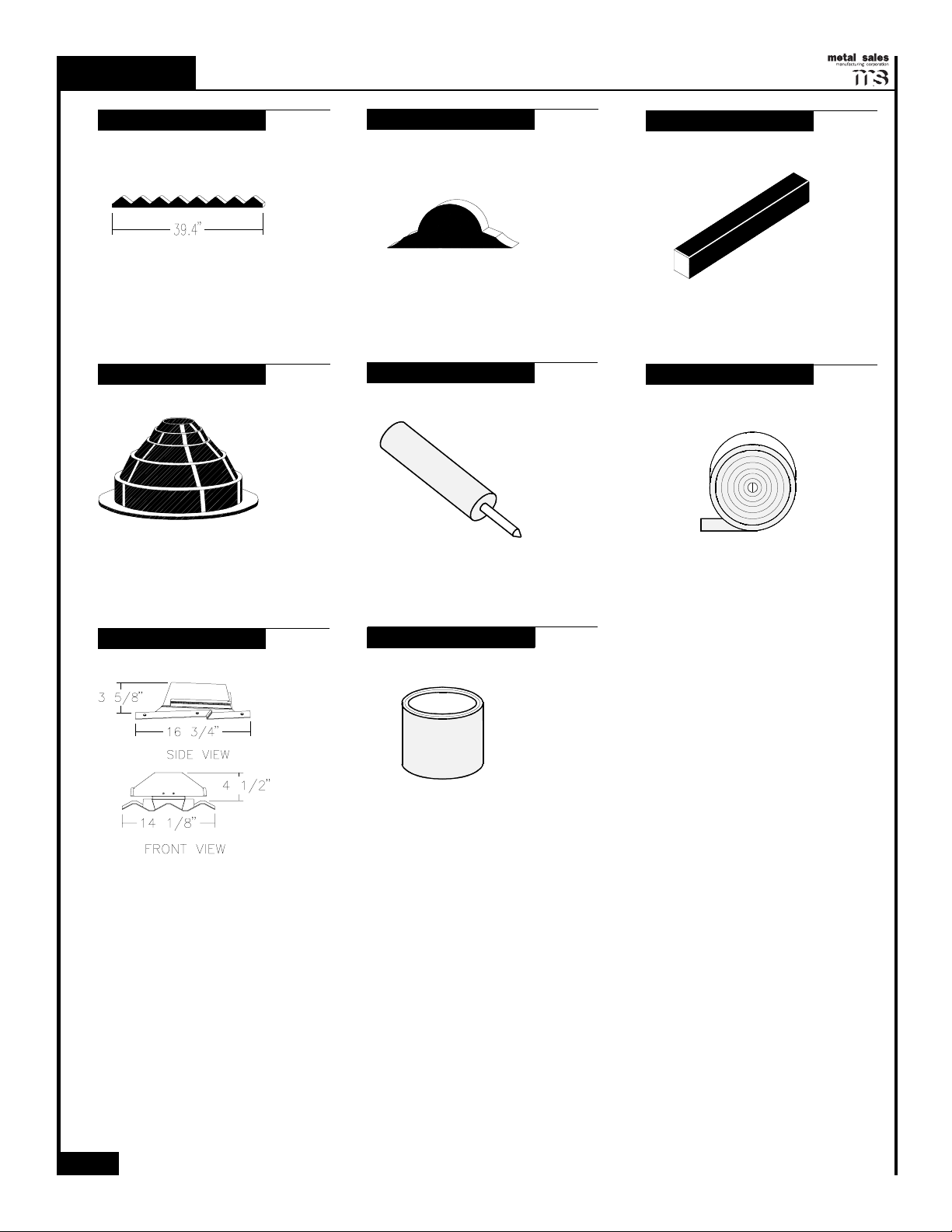

ACCESSORIES

STILE CLOSURE

OUTSIDE/ INSIDE CLOSURE

SYNTHETIC RUBBER

RUBBER ROOF JACK

#2 (11/4" TO 3" O.D. PIPE)

#3 (3" TO 6" O.D. PIPE)

#6 (6" TO 9" O.D. PIPE)

