Metal Sales Seam-Loc 24 Installation

®

Seam-Loc 24

Installation Guide

®

SEAM-LOC 24

The application and detail drawings in this manual are strictly for illustration purposes and may not be applicable to all

building designs or product installations. All projects should conform to applicable building codes for that particular area. It

is recommended to follow all building regulations and standard industry practices.

Metal Sales Manufacturing Corporation is not responsible for the performance of the roof system if it is not installed in

accordance with the suggested instructions referenced in this manual. If there is a conflict between this manual and the Metal

Sales approved erection drawings, the approved erection drawings are to take precedence.

Prior to ordering and installing materials, all dimensions should be verified by field measurements.

Metal Sales reserves the right to modify, without notice, any details, recommendations, or suggestions. Any questions

you may have regarding proper installation of the Seam-Loc 24 roofing system should be directed to your Metal Sales

representative, (see pages 2 and 3).

Oil canning is not a cause for rejection. Oil canning can be described as the amount of waviness found in the flat areas of metal

panels. Oil canning is an inherent characteristic of light gauge cold formed metal products, particularly those with broad flat

areas. There are many factors which may contribute to oil canning that Metal Sales is not able to control. These factors

include: misalignment of the support system, over driving of fasteners used on the panels, stress (whether inherent in the panel or

induced), thermal expansion and contraction of the panel, material handling, width, gauge, length, color of panels, and installation

(Reference Metal Construction Association “Oil Canning Position Paper” - Appendix A).

Exposure of metal roof and wall materials to areas subject to corrosive, harmful and aggressive environment condition but not

limited to salt water regions, marine atmosphere, repeated salt spray, corrosive chemical, ash, fumes, chemical dust, corrosive

vapors, animal waste, confinement, run off from non-compatible metal, can cause premature rusting and other failure of metal

materials (including panels and trims) and therefore is not a cause for claim or rejection.

IMPORTANT INFORMATION

Consult Metal Sales representative for any additional information not outlined in this manual (see pages 2-3).

This manual is designed to be utilized as a guide when installing Seam-Loc 24 roofing system. It is the responsibility of the

erector to ensure the safe installation of this product system.

SAFETY

STUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFORE

FOLLOWING THESE INSTRUCTIONS.

The installation of metal roof systems is a dangerous procedure and should be supervised by trained

knowledgeable erectors. USE EXTREME CARE WHILE INSTALLING ROOF PANELS. It is not possible

for Metal Sales to be aware of all the possible job site situations that could cause an unsafe condition

to exist. The erector of the roof system is responsible for reading these instructions and determining

the safest way to install the roof system.

These instructions are provided only as a guide to show a knowledgeable, trained erector the correct

parts placement one to another. If following any of the installation steps would endanger a worker, the

erector should stop work and decide upon a corrective action.

Provide required safety railing, netting, or safety lines for crew members working on

the roof.

Do not use the roof panel as a walking platform. The roof panels will not withstand the weight of a

person standing at the edge of the panel.

Do not stand on the roof panel at the ends until the panels have been attached.

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

1

SEAM-LOC 24

®

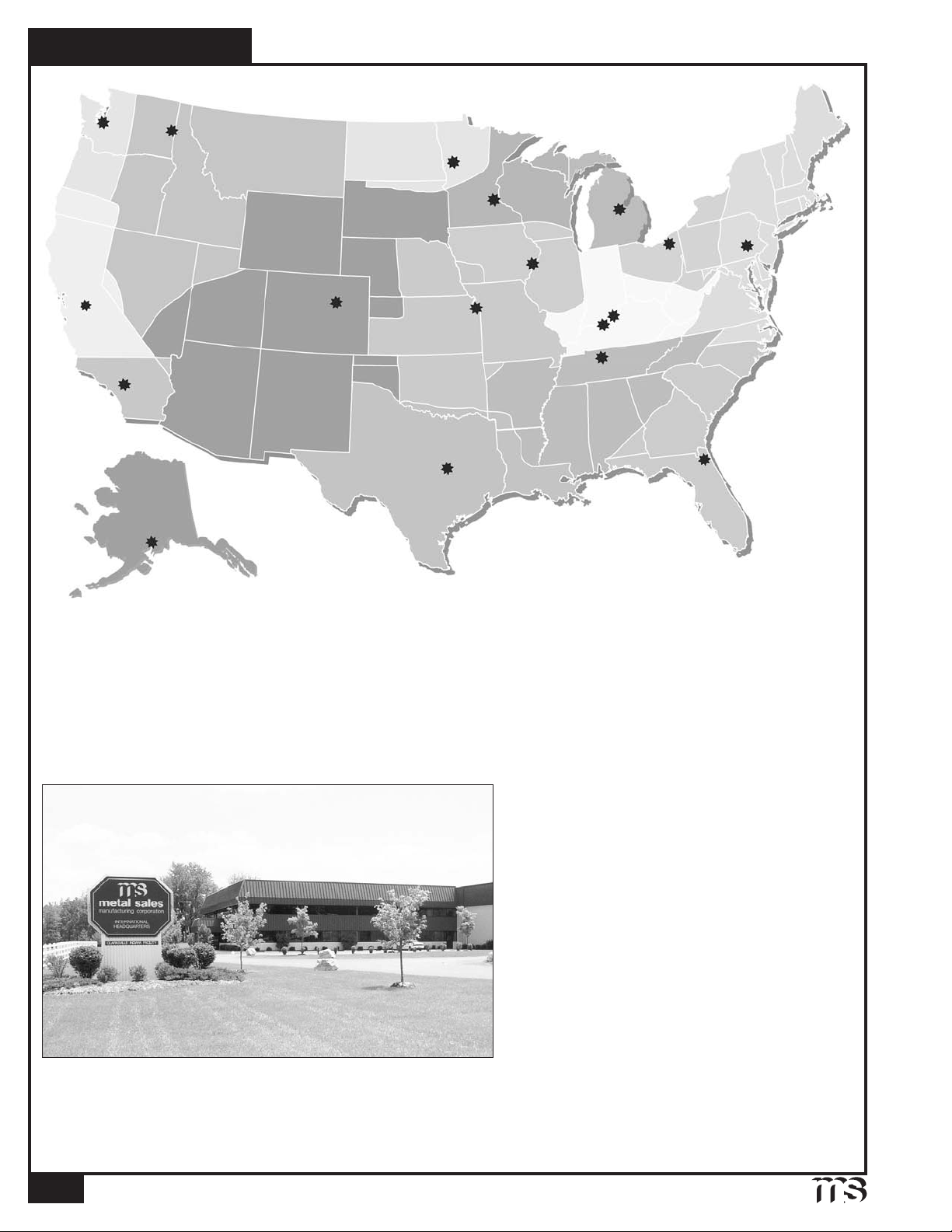

METAL SALES LOCATIONS

METAL SALES LOCATIONS

*

NOTE: Shaded areas represent regions

served by each location.

CORPORATE OFFICE

SELLERSBURG, INDIANA

Metal Sales offers a complete line of metal roof, wall, and fascia panel systems for the commercial, architectural, industrial,

residential, and agricultural markets. Metal Sales offers over 75 profiles with a wide selection of widths, colors, and gauges new construction or retrofit.

2

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

SEAM-LOC 24

METAL SALES LOCATIONS

®

CUSTOMER SERVICE

LONGMONT BRANCH

7990 E. I-25 Frontage Rd

Longmont, CO 80504

(303) 702-5440

(800) 289-7663

(800) 289-1617 /FAX

JACKSONVILLE BRANCH

7110 Stuart Avenue

Jacksonville, FL 32254

(904) 783-3660

(800) 394-4419

(904) 783-9175 /FAX

JEFFERSON BRANCH

352 East Erie Street

Jefferson, OH 44047

(440) 576-9070

(800) 321-5833

(440) 576-9242 /FAX

(800) 233-5719 /FAX

INDEPENDENCE BRANCH

1306 S. Powell Road

Independence, MO 64057

(816) 796-0900

(800) 747-0012

(816) 796-0906 /FAX

SELLERSBURG BRANCH

7800 State Road 60

Sellersburg, IN 47172

(812) 246-1866

(800) 999-7777

(812) 246-0893 /FAX

(800) 477-9318 /FAX

ANTIOCH BRANCH

4314 Hurricane Creek Blvd.

Antioch, TN 37013

(615) 641-7100

(800) 251-8508

(615) 641-7118 /FAX

SPOKANE BRANCH

East 2727 Trent Avenue

Spokane, WA 99202

(509) 536-6000

(800) 572-6565

(509) 534-4427 /FAX

KENT BRANCH

20213 84th Avenue, South

Kent, WA 98032

(253) 872-5750

(800) 431-3470 (outside WA)

(800) 742-7900 (inside WA)