#8 (7" TO 13" O.D. PIPE)

STILE FORMED RIDGE

CLOSURE

SYNTHETIC RUBBER POLYETHYLENE FOAM

TUBE SEALANT

10.3 oz. CARTRIDGE

URETHANE - GRAY

UNIVERSAL CLOSURE

TAPE SEALER

3

/8" X 3/32" X 50'

BUTYL - GRAY

STILE ROOF VENT

TOUCH-UP PAINT

AVAILABLE IN PINTS

10

© Metal Sales Manufacturing Corporation/ Subject to change without notice

STILE

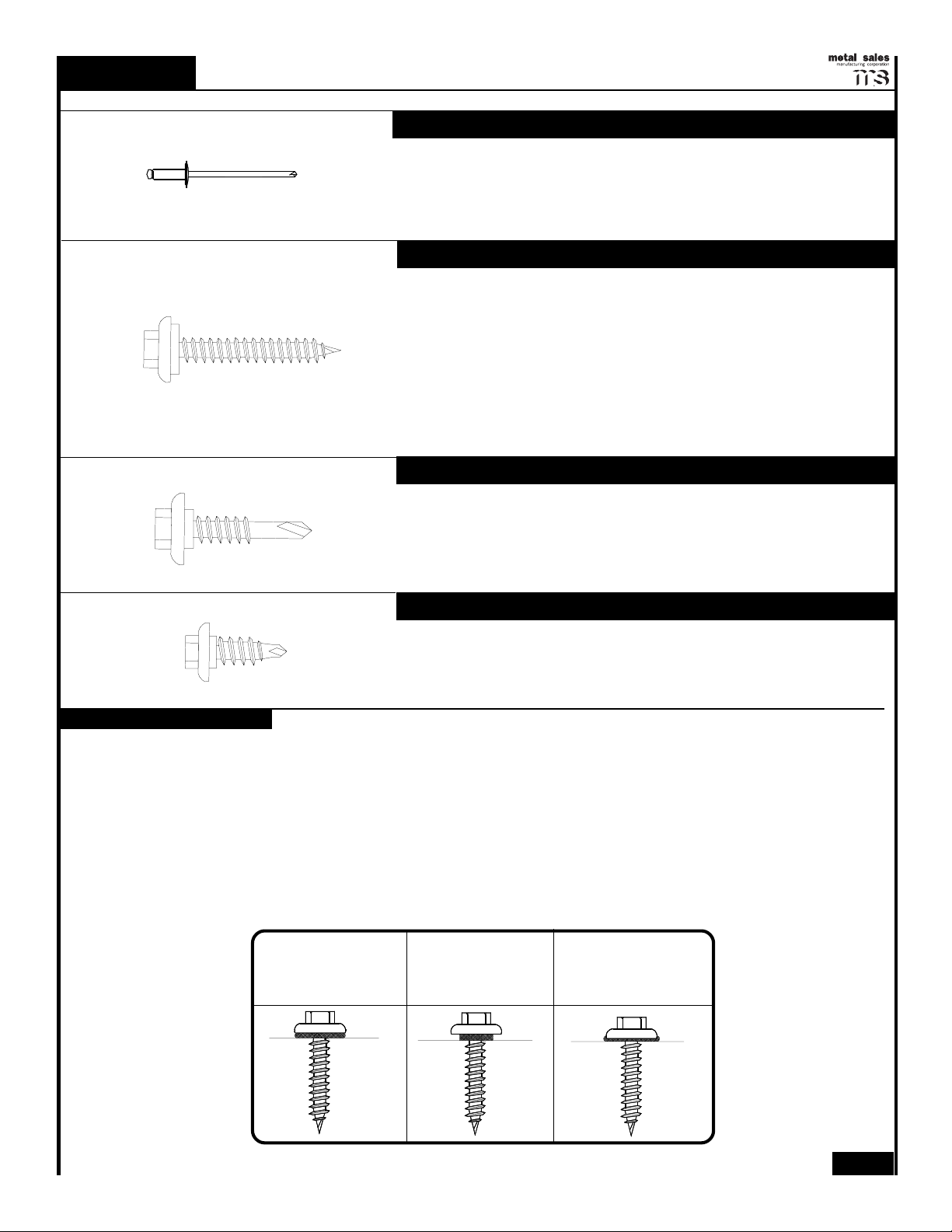

FASTENER SELECTION GUIDE

POP RIVET

WOODSCREW XL

SELF DRILLER XL

SIZE MATERIAL FINISH APPLICATION

1

/8" x 3/16" Stainless Steel Painted Attaching Flashings to

Panels or Flashings

SIZE TYPE FINISH APPLICATION

1

/4-14 x 1" ABMP XL-Painted Attaching Panels

1

/4-14 x 11/2" ABMP XL-Painted wood roof deck

SIZE TYPE FINISH APPLICATION

12-14 x 11/4" Driller XL-Painted Attaching Panels or

or Flashings to

on Exposed

Flashings to metal decking

STITCH SCREW XL

SIZE TYPE FINISH APPLICATION

1

/4-14 x 7/8" Stitch XL-Painted Attaching Flashings to

Panels or Flashing

EXPOSED FASTENER INSTALLATION

RECOMMENDED TOOL TYPE - Use depth locating nose or adjustable clutch on screw gun to prevent overdrilling and

strip out. DO NOT USE IMPACT TOOLS OR RUNNERS.

SEATING THE WASHER - Apply sufficient torque to seat the washer - do not overdrive the fastener.

TO PREVENT WOBBLING - Make sure fastener head is completely engaged in the socket. If the head does not go all

the way in the socket - tap the magnet deeper into the socket to allow full head engagement. Metal chips will build up

from drilling and should be removed from time to time.

PROTECT DRILL POINT - Push only hard enough on the screw gun to engage clutch. This prevents excess friction and

burn out of the drill point. Correct pressure will allow screw to drill and tap without binding.

CORRECT

Sealing material slightly

visible at edge of metal

washer. Assembly is

watertight.

TOO LOOSE

Sealing material is not

visible; not enough

compression to

seal properly.

TOO TIGHT

Metal washer deformed; sealing

material pressed beyond washer

edge.

© Metal Sales Manufacturing Corporation/ Subject to change without notice

11

STILE

GENERAL

DESIGN / INSTALLATION CONSIDERATIONS

Metal Sales' Stile panel is recommended to be installed directly over a wood substrate (minimum 5/8")

with 30# felt moisture barrier.

Always check with local building codes prior to all installations for any additional requirements that

may be specific to your area.

CONDITION OF SUBSTRUCTURE

The roof should be inspected for any trapped moisture or structural damage such as warped or loose

roof decking. These areas should be repaired prior to installing new metal panels.

Prior to installation make sure there are no nails or fasteners protruding from the wood substrate

which could damage the panels and impede the installation process. Special attention must be given

to Valleys, Ridge, Rake and Eave areas when roofing with Stile panels.

When installed, panel distortion may occur if not applied over properly aligned and uniform

substructure.