(253) 872-2008 /FAX

ROCK ISLAND BRANCH

8111 West 29th Street

Rock Island, IL 61201

(309) 787-1200

(800) 747-1206

(309) 787-1833 /FAX

ORWIGSBURG BRANCH

29 Pinedale Industrial Rd

Orwigsburg, PA 17961

(570) 366-2020

(800) 544-2577

(570) 366-1648 /FAX

(800) 544-2574 /FAX

WOODLAND BRANCH

1326 Paddock Place

Woodland, CA 95776

(530) 668-5690

(800) 759-6019

(530) 668-0901 /FAX

FONTANA BRANCH

14213 Whittram Avenue

Fontana, CA 92335

(909) 829-8618

(800) 782-7953

(909) 829-9083 /FAX

ANCHORAGE BRANCH

4637 Old Seward Hwy.

Anchorage, AK 99503

(866) 640-7663

(907) 646-7663

(907) 646-7664 /FAX

BAY CITY BRANCH

5209 Mackinaw Rd.

Bay City, MI 48706

(866) 640-7663

(907) 646-7663

(907) 646-7664 /FAX

DETROIT LAKES BRANCH

1435 Egret Avenue

Detroit Lakes, MN 56501

(218) 847-2988

(888) 594-1394

(218) 847-4835 /FAX

(888) 594-4835 /FAX

ROGERS BRANCH

22651 Industrial Blvd.

Rogers, MN 55374

(763) 428-8080

(800) 328-9316

(763) 428-8525 /FAX

(800) 938-9119 /FAX

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

TEMPLE BRANCH

3838 North General Bruce Dr.

Temple, TX 76501

(254) 791-6650

(800) 543-4415

(254) 791-6655 /FAX

(800) 543-4473 /FAX

TECHNICAL SUPPORT

TECHNICAL SERVICES

7800 State Road 60

Sellersburg, IN 47172

(812) 246-0819 (800) 406-7387

(812) 246-0829 /FAX (800) 944-6884 /FAX

info@metalsales.us.com

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

3

SEAM-LOC 24

®

TABLE OF CONTENTS

General Information

Important Information .........................................................................................................1

Metal Sales' Locations ....................................................................................................... 2

Customer Service ............................................................................................................... 3

Table of Contents .........................................................................................................4 & 5

PAGE NO.

Panel Profile .................................................................................................................... 6

Flashing Profiles .......................................................................................................... 6-8

Accessory Profiles ...................................................................................................... 8-9

Handling Material

Receiving Material ............................................................................................................ 10

General Handling ............................................................................................................. 10

Mechanical Handling ........................................................................................................ 10

Manual Handling .............................................................................................................. 11

Storage

General ............................................................................................................................ 12

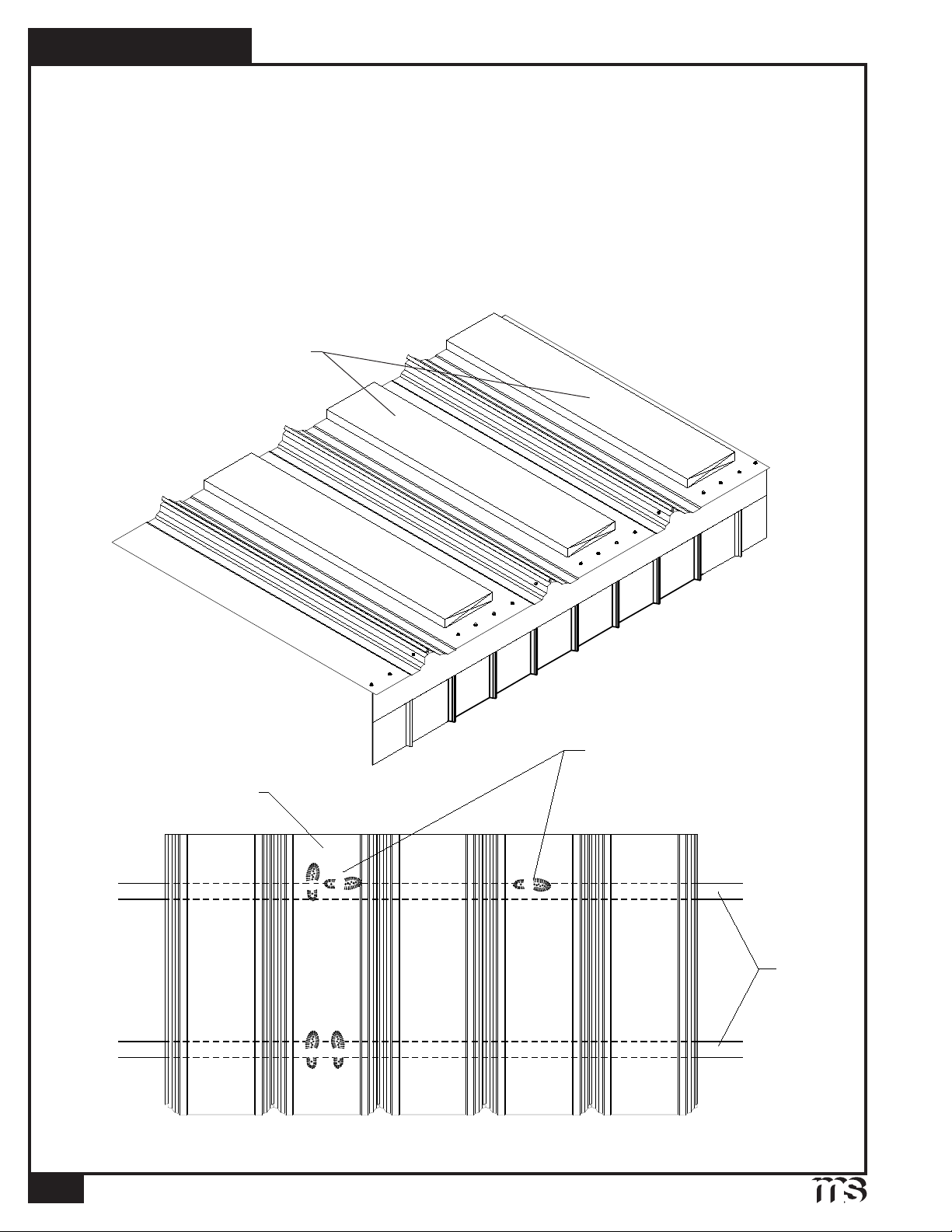

Storage on Roof ...............................................................................................................13

Foot Traffic ................................................................................................................... 14

Field Cutting and Touch-up

Field Cutting .....................................................................................................................15

Touch-up Paint ................................................................................................................. 15

Fastener Selection Guide ....................................................................................... 16-17

Design / Installation Considerations

Fastener Installation Technique ........................................................................................ 18

Condition of Substructure ................................................................................................. 18

Ventilation ........................................................................................................................ 19

Insulation .......................................................................................................................... 19

Selection of System Components ...................................................................................20

Panel Endlapping Considerations................................................................................21-22

Installation Procedure Overview ................................................................................. 23

Installation of Panel Over Open Framing

Installing Floating Rake Angle (Step 1)............................................................................. 24

Installing Eave Plate (Step 2) ............................................................................................ 25

Installing Metal Inside Closures (Step 3)........................................................................... 26

Installing First Panel (Step 4) ............................................................................................ 27

Installing Panel Clips (Step 5) ...................................................................................... 28-29

Installing Panel Endlaps (Step 6) ................................................................................. 30-31

Installing Panel Sidelaps (Step 7) ................................................................................32-33

Installing Panel Terminations (Step 8)............................................................................... 34

Seaming Panels (Step 9) .............................................................................................35-36

Sculptured Eave ............................................................................................................... 37

Sculptured Gutter..............................................................................................................38

Endlap ..............................................................................................................................39

SSR Drop Valley ...............................................................................................................40

SSR Sculptured Rake (Off Module) .................................................................................41

SSR Sculptured Rake (On Module) ..................................................................................42

Rakewall (Off Module) with Counter Flashing ..................................................................43

Rakewall (On Module) with Reglet Flashing ....................................................................44

Expansion Joint ................................................................................................................ 45

Endwall with Counter Flashing ......................................................................................... 46

Endwall with Reglet Flashing ...........................................................................................47

Sculptured High Side Eave ..............................................................................................48

SSR Ridge ....................................................................................................................... 49

Vented Ridge .................................................................................................................... 50

4

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

SEAM-LOC 24

®

TABLE OF CONTENTS (CONT.)

Installation of Panel Over RIgid Insulation

Sculptured Eave ............................................................................................................... 51

Sculptured Gutter..............................................................................................................52

SSR Drop Valley ...............................................................................................................53

SSR Sculptured Rake (Off Module) .................................................................................54

SSR Sculptured Rake (On Module) ..................................................................................55

Rakewall (Off Module) with Counter Flashing ..................................................................56

Rakewall (On Module) with Reglet Flashing ....................................................................57

Endwall with Counter Flashing ......................................................................................... 58

Endwall with Reglet Flashing ...........................................................................................59

Sculptured High Side Eave ..............................................................................................60

SSR Ridge ....................................................................................................................... 61

Installation of Metal Outside Closures

Clip Detail Over Rigid Insulation

....................................................................... 62

................................................................................. 63

PAGE NO.

Roof Penetrations

Installation Notes............................................................................................................... 64

Care and Maintenance

General Notes................................................................................................................... 64

................................................................................................. 65

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

5

SEAM-LOC 24

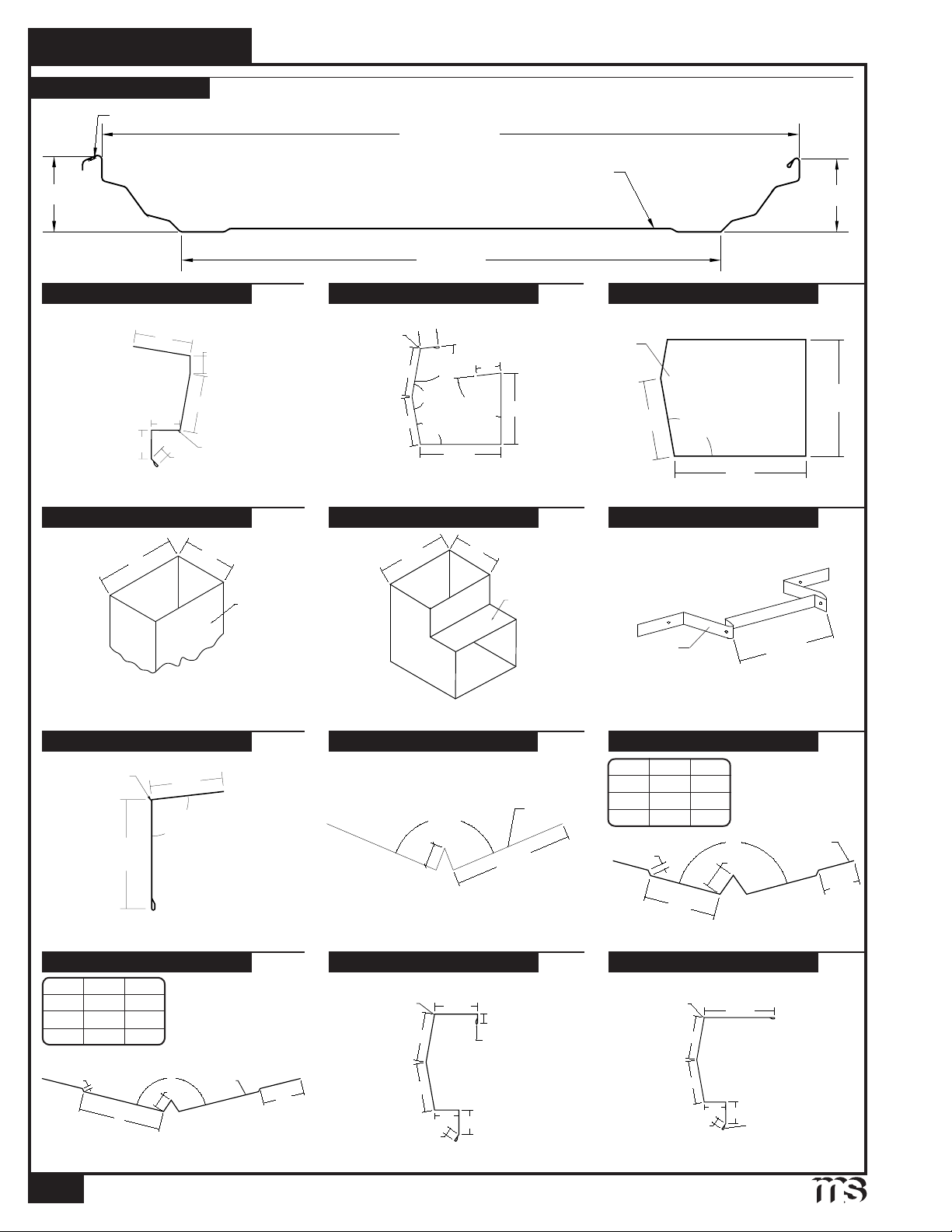

PANEL PROFILE

Factory Applied Sealant

211/16"

®

PANEL / FLASHING PROFILES

24" Coverage

C

25/8"

181/2"

SEAM-LOC 24

SCULPTURED EAVE

4"

SEAM-LOC 24

SCULPTURED GUTTER

11/2"

C

11/4"

X*

4"

2"

2"

Length 10'-2", 20'-3" - *Specify Slope Angle

C

5

/8"

*Specify Slope Angle For A and B, and Length for D.

A*

4"

160°

4"

100°

65/8"

Length 10'-2", 20'-3"

DOWNSPOUT 6" x 4" 950 ELBOW 6" x 4"

6"

Length 10'-2", 20'-3"

(Also available 4" x 31/2")

4"

C

6"

(Also available 4" x 31/2")

VALLEYGUTTER DRIP

C

41/2"

3"

X*

*(For use with Utility System/Clip)

X*

2"

B*

4"

2"

D*

C

10"

SEAM-LOC 24

SCULPTURED GUTTER END

C

57/8"

4"

100°

65/8"

DOWNSPOUT BRACKET

C

(Also available 4")

6"

SSR 4.5" DROP VALLEY

A

A B

3

/8"

1"

1 3/8"

41/2"

4 1/2"

3 7/8"

3 1/2"

X*

11/2"

C

B

SYSTEM

LOW

C

MID

HIGH

SSR 7" DROP VALLEY

MID

A

A B

3

/8"

1"

1 3/8"

7"

4 1/2"

3 7/8"

3 1/2"

X*

2"

C

B

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

SYSTEM

LOW

HIGH

Length 10'-2", 20'-3" - *Specify Slope Angle

6

Length 10'-2", 20'-3" - *Specify Slope Angle

SSR SCULPTURED RAKE

(ON MODULE)

C

31/2"

3

100°

4"

160°

4"

100°

2"

5

/8"

Length 10'-2", 20'-3"

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

/4"

Hem

2"

Length 10'-2", 20'-3" - *Specify Slope AngleLength 10'-2" - *Specify Slope Angle

SSR SCULPTURED RAKE

(OFF MODULE)

C

Length 10'-2", 20'-3"

4"

4"

160°

5

/8"

100°

100°

2"

61/2"

2"

Hem

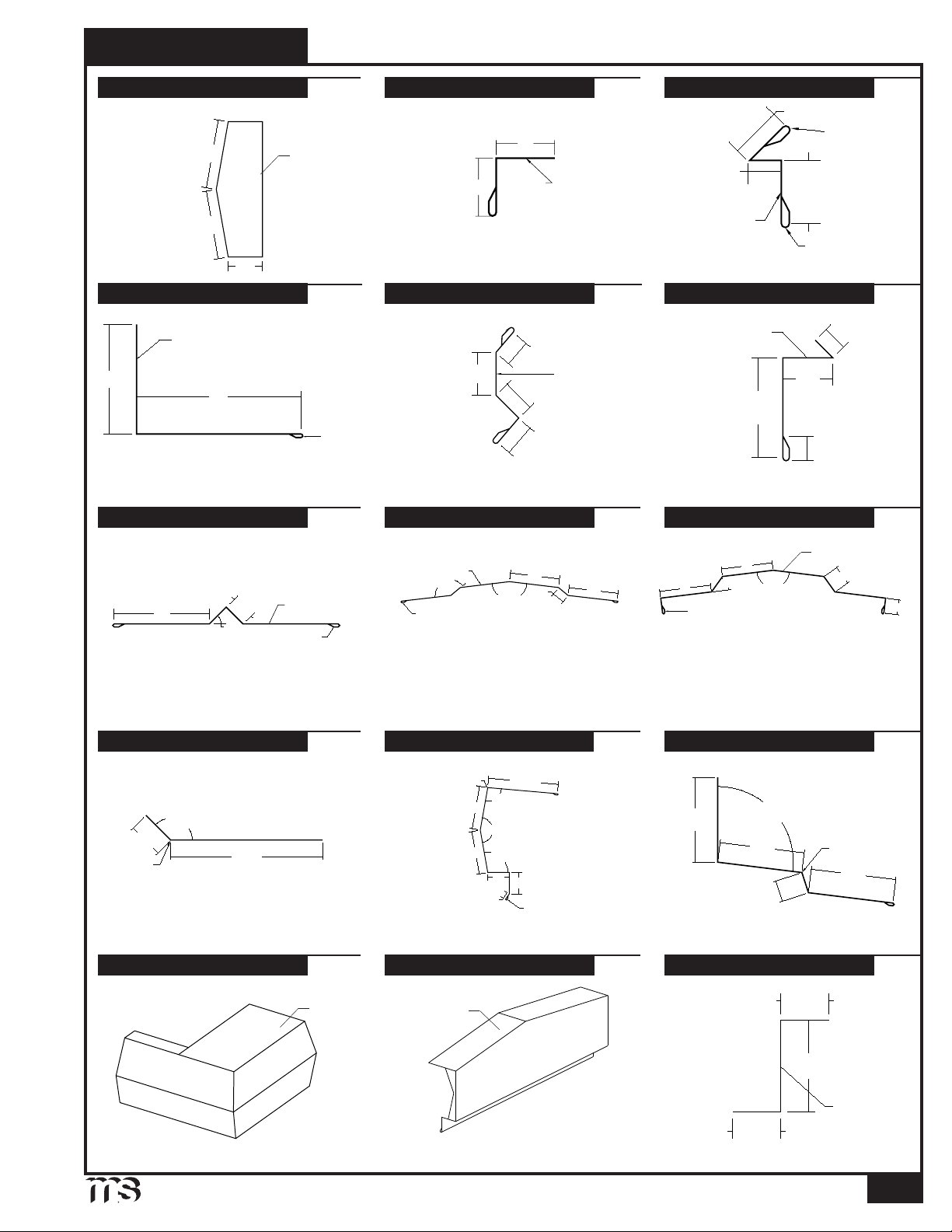

SEAM-LOC 24

®

FLASHING PROFILES (CONT.)