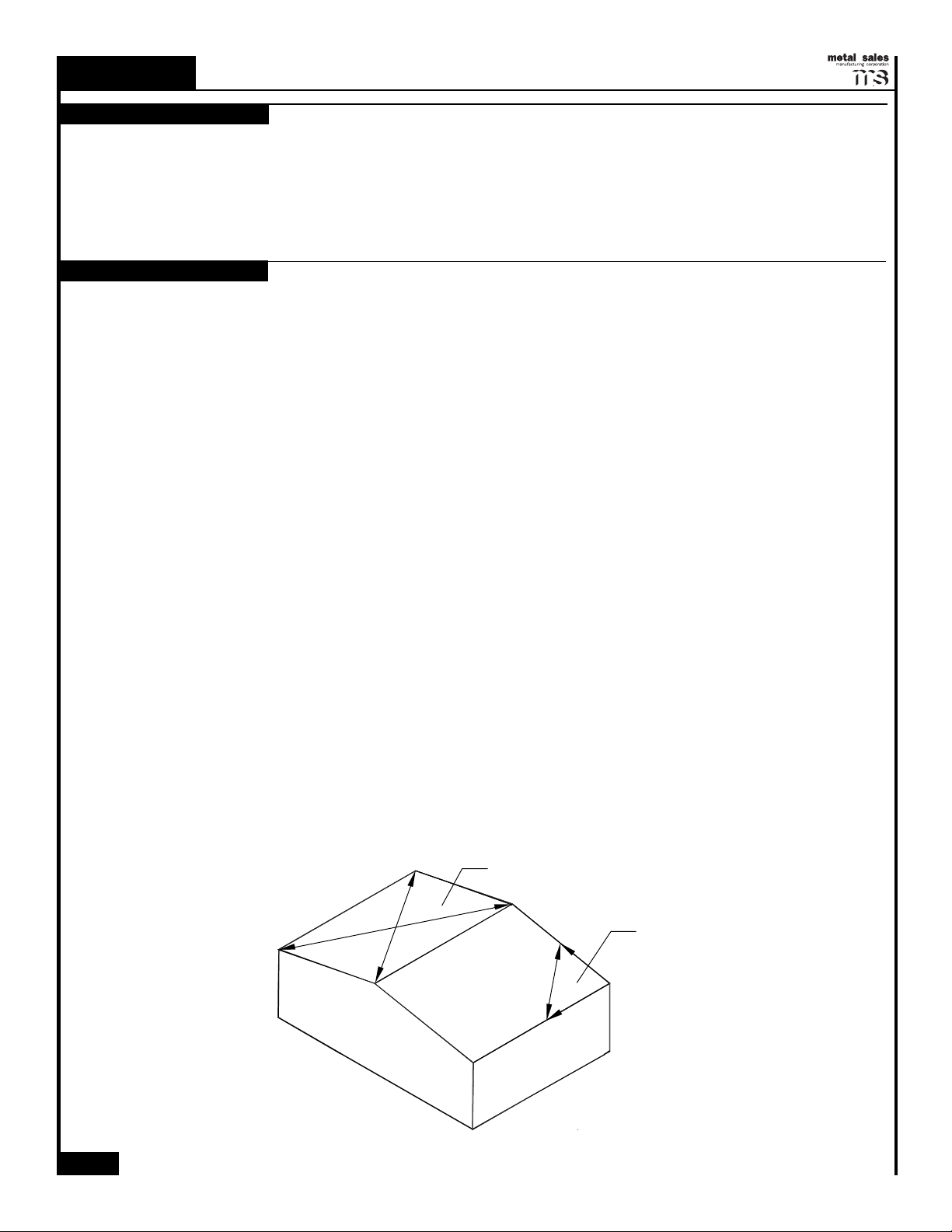

Whether installing over new or existing roof, the installer should check the roof deck for squareness

before installing Stile panels. Several methods can be used to verify squareness of the structure for

proper installation of the panels.

METHOD "A" - One method for checking the roof for squareness is to measure diagonally across one

slope of the roof from similar points at the ridge and eave and obtain the same dimension.

METHOD "B" - The 3-4-5 triangle system may also be used. To use this system measure a point from

the corner along the edge of the roof at a module of three (3). Measure a point from the same corner

along another edge at a module of four (4). Then by measuring diagonally between the two points

established, the dimension should be exactly a module of five (5) to have a square corner. Multiple

uses of this system may be required to determine building squareness. If the endwall cannot be made

square, the roof system cannot be installed as shown in these instructions.

METHOD "A"

10

10

METHOD "B"

3

5

4

12

© Metal Sales Manufacturing Corporation/ Subject to change without notice

STILE

DESIGN / INSTALLATION CONSIDERATIONS (CONT)

VENTILATION

Proper design and installation of vapor barriers and ventilation systems are important to prevent

condensation and the resulting problems of moisture damage and loss of insulation efficiency.

On buildings that have an attic space, vents should be placed at both the eave and peak of the roof in

order to prevent a buildup of moisture (humidity) in the attic space.

VENT

ATTIC INSULATION

VENT AT EAVE

BUILDING WITH ATTIC

FLASHING ANGLE SPECIFIER CHART

This chart should be used to determine the required specified angle when considering the following

Stile flashings.

PROFILE

FLASHING

RIDGE

VALLEY

PITCH BREAK

PEAK

EAVE

1:12 2:12 3:12 4:12 5:12 6:12 7:12 8:12 9:12 10:12 11:12 12:12

170

173

94

87

94

o

o

o

o

o

161

152

143

135

o

o

o

166

160

o

o

99

104

o

o

81

76

o

o

99

104

o

154

148

o

o

108

112

o

o

71

67

o

o

108

112

o

127

120

o

o

143

138

o

o

116

120

o

o

63

60

o

o

116

120

o

o

113

o

133

o

123

o

56

o

123

o

106

o

129

o

126

o

53

o

126

o

100

o

126

o

128

o

o

128

50

95

o

123

o

132

o

47

o

132

o

o

90

o

o

120

o

o

135

o

o

45

o

o

135

o

o

o

o

o

o

GUTTER

94

99

104

108

112

116

120

o

© Metal Sales Manufacturing Corporation/ Subject to change without notice

123

o

o

o

o

126

128

132

135

o

13

STILE

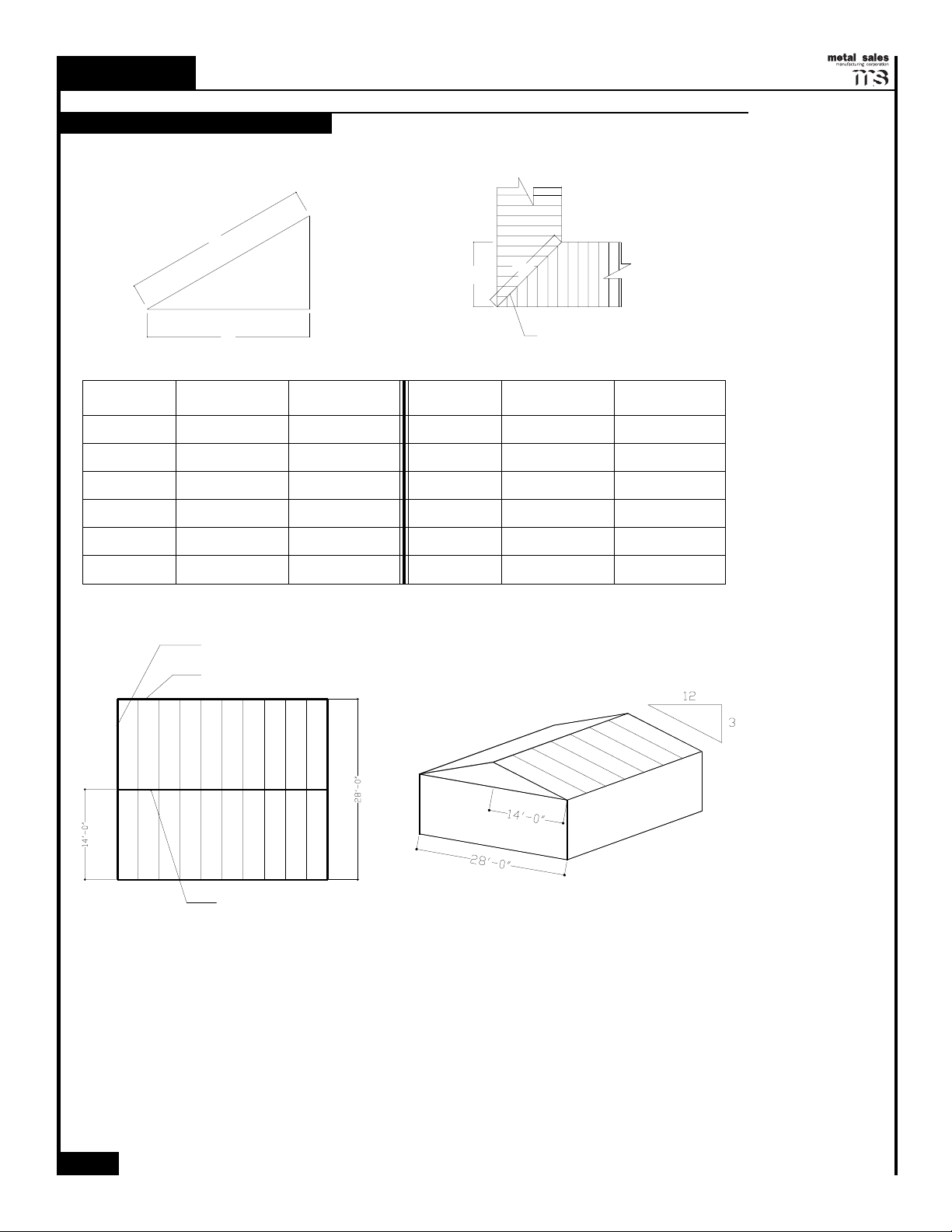

ROOF SLOPE FACTOR CHART

DESIGN / INSTALLATION CONSIDERATIONS (CONT)

This chart should be used when specifying and ordering Panels and Flashings. It will help you determine

overall required length of material on sloped applications.

PEAK

S

EAVE

L

(L) X (SLOPE FACTOR) = S

SLOPE FACTOR MULTIPLIER

1:12

2:12

3:12

4:12

5:12

6:12

SLOPE HIP/VALLEY

1.0035

1.0138

1.0308

1.0541

1.0833

1.1180

1.4167

1.4240

1.4362

1.4530

1.4743

1.5000

EXAMPLE:

RAKE

EAVE OR GUTTER

L

SLOPE FACTOR MULTIPLIER

7:12

8:12

9:12

10:12

11:12

12:12

H

HIP OR VALLEY

(L) X (HIP VALLEY MULTIPLIER) = H

SLOPE HIP/VALLEY

1.1577

1.2019

1.2500

1.3017

1.3566

1.4142

1.5298

1.5635

1.6008

1.6415

1.6853

1.7320

SLOPE

RIDGE

Your Building is 28'-0' wide with a 3:12 pitch.

To determine the panel lengths for each side:

(L) X (SLOPE FACTOR) = S

14'-0" x 1.0308(from chart above for 3:12 slope) = 14.4312' OR 14'-5"