SSR SCULPTURED

SSR RAKE CLEAT

RAKE END

4"

4"

100°

160°

100°

C

1"

2"

1"

Length 10'-2"

SSR RAKEWALL COUNTER FLASHING

C

4"

6"

Length 10'-2"

EXPANSION JOINT

Hem

SSR RIDGE VENTED RIDGE COVER

5

1"

3

3

Length 10'-2"

COVER

C

4"

45°

1"

C

Hem

135°

Hem

X*

/8"

/4"

/4"

4"

C

1"

SSR RAKE SLIDE

3

/4"

Hem

1

/2"

1"

C

Hem

Length 10'-2"

REGLET FLASHING

1

1"

Hem

C

/2"

11/8"

7

/8"

C

C

2"

Length 10'-2"

3"

1"

4"

3"

X*

Hem

Length 10'-2"

VENT DRIP SSR HIGH SIDE

Length 10'-2", 20'-3" - *Specify Slope Angle

SSR SCULPTURED

HIGH SIDE EAVE

C

61/2"

X*

135°

3

/4"

C

Length 10'-2"

31/4"

Length 10'-2", 20'-3" - *Specify Slope Angle

4"

4"

5

/8"

160°

100°

2"

2"

Hem

SSR SCULPTURED SSR SCULPTURED

CORNER BOX

C

PEAK BOX

C

Length 10'-2", 20'-3" - *Specify Slope Angle

PITCH BREAK

4"

Length 10'-2", 20'-3" - *Specify Slope Angle

X*

4"

1"

SEAM-LOC 24

Z-CLOSURE

13/8"

*Specify Slope Angle *Specify Slope Angle

Length 10'-2"

C

4"

13/8"

25/8"

C

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

7

SEAM-LOC 24

SSR GUTTER SUPPORT

®

FLASHING PROFILES (CONT.)

1"

Length 0'-10"

C

7

/8"

3

/4"

SEAM-LOC 24

SEAM-LOC 24 CLIP

Height 25/8", 31/8", 35/8", 41/8"

Galvanized

EAVE PLATE

3

/8"

®

ACCESSORY PROFILES

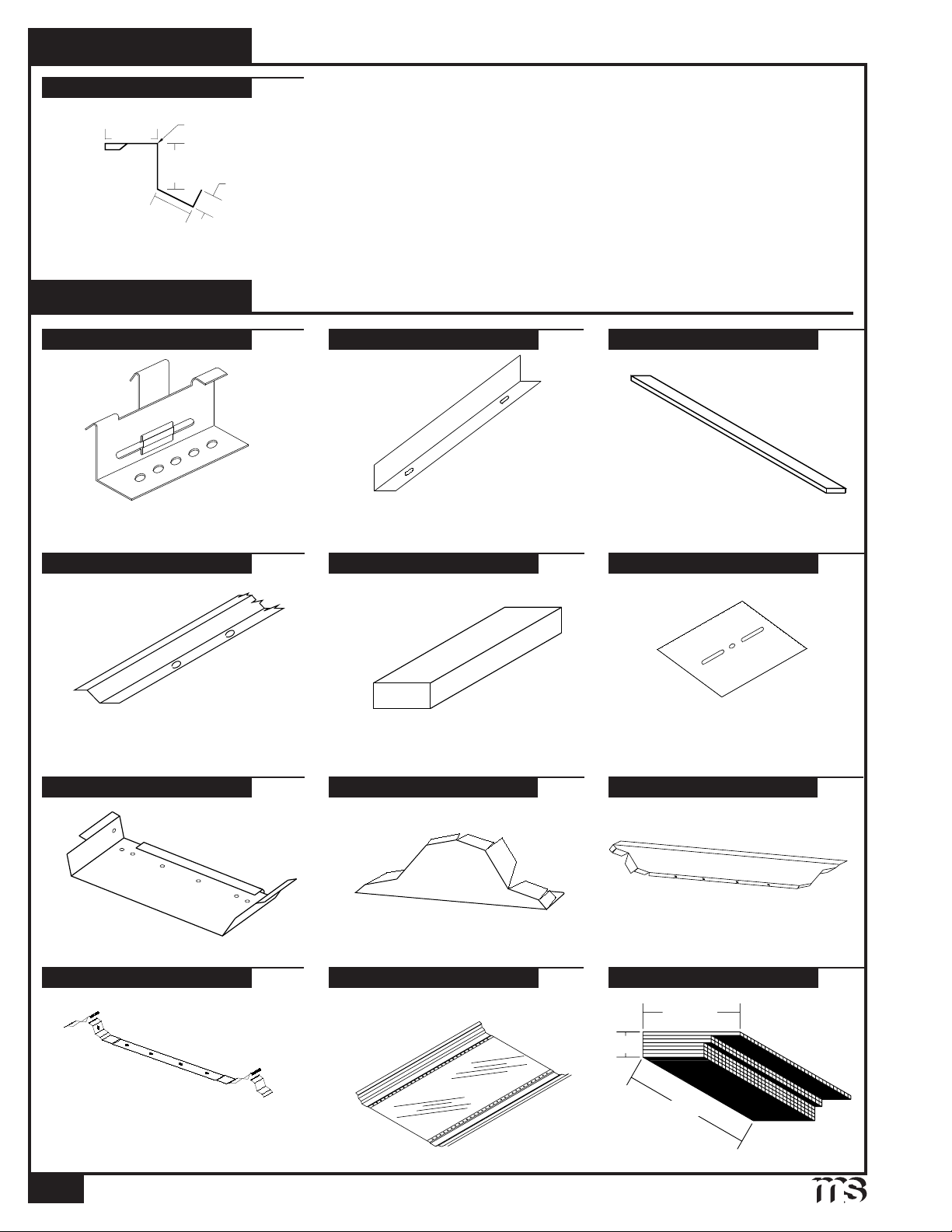

FLOATING RAKE ANGLE ENDLAP PAD

THERMAL BLOCK

C- Indicates color side of flashing.

Length 10'-0"

Height 25/8", 31/8", 35/8", 41/8"

Galvanized

11/2" x 3/32" x 261/4"

Butyl - Gray

BEARING PLATE

Length 10'-0"

Height 3/8", 1", 13/8"

Galvanized

COMPRESSION PLATE

METAL INSIDE CLOSURE METAL OUTSIDE

1" x 3" x 24"

Polystyrene Foam

CINCH STRAP SEAM-LOC 24 LIGHT

TRANSMITTING PANEL

20 Gauge - Galvanized

CLOSURE

VENT MATERIAL

33/8"

7

/8"

4'-0"

4" X 5"

8

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

SEAM-LOC 24

®

ACCESSORY PROFILES (CONT.)

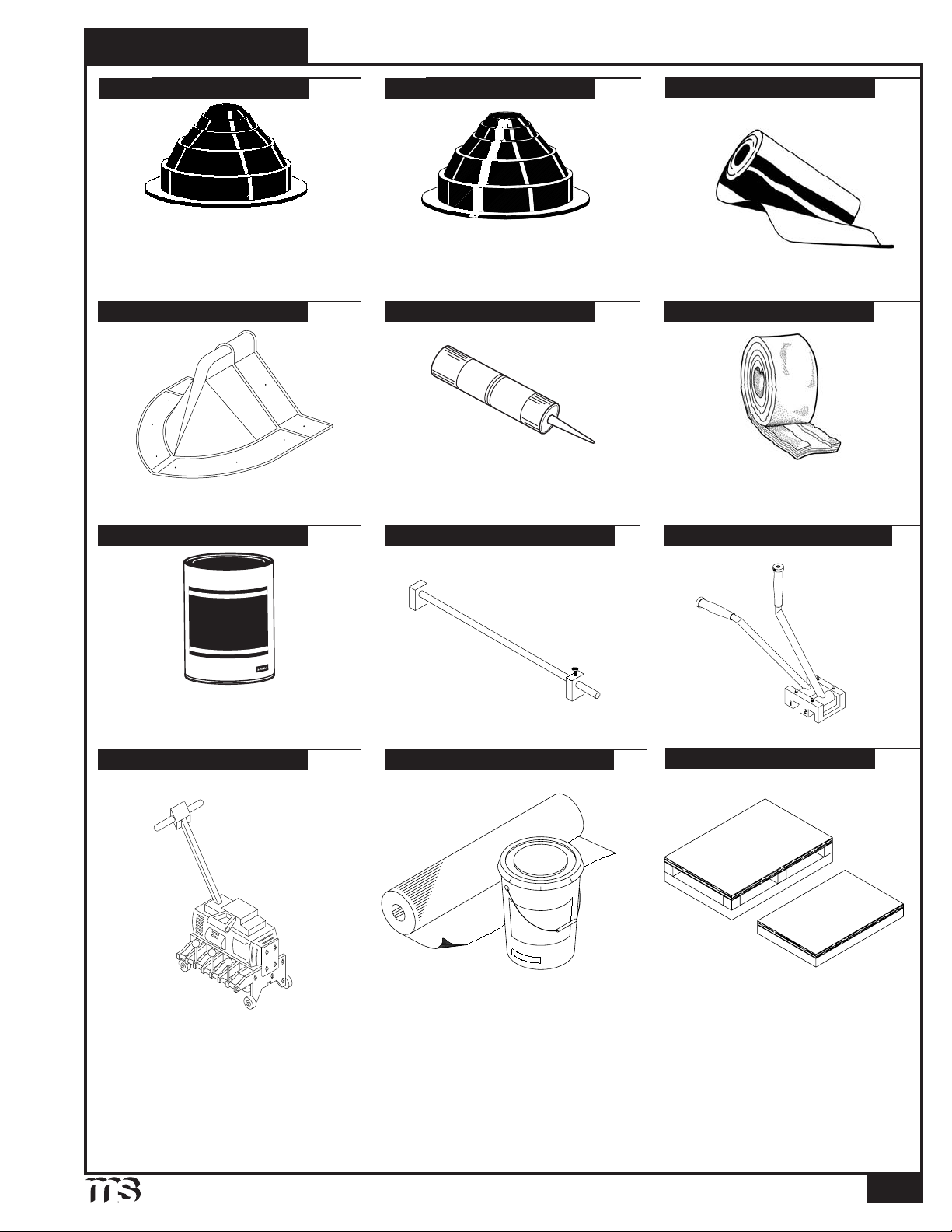

RUBBER ROOF JACK

MINI (1/4" to 11/8" O.D. Pipe)

#2 (13/4" to 3" O.D. Pipe)

#4 (3" to 6" O.D. Pipe)

#6 (6" to 9" O.D. Pipe)

#8 (7" to 13" O.D. Pipe)

DECK CAP

TOUCH-UP PAINT

RETRO ROOF JACK

RUBBER ROOF

FLASH KIT

RETRO

#801

#802

#803

(3/4" to 23/4" O.D. Pipe)

RETRO

(2" to 71/4" O.D. Pipe)

RETRO

(31/4" to 10" O.D. Pipe)

12" x 50'-0" Flash Kit

18" x 50'-0" Flash Kit

TUBE SEALANT TAPE SEALANT

7

10.3 oz. Cartridge

Urethane

/8" X 3/16" X 25'

Double Bead

Butyl - Gray

ADJUSTABLE SPACER BAR SEAM-LOC HAND CRIMPER

Available in Pints

PVDF / MS CF30

MECHANICAL SEAMER

UNDERLAYMENT & PRIMER

Contact Metal Sales for information

NAILABLE INSULATION

Contact Metal Sales for information

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

9

®

SEAM-LOC 24

RECEIVING MATERIAL

It is the responsibility of the installer to unload material from the delivery truck. The installer shall be responsible for providing

suitable equipment for unloading of material from the delivery.

After receiving material, check the condition of the material, and review the shipment against the shipping list to ensure all

materials are accounted for. If damages or shortages are discovered, it should be noted on the Bill of Lading at the time of delivery.

A claim should be made against the carrier as soon as possible. Metal Sales is not responsible for any damages or shortages unless

they are documented in writing and presented to Metal Sales within 48 hours.

GENERAL HANDLING

Each bundle should be handled carefully to avoid being damaged. Care should be taken to prevent bending of the panel or abrasion

to finish. Whenever possible, the bundle should remain crated until it is located in its place of storage. If bundles must be opened,

we recommend you recrate them before lifting. To avoid damage please lift the bundle at its center of gravity.

HANDLING MATERIAL

CAUTION

Improper loading and unloading of bundles and crates may result in bodily harm and/or

material damage. Metal Sales is not responsible for bodily injuries and/or material

damages resulting from improper loading and unloading.

MECHANICAL HANDLING

Forklift - A forklift may be used for panels up to 20'-0" long. Please make sure the forks are at their maximum separation. Do

not transport open bundles. When transporting bundles across rough terrain, or over a longer distance, some means of supporting

the panel load must be used.

Crane - A crane should be used when lifting panels with lengths greater than 20'-0". Please be sure to utilize a spreader bar to

ensure the even distribution of the weight to the pick up points. As a rule when lifting panels, no more than 1/3 of the length of the

panel should be left unsupported. Never use wire rope because this will damage the panels.

10

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

®

SEAM-LOC 24

MANUAL HANDLING

When handling painted steel care should be taken to prevent scratching of material. Clean gloves should be worn at all times

to prevent a reaction with salts found on bare skin. Installers should wear rubber sole shoes to keep from scuffing material

while walking on the roof.

Handling of individual panels should be done carefully and properly to avoid bending or damaging. Seam-Loc 24 panels should be

carried by grasping the edge of the panel so that the Seam-Loc 24 panel is vertical to the ground. The Seam-Loc 24 panel should

not be carried with the panel horizontal to the ground as this could cause the panel to buckle or bend in the center.

Normally individual panels can be handled by people placed every 6'-0" to 8'-0" along the length of the panel.

HANDLING MATERIAL (CONT.)

6' - 8' MAX

CORRECT

INCORRECT

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

11

®

SEAM-LOC 24

GENERAL

Please inspect panels for moisture accumulation. If moisture has formed, the panels should be unbundled, wiped dry, and allowed

to dry completely. Once dry, carefully restack the panels and loosely recover allowing for ample air circulation.

Bundled sheets should be stored high enough off of the ground to allow for air circulation and prevent contact with accumulating

water. If possible, elevate one end of the bundle to allow any moisture to run off the panels. Metal Sales recommends covering the

bundle with a tarpaulin. Do not use tight fitting plastic-type tarpaulins as panel bundle covers. While they may provide protection

from heavy downpours, they can also retard necessary ventilation and trap heat and moisture that may accelerate metal corrosion.

If panels are to be stored in possible bad weather, we suggest they be stored inside. Extended storage of panels in a bundle is

not recommended. Under no circumstances should the sheets be stored near or come in contact with salt water, corrosive

chemicals, ash, or fumes generated or released inside the building or nearby plants, foundries, plating works, kilns,

fertilizer, and wet or green lumber. These conditions will cause premature rusting of panels.

STORAGE

Tarpaulin

Elevate end of Bundle

Seam-Loc 24 Panels

Tarpaulin

12

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

®

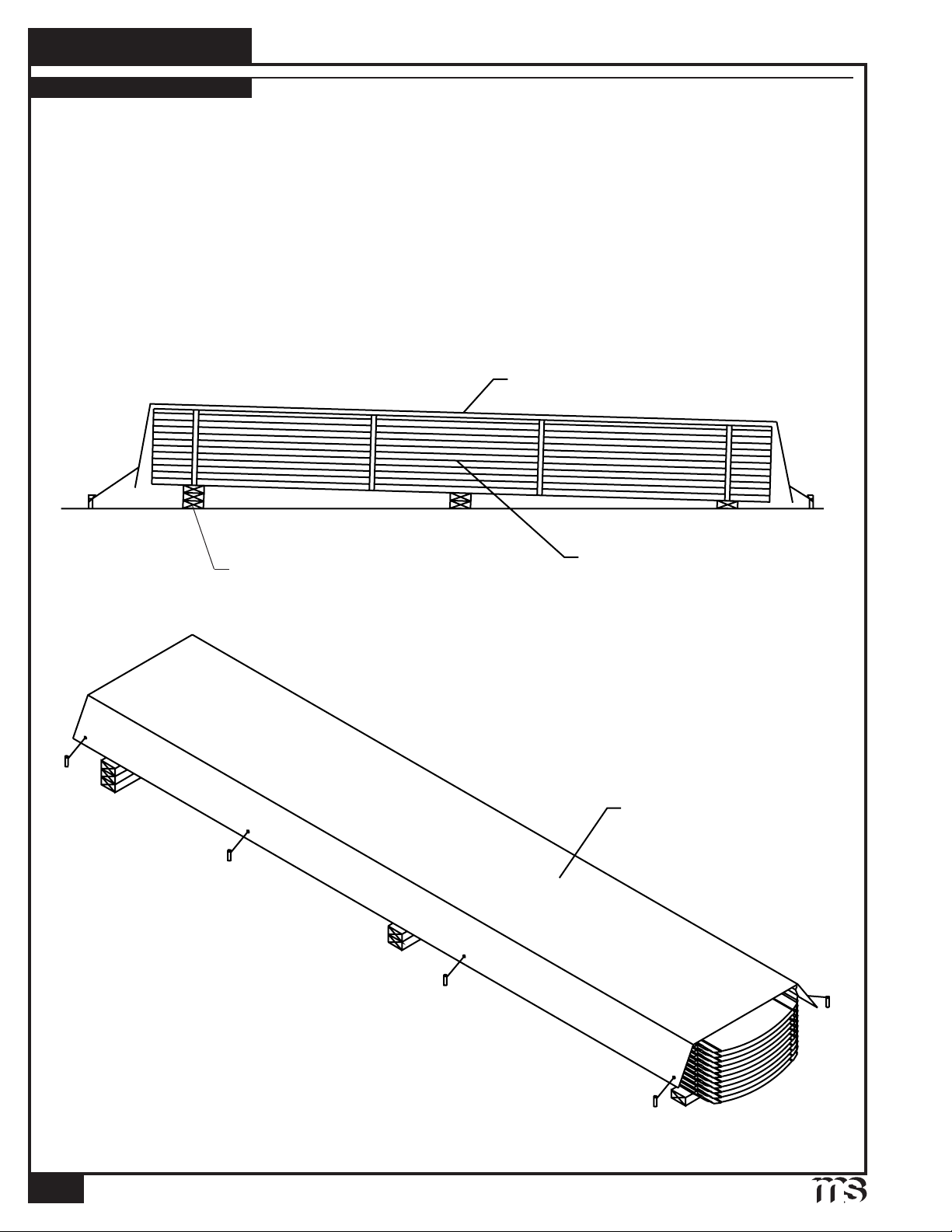

SEAM-LOC 24

STORAGE ON ROOF

To facilitate the handling of Seam-Loc 24 panels, panel bundles can be lifted and placed on the roof. Bundles need to be placed on

the roof in order for the roof structure to handle the weight. Loading capabilities of the structure must be checked.

When lifting packaged sheets, make certain they are adequately supported. Panels less than 20'-0" in length can normally be lifted

with a forklift; however, when lifting panels in excess of 20'-0", it is recommended that a spreader bar and slings be used. As a

rule, when lifting, no more than 1/3 of the length of the panel should be left unsupported.