14

© Metal Sales Manufacturing Corporation/ Subject to change without notice

STILE

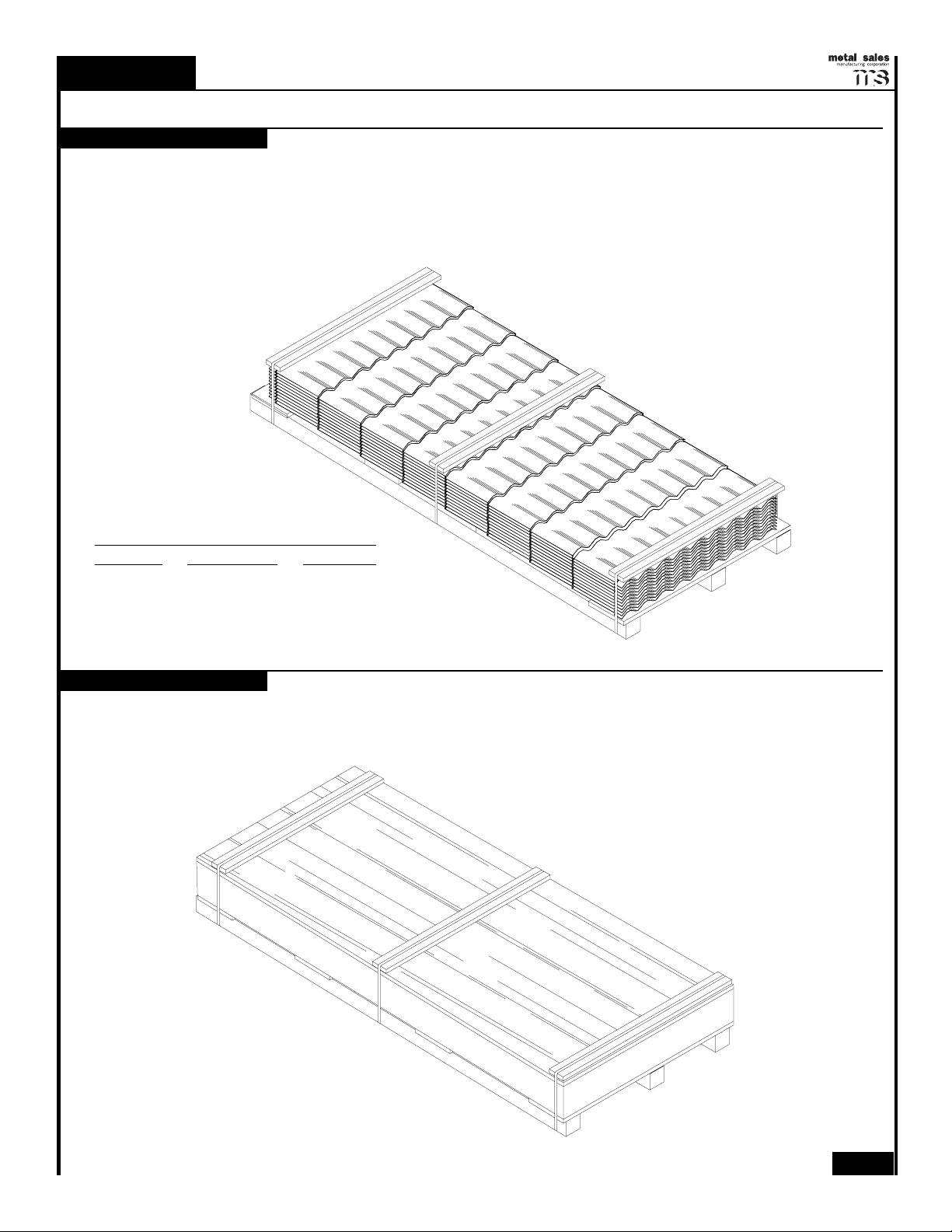

STANDARD PACKAGING

PACKAGING

BLOCKED AND BANDED - This method is utilized for standard packaging of Stile roofing panels.

Panels are stacked on a wood skid with a cover sheet on top. Boards are placed on top of the

cover sheet. Banding is then placed around the skid, panel, and board.

STANDARD PACKAGING

Skid Length Panels per Skid Max lbs/Skid

4'-0" 100 1335

8'-0" 95 2500

12'-0" 65 2500

16'-0" 50 2500

20'-0" 40 2500

OPTIONAL PACKAGING

FULL CRATE - This method is utilized for all LTL and overseas shipments or at customer's request.

© Metal Sales Manufacturing Corporation/ Subject to change without notice

15

STILE

RECEIVING MATERIAL

It is the responsibility of the installer to unload material from the delivery truck. The installer is not

responsible for providing suitable equipment for unloading of material from the delivery truck.

After receiving material, check the condition of the material, and review the shipment against the shipping

list to ensure all materials are accounted for. If damages or shortages are discovered, it should be noted on

the Bill of Lading at the time of delivery. A claim should be made against the carrier as soon as possible.

Metal Sales is not responsible for any damages or shortages unless they are documented in writing and

presented to Metal Sales within 48 hours.

GENERAL HANDLING

HANDLING MATERIAL

CAUTION

Improper loading and unloading of bundles and crates may result in bodily harm and/or

material damage. Metal Sales is not responsible for bodily injuries and/or material

damages resulting from improper loading and unloading.

Each bundle should be handled carefully to avoid being damaged. Care should be taken to prevent bending

of the panel or abrasion to finish. Whenever possible, the bundle should remain crated until it is located in

its place of storage. If bundles must be opened, we recommend you recrate them before lifting. To avoid

damage please lift the bundle at its center of gravity.

Some products may have a peel-off (strippable film) plastic coating over the painted surface. This coating

was factory applied to prevent damage to the finish that may occur during manufacturing or shipping. If

this coating is present, avoid exposure of the "strippable film" parts to sunlight and remove the "strippable

film prior to installation.