Make a plan for bundle placement by determining how much area a bundle of panels will cover. Bundles should be placed on the

roof in accordance with the direction the panel will be installed. Consider where the string line, if any, is to run at the eave to set

roof panels by. Roof bundles should not interfere with this string line.

STORAGE (CONT.)

Open Framing

Wood Blocking

Spacer Bar

Seam-Loc 24

Panels

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

13

®

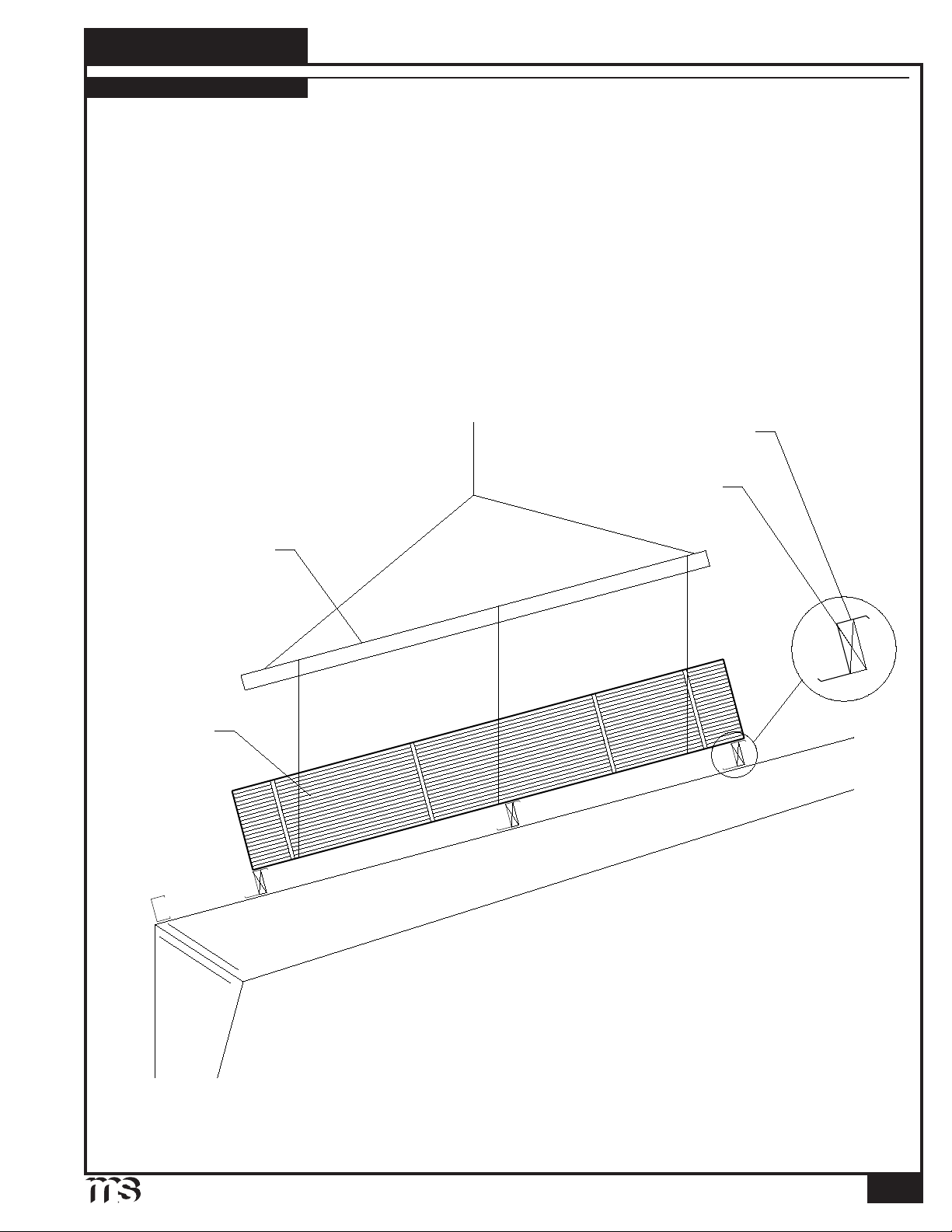

SEAM-LOC 24

Care of metal panels and flashings must be exercised throughout erection. Foot traffic can cause distortion of panel and damage

to finish. Traffic over the installed system must be kept to an absolute minimum. If continuous foot traffic is necessary for

maintenance over certain areas of the roof, then a permanent walkway should be installed.

If metal panels are installed over open framing, do not use the roof panel as a walking platform. The roof panels will not

withstand the weight of a person standing at the edge of the panel. Provide walking platforms to avoid any panel damage as

shown below.

When walking on the roof panels is unavoidable, walk only in the flats of the panel. Walking on the ribs can cause damage

to the panels. If Seam-Loc 24 is installed over open framing, step in the flat of the panel only and as close to the framing

as possible.

FOOT TRAFFIC

Over Open Framing

Walking Platforms

14

Foot Traffic

Seam-Loc 24 Panels

Framing

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

®

SEAM-LOC 24

FIELD CUTTING

Tin snips or a "nibbler" type electric tools are recommended for field cutting Seam-Loc 24 panels. Cutting the steel generates

slivers or metal chips. These slivers and metal chips must be immediately removed from the Seam-Loc 24 panels because they will

damage the finish and shorten the life of the product.

One method of preventing this problem is to flip the Seam-Loc 24 panels over when cutting. This allows the slivers and metal

chips to be brushed from the back side and avoids damaging the paint on the top side of the panels.

When cutting Seam-Loc 24 panels, goggles must be worn for eye protection.

FIELD CUTTING AND TOUCH-UP

CAUTION

All product surfaces should be free of debris at all times. Installed surfaces should be

wiped clean at the end of each work period. Never cut panels over metal surfaces.

Metal shavings will rust on the surface, voiding the warranty.

TOUCH-UP PAINT

All painted panels and flashings have a factory applied baked on finish. Handling and installing panels may result in some small

scratches or nicks to the paint finish. Touch-up paint is available in matching colors from Metal Sales. It is recommended that a

small brush be used to apply touch-up paint to those areas that are in need of repair. Touch-up paint does not have the superior

chalk and fade resistance of the factory applied paint finish and will normally discolor at an accelerated rate. Aerosol paint should

not be used because of the overspray that may occur.

SPRAY PAINT

TOUCH-UP PAINT

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

15

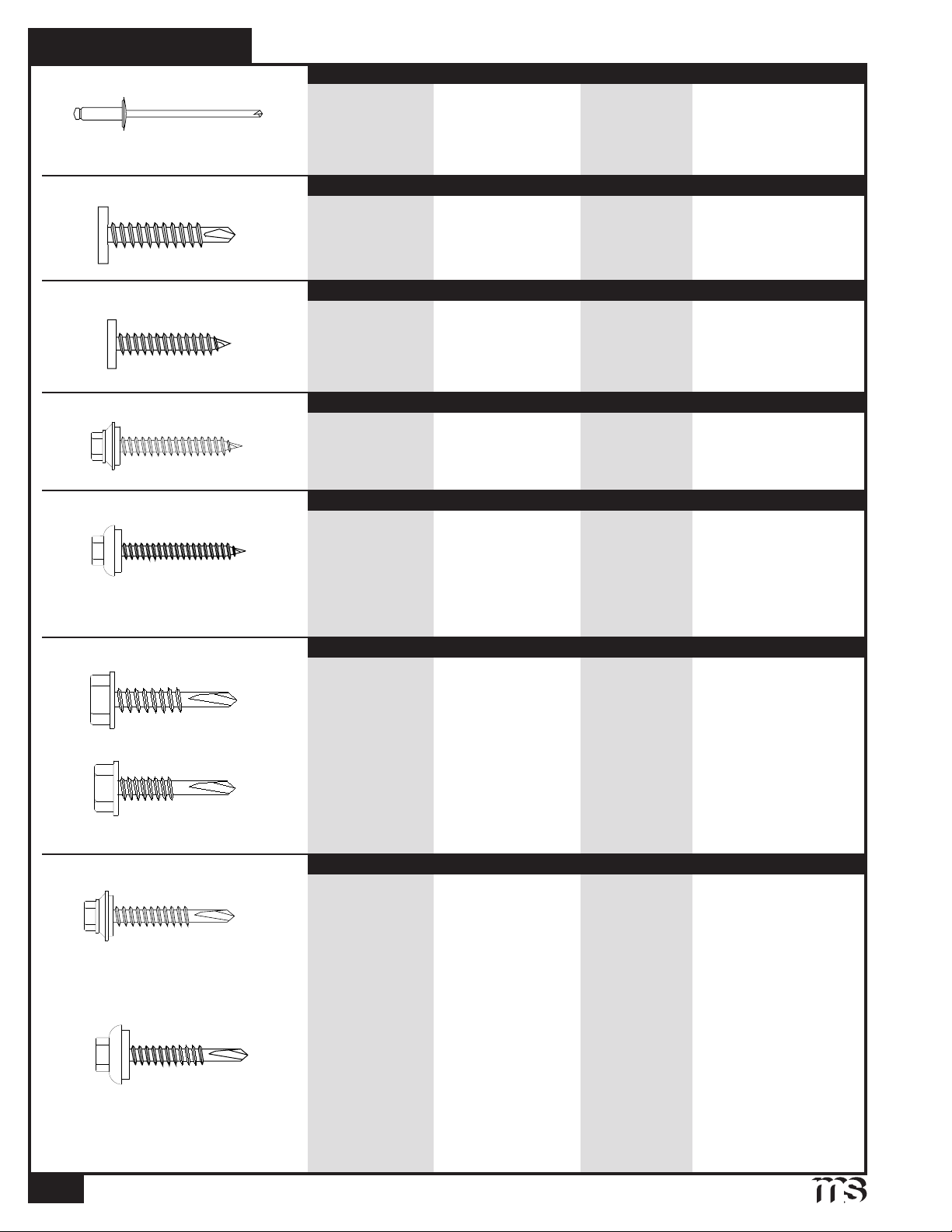

SEAM-LOC 24

POP RIVET

®

FASTENER SELECTION GUIDE

SIZE TYPE FINISH APPLICATION

1/8" x 3/16" A Unpainted Flashing to Panel

or Flashing

1/8" x 3/16" A Painted Flashing to Panel

or Flashing

PANCAKE HEAD DRILLER

PANCAKE HEAD WOODSCREW

WOODSCREW

WOODSCREW XL

SIZE TYPE FINISH APPLICATION

#10-16 x 1" Driller Plated Panel/clip/flashing to

(#2 Point) metal framing or

decking

SIZE TYPE FINISH APPLICATION

#10-12 x 1" A Plated Panel/clip/flashing to

wood substructure

SIZE TYPE FINISH APPLICATION

#9-15 x 1" A Painted Panel or Flashing

#9-15 x 11/2" A Painted to wood substructure

#9-15 x 2" A Painted

SIZE TYPE FINISH APPLICATION

#9-15 x 1" A Unpainted Panel or Flashing

#9-15 x 11/2" A Unpainted to wood substructure

#9-15 x 2" A Unpainted

#9-15 x 1" A Painted Panel or Flashing

#9-15 x 11/2" A Painted to wood substructure

#9-15 x 2" A Painted

SELF DRILLER NO WASHER

SELF DRILLER

SELF DRILLER XL

SIZE TYPE FINISH APPLICATION

#1/4-14 x 11/4" Driller Plated Panel clips to

metal substructure

#12-14 x 1" Driller Plated Accessories to metal

substructure and used

with framing on Retrofit

#12-24 x 11/4" Driller Plated Panel clips to bar joists

(#4 point) up to 3/8" thick

SIZE TYPE FINISH APPLICATION

#12-14 x 11/4" Driller Painted Panel or Flashing

#12-14 x 11/2" Driller Painted to metal substructure

#12-14 x 11/4" Driller Painted

#12-14 x 11/4" Driller Unpainted Panel or Flashing

#12-14 x 1

#12-14 x 1

#12-14 x 11/4" Driller Painted Panel or Flashing

#12-14 x 11/2" Driller Painted to metal substructure

#12-14 x 11/4" Driller Painted

1

/2" Driller Unpainted to metal substructure

1

/4" Driller Unpainted

16

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

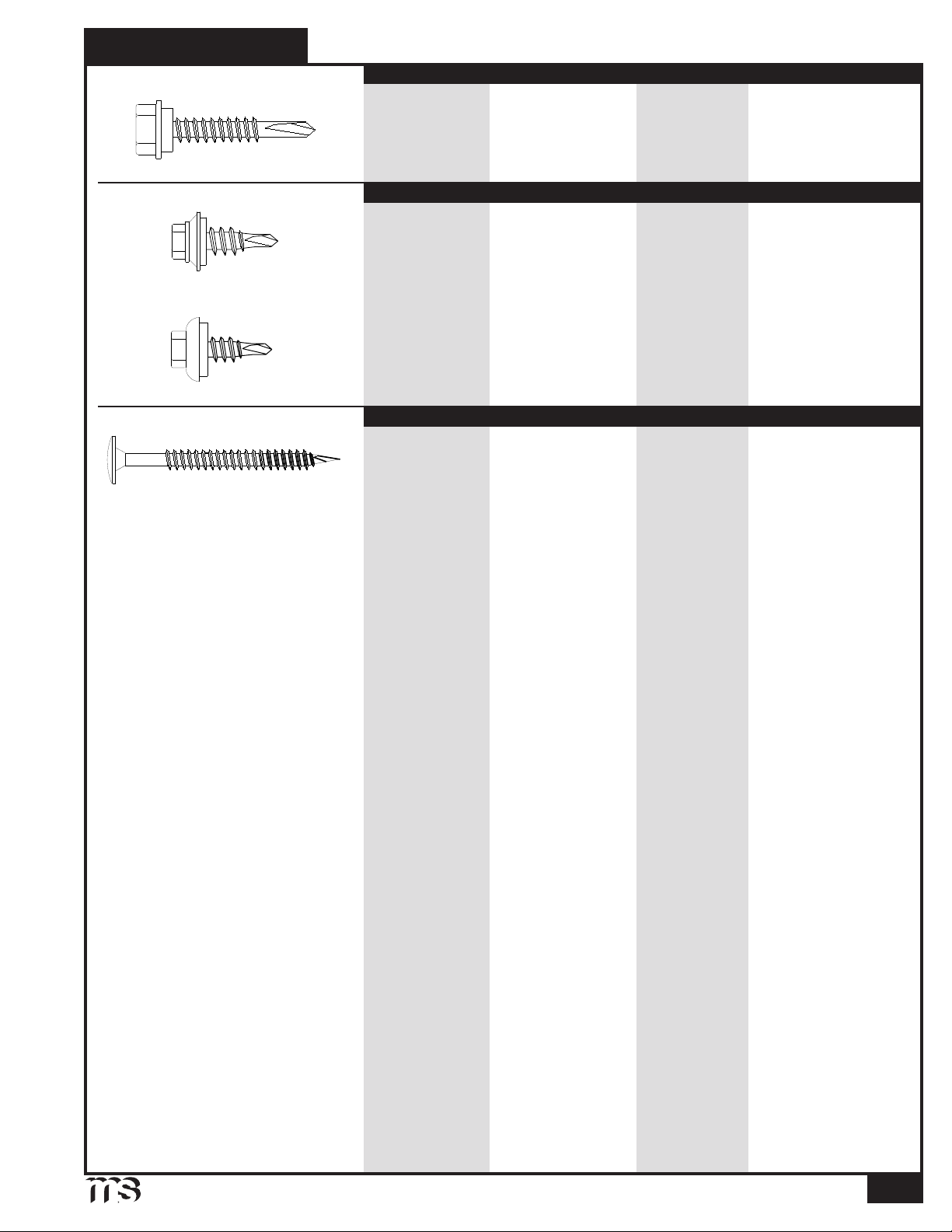

SEAM-LOC 24

SHOULDER SELF DRILLER

®

FASTENER SELECTION GUIDE (CONT.)