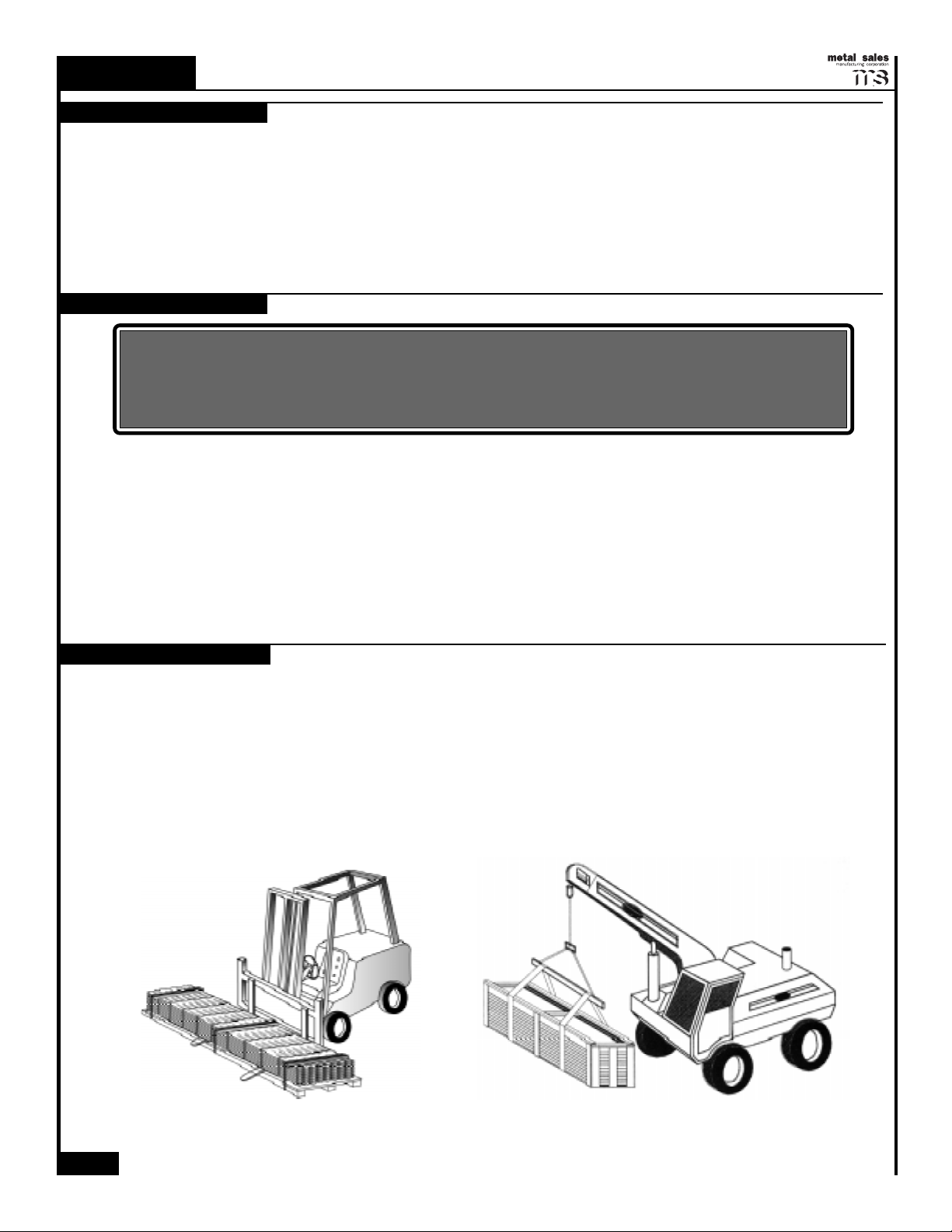

MECHANICAL HANDLING

FORKLIFT - A forklift may be used for panels up to 20'-0" long. Please make sure the forks are at their

maximum separation. Do not transport open bundles. When transporting bundles across rough terrain,

or over a longer distance, some means of supporting the panel load must be used.

CRANE - A crane should be used when lifting panels with lengths greater than 20'-0". Please be sure to

utilize a spreader bar to ensure the even distribution of the weight to the pick up points. As a rule when

lifting panels, no more than 1/3 of the length of the panel should be left unsupported. Never use wire rope

as this will damage the panels.

16

© Metal Sales Manufacturing Corporation/ Subject to change without notice

Loading...

Loading...