SIZE TYPE FINISH APPLICATION

#12-14 x 11/4" Driller Plated For use with

to substructure

Floating Rake Angle

STITCH SCREW

STITCH SCREW XL

DEKFAST

SIZE TYPE FINISH APPLICATION

#1/4 - 14 x 7/8" Stitch Painted Flashing to Panel

or Flashing

#1/4 - 14 x 7/8" Stitch Unpainted Flashing to Panel

or Flashing

#1/4 - 14 x 7/8" Stitch Painted Flashing to Panel

or Flashing

SIZE TYPE FINISH APPLICATION

#14-13 x 2" Driller Black Panel Clip to metal

deck and rigid board

#14-13 x 4" Driller Black insulation assembly

or wood substructure

#14-13 x 5" Driller Black

#14-13 x 6" Driller Black

#14-13 x 8" Driller Black

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

17

®

SEAM-LOC 24

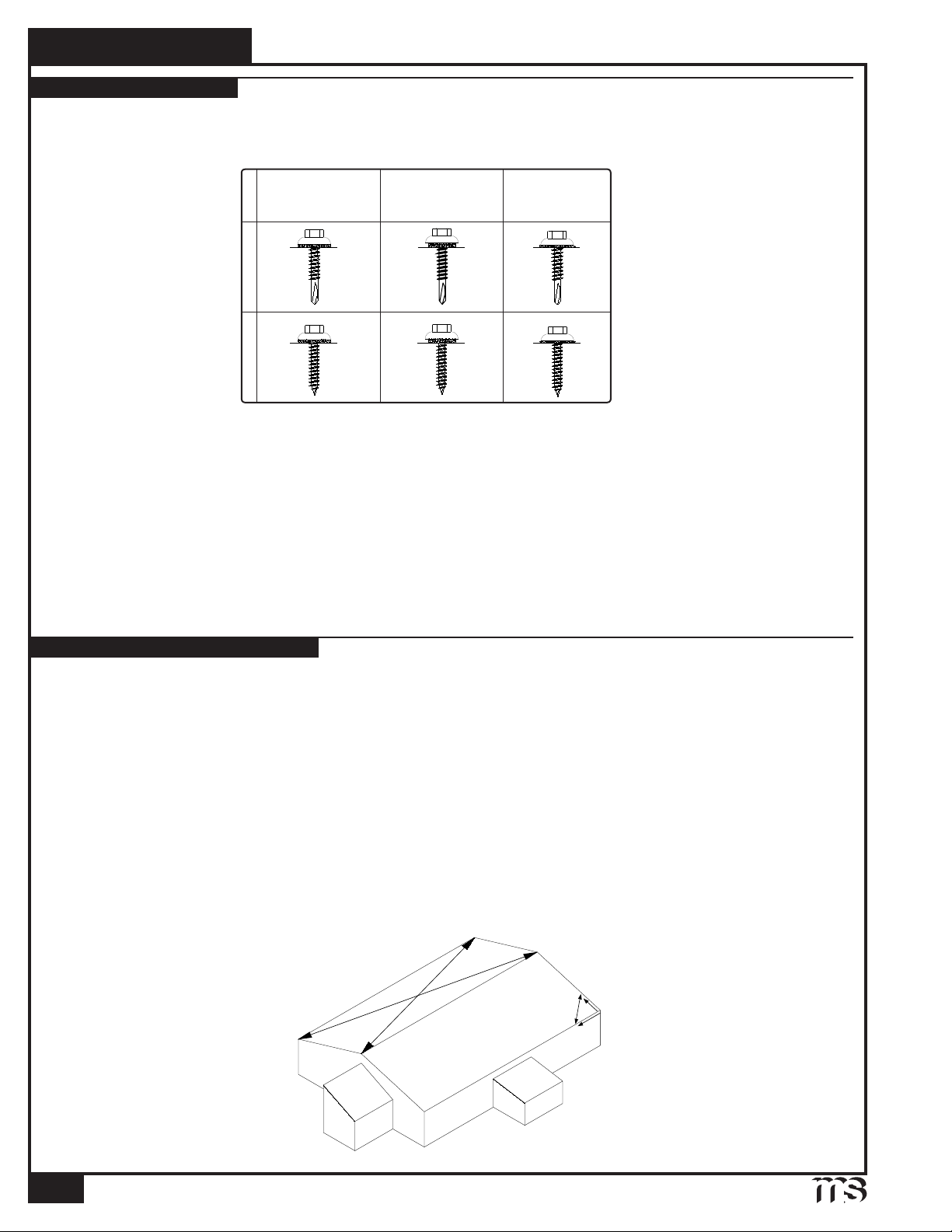

DESIGN / INSTALLATION CONSIDERATIONS

TECHNIQUE

Recommended Tool Type - Use depth locating nose or adjustable clutch on screw gun to prevent overdrilling and strip out.

Do not use impact tools or runners.

Seating the washer - Apply sufcient torque to seat the washer - do not overdrive the fastener.

CORRECT

Sealing material slightly visible

at edge of metal washer.

Assembly is watertight.

SELF DRILLER

WOODSCREW

TOO LOOSE

Sealing material is not visible;

not enough compression to

seal properly.

TOO TIGHT

Metal washer deformed;

sealing material pressed

beyond washer edge.

To prevent wobbling - Make sure fastener head is completely engaged in the socket. If the head does not go all the way in

the socket - tap the magnet deeper into the socket to allow full head engagement. Metal chips will build up from drilling and

should be removed from time to time.

Protect drill point - Push only hard enough on the screw gun to engage clutch. This prevents excess friction and burn out of the

drill point. Correct pressure will allow screw to drill and tap without binding.

Drilling through sheet and insulation - Ease up on pressure when drilling through insulation to avoid striking the purlin or girt

with the point - apply more pressure after drill point contacts purlin or girt.

Drilling through purlin overlaps - Drilling through lapped purlins requires extra care. Excessive voids between purlins

sometimes damages drill points and two self-drillers might be necessary to complete the operation. It is sometimes advantageous

to predrill.

CONDITION OF SUBSTRUCTURE

Whether over solid substrate or open structural framing, panel distortion may occur if not applied over properly aligned and

uniform substructure.

The installer should check the roof deck for squareness before installing Vertical Seam panels. Several methods can be used to

verify squareness of the structure for proper installation of the panels.

METHOD "A" - One method for checking the roof for squareness is to measure diagonally across one slope of the roof from

similar points at the ridge and eave and obtain the same dimension.

METHOD "B" - The 3-4-5 triangle system may also be used. To use this system measure a point from the corner along the edge

of the roof at a module of three (3). Measure a point from the same corner along another edge at a module of four (4). Then by

measuring diagonally between the two points established, the dimension should be exactly a module of five (5) to have a square

corner. Multiple uses of this system may be required to determine building squareness. If the endwall cannot be made square, the

roof system cannot be installed as shown in these instructions.

Method A

30

30

3

5

4

Method B

18

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

®

SEAM-LOC 24

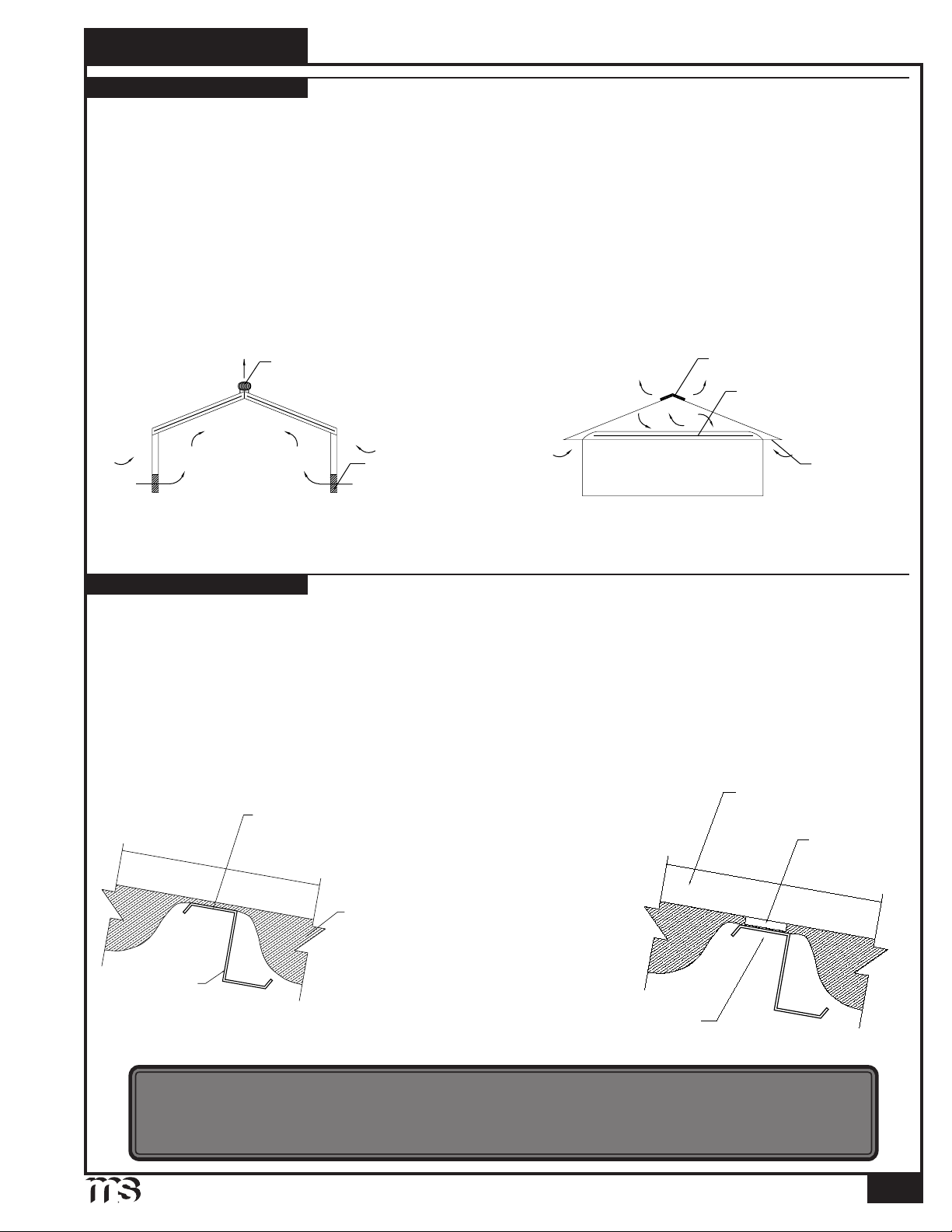

VENTILATION

Proper design and installation of vapor barriers and ventilation systems are important to prevent condensation and the resulting

problems of moisture damage and loss of insulation efficiency.

Condensation occurs when moisture laden air comes in contact with a surface temperature equal to or below the dew point

of the air. This phenomenon creates problems that are not unique with metal buildings; these problems are common to all

types of construction.

The underside of the metal roof on a typical metal building (no attic) should be protected from condensation by insulating with a

faced insulation. This should reduce the potential of condensation forming on the underside of the panels.

On buildings that have an attic space or are being retrofitted with a metal roofing system, vents should be placed at both the eave

and peak of the roof in order to prevent a buildup of moisture (humidity) in the attic space.

DESIGN / INSTALLATION CONSIDERATIONS (CONT.)

Vent

Vent

Insulation

Vent at wall

Typical metal building (no attic)

INSULATION

In most cases insulation is installed directly under roof panels. Insulation is recommended on all applications to act as a sound

barrier, prevent condensation, and increase insulating value of a roof system.

Many different types of insulation can be used with the metal roof panels. Please contact your insulation supplier for specific

recommendations on installation of insulation and vapor barriers.

When applying a compressible type of insulation over open framing members. Rigid thermal blocks can be used to help eliminate

heat lost at purlin locations.

Area of least resistance to heat loss

Building with attic or retrofitted

Seam-Loc 24 panel

Vent at eave

Thermal block

Compressible Insulation

Purlin

Resistance to heat loss is increased

CAUTION

Use extreme care when working next to insulation. The insulation will provide a false sense of

security by hiding the view of the ground below the insulation.

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 12/03

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

19

Loading...

Loading...